S.T.A.R. Awards Recipient Register Roofing & S/M Low Slope

S.T.A.R. Awards Recipient Register Roofing & S/M Low Slope

®

Easy-to-use ROOF DECK TAPE® is a 40-mil, self-adhering waterproofing tape composed of a non-slip film coated with an aggressive asphalt-based adhesive system. Simply cut to length, peel off the release liner and roll with a hand roller for instant protection from water, air and moisture entering the structure.

ROOF DECK TAPE® Features

• Aggressively adheres to plywood, OSB, foam board and other common roof deck materials

• Textured surface for excellent foot traction

• Self-seals around common roofing fasteners

Scan here to watch the ROOF DECK TAPE® application video.

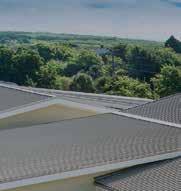

Jacksonville Jaguars Sports Performance Center, Jacksonville. Register Roofing & Sheet Metal received Third Place for this project in the Low Slope Category of FRSA's S.T.A.R. Awards.

FRSA-Florida Roofing Magazine Contacts:

For advertising inquiries, contact: Skip Heymann at: skip@floridaroof.com (800) 767-3772 ext. 127

All feedback and reprint permission requests (please include your full name and address) contact: Lisa Pate, Editor lisapate@floridaroof.com (800) 767-3772 ext. 157

Florida Roofing Magazine PO Box 4850 Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/ #FRSA #roofingprotects

View the case study

Equally strong and attractive, these metal roofing panels are available in Florida in our full line of PAC-CLAD painted steel, aluminum and Galvalume Plus coatings, ensuring that your roof will endure whatever comes its way. All panels are Miami-Dade County and Florida Building Code approved.

Thanks to the work of countless people over the past century, FRSA is a thriving trade association. The key to future success lies not only in the strength of our current leaders and membership but in the development of the next generation of leaders. These emerging professionals will one day take the reins and drive FRSA to new heights of innovation, influence and excellence. As industry trends evolve and new challenges arise, it becomes increasingly essential for us as an organization to invest in the growth and development of new members, ensuring that they are equipped with the skills, knowledge and mindset needed to succeed in our dynamic industry.

FRSA’s success and longevity depend on its ability to adapt, innovate and evolve. For this to happen, it is crucial that emerging professionals are not only welcomed into the fold but are actively mentored with the goal of taking on greater responsibilities. The workforce is constantly changing as is the skill set required to excel in the roofing industry. By nurturing new members and preparing them for future leadership, we help ensure that they are equipped with the forwardthinking capabilities necessary to thrive. Moreover, professional excellence doesn’t happen by chance. It requires a deliberate effort to build a strong foundation for growth, providing new members with tools and experiences that promote the continuous development of their careers. This process not only benefits the organization but also strengthens the industry as a whole by creating a network of skilled professionals who are ready to tackle complex challenges with confidence and competence. After all, we are not just roofers – we are professional roofing contractors.

One of the most effective ways to develop new members is through mentorship. Pairing emerging professionals with seasoned members who have a wealth of experience can provide invaluable guidance and insight. A good mentor relationship offers much more than technical knowledge; it provides proteges with soft skills, leadership strategies and an appreciation of FRSA’s culture and values. Mentors can share their own career journeys, offering advice and practical knowledge about navigating challenges and seizing opportunities. This guidance helps emerging leaders

build a strong foundation, allowing them to step confidently into roles of increasing responsibility.

At FRSA, mentorship happens organically as networking within the Association brings people together. FRSA has established the Young Professionals Council to bridge the gap between current and future roofing industry professionals through networking, technology and education. In 2024, we added the FRSA Mentorship Program created to allow young professionals to gain industry knowledge and insight from seasoned FRSA professionals.

Skilled labor shortages continue to persist and investment in young professionals to replace an aging workforce is essential to the continued quality and success of FRSA and the roofing industry as a whole.

An important aspect of leadership development is allowing new members to take ownership of important tasks or projects. Encouraging them to step up and contribute meaningfully not only helps them gain experience but also fosters a sense of accountability. By becoming personally invested in the outcomes of their efforts, emerging leaders develop problem-solving, decision-making and organizational skills. Ownership also builds confidence, showing them that their contributions are valued and integral to the success of the organization.

Networking is a crucial part of any leadership development plan. However, a strategic approach is essential, focusing on building one meaningful relationship at a time. Fostering connections with peers, mentors and industry leaders provides valuable opportunities for knowledge exchange and collaboration. A strong network not only opens doors to new business opportunities but also allows emerging leaders to learn from the experiences and insights of others in the field. These relationships create a support system that aids in professional growth and encourages future leaders to think outside the box. FRSA has committees that cover every area of operations. Members who volunteer their time to participate in these committees quickly discover that they receive at least as much as they give in professional insight.

Investing in the professional development of new talent has wide-reaching benefits, for both the individuals and the organization. Here are some of the key advantages:

Enhanced Organizational Culture – By prioritizing leadership development, organizations create a culture of continuous improvement and excellence. This encourages members to strive for higher standards and fosters an environment where new ideas can flourish.

Increased Retention Rates – Providing opportunities for career advancement and personal growth makes members feel valued and invested in the organization’s success. As a result, retention rates rise and the organization benefits from long-term commitment and loyalty.

Stronger Industry Presence – An organization that actively develops its new members into effective leaders can position itself as a forward-thinking, innovative entity within the industry. This enhanced reputation attracts new talent and opportunities for partnerships and collaborations.

Sustained Organizational Growth – When new leaders are properly trained and prepared, they are more likely to bring innovative ideas and approaches that help the organization adapt to changes in the industry and expand its reach.

The future of FRSA lies in the hands of its emerging leaders. By fostering a culture of development and mentorship, we can ensure that the next generation of professionals is equipped with the skills and insights needed to drive success. These efforts will not only help elevate the industry to new levels of achievement but also contribute to the broader growth and evolution of the industry as a whole.

By investing in the development of new members, FRSA will secure a legacy of professional excellence and build a pipeline of talented leaders who will sustain FRSA for years to come. The time to act is now, so that tomorrow’s leaders are prepared to rise to the occasion and lead with confidence, vision and purpose, following in the footsteps of those who have walked this path before them.

Best wishes,

1,332,902

Manny Oyola, Jr. FRSA President manuelo@eagleroofing.com

SRS posted a social media campaign supporting those who have been affected by the devastating California wildfires. SRS and their Raise the Roof Foundation are launching the One Family, One Fight for Wildfire Relief Campaign to support individuals and families displaced by the fires and to support the first responders who have courageously fought them.

SRS’s Raise the Roof Foundation will match every donation made, doubling down on efforts to provide relief to the affected communities. Your contribution will go directly to trusted nonprofits in Southern California, bringing critical aid where it’s needed most. Make your impact today by donating at SRS Raise the Roof Foundation Inc – One Family, One Fight for Wildfire Relief and helping spread the word. Together, we can help rebuild lives and provide hope. Donations can be made at www.floridaroof.com/srswildfirerelief.

ABC Supply Co. Inc. announced that Mike Jost has been promoted to President of the company. In his expanded role as President, Jost will continue as Chief Operating Officer of ABC Supply, leading the performance of company locations across North America. He will also manage ABC Supply’s branch, manufacturing operations and divisional companies, including L&W Supply. Jost will continue to oversee the company’s marketing, merchandising, real estate, education,

fleet, safety and national business development teams, driving strategic growth and operational excellence across the organization.

Jost joined ABC Supply in 2002 as a Branch Manager following the company’s acquisition of Washington Roofing as part of its purchase of Cameron Ashley Building Products. Throughout his tenure at ABC Supply, he has held various roles, including Sales and Marketing Manager for the Northeast Region in 2005, Business Manager for siding and windows, District Manager of the Mid-Atlantic Region in 2012 and, most recently, Chief Operating Officer. Jost has a Master of Business Administration from George Washington University and earned his undergraduate degree at the University of Virginia.

“In every role he’s held, Mike has been a driving force behind our growth and success,” said CEO Keith Rozolis. “His deep understanding of ABC Supply, combined with his passion for our associates and customers, makes him the ideal leader for this position. We’re excited to see him build on that momentum, bringing his energy and expertise to lead us forward.”

Trent Cotney, Partner, Adams and Reese LLP

Non-disclosure agreements (NDAs) are quickly becoming an essential part of doing business in the construction industry. For construction company owners, understanding how to navigate and implement NDAs effectively is critical to safeguarding your interests and maintaining trust with clients. The recent case of Venture Global Calcasieu, LLC vs. Kiewit Louisiana Co. highlights the potential risks and challenges associated with NDAs in construction projects, making it imperative for contractors to establish clear guidelines and protections.

Liquified natural gas (LNG) developer Venture Global entered into an agreement with Kiewit, a construction company, to complete work at its LNG facility in Louisiana. During the course of this project, Venture Global claimed that Kiewit provided confidential information to Shell, one of its competitors, in spite of the NDA included in the contract. Venture Global sued and obtained a temporary restraining order against Kiewit in August 2024. The companies reached a settlement shortly thereafter and the terms were not disclosed.

One of the most common pitfalls of NDAs is ambiguity. Construction company owners should ensure that their NDAs clearly define what constitutes confidential information. It is advisable to avoid broad statements such as “everything” being confidential. Instead, companies should specify the types of information that are protected, whether it’s design plans, project methodologies, pricing details or client lists.

For instance, in the Venture Global case, the NDA was so restrictive that even the existence of the facility was confidential. While such stringent requirements may be appropriate for specific projects, they can be difficult to enforce on active construction sites with numerous subcontractors, tradespeople and suppliers involved. Ensuring that the terms of the NDA are realistic and enforceable is key to avoiding disputes.

Additionally, it is crucial to have a system for labeling and identifying confidential information. Marking proprietary documents with labels such as “Confidential” ensures that all parties understand what falls under the NDA. This approach is fundamental on large projects with multiple stakeholders, where miscommunication can lead to unintentional breaches.

One challenge construction company owners often face is balancing the need to protect a client’s confidential information with leveraging their experience for future projects. NDAs can sometimes restrict a contractor’s ability to discuss or showcase previous projects, which can hinder marketing efforts and new client acquisition.

However, there are ways to navigate this limitation. While sharing specific blueprints or project plans may violate an NDA, using knowledge gained from past projects to solve similar challenges on new ones is generally permissible. For example, if a company developed an innovative workaround on one project, applying that solution to a similar issue on a new project is acceptable as long as proprietary details are not shared. When in doubt, companies must consult their legal team to ensure compliance.

Construction projects often involve a web of subcontractors, suppliers and consultants. General contractors must ensure that all parties working on a given project are aware of and comply with the NDA. Copies of the NDA must be provided to subcontractors, emphasizing the importance of adhering to its terms.

However, general contractors should avoid taking on the role of enforcer. If a subcontractor violates the NDA, the responsibility should fall to the project owner to take legal action. This approach protects the company from liability and allows focus on project delivery. During NDA negotiations, contractors should make reasonable efforts to ensure compliance but ultimate enforcement is the client’s responsibility.

NDAs should include a time limit for confidentiality obligations, typically ranging from two to five years. This parameter ensures that contractors are not indefinitely burdened with maintaining records or safeguarding information. The appropriate duration depends on the

nature of the protected information. For example, confidentiality related to a project’s design may need to be extended for several years, while information tied to a one-time proposal request may have a shorter lifespan.

Additionally, keep in mind that NDAs may have limited enforceability in public projects since open records laws apply. Understanding these nuances can help you craft agreements that are both practical and enforceable.

The use of NDAs is becoming more prevalent in the construction industry, particularly in sectors such as alternative energy, high-end retail and luxury sports venues. Clients often seek to protect unique designs, proprietary processes and high-end features. Additionally, as workers and contractors move between jobs more frequently, clients are increasingly concerned about safeguarding their competitive advantages.

To adapt to this trend, construction company owners should work with their attorneys to draft NDAs that balance the client’s need for confidentiality with the practicalities of running a construction business. This proactive approach not only helps avoid disputes but also protects project timelines and budgets from unnecessary delays.

For construction company owners, NDAs are not just legal formalities. They are becoming essential tools for building trust with customers and protecting your business.

FRM

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a Partner and Construction Team Leader at the law firm of Adams & Reese, LLP and FRSA General Counsel. For more information, you can contact him at trent.cotney@arlaw.com or by phone at 813-227-5501.

Adams and Reese LLP is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. Contact Trent at 813-227-5501.

John Kenney, CPRC, CEO, Cotney Consulting Group

In the fiercely competitive roofing industry, contractors face numerous challenges, from fluctuating material costs to increasing competition. Many roofing professionals are under constant pressure to underbid to secure projects, often sacrificing profits in the process. While submitting as many bids as possible may seem like the only path to success, a more innovative approach focuses on understanding and optimizing your numbers. One of the most critical metrics in this process is the bid-hit-win ratio, which clearly shows your bidding strategies’ effectiveness and identifies the jobs that lead to profitability.

Simply put, your bid-hit-win ratio is the percentage of bids won compared to the total number of bids submitted. This metric serves as a compass, guiding you to the right opportunities and helping you avoid the pitfalls of chasing low-margin or overly competitive projects. Contractors who track and analyze this ratio can refine their strategies, focus on the right clients and ultimately achieve higher profitability. Whether you specialize in residential roofing, commercial projects or niche services like green roofs or metal systems, knowing your numbers will help you grow your business more effectively.

Understanding your bid-hit-win ratio begins with grasping its importance. It’s a simple yet powerful indicator of whether your bidding process is aligned with your business goals. A low ratio might indicate that you’re bidding on the wrong types of projects or that your proposals are not competitive enough. A high ratio suggests that you’re targeting the right opportunities and are in sync with your client’s expectations. For example, a roofing contractor focusing on large commercial projects might have a lower ratio due to the competitive nature of that market. However, the high value of each contract could still make it worthwhile. Conversely, a contractor specializing in residential reroofs may aim for a higher ratio, as these jobs tend to have quicker turnaround times.

Establishing benchmarks for your bid-hit-win ratio is crucial. While there’s no universal standard, many successful roofing contractors aim for a 20 to 25 percent ratio. This range ensures you secure enough projects to keep your crews busy and your revenue flowing while avoiding overextension. However, the ideal ratio will vary depending on your business model and market conditions. A contractor working primarily on public bids may see a lower ratio due to the sheer

number of competitors and low bid requirements. In comparison, a contractor with strong client relationships and a reputation for quality may consistently achieve a higher ratio. Tracking your numbers allows you to set realistic goals and continuously improve your performance.

Improving your bidhit-win ratio requires a deliberate and strategic approach. The first step is to target the right projects. Not every job is worth pursuing and spreading yourself too thin by bidding on every opportunity is a surefire way to waste time and resources. Focus on projects that align with your strengths, whether TPO roofing, residential reroofs or complex commercial builds. For example, if you’ve historically excelled in metal roofing for higher-end homes, double down on that niche rather than chasing unfamiliar opportunities.

Another critical element is refining your estimating process. Accurate estimates are the backbone of successful bids and mistakes can quickly erode your margins. Use reliable software tools to streamline your estimating process and ensure all costs – materials, labor, overhead and contingencies – are accounted for. A detailed, well-structured estimate builds trust with potential clients and reduces the likelihood of scope creep during the project.

Building strong relationships is another proven strategy to improve your bid-hit-win ratio. Clients are more likely to work with contractors they trust, so cultivating relationships with property managers, general contractors and repeat customers can lead to more negotiated contracts. Negotiated work often has less competition, giving you better chances of winning the job at a profitable price. Furthermore, maintaining open and consistent communication with clients throughout the bidding process can set you apart from competitors who may only focus on price.

The presentation of your proposal also plays a vital role in winning bids. A professional, polished proposal outlining the project scope, timeline, materials and

warranty details demonstrates your expertise and attention to detail. Clients are more likely to choose contractors who instill confidence through clear and comprehensive documentation.

Tracking and analyzing your performance is essential to continuously improving your bid-hit-win ratio. Implement a system to record every bid, noting details such as project type, location and client. Regularly review this data to identify patterns and trends. For instance, you might find that your success rate is higher for projects within a particular geographic area or with specific types of clients. This insight lets you focus your efforts where they’re most likely to yield results.

Consider the hypothetical case of ABC Roofing, a contractor specializing in residential and commercial projects. Initially, their bid-hit-win ratio was 1:10, meaning they won only one job for every ten bids submitted. After analyzing their data, they discovered that the success rate of residential reroofs was significantly higher than that of large commercial projects. Narrowing their focus and optimizing their estimating process improved their ratio to 3:10 within six months. This shift increased revenue and a healthier profit margin, showcasing the transformative power of tracking and refining your ratio.

While improving your bid-hit-win ratio is essential, avoiding common pitfalls is vital. One major mistake is overbidding to secure work. Contractors often lower

their prices too much in order to win bids, leading to razor-thin margins and financial strain. Instead of competing solely on price, focus on demonstrating the value of your work through quality, reliability and expertise. Another common error is failing to seek feedback from lost bids. Understanding why a client chose a competitor provides valuable insights that can improve your future proposals.

Mastering your bid-hit-win ratio is crucial to building a profitable and sustainable roofing business. By understanding your numbers, targeting the right projects, refining your processes and leveraging strong relationships, you can transform your approach to bidding and achieve better results. Start tracking your ratio today and use it as a guide to make data-driven decisions, improve your profitability and seize the best opportunities in the market. In an industry as competitive as roofing, a strategic approach to bidding is not just an advantage, it’s a necessity.

John Kenney, CPRC has over 50 years of experience in the roofing industry. If you would like further information on this or another subject, you can contact John at jkenney@cotneyconsulting.com.

“It’s Time to Write Asphalt

of the

a Firestorm

Mike Silvers, CPRC, Owner, Silvers Systems Inc. and FRSA Technical Director

From time to time a subject captures the interest of both the roofing industry and the public at large. Most recently, this occurred in a very significant way when Florida Insurance Commissioner, Michael Yaworsky, made several statements concerning the future of the most widely used roof covering in Florida and the rest of the country. These comments were shared in both business and consumer publications that are widely distributed. Some quotes include the following:

Michael Yaworsky – Florida Insurance Commissioner

■ It’s time to write asphalt shingles out of the plot in Florida.

■ It’s probably time to look past asphalt shingles.

■ Thousands of claims are the result of wind damage to shingles.

■ You know, these products that are guaranteed to last for 30 years. They don’t last for 30 years in Florida. They just don’t.

If these comments were meant to bring attention to the subject, they certainly did. For many of us this is not a new topic. FRSA has been working with roofing product manufacturers and their representative groups to improve roof covering performance for decades. We are committed to learning from our post-hurricane observations and sharing that information with our members and the public. We build consensus through meetings and discussions with all segments of our industry. We, with our leadership’s approval, then go about implementing changes through participation in the Florida Building Code (FBC) modification process. We also interact closely with legislators and regulators on issues that could have an impact on our trade. The remarks made

by such an important player in the property insurance arena have our attention.

I want to share a few insights that my more than 50 years of experience, as a roofing contractor, volunteering as an FRSA member and, more recently, as FRSA’s Technical Director, has taught me. I am often asked “what is the best type of roof?” That is a question that I can’t answer. There are too many variables for one roof covering type to address all of them. Let me list a few of these that impact the best type of roof covering to select.

■ The design of the building, type of construction, roof configuration and the amount of slope it will provide are all critical considerations.

■ The building’s location is also of major importance. Engineering standards dictated by the building code consider both anticipated wind speeds and the surrounding topography. These standards tell us how much resistance to wind uplift we must include in the design of roof coverings and of course, the structure overall. The building's proximity to salt water should also be taken into account.

The insurance industry's insistence on the premature roof replacement of viable roofs that are only 15 years old or less has certainly made convincing an owner to invest in high-quality roof coverings that offer resilience and longevity a hard sell.

■ The owner’s circumstances are very relevant. Is the building a condominium where decisions are being made for a larger group? Is it an investment property that you plan to sell soon? Is it your home or business property that you intend to own for decades? In most of these examples, cost is always a consideration. The cost is not only the initial expenditure but the return on that investment based on the roof’s longevity. The amount of maintenance also should be a factor. In our current market, the cost of property insurance also has a major impact. The insurance industry's insistence on the premature roof replacement of viable roofs that are only 15 years old or less has certainly made convincing an owner to invest in high-quality roof coverings that offer resilience and longevity a hard sell. Sometimes the money just isn’t available to buy a better or the best product available; letting your

When it comes to roofing, the foundation matters. APOC offers a line of traditional, hybrid and synthetic underlayments to provide the ultimate protection and durability the roof needs. Our premium underlayments are designed with contractors in mind, offering time and labor savings, enhanced safety features, and the durability to withstand the harshest weather conditions, ensuring a robust and long-lasting foundation.

Weather-Armor® FT3 Fleece-Top Roof Underlayment

• Ice & water barrier

• Non-skid surface

• Temperature resistant up to 265°F

• Up to 180 days exposure

• For use under tile, metal, shingles & other mechanically fastened roof systems

Weather-Armor® SB1 Self-Bond® Roof Underlayment

• Ice & water barrier

• Self-adhered

• Non-skid surface

• Durable, walkable & scuff resistant

• Up to 90 Days exposure - UV resistant

• For use under shingles, slate, wood shake & more

APOC is the destination for professional grade commercial and residential building products of all kinds - roof coatings, adhesives, waterproofing solutions and more. Learn more about our full line of underlayments and other restoration products by visiting www.apoc.com.

Weather-Armor Cross-Over® CX-L Hybrid Roof Underlayment

• Nail sealable unlike other synthetics

• Lightweight and flexible

• 2X the coverage of a traditional 30 lb. felt; more per roll with less weight!

• Lays flatter and easier to install than traditional 30 lb. felt underlayments

• Non-skid surface

• Water shedding and moisture resistant

Check out our loyalty program where contractors can earn points for purchases, marketing support, and more! Scan the QR code or visit www.apoc.com to learn more.

www.apoc.com | www.icpgroup.com info@icpgroup.com

building be ruined, on the other hand, not by a storm but simply by water intrusion, is not a reasonable option either.

■ Personal preference should be considered. Some folks like the aesthetics of a particular roof covering or their HOA deed restrictions only allow certain types. Shouldn’t a group of owners be allowed to have a preference in how their neighborhoods look?

For all the reasons I covered and many more that haven’t been touched on, having a wide variety of roof covering options serves us well. FRSA is dedicated to improving the performance of every roof system and maintaining these choices. From my observations, all roof coverings have their pros and cons. By weighing these options we can make the best choice to protect our buildings. But asphalt shingles are the subject here so let’s address some important considerations and examine some misconceptions.

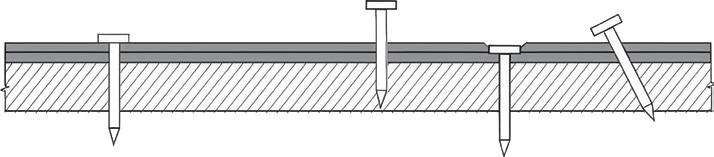

First, let’s start with an understanding that the primary purpose of a roof system is to keep the water out of the building. If it can’t accomplish this, then it doesn’t matter if it can resist high winds or not. All types of shingles and, for that matter, roof tile, slate and nearly all early metal roofs use fasteners that are overlapped (concealed) by the next higher (up slope) course or row of material, thereby protecting the fasteners below from weather exposure. This

Properly Driven

basic approach has proven to be highly effective in providing weather protection for centuries. It doesn’t, however, lend itself to easy verification of the quantity and placement of fasteners during post installation inspections.

Asphalt shingle design has evolved from early strip shingles to today’s most often used laminated shingles, which are commonly referred to as architectural or dimensional shingles. There are also multi-layer laminated shingles often referred to as designer shingles. I have this type of shingle on my home. They are 28 years old and were performing flawlessly until they sustained some aesthetic damage in Hurricane Milton’s 100 mph-plus winds. All modern shingles incorporate a seal strip that adheres the leading edge of shingle to the layer below. This feature is there to resist wind uplift and its effectiveness is critical. Asphalt roofing manufacturers have been striving to improve the performance of these sealants and are making great strides.

Improperly Driven

Underdriven inadequate deck penetration

The fasteners are also very important for a wind resistant system. The proper placement and application of the nails are critical. Misplacement of fasteners and fasteners that are driven through the surrounding shingle material are common causes of failure and have little to do with the product itself (see diagram below). The most common application method used for applying shingle fasteners is a pneumatic nailer. The rapid installation made possible by pneumatic straight, good penetration and flush with shingle surface

Overdriven too deep, cuts into shingle

Continued on page 17

Crooked inadequate anchorage

nailers unfortunately contribute to nail misplacement. They also lead to overdriven fasteners that weaken the surrounding shingle material. The quality of the installation is of the utmost importance for all roof coverings but, unfortunately, the actual installation results can vary widely. This is particularly true with asphalt shingles. Many assume that shingle applications are simple and nearly foolproof so anyone can do it. Nothing could be further from the truth, particularly when it comes to achieving wind resistance.

In Florida, except during a state of emergency, shingles are the only type of roof covering that can be installed by a contractor (Division 1 contractors: building, general and residential) other than a licensed roofing contractor. This is true unless the building owner decides to self-contract their roof replacement. Asphalt shingles are almost exclusively the roof material used by do-it-yourselfers and other unlicensed installers.

It is difficult to verify the quality of the installation and who did it when observing post-hurricane damage. Conclusions reached during post-hurricane assessments are seldom based on digging deep into the cause of a particular failure, they are usually anecdotal but can still be helpful. Seldom are true forensic investigations done. So, we must be careful about the conclusions that we reach based solely on visual observations and consider all the variables.

This leads us to the important question of what should be considered a roof failure? Is it a small amount of cosmetic damage after a roof system has been exposed to winds approaching or exceeding 100 mph? Or should we consider it a failure when there is water intrusion and interior damage? Going back to the primary purpose of a roof system: if it kept the water out during a hurricane and allowed the building to continue to be occupied shouldn’t that be considered success?

I recently addressed the Asphalt Roofing Manufacturers Association (ARMA) at their Board of Directors meeting in Indianapolis and made a presentation titled Post-Hurricane Perceptions Matter. My goal was to bring them a Florida perspective and to reinforce ARMA’s interest in improving asphalt shingle roof performance after high wind events and how the perception and the narrative in Florida was not favorable to asphalt shingles. They were very receptive to the message and have been forthcoming in sharing the improvements in materials being made by many manufacturers. We will continue to work together through building code changes to improve materials, testing and application methods. ARMA is currently working with FEMA and conferring with FRSA to improve hip and ridge performance. This roof condition is where post-hurricane observations have found many failures in all roof covering types but especially with asphalt

shingles. Addressing this issue could go a long way to reducing these failures. It is important to note that most often these hip and ridge failures do not lead to water intrusion. They are a part of a redundant roof system with multiple layers of material in these areas. They do, however, get recorded as damaged and thereby a "failure."

When accessing the amount of damage to asphalt shingles post-storm, one needs to remember that, nationally, asphalt shingles represent approximately 80 percent of residential roof coverings; in Florida it’s closer to 65 percent. Those percentages go up significantly if we look back a decade or two. This makes the large majority of older roof coverings asphalt

shingles. In 2024, approximately 1.5 billion square feet of asphalt shingles were shipped into Florida. Because of lower costs, they are the predominant choice for affordable housing. We all want better performing roof systems but for many there are financial limits that we may have already exceeded.

Better quality asphalt shingles are available from nearly all manufacturers. They are, of course, more expensive and thereby seldom used. Shingle manufacturers and roofing contractors need to find ways to demonstrate to those outside the roofing industry that these premium products are available and may be worth a slight price increase when looking at the overall cost of a new roof. When wind ratings and

warranties are all the same, it makes it a hard sell. Insurers should strive to recognize the differences, both during underwriting and claims handling.

As has been reported, Press Secretary for Yaworsky’s office, Shiloh Elliott, wrote in an email, “Florida’s building codes are working and we do not want progress to go backwards,” and FRSA is in complete agreement. We and our industry partners have been working diligently to make sure we can continue that progress. According to nearly all reports and our own observations, we know we are making significant progress. Let’s continue to work through the building code arena and encourage the insurance industry to reward those who can afford to help mitigate their losses by choosing resilient options, without taking a

punitive approach against a practical and affordable product that has a very strong history of success. We will be meeting with Commissioner Yaworsky’s office soon to share our mutual interest in providing more resilient roof systems and to bring his team our industry knowledge and perspective on how to best achieve that.

FRM

Mike Silvers, CPRC, is owner of Silvers Systems Inc., and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.

BITEC, Inc.® introduces Imperflex SA2 two-square self-adhered base sheet as a convenient-to-install option for its Imperflex self-adhered roofing system. Ideal for residential roofs where slope prevents the effective use of shingles, tile, or metal.

Gary A. Cohen, Vice President, Certified Contractors Network

In the world of contracting, success is often measured by tangible outcomes like completed projects, satisfied customers and profit margins. While technical skills, operational efficiency and marketing strategies are essential to your success, one less visible yet equally powerful factor underpins long-term success and that is your mindset. Your mindset influences how you approach challenges, seize opportunities and lead your team. In an industry as competitive and demanding as home improvement and remodeling, cultivating a strong and resilient mindset can be the difference between thriving and merely surviving.

Mindset refers to your attitudes, beliefs and thought patterns that shape how you perceive and respond to the world. Psychologist Carol Dweck famously categorized mindset into two main types:

1. Fixed Mindset: The belief that abilities and intelligence are static traits that cannot change.

2. Growth Mindset: The belief that abilities can be developed through effort, learning and persistence.

For contractors, a fixed mindset might lead to stagnation – avoiding new technologies, resisting process improvement or fearing feedback. In contrast, a growth mindset encourages adaptability, innovation and resilience, which are crucial in an industry shaped by fluctuating market demands, economic shifts and ever-evolving customer expectations.

Problem-Solving and Adaptability – In our industry, challenges are inevitable: unforeseen structural issues, supply chain disruptions or difficult clients. A contractor with a fixed mindset might see these as insurmountable problems, while someone with a growth mindset views them as opportunities to learn and innovate.

For example, during the pandemic, contractors who adapted to virtual consultations and embraced remote project management tools not only survived but they often thrived and experienced record growth. These businesses were driven by leaders who embraced change rather than resisting it.

Leadership and Team Building – Your mindset directly affects how you lead your team. A growthoriented leader fosters a culture of continuous improvement, encouraging employees to take owner-

ship of their work and develop their skills. This approach builds loyalty and morale, reducing turnover, a common challenge in the home improvement industry. On the other hand, a leader with a fixed mindset may micromanage or fail to invest in employee development, leading to a disengaged workforce and missed opportunities for innovation.

Customer Relationships – A positive and solution-oriented mindset enhances your ability to build trust with clients. When customers sense that you’re genuinely committed to solving their problems and delivering exceptional results, they’re more likely to recommend your services. Conversely, a negative or defensive mindset can erode trust and harm your reputation.

While technical skills get you in the game, your mindset determines how far you’ll go. Here are some ways positive thinking can transform your business:

Overcoming Fear of Failure – In contracting, no project is without risk. Fear of failure can paralyze decisionmaking but a positive mindset reframes failure as a steppingstone to success. Learning from setbacks and applying that knowledge positions your business for long-term growth.

Enhanced Productivity – A positive outlook reduces stress and promotes focus. When you approach each day with optimism, you’re better equipped to tackle tasks efficiently, inspire your team and exceed customer expectations.

Better Decision-Making – A negative mindset often clouds judgment, leading to reactive decisions. A positive mindset fosters clarity, allowing you to evaluate options and choose the best course of action, even under pressure.

Embrace Lifelong Learning – Stay open to new ideas, tools and techniques. Attend industry conferences, invest in training and network with other contractors

to gain fresh perspectives. Continuous learning keeps you ahead of the competition.

Set Clear Written Goals – Goals memorialized in writing provide direction and motivation. Break down larger objectives such as increasing annual revenue or improving customer satisfaction into smaller, actionable steps. Celebrate milestones along the way to maintain momentum.

Practice Gratitude – It’s easy to focus on what’s going wrong, especially in high-pressure situations. Take time each day to acknowledge what’s going right. Gratitude shifts your focus from problems to opportunities, fostering a positive outlook.

Surround Yourself with Positivity – Your environment greatly influences your mindset. Surround yourself with supportive colleagues, mentors and industry peers who inspire and challenge you. Avoid negative influences that drain your energy or confidence. Manage Stress Effectively – Stress is inevitable but how you handle it matters. Develop healthy coping mechanisms, such as exercise, meditation or hobbies outside work to maintain your mental and emotional well-being.

Reframe Challenges as Opportunities – Instead of dwelling on obstacles, focus on what you can learn or gain from them. For instance, a project delay could be an opportunity to refine processes or improve communication with your team.

Cultivate Resilience – Resilience is the ability to bounce back from setbacks and is a hallmark of a strong mindset. Build resilience by focusing on what you can control, maintaining perspective and learning from adversity.

A contractor faced a significant setback when a homeowner canceled a very large residential contract unexpectedly. Instead of dwelling on the loss, the contractor shifted focus to communities adjacent to their current market area and won several residential projects. This pivot not only filled the revenue gap but also opened up a new, lucrative market segment for the business.

A contracting company noticed high turnover among its crew members. The owner implemented a growth-focused training program, encouraging employees to learn new skills and take on more responsibility. As employees grew professionally, job satisfaction and retention rates soared, leading to higher productivity and customer satisfaction.

Your mindset doesn’t just affect you, it influences your team, your clients and even your industry. A contractor who approaches work with passion, positivity and purpose creates a ripple effect, inspiring others to strive for excellence.

When your team sees you tackling challenges with confidence and optimism, they’re more likely to mirror that behavior. When clients experience your commitment to solving their problems, they’re more likely to become loyal advocates for your business.

In a crowded marketplace, mindset can be your secret weapon. While competitors focus solely on cutting costs or boosting sales, your mindset allows you to

FRSA Self Insurers Fund is the best Workers’ Compensation carrier for Roofing Contractors in Florida.

The Fund’s exceptional service and dividend returns are unmatched in the industry.

In 2023, Fund members received $5 million in Dividends and in June another $2 million based on 2023 performance –while workers’ comp rates are the lowest in history.

innovate, build stronger relationships and weather economic storms.

Contracting is about more than installing and repairing roofs: it’s about creating value for customers and communities. With the right mindset, you can transform not only your business but also the lives of those you serve.

Conclusion

The power of mindset cannot be overstated. By cultivating a growth-oriented, positive and resilient mindset, you set the foundation for success that goes beyond technical expertise. Your mindset influences how you lead, innovate and connect with clients, all of which are critical to building a thriving business. Start today by embracing challenges, seeking growth opportunities and fostering positivity in every aspect of your work. With the right mindset, there are no limits to what you can achieve.

FRM

Gary A. Cohen is Vice President of Certified Contractors Network (CCN) and is responsible for the day-to-day operations of the company. CCN is the leading comprehensive training, coaching and networking membership organization in North America. Gary is also a 30-year veteran of the home improvement industry, spent 11 years at the Robert H. Smith School of Business at the University of Maryland as a Professor of Business and served four years as Associate Dean of the Business school. Gary has been a Certified Leadership Coach for the past 18 years. His email address is gary@contractors.net.

Brad Bush, Senior Vice President, HUB International Florida

Florida’s construction industry faces another year where an improving economy and relenting inflation are countered-balanced by uncertainties that will challenge even the most nimble of players.

The state’s roofing contractors will find that adaptability continues to be their most valuable asset for thriving despite the uncertainties, as they employ smart strategies to protect people and projects against the risks that can weaken resiliency. Here’s what’s ahead.

On the national front, 2025 is expected to see new construction spending reach $2.145 trillion and continue on that track through 2028. Much of the momentum in Florida will be propelled by non-residential construction. Hotel, retail and healthcare construction should lead those gains of 5.9 percent, while federal funding for highways and bridges will push nonbuilding construction up by 8.8 percent.

Relenting inflation and mortgage rates also will benefit Florida’s stalled housing market to some extent. Construction of single-family homes, townhomes and multifamily units will begin to pick up but affordability will remain an issue because inventory remains tight as construction expenses continue to rise.

While the improved environment for inflation and interest rates is positive for incoming work, roofing contractors will need to be wary of the downside risks of upward pressures on labor and supply costs. A variety of labor supply challenges will keep wages trending up, at least moderately, while profitability may also be affected by fluctuating material prices.

The shortage of labor in the construction industry shows no sign of improving. It’s likely to be especially hit by the Trump administration’s promised deportation policies.

The industry overall can expect a deficit of 450,000 workers in 2025. That will worsen with mass deportations, as construction’s share of non-U.S. citizen workers is the highest of any other sector at 2.45 million out of 11.38 million employees. Florida’s construction industry fits that pattern as a quarter of its workers, roughly 109,000, are illegal, largely from Mexico and Central America. Roofers are particularly affected. Demand for services is consistently high with increasing frequency of weather events, aging housing

stock and the labor pool shrinks even more as existing workers retire.

The labor issue has been a long-standing drain to the industry’s vitality, requiring it to double down on efforts to address it.

Registered apprenticeship programs have grown 40 percent in the last decade, with the construction trades accounting for more apprentices than any other sector. Technology can help, too: wearables, for example, can detect falls or lack of movement, making roofing safer and a better employment bet.

Rethinking benefits can also help. Personalized benefits are a growing trend, developed through a deep dive into employee data to uncover what people value to deliver what individuals truly want and need. The end result is an environment that encourages engagement and productivity and improves recruitment and retention capabilities.

It’s not just economic challenges that will keep Florida’s roofers on their toes in 2025. Even less predictable are atmospheric changes of weather extremes and the risks to workers and businesses.

The 2024 hurricane season, for example, was one of the most destructive on record, as 18 named storms, 11 hurricanes and five major hurricanes battered the Atlantic coastline. Add to that the “endless summer” of 2024 in Florida: by mid-September, South Florida alone experienced over 85 days of extreme heat reaching over 100ºF.

Weather extremes may create more rebuilding work in the long term but in real time they play havoc with project timelines and are a huge risk for workers. Roofing is dangerous work anyway and extreme heat is a leading cause of death for workers laboring outside. When work schedules must be adjusted for weather conditions, the physical work can stretch out by 35 percent. Such conditions, combined with economic forces like inflation and its effect on material costs and their supply, mean contractors must keep a tight focus on risk management, especially since

Revolutionize your roofing projects with STINGER’s Moisture Defense System. The powerful combination of EXO Underlayment, NailPac®, and CN100B not only shields against moisture but also streamlines installation, saving you valuable time and money.

STINGER NailPac and EXO 25, 35, and 50 meet the standard requirements of a FORTIFIED Roof™ - a level of protection in the Insurance for Business & Home Safety’s (IBHS®) FORTIFIED Home™ program.

Experience the pinnacle of roofing technology with STINGER.

Seay Management Consultants

With a 2023 valuation of $23.35 billion, the U.S. roofing market is forecasted to grow at a 6.6 percent compound annual growth rate from 2024 to 2032. In addition, the average roofing contractor business in the U.S. now employs more workers than it did five years ago. In the ever-growing construction industry, roofing and sheet metal companies are constantly seeking innovative strategies to improve their hiring processes.

Florida has the largest share of roofers in the U.S., at 25,190 (representing 18.6 percent of all U.S. roofing industry workers). It is important for roofing contractors to find the best candidates.

One tactic that is gaining ground in the industry is offering “tryouts” or “ride-alongs” before extending a permanent job offer to a new roofing employee. This practice involves providing candidates with a conditional job offer, ranging from a day to a week, to evaluate their suitability for the role.

Without an effective onboarding process, businesses risk getting trapped in a costly cycle of turnover. This is particularly important in the roofing industry where the average amount of time an employee stays with one company is about 16 months compared to a 4.6year average across other industries, according to the Bureau of Labor Statistics.

The financial burden of recruiting, hiring and onboarding a new roofing or sheet metal employee can be substantial, with the average cost-per-hire across industries sitting at a whopping $4,700 in 2022, according to the Society of Human Resource Management. On average, companies have 44 days to influence a new hire’s long-term retention. However, 44 percent of employees report having regrets or second thoughts about their new job within the first week. This highlights the critical need for companies to ensure a good fit from the outset, which is where tryout periods come into play.

While companies may be eager to implement tryout periods, there are important considerations for employers to keep in mind before taking this approach. Understanding the legal and procedural requirements is crucial to ensure a smooth and compliant trial period. Here are key points roofing employers need

to know if they plan to offer a tryout period: Compensation and Benefits. Legally, a tryout period must be paid time and count toward seniority and eligibility for company benefits and paid time off (PTO). Candidates working on a trial basis are subject to all labor regulations (federal and local) regarding pay and worker classification. Additionally, the employer must have workers’ compensation coverage for all workers. Documentation. Proper documentation is crucial. Businesses should have candidates sign an agreement outlining the requirements of the trial period, including the term, expectations and compensation. This protects both the employer and the candidate and sets clear expectations from the start.

Tryout periods offer significant advantages for both employers and candidates. By allowing both parties to test the waters before committing, this approach can lead to better long-term matches and a more positive work environment. Here are some of the key benefits of a tryout period:

■ Skill Verification. Managers can directly observe whether the candidate possesses the required skills to do the job well in a hands-on situation.

■ Reduced Hiring Risks. A tryout period minimizes the risk of investing further time and money into a candidate who may not be a good fit for the company or the position.

■ Cultural Fit. Employers can assess whether the candidate aligns with the company’s culture and values.

■ Practical Experience. Candidates get the opportunity to try the role, meet potential co-workers and experience the company culture in a practical way before committing to a long-term position.

■ Informed Decision-Making. This trial period allows candidates to make more informed decisions about their fit and future with the company.

The tryout period is an HR trend that can offer mutual benefits for employers and candidates as long as HR departments navigate the legal and logistical aspects appropriately. By providing a practical evaluation period, companies can reduce hiring risks and improve employee retention, ultimately fostering a more stable and productive workforce.

Employers who are interested in hiring a qualified job applicant on a tryout basis should consider the following:

1. That the individual being considered for employment be hired under all of the company’s current normal hiring practices, including completing an employment application and the regular new hire documentation (I-9, W-4 and state tax withholding, etc.).

2. Individuals hired under this scenario must be compensated at minimum wage or above for each hour worked in the week and time-and-ahalf for any time worked over 40 hours in the workweek.

3. A document (signed and dated by all parties) should be drawn to state that the offer for employment is for a tryout period only. The length of the tryout should be determined by the employer and the applicant and both agree and understand that there is no stated or implied guarantee of continued employment beyond the trial period and that management has complete discretion regarding continued employment.

4. That it is understood upon completion of the “trial period” that an evaluation will be made as to the worker’s continued employment and that the trial period may or may not be considered

Positive Trends, continued from page 24

insurance costs and availability at required limits can be pressured.

A first-class broker is essential to help firms develop a comprehensive claims management plan to get through any type of business disruption. An effective loss mitigation strategy is another way to reduce claim severity by leveraging coverages like extra expense to reduce downtime and minimize losses.

Roofing firms may also benefit by researching insurance solutions relevant to their circumstances. Parametric insurance pays policyholders when weather thresholds pass a pre-specified mark. It’s an option over traditional lines that don’t cover losses stemming from, for example, heatwaves.

as part of the company’s normal probationary period, such as 60 days. If so, the employee must successfully complete the remainder of the company’s normal probationary period upon finishing the trial period.

5. An addendum should be attached and included in the employer’s handbook stating that on occasion the company may decide to hire an applicant on a trial basis as deemed necessary. This decision will be made at management’s discretion, to determine if a potential job fit is evident and provide the employee with a first-hand view of the position for which they have an interest. Final decision on continued employment will rest with management upon completion of the trial period.

In addition, applicants hired on a trial period basis are subject to the same state and federal regulations as all other employees relating to employment law and nondiscriminatory policy and practice. Therefore, roofing and sheet metal companies should regularly monitor the use of this practice to ensure it continues to meet the standards.

As a member benefit, FRSA members have complimentary access to a human resource professional in partnership with Seay Management Consultants. This resource is available to provide answers to your HR, personnel management and employment-related questions including topics such as payroll, leave of absence, discrimination, discipline, workers’ compensation and disabilities. Sometimes a simple question can turn into a complicated and costly concern if it is not handled properly. When you have a question and need an accurate and concise answer, contact us by phone or email and identify yourself as an FRSA member. Email admin@seay.us or phone 888-2456272. There is no fee for a 15-minute consultation. Discounted fees apply for in-depth consultations.

Above all, firms should enter 2025 having put their houses in order to effectively manage constantly changing business dynamics. This should include a strengthened risk management strategy supported by an insurance program that’s right for evolving conditions.

FRM

Brad Bush is a Senior Vice President in the Jacksonville region for global insurance brokerage HUB International Florida. Brad works throughout the Southeast and specializes in construction, working with contractors on both their surety and insurance needs. He spent the first 10 years working on the insurance carrier side and the balance as an insurance broker.

Mitch Levine and Lee Rust, Corporate Finance Solutions

In many cases, if properly structured, reward or incentive compensation can help a company’s revenues and profits increase. They align the company’s managers’ goals with the company’s owners’ goals and can also be used to keep those managers from leaving for another job. If the incentives are effective, the increase in a manager’s pay makes it difficult for another company to match their total salary and bonus.

It is crucial for you to engineer your company’s growth. However, incentive compensation has a cost in addition to the cash payments to participating managers. No incentive is effective unless it is simple for the person receiving it to comprehend. Furthermore, that individual must be able to calculate his or her progress toward the incentive, as well as the amount of the incentive earned, at any given time.

This necessitates providing each manager with the financial data required to make those calculations. However, you should share your company’s financial statements with all managers who have the ability to influence its financial performance. Don’t hoard the information that your managers can use to identify problems, make corrections and boost profits. In terms of bonuses, you must decide who should participate in addition to the structure and amount. In general, I believe that bonus compensation should be extended to all employees who have a direct im pact on a company’s financial performance.

Structure bonuses as annual payments at the highest levels of management. Base a portion of the bonus on the results of the department or function under the manager’s direct supervision and control, as well as a portion on the company’s overall perfor mance. This structure not only rewards the manager for individual performance but it also encourages collaboration with other departments and concern about the overall operations of the company.

Quarterly bonuses may be more appropriate for lower-level managers than annual bonuses. Employees at lower levels of a company are generally best rewarded over shorter periods of time. A foreman may find that a payment made within three months is more effective than a payment made over the course of a year.

Bonus payments for hourly or non-manage ment employees should typically be made monthly and based on a single performance objective. For example, pay a monthly bonus to all hourly employ ees who exceed a certain level of production per man-hour.

One of my clients, who owns a number of retail stores, now rewards store employees for monthly sales levels that exceed a certain threshold. In each

employee’s weekly payroll check, the company calculates the store’s month-to-date sales and issues bonuses. A manufacturing company may post the production level each week on a large sign in the shop to make these lower-level bonuses effective. Each week, shop employees can see if they are on track to reach the bonus level. You can also do it for safety protocol.

If you’re concerned about the cost of such bonuses, keep in mind that if they’re structured properly, the increase in your company’s profits will more than cover the cost of the bonus. In the meantime, think about how you can use bonus plans to boost your company’s profits and enterprise value while rewarding the employees who help you get there.

Mitch Levin and Lee Rust, Corporate Finance Solutions, specializing in mergers and acquisitions, succession planning, strategic planning and financing. For more information, visit www.colfinsol.com or call 888-885-5656.

FRSA Members Giving Back to the Community

Late last year, the Northeast Florida Roofing and Sheet Metal Contractor’s Association (NEFRSA) held its 36th Memorial Golf Tournament at Eagle Harbor in Fleming Island. The tournament honored the memory of Ralph DeCicco, who lost his courageous battle with cancer in November 2023. Ralph was a contractor and served for many years as the NEFRSA Affiliate Executive Director.

The event brought together members of the Northeast Florida roofing community for a day of camaraderie, competition and charity. With a record number of sponsors, led by the title sponsor ABC Supply, the tournament achieved remarkable success, raising over $22,000, an increase of nearly 25 percent from the previous year. These funds will support NEFRSA’s charitable initiatives for 2025, reinforcing their commitment to give back to the community. The first project on the horizon will benefit Pine Castle, a Jacksonville based organization dedicated to empowering adults with intellectual and developmental

differences. NEFRSA will spearhead a roof replacement for a shop building within the Pine Castle campus, ensuring that this vital facility continues to serve its mission of helping individuals learn, work, connect and achieve their fullest potential.

The golf tournament exemplified the strength and unity of the Northeast Florida roofing community, demonstrating how collaboration can create a meaningful impact. The enthusiasm and generosity of participants and sponsors ensure that Ralph DeCicco’s legacy will be honored through lasting contributions to the community. Thank you to everyone who participated in this memorable day. Together, we are building more than roofs, we’re building a brighter future.

FRM

FRSA is proud of the volunteer work completed by members in the industry and would like to share those projects as often as possible. If you have a community service project you’ve completed, please send it to Lisa Pate at lisapate@floridaroof.com.

THE EXPERTS IN METAL ROOFING ABOVE AND BEYOND THE ROOF

On-Site roll forming

Fast Deliveries

Free Metal Quotes by EZtimate

Military and first responder discounts

Florida Product Approvals or Miami-Dade NOAs on all products

Wide selection of panel systems – over 70 different options

6040 Old Dixie Highway, Vero Beach, FL 32967

2836 NE Waldo Road, Gainsville, FL 32609

2160 SW Poma Drive, Palm City, FL 34990

99450 Overseas Hwy, Key Largo, FL 33037