Digital print technologies continue to permeate new segments of the overall print industry. In this issue we focus on the role digital print and supporting technologies play in the packaging space.

The opportunity for digital print in relation to folding cartons is driven by technology advancements in regards to speed and quality. The supply chain flexibility it provides is another benefit of digital, as well as sustainability considerations.

In this issue we focus on the role digital print and supporting technologies play in the packaging space.

We discuss the evolving landscape of folding carton packaging as the use of digital print and finishing tools accelerates in The Future of Folding Cartons and Accurate Cuts and Creases

This issue also looks at changes happening in the flexible print space where digital print and finishing technologies shine. Read more in Focused on Flexible

We veer away from packaging to highlight the benefits web to print (W2P) brings to both business to business and business to consumer print environments. Different functions support each target market to bring improved reach, better customer experiences, and automation. Read more in W2P Advances. This issue also includes a complementary Target Chart on W2P tools.

Best regards,

Cassandra Balentine, editor cbalentine@rockportpubs.com

dpsmagazine.com

Volume 26, Number 6 • ISSN: 1529-2320

EDITOR IN CHIEF

Thomas Tetreault 978-921-7850

EDITOR

Cassandra Balentine cbalentine@rockportpubs.com

ASSOCIATE EDITOR

Melissa Donovan mdonovan@rockportpubs.com

ART DIRECTOR

Sarah M. White swhite@rockportpubs.com

WEB EDITOR

Melissa Mueller

CONTRIBUTORS

Kemal Carr, Olivia Cahoon, Gina Ferrara, Mark Hanley

ADVERTISING SALES

PUBLISHER

Thomas Tetreault

64 Thissel Street #272 Prides Crossing, Massachusetts 01965 Ph 978-921-7850 x110 • Fx 978-921-7870 edit@rockportpubs.com

SALES

Amanda Doyon Ph 978-921-7850 x170 • Fx 978-921-7870 adoyon@rockportpubs.com

Subscribe online at dpsmagazine.com

CORPORATE & PUBLISHING OFFICE 64 Thissel Street #272 Prides Crossing, Massachusetts 01965

ROCKPORT CUSTOM PUBLISHING, LLC

CHAIRMAN

Jeffrey Jensen

PRESIDENT & CEO

Thomas Tetreault

CONTROLLER Missy Tyler

By Cassandra Balentine

Digital print technologies enable capabilities like customization, shorter turnaround times, and reduced waste. As marketers look to test new markets, these capabilities are in higher demand than ever in the flexible packaging space.

“Rapid turnaround time does not merely get products to shelves faster; it also empowers consumer packaged goods (CPG) companies to innovate and execute with greater agility by leveraging digital technology. By enabling more efficient A/B testing and shortening feedback loops, companies can make more informed decisions and iterate products more swiftly, maintaining a competitive edge in the market,” shares Ryan Chai, strategic account solutions specialist, Nobelus.

Eli Mahal, head of L&P Marketing, HP Indigo, says market trends such as the rise of smaller brands, growth in the number of SKUs, consumer need for personalization and convenience, demand for sustainability, and fast delivery are shifting volume from the flexographic sweet spot into the digital sweet spot. “The

main driver for digital is a brand’s need for supply chain agility, including ondemand delivery, sustainable with low minimum orders.”

Giselle Robeson, senior product marketing manager, Fiery, agrees, noting that more brand owners are pushing converters to offer digital printing. “It’s a cost-effective way to produce short-run, seasonal, or limited-edition packaging. With recent advances in digital printing technology, digital presses and hybrid

The main driver for digital is a brand’s need for supply chain agility, including on-demand delivery, sustainable with low minimum order.

— Eli Mahal, head of L&P Marketing, HP Indigo

digital presses have emerged as a full production alternative to flexography.”

Robeson adds that flexographic print providers that invest in a 100 percent digital press or a hybrid digital-plus flexographic configuration are able to expand service offerings and improve profitability while reducing makeready costs.

Windell McGill, digital launch manager, BW Converting – PCMC, points out that while speed to market and faster turnarounds drive users to digital, second

1. BW Converting’s PCMC brand has commercialized a digital hybrid platform targeted at flexible packaging and light board applications. 2. HP Indigo offers an endto-end digital pouch factory, including an upstream workflow solution, the HP Indigo 200K digital press, Karlville and Nordmeccanica solvent-less and thermal laminator, slitter from Karville with optional JetFx digital selective coating unit, and the Karlville pouch maker. Photo by HP.

generationdigital presses arenow wider and faster, offering operational efficiency for medium to short runs.

"Flexible packaging is a mainstream technologysuitable for more, if not most of the market,'' attests Simon Buswell, sales and marketing director, Eco Flexibles. "The days of digitalbeingseen as a technology for short runs and personalization are a distant memory. Of course, runs keep getting shorter and SKU proliferation is making the ability to print variations a valuable tool but these are part of digital's overall toolbox. Rather, digital today benefits a broad spectrum of customers and flexible packaging applicationsin severalways."

Buswell says optimization is now the best term used to describe the holistic and intrinsic impact of digital on flexible packaging production. "For example, immediately actionable proofs

process; non-contact printing optimizes the production process; by only printing what is needed and ganging varieties, material usage is optimized and waste minimized; a water-based inkjet process reduces and optimizes the use of consumables; and clever machine design and specification optimizes drying and curing."

The adoption of digitally printed flexible packaging is steadily increasing. Chai expects it to continue to grow in volume, much like how commercial printing expanded decades ago. "The advantages of digital printing, including customization, quick turnaround times, and reduced waste, are driving this ongoing growth and solidifying digital printing's place in the industry."

More of the market is hearing and seeingthe potential ofdigital to optimize the manufacture of recyclable flexible packaging. "You can see from the headlines around the recent Drupa trade show the number and profile of companies investing in digital for flexible packaging. This increases capacity in the market and helps raise awareness and adoption. We are delighted to be at the optimize the prepress and approval forefront of this and will continue to lead

the way in using digital to manufacture recyclable and environmentally friendly flexible packaging,'' shares Buswell.

Whiledigitalpressesforflexiblepackaging have been commercially available for about ten years, they have captured less than one percent of the market, says McGill. ''As more wider and faster targeted to mainstream run lengths are available the adoption will accelerate and more of the market will be digitally printed. The next ten years are shaping up to be an exciting time for digital print for flexible packaging," he predicts.

Challenges associated with digital adoption in the flexible packaging space include material compatibility, higher cost, and color consistency. Modern technologiesworktoaddressthesechallengesand areless restrictedwhen it comes to material compatibility and colorconsistency.

For example, Nobelus actively provides in-depth and engaging training to help converters address concerns about materials, cost, consistency, and many other issues. "Regarding higher costs, it is important to consider the overall value proposition of digital flexible packaging. Just as those who purchase a luxury car do not typically complain about higher costsbecausetheyunderstandthepremium quality they are receiving, converters and CPG companies that prioritize innovation find digital printing to be a worthwhile investment. If cost is the primary concern for a converter, digital printing may not be the best fit,'' says Chai.

Investment cost is a consideration, but this is expected to evolve as capacity and demand grows in themarket. Reducing the price of inks is an example. "Cost must also be framed within the 3. Fiery Impress is a flexible, turnkey DFE designed forindustrialinkjet applications. Itprovidesacost-effective solution that combines the streaming speed, imagequality, brandcolor accuracy, andautomation customersneedwiththeflexibilitypressmanufacturers require to drive any high-speed inkjet press and integratewithanyworkflow.

context of what digital can do and does for your business. This is an issue of education and is one of the things we are championing in conversations with the market as we push digital into the mainstream. We’re fast approaching the nexus point between the old ways of buying and selling flexible packaging by volume, and the modern method of digitally manufacturing functional pouches and packs that also work as high-value brand ambassadors and impactful marketing materials fit for the 21st century,” asserts Buswell.

Mahal feels the main concern is digital print productivity and cost versus central impression flexography. “Market trend push growing amounts of volume from flexo/roto to the digital sweet spot.”

New digital presses such as the HP Indigo 200K are more productive, allowing digital to be more cost effective. “For the foreseeable future digital and conventional will co-exist, allowing converters to be more productive by using the right press for the job,” adds Mahal.

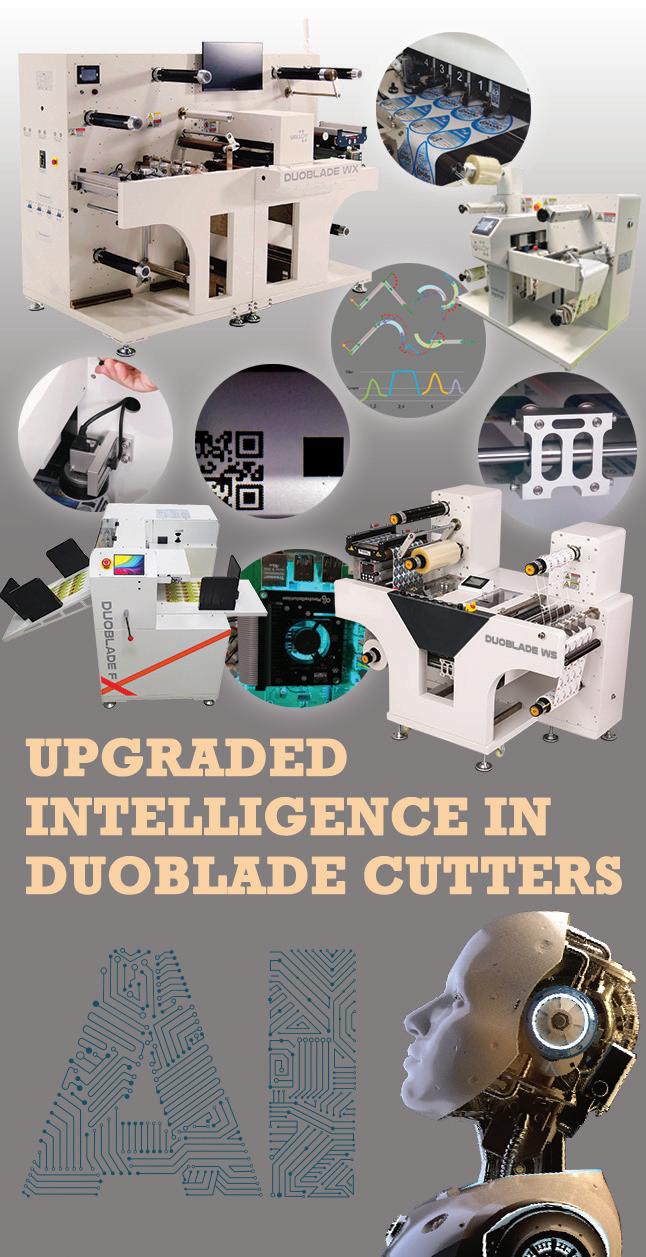

Finishing also plays an important role in the success of digitally printed flexible packaging. Roy Burton, managing director, Eclipse Label Equipment, points out that roll-to-roll finishing systems bring a savings on both financial and waste for the user by being able to digitally cut blank labels, on an as- and when-needed basis. “This brings a massive stock holding reduction. Many of our customers have enjoyed a payback return on investment in as little as 12 weeks.”

Robeson says the challenges in flexible packaging are similar to those faced in the cutsheet market 20 years ago. “Customers demand fantastic color that meets brand owner expectations, productivity to keep presses running at full capacity, integration with their other systems, and a system that’s easy to use. This is where a digital front end (DFE), or RIP, can play a big role in driving inkjet presses and addressing challenges around color and image quality.”

Fiery brings RIP and workflow innovation to digital packaging printing with Fiery Impress, a DFE designed for industrial inkjet applications. Fiery Impress includes imaging technology combined with integrated color management tools to help match industry standards and customize color to brand specifications. “Flexographic printers can optimize print quality such as font and barcode edge enhancement to compensate for ink drop spreading and integration with inspection systems for on-the-fly imaging correction. Integration with prepress and color workflows from Esko gives printers the confidence that digital capabilities can be added to existing analog workflows,” says Robeson. “Investing in a digital or hybrid press and its accompanying DFE is a strategic move. The role of the DFE and supporting workflow software helps flexographic printers hit the ground running with new investments and start profiting immediately.”

“We are happy to see suppliers investing in the development of the next generation of digital printing technologies to make sure that the widest range of materials can be converted and the broadest range of end-use applications served,” comments Buswell.

McGill believes there is still some work to do. “The existing technology has not fit the mainstream market because it’s been too narrow and slow. The next-generation technology—wider and faster—is addressing more of the mainstream market. It’s cost competitive at longer run lengths, which is what the industry needs,” he adds.

Certain flexible packaging applications are primed to enjoy the benefits of digital print technologies, like customization, shorter turnarounds, and reduced waste. The adoption of digital continues as more marketers demand these capabilities. dps

KODAK PROSPER Plus Imprinting Systems offer packaging printers digital fiexibility and adaptabilityinanever-changingmarketplace

By Kodak 0---

Digital printing is establishing itself in more and more segments of packaging production, driving growth in flexible packaging, folding cartons, corrugated boxes and labels. Packaging printers and converters are using the technology to produce more agile, efficient and cost-effective solutions to better meet the needs of brand owners as well as e-commerce platforms and retail chains.

The demand for faster time-to-market drives the spread of digital printing in packaging applications because the long lead times and upfront costs of platemaking or preparation of cylinders for analog printing processes are eliminated. Brand owners are constantly looking for solutions to support more frequent design changes and cost-efficient short-run production, therefore needing greater flexibility. Brands are also looking for personalization and versioning of packaging to foster consumer engagement and drive business success, such as code-based sweepstakes or connected, smart packaging applications. These attributes contribute to packaging printers' return on investment by creating new opportunities, increase revenues, and highlighting competitive advantage.

Given these usage options and application benefits, it is no surprise that digital packaging printing is predicted to grow at an average annual rate ofover 5% globally from 2023 to2033.

In addition to fully digital packaging presses or specially designed hybrid presses, there is another option for making packaging printing digital: the integration of digital imprinting systems that can match quality and printing speeds onto existing conventional equipment. This allows for a solution that is 100% tailored to a packaging converter's needs and breathes new life into their existing equipment without having to make a huge financial investment.

An outstandingexampleofthis is trackand trace applications that utilize serialized QR or 2D codes for product and brand protection, as well as support anti-counterfeiting measures, such as those provided by KODAK PROSPER Plus Imprinting Systems. Kodak's PROSPER Imprinting System portfolio features high image quality and high-speed solutions. The systems use KODAK Stream Continuous Inkjet Technology, which enables high speed and

high ink coverage on glossy substrates thanks to precise, round drop placement.

KODAK PROSPER Plus Imprinting Systems were designed for integration into flexo, gravure and offset packaging presses and packaging converting machines such as folder gluers. The versatile imprinting solutions are suitable for corrugated, folding carton, label and flexible packaging applications. With their fast speeds of up to 600 mpm, PROSPER Plus Systems rule out any impairment to analog packaging production equipment productivity as a result of the digital component.

PROSPER Plus Systems offer speeds of up to 600 mpm (2,000 fpm) and produce image quality that is difficult to distinguish from traditional printing. The print width of the base configuration is 105 mm; CMYK color printing is enabled by cascading four of these in!tjet modules. The systems are available in different speed and width versions, allowing the converter to customize the solution to fit their business needs.

PROSPER printheads can be configured up to 12 across, creating a customized solution to fit the needs of a large variety of applications. With exceptional scalability, packaging printers can start small, then add additional imprinting heads with a field upgrade. Depending on the configuration, systems can include up to 12 print stations and 24 printheads and can be easily integrated into existing equipment using Kodak or third-party solutions. Printers can start with monochrome printing and later add spot and process colors as their business needs evolve.

The new KODAK PROSPER Print Bar takes inkjet printing with PROSPER Imprinting Systems to another level. It enables seamless and accurate digital printing with scalable print widths in 105 mm increments using multiple PROSPER printheads. The powerful integration solution offers enhanced automatic color registration, cutting down on waste and reprints. In addition, the innovative Smart Stitch functionality helps ensure consistently high print quality with seamless wide-format output. For maximum flexibility, the PROSPER Print Bar is available in pre-configured monochrome and CMYK options as well as custom configurations to accommodate a variety of applications.

PROSPER Plus Imprinting Systems employ water-based pigment and dye-based KODAK EKTACOLOR Inks developed and manufactured by Kodak, which dry fast owing to their chemical composition. A key advantage of the inks lies in Kodak’s proprietary pigment micromilling process which creates extremely fine nanoparticulate pigments with a very narrow size distribution. The finer pigments make the ink easier to jet, reduce light scatter to achieve richer and purer colors, and deliver a superior color gamut as well as ultra-thin dried ink layers. In addition, Kodak’s inkjet inks differ from competitive inks by having a lower level of humectants. This results in faster drying,

1.

even when printing with high ink coverage on difficult substrates. All of these benefits of EKTACOLOR Inks enable PROSPER Plus Systems to print vivid images with vibrant colors and reliably render the offset color gamut. Packaging printers also benefit from the fact that Kodak offers not only CMYK process color EKTACOLOR Inks but also customized spot color inks. This means, PROSPER Plus Imprinting Systems users can accurately reproduce brand colors and more easily meet the color expectations of brand owners.

One particularly important aspect as far as packaging is concerned is that EKTACOLOR Packaging Inks may be used on the non-foodcontact side of paper, paperboard and film packaging intended to contain dry foods and when used as intended may be properly considered “safe” in accordance with the following legal and industry requirements:US Federal Food, Drug, and Cosmetic Act and applicable food additive regulations (21 C.F.R. Parts 170 et. seq.)

•Canadian Food and Drug Act and the Canadian Food and Drug Regulations (C.R.C., c. 870 Part B, Division 23)

•Article 3 of EU Framework Regulation No. 1935/2004 and do not pose a health or safety risk when printed on the on the exterior, non-food-contact side of paper and paperboard packaging for dry foods

• Good Manufacturing Practices (GMP) of the European Union, EU Regulation No. 2023/2006

• EuPIA (European Printing Ink Association) Exclusion Policy for Printing Inks and Related Products 4th Edition

•Annex X of the Swiss Ordinance on Materials and Articles in Contact with Food (SR 817.023.21)

•Nestlé Guidance Note on Packaging Inks, October 2018

• Annex A of the Indian Standard IS 15495:2004 “Printing Ink for food packaging – Code of Practice”

PROSPER Plus Imprinting Systems also benefit from water-based, ink-receptive KODAK OPTIMAX Primers that are optimized for EKTACOLOR Inks. In addition to creating a thin layer to increase ink adhesion, the primers immobilize the pigment, allowing high-speed

printing even with high ink coverage. Just like EKTACOLOR Inks, OPTIMAX Primers do not contain any volatile organic compounds (VOCs) or environmentally hazardous substances, which benefits sustainability. OPTIMAX Primers improve sustainability even further by facilitating deinkability, thus increasing the recyclability of paper and fiber-based post-consumer packaging materials.

Kodak has designed a range of high-performance OPTIMAX Primers for a wide range of substrates and applications. These include an OPTIMAX Standard Primer for uncoated papers and an OPTIMAX Enhanced Primer for coated papers. OPTIMAX Packaging Primers are available for uncoated and coated corrugated and folding carton packaging applications, as well as for non-absorbent substrates such as plastic, film, and materials for personal care products.

PROSPER Plus Imprinting Systems are comprised of printheads, data and fluid controllers, EKTACOLOR Inks and dedicated OPTIMAX Primers. Kodak has a wealth of expertise in the engineering and manufacturing of inkjet towers and mounts for the effective integration of imprinting systems into analog printing presses and packaging converting lines. This allows Kodak to quickly provide each customer with a custom-engineered solution to enable practically any digital packaging application.

“With PROSPER Plus Systems, packaging printers can implement hybrid solutions in a very flexible and cost-effective way, allowing highquality printing on sometimes difficult substrates without compromising the productivity of the entire production line. Our imprinting systems facilitate the implementation of innovative ideas that change the way packaging impacts consumers,” said Randy Vandagriff, Senior Vice President, Digital Print, Kodak. “As a single-source supplier of the total solution, including imprinting systems, inks, primers and integration solutions, we can respond quickly to changing requirements in the development of inks and primers as new packaging substrates are launched.” dps

© Kodak, 2024. Kodak, Ektacolor, Optimax and Prosper are trademarks of Eastman Kodak Company.

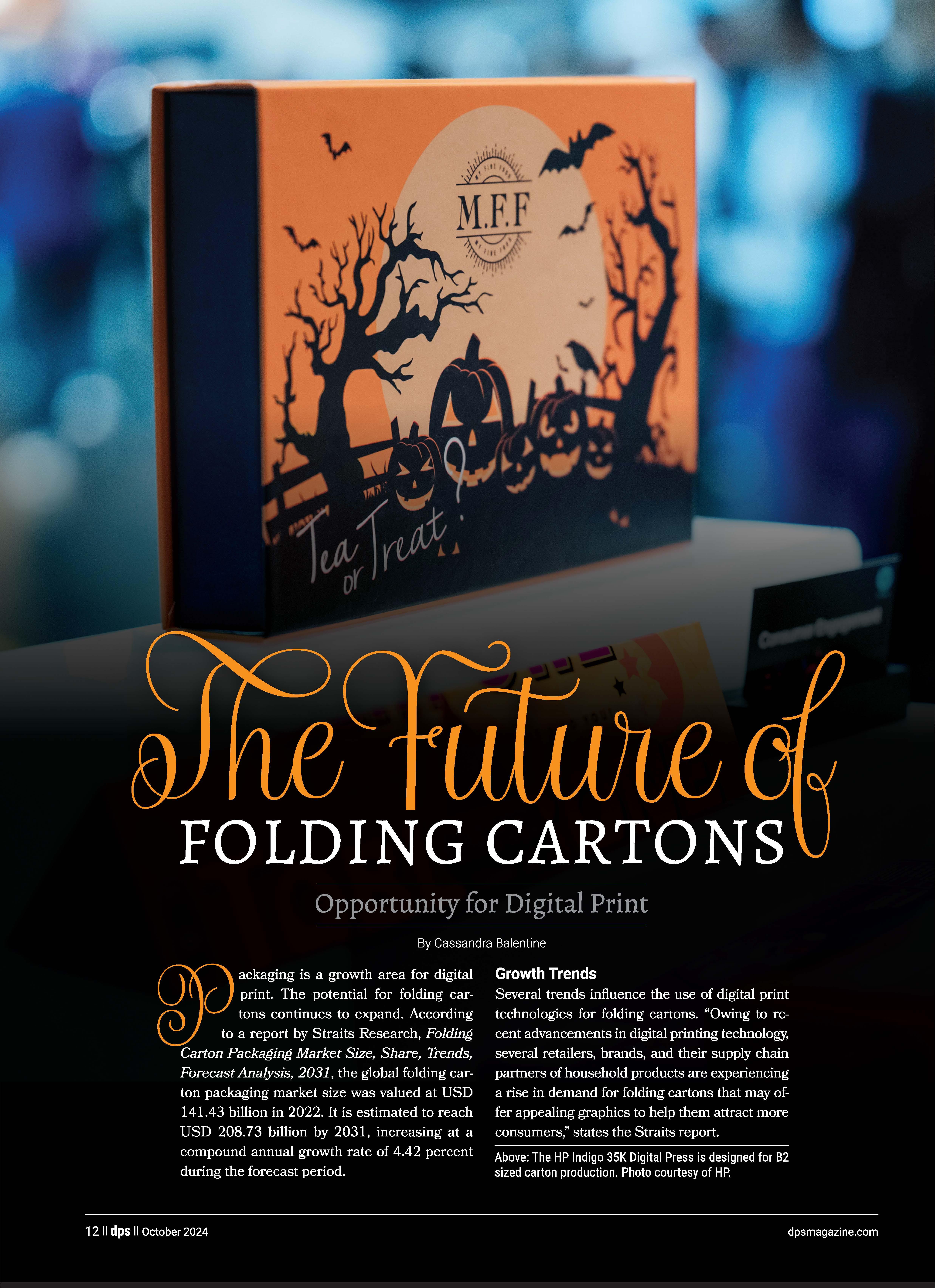

Among these trends is improvements in digital print technologies. “Digital printing technology ensures exceptional print quality, meeting the demanding standards of various industries, including luxury goods, cosmetics, and pharmaceuticals,” says Shahar Lev-Ari , product marketing manager, HP Indigo Folding Cartons.

“The advancement of technology is leading to the development of highspeed digital solutions, driving an increased adoption rate and growth. Linked to that, the technology available is demonstrating year on year offset-like quality and cost-effective prices,” says Matt Brooks, head of packaging, Digital Printing Solutions, Agfa.

Linked to technology and quality is the ability to now print volume at speed, making digital solutions viable for mainstream production. “This provides a digital alternative capable of handling both large-volume and short-run jobs—including versioning, which have become an expected feature,” adds Brooks.

Logistics also play a role as digital print supports an agile supply chain. “We’ve seen just-in-time production and reduction of inventory back in full swing, both for operational reasons as well as the need to be proactive and up to date with product marketing on-pack,” shares Amir Shalev, market development director, Landa Digital Printing.

“Modern supply chains prioritize flexibility, with a focus on just-in-time production and on-demand printing. Digital printing supports this by allowing companies to minimize inventory and reduce lead times, ensuring products are delivered swiftly and efficiently,” comments Lev-Ari.

“Runs keep getting shorter and delivery times are shrinking, as such, more of the market realizes that digital flexibility is key,” points out Shalev.

Near-shoring and/or re-shoring is driving product and package production back to developed markets, which Shalev notes are typically the first to introduce high-end digital printing systems.

“Digital printing allows for rapid production and quick turnaround times, enabling brands to respond swiftly to market trends and consumer demands,” adds Lev-Ari.

The demand for personalized packaging continues to grow, with businesses seeking to create unique consumer experiences through multi-SKU and shorter print runs. “Digital printing technology enables brands to tailor packaging to specific audiences, resulting in more engaging and memorable products,” explains Lev-Ari.

Customer loyalty is positively impacted by more engaging and personalized design made possible by digital printing—e.g., quick response codes, contests/ special events, story-telling, adds Shalev.

Sustainability is another consideration. “Consumers are driving brands toward more earth-friendly packaging and overall sustainability conformance,” comments Shalev.

Brooks agrees, noting that there is a strong focus on sustainability with increasing discussions about the shift toward sustainable practices as well as the circular economy. “This includes the use of lighter weight, paper-based materials that are more suited to digital printing processes.”

As environmental concerns become more prominent, Lev-Ari says businesses are adopting sustainable practices. “Digital printing offers minimal waste compared to traditional offset printing, aligning with eco-friendly initiatives and reducing the carbon footprint. Decreasing waste and inventory costs, allowing brands to produce only what is needed with almost no waste.”

Further, Shalev points out that cartonboard, including recyclable options, can replace less sustainable, plastic 1. Agfa's SpeedSet Orca offers a dedicated digital solution for folding carton packaging.

packaging in consumer packaged goods and fast moving consumer goods markets; and is therefore more attractive to brands, their distributors, and customers.

Regulatory restrictions are also driving demand for sustainable packaging. “Many businesses want to have all of their packaging recyclable or compostable by 2025,” adds Shalev.

There are challenges to navigate when it comes to the digital production of folding cartons.

Time to market, price point, and automation challenges are currently being worked out for digital print in the folding carton space. “Sometimes digital is perceived to be excellent technology but slow in being introduced

to the market. Challenges are posed around price point and running costs versus analog and now ink price must be factored into the return on investment. And then there is the topic of automation, continuous feeding, and automatic job changeover. We have seen analogue in the ascendancy here but partnering with third-party OEMs can allow digital to catch up and mitigate some of the challenges associated with automation,” says Brooks.

Competition for market share among converters is high. “The macro-economic situation is uncertain; and these organizations are nevertheless being pushed on pricing while costs remain elevated. To make matters more challenging, packaging companies seeking to differentiate themselves are

compelled to offer higher levels of service—including the assurance of supply and short lead times,” shares Shalev.

Further, the adoption of innovative technology—transitioning from analog to digital—requires a shift in work methods and mindset. “Companies need to invest in training and development to ensure seamless integration of digital technology,” suggests Lev-Ari.

The use of digital print technologies for folding carton production is expected to continue to grow. The demand for justin-time production and environmental sustainable solutions attract new segments of packaging to this maturing technology. Read more on folding cartons at dpsmagaaine.com. dps

By Melissa Donovan

Perfectly designed, well placed packaging can make the difference between a failed and successful branding campaign. Marketers are well aware of this and in an effort to maintain buyer interest look to create marketing tools that are both memorable and effectively sell product through a

combination of messaging and physical packaging. Folding cartons are increasingly digitally printed due to the attractiveness of shorter print runs and ease of customization. Finishing options are open ended, with laser cutting, digital flatbed cutters, platen, and rotary die cutting methods all utilized.

A continued pattern of growth is apparent in the digital folding carton space. This is due to digital offering ease of customization as well as a preference toward paper-based packaging.

Above: Examples of folding cartons finished on the KAMA ProCut 76 die cut and hot foil stamp machine.

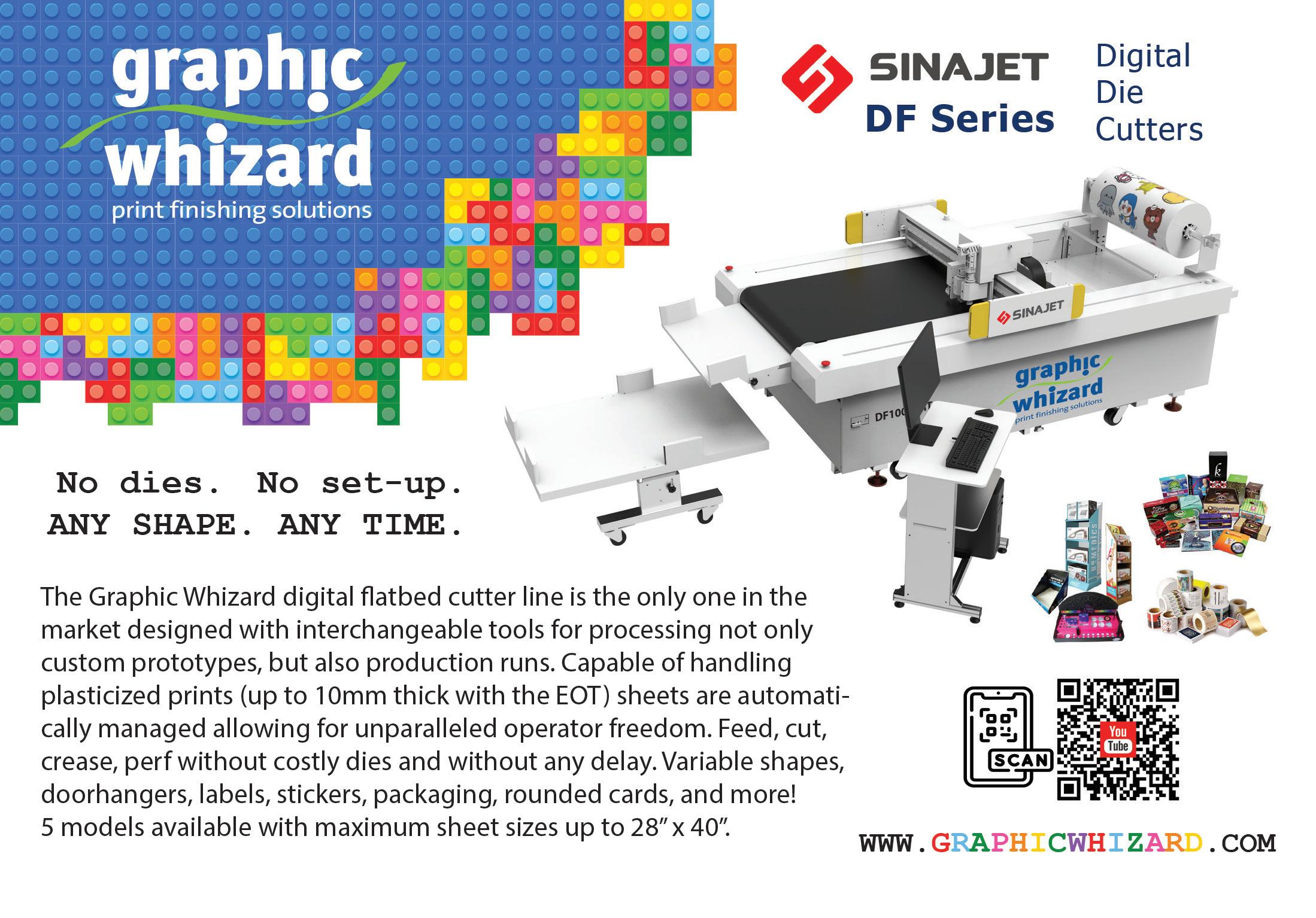

Coincidentally, factors like less skilled operators and the phasing out of traditional die cutting equipment increase demand and influence product development. For example, Graphic Whizard developed a more user-friendly approach to die cutting in order to make it more accessible to a variety of commercial printers. “Our development is centered around adding more value in our current models by allowing them to run roll-to-roll labels with weeding or add embellishment on a digital die cutter inline,” shares Allen.

The finishing aspect of the folding carton process shouldn’t be overlooked. Automated methods that keep pace with fast print speeds are preferred. Folding

cartons have specific finishing requirements just like any other application.

“When running small and medium quantity orders of digitally printed small boxes, the most important issues include minimizing tooling cost and set up time, while providing high throughput speed, high die cut and score quality, and automated waste stripping,” shares Van Pelt.

A good registration system is important “to accurately match the cut—crease, score, perforations—to the print. A registration system that can actually do this from the bottom of the sheet—with the print side facing down—is helpful in order to get around the need to perform any flip/ cut operations,” shares Drury.

Working in conjunction with the registration system, skew adjustment ensures maximum register accuracy for every

sheet, even for sheets printed at an angle. “Which has already saved many a production run in practice,” shares Giralt.

“Each style of cutter will effectively cut carton materials, but to make a beautiful finished package it is important to have a clean score so the package can fold properly without cracking along the edges,” admits Allen.

Corwin points out that finishing equipment used for folding carton production must have the ability to accurately cut and crease simultaneously. “Since the products are folded, the crease or score must be applied with the appropriate level of force to reach the desired depth of crease.”

“The equipment needs to be simple to operate compared to traditional die cutting methods. Adequate production

speeds need to be maintained, added enhancements are desirable, and the ability to remove the matrix while streamlining the off-loading of the product are other factors to consider,” continues Corwin.

There are a number of finishing options in the folding carton production space

“Short-run packaging is an ideal application for digital cutting solutions, however they also make great proofing devices before making a die for a longer production run,” points out a representative from Plockmatic Group.

For our purposes, we are discussing those finishing options well suited for smaller, customized print runs. Each bring their own advantages and disadvantages to the table.

An advantage of using a laser to die cut folding cartons is maintenance.

“The lack of contact with tooling and the finished product makes it so there is much less wear and tear or consumable use in a laser cutter. They also lend themselves to cutting much more complex and intricate patterns than a blade or rotary finisher that makes contact with the carton,” explains Allen.

No cutting dies are required, which translates to no “hard” tooling cost, explains Van Pelt.

“The largest disadvantage to laser finishing is the lack of scoring. Some operators will use oblation, which removes part of the material to create a fault line in the carton to fold, but it does not compress the material like a crease or

score, which can lead to cracking in the finished product,” admits Allen.

Similarly to laser cutters, digital flatbed or blade cutters benefit from having no cutting dies.

“Because of their versatility and ability to customize products on the fly, smaller footprint, modular, digital flatbed cutting systems are a great choice for folding carton applications. While full automation for longer run production has yet to be developed, various options are available for making manual and semi-automated processing—including creasing, cutting, and perforating—as productive as possible,” suggests Drury.

“For shorter runs and customizations flatbed die cutters give the perfect

balance of quality and flexibility with no start-up cost for a personalized carton,” shares Allen.

When choosing the right digital flatbed cutter for the job “the important deciding factors for a digital flatbed cutter will be sheet size and tool options,” notes Allen.

A general advantage of KAMA’s ProCut die cutters is its range of applications and fast changeovers between die cutting and embellishment with hot foil, admits Giralt. “This makes the post-press flexible and leads to a high uptime of the machine for efficient finishing.”

While digital is associated with speed, digital flatbed finishers “need to follow each tool path so their throughput is much slower than a die system. For shortrun work the fast setup can offset the turnaround time of building a die, but for long runs the slower throughput per piece can

tie up the die cutter and be a hindrance in efficient production,” says Allen.

“While technology and cutting methods have made a lot of progress, some jobs still require the use of a counter or matrix to achieve the kind of crease quality end users may be expecting. To date, this process remains incompatible with any type of conveyorized material handling, which is a limiting factor when it comes to production automation and throughput maximizaton,” adds Drury.

Van Pelt says edge quality and lack of inline waste stripping are other issues.

According to Allen, a rotary die cutter’s biggest asset is speed. “A rotary die cutter has a much higher throughput versus a blade or laser finisher as it can produce a full-size sheet in a single revolution.”

“Rotary die cutters are ideally suited for converting folding cartons since they are able to accurately cut and crease at the same time. Other elements are built into the die such as embossing, perforating, kiss cutting, sombrero holes, and twoside creasing to create Z-fold patterns—all of which are performed in one process with just one operator,” says Corwin.

The primary disadvantage to a rotary system is turnaround time and cost per

piece. “For short-run work that is customized whether the run is one or a hundred a die needs to be produced, which will slow down production and also increase the cost per piece,” explains Allen.

Van Pelt points out that some rotary die cutters cannot support upper and lower flexible dies. “As a result, they can die cut but not score. It is also difficult to die cut laminated stocks, as well as substrate type and thickness limitations.”

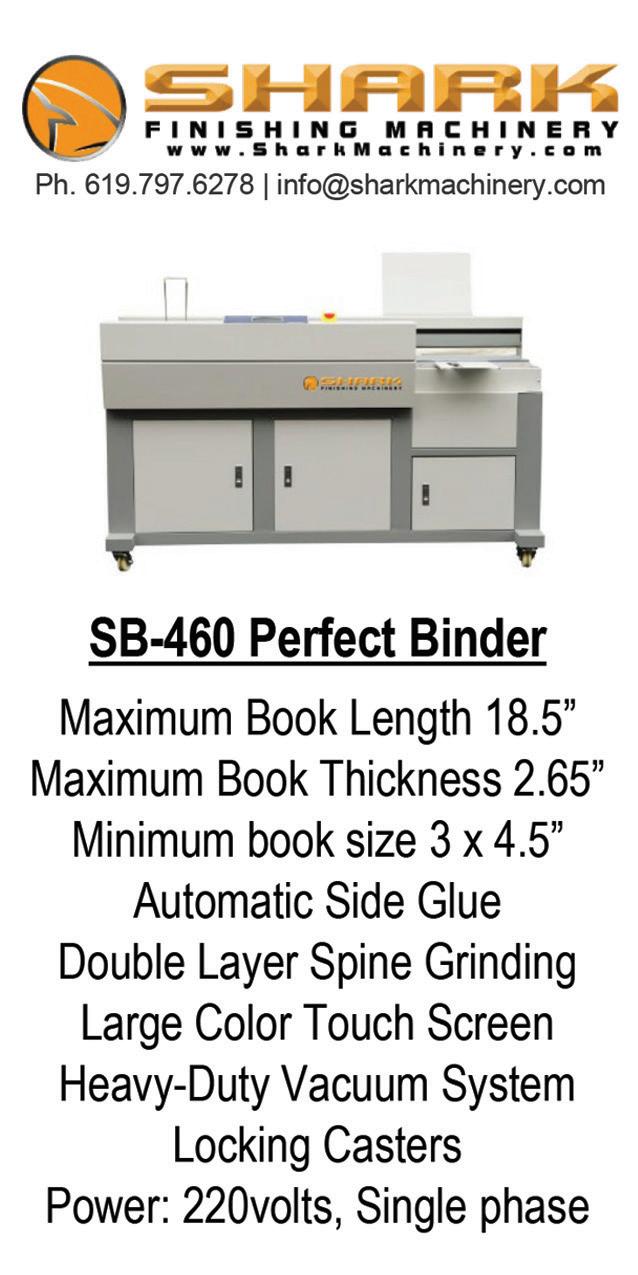

Van Pelt maintains die cutting, using a steel rule die, is still an ideal option for minimizing tooling cost, set up, and to ensure high cut, score, and perforation quality. “The ability to step and repeat multiple boxes per sheet further minimizes tooling cost and set up time, which is especially important for small quantity orders. Steel rule dies can also be economically ‘re-ruled’ if they become damaged or worn. Using a steel rule die to die cut and score also allows operators to select between multiple matrix options to achieve the best score while running the widest range of material types and thicknesses.”

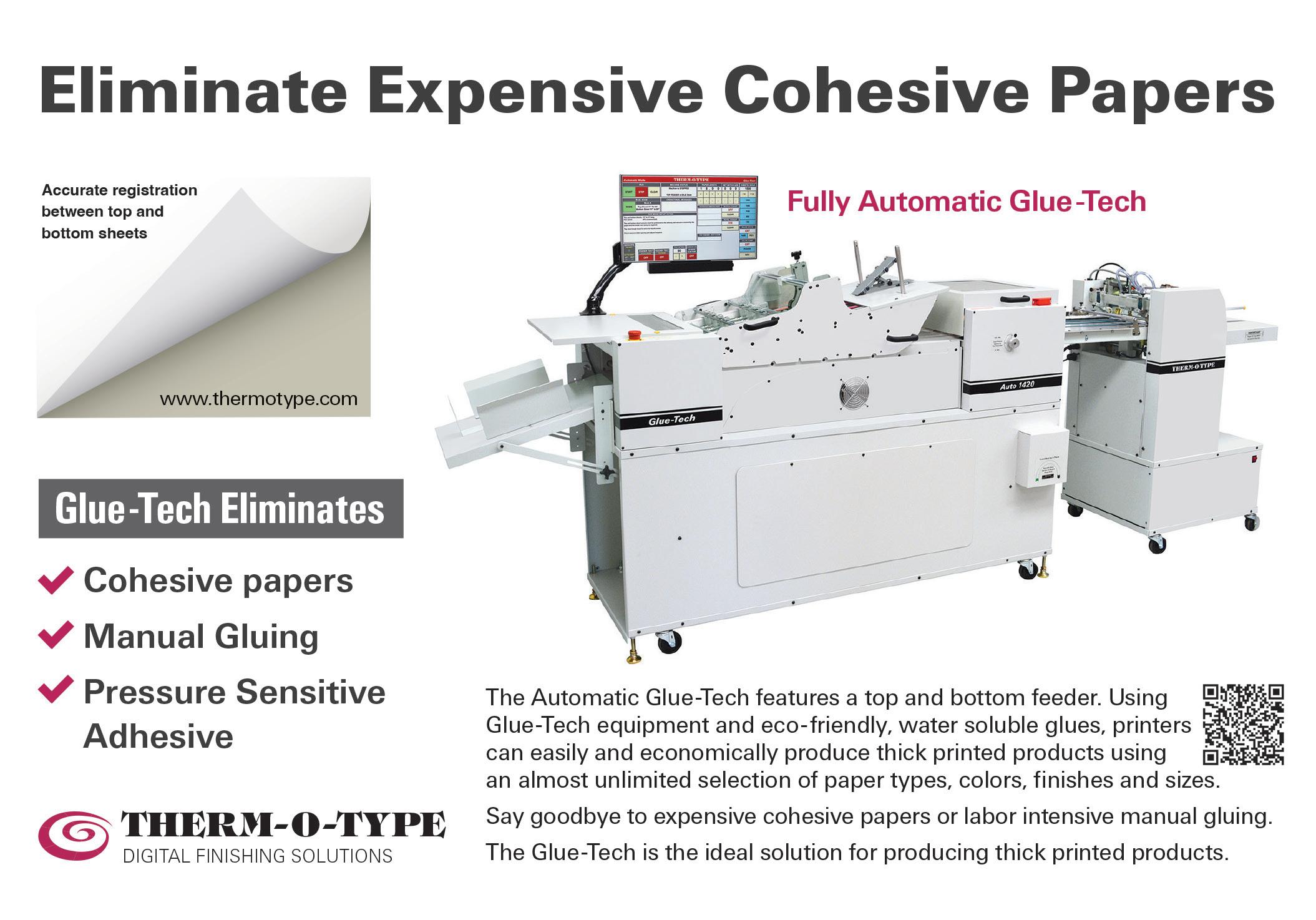

In additional to die cutting, Van Pelt points to Therm-O-Type’s NSF platen presses, which allow customers to add flat foil, blind, or foil embossed embellishments to their products.

There are negatives to platen dies to consider, including initial operator skill requirements like learning how the matrix dies, basic press set up, and adjustments, shares Van Pelt.

The cutting equipment used for folding carton production needs to keep pace with output speeds powering the front end of the process. In addition, accurate cuts and creases as well as minimized tooling costs and set up time are important factors. Laser, digital flatbed, platen, or rotary die cutters are current options to consider.

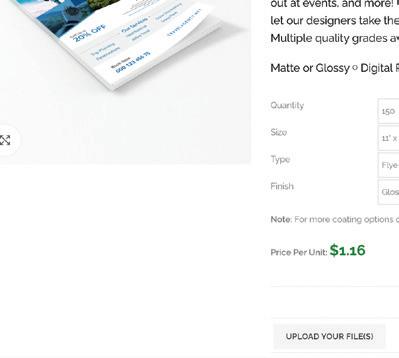

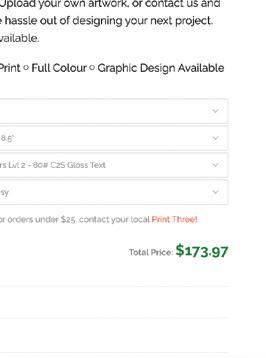

PrintThree's

By Cassandra Balentine

web to print (W2P) tools enable print providers-both business to business (B2B) and business to consumer (B2C)-to harness the power of ecommerce to bring in new business, better serve customers, and automate processes.

"Our customers have been very successful in this business climate and are bucking the trend with increased order volumes while the industry is seeing stagnant growth. Today's customers want to receive

instant pricing and offloading of the job immediately. By creating a B2C site, customers expand their reach to other geographic areas," shares David Graves, CEO, Aleyant.

In the B2B space, Austin Wyman, marketing director, Propago, says print businesses use W2P platforms to win larger customers, create stronger

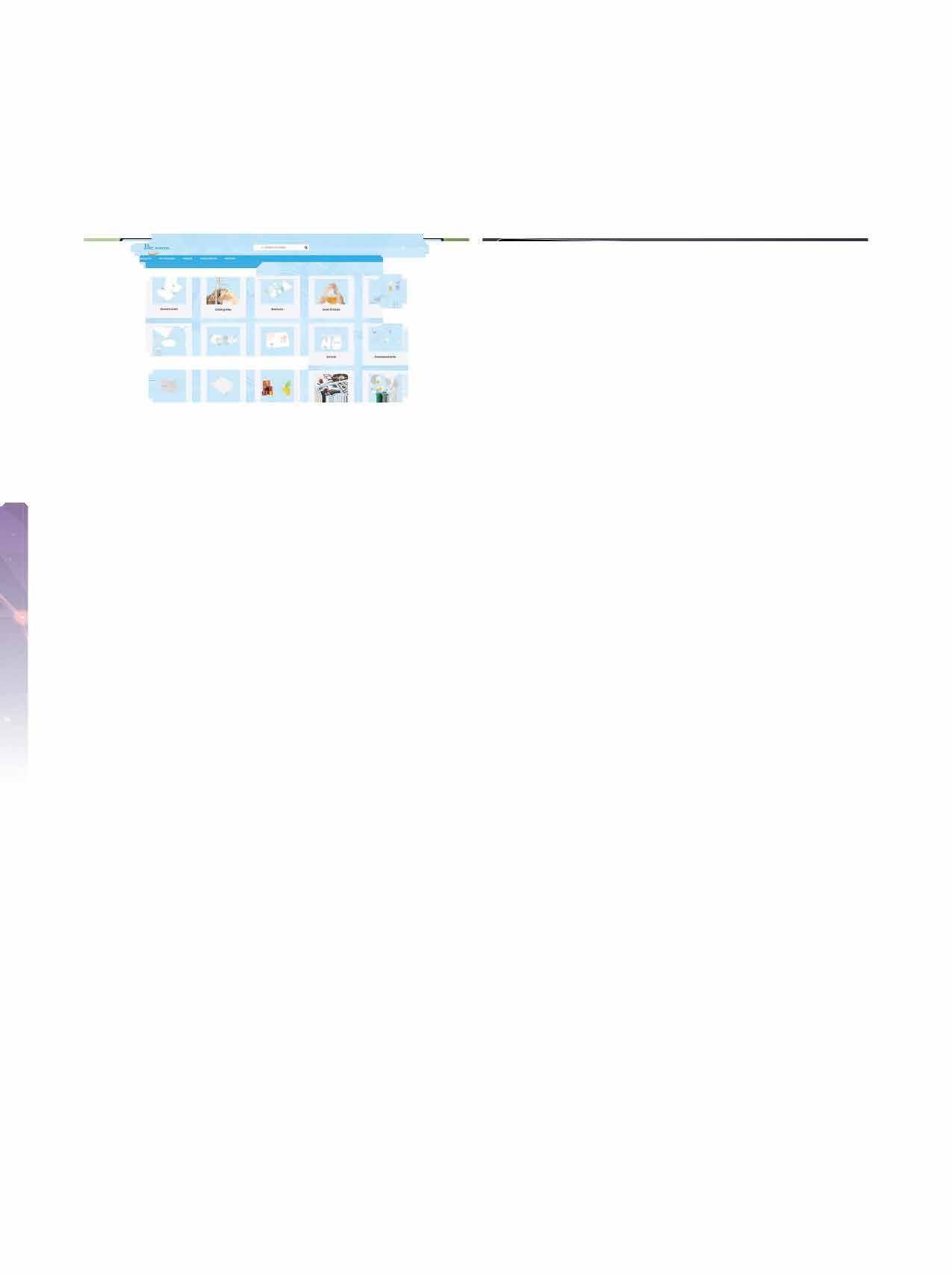

Above: RacadTech W2P Shop is a modular platform offering that works with a number of trusted technology providers.

relationships with existing customers, streamline and automate operations, and diversify their revenue.

Sarah Dishy, marketing and product development, WebToPrintSolutions, RacadTech, sees better exposure and visibility for print providers after adding W2P to their web offering. "Their websites are created in a way that maximizes visibility on search engines and social media sites. Better visibility and W2P tools that allow them to engage their customers on the spot turn visitors into customers."

"Most importantly, printers can use W2P in the B2B space to shift away from positioning themselves solely as print providers to undertaking a more comprehensive role in the supply chain for marketers. This enables printers to market themselves as innovative solution providers and establish lasting partnerships with some of the biggest brands and enterprise clients," adds Wyman.

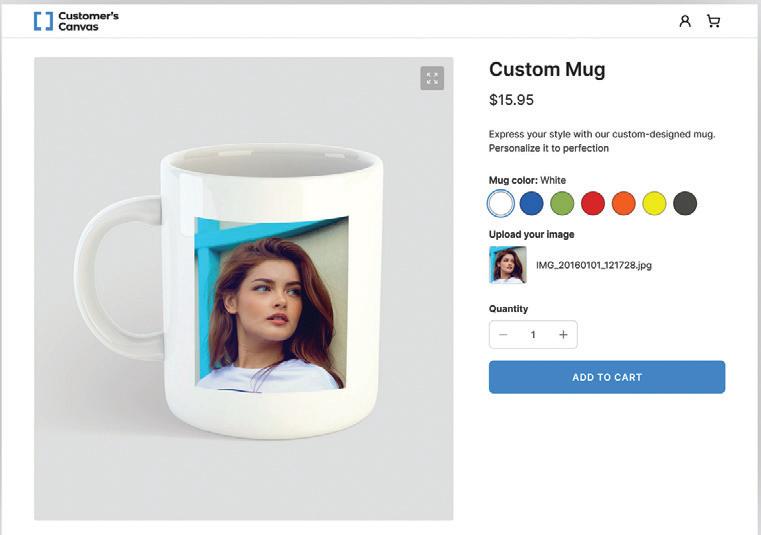

Several core functions of W2P are essential and/or appealing for B2C clients, including site building tools that improve ease of use and management insights.

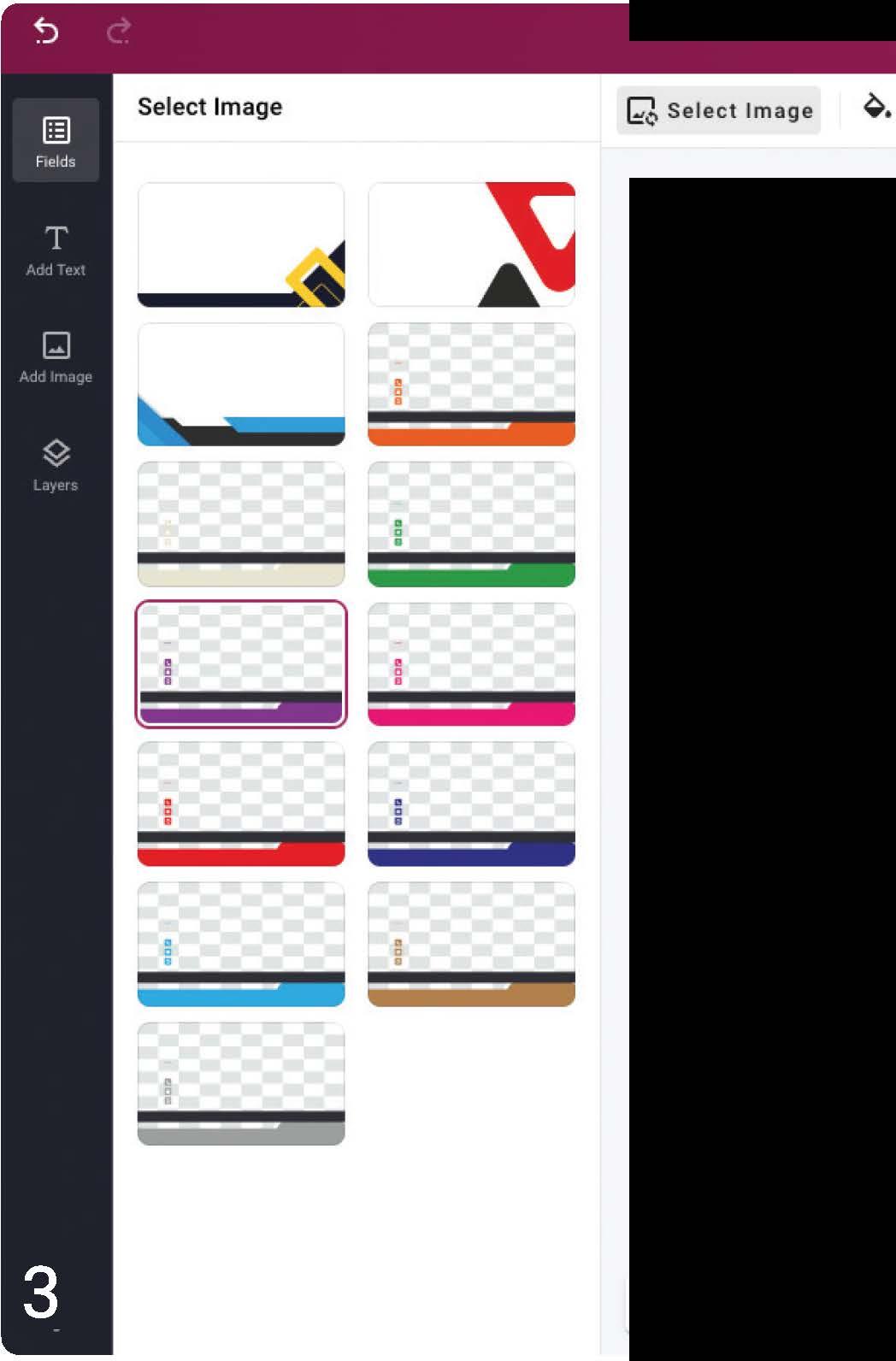

Naimish Patel, VP of sales, OnPrintShop, adds product personalization options, automated prepress, and integrated shipping solutions to the list of W2P functionalities that streamline operations and improve the customer ordering experience.

Modern no-code site designer tools are simple, easy to use, and offer selfhelp features enabling non developers to build or design their own sites. "Just choose a template close to your preferred design and edit it to match your needs. This is a cost-effective option with no maintenance as there is no need to hire a web designer to build and maintain the site," explains Vikash Bardia, CEO, Infomaze Elite Pvt. Ltd.

Today's dashboards provide site owners/operators with real-time system performance and health data, in simple, clear, and easy-to-read dashboards. "Managers love the insights and data provided that helps them make faster decisions about their business," shares Aaron Tavakoli, senior product marketing manager, MarketDirect, eProductivity Software.

Clive Buckley, product and portfolio Online design tools,instant price calcula- manager, Software Solutions & Sertors, order tracking, and integration with vices, Ricoh North America, points to payment gateways are popular features the attractiveness of a responsive deof W2P sought by B2C printproviders. sign, which ensures compatibility across

devices, while modern aesthetics enhance engagement with B2C W2P.

User-friendly interfaces with mobile support ensure higher conversion rates as an intuitive and easy-to-navigate platform encourages customers to complete orders with minimal frustration, comments Dmitry Sevostyanov, CEO, Customer's Canvas.

Integration with third-party tools is increasingly important. Tavakoli says integrated payment gateways and shipping calculators provide the easiest and simplest ways for customers to conduct business and ship products with big carriers.

For B2B-focused print environments, W2P tools play a different role compared to B2C.

Michel Lacaille, VP marketing, Mediaclip.ca, feels that the B2B approach requires the masteries and efficiencies of typical retail commerce.

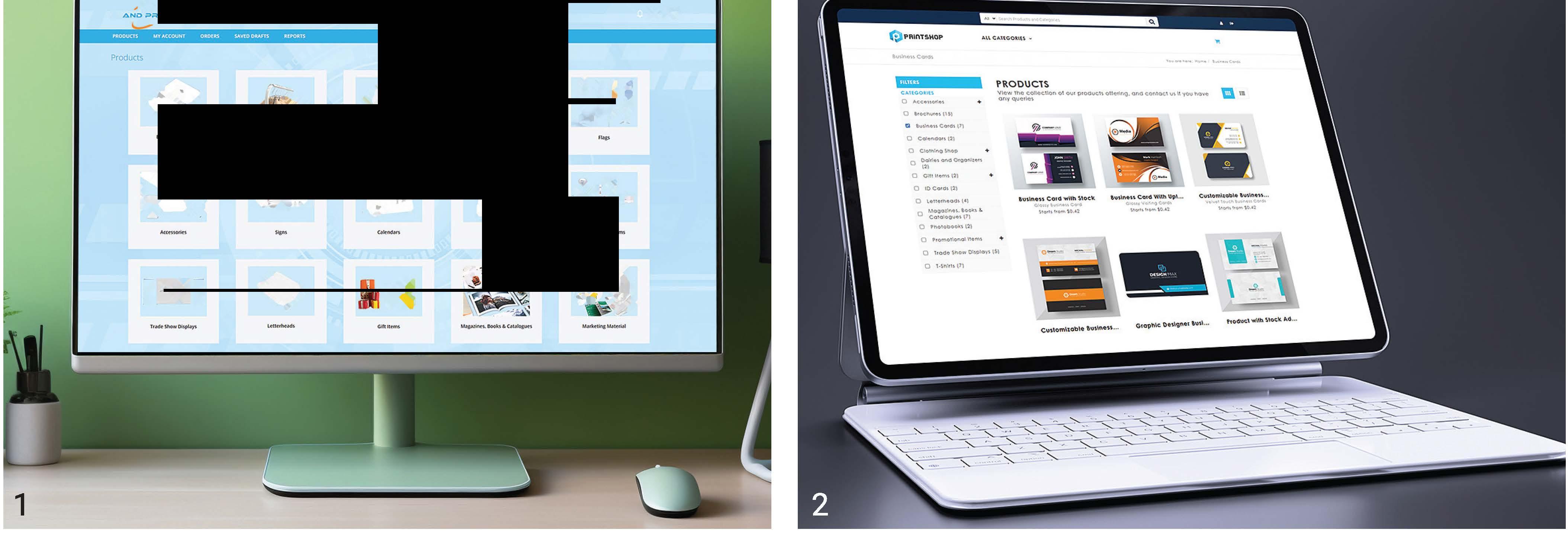

W2P for B2B is a rapidly developing segment, both in terms of the technology behind these solutions and the market opportunities for implementation. "Perhaps most significantly, advancements in 1. & 2. PrintPLANRisa cloud-based printmanagementsoftwarethatworksforalltypesofprinting.3. Aleyant's Pressero allows users to create multiple printecommerceB2Bonlinestorefronts.

John Hughes PrepressManager

m 000.222.6666

9david@emailcom

rl!lwww.company.com

integration technology make it easier for printers to connect their W2P solution with other systems in their tech stack," offers Wyman.

Apart from placing orders, features like repeat ordering, real-time order status, budget management spend limits, approval system, and reporting are all functions offered by a W2P in a B2B environment, says Bardia.

B2B print businesses commonly use functionalities like customized corporate storefronts, single sign-on (SSO) integrations, multi-user access with defined roles, and budget management tools, according to Patel.

Warehousing is an important W2P function for B2B print providers. "Customers can easily manage their product's stock from a B2B. Not only can they see available stock on every product;

when the stock is low they can replenish them," notes Bardia.

Flexibility to manage payments comes in handy. "Every B2B can have a different payment method enabled or no payments while ordering pay-only when invoiced. If the customer chooses to go hybrid, both options are enabled and the customer can to choose either to pay online while ordering or when invoiced;' comments Bardia.

Print businesses in the B2B space utilize both customer-facing and backend operational W2P functionalities to centralize their clients' marketing portfolio, give clients control and convenience, and streamline production and fulfillment of orders. "These functionalities include the client's ability to enforce complex businesses rules to control which organization members can see, access, edit, and order which products.

Back-end functionalities such as inventory management, high-volume fulfillment tools, and the ability to link products to third-party vendors empower printers to scale business, optimize workflows, and support any product type that their clients need," shares Wyman.

Analytics and business insights dashboards that provide crucial data for making informed business decisions are another function for B2B, notes Tavakoli.

Reporting continues to improve, agrees Graves. For example, Pressero enables one full custom dashboard per site to be customer facing. "This can allow the marketing team full sight of best products, most engaged users, and inventory. Also, our Professional Services team can assist in this area. While we can't create a perfect environment for each business, our team can create a personalized environment to include look and feel to custom developments."

Upcoming technologies like artificial intelligence (AI) also play a role in the evolution of B2B W2P. It is changing the way everyone works and it is no different for W2P. "AI will make it faster to deploy and build ecommerce sites, faster to manage jobs through production, to track jobs to delivery, and easier than ever to design and customize artwork for print," shares Tavakoli.

Lacaille lists AI in software creative solutions; production processes; as well as communications and marketing as upcoming functions to look for in this space.

W2P gives an assist to print providers focused in both B2B and B2C environments. New technologies, like Al, improve the capabilities.

Tune into a webinar on W2P this October at dpsmagazine.com/webinars. dps