INNOVATION AS STANDARD ® TOLEDO ENGINEERING / TECOGLAS / ZEDTEC / KTG ENGINEERING / KTG SYSTEMS / EAE TECH www.teco.com tc665_TECO_GlassIntl_Ad_Sep2022_v01.qxp_Layout 1 13/09/2022 15:37 Page 1 TECHNICAL SUPPLEMENT INDUSTRY 4.0 EXCLUSIVE INTERVIEWS SUSTAINABILITY www.furnaces-international.com - SEPTEMBER 2023

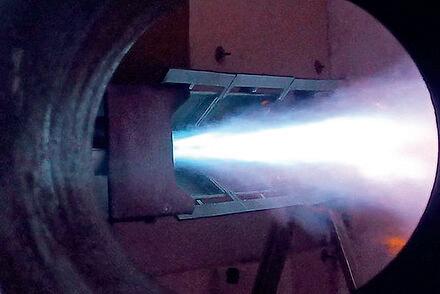

Temperature •Complete product temperature profile •Measure up to 20 points •No Trailing Thermocouples so quick, safe and cost effective •Custom systems to meet specific application challenges including Oil Quench! •Understand, control and improve your process TUS •Fully compliant to AMS2750 or CQI-9 •Live RF Telemetry TUS Data •Batch, Semi and Continuous Furnace Operation •Minimal Production Down Time •Quick easy TUS report generation Video •Inspect your furnace during live production •Find, fix and forget your furnace issues •Keep your furnace operational and productive . . . and Maintain ! Measure, Certify PhoenixTM GmbH Germany info@phoenixtm.de PhoenixTM Ltd UK sales@phoenixtm.com PhoenixTM LLC USA info@phoenixtm.com www.phoenixtm.com Visit us for more information: ... where experience counts ! Thru-process Temperature and Optical Monitoring

Editor: Nadine Bloxsome nadinebloxsome@quartzltd.com

Tel: +44 (0) 1737 855115

Assistant Editor: Zahra Awan

Tel: +44 (0) 1737 855038 zahraawan@quartltd.com

Production Editor: Annie Baker

Sales Manager/Advertisement

production: Esme Horn esmehorn@quartzltd.com

Tel: +44 (0) 1737 855136

Welcome to the September issue of Furnaces International.

With a number of important industry events taking place over the next few months, we thought it would be a great opportunity to print this issue and make it available to a wider audience.

Whether you are a regular reader of the digital version, or this is the first time you are reading a physical copy of the magazine, Furnaces International contains a digest of global news, events, and statistics as well as more detailed technical articles, company and country profiles, conference reports and regular regional economic briefings.

This issue is packed full of in-depth features from across the world of glass, aluminium and steel furnace technology. There is also a full review of the recent Furnace Solutions Conference, which took place in June and welcomed more than 120 glass industry professionals to also celebrate the opening of Glass Futures Global Centre of Excellence, a furnaces research centre in the UK.

I hope you enjoy this issue and whichever industry event you are reading it at!

Nadine Bloxsome, Editor, Furnaces International, nadinebloxsome@quartzltd.com

Subscriptions: Jack Homewood subscriptions@quartzltd.com

Managing Director: Tony Crinnion

1 Furnaces International September 2023

www.furnaces-international.com

Published by: Quartz Business Media Ltd, Quartz House, 20 Clarendon Road, Redhill, Surrey RH1 1QX, UK. Tel: +44 (0)1737 855000. Email: furnaces@quartzltd.com

Furnaces International is published quarterly and distributed worldwide digitally © Quartz Business Media Ltd, 2023 Front cover: TECO CONTENTS

www.furnaces-international.com

GREENER FURNACES 2 Greener Furnaces News 3 Enduring EAF optimisation technology plays a part in steel’s sustainable future GLOBAL FURNACES 6 Global Furnaces News 8 On-site hydrogen generation essential for Riverhawk company’s heat treat operations 12 Furnace Solutions LIFE OF A FURNACE 15 Life of a Furnace News 16 Overcoming the challenges of aluminium temperature measurements 19 Getting to the true core of the matter! 24 Assessing Boilerwatch® for potential benefits in glass manufacturing 28 Second steps of energy and CO2 reduction - use of Isotherms 31 New SMS reheating furnace at DanSteel for processing of thick continuously casted slabs

Verallia CEO: Decarbonisation projects remain on track

Glassmaker Verallia’s two key decarbonisation projects remain on schedule, said its CEO.

The company is developing two new technologies which will allow it to reduce its CO2 emissions.

Speaking to analysts during a financial call, CEO Patrice Lucas said the electrical furnace to be launched at its Cognac, France site is on track ready for next year.

The second technology is its hybrid furnace located in Zaragoza, Spain and start of production is scheduled for 2024.

He added two further decarbonisation solutions were also underway.

“Implementing our decarbonisation roadmap is also about being creative and being able to look at all the different solutions,” he said.

The Zaragoza plant has been using bio heating since 2022, meaning 20% of its natural gas has been replaced with bio heating, resulting in a 10% reduction in CO2 emissions.

This was a first pilot and will be implemented in all the divisions within Verallia.

The second project is what we call batch preheaters. It is about the use of batch heaters and the energy from fumes to heat raw materials before introduction into the furnace, which makes melting easier and less energy intensive.

The first application took place at its Bad Wurzach, Germany site at the beginning of 2023 with others planned in Portugal and Italy this year. This will reduce CO2 emissions by 12%.

Fives launches its first 100% hydrogen duct burner

Manufacturers are looking for alternatives to reduce their carbon footprint and since the combustion of hydrogen emits no CO2, it is one of the solutions to reduce their environmental footprint.

Always one innovation ahead thanks to its ability to anticipate customer needs, Fives has designed its first duct burner firing 100% hydrogen. Fives innovative solution, the Hy-Ductflam™, enables its customers to easily switch fuels going from 100% natural gas (NG) to 100% hydrogen (H2) without any changes made to the equipment.

Fives has announced the launch of its first 100% hydrogen duct burner. The Hy-Ductflam™ is a key step towards the decarbonization of heating and drying processes worldwide as hydrogen emits zero carbon when burnt. Designed for new installations or to replace standard duct burners, Fives’ solution can be easily implemented by manufacturers with very limited process modification.

Combining economic and environmental performance for customers

For example, by using Fives’ Hy-Ductflam™ set on 100% hydrogen, a paper plant will emit 170 kg less of CO2 per ton of paper produced which significantly reduces its carbon footprint (by about 2/3).

Providing high efficiency and mechanical reliability, the Hy-Ductflam™ is suitable for any duct configuration. This mean it can be installed both in new installations and as a replacement of standard duct burners thus limiting costs for manufacturers.

“Fives is at the forefront of hydrogen development and offers the largest range of hydrogen compatible burners on the market. We are proud to provide a new solution that answers the need for decarbonization of our customers and are exited for new innovations to come” declares Francesco Giudici, General Manager at Fives ITAS.

This technology is mainly dedicated to drying application in ceramic, minerals, pulp, etc. to name a few but could be extended to other applications such as heat recovery boilers.

NEWS GREENER FURNACES 2 Furnaces International September 2023 www.furnaces-international.com

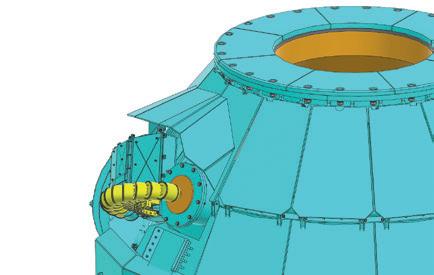

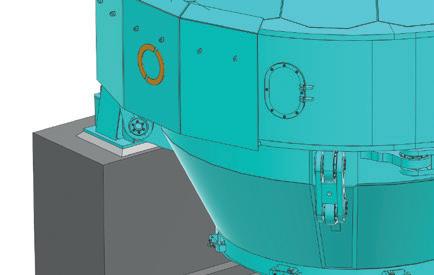

Enduring EAF optimisation technology plays a part in steel’s sustainable future

Zahra Awan* spoke with Frederik Esterhuizen** and Zaeim Mehraban** from ABB on the latest developments in electromagnetic stirring (EMS) technology and its benefits for the steelmaking industry. EMS is not a new technology, since it was first patented around 80 years ago [2], but as Furnaces International found out, ongoing advances mean it remains highly relevant today.

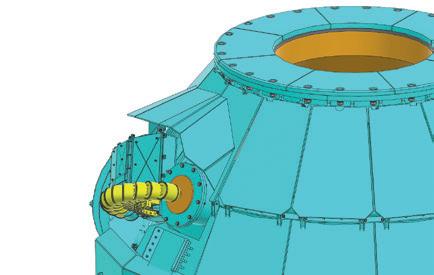

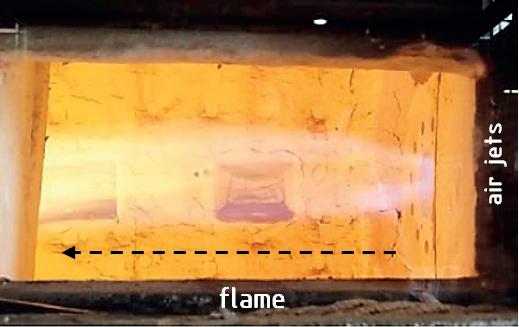

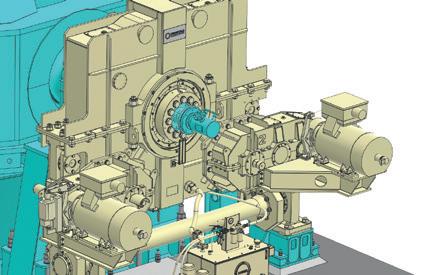

Electromagnetic stirring on the world’s most productive Electric Arc Furnace (EAF) with Tenova and ABB at Acciaieria Arvedi, Italy

COULD YOU GIVE A BRIEF HISTORY ON ABB AND ITS ROLE IN THE METALS INDUSTRY?

Frederik Esterhuizen (FE): ABB is a global technology with more than 130 years of history across industries, providing everything from the smallest electrical components to large motors and drives, powering mines, trains, paper mills and even cruise ships. In the metals industry, ABB leads the way in electrification and automation for our customers, enabling a more sustainable and resource-efficient future. The company’s solutions, incorporating specific metallurgy products and digital, connect engineering know-how and software to optimise how things are manufactured, moved, powered, and operated.[1]

Zaeim Mehraban (ZM): ABB has been a leading supplier and a trusted partner for the metals industry for many decades, collaborating with steelmakers, producers, original equipment manufacturers (OEMs) and other suppliers to develop customer-specific solutions to increase productivity, efficiencies, quality, and safety, while also driving the transition towards more autonomous plants.

GREENER FURNACE 3 Furnaces International September 2023 www.furnaces-international.com

* Assistant Editor, Furnaces International

** Global Business Line Manager, Metals, ABB

*** Global Sales Manager, Metallurgy Products at ABB (on EAF)

Zaeim Mehraban

WHAT IS THE ROLE OF AN EAF IN THE FUTURE OF THE STEEL INDUSTRY?

ZM: The EAF is expected to play a significant role in the future of the steel industry due to its flexibility, lower carbon emissions, resource efficiency, adaptability, and recycling capabilities. As the industry continues to pursue sustainable and low-carbon steel production, EAF technology will continue to evolve and contribute to the advancement of the steelmaking processes.

EAFs offer more possibilities when compared with traditional blast furnaces. They can efficiently process a wide range of raw materials, including scrap steel, direct-reduced iron (DRI), and hot metal, allowing for a more diverse feedstock. This enables steel producers to respond quickly to market demands and changing availability of raw materials. Crucially, they have a lower carbon footprint compared to blast furnaces and can be powered by renewable energy sources, further reducing their environmental impact and contributing to the transition towards green steelmaking.

EAFs can serve as a platform for integrating emerging technologies and processes in steelmaking. As the industry progresses towards carbon-neutral steel production, they can be modified and optimised to accommodate innovations such as direct electrolysis, carbon capture and storage, and other breakthrough technologies. This adaptability positions EAFs as a key component in the steel industry’s transition towards a more sustainable future.

FE: There is traditionally a lot of carbon in the steelmaking process, which is where the EAF comes in. It reduces the carbon content significantly. Customers are also testing their electrical furnaces with different configurations, beyond standard methods, to help achieve sustainability targets around the globe. Movement towards electric options vary depending on geographical region and legislative objectives set, but meeting sustainability targets is in the minds of industry operators and management teams.

WHAT ROLE DOES AN EMS PLAY IN THE EAF?

ZM: EMS is not a new technology: it was first patented by ABB about 80 years ago [2] , but it has evolved. Electromagnetic stirrers (EMS) play a significant role in the operation of an EAF by improving the mixing and homogenisation of the molten metal. The primary function is to induce fluid flow and agitation within the metal bath. By generating a magnetic field that interacts with the conductive molten metal, EMS promotes circulation to homogenise the temperature and composition and ensure more uniform steel.

The stirring effect created by EMS enhances heat transfer within the molten metal. This improved heat transfer allows for faster melting of scrap steel and other raw materials in the EAF, leading to increased productivity and shorter processing times. It also aids in maintaining a consistent and uniform temperature within the furnace.

The agitation provided by EMS facilitates chemical reactions between slag and metal while also improving the mixing of additives and alloying materials. By this way EMS enhances iron yield and solves the bottom skull problem.

The improved heat transfer and mixing effect of EMS, ensure the rapid homogenisation of temperature and composition throughout the molten metal bath. This uniformity allows for more precise, efficient control of the steelmaking process, resulting in a more consistent and repeatable process.

By fulfilling these roles, EMS contributes to the overall efficiency, quality, and consistency of steel production in an EAF. It helps steelmakers achieve better control of the EAF processes, improve efficiency and productivity. According to our research, typical benefits based on 160+ ArcSave electromagnetic stirrer installations worldwide include 5-7% increase in productivity, 3-5% reduction in energy consumption and related carbon emissions, up to 1% higher yield and lower use of alloys, lime and other process additions.

INSTALLATIONS EAF-EMS TECHNOLOGY [2]

ABB has 165+ EAF-EMS technology installations globally including 149 first generation. According to ABB, steelmakers who have installed or will install ArcSave, the latest generation of this technology, representing all furnace types – carbon steel, stainless/specialist and Consteerer™ include:

� Steel Dynamics Inc., Roanoke, USA, 2014, on a 90 tonne EAF for carbon steel production.

� Outokumpu Stainless AB, Avesta, Sweden, 2014, on a 90 tonne EAF for stainless steel production.

� POSCO, Pohang, South Korea, 2018, on a 95 tonne EAF for stainless steel production.

� SeAH Changwon Integrated Special Steel, Chang-Won, South Korea, 2018, on a 70 tonne EAF for stainless steel and tooling steel production.

� Yongfeng Steel, Shandong, China, 2019, on two 160 tonne Consteel™ furnaces for carbon steel production.

� Böhler Edelstahl, Kapfenberg, Austria, 2020, on a 50 tonne EAF for special steel production.

� Nippon Yakin, Kawasaki City, Japan, 2021, on a 70 tonne EAF for special steel production.

All information from this box has been sourced from source 2.

GREENER FURNACE 4 Furnaces International September 2023

HOW DOES USING AN EMS BENEFIT THE PRODUCTION OF STEEL REGARDING ECONOMICS, EFFICIENCY, SAFETY AND THE ENVIRONMENT?

ZM: EMS helps reduce the environmental impact of steel production by improving energy efficiency and reducing carbon emissions. The enhanced mixing and heat transfer facilitated by EMS can lead to shorter processing times and lower energy consumption. Use of alloys, other process additions as well as electrodes and refractory materials is also reduced using EMS, further contributed to resource efficiency and lowering overall environmental impact. Additionally, when combined with the use of renewable energy sources, EMS contributes to the reduction of greenhouse gas emissions and helps achieve sustainable steel production.

EAF-EMS has a measurable impact on furnace productivity. At Steel Dynamics, for example, productivity increased by 6%; at Outokumpu Stainless by 6-8%; and at SeAH, the increase was 5-7%. There is also an increase in yield, typically by about 1%. [2]

The agitation and improved heat transfer provided by EMS result in faster melting of scrap steel and other raw materials in the EAF. This leads to increased productivity, shorter processing times, and higher overall efficiency in steelmaking operations. EMS ensures the homogenisation of temperature and composition throughout the molten metal bath. This uniformity allows for more precise control over the steelmaking process, resulting in consistent and high-quality steel products.

The faster melting and processing enabled by EMS contribute to higher production rates and increased throughput. This enhanced productivity can positively impact the economics of steel production by reducing costs per ton of steel produced.

Steelmakers with EAF-EMS are able to maintain greater control of costs. Critically, energy costs are reduced, as power-on time is shorter and complete melting is achieved more efficiently. Energy consumption fell by 5% at Steel Dynamics, and by 3-4% at both Outokumpu Stainless and SeAH. These energy savings are inclusive of the energy used by the stirrer, which is roughly 2-3kWh per tonne of liquid steel. [2] The use of EMS can improve safety in steelmaking operations. By enhancing the mixing of the molten metal, EMS reduces the likelihood of stratification, which can lead to localised overheating and potential accidents.

WHAT WAS LEARNT FROM THE IMPLEMENTATION OF AN EMS IN ACCIAIERIA ARVEDI’S EAF IN ITALY?

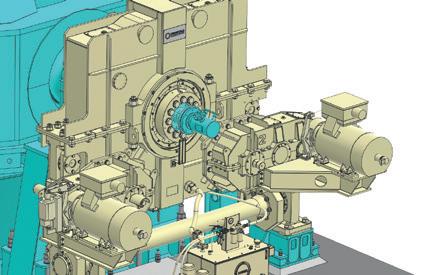

ABB partnered with Tenova for their customer Acciaieria Arvedi in Cremona, Italy, to meet demand for higher productivity and increased electrical energy efficiency of the recently improved endless strip production (ESP) line. Acciaieria Arvedi placed an order in 2018 for a new 450ton Tenova Consteel® electric arc furnace (EAF) to replace the existing 350-ton Consteel® EAF. ABB Metallurgy supported this project with the EAF-EMS application known as Consteerrer®, which was co-developed with Tenova.

ZM: The Acciaieria Arvedi furnace is a jumbo furnace. It is a type of furnace that did not exist before. We have learned much more about the benefits EMS can bring to these large furnaces, improving the process, productivity and also removing the pervasive bottom skull problem for steelmakers.

HYDROGEN HAS BECOME THE MAIN BUZZWORD IN THE LAST FEW MONTHS, IN INDUSTRY. CLOSING THE INTERVIEW: WHAT IS YOUR ABB’S POSITION ON HYDROGEN FUEL?

FE: As a fuel, hydrogen is one possible solution and can be the right move for many industries. There are many challenges to its roll-out, including current high costs, transportation and infrastructure.

ABB is part of the hydrogen business. We have a company in Sweden who we are collaborating with on a pilot project to see how hydrogen can then be further optimised, developed and scaled. One of the biggest challenges for hydrogen is making it scalable. Hydrogen doesn’t counter all the challenges we have, but a key benefit is that it helps with carbon neutrality. We can look forward to a future where hydrogen is very much part of the mix.

WHAT ABB LEARNT FROM THE ACCIAIERIA ARVEDI PROJECT [3]

As a part of the Acciaieria Arvedi project, we have learned that the stirring power has a clear effect on stirring efficiency. The higher the EMS power, the higher the stirring efficiency. Apart from improving furnace performance, Consteerrer® will improve the EAF process and reduce its carbon footprint. The key takeaways from the project are given below:

� Temperature homogenisation time is considerably longer at 447 seconds with 5% EMS and only 113 seconds with 100% EMS

� The temperature gradient between the furnace bottom and the surface during arc power-on is reduced from 114oC with 5% of EMS power to 26oC with 100% EMS

� The heat flux transferred to the scrap increases with increased EMS stirring power. The average heat flux transferred to the scrap with 100% EMS is 2.7 times higher than that with 5% EMS

� Consteerrer® stirring improves heat and mass transfer in the EAF process and also reduces energy and electrode consumption, besides increasing productivity.

� The guaranteed KPIs with EMS are fully achieved in the new Consteel® furnace project

All information in this box has been sourced from source 3.

LINKS:[1] https://global.abb/group/en/about/our-purpose [2] https://new.abb.com/metals/abb-in-metals/references/electromagnetic-stirring-andelectric-arc-furnaces [3] https://new.abb.com/metals/insights/electromagnetic-stirringtechnology-for-450t-consteel-furnace

GREENER FURNACE 5 Furnaces International September 2023 www.furnaces-international.com

Sorg secures Chinese glass furnace order

Sorg has secured a furnace order from China’s Nanjing Electric.

In 2014, Sorg received the first order for the delivery of a regenerative endport furnace with a working end and two forehearths for the manufacture of such insulators.

The insulators produced by Nanjing are subject to a tight glass chemistry specification, which is different for direct current (DC) and alternating current (AC) insulators.

With an article weight of up to 12kg, extreme demands are placed on the glass in terms of glass homogeneity, melting relics, and inclusions from unmolten batch particles and seeds.

The first furnace delivered by Sorg exceeded the requirements regarding the factors mentioned above and the operating time.

Nanjing Electric has commissioned Sorg to deliver a further system.

To comply with the Chinese government’s new emission regulations, a VSM type all-electric melter was supplied.

Sorg reports that the customer was

BlueScope Steel to reline Port Kembla blast furnace

BlueScope Steel has approved the relining of its dormant number six coal-fired blast furnace, which will be the most expensive infrastructure project in the company’s history.

Responding to criticism, the company has said that the decision to reline the furnace will not lock the company to coal-based steelmaking for the next two decades.

The project was initially estimated to cost between $700 million and $1 billion, however the steelmaker has updated the cost to about $1.15 billion.

Following pressure to abandon the reline due to the heavy environmental impacts of blast furnaces, chief executive Mark Vassella confirmed: “There are not technologies which are commercially viable to replace the blast furnace so, we are building a bridge to the future. This allows us to continue to grow and generate the profits that will allow us to invest in the newer technologies, the lower emissions steelmaking technologies as they emerge.”

The new blast furnace would have a ‘campaign life’ of 20 years, however, Vassella said it did not mean BlueScope was committed to using coal to make steel for the full period.

“We have set a net-zero goal but have been really clear that what we need in Australia to support that are enablers around renewable energy, hydrogen, raw materials.”

NEWS GLOBAL FURNACE 6 Furnaces International September 2023 www.furnaces-international.com

highly satisfied with the technology and emphasised the outstanding service and support.

In a gracious ceremony, some of the Sorg employees were made honorary members of the Nanjing Electric company.

Engineering. Manufacturing. Global Support. Excellence is our standard. 100% Employee-owned Contact us to discuss your next project. +1-800-918-2600 | www.grancoclark.com We are 100% customer focused. GRANCO CLARK, a global leader in the aluminum extrusion industry building a full range of aluminum extrusion equipment including some of the world’s largest aluminum extrusion systems. GRANCO CLARK produces all required equipment to heat, cool, pull, stretch, cut, stack, age, and store aluminum extrusions. Leading in the optimization of extrusion technologies and processes, our automated equipment is designed, fully assembled and shop tested to the specific requirements of your extrusion process to deliver exceptional efficiency, productivity and longevity. Contact us to discuss your next project.

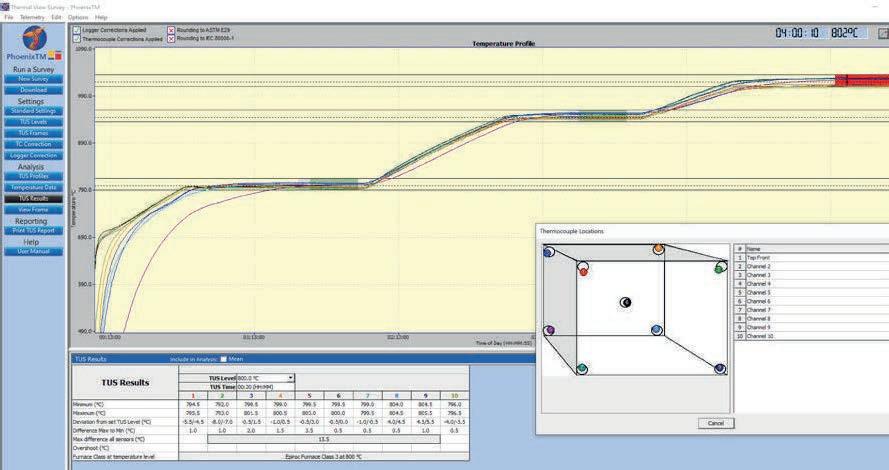

On-site hydrogen generation essential for Riverhawk company’s heat treat operations

By Marie Pompili*

By Marie Pompili*

This article has been provided by Heat Treat Today

For heat treat operations, use of hydrogen comes with questions about price-point, safety, and storage or delivery. Read this case study to learn how a manufacturer with in-house heat treat, Riverhawk Company, contended with these questions and decided to meet stringent production requirements for pivot bearings by leveraging on-site hydrogen and a hydrogen furnace.

For companies using hydrogen furnaces for heat treating operations, questions always surface surrounding the provision of the necessary hydrogen. Should we have it delivered in cylinders? Do we have the room outdoors for a large storage tank? Can we generate it ourselves? For Randy Gorman, maintenance supervisor at Riverhawk Company, the overriding question is always, “How do we handle hydrogen safely?” The ultimate solution the company chose was the installation of an on-site hydrogen generator. How and why the in-house heat treater came to that conclusion is an interesting story.

Making a History

Located in New Hartford, NY, USA, Riverhawk Company was established in 1993 as a value-added provider of hydraulic tooling. The company quickly grew from a “buy and assemble” operation to a manufacturer with 14 CNC machine tools, 21 conventional machines, and all the necessary peripheral devices, tools, and software. Through a period of smart acquisitions and the development of new product lines, Riverhawk became one of the leading manufacturers of tensioners, powertrain couplings, and accessories for the turbomachinery industry; the instrumentation product line of legacy torque and vibrations measuring instruments; and the Free-Flex® pivot bearings, which

GLOBAL FURNACES 8

Furnaces International September 2023 www.furnaces-international.com

Riverhawk staff (L to R): Spencer Roose, Flex Pivots Manager; Randy Gorman, Maintenance Supervisor; and Josh Suppa, Pivot Department Engineer

*Freelance Writer

are very well known in high performance industry sectors.

Pivot Bearing Line Requires Improved Heat Treat Abilities

The Free-Flex® pivot bearing line is the focus in this heat treat/hydrogen story. Riverhawk purchased this line from Goodrich in 2004. It is the same product that was developed by Bendix more than 60 years ago. In fact, many of the original part numbers are the same, and the manufacturer strives to maintain the quality and performance characteristics that Bendix established more than six decades ago. Many of the manufacturer’s clients have been purchasing flex pivots for long-running applications, some of which are 25 to 50 years old. Figure 1

If a product line could talk, the flex pivots could share some tales and compelling accounts about all it has seen and done in the world’s most critical and sophisticated applications — many in the military, commercial aerospace, outer space, industrial robotics, medical, clean rooms, information technology, semiconductors, and many more. In all of these challenging sectors, clients are wellknown and demand exacting results.

Shortly after integrating the pivot line into its existing production processes, it became clear that the company needed to improve its heat treat function. After researching several options, Riverhawk purchased a new Camco batch hydrogen furnace.

The pivot line consists of flat springs crossed at 90° and supporting cylindrical counter-rotating sleeves. Standard FreeFlex® pivots are made from 410 and 420 stainless steel; however, certain special material compositions include 455 stainless, Inconel 718, titanium, and maraging steel. During the manufacturing process for the flexure bearings, Riverhawk uses the batch atmosphere heat treat furnace to braze the springs to the body halves using a braze alloy, and to simultaneously heat treat certain components in the assembly. The atmosphere used for the heat treating and brazing is a 100% hydrogen atmosphere — chosen because it is universally applicable to all the different metallurgy used for the flex pivots.

The Tension: Delivered vs. On-site Hydrogen?

The use of a batch atmosphere heat treat furnace requires that the hydrogen

atmosphere be flushed from the furnace with inert nitrogen when a finished batch is unloaded and a new load is added. Likewise, the furnace must return to inert atmosphere again with nitrogen after the new load is added, and before hydrogen is again injected; hence, hydrogen is used in a batch-wise fashion. The function of the hydrogen atmosphere is to prevent oxidation of the metal surfaces, and to promote fluxing of the braze alloy during the thermal cycle.

Until 2009, Riverhawk used hydrogen-filled cylinders to provide hydrogen to their batch heat treat furnace. Each run of the furnace would use several cylinders of hydrogen. Increases in production rates required careful management of hydrogen gas supply to the furnace. Running out of hydrogen mid-run could sacrifice a whole batch of nearly completed parts.

In 2009, the company elected to move away from hydrogen cylinders and transition to a hydrogen supply approach less disruptive to their production process. The choices were either bulk stored hydrogen or on-site hydrogen generation. After extensive consideration, they chose a model H2 hydrogen generator from Nel Hydrogen because the zero-inventory hydrogen generation saved the company money as compared to the cost of permitting, construction, and compliance for bulk stored hydrogen approaches.

The approach that was not chosen — delivered, stored bulk hydrogen — was unappealing for several reasons. Chief among these were the capital cost of the hydrogen storage infrastructure, the requirement for permitting for the necessary hydrogen storage, the accompanying project schedule risk for permitting, the continuous compliance issues with stored

hydrogen, and the price volatility of delivered hydrogen that would have made cost accounting more difficult.

“The state and local regulations were likely necessary; however, there was a lot to wade through to become compliant,” said Gorman.

Finding the Best Way

Fast forward 14 years to today and Riverhawk is once again analysing its approach to handling its hydrogen requirement.

“The H2 model generator that we have has served us well for 14 years, several years beyond the typical life of a cell stack,” said Gorman. “But we need more capacity and redundancy due to the increased demand for our Free-Flex® products and to cost-effectively mitigate the risk of a hydrogen generator issue, leaving us without the use of our furnace.”

The company decided to go with a model H4 hydrogen generator from Nel Hydrogen, which doubles their capacity with two cell stacks and the capacity for three if and when needed. The new system features the same footprint as the former H2 model, which is important to them, and they are even gaining floor space as they will eliminate the number of cylinders formerly stored nearby. The additional free space to move about also appeals to Gorman’s top mandate for safety. Figure 2

Josh Suppa — engineer of the Pivot Department at Riverhawk — has had hands-on experience with this particular generator series (pictured on page 16).

“The maintenance of it is easy, and if there ever is a rare issue, Nel is quick to respond either in person or if it’s something that they can walk us through, they take all the time we need to resolve the matter and get us back online quick-

GLOBAL FURNACES 9 Furnaces International September 2023 www.furnaces-international.com

Figure 1. Cantilevered-double ended thick spring. Riverhawk purchased the Free-Flex® pivot bearing line from Goodrich. Many of the company’s clients, in a wide range of critical industries, have been purchasing flex pivots for long-running applications.

ly. From a product line and customer satisfaction perspective, we cannot take the risk of our heat treat operation to go down for long. It’s that integral to our success. It’s essential, really, and one of our core competencies.”

Choosing On-Site Hydrogen Generation

Looking back on the initial decision to generate on site, one of the important issues that Riverhawk and Nel personnel had to determine was the most cost-effective configuration of the hydrogen generator and ancillaries to supply the hydrogen required for thermal processing. Had the manufacturer used a continuous furnace such as a belt furnace, then the calculations would have been easy, as the flow rate required would have been level and continuous. Instead, the batch furnace required more complex calculation because the hydrogen flow rate varies depending on the stage of the furnace cycle: fast hydrogen flow to fill the furnace, then slow to maintain the atmosphere, then no flow during parts removal and during loading. Additionally, there were many factors that affected the precise furnace cycles employed, including the size of the pivots in each batch, the number of parts loaded, and the specific metallurgy of the flex pivots in the batch. Overall, the cycle times can vary between 6 and 12 hours per batch.

It is important to seek out a knowledgeable hydrogen partner in this endeavor to specify exactly what’s needed, no more and no less. For heat treat applications, users generally would want compact equipment, extreme hydrogen purity, load following, near-instant on and instant off, and considerable hydrogen pressure that make it flexibly suited for a variety of thermal processes.

By combining on-site hydrogen generation with a small amount of in-process hydrogen surge storage if needed, on-site hydrogen generation can be used to meet the needs of batch processes, such as batch furnaces. By carefully choosing generation rate and pressure, and surge storage vessel volume, the process can provide maximum process flexibility while minimising the amount of hydrogen actually stored.

In practice, client priorities such as minimum hydrogen storage, or lowest system capital cost, or highest degree of expandability, or least amount of space

occupied can be met by choosing the specific hydrogen generator capacity and surge storage system employed for any particular production challenge.

In this case study, the optimum solution chosen was based on lowest capital cost and operating cost (including maintenance) while preserving the maximum possible expandability for production increases, and safety. These sound like common reasons and may be yours as well. Success continues at Riverhawk with the arrival of the new H4 generator in the coming weeks. �

For more information: Visit nelhydrogen.com and www.riverhawk.com.

GLOBAL FURNACES 10 Furnaces International September 2023 www.furnaces-international.com

Figure 2. Riverhawk will soon use a model H4 hydrogen generator from Nel Hydrogen, which doubles their capacity with two cell stacks and the capacity for three if and when needed. The new system features the same footprint as the former H2 (pictured here).

(Photo Source: Nel Hydrogen)

GLASS SERVICE Tying Technology Together Help the planet existing chnology educe CO2 with: l Boost l More boost l Electric forehearth l Superboost l Hybrid ur naces ble future from Glass Service and FIC The World,s Number One in Fur nace Technology FIC (UK) Limited Long Rock Industrial Estate, Penzance, Cornwall TR20 8HX, United Kingdom www.fic-uk.com +44 (0) 1736 366 962

Furnace Solutions

The 17th Furnace Solutions conference explored the route to sustainable production, for the glass and furnace industry, despite the challenges faced by the industries. It was noted that throughout the years, the conference agenda has dramatically changed. Attention and awareness on the actions, and consequences of production, and the importance of sustainability, is now a key topic of conversation. It was also observed that although the industry has made drastic changes, a push to decarbonise is required to ensure the industry is a role model to all heavy manufacturing industries.

The Furnace Solutions Conference hosted over 120 glass industry professionals in St. Helens, a historic town with a deep connection to industry. Zahra Awan* reports on the conference.

“We hope that we will see future developments and commitments to improving sustainable production” – Arun Varshneya, President of the Society of Glass Technology and CEO and President of Saxon Glass Technologies.

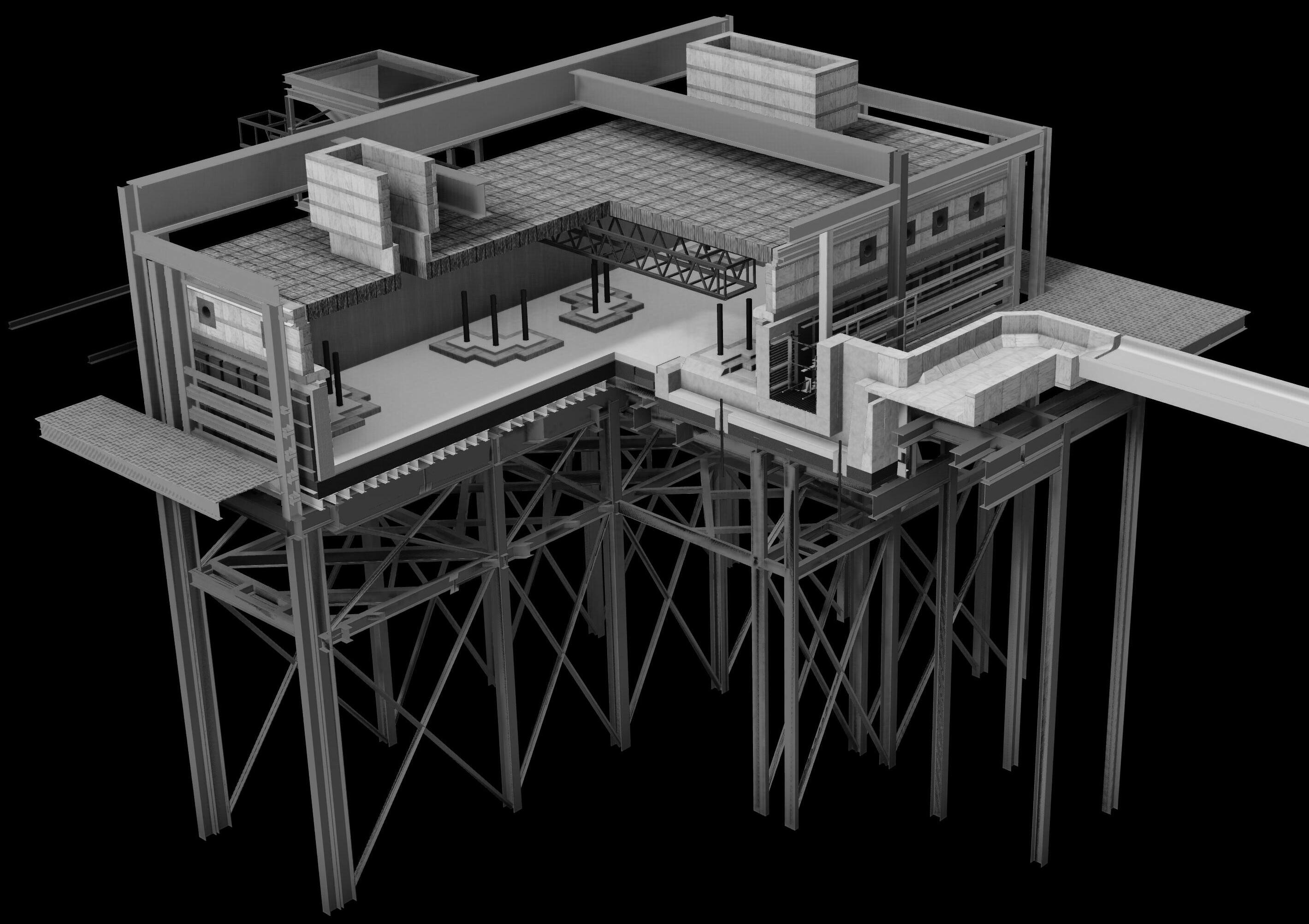

Glass Futures

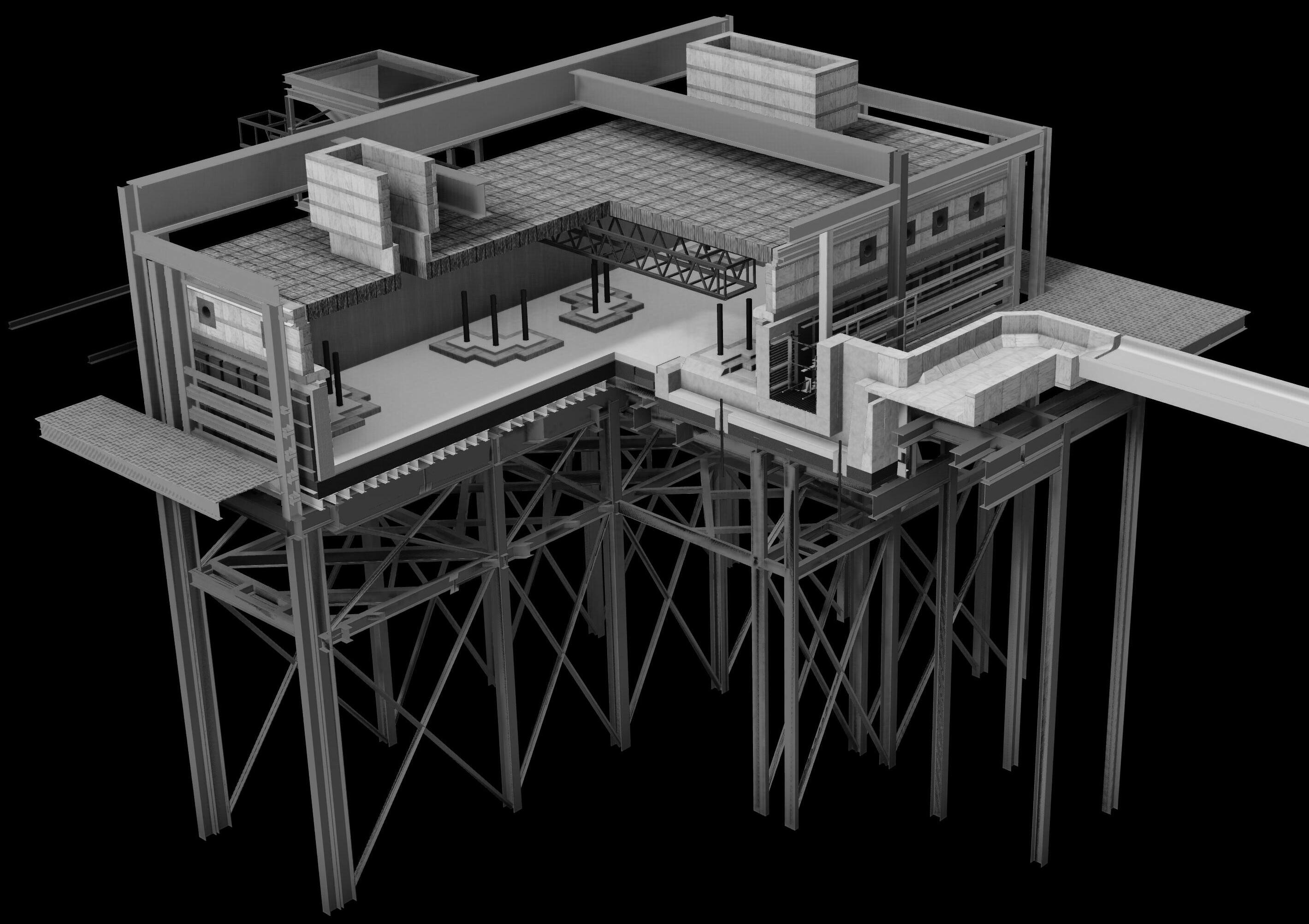

The event was hosted in conjunction with the opening of Glass Futures Global Centre of Excellence, a furnaces research centre.

On the occasion, Aston Fuller, Glass Futures General Manager, said: “This opening marks a new chapter for Glass Futures with St Helens as our home. A key part of that for us is working with as many local partners as possible, supporting local businesses, creating jobs, and attracting new companies and start-ups to come and join us in the borough.”

Richard Katz, CEO, Glass Futures added: “Removing carbon emissions from global manufacturing is our world’s greatest challenge, and we need to change how we do things.” With this, Furnaces Solutions followed with a two- day conference, including 14 presentations from various global companies.

The Conference

“The technology used in producing glass has not changed for centuries. What has changed, however, is how we use that technology.” – Attendee of Furnaces Solutions

*Assistant Editor, Furnaces International

The presentations included discussions on sustainable solutions, and new technology: Debates on the best way to transition to net zero continued, but a focus on

GLOBAL FURNACES 12

Furnaces International September 2023 www.furnaces-international.com

electric and hybrid melting made an appearance, as well as the potential implementation of hydrogen fuel, alternative raw materials, and sustainable refractory development.

Policies and Government

“I wish we could have more significant support and investment and money from the government to help decarbonisation.”

– Attendee of Furnaces Solutions

Opening the conference, Jenni McDonnell (MBE), Thermal Energy Specialist at Innovate UK, discussed the Industrial Energy Transformation Fund (ITEF). Over the years, the fund has allocated £315 million in assisting the industry with the financial burden of decarbonisation and has funded over 130 projects since April 2020. Ms McDonnell announced that the fund is due to return in 2024 with an additional £185 million.

Later, a debate between Matthew Demmon, Managing Director, MKD32, Steve Whettingsteel, CEO, Krystelline Technologies, and Nick Kirk, Technical Director, Glass Technology Services noted the significant losses that the glass industry faces, and methods to combat this. In the debate, the three discussed their view on cullet, and recycled glass.

“Globally 50 million tonnes of glass is lost annually”; “glass is infinitely recyclable with no loss of quality, … All glass can and should go back to remelt to produce new bottles”

- Steve Whettingsteel, CEO, Krystelline Technologies

Mr Demmon concluded that the export of cullet was encouraged by the Producer Responsibility system, which in turn, deprives the UK of recycled glass and therefore, a circular economy. Dr Kirk related to this conclusion in his findings: Cullet export was up 30% in 2022, and UK remelt decreased by 48,000 tonnes in the same year. To tackle this challenge, the Extended Producer Responsibility (EPR) strategy is said to be put in place, starting from 2025 in the UK.[1]

The Extended Producer Responsibility (EPR) is a policy tool that extends the producer’s financial and/or operational responsibility for a product to include the management of the post-consumer stage, in order to help meet national or EU recycling and recovery targets. EPR policies thus generally shift the waste management cost

or physical collection partially or fully from local governments to producers [2]

This strategy aims to hand over the responsibility of accounting for waste to producers, or local governments, giving them more autonomy over the systems in place for recycling, relying on their desire to enhance and evolve recycling programs. Mr Demmon stated that “between now and 2030, the EPR is expected to increase glass collection by 350 KT, by drawing cullet out of IBA (Incinerator bottom ash) and landfill. As well as increase remelt by 400 KT.”

Steve Whettingsteel raised his concerns to the conference with regards to the effectiveness of the EPR and cullet recycling. The circularity of glass is key to furthering its decarbonisation. Mr Whettingsteel suggested that rather than resorting to optical sorting for landfill and cullet, a revolution to sorting ands and powder productions should be made. His concepted aimed at converting “all incoming glass int high valuable alternatives.” Which could then be used in new developing markets.

With this suggestion, it became apparent that although the EPR provides a solution to one of the many challenges

that are faced when tackling decarbonisation, there are still many routes that can, and could be taken to assist in the industries transition to net zero. It raised the question: how should the industry adapt to unique situations, should they invest in multiple strategies, or do we attempt to all fit into one box?

Digitalisation and New Technologies

With the digitalisation of an industry which has seen centuries of development, it is only natural that there are challenges that come with this progression, as well as tremendous benefits. However, the glass industry is no luddite.

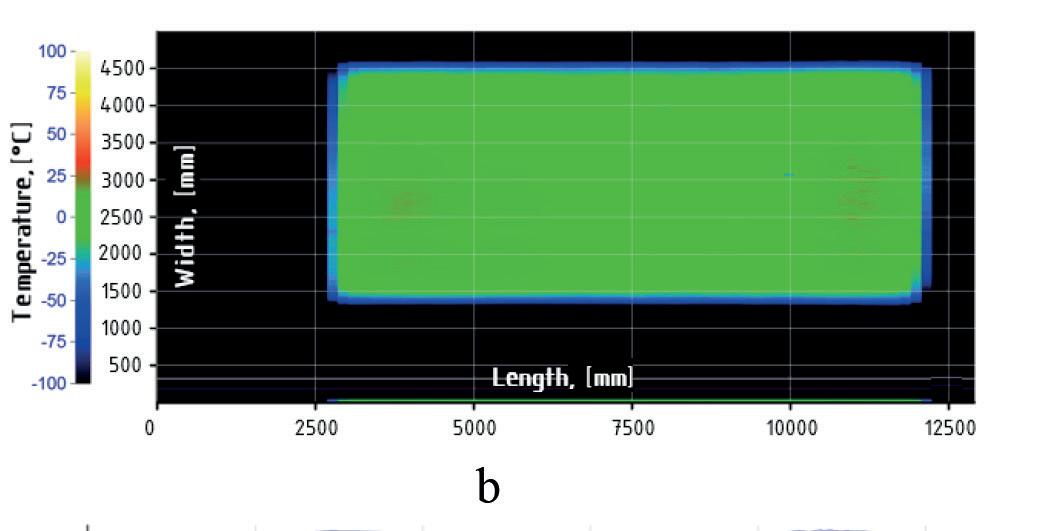

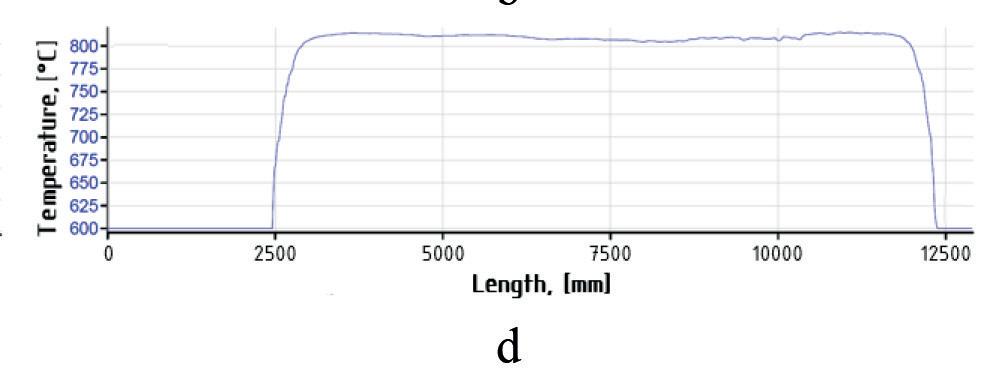

Burcin Gul Arslanoglu, Executive Senior Researcher, ŞiŞecam spoke on ‘pushing the limits of production in float furnaces’. With the prediction of a high growth in demand for global float glass Ms Arslanoglu discussed the benefits of implementing digital solutions into furnaces, namely the use of computational fluid dynamics (CFD) modelling. She noted the importance of modelling with regards to testing possible solutions to experiment the limits of the technology we currently have.

The software could be used to explore different parameters within the furnace, such as adding more cooling nozzles, velocity, flow rate and exhaust location. Using the knowledge from the tests, she believed that CFD can help develop roadmaps for the next 50 years. In her closing notes, Ms Arslanoglu concluded that the biggest challenge is the conflict between increasing capacity at the same time as reducing emissions.

The conference hosted a range of key players and experts in the field of furnaces. With this, a range of opinions circulated. One conflict of opinion questioned whether a longer life furnaces better despite times of rapid change?

GLOBAL FURNACES 13 www.furnaces-international.com

Burcin Gul Arslanoglu made her opinion clear that the life of a furnace should be improved and made longer. In contract, Stuart Hakes, FIC, stated: “We must moveout of these long-life furnaces, so we do not lock ourselves in with a set of technology.” He was supported by Andrew Reynolds, Fives, who said that long-life furnaces aren’t necessarily the solution to the industry’s problems.

With this in mind, what is the solution, and how do we find it?

Glass Futures representative Dr. Sebastian Woltz, Sales Director, EME discussed the importance of conceptual engineering with regards to new furnaces, and how it should be used to continue to adapt and develop existing furnaces, to make way for new technology and ideas. Later it was suggested by Stuart Hakes, Chief Executive at FIC, and Andrew Reynolds, Business Development Director at Fives, that electric furnaces were the answer to effective yet adaptable furnaces.

Carbon Capture and Storage (CCS) was another topic of conversation. HyNet speaker, John Egan, Progressive Energy Ltd discussed plans for implementing CCS infrastructure. The plan included “CO2 being transported through a pipeline under the sea, to an offshore platform located approximately 30 km offshore in Liverpool Bay. From there, the CO2 will be injected into the depleted gas reservoir.” This futuristic solution faced some challenge from the audience as they questioned the impact (long and short term) that this would have on the environment. The implementation of CCS was also discussed by the NSG Group.

Alternative/New Fuels

“We must look at a holistic approach when discussing fuels”- Rob Ireson, Innovation and Partnership Manager, Glass Futures

The topic of alternative fuels is, undoubtably, going to raise eyebrows. Rob Ireson set the scene for alternative fuels noting that one of the Glass Futures pilot project objectives is to test alternative fuels to a high standard, and at a high level. Getting to the point: Hydrogen. Hydrogen is one of the most complex fuels, despite being the simplest element. Its volatile nature makes it not only hard to contain and distribute, but difficult to utilise safely.

St. Helens Glass futures site has plans to test hydrogen as both a mixed and pure fuel. Tests for this were discussed by the NSG Group who ran a float glass furnaces using 20% hydrogen to 100% hydrogen in 2021. “The test resulted in a 7% reduction in over CO2 footprint of the glass produced during the trial” - Barry Fish, Decarbonisation Technology Team Leader, NSG Group.

John Egan also presented HyNet’s support and intention to investigate hydrogen fuel, stating “Low carbon hydrogen will play a key role alongside low carbon electricity” and discussed their demonstration trials at NSG Pilkington Glass and Unilever.

Biofuels was also discussed by Mr Fish, the NSG Group announced a successful

trial of float glass production with 100% biofuel and 100% renewable energy. The 2022 trial saw a >40% reduction in overall CO2 footprint of the glassed produced. However, Barry Fish admitted that these fuels had a long way to go before being a solution in the industry.

Conclusion

In this event overview, a section specifically dedicated to green production has not been included. This is because most, if not all, of the presentations at this year’s Furnaces Solutions conference fell into the topic of green production. The conference has undergone many changes over the years; the fact that the 2023 conference was hyper aware of its responsibility and commitment to sustainable manufacturing is one of its greatest developments.

In an exclusive interview, Arun Varshneya concluded:

“We, as glass technologists, are known to be those who say ‘hey, don’t rock the boat’ because we cannot take a chance. However, it’s clear that the foundation industries need to think about sustainability. So that we leave a liveable, precious, planet for our children, our grandchildren, our great grandchildren and so on. We need to pay attention to that, and that calls for newer technologies to be conceived and developed. I was amazed to see how people are going beyond the norms [at the conference].” �

GLOBAL FURNACES 14

Furnaces International September 2023 www.furnaces-international.com [1] https://www.gov.uk/guidance/extended-producer-responsibility-for-packaging-who-is-affected-and-what-to-do [2] https://www.europen-packaging.eu/policy-area/extended-producer-responsibility/

The Furnace Solutions announced that the conference will be returning on 5th – 6th June 2024.

Guardian Glass Bascharage furnace to restart in Q4 2023

The furnace at Guardian Glass’ Bascharage, Luxembourg plant is on schedule to be operational in Q4 2023 after a cold tank repair.

The oven will be the most energy efficient Guardian Glass furnace.

Once put into operation, the furnace is expected to be more than 25% more energy efficient.

The furnace will also provide extra capacity for the plant to be able to produce both Guardian ExtraClear float glass and Guardian UltraClear low-iron float glass.

The installation of a transferred lami-

nated glass line is also expected to be completed in Q4 2023.

Guus Boekhoudt, Guardian Glass Executive Vice President said: “We invested in the latest melting technology to provide our customers with the most advanced glass products, while using fewer resources.”

The Bascharage plant already hosts a coater that produces Guardian ClimaGuard low-emissivity (low-E) and Guardian SunGuard coated solar control glass for residential and commercial applications.

Boekhoudt added: “Having all these assets consolidated on one site in Luxembourg, close to many of our key customers, will improve our service offering and underlines our long-term commitment to them and the glass industry.”

Bernard Gheysen, Guardian Glass Bascharage Plant Manager said: “I am very proud of the team here – everyone has gone the extra mile on this project. We are excited about the new opportunities it opens, as well as grateful for the strong support we have received from the Luxembourg authorities.”

Primetals to supply ArcelorMittal’s Brazil plant

ArcelorMittal has recently contracted Primetals Technologies for the revamping of two LD converters (BOFs) at its steel plant in Jõao Monlevade, Brazil.

The order includes two new 135-ton converters, an upgrade of the primary dedusting systems, and complete electrics and automation packages.

The upgraded wet-type primary dedusting systems capture dust from the converters and send it to a water treatment plant. The resulting emissions will be significantly below the legal limit set by the Brazilian government, says Primetals. Additionally, the new solution will require much less maintenance than the equipment currently in use.

The start-up of the new equipment is scheduled for the first quarter of 2025.

With a history spanning close to 90 years, ArcelorMittal Monlevade produces wire rod for industrial applications such as steel wool and steel cord. The site is part of ArcelorMittal Brazil’s Long Steel division and has an annual capacity of 1.2Mt.

NEWS LIFE OF

FURNACE 15 Furnaces International September 2023 www.furnaces-international.com

A

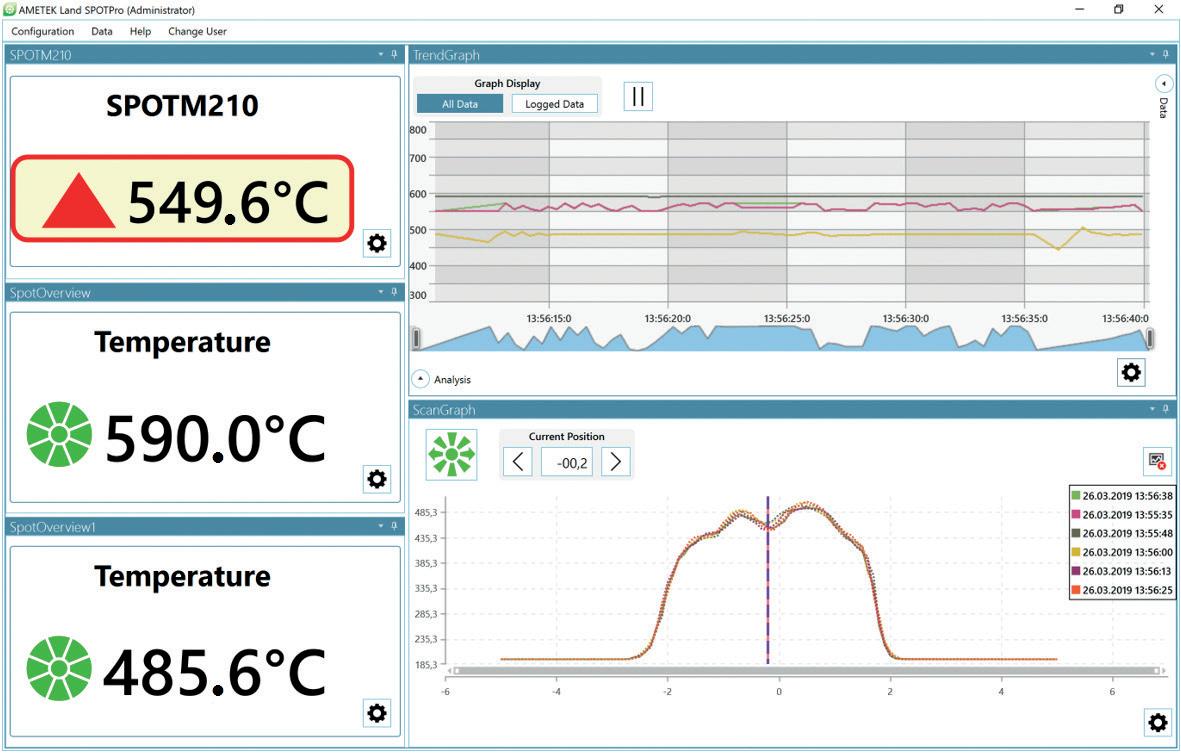

AMETEK Land SPOT+ AL

By Prasath Venkatasamy*

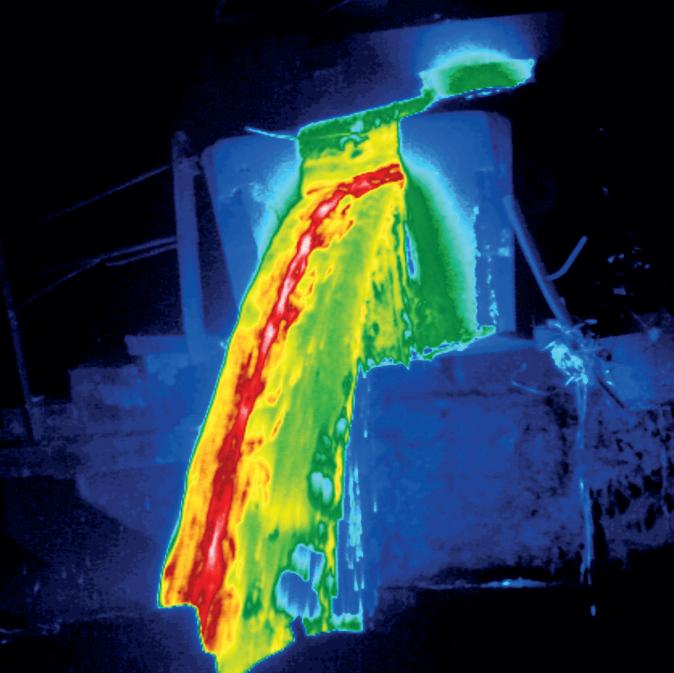

The accurate temperature measurement of liquid aluminium during melting and pouring is important to ensure high-quality casting and efficient process operation. Liquid aluminium temperature measurement during tapping ensures product quality and process efficiency while minimising waste or rework.

Furnaces are used in aluminium production to melt raw material and scrap at the primary stage, then for preheating ahead of processes such as rolling, extrusion, forming and forging.

Aluminium industry furnaces are designed to handle high temperatures, maintain precise temperature control, and ensure efficient energy usage. They are vital for the conversion of raw materials into molten aluminium, which can then be further processed into various forms, such as ingots, sheets, or extrusions, for use in different industries.

Temperature measurement of the metal is critical for the effective operation of aluminium furnaces. It provides essential information for the control and optimisation of the various processes involved in aluminium production, ensuring that energy use is minimised, and the processes are not overheated.

Additionally, it helps support safe and efficient furnace operation, along with quality assurance of the aluminium products.

Infrared thermometry is ideal for these types of measurement: it has a fast response, it is non-contact, and it works well on hot materials. A non-contact temperature measurement method is particularly useful, as it enables measurement of the material rather than the furnace wall.

Unfortunately, several of the characteristics of aluminium make it challenging for measurement instruments of all types to achieve accurate temperature readings. For example, its emissivity is low and varies with temperature, while each alloy has a different value.

That means it is not possible to correlate the intensity of infrared radiation emitted by the metal with its temperature, as is commonly done with steel, glass, and other industrial processes.

16

AMETEK Land SPOT+ AL

Furnaces International September 2023 www.furnaces-international.com LIFE OF A FURNACETECHNICAL FOCUS

* Global Industrial Manager Metals

Single-spot pyrometer measurements

Pyrometers are passive devices, detecting the infrared radiation emitted by the measurement object – they do not emit any radiation themselves. This makes spectral emissivity one of the most important parameters in non-contact temperature measurement.

Aluminium is difficult to measure because its surface has a low emissivity and therefore is extremely reflective – much like trying to make an optical measurement of a mirror.

When using mono pyrometers – that is, devices using a single wavelength – the spectral emissivity value for the object to be measured must be known, so that the pyrometer can determine the correct object temperature. Emissivity tables are available, but emissivity can vary with temperature, measurement wavelength, and surface conditions such as oxide film structure.

Ratio and Application pyrometers measure radiation at more than one wavelength to partially compensate for surface emissivity. Application pyrometers can also calculate and report the emissivity value as well.

For example, AMETEK Land’s SPOT+ AL non-contact pyrometer uses measurements at carefully-selected wavelengths, combined with proprietary algorithms, to determine the temperature of hot aluminium.

Each SPOT+ AL has algorithms optimised for measurements of oxidised aluminium billets, freshly-extruded aluminium, and cooling aluminium at the quench exit.

The algorithms can also be adjusted to match the exact temperature characteristics of a specific alloy, using a one-time comparison with a thermocouple measurement.

The SPOT+ AL also offers a Liquid Aluminium Mode, for accurate, real-time, high-speed measurements of tapping stream temperatures in applications such as melting and pouring.

Melting and pouring

The optimum pouring temperature for liquid aluminium depends on alloy type and casting geometry. The solid alloy must all be melted, but not overheated.

If the temperature is too hot, the chemical and physical properties of the aluminium and the casting may not meet

specifications and energy is wasted. If the temperature is too low, molten metal will not flow into all the cavities and apertures of the casting due to solidification.

Liquid aluminium temperature measurement during tapping ensures product quality and process efficiency, and minimises waste or rework.

The SPOT+ AL’s unique Liquid Aluminium Mode enables accurate live high-speed measurements of tapping stream temperatures, even on the most reflective liquid aluminium surfaces.

By choosing the preset liquid mode and aligning the patented green target spot with the pouring stream, the pyrometer gives continuous readings through the digital and analogue interfaces within 15 ms.

The integrated visual camera and SPOT+ AL patented green LED clearly indicate the target area to aid alignment. Combining the SPOT+ AL with the smart SPOT actuator, the spot detects and tracks the tapping automatically without the need for manual adjustment.

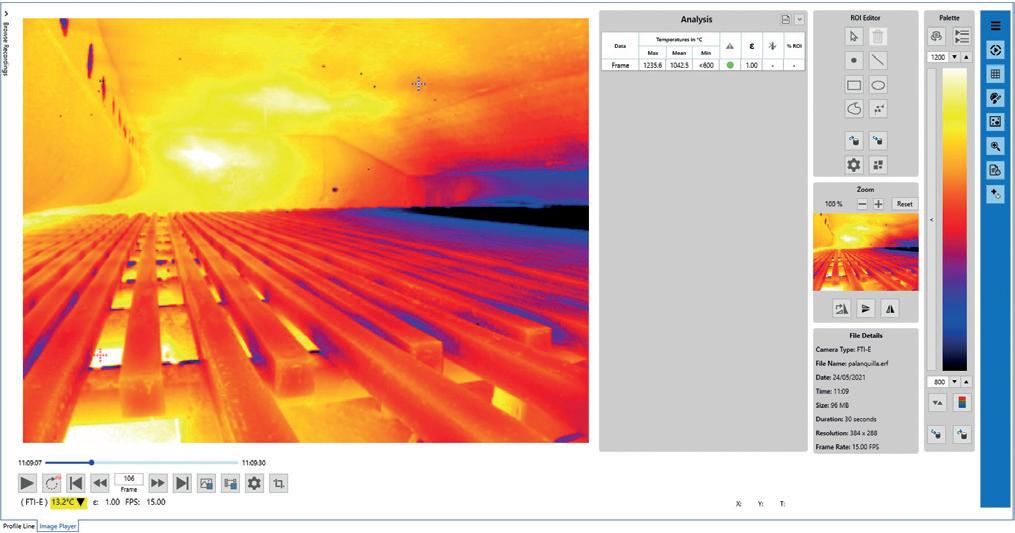

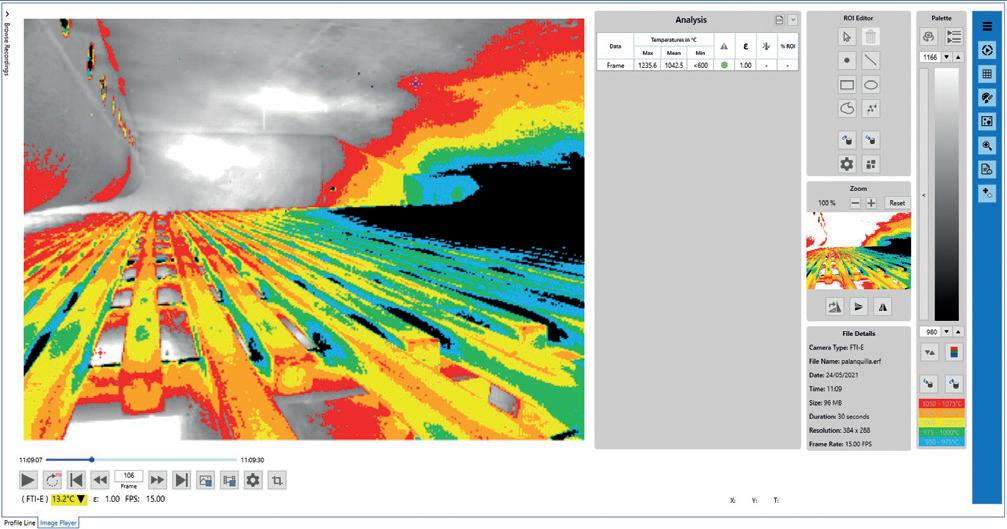

Furnace measurements

Delivering accurate temperature measurements inside smelting furnaces is particularly difficult because of reflections from hotter walls, fumes and particulates, dross buildup and surface materials.

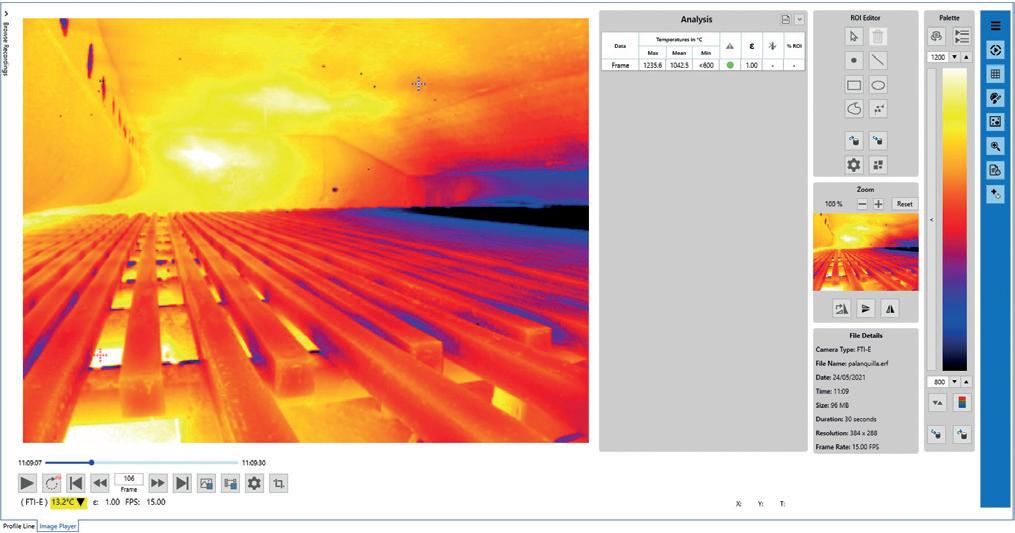

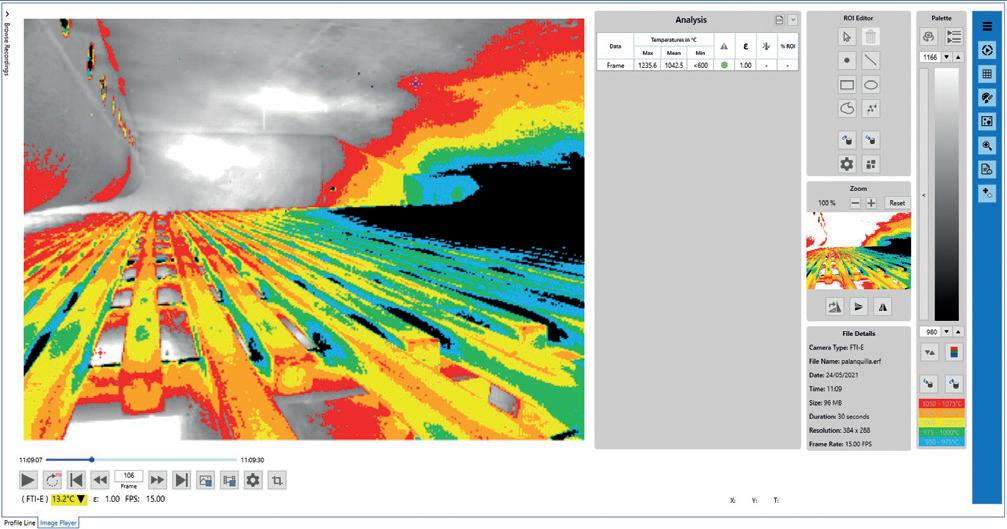

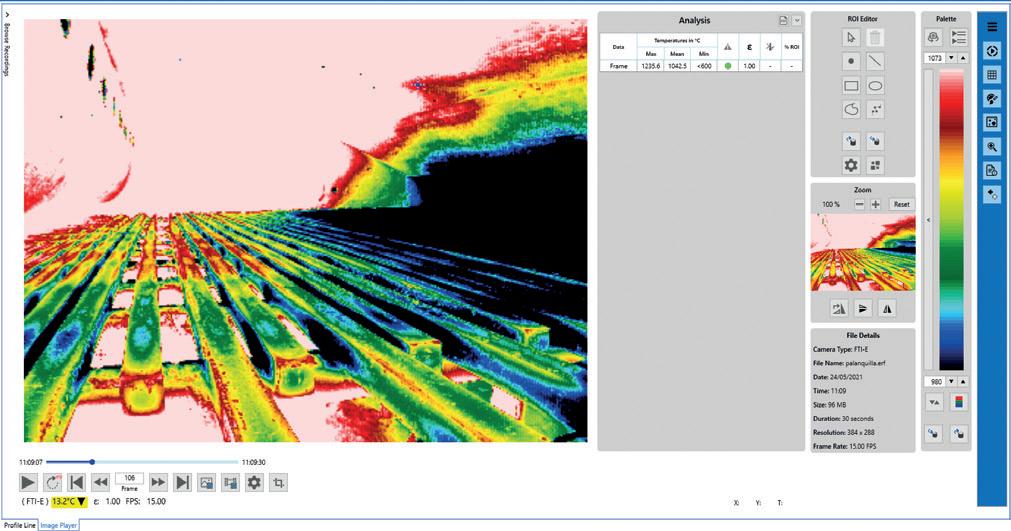

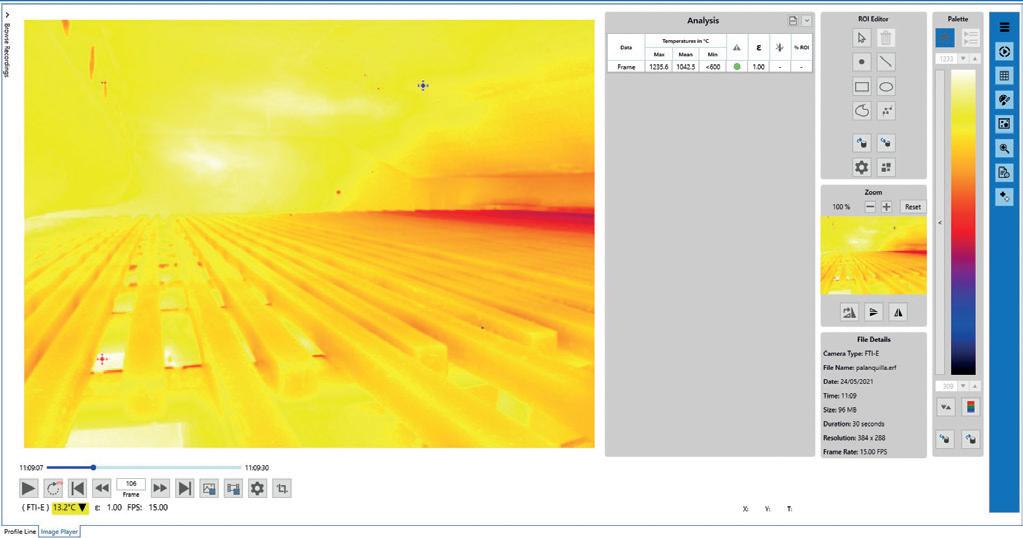

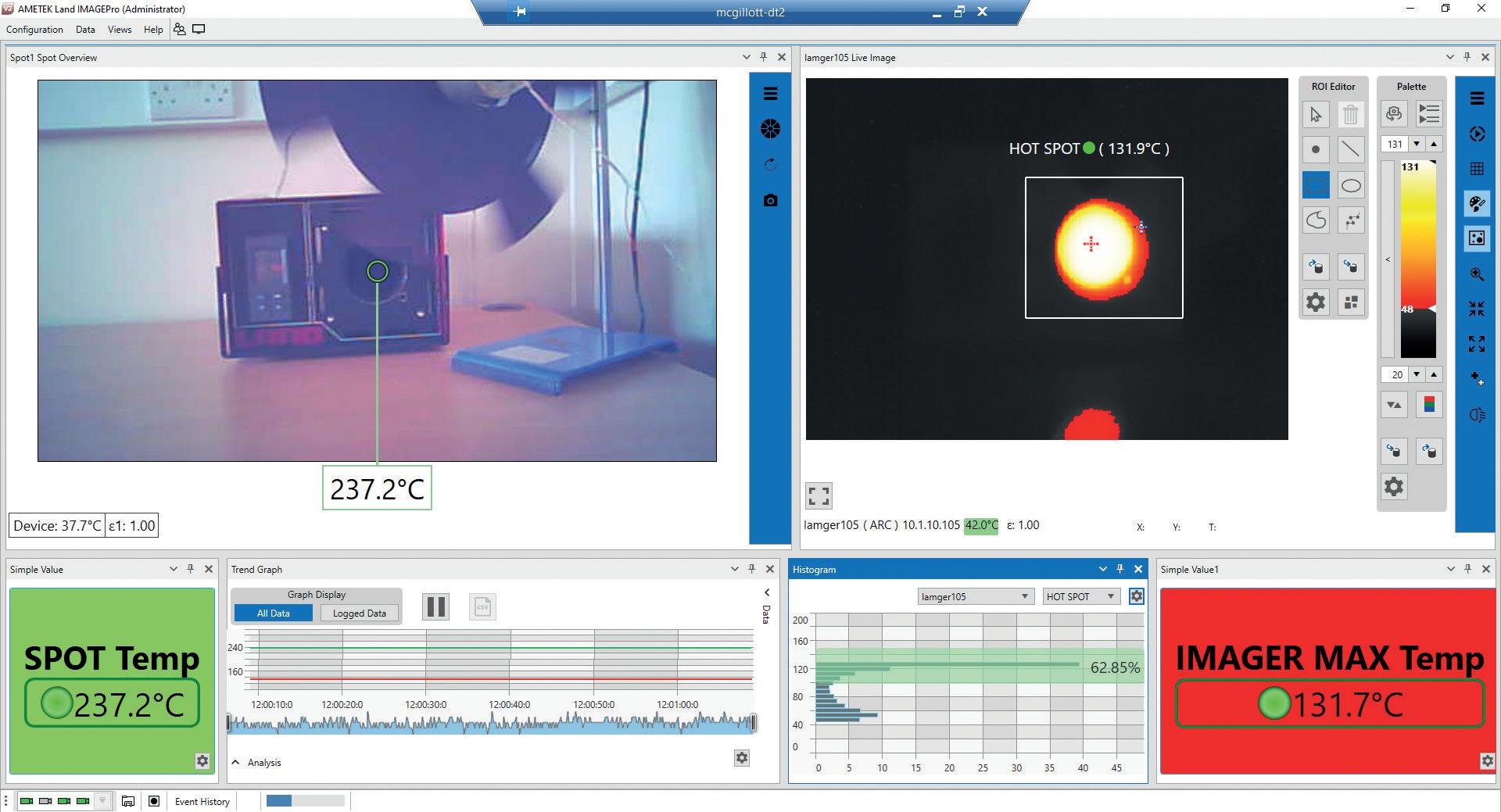

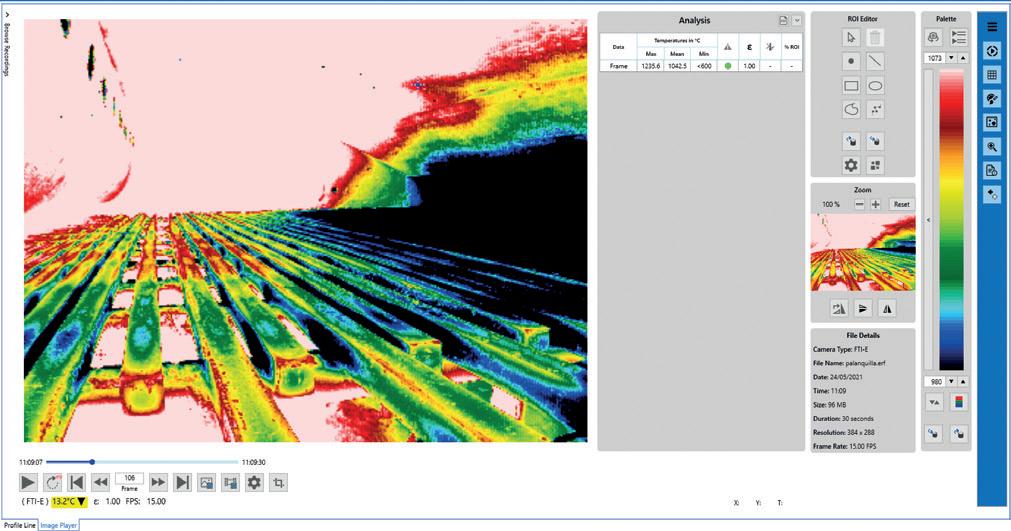

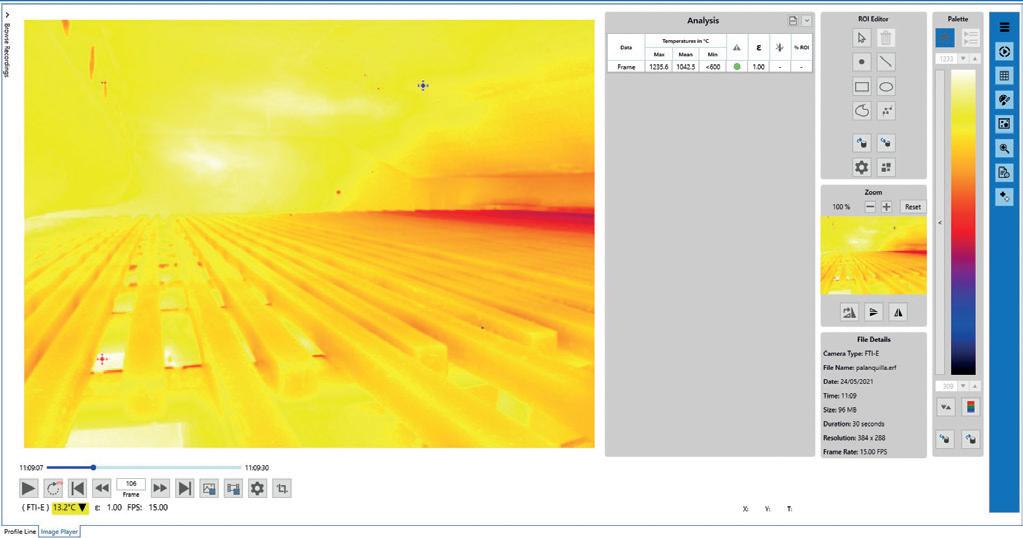

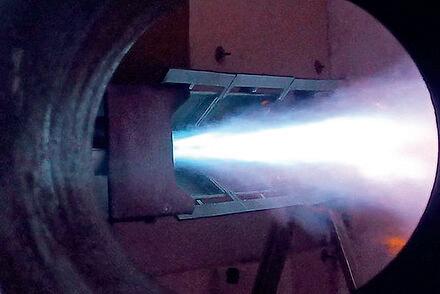

To overcome these issues, AMETEK Land has developed the MWIR-640 thermal imager.

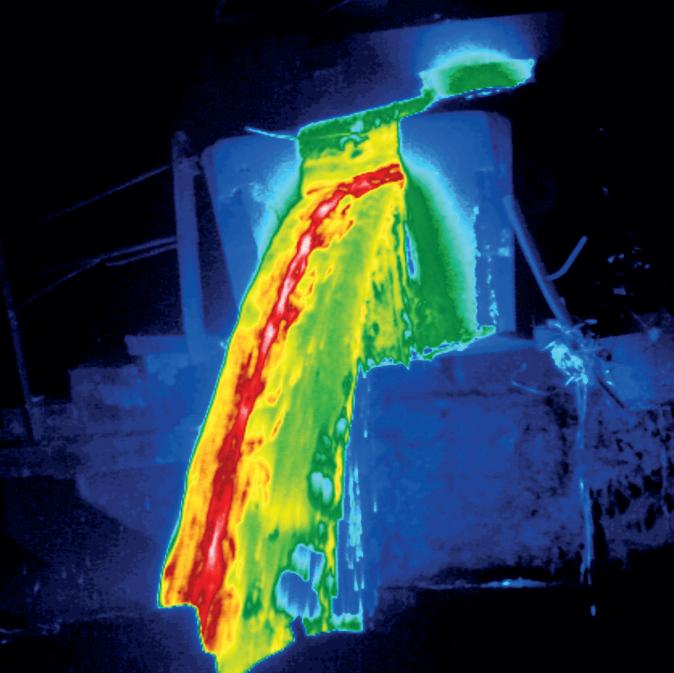

Using a mid-range wavelength of 3.9 μm, the MWIR-640 is able to achieve a clear, continuous view through heavy smoke and hot furnace atmospheres – unlike visual camera systems – and provides an unparalleled view inside melt furnaces.

17 Furnaces International September 2023 www.furnaces-international.com

TECHNICAL FOCUS

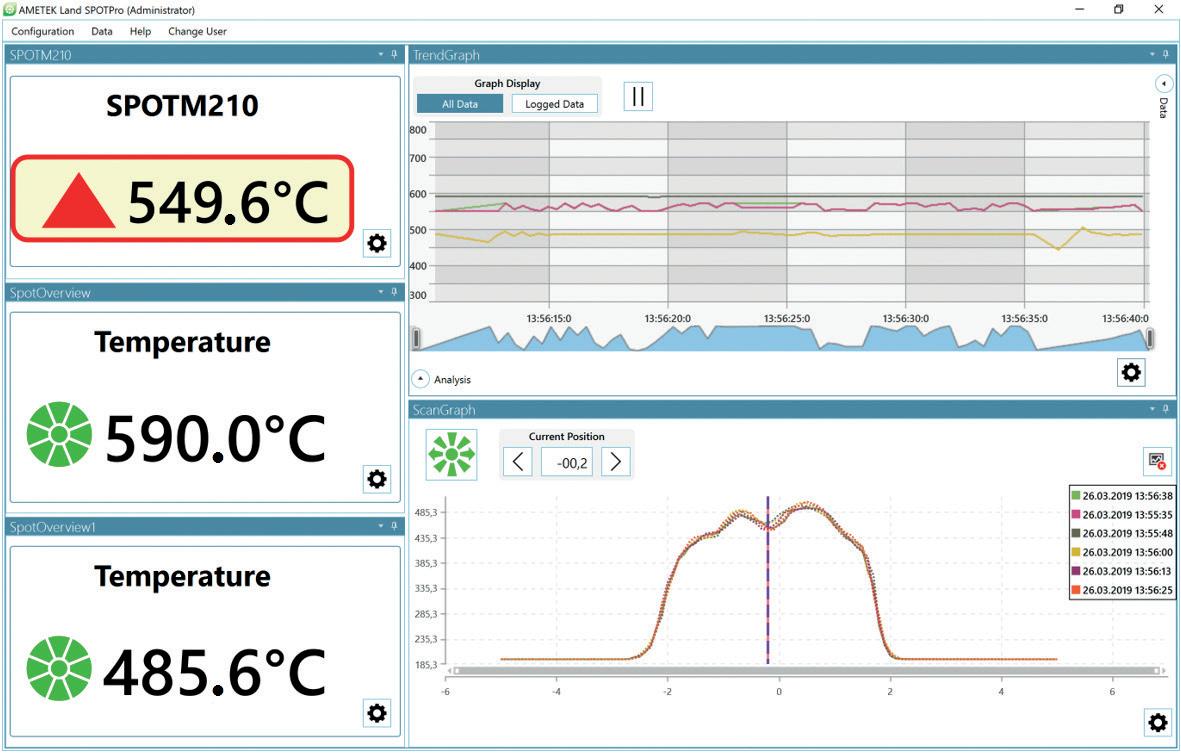

Thermal Imaging & Processing Software

LIFE OF A FURNACE

This enables highly accurate and fully radiometric temperature measurement image data to be taken, stored, and trended over the lifetime of the furnace or boiler.

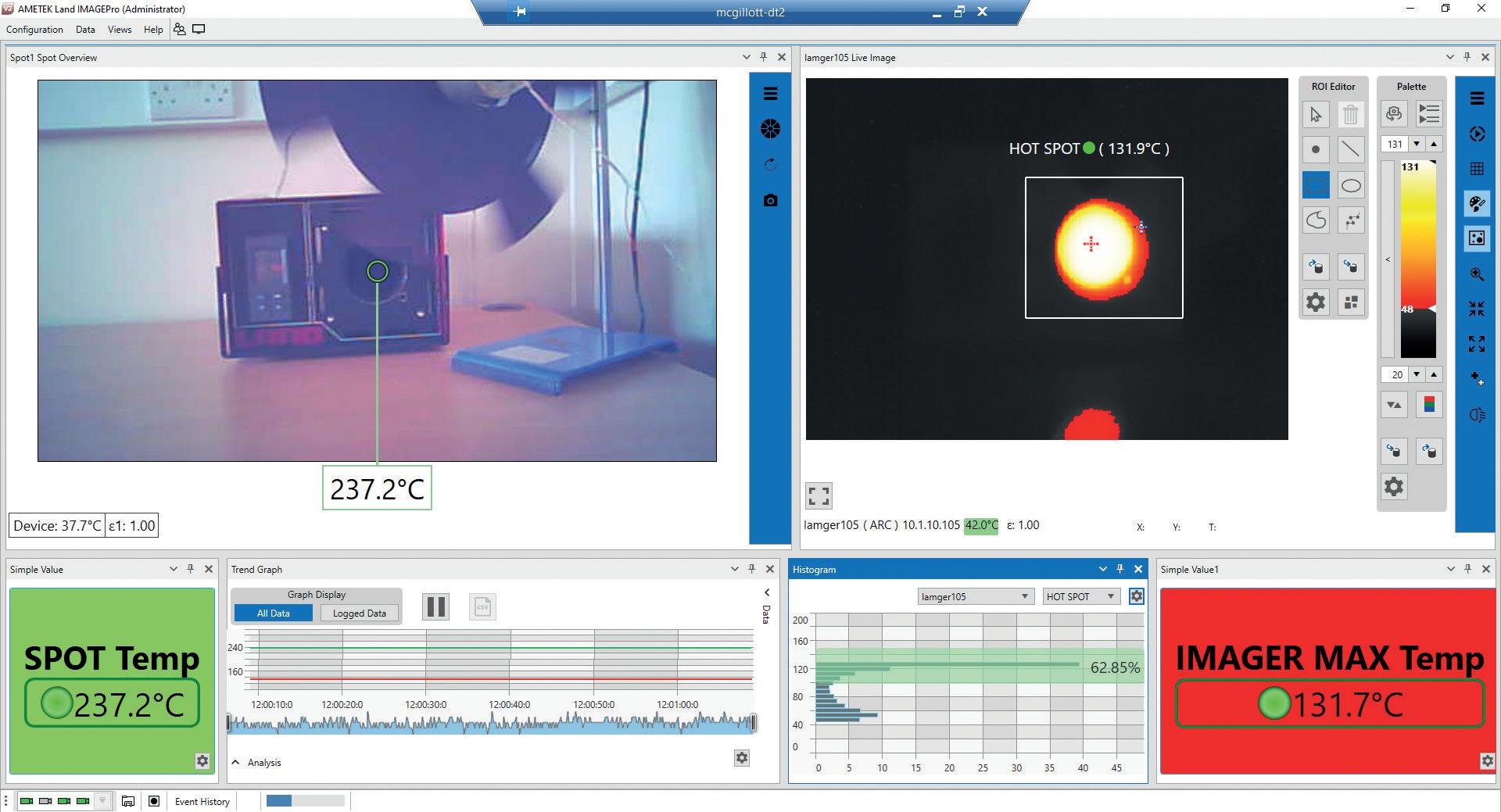

The MWIR-640 is supported by advanced IMAGEPro thermal imaging and data processing software, which allows long-term data trending and enables the early detection of leaks and temperature variations to help optimise processes.

Operators have a clear view of the critical areas within the furnace or boiler with more than 300,000 accurate point temperatures, measuring in the range of 300-1200 °C (572-2192 °F) and 500-1800 °C (932-3272 °F).

Providing advanced digital communications via IMAGEPro, the performance of the furnace or boiler can be monitored to easily identify hot and cold areas and any uneven heating can be viewed in real-time from the safety of the control room.

The high-resolution image, combined with the wide-angle field of view (90°), allows multiple areas to be imaged and measured simultaneously.

The MWIR-640 uses proven thermal imaging technology to accurately and continuously profile the temperatures within the furnace or boiler, providing improved data accuracy through automation and minimising risk to personnel by reducing the need for personnel to be in the hazardous area around the furnace or boiler.

Advanced process control

AMETEK Land’s MWIR-B-640 is used in Idletechs’ advanced process control system, which builds on the thermal imager’s capabilities to increase furnace efficiency.

Idletechs provides software for online analysis of large streams of data, extracting the essence using explainable AI and presenting it to operators in a way that enables them to make better decisions.

The result is better process control and improved maintenance – increasing profits and ensuring stable operations.

The Idletechs Furnace Monitoring solution makes it possible to optimise the aluminium smelting process by providing real-time infrared images of the furnace melt surface, accurate tracking of metal temperatures during each production phase, quantification and predictions of the melting of solids, monitoring of dross formation and removal, and the ability to analyse process changes.

The solution is designed for retrofit on existing furnaces and can integrate with existing data sources.

The MWIR-B-640 generates huge quantities of desperately-needed thermal behavioural data that were never previously available. Idletech’s system handles, distils, and intelligently interprets this key information to improve process efficiency.

By combining the high-performance thermal camera with real-time analytics, the system allows better process control, as operators can avoid running the process too long, saving time and fuel, and can plan operations better.

Process insight is also improved, with the ability to quantify and track key performance indicators such as formation of dross and slag, system temperatures, and melt times. This provides the basis for understanding how to improve operations and change recipes.

By tracking the melting process to avoid filling too early, and tracking maintenance operations to avoid manual errors, quality is enhanced. The system also delivers early warnings of changes in the furnace, and the detection of slow changes in the furnace, improving maintenance.

Conclusion

The advantages provided to aluminium furnaces by thermal imaging allow for more repeatable and reliable temperature measurements to be taken, as well as a greater understanding of furnace conditions during the process.

The ability to integrate these measurements into process controls can further improve product quality, including surface finish and desired metallurgical properties.

By measuring the variables involved, and understanding their effects on the process, aluminium operators benefit from a competitive advantage, attracting customers who demand high-quality aluminium products.

Moving forward, implementing thermal imagers into automated process control systems will enable a more efficient, optimised and automated factory for the future. �

18 Furnaces International September 2023 www.furnaces-international.com

AMETEK Land MWIR-640-Borescope

TECHNICAL FOCUS

LIFE OF A FURNACE

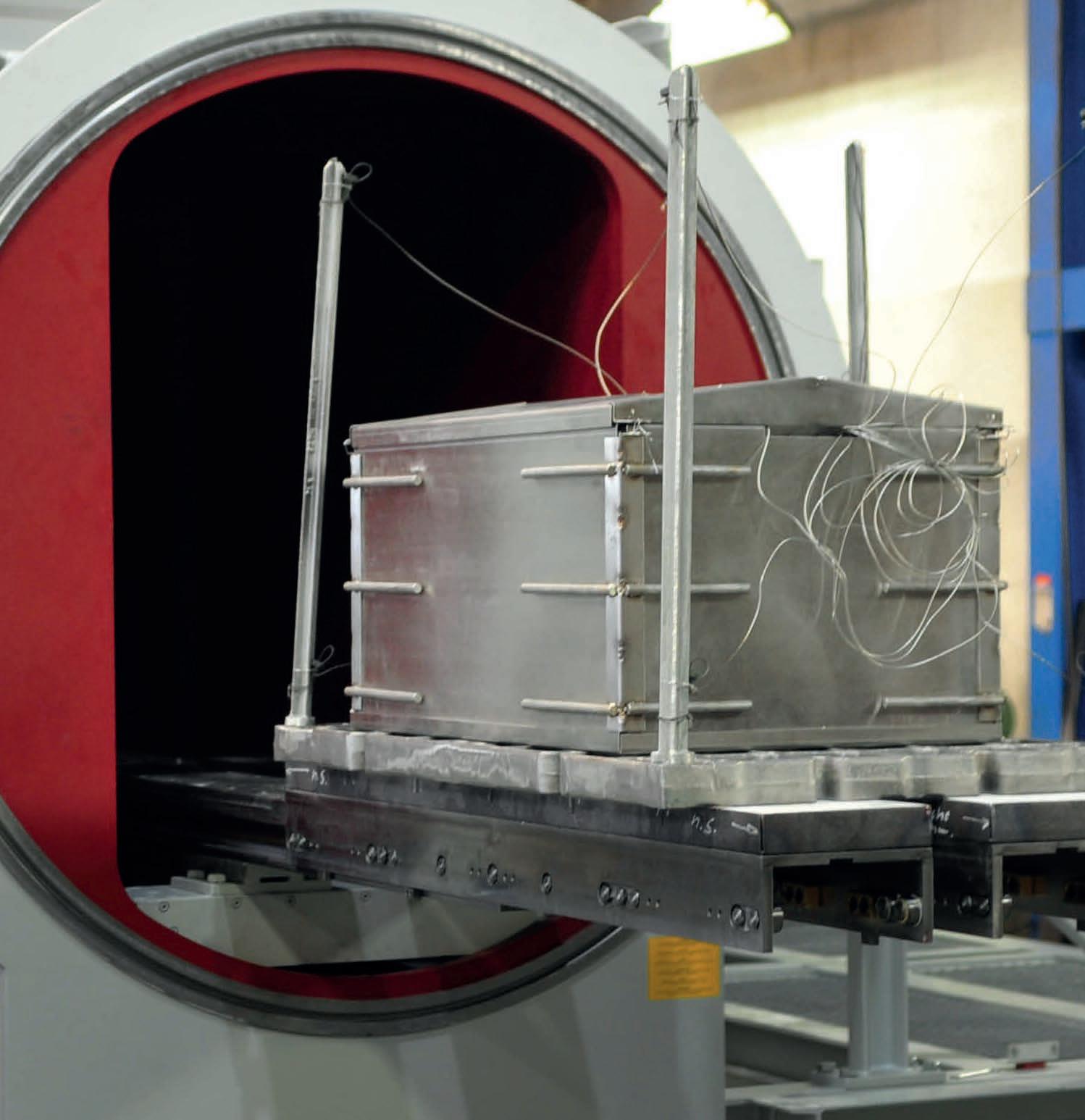

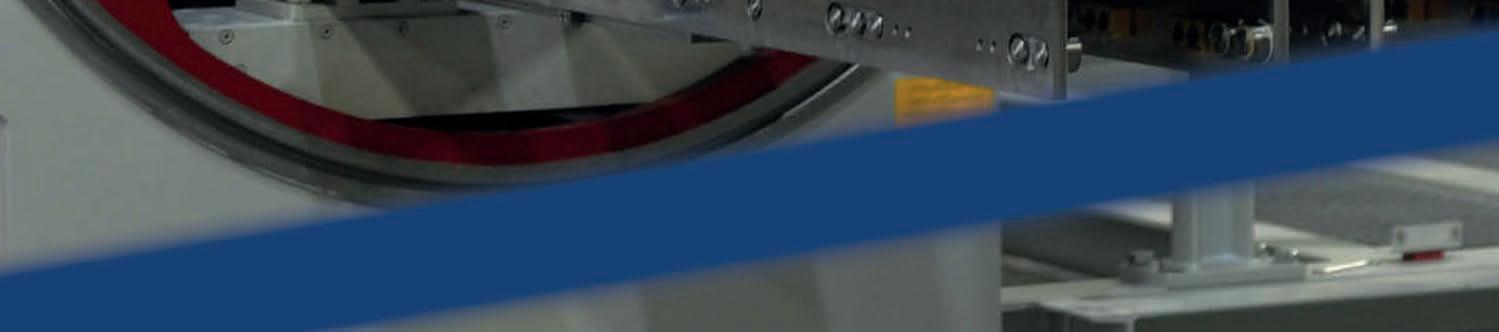

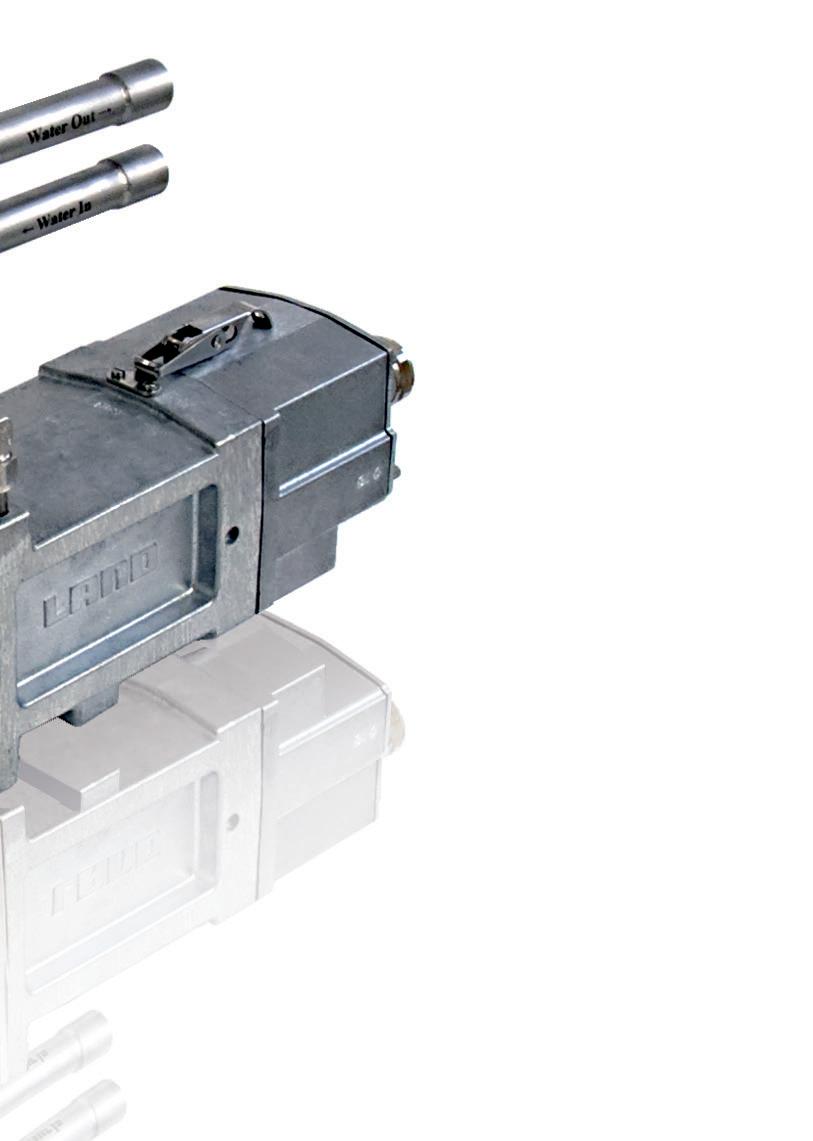

Getting to the true core of the matter!

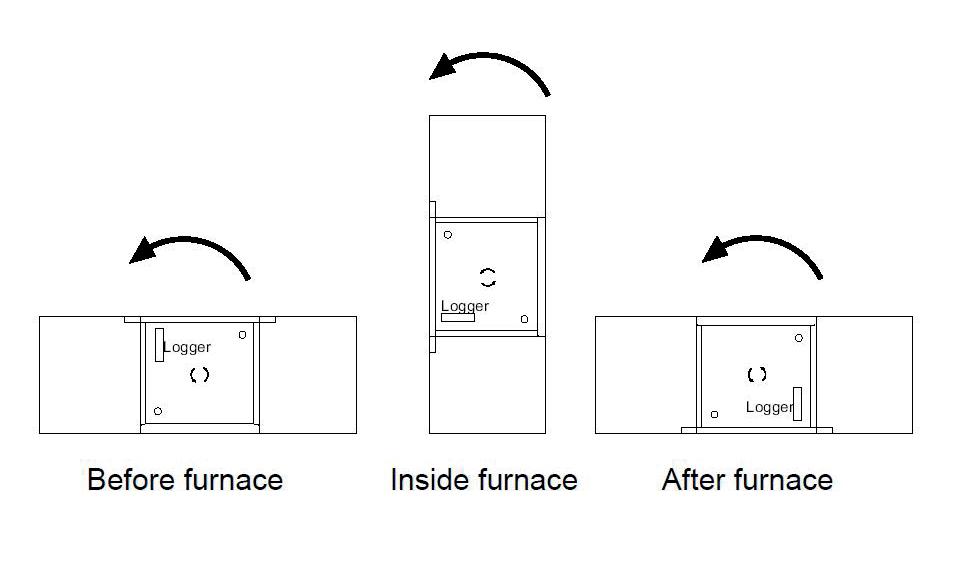

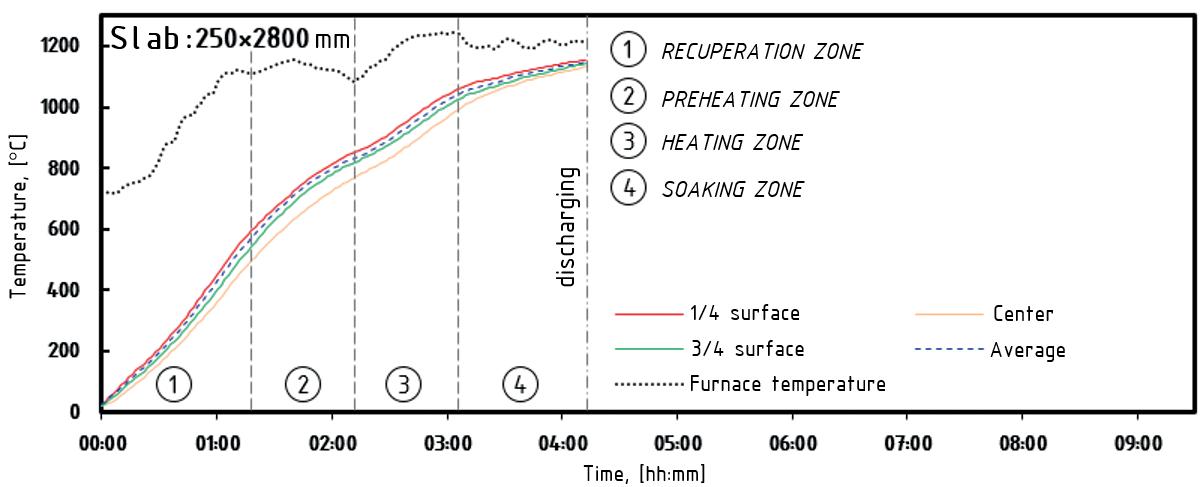

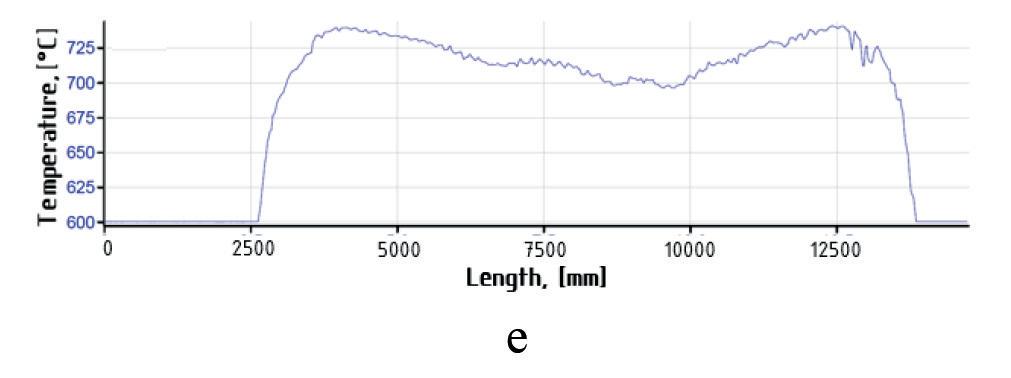

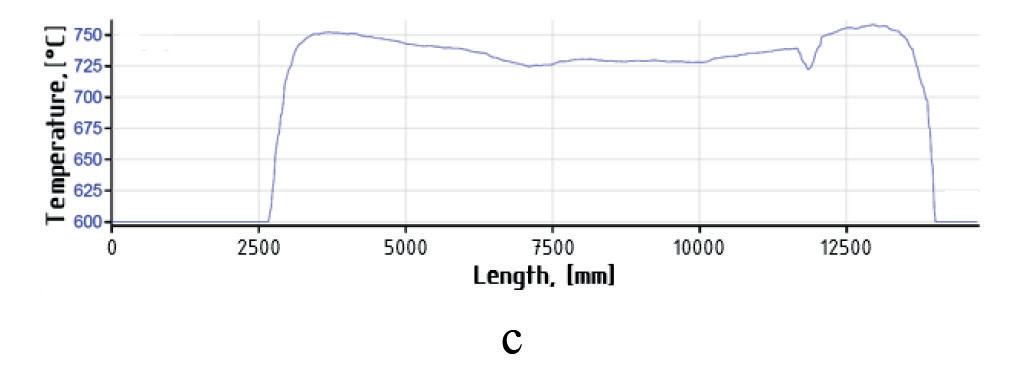

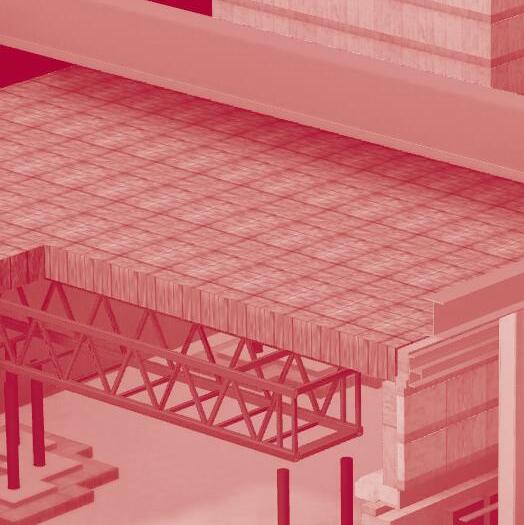

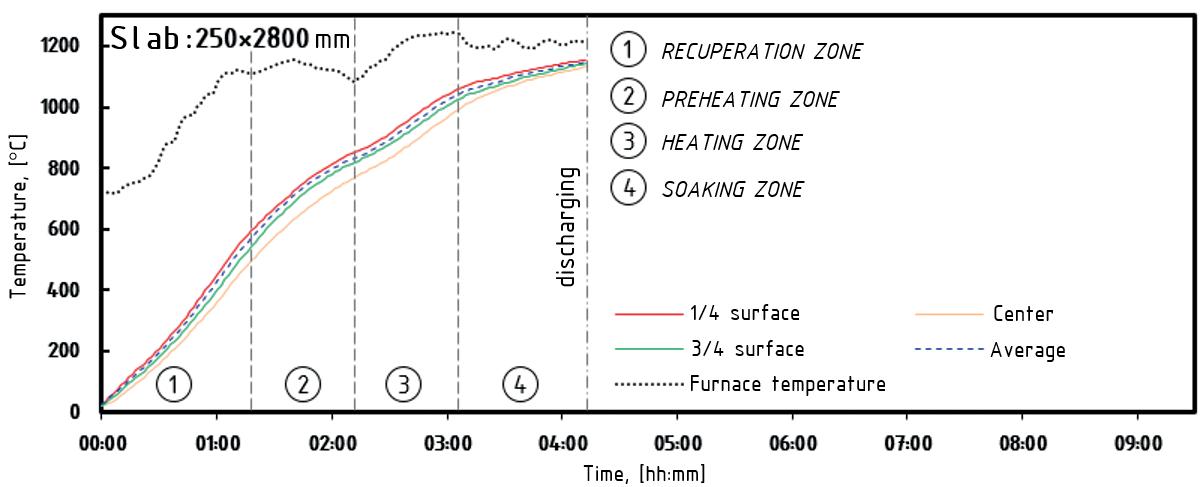

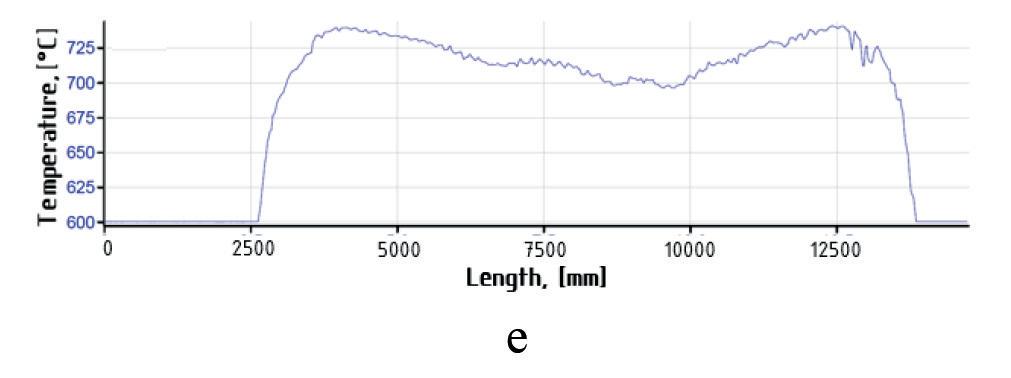

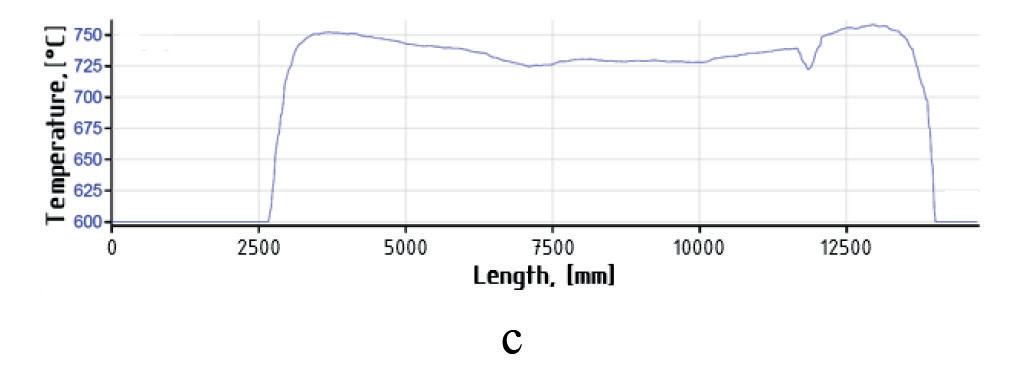

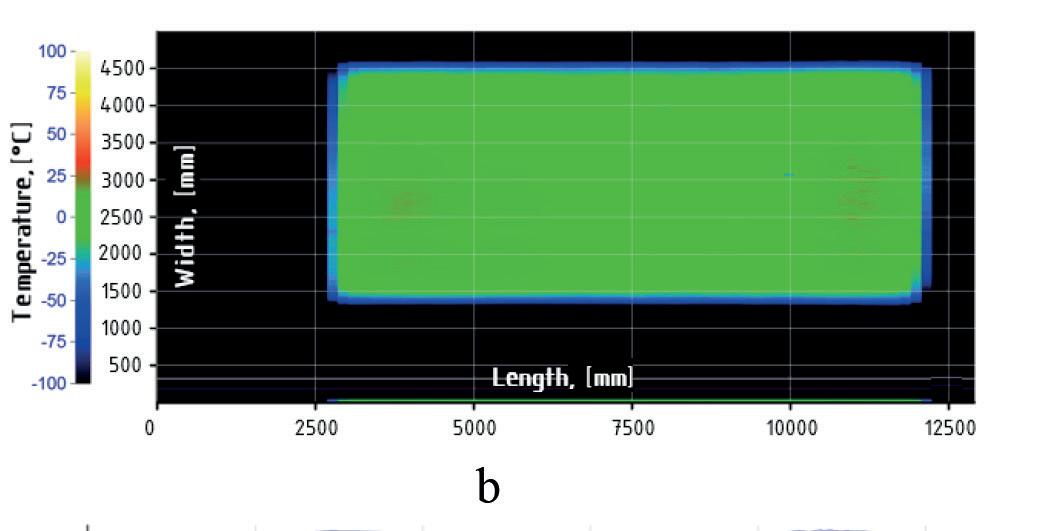

Thru-process temperature monitoring of aluminium slabs and ingots in continuous pusher furnace heat treat processes prior to rolling operations.

By Dr Steve Offley*

Introduction: Aluminium Flat Rolled Product Market

In today’s manufacturing market, aluminium, being lighter, safer and more sustainable, is increasingly becoming the material of choice. A key player in this market is aluminium flat rolled products. These include sheet, plate and foil. The market size is estimated to be worth USD 114240 million in 2023 with a CAGR of 4.8% during the forecast period 2023-2030.

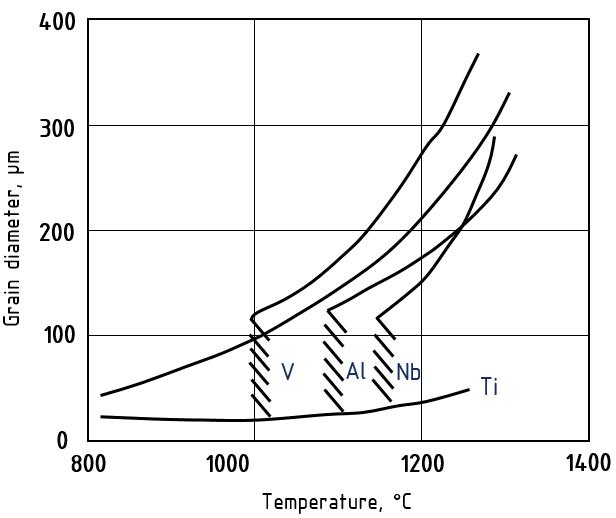

Aluminium flat rolled products are usually manufactured by rolling thick aluminium (slabs, ingots or billets) between rolls that reduce the thickness. Aluminium rolling can be performed cold (cold working), where the rolling process hardens and strengthens the material through changing the micro-structure, but this may leave the final product brittle. Hot rolling in contrast requires heating of the stock material (hot working) between 260 and 550 °C (500 and 1022 °F) before being processed through roller mills of decreasing thickness applying force to the top and bottom of the slab. Hot rolling prevents most, or all work hardening and allows the aluminium to remain ductile. The classification of the final rolled product is determined by thickness plate (<0.25 inches / 6.3 mm), sheet (0.008 inches / 0.2 mm to 0.25 inches / 6.3 mm) or foil (< 0.008 inches 0.2 mm).

Aluminium Slab/Ingot Reheat Processing Control

In the hot working of aluminium stock, the initial cast slab is passed through continuous pusher furnaces to reheat and homogenise at temperatures up to typically 550 °C (1022 °F). The actual set-point temperature and soak time employed in the process is obviously influenced by the stock characteristics including type of alloy and the physical dimensions of the slab, thickness, and overall thermal mass. Although modern furnaces incorporate sophisticated temperature control methods, often based on intelligent mathematical models, the success of the heat treat programs requires independent validation. The process engineer needs to understand how the furnace program characteristics, unique to each furnace (temperature and time) effect the temperature of the aluminium slab throughout the complete production heat treatment cycle (passage through the furnace) at different locations within the slab structure (length, width, and depth). Other techniques used for product temperature measurement in process, including furnace contact thermocouples and IR temperature measurement (spot, scanner, or camera) limit temperature to the slab surface and often are restricted to one face of the slab only. To achieve efficient hot rolling, it is critical the correct slab drop out temperature is achieved through the entire slab core.

Validation of Furnace Control Programs – Slab Temperature Profiling Challenge

Marketing Manager PhoenixTM Ltd UK

To validate the performance of the heat treat process, a temperature profile of the slab temperature at different locations within the slab through the heat treat furnace 19

Furnaces International September 2023 www.furnaces-international.com

*Product

LIFE OF

FURNACETECHNICAL FOCUS

A

is needed. Historically the temperature profile was achieved using the method of trailing thermocouples. An external data logger would collect temperature data from thermocouples attached to the slab fed through the furnace during the slab transfer. This measurement approach is not ideal for the following reasons;

� The number of temperature measurement points is limited due to cost and the difficulty of manoeuvring multiple long thermocouples through the furnace

� Due to thermocouples trailing into the furnace it is often not possible to charge slabs behind the test piece, meaning that the trial is carried out in a furnace that is not fully loaded. Temperature data is not therefore an accurate rep-

resentation of true production conditions.

� Opening and closing of furnace doors may inhibit the use of long thermocouples.

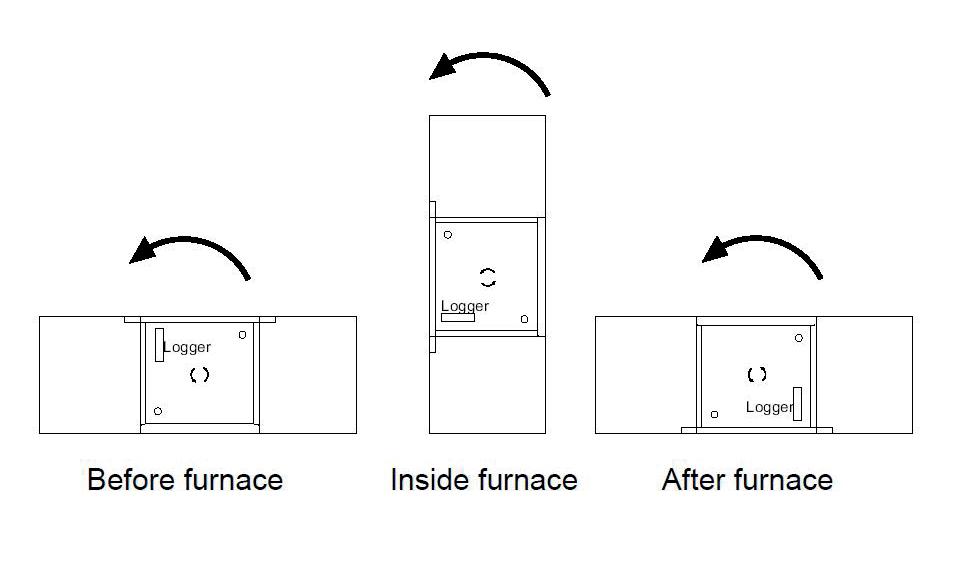

� In the pusher furnace the slab is rotated 90 ° at entry and exit from furnace which creates damage or disconnection risks to the fitted trailing thermocouples.

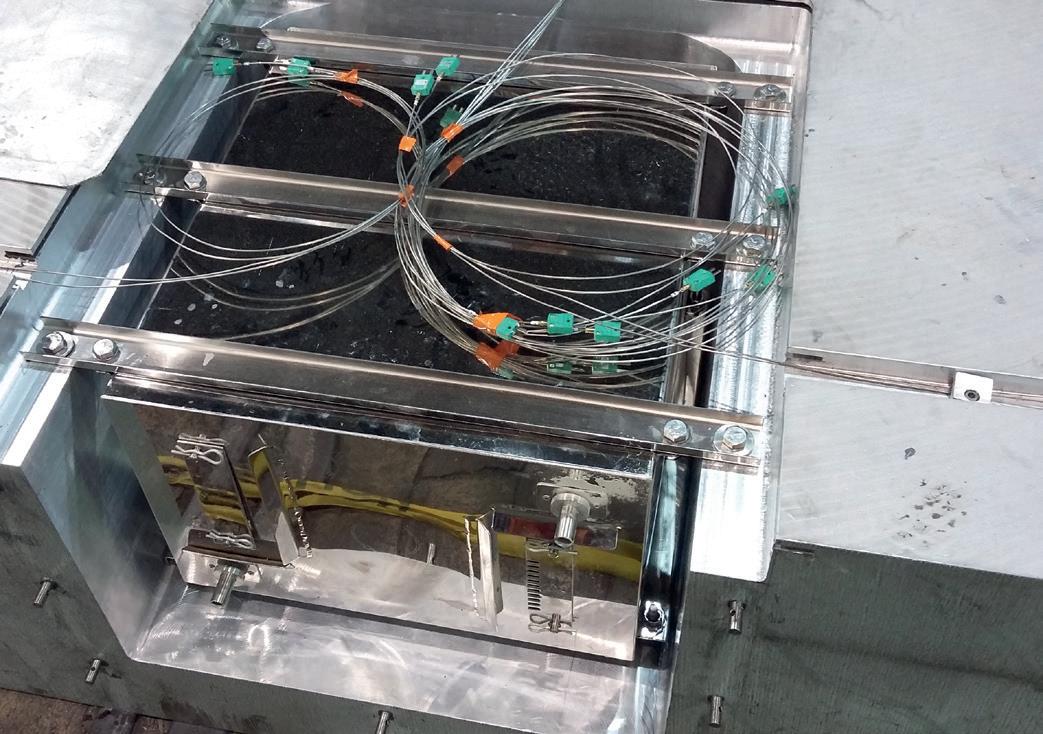

To eliminate the inherent problems of the trailing thermocouple approach, the alternative method of thru-process temperature profiling is recommended. As its name suggests the measurement system (data logger) passes through the process attached to the test slab during normal production conditions, measuring the temperature of the test slab using short

thermocouples at up to 20 critical points. The data logger is protected from the heat of the furnace by a highly efficient thermal barrier which keeps it at a safe operating temperature. As the monitoring system is self-contained within the test slab, the system is free to travel safely through the furnace without any of the inherent challenges of long trailing thermocouples as part of the standard production cycle within a fully loaded furnace.

Thru-process Temperature profiling system design

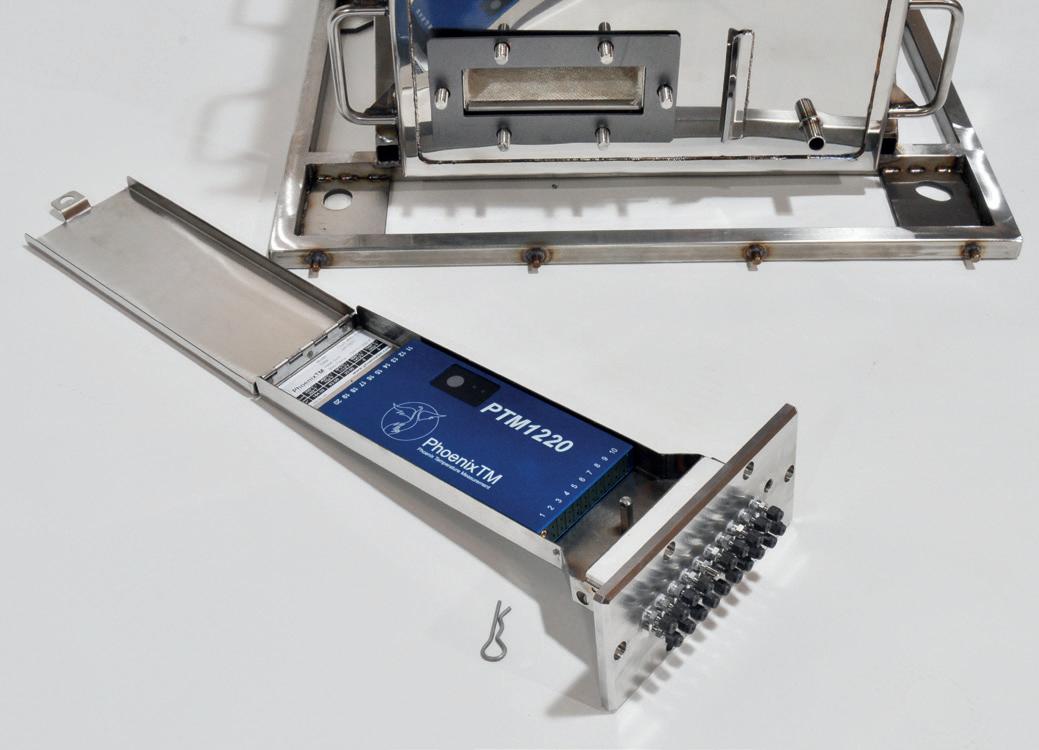

PhoenixTM Data logger Range

At the heart of the monitoring system is the data logger designed specifically for

20 Furnaces International September 2023 www.furnaces-international.com

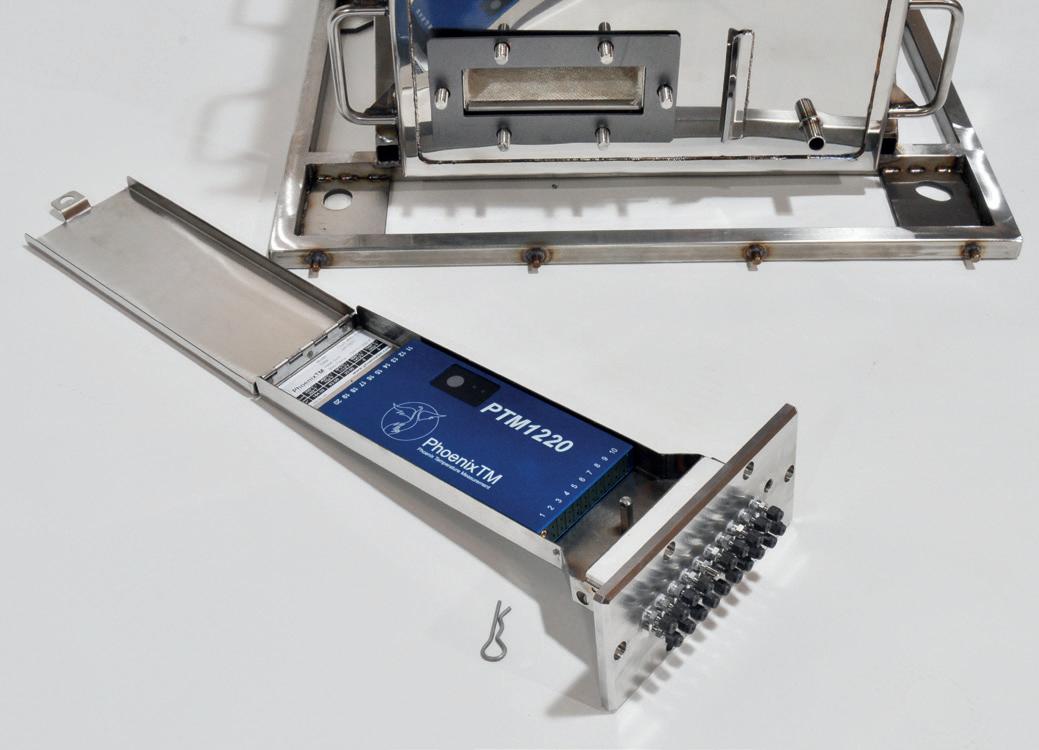

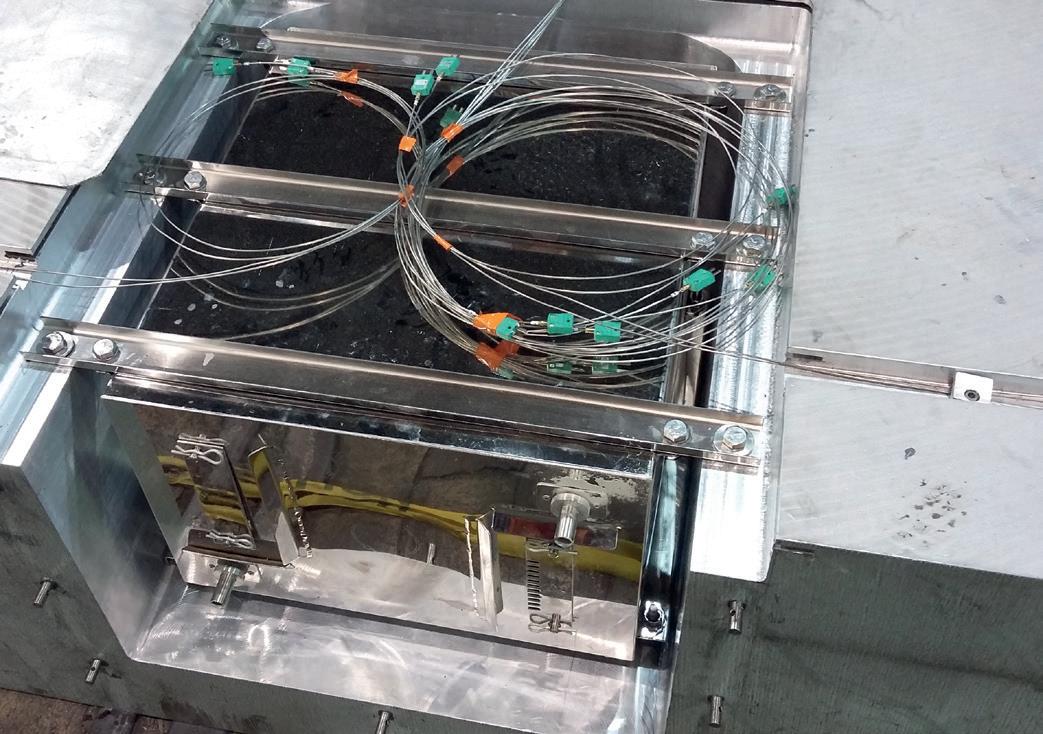

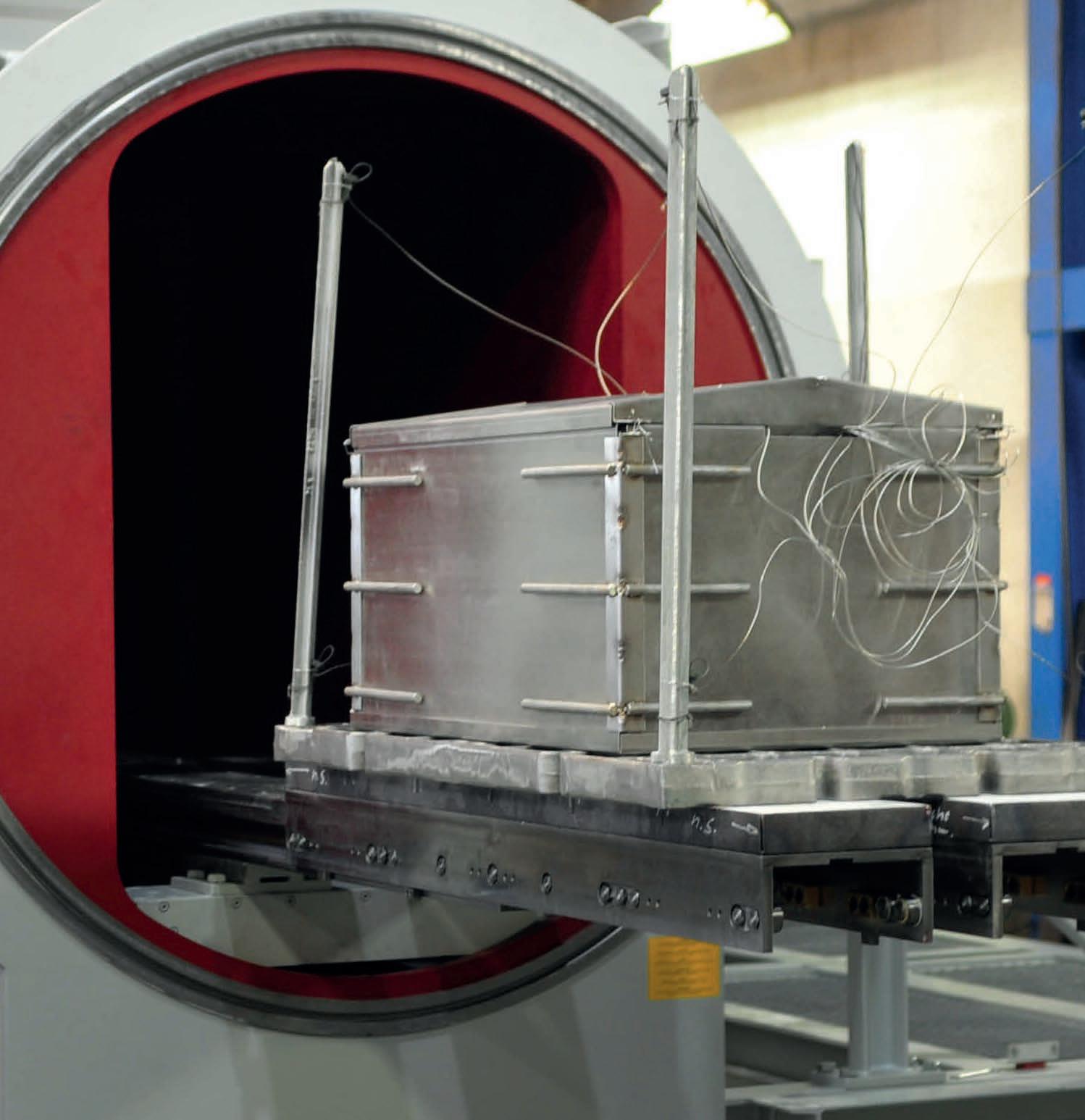

Figure 1. PhoenixTM PTM1220 20 Channel high temperature data logger shown in data logger barrier tray with IP67 thermocouple compression fittings ideal if water spray quenches are employed.

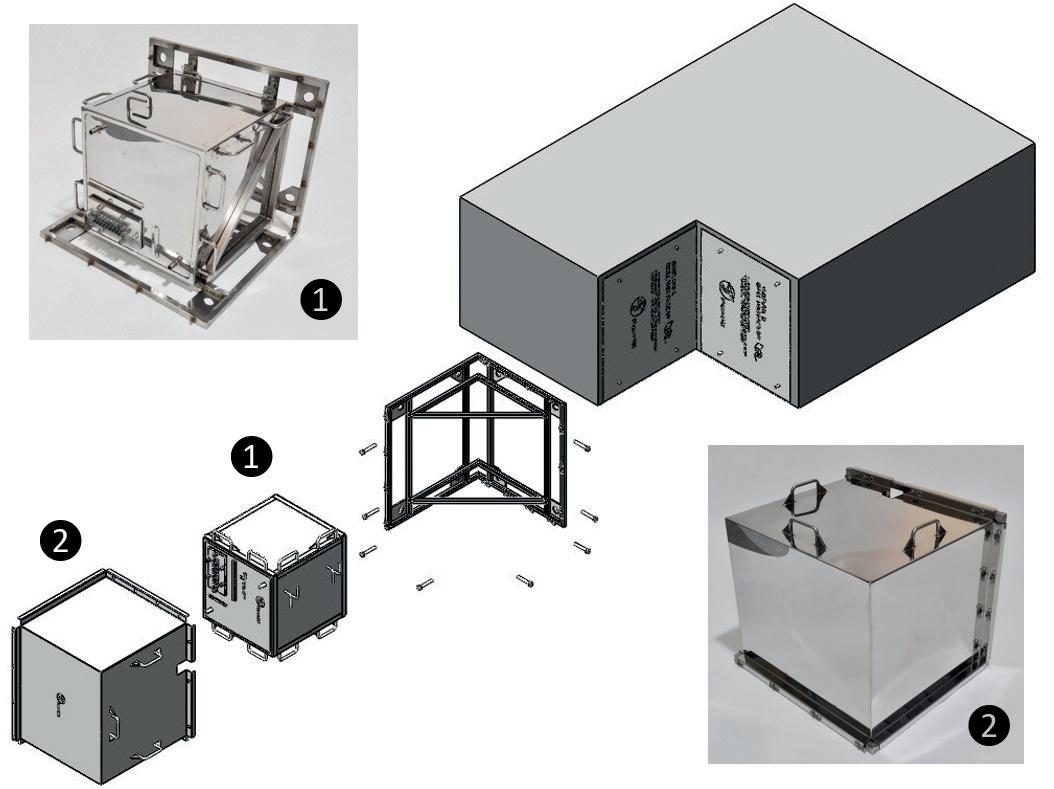

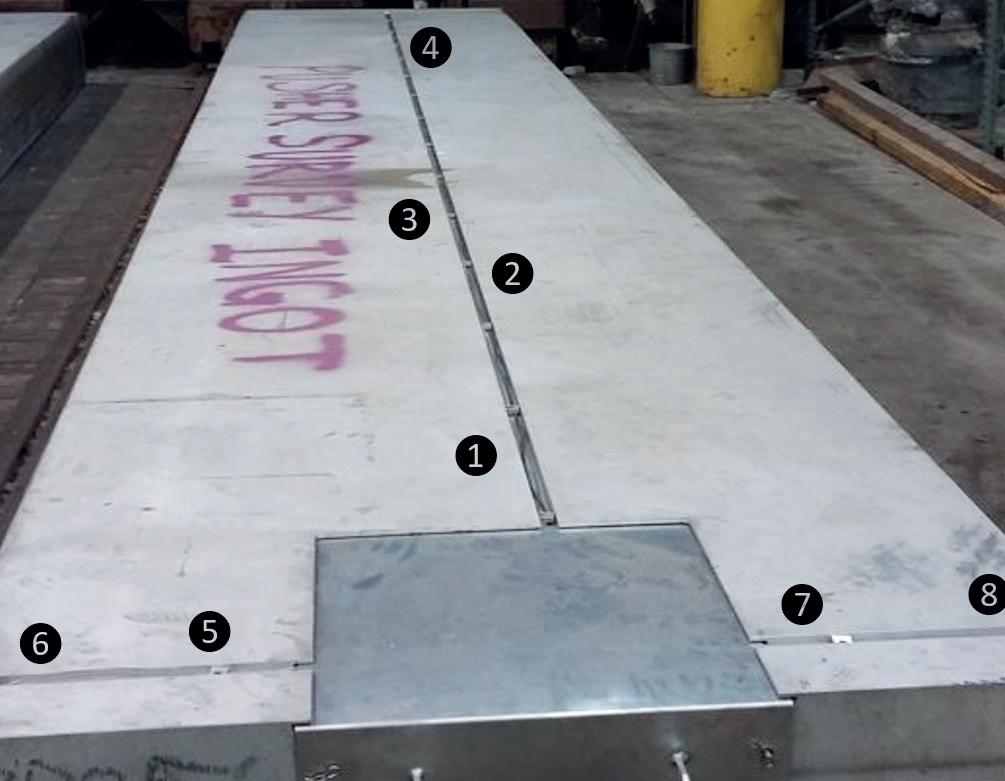

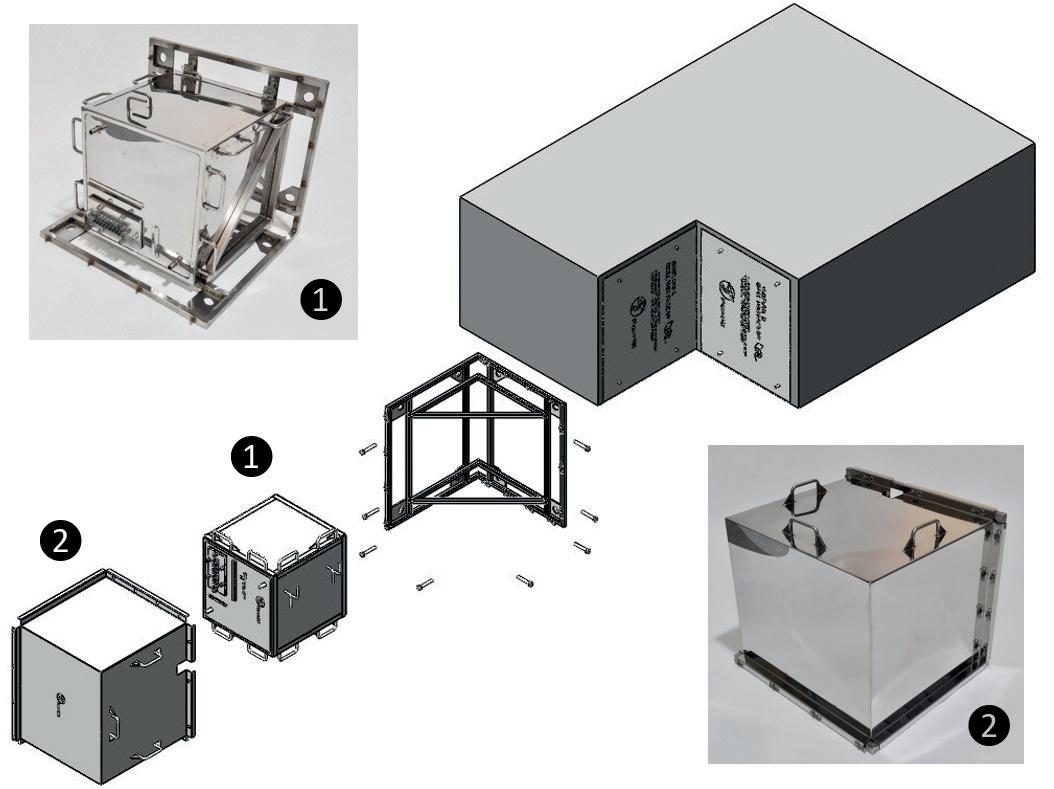

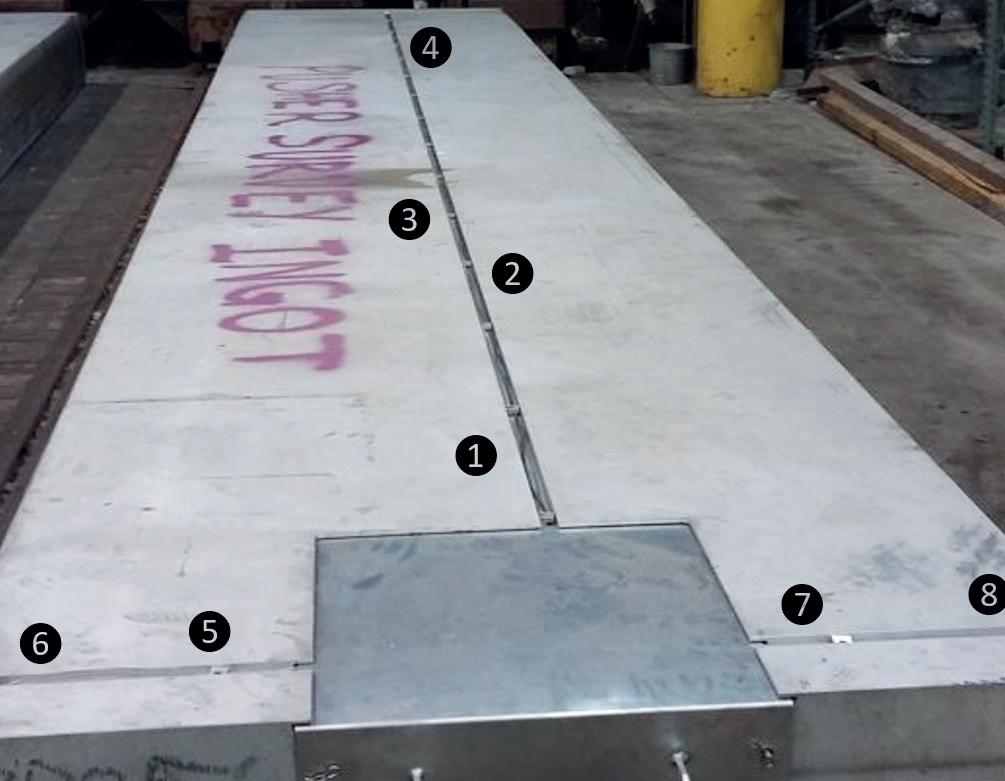

Figure 2. Aluminium slab thermal barrier showing (1 & 2) dual data logger tray within water tank and (3) filler and exhaust pipes and (4) slab mounting points.

Figure 3. PhoenixTM System embedded in aluminium slab/Ingot (1) - stainless steel cover to protect from high velocity air flow in furnace (2).

Figure 1

Figure 2

Figure 3.1 thru-process

TECHNICAL

Figure 3.2 thru-process

LIFE OF A FURNACE

FOCUS

use in the hostile heat treat environment. Data loggers can be provided in a variety of configurations to suit the specific demands of the process being monitored. Models ranging from 6 to 20 channels can be provided with a variety of thermocouple options (types K, N, R, S, B) to suit measurement temperature and accuracy demands (AMS2750 & CQI-9).

The loggers can be offered in either standard <80 °C (176 °F) or high temperature operating temperatures (Barrier Core Temperature <110 °C (230 °F) variants to allow use of either standard thermal barrier designs (Dual Phase - Heat Sink) or high performance (Phased Evaporation – Water Tank) as recommended for use in the demanding aluminium reheat pusher furnace monitoring application.

Although thermally protected by the thermal barrier, the operating temperature of the data logger during transfer through the furnace will increase up to the safe maximum operating conditions (100 °C (212 °F) in evaporative water barrier). The data logger temperature change, which would normally affect the thermocouple reading, is automatically compensated for using an accurate internal temperature compensation feature protecting the measurement accuracy in process.

Built to cope with hostile industrial environments the IP67 logger is capable of managing even the most demanding

processes where water spray quenching may be necessary.

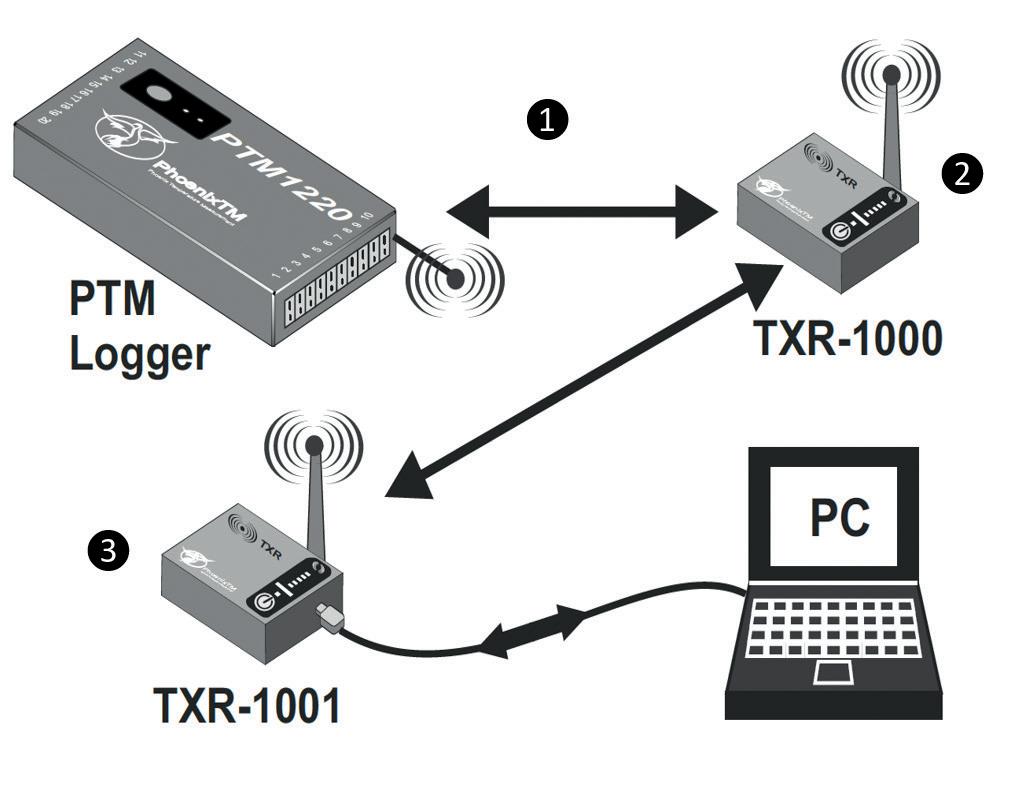

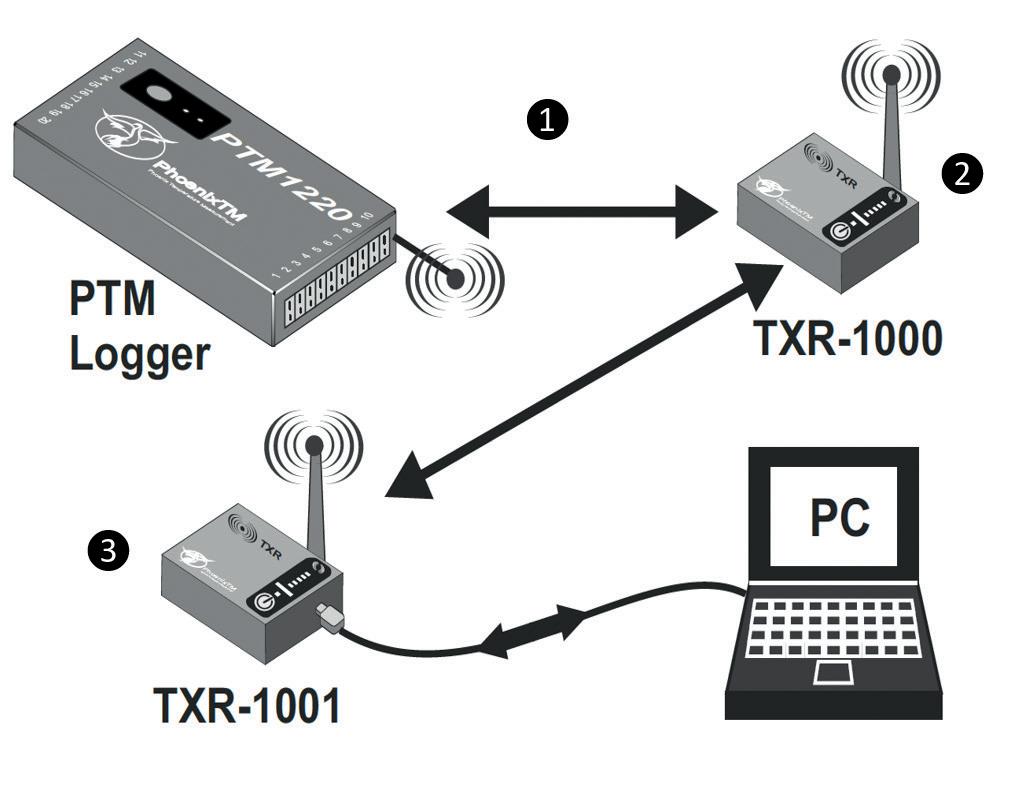

Provided with Bluetooth wireless connection for short range localised download and reset (direct from within the barrier) the logger memory of 3.8M allows even the longest slab reheat processes (20 hours) to be measured with highest resolution to deliver the detail you need. An optional unique 2-way telemetry package offers live real time logger control and process monitoring with the benefits detailed in the later following section. (Figure 1&7)

Thermal Barrier Design

Heat treating a 30 tonne 600 mm / 24 inch thick aluminium slab requires significant heat to achieve homogeneity. Processes are typically therefore up to 20 hours at 500 °C / 932 °F and as such the thermal barrier used to protect the data logger needs to be very efficient but at the same time be compact enough to allow safe installation within the slab. For such process the recommended thermal barrier design is based on a dual phased evaporation technology. The high temperature data logger operating safely

21 Furnaces International September 2023 www.furnaces-international.com

Figure 4. PhoenixTM System schematic showing exploded thermal barrier configuration with slab mounting frame (1) Thermal barrier photo positioned on frame (2) Thermal barrier with fitted protective high velocity air cover.

Figure 4

Figure 5

Figure 5. Test Slab with installed monitoring system being loaded into the furnace (1) and schematic showing rotation steps (2).

TECHNICAL FOCUS

Figure 6. Test Slab with thermocouple channels routing MI thermocouple cable to point of measurement at the desired depth (channel 1-8).

LIFE OF A FURNACE

at temperatures up to 110 °C / 230 °F is housed within the dry cavity of a water tank. Data logger sealing options within the thermal barrier are available including IP67 compression fittings, recommended if water spray quench steps are employed in process (Figure 1). During transfer through the furnace, the water heats up to its boiling point at 100 °C / 212 °F and then maintains the temperature as water phase changes from liquid to gas (steam). The rate by which the water temperature in the tank rises is further controlled by an outer skin of microporous insulation, which helps reduce rapid temperature changes and associated risk of distortion problems for the thermal barrier structure.

The exact thermal barrier protection is governed by the capacity of the water tank. When specifying the correct thermal barrier design often there is a fine balance between maximising the size of the water tank and volume of water available to the outer dimensions of the thermal barrier suiting the size of the slab being monitored.

A feature of the pusher furnace design is that the slab is rotated at the entrance and exit of the furnace to maximise loading capacity. The rotation of the slab (Figure 5) and therefore also thermal barrier could create problems with water loss and deterioration in thermal capacity. The water tank construction is designed therefore in a unique way to orientate water filler and steam exhaust pipes to minimise water loss during any rotation

Fitting the monitoring system to the test slab

Generally, a test slab is prepared by machining a portion out to accept the monitoring system with the thermal barrier often positioned centrally and in a position where it will not impede any equipment used to load / unload the slab (Figure 3). Bolts securing the thermal barrier to the slab should be of a sufficient depth and diameter to ensure they don’t break away from the hot aluminium as the slab rotates at the furnace exit.

The assembled monitoring system fitted within the slab cavity is covered with an external metal shield (Figure 3). The shield has two purposes to firstly protect the thermal barrier from high levels of heat transfer from high velocity hot air convection and maintain air flow patterns over the slab itself to maintain normal production heating conditions.

Thermocouple Placement

Temperatures within the slab are measured from the tip of the mineral insulated thermocouple as shown in figure 6. To position the tip at the exact location / depth within the slab pilot holes need to be drilled in the slab. Depending on the type and diameter of thermocouple to be used, aluminium bushes may need to be used as guides. If a small diameter thermocouple is used, for example a 1.5mm 1/16 inch diameter mineral insulated type, then it would be impractical to drill a small hole say 300mm / 11.8 inches deep to the measuring point. In this case a large diameter hole can be drilled, and bushes used. It is essential that the thermocouples are firmly secured to the

slab as they travel from the data logger to the measuring point. Often the thermocouples are channelled along groves in the slab surface so that the cables are confined within the slab eliminating snagging risks in the furnace, or on charging / discharging the equipment.

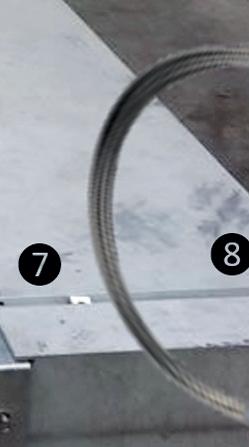

Real Time Communication

Conventionally profile data collected during the test is downloaded to a PC running analysis software post run. Alternatively, it is possible to collect data in real time live utilising an RF telemetry option. The data logger is available with a unique 2-way RF system option allowing live monitoring of temperatures as the system travels with the product through the furnace. Furthermore, if necessary using the RF system it is possible to communicate with the logger, installed in the barrier, to reset/download at any point pre, during and post-run.

Provided with a high performance ‘Lwmesh’ networking protocol, the RF signal can be transmitted through a series of routers linked back to the main coordinator connected to the monitoring PC (Figure 7). The routers being wirelessly connected are located at convenient points in the process to capture all live data without any inconvenience of routing communication cables as needed on other commercial RF systems. The operator from the convenience and comfort of his control room / office can see what is happening in the process live. For a 20 hour slab reheat process, such live data gives the operator confidence that process is working in real time, without that nervous wait with a non-RF system to download from the logger at the end of the run.

22 Furnaces International September 2023 www.furnaces-international.com

Figure 7. Installed system on slab showing (1) RF telemetry Antenna and (2) portable RF repeater unit transferring live temperature data direct from furnace back to (3) RF coordinator linked to the monitoring PC.

step. (Figure 2)

TECHNICAL FOCUS

LIFE OF A FURNACE

In many processes, there will be locations where it is physically impossible to get a RF signal out of the furnace. With conventional systems this results in process data gaps. For the PhoenixTM system this is prevented using a unique fully automatic ‘catch up’ feature. Any data that is missed will be sent when the RF signal is re-established ensuring in most applications 100% in-process data review.

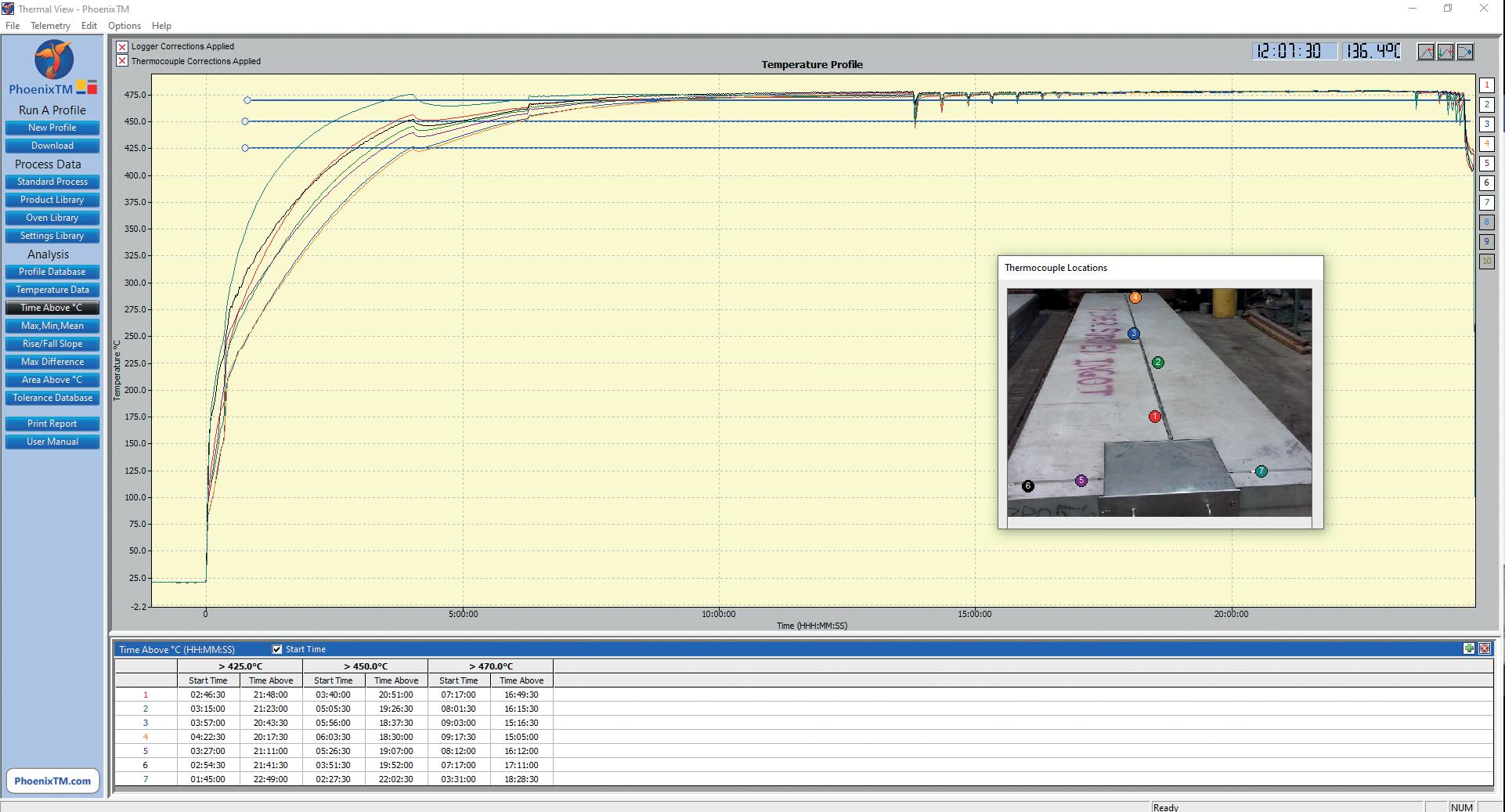

Handling the Data

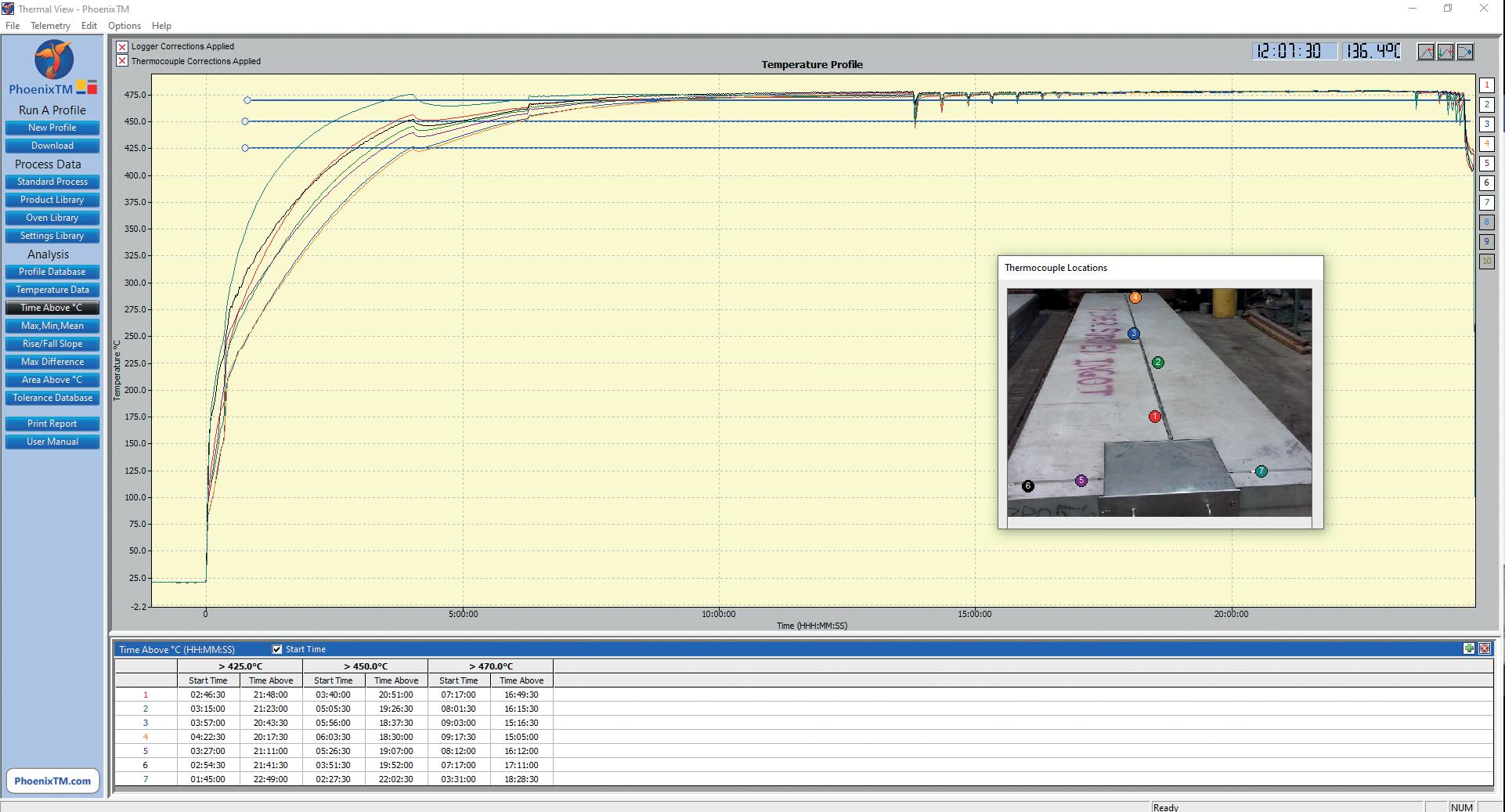

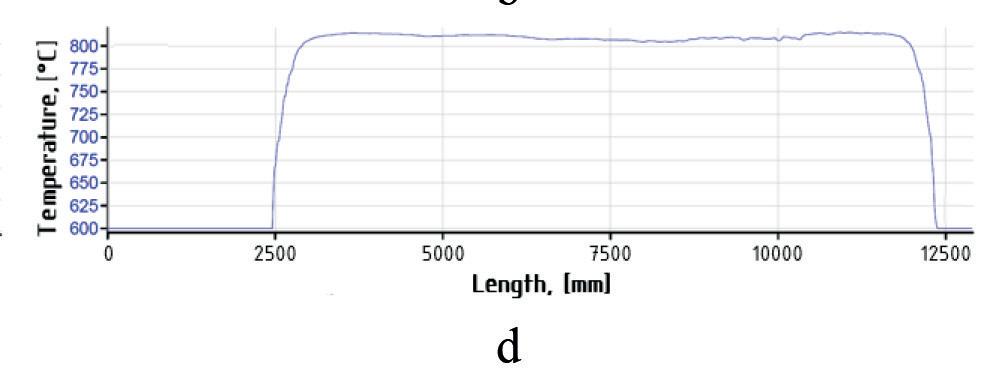

The result of the thru-process monitoring step is the invaluable temperature profile graph (Figure 8). The profile graph represents a thermal fingerprint of what temperatures the aluminium slab achieved through the process at the selected locations over the slab foot print and at specified depths within its core. The profile data can be interrogated in detail to fully understand the heat treat operation at the critical product level and be used to control, optimise and validate the furnace operation. Such data is essential to accurately set-up and verify mathematical model predictions used to control the furnace operation and ensure that the process is run efficiently to save energy, improve productivity and reduce

carbon emissions.

Conclusion

Thru-process product temperature profiling is an accurate and efficient method to measure aluminium slab internal core temperatures in pusher furnaces prior to hot rolling operations. Product temperature information gleaned helps to ensure that the correct thermal balance

is achieved efficiently throughout the product thickness. Non-homogeneous temperature conditions can be prevented that would potentially cause variation in downstream processing and compromised final product quality, ultimately leading to energy wastage, higher costs, and rejections. �

www.phoenixtm.com

We are your premium refractory partner

As a supplier of high-quality customized refractory solutions we can assure you of:

• A comprehensive range of refractory materials for applications up to 1800 °C for all types of industries

• Expert know-how of customer processes, engineering and installations

• Long-term partnership in technology and services

• Solutions to reduce your carbon footprint and to save energy

www.rath-group.com Think higher! Accept only the best refractory solutions and expertise

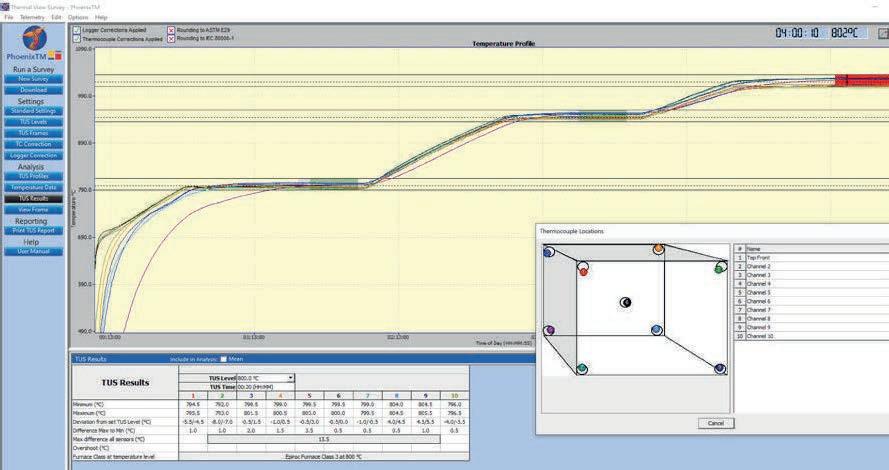

Figure 8. Temperature profile graph showing the temperature variations within the aluminium slab core over the entire heat treat process. Soak times at critical temperatures can be accurately calculated to ensure that drop out temperatures and rolling operations are performed correctly.

LIFE OF

FURNACETECHNICAL FOCUS

A

*Principal Consultant, Glass Container Manufacturing Consulting Ltd. (GCMC), peter.firth@gcmc-worldwide.com, www.gcmc-worldwide.com

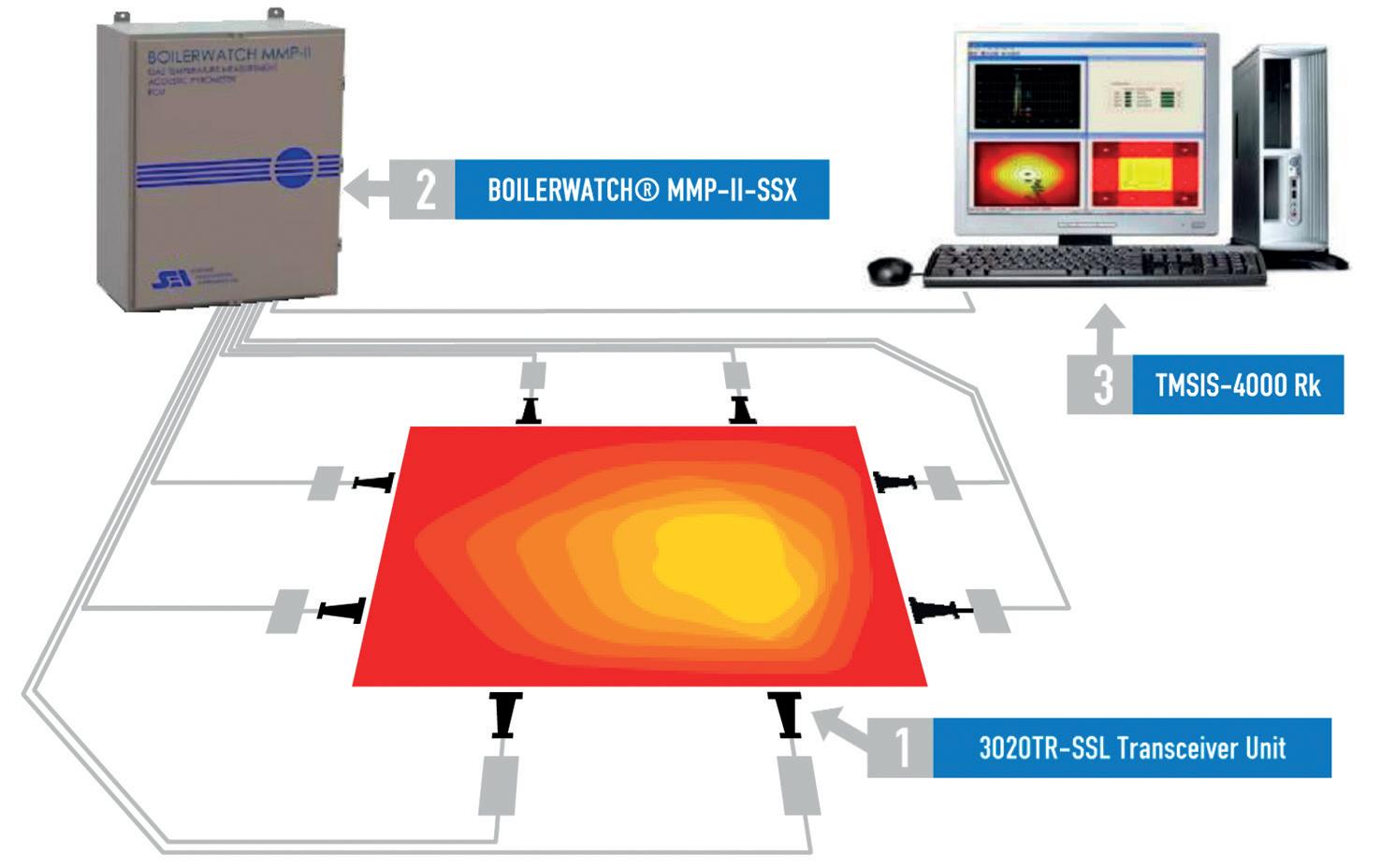

Assessing Boilerwatch® for potential benefits in glass manufacturing

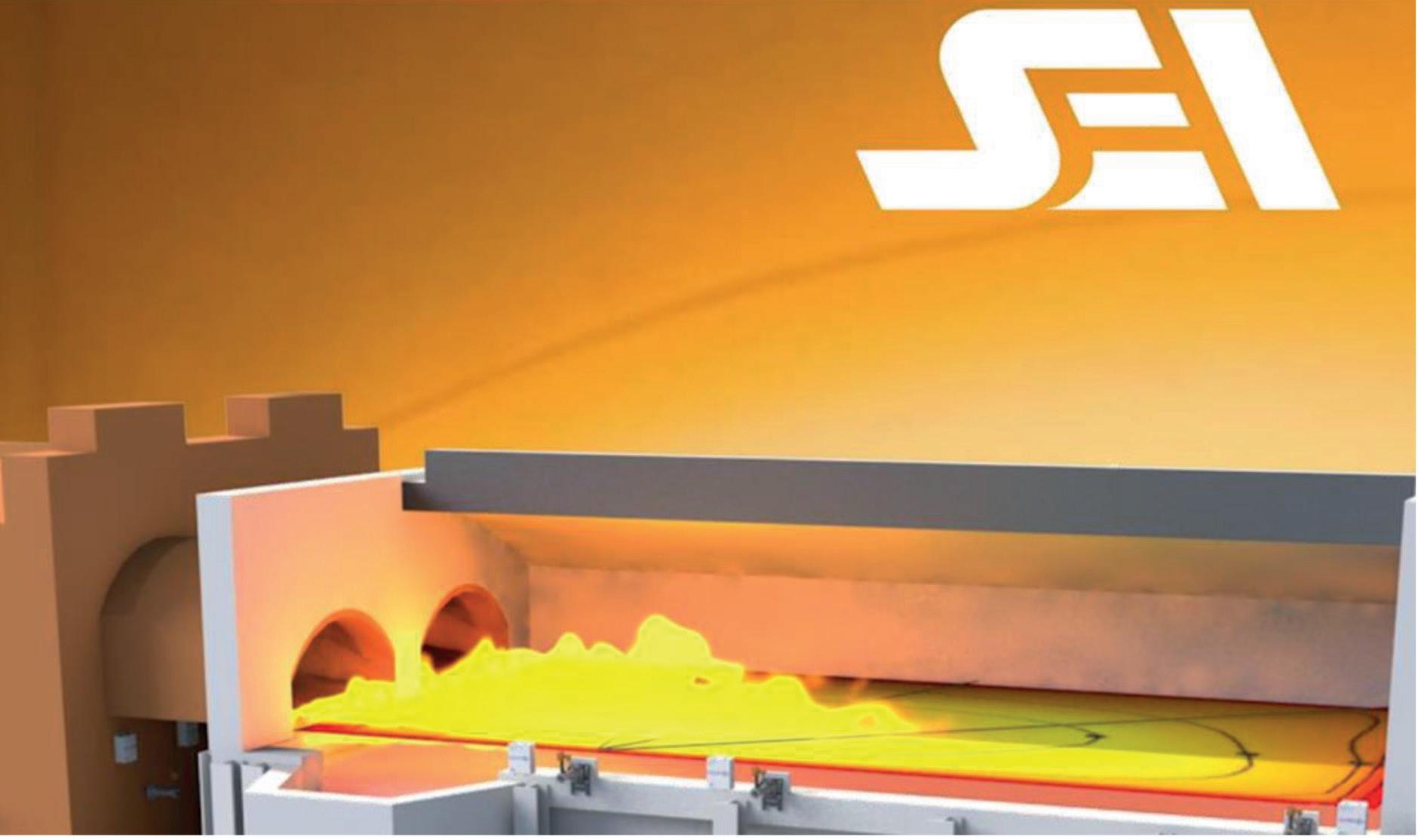

Meet the Scientific Environmental Instruments Inc. (SEI Inc.) GUYS.

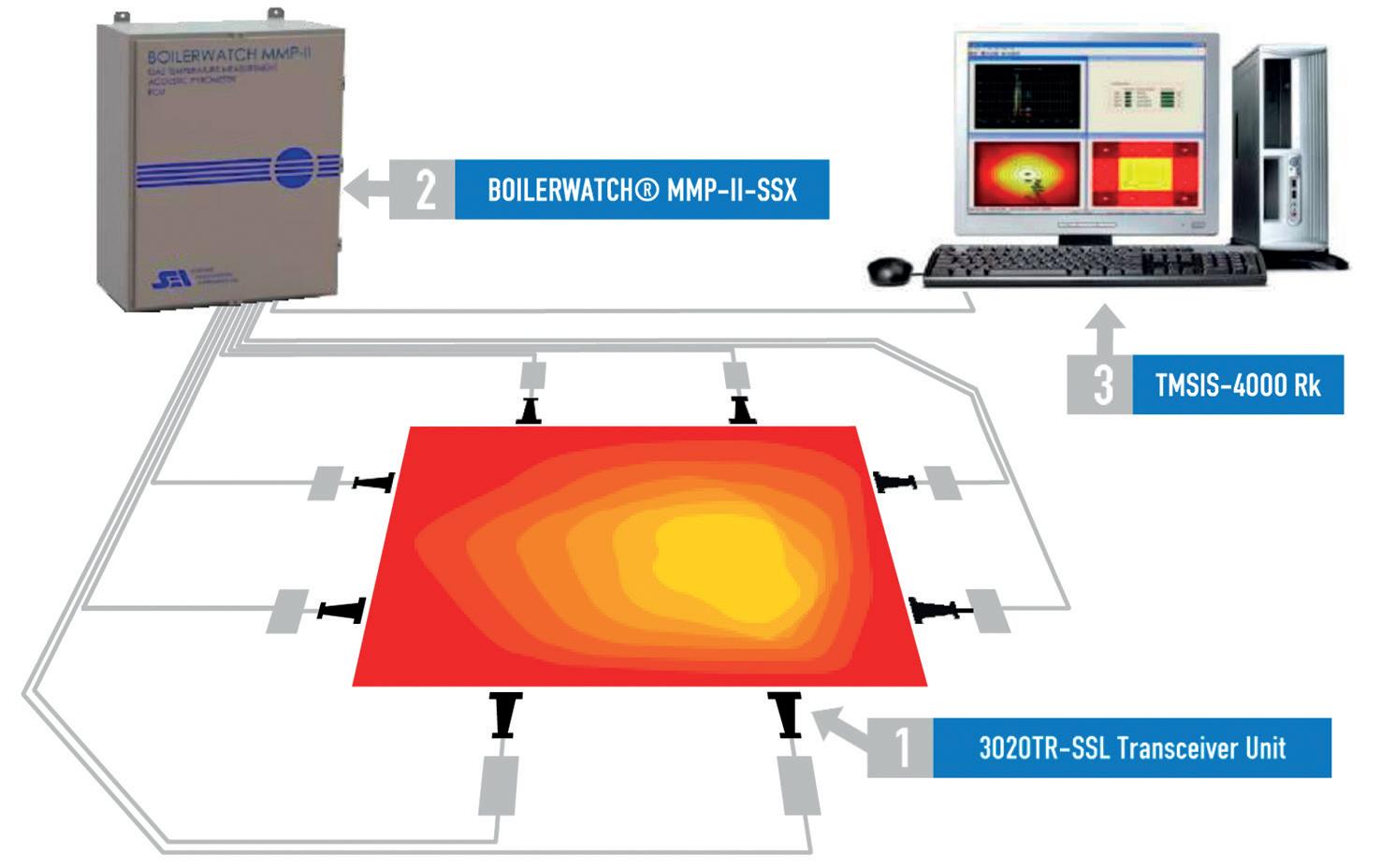

These GUYS have been providing flame combustion monitoring and control to various industries using acoustic technology and a reliance upon the ideal gas law.

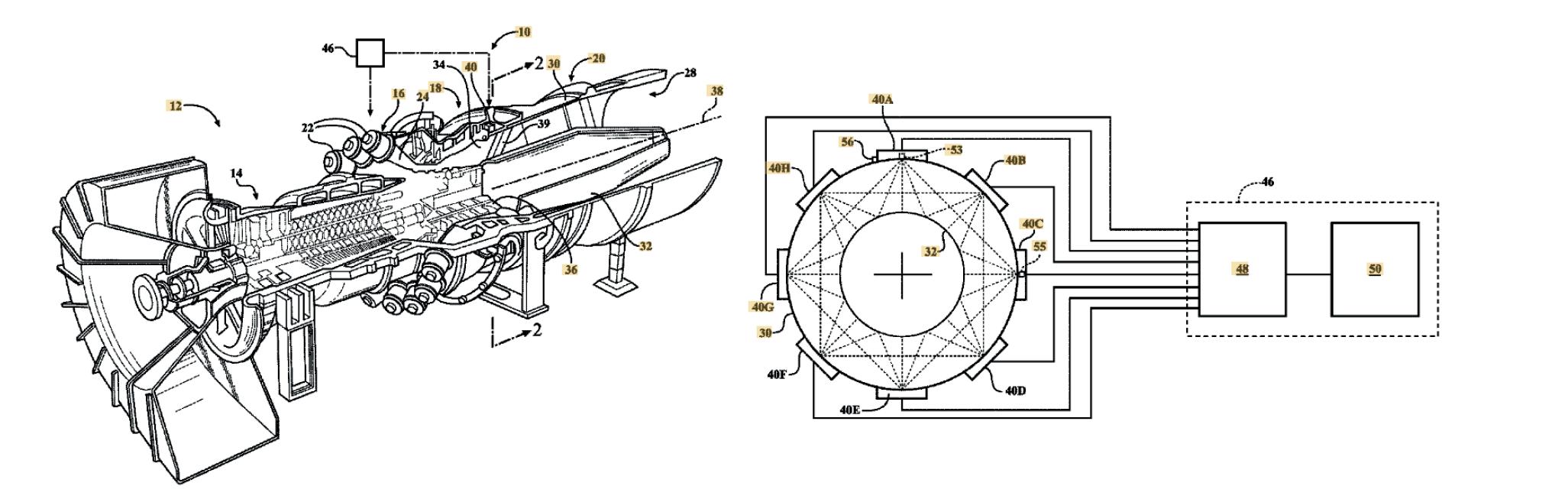

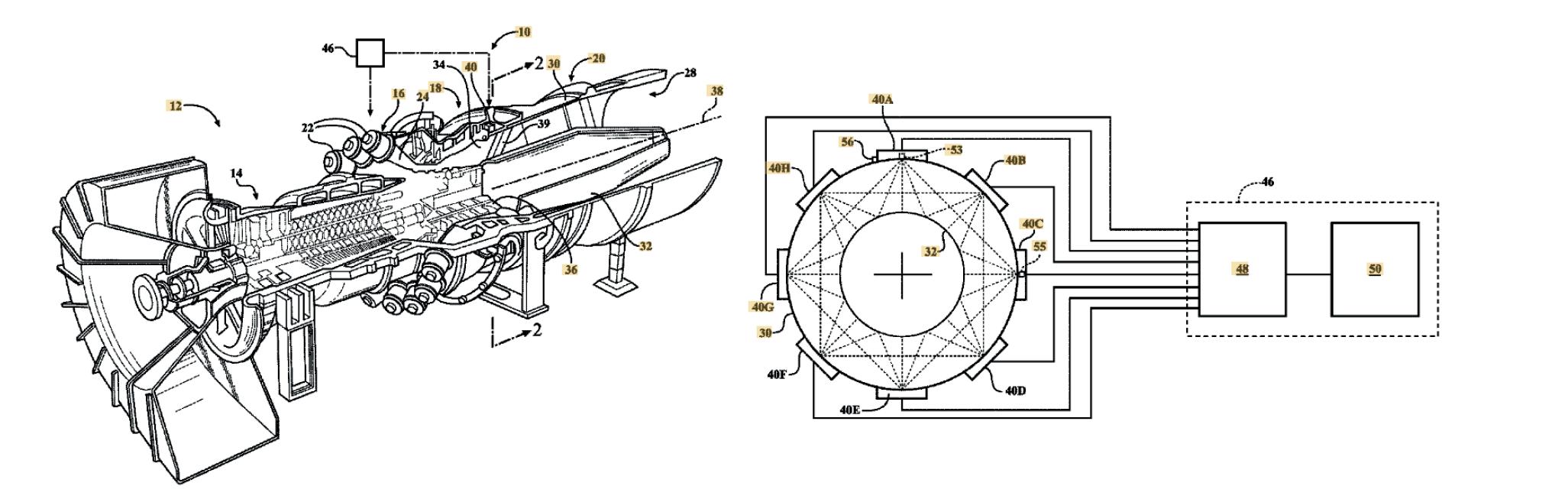

The system trade name BOILERWATCH comes from the original application in coal power plants which have very high internal combustion thermal sheers and tremendous fuel usage with multiple burners. Since then, the BOILERWATCH system has been installed in many other industries that burn fossil fuels, like oil refineries, petrochemicals, and combined cycle power plants. Siemens even have a patent for using the BOILERWATCH system at the exit plane of a gas turbine. See Patent No. US8565999B2 dated October 22, 2013.

Search any online patents database using that patent number, or use the short code link given here to access the patent document www.bit.ly/US8565999B2 . An illustration extracted from the patent document is shown in Figure 1, of which the illustration on the right will mean more to you by the end of this article.

Now the SEI Inc. GUYS are turning their attention to the benefits it can bring to the glass industry. They are actively looking for glass industry partners to prove the envisaged benefits in glass manufacturing. Recently I have been assisting SEI Inc. in raising awareness of their system through my “Meet the GUYS” initiative on LinkedIn.

NOTE: GUYS stands for Glass Up-and-coming Young Suppliers. The background to the reason for my support for the GUYS is covered in my article published in the November/December 2022 edition of Glass International. Refer to that article if you are interested to know more about this. A short link to that article is given here: www.bit.ly/MTGGI

LIFE OF A FURNACETECHNICAL FOCUS 24

Furnaces International September 2023 www.furnaces-international.com