ROOFING

S.T.A.R. Awards Recipient

PSI Roofing

Low Slope Category

PSI Roofing

Low Slope Category

We couldn’t agree more.

Peel & Seal® is the best and simplest solution for low-slope roof and flashing repairs. Just peel off the release liner, press into place, and roll smooth to seal the leak. That’s all it takes. Leave exposed for years of worry-free protection.

Learn more at www.mfmbp.com or by calling 800-882-7663.

FRSA-Florida Roofing Magazine Contacts: For advertising inquiries, contact: Lisa Pate at: lisapate@floridaroof.com

(800) 767-3772 ext. 157

All feedback and reprint permission requests (please include your full name, city and state) contact: Lisa Pate, Editor, at: lisapate@floridaroof.com

(800) 767-3772 ext. 157 Florida Roofing Magazine, PO Box 4850

Winter Park, FL 32793-4850

View media kit at: www.floridaroof.com/ florida-roofing-magazine/

#FRSA #roofingprotects

a culture of safety. Make sure your safety manual is updated to reflect current laws and regulations, as well as the most current OSHA guidelines. Regularly schedule toolbox talks so your supervisors can discuss safety topics with your workers. Ensure that every worker undergoes safety training, knows how to prevent accidents on the worksite and can recognize signs of distress in other workers.

Make sure to perform and document regular safety audits including daily equipment checks and frequent anonymous site visits to identify safety issues. Follow your disciplinary policy if you find a safety violation but make sure to retrain and document that retraining.

These materials outline expectations for employment and detail processes and policies for your company. Regularly update your employment manual, including making sure that your manual contains the latest state law revisions. Address minimum wage and overtime, I-9 requirements, discrimination and harassment training and applicable guidelines for drug testing. Include HR policies to assist in implementation. Also include standard operating procedures so all workers understand their responsibilities and rights. Ensure that everyone receives a copy.

As laws change, make sure that your HR staff or someone in your company is training your employees on new policies and procedures. Consider things like confidentiality provisions to protect customer lists and non-solicitation of employees in the event an employee leaves the company.

Your contracts, safety and employee documents should be reviewed at least every six months to make sure they contain the current terms and policies

needed for compliance. Work with your staff to stay on top of changes and remember, when it comes to defending any type of claim, the party with the best paper wins the day!

If you have any questions about employee documents, take advantage of your FRSA member benefit and contact me at 813-227-5501 or email me at trent.cotney@arlaw.com.

The information contained in this article is for general educational information only. This information does not constitute legal advice, is not intended to constitute legal advice, nor should it be relied upon as legal advice for your specific factual pattern or situation.

Trent Cotney is a Partner and Construction Practice Group Leader at the law firm of Adams and Reese LLP and FRSA General Counsel. For more information on this subject, please contact the author at trent.cotney@arlaw.com.

Adams and Reese LLP is a full-service law firm dedicated to serving the roofing industry. FRSA members can contact Trent Cotney to discuss and identify legal issues and to ask general questions through access to specialized counsel. They offer free advice (up to 15 minutes) for members. If additional legal work is required, members will receive discounted rates. This is a pro bono benefit provided to FRSA members only. To use this service, contact Trent Cotney, 813-227-5501.

The Florida Legislature convened in February for a special session on a variety of topics such as continued hurricane relief, establishing a statewide prosecutor for election crimes, immigration enforcement, student athlete compensation and special districts (including the Reedy Creek Improvement District). The special session took place one month in advance of the 2023 regular session. Let’s take a look at the bills placed on the fast track.

HB 1B by Representative Mike Giallombardo (R – Cape Coral) and SB 2B Emergency Response by Senator Ben Albritton (R – Bartow)

■ Creates Local Government Emergency Bridge Loan Program within DEO, subject to appropriation

■ Provides program’s purpose

■ Specifies program eligibility requirements

■ Authorizes DEO to provide interest-free loans to eligible local governments through specified means

■ Provides for expiration of program

■ Provides $700,000,000 appropriation

■ Effective Date: Upon becoming a law.

HB 3B by Representative Juan Fernandez-Barquin (R – Miami) and SB 4B Statewide Prosecutor by Senator Jonathan Martin (R – Ft Myers)

■ Specifies that certain crimes facilitated by or connected to the use of the Internet occur in every judicial circuit within the state

■ Authorizing the Office of Statewide Prosecution to investigate and prosecute crimes involving voting in an election for a federal or state office, voting in an election on a referendum, an initiative or an issue, the petition activities for a federal or state office, the petition activities for a referendum, an initiative or an issue or voter registration, etc.

■ Effective Date: Upon becoming a law.

HB 5B by Representative John Snyder (R – Palm City) and SB 6B Transportation of Inspected Unauthorized Aliens by Senator Blaise Ingoglia (R – Spring Hill)

■ Provides legislative findings, creates Unauthorized Alien Transport Program within Division of Emergency Management to facilitate transport of inspected unauthorized aliens within the United States

■ Authorizes division to contract for services to implement program

■ Authorizes division to adopt rules to implement program

■ Provides for future expiration

■ Removes s. 185 of chapter 2022-156, Laws of Florida

■ Deems certain payments approved

■ Reverts appropriated funds

■ Provides $10,000,000 appropriation

■ Effective Date: Upon becoming a law.

HB 7B by Representative Chip LaMarca (R – Lighthouse Point) and SB 8B Intercollegiate Athlete Compensation and Rights by Senator Travis Hutson (R – Palm Coast)

■ Revises provisions relating to athlete agents representing intercollegiate athletes for certain purposes, compensation that intercollegiate athletes may receive, postsecondary educational institutions requirements and specified workshops

■ Provides specified individuals are not liable for damages

■ Effective Date: Upon becoming a law.

HB 9B by Representative Fred Hawkins (R – Orlando) Reedy Creek Improvement District, Orange and Osceola Counties

■ Reenacting, amending and repealing chapter 67-764, Laws of Florida, relating to district

■ Provides for continuation of authority for revenue collection and powers to meet outstanding obligations

■ Renames district

■ Provides boundaries

■ Revises manner of selection of board of supervisors

■ Provides term limits

■ Revises board member compensation

Continued on page 22

Metals of Vero Beach, Fla. has named Bo Copeland as its new Business Development Manager, where he will play a critical role in the company’s growth plan. Copeland will focus on sales, service and market expansion through strategic partnerships with both key distributors and contractors throughout the state.

“Bo comes to us with extensive knowledge of our industry, a deep understanding of the needs of our customers and employees and a record of proven success,” states Joe Keene, Owner of Integrity Metals. “I’ve been blessed to call Bo a friend for almost 15 years. I’ve watched him develop into a dedicated and effective leader as we worked side by side in the early days of our careers. More importantly, I’ve watched Bo become a devoted husband to his wife, Deborah, and a hero of a Dad to his three children, Kinley, Peyton and Reed. The values that go into leading and raising a family are the same principles we hold most dear at Integrity Metals, making Bo a natural fit here. Our customers can look forward to seeing and speaking with Bo very soon as he settles into his role.”

Born into the construction industry, Copeland developed his love for the business from his father. His passion for customer service and building relationships was instilled by his mother who managed a beachside restaurant for nearly 25 years. Bo holds a bachelor’s degree in Animal Science from the University of Florida, which led to his first outside sales position at Purina Animal Nutrition. He returned to his roots in the construction business when he joined Gulf Coast Supply as an outside salesperson, later becoming Inside Sales Manager. Since joining the roofing industry, Copeland has been active in his local roofing and sheet metal association NCFRSA and very active at the Florida Roofing and Sheet Metal Contractors Association (FRSA) where he has chaired and co-chaired numerous committees and continues to remain a very active contributor. In 2018, Bo was awarded the Earl Blank Memorial Heart Award from FRSA for the dedication and passion he consistently demonstrates for the roofing industry.

“I have fun each and every day in this business and love the people I get to meet, talk to, learn about, work

with and serve,” shares Copeland, adding “sure, there are challenges that come and go, but with an industry like this and the team at Integrity Metals, it’s hard not to enjoy what we do. I am looking forward to this new chapter in my life and sharing it with the people who are part of it. The mission and core values that define Integrity bring me back to my roots of family and the traditional mindset of service, focusing on doing what’s right for our customers, being timely and doing it all with a smile. I am very excited and so very proud to join the strong and amazing team at Integrity Metals.”

Saint-Gobain North America, through its building products subsidiary CertainTeed Roofing, has acquired the rights to technology from recycling partner Asphaltica, that will allow the company to recycle asphalt shingle waste, diverting it from landfills and furthering the company’s commitment to creating a circular economy in its production of roofing shingles.

The proprietary technology from Asphaltica will allow Saint-Gobain to pelletize both post-industrial and post-consumer shingle waste. This process creates pellets out of ground shingles that blend well in hot mix asphalt and are an ideal component in an asphalt paving mix. In addition, the pellets are highly water resistant and can be used in variable climate conditions.

The ambitious initiative comes as Saint-Gobain continues to implement its global Grow and Impact strategy, which includes reducing waste and increasing the circularity of raw materials in its production processes, allowing Saint-Gobain to achieve a net zero carbon footprint by 2050.

“By taking an innovative approach and embracing new technologies, Saint-Gobain and CertainTeed Roofing are making strides to maximize our positive impact while minimizing our environmental footprint,” said Carmen Bodden, Vice President of CertainTeed Roofing. “CertainTeed takes our sustainability commitments seriously. The Asphaltica technology is proven and will help us achieve our goal of keeping shingle manufacturing waste across our network out of landfills.”

Asphaltica principals Bill Dempsey, PE and Bill Bailey, PhD, experts in paving and bitumen with over 40 years of experience, will continue to support landfill diversion efforts with CertainTeed. “It was important to me personally, to partner with an organization that has the global vision and resources to do big things and that is why I am so proud to partner with Saint-Gobain and CertainTeed,” said Bill Bailey, CEO of Asphaltica. “Their commitment to sustainability is

unmatched and I look forward to working with their roofing team as they continue their work to be leaders in light and sustainable construction.”

Beacon Building Products has opened a new branch in Homestead, Fla. This new four-acre branch is available for pickup and handles delivery for southern Miami-Dade and the entire Florida Keys. It is located at 13055 SW 238th Street, Homestead, Fla. 33032. The Grand Opening was held on February 17. Adding the Homestead branch, gives Beacon Building Products 28 locations throughout Florida.

Anusbigian Sales LLC is proud to announce that they are now representing Ludowici Roof Tile in the Caribbean. The origins of Ludowici Roof Tile began over 400 years ago in Rome with the Ludovisi family. Ludowici Roof Tile has been proudly manufactured in the USA since 1888. Their manufacturing facility, located in New Lexington, Ohio, has been in continuous operation since 1888, making it America’s oldest clay roofing tile manufacturer.

The blend of old-world craftsmanship and modern production technology allows Ludowici to stand behind its products with the best warranty in the construction industry. With their proven track record of durability in all climates, they are perfect for the heat of the tropics. From the Bahamas to Trinidad and Tobago and everywhere in between Ludowici is the roof tile for the islands. With made-in-the-USA Ludowici Roof Tile, you get enduring beauty, proven performance, a quality that is second to none, and a world-renowned product.

Ludowici’s history speaks for itself. Their customers can expect their investment to last a lifetime and rest easy knowing they will be here now and for years to come. Ludowici Roof Tile is available in the Caribbean through wholesale roofing distributors in southeast and southwest Florida.

Triangle Fastener Corporation announced the launch of their new website. The new format provides easy access to product information for the metal roofing, flat roofing, post frame and commercial drywall industries. New features include:

■ Updated dropdown navigation to include more products

■ Extensive technical information and installation tips for a variety of fastening systems

■ New search tool for faster navigation

■ View, download, email or print product information via PDF format

■ Product videos.

TFC provides a full line of standard and specialty fasteners, sealants, flashings and tools for metal building, metal roofing, low slope roofing, steel decking, steel framing and miscellaneous cladding materials. They have 24 locations and provide technical assistance and an inventory management program.

CertainTeed unveiled its new brand identity at the International Builders’ Show in January. This milestone represents a major paradigm shift for the manufacturer, reinforcing its customer-focused, comprehensive offering of light and sustainable building solutions and systems. The new chapter emphasizes the company’s category leadership, strengthening how the North American manufacturer positions, supports and educates building professionals on its products, which include roofing, siding, ceilings, insulation and gypsum solutions for the residential and commercial markets.

“As a leader at the forefront of the building sector, we recognized an opportunity to evolve how our customers specify our products,” said CertainTeed CEO Mark Rayfield. “We’re taking ‘one-stop shop’ to the next level by serving as a preferred source for cohesive systems and complementary products that not only help builders grow their reputation but make it easier than ever to deliver on what matters most: performance, sustainability and longevity.”

At the foundation of this evolution: CertainTeed’s deep, industry-leading knowledge in building science – an intelligent systems-based approach to build for optimum performance, energy efficiency and comfort. A team of building science experts serve as trusted advisors to ensure the solutions and their coordinating products will successfully meet the needs of each job. “Rethinking how we build requires embracing how each element of a home’s construction can collectively maximize its performance and comfort,” said Rayfield. “Our building science team makes the specification process easier – eliminating any guesswork that can often come when building professionals are exploring multiple options to increase a building’s performance and sustainability.”

Within its Building Products division in 2022, SRS opened 20 new greenfield locations, enhancing its growing national network of independent distributors. The expansion includes openings across every region of the country with an emphasis on markets with attractive growth profiles. The locations are staffed by experts dedicated to exemplary customer service and carry a full line of residential and commercial roofing products as well as other exterior building products. Supported by Roof Hub and other industry-leading digital technology, SRS customers enjoy both a hightouch and high-tech experience that is streamlined, efficient and meets their unique needs.

The new locations in Florida under the Suncoast Roofers Supply brand include Ft. Pierce, Homestead and Flagler Beach. The opening of new locations in high-growth markets reflects the company’s continued focus on expanding its national Building Products footprint and mission to be the preferred supplier to its customers. The locations include additional presence in existing markets as well as entry into new areas that allow SRS to enhance service to more customers. Greenfields play an integral role in the company’s path to building the strongest national network of independent distributor brands in the industry.

“We are pleased to announce the opening of 20 greenfields across our growing footprint. Thanks to the tenacious effort of our branch expansion and operations teams, our capabilities to expand in strategic markets have never been greater,” said Dan Tinker, President and CEO of SRS Distribution. “With the addition of these new locations, SRS will continue to provide unparalleled service to our loyal customer base, reach more customers and enjoy even greater geographic reach in these regions. Greenfields are an important part of our strategy to accelerate the growth of the companies that join our family and we expect to open additional locations in 2023 and beyond.”

Standard Industries, a privately held global industrial company operating in more than 80 countries with more than 20,000 employees, has announced the appointment of John Altmeyer as CEO of GAF, North America’s largest roofing manufacturer. Jim Schnepper, who was appointed GAF President in 2017 and became CEO in 2021, has stepped down after 28 years at GAF and is joining the Standard advisory board.

Altmeyer’s new role is effective immediately. He joined GAF in 2021 as Executive Chairman, commercial roofing. Under his leadership, GAF commercial sales have more than doubled and significant strategic

progress has been made to set the business up for continued growth. Altmeyer previously served for 21 years as President of Carlisle Construction Materials.

“John Altmeyer is a renowned industry leader who will draw upon his deep experience, relationships and track record to drive GAF’s next stage of growth,” said David Millstone, co-CEO of Standard Industries. “Over the past few years, as Executive Chairman, commercial roofing, John set GAF up to be as successful in commercial as it is in the residential market. We now look forward to working with him as he leads the entire company into the future.”

Schnepper led GAF during a period of tremendous growth and transformation and through the challenges of the COVID-19 pandemic. “We are grateful to Jim Schnepper for his dedication to GAF over his many years with the company and wish him success in his next chapter,” said David Winter, co-CEO of Standard Industries. “As one of the industry’s most respected executives, John is the right person to step in as CEO of GAF. He will build on the momentum he helped create in GAF’s commercial business and continue to strengthen and expand GAF’s broader leadership in the industry.”

Gulfeagle Supply announced its newest branch in Englewood. The branch is located at 6520 Industrial Lane and shares a property with its sister-company, Kimal Lumber. The location will support contractors as they rebuild areas most impacted by Hurricane Ian. The location brings Gulfeagle’s Florida presence to 25 branches across the sunshine state. The Englewood branch will also fulfill a need for material supplies between Gulfeagle’s existing Sarasota and Ft. Myers locations. John Gregory is the new Englewood Branch Manager. John has been with Gulfeagle Sarasota for almost a decade in both sales and operations.

Holcim has signed an agreement to acquire Duro-Last, a US leader in commercial roofing systems, with pro forma net sales of $540 million. Duro-Last has a track record of double-digit growth in North America’s highly profitable $40 billion roofing market, driven by premium brands, proprietary technologies and custom-made solutions. Duro-Last’s systems will complement and strengthen Holcim’s integrated roofing offer, with expected synergies of $60 million per year.

Jan Jenisch, CEO said, “I’m excited to welcome Duro-Last into Holcim’s broad range of innovative and sustainable building solutions. Duro-Last is a perfect strategic fit for our roofing business. Its proprietary technologies and premium brands complement our offering in the stable and fast-growing North

American market. Its energy-efficient systems and commitment to recycling will further advance our leadership in sustainability. I congratulate the Burt family and its leadership team for developing such a thriving business, based on its strong customer relationships and most of all, its empowered and dedicated people. I am excited to further strengthen the Duro-Last brand and welcome all 840 employees to the Holcim family.”

Tom Saeli, CEO of Duro-Last stated, “Over the past 45 years, our family business has continually reinvested in Duro-Last to create the solid, financially strong and well-recognized company we are today. We are delighted to be joining the Holcim family, which shares our core values and we look to the future to accelerate our success. Holcim recognizes the opportunities at Duro-Last and we are confident it will support us in our future growth plans.”

Duro-Last is recognized for its leadership in innovation and sustainability. Its leading Research & Development organization is continuously expanding its range of proprietary technologies and custom-made solutions for superior performance. At the forefront of sustainability, Duro-Last’s systems range from cool roofs and insulation boards that enhance building energy efficiency, to its award-winning “Recycle Your Roof” program, driving circularity in roofing. Duro-Last is the first company in the United States to offer third-party verified environmental product declarations for its thermoplastic roofing solutions. With these credentials, Duro-Last’s systems are in line with the most advanced green building certifications such as LEED.

Finalists – Honorable Mentions Announced NRCA’s Foundation, the Roofing Alliance, proudly announced the 2022-23 Most Valuable Player (MVP) Awards finalists and honorable mention recipients.

The winners for Outstanding Performance and Leadership, Outstanding Community Involvement and the recipient of Professional Roofing’s Best of the Best, a recognition co-sponsored by OMG Roofing Products and Professional Roofing magazine, will be announced during NRCA’s Awards Ceremony on March 8 at the International Roofing Expo in Dallas. Through the MVP Award program, the Roofing Alliance honors leadership in the field. Roofing contractors nominate field roofing workers, foremen or superintendents. Distributors and supplier firms nominate warehouse employees, warehouse foremen, drivers or equipment operators. Individuals can be nominated for their outstanding performance and leadership or outstanding community involvement. Since the program’s inception 20 years ago, 738 employees have been nominated and 279 winners and finalists have been recognized. The 2023 MVP Award

Finalists include:

■ Terry Tilsen, Superintendent, Advanced Roofing Inc., Ft. Lauderdale, Fla.

■ Rick Amellin, Machine Operator, OMG Inc., Agawam, Mass.

■ Shane Day, Superintendent, The Durable Slate Company, Columbus, Ohio

■ Christopher Knott, Field Worker, East Coast Roofing, Siding & Windows, Mayas Landing, N.J.

■ Ken Roderick, Superintendent, United Roofing Group Inc., Anchorage, Alaska

■ Oscar Salas, Superintendent, KPost Roofing & Waterproofing, Dallas, Texas

Rodney Miller as CEO

The Fi-Foil Company announced that Rodney (Rod) Miller has been appointed Chief Executive Officer (CEO). Fi-Foil offers an extensive line of cost-effective solutions to improve energy efficiency and comfort in residential, commercial, agricultural and institutional buildings. An experienced leader in building materials, Rodney will succeed William (Bill) Lippy. Bill Lippy has been a significant leader in the industry, notably driving awareness and growth of the reflective insulation sector for 27 years and as CEO has led Fi-Foil to achieve over 250 percent growth in the last 10 years. He will continue his role on the Board and act as Strategic Advisor for the company.

Miller brings a proven track record of executive leadership. He has been integral to driving steady growth at several mid-cap companies and is adept at managing and leading teams through acquisitions. Prior to coming to Fi-Foil, Rod was the Chief Commercial Officer at Southern Siding and prior to that, President of Custom Window Systems.

Validor Capital Managing Partner and Board Chairman Matthew Kaufman said, “Rodney has an impressive record of delivering results. We are excited to have him carrying the momentum at Fi-Foil and look forward to our continued growth in the years ahead.”

Recently, the Florida Legislature, as part of SB-4D, added an exception to the sections of the Florida Building Code (FBC) which are often referred to as the 25% Rule. The Commission adopted very similar language as part of the 2021 Supplement to the 7th Edition (2020) FBC. The new exception, shown below, and other changes in Supplement 2 became effective May 27, 2022.

Exception: If an existing roofing system or roof section was built, repaired, or replaced in compliance with the requirements of the 2007 Florida Building Code, or any subsequent editions of the Florida Building Code, and 25 percent or more of such roofing system or roof section is being repaired, replaced, or recovered, only the repaired, replaced, or recovered portion is required to be constructed in accordance with the Florida Building Code in effect, as applicable. Pursuant to s. 553.844(5), Florida Statutes, a local government may not adopt by ordinance an administrative or technical amendment to this exception.

The exception to the 25% Rule excludes roofs installed under the 2007 FBC or any later versions of the code. It is, however, important to understand that the 2007 FBC was not effective until March 1, 2009. The effective dates are shown in the table included on page 14. The new exception states “in compliance with the requirements of the 2007 FBC.” That doesn’t make for an easy assessment of where the line (date) is drawn. Typically, when a new code is adopted, it is more stringent than the previous version. As it is about to take effect, many contractors pull permits based

on the then current, less-stringent code. The actual work may not take place for several months after the new code takes effect. If the work was done prior to March 1, 2009, then the 25% Rule would still apply. It is the work that was done months after that date that could be in question. The only way to be sure which version of the code the work was permitted and completed under the 2007 adoption period, is to confirm it through the building permit records.

An upcoming 25% Rule change will take effect with the 8th Edition FBC (2023), which will have an effective date of December 31, 2023. The revised language will read:

Not more than 25 percent of the total roof area or roof section of any existing building or structure shall be repaired, replaced or recovered in any 12-month period unless the roof covering on the entire existing roof system or roof section is replaced or recovered to conform to the requirements of this code

This change to the 25% Rule will eliminate an interpretation of the current rule that would prohibit recovering an entire building or anything more than 25% of the building or roof section.

Both of these changes apply (or will apply) to FBC Building 1511.1.1, FBC Residential 908.1.1 and FBC Existing Building 706.1.1 The included table should help you understand all of the Florida Building Code and Supplement effective dates. You can get more detailed information on the specific FBC implementations shown in the table using the following link: www.floridarbuilding.org/fbc/Links_to Code_ Resources.html.

The 25% Rule has been the subject of many questions, misunderstandings and, sometimes, misinterpretations. The legislative change will certainly add to the confusion. Some view the change as overreach, but the legislature felt compelled to make this change to assist in attracting and retaining property insurers to the state and to reduce the use of the rule to justify often unnecessary roof claims. As with many other burdensome regulations, the many will suffer due to the abuses of a few. The change will force contractors to tie into roof coverings that will only become older and less serviceable as we move further away from

the 2007 code cited by the legislature. It will also hurt many property owners who have legitimate claims. Hopefully, the changes made to the rule itself, which were made through the normal code modification process, will help to at least clarify it to some degree.

Mike Silvers, CPRC is owner of Silvers Systems Inc. and is consulting with FRSA as Director of Technical Services. Mike is an FRSA Past President, Life Member and Campanella Award recipient and brings over 40 years of industry knowledge and experience to FRSA’s team.

Roof coatings are applied to low slope roofs on residential, commercial and industrial buildings to extend the life of a roof by preventing water, chemical or physical damage, which saves money for the building owner. Certain roof coatings even provide an extra level of waterproofing protection to help shed water to keep building interiors dry. Also, roof coatings are the most effective and least costly option to help buildings save energy.

Reflective roof coatings reflect visible light and infrared and ultraviolet radiation. This leads to lower roof temperatures, which, in turn, helps reduce cooling costs for buildings with air conditioning units and reduce interior temperatures in buildings with no cooling units. By minimizing cooling costs in warmer climates, peak energy usage is reduced, decreasing the risk of power outages and the strain on the electrical grid.

Every building owner will eventually be faced with the decision to completely tear-off an existing roof or to repair it. In fact, 2.5 billion square feet of roofs are either replaced or re-coated each year. Given that roofing materials are the third greatest contributor to waste in landfills, roof coatings are an ideal solution to extend the life of a roof and delay tear-off and waste.

Roof coatings are available with a wide range of properties and consistencies to fit a multitude of purposes. These include:

■ Low viscosity, non-fibered coatings: formulated as penetrating primers and dampproofing coatings.

■ Medium viscosity, fibered and non-fibered coatings and cements: formulated as inter-ply adhesives and top coatings for use on commercial, industrial and residential roofs. Some of these coatings incorporate pigments to reflect the damaging rays of the sun, creating a longer performing and more energy-efficient roof.

■ High viscosity, heavy bodied cements: designed for adhering waterproofing membranes and components and for patching and repairing leaks.

Which are better: solvent, water-based or moisture cure elastomeric coatings? Solvent, water-based and moisture cure coatings each have their advantages. Solvent based tend to be more waterproof, can be used in colder weather, won’t freeze, are less affected by humidity and rain after application and will adhere to certain surfaces, such as TPO, that water-based coatings often will not.

Water based coatings have lower odor, are “breathable” (so are more suitable for masonry), are less prone to “bleed through” or discoloration when applied over asphalt and are generally easier to spray as they don’t change viscosity significantly at different temperatures.

Moisture cure coatings allow solids of up to 100 percent, so the film thickness per applied volume is greater. They are generally low odor and low volatile organic compounds (VOC). The tradeoffs are shorter shelf life and limited adhesion to some surfaces, including TPO and asphalt that require primers. While they won’t freeze, moisture cure coatings will not cure normally when temperatures are below freezing and there is little free moisture in the air.

What is the dew point and why is it important? The dew point is the point at which moisture in the air condenses into liquid water. Many coatings require a dry surface. Surfaces may appear dry but moisture will condense as the coating is applied because the application of coating will often lower the surface temperature of the roof surface at the point of application, causing liquid water droplets to be trapped under or encapsulated in the coating.

What are reflectivity and emissivity and why are they important? Reflectivity is the percentage of solar energy reflected by the coating back into the atmosphere. The remaining energy that is absorbed increases the temperature of the roof surface. Higher reflectivity results in less absorbed energy, which results in less potential heat gain.

Emissivity is a measure of the coatings ability to emit absorbed solar energy as infrared radiation. Higher emissivity will generally result in a cooler

ProVia’s Metal Roofing System is thirdparty tested and approved in Florida, meeting TAS 100, 110, and 125 requirements. Our stamped panel metal roofing system is certified for High Velocity Hurricane Zones in Miami-Dade and Broward counties and for Non-HVHZ regions in the entire state, withstanding wind speeds up to 180 mph.

ProVia’s metal roof panels are constructed with 26-gauge steel—up to 30% more galvanized steel than competitive stamped metal roofing products. Our 4-Point Locking System includes a top lock, under and over locks on the sides, and our exclusive WaveLock™ ribbed feature on the bottom that increases the rigidity and strength of the panel.

for a metal roof that won’t leave you twisting in the wind?

surface for two materials with the same reflectivity. The relationship between emissivity and roof temperature is complicated by factors such as conductivity of the roof surface and wind speed that will allow some lower emissivity surfaces to shed heat energy more efficiently.

What type of coating is more energy efficient: black, aluminum or white? The answer depends upon climate and the percentage of energy used heating and cooling a structure. In hot climates white is most efficient; in temperate climates, aluminum coatings with high reflectivity and lower emissivity yield the best result; in extreme northern regions, dark-colored roofs will save the most energy as air-conditioning is uncommon.

What’s the difference between asphalt and coal tar? Asphalt is derived from crude petroleum. It’s an aliphatic or straight-chain hydrocarbon resin. Coal tar is derived from the destructive distillation of coal. It is an aromatic ring shaped hydrocarbon resin. The two

are different and generally incompatible. Asphalt is normally lower in cost, can be used on pitched roofs to vertical, has fair resistance to UV degradation and can be left bare or surfaced in a variety of manner, but it has poor resistance to ponding water. Coal tar can only be used on near to dead level roofs and has poor resistance to UV degradation so it must always be surfaced with a layer of gravel, pavers or vegetation. Coal tar has good resistance to ponding water and exhibits cold flow or self-healing characteristics.

How do I tell the difference? There are a number of factors that indicate the type of built-up roof. The first is that coal tar is always surfaced with gravel, pavers or vegetation. If it’s bare, coated or surfaced with sprayed-in granules, it’s asphalt. If it is a gravel roof, the simplest method to determine the type of roof is to wipe the roof with a clean rag soaked in mineral spirits paint thinner. Mineral spirits is an aliphatic solvent and is only capable of dissolving asphalt, which is aliphatic as well. Asphalt roofs will leave a black or dark brown residue on the cloth while coal tar will leave a yellow or slightly green residue. Several passes with a clean cloth may be necessary if the roof is dirty.

How should I evaluate the relative quality of different aluminum roof coatings? Unfortunately, there is no clear standard beyond the minimum requirements of ASTM D-2824. The reputation of the manufacturer is paramount. The simplest method to sort out aluminum coating is by aluminum pigment content. Some people object to this standard by claiming that a coating with 2 lbs of ground up aluminum cans would rate the same as a coating with 2 lbs of high-quality leafing aluminum paste. For this reason, we recommend that users ensure that, when aluminum coatings are graded by pigment weight, the aluminum paste is quoted as meeting ASTM D-962 type 2 Specification for Aluminum Powder and Paste Pigments for Paints. Another excellent source of information is the EPA’s Energy Star Program, which lists reflectivity values of various roofing materials.

5,000 Industry Professionals 100,000 Industry-focused Digital Impressions monthly

When should aluminum roof coating be applied to a new asphalt or modified bitumen roof? As soon as possible or after the roof has cured? The best time to apply aluminum roof coating to a new built-up roof is after the roof has fully cured. This will take at least six weeks. Application of aluminum roof coating to uncured asphalt will likely result in sulfur and oil bleedthrough and sometimes severe cracking or splitting.

SBS modified bitumen should be coated as soon as practical. APP modified bitumen is the most challenging roof to coat with aluminum roof coating. Applying the coating immediately will reduce exudation or bleed-through, but it will not be eliminated: expect temporary discoloration. Waiting

until the membrane has cured will allow most of the exudate to bleed out. If the roof has positive drainage, the exudate will wash off the roof and the modified bitumen will present a clean and stable substrate. Roofs with ponding water may retain exuded oil and sulfur compounds in low areas. This retained contamination will interfere with adhesion, discolor the coating and can cause the coating to crack. This contamination should be removed with a suitable power washer and detergent. It is the prerogative of the roofing contractor to examine the conditions present on a particular roof and choose the appropriate action.

Are all rubberized roof cements elastomeric? Not necessarily. Rubberized means that rubber has been added to the mix. Elastomeric implies that the material has the rubberlike properties of elongation and recovery. Some rubbers such as butyl, neoprene and SBR will not impart elastomeric qualities on an asphalt mixture. Rubbers such as SBS and SEBS will, but only if added in sufficient quantities to an asphalt that is suitable and not overly corrupted with economizing fillers.

What is the difference between water-proofing and damproofing? Damproofing will resist penetration of moisture through a foundation into the interior under normal conditions. Waterproofing will do the same even in the presence of hydrostatic pressure.

What are the advantages and disadvantages of applying coatings by brush, roller and spray? Brush application allows the coating to be worked into the surface. This will ensure an adequate bond, particularly if the surface is less than ideally clean and smooth. Brush application is the most time consuming method and will often result in visible brush marks.

Rollers are faster than brushes and still allow a measure of mechanical assistance in adhesion to the surface. Rollers also eliminate brush marks but may still leave a textured surface. Applicators should be aware that rollers will lower the natural rate of coverage below the recommended rate.

Spray application is the fastest method of coating application and generally leaves the smoothest surface. Total lack of mechanical assistance in adhesion, difficulty in assessing coverage rates and the danger of over-spray limit the suitability of spray applications.

What is the difference between silanes, siloxanes and silicone? All three are silicon-based molecules with masonry waterproofing applications. Silanes are monomers, the smallest and most simple of the three molecules. Silanes are best suited for dense surfaces like concrete and cultured stone. High concentrations of about 40 percent are necessary because of silane’s volatility.

Siloxanes oligomers are larger and more complex molecules than silanes. At lower concentrations, they provide excellent moisture protection to more porous surfaces like split face concrete block. Siloxanes can be blended with silanes to produce a treatment with the advantages of both materials.

Silicone polymers are large functional molecules that are used in caulks and sealants. Silicones can be useful for protecting porous natural stone that has a neutral pH. For concrete and masonry applications, silanes and siloxanes penetrate farther and preserve the surface’s original appearance.

Coatings are considered restoration and not a new roof system installation. Therefore, they can usually be expensed in the fiscal year during which they are applied instead of amortizing the cost over the life of the roof (as in a new membrane installation). This can be a huge tax benefit to some building owners.

FRMR.M. Lucas manufactures coatings for roofs, walls, pavement and below grade applications. For over 100 years they have produced everything from asphalt materials to the most advanced modern moisturecure and reactive formulas.

RCMA is a leading industry voice, promoting the benefits of roof coatings and providing its membership with up-to-date information on building codes and standards, technical developments and other industry topics of interest.

Since a completely corrosion free fastener does not exist, select a fastener that is as durable as the members it is fastening.

Corrosion can be placed into two categories, general corrosion and galvanic corrosion. General corrosion is caused by air and moisture. We know that it is accelerated by salt and harsh chemicals. The second category is galvanic corrosion. There is a little more chemistry involved with galvanic corrosion and it can be a little confusing. Putting two incompatible metals together, even if they are both corrosion resistant on their own, can lead to galvanic corrosion.

First, work on mitigating general corrosion. Think about where the fastener will live. The environment in which a fastener is exposed affects the rate of corrosion immensely. Corrosion is accelerated in coastal regions or highly industrial areas. The vast majority of fasteners are steel and have a protective finish applied. Different finishes have different levels of corrosion protection and we cannot accurately predict when corrosion will develop. What we can do is compare different finishes and materials using the common ASTM B117 salt spray test. Test pieces are placed in a salt spray chamber and observed to see when the first sign of red rust or corrosion is visible.

Unprotected steel is quick to rust under normal environmental conditions. Metals like zinc, aluminum and stainless steel can protect themselves from general corrosion. For a dry, indoor application, a black oxide or phosphate finish might be enough to protect a steel fastener but if you need a little more protection, a zinc plated finish will help. The longevity of a zinc plated fastener depends a lot on the thickness of the zinc plating and how it was applied. We might expect a zinc plated fastener to reach anywhere from 15-120 hours to red rust in the salt spray test.

If a fastener is going to be exposed to the elements, it will need more than zinc plating. Hot dip galvanized (HDG) finishes have been a workhorse for corrosion protection throughout the years but it is not ideal in all situations. You won’t be able to find a self-drilling or self-tapping fastener in HDG and it is not recommended in coastal applications. There are other options for long-life fasteners. A number of companies offer proprietary organic coatings and finishes that do well in normal environments and reach 500-1000 hours in salt spray testing. Harsher environments like industrial and coastal areas require fasteners that can go beyond a 1000-hour threshold. You can also

choose a fastener with a zinc or stainless steel cap. The exposed caps are highly corrosion resistant. For the harshest environments, 304 or 316 stainless steel offer the highest corrosion resistance.

Now, let’s discuss galvanic corrosion. Galvanic corrosion occurs when two dissimilar metals are immersed in a conductive solution and are electrically connected. That means that if you have two different types of metals, they have direct contact and there is a salty liquid present, galvanic corrosion may occur. If you can eliminate any one of those three components, you prevent the galvanic reaction.

To help in your selection, fastener suppliers publish compatibility guides for fasteners and various metal panels. Ask your favorite fastener supplier for their guide. These guides are a great way to help you select the best fastener material for corrosion protection for your application and to put your mind at ease.

The Senate decided not to impose the quadruple financial penalties passed by the House of Representatives in August 2022, that would have raised the maximum penalty to $700,000 per alleged violation. This is good news for contractors as there will be no increase in OSHA penalties for 2023. Penalties for other-than-serious violation, a serious violation and a failure-to-abate violation will remain at $14,502 per violation. Willful and repeat violations remain at a maximum penalty amount of $145,027 per violation.

However, the department budget was increased by $68 million dollars and has therefore added 19 percent more inspectors to heighten its focus on compliance enforcement in the field. Since there has been no increase in the value of citations and there are more inspectors as well as offices in the state of Florida, there is reason to believe that more citations will be

Other-Than-Serious Violation

A violation that has a direct relationship to job safety and health, but probably would not cause death or serious physical harm.

Serious Violation

A violation where there is a substantial probability that death or serious physical harm could result and that the employer (business owner or manager) knew or should have known of the hazard.

Failure to Abate

Failure to correct previous violations cited by OSHA.

Legislative Session, continued from page 6

■ Revises powers of board

■ Revises powers of district

■ Provides for transition

■ Provides for continued effect of stipulation between the district and Orange County

■ Provides exception to general law

■ Effective Date: Upon becoming a law.

HB 11B by Representative Dan Daley (D – Sunrise) Sunshine Water Control District, Broward County

■ Codifying, reenacting, amending and repealing district charter

■ Provides for continuation of authority for revenue collection and powers to meet outstanding obligations

■ Removes chapters 63-609 & 2021-255, Laws of Florida, relating to district

■ Provides exception to general law

■ Effective Date: Upon becoming a law.

issued this year than previous years. As a reminder, the State of Florida now has a total of four compliance offices in the state, they are located in Jacksonville, Tampa, Ft. Lauderdale and Orlando.

Safety should always be a top priority for your employees on work sites and employers are encouraged to revisit company safety programs to make sure you are taking the steps necessary to ensure a safe work environment for your employees. This includes making sure employees are following the safety guidelines as outlined by OSHA. Prevention is the best tool to avoid costly fines as well as employee injury claims.

FRSA Members can access 130 OSHA documents and 260 Toolbox Talks in English and Spanish through the “Member Login” section of FRSA’s website, www.floridaroof.com.

Willful Violation

A violation that the employer intentionally and knowingly commits. The employer either knows that what he or she is doing constitutes a violation or is aware that a hazardous condition exists and has made no reasonable effort to eliminate it.

Repeat Violation

A violation of any standard, regulation, rule or order where, on re-inspection, a substantially similar violation is found and the original citation has become a final order.

HB 13B by Representative Jason Shoaf (R – Port St. Joe) Eastpoint Water and Sewer District, Franklin County

■ Reenacts, amends and repeals special act relating to district

■ Provides for continuation of authority for revenue collection and powers to meet outstanding obligations

■ Revises definitions

■ Removes separate positions of board Secretary and board Treasurer

■ Creates position of board Secretary-Treasurer

■ Removes chapter 67-1399, Laws of Florida, relating to district

■ Provides exception to general law

■ Effective Date: Upon becoming a law.

Falls are one of the leading causes of serious injuries and deaths in the construction industry and many of them happen to be from ladders. There are many ways a person can be injured from a ladder, whether it’s from inappropriate use, improper set up, malfunction or a lack of knowledge and training. Here are some basic Dos and Don’ts for working on ladders but, of course, these are no substitutes for proper safety training.

Set the ladder up at a 4:1 ratio. This can usually be checked by placing your feet at the bottom of the ladder and reaching out to touch a rung. If you bend your arms or lean into it, it is at the wrong angle.

Ensure the ladder is three feet above the landing area on the roof. Three rungs is not high enough, as most employees will have the third rung at the eave of the home or building.

Always tie the ladder off to ensure that it does not slip or slide.

Be certain to fully open all folding step ladders and make sure the spreaders are properly in place. Avoid setting the ladder up too close to energized power sources.

Select the proper ladder for the job to be done. Not every ladder is made for every task.

Maintain three points of contact while on a ladder. Two hands and a foot or two feet and a hand must be in contact at all times while climbing.

Inspect your ladder for bent rungs or rails.

Ensure the ladder is free of debris and of slippery substances on the rungs and rails.

Place your ladder on a level surface or shore it up to level it.

Make sure the locks on extension ladders are fully locked in place.

Step on the top step of a stepladder or step above where an extension ladder meets the roof. Have more than one person on the ladder at any time. Exceed the maximum weight rating for the ladder. Use a folding stepladder in the folded position. Use unstable materials to gain more height.

Use sections of an extension ladder separately as two ladders.

Move a ladder while someone is on the ladder. Work with your body weight outside the rails of the ladder. This is commonly called the “belt buckle rule,” once your belt buckle is outside of the side rails of the ladder, you are effectively pushing the ladder away from you.

Of course, proper training and hands-on examples are always needed to keep your employees safe. Please use this brief list of Dos and Don’ts as a guide for safe ladder handling.

There are many ways to attain ladder safety training for your employees. If you are a member of the FRSA Self Insurers Fund, your safety consultant is available to provide ladder safety training as well as many other types of trainings.

The FRSA Self Insurer’s Fund (FRSA-SIF) has professional safety consultants throughout the state who will provide SIF members with safety training at no additional cost. To find out if you qualify for FRSA-SIF membership, please contact Alexis at 800-767-3772, ext. 206 or email alexis@frsasif.com. To learn more about the FRSA Self Insurers Fund, please visit www.frsasif.com.

Sitting in a recent roofing association meeting, I found myself visiting with colleagues about the importance of building ongoing relationships in the industry. One woman in particular, shared with me that recently her boss had congratulated her on significantly increasing the exposure of their company within the industry. In fact, he believed that their record-making quarter could be attributed to the emphasis they have been placing on industry networking through their employees.

Many companies are realizing the importance as a marketing benefit of encouraging professional involvement. They understand the commitment to keeping employees involved in associations and community outreach is an extremely important marketing tool. Not only does it help sales and marketing but it engages employees at a stronger, more professional level that helps build the strength of overall business.

This trend is currently being referred to as the establishment of employee brand ambassadors.

Technology start-up companies have been focused on brand ambassadors for a number of years using early adopter customers. They have focused on turning their first passionate customers into their biggest fans. These brand ambassadors spread the word about a company’s products and services, in turn creating demand. We see this happening with viral campaigns that spread like wildfire through social media. The “trick” is to harness the power of these referrals and feed the flames so that not only are they talking about the company but they are also promoting the products and services.

Rather than customers, companies are starting to realize that their best brand ambassadors are working side-by-side every day in the form of employees. The 2012 Edelman Trust Barometer, a trust and credibility survey that collects data from more than 30,000 people, found that regular rank-and-file company employees have more credibility than executives.

According to Forbes Magazine, “It is very visible when the company has passionate employees who love the brand they work for. Having an adoring employee base isn’t just great for word-of-mouth marketing, but for the bottom line as well. In one of their studies, Gallup showed that companies with high employee engagement levels have 3.9 times the earning per share compared to their industry peers or competitors.”

There is a strong opportunity here for roofing companies to build not only their brand but highquality reputations. It is an opportunity to let employees promote the business they believe in. The passion for what they are doing will show as they work with their local and professional organizations. In turn, they will be one of your best marketing tools.

It starts with asking for their opinion. Don’t just ask them to promote the business but ask for their feedback on what they believe are the company’s strongest assets and where there may be room for improvement. By including them in the process of improving the company they gain ownership in the overall enterprise, increasing pride and confidence. Create channels of communication. Be sure your employees know what is going on within the company. Take the time to educate and get them excited about new products, projects or services that make your company distinctive. Include them on company newsletter mailings or emails. Make it easy for them to share the excitement.

Encourage social media interaction and advocacy. This is an area that is still hard for many companies. Is the employee engaged or just scrolling through Facebook? In this day and age, it is both. Employees live their lives at work and at home. They are liking posts, commenting on new information and making referrals. How powerful is it when they do it for their own place of work?

Allow employees to help strengthen customer relationships. Every positive meeting is a great sales and marketing opportunity for the company. Whether it is accounting, production, sales or the front desk, employees should leave the customer smiling and happy. Employees need the time to introduce themselves and be a part of fixing or improving the process. It is okay to ask for referrals after a good experience but it takes every employee being an amazing brand ambassador to create that perfect referral and sustainable business model.

Financially and emotionally encourage involvement. Help employees be involved in professional and community associations. Having employees attending Chamber of Commerce events, sponsoring school sports or helping with community service projects gives them the time to advocate for their place of work while being involved. It shows that the company is committed to the community it works in and is willing to support their employees’ involvement.

Make sharing easy. Help employees share this information with each other and your customers. Monthly lunch and learns that share how to be a brand ambassador, social media discussion groups and company newsletters are all ways to engage and educate employees. Encourage employees to follow the company on all social media. These exercises can make a huge

Continued on page 29

Last month in part one, we covered the business language, Accounting. We discussed accounting systems, percentage of completion and over-under billings. In this month’s article, we focus on revenue impacts, cost control, timelines, tracing costs and working without information.

Total revenue is the first line in the income statement and directly impacts stated profit or loss, which on a fiscal year basis directly affects assets or liabilities on the balance sheet. The accuracy of the total revenue figure is critical because of its impact on your company’s financial statements.

The following graphic describes how this information should flow through your company’s structure and be used to calculate total revenue:

about it. If sales are recorded in a timely manner and some costs are entered a month later, each job will look great on paper until a month after it’s finished.

The most sophisticated computerized cost control (job cost) systems are worthless if they contain partially inputted data or good data with the wrong dates. When this happens, getting the wrong information and relying on it to manage your company is worse than no information because your project management decisions are based on inaccurate information.

As you can see, the percent completion of a project is seen most clearly in the field and the project manager uses this field data to prepare the estimate of the cost to complete. The accounting department then uses costs incurred and the estimated cost to complete to calculate the percentage completion of the project and then use this calculation to determine total sales. It adjusts or justifies any discrepancy between the project’s completion stage and the percentage billed on the project.

Because of the adverse effects on cash flow, a wise business owner would always avoid underbilling. However, the “cost in excess of billings” is too typical in roofing companies. Suppose you are not tracking your projects and correctly using the cost-to-complete method. In that case, you will have no way of accurately knowing how many projects are underbilled, which puts you at risk of running out of operating cash.

To be a successful and consistently profitable roofing company, you must have an excellent job costing system that captures all of the project costs on time so that you know whether or not a job is making money. Timelines of information are essential because you need to see this information in time to do something

A roofing company needs timely profit and loss information by project and by cost codes. A job cost system does not control anything. Its purpose is to provide the necessary information about how the project runs against planned or budgeted amounts, enabling management to oversee the project better. Your job cost system should collect costs in categories that can be tracked against the originally estimated cost for each activity.

The key to a successful job cost system is getting the information in time to make decisions on the project. Still, the information needs to be accurate to be of any value. Trading off accuracy for timeliness doesn’t work. Your company must have both. Therefore, all available information must be input immediately. If a bill for the membrane is received, it should not be delayed by waiting for someone to verify the quantities. It should be put into the system immediately as an incurred cost. If it has to be changed later, it can be changed in the system by a correcting entry. Having it entered is more important than finding out later that there is a two percent discount or that the invoice is in error by a certain percentage.

In the real world in which we operate, invoices will be missing from any system because they haven’t been received yet. The fact that your company hasn’t received an invoice doesn’t mean you haven’t incurred a cost. Your system should understate the profit rather than overstate it because there are enough pressures within our business without overstating performance

and profits. There is a straightforward reason you do not want to overstate: when profit is overstated, no action is taken because you are content with how things are going. But when it’s understated, you are less pleased and take steps to improve performance.

Accounting for all costs may be more complicated than it should be if certain costs are tracked unnecessarily. For instance, subcontractor costs. Subcontracted costs are committed early in the project process as a subcontract for a fixed sum. Excluding change orders, the total amount of this subcontract will be incurred as the job gets done. Knowing how much to pay against the contract as the job progresses is a different subject. These figures don’t come from the job cost system. It is the opposite. When a subcontractor is paid, that information is fed back into the job cost system as the amount paid. Therefore, it makes sense to have your project managers track the subcontractor’s progress outside the accounting system when calculating their percent complete for progress payments.

Don’t use it if job cost information isn’t accurate or on time. Bad information is worse than none. The alternative is much better in these circumstances: trust your gut feelings. If you spend any time in the field, you will have a good sense for judging whether things are going well. And, it is beneficial if you act on these

judgments. If you can’t get to the field, you need to talk to the people who do about their gut feelings. The people with the best performance perspective are those who visit the field periodically. Full-time field supervisors usually have an optimistic view of things and are hesitant to report bad news. If you don’t get a good feeling about what you’re hearing, you need to go to the field and find out for yourself. It’s time to use all your experience and know-how as a roofing contractor. What is felt on field visits is essential and roofing contractors should follow their instincts even if the paperwork discloses the opposite. Experience has taught us that our gut responses will be right most of the time. You should rely on them until you can establish an effective job cost system.

It may seem evident that contractors who fail to make a profit do so because they didn’t make money in the field. But it is not so straightforward once you realize that more than half of distressed contractors didn’t know they were losing money until it was too late to do anything about it. Not evaluating contract profitability by project, month and cost code is one of the most severe and avoidable causes of nonperformance. Job costing is fundamental to managing a profitable roofing business. The only thing worse than losing money is not knowing it happened.

John Kenney, CPRC has over 45 years of experience in the roofing industry. If you would like any further information on this or another subject, you can contact John at jkenney@cotneyconsulting.com.

difference in building morale, commitment and helping employees message the uniqueness of the company! Make sure every employee is enabled to be a brand ambassador. From the rooftop to the front desk, every employee should be able to talk about the mission and differentiating qualities of the company. Why is this the best roofing and exterior contracting company? What do we offer that is different? How can our employees help create raving fans or amazing customer brand ambassadors? By asking these questions and taking the time to train employees on the company’s marketing materials and messaging it will reap great rewards. Share how this important employee engagement will not only help the company but will help their own personal performance and potential financial benefits.

As you use these steps to create brand ambassadors in your company, be sure to look across the board for opportunities not just locally but regionally and nationally. I was fortunate to be involved with the formation of National Women in Roofing (NWiR). This was a new organization that is focused on networking, mentoring and education for women within the roofing

industry. I have been able to meet amazing women from manufacturing, distribution, services and roofing companies.

Through this experience, I have been able to continue to share my story with people I may never have had the chance to meet. I have not only met amazing colleagues but I have also been able to help market my own company, hopefully gaining new customers.

This is the same for the regional and community organizations in your area of business. By being involved throughout your profession at all levels, you and your employees have the opportunity to gather information that can be shared throughout the entire company. This type of involvement is invaluable not only for finding new customers but also for gathering information that will grow your business overall.

After a devasting apartment fire, Gainesville resident Thine Strawder is ready to sleep under a new roof.

Strawder, a single mother of eight and grandmother of 14, lived in her Gainesville apartment for 28 years. She was heartbroken to see the home where her children grew up engulfed in flames.

Tragedy turned into triumph, however, when Alachua County’s Habitat For Humanity accepted her application to build a brand new house. Alachua Women Build, a volunteer program of Alachua Habitat, helped to build Strawder and her family a new place to call home.

“God is answering prayers. I really have no words,

because I could just go on and on all day,” Strawder said. “I am most excited to host my family in a home that truly belongs to me. I look forward to every aspect of the process – from construction to moving in, to the first time celebrating with loved ones.”

Of course, no home is complete without a roof to sleep under, which is where Tadlock Roofing came in. The North Central Florida company heard Strawder’s story and offered to provide the roof materials and labor at no extra cost.

“We’re looking forward to presenting Ms. Thine with a free roof during our Grand Opening and building a lasting relationship with Alachua Habitat for Humanity,” says Dale Tadlock, Founder and President of Tadlock Roofing.

“At Tadlock Roofing, we’ve built our foundation on not only making a difference in the roofing industry but also in the lives of our dedicated employees and the communities we serve. While roofing is what we do, making a difference is why we do it,” states Tadlock.

Tadlock Roofing is a familyowned and operated business with strong Christian values and they feel it’s their duty to be of service to others. They state they’ve been blessed with the opportunity to do what they love and are grateful to be able to bless others. FRM

FRSA is proud of the volunteer work completed by members in the industry and would like to share those projects as often as possible. If you have a community service project you’ve completed, please send it to Lisa Pate at lisapate@floridaroof.com.

Everyone pays the same workers' comp rate, but does your workers' comp insurance carrier provide you with the potential for a yearly dividend for operating safely? If not, you need to consider the FRSA Self Insurers Fund. These members received their share of $3 million during FRSA's Convention. For more information about joining the Self Insurers Fund, contact Alexis at 800-767-3772 ext. 206 or by email: alexis@frsasif.com

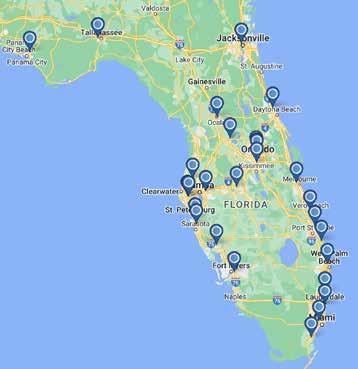

Homestead, FL 33032

(786) 829-2761

Jacksonville, FL 32209

(904) 503-9400

Tallahassee, FL 32304

(850) 574-7600

Odessa, FL 33556

(813) 749-5354

Orlando, FL 32804

(407) 291-7244

Tampa, FL 33619

(813) 740-8790

Fort Myers, FL 33916

(239) 935-5077

Deerfield Beach, FL 33442

(954) 969-8000

Miami, FL 33142

(305) 635-7177

Orlando, FL 32809

(407) 367-6246

Ocala, FL 34474

(352) 622-3933

Melbourne, FL 32904

(321) 369-7892

Ormond Beach, FL 32174

(386) 301-4471

Palmetto, FL 34221

(941) 722-6800

Leesburg, FL 34748

(352) 818-6120

Orlando, FL 32804

(407) 859-9997

Winter Haven, FL 33880

(863) 293-1555

St. Petersburg, FL 33716

(727) 565-4630

Sarasota, FL 34243

(941) 203-6320

Fort Pierce, FL 34982

(772) 466-3461

Stuart, FL 34997

(772) 223-8881

Vero Beach, FL 32960

(772) 778-0549

Orlando, FL 32810

(321) 442-0061

Fort Lauderdale, FL 33315

(954) 525-1158

Riviera Beach, FL 33407

(561) 863-9899

Clearwater, FL 33762

(727) 573-6075

North Port, FL34289

(941) 732-1029

Panama City, FL 32405

(850) 763-0851

Find your local branch with the Beacon PRO+ Mobile App. Download the Mobile App today!