S U S TA I N A B I L I T Y REPORT 2021 Towards a sustainable future.

CO N T E N T S Introduction ............................................................ 05 Managing Director Report ................................ 06 Sustainable Development Goals ..................... 08 Our Business Pillars ........................................... 13 Our Successes ....................................................... 14 Material Solutions................................................ 20 Recycling & Waste ............................................... 24 Energy....................................................................... 28 Shared Services .................................................... 32 Board & Executive Leadership Team ............ 36 Ensuring a Sustainable Workforce ................ 38 Returning Home Injury Free ............................ 44 The Environment .................................................. 50 Communities.......................................................... 52 Our Discoveries ..................................................... 54 The Future............................................................... 56 GRI Reporting Standards................................... 58

In the spirit of reconciliation ResourceCo acknowledges the Traditional Custodians of country throughout Australia and their connections to land, sea and community. We pay our respect to their Elders past and present and extend that respect to all Aboriginal and Torres Strait Islander peoples.

T O W A R D S A S U S TA I N A B L E F U T U R E

S U S TA I N A B I L I T Y R E P O R T 2 0 2 1

WE BELIEVE WE CAN NO LO N G E R J U S T D I S C A R D T H I N G S B E C A U S E W E H AV E U S E D T H E M B E FO R E . W E N E E D TO F I N D N E W W AY S TO R E C Y C L E A N D R E U S E EVERYTHING. WE ARE R E S O U R C E CO .

RESOURCECO.COM.AU

03

R E S O U R C E CO I S I N T H E B U S I N E S S O F R E S O U R C E R E CO V E R Y TRANSFORMING WASTE INTO USEABLE PRODUCTS - PRESERVING THE PLANET’S LIMITED RESOURCES B OT H F O R TO D AY A N D F U T U R E G E N E R AT I O N S .

04

T O W A R D S A S U S TA I N A B L E F U T U R E

INTRODUCTION

At our very heart is the inescapable notion that a sustainable business benefits everyone - our customers, our partners and the planet.

Since we began, our philosophy has been simple: that the rubble we handle, the tyres we recover and the waste we collect will not simply go to landfill but be remade as useful and valuable products. Today that’s the case for 90% of the material we handle. That requires a creative and agile culture and makes us a valuable company, as well as a significant contributor to the global effort of our time. Our first Sustainability Report for the year ending December 2021, charts our successes on that path, our discoveries and our unique perspectives from the ground up. Along the way you’ll understand what drives us, what makes us a valuable business partner, the proof of our processes, the directions and disciplines we’ve adopted and pioneered as well as the quantified metrics that we serve. We are confident that one day we will be able to unequivocally say:

“T H E R E I S N O S UC H T H I N G A S WA STE.”

RESOURCECO.COM.AU

05

MESSAGE FROM THE M A N A G I N G D I R E CTO R “For the past 30 years, we have challenged the norms, finding new ways that not only improve processes, but also create useful products that can be used and reused over and over again. ResourceCo is not just a value taker, but a value maker.”

The pillars of our business serve the market sectors that exist, but we have also seen that the cross fertilisation of ideas between pillars and their clients has charted new territories - we are determined with partners, to invest and prosper from those ideas. The reason we exist is not only climate change. Our purpose is sustainable resource recovery by a sustainable business. Along the way what we’ve discovered is that our very responses to the resources we have collected have presented opportunities to change the nature of business practices and introduce new technologies. We are determined to be a contributor by changing what is acceptable in order to benefit the planet, discarding nothing but outmoded practices.

Not one individual or conglomerate that prospers from our planet can continue to use the Earth’s valuable resources and not account for that. That doesn’t mean the end of business as such, it means using the resources we require in a smarter way. To continue on that path requires reusing the resources that are not ‘totally’ spent, bringing them into a useful second and third life as well as re-evaluating our requirement from virgin resources as well. It’s a huge task, but we know that to be sustainable, is to prosper and re-invent our collective future.”

“WE SEE WASTE AS A PRODUCT”

Simon Brown Managing Director, ResourceCo

06

T O W A R D S A S U S TA I N A B L E F U T U R E

C I R C U L A R C A R B O N A B AT E M E N T

A G LO B A L L E A D E R I N RESOURCE RECOVERY AND A PIONEER IN CIRCULAR ECONOMY C A R B O N A B AT E M E N T A CC E L E R AT I N G G R O W T H FO R A S U S TA I N A B L E F U T U R E

Since 1992, ResourceCo has repurposed over 60 million tonnes of waste avoiding over 370,000 tonnes of carbon dioxide emissions per annum. This is the equivalent to taking 75,000 cars off the road. ResourceCo has been in the forefront of generating circular carbon abatement sales with over 2.5 million tonnes sold until 2021 and was the first company to register under the Emissions Reductions Fund (ERF) Australia. The Resource Recovery industry has a critical role to play in decarbonising the economy to achieve a low carbon transition aligned to the ‘Paris Agreement goals on climate change’ and global commitments to achieve ‘Net Zero’ by 2050. As an increasing number of organisations commit to reducing emissions, and investors demand clear, credible transition plans, the resource recovery industry will be critical to help organisations achieve Net Zero targets and progress the circular economy.

With a strong focus on reducing emissions through our core business activities of repurposing materials otherwise destined for landfill, we are committed to supporting Net Zero aspirations of organisations with a shared sense of purpose and direction to support them through decarbonisation to preserve Earth’s limited resources. That is why we are focused on accelerating our growth through innovation and investments, with well-established circular carbon abatement opportunities. ResourceCo’s business is structured to drive sustainability transformation by offering high quality repurposed products and solutions whilst generating circular carbon abatement opportunities. Our investments beyond 2021 to expand and grow our business footprint will enable us to partner with organisations for better environmental social and economic outcomes whilst reducing waste to landfill and progressing a circular economy.

RESOURCECO.COM.AU

07

S U S TA I N A B L E D E V E LO P M E N T GOALS

T H E VA L U E O F W A S T E T O A B I G G E R O B J E CT I V E With less than a decade left to meet the UN’s Sustainable Development Goals, we understand that the next eight years will be critical in making the world a more sustainable place. ResourceCo is committed to delivering the UNSDGs and understanding the impact of the industry in delivering their global goals. As a global leader in waste recycling and a pioneer in delivering carbon abatement, ResourceCo is committed to supporting Net Zero aspirations of organisations across Australia. We continue to work with them on shared goals for greener supply chains by decarbonising through credible carbon transition plans. With over 30 years of experience and 60 million tonnes of materials repurposed, we have a lot to give in this sustainability transformation as we progress a circular economy.

08

T O W A R D S A S U S TA I N A B L E F U T U R E

Post COVID-19, there is renewed hope and opportunity to reboot our economy and make profound changes to recover, in a way that prioritises sustainable development and the delivery of the SDGs.

S U S TA I N A B L E D E V E LO P M E N T G O A L S

U N I T E D N AT I O N S G LO B A L CO M PA CT P R I N C I P L E S ResourceCo is a partner of the United Nations Global Compact. As an organisation we are committed to play our part to continue operating in ways that, at a minimum, meet fundamental responsibilities in the areas of human rights, labour, environment, and anti-corruption. As a responsible business, ResourceCo has incorporated the UNGC ten principles wherever possible including strategies, policies and procedures whilst establishing a culture of integrity to make sure our responsibilities towards our people and planet are met.

HUMAN RIGHTS Principle 1: Businesses should support and respect the protection of internationally proclaimed human rights; and

Principle 2: Make sure that they are not complicit in human rights abuses.

LABOUR Principle 3: Businesses should uphold the freedom of association and the effective recognition of the right to collective bargaining;

Principle 4: The elimination of all forms of forced and compulsory labour;

Principle 5: The effective abolition of child labour; and

ENVIRONMENT Principle 7: Businesses should support a precautionary approach to environmental challenges;

Principle 6: The elimination of discrimination in respect of employment and occupation.

ANTI-CORRUPTION Principle 8: Undertake initiatives to promote greater environmental responsibility; and

Principle 9: Encourage the development and diffusion of environmentally friendly technologies.

Principle 10: Businesses should work against corruption in all its forms, including extortion and bribery.

RESOURCECO.COM.AU

09

DELIVERY OF THE SDGS

As an organisation actively contributing to the delivery of UNSDGs, we recognise the interdependence of all 17 goals and the 169 related targets. ResourceCo has prioritised focus areas covering 4 broad SDGs, as most relevant to the business we operate in, aligned to our own values and beliefs, where we can create a bigger impact and make a more meaningful contribution. Whilst this Sustainability Report highlights our business contribution to all 17 goals, our biggest impact is on goals 3, 9, 13 and 17 and the related targets. As we strive for continuous improvement along with our ambitious growth plans, will help deliver, greater environmental, social and economic outcomes. We are confident that our contribution to the UNSDGs will have a broader positive impact in the lead up to 2030.

GOOD HEALTH AND WELL-BEING Ensure healthy lives and promote well-being for all at all ages.

INDUSTRY, INNOVATION AND INFRASTRUCTURE Build resilient infrastructure, promote inclusive and sustainable industrialisation and foster innovation.

CLIMATE ACTION Take urgent action to combat climate change and its impacts.

PARTNERSHIPS FOR THE GOALS Strengthen the means of implementation and revitalise the global partnership for sustainable development. 10

T O W A R D S A S U S TA I N A B L E F U T U R E

S U S TA I N A B L E D E V E LO P M E N T G O A L S

O U R VA L U E S A R E AT T H E CO R N E R S TO N E O F O U R B U S I N E S S , S U P P O R T I N G T H E V I S I O N , S H A P I N G T H E C U LT U R E A N D R E F L E CT I N G O U R P U R P O S E & B E L I E F S . OUR VISION

Excel in resource recovery and commercial performance by using innovative technology to transform waste into usable products. O U R VA L U E S

SUSTAINABLE

COMMITTED

CREATIVE

AGILE

We are in the business of resource recovery transforming waste into usable products. We are focused on preserving the planet’s limited resources, both for today and future generations.

We are committed to consistently delivering on our brand promise and going the extra mile to get the job done, ensuring we leave a positive legacy.

Creativity is part of our DNA, embedded in the actions of our Executive, employees and business partners. We challenge the way we operate to drive progress towards a circular economy.

We are dynamic and responsive, acting with speed & nimbleness in providing innovative solutions for our customers and stakeholders.

RESOURCECO.COM.AU

11

Korea

Japan

TO B E A S U S TA I N A B L E B U S I N E S S W E N E E D T O H AV E A N A G I L E , I N V E N T I V E A N D A CT I V E C U LT U R E . Site Locations

Ipoh

TYRE RECYCLING

12

RECYCLING & WASTE

T O W A R D S A S U S TA I N A B L E F U T U R E

MATERIAL SOLUTIONS

ENERGY

SHARED SERVICES

OUR BUSINESS PILLARS ResourceCo key operating entities and operations are as follows: TYRE RECYCLING - TYRECYCLE Tyrecycle is Australia’s leader in tyre recycling, with a national network of collection and processing capabilities. Tyrecycle collects and recycles endof-life tyres and conveyor belts to deliver strong environmental and economic outcomes. Tyrecycle has 7 dedicated tyre processing plants across Australia. The plants are equipped with advanced rubber re-manufacturing capabilities. We produce complex high quality repurposed material for the local and global market.

RECYCLING & WASTE ResourceCo collects and processes Construction & Demolition (C&D) waste materials consisting of asphalt, concrete, bricks and rubble. This waste is then used to manufacture a range of recycled aggregates and recycled asphalt products. Recycling C&D material conserves resources by extending the life of quarries and offering a full lifecycle of materials from demolition through to resupply to site for construction carbon benefits. Southern Waste provides specialised treatment and final disposal options for non-recyclable waste materials.

M AT E R I A L S O L U T I O N S ResourceCo Material Solutions adds value to otherwise discarded materials by capturing and repurposing construction waste, soils, and excavated materials to create new bulk fill solutions, asphalt products and aggregates. The business delivers complete material supply, transport and disposal solutions for site remediation, rehabilitation and development projects with a full chain of custody.

ENERGY ResourceCo’s energy business accepts C&D and Commercial & Industrial (C&I) waste streams otherwise destined for landfill and remanufactures the waste into Process Engineered Fuel (PEF). The PEF is used as a fuel source by cement kilns locally and internationally. Our Asian operations ensure non-recyclable waste streams contribute to significant reductions in coal use and subsequent carbon emissions.

SHARED SERVICES Shared Services business provides strategic direction and support to the ResourceCo Group including finance, treasury, strategy, human resources, and corporate development functions.

RESOURCECO.COM.AU

13

OUR S U CC E S S E S

20K TONNES RUBBER CRUMB PRODUCED P/A

99%

RESOURCE RECOVERY

120K TONNES TDF PRODUCED P/A

14

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

TYRECYCLE As Jim Fairweather, the CEO of Tyrecycle puts it: “The interaction between the pillars of our business keep us all on our toes. It has led to some amazing initiatives.” When I joined ResourceCo, there was a firm belief that we were not a waste collector, but a provider of integrated, environmental services and leadership. And that has not changed over the years. As the human race now clearly sees, industry cannot continue to use the finite resources on this planet and simply stockpile the waste from those operations. It is not sustainable. And this is the case for all construction, mining and manufacturing, from rocks to tyres, to polymers, to plastics and beyond. So, in our eyes, the value of the waste material that sits in front of us, lies not in what it is, but what it’s capable of being. Our greatest wish for the future, is that all new product, no matter what it is, will build-in its own re-usability whether it derives from virgin or reused resources. Of course, the immediate future has us committed to finding ways to turn all current waste into useable product. We already use construction and demolition waste into fuel as well as road materials. At Tyrecycle we’ve given ‘end of life tyres’ a ‘new life’ as TDF used as fuel that burns hotter than fossil fuels and with significantly less CO2 emissions. This same crumb at a smaller size is also used to create permeable pavements, road surfaces when paired with crushed construction rubble, sporting and play surfaces and even in tile adhesives. “It’s not what it is, it’s what it’s capable of being.”

JIM FAIRWEATHER CEO, Tyrecycle

TYRECYCLE LEADS IN THIS INDUSTRY WHERE ‘NEW’ PRODUCT COMES FROM ‘ R E C Y C L E D ’ M AT E R I A L . A N D W E P L AY A N I M P O R TA N T ROLE, BRIDGING THE F O U N D AT I O N O F R E S O U R C E C O WITH THE HIGH SCIENCE OF PROCESSING. With the clarity and consistency of the ResourceCo vision and now our extended and often vocal team, we have capabilities that have seismically shifted our ability to achieve what we have always held important. It’s funny, when you’re in it, you don’t often see how pursuing and achieving a small ‘impossible’ can lead to even greater ‘possible’. Each year, Tyrecycle collects 20 million tyres with a recycling rate of 99%. Tyrecycle produces complex, high quality repurposed material for the local and global market including 120 thousand tonnes of TDF every year.

RESOURCECO.COM.AU

15

W E A R E CO M M I T T E D TO D R I V I N G T H E C I R C U L A R E CO N O M Y At Tyrecycle, we’ve been giving old tyres new life for over 30 years. With a national network of dedicated tyre processing plants Australia-wide, we deliver strong economic and environmental outcomes by re-purposing materials otherwise destined for landfill.

1

2

COLLECTION AND SORTING

TDF PRODUCTION CRUMB AND GRANULE PRODUCTION

SHEAR OR SHREDDING FOR SIZE REDUCTION Waste tyres are cut down in size to ensure safer handling as they undergo the first steps in the tyre recycling process, or are manufactured into TDF.

Tyrecycle collects and sorts approximately 20 million tyres every year, diverting them from landfill.

3 FEEDSTOCK Tyrecycle’s advanced rubber recycling process can turn feedstock into either Tyre Derived Fuel (TDF) or a wide range of rubber crumb products.

4 SHRED ENTERS RASPER TO LIBERATE STEEL

4 TDF SHIPPED TO ALTERNATIVE FUEL END USERS

Tyrecycle rubber is processed through four stages of magnetic separation to ensure it has steel removed, helping Tyrecycle maintain its recycling rate of 99%.

Our full chain of custody and strict testing and control regimes, means our customers can be guaranteed quality TDF with sustainable environmental outcomes.

5 ENTERS THE GRINDING MILLS FOR SIZING

Drainage aggregates

16

5

6

Rubber is reduced to a range of sizes and products, including rubber granulate of varying dimensions or rubber crumb.

END PRODUCTS OF RUBBER CRUMB AND GRANULES Tyrecycle’s recycled rubber is highquality ideal for a wide range of applications, including playground surfaces and road construction.

Road surface

T O W A R D S A S U S TA I N A B L E F U T U R E

Sporting, playground and soft fall surfaces

TDF BENEFICIALLY REUSED TO REDUCE FOSSIL FUEL CONSUMPTION 150,000 tonnes of TDF is equivalent to taking 37,286 cars off the road for a year.

Brake pads

Tyre Derived Fuel (TDF)

OUR SUCCESSES

“ W E A R E C U R R E N T LY E X PA N D I N G A N E T W O R K O F A D VA N C E D M A N U FA C T U R I N G PLANTS AROUND AUSTRALIA.”

AT T Y R E C Y C L E W E ’ V E G I V E N ‘END OF LIFE TYRES’ A ‘NEW LIFE’

Products

Usages

30 mesh

Roads & adhesives

2mm

Used as infill in sports field

4mm

Grass infill, running track, hockey field

5mm

Shock pads, rubber ramps

15mm

Playground surfacing, soft falls, equestrian surfaces

RESOURCECO.COM.AU

17

T H E VA L U E O F T H E W A S T E M AT E R I A L T H AT S I T S I N FRONT OF US, LIES NOT I N W H AT I T I S , B U T W H AT I T ’ S C A PA B L E O F B E I N G .

18

T O W A R D S A S U S TA I N A B L E F U T U R E

M A N U FA CT U R I N G OVERVIEW

30,000 $12.5 M

28,000 T

45,000 $1.5M

35,000

15,000 T

$12M

25,000

25,000

45,000

$1.5M

$12.5M

15,000 T

12,500 T

12,500

25,000 T

$0M

35,000 $3.0M

43m

TOTAL INVESTMENT

$ CRUMB

4,500

TDF

SOMERTON

LONSDALE

O’CONNOR

WELSHPOOL

PRE-INVESTMENT

PRE-INVESTMENT

PRE-INVESTMENT

PRE-INVESTMENT

POST-INVESTMENT

PRE-INVESTMENT

PRE-INVESTMENT

2022 POST-INVESTMENT

Available Products

Available Products

Available Products

Available Products

*Truck Processing

Available Products

Available Products

- 6 inch TDF - 1.5 inch TDF - Granules & Crumb

- 6 inch TDF (Oversize) - 6 inch TBR

- 6 inch TDF

- 6 inch TDF - 6 inch TBR

Available Products

- 6 inch TDF - 6 inch TBR

- 6 inch TDF - 6 inch TBR

Capacity (Tonnes)

Capacity (Tonnes)

- 28,000

- 25,000

- 25,000 POST-INVESTMENT

Available Products - 6 inch TDF - 1.5 inch TDF - Granules & Crumb - Fabric Separation - Steel Cleaning - Debeading Capacity (Tonnes) - 35,000

NEWCASTLE

Capacity (Tonnes) Capacity (Tonnes)

Capacity (Tonnes)

HOBART

- 4,500

Capacity (Tonnes)

ERSKINE PARK

- 6 inch TDF - 1.5 inch TDF - Granules & Crumb - Fabric Separation - Steel Cleaning

- 15,000

- 12,500

POST-INVESTMENT

POST-INVESTMENT

Available Products - 6 inch TDF (In Spec) - 6 inch TBR

Available Products

- 45,000

- 6 inch TDF - 6 inch TBR

Investment (M)

Capacity (Tonnes)

Capacity (Tonnes)

- 25,000

- 12,500

Investment (M)

Investment (M)

- $1.5

- $0

Capacity (Tonnes)

- $12.5

REDBANK PLAINS

POST-INVESTMENT

Available Products - 6 inch TDF - 6 inch TBR - 1.5 inch TDF

Available Products - 6 inch TDF - 1.5 inch TDF - Granules & Crumb - Fabric Separation - Steel Cleaning

Capacity (Tonnes) - 35,000

Investment (M) - $12.5

Capacity (Tonnes) - 45,000

Investment (M) - $1.5

Investment (M) - $3.0

RESOURCECO.COM.AU

19

M AT E R I A L SOLUTIONS

REAL TIME MATERIAL TRACKING WITH FULL CHAIN OF CUSTODY

80%

RESOURCE RECOVERY

5M CUBIC METRES REUSED & RECYCLED P/A

20

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

STEVE HARRISON CEO, Material Solutions

Steve Harrison, CEO of Material Solutions, is at the forefront of driving cost effective, sustainable solutions for all material movements. “Material Solutions provides end to end solutions with full chain of custody” Steve adds, “we keep our customers moving with sustainable solutions to all waste streams encountered in the construction lifecycle - everything from commercial building and demolition waste right through to contaminated soils and structural materials found in the bulk excavation process.

“ W E ’ V E A LW AY S E N D E AV O U R E D T O P R O V I D E O U R C U S TO M E R S W I T H A C C E S S TO T H E M O S T COST EFFECTIVE AND S U S TA I N A B L E S O L U T I O N S AVA I L A B L E I N T H E M A R K E T.” “As our business develops, we are taking more of the materials we manage back into our network where we leverage our long history in recycling to create value added products for sale back into the construction market. Our leading edge material management systems also allow us to directly reuse significant volumes of structural material taking them directly back into new development projects for immediate use. In a market that moves rapidly our team remains at the forefront of this change to ensure our customers are provided the most efficient and sustainable solutions available.”

At ResourceCo we are able to see the intrinsic value of waste soils, our focus on adding value to otherwise discarded materials sets us apart, whether it’s repurposing soils from significant infrastructure projects to create new bulk-fill solutions, capturing discarded sandy loams to create top soil and landscape products or treating contaminated soils to reduce waste to landfill and recover soils for recycling. We remain steadfast in our view that there is no such thing as waste. As Australia progresses in its infrastructure boom, tunnelling and deep excavation require the diversion and repurposing of millions of tonnes of soil – “You could say we move mountains every week”. We provide complete material supply, transport and disposal services for site remediation, rehabilitation and development projects. And yes, that includes long-term environmentally responsible options for final disposal of currently non-recyclable waste - we are working hard on that challenge. “Zero waste will always be our goal.” We are industry leaders when it comes to providing sustainable material solutions, what we are now seeing and hearing from our customers at all levels is “What’s actually happening with our waste?”

RESOURCECO.COM.AU

21

This Sustainability Report begins to answer that question, but it’s our continued action, our persistence that ‘there is always a better way’ that ensures we stay at the forefront of the latest technology and industry advancements in resource recovery. At the same time, we’ve resolved to help change industry behaviours as well – creating a market where sustainability outcomes are valued as highly as commercial outcomes.

connection and value to all levels of the market. And that’s the way it should always be – “As we work with governments and Tier 1 contractors to advance the circular economy we ensure these enhancements filter through the market at all levels. We believe that the way to sustainable practice is to continue to continually challenge the status quo, learn from and collaborate with our peers and continue to educate our industry and broader public.

Steve also points out that we are proud of our partnerships with Tier 1 contractors and Government projects through to the smaller owner operators in our industry. This diversity provides an incredible

Collaboration is fundamental to the dynamic of our internal business pillars in ResourceCo and the same applies to all our external partners, big and small.”

T H I S I S N OT O N E R O A D , B U T M A N Y T H AT W E T R AV E L , T H R O U G H T H E C I R C U L A R E CO N O M Y TO O N E D E S T I N AT I O N - S U S TA I N A B I L I T Y .

M AT E R I A L T R A C K I N G & TRACEABILITY 3

1

LOAD MANAGER

ASSESSMENT

2 Our Material Assessment Form provides clients with a comprehensive yet efficient overview of:

E-DOCKET

• Display of real-time load movements.

• Material due diligence records. • Material assessment & suitability. • Environmental reports.

Our e-Docket system is completely contactless and provides real-time traceability of: • Capture of load information & receipts. • Client QR code sign offs. • Complete audits of daily projects.

22

T O W A R D S A S U S TA I N A B L E F U T U R E

Our Load Manager dashboard allows for up-to-the-minute project management through:

• Current & detailed job status updates.

OUR SUCCESSES

STRONG PERFORMANCE • Sourced OVER 7 MILLION TONNES of Material – NSW. • MAJOR INFRASTRUCTURE PROJECTS include; West Connex M5, West Connex M4-M5 link tunnels, Rozelle Interchange. • Adhere to STRICT MATERIAL SPECIFICATION requirements. • Expanded team of BUSINESS PROFESSIONALS.

LEADING INDUSTRY RISK MANAGEMENT SYSTEMS • MATERIAL ASSESSMENT forms, environmental reports, geotechnical reports. • REAL TIME material tracking and traceability through e-dockets. • FULL CHAIN OF CUSTODY from excavator loading to dozer material placement.

4 SOLUTION ANALYSIS

• CUSTOM BUILT SOFTWARE providing real time access to all data.

STRONG ENVIRONMENTAL SAFETY & QUALITY SYSTEMS Our client dashboard collates and displays all project information, simplifying: • Review of all chain of custody data. • Zone analysis for placement of each load at destination site.

• ESTABLISHED PROCESSES in place for safety, quality and the environment. • STRONG RELATIONSHIPS with Tier 1 contractors in civil construction with highest safety standards. • Systems to manage COR RESPONSIBILITIES for transporters and material receivers.

RESOURCECO.COM.AU

23

RECYCLING & WASTE

GEOGRAPHICALLY

SPREAD

90%

RESOURCE RECOVERY

2M TONNES

CONSTRUCTION WASTE RECYCLED P/A 24

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

ResourceCo was originally formed around Construction & Demolition waste - capturing C&D waste and turning it into usable products. It was in fact a great example of the circular economy before people were even talking about a ‘circular economy’. Brad Lemmon – CEO, Recycling & Waste, focuses on that. “It’s in ResourceCo’s DNA to be collaborative and history shows that we have always been driven by the overarching principles of the Circular Economy: We have always seen problems as opportunities and we will continue to keep products and materials in use as we have for 30 years - we will recycle, reconstitute and ultimately repurpose. We’ve been at the forefront of established and emerging markets for recycled materials for 30 years and have a strong understanding that to build a sustainable future, you need to accelerate growth through innovations and investments. ResourceCo has recycled and repurposed 60 million tonnes of waste which would have otherwise ended in landfill. These include over 2 million tonnes of construction waste per annum consisting of glass, asphalt, bricks and concrete repurposed back into the construction sector for reuse. Over the years business expansion has ensured more jobs across the footprint, diversion of waste from landfill - avoiding the release of greenhouse emissions whilst producing raw materials to be included back into creating products and for use in infrastructure projects - further supporting the circular economy. The ResourceCo business model has evolved from its origins, focusing on construction and demolition waste, into a sophisticated resource recovery and recycling business, repurposing a wide range of waste streams including, commercial and industrial

BRAD LEMMON CEO, Recycling & Waste

waste, tyres and specialised management of soils. Our growing base of customers share similar aspirations and support our philosophy - ‘there is no such thing as waste’. Our expansion plans across Australia and Asia will allow us to build capabilities to convert identified waste streams to repurposed products at multiple locations. Our investments in R&D help us create the right products for our customers - producing high quality materials that have multiple environmental and value in use benefits.

OUR EXPERIENCE IN PROVIDING H I G H Q U A L I T Y M AT E R I A L FO R C O N S T R U CT I O N P R OJ E CT S A LO N G W I T H O U R G E O G R A P H I C A L SPREAD MAKES US WELL PLACED TO P R O V I D E I N N O VAT I V E , S U S TA I N A B L E S O L U T I O N S W E L L I N TO T H E F U T U R E . As a business we are innovating and investing at every level to achieve increased resource recovery rates, supporting the Federal Government’s aim of 80% recovery from all waste streams by 2030. Currently, Australians produce 74 million tonnes of waste per year - we are looking forward to continuing our partnerships with governments, communities, and businesses to ensure that waste is never wasted.

RESOURCECO.COM.AU

25

P R O G R E S S I N G A C I R C U L A R E CO N O M Y

1 INCOMING RAW MATERIAL ResourceCo receives construction and demolition, commercial and industrial and mixed construction and demolition waste streams, which includes concrete, bricks, asphalt and masonry totalling around 1.2 million per annum.

WASTE MATERIAL DELIVERED

PRIMARY JAW

PULVERISOR

WEIGHBRIDGE

QUALITY INSPECTION

2 PROCESSING This material is sorted and the ferrous and non-ferrous metals, inert fractions (bricks, concrete, asphalt, masonry etc) and non-recyclables are removed.

CONTROL ROOM

PICKING STATION 1

SCREEN 1

CRUSHING PLANT

PUGMILL OR STOCKPILE

CUSTOMER DISPATCH

3 OUTGOING FINISHED PRODUCT The inert fractions are recycled and resupplied to the civil construction market as an alternative to traditional quarried products: eg. recycled pavement materials, aggregates, sands, bulk fills & asphalt products at various facilities. End users: builders, earthmovers, landscapers, civil companies.

26

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

Products

Usages

PM1 Base Course

Class 1 Pavement Materials are intended for use as pavement layers on high trafficked roads.

PM2 Recycled Rubble

High quality subbase material, with density advantage over quarried material. Manufactured to DIT specification. Used in road, residential and commercial building construction.

Recycled Sand

Bedding and trenching sand. Highly compactible.

10mm Concrete Aggregates

This product is used in the manufacture of sustainable ‘green’ concrete as an alternative to quarried materials.

20mm Recycled Screening Aggregators

Recycled 20mm asphalt product.

Glass

Recycled 5mm glass sand. Used in asphalt production and various civil applications. Made from recovered MRF glass previously destined for landfill.

RESOURCECO.COM.AU

27

ENERGY

10 YEARS EXPERIENCE IN PRODUCING

ENERGY FROM WASTE

90%

RESOURCE RECOVERY

OVER

1M TONNES PEF PRODUCED

28

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

The ResourceCo Energy business pioneered ‘waste to energy’ generation in Australasia with Process Engineered Fuel (PEF). As Henry Anning CEO of ResourceCo Energy says, “In finding a better purpose that benefits the circular economy and the environment, carbon abatement is a big part of what we do at ResourceCo. Being the ‘Energy’ pillar, we concentrate on producing an effective fuel, expressed purpose of replacing a fossil fuel either directly or indirectly.

RESOURCECO SERVICES W E L L - E S TA B L I S H E D MARKETS FOR ‘HIGH ENERGY U S E R S ’ I N B OT H A U S T R A L I A AND SOUTH-EAST ASIA WHERE PEF IS CONSUMED FO R E N E R G Y P R O D U C T I O N IN CEMENT KILNS WITHOUT G E N E R AT I N G R E S I D U E S .” Henry says tackling the diversion of waste that ends up in landfill is at the forefront of the strategic plan of new Resource Recovery Facilities (RRF) in Queensland, Victoria, New South Wales and Western Australia to divert more C&D and C&I material from landfill. This also means better environmental, social and economic outcomes with more recycling, renewable energy, jobs and carbon abatement.

HENRY ANNING CEO, Energy

Nearly 15 million tonnes of Construction & Demolition (C&D) and Commercial & Industrial (C&I) waste still ends up in landfill each year. However, organisations are more and more conscious of recycling their waste with ‘zero waste to landfill’ policies being implemented. Sustainability strategies of companies now have an accelerated focus on carbon abatement plans with net zero commitments. As a result there is now an increase in demand for ‘circular carbon abatement’, where organisations benefit from recycled and repurposed waste, further progressing a circular economy. Generally, every tonne of waste diverted from landfill saves about a tonne of carbon. As we continue to develop new projects with a pipeline of resource and energy recovery facilities, it will help us unlock carbon abatement opportunities. The waste sector has huge potential for circular carbon abatement both in helping other industries decarbonise their waste and in providing renewable heat and baseload electricity.

RESOURCECO.COM.AU

29

In our plants across Australia and Asia, we manufacture PEF as a finished product, from select material and not from municipal waste. It’s a ready-to-use alternative fuel source. Created from dry non-recyclable commercial, industrial, mixed construction and demolition materials, PEF’s ability to harness the energy value of this matter, currently going to waste in landfill sites, is unrivalled. PEF has a lower emissions profile and displaces millions of tonnes of fossil fuels at a lower price point, as well as abating hundreds of thousands of tonnes of CO2. ResourceCo Energy Systems has been established to develop additional end-user opportunities for the rapidly expanding global market for recovered fuel products. This includes the development of small

to mid-scale Energy Recovery Facilities (ERFs) to service the energy needs of specific end-users and / or the electricity grid. These energy facilities would take the recovered fuel produced at ResourceCo’s existing and future network of Resource Recovery Facilities (RRF’s). The RRF pre-processes incoming mixed waste streams from construction & demolition (C&D) and commercial & industrial (C&I) feedstocks and recovers resources for beneficial use including aggregates, metals, and soil. Residual dry and non-putrescible feedstock is then processed in the RRF to produce Process Engineered Fuel (PEF), with materials not suitable for PEF removed from the waste stream in the RRF and disposed responsibly.

O U R C U S TO M E R S A R E N OT J U S T D E M A N D I N G E C O N O M I C O U T C O M E S B U T C A R B O N O U TC O M E S A N D W H E N W E R E C Y C L E O U R W A S T E I N TO P E F I T H A S M A S S I V E C A R B O N B E N E F I T S , A B AT I N G H U N D R E D S O F T H O U S A N D S O F TO N N E S O F C O 2 .

ELECTRICITY TO THE RRF

RESOURCE RECOVERY FACILITY (RRF)

RECOVERED FUEL FROM RRF

RECOVERED FUEL

30

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

Products

Usages

Process Engineered Fuel (PEF)

A ready-to-use alternative fuel source generated from select dry commercial, industrial, mixed construction and demolition materials.

ELECTRICITY TO THE GRID

ENERGY RECOVERY FACILITY (ERF)

STEAM TURBINE

FLUE GAS CLEANING

RESOURCECO.COM.AU

31

SHARED SERVICES

32

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

PAUL RYAN CFO, Shared Services

Shared Services at ResourceCo, brings consistency to all business pillars – brings them to a shared understanding on delivering on stakeholder expectations with a positive impact on Environmental Social and Economic outcomes. During the reporting period and beyond, we continue to be on a journey to grow and strengthen the business living true to our vision to ‘excel in resource recovery and commercial performance’ by using innovative technology to transform waste into usable products.

O U R C O L L E C T I V E E F FO R T TO E X PA N D A N D G R O W T H E B U S I N E S S R E Q U I R E S A G R E AT FO C U S O N S T R AT E G Y A N D D I R E C T I O N A LO N G W I T H O P E R AT I O N A L E X C E L L E N C E TO E N S U R E T H AT T H E ‘ S U S TA I N A B I L I T Y T R A N S FO R M AT I O N ’ W E L E A D , T R A N S L AT E S I N TO R E A L OUTCOMES. OUR DYNAMIC AND D I V E R S E T E A M C O M E S TO G E T H E R UNDER SHARED SERVICES T O FO S T E R A C U LT U R E T H AT FA C I L I TAT E S G R O W T H I N E V E R Y A S P E CT O F T H E B U S I N E S S .

Our focus is not limited to our internal human resources, the metaphorical road we have cut through waste to reusable and valuable products demands ongoing best practice and collaboration across all stakeholder groups. We are on a journey for greater success in every aspect of our business, from producing circular products from waste with carbon abatement benefits and helping organisations make their supply chains greener, our commitment remains to ensure that we leave the planet in a better state that we found it – and that is our brand promise. We understand and acknowledge the critical role we play in the waste recycling industry in decarbonising the economy and progressing circular economic outcomes. Therefore, as we focus on the next phase of growth as a responsible business entity, our sustainability practices will ensure that we remain relevant and contribute to achieving global goals with a local focus in every country and state we operate in. There are still millions of tonnes of waste going to landfill every year. That’s an opportunity to create an astounding sustainable business with an assured future. Our continued commitment and the partnerships that we are forging, will lead to bigger opportunities and sustainable outcomes.

RESOURCECO.COM.AU

33

THE FINANCIALS O F A S U S TA I N A B L E BUSINESS

34

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR SUCCESSES

ResourceCo’s strong financial performance is a testament of its sustainable growth over the years. Our industry has many decades of growth ahead and ResourceCo continues to invest throughout Australia and Asia. Our ambitious growth plans will enable us to be a leader in the circular economy delivering real outcomes from adding value to waste.

Group Revenue (100% Consolidated)

FY21A

$244.4m

Revenue by Division Energy

18%

Recycling & Waste

26%

FY21 ACTUAL

Material Solutions

33%

Tyre Recycling

23%

RESOURCECO.COM.AU

35

BOARD & EXECUTIVE LEADERSHIP TEAM Our Board and Leadership Team is collectively responsible for implementing the ResourceCo Group strategy and ensuring that the Group is led within a framework of controls whilst embedding a values driven culture.

ANDREW POULTER Chairman

SIMON BROWN Managing Director

DAVID MCMAHON Non-Executive Director

CLARK PERKINS Non-Executive Director

JIM FAIRWEATHER Chief Executive Officer Tyre Recycling – Tyrecycle

BRAD LEMMON Chief Executive Officer Recycling & Waste

STEVE HARRISON Chief Executive Officer Material Solutions

HENRY ANNING Chief Executive Officer Energy

36

T O W A R D S A S U S TA I N A B L E F U T U R E

BOARD & EXECUTIVE LEADERSHIP TEAM

OLIVER TOMPKINS Non-Executive Director

DEAN PAGONIS Non-Executive Director

PAUL RYAN Chief Financial Officer

NICOLE BENNETT General Counsel

SANJ DE SILVA Director of Corporate Affairs & Sustainability

RESOURCECO.COM.AU

37

ENSURING A S U S TA I N A B L E W O R K FO R C E

6%

FEMALE REPRESENTATION SINCE FY20 38

T O W A R D S A S U S TA I N A B L E F U T U R E

900+

WORKERS

S U S TA I N A B L E W O R K F O R C E

People are central to our business with over 900 a part of our entire workforce across our business footprint in Australasia. ResourceCo’s core focus is to be sustainable in every respect - encouraging a safe, flexible, inclusive and collaborative work environment that inspires change, working as one team to achieve our goals. That also means providing significant and timely support to all our employees to sustain their physical and mental wellbeing. ResourceCo is committed to maintaining and promoting high levels of labour standard whilst respecting human rights across our business pillars.

The COVID-19 pandemic meant a sudden change in routine for many of our stakeholders, most importantly to our employees. As an organisation providing essential services to the nation, this uncertainty meant that we needed to live true to our values – be agile and adopt to new ways of working. A culture which our employees embraced displaying resilience and agility. During the pandemic, ResourceCo continued to offer support outside of the company via a third-party Employee Assistance Program (EAP). The program provides qualified professionals to hold discussions with workers. It’s all about making it easy for our employees to seek further support if they don’t feel comfortable talking about a particular issue at work or with a colleague.

RESOURCECO.COM.AU

39

Total Employees by State/Region VICTORIA

100

QUEENSLAND

18

NEW SOUTH WALES

134

SOUTH AUSTRALIA

131

WESTERN AUSTRALIA

16

ASIA

33

432

Employees ResourceCo Group Full time / part time and contractual

ResourceCo Group Employee Demographic Male

Female

80

FY21: 432

352

Demographic spread by location 14%

14%

86%

81%

19%

Male employees TOTAL

Female employees TOTAL

VIC 2021

94%

6%

94%

6%

28%

24%

86%

VIC

NSW

WA

QLD

SA 72%

VIC 2021

NSW 2021

T O W A R D S A S U S TA I N A B L E F U T U R E

VIC 20

40

WA 2021

NSW 2021

WA 2021

QLD 2021

SA 2021

76%

ASIA

ASIA 2021

S U S TA I N A B L E W O R K F O R C E

2 0 2 1 W A S Y E T A N OT H E R Y E A R O F G R O W T H A N D B U S I N E S S E X PA N S I O N D E S P I T E T H E S E T B A C K S D U E TO T H E PA N D E M I C . T H I S M E A N T T H AT W E N E E D E D TO B E C R E AT I V E I N R E C R U I T I N G , T R A I N I N G A N D D E V E LO P I N G O U R E X PA N D I N G W O R K FO R C E W H I L S T D E V E LO P I N G O U R I N T E R N A L TA L E N T P I P E L I N E . Our full time, part time and contractual employees increased to 432 during the year, with our entire workforce which includes labour hire and subcontractors grew above 900. At ResourceCo we are proud of our diverse and multicultural workforce. We continuously strive to provide a stronger, safer and more supportive workplace environment that fosters a culture of performance and growth. During 2021 we were excited to recruit and promote females who broke the bias working in traditionally male dominated roles.

The Cadetship programme initiated during the year has proven to be a success with the selected employee working across all business units to gain a complete understanding of the business and upskilling them to take on a bigger role whilst contributing to business growth. As the business expands, we are conscious that we need to create and maintain a values driven performance culture that supports learning & development whilst building on our existing platforms of accelerating growth. We look forward to launching new platforms and programmes to help us grow our talent pipeline to support the next phase of growth of our business.

RESOURCECO.COM.AU

41

O U R CO M M I T M E N T TO I D E N T I F Y , A D D R E S S A N D M I T I G AT E P O T E N T I A L M O D E R N S L AV E R Y R I S K S I N R E S O U R C E CO ’ S O P E R AT I O N S A N D S U P P LY C H A I N S .

ResourceCo has a well-established strong governance structure and values the rights of all our people, our business partners along our supply chains and the communities within which we operate, working with stakeholders across the world.

We recognise our responsibility to work with stakeholders across our operations and supply chains including suppliers, subcontractors and contractors to understand, identify and mitigate any modern slavery risks arising in our operations and supply chains.

As such, we are conscious of potential risks across our global supply chains. We have continued to invest in our people, processes, and systems to further improve governance and controls to ensure we are effectively managing any potential risks.

The ResourceCo Board remains committed to continue our business practices across all our business pillars, in the most ethical, sustainable, and responsible manner to reduce any potential risks for a better tomorrow. Some of the key initiatives to reduce potential risks to the business during 2021 are highlighted below:

The year 2021 has been a challenging one for the entire world as we continue to battle the COVID-19 pandemic. Throughout the pandemic we have maintained strong supplier relationships and fostered open communication with them about any potential COVID-19 risks. We have established sophisticated systems with enhanced processes to set us up for the future to further promote greater awareness amongst our staff and suppliers on this global issue.

WHILST UPHOLDING THE U N I T E D N AT I O N S G U I D I N G PRINCIPLES ON BUSINESS AND HUMAN RIGHTS, P R OT E C T I N G T H E H U M A N RIGHTS OF ALL THOSE WHO W E E M P LO Y A N D W O R K W I T H H A S A LW AY S B E E N A K E Y P R I O R I T Y.

42

T O W A R D S A S U S TA I N A B L E F U T U R E

ResourceCo is committed to promoting good labour standards and protecting human rights in our own operations and throughout our supply chains and is determined to play our part in working towards eradication of modern slavery.

KEY INITIATIVES FY21 Partnership Partnering with a third party expert to provide guidance, assistance and advice. Supply Chain Mapping Developing a robust understanding of our direct suppliers. Risk Matrixing Scoping risk in our operations and supply chains to take a targeted risk based approach to due diligence. Supplier Platform Launching a “Know Your Supplier” platform to systematically mitigate and track risks of suppliers. Due Diligence Expanding our due diligence framework on our suppliers.

S U S TA I N A B L E W O R K F O R C E

We are committed to the highest levels of ethics and integrity in the way that we do business and understand that this imperative to the continued success of the way we do business across our footprint.

This policy applies to all current and former: •R esourceCo officers or employees regardless of entity name or type, including directors, executives, managers, staff, volunteers and interns, whether permanent, part time, fixed term or temporary; • I ndividuals who supply goods or services to ResourceCo (whether paid or unpaid), including their employees, contractors, consultants service providers or business partners; • Individuals who are associates of ResourceCo; and

Our values, beliefs and policies guide our everyday conduct. Our Whistleblower Policy is a key element in detecting corrupt, illegal or unethical behaviour. The ResourceCo Whistleblower Policy sets out how we support our employees and other stakeholders to safely express concerns, know who to contact, how to report and the protections available.

•R elatives, spouse or dependants of any of the abovenamed persons, (eligible whistleblower). The policy is made available to all employees and publicly available on the ResourceCo website. ResourceCo’s Risk Committee is responsible for oversight of this policy. We strongly encourage those to whom the Whistleblower Policy applies to, to speak up if you suspect or witness any matters of concern.

RESOURCECO.COM.AU

43

S U S TA I N A B I L I T Y ALSO MEANS RETURNING HOME INJURY FREE

44

1,527,920

0

90%

HOURS WORKED FY21

FATAL INCIDENTS (FTL)

LOST TIME INJURIES SINCE FY04

T O W A R D S A S U S TA I N A B L E F U T U R E

VIC 2021

N

RETURNING HOME INJURY FREE

AT R E S O U R C E CO , W E PROVIDE A ROBUST S A F E T Y C U LT U R E I N A L L O U R O P E R AT I O N S .

QLD 2021

Our business activities often include potentially hazardous tasks; the operation of plant machinery, conveyers, working at heights, moving vehicles and exposure to loud noise in sometimes difficult environments. But we approach these conditions with a continuous eye on improvement, updating policies and procedures to ensure that all who work for and with us are protected and informed. ResourceCo’s Occupational Health and Safety Policy and proactive approach to hazard management, have resulted in a steady decline of reportable incidents and significant reduction in workplace accidents -

Lost Time Injuries decreasing by 90% since 2004. We attribute this success to the commitment by all levels of our business, as we collectively strive to minimise health and safety risks within our operating environment. 0hrs

Total hours per month

ResourceCo Group Recorded Incidents

Total FY21

29

5 0 LTI

MTI

FTL

LTI = Lost time incident MTI = Medical treatment injury FTL = Fatal incidents

RESOURCECO.COM.AU

45

L I F E S AV I N G R U L E S TO K E E P US ALL SAFE

In 2021, we developed and proudly adopted “ResourceCo’s Nine Life Saving Rules.” They are aimed at strengthening even further our workplace safety and making it mandatory for all employees, contractors and subcontractors, to learn and follow them. Underpinning those disciplines, our safety campaign, ‘Project Prevention – Think, Act, Be Safe’ is delivered continuously to all our staff and reinforces our values and dedication to keeping people safe. This essential message is also communicated to our customers, visitors and contractors visiting our sites, to ensure that all works are undertaken in the safest possible manner at all ResourceCo locations.

46

T O W A R D S A S U S TA I N A B L E F U T U R E

RETURNING HOME INJURY FREE

R E S O U R C E CO NINE LIFE S AV I N G R U L E S

I will be drug and alcohol free at work.

I will drive to the conditions and comply with all road rules.

I will not alter, modify or bypass safety devices.

I will verify energy is isolated before starting work.

I will have all controls in place before entering a confined space.

I will only work at height with fall protection in place.

I will obtain and follow a hot permit to work.

I will not smoke outside designated areas.

I will not put myself or others in the line of fire.

RESOURCECO.COM.AU

47

48

T O W A R D S A S U S TA I N A B L E F U T U R E

RETURNING HOME INJURY FREE

T O TA L H O U R S W O R K E D 2 0 2 1

1,527,920hrs

150,000hrs

FTL = Fatal incidents LTI = Lost time incident MTI = Medical treatment injury

FTL

LTI

MTI

HAZARD REPORTS

WORKING HOURS

0 5 29 320 1,527,920

TOTA L R E CO R D A B L E I N J U R I E S ( T R I ) FO R 2 0 2 1 : 2 . 8

Certifications ResourceCo’s strict integrated management system comprises inspection, auditing, training and competencies, risk and hazard management and other legal requirements. We continue to earn multi-site certification during annual audits of operations and facilities. ResourceCo is certified across the 45001:2018, ISO 14001 systems & ISO 9001.

49

THE ENVIRONMENT W E P R OT E CT

50

T O W A R D S A S U S TA I N A B L E F U T U R E

THE ENVIRONMENT

We live in a world where climate-related changes have brutal effects. As sea levels rise and with more frequent extreme weather events, the risk of environmental impact also increases. The effect we have in any case is of prime importance to us. Our environmental management system, which is independently certified to meet the requirements of ISO 14001, establishes the framework for our activities. It conforms to all relevant legislation, standards, practices and any other requirements. But it doesn’t end there. Like all our operations, we strive for continuous improvement. We take all reasonable and practicable measures to minimize the pollution impacts to air, land, water, amenity, flora and fauna associated with site activities. We report annually, for all our sites, to both National Greenhouse and Energy Reporting and National Pollutant Inventory Reporting in line with these requirements. As waste recyclers and energy providers, we strive to comply with all EPA standards and add improvements where we can. We advocate for ecologically sustainable development promoting the circulation of materials as exponents of the Circular Economy - our livelihood and our reputation depends on it.

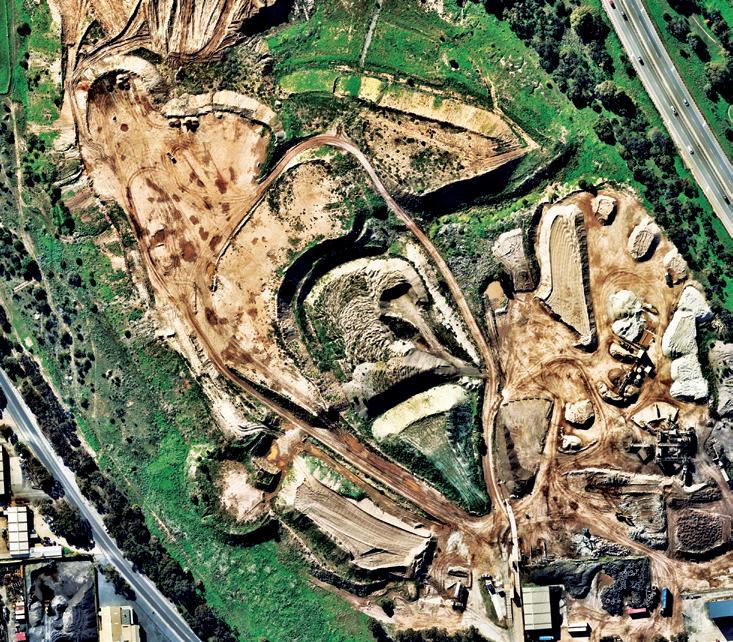

Our fill sites in Victoria and South Australia reuse clean fill material to rehabilitate quarries after the sand and gravels have been mined from the sites. This restores the landform to similar levels that it was prior to mining and enables the land to be utilised again in the future for a range of uses. These sites deal with a range of stakeholders and we work together with quarry owners and regulators to find the best solution for rehabilitating these sites. ResourceCo will always seek to promote the best and safest use of recovered resources and reduce the amount of waste going to landfill. Our landfill sites in South Australia provide a final disposal solution for various waste streams that are unable to be recycled, including a double composite lined hazardous waste disposal cell at McLaren Vale. ResourceCo’s waste derived material like TDF and PEF, as well as immediately useable recovered materials comply with all relevant state and federal legislation, regulations and policies made under relevant laws, Australian Standards, market or engineering specifications. The way we leave the environments we work in, or the environments in which we process our products, need to be an exemplar of our commitment to the planet.

Most Preferable AVOID SUSTAINABILITY

REDUCE REUSE RECYCLE RECOVER (including energy) TREAT DISPOSE

Least Preferable RESOURCECO.COM.AU

51

T H E CO M M U N I T I E S W E S U S TA I N AND SUPPORT

ResourceCo volunteers handpicked the last residues of the former 6,000mt stockpile before the handover to the land owner. Diverted from landfills, all this material accomplished its passage into a new life as alternative fuel for local cement industry.

Across Australia and Asia, ResourceCo provides work and livelihoods for many communities, some remote and many in large cities.

52

T O W A R D S A S U S TA I N A B L E F U T U R E

The varied community partnerships that ResourceCo provides have a common thread - our programs supports high performance in trades and tertiary education as well as sport. We also have some very productive R&D partnerships with universities and industry bodies seeking performance aspects as we process our products.

COMMUNITIES

2021 Premiers of the Adelaide Footy League, the ‘Reds’ have worn the ResourceCo logo on their uniforms for 15 years, proudly sharing our organisation’s values of community and commitment. FROM HEAD COACH CRAIG PITT: “Having major sponsors like ResourceCo on board for such a long time has definitely helped. We have worked our way up through the competition and this helps us stay at that elite level. It’s a very family-orientated club, and that’s reflected in the people who come out and support us each week volunteers and board members who set up chairs and marquees every week, life members, current students, water runners, people manning the barbecues, and ex-players in their 70s and 80s who would never miss a game.

FROM HEAD OF COMMERCIAL PARTNERSHIPS, PETER MAYNARD:

“It’s a significant show of support for the club, particularly due to the issues and challenges faced in the last two years. Ongoing support from our Major Partners is critical and this is a tremendous show of faith in the program that has been developed at Casey Fields”

“ W H E T H E R W E W I N O R LO S E , T H E Y CO N G R AT U L AT E U S ”

Our commitment goes way beyond sponsorship as we work with the club to drive and promote the ResourceCo purpose - we believe that we have an obligation to leave the planet in a better state than we found it. “We look forward to an amazing season. Already the VFLW team sits on top of the ladder winning 6 from 6. And the AFL team looks certain to follow, even after the opening rounds.” All around the country, ResourceCo celebrates individual endeavour and team achievement. For us, the pride is not just in the logo on the uniform, but the human development behind it. We’re all working for a sustainable future.

- PROUD PARTNERS OF Casey Demons Football Club

Onkaparinga Valley Football Club

McLaren Football Club

Prince Alfred Old Collegians Football Club

Glenunga Football Club

Walkerville Cricket Club

Brighton Rugby Union Football Club

Eastern Suburbs Junior Cricket Club

Walkerville Junior Football Club

.

RESOURCECO.COM.AU

53

O U R D I S CO V E R I E S A N D W H E R E T H AT CO U L D L E A D Particularly over the last decade or so, as Climate Change moved to a universally accepted truth, we’ve been continuing our daily task of collecting waste that we turn into useable products. But as a consequence of nothing but ingenuity, the people who work for us and with us have made discoveries, some small and some of great impact. At the centre of this is the notion that we will never look past an opportunity.

54

T O W A R D S A S U S TA I N A B L E F U T U R E

OUR DISCOVERIES

U N LO C K I N G T H E T R U E P O T E N T I A L OF WASTE:

THE STORY OF RESOURCECO P R O V E S T H AT THERE IS NO SUCH THING AS WASTE. • Circular carbon abatement - that there will be recognition that by always recycling waste, we can strengthen our economies, as we give back to our environment driving towards a net zero aspiration by 2050. • We’re working hard on turning contaminated soils into useable products progressing a circular economy.

• We are soon to embark on building a network of power plants to produce renewable energy from waste. (There is currently 7 million tonnes of this material going to landfill. Over the next decade that will be recycled into alternate forms of energy). This will help organisations achieve sustainability targets and minimise waste to landfill. • Australia will recycle and repurpose all waste tyres diverting them from landfill, being stockpiled or buried.

ResourceCo pioneered carbon abatement sales from recycling in Australia. It has contributed to our ability to process products that have a long useable future, as we reduce CO2 emissions. If only industry manages waste appropriately, we will all be able to access this abatement and use it back in our own businesses. Recycling and carbon abatement means that waste doesn’t go landfill and in turn it doesn’t produce landfill gas. That’s a truth that should be told more often.

RESOURCECO.COM.AU

55

THE FUTURE Our partners are large corporations, government and businesses of all sizes with a common need - to comply with national and international standards and efforts to decarbonise our economy, so we are only as successful as the market allows. But there’s now a moral need as well, that presents a business imperative with irrefutable value. Initiatives come not just from us, but from the integrity we apply to practices and willingly share with our partners. We are ‘doers’ not just ‘talkers’ and we’ve found that our partners also want action. The enterprise of waste repurposing has far reaching benefits for the planet. But it is not just about the collection of waste. Our experience at every level is valuable. We are leaders in Carbon Abatement in Australia, we are leaders in Waste Repurposing, we are a leader in Fuel Production for energy - with minimal residual waste and much lower carbon loads. Our partners are not only part of our success, many of them share in that, either directly in their enterprise or indirectly by sharing in our abilities as they grow their own.

56

T O W A R D S A S U S TA I N A B L E F U T U R E

As Managing Director, Simon Brown puts it: “ResourceCo has been growing at over 20% a year for the last decade and our industry has many decades of growth ahead of it as the waste stream evolves. “We believe that everyone in industry, large or small, can be involved in unlocking the value of waste and its products. We have ambitious growth plans, we continue to be a leader in the Circular Economy, delivering real outcomes from adding value to waste. The recycling industry has a critical role to play in decarbonising the economy. We don’t see waste as waste but as raw material that is 100% circular. We all have a responsibility to know where our waste ends up - not in landfill but a product.”

THE FUTURE

M E M B E R S H I P A S S O C I AT I O N S

ACOR Australian Council of Recycling ALOA Australian Landfill Owners Associaltion ATRA Australian Tyre Recyclers Association Bioenergy Australia Civil Contractors Federation Victorian Waste Management Association Waste Contractors & Recyclers Association of NSW WMRR Waste Management & Resource Recovery Association Australia WRIQ Waste Recycling Industry Association Queensland WRINT Waste Recycling Industry Association Northern Territory WRISA Waste Recycling Industry Association South Australia WRIWA Waste Recycling Industry Association Western Australia

RESOURCECO.COM.AU

57

S U S TA I N A B I L I T Y REPORT 2021 FY21 Page reference

Material aspect

Alignment to GRI

UN Sustainable Development Goals

GRI 102: GENERAL DISCLOSURES 2016 Pages 1-2, 4, 12-31, 38-41, 57-58, 60

Organisational profile

102-1

102-2

102-3

102-4

102-5

102-6

102-7

102-9

102-10

102-11

102-12

102-13

102-52

102-53

403-2

403-3

Page 6

Strategy

102-14

Pages 8-11

Ethics and integrity

102-16

Pages 36-37

Governance

102-18

Pages 5, 58

Reporting practice

102-50 102-55

Pages 44-49

Occupational health and safety management system

NATURE OF OWNERSHIP AND LEGAL FORM ResourceCo is a privately owned Company.

58

T O W A R D S A S U S TA I N A B L E F U T U R E

403-1 403-9

“A N Y T H I N G W E C A N N OT D O FO R E V E R IS BY DEFINITION U N S U S TA I N A B L E .” David Attenborough

RESOURCECO.COM.AU

RESOURCECO G R O U P LO C AT I O N S RESOURCECO

MATERIAL SOLUTIONS

SOUTHERN WASTE RESOURCECO

TYRECYCLE

SUEZRESOURCECO

Head Office Level 1, 162 Fullarton Road, Rose Park SA 5067

Mulgrave Level 3, 6 Nexus Court, Mulgrave VIC 3170

Mclaren Vale 2605 Main South Road, McLaren Vale SA 5171

Melbourne 30-56 Encore Avenue, Somerton VIC 3062

Wingfield Lot 246 Wilkins Road, Wingfield SA 5013

Wingfield 144-150 Wingfield Road North, Wingfield SA 5013

Alexandria 86 Bourke Road, Alexandria NSW 2015

Adelaide 8 Meyer Road, Lonsdale SA 5160

Lonsdale Lot 6 & 6B Meyer Road, Lonsdale SA 5160

Coomera 200 Beatie Rd Coomera QLD 4209

Lonsdale Onkaparinga Eco Precinct, 19 Christies Road, Lonsdale SA 5160

Hampton Park Hampton Park Resource Recovery Facility, 274 Hallam Road, Hampton Park VIC 3976

Dry Creek Waste Derived Fill Site – Hanson Road Extension, Dry Creek SA 5094

RESOURCECO ASIA

ENERGY Head Office Level 1, 162 Fullarton Road, Rose Park SA 5067

Malaysia PEF Plant Lot 149522 Lebuh Perusahaan Klebang 10, IGB Industrial Park 30010, Ipoh Perak Malaysia

Hartley North Bremer Road, Hartley SA 5255 Mt Compass Pambula Road, Hindmarsh Valley SA 5211 Tatachilla Southern Corner of Tatachilla & Main South Roads, McLaren Vale SA 5171

Brisbane Lot 1, Gypsum Drive, Redbank Plains QLD 4301 Perth 10 Keegan Street, O’Connor WA 6163

CLEANAWAY RESOURCECO

Sydney 36 Stenhouse Drive, Cameron Park NSW 2285

Wetherill Park 35-37 Frank Street, Wetherill Park NSW 2164

1/21 Grady Crescent, Erskine Park NSW 2759 Company Collections (any state) 1300 489 732

Kuala Lumpur Office Sdn Bhd (KL), A-2-15 Plaza Damas 3, Block A Jalan Sri Hartamas 50480 Kuala Lumpur Ipoh Office (M) Sdn Bhd (Ipoh), 165A, Persiaran Kawasan Perusahaan IGB, 31200 Chemor, Perak Singapore ResourceCo Asia Pte Ltd 33 Maude Road #02-01 YTC Building 208344 Singapore Philippines ResourceCo Asia (PH) Inc 28th Floor, World Plazza 5th Avenue, Bonifacio Global City 1634 Taguig, Metro Manila

FIND OUT WHAT WE CAN DO FOR YOU. enquiries@resourceco.com.au 1300 696 733 resourceco.com.au

This report is printed on 100% Recycled stock. ecoStar+ 100% Recycled Uncoated ecoStar+ is an environmentally responsible paper made carbon neutral and is FSC Recycled certified. ecoStar+ is manufactured from 100% post consumer recycled fibre in a process chlorine free environment under the ISO 14001 environmental management system.