STRUCTURAL TIMBER

The latest in structural timber building design and technologies

STRUCTURALTIMBERMAGAZINE.CO.UK

B&K HYBRID SOLUTIONS

THE RIGHT MATERIAL IN THE RIGHT PLACE WITH HYBRID DESIGN

P26

Structural Timber Awards

The 2023 shortlist reveals the huge strength and depth of those working in timber construction

P38

Designing Simplicity

A collaborative approach helped design out many complexities in the structure of ‘Paradise’

P42

Artificial Intelligence

AI and the first program to automate timber floor design offers limitless opportunities

SUMMER 2023 | £4.95 DESIGN TECHNOLOGY SUSTAINABILITY INTERVIEWS NEWS ANALYSIS CASE STUDIES

Fast,Light & Green www.metsawood.com Kerto® LVL is incredibly strong and dimensionally stable, and it does not distort or shrink. It derives its high strength from the homogeneous bonded structure and is an excellent construction material. Kerto LVL is also used as the core flange component of Metsä Wood's Finnjoist range, combined with an OSB web to provide a lightweight yet incredibly strong I-Joist, resulting in quick and reliable installation within floor, roof and wall construction. • BUILD MORE WITH WOOD • BUILD MORE WITH LESS MATERIAL AND RESOURCES, • BUILD MATERIAL EFFICIENTLY WITH KERTO® LVL AND FINNJOIST FOR FURTHER INFORMATION CALL 0800 00 44 44 OR VISIT US ONLINE Ker to® LVL & Finnjoist

FOLLOW US ON TWITTER UNDER: twitter.com/STMagUK

ADVERTISING ENQUIRIES PLEASE CONTACT: JULIE WILLIAMS// T: 01743 290001

E: julie.williams@radar-communications.co.uk

BACK ISSUES VISIT: www.structuraltimbermagazine.co.uk

SUBSCRIPTIONS VISIT: www.structuraltimbermagazine.co.uk

FRONT COVER: B&K Hybrid Solutions

Welcome to the summer issue of Structural Timber Magazine. Inside you will find the allimportant shortlist for the Structural Timber Awards 2023 plus further evidence that timber is the number one mainstream sustainable building material.

Amazingly, it is that time of the year again and the judges of the Structural Timber Awards recently completed their deliberations to whittle down over 200 entries to a select group going above and beyond the norm.

PUBLISHER: Structural TImber Magazine is produced and published by Structural Timber Media Ltd, 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS T: 01743 290001

of the building design from the start. A collaborative philosophy delivers a net zero approach and brings a ‘warmth and delight to a space that other materials often miss.’ In keeping with the essentials of circularity, its innovative detailing and connections means the building can be deconstructed and reformatted in the future.

©Structural Timber Media Ltd.

RELATED EVENTS: www.structuraltimber.co.uk/events

www.structuraltimberawards.co.uk www.offsite-expo.co.uk

DISCLAIMER: The content of Structural Timber Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

PRODUCTION

ADVERTISING CIRCULATION PRODUCTION ACCOUNTS

Each year is an eye opener for all concerned at the architectural and engineering excellence that takes place every day across the UK’s built environment. All those that have been tipped as possible winners are inside. Remember it is always a big night out and a soiree to remember, so earmark 4 October 2023 at the National Conference Centre, Birmingham in your diaries. Tickets and tables are close to sell out as I type, so don’t miss out. You can book via the Awards website.

Of special mention this issue are two lead pieces dealing with collaborative effort and the inexorable advance of Artificial Intelligence (AI). Joe Jack Williams and Andrew Abraham from FCBStudios with Alex Lynes at Webb Yates, take us on a journey to Paradise – the new workplace development by Bywater. Here they have embarked on a complex timber design solution that put wellbeing and sustainability at the forefront

PRINTED ON: FSC Mix paper by Buxton Press AUTOMATIC

There is no escaping AI. The publicity surrounding its effects – both positive and negative – has gathered pace over recent months. For a taste of what it can do for the timber designer, Dr Luke Whale, Technical Director at DAISY AI reveals how the team has designed the first program to automate timber floor design using AI. This can find an optimal floorplan design for any type of timber floor using ‘genetic programming’ to give limitless opportunities – and does not involve a machine-led cyber takeover of human activity.

Many thanks to all our contributors, advertisers and supporters for their help this issue, it is always genuinely appreciated.

Gary Ramsay | Consultant Editor

E: gary.ramsay@structuraltimbermagazine.co.uk

E: gary.ramsay@structuraltimbermagazine.co.uk

WELCOME

OPTIMISING & DEFECTING CROSSCUT SAW

www.proctorgroup.com 01250 872 261 contact@proctorgroup.com @proctorgroup PRODUCTS IN FOCUS Procheck A2, is an Air and Vapour Control Layer (AVCL). With it’s class A2-s1,d0 fire classification to BS EN 13501-1, it is considered to be non-combustible with no significant contribution to fire.

THIS ISSUE...

P06

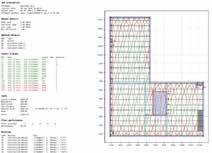

COVER STORY - B&K HYBRID SOLUTIONS

B&K Hybrid Solutions specialise in the design and delivery of timber and steel structures, from concept to completion, and are committed to helping clients reduce cost, programme, and carbon by utilising the benefits of a hybrid approach.

P08

UK INDUSTRY NEWS

A quick round-up of some recent news stories from the timber and construction sectors that you may have missed including: STA get revved up to showcase timber at Offsite Expo, an innovative new adhesive could enable 90% of engineered wood to become fully recyclable and the EAC calls for more wood in construction to achieve net zero targets.

P24

WOMEN RAISING THE ROOF

When you think of roof structures, you may well picture a man working on-site, erecting the roof. What you might not realise, says Nick Boulton, Chief Executive, Trussed Rafter Association, is that the person who designed it is increasingly female.

P26

STRUCTURAL TIMBER AWARDS 2023

This year’s shortlist once again showcases the huge strength and depth of all those working in timber construction. Whom have the judges decided to highlight as going beyond the norm and are in line for a prestigious award?

P32 PRIORITISE MOISTURE MANAGEMENT

The Structural Timber Association’s Andrew Orriss explains why a planned approach to moisture management and durability, is an essential part of building design and construction.

P34 OSB: A SMART CHOICE

FOR HOUSEBUILDERS

It’s essential to utilise materials that offer superior performance. One such material that has gained significant recognition across the construction industry for many years is Oriented Strand Board.

P36

BUILDING POSITIVE FUTURES

Mark Murphy, Chief Risk Officer for the Donaldson Group, explains why a clear organisational environmental strategy must be more than just a box-ticking exercise.

P38

DESIGNING SIMPLICITY

A collaborative approach from Joe Jack Williams, Partner and Andrew Abraham, Architect at FCBStudios plus Alex Lynes, Associate Director at Webb Yates, helped to design out the many complexities in the timber structure of Paradise.

P42

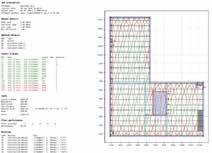

LIMITLESS OPPORTUNITIES

Dr Luke Whale, Technical Director at DAISY AI Inc, is part of the team that has designed the first program to automate timber floor design and has employed artificial intelligence (AI) to help.

P48

STA ADVICE NOTE 18 AMENDED

Glidevale Protect, one of the UK’s leading manufacturers of external wall breather membranes, welcomes the recent updates to the STA’s Advice Note 18 which highlights the importance of trusted – and tested – technical product information.

P50 CHANGING THE GAME

Modified wood comes in several guises with Accoya one of most popular choices. Dr Pablo Steenwinkel, Group Head of Technology, at Accsys

CONTENTS

National Conference Centre Birmingham

THE RIGHT MATERIAL IN THE RIGHT PLACE

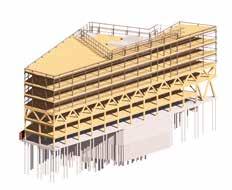

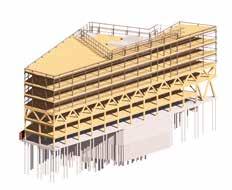

Timber and steel possess different structural properties that complement one another: whilst timber provides a low carbon and visually appealing solution, steel offers high strength and stiffness. Additionally, timber-steel hybrid solutions allow for creative and unique architectural designs – CLT panels can be prefabricated in different shapes and with precut openings, while steel can span long distances, providing more open and flexible interior spaces.

The prefabrication of hybrid solutions can significantly reduce on-site construction programme, resulting in commercial savings and shorter project delivery times. Additionally, the lightweight nature of timber reduces transport and foundation loads – particularly advantageous for refurbishment schemes.

B&K Hybrid Solutions (BKHS) specialise in the design and delivery of timber and steel structures, from concept to completion, and are committed to helping clients reduce cost, programme, and carbon by utilising the benefits of a hybrid approach.

For the UK to meet its ambitious net zero goals for 2050, the construction industry must play its part by reducing its substantial carbon footprint, cutting emissions wherever possible. The role of timber cannot be overstated, but there must be pragmatic decisions made about using the right material in the right place. Pushing the boundaries of hybrid solutions, BKHS believe timber and steel systems hold the key to sustainable construction.

Hybrid Solutions

Hybrid timber-steel solutions utilise the flexibility of both materials to create sustainable, efficient, and versatile building structures. Often specified for their sustainability credentials, using structural timber products such

as cross laminated timber (CLT) and glulam effectively reduces the carbon footprint of a building in comparison to alternative construction methods. Engineered timber stores biogenic carbon during growth, acting as a carbon sink, and the process of manufacturing timber is far less carbon intensive than other materials.

However, commercial and design challenges can often become barriers for clients specifying timber. By incorporating steel, net zero targets can be hit while challenges are simultaneously mitigated. As well as this, other significant benefits can be harnessed by favouring a hybrid approach.

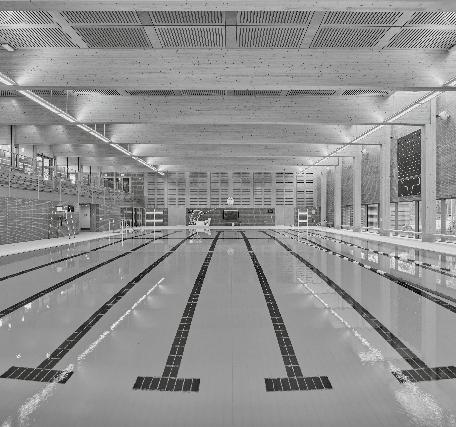

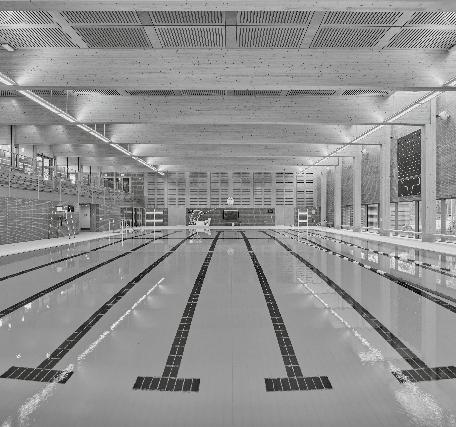

Recent hybrid timber-steel projects, such as Spelthorne Leisure Centre –the UK’s largest wet and dry leisure centre, where B&K Hybrid Solutions are currently delivering a CLT, glulam and steel package to Passivhaus standards – are testament to the exceptional standards of sustainability that hybrid solutions can achieve, while hitting commercial budgets for the client. Overall, timber-steel hybrid structures present a compelling solution for sustainable, innovative, and efficient building projects, combining the best properties of both materials to create resilient and environmentally responsible structures.

Sustainable Practices

While B&K Hybrid Solutions aim to create sustainable structures for every scheme, utilising the benefits of timber and timber-steel hybrid solutions, they are also committed to developing their own sustainability practices and reducing their carbon output. Recently partnering with sustainable certification and net zero organisation Planet

STRUCTURALTIMBERMAGAZINE.CO.UK w 6 COVER STORY B&K HYBRID SOLUTIONS

01

Mark, to measure and reduce their operational impact on the environment, BKHS are also focusing efforts on embedding a sustainable culture within the organisation.

“Internal engagement and alignment are key to embedding a sustainable culture within the business, which is then reflected in our work and internal practices.” says Lee Roberts, Pre-Construction Director at BKHS. “As such we have implemented an internal sustainability committee, with representatives from all departments contributing to making BKHS’ impact on the construction sector as environmentally friendly as possible.”

“We are also in the process of writing a Carbon Reduction Policy, which aims to set clear goals and reduce our own carbon emissions. This will provide us with a roadmap and will set a direction for the business and all our employees. We hope to see many of our project partners and supply chain embracing this by reviewing their own internal sustainability efforts, to help the construction industry reduce its carbon footprint.”

B&K Hybrid Solutions also ensure all timber products are sourced from sustainably managed PEFC or FSC-certified forests, which follow responsible logging practices, promoting biodiversity and minimising environmental impacts. Additionally, BKHS endeavour to procure materials from BES 6001 accredited organisations; ensuring companies follow sustainable and ethical practices

throughout their supply chain and consider social aspects, including labour practices, health and safety, and fair employment, which contributes to a project’s overall BREEAM score. Lee adds: “Whether delivering a timber or timber-hybrid scheme, sustainability throughout the supply chain is key to construction’s sustainable future.”

Refurbishment: Reduce, Reuse, Renew Choosing the right material in the right place is vital for any project, but particularly when specifying structural timber for refurbishment schemes. The lowest carbon solution for many projects is to repurpose an existing structure; this is where a hybrid approach may be more logistically advantageous and commercially viable than a complete timber approach, particularly when cost and structural integrity are equally key to the client as sustainability.

The Gramophone Works – which won Project of the Year at the 2022 Structural Timber Awards – is a fantastic example of a hybrid building that has made a true difference in lowering the environmental impact of construction, whilst at the same time improving the existing building by utilising the structural benefits of steel. Situated alongside the Grand Union Canal in West London, The Gramophone Works comprises a mix of refurbished, extended and newbuild contemporary office spaces. Retaining the existing concrete elements to the two-storey record factory allowed the project team to integrate the striking property into the historic and social fabric of the

surrounding neighbourhood, while at the same time adopting advanced timber technology to help deliver a sustainable and healthy phased scheme.

Similarly, Newson’s Yard – a high-profile new design hub in the Pimlico Road Design District – has demonstrated the advantages that hybrid systems can provide to refurbishment projects and has been shortlisted for Hybrid Project of the Year at the 2023 Offsite Awards and Retail and Leisure Project of the Year at the 2023 Structural Timber Awards. The scheme employs an offsite manufactured, hybrid steel and engineered timber design to create a new internal structure, which has repurposed the former timber yard and made use of the existing brickwork to create a high-end retail destination.

B&K Hybrid Solutions’ aim is to bring the exponential capabilities of hybrid solutions to the forefront of modern construction. Their robust supply chain has afforded them extensive experience with a vast portfolio of engineered products, including structural steelwork, CLT and glulam. In-house supply, supported by their advanced manufacturing facility, allows BKHS to offer complete design and build solutions – from concept to completion.

COVER STORY B&K HYBRID SOLUTIONS STRUCTURALTIMBERMAGAZINE.CO.UK w 7

02 IMAGES: 01. The Gramophone Works 02. Newson’s Yard 03-04. Spelthorne Leisure Centre www.bkhybridsolutions.co.uk 03 04

STA SET FOR OFFSITE EXPO 2023

As the largest UK trade association within the structural timber sector, the STA will be exhibiting on stand F10 to highlight its mission to promote the use of structural timber in construction, as timber presents the best opportunity for meeting the UK’s net zero commitments by 2050. As such, the quality and standards of timber construction must be to the highest degree; making accreditation crucial to providing investors and insurers with evidence that companies are held to high standards.

also sponsoring the ‘Best Use of Timber Technology Award’ for this year’s event. The awards celebrate companies and projects that are at the forefront of the industry in terms of innovation and expertise.

Following the success of previous years’ partnerships, the Structural Timber Association (STA) is proud to once again be an Industry Partner with Offsite Expo, taking place on the 19-20 September at the Coventry Building Society Arena. Playing host to leading offsite manufacturers and suppliers over a two-day event, Offsite Expo is focused on supporting those that are driving change in the construction sector.

SR TIMBER PROVIDES ‘GUIDE TO GUIDELINES’

At the event, the STA will explain how its STA Assure scheme provides solid reassurances to the construction community that members meet or exceed current legislation and regulatory requirements. Recognised by warranty providers, as well as other key stakeholders including insurers, STA Assure ensures that we remain on top of the constantly evolving changes to quality and standards. The team will also be there to discuss how structural timber systems and offsite construction combined can support carbon neutral goals.

The Offsite Expo is also host to the Offsite Awards, which take place in the same venue on the 19h September; with the STA’s Andrew Orriss again on the judging panel. Additionally, the STA are

Andrew Orriss, from the STA, said: “It’s always an honour to be part of this event and I’m very pleased to have been invited to return to the judging panel for the 2023 Offsite Awards. The standard of entries has been exceptionally high this year and it’s very encouraging to see the progress and achievements that are being made across the industry. Awards like this are an excellent way of ensuring this innovative thinking is recognised and replicated.”

STA Chief Executive, Andrew Carpenter, will be leading a Q&A Session as part of the Masterclass seminar programme. Held in Seminar Theatre 1, at 10.30 am on the 19 September, Andrew will be on hand to answer any questions about integrating structural timber into offsite construction projects.

Visit STA on stand F10 by registering here for Offsite Expo 2023: www.offsite-expo.co.uk www.structuraltimber.co.uk

While there is greater awareness for the need to ensure battens meet British Standards BS 5534, some confusion still remains over what is specifically covered by guidelines. In order to cut through the confusion, SR Timber have released a ‘Guide to Graded Roofing Battens’ booklet to provide clarity on grading, and what to look for.

The booklet focuses on the four key areas which the supply chain, including contractors, should look out for to ensure that their roofing battens follow BS 5534. These four areas are: sizing, knots, markings, and due diligence. Speaking on the purpose of the booklet, Shaun Revill, Trading Director at SR Timber said. “Thankfully, awareness of the rise of substandard batten has really risen within the industry however there is still inferior stock within the market. However, when it comes to fully understanding and applying BS 5534, there’s still a question mark over what merchants or contractors should be looking out for.”

“I’ve grown up in this industry so it’s second nature for me. For importers or merchants, it might be harder to know what to look for. In response, we’ve set out this booklet to make identification fast and easy, no matter if you’re buying from suppliers or merchants. By doing this, we hope to provide clarity on what the industry needs to look out for in roofing battens and how

it compares to what BS 5534 states. This will allow the industry to make an informed decision and ensure safety and conformity going forward.”

By breaking down the standards into bitesize pieces of information, the hope is that the information we have provided helps further understanding around the grading rules set out within BS 5534. Increasing the confidence that merchants and contractors have that they are purchasing and fixing true graded roofing batten. Available from both SR Timber’s website and in a physical copy, the booklet will bring greater clarity about what to look for when wanting to make sure that roofing battens meet the required standard set by BS 5534.

To download the guide visit: www.sr-timber.co.uk

8 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

Flexible. Individual. Sustainable. Your solution for timber construction.

As world market leader, we offer an entire range of state-of-the-art technologies for efficient timber construction. This includes standalone machinery and production lines, flexible software solutions, consulting services and comprehensive after-sales service.

Together with you, we develop innovative and customised concepts, creating a production solution to ensure your success.

From independent carpenters to large prefabricated housing manufacturers, we support timber construction businesses of any size allowing them to place their trust in the quality of our machines and our consulting services.

WEINMANN - Your partner for timber construction.

HOMAG UK Tel. 01332 856500 | Email. info-uk@homag.com | www.homag.com YOUR SOLUTION

NEW GLUE OPTION FOR ENGINEERED TIMBER

BindEthics, the sustainable glue company behind this innovation was founded by Maria Garcia, a chemist with an MSc in molecular design from the University of Amsterdam and Callum Smith a 21-yearold materials engineer from Esher who is completing an integrated Masters (MEng Material Science and Engineering) at the University of Birmingham.

BindEthics has received commercial, scale-up and lab-based support from the Biorenewables Development Centre in York under their European Regional Development Programme business assist scheme and Innovate UK. Additionally, it is receiving network access, business space and financial aid from the University of Birmingham and Innovate UK which help accelerate the innovation.

An innovative new adhesive, derived from purified and refined industrial bio-waste, should enable 90% of engineered wood products, including furniture and construction boards, to become fully recyclable and helping to develop a sustainable circular economy in this sector. The new adhesive, derived from extracted and purified waste is sustainable, non-toxic and possesses a step-change improvement in recyclability and circularity.

DONALDSON TIMBER SYSTEMS LAUNCH HOUSE RANGE

Leading UK offsite timber frame manufacturer, Donaldson Timber Systems (DTS), has launched the Donaldson Timber Systems House Range. The range of 18 core house types includes cottage flats with a mix of one and two bedrooms, semi-detached and detached twobed bungalows and a selection of detached, semi-detached, and terraced homes of two, three and four bedrooms.

Utilising DTS’ Sigma II closed panel timber frame system, the house range provides long-term energy efficiency; meets and exceeds Homes England’s minimum requirement for a premanufactured Value (PMV) of 55%

BindEthics has won the Armourers & Brasiers Venture Prize seed funding award. “Our glue is ethically sourced, has endof-life biodegradability and has properties suited to replacing traditional formaldehyde adhesives,” says Callum Smith. “As well as being fully recyclable the glue can be produced with almost no additional cost to the manufacturer and has a carbon footprint that is 86 percent lower than traditional adhesives.”

In 2022 preliminary trials conducted at the Biorenewables Development Centre (BDC) in York were backed up by analytical experimental studies enabling the development of the first minimum viable product. BindEthics is currently working with one of the three largest engineered wood companies in the UK and one of the UK’s largest packaging companies for technical insight.

using only the timber frame build system and allows the frames to be windproof and watertight on site in one day. The homes are also land-efficient, with the width of each floorplan reduced to ensure roads, footpaths and services are minimised, and a consistent depth of floorplan allows different house types to be simply built as terraced blocks.

John Smith, Technical Director at DTS, said: “We are working closely with the wider housing sector to drive continued quality and performance standards, and our new house range provides both to the market. We conducted extensive research in the sector across the UK to understand the needs of residents, developers, planners, and all relevant regulations, and these house types provide homes that are designed to offer maximum flexibility while meeting all space standards in the most efficient way possible.

“Sustainability and efficiency are also key to the sector, both for speed of build and

“BindEthics is showing how research and innovation has the potential to improve the recyclability of modern furniture and construction panels,” said Julian Beare, Chairman of the Armourers and Brasiers Venture Prize judging panel. “Our prize looks to encourage scientific entrepreneurship in the UK and provide funding to help innovative developments like this realise their potential.”

“Our vision is that our new bio-adhesive derived from food waste will replace a range of adhesives used across industry,” said Callum Smith. “The initial focus is on replacing the formaldehyde-based glues used in the manufacture of engineered wood products, but we also envisage applications for our sustainable adhesive within the shoe and automotive industries.”

www.armourershall.co.uk/venture-prize/ www.biorenewables.org/

longer-term performance for residents. Our timber frame system’s fabric-first approach comes with embodied carbon calculations and PMV assessment for each house type, to ensure sustainable, resilient, and affordable homes that efficiently meet the current build regulations and can be easily and simply updated to achieve the requirements of the Future Homes Standard.”

The house range is supported by a suite of architectural design information with Level 1 BIM models. DTS is also developing further supporting information, including SAP calcs, specifications, schedules and build costs for the full house range. Having this information in place will not only allow customers to reap the benefits of the efficiency of the house types, but vastly reduce the lead-times and up-front costs associated with developing a range of house types from scratch.

www.donaldsontimbersystems.com

10 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

BOLD & BEAUTIFUL THE NATURALLY PERFECT ® WAY

Naturally Perfect ® Factory Finishes With Proven Protection and Performance.

Sansin’s Woodforce offers unparalleled beauty and protection in an environmentally friendly formula - allowing wood to weather gracefully. Contact us about our specification program so we can help you achieve the perfect finish and protection, every time.

Precision Coat factory finishes and treatments deliver the colour, transparency and performance that architects, engineers and builders can count on.

Private Residence | Coast of Spain Photography courtesy of Tomeu Canyellas

Private Residence | Coast of Spain Photography courtesy of Tomeu Canyellas

BWF PROVIDE POSITIVE MESSAGES ON WINDOWS AND RECYCLING

Helen added: “With the cost of living and energy crisis ongoing, it comes as no surprise that cost and energy efficiency are the primary concerns for homeowners when selecting windows for their property. But while it’s encouraging that timber is viewed positively by many against these criteria, there are still some outdated assumptions over how timber windows perform.

“When it comes to cost, the improved durability of wood window frames means they can last longer – when maintained properly – and therefore actually provide better value over their lifetime than alternatives. In terms of energy efficiency, timber has naturally insulating properties, meaning timber windows can offer improved thermal performance. We want to challenge these misconceptions and help show that whether a property is a new build, a period home or anything inbetween, wood windows and doors are the natural choice and can add value for any homeowner.”

New research from the British Woodworking Federation (BWF) reveals signs that timber windows and doors are viewed positively by homeowners, but that misunderstandings over their performance persist. The survey of 1,500 homeowners unearthed the main factors guiding product choice. It found that, aside from cost, for both windows and doors energy efficiency was the main priority for homeowners when selecting products (50% for windows and 39% for doors).

When it came to windows, cost and energy efficiency weren’t the only significant factors for homeowners. Aesthetic appeal was most important to almost a third (32%), while the source and sustainability of timber was an important consideration for almost half (48%) of all homeowners, and almost three quarters (73%) of period property owners.

For doors, aesthetic appeal was also a prominent factor, a top priority for 32%, with product lifespan (31%) and security features (24%) also important. Encouragingly, 59% of homeowners felt

that timber windows offered a wider opportunity for design and style options than alternatives, and 56% thought timber windows were more sustainable.

Helen Hewitt, CEO at the BWF, said: “The beautiful aesthetic of timber has always been its enduring appeal, whatever the property type. And with timber products being designed to be repaired rather than replaced, they are a naturally sustainable choice. It’s hugely encouraging that the benefits of timber are recognised by those who may be considering replacing windows or doors in their homes or buying properties in need of renovation.”

Despite positive perceptions, research also revealed a number of misconceptions over timber windows as compared to alternatives:

• Fewer than half (40%) believed timber windows offer high energy efficiency performance

• Only 35% thought timber windows have the same U-value performance

• More than half (57%) believed timber windows cost more to purchase and install

• 70% of homeowners believed timber windows have a shorter lifespan.

The BWF has also joined forces with the Glass and Glazing Federation (GGF) and Community Wood Recycling to support timber window frame recycling across the construction industry. Open to all BWF members, the recycling scheme will collect any waste wood for recycling – including timber frames and off-cuts – where a designated volume has been accumulated.

Through Community Wood Recycling, 100% of the wood supplied is reused or recycled, meaning none of the waste collected will end up in landfill. Not only does this make timber a more sustainable construction material than ever, but the scheme also creates jobs, training, and volunteering opportunities for disadvantaged people. The UK creates 4.5 million tonnes of waste wood each year. Last year, Community Wood Recycling retrieved nearly 24,000 tonnes of wood, a figure the scheme’s partners aim to increase through this initiative.

www.bwf.org.uk

12 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

Passivhaus pioneer and modular construction specialist Beattie Passive has been included in J.P. Morgan Private Bank’s annual list of the UK’s Top 200 women-powered businesses. J.P. Morgan Private Bank and research provider Beauhurst analysed 46,300 companies in the UK and found that 13,255 are either founded, led, owned or managed by women. Beattie Passive was ranked at number 171 in the Top 200.

The report recognises the tremendous contribution that female-led businesses make in terms of development and innovation, raising £5.75billion of private equity investment across 2,097 deals in 2022. Beattie Passive’s inclusion underlines the high number of women-powered businesses in the East of England, which accounts for 26.7% of the total population by region.

Rosemary Beattie, a Director at the Norwich-based firm, said: “We’re very proud to be named in this report. Construction has traditionally been a maledominated sector, but that’s changing and addressing the gender imbalance will have many benefits. A shortage of skilled workers is one of the biggest challenges facing our industry, so encouraging more women into construction will help to close the skills gap and widen the talent pool. There’s a very broad range of opportunities out there, so I would urge more women to consider a career in construction.”

In other news, Beattie Passive has been appointed to three major modular construction and retrofit frameworks over the past six months. Most recently, the firm was named on LHC’s £1.2billion Modern Methods of Construction (MMC) of New Homes (NH3) Framework. Beattie Passive secured a place on the Offsite Homes Alliance’s £2billion offsite national modular construction framework. It has been appointed to deliver Category 1 MMC over the next four years on the OSHA Framework, administrated by Great Places Housing Group, to supply homes to its 23 members and to future new members of the alliance.

Matthew Harrison, Chief Executive of OSHA member Great Places Housing Group, said:

“We’re delighted to be working with Beattie Passive on the new OSHA framework. We’re confident they will be able to work with us and the OSHA clients in delivering the sector’s extensive development ambitions. We were pleased with the positive response from the market and received high quality proposals and substantial social value pledges for our communities. We are now looking forward to mobilising the framework and working together on new projects to realise our ambitions of delivering muchneeded affordable homes.”

Image: L-R Rosemary and Isabel Beattie www.beattiepassive.com

HOW MUCH DO WE KNOW ABOUT SCREWS?

Theory, practice, experimental campaigns: putting it all together on screws takes years of lectures, workshops and construction sites. We make it available to you in 70 pages that are extra catalogue. Because our experience is in your hands.

rothoblaas.com

UK INDUSTRY NEWS

BEATTIE PASSIVE RECOGNISED AS A UK TOP 200 WOMEN-POWERED BUSINESS

PERSIMMON GET GREEN LIGHT FOR TIMBER FRAME FACTORY

NEW ADDITION TO JJI-JOIST PRODUCTS

Approval has been granted by Charnwood Borough Council for the creation of a new Space4 timber frame factory – believed to be the biggest in the UK – on the edge of Loughborough. Following approval from Charnwood Borough Council on 22 June 2023, the state-of-the-art facility will bring up to 120 new jobs to Loughborough and the surrounding areas, whilst also utilising the latest automation technology as part of the manufacturing process.

The factory will produce timber frame units for up to 7,000 homes a year and is set to be in full operation towards the end of 2025. Utilising modern methods of construction (MMC) systems within Space4’s products places sustainability at the core of our build practices. Utilising timber over other materials enables the homes to be more environmentally friendly; all the timber used is from sustainable forestry sources. The factory-assembled nature of the product will also help to improve the speed and consistency in quality of the homes built, with timber frame homes being around 20% more efficient to build than other methods.

Gareth Wicks, Managing Director Designate at Space4, said: “We’re delighted to have received approval for our new Space4 facility and I want to thank Charnwood Borough Council for their support. Not only

will the development deliver up to 120 new jobs, it will also further our goal to place sustainable practices at the very heart of our developments. We’re committed to creating vibrant, successful communities with the environment in mind. We’ll continue to work in partnership with the Council and other stakeholders to ensure our new Space4 factory delivers real benefits for local industry and the wider Loughborough community.”

The new Space4 facility will be placed on the Garendon Park Sustainable Urban Extension (SUE), a community of over 3,000 homes on the Garendon Park estate where our North Midlands team is master developer. Across the whole of the SUE, a cumulative figure of over £43million will be paid to support local infrastructure delivery and ensure economic development.

Dan Endersby, Managing Director of Persimmon Homes North Midlands, added: “Approval for the new Space4 facility at our Garendon Park development comes at a particularly exciting time as we welcome our first residents and continue to build our presence in Loughborough. Garendon Park will be one of Persimmon’s flagship communities, with over 3,000 homes, employment and leisure facilities, and a range of preserved historic monuments around the site.”

www.persimmonhomes.com

The Timber Systems Division of forestry and sawmilling business, James Jones & Sons Ltd, has announced the addition of a new product – the JJI Wall Stud. James Jones & Sons operates the largest, fastest and most efficient I-Joist line in Europe. Made in the UK at its engineered timber manufacturing plant in Forres, the JJI Wall Stud offers a low carbon solution to the UK and European construction market.

Angus Macfarlane, General Manager of Timber Systems Division, said: “The JJI Wall Stud has been developed to complement changes in Part L legislation that requires more efficient insulation in timber frame and modular homes. More than ever there is a need for highly insulated, healthy homes and the JJI Wall Stud, in combination with different types of insulation, helps achieve this. We will manufacture the JJI Wall Stud in easy to handle and easy to cut lengths to offer flexibility to the offsite manufacturing process. The JJI Wall Stud is available via our existing distribution network throughout the UK and Europe.

“We are committed to supporting a programme of continued investment and other recent innovations have included development of our JJI Design and Joist Master Software, in addition to the expansion of a new stock yard in 2022 to enable us to ensure security of supply within industry best delivery timescales.”

14 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

www.jamesjones.co.uk

NMITE PRIMED FOR TED 2 COURSE

NMITE (New Model Institute for Technology & Engineering) is set to welcome a new cohort onto its new Timber Technology Engineering Design 2 (TED 2) CPD course, following the success of its TED 1 courses. Starting from 5 June 2023, the new course is once again delivered in partnership with Timber Development UK and Edinburgh Napier University.

The new TED 2 course is designed to appeal to a wide range of Built Environment Professionals, working in architecture firms and construction companies including designers, architectural assistants or those involved in technical sales. Learners are not required to have completed TED 1 but some prior industry knowledge is expected.

TED 2 runs as a 12-week course held within a virtual learning environment, allowing students to work at their own pace, supported by academic mentorship and support. There are also three oncampus residentials at NMITE in Hereford, within the Centre for Advanced Timber Technology (CATT). This is a purpose built 2,500m2 “Living Lab” hybrid structure which demonstrates advanced timber technologies and acts as an exemplar in the region, aspiring to net zero carbon targets.

Professor Robert Hairstans, Centre for Advanced Timber Technology (CATT) Director, comments: “The launch of our

TED 2 course builds on our successful TED 1 course, both of which are designed to help solve the climate crisis problem by championing the use of the natural, renewable capital of timber that we have. TED 1 was a huge success with learners coming away feeling equipped to champion the use of timber in their workplace.

“Fundamental to all NMITE courses is to provide a student-centric approach with a curriculum fuelled by real-world challenges working with external stakeholders, industry practitioners and academic collaborators. I believe this approach is fundamental to our cohorts’ enjoyment and engagement with the course and I suspect is also why we are so successful at attracting diversity on our courses.”

TED 2 includes two design briefs for which students have a chance to construct during the on-campus residentials. The process progresses the TED 1 challenges which went from simple connections to basic supported structures, to integrated design with additional layers within the final structure, for which students exhibit to an invited audience.

In addition to the design element which runs throughout the course, technology and construction are the other modules that are covered in two, six-week blocks. Technology covers off the theory and capacity of computer aided design and manufacture

(CAD/CAM), Building Information Modelling, CNC machines for timber, architectural drawings, connectors and fixings of timber, manufacturing of timber components, hybrid solutions such as metal web joists, and future technologies such as Augmented Reality and Virtual Reality and new biogenic based materials.

Architectural Assistant at dRMM, Olivia Chan, completed the NMITE TED 1 course earlier this year. Olivia comments: “Within the course, I have been encouraged to develop a detailed material understanding which incorporates the lifecycle of timber. This has included a theoretical and practical understanding of how to sustainably grow, procure, apply, and upcycle timber as well as how to maintain the timber supply chain in a way that ensures our sustainable future.

“The opportunity to connect a theoretical understanding and speak to people in forestry, milling and design has fostered a collaborative learning environment. Practical, material-based lab work has allowed me to learn how to research and detail small-scale timber projects. Hands-on experience like being able to test our own theories within a specialist timber laboratory has helped me build my experience and has improved my confidence in advocating for timber.” www.nmite.ac.uk

16 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

LOWFIELD TIMBER FRAMES ASSIST EAC

Lowfield Timber Frames recently hosted the House of Commons Environmental Audit Committee (EOC) who were investigating for their inquiry on sustainable timber and deforestation. The inquiry is to examine the sustainability of timber in the UK and the UK’s contribution to global deforestation. The inquiry will investigate how the UK can best scale up a sustainable, resilient domestic timber sector and reduce its reliance on imports.

In addition, the inquiry will examine the degree to which UK supply chains contribute to deforestation overseas and the effectiveness of the government’s efforts to curb this. Consideration will also be given to how the UK works with international partners to tackle deforestation. Darren Jarman, Managing Director at Lowfield said “It was a pleasure to the show the EOC around our operation and, as well as showcasing some of the exciting net zero

projects we are involved with, highlight some of the challenges faced in sector.”

Lowfield Timber Frames provided the delegates with a presentation and a tour of their manufacturing facility to support the inquiry. The presentation demonstrated the current issues facing the timber frame industry which relies on high quality timber but also understands the importance of sustainability. They also suggested recommendations for the inquiry to look at including an emphasis on policies to reduce embodied carbon within the construction industry. The presentation was then later used as written evidence to the inquiry.

Environmental Audit Committee Chair, Rt Hon Philip Dunne & MP for Ludlow, said: “It was a pleasure to visit Lowfield Timber Frames recently with colleagues on the Environmental Audit Committee. In Net Zero

Britain, we must consider all alternative building materials as our built environment contributes a quarter of all UK greenhouse gas emissions: and timber framed buildings will be part of the solution. It’s encouraging to see thriving local companies – like Lowfield Timber Frames – leading the way in developing and delivering net zero construction.”

Lowfield Timber Frames have recently completed their second Passivhaus school in Welshpool, less than eight miles from their head office. Lowfields have been pioneers in the Woodknowledge Wales, Home-grown Homes project, their Sarn development of seven Passivhaus homes for Powys County Council was shortlisted for the Unlock Net Zero Awards held in Manchester.

www.lowfieldtimberframes.co.uk

Setting the standards for timber fastening

BeA your partner for timber frame and offsite construction manufacturing

Across Europe and worldwide, BeA’s fastening technology, tools and consumables are the trusted choice for some of the biggest and best known names in timber frame and offsite construction.

BeA manufacture an extensive range of market leading fasteners, nails, staples and tools. We offer customers:

• An unrivalled range of manual and semi-automatic fastening solutions combined with a fully automated range in Autotec.

• Using industry leading quality controls, BeA meet or exceed standards such as Eurocode 5.

Reliable products, competitive prices and the kind of service and delivery you can depend on from BeA.

01482 889 911 sales@uk.bea-group.com visit our website www.bea-group.uk THE POWER OF FASTENING

UK INDUSTRY NEWS

SAM £7MILLION COMMITMENT TO MERCHANT SECTOR

The UK’s leading manufacturer of interior and exterior MDF mouldings, SAM, has announced its current £7million investment programme. As a commitment to bringing the best in market products and setting the bar on quality and standard, SAM’s continued investment has meant the business has been able to focus on its relationships with merchant customers and their growth.

The broad £7million significant investment from the Antrim-based company has enabled it to develop in five core areas including a wider £5million investment is into a new 45,000sq ft warehouse in Antrim, of which groundworks have already started. Not only does this enable SAM to fulfil its delivery, stock hold, and stock range goals, but it also embeds SAM deeper into the local business community by continuing to provide opportunities for local people.

Gerard Wilson, Sales Director at SAM comments: “Our customers and merchants have had three really challenging years with industry price increases, supply issues and delayed work with the pandemic. During this time, we’ve worked incredibly hard to maintain good communications with suppliers and scale up our level of sales and marketing support for our customers to make their lives easier and be a trusted and reliable partner. People and relationships are at the heart of what SAM is about, in addition to having the right product, in the right quantity, at the right place, and at the right time for our merchant customers. Even when other suppliers were struggling, we ensured we had stock so that we remained consistent and reliable. Our investment has empowered us to achieve more in this area and provide an even better supplier experience than before - the benefits of our investment are already felt throughout our whole customer base.”

As the industry has faced turbulent times, SAM is proud of its consistency and reliability of delivery and undeniable support for suppliers, which is also reflected in its recent win of ‘Overall Supplier of the Year’ in the annual Jewson awards at the end of 2022.

Lisa Young, Jewson Commercial Director commented on SAM’s win and the team’s commitment to supporting its suppliers: “Proactivity and collaboration are the words used to describe this supplier by colleagues from all parts of Jewson. There have been challenges throughout 2022, however, SAM’s approach has been positive and results-driven throughout. Communications are open and honest, which has built a genuine level of trust with this supplier.”

www.samonline.co.uk

18 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

KNOWLEDGE LIBRARY TO DRIVE HOMEGROWN TIMBER UPTAKE

Transforming Timber – a knowledge library designed to promote the use of homegrown timber in the UK built environment has been unveiled. The online resource aims to provide the sector with the information and understanding it needs to make homegrown mass timber the material of first choice for specifiers, designers, and contractors.

Transforming Timber is the output of an Innovate UK-funded project led by Built Environment – Smarter Transformation (BE-ST) in partnership with Ecosystems Technologies, Edinburgh Napier University and University of Edinburgh to accelerate the commercialisation of UK-grown timber products.

Making this move could significantly improve the carbon footprint of the UK’s buildings, while driving the value of homegrown timber through its use in higher grade, higher value products and applications. By increasing use in commercial construction and housebuilding, the move can also reduce the UK’s reliance on imported timber and create a new manufacturing industry that delivers green jobs and supports a just transition.

Transforming Timber is launching at the ‘Building from England’s Woodlands’ event – a project funded by Forestry Commission and managed by NMITE in partnership with

dRMM Architects, Ecosystems Technologies, Edinburgh Napier University and BE-ST. Supported by a consortium of experts in timber manufacturing and engineering including the Timber Development UK (TDUK), Confederation of Forest Industries (Confor), and Scottish Forestry, the Transforming Timber website will provide the sector free-to-access content including information on life cycle analysis, value chain mapping, quality assurance test work, manufacturing compatibility and case studies exploring key areas such as post occupancy evaluation.

Sam Hart, Head of Modern Methods of Construction, BE-ST said: “The launch of Transforming Timber is an important milestone in the move towards more mainstream use of home-grown timber in the UK’s offsite manufacturing sector. Making the industry aware of natural and renewable resources like UK-grown mass timber, its wide ranging high-value applications, and its transformational potential is the first step in creating a

sustainable and resilient built environment and accessing a range of environmental, cost, and economic benefits for the UK.”

Professor Robert Hairstans at Edinburgh

Napier University and Director of the Centre for Advanced Timber Technologies, NMITE added: “The UK has the renewable resource, internationally recognised expertise and technical capabilities necessary to be at the forefront of a new approach to delivering a sustainable built environment in response to the climate crisis. Extensive research and investment – on the part of my team at Edinburgh Napier University and by other experts –has proved that a mass timber approach to construction is very much feasible. Transforming Timber simply demonstrates this, while providing the sector with the tools it needs to unlock the potential of UK-grown mass timber and make the future of offsite manufacturing a circular and sustainable one.”

www.transformingtimber.co.uk

MAXIMISE THE OFFSITE OPPORTUNITY

OFFSITE EXPO has a range of exhibition packages available to suit any marketing aims, resources and budget.

www.offsite-expo.co.uk/exhibit

UK INDUSTRY NEWS

PASQUILL UNVEILS MAJOR INVESTMENT PROGRAMME

Pasquill, one of the UK’s leading suppliers of trussed rafters, has revealed further details of a multi-million-pound strategic investment programme across its UK sites. The investment includes £4.5million spent in 2022, £3.6million planned across 2023 and an additional £6million to be spent in 2024. The outlay aims to upgrade facilities, improve operations, reduce waste and enhance the customer experience.

A £500k machinery upgrade at Stoney Stanton forms a part of the investment and is part of the next phase at the site following the installation of the Hundegger TurboDrive in 2022. Already in place at Pasquill’s Bodmin and Redhill sites, the Hundegger will increase capacity, reliability and quality while reducing waste by 8%, contributing to a better all-around service for customers.

Meanwhile, a fifth £185k new AV Birch UniRoll will be installed at the Inverness site. The Uni-Roll has been designed to work in tandem with a planned glulam cutting line and cutting table, ensuring seamless

integration within the facility. As a result of the Uni-Roll installation, customers can expect faster order processing, enhanced precision in material handling, and a higher standard of service. In addition to the Uni-Roll, Pasquill has forecast a circa £600k investment this year for a dedicated JJI-Joist line at the Stoney Stanton site. This investment will follow the Uni-roll installation and help Pasquill enhance its production capabilities and meet the increasing demand for joists.

Gabriel Prior, Operations and Continuous Improvement Director at Saint-Gobain Off-Site Solutions, said: “These strategic investments demonstrate Pasquill’s commitment to continuous improvement, enhancing efficiency and creating a more sustainable future for our business as we work to make the world a better home. As we invest in cutting-edge technology and better facilities, we ultimately aim to provide an even higher level of service for our customers, while prioritising the welfare of our colleagues and reducing our environmental impact.”

Looking to the future, the team is currently laying the groundwork for the completion

of a £6million project in 2024, this will see the business install a Randek AutoEye line at Pasquill’s Redhill site – which will be the UK’s first automated truss production line. The system streamlines the manufacturing process by visually identifying roof trusses and automatically picking, placing, positioning, and pressing nail plates. The pressing force is precisely adapted to the nail plate and timber thickness. This improves safety and productivity while at the same time ensuring a high-quality truss is produced every time.

“As we continue to innovate and enhance our facilities, we’re excited about our plans to implement the technology for automated truss machinery,” added Gabriel Prior. “This investment underscores our dedication to staying at the forefront of industry advancements and demonstrates our commitment to providing exceptional services to our customers. By embracing the future, we’re confident that Pasquill will remain the go-to supplier of trussed rafters in the UK market.” www.pasquill.co.uk

20 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

COMBILIFT CONTINUE ELECTRIC EXPANSION

As leading forklift manufacturer Combilift continues its 25 years in business celebrations, another new model truck, was launched in May at Ligna, the international timber and woodworking show in Hanover.

The new Combi-CB70E is a further addition to Combilift’s ever growing range of electric models which offers powerful performance, extensive battery life and unrivalled ergonomics. This model, in the vibrant Combi-green livery first seen on the recently launched Combi-CUBE product, boasts the distinction of being the shortest 7t capacity counterbalance truck on the market whilst also benefitting from multidirectional ability, enabling the versatile space saving handling of both long and bulky loads.

Design features incorporated into the highcapacity Combi-CB70E such as its large super-elastic tyres and compact wheelbase make it ideally suited for the operational demands of the timber industry. With a 7,000kg/15,500lb lift capacity, this model benefits from an impressively small footprint as well as exceptional manoeuvrability meaning that it can easily move bulky loads of timber around in confined spaces.

Combilift’s designers have gone to great lengths to ensure that the latest generation of models are kitted out with top quality components that ensure sophisticated ergonomics for a stress-free in-cab environment. Features in the spacious cab

include generous glazing for excellent allround visibility, the tilting steering column, hydraulic steering and the Grammer MSG65 seat.

What sets the Combi-CB70E apart from other forklifts is its gas strut suspension cab, which uses components such as those found in large scale industrial machinery with cab suspension. Combined with the super-elastic tyres this guarantees the smoothest of rides over uneven or less than perfect ground conditions such as those typically experienced in lumber yards.

The truck also features Combilift’s internationally patented and Red Dot awarded independent electric traction which provides all front and rear drive wheels with 100% traction control. This negates the need for differential lock on slippery surfaces and significantly reduces long load momentum twisting when travelling sideways. Each electric drive incorporates parking and regenerative dynamic braking

for power efficiency. Roll-out access for major electrical components also simplifies maintenance tasks.

This mix of next-gen performance, extensive battery life and exceptional ergonomics combined with all the advantages of the Combi-CB range, makes this the most powerful compact electric multidirectional forklift to date.

Combilift CEO and Co-Founder Martin McVicar said: “The increased capacities that we are offering in our electric range will answer the demand for ever more powerful products which at the same time help companies to achieve their aims for more sustainable operations. We chose Ligna as the platform for launching the CombiCB70E due to its innate suitability for customers in the timber sector, but we are confident that this model will be a popular addition to our portfolio for many other industry applications.”

www.combilift.com

UK INDUSTRY NEWS ALIGN YOUR PRODUCTS AND SERVICES WITH THIS INCREASINGLY IMPORTANT SECTOR

the UK’s biggest showcase of offsite manufactured construction technology and solutions.

...at

www.offsite-expo.co.uk/exhibit

INTERNATIONAL TIMBER ‘BREWS UP’ COSTA COFFEE DEVELOPMENT

International Timber and Jewson have teamed up with local developer, Ascia Construction, to provide sustainable and quality cedar timber for the development of one of Costa Coffee’s latest drive-thru facilities.

Located at the Adanac Health and Innovation Campus in Southampton, the Costa Coffee drive-thru will provide at least 15 new jobs and soon begin to serve those working and visiting the hospital site. The new coffee shop will also cater to University Hospital Southampton staff using the campus’ park and ride facilities at the beginning and end of their shifts.

The building has been designed to include indoor seating for customer use, outdoor tables and a drive-thru window for customers on-the-go. The initial design incorporated red and white render, cedar cladding and grey, powder coated metal roof and windowpanes, as well as turf borders, ornamental planting and newly planted trees surrounding the site’s boundary.

When John Packer, Timber Development Manager at Jewson, was first asked to secure the cedar cladding for this project,

it was discussed whether homegrown UK Cedar or Western Red Cedar would be the best fit. The cladding designs included lots of individual pieces of cedar, all the same size but cut at different angles, to create a unique timber design that has become synonymous with Costa’s coffee shops over time.

Due to the complexity of the design and to ensure the visual aesthetic of the cladding, both John and the team at Ascia Construction decided Western Red Cedar would provide the ideal solution; helping to minimise knots and to prioritise quality, durability and sustainability. “This project was one of the first major enquiries we’d worked on for Ascia Construction,” says John. “We wanted to ensure that the quality of the materials, together with the customer service provided met the company’s expectations. International Timber proved to be the perfect choice of supplier, offering a cost-competitive quote, alongside a highquality, durable product.”

International Timber’s Western Red Cedar is often a favourite for both internal and external cladding due to its natural resistance to decay and insect attack, as well as being an excellent material for thermal insulation - keeping the building

cool in summer and preventing heat from escaping in winter.

Both John and the International Timber team worked closely to deliver 32 finish x 32 finish PSE cedar, providing samples which had been machined to specification and brought onto site to ensure the customer was satisfied right from the beginning. John then made two more visits throughout construction; once when the cedar was first delivered and again when it was fitted – each time with those on site at Ascia commenting on the quality of the timber.

With PEFC certification, the team at Ascia Construction could rest assured that the cedar used would be in line with Costa’s sustainability objectives. “Each time I went on-site, the guys from Ascia Construction would comment on the fantastic quality of the cedar,” adds John. “Even going as far to say it’s the best cedar they had ever worked with, which of course was music to my ears. The project was finished in April this year and it really is a superior build with quality materials and craftmanship.”

22 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

www.internationaltimber.com

MORE WOOD IN CONSTRUCTION ESSENTIAL TO NET ZERO

In its latest report – ‘Seeing the wood for the trees: the contribution of the forestry and timber sectors to biodiversity and net zero goals’ – the EAC has recommended increasing wood in construction and expanding UK productive forestry to help achieve net zero by 2050.

Over the last year, MPs have heard from a range of industry experts on the best ways to scale up a sustainable, resilient domestic timber sector. The inquiry comes following the Climate Change Committee’s (CCC) recognition of timber as crucial to decarbonising the built environment. The EAC has called for greater use of timber in construction, stating the government should ‘support’ the UK sawmilling sector to transition towards ‘producing a higher percentage of construction grade timber products and engineered timber’.

This is due to timber’s carbon storage potential as a construction product, and its essential role in substituting high carbon materials such as steel and concrete in the built environment.

The EAC echoed the recent All Party Parliamentary Group (APPG) for the Timber Industries report, calling on the government to improve supply resilience by increasing UK productive forestry through streamlined planting and commercial softwood species targets. The report notes that domestic production is complementary to imports of timber from forest economies like

Sweden, Finland, and Latvia, which are essential to meeting long-term demand and increasing the use of timber in construction. Throughout the report, the EAC calls for the government to publish its timber in construction roadmap as soon as possible’ to outline how we can expand low-carbon timber construction in the UK.

TDUK CEO and CTI Director, David Hopkins, said: “It is great to see MPs in the Environmental Audit Committee once again acknowledge the pivotal role timber must play in decarbonising construction in the UK. The committee is right to argue for increased domestic timber production, with productive forests in the UK lagging well behind other European states. However, as we have mentioned in our latest APPG report, increasing UK timber supply should be incentivised to complement, rather than replace, imported timber as UK supply alone cannot match demand, even in the medium/long term.

“Additionally, the UK plays a positive role as a net importer of timber, with effective demand-side regulations promoting forest growth around the world. The Environmental

OFFSITE EXPO EXHIBITOR EXCLUSIVE

Audit Committee is a hugely influential advisory body, with its previous report –Building to net zero – culminating in the creation of the Timber in Construction Working Group. I look forward to seeing how the government responds to this latest report as well as the release of the Timber in Construction Roadmap later this year.”

STA CEO and CTI Director, Andrew Carpenter, added: “It is excellent to see the Environmental Audit Committee recognise the importance of using more timber in construction. Timber is best used in long term construction products like timber frames which have a much higher carbon storage potential than other short term uses. We also welcome the call to publish the Timber in Construction Roadmap as soon as possible. With Europe witnessing record temperatures this week, it is now more important than ever we expand lowcarbon timber construction and decarbonise one of our biggest polluters – the built environment.”

You can access the report at: www.cti-timber.org

OFFSITE CONNECT BUYERS AND SPECIFIERS FORUM - facilitating meetings with those seeking the latest offsite innovation.

www.offsite-expo.co.uk/exhibit

UK INDUSTRY NEWS

WOMEN RAISING THE ROOF

In timber engineering specifically, the recruitment of more female designers is already making its mark. This became apparent in our inaugural TRA Roofscape Design Awards earlier this year. In those awards, which seek to recognise and reward the ingenuity and technical skills of designers in this sector, two of the three winners were female.

Sue Darbyshire is the Design Manager at Donaldson Timber Engineering, and her award-winning project was for a new care home in Canterbury. The purpose-built care home accommodates 67 residents and has a complex mechanical and electrical (M&E) component which included plant that needed to be concealed from view. The roof had to be designed to facilitate the installation of the plant while allowing the external roof envelope to be covered. It also needed to allow easy access for future maintenance.

A growing number of women are choosing careers in timber engineering design and manufacturing. This is great news for the construction industry, which has long complained about a skills shortage and still struggles in many areas to attract a more diverse workforce. In 2019, women made up just 12% of the country’s construction workers – a figure the industry is working to improve. In the new Industry Skills Plan from the Construction Leadership Council, a strong focus is being placed on promoting increased diversity, equality and inclusion.

Sue opted for a ‘half attic’ style of trussed rafter design to meet these requirements, incorporating vertical wall members into the truss design. This solution also reduced construction time on-site and made hiding the M&E plant within the roof structure easier. One of the other key challenges of this project was to reduce working at height risks during construction. Sue’s design incorporated the necessary falls to a large flat roof area, significantly reducing the site-fixed firring timbers required during construction. This helped minimise any working at height risks and provided a more efficient and streamlined construction process.

Despite the building’s irregular size, shape, steps, and staggers, Sue’s design skilfully catered for these complexities. By carefully considering every aspect of the roof structure’s design, Sue created

24 STRUCTURALTIMBERMAGAZINE.CO.UK w ROOFING

When you think of roof structures, you may well picture a man working onsite, erecting the roof. What you might not realise, says Nick Boulton, Chief Executive, Trussed Rafter Association, is that the person who designed it is increasingly female.

01

a solution that met the client’s requirements while providing significant cost and time savings during construction.

As the judges commented, Sue achieved a highly innovative roof design, the most complex of all the entries received in all categories. It was a winning combination of design expertise and creative thinking. Sue is a role model for other women in the industry, starting work as a buyer for a building company but then deciding to retrain as a trussed roof designer and now celebrating over 25 years in that role.

Sue said: “This project appealed to me because I enjoy the problem solving and looking at the amount of creativity that can be brought to a roofscape despite existing planning constraints. In today’s care homes, where there is so much equipment that needs to be incorporated, and the need to achieve maximum usage from within the roof space, it is essential to adapt a roof design to suit customer requirements. The skill is arriving at a design that pleases customers and manufacturing depots.”

Tabitha Binding, Centre for Advanced Timber Technology (CATT) lead for external engagements and partnerships at NMITE says, the industry should be learning from these women’s experiences and listening to what they have to say about making better routes into the industry. “Climate change is upon us, and we must transition to more lowcarbon materials such as timber,” says Tabitha. “However, most professional education courses do not teach how to design or build using timber. To address this issue, NMITE has a Timber TED course that is developed by the industry and delivered at NMITE’s Skylon Campus. Our roofing and timber frame businesses need more skilled employees. Women can fill these positions and increase the employee pool by 50%. The industry needs fresh ideas, and opportunities are available for those working towards it. It is time for the industry to promote the change we want to see.”

www.tra.org.uk

IMAGES:

01. CATT is helping to facilitate an influx of women into the timber design field

02. Sue Darbyshire’s winning roofscape

HUNDEGGER TURBO-Drive

THE SUPERCHARGED TIMBER COMPONENT CUTTING

hundegger.com

Cutting Machine TURBO-Drive

The most versatile truss and frame component cutting machine in the UK market

• Impressive 450 x 160 mm cutting capacity

• Cutting timber dimensions in 5 axis

• Excellent for the high production of roofing trusses,and timber framing

• Seamlessly links to all the main CAD software suppliers

• In built Board-Stretcher

• Yields more and waste less timber

• Fast, accurate, flexible and affordable

Hundegger UK Ltd.

Daniel Blades

Snetterton Park, Harling Road

Snetterton, Norfolk NR16 2JU Office: +44 (0)1953 660 331

Mobile: +44 (0)7940 714 599

d.blades@hundegger.com

Innovation in timber engineering

winning

Me

and my Hundegger! Never change a

team!

02 ROOFING

OUR 2023 FINALISTS

The judging is over and the finalists have been announced for the Structural Timber Awards 2023. With an incredible mix of projects and timber technology on offer – here is a reminder of what will be in the running for a prestigious Award.

All roads now lead to the gala presentation evening at the Birmingham National Conference Centre (NCC) on 04 October where the Awards will be presented before a packed audience of over 500 national business leaders and high-profile decision makers from the construction industry. Featuring compelling examples of what can be achieved using the most natural and sustainable of materials, the 2023 Structural Timber Awards will celebrate outstanding projects and inspiring individuals.

2023 STRUCTURAL TIMBER AWARDS

This year saw over 200 entries showcasing how many outstanding, pioneering projects, products and people the timber sector contains. This year’s judges had the tough job of shortlisting entries into each category and have been overwhelmed with the high standard and variety within every category. Typical judge’s comments included: “A truly outstanding project that shows what can be done when all those involved work collectively with an early central sustainable aim. Another example of why we need to use more timber in construction and adopt the latest offsite manufacture techniques to dramatically change the way we build.”

Overleaf you can find the projects and people that have been picked out as outstanding and potentially ‘best in class’ for 2023 by our judges. All the finalists are of the highest quality but who do you think will win?

Join in the celebrations later this year at Birmingham NCC on 04 October to celebrate architectural achievements and engineering ingenuity in timber construction. As a major event in the timber calendar this is an event not to be missed and is always a fun, relaxed and enjoyable evening of celebrations and a high-profile networking opportunity.

Tickets are available for just £165 +VAT and includes complimentary drinks reception, three-course meal, awards ceremony and entertainment. The event presents a fantastic opportunity for you to host and entertain key clients. If you would like to book tickets to attend the 2023 Structural Timber Awards visit: www.structuraltimberawards.co.uk/book

STRUCTURAL TIMBER AWARDS 2023

26 STRUCTURALTIMBERMAGAZINE.CO.UK w

2022 Winners

ACTIS

Eolis HC

REFLECTIVE INSULATION

Cutting edge technology. Cutting time on site.

Installation in a continuous layer For airtightness and SAP improvements

Air cavities between reflective films Provide exceptional thermal performance

Hollow spiral fibres in each cell Trap air to improve thermal performance

Integrated vapour barrier For dual performance and a reduction in thermal bridging

Self-adhesive lap Means quick and easy installation

Our Triplex technology is the newest innovation in dual performance reflective insulation. It’s designed to offer exceptional thermal performance, with a reduction in thermal bridging that provides the most impressive SAP improvements. But it’s also cleaner, with less waste and environmental impact. Now that’s what we call cutting edge.

To find out more visit insulation-actis.com or call 01249 462888

THE 2023 STRUCTURAL TIMBER AWARDS FINALISTS ARE...

Social Housing Project of the Year

Burmor Construction California Road, Huntington

Celtic Offsite

Min-Y-Coed Apartments

Smartroof

The Smartroof Allerton Road Fire and Police Station Development

Private Housing Project of the Year

Buckland Timber

Great Sideling

Citu

Kelham Central

Jake Ireland Architects

3-4 Faulkner’s Alley

SIP Build UK

Derbyshire Longhouse

Unknown Works

CLT House

Education Project of the Year

Auburn Group

Zone 3, Greatfields School

Buckland Timber

Jill Isaac Study Centre, St Swithun’s School, Winchester

Engenuiti and KLH

Southmere Library (The Nest)

Eurban, MCW Architects, Smith & Wallwork and Blumer Lehmann

St John’s Buttery, Café and Bar

HLM Architects, B&K Structures, Stora Enso and Engenuiti

National Manufacturing Institute

Scotland (NMIS)

Innovaré Offsite Limited

West Coventry Academy

Integral Engineering Design

Cheltenham College Nursery School

Lowfield Timber Frames

Ysgol Gymraeg Y Trallwng

Custom & Self Build Project of the Year

Glosford SIPS

Kiln House, Cornwall

Holy Trinity Church, Tulse Hill, London

Straw Bale Neighbourhood Centre –

Community Self-Build

Oakwrights and Kinsey Hearn

Webb’s Meadow

Scotframe

Peace and Tranquility at Whispering

Pines, Reading

Whitby Wood

Ramadan Pavilion

Commercial Project of the Year

B&K Structures, General Projects, Heyne Tillett Steel and Buckley Gray

Yeoman

Technique

Blue Forest (UK)

Treehouses and Woodland Hives at Wildhive Callow Hall

Carpenter Oak Rackley’s Barn

Constructional Timber Manufacturers

Hemel Hempstead Crematorium

Cundall

Rare

Engenuiti, B&K Structures, Stora Enso and Ryder Architecture

Dogger Bank O&M Base, Port of Tyne

Engenuiti, KLH and HOK

The Family Kitchen and Shop at London’s Royal Botanic Gardens, Kew

Jan Kattein Architects and engineersHRW

Angel Yard

The Office Group (TOG)

The Black & White Building

Webb Yates Engineers and Bell Philips Architects

Harwell Hides

Speller Metcalfe

Skylon Campus

Streif UK

HCCAT (Hailsham Community College Academy Trust)

Healthcare Project of the Year

ArkleBoyce

St Gemma’s Hospice – Young Person’s Space

Eurban, SNUG Architecture, Stora Enso and One Small Thing Hope Street

TIMBER

2023 28 STRUCTURALTIMBERMAGAZINE.CO.UK w

STRUCTURAL

AWARDS

Winner - Social Housing Project of the Year 2022 Ramboll UK

Winner - Custom & Self-Build Project of the Year 2022 Hayhurst & Co

Winner - Commercial Project of the Year 2022 De Matos Ryan

Retail & Leisure Project of the Year

Aldi Stores

Low Carbon Store – Leamington Spa

Arup

Sky Pavillion

B&K Structures, Grosvenor, Heyne

Tillett Steel and Stiff + Trevillion

Newson’s Yard

Constructional Timber