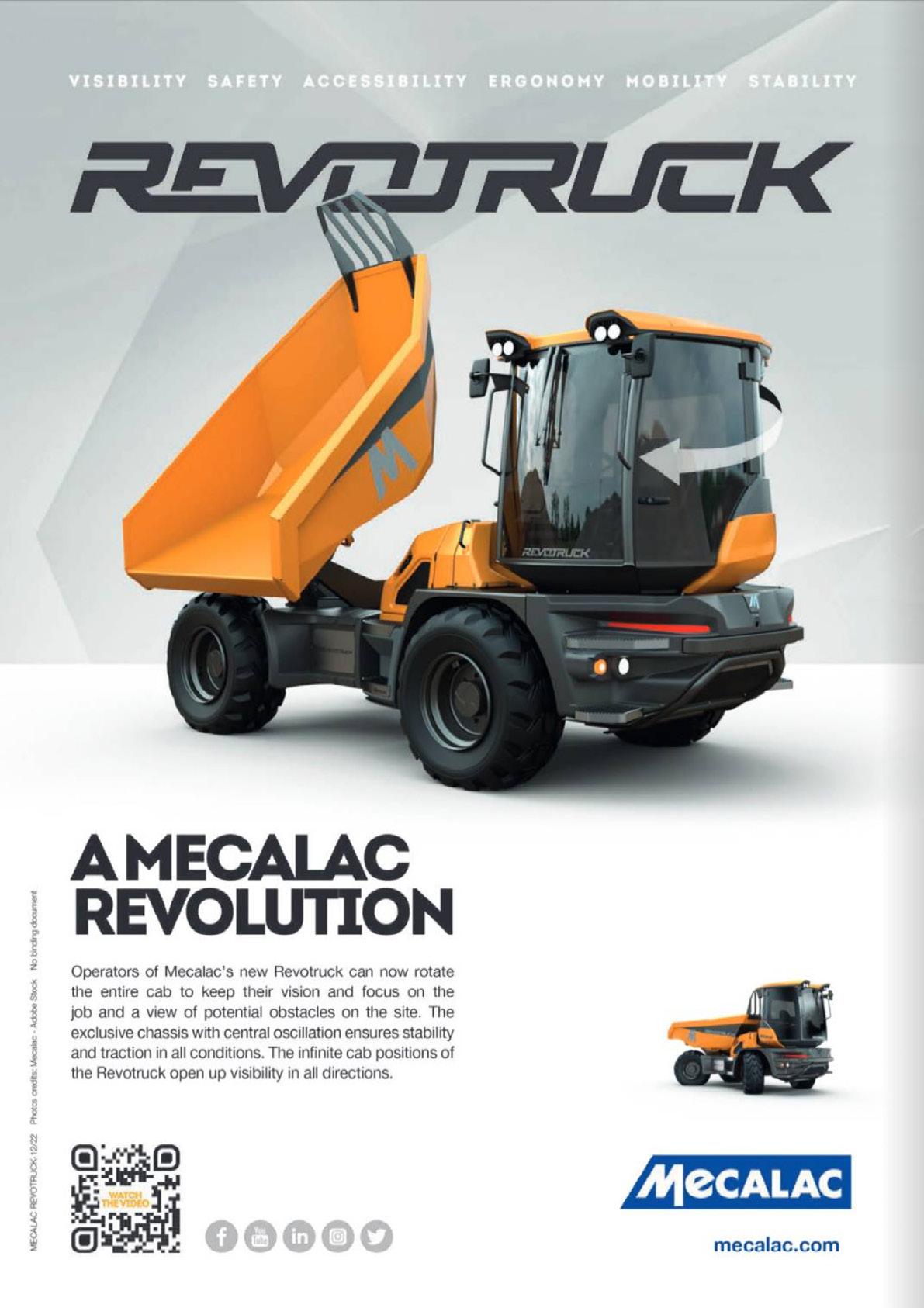

WHETHER YOU’RE TALKING ABOUT ITS SEALANTS, ADHESIVES, BUILDING CHEMICALS OR LANDSCAPING SOLUTIONS, BOND IT HAS ALWAYS BEEN A SUPPLIER OF TRAILBLAZING PRODUCTS. THE LATEST ADDITION TO THE COMPANY’S RANGE LOOKS SET TO MAINTAIN THAT TRADITION. CREATIVE BUILD FINDS OUT MORE.

Innovation has always been a cornerstone of Bond It’s approach. Throughout its 20-year history, this British manufacturer has continued to bring to market new products which offer revolutionary benefits and improved ways of working.

Given this track record, the company’s decision to become the new and exclusive UK and Ireland distributor of Geo-Fix® was a natural one.

The business may not have developed this advanced jointing compound for paved and similar areas, but it is a perfect fit with the wider Bond It product portfolio thanks to its next generation capabilities.

Geo-Fix® has been developed by paving expert, John Andrews and draws on the extensive insight and knowledge he has gained from decades of working in this specialist area of landscaping.

Available in both an Original and an AllWeather formulation, Geo-Fix® provides users with a superior means of pointing pavers, cobbles, flags, slabs, and stone setts.

Unlike other products, which require

the addition of water or the mixing of separate components such as sand, cement and water, Geo-Fix® is supplied pre-mixed and ready to use. This saves time, effort, and mess both in terms of preparation and post-work clean up.

Geo-Fix® is also incredibly quick and easy to install. It is applied simply by brushing it into the joints and can be finished by compacting with a pointing tool. From there, a completely safe, chemical reaction causes it to cure and harden.

Trials conducted with professional contractors highlight just how effective Geo-Fix® is at saving time and labour.

During these tests, which were conducted under real world conditions and on a live project, it was found that Geo-Fix® enabled paved areas to be pointed an impressive twenty times faster than they could be with a traditional wet mortar.

In a world where time is money, GeoFix®’s speed and ease of installation delivers major commercial benefits.

It saves on the associated labour costs of a project and these dividends can be amplified by a project’s size. The bigger the job, the bigger the savings that are made.

In addition, by making projects quicker to complete, Geo-Fix® can allow users to complete more jobs in less time. This enables landscaping professionals to increase the amount of work they take on and the total level of revenue they can make overall.

Speed and ease of application aside, there are other equally impressive benefits to Geo-Fix®. This includes the fact that its technical performance surpasses that of both wet mortars and of other dry mortars that use polymeric sand.

As a prime example, the length of time required for Geo-Fix® to cure is much shorter than that for other solutions

on the market and it can reach full loadbearing capacity in hours rather than the more usual days.

In addition, Geo-Fix® offers greater flexural and compressive strength compared to similar products and is non-staining if any excess is swept off surfaces after use.

Plus, as it is supplied vacuum packed in extra strong, sealed foils, which are then placed into an outer tub, Geo-Fix® offers an increased shelf life. The outer tub is also made using post-consumer recycled (PCR) plastic, diverting waste from landfill, and contributing towards greater sustainability.

Geo-Fix® even provides greater flexibility as to when work can be carried out. GeoFix® Original for instance can be used at temperatures down to - 5oC whilst GeoFix® All Weather, as its name suggests, can be used in all conditions – including the wet.

As a further benefit, Geo-Fix® All Weather is also perfectly suited for use with porcelain paving which is becoming an increasingly popular choice thanks to its durability, longevity, and ease of maintenance.

As porcelain paving is just 20mm thick, it’s essential that any jointing compound used alongside it can still deliver effective performance in a joint with a dramatically reduced depth. Geo-Fix® All Weather provides precisely that capability and can be used in joints as shallow as 15mm.

To accommodate the growing trend towards using porcelain paving, Bond It will be introducing further complementary and specialist products over the coming months.

Ultimately, Geo-Fix® is one of those mould-breaking developments that redefines expectations.

In fact, since adding it to the Bond It range, the company has found that customers who try it wish they had discovered it sooner and are adamant that they won’t go back to using anything else.

Tradition meets Innovation: Graphenstone, the most advanced ecological and natural paint on the market, unique in harnessing graphene technology in collaboration with the World’s oldest public museum to capture the colours of art and culture through the ages in an exclusive Ashmolean Paint Collection

Graphenstone, the world’s most certified eco paint company has launched an exclusive paint collection with the Ashmolean Museum, Oxford, the world’s oldest public museum celebrating 340 years.

Taking some of the Ashmolean’s most treasured objects as inspiration, the range comprises 16 carefully curated and complementary shades that are practical for both home and commercial use. Colours range from the burnt orange of the maple wood used by master violin maker, Antonio Stradivari, to the vibrant teal of the feathers in John Ruskin’s ‘Study of a Kingfisher’.

Each colour has been chosen and matched to the original artworks by the Graphenstone team.

Dec McCarthy, Commercial Manager, Ashmolean Museum, comments, “We have often mixed our own paints for our interiors by matching colours with our collections, so it is great to launch this new range with Graphenstone and offer

it to the public. The range Is 100% natural and non-toxic in line with Graphenstone’s unrivalled environmental credentials; and sales will support the Museum and our work.”

Graphenstone is made using the highest quality lime and sustainable natural minerals, perfectly suited to both modern and traditional interiors. Containing Graphene, a nontoxic pure carbon that is the strongest material known to science, it offers exceptional performance, durability, and coverage.

Graphenstone’s healthy paints are petrochemical and plastic free, with only trace elements of VOCs (less than 0.1%), free from carcinogens, hazardous chemicals, and preservatives. The paints are virtually odour free so will not release harmful off gasses or synthetic additives often associated with breathing difficulties and allergies.

The environmental impact is rigorously controlled, and the manufacturing process is powered entirely by

renewables (hydro (37%), wind (51%) and solar (12%)) with waste water being reused in the production process. All packaging is cardboard, and the paint tubs are made using 100% PCR plastic (post-consumer) meaning everything is 100% recyclable.

Patrick Folkes, Graphenstone Director said, “We are often approached by global partners to collaborate. When the Ashmolean explained what they wanted to do, we could not say no to this unique opportunity to create stunning colours that will also help to support one of the

UK’s most important cultural institutions and we are honoured to be working alongside them.”

The range is available in two finishes ideally suited for internal applications. GrafClean and Grafclean Eggshell are mixed mineral paints composed of vegetable resins and ecological materials, certified as Eurofins ‘Indoor Air Comfort Gold’ complying with the lowest emission rates in Europe, ensuring quality and the brands contribution to a healthy indoor environment.

The Ashmolean paints will be sold nationally via selected Graphenstone UK distributors and exclusively online at www.graphenstone-ecopaints.store Further details of the collaboration will be available the Graphenstone x Ashmolean web page

New from Rinnai is a comprehensive range of heat pumps plus all ancillary products such as hybrid hot water tanks are now available for direct delivery to site in one complete system consignment.

Rinnai Heat Pumps are an integral part of the H3 list of solutions to achieve lower carbon. Rinnai heat pumps are the optimal choice in decarbonising technology that ensures immediate domestic and commercial carbon neutrality.

Rinnai’s range of Monobloc air source heat pumps are available in an assortment of variants, from 4 to 110kW. Rinnai Monobloc air source Low-GWP heat pump technology allows up to seven units to be cascaded together, making the Rinnai heat pump range an

ideal choice for any heating or hot water demand. The innovative ability of the system to switch between heating, hot water, and cooling mode ensures that the Rinnai range has flexibility and durability as standard.

The units omit minimum acoustics via an installed ultra-low sound capability making Rinnai heat pumps suitable for any area with prohibitive sound legislation. Rinnai’s range operates within compliance of all stringent sound standards ensuring low-sound functionality.

All Rinnai heat pumps use R32 refrigerant, renowned for reducing electricity consumption by up to 10% and for holding a lower global warming potential (GWP). R32 has a GWP one-third lower than other refrigerants. Rinnai’s HPI heat pump range is ratified with an ERP rating of A +++ and includes an ability to switch between settings of heating, hot water and cooling.

Rinnai’s heat pump range delivers all domestic and commercial requirements whilst negating the release of any harmful toxicants into the atmosphere. Rinnai’s

heat pump range maintain a high level of operational performance and can service all domestic and commercial needs.

Rinnai’s H3 LowGWP 55kW Heat Pump/ Hybrid Hot Water Tanks with cascaded continuous flow hot water heating units were recently specified at a new development in the heart of the Farringdon district of London. The site is for a luxury hotel plus prestigious office complex and affordable homes.

The site will eventually have a 150+ bedroom luxury hotel, almost 20,000 sq ft of opulent capital city office space and nine new-build affordable residential units. The hotel group already has one other hotel in London with two others planned.

Rinnai products are designed to perform at a high operational level, maintain a robust product lifecycle whilst reducing customer cost and environmental impact across the entire purchase process.

Rinnai’s HPI heat pumps, hybrid formations, electrical formats and hydrogen gas mix powered water heaters are part of the H3 range of products. All new models are designed to reduce decarbonisation, energy efficiency and reduce customer costs by offering practical, affordable and technological solutions to UK customers. ***************************************************** *******************************************

RINNAI’S H3 DECARBONISATION

OFFERS PATHWAYS & CUSTOMER

COST REDUCTIONS FOR COMMERCIAL, DOMESTIC AND OFF-GRID HEATING & HOT WATER DELIVERY

www.rinnai-uk.co.uk/about us/H3

Rinnai’s H3 range of decarbonising products include hydrogen / BioLPG ready technology, hybrid systems, and a wide range of LOW GWP heat pumps and solar thermal. Also, within Rinnai’s H3 range is Infinity hydrogen blend ready and BioLPG ready continuous flow water heaters which are stacked with a multitude of features that ensure long life, robust & durable use, customer satisfaction and product efficiency.

Rinnai’s range of decarbonising products - H1/H2/H3 - consists of heat pump,

solar, hydrogen in any configuration, hybrid formats for either residential or commercial applications. Rinnai’s H3 range of products offer contractors, consultants and end users a range of efficient, robust and affordable decarbonising appliances which create practical, economic and technically feasible solutions. The range covers all forms of fuels and appliances currently available - electric, gas, hydrogen, BioLPG, rDME solar thermal, low GWP heat pumps and electric water heaters.

Rinnai H1 continuous water heaters and boilers offer practical and economic decarbonization delivered through technological innovation in hydrogen and renewable liquid gas ready technology.

Rinnai’s H1 option is centred on hydrogen, as it is anticipated that clean hydrogen fuels will become internationally energy market-relevant in the future; Rinnai water heaters are hydrogen 20% blends ready and include the world’s first 100% hydrogen-ready hot water heating technology.

Rinnai H2 – Decarbonization simplified with renewable gas-ready units, Solar Thermal and Heat Pump Hybrids. Rinnai H2 is designed to introduce a practical and low-cost option which may suit specific sites and enable multiple decarbonisation pathways with the addition of high performance.

Rinnai H3 – Low-GWP heat pump technology made easy - Rinnai heat pumps are available for domestic and commercial usage with an extensive range of 4 - 115kW appliances.

Rinnai’s H3 heat pumps utilise R32 refrigerant and have favourable COP and SCOP.

Rinnai is a world leading manufacturer of hot water heaters and produces over two million units a year, operating on each of the five continents. The brand has gained an established reputation for producing

products that offer high performance, cost efficiency and extended working lives.

Rinnai’s commercial and domestic continuous flow water heaters offer a limitless supply of instantaneous temperature controlled hot water and all units are designed to align with present and future energy sources. Rinnai condensing water heaters accept either existing fuel or hydrogen gas blends. Rinnai units are also suited for off-grid customers who require LPG and BioLPG or DME.

Rinnai products are UKCA certified, A-rated water efficiency, accessed through multiple fuel options and are available for purchase 24/7, 365 days a year. Any unit can be delivered to any UK site within 24 hours. Rinnai offer carbon and cost comparison services that will calculate financial and carbon savings made when investing in a Rinnai system. Rinnai also provide a system design service that will suggest an appropriate system for the property in question. Rinnai offer comprehensive training courses and technical support in all aspects of the water heating industry including detailed CPD’s. More information can be found on Rinnai’s website and its “Help Me Choose” webpage.

Visit www.rinnai-uk.co.uk

Or email engineer@rinaiuk.com

For more information on the RINNAI product range visit

www.rinnaiuk.com

heat sources, this product leads the way as a solution to meet those needs.”

The new Relax Hybrid combines minimalist design and advanced technology to offer a future proof solution that is compatible with both traditional boiler heating systems and heat pump installations.

The new Relax Hybrid performs as a highly efficient, contemporary radiator, using both radiant heat and fan coil assisted technology to quickly reach and maintain the ideal temperature throughout the room. Thanks to its cutting-edge design, this groundbreaking new product offers further benefits for homeowners who have, or who are looking to install, a heat pump system. Here, the Relax Hybrid automatically isolates the heating components to prevent the formation of condensation, to act as a cooling unit.

With a slim 107mm profile, this sleek product from The Radiator Company features geometric lines and

sophisticated touch controls to create a stunning addition in any room, particularly where the space and design needs are paramount. The unit can also be equipped with optional LED lighting to enhance its elegant profile and create an evocative mood in the environment.

The Radiator Company’s National Sales Manager, Richard Lister expects the Relax Hybrid to revolutionise home comfort as temperatures in the UK reach record highs and lows, and the adoption of heat pumps continues to accelerate.

“This product offers users with complete flexibility to adjust the room temperature according to season, providing consistent heat in the winter and, with appropriate system specification, cool air in the summer. Furthermore, as the demand for heat pump systems is expected to change dramatically over the coming years to meet Part L regulations and shifting consumer appetite for alternative

Richard continued: “The Relax Hybrid offers far more than heating or cooling a room. Sensory design is increasingly sought after and the Relax Hybrid makes use of a timeless colour palette, with neutral and natural colours as the main focus. Its slimline design and optional LED lighting system make this unique product the perfect choice for contemporary, future-proofed fit outs.”

The Relax Hybrid is available in horizonal and vertical formats, in two heights and four widths and can be finished in a choice of five colours: Grey Skies, Grey Sparkle, Matt White, Sand, and Carbon. To work as an air cooler, the Relax Hybrid should be connected to a system powered by a heat pump, which has been designed to manage the circulation of cold water.

To find out more about the new Relax Hybrid and to explore The Radiator Company’s entire range of heating solutions, visit www.theradiatorcompany.co.uk

Leading radiator manufacturer The Radiator Company, has launched an innovative new product that warms AND cools depending on user preference.

Another difference is in the burner use as the Firebird HVO boiler has a modified burner that is designed to handle the different viscosity of HVO. The burner is also designed to operate at a higher temperature, which is necessary to vaporise the HVO.

Speaking about the upgrade in his heating system, Karl said, “I couldn’t be happier with my new HVO-ready boiler from Firebird. Over the past two months, I’ve found HVO to be an incredibly sustainable and efficient alternative to traditional kerosene. We have seen a 35% reduction in our heating bills so far. With Firebird’s innovative technology, I’m confident that I’m doing my part for the environment while enjoying our warm and comfortable home.”

Firebird installer, Oliver provided his expertise and was eager to contribute to the project.

Recently, it had the pleasure of engaging with Karl Henry, who expressed an interest in upgrading his outdated heating system.

Having relocated to his dream home in West Cork, Karl sought Firebird’s expertise in sustainable home heating solutions. With an older and relatively larger home posing retrofitting challenges, Karl sought Firebird’s advice on the installation of the most efficient boiler for his home.

Following a thorough evaluation of Karl’s previous heating systems, Firebird made a recommendation for an energy-efficient and dependable option: the HVO-ready Envirogreen Popular 44kW boiler. This Firebird boiler boasts impressive heat output while utilising minimal fuel, thanks to its remarkable efficiency.

Not only will this translate to significant fuel bill savings for Karl, but it will also help him reduce his carbon footprint. Furthermore, this boiler is a robust and long-lasting unit that can provide years of trouble-free operation with proper maintenance.

After extensive discussions with Karl and his plumber, Oliver Buckley, about sustainable fuel options, Firebird proposed a trial of HVO (Hydrotreated Vegetable Oils) in his home, giving him an opportunity to experience the benefits

first-hand. A viable and sustainable dropin replacement to kerosene, HVO fuel is fossil-free, and can reduce greenhouse emissions by over 90%. The HVO was supplied by MJ Kelleher Oils in Cork.

Mark Doyle, General Manager with Firebird explained how the introduction of HVO for household and commercial boilers would be an instant gamechanger for Ireland.

“There are 700,000 or so homes in Ireland like Karl’s with existing liquid fuel boilers and with few other choices available for homeowners to adopt cleaner, greener heat solutions.

“HVO can work with any liquid fuel boiler and, if used in homes, can potentially make these homes almost carbon neutral immediately.

Firebird’s trials of HVO for home heating in Ireland and Northern Ireland have proved how household greenhouse gas emissions could be reduced by 90% and with CO2 emissions decreasing by up to six tonnes annually.”

The installation of a Firebird HVO compatible boiler is similar to a standard Firebird boiler in many respects, but there are some differences in the components of the boiler installation and how it operates.

Firebird worked with Oliver to identify the best appliance in terms of size and suitability and the project was delivered in less than two days.

Speaking about the project, Oliver said, “Working with Firebird to install Karl’s new Envirogreen Popular 44kW boiler was a great experience. It was great to have Firebird’s technical team on hand for any questions, as even though the installation of the Firebird boiler was very straightforward, the upgrade of the heating system itself was complex. The team’s expertise and dedication to sustainability made the installation process seamless, and we’re thrilled with the results.

HVO is a game-changer in terms of efficiency and reduced emissions, it is odourless and much cleaner to work with compared to kerosene. It is great to see a local Cork company leading the way in sustainable home heating.”

This innovative approach to problem solving is just one of the reasons why Firebird is a market leader in home heating; always adapting and always developing practical world-class solutions with a mission to set new standards of sustainability for the home heating market.

For more information, visit: www.firebird.ie

At Firebird, the firm takes pride in providing excellent customer service.

Work has commenced on the £74 million industrial warehouse scheme - Project Holst - located in Coventry’s renowned Prospero Ansty Park.

A ground-breaking ceremony held on 12 July marked the start of the pivotal scheme at the landmark technology hub, attended by representatives of McLaren Construction (Midlands and North) and Manse Opus.

Consisting of four industrial warehouses with associated offices, construction works led by McLaren Construction (Midlands and North) on behalf of Manse Opus, started earlier this year and are due to complete in March 2024.

Spanning a total of 1,739,598 sq. ft, the four commercial speculative units will predominantly comprise a cladded portal frame with a CAT A open plan layout and the site will feature an external logistics yard with a level and dock access area and dedicated car parking spaces with electric charging points, alongside landscaped communal areas.

Designed to meet a BREEAM Excellent rating, units will be highly energy efficient in design with the application of roof top PVs and rainwater harvesting tanks.

Offices have been designed as largely open plan to provide flexibility to prospective tenants, and the architecture has focused on the business culture and purpose of the technology park, reflecting the current variety of highly skilled professions already present within the surrounding developments.

The scheme will also entail a large and complex earthworks operation prior to construction with extensive infrastructure works needed to access the plots and associated balancing ponds to accommodate storm water. All removed earth will also be reused back within the site to reduce waste and provide a greater circular approach.

Prior to works commencing, great crested newts were identified and relocated, and protective fencing was erected to the perimeter of the site. As part of the wider landscaping scheme, new ecological areas will continue to be developed during the construction and population of the site.

Giving back to the local community, voluntary works are due to be carried out at the Grace Academy during the summer, to create a sensory open space for the students to enjoy.

Last year, McLaren Construction (Midlands and North) completed construction works for Manse Opus, on a new 94,000 sq. ft regional headquarters for Cadent Gas – the UK’s largest gas distribution network.

Project Holst marks the second scheme at the park that McLaren Construction and Manse Opus have partnered together for, following more than three years of collaboration.

Managing director, Gary Cramp, said: “It’s excellent to be partnering with Manse Opus again for the further expansion of Prospero Ansty Park and we have a strong relationship formed over many years successfully working together.

“Prospero Ansty Park is a fast-growing business and industrial hub for the West Midlands, and we’re very pleased to be bringing our client’s vision to life with Project Holst, providing central highspecification commercial office space, ideally positioned to cater to clients in the industrial and logistics sector.

“We have managed to overcome challenges with this site – including battling with the wettest March on record in 20 years. However, our dedicated team of skilled contractors managed to stay dedicated to the programme and timeline.”

Richard Smith, director of Manse Opus, said: “I am delighted for the third time now to be working with McLaren in delivering this massively important logistics and industrial scheme comprising four buildings between 117,000 sq. ft and 300,000 sq. ft, to be completed between December 2023 and March 2024.”

Labour costs are set to overtake the cost of materials as the biggest challenge facing the construction industry during the year ahead, according to new analysis from the Building Cost Information Service (BCIS).

As part of its quarterly data briefing on construction inflation, BCIS is forecasting a 10 per cent uptick in labour costs over the next year, as high inflation and the cost-of-living crisis put pressure on wages.

The impact of inflation is compounded by ongoing labour shortages across the industry, with 69 per cent of British civil engineering firms reporting difficulties finding skilled operatives for infrastructure projects that include HS2.

Dr David Crosthwaite, chief economist at BCIS, reported that annual growth in the BCIS labour cost index is predicted to increase to five per cent in the third quarter of this year, rising to 8.3 per cent in the second quarter of 2024.

He said: “While the cost of materials is now stabilising, labour is set to become the next biggest cost driver for construction going forward.

“Labour site rates continue to rise faster than wage awards. We’re expecting a period of catch-up, with people

demanding wage increases that go towards offsetting some of the price rises we’ve seen across the rest of the economy.

“It’s also important to remember that while material cost increases are slowing, levels are still significantly higher than they were three or four years ago.“

According to data from the Office for National Statistics (ONS) analysed by BCIS, there has been a declining trend in total employment in construction since the pandemic, mostly driven by a fall in self-employed workers.

Although the number of insolvencies is high - with more than 1,000 construction firms going bust in the last quarter – the total number of construction businesses operating has grown exponentially, from just under 200,000 in 2014 to approximately 375,000 in 2022, despite recent crises.

Dr Crosthwaite added: “Since 2019, the overall construction workforce has shrunk by 181,000 people – 98 per

cent of whom were self-employed. The number of those employed has also fallen, but by a smaller proportion.

“The volume of this decline is significant. What’s interesting is that despite the number of insolvencies having risen and the number of workers falling, the number of firms and labour productivity both appear to be increasing, suggesting that the industry is becoming more efficient.“

BCIS forecasting data and figures from the Office for National Statistics (ONS) show total construction work output is now above pre-pandemic levels, at £46,409m for Q1 2023, driven by growth in the repair and maintenance industry. However new work output has declined in the last quarter and remains below levels recorded in 2017, at £27,822m for Q1 2023.

For more information about BCIS, visit the website at www.bcis.co.uk

Grant Shapps visited JCB Power Systems in Derbyshire last Thursday to get the low down on how the construction industry is moving away from fossil fuels.

He then visited JCB’s Staffordshire proving ground where he drove a prototype hydrogen-powered JCB backhoe loader and had a go at refuelling it.

JCB has built more than 50 prototype hydrogen combustion engines for use in construction and agricultural equipment and several machines are currently in testing.

Mr Shapps said: “This is a unique prospect that works well, and I’ve challenged JCB by the middle of next year – by 2024 – to be operating some of these on our roads and on construction sites. And JCB told me that it will be happy to try and achieve that objective, and good luck to them.”

Mr Shapps was hosted by JCB chairman Lord Bamford and chief executive Graeme Macdonald. He was told how JCB had launched a range of battery-

electric compact machines, with more than 20,000 units already sold. He was shown how battery-electric technology was largely unsuitable for heavier equipment due to the higher energy demands, and the longer working hours of such machinery in remote locations where access to grid connections is limited.

Mr Shapps added: “JCB operates in two fundamentally quite difficult areas to decarbonise: construction and agriculture. I have to say they’re making decarbonisation look easy, and I’ve been very impressed with what I’ve seen.”

Lord Bamford said: “It was a pleasure to show the secretary of state the great progress JCB’s British engineers are making in developing a zero-carbon solution to power our future machines. They need to be powered by something other than fossil fuels in the future and super-efficient, affordable, high-tech hydrogen combustion engines with zero emissions can be answer for the construction industry and agriculture. What’s more, they can be brought to market quickly using our existing supply base.”

Energy secretary Grant Shapps has challenged JCB owner Lord Bamford to get his hydrogenpowered diggers on site within the year.

In the mid-1990s Caterpillar changed its approach to automation in mining. A decade after it began a pioneering research program to drive the tech forward, the company realised that the sector was not ready for automation. Instead, it focused on the building blocks that would need to be put in place to make automation possible in future. Here, Roger Brereton, head of sales at steering system manufacturer Pailton Engineering, assesses whether the construction sector is finally ready for autonomous driving.

In 1985, Caterpillar began a research program into automation. A little over a decade later, it demonstrated two autonomous trucks running at the Caterpillar Proving Ground in Tucson, Arizona. At this stage it was clear the company was well ahead of its time, but the feeling was that the sector was not ready for automation. This brought an end to the first generation of automation.

In the next phase, rather than continuing to focus on the development of the trucks, the engineers therefore stepped back and began looking at the building blocks that would be needed to make

automation a reality, such as improved GPS and on-board monitoring systems.

Today, Caterpillar remains a pioneer in this particular field of driverless tech. Currently, there are Command autonomous haulage system fleets operating at 17 mine locations around the world. However, Caterpillar faces stiff competition from other OEMs developing driverless off-highway vehicles. Volvo Autonomous Solution (VAS) is one example of a company that is making inroads. Partnering with Holcim, the company has developed an autonomous hauler that is currently being trialled at Holcim’s limestone quarry in Switzerland and it hopes that this will be commercially available soon.

Do these technological developments mean the construction sector is finally ready to embrace automation after all these years?

The development of driverless vehicles has thrown up many novel engineering challenges that were not anticipated a decade ago, from user scepticism to

the difficulties of developing an artificial intelligence (AI) that can respond correctly to situations that have never been encountered before, the so-called ‘‘edge case’’.

What is becoming clear in this story is that each sector throws up different challenges and opportunities. For example, the development of ‘‘robo taxis’’ was thwarted by the complexity of urban environments, but long-haul trucking,

which involves more predictable journeys on long, straight roads, is now emerging as a key area for technological uptake.

In the construction sector, there are many different vehicles that fulfil different roles. This makes it difficult to generalise about the prospects for automation. According to research by Arthur D Little associates, automation will play only a ‘‘minor role’’ in the near future, with the majority of vehicles remaining at level two for the next ten to fifteen years. In this context, level two autonomy refers to operator assistance, like auto-steering, technology which is already widely in use.

The report concluded that construction was a particularly difficult area for automation, because of complex and dynamic construction environments, the fact that machines are used for only limited periods of time and at changing locations, and the need for precise interplay between multiple machines.

VAS has chosen to focus its energy on haulage systems, such as those found at quarries and mines, where the case for automation is strongest. These vehicles fulfil a single, simple function,

they operate in a closed-off environment and involve no on-road use. In these instances, the case for automation is a good one.

Although the key determinant will always be cost and return on investment, the arguments here are becoming stronger. Autonomous mining is more efficient, thereby reducing overall costs. Near continuous utilisation of machines and the elimination of shift change also enhance productivity. Improvements in cameras, sensors and data compression technology are all things that will help bring the cost down in the coming years.

Another key advantage is safety improvements, as these vehicles can remove the need for human operators in dangerous environments. According to Caterpillar, trucks equipped with its Command for hauling have moved more than three billion tonnes of material without a single lost-time injury.

One challenge for these vehicles is navigating inhospitable terrains. Even where these vehicles face only simple, repetitive routes in closed-off environments, they are often exposed to harsh under-chassis environments. As well as extensive testing to make sure

the AI can cope with these conditions, the conventional vehicle components, such as the steering parts, also need to be tested extensively to ensure they are designed to last.

Although OEMs will be determined to reach a more competitive price point, compromising on the quality of something like a bevel box has the potential to raise the whole-life costs of vehicle ownership, thereby undermining the arguments about gains in productivity.

We have come a long way since Caterpillar introduced its first research program into autonomous driving in 1985. In 2022, some of the world’s leading OEMs have developed sophisticated driverless off-highway vehicles that are already successfully in operation at mines and quarries around the world. Driverless tech seems ideal for haulage vehicles, particularly in cases where its introduction can remove workers from unsafe environments. However, whether we can expect more widespread uptake across the sector remains to be seen.

Pailton Engineering supplies custom steering parts and full steering system for off-highway vehicles. To find out more, visit pailton.com

The Vita Load Navigator was developed originally to prevent loads suspended from helicopters – particularly humans being rescued – from spinning. It has since been adapted for industrial lifting applications.

German crane manufacturer Wolffkran has now struck a global sales agreement with Vita Industrial to offer Vita Load Navigator technology customers of its rental operations around the world.

It is a global agreement that originated in the UK, says Richard Coughtrey, managing director of Sheffield-based Wolffkran Ltd, which is the first Wolffkran rental operation to stock the device.

The Vita Load Navigator (VLN) is described as a propulsion-driven device that connects below the hook of all cranes. It can be autonomously and manually controlled. Measuring more than 1,000 data points per second, the system detects load movement in real-time

and adjusts the load with fans that are sufficiently powerful to eliminate spinning, rotations, swaying and other problems that cause site damage or injuries.

It is suggested that incorporating VLN system into crane operations can lead to insurance savings to operators, as Vita works with industry partners to design a formal insurance program.

Wolffkran chief executive Duncan Salt said: “Aligning with Vita Industrial to enhance the worldwide distribution of our cutting-edge products, the Vita Load Navigator and Wolffkran cranes, will strengthen our commitment to propel the construction industry forward by integrating safety and technology seamlessly. Together, we will revolutionize the way construction projects are executed worldwide.”

Caleb Carr, founder and chief executive of Vita Inclinata Technologies, added: “The synergies between the two

companies to provide state-of-the-art solutions to everyday construction challenges will bring immense value to our current and future clients and partners.”

Caleb Carr founded Vita after witnessing the need for a solution to spinning cables. In 2009, he was practicing as a search and rescue volunteer in high school. During a routine training mission, his friend and mentor Don went into cardiac arrest next to him. A helicopter arrived to transport Don to hospital but couldn’t insert its rescue litter due to gusty winds, rotor wash and mountainous terrain. After multiple attempts, the helicopter was forced to turn back without them and Don died as a result. Caleb learned that this was a fairly common problem that caused the loss of many lives. He enrolled in medical school at the University of Colorado where his professor, Dr Randall Tagg, listened to his story and challenged him to solve the problem.

UK Bathrooms, a renowned provider of top-quality bathroom products, is delighted to unveil Amara Design, its new exclusive brand that offers an exquisite range of designer-led bathroom products.

Amara Design combines contemporary aesthetics, on-trend designs, and meticulous curation to empower customers in creating their own stylish and premium bathroom spaces.

Amara Design by UK Bathrooms is a testament to the brand’s commitment to delivering exceptional quality and style. The brand has carefully curated a collection of bathroom products that reflect the latest trends while embodying a contemporary, designer-led sensibility.

“We are thrilled to introduce Amara Design to our customers, providing them with an exclusive range of bathroom

products that exude elegance, style, and uncompromising quality,” said Graeme Borchard, Managing Director of UK Bathrooms. “With Amara Design, we aim to inspire homeowners and interior enthusiasts to create their own designerled bathroom spaces that reflect their unique tastes and preferences.”

The Amara Design collection encompasses a wide array of premium bathroom products, including brushed brass and black brassware, contemporary bathroom furniture ranges, walk-in showers, water-saving toilets, baths, basins, and accessories. Each product has been meticulously selected to meet

the brand’s strict criteria for quality, durability, and exceptional design.

One of the standout features of Amara Design is its commitment to providing customers with access to designer products at great prices. UK Bathrooms leveraged its extensive knowledge of the marketplace to curate a collection that offers exceptional value without compromising on style or quality.

“We understand that customers seek a balance between premium quality and affordability,” added Graeme.

“With Amara Design, we have carefully handpicked products that meet the high standards expected of designer brands, while ensuring they are accessible to a wider audience.”

In addition to offering an exceptional product range, UK Bathrooms continues to provide its renowned customer service and expertise. The knowledgeable team of bathroom specialists is available to assist customers in selecting the perfect products for their unique vision, ensuring a seamless and enjoyable experience.

To explore the Amara Design collection and elevate your bathroom to new heights of style and sophistication, visit the UK Bathrooms website at www.ukbathrooms.com.

Zentia celebrates in style as popular Dune eVo family is renamed Aruba.

Leading UK ceilings manufacturer Zentia has refreshed one of its most popular ranges of ceiling tiles with a new name, including a new high humidity variant.

As part of the company’s transition from Armstrong to Zentia, Dune eVo will now be known as Aruba, a name inspired by the white sandy beaches of the Caribbean and the finely sanded finish of the tile’s surface.

The new high humidity variation is being introduced to support the product family’s flexibility. Aruba hH offers stability at humidity levels of up to 99% RH, making it particularly ideal for high humidity areas such as changing rooms. It also offers Class C sound absorption and good sound attenuation for excellent acoustic performance.

This new addition sits alongside Aruba, Aruba Max and Aruba dB, each bringing their own performance capabilities. Together, they deliver a complete acoustic ceiling solution with the benefits of a continuous face pattern across entire projects.

As a product family, Aruba offers a tile for any environment including education and healthcare through to commercial, leisure, retail, and transportation – for either new-build or refurbishment.

Graham Taylor, Sales and Marketing Director at Zentia, has been with the company for over 30 years and has been witness to the evolution of the original Dune product family as well as the journey from Armstrong to Zentia.

He comments: “The Dune range has been a stalwart of the ceiling tile industry for even longer than I have been around. With its fresh bright surface finish it was a game changer when first launched to market in the early 1980s. Now, we are ready to unveil the first Zentia version, taking the opportunity to reflect our transition from A to Z by renaming Dune to Aruba. Think Dune eVo, say Aruba.

‘It’s a product that has been trusted by generations of architects and installers alike and today, it’s still the reliable and versatile product it’s always been, but with a new name and some exciting family additions, many of which will be released over the coming months.”

This product range is a favourite with specifiers due to its optimum mix of acoustic and aesthetic performance, sustainability credentials and costeffectiveness. The range gives architects three levels of acoustic performance, high levels of recycled content and 100% recyclability.

To celebrate the launch of the Aruba range, Zentia is running a competition to win £5,000 worth of holiday vouchers. Please see the Zentia website for full T&Cs and details on how to enter.

www.zentia.com/en-gb/the-arubafamily/

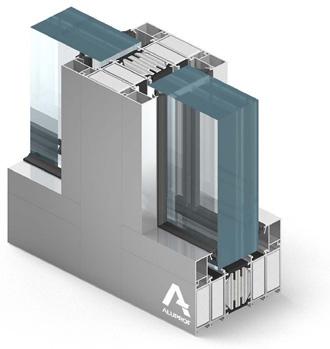

As a prominent systems company in Europe, Aluprof have established themselves as a leader in the field of aluminium framed fire rated windows, doors, screens and curtain walls. Today, Aluprof are delighted to announce that they have opened a new glass processing company within the group dedicated to manufacturing class leading, fire resistant glazing. As a building project supplier, this places Aluprof in the enviable position not only of being able to develop and test both framing and glazing together, but to be able to supply complete and fully tested products direct to site.

The new company ‘Glassprof’, whose headquarters is located in Ogrodzona near Cieszyn, specialises in the production of fire-resistant glass and the processing of glazed units that work in harmony with Aluprof’s fire rated aluminium systems. Thanks to the use of the latest and fully automated production technology, the newly formed company offers glazed units that combine various glazing options that include

fire protection, thermal insulation, solar control and sound insulation. Aluprof firmly believes that the collaboration with Glassprof will offer comprehensive and hassle-free glazing solutions that will prove advantageous to a wide range of buildings, including libraries, schools, hotels, and student accommodations. Given the paramount importance of fire safety as a critical design consideration, this partnership strives to provide architects and specifiers with a profound sense of assurance and peace of mind.

The new Glassprof brand in the Aluprof family is the next stage of the company’s long-term strategy, which aims to increase the competitiveness of the offer by providing products and services that complement each other. A full package that aims to improve the safety and comfort of spaces created for people.

Jacek Cholewa, President of Glassprof sp. z o.o. comments: “Glassprof products are manufactured in accordance with European CE marking standards and are additionally subjected to rigorous quality

control. Being part of a strong brand such as Aluprof, we gain access to Aluprof’s modern Research and Innovation Centre, where new products are developed and fire protection systems can be tested in a laboratory test furnace that is able to fit structures measuring 4.5 m x 5 m. The Aluprof laboratory has signed agreements with the Polish ITB and CERTBUD, which offers standards compliance that helps reduces logistics costs whilst ensuring shorter test lead times.”

The new company’s products includes fire resistant glazing in classes EI30, EI60, EI90 and other types of insulating glass, double glazed or single glazed, which combine various options that can be used for the construction of windows, doors, partition walls and facades. Glassprof products are made of tempered glass which significantly reduces the risk of breakage during transport and site installation. Additionally, using tempered glass means that units do not have to be covered with foil or shielded to protect against UV radiation. Thanks to the use of a special radiation resistant gel in Glassprof products that crystallises in the event of a fire, glass remains in place and becomes opaque to help slow the spread of any fire enabling safe routes of escape. Amongst the main features of Glassprof fire-resistant glass is its neutral colour and high level of transparency, which is up to 88% clarity with no perceptible yellowing effect of the glazing over time. The new Glassprof manufactured glazing has also obtained the highest possible safety class 1B1 according to EN 12600 and, in addition, carry a high level of sound attenuation, of up to 93% reduction in some unit combinations.

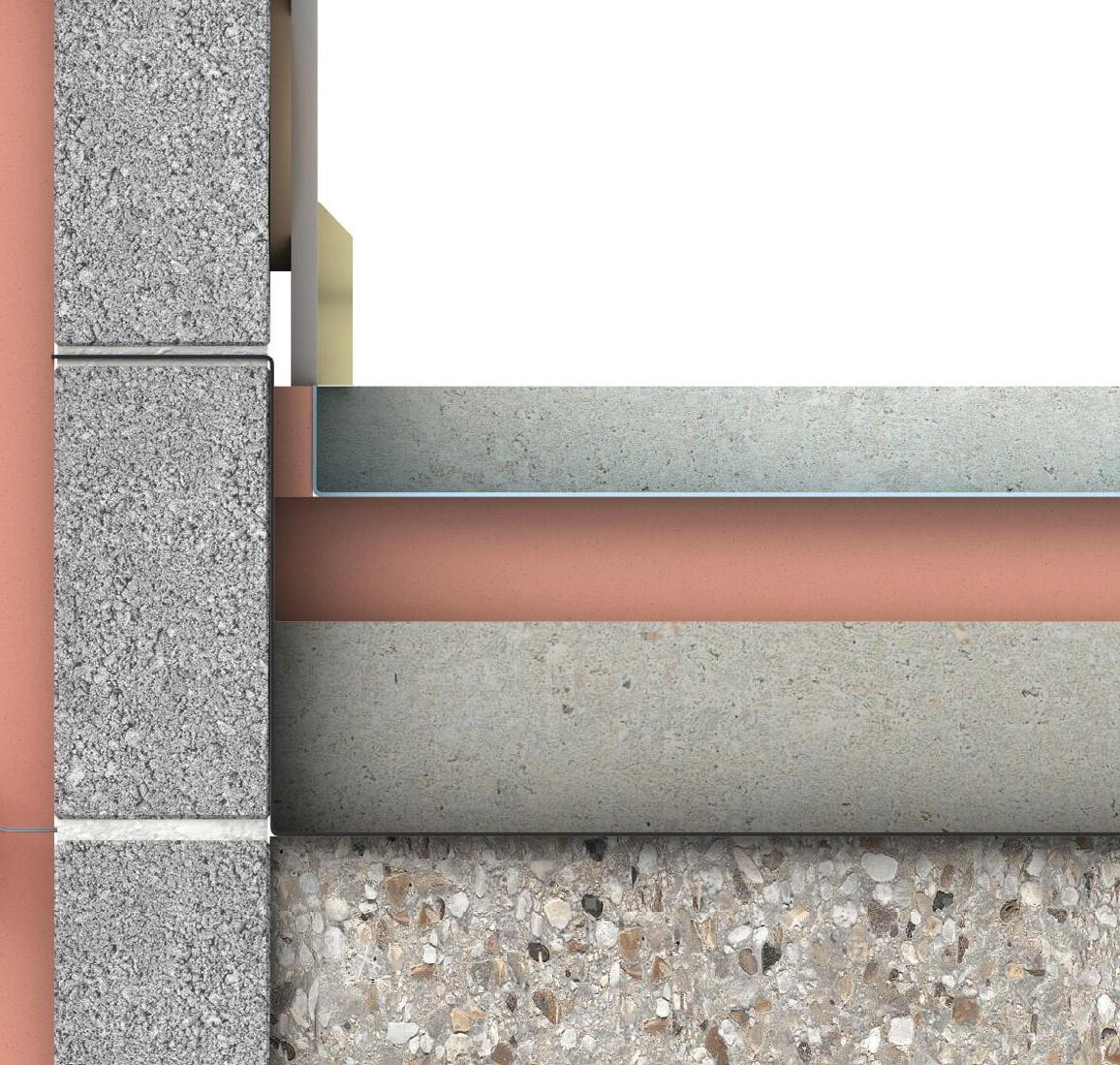

Together with the new glazing products, Aluprof offer a comprehensive range of aluminium fire resistant systems to cater for all building requirements. The MB-118 EI is designed to offer internal or external fire rated partitions that can offer resistance up to EI120. The system suites with Aluprof’s MB-78EI and carries many of the same fire restart components. With a structural depth of just 118mm the system carries a generous 34mm wide thermal break for thermal insulation.

The MB-78EI door with its own 78mm wide framing system can be made up into screens that offer various fire resistance classes up to EI90 when tested to the

standard, PN-EN 13501-2+A1:2010. The MP-78EI system offers an excellent thermal insulation coefficient Uf due to the adoption of 34 mm wide thermal break. Depending on the required fire resistance class, GKF (fire protection plasterboard) or CI (polymer–ceramic composite) strips are inserted inside the chambers of profiles and within the thermal insulation space between the aluminium profiles. Fire rated glasses of up to 49mm in width can be accommodated within the system.

Complimenting the windows, doors and screen systems is the MB-SR50N EI, a stick curtain wall system which can offer various fire resistances up to EI60 when tested to the standards PN-EN 1364-3 and PN-EN 1364-1. The curtain wall can also be used in glazed roof coverings and offer a fire resistance class of RE30 as per the standard PN-EN 1365-2. Along with this 50mm wide capped curtain wall system, a further version of the curtain wall system, the MB-SR50N EI EFEKT offers fire resistance of up to EI60 in a cap-less curtain wall system as used at high level on the The Core,

a refurbishment project in Manchester which uses the cap-less curtain wall which is unique to Aluprof. These curtain wall systems are enhanced within the profile to cater for an EI60 fire resistance. Specifiers can use the non-enhanced system for the complete building and only use the fire resistant construction in areas where fire resistance is required, this enables consistency in visible sight lines across the build.

Aluprof UK, part of Aluprof based in Poland have been supporting specifiers in the UK for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks.

Further information about systems and specification support is available through the company’s website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

The bustling 47,000m2 urban campus, known as BLACK, is set to provide users with a true ‘workplace of tomorrow’ by creating a sustainable and inspiring modern workspace within commutable distance from La Défense, Paris- the busiest business district in Europe.

BLACK is a unique project which has been designed with sustainability at its core. Situated right beside Parc des Impressionnistes, the project’s ethical design blends nature’s elements with unique architecture to create a space that sits in harmony with its surroundings.

The distinctive timber cladding has undergone the Japanese charring technique of Shou Sugi Ban. This ancient art involves burning the wood to create a decorative and protective layer of charcoal on its surface.

By opting for a façade using Accoya timber that has been treated using this process, the architect saved 1,000 tonnes of CO2 without compromising on performance.

The carbon savings resulted from the fact that the initial design had recommended the use of aluminium. The decision to replace this with charred Accoya wood was one of a number of material decisions made to enhance the building’s environmental performance and credentials.

Overall, the use of low-carbon materials resulted in a saving of 3,000 tonnes of carbon[1].

The charred wood façade is installed on the GRAD railing system to combine modernity with the traditional. The GRAD system holds the wood in place whilst remaining completely hidden to preserve the building’s unique biophilic design.

Emmanuel Combarel, director at Emmanuel Combarel Dominique Marrec architectes (ECDM), said: “This project was guided by the desire to create a

workspace which would sit in harmony with its surroundings. The design was inspired by the neighbouring park and we aimed to bring together the indoors and outdoors.

“As nature was at the heart of this project, we were guided by environmental considerations throughout its inception. For example, we upgraded our initial material choices to make carbon savings and opted for carbon efficient construction methods which would have minimal impact on local environment.

“These environmentally conscious choices enabled us to create a space which adds social value to Clichy.”

Laurens Notenboom, head of sales for France at Accsys, added: “Using Accoya aligns with the sustainability criteria of the project. BLACK embodies a vision for urban developments of the future. Its low carbon credentials place it amongst the most ambitious projects in France.

“We worked closely with Henry Timber, who supplied the Accoya, profiled to the specific size for this unique project.

“The project is another result of the great partnership between Accoya, Henry Timber and Les Bruleurs de bois within the established value chain in the French market– and the first one involving a low carbon cladding

application. The GRAD clipping system has been used with the ultra-high performing wood; with Accoya being chosen for its durability, stability in Shou Sugi Ban form and its high sustainability credentials.

Henry Timber worked with Les Bruleurs de Bois, who completed all the charring on Accoya for the BLACK’s exterior. Les Bruleurs de Bois are one of few manufacturers in France mastering the art of charring wood using the ancestral Japanese Shou Sugi Ban technique.”

Project information:

• Client: Redman

• Architect: Emmanuel Combarel Dominique Marrec Architectes (ECDM)

• Area 47,000 m2

• Quantity of Accoya wood: 6740 m2

• Charring: Les Bruleurs de Bois

• Accoya distributor: Henry Timber

• Clip system: Grad

• Year: 2023

An urban renewal project in the Parisian suburb of Clichy-La-Garenne will become the largest low-carbon building in France.

A key stage in the redevelopment of Berlin’s historic Tempelhof Airport has recently completed, with the opening of a 600m² rooftop walkway and 360° viewing platform on the 26m high airport tower, constructed with Kebony wood decking.

Opened to the public on Thursday 20th July, the new installation THF Tower marks a significant step in the regeneration of the former aviation centre which closed its hanger doors in 2008. The wood-panelled rooftop terrace creates a new exhibition and event space, offering visitors not only stunning views across the skyline of the German capital, but an expansive viewing platform to experience the regular programme of cultural events hosted at the airport, including trade fairs, concerts such as annual Tempelhof Sounds festival, and sports events including the 2023 Berlin Formula E-Prix.

The combination of the building’s famous historical character and modern construction requirements presented architects :mlzd and designers Karle & Rubmer with a unique challenge. When choosing the materials for the roof terrace, accessed via a suspended steel staircase that guides visitors up from the central terminal, both the technical and aesthetic characteristics of the building product were paramount to create a quality, long-lasting facility to support regular use.

Kebony Clear cladding was selected to give the space a durable and visually sophisticated finish. Developed in Norway, Kebony wood provides a sustainable alternative to tropical hardwoods, helping to ease the global dependence on traditional construction materials, thereby reducing the continued environmental damage caused by deforestation. Through the production of enhanced dually modifiedTM timber,

sourced from sustainable softwoods such as pine, Kebony offers architects a wood product with the same built characteristics of protected wood species such Ipe and Cumaru, without the same cost to the carbon footprint.

Kebony’s patented modification process enhances the dimensional stability of the wood cell walls, and, over time, its surface develops a silver-grey patina that adds depth and character. This unique combination of features renders Kebony an ideal solution for projects like the THF Tower terrace, that are constantly exposed to the elements, but still require the highest standards in design aesthetics, durability, and sustainability.

The successful implementation of the THF Tower project is a demonstration of the innovative ways in which historical, high-carbon emitting industrial sites, such as decommissioned airports, can be repurposed into new long-term social and sustainable contexts.

Pat Tanner, Architect for :mlzd, comments: ‘’The decision to use Kebony wood in the design of Tempelhof Tower was an obvious choice to create a space that is both functional and beautiful. The robust quality of the wood is ideal to withstand the high number of visitors we see here every day. Not only is it aesthetically pleasing, but it is also an incredibly durable that can stand the test of time’’.

Nina Landbø, International Sales Manager for Kebony, adds: ‘’We are proud to see Kebony selected as part of the next chapter for the iconic Berlin Tempelhof. Transforming a former carbon emissions site into a stunning recreational facility is a fantastic concept. We congratulate all the partners involved in the delivery of this project and wish that visitors take leisure not only in the views, but the conscious, sustainably-inspired design of their surroundings.‘’

Project Details:

Tempelhof Airport, Head Building West, Tempelhofer Damm 45, 12101 Berlin

Design: 600 m² roof terrace at a height of 26m, ramp construction with slope in combination with steps

Decking: Terrace boards made of Kebony Clear

Substructure: Isostep system rails to accommodate wind load of wind load and fire protection components

• Architects – :mlzd

• Roof Technology – East Poburski

• Engineering – Bartke & Partner GmbH

• Kebony AS

• Karle & Rubner

Leicester College is undertaking several new building projects to refurbish and create new facilities across its three campuses in Leicester, set for completion this summer and later in 2023.

The combined multi-million-pound projects have been funded by Leicester College and the Department for Education, The Savoy Educational Trust, and the Office for Students (OfS). The projects include:

A new Higher Education Hub is being created at Abbey Park Campus with funding from the OfS. This will be for degree level students to use as a dual social/study space and create a greater sense of a higher education undergraduate culture. Two classrooms will be merged, refurbished, and fitted with conferencing and meeting technologies

The art workspace for Supported Learning at Abbey Park Campus will be refurbished and updated

The College has secured £1.6 million from the Department for Education to refurbish the Construction Block at the Freemen’s Park Campus. The project includes the relocation and redevelopment of the current electrical workshops into a two-storey workshop that will create an identifiable electrical skill teaching centre within the construction trades centre. The planned completion date is September 2024

The Careers Hub at the Abbey Park Campus has recently been revamped, making it an even more welcoming space for adult learners and students aged over 19, improving this valuable resource for those seeking advice on future career paths

The Engineering and Technology Centre at the Abbey Park Campus is undergoing a complete internal redesign to make way for new and updated facilities. Costing more than £3 million, the Department for Education has provided more than £1 million for the project with its T level Capital Grant. Work is due to be completed by autumn 2023

Funded by the Office for Students, a new 400+sq metre aeronautical/advanced engineering training facility will be built at the Abbey Park Campus to enable the delivery of Level 4 and 5 higher education technical and apprenticeship programmes

Supported by funding from the Savoy Educational Trust, two training kitchens used by students across 14 hospitality and catering programmes will be redesigned and refurbished at the College’s Freemen’s Park Campus

A teaching area at the Abbey Park Campus is being re-purposed to create two training hospital wards that will enhance the learning experience for students on its Health and Science T level course

A range of HE curriculum equipment is being upgraded across multiple campuses including new computers, smart displays, drone technology and VR, also funded by OfS

At least four rooms will be upgraded to further enhance delivery and the student experience for our L4+ cohorts including

a new healthcare consultation space, a computer suite and lecture rooms

Principal and CEO of Leicester College, Verity Hancock said: “The summer holidays provide an ideal opportunity to drive forwards with our ambitious infrastructure programme with some works completing during this time and some new work starting that will be completed in 2023/24. This will rebuild, refurbish and create new, state of the art facilities for our existing and new student cohorts at the College.”

Talking about the T level Capital Buildings and Facilities Improvement Grants nationally, Minister for Skills, Apprenticeship and Higher Education Robert Halfon said: “This boost of over £100 million is our latest investment in T levels. These are robust, high-quality technical qualifications providing a unique ladder of opportunity for students to gain both classroom knowledge and on-the-job experience.

“From robotics suites that support digital T levels to simulated health wards where students can get a real sense of what it means to work in Healthcare Science, T levels will support young people into rewarding careers and back businesses with the skills of the future.”

In these challenging times, the drive to achieve a net zero carbon built environment is an ever-increasing focus in the construction industry. Recent and upcoming changes to the Building Regulations and Standards in England, Wales and Scotland require more demanding levels of thermal performance.

The Kingspan Kooltherm® range of phenolic insulation comprises the thinnest commonly used insulation products for any specific U-value. Kingspan Kooltherm® K103 Floorboard insulation is ideal for use with solid concrete or suspended timber floors, allowing U-values to be reached with minimal thickness.

The world-leading plastics manufacturer is providing the high-performance, transparent polycarbonate for Everton’s impressive new ground at Bramley Moore Dock, a £555m project that is seen as key to the regeneration of that part of Merseyside.

Covering over 6,000 sq m of the stadium roof, the specialist polycarbonate material will transmit sunlight through to the pitch, helping to ensure a high-quality surface for many of the world’s top footballers to play on.

Manufactured at the company’s worldclass manufacturing facility in county

Antrim, Brett Martin’s Marlon CS Polycarbonate corrugated sheet has already been used in some of the top stadia in sports such as rugby, football, cricket and horse-racing.

Brett Martin is the UK market leader in this specialist sector and has therefore completed a range of Premier League club projects including Manchester United’s Old Trafford and Manchester City’s Etihad.

Paul Martin, from Brett Martin, said: “Our team at Mallusk delivers projects that have a huge impact on the world around us, whether in sport, business,

healthcare, education or agriculture. It’s hard to overstate the importance of the material that we supply for the success of top football clubs. Without a highquality playing surface, these teams can’t succeed. Through significant R&D, we have developed a product that meets the needs of stadia roofing in terms of strength, durability and the ability to emit sunlight to the pitch.”

“Everton’s stadium project is truly worldclass in terms of its design, sustainability credentials and potential positive impact on Liverpool. So it is one that are very much proud to be involved with,” Paul added.

that will generate an estimated £1.3bn economic

Assent is a multi-licence, national, private Building Control Approved Inspector that offers a wide range of building control services.

We provide a flexible, responsive service to ensure that building regulation, safety and compliance is integrated into projects from inception to completion.

Our qualified surveyors and experienced support teams are dedicated to providing a high quality service, which achieves compliance and delivers safe, inspirational buildings for our future.

Through real-time technology, teamwork, a consistent approach and uncompromising standards, our services go beyond compliance.

Responsive and knowledgeable building control services for commercial and domestic projects.

We work with you to develop fire safety solutions that meet both approving authorities and client objectives.

Keep up-to-date with the latest Building Control legislation through our education and training packages.

Enhance competence of fire safety professionals with fire safety and fire engineering training, courses, apprenticeships and qualifications - delivered by our subsidiary business Xact.

Learn more - assent.co.uk

01924 229180

The firm saw pre-tax profit surge nearly 60% to £55m in the year to December 2022, not including a one-off gain of £29m the year before from the sale of its infrastructure services business.

In the office, Solibri is your gatekeeper for quality, bringing all the models from different disciplines together for highly advanced model checking and quality assurance, making it easy for the BIM manager, engineers, designers and other involved parties to collaborate and solve any found issues.

Revenue was also up a quarter to £1.4bn as the firm benefitted from HS2 throughput and secured new contracts.

Big wins included a £235m deal for offices at Victoria Street in London, a £259m vehicle storage hub for the army in Tewksbury and the A46 Newark

Bypass expected to cost between £400m and £500m.

Chief financial officer and executive vice president Meliha Duymaz, who joined Skanska UK from Network Rail in September, said the business was in a strong position for the year ahead.

Skanska’s UK construction business continued to deliver strong profit growth last year despite challenging market conditions.

over as new president and CEO of Skanska UK in May, replacing Gregor Craig who has retired.

The information is effortlessly available at the construction site, where site managers can easily view the models and take off not just the needed quantities but much more. For the subcontractors and other involved parties, Solibri allows anyone to view the model anywhere, anytime and get the information they need to get their job done.

Skanska closed 2022 with £1.5bn of orders, up 15% on the prior year, supported by £441m of cash.

Dowding has been at Skanska for 20 years most recently as a member of Skanska UK’s Executive Management Team and since 2017 as executive vice president with responsibility for Skanska UK’s building and building services businesses.

SEE HOW IT FITS YOUR WORKFLOW SOLIBRI.COM

Since the year-end Katy Dowding took

Average headcount at Skanska dipped by around 420 to 3,435 staff last year.

Solibri

The right tools for the right people.

Solibri Anywhere

Model viewing and access to the digital information flow for free.

Solibri Site

Get the information you need, right when you need it.

Solibri Office

The complete solution to meet the toughest QA/QC needs.

Solibri Enterprise

Customized solution for maximum scalability.

With Solibri you can take your quality assurance to a whole new level and ensure that the information flows seamlessly from design to build. No more hiccups – the future of building better is here.

US studio Substance Architecture has created a conference centre on a verdant site in Iowa, which is clad in elongated black bricks by material manufacturer Glen-Gery.

Named Tree Huis, the 650-square-metre building in Marion County is adorned with Ebonite Velour bricks laid in a horizontal arrangement and chosen for a timeless appearance.

The Ebonite Velour bricks specified by Substance Architecture for the project are norman size and were manufactured by Glen-Gery nearby in one of its Iowa factories.

The norman-sized bricks are roughly 10 centimetres longer than Glen-Gery’s traditional bricks and were chosen to create “a very pronounced long, linear appearance”.

“The material, colour and texture selection, Ebonite Velour brick,

significantly impacted this project and its overall feel,” said Glen-Gery.

“The sheen of the brick creates a metallic reflection – in some lights, it appears dark grey and others blue,” the brand continued. “This creates something beautiful with its surroundings and emphasises the timeless feel that will be there forever.”

Ebonite Velour bricks have also been used inside the Tree Huis, where there is space intended for both family gatherings and business conferences.

The building has the capacity to host up to 100 guests for dining or lounging while immersing themselves in the surrounding landscape from the adjoining deck.

Throughout the project, the bricks have been laid with raked bed joints and head joints that are nearly flush. According to Glen-Gery, this is a detail by Substance Architecture intended to exaggerate “the horizontal lines of the entire building”.

Alongside these norman bricks, GlenGery’s Ebonite colour is available in additional sizes and also comes in a smooth finish.

Another project that recently utilised Glen-Gery bricks is the Grand Mulberry in New York designed by US architect Morris Adjmi. Glen-Gery bricks were chosen to promote both the building’s new role as the home of the Italian American Museum and the site’s heritage.

Also, the brand’s Black Roman Maximus bricks were chosen as cladding for a New Jersey residence designed by Brooklyn-based architecture firm Studio PHH, named La Clairiere.

The house is located in Princeton, New Jersey, and is made up of two brick-clad volumes that are connected by a glass central void containing communal areas.

Certified IPAF PAL Card is proof of platform operator training to the highest standard.

Available as eLearning or instructor-led course

Regularly audited to ensure the highest standard of training is delivered

Online verification of PAL Cards: www.ipaf.org/checkpal

Smart technology & fraud protected

Courses available in multiple languages

Optimal instructor-tocandidate ratio

Comprehensive range of training courses

Used by manufacturers of equipment worldwide

Operator theory module can be taken remotely via eLearning

Safe. Audited. Internationally recognised.

The IPAF Powered Access Licence or PAL Card is recognised worldwide across industries as proof of platform operator training to the highest standard. It is issued by the International Powered Access Federation (IPAF) to platform operators who successfully complete a training course and pass a test at an IPAF-approved training centre. Ask for the PAL Card as proof of operator training! Now available digitally on the ePAL app.

Find your nearest IPAF approved training centre at www.ipaf.org

PAL Card now available on IPAF’s ePAL app

www.ipaf.org/ePAL

Annually reviewed by the industry to ensure relevant and up to date content

40 years of industry experience

Reassurance: A valid PAL Card proves the holder has passed an approved and audited IPAF theory and practical test within the past five years

Nude | Matt White +System Sync 500mm with FlexRack | Terracotta | Scandi Grey +System Sync 340mm with Colander

Abode, award-winning designer and distributor of market leading kitchen taps & sinks, Pronteau hot water taps, bathroom taps & showering solutions continue to personify the UK wash zone with its latest range of contemporary shades for one of its signature and bestselling kitchen tap families, Althia.

Now available in four modern paint colours, the new Althia Colours are designed to capture the latest interior trends and present a Mediterranean-style Terracotta, neutral Nude, Nordic-style Scandi Grey and Matt White, dubbed the fastest emerging tap colour inspired by the Scandinavian design trend.

Dan Biddle, Product Manager at Abode says, “The kitchen space continues to be guided by the calm of nature and this year’s colour palette is embracing a confident use of colour across the fixtures and fittings in 2023. Stand out shades emerging this year are offering a new take on warm neutrals and earth-tone paint colours and it is these variations, which are creating a strong style identity and giving new life to the kitchen mixer tap.”

The new Althia Colours extend the Althia Finish Library from 6 to 10 options,

meaning you can now choose between a range of colours and metals across a mix of single lever, monobloc and pull-out designs from the Althia Tap Family by Abode.

Exclusively available for Althia single lever mixer taps, the new Althia Colours help to highlight the beautifully contoured spout and slim lever handle, which offers a subtle blend of square and round forms in one design. The ideal choice for a large kitchen or compact utility room, the new Althia Colours are expertly handcrafted from quality raw materials and feature an innovative control valve and anti-splash spout to ensure stylish durability and allow for optimum usage with minimal water waste!

Designed with copper tailpipes for greater stability and flow when fixing to the mains supply, the Althia Tap Family is highly versatile and now, is proud to offer:

• NEW Althia Colours (Single Lever) Nude, Matt White, Terracotta and Scandi Grey

• Althia Metals (Single Lever) Chrome, Brushed Nickel, Brushed Brass, Urban Copper, Graphite and Matt Black

• Althia Monoblocs (Dual Lever)

Chrome and Brushed Nickel

• Althia Pull Outs (Single Lever with Spray) Chrome and Brushed Nickel

Leanne Adamson, Marketing Manager at Abode says “Personalisation through colour is becoming increasingly important as homeowners want to create a distinctive décor, which reflects their personal style without compromising on utility and performance. By capturing the latest style trends with the release of four new tap colours, we want to inspire our customers to shape the kitchen space with a complementary or contrasting colour that embodies their own personal style and home décor.”

The new range of Althia Colours are available from June 2023, and prices start from £269 including vat. All Althia taps are supplied with a 5-year warranty and the new Matt White and Scandi Grey models are shown with the latest sink collection by Abode, System Sync: priced from £329 including vat with complementary accessories starting from £49 each.

For further information, please contact Abode: t 01226 283 434 | e info@abodedesigns.co.uk | w www.abodedesigns.co.uk and www.pronteau.co.uk | For the latest brand news, please follow Abode on Pinterest, Facebook, Twitter and LinkedIn #WaterTheWayYouWantIt

• The Bento box principle: sophisticated and elegant with intelligent separation of the wet and dry areas • Design by Philippe Starck: from the washbasin through the freestanding infinity bathtubs including the toilet

• Innovative and high-quality materials such as

Arranged like a Japanese lunchbox: the new Duravit Bento Starck Box bathroom series, Duravit and designer Philippe Starck are making an extraordinary design statement and meeting the most exacting architectural demands. Inspiration is drawn from a traditional Japanese bento box – which are subdivided into several internal compartments by separators.

“The Bento Starck Box collection is the start of an elegant serenity,” said Starck, describing the washbasins and bathtubs. With intelligently divided wet and dry areas, the clean, clearly structured washing areas and bathtubs enable countless options for personal design.

Bento Starck Box is part of the Duravit Artisan Lines range of products. The Artisan Lines feature outstanding and iconic design products with a character that Duravit develops with renowned international designers. The design and

manufacture of the Artisan Lines requires an extraordinary level of knowledge, craftsmanship, and precision.

The spacious Bento Starck Box washbasins offer practical and convenient storage areas. All personal care products and accessories can be placed within easy reach. The new series, includes a washbasin, toilet sets, plus bathtub, featuring a clear-cut design that is perfectly matched to different variants and dimensions of the bathroom furniture..

The Bento Starck Box single washbasins are made from DuraCeram®, and the double washbasins from DuroCast UltraResist. Enabling Duravit to demonstrate how a range of different materials can be used to produce unconventional designs.

As a material, DuraCeram® enables above-counter basins with an extremely thin rim thickness to be created that are robust and extremely easy to care for. The highly effective, antibacterial ceramic HygieneGlaze ensures an optimum level of hygiene. Baked into the basin, the glaze kills around 90 percent of pathogens within just six hours, and approximately 99.9 percent after 24 hours. In addition to the toilets, all

ceramic washbasins in the Bento Starck Box series are also exclusively available with HygieneGlaze for the first time. Duravit offers a lifetime guarantee for all ceramics.

Alongside the 650 mm-wide washbasins, the Bento Starck Box collection comprises above-counter basins in a range of sizes, all available in White and White Satin Matt: round variants with a diameter of 460 mm, and rectangular versions with a width of 550 mm as individual basins or, for two faucets, in widths of 1140 mm and 1340 mm – made from DuroCast UltraResist. The faucet is mounted inside the inner basin on all models.