Progress Rail’s Nitro Suite ef ciently manages density, capacity and pacing to bridge the gap between planning and actual operations. Each Nitro Suite solution integrates well with existing systems to ease implementation. The Nitro Suite includes:

> NitroETA - Optimizes train dispatch, track maintenance, and crew management, ensuring a real-time responses for a more uid rail network.

> NitroPacing - Pace trains to save fuel without losing capacity.

> NitroYard - Plan yard activity to optimize arrivals, scout locomotives, loading, unloading and train formation.

Combining arti cial intelligence and modern software engineering is one more way we help your railroad increase network uidity every day.

Follow this QR code for an in-depth look at the Nitro Suite.

We keep you rolling.

Vol. 121, No. 4

Print ISSN # 0033-9016, Digital ISSN # 2160-2514

EDITORIAL OFFICES

1025 Rose Creek Drive Suite 620-121 Woodstock, GA 30189

Telephone (470) 865-0933 Website www.rtands.com

DAVID C. LESTER Editor-in-Chief dlester@sbpub.com

JENNIFER McLAWHORN Managing Editor jmclawhorn@sbpub.com

EDITORIAL BOARD

David Clarke, University of Tennessee

Brad Kerchof, formerly Norfolk Southern Jerry Specht, CPKC/AREMA

Scott Sandoval, Genesee & Wyoming

Robert Tuzik, Talus Associates Gary Wolf, Wolf Railway Consulting

CORPORATE OFFICES

1809 Capitol Avenue Omaha, NE 68102

Telephone (212) 620-7200 Fax (212) 633-1165

ARTHUR J. MCGINNIS, JR. President and Chairman

JONATHAN CHALON Publisher

MARY CONYERS Production Director

NICOLE D’ANTONA Art Director

HILLARY COLEMAN Graphic Designer

JO ANN BINZ Circulation Director

MICHELLE ZOLKOS Conference Director

CUSTOMER SERVICE: 847-559-7372

Reprints: PARS International Corp.

253 West 35th Street 7th Floor New York, NY 10001

212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

By David C. Lester, Editor-in-Chief

Railroads are operated by people. While the advent of technology and artificial intelligence may leave one wondering sometimes, the truth is clear –– people run our railroads. From the CEO to the track worker, thousands get up every morning and head to work in what is often a very difficult industry. Regulations and rules. Operating large, dangerous, and unforgiving equipment, often over difficult terrain. Outside in all kinds of weather, including brutal winters and scorching summers. Revenue. Profit Margins. Customer Service. Broken Rails. Stock Price. Derailments. All in a day’s work.

While the accomplishments of railroad employees are usually recognized internally through raises and promotions that usually come with additional responsibility, it’s important for the industry to recognize them, too. That’s why we’ve devoted a considerable amount of space in this month’s issue to Young Engineers Under 40. This recognition program has grown in popularity over the past few years, and this year we’re proud to announce 12 winners who you can read about beginning on page 8.

Railway Track & Structures has several recognition programs throughout the year. The first is in April, Young Engineers Under 40, which you’re holding in your hands.

In March of this year, we had an insightful piece called Engineering Perspectives which profiled several engineering companies through interviews with either the CEO or another senior executive. In June, we have our Top Projects program, and July brings us the RT&S Women in Railroad Engineering program. In August, we’ll feature a piece on Construction Perspectives, where we will interview the CEOs or senior executives of major construction companies who specialize in rail. Finally, we have the RT&S Engineer of the Year award

Our Perspectives series began last year and continued this year with Engineering Perspectives in March, and we’ll have

Construction Perspectives in August. While this series is new and not many people are familiar with it, we believe it provides an opportunity for the industry to hear from folks and companies that don’t often have or take the opportunity to speak to a wide audience.

Our industry is continuously focused on projects of one kind or another. While there are other organizations who recognize excellence in engineering projects, our annual review of Top Projects that are nominated by peers in the industry, appears in June.

We also enjoy the RT&S Women in Railroad Engineering program, and we publish the results in our July issue. Women are making strong inroads to the industry, but there is a lot yet to do. One is to increase STEM learning in high schools and colleges. Another is to provide more opportunities in engineering for women who want to work on the railroad. We also partner with our sister magazine, Railway Age, to put together the super successful Women In Rail program each fall. We’ve had two in-person events and they have been enthusiastically received by both women and men in the industry. Our awards program wraps up for the year with the selection of the RT&S Engineer of the Year. This award usually goes to a senior engineering executive who has demonstrated strong leadership and engineering excellence. The Engineer of the Year is introduced at the opening session of the annual AREMA conference and joins me for a fireside chat around the latest developments in engineering at the annual Railway Age Next Gen conference. And, of course, the granddaddy of all RA and RT&S award programs is the annual Railroader of the Year event held in Chicago early each year.

DAVID C. LESTER Editor-in-Chief

Using machine learning to classify ultrasonic A-scan signals for defective and non-defective rails.

Anish Poudel, Ph.D., Scientist, Research & Innovation, MxV Rail

Since Dr. Elmer Sperry introduced the world’s first nondestructive evaluation (NDE) method for rail inspection in the 1920s, NDE methods have been used to detect internal discontinuities and defects in rails worldwide. Today, ultrasonic testing (UT) technology is typically implemented on hi-rail or railbound vehicles, commonly referred to in the rail industry as “rail detector cars” or “detector cars.” These vehicles use advanced software systems that rely primarily on B-scans for data presentation, visualization, and anomaly detection. Due to their data size and storage limitations, A-scans are generally not retained or stored. In NDE, A-scans (amplitude scans or time-series data) display the amplitude of reflected sound waves (echoes) over time, representing signal strength at different depths within a given material. B-scans, on the other hand, are created using a technique called “cross-sectional imaging,” which records the maximum signal amplitude values within predefined gates in the A-scans. A-scans contain numerous features and details that are not easily discernible to the human eye, and they offer valuable opportunities for trending and data fusion with other inspection modalities. Figure 1 illustrates A-scan and B-scan displays for rail UT.

Recent advancements in artificial intelligence (AI) and machine learning (ML) have made it possible to automate systems that are difficult to define algorithmically, thereby solving many classification problems. With improvements in AI/ML and faster graphics processing unit (GPU) capabilities, researchers can now use more complex algorithms/models that perform at and beyond human levels in tasks such as image classification, pattern recognition, and data prediction from large datasets. This progress has also been applied to

track inspections, where accurately detecting anomalies is crucial for the safety and reliability of railway systems.

The use of A-scans in inspection vehicles for real-time, automated rail flaw detection and classification presents many opportunities and benefits to the rail industry. To

further pioneer innovative solutions, MxV Rail is using A-scans to integrate AI/ML into rail UT. MxV Rail’s goal is to enhance the accuracy and efficiency of rail defect detection through a rigorous research methodology, addressing current UT A-scan data interpretations and storage limitations. This article

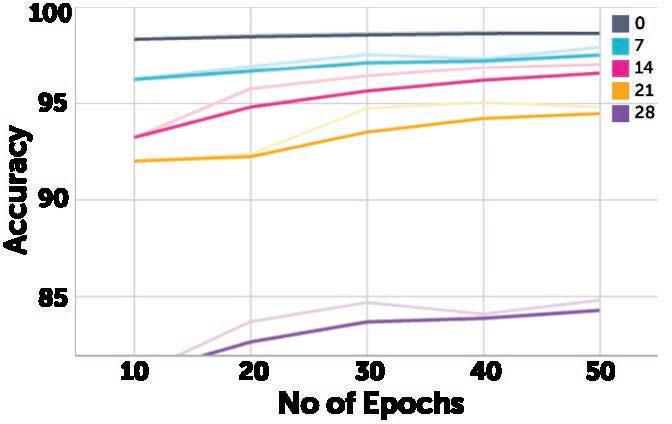

4. Results for ablation studies. (a) K-fold cross validation; (b) Impact of training size; (c) Impact of Curriculum Learning.

highlights MxV Rail’s early efforts to leverage AI/ML techniques for classifying raw A-scan ultrasonic signals, distinguishing between rails with and without defects. This research seeks to drive innovation and improve rail safety and reliability by advancing automation in rail inspection.

UT A-scan Data Repository

Reliable and meaningful data is essential for the training and testing of AI/ML systems. Significant effort was dedicated to collecting hand UT A-scans from defective and nondefective rail features. The dataset comprises 2,767 unique time-encoded A-scan signals

from approximately 145 rails of various sizes, ranging from 115 RE to 136 RE, and includes 10 different rail features. In a time-encoded scan, the flaw detector continuously captures ultrasonic signals at fixed time intervals, enabling the reconstruction of the B-scan. The time-encode scanning method also allows

researchers to collect and extract multiple signal frames, resulting in over 207,000 A-scan frames for all rail features. Figure 2 illustrates the distribution of A-scan frames across different classes of rail defect and non-defect features. As shown in Figure 2, the number of signals varied across different rail features, leading to an imbalanced dataset, which poses challenges for AI/ML algorithms, as these algorithms typically assume equal class distribution. Additionally, when trained on imbalanced data, ML classifiers tend to favor the majority class, resulting in poor classification of the minority class. To address this issue, a random sampling approach was used to select a balanced subset of signals from the 2,767 unique scans across the 10 rail features. This approach reduced the dataset to 1,016 unique raw A-scans. Also, to evaluate the model’s performance and generalization ability, the preprocessed data was split into training, validation, and test sets using an 80:20 ratio. Specifically, 817 unique A-scans were used for training and validation, while 199 were reserved for testing. The training set was used to instruct the model; the validation set was used to fine-tune learning parameters and model selection; and the test set was used

PRESENTING SPONSOR FOR PRINCIPLES COURSE

for the final performance evaluation. Data splitting was performed in a stratified manner to ensure a proportional representation of each class across the subsets.

Establishing a baseline model in ML is crucial for guiding development, evaluating performance, and reducing risks associated with complex models. MxV Rail used a non-parametric supervised learning method based on k-nearest neighbors (kNN) as the baseline. For this step, nine time-domain and frequency-domain features were extracted from each A-scan and used as inputs for the model. The kNN model achieved an overall accuracy of 65 percent. The next goal was to improve the accuracy using a deep learning model without the need for signal processing and feature extraction.

A CNN is a feed-forward artificial neural network (ANN) that automatically extracts features through filter optimization (or kernels). Its ability to capture spatial dependencies makes it well-suited for image-based

computer vision tasks. A CNN effectively extracts meaningful features by leveraging convolutional layers (network layers), thereby improving classification accuracy. This study used the Modified National Institute of Standards and Technology (MNIST) database for CNN architecture. A widely recognized dataset often used as a benchmark for computer vision ML models, the MNIST consists of thousands of handwritten digits (0–9) and is commonly used to test CNN architectures. A curriculumlearning approach was adopted to enhance model performance by integrating rail UT raw A-scans (without signal processing and feature extraction) with MNIST images. Curriculum learning involves training an ML model using a group of examples that gradually increases in difficulty. In this approach, raw A-scans were progressively injected into the MNIST dataset using a frame-by-frame process, and this data gradually increased the complexity of the training data. This approach can help the model focus on simpler patterns before gradually learning how to handle more complex and ambiguous instances. Following this approach could help the model 1) avoid getting stuck in suboptimal solutions early in

The Educational Railroading Conference Leader Since 1994

The Principles of Wheel/Rail Interaction: Revitalized and reimagined with a tighter focus on practical application for 2025, The Principles of Wheel/Rail Interaction, is an intensive, full-day course covering the fundamental aspects of wheel/rail and vehicle/ track interaction.

The course will begin with a case study — an examination of an actual wheel/rail interaction-related derailment. Presenters will cover the primary aspects of track, vehicle suspension systems, wheel/rail contact, the dynamics of vehicle/track interaction, damage mechanisms, friction management, and vehicle and track measurements systems — all the topics we have traditionally covered — but will also connect the dots between theory and what actually happens in the field. A wrap-up session will review the causes attributed to the case study derailment in light of the Principles examined throughout the course.

We will also look at approaches that can be taken to mitigate wheel/ rail- and vehicle/track-related derailments in the future.

Register at www.wheel-rail-seminars.com

Questions? Contact Brandon Koenig, Director of Operations

847-808-1818 or email at brandon@wheel-rail-seminars.com

PRESENTING SPONSOR FOR HEAVY HAUL

The Heavy Haul Seminar is devoted to examining wheel/rail, vehicle/track interaction on rail freight systems. The Seminar brings together track and mechanical users, researchers and suppliers in a positive, educational setting like no other in the industry. Information on where and how the latest technology is being used to improve wheel/rail interaction and overall performance on freight railways is presented through a combination of seminar sessions, dedicated Q&A periods, and technical “InfoZone” sessions.

Topics will include:

• Mitigating Derailment Risk at Switch Points and Guard Rails

• CPKC’s Track Geometry Program: Making the most of Automated Track Inspection Data

• Risk Management in Train Marshalling Through Real Data Analysis

• Technologies used to validate air brake, safety and maintenance exemptions at CPKC

• Assessing the Effect of Total Friction Management on Legacy KCS Rail Wear

the training process and 2) improve its ability to recognize complex patterns in the data over time. This blended approach, i.e., combining raw A-scan data (without feature extraction) with modified MNIST images, leverages both the domain-specific information from the rail-UT sensor data and the robustness of the modified MNIST architecture. Additionally, efforts were made to design a lightweight CNN model suitable for deployment on low-cost edge devices for field applications. All initial computations were performed using V100 GPUs via Amazon Web Services (AWS).

Figure 3 shows the CNN classification results. Figure 3(a) shows the confusion matrix that summarizes the model’s performance, with entries representing true positive, true negative, false positive, and false negative instances, and provides insights into model accuracy and errors. Similarly, Figure 3(b) shows the classification results for each feature, and it indicates that the model performs well overall, with 88 percent accuracy in finding a specific flaw. Ablation studies were conducted to evaluate the model’s performance under various

conditions. These studies included three-fold cross-validation, the impact of data size, and the impact of curriculum learning. Crossvalidation is essential for assessing model robustness, optimizing hyperparameters, mitigating data variability, and ensuring reliable performance on unseen data. To analyze the impact of A-scan injection, MxV Rail compared results when injecting 1, 14, and 28 unique A-scan signals into the modified MNIST dataset. Across all three cross-validation folds (Figure 4a), injecting 1 or 14 A-scan signals consistently resulted in accuracy above 98 percent. However, with 28 injected A-scan signals, accuracy dropped slightly to 91 percent in folds 1 and 2 and 93 percent in fold 3. This decline in the model’s accuracy (indicated by the dark green line in Figure 4a) may be due to variations in defect signal characteristics or other factors not captured by the model. Model performance depends on the dataset size used during training. As expected, the model accuracy increased as dataset size increased (Figure 4b).

The impact of curriculum learning was further evaluated by fine-tuning the model on the modified MNIST dataset without using

a structured curriculum-learning approach. In this setup, the model accuracy gradually declined as the number of injected A-scan signals increased, suggesting that curriculum learning is crucial for enabling the model to learn complex defect patterns progressively. Without curriculum learning the model struggled to generalize to unseen defect frames. Additionally, accuracy plateaued after several epochs, indicating the model achieved optimal performance (Figure 4c). Further training provided minimal improvement, confirming the curriculum-learning approach helps the model efficiently learn underlying data patterns within a limited number of training epochs.

MxV Rail demonstrated the feasibility of using machine learning to classify ultrasonic A-scan signals for defective and nondefective rails. MxV Rail’s main goal of this research is to promote technological advancement and explore applications beneficial to the railway industry to encourage others to pursue the development of AI/ML systems for rail flaw detection.

By David C. Lester, Editor-in-Chief

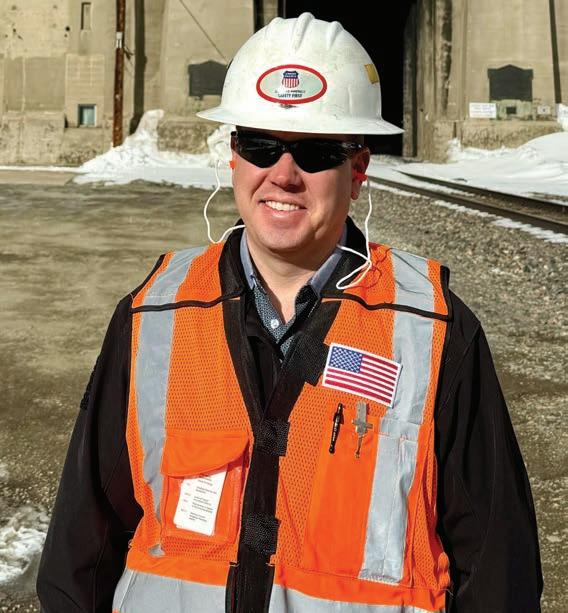

Each year, we ask the railroad industry to nominate those young engineers it sees as being the leaders of tomorrow. Of course, with all the engineers in the industry, there are many worthy candidates who are not nominated. However, among our readership, we received approximately 40 nominees of candidates thought highly of by their peers, and the RT&S Staff chose 12 of them for the

With increasing traffic, longer freight trains, and more unpredictable weather often wreaking havoc on rail infrastructure, the engineering teams at our nation’s railroads face tremendous challenges. Not only mental and intellectual challenges supported by the bachelor’s and master’s engineering study but also the willingness and capability to be out in all kinds

of weather any time day or night. Railroad engineering is not for the faint of heart. Nevertheless, without these teams of dedicated and talented individuals, the industry could not provide the transportation service needed to keep our economy humming.

We hope you enjoy reading about these remarkable members of our industry who focus on engineering excellence every day.

STEPHEN HAGER RailPros Rail Engineer – Engineer IV

Irving, Texas

As a project engineer and project manager with over seven years of experience in the rail industry, Stephen is making a strong impact through his contributions to projects throughout California and the western United States. With a bachelor’s degree in civil engineering from California Polytechnic State University in San Luis Obispo, he specializes in track design and has extensive experience with geometric design, track grading and drainage, plan production and cost estimating. His design experience also encompasses rail-highway grade crossings, train horn Quiet Zone improvements, railroad stations, roadways and sidewalks, bus stops, and bus/light rail maintenance facilities. When tackling challenging design projects, Stephen is skilled at balancing multiple design objectives as he comes up with creative solutions that consider both the client and community needs. One example of this is his work on a track alignment alternatives analysis for a railroad tunnel under the City of Del Mar, which would bypass the existing track atop the geographically unstable Del Mar Bluffs along the Pacific Ocean. As Stephen designed multiple alternative horizontal alignments in CAD design software, he balanced several objectives, including the need to minimize private property takes at the tunnel portals, maximize track speed objectives for passenger trains, and use suitable degrees of curvature and superelevation that would be an acceptable compromise between faster-moving passenger trains and slower-moving freight trains. The alternative horizontal alignments Stephen created were ultimately used in the Project Study Report as it laid out the project needs, alternatives, and projected costs.

LAKEIAH A. JOHNSON Metra Senior Telecommunication Engineer Chicago

With a bachelor’s in electrical engineering technology from Grambling State University and a master’s in engineering management from the University of Chicago, Lakeiah played a key role in enhancing physical security at Metra by leading a project to upgrade the existing video system with AI technology, significantly enhancing surveillance capabilities. Lakeiah has contributed to designing projects and developing proposals for infrastructure enhancements. Additionally, participation in Positive Train Control deployment and FCC licensing have strengthened operational safety and compliance. Lakeiah is enhancing AI integration, improving system reliability, and pursuing professional development. Also, strengthening leadership by mentoring colleagues, advancing PTC and compliance efforts, and fostering crossdepartment collaboration are big areas of focus for her. Finally, Lakeiah has strengthened Metra’s culture by actively participating in events like Family Days, fostering community, teamwork, and inclusivity. This has enhanced morale, workplace camaraderie, and enhancing employee satisfaction, reinforcing Metra’s family-oriented values.

DANIEL LOUREIRO

Canadian National Chief Assistant Capital Planning and Track Standards Montreal, Quebec, Canada

A graduate from the University of Toronto with a bachelor’s degree in civil engineering, Daniel is a seasoned railway engineer with over 15 years of leadership experience across the CN system, specializing in railway maintenance, operations, and capital program planning and execution. Committed to driving service excellence while maintaining the highest standards of integrity, ensuring the safety of people, the public, and CN’s infrastructure. Daniel has consistently demonstrated a strong commitment to giving back to the community, particularly through his involvement with local food banks. His dedication to this important cause reflects his sense of social responsibility and his drive to make a positive impact in the fight against cancer, showcasing his genuine commitment to improving the lives of others in the community. Daniel faced significant challenges developing a health and sustainable safety culture during some of his operational roles. Despite initial skepticism, he remained determined to emphasize the value and long-term benefits of the change. Rather than pushing his perspective, Daniel took a collaborative approach by organizing informative sessions where he presented clear data, real-life examples, and the broader impact of the initiative. He also actively listened to concerns, addressing any misconceptions or doubts with patience and understanding.

MATTHEW MORELLI Metrolinx

Senior

Engineering

Lead, Signals & Communications Ontario, Canada

With a bachelor’s degree in electrical engineering from Ryerson University, Matt has been on the front line of railway safety through signal engineering design and assurance. His contributions to railway signaling safety include:

• Performing signal designs for many fixed block Centralized Traffic Control (CTC) wayside systems including end-of-siding, intermediate, and multitrack controlled locations.

• Performing signal designs for crossing warning systems (CWS) in single and multi-track environments.

• Creating and modifying track plans, route and aspect plans, and board plans in accordance with Transport Canada requirements.

• Modifying Alstom Electrologixs custom applications to control wayside systems and performing simulation of the application logic using signal application testing system software.

• Modifying Safetran GEO applications to control wayside systems, and simulation of the application logic using GEO configuration suite.

Matt believes in giving back to the community in several ways. One is his plan to coach the upcoming five and under youth girls soccer team at the City of Vaughn Soccer Club in summer 2025.

JANAKIRAMAN (JAN) MUTHAIAH

CPKC Winnepeg Senior Manager Track Engineering Manitoba, Canada

Jan has a bachelor’s degree in mechanical engineering and a master’s degree in engineering design & analysis. He also earned a post graduate certificate in engineering business and safety management. He began his career in the rail industry as a track inspector, where he developed a robust foundational knowledge of track systems. His expertise in budget oversight and maintenance quickly became apparent, leading to his promotion to a management role within the structures (bridges) group. Jan has completed hydrology training and management for water, and he has researched how it interacts with different types of bridges. He implemented emergency procedures for ice flow management during flood stages. Jan is driven by a clear ambition to progress from a hands-on leadership role to the position of Director, with the ultimate goal of becoming a senior leader within the engineering field. Jan is a dedicated volunteer for the Canadian National Institute for the Blind (CNIB), an organization that supports individuals affected by blindness or vision impairment. In his volunteer role, Jan contributes by training dogs to become service animals. His efforts ensure that these dogs are well-prepared and equipped to be placed successfully in homes, providing essential assistance.

PATRICK PAYNE

Union Pacific General Director, Maintenance of Way

Omaha, Nebraska

With a bachelor’s degree in civil engineering from the University of Nebraska at Lincoln, Pat is a senior leader in Union Pacific’s track maintenance team, overseeing 700+ employees. Pat’s team maintains and repairs 8,000+ track miles across challenging mountainous terrain in the Rocky Mountains, Sierra Nevada, Northern California, and the Pacific Northwest. The team handles extreme weather conditions to protect infrastructure, including 1,200 miles of passenger operations, with zero error margin. Pat leads expansion joint initiatives to accommodate temperature changes and has implemented snow fencing and winter response strategies, significantly enhancing winter preparedness. His team, equipped with advanced snow-fighting equipment, often assists local first responders. A husband and father to two young children, Pat dedicates his time outside the railroad to his family. Whether it’s school fundraisers, involvement in his family’s church or support of the community’s Global Outreach Charities organization, Pat works tirelessly to balance parenthood with the demands of the railroad. Professionally, Pat is a member of Union Pacific’s VETS resource group whose mission is to recruit, develop and retain military veterans on the railroad.

DANIEL DIAZ RAMIREZ

Icomera Field Service Engineer

Rockfield, Maryland

With a bachelor’s degree in telecommunications engineering, Daniel is a skilled auto-electrician with advanced networking expertise. Working directly on road and rail vehicles, Daniel specializes in the high-performance installation, commissioning, and upgrading of cutting-edge connectivity solutions. In his role as a full-time onsite service engineer, he partners with leading industry players to deliver innovative technologies that power smarter, greener, and safer transportation systems. Community service has always been a meaningful part of Daniel’s life, especially when he can give back to children in need. His most recent experience was last Christmas when he traveled to Colombia to support his mother-in-law, who owns a hotel. Every year, she hosts an event for local children, offering musical performances, food, and presents. Daniel is grateful for having the opportunity to contribute by helping with the charity event preparations, ensuring the event runs smoothly. He also volunteers for similar charity events focused on children with special needs. While the setting and specific group of children may be different, the essence of the events –– spreading love, kindness, and joy –– has stayed with him and greatly enhanced the lives of the children he serves. He sets a wonderful example of what it means to care for the next generation.

Congratulations to Scott Sandoval for being named one of this year’s Young Executives Under 40!

Scott’s

KENETH REAVES BNSF

General Director, Line Maintenance, Southwest Division Albuquerque, N.M.

With a bachelor’s degree in mathematics from Morehouse College, and a bachelor’s degree in civil engineering from the Georgia Institute of Technology (Georgia Tech), Keneth has made substantial contributions throughout his career to fortify the safety culture at BNSF. During his time in the engineering safety organization, Keneth was integral in challenging the status quo and expanding the training platforms to educate the workforce on risk tolerance and mitigation identification. Keneth challenged the norm of safety messaging to include more long-range data trends. He then integrated this data into supplemental operations testing scenario-based training to help the newer tenured employees be more impactful with their feedback when observing field behaviors. This strategy has been essential in the downward trend in engineering safety IFR over the past few years. Keneth was the leading manager during the Dixie wildfire in the summer of 2021 on the Gateway Sub. Keneth is a long-standing contributor to the United Way and a contributing member to BNSF RailPAC. Keneth also volunteered his time as a mentor to the youth in his community through the local ISD and church affiliation when he was in Ponder, Texas (up until spring 2024 when he was promoted and relocated).

LOGAN ROSE CSX Track Supervisor

Nashville

With a bachelor’s degree in business and finance from the University of Tennessee at Chattanooga, Logan Rose has been a key figure in driving the success of CSX within the Nashville region, leveraging his strong technical union background and exceptional foresight to deliver outstanding results. His leadership has been instrumental in planning and executing large scale, high-impact projects on the Chattanooga Subdivision. These initiatives required careful coordination, precise execution, and a deep understanding of railway operations, all which Logan handled with expertise and efficiency. He is consistently recognized by his peers and leaders for his innovative thinking. Logan is deeply committed to giving back to his community, particularly in supporting the fight against Multiple Sclerosis (MS). He actively participates in fundraising events and awareness campaigns that aim to improve the lives of those affected by MS. Logan has been involved in local charity walks, bike rides, and other community-driven initiatives designed to raise funds for research and provide resources to individuals and families living with the disease. Through his dedication to these causes, Logan has helped generate significant contributions toward advancing MS research and supporting community programs.

Union Pacific congratulates Patrick Payne, general director –Maintenance of Way, for being named one of Railway Track and Structure’s Top 10 Under 40 Engineers.

SCOTT SANDOVAL Assistant Vice President, Regional Engineering Genesee & Wyoming Jacksonville

With a bachelor’s in civil engineering from the University of Florida, Scott’s leadership has been invaluable to the company. He began his career as a management trainee at Norfolk Southern before coming to G&W in 2014. He started in front-line management and worked up to his current position in the engineering department. He established himself as an expert in rail integrity while leading our track testing group and played a strong role in implementing laser, X-ray, and LIDAR use in tie inspections. He was a major catalyst in the transition G&W has made to the digitalization of our inspections, records, and various forms of data and the resulting capability for analysis. His positive influence and integrity earn the respect of the people he leads. Colleagues continually see employees who have worked under Scott become safety leaders and fill the lists of potential candidates when there are promotion opportunities. In his current position (since May 2024), Scott has taken on a division with challenging track conditions and shown an immediate impact on track safety stats. He accomplished this through changing the work culture and inspiring his employees to be the best. He is also a member of the Editorial Board of Railway Track & Structures, but those involved with the magazine recused themselves for part of the award process.

Congratulations!

Congratulations to Stephen Hager, Rail Engineer, on being a 10 Under 40 honoree! Stephen’s expertise and passion are helping us shape the future of rail, and we’re proud to have him on our team. Join our Team at: Go.RailPros.com/Career

ALEXANDER SEREDICH

ENSCO Rail Division Manager

Vienna, Va.

With a BA in Business Administration, Management & Operations from the University of Maryland Global Campus, Alexander Seredich is a seasoned rail industry professional with more than 19 years of experience in rail technology and infrastructure inspection. Since joining ENSCO in 2019, he has played a critical role in advancing track inspection solutions and delivering innovative technologies to the industry. As Division Manager at ENSCO Rail since July 2023, Alex has led key initiatives in commercial track inspection and driving the development and deployment of cutting-edge solutions. Prior to ENSCO, Alexander served as Director of Automated Track Inspection at the Washington Metropolitan Area Transportation Authority (WMATA). Alexander’s expertise spans track geometry systems, vision inspection systems, thermal inspection, and ultrasonic rail flaw systems. Alexander is dedicated to giving back through community service and industry leadership. In 2024, he organized a group of 16 rail employees to participate in the 9/11 Day of Service, demonstrating his commitment to teamwork and helping to pack thousands of nutritious, non-perishable meals for members of the local community at risk of hunger. This Day of Service also recognizes the horrific impact of that terrible day in 2001.

JOE WHITE Watco

Assistant Director of Engineering Pittsburg,

Kan.

As a graduate of the University of Mississippi with a bachelor’s in engineering, Joe is the youngest member of one of Watco’s threeperson engineering teams, but has been very effective during his eight years with the department. One of his largest undertakings is his role in the expansion of a polyethylene manufacturing plant for a large chemical company. Joe took on a large role developing track layout for:

• The rail support infrastructure that would attach to a new rail loadout facility, designed to increase daily throughput from a current average of 39 to 57 railcars per day.

• A secondary storage yard needed for an additional 315 hopper cars and 50 raw-material tank car spots.

• An additional strategic yard to allow for storage capability for 60 railcars.

• A hopper car wash facility expansion that increases capacity from 53 to 75 cars per day.

While studying engineering at the University of Mississippi, Joe became involved with the university’s chapter of Engineers Without Borders (EWB). Over a two-year period, he made two trips to West Africa to help build a school in a remote village in the nation of Togo. Joe contributed in several ways to the success of this project.

Brad Kerchof, formerly Director of Research & Tests at Norfolk Southern, and Senior Track Engineer at Global Rail North America.

The Great Dismal Swamp. An ominous name. And in June of 2019, it was the site of a Norfolk Southern derailment. At NS, all derailments are investigated to determine the cause(s) and to provide data that could help prevent future incidents. Brad Kerchof, formerly Director of Research & Tests at Norfolk Southern, and currently Senior Track Engineer at Global Rail North America, has investigated many derailments. And in the case of the Dismal Swamp derailment, he asks: was the right cause found?

The Great Dismal Swamp National

Wildlife Reserve overlaps Norfolk Southern’s Bluefield-Norfolk mainline. This is where unit coal train 820 derailed. The investigation of the derailment took place shortly after Kerchof’s retirement from NS, and he was therefore not part of the investigation — but he was very familiar with the relevant data and had previously led many of NS’s derailment investigations. He provided his analysis of the final report on the derailment at the 2024 Wheel/Rail Interaction Heavy Haul Conference.

Train 820 derailed at milepost N15.7 (Norfolk is located at N0) while traveling eastbound at 50 mph; 36 cars (designated

cars 45-80) derailed. “Two questions should be asked at the start of a derailment investigation,” Kerchof said. “What’s the point of derailment (POD), and which car was the first to derail?”

In this case, investigators determined that the first car to derail was likely car 46. “Investigators likely determined this based on ballast marks on the wheel treads,” Kerchof said. The POD couldn’t be determined initially via site inspection, since the site was likely buried under ≈500 ft of mangled metal and coal, he said.

According to NS investigators, the first five cars rolled on their sides, causing the

by Jeff Tuzik

following 31 cars to accordion in a pileup. Likely causes of a derailment of this nature include a broken rail, a burned-off journal bearing, a broken wheel, or a broken axle, Kerchof said. He added that some causes could be excluded, such as train handling — because the cars were all loaded and travelling on level grade — and a wheelclimb initiated derailment, because no wheel marks were found on the ground leading to the pile-up.

In addition to inspections at the derailment site, there are also important transportation-related elements to include in any investigation: the locomotive event

recorder, forward-facing camera footage, and train crew interviews. The mechanical aspect of the investigation should also include wheel impact load detector (WILD) data, and inspection of the wheel treads on the last good cars (the cars immediately in front of the derailed cars): “This is where you want to look for impact marks associated with a broken rail,” Kerchof said.

On the track side, he said that important data to consider includes the most recent track geometry inspection data, downward facing camera images (from the geometry car), vehicle/track interaction results, and recent rail-flaw inspection results.

Only a small number of broken rail pieces were recovered. Pieces 1 and 2 show signs of tread contact on the web, a result consistent with a vertical split head defect.

The mechanical inspection of the derailment found a broken wheel on the lead truck of the third derailed car (car 47). This was determined to be a result of the derailment, rather than a cause, due to ballast marks on the tread, indicating that the wheel failed sometime after it contacted the ballast. Investigators also found rail abrasion marks on the bottom, inboard side of the south-side side frame of car 45 (the first derailed car), Kerchof said. On car 47, investigators found a broken rail piercing the south-side of the truck bolster; “This means either the south rail would’ve

had to raise up to bolster-level, or the bolster dropped down to rail-level.” Figure 1 shows the location of these cars and the orientation of the north and south rails.

The track inspection of the site turned up a few more pieces of the puzzle; seven small pieces of broken rail. Pieces 1 and 2 (see figure 2) were particularly important, Kerchof said, because they showed evidence of wheel tread contact on the web of the rail. “That’s only possible if the rail head breaks off and wheel treads run along the web while the rail base is still sitting in the tie plates.” Unfortunately, whether these pieces came from the north or south rail could not be determined, as none were large enough to include a brand. Investigators also identified other broken rails, but none of these contained an initiating defect, he said, so a causal rail failure could not be confirmed.

The locomotive event recorder showed nothing anomalous, the throttle setting suggesting only “light-to-moderate draft forces in a steady state” per NS’s report. A close review of the forward-facing locomotive camera noted a “small discontinuity on the gage side of the South rail head,” but also noted that had the location not been marked as close to the suspected POD, this discontinuity would “likely not be considered significant.” As there is no mention in the official report, it seems that no relevant information was obtained from crew interviews, Kerchof said.

Mechanical Analysis

Kerchof pointed out that the WILD data used in the investigation was obtained from a detector in Waverly, roughly 50 miles from the POD, meaning that the data represents conditions roughly one hour prior to the derailment. Data from the last two good cars and the first two derailed cars is shown in figure 3. Though the data for peak vertical kips shows evidence of some out-of-round wheels, nothing is severe enough to trigger a wheel changeout, he said. Peak lateral kips are similarly unremarkable. “In the context of lateral over vertical loads, you’re looking at a peak L/V of 0.2 or 0.3 — nothing that would cause a derailment.”

Close analysis of the wheel treads found impact marks on three of the last good cars, some of them indicating very forceful strikes. “To get a dent like this in a wheel tread, you’ve got to have a fairly heavy car a high-impact situation such as when the wheel falls to the ground and then strikes

the face of the broken rail,” Kerchof said. Figure 4 shows such a wheel impact mark, and the battered end of a broken rail at the derailment site. The broken rail piece showed evidence of both tread and flange impacts. “This was certainly involved in the derailment, but the fracture face [of the broken rail] showed no defect,” he said. As was the case with the broken wheel from car 47, this indicates a result rather than cause.

Impact marks were found on the northside wheels of cars 42 and 43, both of which were traveling with the A-end in the lead, and on the north- and south-side wheels of car 44 (the last car to not derail) which was traveling with the B-end forward.

Track geometry and track chart data provided an overview of the derailment site:

• Tangent track

• 0.04% descending grade (effectively level)

• South rail type: 132RE Illinois Steel September 1981

• North rail type: 132RE Bethlehem Steel September 1981

• Gage, surface and alignment met relevant FRA class 4 standards, based on a test three weeks prior to the derailment

• Downward-facing cameras showed a clean running surface (no RCF) on both rails

Sperry Rail Service performs internal flaw detection on NS. Figure 5 shows a diagram of the ultrasonic sensor array Sperry used circa 2019. The 2-dimensional location, shape, and thus, the likely type, of internal flaw (if present) is represented by the collection of transducer responses it triggers, Kerchof said. These tests produce brightness-scan charts, often called B-scans, which show a side-view of the rail in 10-foot sections.

Ultrasonic testing was performed on the track in both February and May of 2019, prior to the June derailment. The February test triggered 70-degree, 45-degree, and side-looker (which takes a scan perpendicular to the rail) transducer responses on the south rail over a distance of 36 feet, indicating a potential vertical split head, he said. This was a start-and-stop test, meaning the inspection took place at low speeds and stopped for hand test verifications. At the time, however, hand testing at this location was negative; it did not confirm an internal defect.

The May 2019 test of the same location and rail did not reproduce the same 70- and 45-degree transducer responses, although it did trigger a similar side-looker response, but now spanning a distance of 37.5 feet, Kerchof said. The May test was also different in that it was a continuous test, meaning the operation took place at

Figure 6. A comparison of B-scans from the Dismal Swamp location (top) and the site of a VSH-related derailment at New Haven (bottom). The blue and beige responses highlighted in yellow and red are the side-looker transducers. The circled VSH icons were generated by Sperry’s pattern-recognition system and are triggered by length and frequency thresholds.

a higher speed and did not stop for handtest verification. Hand testing was only done (the next day) if there was a change in the data from the previous test, such as the appearance of a new potential defect. In this case, the differences between the February and May tests did not meet the criteria for follow-up hand-testing.

Sperry and NS determined that the differences in signal response between the two tests were due to “excessive beam scatter and not to specific internal defects,” according to the official report. The report continues: “Since rail containing an initiating defect was not recovered from the derailment site, the defect type and location (north vs. south rail) could not be determined.” The report concludes that the derailment was initiated by a “broken rail of unknown origin” and given the FRA Cause Code T207 Broken Rail – Detail Fracture from shelling or head check, Kerchof said.

Was this the true cause of the derailment?

Track Safety Standards Subparts A-F

Track Safety Standards, contains the Track Safety Standards, Subparts A-F, for Classes of track 1-5. The standards cover general information, Roadbed, Track Geometry, Track Structure, Track Appliances and Track-Related Devices, and Inspection. Includes Defect Codes. Updated December 28, 2023

BKTSSAF Track Safety Standards, Subparts A-F $13.95 Only $12.50 for orders of 50 or more!

FRA Part 237 establishes Federal safety requirements for railroad bridges. This rule requires track owners to implement bridge management programs, which include annual inspections of railroad bridges, and to audit the programs. Part 237 also requires track owners to know the safe load capacity of bridges and to conduct special inspections if the weather or other conditions warrant such inspections. Updated December 28, 2023

BKBRIDGE Bridge Safety Standards $14.00

Only $12.60 for orders of 50 or more!

This reprint includes the FRA's Railroad Workplace Safety Standards addressing roadway workers and their work environments. These laws cover such things as: personal protective equipment, fall protection, and scaffolding for bridgeworkers; and training issues. Also includes safety standards for on-track roadway vehicles. Updated December 28, 2023

BKWRK Railroad Workplace Safety $13.95

Only $12.50 for orders of 50 or more!

The Track Safety Standards Calculator is a must for anyone who works on track. This slide rule type calculator contains many of the details for Classes of track 1- 5. Deviation from uniform profile and from zero cross level. Difference in cross level. Compliant with part 213.

BKTCAL Track Calculator $12.50

Only $11.25 for orders of 50 or more!

Kerchof thinks not. The rail surface condition at the time of derailment was clean; There was no shelling or head checks, he said. “The transducer responses were not beam-scatter due to a surface condition, because there was no RCF.” In order to produce a beam-scattering response in an ultrasonic flaw detector, RCF has to be present and quite severe, easily visible to the naked eye, he said. Based on all the evidence gathered by investigators and a close reading of the Sperry B-scans, he surmises that the transducer responses in May and February of 2019 reflected a real internal defect.

The total length of side-looker transducer response in the May 2019 ultrasonic test was 37.5 feet. In 1981, when the rail at the derailment site was produced, mills produced rail in 39-foot lengths. “And what type of defects tend to run the entire length of the rail? Split webs, pipe rail, head and web defects, and vertical split heads (VSH),” Kerchof said.

Kerchof compared the data, including B-scans, of the Dismal Swamp derailment with another derailment (in New Haven, Indiana) that he had investigated — one

that was unquestionably due to a VSH. There were many similarities. In both cases there were “intermittent side-looker transducer responses that were long enough to trigger Sperry’s VSH pattern recognition,” he said. Figure 6 shows a comparison of Dismal Swamp (top) and New Haven (bottom) B-scans.

The final resting position of the first four derailed cars in the Dismal Swamp derailment holds another piece of evidence. In order to fall to the south side, the wheels on that side would have to fall first, indicating that the south rail was the first to break. Combined with all the other evidence, including the rail abrasion mark on the south side of the side frame of the first car to derail, and the wheel tread impact marks on the web of the north rail, Kerchof said that the majority of the evidence points to one conclusion; “I’m convinced we had a south rail VSH in the Dismal Swamp.”

The only piece of evidence that supports another conclusion was impact marks consistent with a broken rail strike on multiple wheels on the north side of the

last three good cars, he said. But this alone stands against significantly more evidence indicating the south rail.

As is the case with most derailment investigations, the Dismal Swamp investigation touched on nearly every aspect of wheel/rail and vehicle/track interaction and provides an opportunity for a deeper understanding of the interplay of these systems. A case like this, in which there is also a kind of investigation of an investigation, illustrates some of the ways in which extant measurement and condition monitoring technologies like track geometry cars, WILDs, ultrasonic testing, can be leveraged as investigative technologies — the data is there, but sometimes it takes a different perspective to pull the information from it.

Jeff Tuzik is Managing Editor of Interface Journal. https://interfacejournal.com/

This article is based on a presentation made at the 2024 Heavy Haul Wheel Rail Interaction conference. https://wheel-rail-seminars.com/

All illustrations courtesy of Norfolk Southern / Brad Kerchof.

By David C. Lester, Editor-in-Chief

Rarely a day passes that there isn’t a news report of some type of cyber breach. Hospitals, insurance companies, and just about any business can be “attacked” and the criminals can release some of the most sensitive information about individuals and organizations there is. These attacks are generally executed using “ransomware,” which can steal and distribute data or lock up a system such that the people or organizations owning it cannot use it at all unless they pay a ransom demand.

Cyberattacks are not usually publicized unless they must be. If large breaches of personal data, like health, identification, or financial information occur, the company that was the target of attack must disclose that this occurred and warn customers to watch their accounts and credit reports for signs of unusual activity. While it’s always disconcerting to hear that a system is down, the first thing people usually think of is a cyberattack. However, it is very possible for a system to go down without having been the victim of a cyberattack or data breach. For example, hardware failures can occur, and most systems connect a great deal of hardware to provide end-users with the information they need. Software failures

occur, too. These can be caused by the software trying to execute a process that hasn’t been tried before, revealing a defect in the code or algorithm being used. Most systems also require a fair amount of maintenance, including code upgrades, which, if not properly tested in a nonproduction environment, can reveal a software defect. Most of the time, these defects will impact the operation of one or more parts of the system but can occasionally bring down the whole system.

Railroads and railroaders are very heavy users of computer hardware and software, usually referred to together as information technology. And this information technology has grown more and more sophisticated over time. Very large amounts of data can now be gathered, and hardware must have the capacity to accept and process these vast amounts of data.

The railroad industry has worked together and taken significant steps to prevent cyber breaches over the past few years. The Association of American Railroads points out there is a “Rail Information Security Committee”, which is “an industry-formed and led coordination group that is the focal point of the industry’s unified, cooperative, cybersecurity efforts. The group comprises chief

information security officers and information assurance officials for railroads and industry organizations, augmented by AAR security staff. Representatives of the six Class I railroads and Amtrak established RISC in 1999, meaning the industry has proactively enhanced cybersecurity through a dedicated forum for over 20 years.”

The AAR adds “Each year, the rail industry and other critical infrastructure sectors participate in the North American Railroad Industry Joint Security Exercise to test the security plan, evaluate preparedness, and enhance capabilities and procedures using lessons learned. This exercise involves security, police, and operations professionals from freight and passenger railroads in the U.S. and Canada; the security team and other functional staff from the AAR; IT leads from Railinc; and officials from government security and law enforcement agencies, including the TSA, DHS, and FBI.”

The need for vigilance around watching for and preventing cyberattacks will only grow as technology becomes more sophisticated. However, as cyber protection grows in sophistication, systems may be more difficult to hack than they are now. Let us hope.

The Educational Railroading Conference Leader Since 1994

To better cater to the diverse needs of our attendees, the WRI 2025 Conference will split into two specialized events in 2025.

COMING TO KANSAS CITY, MO • JUNE 10–12, 2025

Presenting Sponsor

Early-Bird Registration ends April 23, 2025

COMING TO SEATTLE, WA • AUGUST 26-28, 2025

Presenting Sponsor Local Host Local Host

Each conference will feature a comprehensive Principles Course meticulously crafted to meet the distinct needs of each discipline. We believe this division will provide an enriched experience for all participants, allowing for deeper insights, targeted discussions, and enhanced networking opportunities.

The Heavy Haul Seminar is devoted to examining wheel/rail and vehicle/track interaction on heavy haul freight and shared-track passenger systems. Information is disseminated through a combination of seminar sessions, dedicated Q&A periods and “InfoZone” sessions.

Since 1994, the Heavy Haul Seminar has been bringing together track and mechanical users, government regulators, researchers and suppliers in a positive, educational setting like none other in the industry.

Early-Bird Registration is open • Continuing Education Units (CEUs) offered - Professional Engineering (PE or P.Eng)

The Principles of Wheel/ Rail Interaction Course is an intensive, full-day course that provides fundamental coverage of the primary aspects of wheel/rail, vehicle/track interaction. The Course will focus on real-world, practical applications

The Rail Transit Seminar is devoted to examining wheel/rail, vehicle/track interaction on rail transit systems including light rail and subways. This cross-disciplinary seminar includes presentations from experts in vehicle/track dynamics, noise and vibration, vehicle/track design and maintenance, friction management, and State of Good Repair.

Information at www.wheel-rail-seminars.com

Questions? Contact Brandon Koenig, Director of Operations 847-808-1818 or email at brandon@wheel-rail-seminars.com

Produced by Wheel Rail Seminars

To navigate new digital risks posed to rail infrastructure, railroads need to keep up with new technologies.

By Jennifer McLawhorn, Managing Editor

The rail industry must evolve to meet new challenges and problems. In addition to inspecting the right of way and

implementing maintenance programs, an area of growth within the supplier industry is rail cybersecurity. Rail networks are made of critical infrastructure that is susceptible to cyberattacks. To keep networks safe, railroads must integrate new technologies as they become available. For the second year in a row, Railway Track & Structures is focusing on emerging cybersecurity solutions for rail infrastructure.

ENSCO spoke to RT&S about its Center for Critical Infrastructure Protection (CCIP) at the TTC and its role in

cybersecurity for rail infrastructure, stating “As rail systems integrate more digital technologies, the risk of cyberattacks on critical infrastructure continues to grow. The Center for Critical Infrastructure Protection (CCIP) at the Transportation Technology Center (TTC) provides industry-leading cybersecurity services to safeguard rail networks from evolving threats.

“CCIP specializes in securing both operational technology (OT) and information technology (IT) systems through advanced testing, real-world threat

simulation, and risk mitigation strategies. With expertise in threat and vulnerability assessments, penetration testing, and red teaming, CCIP helps rail operators identify weaknesses in control, communications, and IT networks. These evaluations provide actionable insights to strengthen cyber defenses and mitigate potential disruptions before they occur.

“In addition to security assessments, CCIP offers cybersecurity training and tabletop exercises designed to enhance industry preparedness. These interactive sessions help rail professionals recognize and respond to cyber threats in real time, reinforcing best practices for safeguarding infrastructure. Through ongoing research and collaboration with industry and government partners, CCIP ensures that rail cybersecurity practices evolve alongside emerging risks.

“As the transportation sector continues to embrace automation and digitalization, CCIP remains committed to providing cutting-edge services that enhance the resilience of rail networks against cyber

threats. To learn more about how CCIP at TTC can help protect your rail systems, visit https://ccip- ensco.com/.”

understandably, no one really wants to talk about it. The last thing a company wants to do is discuss its sources and methods for securing its networks. However, it’s possible for companies providing cyber services to make the industry aware of their existence through basic information like that provided by ENSCO earlier in the piece.

Editor’s Note: One of the challenges of reporting on cybersecurity is that,

Nothing in ENSCO’s discussion reveals their sources and methods, but simply makes the industry aware that they have robust services to offer. We at RT&S agree that detailed dialog about cyber solutions should remain primarily within the confines of rail industry specialists, private companies and government agencies, all with some level of national security clearance. We believe, too, this is a legitimate area for our magazine to cover. As we continue to move forward with covering railroad infrastructure, maintenance of way, and engineering projects, we need to be open to sharing basic information about cybersecurity. We need to focus on how to keep everything secure. DCL

C.

Railway Age

David C. Lester

Railway Track & Structures

Kevin Smith International Railway Journal

Railway Age, Railway Track & Structures and International Railway Journal have teamed to offer our Rail Group On Air podcast series. The podcasts, available on Apple Music, Google Play and SoundCloud, tackle the latest issues and important projects in the rail industry. Listen to the railway leaders who make the news.

By David C. Lester, Editor-in-Chief

One of the major steps in the construction of new railroad track or significant refurbishment of an existing line is moving a variety of materials where they need to be and when they need to be there. For example, ballast trains are vital to its movement to where it needs to be on the railroad. Today’s technology can guide a ballast train to where the material is needed and, using GPS mapping, unload the ballast cars right where the ballast must go. Stand-alone machines for transporting and dumping

ballast are also used when the amount of material is relatively small.

The definition of “material” on the railroad can encompass many things. From dirt, to ballast, to ties and rails, all of this is material that requires special handling. Rail trains, which carry “strands” of rail to be welded together to form continuous welded rail are specially designed to move rail long distances. Still, other equipment is used to pull the rail off the train and line it up on the tie plates to be attached to the ties using additional equipment. Tie placement and

removal are also vital functions for material handling equipment, and equipment can be used to insert new ties or pull out old ones for disposal.

Machines that gather old ties along the right of way and load them into trucks or railcars for final disposal are critical for major maintenance of way projects.

Trucks and rail cars used to haul dirt to or from a construction site are critical to project success. There is a wide variety of models and functionality to ensure the material is moved quickly and efficiently.

By Jennifer McLawhorn, Managing Editor

An important yet broad area of the rail industry, material handling equipment encompasses specialized machinery that ensures materials are moved and distributed quickly and safely.

For material handling, Plasser American’s “MFS material handling units are designed as a standard railroad vehicle design, featuring a floor conveyor belt in the hopper and a transfer conveyor belt at the front end of the unit. All conveyor belts are powered hydraulically and a diesel engine supplies the power. There are four models of MFS units: MFS40, MFS60, MFS100, and MFS100 S.

They can convey, store, and unload up to 41 (MFS40), 61 (MFS60), or 90 (MFS100 and MFS100 S) cubic yards of ballast, spoils, or other materials in train formation to and from various work sites. The MFS100 S also includes an additional transfer conveyor belt and ballast distribution devices, which allow precise ballast distribution into the track or the ballast shoulder. The floor conveyor belt enables the hopper to be continuously filled or passing on of the material. The transfer conveyor belt moves the loose material either into the next hopper or to the side of the track at a chosen location. This belt can be slewed 45° to the left or to the right-hand

side, and features tilt warnings and tilt protection systems to prevent vehicle tipping during discharge. The unit comes with a protected workplace equipped with monitoring and control instruments for the conveyor system. MFS units can be linked together in any number to form a material train. They can also be incorporated into a Ballast Distribution System (BDS100/BDS200) or used with ballast cleaning machines. Units with a rigid transfer conveyor belt are typically used in formation as part of the conveyor line and/ or as hoppers, while unloading is carried out by an MFS unit with a slewing conveyor belt.”

From Custom Truck One Source, the

Hi-Rail Material Handler Spec 755 “is a powerhouse solution for rail industry professionals. Equipped with a 23’ to 25’ telescopic straight boom, this material handler delivers 1,250 lbs of lift capacity at full reach, making it ideal for heavy-duty material handling. Built on a 22’ heavy-duty platform body with an abrasion-resistant steel floor (AR500), this unit offers superior strength and stability. Operators benefit from top seat joystick controls and continuous rotation, ensuring precise and effortless maneuvering. A DC 12/24-driven magnet system with a 32” lifting magnet enhances versatility, while the grapple attachment—available in bypass or butt type—accommodates a wide range of material handling needs. Rail-ready, the Spec 755 includes hydraulic rail gear operation, FRA annual inspection rail gear and crane-based inspections, and essential safety features like LED work lights, backup alarm, and conspicuity striping. Customizable with shunt systems, remote creep drive, and tool circuits, it’s engineered for performance in demanding environments.” A spokesperson for Custom Truck said, “At Custom Truck, we take control of lead times with in-house manufacturing, ensuring faster delivery and unmatched quality. From hi-rail pickups to tandem axle material handlers, our railroad division designs and builds to your exact needs.”

Loram Maintenance of Way said its “Dump Train and Dump Train for Curves® ballast delivery trains continue to deliver more ballast faster than any other product on the market. Loram’s DumpTrains can deliver 1,500 tons of material to work sites, stockpiles, or washout locations and unload a full consist in under an hour. Offloading is done up to 45 feet from track centerline. The DumpTrain for Curves® offers all the same features as the traditional DumpTrain but can operate while in curves as well as tangent track. Loram’s 7000 series self-powered slot trains (SPS 7000 series), pulled by a 3,600 HP 6 axle drive power unit, set the standard for power and versatility in material handling. With the ability to pull larger amounts of material in steeper grades the SPS 7000 series is bringing more efficiency to customer work sites. The increase in available horsepower, and driven axles, over previous machines is giving customers new options regarding how much equipment and material can be towed during engineering projects. All of Loram’s slot trains bring an unmatched versatility to material handling by being able to load/unload any type of material that is within the reach of the excavator. These machines pick up, and offload, ballast,

rip rap, rail, ties, and other material that either needs to be placed, or removed during maintenance operations. The Material Handling Car (MHC) comes to the market in both 60 (MHC60) and 80 (MHC80) cubic yard volume capacities with the ability to offload a full hopper in minutes. These machines are capable of carrying ballast, subballast, and spoils from ballast cleaning operations. The material can be discharged up to 23 feet from track centerline, or directly into another MHC car towed behind it. Customers cite the material throughput and offloading capabilities of the MHC product as improving the efficiency of their ballast cleaning operations. GateSync and Solaris were designed with safety and cost savings in mind. Suitable for retrofit of your ballast fleet or new builds, these systems offer a variety of unloading options. Customers can employ high-speed unloading features that utilize customizable surveys. By utilizing this survey information, GateSync automatically opens and closes gates to deliver the ballast precisely where needed while avoiding dumping on crossings, switches and other ‘no dump zones’. Solaris improves the safety and productivity of your ballast fleet by automating your existing gates. A solar powered, hydraulic pump activates hydraulic cylinders to open and close gates. Solaris allows for accurate unloading without auxiliary air. Solaris equipped cars can be unloaded with either on board joy sticks or with Loram’s robust remote control system. Adding the GateSync Solaris solution increases the productivity of any ballast car while also improving operating safety. Safety and reliability are top of mind with the HydraDump®

system. A cost effective side dump unloading system using proven air over hydraulic operations. Suitable for both existing side dump cars or new builds. HydraDump® allows for safer unloading with a controlled lifting of the car body and no ‘launching’ at the top of the dump. Built-in safety features return the body of the car to resting position if pressure is ever lost. HydraDump® is an easy-to-install system that converts your existing side dump cars from pneumatic to hydraulic operation. This makes your cars more dependable to use, more predictable to operate and far less costly to maintain. TSO, Tie Set Out, leverages Loram’s AURORA technology to precisely deliver railroad ties. By utilizing collection data from the Aurora system, TSO generates drop files that systematically guide the excavator operator in how many ties to drop in a given spot. Accurate placement of ties allows gangs to complete projects faster by minimizing the need for excess handling. Excavators equipped with the Loram TSO system are in use across multiple Class Is.”

Herzog states its “Multi-Purpose Machine (MPM®), offers excellent versatility and efficiency for on-track material handling. Developed to enhance the speed and safety of loading and unloading various materials, the MPM addresses both routine maintenance and emergency response needs along the railroad right-of-way (ROW). Equipped with a zero-turn radius excavator that traverses atop a material car gantry system, the MPM adeptly performs tasks such as ballast and rip rap distribution, rail and tie pickup and distribution, rail shearing, ROW ditching, profiling, drainage, brush cutting, tree removal,

snow removal, land clearing, pole removal, and the installation of Positive Train Control (PTC), signals, and communications infrastructure. Designed to Plate C specifications, the MPM is compatible with multi-track environments without fouling adjacent tracks.

In travel mode, it can move at track speed in either direction, ensuring minimal disruption to rail operations. Notably, the MPM requires only a single operator, significantly reducing labor-intensive tasks and enhancing safety. With a reach extending 30 feet from track

center using its roto-tilt head and a 79-cubicyard capacity per car, the MPM can haul a substantial amount of material. Its quickconnect system allows for attachment changes in under five minutes, further optimizing operational efficiency. Since its development in 2000, the MPM has become a strong asset for Class I railroads, short line railroads, rail transit systems, and material yards.”

Pettibone tells RT&S its “Speed Swing 445F2 is the newest model of the industry’s original do-it-all rail crane. The machine is compatible with more than a dozen attachments for laying rails, setting ties and numerous other maintenance-of-way tasks. Providing 180-degree boom rotation, the Speed Swing is primarily used to thread out old rail and thread in new rail. An optional magnet package quickly cleans up old plates, spikes, and small pieces of rail. The unit can also tow rail carts and move railcars. The 445F2 offers a maximum front load capacity of 10,000 pounds and maximum side load capacity of 8,000 pounds. It is powered by a fuel-efficient 163-horsepower Cummins QSB4.5 Tier 4 diesel engine and offers a 49-gallon fuel tank, allowing for extended

working intervals. Featuring a Dana T20000 3-speed transmission with twist-grip electric shift control that delivers exceptional torque, the Speed Swing quickly transitions between jobsites, traveling at 25 mph on hi-rail and 20 mph with all-terrain rubber tires. Durably built for challenging railroad applications, the 445F2 offers planetary front and rear axles with front differential lock. Four-wheel outboard dry-disc service brakes provide sure stopping power. Pettibone X-Command telematics comes standard for two years.”

DavRail’s “TRACS (Turnout Remover And Carrier System) is impacting turnout panel management in railway maintenance by prioritizing safety, efficiency, and versatility. Its fully remote-control operation allows precise maneuverability from a safe distance, minimizing the need for personnel to be near active rail areas and reducing accident risks. TRACS also creates an instant exclusion zone, keeping unauthorized personnel away from hazardous zones, further enhancing safety. Efficiency is at the forefront, with TRACS offering seamless self-loading onto transport vehicles, reduc ing downtime and transportation costs. It can handle various turnout sizes and track gauges

its combination of advanced safety features and operational efficiency, TRACS provides safe, fast, and cost-effective turnout handling and track maintenance, significantly reducing project timelines and costs while improving

BILL RIEHL AREMA President 2024-2025

Welcome to spring. While generally a reprieve from winter for most of the population, it’s a little different for our field forces. For those in our northern climes, engineering personnel are being released from the drudgery of clearing ice and snow from switches and flangeways, only to be rewarded with spring thaw, higher stream flows, persistent beavers and wild temperature swings. Of course, since it’s still early spring, if you don’t like the current weather, wait a day or two, and it’ll be different.

Change is also coming to the makeup of AREMA’s Board of Governors. If you are not up to date on AREMA governance, there are two leadership bodies that govern the Association and its work. They are the Functional Group Board of Directors (Board of Directors) and the Board of Governors. While the Board of Directors focuses on administering the operations of the 30 Technical Committees, the Board of Governors is responsible for strategic direction, policy, and the business and affairs of the Association. The makeup of the Boards is different as well.

The Board of Directors is chaired by the Senior Vice President and is comprised of six Functional Group Vice Presidents focused on these areas: Communications, Signals & Information Technology, Engineering Services, Maintenance-of-Way, Passenger & Transit, Structures and Track. Each Group also has two respective Directors. This Board meets two times a year in conjunction with the Committee Chairs’ meeting, typically in June and November.

The Board of Governors is chaired by the

President and consists of the Past President, the Senior Vice President, Treasurer, the Executive Director, and three Governors. They also meet two times a year, typically in spring and then in conjunction with the fall Board of Directors’ meeting. A Standing Committee reporting to the Board of Governors is the Strategic Planning Committee (SPC). Comprised of Past Presidents of AREMA, and as their name implies, these have a forward-looking mission to ensure AREMA is positioned for future strength and growth. Among their tasks is to review AREMA’s Governing Documents periodically and propose changes necessary for the continued health of the Association. These proposals are reported to the Board of Governors for further action.

As noted, change is coming. Previously, to be a Governor, the nominee had to meet the following qualifications - “At the time of installation to office the Governors must be currently employed in the capacity of Chief Engineer of a Class I railroad or a passenger or transit railway.” As railroads continue to merge, and the titles of senior engineering officers continue to evolve, SPC recognized this language is too restrictive.

As mergers have occurred and the population of engineers employed by the railroads has shrunk, the footprint of the North American Railway infrastructure hasn’t had a corresponding contraction in some time. Therefore, the supplier side of the industry and the engineering consultants, in particular, have had to assume a larger role in the industry. This has also been reflected in AREMA’s membership over the last few years where membership has been split almost evenly between railroad and rail transit employees and the consultant/ supplier community.

In light of the above, the Strategic Planning Committee in 2022, started to take a deep dive into the bench strength of our railroad and rail transit employee membership to fill these senior roles. Their findings showed the slowing pace of railroad and rail transit employee members entering committee leadership roles, with the potential to limit the candidate pool for future AREMA board level leadership roles. To state the obvious, this is a concern when AREMA’s long history and Bylaws place the responsibility for governance of the Association on our railroad and rail transit employee members.

In response, the SPC launched two projects. The first was focused on improving the bench strength of railroad and rail transit employee members entering committee leadership roles. This was coordinated through the Board of Directors with the goal of encouraging the committees to recruit and engage interested railroad and rail transit employees that could increase the pipeline of future leaders at the committee, and ultimately, the Board levels of the Association. This has proven somewhat successful and the pipeline of railroad and rail transit employee members engaging at the committee level is growing.