JANUARY2025

ING seLUTI , AND PUBLIS

The print industry never stops innovating. As a publication dedicated to the digital side, we at DPS magazine watch as more segments embrace the advantages of the technology, from cost-effective, short runs to personalization, shorter turnaround times, and just-in-time production.

The label and packaging segment is one area where the adoption of digital print is emerging. A variety of digital label printing equipment, from desktop to wide format and roll-to-roll solutions target runs from one to

A variety of digital label printing equipment, from desktop to wide format and roll-to-roll solutions target runs from one to 10,000.

10,000. We discuss how automation and sustainability demands fuel digital growth in Leveling-Up Labels. Find a Target Chart detailing digital label systems also in this issue, as well as more in-depth coverage at dpsmagazine.com and dpsmagazine.com/webinars.

Our last issue featured the annual Year in Review piece. We continue the discussion in this edition with a look at essential advancements to the digital print landscape in Digital Growth Continues. These include inkjet maturity, artificial intelligence, smart automation, and digitization.

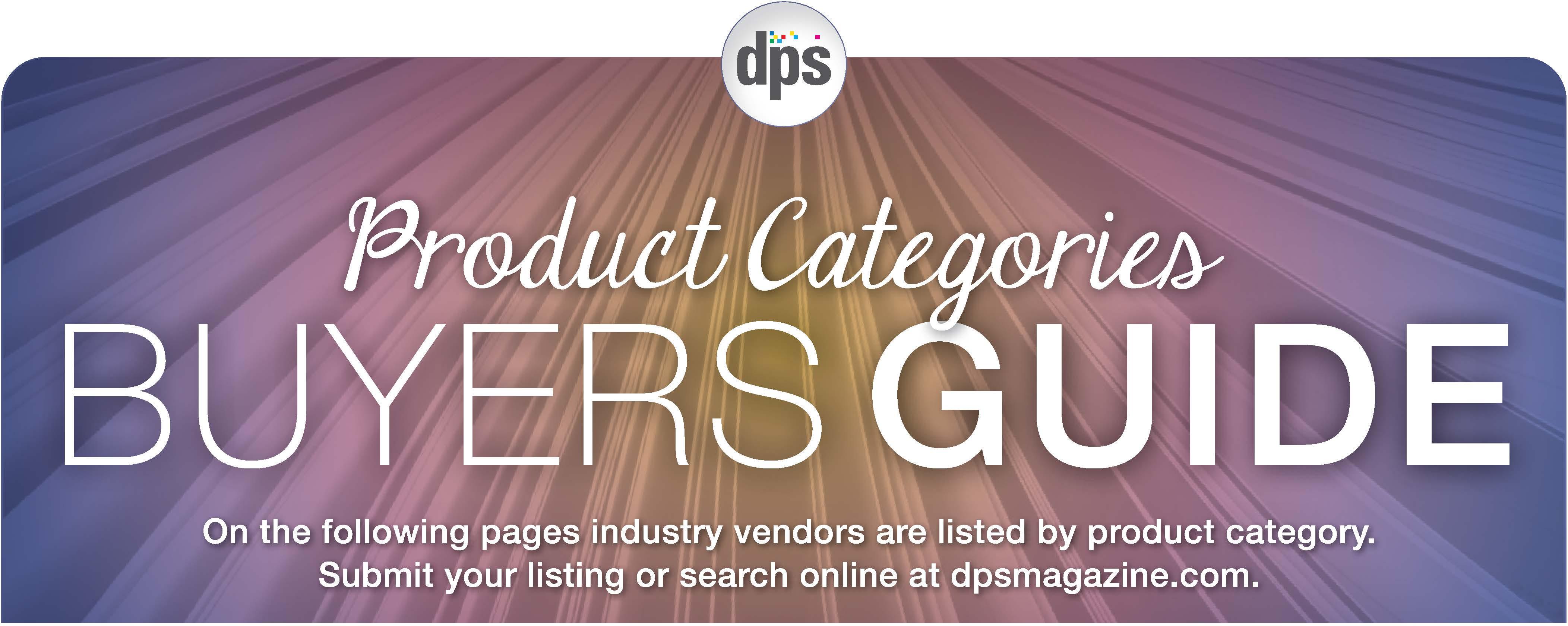

The vendors that lead the growth in digital print are located in our Buyers Guide. Of course, you’re always welcome to peruse it online anytime at rcpbuyersguide.com.

Find the printed version, which is published once a year, on page 20. We also highlight the upcoming Hunkeler Innovationdays, which takes place next month in Switzerland. Find more information on this event at dpsmagazine.com, including exhibitor highlights.

Happy New Year!

Cassandra Balentine, editor cbalentine@rockportpubs.com

dpsmagazine.com

Volume 27, Number 1 • ISSN: 1529-2320

EDITOR IN CHIEF

Thomas Tetreault

978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

300 Newburyport Turnpike, Ste. 11 Rowley, Massachusetts 01965 Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 300 Newburyport Turnpike, Ste. 11 Rowley, Massachusetts 01969

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER

Missy Tyler

By

Hunkeler Innovationdays takes place from February 24 to 27, 2025 at the Lucerne exhibition centre in Switzerland. The international print event is focused on high-performance digital printing and finishing. Under the theme “CONNECT,” a clear message is sent—in Lucerne, the leading minds of the digital printing industry will once again gather to experience and shape the future of the industry by connecting people, solutions, and processes.

Every two years, Hunkeler AG, a leading provider of digital printing and finishing solutions, organizes The Hunkeler Innovationdays event.

Founded in 1922, Hunkeler AG has grown from a small Swiss company into a global leader in paper processing and digital printing technology. The company is known for its high-quality, innovative products and strong customer focus.

Approaching the 15th installment of the event, The Hunkeler Innovationdays started out as a small open house and evolved into what it is today—a significant global gathering for the digital printing and finishing industry.

Approximately 6,700 visitors from 100 nations traveled to the event in 2023, compared to 6,500 visitors in 2019, according to the event website.

The 2025 edition of Hunkeler Innovationdays is expected to feature several changes and enhancements. For example, the event now features more space and expanded premium and standard stands. The catering area has been relocated to a quieter environment to facilitate better networking opportunities. Additionally, there will be more production printing systems on display, including both continuous and sheet-fed systems. These changes reflect Hunkeler AG’s commitment to constantly improving to meet the evolving needs of exhibitors and visitors alike.

Exhibitors represent leading suppliers from the prepress, digital printing, and

finishing to substrates, consumables, and software. These companies plan to present and introduce some of the latest products and solutions.

Notable exhibitors include Canon, Fujifilm, Gelato Connect, Heidelberg, Horizon, HP, Hunkeler, Kodak, Kurz, MBO/Komori Groupl, Muller Martini, Ricoh, Scodix, and Screen.

Grüezi

Hunkeler Innovationdays 2025 offers industry professionals a reason to come together to grow and learn. Find more information on the event, including a web-exclusive round up of exhibitor highlights, at dpsmagazine.com. dps

1.& 2. Hunkeler Innovationdays last took place in 2023. This February it will once again occur in Lucrene, Switzerland.

By Cassandra Balentine

Digital print and supporting technologies meet evolving demands for a growing list of scenarios and applications. "In settings where on demand, short run, or variable printing is required, digital printing can enable quick turnaround and lower changeover costs," confirms John Butler, senior director, North America Sales, Teledyne DALSA.

Dario Urbinati, CEO, Gallus Group, is excited to see the continued rise of digital printing technologies and innovation. ''As the digital landscape grows and evolves, the benefits ofdigital-such as more profitable short runs, personalization, and on demand printing-will become more accessible."

Simon Lewis, SVP marketing, strategy and business development, Highcon, attests that digital maturity means companies are focused on digital impact."This means software,

automation, integration, a holistic approach, an end-to-end view, and lots of hard work."

While investing in a piece of digital print equipment may be "easy" compared to reinventing workflows and production flows, Lewis stresses that it typically requires expertise that may not be present in the organization. "It requires lots of people to change what and how theydo things and different kinds ofcollaboration:'

Advancements in inkjet and other digital print technologies continue to dominate the short-run market with fast turnaround times, flexibility, and color accuracy, confirms Marc Raad, president, Significans Automation.

Above: OutputexamplesfromCanonproductionprintequipment.

"Now more than ever, inkjet has becomeasurvivaltool. It'sinkbutonadigital platform thatanyone can use," shares JesseHeindl, marketingmanager, RISO.

Dustin Graupman, senior direct, inkjetdivision, KyoceraDocumentSolutions America, Inc., agrees, noting that entry-level cutsheet inkjet technology is on the verge of becoming competitive with toner, particularlyinproducinghigh-qualityresultsongloss-coatedmedia.

Inkjet is also making waves in higher production segments. Lance Martin, VP productmarketing,KomoriAmerica,says sheetfedinkjetoptionsmadea"quantum leap in productivity. The proliferation of higher speed B2-plus size inkjet presses isremarkable."

Earlier this year, Komori announced the ]-throne 29 UV Inkjet, B2-plus size press for this market with production speeds of 6,000 sheets per hour, which Martin says doubles previous offerings. "This new technology fits well with existing offset-Komori's other core technology-processes for commercial print. We believe the model of the commercial printerforthenearfuturewillbeahybrid ofoffsetandinkjetprinting, anda myriad of finishing options, all under the same roof," heattests.

The increase of B2-format solutions are designed to facilitate the transition from offset to digital printing. "However, this range of options has, for some customers, resultedin'paralysisbyanalysis,' as they struggle to choose between too manyalternatives,'' admitsGraupman.

Inkjet and other digital print technologies is also influencing label andpackageproduction.

Steve Lynn, director of labels and packaging, Durst North America, believes that 1,200 dpi inkjet took a strong foothold in the label industry over the past year. "This technology has been around for a few years but this year we saw acceptance that it is a stable technology that can replace flexography and slower, inefficienttonertechnology."

The packaging print sector is experiencing growth driven by ecommerce and the consumer's need for innovative and interactive packaging solutions that also serve as marketing tools, comments Raad. "On demand printing services are also expanding, especially opportunities forcustomizedandpersonalizedprint."

"Inkjetisquicklybecomingamorecost effective and sustainable way to produce customized, short-run packaging and labeljobs. One of the most exciting launchesatdrupa wastheXS Nozomifrom EFI andPacksize.It'sthefirstfull-color,on-demand, right-sized box system that transformsblankcorrugatedintopersonalized, on-demandboxesinseconds," offersJohn Henze,VP,marketingandsales, Fiery.

Theadoptionofadvancedvariabledata printing and codeverificationcapabilities is supportedby the globaltransitionfrom retail barcodes to quick response (QR) codes. "Packaging converters add monochromeprinterstotheiranalogpackaging lines to support the transition, with code inspection and verificationtechnologyoften deployed to providereassurancethat all individual codes generated and printed are valid,'' shares Michael Matthews, product managerDP Colour, Domino PrintingSciences.

The biggest advancements in coding and marking are regulatory products necessary for brands to adhere to new, stricter barcode standards. Printing systems are now capable of producing ultra-fine details-barcodes, QR codes, batch numbers-at high speeds without compromising quality. "The new printheads and ink delivery mechanisms reduce smudging, misprints, or fading, especially important in industries like pharmaceuticalsandfoodandbeverage, where readability is crucial,'' explains Pat Hamett, director of portfolio and development, HP SpecialtyPrinting and TechnologySolutions.

Vision inspection and monitoring are also popular for color label printing applications where consistent, reliable quality can be a key selling point, providing peace of mind for brands and securingthoseall-importantrepeatorders, adds Matthews.

Finally, "inkjet, wide format, and textile printing continues to evolve and impress, enabling unique, customized printproducts,'' says Raad.

Artificial intelligence (AI) has officially entered the discussion, but it hasn't yet takenhold.

Piet De Pauw, head of marketing, Enfocus, says 2024 was the year AI really started to take center stage in the industry, "but we're still only scratching the surface of its potential applications inprinting."

Lewis comments that AI can be part of the road to digitalization now, but it doesn't necessarily have to be. "The AI revolution is yet to arrive. And for many businesses, this frightening and threat

erring reinvention of how to work to

enjoy the digital dividend is sufficiently

· r- 1. Sharp's Digital Production Press Series models include real-time image quality adjustment, precise paper handling, and advanced job management.2. OutputexamplesfromHPPageWide inkjetpresses

challenging without getting into the cutting edge of AI. None of this obviates the need or business case of investing in new equipment. Digital die cutting, for example, is the only way to deliver a never-seen-before carton job within a day or two of receipt. But when the company’s automation infrastructure and workflow capabilities support this kind of performance, it makes it much easier to really deliver the impact for customers and the converter,” he suggests.

Print providers and buyers will be able to leverage AI technology for better targeting, messaging, automated workflows, and optimized print production, etc., predicts Tonya Powers, senior director of marketing, Client Services Group, Canon U.S.A., Inc.

Naimish Patel, VP of sales, OnPrintShop, points out that AI plays a pivotal role in web to print, especially in terms of image and content creation. “Print shops can leverage AI to generate product mock ups or design images based on templates, making it easier to personalize designs without additional resources.”

The rise of AI is relevant to the production domain, where workflow and printing processes saw the introduction of advanced AI tools to improve yield and ensure perfect output, shares Nir Zarmi, SVP, growth and strategy, Landa.

Moreover, the use of generative AI in text, messaging, and image creation is extensive. “This holds the promise of a boost to highly agile, variable data printing at levels unknown previously,” comments Zarmi.

“AI integration is increasingly embedded into printing processes, optimizing workflows, enhancing predictive maintenance, and improving overall efficiency,” notes Mary Gay Pettit, public relations, Markzware, Inc.

Ernie Crawford, M-EDP, president/ CEO, Crawford Technologies, feels that some of the print industry’s biggest advancements have been the integration of AI and other cutting-edge technologies

across the entire production process. “What stands out even more is the industry’s ability to adapt and harness these innovations effectively. AI is now embedded in various aspects of print, from job onboarding to production workflows, with AI-powered robotics and machine learning driving unprecedented levels of automation. Tasks that once took weeks— such as complex job setup or application configuration—are now completed in minutes, drastically improving efficiency.”

Aron Allenson, product manager, highspeed continuous-feed inkjet, Screen Americas, says as its number of machines in field continue to grow globally and the presses themselves print more, he is seeing engineers leverage the mountains of service data and machine learning to design efficiencies and automation into the press. “These innovations are focused on pushing boundaries—color, productivity, reduced running costs. But more recently there has been heightened attention on the question, 'What tasks has an operator historically done that the machine can do itself?’ It turns out there are lots of tasks that fall into two related categories. One, tasks the machine can completely do itself, and two, tasks where the operator makes the subjective decision and the machine does the rest.”

The print industry’s openness to embracing AI as a core component of its operations marks the most significant

innovation this year. “The print sector, which has reinvented itself multiple times over the past century, is transforming once again—this time into a technology-driven, communication engine. The move toward AI-infused processes signifies not just a step forward, but a fundamental shift in how print services are delivered, enabling real-time responses, reducing errors, and lowering operational costs,” shares Crawford.

Automation is necessary and available across every segment of print production.

“As printers face increasing pressures to innovate, assessments show that embracing new technologies and strategies—like adopting automation— can maximize production efficiency and expand service offerings. This proactive approach is critical for meeting evolving customer demands and expectations,” notes Raad.

Powers points out that enhanced workflow automation and improvements in workflow automation software are enabling more efficient print production processes. “These systems help manage jobs, track inventory, and streamline communication, reducing turnaround times.”

Rodney Pennings, sales director, Print & Packaging, BW Converting, sees a push for automation and innovation to address the ongoing workforce shortages seen

throughout the industry. "This includes everything from automation on critical features of presses to make reliable operation more repeatable and less dependent on the operator's skill level, to advances in core technologies like wider and faster digital presses for flexible packaging. Even the simple implementation of combining multiple process into one step-such as inline lamination of digitally printed flexible packaging material-reduces the number of operators needed and simplifies operations in the manufacturing processes."

The focus on "intelligent" automation of production floors is another trend. "This is evident in new, more productive presses, like the HP Indigo 120K, the use of robotics in collaboration with the presses and other physical production equipment, and an holistic view of production floor management," offers Nimrod Cohen, head of strategic marketing, HP Indigo.

William Longua, senior director, Digital Print Group, Quadient, also says advancements in automation were prevalent this past year. Quadient introduced the MACH 9DS, which integrates its newest color inkjet technology with intelligent DS-700iQ inserters to combine functions so fewer operators can complete formerly separate tasks into one seamless operation.

Andy Fetherman, president/CEO, Muller Martini Corp., feels some of the biggest innovations this year relate to Smart Factory solutions that integrate multiple processes into a single system.

3.The KomoriJ-throneisa B2-plusUVinkjetpress.

''A great example of this was the Muller Martini drupa 2024 debut of the new roll-fed SigmaLine Compact book block production system configured directly inline with the new Antaro Digital perfect binder and InfiniTrim robot trimmer all driven by the Connex Workflow System-a true file-tofinished product workflow solution that minimizes labor requirements, while still maximizing the production of the line."

There are several ways to add value to digitally printed applications across a variety of sectors.

''As competition from digital media continues to challenge the industry there is growing demand to make printed pieces even more impactful. This has led to advancements in digital print embellishments, unique finishing applications, and growing demand for personalized print products," shares Terry Antinora, SVP/head of product and engineering, Xerox Corporation.

Dino Pagliarello, VP of product management and production print, Sharp, notes a renewed interest in differentiation in the market. ''A lot of this has to do with our customers wanting to stand out from their competition when it comes to creativity and product development."

Specialty effects that go along with print have been around a while but are becoming more mainstream. This can be metallics, the use of varnishes, and colors beyond CMYK. "Because of the software and tools available today, as well as the education and training available to leverage those types of creative

capabilities better, this differentiation

print have become more mainstream," offers Pagliarello

In 2024 the industry saw major introductions of specialty inks, toners, and coating technologies, enabling the differentiation of print over other forms of media. "Today, manufacturers of digital presses and printers are taking digital to an entirely new level by moving beyond simple CMYK print. This, together with personalization, gives print a competitive advantage with brands when dealing with new target markets," comments Mark Geeves, director of sales and marketing, Color-Logic Inc.

Scodix introduced its Multi-Layer Enhancement technology, which Eli Grinberg, CEO, Scodix, says is designed to revolutionize the embellishment process. "It allows for multiple Scodix layerstobeappliedinasingle pass, offering a more economical solution for complex effects like braille and crystal finishes."

Gallus recently announced its MatteJet technology, which was shared at Labelexpo Americas 2024. "By unlocking fast, cost effective, and high-quality inline matte finishing, MatteJet brings digital inkjet to the wine and spirit label market for the first time-and represents a promising development for the industry moving forward," explainsUrbinati.

Security enhancements are another way to add value. "Due to increasing incidents of fraud and counterfeiting, the print industry is making more use of security features in printed documents. These features include color-shifting inks, holographic watermarks, and the use of highly intricate design detail and complexity. In addition to requiring sophisticated printing technology to produce, the result relies on equally sophisticated lighting and imaging technology to inspect adequately and accurately," offers Butler.

In addition to mechanical and workflow and the ability to do creative things with updates, advancements in primers, inks,

toners, and media also drives digital print adoption.

“Advances in substrates open new opportunities for print and can range from synthetic papers that are water- and tear-resistant to eco-friendly and biodegradable substrates made from renewables that minimize ecological and environmental impact. These all introduce new variables to overcome and promote the evolution of handling, printing, and quality inspection techniques,” says Butler.

Some of the new water-based digital inks, using a wet primer, create new capabilities, and offer the potential to replace conventional printing where previously this was not possible e.g. flexible packaging. “Higher throw distances—distance between inkjet nozzles and item being printed—from high-resolution inkjet printheads will see this

technology transition into printing three-dimensional object e.g. for coding and marking, and more industrial printing applications. Ongoing trends for conventional printing reduce setup time and waste, while digital printing is getting faster and higher in print quality,” explains Philip Easton, managing director, Industrial Inkjet Ltd.

Last year, Andrea Connor, worldwide solutions marketing manager, Kodak, notes that Kodak introduced several significant advances and innovations that help printers meet today’s industry challenges and achieve long-term success. These include the new efficiency-enhancing and cost-saving OPTIMAX Pre-coater for the KODAK PROSPER ULTRA 520 Press.

Scodix introduced the Scodix Uncoated application, which Grinberg

says addresses the growing demand for high-quality printing on uncoated paper. “This innovation not only expands creative possibilities but also supports sustainability efforts by enabling enhancement on eco-friendly substrates.”

Jeff Leto, VP, NBi FlexPack, adds that Electronic Beam Coating technology, which puts a protective coating/finishing over an imaged area and cures it instantly and completely, can also add a layer of protection against biological contamination killing all bacteria and viruses during the curing process that may have been on the films prior to finishing.

Many innovations in the digital print space involve advanced workflow solutions and connectivity that start with the customer.

Craig Powell, GM, North America, printIQ, says with most systems now put the customer in control of their order, from proof approval to live status updates. “We see automated prepress tasks that ensure a file meets all the requirements of the press and even creates the imposed file for printing. Our cloud-based MIS system tracks the order from placement to press, integrates with accounting and shipping solutions, and gives an over-arching view of the business, from anywhere in the world.”

Connor says Kodak introduced PRINERGY Access 2.0, a SaaS Digital Workflow solution that puts print buyers in control of file preparation from upload to approval for seamless connectivity to any digital press or print workflow.

This year marked a pivotal shift from discussing W2P solutions to actively implementing them, shares Dmitry Sevostyanov, CEO, Customer’s Canvas. “Printers are now launching W2P storefronts, driven by the need to keep up with competitors who have already adopted these platforms.”

See page 18 for more information.

InSoft Automation Pvt. Ltd. insoftautomation.com

Kodak graphics.kodak.com

Komori America komori-america.us

Kyocera Document Solutions America, Inc. kyocera.com

Landa landanano.com

Markzware, Inc.

Scodix scodix.com

Screen Americas screenamericas.com

Sharp business.sharpusa.com

Significans Automation significans.com

Teledyne DALSA teledynedasla.com

Xerox Corporation xerox.com

“We’ve seen growing demand for cloud connectivity and data capture functionality, with businesses proactively inquiring after digital capabilities that will provide them with actionable data insights. “Advanced data capture and cloud connectivity support in-depth analysis of production and consumption data—considering the print volume produced, time spent, and the resources consumed, which print providers can use to streamline production processes to run faster and more efficiently in the future,” shares Matthews.

Santosh Mulay, VP, business development, InSoft Automation Pvt. Ltd., feels that while the innovations this year may be subtle, they provide a significant impact. “For example, unmanned setups of multiple jobs printed on different sheet sizes of varying colors and coatings seamlessly streamlined without human intervention.”

We see continued movement in digital adoption, increased focus on workflow, and the use of AI. While the role of print is changing, it is moving in a direction that is smarter, faster, and more sustainable.

Rolando Martinez, head of HP PageWide Commercial Products and Solutions, HP Industrial Print, points out that the ecommerce boom that many industries enjoyed during the pandemic continues and is a major driver for print on demand opportunities as digital buying behaviors revolutionize demand. “As commerce shifts online, businesses require smaller, customized print runs that can match rapid ecommerce delivery speeds and expectations.”

Short-run digital printing offers an agile approach to print production, which enables the on demand production of books, magazines, printed materials, packaging, invoices, direct and transactional mail, branded unboxing materials, return labels, and other collateral. This approach allows variation in colors, finishes, and designs too—unlocking unique branding and marketing opportunities. dps

automation and sustainabil" mands for man . ity top the list of de Y pnnt pr d •and packaging sp T o ucers m the label found with1"n d" . a l ee. he solution is often h. 1g1ta p • is mg technologies. nnt and supporting fin-

In the next few d . years Ja K uct10n solutions Can , U son oyama, advisor pro ued . ' on .S.A. I 'growth m digital lab 1 ' nc., expects continemph · e productio • h as1s on sustainability. ''Aut n wit a stronger omatlon and inte11·1gent

systems will play a ke • of a shri ki y role m counterin h . n ngtraditionallabel g t e pressures c1ent, eco-friendly pr d . market, driving more effi . . 0 uct10n"D1g1tal label prod t· ti d uc ion offer on an effectiveness for h s greater customizareq s orter ru d umng quick t nsan applicat urnaround ''Ad . ions packaging, ecommerce 1 s. . d1tionally, trends in , ncreasmg Above:Xaar'sVersatextech I number of SKUs abledataforpremiumlab lnoogya_ddsvarnishembellish ' e production. mentsandvari-

as well as the need for personalized products will push the demand further beyond the next five years,” predicts Paul Albano, senior product manager, Toner Press Solutions, FUJIFILM North America Corporation, Graphic Communication Division.

“As digital print technology continues to evolve and replace analog machines, the possibilities for personalization and embellishments in labels will expand, allowing brands to meet the increasing consumer demand for products that feel as unique as they look,” comments Justin Noble, director of sales, Xaar.

In the coming years Kevin Davis, CEO, SnapPress, company of Allen Datagraph Systems, LLC, expects digital label production to focus heavily on sustainability, personalization, and technology integration.

Automation, quality, sustainability, and added value are all factors driving digital adoption in the label space.

Juan Kim, CEO, Valloy Inc., says digital label production must fulfill the demand of real automation from prepress to finishing, similar to other industries like book manufacturing, textiles, and packaging. “The speed game has almost ended and now the key is to complete labels with a fully automatic process.”

Advancements in speed and automation allow digital printing to support faster, just-in-time production that enables brands to react quickly to trends and launch personalized products. “The result will be more efficient, flexible, and sustainable label solutions that align with evolving consumer expectations,” says Davis.

John Cusack, product line leader—inspection, color, registration, BW Converting, expects the evolution of digital label production to emphasize automation, precision, and high-speed efficiency.

“With digital press systems in this space currently achieving speeds that exceed more than 400 feet per minute (fpm), the demand for robust inspection solutions that offer automated Delta-E color monitoring, barcode recognition, and dynamic learning will increase as converters look for ways to streamline quality control to match the pace of these recent advancements in press speeds. As standalone digital and hybrid press systems increasingly capture more traditional flexographic markets, sophisticated inspection solutions become vital in maintaining consistency and quality across end-use segments.”

Mike Pruitt, senior product manager, Epson America, Inc., expects digital label production to fill in all volume and print quality segments with presses that improve reliability and feature lower costs per label in the near future.

Sustainability needs are inherently addressed with digital print’s ability to print on demand. Additional advancements support a push for eco-friendliness.

“There’s a big demand from our customers for increased sustainability in their packaging, which includes digitally printed labels,” offers Jennifer Loegering, director of marketing, Primera Technology, Inc. “To meet this demand, the company is working with a number of pressure-sensitive materials suppliers to offer compostable and recyclable alternatives for labels, liners, and adhesives. At the same time, we’re working with ink companies to offer inks that are also compostable. They’re not here yet, but they’re in the labs being developed.”

Taylor Buckthorpe, director of sales and marketing, Colordyne Technologies, agrees, noting that sustainability focused innovations, including eco-friendly inks and recyclable substrates, align inkjet with brands’ environmental goals. Together, these developments make inkjet more adaptable, efficient, and environmentally responsible, meeting the market’s demands for flexibility and quality.

Digital print and finishing technologies also add value through personalization and embellishment.

Noble offers that textured and highbuild print effects, varnishes, foils, and mass personalization all become available with Xaar’s Versatex Printbar, which can both be integrated with new machine configurations or retrofitted onto existing presses. “By enabling opacities of 85 percent at 50 meters per minute, the Versatex achieves brilliant whites and vibrant colors, producing eye-catching digitally printed labels that are comparable to screen print technology.”

Embellishments and tactile features and foils are easily added into labels “not only differentiating premium products on crowded shelves, but also strengthening brand identity and consumer engagement. Raised textures and highbuild varnishes through to matte finishes and spot varnishes can all be printed in a single pass, meeting the demand for efficient production. In addition, the Versatex’s ability to jet high viscosity fluids improves the efficiency of digital label production as well as adding more functionality,” shares Noble.

Davis also notices a shift towards interactive packaging through augmented reality and smart labels, and the ability to produce highly customized designs on demand.

Digitalization of printing equipment continues to be a trend, and Michael Matthews, product manager – DP Color, Domino Printing Sciences, foresees a further increase in popularity going forward.

“Companies such as commercial printers and brand owners/in-plants show more interest in bringing label production in house and we will continue to see this expand,” shares Russell Doucette, product marketing manager, Konica Minolta Business Solutions U.S.A, Inc. “The ease of use and efficiency of these products enable companies to offer more services

and products. Commercial printers who thought it was too expensive or complicated to expand into label production are seeing digital technology that is as easy to operate. As brand owners and inplants assess and streamline their manufacturing processes, they will quickly notice the advantages of controlling often overlooked components (i.e. labels) to influence and improve their production lines. Just-in-time production offers companies the ability to move and pivot accordingly to meet market demands.”

Strides in inkjet are also making an impact on adoption. “Digital label production—particularly 1,200 dpi inkjet— will be a large part of label production in the next five years,” predicts Steve Lynn, director, labels and packaging, Durst Image Technology US LLC.

Lynn explains that at this level, inkjet delivers the required quality at high speeds and low cost to deliver short, medium, and long-run jobs effectively.

As digitization continues in the label space, James Thomas, head of sales and business development, Focus Label Machinery Ltd., sees the consolidation of machinery suppliers, smaller businesses being sold or merged with larger companies, ever shorter run lengths, and on demand production demands growing, all-inclusive click models from manufacturers becoming the norm—especially for basic reel-to-reel CMYKW equipment.

Digital label production continues to replace traditional analog print technologies to meet consumer demand for unique, tailored products. “As part of this

step change, hybrid approaches increase as label producers look to add digital capabilities to existing presses to provide the personalization and embellishments on labels that are increasingly required,” says Noble.

Matthews predicts adoption of digital label printing technology to increase— with a particular interest in hybrid printing. “Hybrid printing enables converters to incorporate downstream coding or labelling at the label converting stage, reducing overall costs.”

Converters looking to maximize production capacity turn to hybrid lines to reduce changeover times between labels and inline RIP software to eliminate setup delays, explains Matthews.

Beyond equipment, Matthews notes growing demand for cloud connectivity and data capture functionality, with businesses proactively inquiring after digital capabilities that provide actionable data insights. “Advanced data capture and cloud connectivity support in-depth analysis of production and consumption data— considering the print volume produced, time spent, and the resources consumed, which print providers can use to streamline production processes to run faster and more efficiently in the future.”

While the advantages of digital and hybrid label production are attractive, challenges still hinder adoption.

Pruitt says the biggest issues he sees today include the high capital expense for reliable digital label presses, as well

3

Another challenge is understanding the growing landscape.

as the lack of personnel to operate machines. "These go hand in hand as installing a digital label press represents a significant expense, not only in the machine itself, but also the related infrastructure required to support the new technology, including the cost of hiring additional, skilled employees to operate the press and offload the business with the expectedincreaseoforders. Both factors-financial and operational-present challenges to the widespread adoption of digital label printing technologies."

3. Focus Label provides specialized stand alone finishing systems, integrated digital print and finishing, and fullhybrid flexographic digitalsolutions integratingtoday'sleadingtechnology.

With the amount ofsuppliers, Thomas admits that it's difficult for companies not in the digital space to know where to purchase. Therefore it is important to understand how to sell digital to their markets in terms of return on investment, TCOP/TCOO, and determining that the lifetime associated costs and pricing work accordingly.

Buckthorpe states that digital printing in the label market faces challenges like high initial costs, material compatibility, and limitations with large-scale runs, "but ongoing innovations and industry efforts are steadily overcoming these obstacles, paving the way for broader adoption and greater flexibility."

Additionally, keeping up with technology advancements and increasing complexity of data requires an initial expense and learning curve as employers will need to invest in up-skilling their workforce. It should be noted that digital label printing is often less ideal for longer production runs, so this may affect adoption especially in environments where there are high-volume labeling needs," says Albano.

Dario Urbinati, CEO, Gallus, points out that printproviderstoday face a volatile market environment and companies are understandably conservative about making significant financial investments. "This is why it's critical to invest in technology that is both flexible and agile, allowing for adjustments as market needs evolve."

Cusack admits the transition from traditional flexographic production to producing labels on digital and/or hybrid presses can be challenging, especially for companies navigating a digital press installation for the first time. "The learning curve of migrating flexographic artwork files to digital can be a daunting given the intrinsic differences between analog and digital front-end processes."

Video inspection systems are another tool to help ease this transition by simplifying job setup and reducing the technical learning curve associated with migrating from flexography to digital print technology. Addressing some of these operational challenges with accessible, automated inspection solutions will be key to broader adoption in the industry, shares Cusack.

Koyamaadmits it can be difficult to integrate next-generation technologies and business models in a way that complements existing workflows and methods. 'Mordability and seamless integration remain crucial to driving wider adoption:'

Advancement Across the Board

Technology advancements address some of the challenges hindering the adoption of digital label printing.

In the entry-level space, which we loosely define as 1,000 labels per run for this article, ease of use and lower investment costs attract new investors.

“As digital printing technology continues to improve, equipment is becoming more affordable, thereby reducing the initial investment,” shares Albano.

Digital printers are engineered with longer lasting components, higher supply yields, and easier maintenance to help reduce overall costs. “These advancements make digital label printing more accessible, efficient, and cost effective, helping to overcome some of the key challenges in this segment of the market,” says Albano.

“Larger printer manufacturers, including Epson, have high-quality printheads that are increasingly becoming available to this market segment. With the adoption of high-quality printheads, manufacturers are able to increase reliability and print quality while driving down end user costs,” offers Pruitt.

Ben Luly, product manager, Mark Andy, points out that the entry-level market also demands workflow automation at all levels, along with easier-to-use solutions to produce high-quality products at fast turnarounds.

Davis says SnapPress helps label businesses optimize short runs, reduce waste, and limit labor needs with user-friendly operations. “By providing smaller, customized print runs, it allows commercial printers to stay profitable with low-volume orders, making small production feasible and financially attractive. This is crucial as brands move to short-run labels that meet consumer preferences and regulatory standards.”

For mid- to high-volume label production environments—nearing 10,000 labels per run—print quality and color consistency are increasingly important.

Thomas says new inks for packaging using LED-UV support growth in this space, along with faster speeds of up to 100 meters per minute.

Manufacturers are working to bring equipment costs down while simultaneously advancing software solutions, making it easier to support versioning and automate jobs that advance web to print orders for mid-level label providers, offers Pruitt.

Koyama explains that advancements in automation, enhanced ease of use, affordability, and sustainability address challenges in mid- and mid-to-high volume environments, and are factors helping businesses achieve better productivity, lower costs, and improved environmental outcomes.

As we go further up the volume chain, targeting lengths of over 10,000 labels per run, Pruitt believes it is all about keeping the printheads healthy. “If the printheads are clear and the press is operating according to manufacturer directions, then web breaks and electronic failures seldom happen. Manufacturers provide techniques and software solutions, such as redundant nozzles and compensating for failed nozzles, that are maturing as well to support the reliability of the printhead, inks, and ink conditioning systems on digital presses.”

Luly says this end of the market is more competitive, creating the need for more efficient solutions, along with the need for data acquisition to maximize facility profits.

Buckthorpe adds that advancements in inkjet technology address key challenges in the narrow web label market through improved ink formulations for diverse materials, faster printheads, and UV-LED curing for higher speeds, and enhanced color management for consistent quality. Integrated finishing options, such as inline varnishing and foiling, streamline production by enabling single-pass, high-value label creation.

Matthews sees machine vision inspection technology becoming key to winning new business and retaining existing customers’ trust, providing the reassurance that every label meets the highest quality standards, and every code printed can be read successfully throughout a product’s lifetime.

Advancements in inspection technology address challenges in higher volume label runs by integrating automated inspection with minimal manual intervention. Automated Delta-E color monitoring ensures consistent color accuracy, while the dynamic learning feature of these systems minimizes false defect detection. “These systems’ real-time defect mapping allows operators to monitor and address any variations immediately, preventing issues from recurring across run sizes. These innovations enhance production efficiency while maintaining the high-quality standards expected in this segment,” offers Cusack.

In the next few years, digital label production is expected to significantly evolve with advancements in customization, sustainability, and automation.

Buckthorpe says these advancements allow brands to respond faster to market demands while reducing environmental impact. “Innovations in ink, finishing options, and digital integration will enable brands to create dynamic, engaging labels that stand out in a competitive market.”

Of course, transitioning to new technologies is not without its challenges. “Financial investment, staff training, and changes to workflows are common barriers to adopting innovations in label printing. Smaller printing companies in particular face difficulties in financing new equipment and justifying the expense if demand for shorter runs is uncertain. However, these same technologies present an opportunity to stand out in a crowded market,” adds Davis. dps

Manufacturer/Website Product Name Technology

300 Anytron ANY-JET II Inkjet anytron.com ANY Press Toner

301 Afinia Label L301/L502/L701 Inkjet afinialabel.com L801/L801+ Inkjet

L901/L901+ Inkjet LT5C Toner

FP-230 Inkjet

DLP-2100 Inkjet

302 AstroNova - QuickLabel QL-E100 Inkjet astronovaproductid.com QL-120Xe Inkjet

QL-120X Inkjet

QL-120D Inkjet

QL-850 Inkjet

QL-300 Toner

303 AstroNova - TrojanLabel T2-C Inkjet astronovaproductid.com T2 IInkjet T2-L Inkjet

T3-OP Inkjet T3-OPX Inkjet T4 Inkjet

304 Bobst

DIGITAL EXPERT 340 Inkjet (+ Flexo) bobst.com

DIGITAL MASTER 340 Inkjet (+ Flexo)

DIGITAL MASTER 510 Inkjet (+ Flexo)

305 Canon LX-D5500 Inkjet usa.canon.com LX-P5510 Inkjet LabelStream LS2000 Inkjet

306 Colordyne Technologies LLC 3600 Series UV Inkjet colordynetech.com 3600 Series WB Inkjet Flex Press Inkjet

307 Dantex Group PicoColour 254 HD Inkjet dantex.com PicoJet 1200 Inkjet PicoJet 1200 DRS Inkjet

308 Domino Printing Sciences N610i Inkjet domino-printing.com N610i-R Inkjet N730i Inkjet

K600i Inkjet

K300 Inkjet

309 Dilli Neo Picasso Plus Inkjet dilli.co.kr Neo Picasso Pro Inkjet Neo Picasso SE Inkjet

310 Durst Image Tech. US LLC Tau 340 RSC-E Inkjet durstus.com Tau 340 RSC Inkjet

Tau 340 RSCi Inkjet

Tau 420 RSCi Inkjet

Tau 510 RSCi Inkjet KJet & XJet Hybrid Inkjet

311 Epson SurePress L-6534VW Inkjet epson.com SurePress L-6534VW with Orange Ink Inkjet

SurePress L-4733AW Inkjet

ColorWorks C6000A/C6000P Inkjet

ColorWorks C6500A/ C6500P Inkjet

ColorWorks C7500 Inkjet

ColorWorks C4000 Inkjet

ColorWorks C7500G Inkjet

312 Focus Label Machinery d-Flex Hi-Q Hybrid Machine Inkjet focuslabel.com d-Pack Hi-Q Hybrid Machine Inkjet

313 Formax ColorMax LP2 Inkjet formax.com

314 FUJIFILM NA Corp. Revoria Press PC1120 Toner print-us.fujifilm.com Revoria Press EC1100 Toner

315 Gerber Technology EDGE FX Thermal Inkjet gerbertechnology.com

316 Hanglory LabStar 3300S UV Inkjet hanglory.com LabStar 330S Hybrid UV Inkjet

317 HAPA AG Hapa 861 Inkjet hapa.ch

318 Heidelberg Labelfire 340 Inkjet heidelberg.com Gallus One Inkjet INFO#

319 HP Inc.

HP Indigo 6K ElectroInk hp.com

HP Indigo 8K ElectroInk

HP Indigo 25K ElectroInk

HP Indigo 35K ElectroInk

HP Indigo V12 ElectroInk

320 InkJet, Inc. Anser U2 Smart Thermal inkjetinc.com Anser U2 Smart One Thermal Anser U2 Pro-S Thermal Precision Series 72mm Inkjet Precision Series 18mm Inkjet

321 INX International Ink Co. NW210 Inkjet inxinternational.com NW350 Inkjet

322 iSys Label The Horizon Dry Toner isys-label.com

323 Konica Minolta AccurioLabel 400 Toner kmbs.konicaminolta.com AccurioLabel 230 Toner

324 Mark Andy Digital Series HD Contact Manufacturer markandy.com Digital Series HD HS 1200 Contact Manufacturer Digial Series iQ-R Contact Manufacturer Digital Series iQ Contact Manufacturer Digital Pro MAX Contact Manufacturer Digital Pro PLUS Contact Manufacturer

325 Miyakoshi MJP13LXV Inkjet miyakoshi.co.jp

326 Monotech Systems Limited JETSCI ColorNovo Inkjet monotech.in JETSCI ColorAqua Inkjet JETSCI KolorSmart Inkjet

327 Mprint mlabel Gen 3 Inkjet mprint.biz MJETplus Inkjet 4C compact (integration) Inkjet 4C ultracompact (integration) Inkjet

328 MPS Systems North America EF SYMJET Contact Manufacturer mps4u.com

329 MTEX NS ATOM Inkjet mtexns.com NS TIGER Inkjet

330 NEOS Fighter F-Roll Inkjet neoslab.it/em

331 NeuraLabel Printing Solutions NeuraLabel 300x Inkjet neuralabel.com NeuraLabel 600e Laser/LED NeuraLabel Sirius Laser/LED

332 Nilpeter DP-3 Inkjet nilpeter.com

333 Primera Technology, Inc. LX500 Color Label Printer Inkjet primera.com LX600 Color Label Printer Inkjet LX610 w/ Plotter Cutter Inkjet LX910 Color Label Printer Inkjet LX4000 Color Label Printer Inkjet

334 SCREEN Americas Trupress LABEL 350UV Inkjet screenamericas.com

335 SnapPress SnapPress LP-1 Inkjet makelabels.com

336 UniNet IColor 700/900 Toner icolorprint.com IColor 200/250 Inkjet

337 Uteco Sapphire EVO M Inkjet uteco.com Sapphire EVO W Inkjet

338 Valloy Incorporation TOPAZET UV 13R Inkjet valloy.com TOPAZET UV 8R Inkjet

BIZPRESS 13R Toner

BIZPRESS 13R White Edition Toner

339 Xeikon CX30 Toner xeikon.com

CX50 Toner

CX300 Toner

CX500 Toner

PX2200 Inkjet

PX3300 Inkjet

PX30000 Inkjet

SX30000 Toner

SX20000 Dry Toner

Find more detailed 1nformat1on on all ofthese listings at dpsmagazine com

Absolute Printing EquipmentService, Inc

5501S.FranklinRd.,Indianapolis,IN46239U.S.

Tel:317-862-9096 absoluteprintingequipment.com

We are the distributor for the German made KAMA die cutters, foil, stampers, folder gluers, and positioning systems. The KAMA is a great solution for medium and short run work. We are also the importers for the German made Perfecta paper cutters and Baumann handling equipment. Perfecta cutters from 30.5 to 88.5 inches and Baumann joggers, lifts, unloaders, pile turners, and robotic handling.

BaldwinTechnology - BW Converting 2300S.AshlandAve.,GreenBay,WI54307-9005U.S.

Tel:920-494-5601

bwconverting.com

Under their BaldwinTechnologybrand, BW Converting manufactures industrial enhancement technology for the printing, packaging, textile, film extrusion, advanced battery, nonwovens, and other high-performanceindustrial applications.

Canon

1Canon Park, Melville,NY11747U.S.

Tel:800-815-4000

usa.canon.com

Canon U.S.A., Inc. is committed to helping our customers grow by providing an integrated array of automated, productive, user-friendly, and profitable solutions. With one of the broadest portfolios in the industry we develop hardware, such as digital inkjet and toner presses and wide format printers, workfiow software, and professional services to assist a commercial printer in growing their business and profits. Canon is dedicated to its Kyosei philosophy of social andenvironmentalresponsibility.Seeourad, page2.

Document Data Solutions

91CommerceRd., P.0.Box919,Brookfield, CT06804U.S.

Tel:203-794-0520

dds-usa.com

Document Data Solutions has solutions to move your business forward. We offer complete monochrome and CMYK color inkjet printing solutions for both cutsheet and hybrid/web applications. Our ever-evolving Freedom Series print bars feature the latest printhead technology and our world class universal print controller.

DTFStation

No.18, Road No 2, Dawohengfeng, ChangpingTown, Dongguan, Guangdong 523000China

Tel:+86 755 28225550

dtfstationglobal.com

DTF Station is a leading provider of direct to film (DTF) printing solutions worldwide. Our comprehensive range includes A4, A3, A2, and 60 centimeters DTF solutions, along with cutting-edge UV DTF printers and heat press machines, empowering you to unleash your creativity and achieve exceptional results in the world of digital textile printing.

fromorint todocuments Duplo USA Corporation

3050S.DaimlerSt.,SantaAna, CA92705U.S. Tel:800-255-1933 duplousa.com

Established in 1979, Duplo USA Corporation is the leading provider of innovative print finishing solutions. Our highly efficient, modular products streamline post-press production for digital color and offset applications and perform with incredible precision that is second to none. In recent years, Duplo has expanded its product offerings to bring on demand print embellishment, packaging, and B2 finishing technologies to market. Visit us at duplousa.com for more information.

Durst ImageTechnology U.S. 667PanoramaTrailW., Rochester,NY14623U.S. Tel:888-480-3588 durstus.com

Durst Image Technology U.S. is a world class manufacturer of professional wide and grand format digital UV inkjet printers for today's imaging industry. Durst products are designed for performance, reliability, and longevity offering you the highest print quality, productivity fiexibility, and efficiency. Learn more about Durst product offerings and discover new business opportunities. Durst-From Pixel To Output, We Keep You Printing.

Eastman Kodak Company

343 State St., Rochester, NY 14650 U.S. Tel:866-563-2533 kodak.com

Kodak is a leading manufacturer in commercial print and advanced materials and chemicals. With 79,000 patents earned over 130 years, we believe in the power of technology and science to enhance what the world sees and creates. Our innovative, award-winning products, with our customer-first approach, make us the partner of choice for commercial printers worldwide. Kodak is committed to environmental stewardship, including industry leadership in developing sustainable solutions for print.

Enfocus, an Esko Company

TheLoop-BuildingNetworksRaymondedeLarochelaan 13, Gent9051Belgium Tel:+32092169801

enfocus.comIesko.com

Enfocus develops affordable, fiexible automation software for commercial and wide format printers. Our products, PitStop, Switch, Review, Phoenix, and Griffin enable print service providers to automate their business toward profitability while ensuring quality. Key to our platform is collaboration with industry partners and customers to foster mutual success. Enfocus automation solutions provide a seamless link between multiple systems by many vendors in prepress, press, and finishing. By connecting separate systems we transform production environments into unified automated workfiows. That translates into business tools that allow our customers to perform efficiently, accurately, and consistently. Enfocus, an Eska business unit, was established in 1993 and is headquartered in Gent, Belgium.

Find more deta,ted ,nformat,on on all ofthese /1st1ngs at dpsmagaz,ne com

KCJMCJFII GROUP

MBOAmerica

4 E. Stow Rd., Ste. 12, Marlton, NJ 08053 U.S.

Tel: 609-267-2900

mboamerica.com

MBO America offers a broadarray ofcuttingedge, high-performance finishingsolutionsfor inkjet and other digital print production environments. Whether cutsheet or roll-fed, inline or nearline, commercial print or packaging, MBO America can offer solutions expertise to make your production process more efficient. We have expanded our product portfolio to contain sheetfed finishing and folding, web finishing and folding, die-cutting, and pharmaceutical literature finishing. We specialize in automation, robotics, and one-step production systems that reduce labor, increase productivity, and provide a competitive advantage.

MGX

1500 Fenpark Dr., Fenton, MO 63026 U.S.

Tel: 636-349-6401

mgxdigital.com

A manufacturing and coating center for digital printingsubstrates, MGX offers synthetic paper and specialty substrates for HP Indigo, Xerox, Konica Minolta, Ricoh, Fuji, and Canon digital presses. The company also provides toll coating services for a variety of applications. To learn more visit mgxdigital.com.

Muller Martini Corp

456 Wheeler Rd., Hauppauge, NY11788 U.S.

Tel: 888-2-Muller

mullermartini.com

Muller Martini is the world's largest producer of print finishing solutions for commercial and book printers, trade binderies, and newspapers as well as short run and digital book manufacturers. See ourad, page 5.

anECO§lcompany

New ProlmageAmerica

8 Campus Dr., Ste.105 #3017, Parsippany, NJ 08540 U.S.

Tel: 929-322-8884

new-proimage.com

Prolmage America is a leading developer of innovative browser-based automated production workfiows, ink optimization and color toning and correction software, and press registration solutions for commercial and newspaper printers.

4841LumberLn., Knoxville, TN 37921 U.S. Tel: 800-895-2747 nobelus.com

Nobelus offers a wide range of thermal laminates, adhesive-free films, pre-laminations, and thermal laminating equipment to digital print service providers across the print and packaging industry. From essential gloss and matte films to premium finishes and special effects, our solutions enable digital printers and converters to make products brands love. We also offer innovative solutions for the digital fiexible packaging market, including print web films, thermal pre-laminations, and PE films that support recyclable applications. Our line of thermal laminators includes units for nearly any print application, including single-sided lamination, double-sided lamination, embossing, cold foiling, and more. Nobelus provides industry leading service and support in nearly every market, including commercial print, prime labels, fiexible packaging, publications, digital photofinishing, and print on demand. Nobelus solutions are driven by continuous innovation, ingenuity, and a desire to see our customers succeed. In every endeavor, we are committed to enhancing people, partners, and the world's brands. See our ad, page 25.

PressWise by SmartSoft 31111 AgouraRd., Ste.250, WestlakeVillage, CA 91361-4448 U.S.

Tel: 888-227-7221

presswise.com

PressWise is an end-to-end SaaS-based MIS and Print Workfiow Automation solution that comes complete with robust features such as unlimited web storefronts, estimating, quoting, order processing, workfiow management, complete shipping integration, fulfillment, and the ability to integrate with most other third party storefronts.

Primera Technology, Inc.

Two Carlson Parkway N., Plymouth, MN 55447 U.S.

Tel: 763-475-6676

primera.com

Headquartered in Plymouth, MN, Primera Technology, Inc. is one of the world's leading developers and manufacturers of specialty printing equipment, including the LX-Series Color Label Printers, AP-Series Label Applicators, Signature Slide and Cassette Printers, Bravo-Series CD/DVD/BD Disc Publishers, and Eddie, the Edible Ink Printer. Primera sells its products in more than 200 countries and territories globally.

Quantum Design Inc.

7550 Quantum Crt., Caledonia, IL 61011 U.S.

Tel: 815-885-1300 quantumdi.com

For over 35 years Quantum Design strives to meet the needs of customers by providing quality equipment, reliable, speedy service, and innovative design. Originally founded in 1986 as a Control Systems Integrator, Quantum Design has added product lines such as KTI, CTC, and Quantum Roll Sheeters to directly serve the printing and packaging industries with converting equipment such as turret rewinders, butt and lap splicers, unwind tension controls, roll sheeters, service, and more.

RISO, Inc.

10 State St., Ste.210, Woburn, MA01801 U.S. Tel: 978-777-7377 us.riso.com

RISO, Inc., headquartered in Woburn, MA. is a wholly owned subsidiary of RISO Kagaku Corp., Japan's leading manufacturer and distributor of high-speed inkjet printers for the production print market. Its compact design and heatless imaging system reliably produces millions of variable data prints at speeds of up to 320 images per minute/160 pages per minute duplexed. RISOs are environmentally friendly, inexpensive to operate, and easy to use.

Rollem International

1650 S.Lewis St., Anaheim, CA 92805 U.S. Tel: 800-272-4391 rollemusa.com

Rollem specializes inautomatedslitting, scoring, andperforatingsystems and sheet-fed, rotarydie-cuttingsystems. TheInsignia die cutting systems offer ease of operationand quick changeovers. Ideal for folded cartons, packaging, gift cards, and more. Proudly made in the U.S.A. Jetstream is our bidirectional slitting, scoring, perforating system, ideal for postcards, business cards, shelf tags, and, with a folder/gluer, it is a fully automated direct mail finishing system. The Semi-Slitter kiss-cuts pressure-sensitive adhesive stock for stickers and labels. The Champion 990 is our economical scoring and perforating system. Tell us about your finishing issues or bottlenecks and we'll provide you with options to streamline production, eliminate excess labor and waste while expanding your product offerings. Sizes compatible with all press sizes up to B2 sheets. We look forward to assisting your team. Visitrollemusa.com/production-matchor call us at 800-272-4391.

Shark Finishing Machinery

7745NW 56St., Miami, FL 33166 U.S.

Tel: 619-797-6278

sharkmachinery.com

Shark Finishing Machinery manufactures and distributes digital print finishing solutions. The Shark line offers a variety of equipment such as creasers, perforators, paper cutters, corner rounders, business card cutters, stitchers, UV coaters, perfect binders, paper joggers, and much more. Shark distributes through a global network of dealers and distributors and aims to become the most trusted name in the digital print finishing Industry. See ourad, page 18.

Sharp Imaging and Information CompanyofAmerica 109 CarolinaTownLn., HollySprings, NC 27540 U.S.

Tel: 800-BE-SHARP

business.sharpusa.com

Sharp Imaging and Information Company of America (SIICA) helps businesses achieve simply smarter work by assisting in workfiow management, creating immersive environments, and increasing productivity. SIICA offers secure production printers, office printer and copier solutions, commercial displays and projectors, Dynabook laptops, management and productivity software, and fully managed services.