A Publication of FRSA – Florida’s Association of Roofing Professionals

S.T.A.R. Awards Recipient

Blues Brothers Construction

Steep Slope Category

S.T.A.R. Awards Recipient

Blues Brothers Construction

Steep Slope Category

MFM introduces IB-3™ StormStopper Plus, designed specifically for the Florida roofing market. Stop storm damage in its tracks and offer your customers a qualified FORTIFIED PROGRAM product for years of worry-free service. This 50-mil, self-adhering roofing underlayment features a granulated surface and a non-removable selvedge edge for a secure seal on overlaps for whole roof protection.

IB-3 StormStopper Plus meets ASTM D 1970 and Florida Building Code FL# 41919.1.

FRSA-Florida Roofing Magazine Contacts:

For advertising inquiries, contact: Skip Heymann at: skip@floridaroof.com (800) 767-3772 ext. 127

All feedback and reprint permission requests (please include your full name and address) contact: Lisa Pate, Editor lisapate@floridaroof.com (800) 767-3772 ext. 157

Florida Roofing Magazine PO Box 4850 Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/ #FRSA #roofingprotects

Equally strong and attractive , these metal roofing panels are available in Florida in our full line of PAC-CLAD painted steel, aluminum and Galvalume Plus coatings, ensuring that your roof will endure whatever comes its way. All panels are Miami-Dade County and Florida Building Code approved.

FRSA President Manny Oyola, Jr., Eagle Roofing Products

For many years, I have roofed throughout the Florida market and worked on many beautiful and unique roof tile installations. A favorite roof style among homeowners uses barrel roof tile that probably originated in the Mediterranean and Latin countries, which possessed an abundance of clay. Over the years, manufacturers sought to mimic the clay pan and cap motif, using molds and concrete to produce barrel and s-tile that evokes timeless appeal and became extremely popular.

As you can see from the photos, these high-profile tiles add a lot of old-world beauty and Mediterranean or southwest style to a roof.

The barrel tile (or pan and cap) also gives life to a turret or "witch's hat" style roof that you sometimes

see on buildings with a round shaped roof. The professionals who create this look are real craftsmen that take pride in their work – it is not something that is installed every day. It’s a special skill set and a dying trade. It’s our job to train the next generation to create these beautiful roofs.

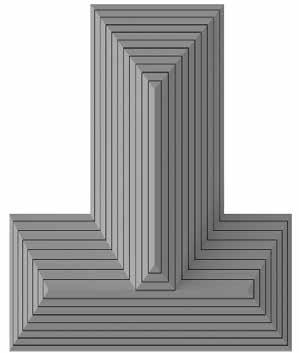

Another remarkable instance of craftsmanship is the installation of tile without the use of any hip or ridge cap or trim tile. This is called a closed mitered hip and ridge roof.

For this section, reference the FRSA-TRI 7th Edition High Wind Concrete and Clay Tile Installation Manual. FRSA members are entitled to one complimentary copy: if you don’t have one, please contact FRSA at kelly@floridaroof.com. This system does not incorporate the use of any type of structural support. To install:

1. All partial field-cut tile at the hip, ridge and valley shall be attached to the cap sheet and the adjacent tile with an approved roof tile adhesive or mortar.

2. The tile installed at the top of the ridge might have to be cut below the screw line to avoid seeing screw holes. The screw holes can also be filed with caulking to match the tile color.

3. Determine the desired overhang at the eave with a full tile and snap lines that go around the entire roof.

4. Snap chalk lines at all hips, ridge and valleys that meet at all points.

5. You’re going to install the ridge tile directly onto those lines marked continuously on all roof sides (see Figure 1); this is the line you would measure down from to the eave line.

6. Once that measurement is determined between those two points, go to the layout table (at right) and find the course spacing that will work best for this project.

Note: Don’t start marking any lines until you have measured and determined that the line will work completely around the entire roof.

All tiles must have a compound cut of 45 degrees in both directions when it’s installed in the hip, valley or ridge line.

Carlisle SynTec Systems is dedicated to leading the industry by developing and manufacturing the most progressive and innovative roofing materials on the market. Every Carlisle product is designed to enhance building performance and contractor efficiency. Carlisle has pioneered productivity-boosting products such as SeamShield™ Technology, Self-Adhering Technology (SAT ™ ), Sure-Weld 16' TPO, 12' InsulBase with ReadyFlash Technology, and many others.

For more information on Carlisle’s productivity boosting products scan here

UTILIZING SPECIALLY MARKED MEASURING TAPE

To achieve optimum beauty, the area between the eave and ridge should be divided into equal tile courses when possible. Minimum 3” overlap must be maintained for all tiles unless design of tile precludes.

Measuring Tape

Notes:

Course Spacing “D”

Top Course Mark at 1-1/2” from Center of Ridge

Mark First Course for Desired Overhang

Note: Additional Considerations May Be Required for Venting

Consider Size and Placement of Gutter When Setting First Course Overhang

1. Using a full tile, determine desired overhang at eave and snap horizontal chalk line across roof at head end of tile or top of batten. Use of rain gutters and eave closures should be considered in determining tile overhang.

2. Snap a horizontal chalk line at the top of the roof 1-1/2” from the center of the ridge (adjust for direct deck).

3. With measuring tape, marked for maximum “exposed length” of tile being installed, measure vertically from the course nearest the ridge at either end of the roof (e.g., 14” for a 17” length tile).

4. If a mark on your tape does not fall exactly upon top line, move the tape to the left or the right until the next mark intersects the line.

5. Mark the deck at every mark on the tape.

6. Repeat this process at other end of roof.

7. Snap lines between marks on the deck. All courses will be equal with minimum recommended headlap maintained.

8. Repeat above steps on all roof planes.

9. Nail top of battens or tiles at each horizontal line. ROOF LAYOUT FOR

Using a full tile, determine desired overhang at eave and snap horizontal chalk line across roof at head end of tile. Use of rain gutters and eave closures should be considered in determining tile overhang. At the top of the roof deck, mark a reference point by measuring 1-1/2” from the center of the ridge, plus the distance of one full

Measure up the roof slope to the reference point and divide by the manufacturer’s maximum exposure in an effort to determine if the roof section will terminate with a full tile. Mark roof deck for each course of tile and snap chalk lines over entire section. If roof section does not terminate with a full tile at the ridge, decrease the course exposure in small increments (typically 1/4”) in

If the last course does not terminate with a full tile, cut to dimension, as required, and fasten with mechanical fastener or other

To ensure proper vertical alignment, determine the manufacturer’s stated maximum on-center spacing requirements and snap

For gable end roof sections, determine the proper distance from left and right rakes and mark the eave and ridge section to

Measure between the two marks and divide by the manufacturer’s stated maximum on-center spacing. If required, decrease the on-center spacing slightly in an effort to terminate with a full tile at the gable end(s). Ensure that the installed tiles are within the manufacturer’s minimum/maximum on-center spacing requirements.

Tiles are allowed, by ASTM C1167/C1492, for a plus-or-minus five percent variance from the manufacturer’s stated “nominal dimensions,” It is the installer’s responsibility to verify the “delivered” roof tile dimensions prior to commencing with roof layout and to ensure that the tile is installed within the manufacturer’s minimum headlap and on-center spacing requirements. Most diagonal-cut tiles will allow slight course exposure adjustments, typically 1/4” per tile.

This mitered hip and ridge installation requires a good deal of time and effort. The roofing professional who completes the project will have something to be proud of and will provide a distinctive roof with a look that stands out for many years to come. Let’s remember that as professionals, we must continue our legacy of sharing our roofing knowledge to the next generation.

Best wishes,

Drawing FHW‑26 depicts the application of all tile profiles. Unless otherwise noted, it would apply to either concrete or clay tiles.

NOTE – Drawings are for illustrative purposes and do not reflect all methods of installation. Please refer to written text.

© FRSA-TRI

For those who would like to know more about roof tile installation, attend FRSA’s Convention. A tile installation seminar will be presented on June 4.

Manny Oyola, Jr. FRSA President manuelo@eagleroofing.com

12/31/23

Added strength without any added weight.

ProVia metal roofing is constructed of highly durable 26-gauge galvanized steel—up to 30% more than the industry average. It’s also 3x lighter than asphalt shingles, so it’s easier to work with.

It’s the right thing to do.

6 Reasons to Partner with ProVia Metal Roofing

Alex Hernandez, Clark Roofing Company, was elected Chairman of the Board and Chad Collins, Roofing Corp of America, was elected Chairman of the Board-elect.

Jean-Paul Grivas, Ray Nolan Roofing; Christian Madsen, Madsen Roofing & Waterproofing Inc. and Diana Petersen, Red Pointe Roofing LP, were elected Vice Chairmen for two-year terms. Sherri Miles, J.D. Miles and Sons Inc., was elected Vice Chairman for a oneyear term.

Additionally, Tyler Allwood, Eagle Roofing Products, was elected to a three-year term and Tammy Hall, CFS Roofing Services LLC, was elected to a one-year term on NRCA’s Board of Directors.

ICP Group, a leading specialty chemical manufacturer in North America and global leader in professional building products, proudly welcomes Deb Lechner as its new Vice President of Marketing. Lechner will report directly to CEO Jay Doubman and serve on the Executive Leadership Team, acting as a strategic

marketing partner for the company. With a proven track record of developing and executing customerfocused marketing and business strategies, she will bring her expertise to ICP’s business units, supported by the company’s dedicated marketing team.

“We’re delighted to welcome Deb to ICP,” said CEO Jay Doubman. “With more than 30 years of experience in the building products industry, she brings a deep understanding of the market. Deb is results-oriented, customer-focused and brings strategic leadership to an already strong marketing team.”

Lechner is passionate about innovation that enhances customer experience, employee development and upholds the highest standards of integrity and excellence. A strong communicator and relationship builder, she is known for her ability to collaborate across teams and all levels of an organization to drive company-wide success.

“From some of my very first conversations with the ICP team, it was clear that we share a strong, long-term vision for the company,” Lechner said. “The marketing team is made up of some of the most insightful, creative people in the industry and I’m ready to dig in, support their existing strategies and expand their efforts. I can’t wait to get started.”

The Roofing Alliance announced this year’s winners of the Construction Management Student Competition. Winners were recognized at NRCA’s Industry Awards and Reception held during the International Roofing Expo in San Antonio in February.

The six finalist teams gave oral presentations as the final stage. This year, the teams were tasked with submitting a qualified bid package for the Embassy Suites by Hilton San Antonio Airport Hotel. The oral presentation scores were combined with the teams’ written proposal scores to determine the winning team.

The Roofing Alliance is proud to announce the top three schools and the best individual presenters:

■ First Place: Texas A&M University

■ Second Place: Auburn University

■ Third Place: Clemson University

Best Individual Presenters

■ Arjun Varadhan, Auburn University

■ Cheyenne Campbell, University of North Florida

RoofersCoffeeShop, the award-winning website where the industry meets for technology, information and everyday business, launches a one-of-a-kind speakers bureau for the roofing industry. Pulling from the enormous network of RoofersCoffeeShop (RCS), the speakers bureau is part of the overall RoofersCoffeeShop directory offering informational listings and contact information for professional speakers who offer insights and education with a firm understanding of the roofing industry.

“We are regularly asked if we know good speakers for association and company events, continuing education and trainings,” stated RoofersCoffeeShop President Heidi J. Ellsworth. “The RCS speakers bureau highlights exceptional speakers in a directory

format, offering insights into their past experience and overall roofing industry knowledge. We are very proud to offer these types of resources to the industry.”

The speakers bureau lives on the RCS directory where it is easily accessed at the top of the page. It features listings for industry speakers and RCS Influencers such as John Kenney, Cotney Consulting Group, Trent Cotney, Adams and Reese and Heidi J. Ellsworth of RoofersCoffeeShop. The directories include information on the speakers, their topics and contact information. It will continue to expand as the number of speakers grows. For those interested in joining the speakers bureau, reach out to Alex Tolle at alex@rooferscoffeeshop.com.

“The Coffee Shops continue to offer content that not only informs but educates, while providing associations, contractors and companies with the information and resources that they need,” concluded Ellsworth. “Our online community is all about connecting and networking for success.” Visit the RCS speakers bureau at www.floridaroof.com/rcs-speakers.

FrM

Trent Cotney, Partner, Adams and Reese LLP

In Florida, the intersection of lien foreclosures and arbitration is a complex area where legal interpretations play a crucial role. A key point to understand is that while the validity of a lien may be determined through arbitration, any judgment enforcing a foreclosure of that lien must be issued by a court of competent jurisdiction, as mandated by Florida Statutes § 713.21.

Arbitration often serves as a preferred method for resolving disputes in construction-related contracts. Florida courts have consistently upheld arbitration agreements and allowed arbitrators to make determinations regarding the validity of mechanic’s liens. In Village at Dolphin Commercial Center, LLC v. Construction Services Solutions, LLC, 143 So. 3d 942, 944 (Fla. Dist. Ct. App. 2014), the court affirmed that arbitration panels have jurisdiction over issues agreed upon by the parties, including lien validity.

This principle aligns with the strong public policy in Florida favoring arbitration, as seen in K.P. Meiring Construction, Inc. v. Northbay I & E, Inc., 761 So. 2d 1221, 1225 (Fla. Dist. Ct. App. 2000). Courts typically resolve challenges to arbitration agreements in favor of upholding them, highlighting their binding nature.

While arbitrators may determine whether a lien is valid, the enforcement of that lien through foreclosure remains exclusively within the court’s jurisdiction. This

practice was emphasized in Beach Resorts International, Inc. v. Clarmac Marine Construction Co., 339 So. 2d 689, 692 (Fla. Dist. Ct. App. 1976), where the court clarified that arbitration awards concerning lien claims do not authorize arbitrators to foreclose on liens. Instead, courts must adjudicate foreclosure rights following an arbitration award.

Similarly, in McDaniel v. Bernhalter, 405 So. 2d 1027, 1029 (Fla. 4th DCA 1981), the court reinforced that arbitration may resolve payment entitlement issues. However, the court retains the authority to enforce such awards through mechanic’s liens.

The case of Royal Palm Collection, Inc. v. Lewis, 2010 WL 2178757 (Fla. 4th DCA June 2, 2010), provides a notable example of these principles in action. Royal Palm Collection, Inc. (Royal), a general contractor, sought to foreclose on a construction lien and recover damages after disputes with homeowners George and Carlene Lewis.

Following arbitration, the arbitrator awarded Royal $38,528.88 but did not specifically address foreclosure rights. Despite affirming the arbitration award, the trial court denied Royal’s request to foreclose the lien, reasoning that the arbitrator’s award was silent on foreclosure. On appeal, the court reversed this decision, emphasizing that the court, not the arbitrator, must decide foreclosure rights. The appellate court ruled that Royal retained its right to seek foreclosure despite the arbitration process.

The legal landscape surrounding lien foreclosures and arbitration in Florida is shaped by several key principles:

■ Deference to arbitration agreements: Courts generally uphold arbitration agreements as binding when included in construction contracts.

■ Arbitration scope: Validity determinations of liens can be resolved in arbitration.

■ Court authority over foreclosure: Foreclosure judgments can only be issued by a court of competent jurisdiction, even when lien validity is determined in arbitration.

To protect the right to foreclose a construction lien, contractors should ensure compliance with statutory requirements. Florida law typically requires that actions to foreclose a lien be initiated within one year from the lien’s recording. Bringing such an action before a court within this timeframe preserves the right to enforce the lien through foreclosure.

Even when disputes are subject to arbitration, it is essential for parties to remember that arbitrators cannot foreclose liens. Instead, after arbitration resolves payment and validity issues, parties must seek a court order to foreclose on the lien.

Navigating lien foreclosures in Florida requires a clear understanding of the roles arbitration and courts play. While arbitration may settle disputes about lien validity and payment entitlement, only courts have the authority to enforce foreclosure. By adhering to legal timelines and preserving their rights, parties can effectively manage the complexities of lien enforcement and arbitration.

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a Partner and Construction Team Leader at the law firm of Adams and Reese, LLP and FRSA General Counsel. For more information, you can contact him at trent.cotney@arlaw.com or by phone at 813-227-5501.

Adams and Reese LLP is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. Contact Trent at 813-227-5501.

John Kenney, CPRC, CEO, Cotney Consulting Group

Running a successful roofing business involves much more than installing quality roof systems. It requires mastering business fundamentals, people management, risk mitigation and leadership development. By focusing on these critical areas, roofing contractors can build resilient, profitable companies ready to thrive in a competitive and ever-changing industry.

This article explores the four pillars of roofing business excellence: financial literacy, workforce development, operational efficiency and leadership strategies. These foundational elements ensure dayto-day success and position roofing businesses for sustained growth and adaptability.

Financial management is the backbone of any successful roofing operation. Contractors must understand the financial metrics that signal business health, such as profit margins, cash flow and backlog. Unfortunately, many contractors overlook this critical aspect, leading to challenges like cash shortages, inefficient resource allocations or missed growth opportunities.

Tracking and benchmarking financial performance are essential steps for contractors. Regularly reviewing financial statements helps contractors track progress and pinpoint areas for improvement. Benchmarking industry data, such as NRCA’s financial surveys, provides insights into how a business compares to its peers. Metrics like operating costs, revenue projections and administrative expenses can guide strategic decision-making.

Financial tools and software designed for construction businesses can simplify processes like budgeting, forecasting and job costing. For instance, tracking job-specific profitability can reveal which projects are most lucrative and which require reevaluation. This data helps contractors avoid costly mistakes and focus on projects that align with their business strengths.

Additionally, understanding financial ratios – like debt-to-equity or quick ratios – can help contractors evaluate liquidity and operational efficiency. These insights ensure the business remains financially stable even during economic downturns.

An actionable tip for financial literacy is to develop a monthly review process to analyze key metrics and share these insights with the team. Transparent communication about financial goals and challenges

fosters a unified approach to achieving business success.

At the heart of every successful roofing business is its people. Effective people management, from field crews to office staff, ensures projects are completed safely, on time and within budget. Yet, roofing contractors face persistent challenges, including labor shortages, an aging workforce and shifting generational expectations.

Attracting and retaining talent requires more than competitive wages. Contractors must create a culture of safety and continuous learning. Training programs improve employee productivity and demonstrate a company’s commitment to its workforce. Offering certifications, apprenticeships or advanced skill training enhances performance and builds employee loyalty.

Mentorship programs are another effective tool for workforce development. Pairing experienced staff with newer employees fosters skill development, encourages collaboration and prepares the next generation of leaders. This mentorship model can be integral to succession planning, ensuring the business remains resilient as key team members retire or move on.

Providing regular feedback and recognition is equally important. Constructive performance reviews, paired with useful suggestions, help employees understand their strengths and areas for improvement. Recognizing achievements through bonuses, promotions or public acknowledgment boosts morale and engagement.

To address labor shortages, roofing contractors can also consider nontraditional recruitment strategies. Partnering with local trade schools, engaging in community outreach or offering internships can help attract fresh talent to the industry.

An practical tip for workforce development is to host quarterly training sessions focused on safety, technical skills and leadership development. These

sessions reinforce company values and demonstrate an ongoing investment in employee growth.

Operational efficiency ensures roofing projects are completed profitably and without unnecessary delays. This involves managing risks associated with contracts, compliance and unforeseen challenges like weather or material shortages.

Contracts are the foundation of every project. Roofing contractors must review agreements thoroughly to ensure terms align with their understanding of the job’s scope. Standardized contract templates and access to specialized construction legal firms can minimize disputes and clarify obligations. Contracts should explicitly define payment schedules, warranties and responsibilities to avoid misunderstandings.

Developing a crisis management plan is another crucial aspect of operational efficiency. A comprehensive plan should address potential crises like cybersecurity breaches, natural disasters or workplace accidents. It should include communication protocols, data protection measures and contingency strategies to ensure the business can respond swiftly and effectively.

Tracking performance metrics, such as safety records, job-specific profitability and project timelines, allows contractors to identify inefficiencies and make timely adjustments. Implementing a company scorecard to monitor these metrics on a per-job basis, rather than quarterly or annually, provides actionable insights that drive improvements.

Risk management extends beyond operations to include compliance with local regulations and safety standards. Roofing contractors must stay informed about industry changes, such as updated OSHA guidelines or building codes, to avoid penalties and maintain a strong reputation.

A usable tip for operational efficiency is to implement a job-cost tracking system. This system evaluates profitability in real-time, allowing project managers to address cost overruns early and ensure the job stays on budget.

Leadership is not only about managing day-to-day operations but also about setting a vision for the future. Roofing contractors investing in leadership development and growth strategies create businesses that adapt to changing market conditions and customer demands.

Educational opportunities are vital for leadership growth. These programs should provide valuable insights into strategic planning, financial management and operational excellence. Participating in these

programs helps contractors refine their leadership skills and gain new perspectives from industry peers.

Market differentiation is another key to sustained growth. Specializing in a niche, such as green roofs, complex commercial projects or historic restorations, reduces competition and attracts clients seeking expertise. Communicating professionalism and quality through marketing initiatives reinforces your brand and builds customer trust.

Building strong relationships with architects, general contractors and property managers creates repeat business opportunities. Transparency, reliability and consistent communication strengthen these connections, making your business a preferred partner.

Growth strategies should also include regular evaluation of risks and opportunities. Assessing the market landscape, analyzing customer needs and staying ahead of trends enable contractors to remain competitive. For example, adopting sustainable practices or leveraging new roofing technologies can position your business as an industry leader.

An actionable tip for leadership development is to schedule annual strategy meetings. These meetings provide an opportunity to assess the company’s position, identify growth opportunities and evaluate risks. Use these insights to refine your business plan and set actionable goals for the coming year.

Contractors who embrace the four pillars of business excellence – financial literacy, workforce development, operational efficiency and leadership – can build businesses that withstand challenges and thrive for generations. By refining the way you think about these core fundamentals, you can create a roofing business that achieves profitability and leaves a lasting legacy. Take action today by evaluating your current practices and identifying areas for improvement. Success in roofing isn’t just about installing great roofs – it’s about building a great business.

John Kenney, CPRC, has over 50 years of experience in the roofing industry. He started his career by working as a roofing apprentice at a family business in the Northeast and worked his way up to operating multiple Top 100 Roofing Contractors. As CEO, John is intimately familiar with all aspects of roofing production, estimating and operations. If you would like further information on this or another subject, you can contact John at jkenney@cotneyconsulting.com.

Mike Silvers, CPRC, Owner, Silvers Systems Inc. and FRSA Technical Director

The last several weeks have been extremely busy; maybe hectic would be a better word. We’re on the frontline on many issues – some that we’ve not faced before but are working with industry partners to ensure we can keep doing what we do best. Sadly, there are those that think they know more than we do about roofing systems we install every day.

Fortunately, FRSA’s had an opportunity to influence or offer additional language to make most of these items palatable for contractors. We do our best to stay in front of issues but at times, it’s challenging. This is especially true when the state Legislature is in session, the Florida Building Commission codes modification submission process is in full swing and several pressing issues coalesce at one time.

The Building Commission

Recently, we completed phase one of the code modification process that integrated changes made in the 2024 International Building Code (IBC) into the 2026 9th Edition Florida Building Code (FBC). Phase two is where members of the public (FRSA included) can propose modifications (mods) to be considered for incorporation into the new code. Submissions ended mid-February and, at the beginning of March, they were posted on the FBC website. I reviewed all 557 mods, looking for ones that merited our attention.

FRSA proposed 39 modifications, all approved by our Codes Subcommittee and the Codes Committee. From mods proposed by other entities, I pulled 162 for review during several upcoming meetings with the Codes Subcommittee to determine whether we support or oppose each change. As time permits, we will also seek approval from the Codes Committee. In between quarterly committee meetings, FRSA’s Board of Directors has given the Codes Subcommittee the authority to make decisions on FRSA’s behalf regarding these matters.

The group will present FRSA's positions to the Commission’s Technical Advisory Committees (TACs) during the first of two reviews scheduled for midto-late June. Moving forward, I will try to keep you informed on the progress of the changes – mods that we like and, just as importantly, those we don’t. This is a grueling process that takes most of the three-year code cycle to accomplish. We deeply appreciate the volunteers who devote their time and energy to make this process so successful. Often, we work with other industry partners to accomplish some of this work. Most recently, we’ve worked with the Asphalt Roofing Manufacturers Association (ARMA) on many of FRSA’s and ARMA’s modifications, as well as some submitted by others, that will continue to improve the performance of roof coverings in Florida. This is a process that we can take the lead on or one that is forced on us by folks – unhindered by their lack of experience and knowledge – who propose unreasonable and inneffective modifications.

Fund a scholarship today at www.FloridaRoof.com/charity or contact John Hellein at 800-767-3772 ext. 123

Speaking of grueling processes, the legislature is in session and the ride is fast and can get a little bumpy at times. Much like the building code, it’s about looking at everything that can help and hurt you (a big job), taking positions and suggesting improved language. It is also a time when we can move our positions forward. I’ll mention a few of those positions here that have been on our radar recently. One thing we like and have been working on is adding the evaluation of roofto-wall connections to the roofing contractor license scope including training enhancement for contractors who want to perform such work. One of the things we don’t like is the attempt by some in the government to place their thumb on the scale, so to speak, concerning which roof coverings we or homeowners can choose.

A ND T R US T.

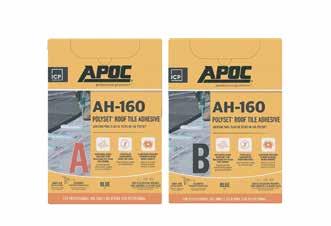

APOC Polyset AH-160 has been reformulated with a low global warming potential (GWP) blowing agent to meet the nationwide regulations while staying true to the features and benefits you are familiar with.

PROVIDES MORE SUPPORT FOR WALKABILITY THAN FASTENERS

VIRTUALLY ELIMINATES PENETRATIONS

SUPERIOR HOLDING POWER DURING WIND EVENTS

This two-component, polyurethane foam adhesiv adheres each individual tile in place with superior holding power compared to nails, screws, mortar and wire tie systems. Depending on roof pitch, it can be used without mechanical fasteners so it won’t puncture the waterproofing membrane or the roof deck

www.apoc .com | www.icpgroup.com info@icpgroup.com

FRSA is collaborating with ARMA and other industry groups to keep all proven roof systems competing on a level playing field. Knowledgeable roofing industry professionals understand that there isn’t enough solid data on roof system failures to eliminate any roof type. We are extremely fortunate to have Chris Dawson, GrayRobinson, as our Legislative Counsel, doing great work on our behalf in Tallahassee. Also, a personal thanks to Ralph Davis, Streamline Roofing and Construction, Tallahassee for being available to testify on our behalf before the legislature. Because Ralph lives in Tallahassee, we often call on him last minute to testify on FRSA's behalf. He does an amazing job and represents us well.

I was recently in Tallahassee to be part of a panel for the Florida House Subcommittee on Industries and Professional Activities. The topic was on licensure and regulation affecting contractors. It was very interesting to hear where other professionals and the legislators stood on several issues at the meeting. I mentioned one item that is an impediment to new contractors is the availability and cost of insurance. A topic that most of the other panelists reinforced. The appearance also gave me a chance to pitch our roofto-wall connection issue to the subcommittee that will be hearing it. So far, so good.

In the last two issues of Florida Roofing magazine, I dedicated my column to the comments and actions on roof type selection by OIR and various House and Senate hearings mentioned above. These discussions have been the cause of the most recent roof covering issues. Since then, an attempt by OIR to rewrite the OIR-B1-1802 Adopted by Rule 69O-170.0155 wind mitigation form has been seen by many as a chance to push a self-serving agenda that would be misleading and harmful for Florida’s property owners. OIR’s attempts to make changes are clearly well intended but may be relying on slanted or incomplete information. FRSA will carefully monitor related activities and offer our opinions and relative information at every opportunity as this process moves forward.

The roof covering issue has focused a lot of attention on the roofing industry, both locally and nationally. We have presented programs on the subject to some of our local affiliates and, more recently, at the Roofing Industry Committee on Weather Issues annual meeting held in Orlando. It will continue to be a hot topic during the coming months. FRSA will continue to make our presence known in the discussions that will influence this issue and many others going forward.

FrM

Mike Silvers, CPRC is owner of Silvers Systems Inc., and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 50 years of industry knowledge and experience to FRSA’s team.

Experience the pinnacle of roofing technology with Stinger.

Combine EXO Underlayment, NailPac, and CN100B for the Ultimate Moisture Defense System.

Experimenta lo mejor de la tecnología para techos con Stinger.

Combina el revestimiento EXO, NailPac y la clavadora CN100B para lograr el Mejor Sistema de Defensa Contra la Humedad.

FRSA Self Insurers Fund is the best Workers’ Compensation carrier for Roofing Contractors in Florida.

The Fund’s exceptional service and dividend returns are unmatched in the industry.

In 2023, Fund members received $5 million in Dividends and in June another $2 million based on 2023 performance –while workers’ comp rates are the lowest in history.

Thursday, June 5 | 11:00 am – 5:00 pm

Friday, June 6 | 10:00 am – 3:00 pm

In 2024, over 5,000 roofing and sheet metal contractors, building officials, architects and industry professionals registered for the Convention and Expo. The 2025 Expo is sold out with over 230 exhibiting companies offering the latest products and services to the industry.

JUNE 4 – 6

Check out items onsite at the Expo and bid from anywhere! Looking to donate? Visit www.floridaroof.com/donate to register and bid online.

Bidding starts on May 30 at 8:00 am and concludes on June 6 at 2:00 pm.

All proceeds benefit the industry through the FRSA Educational and Research Foundation.

The Expo is free for roofing contractors. For all non-exhibiting manufacturers, suppliers and distributors, there is a $295 per person fee to attend the Expo and a $995 per person fee for industry service providers to attend the Expo.

sponsored by GAF

FRIDAY, JUNE 6 11:00 am – 2:00 pm

Stop by the Lounge area for a cold beer, compliments of GAF.

sponsored by Petersen | PAC-CLAD

THURSDAY, JUNE 5 | 11:00 am – 2:00 pm

FRIDAY, JUNE 6 | 11:00 am – 2:00 pm

Hungry? Grab a bite to eat at the Food Court located on the Expo floor, compliments of our lunch sponsor.

WEDNESDAY, JUNE 4

sponsored by Drexel Metals

Tenoroc Shooting Range Lakeland

JUNE 4 | 10:00 am – 1:00 pm

The tournament is comprised of several stations with a variety of shooting levels. Range fees, ammunition, lunch and prizes are included in the ticket price. Each participant must provide their own gun or arrange gun rental ahead of time.

REGISTRATIONS WILL BE LIMITED TO 75 PARTICIPANTS

$125 by May 1 | $175 after May 1.

sponsored by Walker Rep Group

Marina

Port Canaveral

JUNE 4 | 7:00 am – 1:00 pm

Boats carrying groups of six will set out along Florida’s beautiful East Coast to find the catch of the day. Check-in begins at 6:30 am with the tournament running from 7:00 am to 12:00 pm. Following the tournament, winners will be announced and graband-go lunches will be available.

REGISTRATION FEE INCLUDES BOAT, ROD AND REEL, TACKLE, BEVERAGES, LUNCH AND PRIZES. INDIVIDUAL REGISTRANTS WILL BE PAIRED AND SPACE IS LIMITED.

$175 by May 1 | $275 after May 1. Register a full boat of 6 people by May 1 for $1,000 | $1,400 after May 1.

by May 1 to save money and guarantee your spot.

sponsored by Acrisure and Sika Roofing

Falcon’s Fire Golf Club Kissimmee

JUNE 4 | 8:00 am – 1:00 pm

Falcon’s Fire Golf Club is recognized both regionally and nationally as one of the finest public Golf Courses in Orlando. Check-in begins at 7:00 am, with the tournament beginning at 8:00 am.

REGISTRATION INCLUDES GREEN FEES, CART, RANGE BALLS, REFRESHMENTS, CONTINENTAL BREAKFAST, LUNCH AND PRIZES. TEAMS ARE 4-PERSON SCRAMBLE FORMAT AND INDIVIDUAL REGISTRANTS WILL BE PAIRED. THIS TOURNAMENT SELLS OUT QUICKLY, SO REGISTER EARLY. REGISTRATIONS WILL BE LIMITED TO 128 PLAYERS ON A FIRST-COME, FIRST-SERVED BASIS.

$175 by May 1 | $225 after May 1.

sponsored by Adams and Reese LLP, Carlisle SynTec Systems, Leap and Progressive Materials

WEDNESDAY, JUNE 4 | 5:30 pm – 7:00 pm

Join us as we kick off FRSA’s 103rd Convention. Food stations and an open bar at this FREE event create the perfect opportunity to network with industry peers.

WEDNESDAY, JUNE 4 | 3:30 pm – 5:30 pm

Join National Women in Roofing for an insight-filled session where you can network with other NWiR members and hear from women in the industry as they share their career experiences.

sponsored by Millennium Metals Inc

THURSDAY, JUNE 5 | 11:15 am – 1:00 pm

Elections for FRSA Officers and Directors will be held, Life and Honorary Memberships bestowed along with other industry awards and recognition of Foundation scholarship recipients.

sponsored by Gulfeagle Supply and Power Bolt and Tool Inc.

THURSDAY, JUNE 5 | 6:00 pm – 9:00 pm

Join us for FRSA’s San Juan Casino Party, an entertaining night of casino games, food stations, open bars, dancing and prizes. Casual tropical attire is encouraged. We’ll kick off the evening with FRSA Officer installation, the Campanella Award and recognition of S.T.A.R. Award recipients in an abbreviated presentation, leaving plenty of time for gambling and socializing.

THURSDAY, JUNE 5 | 7:00 pm – 8:30 pm

Affiliate chapters from across the state will compete in a Texas Hold ‘Em tournament during the Casino Party to lead their Affiliate to victory. Proceeds benefit FRSA’s 2025 Charity of Choice, Foundation Scholarships.

sponsored by Certified Roofing Specialists Inc.

WEDNESDAY NIGHT, JUNE 4

5:30 pm – 9:00 pm

Kids will enjoy an evening of fun with an entertaining and interactive balloon show. Then it’s time to get creative in a cookie decorating extravaganza to show off their creative talents. Ticket includes dinner, entertainment and all supplies.

THURSDAY DAY, JUNE 5 | 9:00 am – 3:00 pm

THURSDAY, JUNE 5 | 9:00 am – 11:00 am

Choose to create either a candle or wax melts and a scented sachet of your own unique scent combination to take home. All supplies, morning beverages and muffins are included in the ticket price.

Wizards & Lizards will lead this hands-on tiedye workshop showing the kids how to fold, tie and dye their very own creations to take home. Ticket includes supplies, lunch and snacks.

THURSDAY NIGHT, JUNE 5 | 5:30 pm – 9:00 pm

FRIDAY, JUNE 6 | 9:00 am – 11:00 am

This hands-on workshop will make baking your own bread at home a breeze! A Gaylord chef will present several types of bread and the role of oils and herbs in breadmaking. Enjoy a hands-on experience with proper kneading techniques, decorations and toppings to create your own bread masterpiece. Beverages and breakfast pastries are included in the ticket price.

Back by popular demand – two giant game trucks packed with large screen TVs, the latest game consoles and a huge variety of video games including Mario Kart, Minecraft, Fortnite and other popular video games. Ticket price includes dinner, two hours of unlimited game play and bounce house access.

FRIDAY DAY, JUNE 5 | 9:00 am – 3:00 pm

Ready for some real fun? Here’s your ticket to competitive arcade-style games in a private room. Ticket price includes activities, lunch and snacks.

WEDNESDAY, JUNE 4

6:00 am – 5:00 pm | FRSA Registration Desk Open / Gaylord Palms Convention Center

7:00 am – 1:00 pm | Fishing Tournament / Sunrise Marina, Port Canaveral – sponsored by Walker Rep Group

8:00 am – 10:00 am | Seminar #1: ASCE 7 Wind Calculations Greg Keeler – 2.0 Hours G

8:00 am – 1:00 pm | Golf Tournament / Falcon’s Fire Golf Course sponsored by Acrisure and Sika Roofing

8:00 am – 2:00 pm | Seminar #2: CCN’s Contractor Bootcamp: KPI –Managing by the Numbers / Gary Cohen – 6.0 Hours – No CE credit

9:00 am – 10:00 am | Seminar #3: Advanced FRSA-TRI Tile Manual Paul Oleksak and David Eubanks – 1.0 Hour ADV

10:00 am – 1:00 pm | Clay Shooting Tournament / Tenoroc Shooting Range, Lakeland – sponsored by Drexel Metals

10:15 am – 12:15 pm | Seminar #4: Licensing Issues & Contracts Trent Cotney – 2.0 Hours L&R/BSP

10:15 am – 12:15 pm | Seminar #5: Metal Roofing: A Closer Look Bo Copeland – 2.0 Hours G

12:30 pm – 1:30 pm | Seminar #6: Low-Slope ASTM Standards Brian Chamberlain – 1.0 Hour G

12:30 pm – 1:30 pm | Seminar #7: Estimating the Right Way –Commercial / John Kenney, CPRC – 1.0 Hour BSP

1:45 pm – 2:45 pm | Seminar #8: Wind Mitigation Methods Mike Silvers, CPRC – 1.0 Hour WMM

1:45 pm – 2:45 pm | Seminar #9: OSHA Recordkeeping Requirements

Trent Cotney – 1.0 Hour BSP

3:30 pm – 5:30 pm | NWiR Table Talk Session

5:00 pm – 5:30 pm | VIP President’s Reception / Gaylord Atrium

5:30 pm – 7:00 pm | Welcome Reception / Gaylord Atrium sponsored by Adams and Reese LLP, Carlisle SynTec Systems, Leap and Progressive Materials

5:30 pm – 9:00 pm | Kids’ Program / Crazy Balloon Show & Cookie Decorating – sponsored by Certified Roofing Specialists Inc.

THURSDAY, JUNE 5

6:00 am – 5:00 pm | FRSA Registration Desk Open / Gaylord Palms Convention Center

7:00 am – 8:00 am | Seminar #10: Understanding Workers’ Comp Debbie Guidry, CPCU and Alexis Ayala – 1.0 Hour WC

7:00 am – 8:00 am | Seminar #11: KPI – Navigating by the Numbers Gary Cohen – 1.0 Hour – No CE Credit

7:00 am – 8:00 am | Seminar #12: Top Five Insurance Issues Tray Batcher – 1.0 Hour L&R

8:00 am – 11:00 am | ARCHITECT & BUILDING OFFICIALS PROGRAM Seminar #13: ASCE 7 Wind Calculations / Greg Keeler – 2.0 Hours G Low-Slope ASTM Standards / Brian Chamberlain – 1.0 Hour G

8:15 am – 9:15 am | Seminar #14: Ladder & Skylight Safety Kevin Lindley – 1.0 Hour WPS

8:15 am – 9:15 am | Seminar #15: Estimating the Right Way –Commercial / John Kenney, CPRC – 1.0 Hour BSP

8:15 am – 10:15 am | Seminar #16: Metal Roofing: A Closer Look Bo Copeland – 2.0 Hours G

9:00 am – 11:00 am | Ladies’ Program / Candle Crafting Workshop

9:00 am – 3:00 pm | Kids’ Program / Wizards & Lizards Tie-Dye Party sponsored by Certified Roofing Specialists Inc.

9:30 am – 10:30 am | Seminar #17: Google’s Silver Bullet: You! Dan Shurtz – 1.0 Hour – No CE credit

9:30 am – 10:30 am | Seminar #18: Attract & Retain Great People Marci LaRouech – 1.0 Hour – No CE credit

9:30 am – 10:30 am | Seminar #19: Construction Law Updates Trent Cotney – 1.0 Hour BSP

11:00 am – 2:00 pm | Lunch in the Expo Hall sponsored by Petersen | PAC-CLAD

11:00 am – 5:00 pm | FLORIDA ROOFING & SHEET METAL EXPO

11:00 am – 5:00 pm | Foundation Auction

11:15 am – 1:00 pm | Business Lunch – sponsored by Millennium Metals Inc.

5:30 pm – 10:00 pm | Kids’ Program / Extreme Video Game Night sponsored by Certified Roofing Specialists Inc.

6:00 pm – 9:00 pm | Casino Party – sponsored by Gulfeagle Supply and Power Bolt and Tools Inc.

7:00 pm – 8:30 pm | Affiliate Competition

FRIDAY, JUNE 6

6:00 am – 3:00 pm | FRSA Registration Desk Open / Gaylord Palms Convention Center

7:00 am – 8:00 am | Seminar #20: Metal Deck Replacement

Michael Polizzi – 1.0 Hour G

7:00 am – 8:00 am | Seminar #21: Documenting a Roofing Project

Chad Westbrook – 1.0 Hour G

7:00 am – 9:00 am | Seminar #22: Licensing Issues & Contracts

Trent Cotney – 2.0 Hours L&R/BSP

7:00 am – 9:00 am | Seminar #23: ASCE 7 Wind Calculations

Greg Keeler – 2.0 Hours G

8:00 am – 9:30 am | Exhibitor Meeting / Booth selection for the 2026 Expo

8:15 am – 9:15 am | Seminar #24: Wind Mitigation Methods

Mike Silvers, CPRC – 1.0 Hour WMM

8:15 am – 9:15 am | FOREMEN & SUPERINTENDENTS PROGRAM

Seminar #25: Safety & Housekeeping / Jim Brauner – 1.0 Hour WPS

8:15 am – 9:15 am | Seminar #26: Hiring & Retaining Good Employees

Ben Briggs – 1.0 Hour BSP

9:00 am – 11:00 am | Ladies’ Program / The Art of Baking Bread

9:00 am – 3:00 pm | Kids’ Program / Arcade Blitz sponsored by Certified Roofing Specialists Inc.

10:00 am – 2:00 pm | Foundation Auction

10:00 am – 3:00 pm | FLORIDA ROOFING & SHEET METAL EXPO

11:00 am – 2:00 pm | Lunch in the Expo Hall sponsored by Petersen | PAC-CLAD

The FRSA Registration Desk, Expo and Foundation Auction will be located on Level One of the Convention Center, Halls A-E. See the onsite Convention Program or check FRSA’s App for live updates and room assignments.

WEDNESDAY, JUNE 4

SEMINAR #1 | 8:00 am – 10:00 am

ASCE 7 Wind Calculations

Greg Keeler

Methods to determine ASCE 7-22 wind loads and required wind resistance for steep- and low-slope roof assemblies. ASCE 7-22 includes changes from the 7-10 and 7-16 editions. | 2.0 Hours G

SEMINAR #2 | 8:00 am – 2:00 pm

CCN’s Contractor Bootcamp: KPI –Managing by the Numbers

Gary Cohen

To scale your revenue for optimum profitability, it’s important to monitor various key aspects of your business. As a business owner, there are numerous details to pay attention to and it’s easy to become overwhelmed. That’s where Key Performance Indicators (KPI) come in. They help measure metrics and improve your business without getting overwhelmed with details and data. This 6-hour

seminar goes into detail on what KPIs you should be tracking and which numbers you need to know to make critical business decisions. | 6.0 Hours – No CE credit

SEMINAR #3 | 9:00 am – 10:00 am

Advanced FRSA-TRI Tile Manual

Paul Oleksak and David Eubanks

The FRSA-TRI Tile Manual is referenced in the Florida Building Code for tile roof installations in 65 Florida counties. How to use the 7th Edition manual with realworld examples. | 1.0 Hour ADV

SEMINAR #4 | 10:15 am – 12:15 pm

Licensing Issues & Contracts

Trent Cotney

Chapter 489 licensing and regulations. Who is exempt, consequences of unlicensed activity and CILB disciplinary actions. Review contract terms: price, scope, notices, time of delivery and more. | 2.0 Hours L&R/BSP

SEMINAR #5 | 10:15 am – 12:15 pm

Metal Roofing: A Closer Look

Bo Copeland

A step-by-step look at metal roofing from both a technical and aesthetic aspect. Product information, building code requirements, proper product recommendations, installation, warranties and more. | 2.0 Hours G

SEMINAR #6 | 12:30 pm – 1:30 pm

Low-Slope ASTM Standards

Brian Chamberlain

Testing and installation of TPO, PVC and KEE materials, systems and assemblies including coverings, cover boards, insulation, securement methods, quality assurance and performance for assemblies and edge metals | 1.0 Hour G

SEMINAR #7 | 12:30 pm – 1:30 pm

Estimating the Right Way – Commercial

John Kenney, CPRC

How do you produce accurate commercial estimates? Isolate improper estimating, evaluate strengths and weaknesses of your team and improve the quality of your bids. | 1.0 Hour BSP

SEMINAR #8 | 1:45 pm – 2:45 pm

Wind Mitigation Methods

Mike Silvers, CPRC

8th Edition Florida Building Code requirements include wind zone areas, insured and ad valorem tax criteria compliance, reroofing, water barriers, fasteners and bracing, retrofitting and more. | 1.0 Hour WMM

SEMINAR #9 | 1:45 pm – 2:45 pm

OSHA Recordkeeping Requirements

Trent Cotney

Identify, complete and maintain required OSHA forms. Which injuries require reporting? Manage the documentation process for defense of OSHA inspections and citations. | 1.0 Hour BSP

THURSDAY, JUNE 5

SEMINAR #10 | 7:00 am – 8:00 am

Understanding Workers’ Comp

Debbie Guidry, CPCU and Alexis Ayala

Understand workers’ comp employer responsibilities, plan benefits, direct and indirect costs, how to calculate premiums, premium mods and credits as well as what to expect during an audit. | 1.0 Hour WC

SEMINAR #11 | 7:00 am – 8:00 am

KPI – Navigating by the Numbers

Gary Cohen

To scale your revenue for optimum profitability, monitor key aspects of your business. Key Performance Indicators (KPI) allow you to analyze business performance without becoming overwhelmed. | 1.0 Hour – No CE credit

SEMINAR #12 | 7:00 am – 8:00 am

Top Five Insurance Issues

Tray Batcher

Insurance issues facing Florida roofing contractors and legislative changes. Addresses general liability, subcontractor and builder’s risk insurance. | 1.0 Hour L&R

SEMINAR #13 | 8:00 am – 11:00 am

BUILDING OFFICIALS & ARCHITECTS PROGRAM

ASCE 7 Wind Calculations

Greg Keeler

Methods to determine ASCE 7-22 wind loads and required wind resistance for steep- and low-slope roof assemblies. ASCE 7-22 includes changes from the 7-10 and 7-16 editions. | 2.0 Hours G

Low-Slope ASTM Standards

Brian Chamberlain

Testing and installation of TPO, PVC and KEE materials, systems and assemblies including coverings, cover boards, insulation, securement methods, quality assurance and performance for assemblies and edge metals. | 1.0 Hour G

THURSDAY, JUNE 5 (Continued)

SEMINAR #14 | 8:15 am – 9:15 am

Ladder & Skylight Safety

Kevin Lindley

OSHA ladder and skylight regulations, training requirements and best practices. Jobsite ladder equipment selection, setup and use. Skylight safety, hazards and proper fall protection equipment. 1.0 Hour WPS

SEMINAR #17 | 9:30 am – 10:30 am

Google’s Silver Bullet: You!

Dan Shurtz

Showing up first on Google’s results page may seem impossible. But there’s a silver bullet: your brand. Build a strong brand to improve organic search, word-of-mouth, revenue and profitability. | 1.0 Hour - No CE credit

SEMINAR #18 | 9:30 am – 10:30 am

SEMINAR #15 | 8:15 am – 9:15 am

Estimating the Right Way – Commercial

John Kenney, CPRC

How do you produce accurate commercial estimates? Isolate improper estimating, evaluate strengths and weaknesses of your team and improve the quality of your bids. | 1.0 Hour BSP

SEMINAR #16 | 8:15 am – 10:15 am

Metal Roofing: A Closer Look

Bo Copeland

A step-by-step look at metal roofing from both a technical and aesthetic aspect. Product information, building code requirements, proper product recommendations, installation, warranties and more. | 2.0 Hours G

Attract & Retain Great People

Marci LaRouech

Delve into the significance of company culture, focusing on its ability to attract and retain top talent. Identify strengths and weaknesses and implement strategies to foster a positive work environment. | 1.0 Hour - No CE credit

SEMINAR #19 | 9:30 am – 10:30 am

Construction Law Updates

Trent Cotney

What construction industry legal issues have changed this year? Includes marijuana usage on the job, OSHA and case law updates regarding contracts, liens, insurance and arbitration. | 1.0 Hour BSP

FRIDAY, JUNE 6

SEMINAR #20 | 7:00 am – 8:00 am

Metal Deck Replacement

Michael Polizzi

Commercial re-roof projects often need to replace the structural metal deck due to rust, weather damage or renovations. How to identify, match, quote and install metal deck. | 1.0 Hour G

SEMINAR #21 | 7:00 am – 8:00 am

Documenting a Roofing Project

Chad Westbrook

Document your roofing projects using best practices. Roofing professionals are now expected to be photographers who correctly document projects to address future performance and legal issues. | 1.0 Hour G

SEMINAR #22 | 7:00 am – 9:00 am

Licensing Issues & Contracts

Trent Cotney

Chapter 489 licensing and regulations. Who is exempt, consequences of unlicensed activity and CILB disciplinary actions. Review contract terms: price, scope, notices, time of delivery and more. | 2.0 Hours L&R/BSP

SEMINAR #23 | 7:00 am – 9:00 am

ASCE 7 Wind Calculations

Greg Keeler

Methods to determine ASCE 7-22 wind loads and required wind resistance for steep- and low-slope roof assemblies. ASCE 7-22 includes changes from the 7-10 and 7-16 editions. | 2.0 Hours G

SEMINAR #24 | 8:15 am – 9:15 am

Wind Mitigation Methods

Mike Silvers, CPRC

8th Edition Florida Building Code requirements include wind zone areas, insured and ad valorem tax criteria compliance, reroofing, water barriers, fasteners and bracing, retrofitting and more. | 1.0 Hour WMM

SEMINAR #25 | 8:15 am – 9:15 am FOREMEN & SUPERINTENDENTS PROGRAM

Safety & Housekeeping

Jim Brauner

Jobsite accidents cost lives, time and money. Get a grip on fall hazards, site safety, demolition, debris removal, what’s trending with OSHA and available training programs. The fee for this course is $25 per person for foremen and superintendents which will be refunded to employer via a $25 gift certificate good for any FRSA product or service except the Foundation Auction. Attendees who pre-register will also receive a special gift bag.

1.0 Hour WPS

SEMINAR #26 | 8:15 am – 9:15 am

Hiring & Retaining Good Employees

Ben Briggs

Prepare employees for long successful careers in construction. The best onboarding practices, the importance of investing in training and how to build engagement for new and existing employees.

1.0 Hour BSP

Register for FRSA’s Convention and Expo online. Sign up with a unique email address, add the events you would like to attend and check out using a credit card.

As always, the Florida Roofing & Sheet Metal Expo is FREE for roofing contractors. Each representative of non-exhibiting manufacturers, distributors and suppliers will be charged a $295 fee and service providers will be charged a $995 fee for entry to the Expo hall.

A badge is required to enter the Expo and an expedited line is available at the Registration Desk for those who register in advance!

FRSA’s Annual Convention and Expo is an educational and networking event for the roofing and sheet metal industries. As we continue to face an ever-changing work environment, FRSA brings you the most relevant and up-to-date seminars on topics that affect your business.

FRSA’s Educational and Research Foundation, CILB Provider #0000910 (select courses), is offering a total of 32 hours of continuing education (CE) credit and 8 hours of seminars without CE credit. All courses are designed specifically for contractors. Our goal is to provide you with the educational tools you need to make your business successful.

FRSA Members receive a 20% discount on seminars at checkout.

SEMINAR TICKETS

Individual Seminars

FRSA Members receive a 20% discount at checkout.

CCN’s Contractor Bootcamp

FRSA Member

FRSA Non-member

$50/per hour

$325 by 5/01/25 | $350 after

$375 by 5/01/25 | $400 after

Tickets to all social events must be purchased individually and include:

Thursday Business Lunch

$60

Thursday Casino Party $125

Ladies’ Program

Thursday | Candle Crafting Workshop

Friday | The Art of Baking Bread

Kids’ Program

$75

$75

NOT A MEMBER? JOIN TODAY!

Contact Kelly Sealander at 800-767-3772 ext. 142 or kelly@floridaroof.com

Wednesday Night | Crazy Balloon Show & Cookie Decorating $50

Thursday Day | Wizards & Lizards Tie-Dye Party $45

Thursday Night | Extreme Video Game Night

$65

Friday Day | Arcade Blitz $50

Sports Tournament Pricing

Clay Shooting Tournament

$125 by 5/01/25 | $175 after Fishing Tournament

$175 by 5/01/25 | $275 after Boat for 6 People

$1,000 by 5/01/25 | $1,400 after Golf Tournament $175 by 5/01/25 | $225 after

must be completed online at:

www.floridaroof.com

Event tickets may be purchased in advance or at the FRSA Registration Desk during the Convention and Expo if available. See the Schedule of Events on PAGES 6 & 7 for FRSA Registration Desk hours. Tickets will be collected at the door for each event, including all educational seminars.

Located at 6000 W. Osceola Parkway in Kissimmee, Florida. FRSA has a special room rate of $185 plus tax for single or double occupancy. Resort fees are included in this discounted rate. The group rate will be available until May 1 or until the room block is sold out, so be sure to book early!

Seminars and all social events are business casual. Please remember to wear comfortable shoes. Meeting room temperatures vary, so you may want to bring a sweater or jacket. Casino Party – Casual tropical attire is encouraged.

Reservations can be made by visiting https://book.passkey.com/go/FRSA2025 and entering 2025FRSA as the access code.

THANKS TO OUR

D.I. Roof Seamers

Direct Metals

H.B. Fuller Construction Adhesives

Sherwin Williams / Uniflex

SRS Building Products

Central Florida Roofing & S/M Contractors Association (CFRSA)

Duro-Last

Petersen | PAC-CLAD

Roof Hugger

Tarco

SPONSORS

Northeast Florida Roofing & S/M Contractors Association (NEFRSA)

Southwest Florida Roofing Contractors Association (SWFRCA)

West Coast Roofing Contractors Association (WCRCA)

ABC Supply

Acrisure

Adams and Reese LLP

Carlisle SynTec Systems

CertainTeed LLC

Certified Roofing Specialists

D.I. Roof Seamers

Drexel Metals

East Lake Metals

FRSA Self Insurers Fund

GAF

Gulfeagle Supply

Handy Distribution

IKO Industries Inc.

Leap

Millennium Metals Inc.

Owens Corning

Petersen | PAC-CLAD

Polyglass USA Inc.

Power Bolt and Tool Inc.

Premier Metal Roofing LLC

Progressive Materials

Sika Roofing

TCParker & Associates

Walker Rep Group

PLATINUM SPONSOR

DIAMOND SPONSORS

SAPPHIRE SPONSORS

SPECIAL EVENT SPONSOR

GOLD SPONSORS

EMERALD SPONSORS

Hailey Dedmon, Shorebird Biologist, Florida Fish and Wildlife Conservation Commission

Many of Florida’s birds are imperiled due to habitat loss and disturbances to natural nesting habitat. Some species of seabirds and shorebirds regularly nest on open sandy beaches but have started nesting on gravel rooftops as a substitute for beach habitat. These rooftop-nesting seabirds and shorebirds are protected by state and federal law, so it is important to recognize their presence and spread awareness about rooftop nesting. Property owners who maintain these rooftops are important conservation partners and we look forward to continuing to work with them to meet their needs while they provide for the needs of the birds.

Species commonly found nesting on gravel rooftops are least terns, roseate terns, black skimmers, killdeer and American oystercatchers. Nesting season throughout Florida can vary but typically occurs March 1 through September 1.

Least terns, roseate terns, black skimmers and other seabirds nest in large groups known as colonies. Black skimmers and least terns can often be found nesting among each other. Least terns have become highly adapted to nesting on alternative habitats and

approximately 50 percent of the statewide nesting population nests on gravel rooftops. Killdeer and American oystercatchers are shorebird species. Shorebirds are solitary nesters, meaning a single pair will nest together and defend a small territory from other birds.

Both seabird and shorebird pairs construct nests by simply working a shallow depression or scrape into the loose sand or gravel on the rooftop. The female then lays the eggs. Males and females both tend to the nest, taking turns incubating the eggs. Hatch times vary depending on species and range anywhere from 21 to 27 days. Once the chicks hatch, they are highly mobile within two to three days and will roam from the nest. These

mobile chicks may accidentally run off the rooftop if the building doesn’t have parapets or chick fencing to prevent falling. If you happen to find a chick on the ground, please notify managers or staff of the building immediately. The managers or staff of the building should contact their regional Florida Fish and Wildlife Conservation Commission (FWC) shorebird contact so that trained staff and volunteers can assist with returning the chicks to the roof. Chicks must be returned to the roof carefully since colonies are very sensitive to disturbance. It can take anywhere from 19 to 37 days, depending on the species, for these chicks to be able to fly.

When seabird colonies are disturbed, they will flush into the air, often loudly vocalizing and begin dive-bombing to defend their nests and chicks. American oystercatchers are very territorial; once a pair establishes a territory, they will defend that area from other pairs or any perceived threat. Shorebirds, such as oystercatchers, will also exhibit a behavior when disturbed called a “broken wing display” where they feign injury to try and lure a potential predator away from the nest or chicks. When seabirds and shorebirds are flushed, nests and chicks are exposed to predators such as crows or gulls, as well as harsh weather conditions that may cause eggs to spoil and chicks to perish. Additionally, chicks that are not yet able to fly may be scared off the rooftop and fall to the ground, leaving them exposed to predators. Preventing disturbance to these birds is vital for their survival.

If birds are present on a rooftop, any non-essential maintenance or repairs that disturb the nesting birds should be postponed until after the breeding season. If essential maintenance or repairs are necessary during the nesting season, we recommend the property owner apply for an incidental take permit. More information on how to apply for a permit can be found at www.floridaroof.com/roofbirdspermit. Any harassment or harm, even unintentional, could be considered

“take” under State Law, Chapter 68A-27.003, Florida Administrative Code and is therefore unlawful.

Despite challenges, shorebirds and seabirds have been able to adapt to the many changes humans have made to coastal landscapes. The importance of rooftop colonies continues to grow statewide as coastal development reduces the amount of suitable beach nesting habitat. Gravel rooftops are an invaluable resource to our seabirds and shorebirds and with continued efforts, they will remain productive nesting sites for years to come.

Thank you for your support and patience during the 2025 shorebird and seabird breeding season. Please contact us with any questions or concerns. You can find your regional shorebird contact information at www.floridaroof.com/roofbirds.

Hailey Dedmon is the Northeast and North Central Regional Shorebird Biologist with the Florida Fish and Wildlife Conservation Commission (FWC). FWC regional shorebird biologists work collaboratively with Florida Shorebird Alliance partners to achieve conservation goals for state-designated threatened shorebirds and seabirds. They collaborate with FWC’s Division of Law Enforcement on proactive patrols in nesting areas and engage with local partners on habitat management. FWC regional shorebird biologists also aid in monitoring priority nesting areas throughout the state, provide subject matter expertise and conduct education and outreach within local communities.

Adrian Robledo, Director of Sales, ICP Group

Tile roofs are a common sight throughout Florida and ensuring their ability to withstand the state’s weather conditions depends on sourcing the right securement and underlayment technologies.

Throughout the Florida housing market, concrete and clay tile roofs are a popular option for both their aesthetic benefits and their ability to withstand storms and severe weather more readily than many other types of roof coverings. For roofing professionals working in the state, it’s beneficial to be knowledgeable about tile roofs, including best practices for installation and maintenance.

To those ends, the choice of securement method can make an impact. While mechanical fastening has long been common in roof tile applications, polyurethane foam adhesives – which adhere tiles to the underlayment that is attached to the roof deck, without the need to penetrate it in most cases – have been shown to deliver even higher value. Indeed, roofs utilizing high-performance adhesives can achieve some of the highest possible wind uplift ratings, making them highly advantageous for extreme weather locales like Florida and other coastal and wind prone areas.

In this article, we’ll explore what you need to know about properly installing tile roofs with polyurethane foam adhesives, including the benefits of a highperformance underlayment, key differences between single-component and two-component roof tile adhesive options, the importance of proper training for applicators and more.

Before the roof tiles themselves can be adhered, it is important to select an underlayment system that meets the required design pressures and code approvals of the project location. These components are available in a wide variety of applications and options that provide essential protection for the building envelope beneath the primary roof covering – roof tiles, in this case. Some characteristics to look for when selecting an underlayment technology include:

Compatibility properties. There are various applications for adhering underlayment to a roof deck. Contractors should ensure that the underlayment has been tested and approved for use with foam adhesive products. As direct-to-deck roof applications are growing in the southern part of Florida, it is also important to ensure that the underlayment meets the required design pressures for this application. Directto-deck applications have high performance values and can also help in reducing additional material and

labor costs. The underlayment should address all essential areas of the roof and ensure quick, clean, and easy lapping of rolls as well as water tightness.

Physical and Performance Characteristics. When selecting an underlayment, various performance differences can aid in installation and underlayment life expectancy. Thickness, tear resistance, adhesion, water resistance, slip resistance, roll weight, temperature resistance, walkability and additional UV exposure all play a vital role in choosing the right underlayment for your project.

Advanced Technologies. As underlayment technologies evolve, staying on top of technology and offering advanced products is important. For example, some high-performance underlayment technologies available today are products made without excess filler, providing outstanding protection without extra weight, enabling workers to get the job done more easily. Another crucial technology is addressing all critical lap edges and joints for seamless and instant bonding.

Once you’ve selected your underlayment, it’s time to choose an effective adhesive. First, it’s important to understand the difference between single-component and two-component spray foam adhesive systems. In single-component adhesive products, all chemical and raw material components are combined and the adhesive moisture-cures when dispensed. Two-component adhesives’ adhesion chemistry and other materials are kept separate (A-side/B-side); the chemical reaction begins once the two components are mixed together in the application assembly nozzle. These components are fed through hoses and are combined at the point of application.

Both options will provide high levels of performance but there are some differences that may make one more suitable for a given application than the other. For example, two-component polyurethane adhesives have been shown to maintain the highest available levels of wind uplift performance. Depending on the paddy size, tile profile, paddy placement and gram weight, a properly installed (per manufacturers

installation instructions) two-component adhesive systems have the ability to withstand a category 5 hurricane.

For these reasons, two-component adhesives have been widely used throughout Florida, where hurricane resistance is one of the top priorities for building and construction professionals. Twocomponent options can also deliver additional tile support, contributing to higher break strength and overall long-term durability. Depending on the roof pitch, some twocomponent systems can also eliminate the need for having thousands of screws, nails or tie-wire penetrations on the roof deck which can create roof damage and leaks.

Single-component options serve their purposes as well. These options also maintain high levels of performance and are primarily advantageous in terms of ease of use. Applicators are able to move around the roof area easily since these come in handheld, userfriendly cylinders.

Getting the most from roof tile adhesives doesn't just depend on the products themselves but on proper training and installation. Building officials, inspectors and municipalities often require roofing contractors to have been trained in proper product use by the manufacturer. Once again, this is particularly true in areas prone to extreme weather like Florida. Code officials will want to ensure that construction projects completed with adhesive products are being performed by professionals who’ve been properly trained. Contractors interested in using roof tile adhesives should seek out manufacturers that provide productspecific training and certifications.

Additionally, multiple applicators equipped with individual cylinders can help complete a job more quickly. Singlecomponent systems’ portability also lends itself to easier application around hips, ridges, cut pieces and trim tiles. Singlecomponent systems can also be applied to damp substrates, making it easier to perform work following rain or without waiting for morning dew to evaporate.

Whether you choose single- or two-component adhesive systems, it’s also increasingly important to check the sustainability profile of such products. Because spray foams require the use of a blowing agent, it’s worth checking to ensure that such agents in your selection have low global warming potential or HFO product offerings (environmentally friendly); your supplier should be able to advise.

Overall, roof tile adhesives and underlayment systems offer a wide range of benefits for tile roof applications. Products that have been formulated for the highest levels of performance and ease of use can contribute to more reliable and more durable roofs – even in the most extreme weather environments – while enabling professionals to work more efficiently and boost their bottom line. FrM

With over 20 years of roof tile and adhesive industry experience, Adrian Robledo is Director of Sales for ICP Group and oversees the brand’s APOC Polyset Steep Slope polyurethane roofing adhesives. He is dedicated to helping roofing professionals understand the value of proper training and tile installation methods for concrete and clay roof tiles. His passion, commitment, technical knowledge and service to his customers have helped him build a solid reputation as one of the industry leaders in the residential roofing market. To learn more about roofing tile adhesives, visit www.APOC.com. Adrian can be reached at arobledo@icpgroup.com.

Rodrigo Medina, Business Unit Manager-Roofing, Santafé Tile Corporation

As a roofing contractor in Florida, selecting the best roofing material for your projects is crucial for ensuring durability, aesthetic appeal and long-term value for homeowners. Clay roof tiles have long been an excellent choice in regions with harsh weather conditions due to their proven performance. Clay tiles offer a combination of durability, energy efficiency, low maintenance and timeless beauty.

This article explores the advantages of clay roof tiles and explains why they make a good investment for Florida homes.

One of the most significant advantages of clay roof tiles is their exceptional durability. According to NRCA, clay tiles can last 50 years or more with proper maintenance. In contrast:

■ Metal roofs can last many decades but they are susceptible to denting, corrosion and rust in coastal environments.

■ Concrete tiles are durable but can be prone to cracking and color fade over time, especially under extreme weather conditions.

Florida’s climate presents unique challenges such as hurricanes, heavy rain and intense sun exposure. Clay tiles excel in these conditions, because they are:

■ Fire-resistant

■ Highly resistant to water absorption

■ Less likely to be damaged by strong winds.

Energy efficiency is a critical factor for homeowners in Florida’s hot climate. Clay roof tiles provide natural insulation, helping to regulate indoor temperatures. According to the U.S. Department of Energy, roofing materials that reflect sunlight can significantly reduce cooling costs. The Cool Roof Rating Council also supports the premise that clay tiles contribute to a cooling effect, reducing reliance on air conditioning.

Metal roofs reflect sunlight but can absorb heat quickly, making homes hotter in the evening. Maintenance and repairs can become very costly. Concrete tile roofs retain heat during the day and cool during the night, affecting cooling costs.

Clay roof tiles have a timeless, high-end appearance that enhances a home’s curb appeal and resale value. They are available in various colors and finishes, from classic terracotta to modern matte tones that complement Mediterranean, Spanish and contemporary home designs. Clay tile roofs are often associated with luxury homes and upscale neighborhoods.

In contrast, metal roofs are more commonly used in industrial or modern designs but may not blend well with traditional architecture.

According to the National Association of Realtors, homes with high-quality roofing materials like clay tiles tend to sell faster and at higher prices than those with asphalt or concrete roofs.

To help roofing contractors and homeowners make an informed decision, the table below offers a direct comparison of how clay tiles stack up against metal and concrete tile roofing and highlights why clay roof tiles

are a well-rounded choice, offering both performance and aesthetic advantages over metal and concrete tile roofs.

In today’s environmentally conscious market, sustainability is a key factor in material selection. Clay roof tiles are one of the most eco-friendly roofing options available because they are made from natural, abundant materials and require less energy to produce than metal or concrete. According to the EPA, clay roofing tiles are 100 percent recyclable, reducing landfill waste. Unlike synthetic materials, clay tiles do not emit harmful VOCs.