Grab Your Popcorn

Major Movie Promoted with Digital Print

by Melissa Donovan

The return to movie theaters means an influx of promotional graphics for upcoming releases. The goal is for them to be immersive, exciting viewers for the next big cinematic experience. They range from pressure-sensitive floor graphics to traditional corrugated standees. Textiles are another option. Soft signage is an effective component in marketing campaigns because of its durability, visual aesthetic, and vibrant colors.

It’s-A Me, Mario

Hollywood Monster, based out of Tyseley, Birmingham, U.K., is no stranger to completing signage for movie theaters. The company was established in 2009 when two family businesses merged. Today it works out of a 3,530 square meter facility with a team of over 40 signage and print experts. The wide format printing and

signage contractor covers events and exhibitions, property and construction, sport, entertainment, and retail industries across the U.K.

It was recently tasked with creating graphics for Vue Cinema in Westfield, Shepherd’s Bush, London, which was looking to promote the upcoming The Super Mario Bros. Movie

It wasn’t the first time Hollywood Monster worked with Vue Cinema. According to Noel Tilley, senior project manager, Hollywood Monster, “due to the longstanding relationship with the client, they understand we have the capability and skill set to undertake such an important project.”

This was no ordinary job. Vue Cinema recently decided to utilize a specific area

1 2

Going forward this installation site will be changed quarterly, which is why the track system is a great option for this kind of project.

July 2023 | Digital Output digitaloutput.net { 6 } 1 & 2)

— Noel Tilley, senior project manager, Hollywood Monster

Hollywood Monster printed and installed graphics for the recent The Super Mario Bros. Movie at Vue Cinema in London.

of its theater to promote highly anticipated coming attractions. The goal was to outfit the space with bright, impactful, actionpacked graphics—changing them out each quarter.

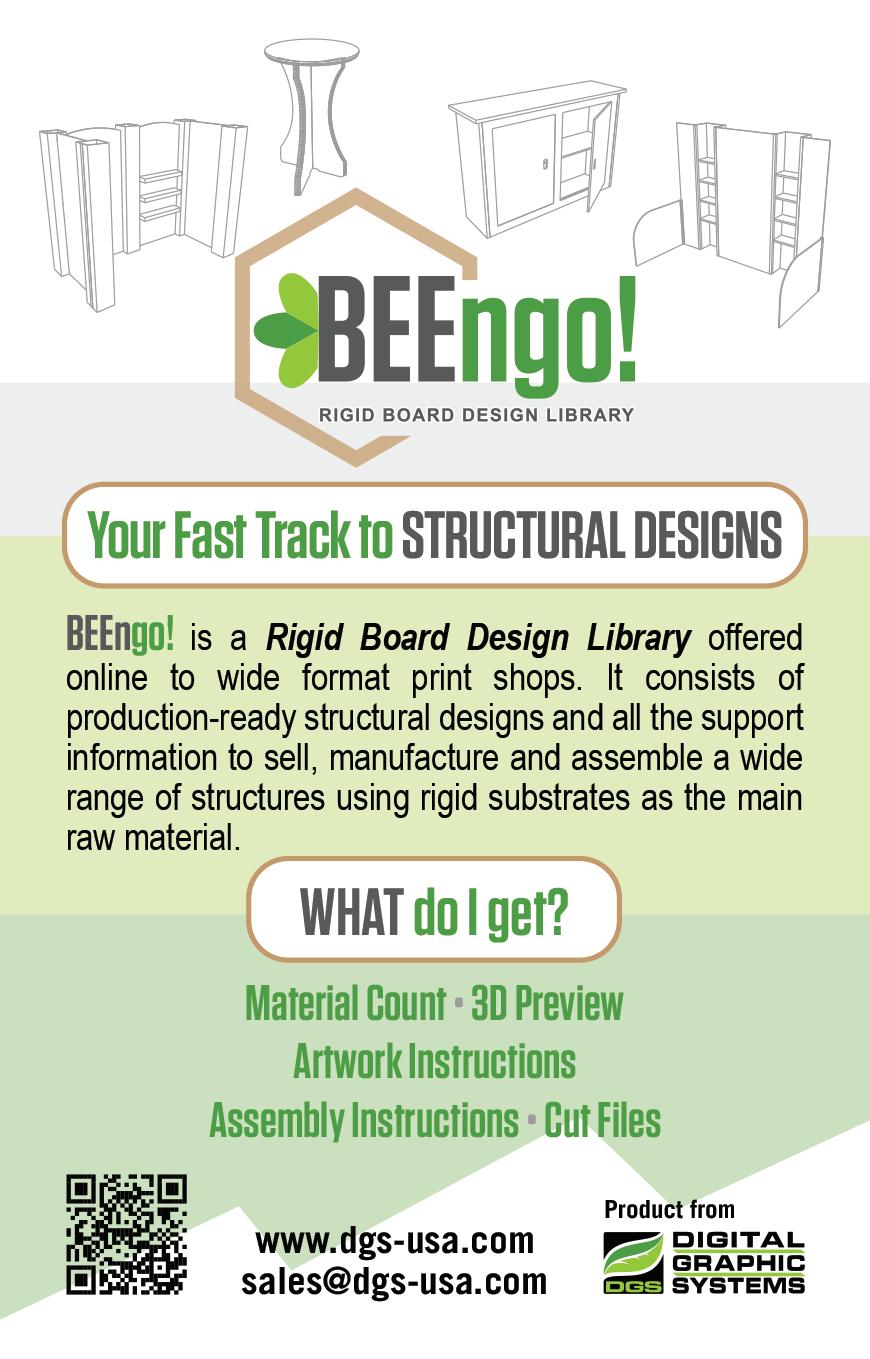

Print and Install

Hollywood Monster surveyed the intended area in December 2022. The project was installed in April 2023. “We had time to arrange the install, but waited for approved artwork, which then was printed and installed in a short time scale,” explains Tilley.

Approved artwork included graphics for a mix of applications—one floor graphic, a wrapped archway, and one ceiling and three wall displays made up of fabric.

All of the media was printed on EFI VUTEk printers, specifically dye-sublimation for the fabric and UV for the floor graphics and archways. The finishing was completed with its fleet of Zünd cutters.

UTACK Multi-Surface Textile from CMYUK was used for the floor and a laminated permanent vinyl for the archway. UFabrik Soft Display Textile was the media of choice for the walls and ceiling.

UTACK Multi-Surface Textile is a unique removable, adhesive-coated textile designed for indoor/outdoor wall and floor graphics, with a lifespan of up to three months. Suitable for carpet, wood, tiles, and concrete surfaces, this antislip vinyl has R12 rating, with B1 and M1 fire certifications.

UFabrik Soft Display Textile is suitable for both long- and short-term

graphics. A soft crease-free display textile with a high knit density that accounts for over 80 percent opacity, it is designed for tension frame systems, banners, tablecloths, and backdrops. Compatible with dye-sub direct or transfer processes, it has an ideal white point, superb stretch, and recovery as well as punchy color reproduction. It is fire rated EN13501-1, B1 and NFPA 701 certified.

“The UFabrik range of textiles covers about 95 percent of all wide and superwide applications. It’s high performing with excellent color reproduction and comes at an excellent price point. Products within the range include materials made from recycled PET plastic waste that have caught the attention of some of the world’s biggest brands that we service,” says Simon McKenzie, CEO, Hollywood Monster.

Graphics for The Super Mario Bros. Movie theatrical release were printed and installed over two nights with a team of four installers. A track system was utilized for the fabric wall and ceiling graphics. According to Tilley, “the track is mechanically fixed to the wall perimeter and around any switches/ sockets. The fabric is rolled out and pushed into the track using a crescent shaped hand tool and any excess fabric is then carefully cut off using a scalpel.”

Use of the track—and the fabric placed in it—was a strategic decision. “Going forward this installation site will be changed quarterly, which is why the track system is a great option for this kind of project,” notes Tilley.

“Our client was delighted with the immersive graphics. They packed a powerful visual punch, elevating the ambient experience and enjoyment of the cinema-going public,” adds McKenzie.

The graphics were removed in May 2023. As of press time Vue Cinema and Hollywood Monster were consulting on the next movie premiere to promote in the space.

Settle In

Movie theaters are an excellent environment to create signage for—as new films are constantly introduced and promoted months in advance, graphics are never short on supply. Digitally printed graphics offer ease of install and removal while providing a highquality look and feel.

See page 21 for more info.

D

#8 digitaloutput.net July 2023 | Digital Output { 7 }

by Cassandra Balentine

agnets are a versatile medium for graphics and signage. From promotional use on refrigerators and vehicles to point of purchase (POP) and signage opportunities that are easy to install and remove in retail environments.

Additionally, the media is available in magnetic and magnetic-receptive options, in a range of widths and thicknesses, and compatible with many print processes. Jack Nellessen, president, New Force Magnetics Co., breaks down the different magnetic options—printable

magnetic sheeting is for printing, magneticreceptive sheeting for attaching to a magnetic surface, and magnetic strip with adhesive for the backs of calendars or shelf marking. In this

July 2023 | Digital Output digitaloutput.net { 8 }

Above) Sheet converting equipment at Adams’ Elmhurst, IL location.

article we go through the advantages, limitations, durability, and recyclability of each solution.

Printable Magnetic Sheeting

One type of magnet common for wide format printing applications is printable magnetic sheeting. This is used for a applications like vehicle graphics, signage, promotional labels, industrial tags, and POP and retail displays.

Magnet applications are often a one-part application with no magnetic base required, as long as there is iron in the surface.

One reason for the popularity of this media is the simple fact that it is the only suitable option for some applications—like refrigerator and vehicle magnets, says Lydia Amburn, operations manager, Newlife Magnetics LLC.

Standard magnetic solutions may also enable a lower cost of doing business in the short term. “End users with non-repetitive business would benefit from traditional magnetic,” comments Brian Ebenger, VP, business development, Xcel Products, Inc.

Ease of installation is another major selling point for magnetic signage options. “Magnetic sheeting is simple to work with so no professional installation is needed,” shares Ebenger.

“It’s a simpler system if you already have a magnet-receptive surface. You only need the one piece of magnetic media and it’s easy to install,” adds Alice Martin, director of marketing, Adams Magnetic Products Co.

The main limitation to magnetic sheeting material is width. Magnetic media is typically found in 48-inch widths or less, points out Ebenger. Comparatively, he says the industry standard for pressure-sensitive vinyl is 54 inches and banner medias are available as wide as 196 inches.

There are a range of compatible printing systems for magnetic sheeting, including digital inkjet—solvent, eco-solvent, and UV-curable, as well as flexography and screen. “Other options are available but may require non-magnetized products during printing based on printer technology. If non-magnetized material is required, a magnetizer is needed post print,” explains Ebenger.

In terms of durability, the life expectancy of printed magnetic sheeting is determined by a number of factors, but Ebenger notes that indoor applications can typically last a long time while outdoor applications will last about a year.

Printed magnetic sheeting can be used indoors or outdoors, but Nellessen says there are some heat and cold limitations to consider.

The materials can easily be used for several years depending on the exposure to sun, adds Nellessen. Indoor use could be up to ten years.

When it comes to finishing, magnetic sheets are fairly straightforward—die cut, routed, even cut by hand are all options according to Ebenger.

digitaloutput.net July 2023 | Digital Output { 9 } #1 #7

“With proper care and maintenance, the magnet should last for years. Environment and ink durability will factor into overall durability,” adds Martin.

Ebenger recommends testing the material on the printer and application to ensure the material is compatible. “Magnetic material is typically heavier than other wide format products so just be aware for print and transportation purposes. Additionally, a clean surface is critical for the success of the application.”

Sustainability, including recyclability, is always a consideration. Depending on the specific materials, recyclability of magnetic sheeting is possible—even when inked, but usually the product must be returned to the manufacturer, shares Amburn.

Ebenger says Xcel Products’ domestically made material can be recycled and the company has set up several recycling programs.

Martin cautions that magnetic media is not always recyclable, but Adams’ GreenMAG is a printable recyclable magnet up to 30

inches wide. It can be recycled with ink. “A durable printable coating is applied directly to our magnet sheet, eliminating the need for a laminated print surface. This makes it completely recyclable. Send it back to us and we’ll use it to make more GreenMAG.”

Magnetic Sheeting Options

Adams offers printable flexible magnet sheet available in 24-, 40-, 48-, 50-, and 60-inch widths, and is available in .015-; .020-; .030-, .045-, .060inch thicknesses.

Magnum Magnetics Corporation provides several different versions of its magnetic sheets from DigiMag Vinyl—a direct printable media for solvent, eco-solvent, latex, and UV inkjet; to MuscleMag, which is a high-energy, thin printable magnet for digital and wide format inkjet presses.

Master Magnetics, Inc. offers PrintMagnetVinyl, which allows printing to white, black, blue, gold, green, orange, red, or yellow magnetic sheet using solvent, eco-solvent, UV, or latex ink. Rolls are available in ten to 50 feet long, 24 inches wide, and 20- or 30-mil thick.

New Force magnetic sheeting widths are available up to 60 inches but the most requested sizes are still between 24.375 and

48 inches due to the popularity of the more affordable small width printers, says Nellessen.

Newlife Magnetics manufactures flexible magnetic materials. “We can make our EM series magnet 60 inches wide. We strive to make products wider, thinner, lighter, and stronger,” shares Amburn. Its magnetic sheeting options are available in 60-inch widths and thicknesses of .007 to .084 inches, depending on the SKU.

Xcel Products offers its ACTION Magnet, which is domestically produced and designed to provide superior consistency with various options and minimal lead times. “Additionally, we have several options including standard energy, high energy, and PVC free,” notes Ebenger. It provides 15-, 20-, and 30-mil thickness as standard products with an option for 60mil. Standard widths are 24.375, 40, and 48 inches, while its standard lengths are 50 and 100 feet. “We have the capabilities to sheet to any size along with custom rolls to help support the needs of the industry,” shares Ebenger.

Magnetic Receptive

Magnetic-receptive media is a unique system with a magnetic base and magnetic-receptive product that sticks to it. Both magnetic sheeting and magnetic-receptive systems have a place and there is some application overlap.

Popular graphics printed for magnetic-receptive systems include small and large displays, menu boards, control charts, POP, educational and museum displays, picture frames, and wallcoverings.

July 2023 | Digital Output digitaloutput.net { 10 } 1

1) Strip converting equipment at Adams’ Carlsbad, CA location.

“Any surface that someone wishes to change out after initial covering” is a fit, recommends Nellessen.

Martin points out that these systems allow for displays to be quickly updated with no tools and minimal training.

“This material is used for ease of installation and quick change out for promotional and short-term events,” agrees Ebenger.

Amburn points out that magneticreceptive prints are lighter and less costly to ship compared to the standard magnetic offerings. Reusability is another advantage.

In terms of limitations, the biggest is that it requires a magnetic base. “Some challenges include a high initial cost to install the magnetic base along with magnetic receptive not being recyclable,” says Ebenger.

Amburn also finds consumer education for magnetic-receptive applications to be a barrier.

Magnetic-receptive materials are optimized for all common ink sets, including solvent, ecosolvent, and latex inks; conventional offset, flexography, lithography, and screen printing; and HP ElectroInk.

In terms of durability, Ebenger says magnetic-receptive applications can last for years based on the environment. “However, most are short term so it is typically not a concern.”

For outdoor use, Amburn notes that UV exposure is the primary factor for the degradation of all media types. “For long-term applications outdoors our PET options allow for years of continued durability and will not yellow or brown like PVC. In addition, our PET options are PVC free. There is little to affect the longevity of printable magnets indoors,” she continues.

Nellessen estimates longevity from three to ten years for indoor use.

In terms of recyclability, Ebenger says magnetic receptive is not recyclable—with or without ink.

Nellessen says it depends on the laminate, but it is usually not considered recyclable.

Newlife Magnetics is working on a process with Mid America Paper for recycling retired magneticreceptive graphics. “We will make further information available soon. For our FF series (540) we incorporate 32.4 percent postconsumer plastics in the binder.”

digitaloutput.net July 2023 | Digital Output { 11 } #3

Magnetic-Receptive Options

Adams MAGbond Magnetic Receptive Sheets are available ten- or 12-mil thick, and come in 50-, 54-, and 60-inch widths with a PET surface for printing. MAGbond sheets are made by coating high-quality films with micro-iron particles and are engineered to be ultra-low profile for a seamless appearance of a single layer, photographic, or fine art quality print.

Magnum Magnetics has three different magnetic-receptive media lines. EnGage is a thin, printable magnetic-receptive media for wide format printers. RubberSteel is a lightweight rubberbased magnetic-receptive media available with multiple laminates. PaperSteel is a magnetic-receptive sheet with a gloss white paper surface on one or both sides.

Master Magnetics’ FlexIRON magnetic-receptive sheeting is made with a high concentration of iron so it attracts all types of magnets. It is part of the company’s Magnetic Graphics System, which is a three-layered system designed for graphics display.

New Force offers an adhesivebacked magnetic sheet that is adhered to a wall or other backer board. A changeable sign is then printed on a magnetic-receptive graphic, which is attached to the magnet. Its magnetic-receptive

sheets are available in 50- and 60-inch wide format rolls.

Newlife Magnetics makes magnetic-receptive options ranging from HP Indigo sheets to 60-inch wide format options, in thicknesses from seven- to 12-mil—20 mils with PSA—and can make thicker by special order.

Xcel Products offers several different versions of magnetic-receptive material. “Our standard 13-mil material is available in 54-, 60-, and 74-inch widths. The company also offers an 18-mil, double-sided and latex version in 15-mil. Both standard roll widths are 60 inches,” shares Ebenger.

In addition, Xcel Products offers the SOLIX frame system, which is a framed magnetic base. Ebenger says these are gaining popularity in restaurants, museums, and trade show booths.

Flexible Magnetic Strip

Flexible magnetic strips are also utilized in the wide format print industry. Most applications for magnet strips do not overlap with that of sheet magnet or magnetreceptive products. The material is generally not printable/printed to.

Magnetic strips are used to hold something on a metal surface, like notepads, labels, and craft items, confirms Nellessen.

“Magnet strip has a wide array of uses and can be used to apply many non-magnet or magneticreceptive media to a metal or magnet base (such as A/B applications),” suggests Amburn.

“Magnetic strips are typically used to support rigid boards rather than flexible products like magnetic and magnetic receptive,” explains Ebenger. “This is ideal for an end user that would prefer a rigid display or freestanding display.”

Martin agrees, adding that a flexible magnet strip can be used around the perimeter of signs printed on several choices of material, so printers can work with materials they are comfortable with, and still make them magnetic by applying the magnet strip.

Limitations associated with magnetic strip media include the lack of options, says Ebenger. This is in addition to the competition of traditional tapes and Velcro. Metal is required for the strips to adhere, which is a disadvantage for some applications.

Martin adds that careful consideration should be used when selecting an adhesive. “You need to be sure it is compatible with the surface you plan to apply it to.”

“The manual labor to apply the strip has been the limiting factor in using the product, but we have solutions,” adds Amburn.

“Magnetic strips are specialty driven but are compatible with most graphics products in the industry,” shares Ebenger.

Magnetic Strip Options

Adams stocks flexible magnetic strip in widths from .25 to three inches. “We can cut or score pieces as short as .25 inches and provide rolls up to 1,500 feet depending on material thickness,” shares Martin.

Magnum Magnetics magnetic strip is available plain or with different surfaces. Choose vinyl or add foam, indoor or outdoor adhesive backing to create magnetic tape. Standard thicknesses range from .025 to .250 inches. Standard widths are .5, .75, one, 1.5, two, and three inches.

Master Magnetics provides magnetic strips with and without adhesive in various widths and thicknesses to the market.

New Force offers flexible magnetic strips in widths from .5 to four inches wide as standard.

Newlife Magnetics’ high-energy strip can offer the holding force of a standard energy magnet strip of nearly twice the thickness, shares Amburn.

Xcel Products offers flexible magnetic strips. The material is domestically produced with a high-quality permanent adhesive.

Magnetic Magnitude

Magnetic media includes printable magnetic and magneticreceptive options to flexible magnetic strips that add holding strength to a printed application. The opportunity for all three categories, specifically in the wide format space, is great thanks to their versatility. D

July 2023 | Digital Output digitaloutput.net { 12 } companies mentioned INFO# COMPANY WEBSITE 187 Adams Magnetic Products Co. adamsmagnetic.com 188 Magnum Magnetics Corporation magnummagnetics.com 189 Master Magnetics, Inc. magnetsource.com 190 New Force Magnetics Co. newforcemagnetics.com 191 Newlife Magnetics LLC newlifemagnetics.com 192 Xcel Products, Inc. xcelproducts.com See page 21 for more info.

by Digital Output Staff

here is a need for speed in today’s society where everyone wants something yesterday. Why should printing be any different?

Print service providers (PSPs) with textile printing capabilities turn to high-speed dyesublimation (dye-sub) printing when production volumes necessitate quick turnaround over large runs. These wide format printers are equipped with the correct combination of

printheads, ink technology, and other mechanisms to minimize downtime and increase throughput.

Define High Speed

So what is high-speed dye-sub? We asked vendors interviewed for this article to provide their definition.

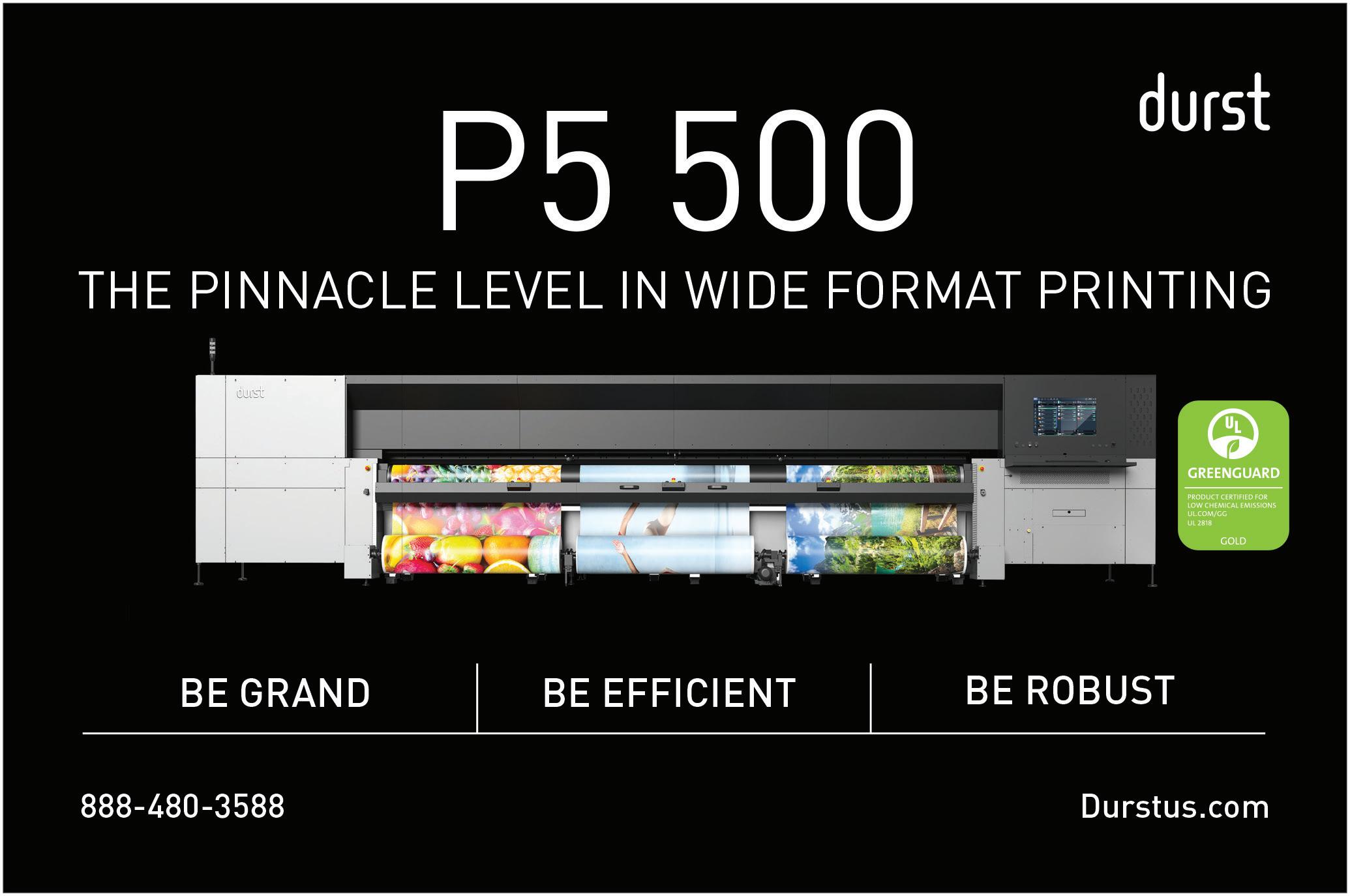

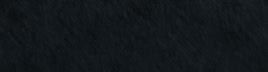

Mike Syverson, textile managerNorth America, Durst US, says “high speed” is a relative term. “A range of printer speeds are on the market. Durst manufactures dye-sub systems

that range from 4,000 to 14,000 square feet per hour (sf/h) for a variety of applications.”

At Mutoh America, Inc., high-speed printing is defined as the maximum speed topping out at over 1,000 sf/h, with production of at least 500 sf/h, says Tony Simmering, product manager, Mutoh.

“We consider high speed as production dye-sub systems capable of producing high volumes of sellable-quality

digitaloutput.net July 2023 | Digital Output { 13 }

finished goods in a day,” shares Tim Check, senior product manager, Professional Imaging, Epson America.

Jos Notermans, product manager digital printing, SPGPrints, cites high speed as a couple of 100 linear meters per hour. “With 1.6-meter wide paper this would mean above 3,400 sf/h. That gives a daily production of up to 4,000 meters per hour, which is really a production volume as it

results in up to one million meters per year.”

High speed means different things depending on the technology, i.e. single-pass printing versus scanning. “Normally high speed means about 150 square meters per hour for a scanningtype inkjet printer, this is about two meters per minute for a 1.2-meter width. To reach two meters per minute with a scanning inkjet at a minimum of four passes, it requires more than three sets of printheads for each color. This means higher manufacturing costs for faster production,” explains Juan Kim, CEO, Valloy Incorporated.

John Ingraham, senior specialist product marketing, Canon USA, Inc., quotes high-speed production as 2,000 sf/h or higher. “This is based on printhead technology and the number of printheads. Typically, high-speed production systems incorporate eight or more printheads—Kyocera or Ricoh Gen 5—with native resolutions around 600 dpi or greater.”

Speed is also relative to print width. Victoria Nelson Harris, senior textile segment specialist, Mimaki USA, Inc., explains that she defines high-speed for less than 76-inch wide printers at 1,500 sf/h, whereas for grand format printers over ten feet in

width, high speed would be considered 1,300 sf/h.

From the perspective of Micol Gamba, senior manager product marketing, EFI Reggiani, a high-speed dye-sub printer produces at least 1,500 sf/h when considering a 71-inch width device.

Check cautions that print speed is just one factor impacting overall throughput. “Increasing uptime and reducing non-print time related to job processing, system maintenance, and inefficient movements can contribute greatly to throughput.”

Make It Speedy

A dye-sub printer reaches the aforementioned high speeds thanks to the right combination of printheads, media handling, and a host of other factors.

“The printhead type and the number of printheads are the

July 2023 | Digital Output digitaloutput.net { 14 } 2 1

1) Available through Canon, the DGI FH-3204 reaches speeds of up to 3,230 sf/hr. The printer is designed to run with either four colors or optionally six colors for fluorescent inks or orange/blue inks for expanded color gamut. 2) The Epson SureColor F10070 offers industrial-level printing.

most important. By putting the colors in symmetrical order in the carriage improves the speed, as the order of color laydown is then the same whether the carriage moves from left to right or from right to left. So this avoids the so called ‘soccer field effect’, banding in uniform areas of the printing,” explains Notermans.

Printheads are key elements in EFI’s case. “We have adopted established, high-end technologies that can then ensure very competitive cost per nozzles combined with very fast jettability performances, which are also ensured by a proprietary ink system and print engine software that bring the printhead to its maximum expression,” shares Gamba.

Simmering admits that “a lot of it is based on the printhead jetting speed in combination with the ability to dry the ink fast enough.”

“The type of printhead, higher number of printheads, and higher number of nozzles the printhead has increases the speed of the printer,” adds Nelson Harris.

Kim agrees it depends on the printhead specifications. “Bandwidth of printhead, number of nozzles, number of printheads, and jetting frequency of printhead. But, ink also needs to flow smoothly to catch up with high speeds and sophisticated negative pressure control may be required.”

Yes, Notermans seconds a consideration of the ink system, “inks need to be of high quality to avoid blockages or other print quality causing problems.”

#5

digitaloutput.net July 2023 | Digital Output { 15 }

#2

While printheads and the ink are notable, there are other components of note. “Media handling, color configuration, and more all impact the print speed of a given platform. However, there are factors to consider such as downtime due to roll changeover, maintenance, and overall reliability,” notes Syverson.

Media handling is important and how it is integrated influences speed. “High-speed production

companies mentioned

printers work with jumbo rolls and need stronger systems to handle the larger media,” explains Ingraham.

“Media handling must be able to keep up with the printing speed but decent design makes this possible,” admits Notermans.

“A high-speed print system is an optimized collection of system components that work efficiently together,” adds Check, which

is why Epson as a vertical manufacture designs all components of the print solutions—printheads, ink chemistry, processor design, software, and image processing to work seamlessly and efficiently to produce volumes of finished goods.

Beneficiaries of Quick

Print providers familiar with dye-sub are the best candidates for high-speed printers.

“The companies benefiting the most from a high-speed system are, generally speaking, already producing some level of work with dye-sub, as the cost of the

equipment—and associated large capacity heat presses—is at the upper end of the scale,” explains Syverson.

Simmering notes that “high-

speed dye-sub printers are

3) SPGPrints Rose textile printer. 4) The Mutoh ValueJet 1939TX is a highly efficient textile device. 5) EFI Reggiani NEXT Plus is an industrial, beltless digital printer that prints on paper for transfer and non-elastic fabrics with up to eight colors.

4 July 2023 | Digital Output digitaloutput.net { 16 } 3

INFO# COMPANY WEBSITE 145 Canon USA, Inc. csa.canon.com 146 Durst US durstus.com 147 EFI efi.com 148 Epson proimaging.epson.com 149 Mimaki USA, Inc. mimakiusa.com 150 Mutoh America, Inc. mutoh.com 151 SPGPrints spgprints.com 152 Valloy Incorporated valloy.com See page 21 for more info.

important for print providers looking at scalability. Purchasing a high-speed printer allows shops to have high production at a relatively low entry cost.”

“High-speed production printers are ideal for print providers looking to upgrade their fleet of existing dye-sub printers to a single printer and outsourcing a large volume of dye-sub work. Since the pandemic, turnaround times for outsourced work has increased from a week to four to eight weeks or longer. Bringing the work in house makes it possible to bring in more business and meet customer critical deadlines,” explains Ingraham.

But, not every print shop requires a high-speed dye-sub printer. “Higher speed brings higher production rates, but flexibility should be considered. If it is a similar cost for multiple, slower speed printers than a single, high-speed printer, sometimes it is better to have multiple printers for more flexibility and

malfunctioning,” explains Kim.

According to Nelson Harris, “the ecommerce print on demand sector is booming, localized manufacturing is being sought, due to the frustration with supply chain issues printing overseas. Expansion of onshore fulfillment centers and faster production speed combined with options to lower the cost of consumables, such as jumbo paper units and ten liter bulk ink systems, lower running costs, and higher return on investment,” are all contributing factors to an increased level of adoption of high-speed, dyesub printers.

lower the cost of consumables,

Applications of Note

PSPs print via dye-sub to produce all sorts of end use applications, including decoration, apparel, and signage. High-speed dye-sub is advantageous for most of these, but some more

Historically, Syverson says high-speed dye-sub printers are installed in textile printing companies that produce printed yardage of fabric for decoration, hospitality, and apparel.

“Traditionally it was mostly the sign and banner market but soon the sportswear market got interested as its polyester fabrics became better and digital allows for a lot of design freedom, an important factor in sportswear. Nowadays other fashion items are made out of polyester so sublimation printing becomes attractive to them as well. The same counts for the home decoration market,” says Notermans.

trade show and retail sectors for fabric printing. This has given way to more PSPs bringing in large, industrial-level equipment to satisfy the demands of the market,” notes Syverson.

Simmering lists common applications for high-speed dye-sub printing like sports apparel, temporary fixtures like event tents, pop-up retail signage—“typically items produced in bulk where attention to extremely fine detail is not necessary.”

In the on demand sector, Nelson Harris says blank goods like blankets and floor mats are ideal for this technology. She also suggests textile converters who have in-house design agencies.

dye-sub printing is already applications like apparel, which world, but also sportswear, home

Gamba agrees that “high-speed dye-sub printing is already showing significant benefits for applications like apparel, which represents approximately 70 percent of the textile digital printing world, but also sportswear, home décor, and soft signage.”

Need for Speed

seen tremendous growth in the

“In the last few years, we’ve seen tremendous growth in the

Is speed the final consideration when determining which dyesub printer is right for the job? No. But for many PSPs it might be what makes the most sense for them based on their daily, weekly, or monthly output and applications produced. D

safe backup when a printer is than others.

safe backup when a printer is than others.

5 digitaloutput.net July 2023 | Digital Output { 17 }

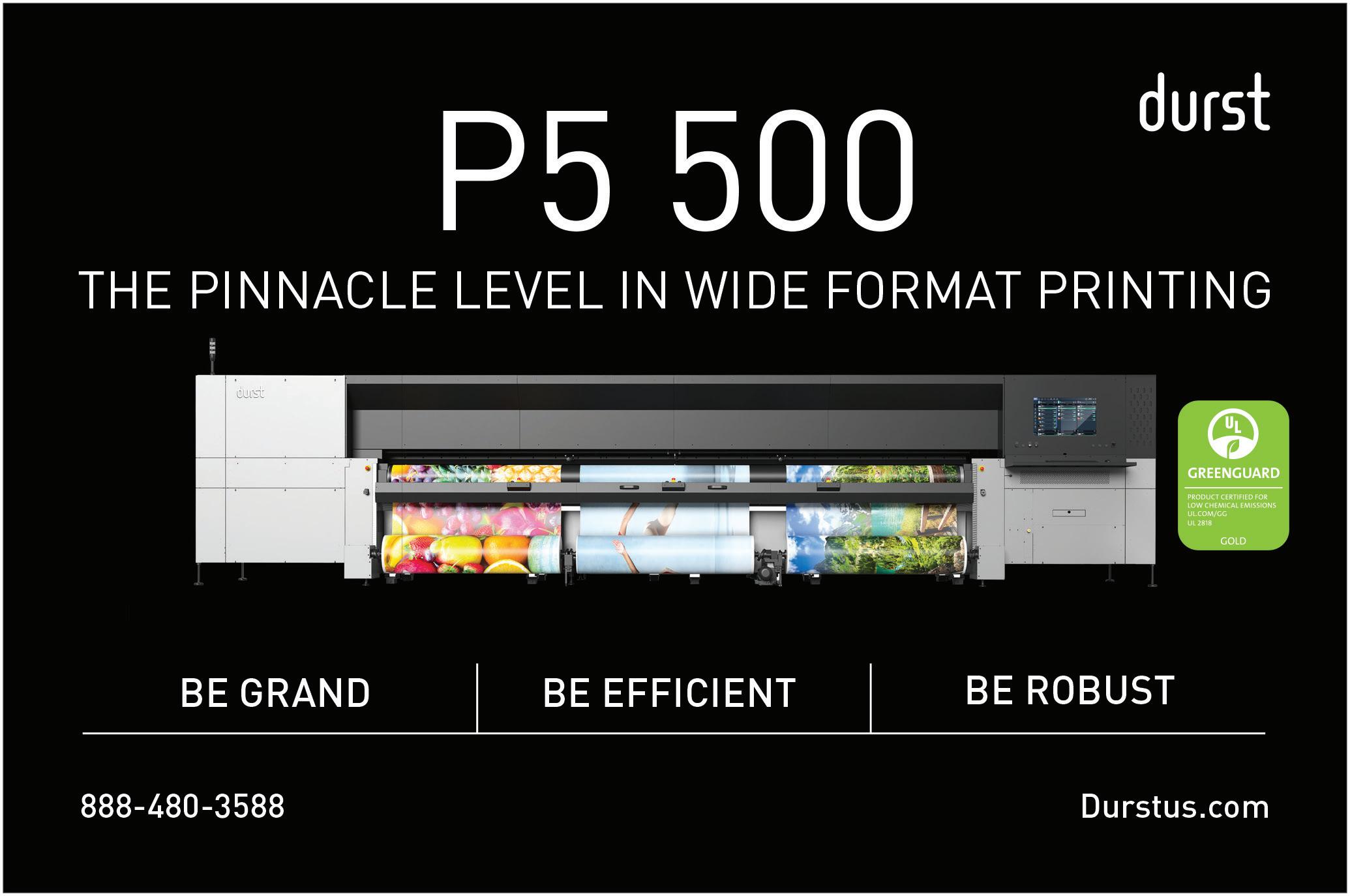

July 2023 | Digital Output digitaloutput.net { 18 } INFO# Company/Website Product Print Process Ink Type Max. Speed (sf/h) Max. Width (Inches) Max. Resolution (dpi) List Price (U.S.) 100 Agfa Avinci CX3200 TDS, DDS WB DS 2,906 126 600x1,800 CM agfa.com/na 101 Amica Systems XB18 DDP WB D, A, REA Dye; WB PIGM CM 70 CM CM amicasystems.com CR33 DDP WB D, A, REA Dye; WB PIGM 1,850 126 CM CM SW16 DS WB 700 63 1,200x600 CM XBM18/XBM20 DDP WB D, A, REA Dye; WB PIGM 211.9 75.9 600 CM CW33 DS DS 1,389 130 1,200x600 CM FR19 DS DS CM 75 600x600 CM 102 Arioli ArioPrint DDP REA, D, A 1,500 78 1,200x1,200 CM arioligroup.com 103 Canon Solutions America DGI FT-3204X TDS, DDS DS 2,690 124 720x1,440 CM csa.canon.com DGI FH-3204 TDS, DDS DS 3,230 126 600x1,200 CM DGI Poseidon TDS DS 2,648 74 600x1,200 CM DGI Poseidon TDS DS 2,260 64 600x1200 CM MS JP4 180 TDS, DDS DS 3,120 70.8 600x600 CM MS JP4 320 TDS, DDS DS 4952 126 600x600 CM 104 ATP OnPaper 1900 TDS AQ DS 1,668 74 2,400 CM globalimaginginc.com/textile-printers OnPaper 2600 TDS AQ DS 2,152 102 2,400 CM OnPaper 3300 TDS AQ DS 2,690 126 2,400 CM OneTex 1900 TDS AQ DS 1,668 74 2,400 CM OneTex 2600 DDS AQ DS 2,152 102 2,400 CM OneTex 3300 DDS AQ DS 2,690 126 2,400 CM OneTex 5200 DDS AQ DS 3,875 208 2,400 CM 105 d.gen, Inc. Artrix H8 DDP PIGM 775 CM 1,200 CM dgen.com Teleios Hexa DDP DS, PIGM, REA 775 74 1,200 CM Arachne Hexa DDP PIGM, REA, A, DS 560 74 1,200 CM Papyrus G5 TDS SUB 1,485 74 2,400 CM Teleios Grande H12 DDS DS, WB CM 126 CM CM Papyrus Grande DDS DS 1,076 130 2,400 CM 106 DigiFab Systems, Inc. StampaJet XP-64 DDS, DDP A, REA, D, PIGM, SUB 1,010 63.3 1,440 $38,900 digifab.com StampaJet EN-64 DDS, DDP A, REA, D, PIGM 1,010 64 1,440 $49,900 StampaJet K8-190 DDS, DDP A, REA, D, PIGM, SUB 3,767 74 600x1,200 CM StampaJet K2-190 DS SUB, PIGM 2,718 74 600x1,200 $74,900 StampaJet K4-190 DS SUB, PIGM 3,261 74 600x1,200 $93,900 StampaJet EN-75 DDS, DDP A, REA, D, PIGM 2,190 74 1,440 $69,900 107 Durst Image Technology US LLC Rhotex 500 DDS, DDP WB D DS 3,300 198 600 CM durstus.com Alpha 190 DDS, DDP WB, PIGM, REA, D, A, SUB 10,655 75 600 CM Alpha 330 DDP WB, PIGM, REA, D, A, SUB 15,820 130 600 CM P5 Tex iSUB DDS, DDP, TDS WB, D, DS 4,120 133 800 CM 108 EFI Reggiani BLAZE CM WB D/DS, DD, A, REA, PIGM 2,045 71 2,400 CM efi.com Reggiani ecoTERRA Gold CM WB PIGM 3,498 71 2,400 CM Reggiani TERRA Silver CM WB PIGM 2,045 71 2,400 CM Reggiani TERRA Gold CM WB PIGM 3,498 71 2,400 CM Reggiani TERRA Platinum 180 - 240 -340 CM WB PIGM 7,685 71/95/134 2,400 CM Reggiani TERRA Titan 180 - 240 - 340 CM WB PIGM 14,854 71/95/134 2,400 CM Reggiani POWER 180 - 240 - 340 CM WB D/DS, DD, A, REA, PIGM 14,854 71/95/134 2,400 CM Reggiani NEXT Plus 180 - 340 TDS, DDS WB D/DS 4,036 71/134 2,400 CM Reggiani HYPER 180 -240 -340 DDP, TDS, DDS WB D/DS, DD, A, REA, PIGM 33,906 71/95/134 2,400 CM Reggiani VOGUE DDP WB D/DS, DD, A, REA, PIGM 3,498 71 2,400 CM Reggiani COLORS 180 - 240 -340 DDP WB D/DS, DD, A, REA, PIGM 7,685 71/95/134 2,400 CM Reggiani BOLT DDP WB REA 87,188 71 4,800 CM VUTEk FabriVU 340+ TDS, DDS WB D/DS 5,172 133 2,400 CM VUTEk FabriVU 340i+ TDS, DDS WB D/DS 2,691 133 2,400 CM VUTEk FabriVU 520 TDS, DDS WB D/DS 4,800 205 2,400 CM COLORS 340 TDS, DDS WB D/DS 9,149 134 2,400 CM POWER 340 TDS, DDS WB D/DS 16,835 134 2,400 CM VUTEk D3r DDP LED 2,196 138 1,200 CM VUTEk D5r DDP LED 2,626 205 1,200 CM VUTEk 3r+ DDP LED 4,370 138 1,200 CM VUTEk 5r+ DDP LED 5,242 205 1,200 CM Pro 32r+ DDP LED 2,756 126 847 CM VUTEk Q3r DDP LED 6,006 138 1,200 CM VUTEk Q5r DDP LED 7,233 205 1,200 CM 109 Epson SureColor F570 Pro TDS DS CM 24 2,400x1,200 $2,895 proimaging.epson.com SureColor F6470 TDS DS 820 44 1,200x600 $8,195 SureColor F6470H TDS DS 400 44 1,200x600 $8,695 SureColor F7200 TDS DS 634 64 1,440x720 $16,995 SureColor F9470 TDS DS 1,169 64 1,440x720 $28,995 SureColor F9470H TDS DS 1,169 64 1,440x720 $32,995 SureColor F10070 TDS DS 2,700 76 1,200x1,200 CM SureColor F10070H TDS DS 2,635 76 1,200x1,200 CM Monna Lisa 8000 DDP A, D, PIGM, REA 1,744 72 1,200x1,200 CM 110 FTEX JS BT-180 DDP A, REA, D, PIGM 1,615 71 1,440 CM ex-co.com JSF 400 DDP A, REA, D, PIGM CM 126 1,200 CM JS FT-180 DDP PIGM, REA, A 861 71 1,440 CM JK-300 DDP A, REA, D, PIGM 1,615 126 600x1,200 CM JS RP-320 DDP SUB, PIGM, REA, A 753 126 1,440 CM 111 Gandy Digital NextJet Paper TDS WB DS 3,552 74 2,400 CM gandydigital.com NextJet Direct DDS WB DS 2,583 208 2,400 CM 112 HP Inc. HP STITCH S500 Printer DDP, DDS DS CM 64 1,200 CM hp.com HP STITCH S1000 Printer DDP, DDS DS CM 126 1,200 CM KEY A = Acid AQ = Aqueous CM = Contact Manufacturer D = Disperse DDP = Direct Digital Print DDS = Direct Dye-Sub DS = Dye-Sublimation PIGM = Pigment REA = Reactive SUB = Sublimation TDS = Transfer Dye-Sub WB = Water-Based KEY

digitaloutput.net July 2023 | Digital Output { 19 } INFO# Company/Website Product Print Process Ink Type Max. Speed (sf/h) Max. Width (Inches) Max. Resolution (dpi) List Price (U.S.) 113 Kornit Digital Presto DDP WB PIGM 2,862 70.8 1,000x800 CM kornit.com Presto S DDP WB PIGM 5,400 70.8 1,000x800 CM Presto MAX DDP WB PIGM 2,628 70.8 1,000x800 CM Presto MAX S DDP WB PIGM 5,103 70.8 1,000x800 CM 114 Kyocera Corporation FOREARTH DDP WB PIGM 2,690 70.8 600x600 CM global.kyocera.com 115 Mimaki USA, Inc. TS100-1600 TDS DS 753 64 900 CM mimakiusa.com TS500P-3200 TDS DS 1,937 130 1,080 CM TS55-1800 TDS DS 1,453 77 1,200 CM TX300P-1800 MkII DDP, DDS, TDS, SUB, D, PIGM, REA, A, 710 76 1,440 CM TX300P-1800B DDP, DDS A, D, PIGM, REA, SUB, 732 75 1,440 CM TX500P-3200DS DDP, DDS SUB 1,399 130 1,080 CM Tiger-1800B MkIII DDP, TDS, DDS REA, SUB 4,144 75 1,200 CM TS330-160 TDS DS 1,453 64 1,200 CM 116 Mosaica Group (The) Panthera S2-1.8m TDS, DDS DS, D 1,500 72 1,200 CM get.printmosaica.com/panthera Panthera S2-3.2m TDS, DDS DS, D 2,000 126 1,200 CM Panthera S4-1.8m TDS, DDS DS, D 3,000 72 1,200 CM Panthera S4-3.2m TDS, DDS DS, D 4,000 126 1,200 CM Panthera S4-1.8m TDS, DDS DS, D 1,800 72 1,200 CM Panthera S4-3.2m TDS, DDS DS, D 2,000 126 1,200 CM Panthera JR TDS, DDS DS, PIGM 1,900 74.8 720x2,400 CM 117 MS Printing Solutions JP4 EVO TDS, DDS AQ, D, DS 4,682 125 600x600 CM msitaly.com JP7 TDS, DDS AQ, D, DS, PIGM, REA, A 6,000 70 600x600 CM JPK EVO 180 TDS, DDS AQ, D, DS, PIGM, REA, A 12,000 70 600x600 CM JPK EVO 320 TDS, DDS AQ, D, DS, PIGM, REA, A 12,000 126 600x600 CM 118 MTEX NS, S.A. Dragon TDS SUB 2,949 75 720 CM mtexns.com Eagle TDS SUB 6,566 126 1,440 CM Falcon DDP PIGM 1,636 126 1,440 CM 119 Mutoh America, Inc. RJ900X TDS AQ 676 44.6 2,880 $7,560 mutoh.com ValueJet 1948WX TDS AQ 2,199 74.8 1,440 $49,995 ValueJet 1938WX TDS AQ 1,327 74.8 1,440 $31,995 ValueJet 2638WX TDS AQ 1,168 103.6 1,440 $49,995 XpertJet 1682WR TDS AQ 1,012 63.6 1,200 $26,495 XpertJet 1642WR Pro TDS AQ 1,325 63.6 1,200 $19,995 ValueJet 1938TX DDP, DDS A, AQ, D, PIGM, REA, WB 914 74.8 1,440 $39,995 120 Roland DGA Corporation Texart RT-640 TDS DS 522 64 1,440x1,440 $19,995 rolanddga.com Texart RT-640M TDS, DDS DS 522 64 1,440x1,440 $19,995 Texart XT-640 TDS DS 1,098 64 1,440x1,440 $29,995 121 SCG Digital America Inc. SUPRAQ 3200-TX6 DS DS 614 128 400 CM scg-america.com GD1800AE-FP DDS DS 592 72 1,440 CM GDHT180-E2 DDP REA, A, PIGM 668 72 1,440 CM 122 SPGPrints Violet DDP REA, PIGM 1,650 70.9 720x1,080 CM spgprints.com Jasmine DDP REA, PIGM 9,257 72.8 600x2,400 CM Magnolia DDP REA 6,889 72.8 1.200x1,200 CM Rose TDS SUB 7,750 72.8 300x1,200 CM PIKE DDP REA 71,688 72.8 1,200x1,200 CM 123 StratoJet Piranha XT-500 Pro DS DS 677 72.0 2,400 CM stratojetusa.com Piranha XT-1000 Pro DS DS 700 126.0 2,400 CM 124 Valloy Incorporation TOPAZET 70R TX DDS, DDP Dye, REA, A, PIGM 550 71 1,200x900 $45,000 valloy.com 125 Zimmer Austria Colaris DDP REA, D, A, PIGM, SUB 5,150 86, 102, 134 1,600 CM zimmer-austria.com INFO# Company Name Website Product Name Max. Print Area (Inches) 130 Aeoon Technologies aeoon.com Compact Series Custom Kyo Series Custom Maikuro 15x17 131 Amica Systems amicasystems.com TS1519 15x19 TSD1519 15.7x19.7 TSA1416 15.7x19.7 TSDX 43.3x31.5 132 Brother International Corp. brotherdtg.com GTXpro 16x21 GTXpro Bulk 16x21 GTX600 24x24 GTX600 Extra Colors 24x24 133 DTG Connection dtgconnection.com DTG-C Model X 16x20 DTG- Model X2 16x20 134 Epson proimaging.epson.com SureColor F2100 16x20 SureColor F2270 16x20 SureColor F3070 16x20 135 Kornit Digital kornit.com Storm Series 20x28 Avalanche Series 23.5x35 Atlas 23.5x35 Vulcan 28x39 INFO# Company Name Website Product Name Max. Print Area (Inches) 136 Lawson Screen & Digital golawson.com Diamond-Jet DTG 16x20 Express-Jet DTG 16x20 Zeus Digital Hybrid 18x18 Epson SureColor F-2100 16x20 Epson SureColor F-3070 16x20 137 MESA by ColDesi dtgprintermachine.com DTG G4 - Vacuum Platen 16x20 138 OmniPrint International omniprintonline.com Freejet 330 TX 12.5x22 Freejet 330 TX Plus 12.5x22 OmniPrint i12 16x20 OmniDTF CM Cheetah 16x20 139 Polyprint USA polyprintusa.com TexJet echo2 16x24 140 Ricoh DTG ricoh-dtg.com RICOH Ri 1000 16x19.6 RICOH Ri 2000 16x19.6 RICOH Ri 100 8.27x11.69 (A4) 141 Roland DGA Corporation rolanddga.com VersaSTUDIO BT-12 11.5x8 (A4) Texart XT-640S 53x64 142 ROQ roq.us ROQ Hybrid 29x35 ROQ NOW 17.7x13.4 #10

#13

#14

#12

#16

#17

#13

#14

#12

#16

#17

July 2023 | Digital Output digitaloutput.net { 20 }

#15

INFO# ADVERTISER PAGE WEBSITE 12 Alpina Manufacturing, LLC 20 fastchangeframes.com 13 Alpina Manufacturing, LLC 20 bannergrip.com 14 Budnick Converting/Banner Ups 20 bannerups.com 15 Delivery Signs 20 yardsignsresellers.com 16 DGS - Digital Graphic Systems Inc. 20 dgs-usa.com 1 Digital Dolphin Products 9 ddp.us 10 DTG Connection 19 dtg-c.com/domag 2 Durst US 15 durstus.com 3 FDC Graphic Films, Inc. 11 fdcfilms.com/3522 4 Fellers 27 fellers.com 5 Flatbed Tools 15 flatbedtools.com 6 ImagineThis 2 imaginetr.com 17 Neenah Inc. 20 neenahpaper.com 7 Newlife Magnetics, LLC 9 newlifemagnetics.com 8 Panel Processing 7 panel.com 9 Signs365 28 signs365.com INFO# COMPANY PAGE 170 Aberdeen Fabrics, Inc. 22 187 Adams Magnetic Products Co. 8 145 Canon USA, Inc. 13 160 CMYUK 6 180 Colex Finishing, Inc. 25 181 Cutworx USA 25 146 Durst US 13 161 EFI 6 147 EFI 13 148 Epson 13 171 Fisher Textiles 22 172 Greentex America 22 188 Magnum Magnetics Corporation 8 189 Master Magnetics, Inc. 8 149 Mimaki USA, Inc. 13 150 Mutoh America, Inc. 13 190 New Force Magnetics Co. 8 191 Newlife Magnetics LLC 8 173 Premex Solutions, Inc. 22 174 RePatriot Flag, LLC 22 175 Serge Ferrari 22 151 SPGPrints 13 162 UFabrik 6 176 UFabrik 22 177 Ultraflex Systems, Inc. 22 152 Valloy Incorporated 13 192 Xcel Products, Inc. 8 182 Xcel Products, Inc. 25 163 Zund America, Inc. 6 183 Zund America, Inc. 25

Ink Floor Graphics State of the Industry Large Format Viewpoint And More! digitaloutput.net July 2023 | Digital Output { 21 }

Textile

number of reasons exist to turn to sustainable-minded products in our daily lives, whether it’s for work or personal choice. On the production �loors of wide format print shops, businesses work with materials that are considered “green” to help the environment and meet their customers’ eco-commitments.

When it comes to printing textiles, there is a selection of products from a handful of

vendors made up of recycled single-use plastic waste or other recycled components.

Recycled vs. Virgin

Textiles made from recycled single-use plastic waste or other recycled components are becoming more important for a number of reasons.

“Textiles are the number one contributor to microplastics in our environment. User recycled

by

content is a great step in a reduction of the seriousness of microplastics,” shares Ken Bach, business development manager, Aberdeen Fabrics, Inc.

Using textiles made up of recycled components is a huge contributor to reducing waste.

July 2023 | Digital Output digitaloutput.net { 22 }

Melissa Donovan

Above) UFabrik offers products using accredited recycled yarn, specifically yarn produced from recycled single waste PET plastic waste.

“On average 80 percent of plastic bottles end up in a land�ill. Using materials made out of recycled polyester is important to reduce and ultimately stop plastic ending up in land�ills or our oceans,” shares Grainne Brennan, head of sustainable products, Premex Solutions, Inc.

Supporting the use of fabrics made of recycled components is good practice. “It minimizes the number of water bottles and other plastics from land�ills and oceans. This aids in conserving natural resources such as oil and water needed to produce virgin polyester,” explains Scott Fisher, president, Fisher Textiles, Inc.

“Recycling reduces the need for virgin materials, which help to conserve natural resources and reduce energy consumption and greenhouse gas emissions associated with extraction and production,” adds Steven Amitai, GM, Greentex America.

The move to fabric made from recycled content supports a circular economy. “With the introduction of another source of raw �iber—domestically harvested, recycled plastic—there is hope that the material supply chain will diversify enough to interrupt the historical trend of price spikes, supply shortages, and politically motivated trade interference,” notes Mike Glaser, co-founder, RePatriot Flag, LLC.

Brett Platt, textiles business manager, UFabrik, sees demand for environmentally responsible, high performing, wellpriced materials from global brands that meet sustainability

goals. “All of us need to develop solutions that consider their environmental impact.”

Understanding Standards

A number of programs certify and verify whether a fabric is made from recycled components like single-use plastic waste.

One is the U.S.-based REPREVE from Uni�i, Inc. Made from recycled plastic bottles, REPREVE yarns include FiberPrint tracer technology, which analyzes and validates the REPREVE �iber content. A third-party laboratory through the U Trust veri�ication program evaluates the fabric and determines the amount of REPREVE polyester.

“To be considered a REPREVE textile, the product must contain a minimum of 30 percent REPREVE yarn. This means at least 30 percent of the material used to make the textile must be made from recycled plastic bottles using the REPREVE FiberPrint technology,” continues Fisher.

Uni�i issues a certi�ication number and certi�icate annually. “This provides accountability in the supply chain and allows customers to verify that the product they purchase is made from sustainable materials,” says Fisher.

“The REPREVE program is revered because it provides a traceable and certi�iable way to verify that a product contains recycled content,” seconds Amitai.

Companies like UFabrik offer products using accredited recycled yarn, speci�ically yarn

produced from recycled single waste PET plastic waste, but it isn’t necessarily accredited by Uni�i or uses REPREVE. According to Platt, UFabrik is a fully certi�ied range, “which is a vital component in the procurement and speci�ication process.”

Another certi�ication method is the Global Recycled Standard (GRS) facilitated by the non-pro�it Textile Exchange. GRS includes a higher—50 percent—minimum recycled content percentage and additional social and environmental requirements related to processing and chemical use. A professional, third-party certi�ication body audits each stage in the supply chain to allow a product to be labeled with the GRS logo.

“Using a certi�ied recycled yarn—whether it be REPREVE or GRS certi�ied—helps monitor how yarns are processed and acquired. This is an integral part of providing recycled content products. It validates and sets a standard for all suppliers to follow,” explains Kylie Schleicher, director of product development and product management, Ultraflex Systems, Inc.

Ultra�lex categorizes its ReSource materials as those that are made with 100 percent GRS certi�ied recycled yarns. “We do have other materials that contain about ten percent recycled yarns,

but we do not qualify it as our ReSource, recycled yarn materials,” notes Schleicher.

Serge Ferrari is another example. As a European manufacturer, it utilizes high-quality, highly regarded European-made products in its Seemee Loop Mesh and Front portfolio.

“All polyester chips, yarns, and fabrics used in the manufacturing of all Loop products are GRS certi�ied according to GRS 4.0. It is certi�ied that the PET chips/ yarns/fabrics are made from 100 percent post-consumer waste,” shares Dr. Peter Siemens, R&D director, Serge Ferrari.

Fabric Type Polyester and

polyester-based fabrics are common contenders

1) Fisher Textiles’ ETP 4310 Uni is an apparel fabric for athletic uniforms. Made with 100 percent REPREVE and 100 percent post-consumer waste, it contains 20.5 water bo les per linear yard and is compatible with dye-sublimation transfer printing.

digitaloutput.net July 2023 | Digital Output { 23 }

1

for textiles made from recycled components, this is because plastic bottles essentially become sustainable polyester.

Other �ibers like nylon and spandex are incorporated with recycled components during manufacturing, admits Fisher.

Natural �ibers like cotton are generally not compatible—speci�ically in relation to REPREVE, according to Amitai, “because the process used to create the recycled polyester �iber requires high heat.”

Brennan says that it’s possible to incorporate recycled polyester into linen. For example, Premex Solutions offers a product that is 48 percent REPREVE polyester, 44 percent polyester, and eight percent linen.

companies mentioned

Bach notes that other fabrics can utilize recycled polyester, “but that limits or eliminates the opportunity for polyester pure recycling. In this case, it is best to keep the product 100 percent polyester contact.”

Despite Drawbacks

While there are advantages of using a textile made up of recycled content, there are also some disadvantages.

REPREVE textiles do cost more than both their non-certi�ied and virgin component counterparts. “This is due to the proprietary manufacturing process and certi�ication offered by REPREVE,” explains Fisher.

“Products made with GRS certi�ied yarns are more expensive

than products made with virgin yarns,” adds Schleicher.

Glaser says that in this vein, if a customer has to pay more for a product, it should be a quality product, in so much that durability and colorfastness be improved upon over its prior form. Although, he notes that the price difference between virgin polyester and recycled polyester is shrinking.

As a result, “print providers may be able to charge more for applications using REPREVE textiles, but the decision ultimately depends on market demand and the perceived value of sustainable products to their customers as well as their commitment to the environment,” admits Amitai.

“REPREVE yarns cost around 20 percent more than standard polyester counterparts. Therefore, this is re�lected in the price, which can be demanded from providers of REPREVE textiles,” suggests Brennan.

Luckily, there are really no other caveats to be aware of like ink compatibility or dot gain, wash fastness, or handling. And if there are any challenges, “companies like Greentex provide guidelines and recommendations for handling and printing to help ensure optimal results,” says Amitai.

“Generally speaking, no special handling is needed. Print and ink compatibility is the same as regular polyester,” shares Fisher.

“We have found there to be no difference in performance, printability, handle, or wash fastness when compared to virgin polyester fabrics. The only difference we have seen is the shade of the cloth. As the yarn is produced from recycled plastic there is a blue tint to the shade of the cloth,” says Brennan.

“The only difference between recycled versus virgin polyesterbased fabrics is the color white point has a slightly darker L* value,” adds Bach.

Glaser says that certain fabrics—while they include recycled components and meet standards put forth by companies like REPREVE—may not meet the necessary standards of the application in question.

“REPREVE nylon cannot be used in the outdoor �lag industry, to date. The luster type of the nylon created by Uni�i—semi-dull and dull—does not possess the required UV resistance to be useful for long duration, outdoor exposure. Should there become a bright luster version of REPREVE nylon, it would have the potential to change the face of the �lag industry as we know it,” acknowledges Glaser.

Fabric Does its Part

Consider working with textiles consisting of recycled versus virgin components the next time you quote a job. There are a variety of reasons to do so from minimizing what goes into land�ills and the ocean to conserving natural resources. Visit digitaloutput.net/ webinars to view a recent broadcast on the topic. D

July 2023 | Digital Output digitaloutput.net { 24 } 2

INFO# COMPANY WEBSITE 170 Aberdeen Fabrics, Inc. aberdeenfabrics.com 171 Fisher Textiles fishertextiles.com 172 Greentex America greentexamerica.com 173 Premex Solutions, Inc. premexsolutions.com 174 RePatriot Flag, LLC repatriotflag.com 175 Serge Ferrari sergeferrari.com 176 UFabrik ufabrik.com 177 Ultraflex Systems, Inc. ultraflexx.com See page 21 for more info.

2) Visual representation of how UFabrik converts post-consumer waste to its fabric.

any printers are familiar with magnetic and magnetic-receptive media options. However, when you consider all of the heavy metal involved in finishing, one might wonder what possible challenges could pop up.

“Magnetic material is relatively easy to work with and can be cut easily. However, the proper blades and settings are required,” says Brian Ebenger, VP, business development, Xcel Products, Inc.

Raum Divarco, GM, Cutworx USA, insists that the application is always one of the key factors for any project—magnetic or not. He points out that when finishing magnetic and magnetic-receptive materials, brand, thickness, and intended cut process should be considered. “For example, maybe the available finishing platform is a traditional platen-style die cutter. If the material is magnetic or magnetic receptive, you may have to take steps to minimize the material wanting to stick to the platen plate.”

For digital die cutting machines, Divarco recommends considering the type of tooling used. “While these materials are generally relatively thin, they can wear out low-grade blades. If your project is for more contour cut shapes you may need to consider if blades will cause a raised edge—otherwise known as a lip—along the cut. Some of these results may be unacceptable for your customer. There

digitaloutput.net July 2023 | Digital Output { 25 }

by Digital Output Staff

Above) Zünd cutters equipped with a Zünd UCT are able to cut any thickness of magnetic foil with a drag blade at full machine speed—40 in/s.

are options for asymmetrical tools that significantly reduce the raised edges on thicker materials.”

Additional considerations may come into play if the magnetic vinyl has adhesive mounted to it. “Certain adhesives might require your operation team to occasionally clean the blade. This is to minimize drag force from friction as well as reduce tracking adhesive residue,” adds Divarco.

According to Sara Marshall, applications specialist, Zund America, Inc., with a Zünd digital cutting system, cutting printed magnet foil is easy. “Even if the material comes off a roll, the vacuum system provides the necessary hold down to keep it flat and enable precisely cut edges with very minimal bleed.” She adds that Zünd digital cutting/routing systems are capable of cutting any material—short of plate glass and steel—including magnetic and magnetic-receptive solutions.

Magnetic-receptive options aren’t magnetized when printed, so they won’t stick to metal. But, Ebenger points out they tend to be thinner and lighter than magnetic materials.

“Magnetic-receptive materials are generally thin and the volume of the job and the setup of the layout might require some extra thought,” agrees Divarco. “If the

layout is set up to be common cut for smaller pieces, you might need to make sure your vacuum zones are optimized. Smaller pieces on what can be more rigid type materials may slide around. An option to minimize parts shifting could be depth control to allow the pieces to be stripped out of the sheet. Your operation team could also consider putting down magnetic sheets as the cutting underlay. For smaller pieces or sets of images this can assist in collating when the sheets come off the table.”

Recommended Tools

Several finishing tools are well suited for magnetic and magnetic-receptive media options including a router; die cutter; digital cutting system; and manual cutters, knives, and scissors.

“Tangential drag knife cutting tools would be some of the most commonly used for cutting magnetic materials. There are various profiles, grades, and thicknesses to choose from for every project,” shares Divarco.

To cut printable magnet foil, Marshall says customers will use a Zünd Universal Cutting Tool (UCT) with a standard drag knife (type Z10) blade. “The tungsten carbide blade easily makes its way through the material on common shapes, complex contours, and tight edges. This material can

be cut at the maximum speed of 40 inches per second (in/s).”

Of all the options, Divarco notes that router and laser cutting are the least practical. “Router cutting can work but is prone to being messy. This is especially true with adhesive-backed materials. There will be shavings and other potential sticky debris and the processing speeds are much slower than using knife blade tools. Overall, it is a poor choice in the process for this application.”

Marshall adds that other blade and tool options can be recommended depending on the thickness of the material and the complexity of the shapes; however, Zünd does not recommend using a laser to cut this type of material.

“Laser processing for this application is not recommended in my opinion. Certain materials shouldn’t be laser cut depending on their composition. You can get burning, melting, and various other effects that are easily avoided with a knife cutting system,” suggests Divarco.

Thickness Considerations

Of course, the thickness or thinness of the material affects which tool should be used and at what setting.

“All settings impact the cutting of the material so the gauge will play a critical role in the success of the material,” says Ebenger.

Thicker materials typically need a robust cutting solution, adds Divarco. “The thin blades used on

thin sheets for contour cuts might not have too much resistance or deflection at .015 inches. The same thin blade might struggle to process materials when the thickness gets to .06 inches. The thicker the material gets, you may need to manage overcuts in interior corners for contour shapes.”

Divarco adds that some tooling options, like asymmetrical tools, help keep cuts smooth on thicker materials.

For larger volume runs Divarco suggests exploring partial depths of cuts similar to kiss cutting. With depth control and the fairly dense nature of the materials, you can easily strip out most of the pieces from the sheet. “This helps manage cycle times for sheets on and off the table.”

Finishing Magnets

The Colex Finishing, Inc. Sharpcut Flatbed Cutter can easily cut magnetic material. It is capable of cutting up to 64 inches wide and up to two inches thick offering versatility, speed, and price.

Among its cutters, Cutworx Miura XY cutters are well suited for cutting flexible magnetic and magnetic-receptive materials.

Zünd cutters equipped with a Zünd UCT are able to cut any thickness of magnetic foil with a drag blade at full machine speed—40 in/s.

Magnificent Magnets

When it comes to finishing magnets, considerations for thickness and material composition should be top of mind. D

companies mentioned INFO# COMPANY WEBSITE 180 Colex Finishing, Inc. colex.com 181 Cutworx USA cutworxusa.com 182 Xcel Products, Inc. xcelproducts.com 183 Zund America, Inc. zund.com See page 21 for more info. July 2023 | Digital Output digitaloutput.net { 26 }

#4

#9

safe backup when a printer is than others.

safe backup when a printer is than others.

#13

#14

#12

#16

#17

#13

#14

#12

#16

#17