Page 6 September Issue worldwide-engineering.com Teledyne FLIR thermal cameras provide ‘6th sense’ in law enforcement Page 18 Page 36 New Gigabit Ethernet Switch with AVB/TSN and Integrated PHYs for Industrial Automation NSK to show live ball-screw condition monitoring at EMO

timely industry news, exclusive features on advancing technology, equipment, materials, show previews, content marketing services for our valued clients and much more!

Contents 6 Teledyne FLIR thermal cameras provide ‘6th sense’ in law enforcement Lantek Reports Impressive Growth with 24.9% Increase in Turnover New Gigabit Ethernet Switch with AVB/TSN and Integrated PHYs for Industrial Automation Owl Autonomous Imaging 3D Thermal Sensor Named a 2023 Best of Sensors Award Winner 10 Altus Announce New Facility in Ireland to Support Growing Customer Base XYZ Machine Tools streamlines medical device development FSP launch new shift to attract part-time workers NSK to show live ball-screw condition monitoring at EMO 18 22 26 30 32 36 Providing

Worldwide Engineering Magazine

Rohde & Schwarz and Greenerwave collaborate to verify RIS modules and drive 6G research

Reconfigurable intelligent surfaces (RIS) are drawing attention in the wireless industry due to their potential for an efficient 5G mmWave rollout as well as future 6G applications. A measurement campaign by Rohde & Schwarz and Greenerwave recently characterized the configurable radio wave reflection properties of a novel FR2 RIS module developed by Greenerwave with an over-the-air (OTA) antenna test system from Rohde & Schwarz. It is one of the first real measurements confirming that a metamaterial-based RIS can improve the coverage and efficiency of wireless communications performance, especially for 5G FR2. The groundbreaking work will pave the way for further 6G developments.

4

Reconfigurable intelligent surfaces (RIS) promise to revolutionize wireless communications. RIS is a key technology for 6G networks, which must be more efficient than 4G LTE or 5G NR in every way. RIS technology uses metamaterials to control the otherwise random radio environment. Metamaterials are the key to fulfilling the promise of RIS. The materials enable unprecedented control over EM waves by manipulating the impedance on a subwavelength scale and have led to significant breakthroughs in imaging, radar and wireless communications.

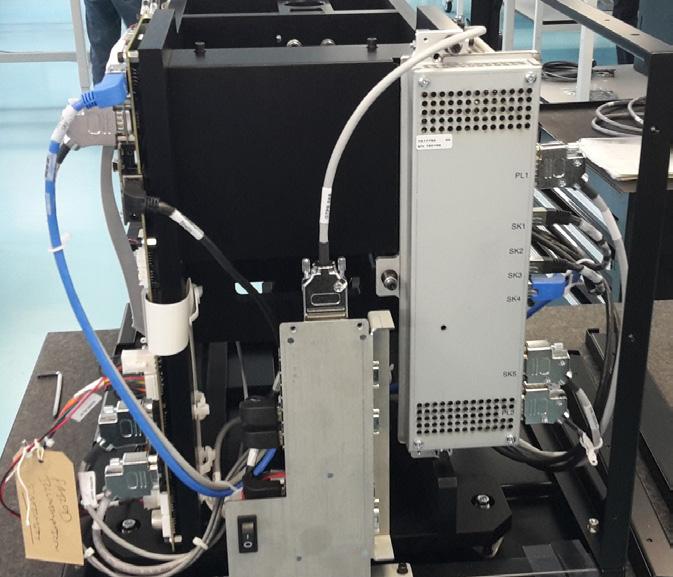

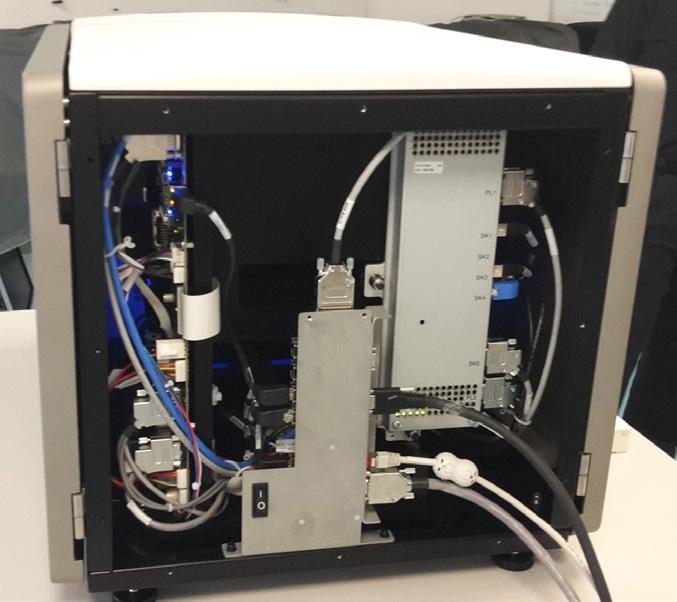

Rohde & Schwarz test and measurement instruments were used to characterize an FR2 RIS from Greenerwave for the recent test campaign. Testing RIS modules requires a test environment that can be illuminated from different incident angles while simultaneously measuring signals at multiple angles. A wireless performance test chamber (WPTC) from Rohde & Schwarz was used for over-the-air (OTA) measurements. A holder was specifically designed for the feed antenna illuminating the Greenerwave RIS.

The RIS from Greenerwave uses a metamaterial proprietary technology. The RIS is an electronic device, composed of many layers and a surface inlaid with a set of patch antennas, called pixels or unit cells, whose electromagnetic responses can be controlled

via a control board. The module operates in 5G FR2 and beyond, covering a bandwidth of 25-30 GHz with instantaneous bandwidth of 2 GHz. The module comes with separate polarization control, beam scanning from -60 to 60 degrees and a beam width as narrow as 3 degrees.

During the measurement campaigns, the RIS reflection characteristics and reflection quality were investigated in the test chamber with respect to modulated 5G signals in the millimeterwave frequency range. The 3D reflection characteristic measurements were performed with the R&S ZVA vector network analyzer (VNA), and the 5G signal reflection quality measurements used the R&S SMW200A vector signal generator and R&S FSW signal and spectrum analyzer. R&S AMS32 software was used to automate measurement and data analysis. Results verified that the Greenerwave RIS can enhance wireless communications capabilities, particularly in the context of 5G FR2 implementations.

Alexander Pabst, Vice President Market Segment Wireless Communications at Rohde & Schwarz says: “We are excited about our successful collaboration with Greenerwave to characterize a FR2 RIS module. Our combined research efforts will chart the course for further advancements in 6G, as we continue to explore

innovative solutions to meet the evolving needs of the wireless industry.”

Geoffroy Lerosey, CEO & CSO of Greenerwave, and Youssef Nasser, Head of 5G/6G Business Unit, agree: “We believe in our RIS technology and its capabilities to develop new 5G FR2 use cases. Our collaboration with Rohde & Schwarz is an important step in proving that our RIS meets the 5G requirements using professional OTA equipment. In the near future, we will explore new opportunities that help shape the technology development in 5G advanced and beyond.”

Rohde & Schwarz actively supports 6G research activities across Europe, Asia and the US, while also contributing to research projects, the work of industry alliances and collaborating with leading research institutes and universities. Greenerwave, a French startup based in Paris, is active in many European research projects and activities for 5G/6G, Satcom, radar and RFID through a cutting-edge and natively energy sober technology. Both Rohde & Schwarz and Greenerwave are members of the one6G alliance and ETSI ISG RIS and are actively involved in shaping the future of RIS technology.

For more information on 6G test solutions from Rohde & Schwarz, visit: www.rohde-schwarz.com/6g

5

Teledyne FLIR thermal cameras provide ‘6th sense’ in law enforcement

Teledyne FLIR, a global leader in the design and manufacture of thermal imaging cameras and sensors, is helping the law enforcement segment to activate its ‘6th sense’ via the use of innovative technology that ensures officers can protect and serve with greater intelligence.

Solutions such as the FLIR Breach® PTQ136 and FLIR Scion® PTM high-performance monoculars are ‘battle-proven’ to withstand the rigours of law enforcement while delivering superior thermal surveillance.

Police officers, military personnel and lifeguards/marine professionals are just some of those who can take advantage of Teledyne FLIR’s ‘6th sense’ to deliver a more effective and efficient outcome. While spotlights and flashlights are essential assets that remain in mandatory use, many unpredictable situations in modern law enforcement call for a far stealthier strategy, one that leverages the benefits of highdefinition thermal optics and low light imaging. Handheld monocular scopes from Teledyne FLIR help users locate suspects lurking in the shadows from a safe standoff position and find evidence that otherwise could remain undetected.

Thermal imaging optics produce images based on heat energy, or infrared radiation, instead of visible

light. Invisible to the naked eye, all humans, animals and objects emit infrared radiation, permitting thermal sensors to function in total darkness, through glaring light, and where there is smoke, fog or vegetation.

A case in point is the FLIR Breach PTQ136 multifunctional thermal imaging monocular. Featuring the company’s innovative Boson core, alongside a high-definition display and compact design, the FLIR Breach delivers unrivalled tactical awareness. Weighing just 210g, users can conceal the FLIR Breach in a pocket or mount it to a helmet (via its mini-rail feature) for handsfree operation. Further attributes include on-board recording and seven palettes for perfect viewing and the rapid detection of suspects, victims or evidence at a range of up to 360m, day or night. Users can also document operations with on-board video recording and image capture.

Another popular and proven solution is the FLIR Scion PTM, which packs high-performance thermal imaging compatibility into

a rugged, IP67-rated handheld monocular. The Scion PTM can instantly stream encrypted thermal video footage of any pursuit, evidence recovery, or search and rescue effort to the command centre via a wireless network. A smooth 60 Hz refresh rate and picture-in-picture zoom capture tiny details from distances up to 1420m and maintain peripheral awareness for constant thermal supervision of suspects, team members and standbys.

Ultimately, Teledyne FLIR’s compact, handheld thermal monoculars quickly detect people and objects of interest to boost situational awareness while on foot or in a vehicle. As a result, users can scan urban environments, fields and forests without revealing their position. This innovative thermal imaging technology empowers first responders such as police officers, military personnel and lifeguards with a 6th sense that is absolutely vital, because when the unthinkable happens, everyone relies on fast decisions and rapid action.

6

The NEW ImageIR® 6300 Z

Compact zoom camera and new SWaP detector (Size, Weight and Power)

Smaller, lighter and without time-consuming lens changes. The ImageIR® 6300 Z is predestined for demanding applications in research and development as well as for stationary or airborne inspection and monitoring tasks. Further applications can be found in quality assurance, materials testing or in a wide range of OEM integration solutions.

Features:

■ Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

■ Standard built-in 7.5x zoom lens with motor focus

■ Focal length of (15 ... 115) mm or (25 ... 170) mm

■ Operation via smartphone or tablet with integrated web interface

■ Compact size and low weight for space-saving system integration

■ Storage of large amounts of data on the integrated SSD

FOR MORE INFORMATION

Category Title to go here

InfraTec distributor in the UK and Ireland: Quantum Design UK and Ireland Ltd, 1 Mole Business Park, Leatherhead, Surrey KT22 7BA Tel: +44 (0)1372 378822 | Email: info@qd-uki.co.uk

Andersen EV doubles production capacity to meet rising demand for premium home chargers

• Andersen’s A2 unit is hand-built in expanded Bedfordshire factory

• Customer demand increases as industry moves towards the 2030 cut-off for sales of new combustionengine cars

• A2 combines awardwinning aesthetics with high-tech functionality

Andersen EV is doubling its production capacity and increasing headcount at its Bedfordshire factory in response to the fast-growing demand for its premium home charger. To facilitate its growth and fulfil order books, the company is doubling the footprint of its factory and investing in new advanced production equipment.

Due for completion by 31 August, the upgraded Andersen EV and EVIOS headquarters and production site in Stewartby, Bedfordshire, will allow the organisation to continue hiring local talent. It is actively recruiting across R&D, installation, customer service and manufacturing functions. The latest expansion and recruitment drive is part of a £1.5 million investment made by parent company EVIOS Plc to step up production, enhance the Andersen EV product offering and further develop its customer service capabilities.

Recent figures from the Society of Motor Manufacturers and Traders demonstrated that EV sales grew by nearly a third (32.7%) during the first half of 2023, compared to H1 2022. EV sales are forecast to more than treble between now and 2030, which will increase the demand for home chargers.

David Martell, CEO of Andersen EV, said: “While premium brands command a growing proportion of all new car sales, the EV home charger market is dominated by offerings lacking in build quality and aesthetic style. These factors are driving the fast-growing popularity of Andersen EV’s A2 charge point, which provides a unique blend of premium craftsmanship and visual appeal.

“We don’t think people should have to compromise, so we developed the A2 to combine the convenience of at-home charging with premium aesthetics to complement any home. Charging at home is easy and convenient, and with the A2’s off-peak functionality and solar integration, it is also the cheapest way to run an electric vehicle. Order books for the A2 continue to grow, and we’re delighted to be able to take very tangible steps that now mean anyone ordering an Andersen A2 will have their unit dispatched the next working day.”

The A2 is the only unit to feature a concealed cable and plug and is available with the widest choice of fascias on the market, with over 125 colour and finish options. It has been a recommended installer for Porsche GB for over three years and is the preferred supplier for Jaguar Land Rover in the UK.

8

Altus Announce New Facility in Ireland to Support Growing Customer Base

Altus Group has recently opened a new facility in Cork, southwest Ireland, to accommodate rapid growth in the country and support its customers within the region.

The new premises supports the company’s growth strategy and strengthens their presence in the region. The facility will be equipped with spare parts, consumables, and equipment to ensure customers in Ireland receive faster deliveries and enhanced support. It will also house an area where off site training and demonstrations of the most innovative hardware and software will take place to enhance pre-sales opportunities.

Joe Booth, Altus CEO said: “After a great 2022 for our business in Ireland with several significant orders and a continuation of that performance in 2023, we have committed to our long-term plans for the region by moving our operations to a dedicated facility.

“With the portfolio we have, and the infrastructure we are building, our aim is to be the number one partner for electronics manufacturing not just in the UK, but in Ireland too. This latest step is helping to achieve those goals.”

Heading up the facility will be Gareth Fenton (Sales Manager), Michal Ostrykiewicz (Senior

Applications Engineer) & new joiner Andras Fekete (Applications Engineer), who as a team have built on existing relationships and nurtured new ones to establish Altus Ireland as a front runner in its field. The new premises will open more possibilities to reach customers and increase business in this territory.

“It has been a joy to watch the journey of our new entity firstly in being established, and now striving as we show commitment to the region, our existing partners and new customers who trust us to fulfil their projects,” said Joe.

“The response to our efforts has been far better than even we were expecting. Our principle has always been to be ‘focused on support excellence’. We believe by making these investments in the region, we are living up to that promise. You only need to look at the industryleading brands in our portfolio to see why we have been successful in the past. With the team and infrastructure in place in Ireland, the sky is the limit for our future.”

10

www.altusgroup.co.uk.

Fluke’s two new Advanced Wire Tracers deliver superior accuracy and safety when locating electric cables in walls, ceilings and floors

Tracer kits simplify the process of troubleshooting energised and de-energised wires in residential, commercial and industrial environments up to safety rating CAT IV 600 V

Fluke, a global technology leader in the manufacture of compact, professional electronic test and measurement tools and software, has launched two new wire tracers that simplify the process of tracing and troubleshooting at energised and de-energised wires in residential, commercial and industrial environments with a safety rating of CAT IV 600 V.

The Fluke 2052 Advanced Wire Tracer and 2062 Advanced Pro Wire Tracer kits consist of two essential pieces of equipment – receiver and transmitter. Both kits also include the i400 AC current clamp accessory for safely inducing a tracing signal on cables without contact to live wires. Also included in the kits are test leads, alligator clips, outlet adapters, magnetic hanger and batteries.

Both kits - which work by detecting signals transmitted via an electromagnetic field rather than locating metal parts or voltage – deliver superior accuracy and safety levels for electricians and technicians who need to locate electric cables quickly in walls, ceilings and floors, find out if there are any breaks or opens and shorts, or identify breakers and fuses. The devices can also be used to trace non-metallic pipes and conduits as well as low voltage wires and data cables.

Passive and active tracing

The new Advanced Wire Tracers use two methods to detect the signal in wires and cables: passive tracing without a transmitter for

non-contact voltage detection and active tracing with the Fluke 2000T transmitter for all other modes. The transmitter automatically senses whether the system is energised or de-energised and selects a 6.25 kHz or 32.768 kHz output signal frequency accordingly.

Following the Fluke philosophy of offering the maximum number of features and capabilities at an affordable price, the new Advanced Wire Tracers incorporate three transmitter modes (high signal, low signal and loop), four receiver tracing modes and eight sensitivity levels for greater flexibility and accuracy when tracing. Additionally, durability and ruggedness are built-in, with all units 1 meter drop tested, IP40rated and backed by a one-year warranty.

The tracers’ four tracing modes are: breaker mode for easy breaker and fuse identification based on the highest recorded signal detected from the transmitter; non-contact voltage (NCV) detection mode to trace energised wires without the use of the transmitter, quick scan mode for quick signal identification (the Fluke 2052); and precision mode for more precise detection of a wire (Fluke 2052).

Patented Smart Sensor™

In addition, the Fluke 2062 Pro Wire Tracer features a patented Smart Sensor™ which identifies the orientation of located energised wires and displays the information on a 3.5-inch TFT LCD colour display. Also, a tip sensor on the Fluke 2062

makes it ideal for tracing wires in corners, tight spaces and junction boxes.

With the safety rating CAT IV 600 V, both Fluke devices offer the highest protection available of any wire tracer on the market (others tend to be CAT III rated). Measurement category CAT IV rating is designed to protect users from the most dangerous levels of transient overvoltage (spikes up to 8,000V) that can occur in industrial and utility environments.

Hans-Dieter Schuessele, Application & Technology Expert, Fluke, says: “Whether fixing equipment to walls or wanting to find cable routings, electricians and technicians need to detect electric cables quickly and accurately and our two new Advanced Wire Tracers simplify this process while ensuring operator safety. Offering such options as embedded help screens for simple, error-free set-up (on the Fluke 2062), we believe these kits will be welcomed by everybody who is tasked with locating energised and de-energised wires and who is looking for an easy-to-use solution.”

For more information, visit www.fluke.com.

12

13

Ultra-smooth motion technology for NSK linear guides

NSK’s new ultra-smooth motion technology, developed for the company’s popular general-purpose NH/NS series linear guides, is the world’s first design of its type. Thanks to the use of elastic rolling elements, the patented technology achieves a highly consistent dynamic friction profile that is ideal for high-precision inspection and measurement equipment.

The low friction and smooth motion characteristics of linear guides make them a valuable addition to all kinds of systems that require high-performance motion control. For this reason, NH/NS linear guides find use in a wide range of applications, including semiconductor and LCD manufacturing equipment, automotive manufacturing equipment, conveyor robots, inspection and measurement equipment, and machine tools.

Today, the equipment used in these applications is subject to everhigher levels of sophistication. In particular, the latest inspection and measurement equipment demands even smoother and more accurate motion, placing high expectations on linear guides.

With these thoughts in mind, NSK set about developing its ultrasmooth motion technology by optimising the shape of the ball circulation path and using elastic rolling elements to suppress irregular ‘micro-stutters’ (brief stuttering or jerking during motion caused by localised friction

fluctuations). These elements reduce the effect of balls colliding with each other in the curved sections of the ball circulation path, which serves to prevent any increase in friction and, in turn, deliver ultra-smooth motion.

As well as inspection and measurement equipment, NSK linear guides with ultra-smooth motion technology benefit applications requiring vertical operation and other mounting positions where operating characteristics tend to deteriorate. Importantly, these innovative linear guides are dimensionally interchangeable with NSK’s standard NH/NS series, facilitating the replacement of units currently in use without any design changes.

NSK’s new ultra-smooth technology is available for NH 15, 20 and 25 series linear guides, as well as NS 15, 20, 25 and 30 models. In total, NSK can supply 28 variations, including different slider lengths and types. The units are compatible with a wide variety of options, such as the NSK K1-L lubrication unit, stainless steel configurations and special surface treatments.

14

Fig. 1 Mechanism of Ultra-Smooth Motion

Fig. 2 Evaluation of Slide Motion Smoothness

Features:

■ Cooled InSb or MCT detectors

■ High spatial and thermal resolution

■ Thermally decoupled optics

■ Fast frame rates

■ High dynamic range

■ 10 GigE interface

Applications:

■ Research and development

■ Automation

■ Aerial thermography

■ Process control

■ Non-destructive testing REQUEST

15 InfraTec distributor in the UK and Ireland: Quantum Design UK and Ireland Ltd, 1 Mole Business Park, Leatherhead, Surrey KT22 7BA Tel: +44 (0)1372 378822 | Email: info@qd-uki.co.uk

Solve the most demanding measurement and testing tasks

High-end Camera Series ImageIR®

AN ONLINE DEMO!

more information visit highendthermography.co.uk

For

500m of cable harnesses with 4,000 wires delivered to FFEI

Convert Ltd, the UK’s leading manufacturer of cable looms and harnesses, announced today on the 30th of August, that it had successfully delivered half a kilometer of cable harnesses to FFEI, the leading integrator and manufacturer of industrial digital inkjet systems and digital life science technology.

FFEI is using the assemblies for a large industrial printer which prints in layers and can have up to five print boards. These required to date over 200 assemblies, each with between one and 40 wires, which included short assemblies measuring 90mm up to longer, up to 2.5m.

FFEI said: “The wiring system is key to the safe and efficient operation of our digital printers, which are at the forefront of the industry, and we know that these harnesses do what they are meant to do, time and time again. We have relied on their timely delivery which has enabled us to deliver for our customers.”

Dave Lord, Convert’s Managing Director, said: “The world of digital printing is changing rapidly and cable harnesses need to support this. FFEI has been at the forefront of these changes and it is fantastic that our assemblies are helping to support this.”

Convert specialises in the automotive, public transport and scientific/medical sectors, manufacturing cable harnesses for car head and rear lights, passenger gates at railway stations and a range of scientific equipment.

With its highly trained staff and continual investment in state-ofthe-art equipment – including a Komax Gamma 255 fully automatic crimping machine and an Artos CR11 crimping machine – Convert’s complex cable looms and harnesses are manufactured to the highest quality, delivered on time and at competitive prices.

For more information, visit www.convertltd.co.uk or www.ffei.co.uk

16

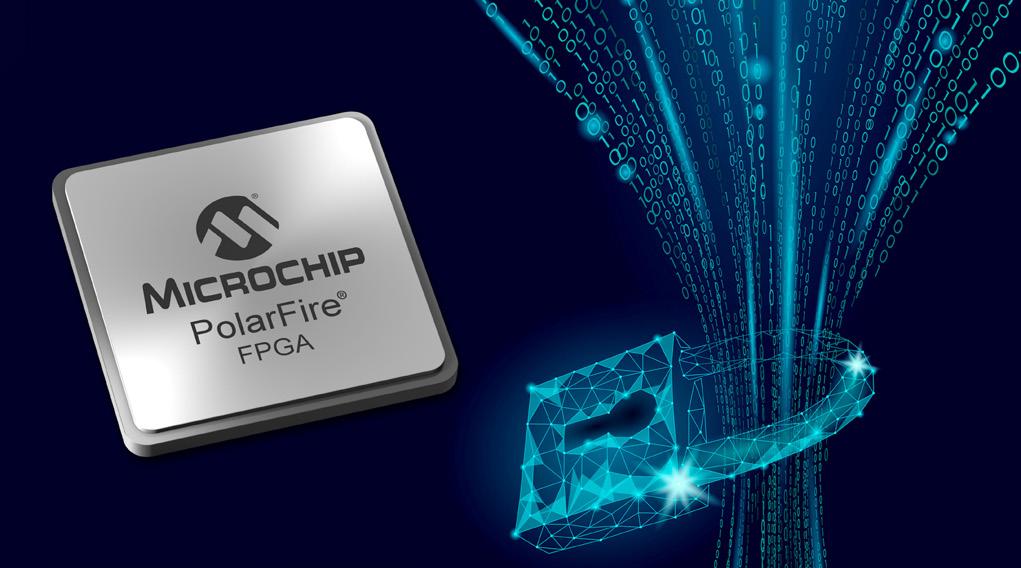

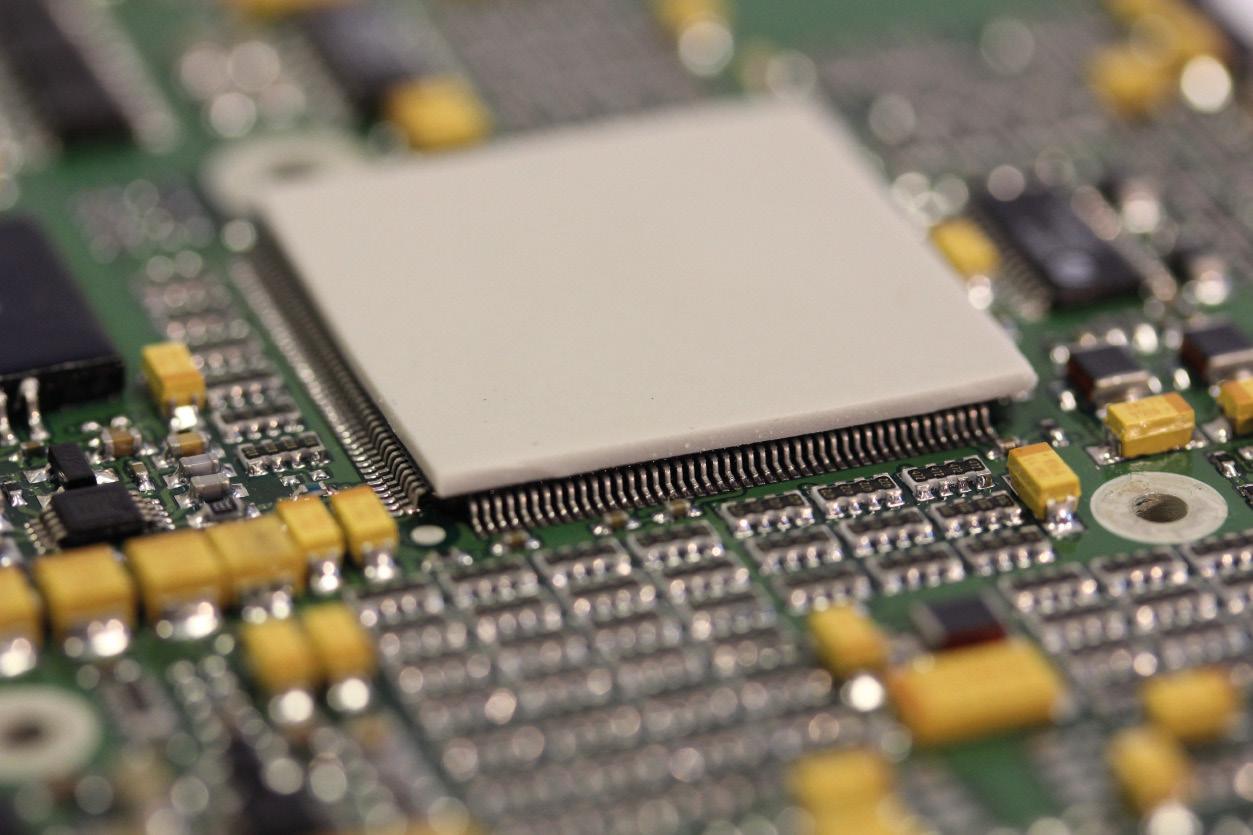

New Gigabit Ethernet Switch with AVB/ TSN and Integrated PHYs for Industrial Automation

The LAN9662 includes a Real-Time Engine to process high-speed cyclical data in flight

Industrial automation and digital transformation are driving market growth for scalable and standardized networking solutions to address the needs of commercial Operational Technology (OT) deployments. To provide automation manufacturers with a comprehensive networking solution, Microchip Technology (Nasdaq: MCHP) today announces the LAN9662 Gigabit Ethernet Switch with four ports, AudioVideo Bridging and Time Sensitive Network (AVB/TSN), two integrated 10/100/1000BASE-T PHYs and a 600 MHz Arm® Cortex®-A7 CPU subsystem.

To support industrial Ethernet applications, the LAN9662 features a Real-Time Engine (RTE) that provides the ability to modify the Ethernet frame in flight, enabling faster cyclical data rates and low latency. The LAN9662 is compliant with key industry standards such as the OPC Unified Architecture (OPC/UA) and PROFINET software stack, offering deterministic communication capabilities

necessary for industrial networking applications.

“Expanding on the LAN966x family, the LAN9662 opens a path to scale with TSN-enabled networking endpoints,” said Charles Forni, vice president of Microchip’s USB and networking business unit. “Our solutions offer customers the advantage of starting their designs with industry standards met, supported by a comprehensive software portfolio.”

With two integrated PHYs, the LAN9662 provides extremely low latency to support various daisy chain topologies. The PHY interfaces enable fast data processing within a specified time to provide a reliable network for automation applications such as motor, conveyor and multi-axis robot controllers.

The LAN9662 supports up to two RGMII/RMII, up to two 1000BASE-X/ SerDes/2.5GBASE-X/KX, and a QuadSGMII/Quad-USGMII interface. The configurable interfaces allow designers to reach various types of physical layers or interconnects they may require.

Microchip is an established supplier of industrial-grade networking

solutions, offering a broad portfolio of robust, energy efficient and highly integrated products with deterministic switching and fault-tolerant redundancy. Its products significantly reduce the complexity and overhead of deploying Ethernet across a variety of industrial applications. To learn more about Microchip’s Ethernet solutions, go to www.microchip.com/en-us/ solutions/ethernet-technology/ industrial.

Development Tools

The LAN9662 is supported by Microchip’s Switch API, the EVBLAN9662 and the EVB-LAN9662Carrier Board. Software support is also offered through Platform BSP, Linux® Switchdev and PROFINET Software Stack.

Pricing and Availability

The LAN9662 is available at $13.10 in volume quantities. For additional information and to purchase, contact a Microchip sales representative, authorized worldwide distributor or visit Microchip’s Purchasing and Client Services website, www.microchipdirect.com.

18

19 Category Title to go here

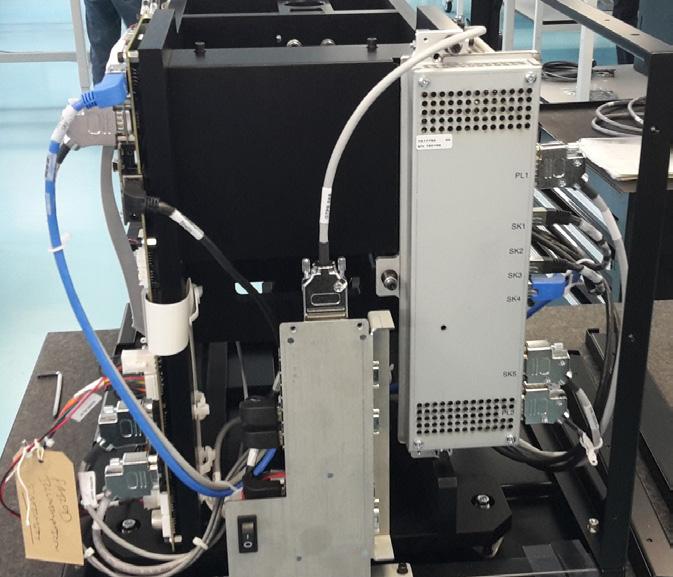

Microchip’s PolarFire® FPGA’s SingleChip Crypto Design Flow “Successfully Reviewed” By the United Kingdom Government’s National Cyber Security Centre

20

The Review confirms strength of PolarFire FPGA’s security solution

Security is now an imperative for all designs in every vertical market. Today, system architects and designers received further evidence of the security of their communications, industrial, aerospace, defense, nuclear and other systems relying on Microchip Technology’s (Nasdaq: MCHP) PolarFire FPGAs. The United Kingdom Government’s National Cyber Security Centre (NCSC) has reviewed the devices when used with the Single-Chip Crypto Design Flow against stringent device-level resiliency requirements.

“The NCSC conducts a very rigorous analysis, and the work done with Microchip on the Design Separation Methodology in the PolarFire FPGA enables the user to take advantage of improved resilience and functional isolation within the device. This reinforces Microchip’s commitment to our comprehensive approach to security,” said Tim Morin, technical fellow at Microchip’s FPGA business unit.

“This analysis provides the option for single-chip cryptography in addition to what already exists

within the devices for protecting IP, securing data and protection against physical tampering—an often overlooked and very powerful threat to every electronic system, especially those at the intelligent edge.”

PolarFire FPGAs implement Microchip’s industry-leading security architecture to protect intellectual property, secure data and secure supply chains.

• PolarFire FPGA IP protection includes:

1. AES 256-encrypted configuration files with SHA 256-based HMAC authentication

2. Processing is protected against Differential Power Analysis (DPA) with technology licensed from Cryptography Research Incorporated (CRI)

3. Public key cryptographic cores: Elliptic Curve Cryptography (ECC) for secure distribution of keys

4. True random number generators

PolarFire FPGA data security

features include:

1. Hardened cryptographic accelerators for use in the end application

2. Pass-through CRI license enables royalty-free development of DPA-protected algorithms using techniques patented by CRI

• PolarFire FPGA supply chain security features reduce the risk of counterfeiting, re-marking and overbuilding and include:

1. Silicon biometrics, including Physically Unclonable Functions (PUFs), that allow each device to be uniquely identified and cryptographically validated

The devices are supported by Microchip’s Libero® SoC Design Suite available to license, including no-charge versions, from Microchip’s Purchasing and Client Services website at www.microchipdirect.com PolarFire FPGA and SoC development kits and hardware are also available on the purchasing and client services website.

21

FSP launch new shift to attract part-time workers

A Midlands manufacturing business is taking an innovative approach to labour shortages by introducing a new shift aimed at attracting part-time workers.

It’s the first time in two decades that Fabweld Steel Products, which manufactures access covers for the water, energy and security sectors, has restructured its shift system.

The company is hoping to increase its headcount with part-time staff working a 6pm-10pm shift for the first time in a move which it hopes will be attractive to those looking for flexibility or second jobs.

There are currently more than 74,000 unfilled factory jobs across the UK, according to manufacturing organisation Make UK. There are also more people looking for second jobs, with recent research from BBC Worklife revealing 47 per cent of people having little to no savings left at the end of each month, with a further 15 per cent saying that paying routine bills was a struggle.

FSP managing director Wayne Carter said the rising cost of living meant increasing people were looking to supplement their income with second jobs and it was hoped the new shift patterns would help attract people looking for flexibility too.

He said: “We are in a cost of living crisis and many people are struggling to make ends meet. This shift would suit someone who is already in work who needs a bit more money coming in, or those who can’t work during the day because of other commitments but have a few hours to spare in the evenings.

“This isn’t just a problem for FSP, as manufacturing businesses across the country are struggling to fill vacancies. Our own approach to recruitment, skills and training means that we are often one of the

first to fill vacancies but people are now also looking for flexibility, which means a new evening shift may suit some workers better.

“It is the role of good employers to innovate and develop ways of working which increases productivity and efficiency but still offers great working patterns and conditions for employees – that’s always what we aim to achieve at FSP.”

The new shift will operate between 6-10pm from Monday to Thursday each week and the roles are for fabricators in the factory.

FSP specialises in the design and manufacture of specialist access covers, gratings and other bespoke steel products.

For more information about FSP or applying for the new shift roles, visit www.fsp.co.uk/ or call 01952 581430.

22

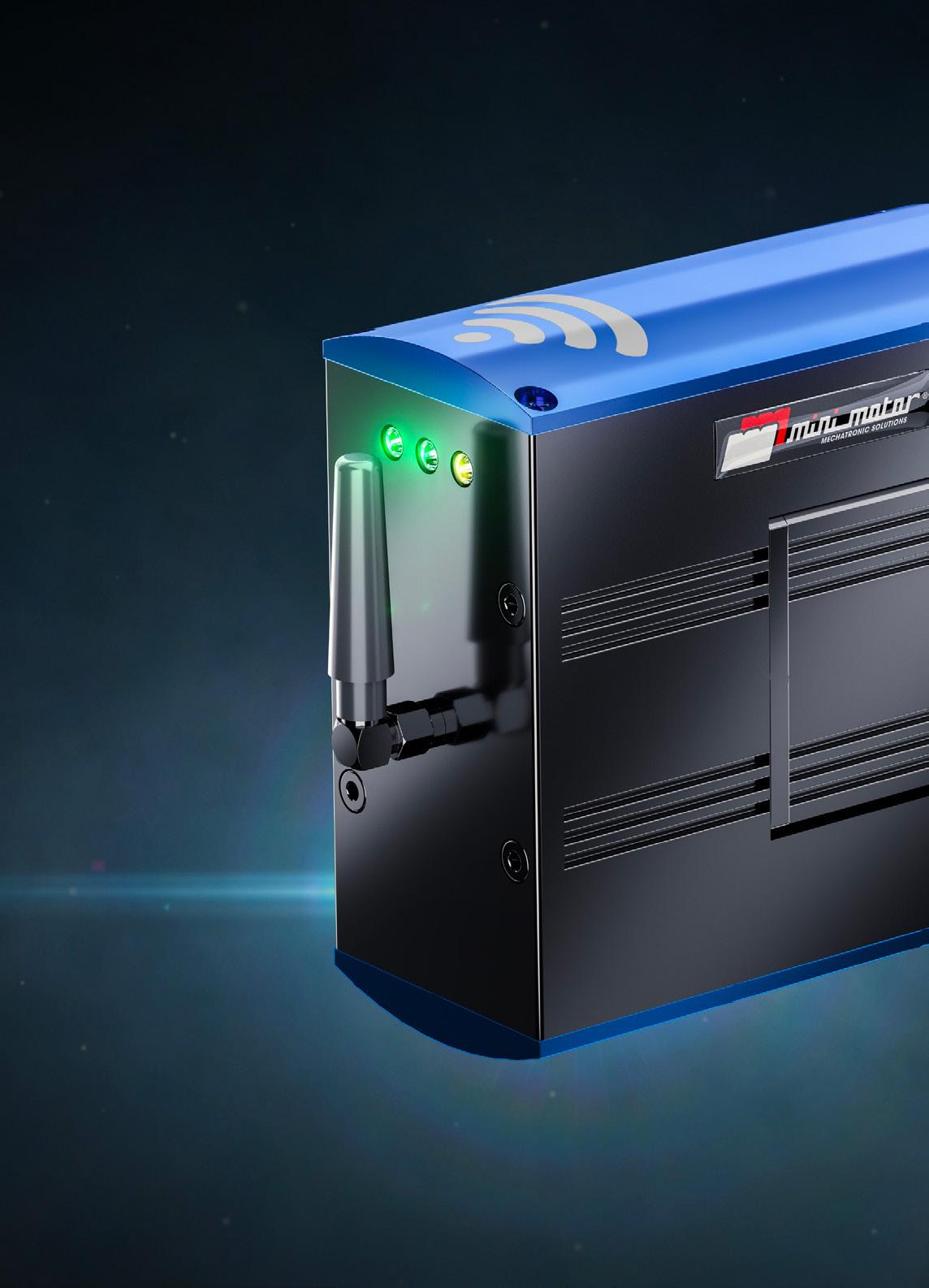

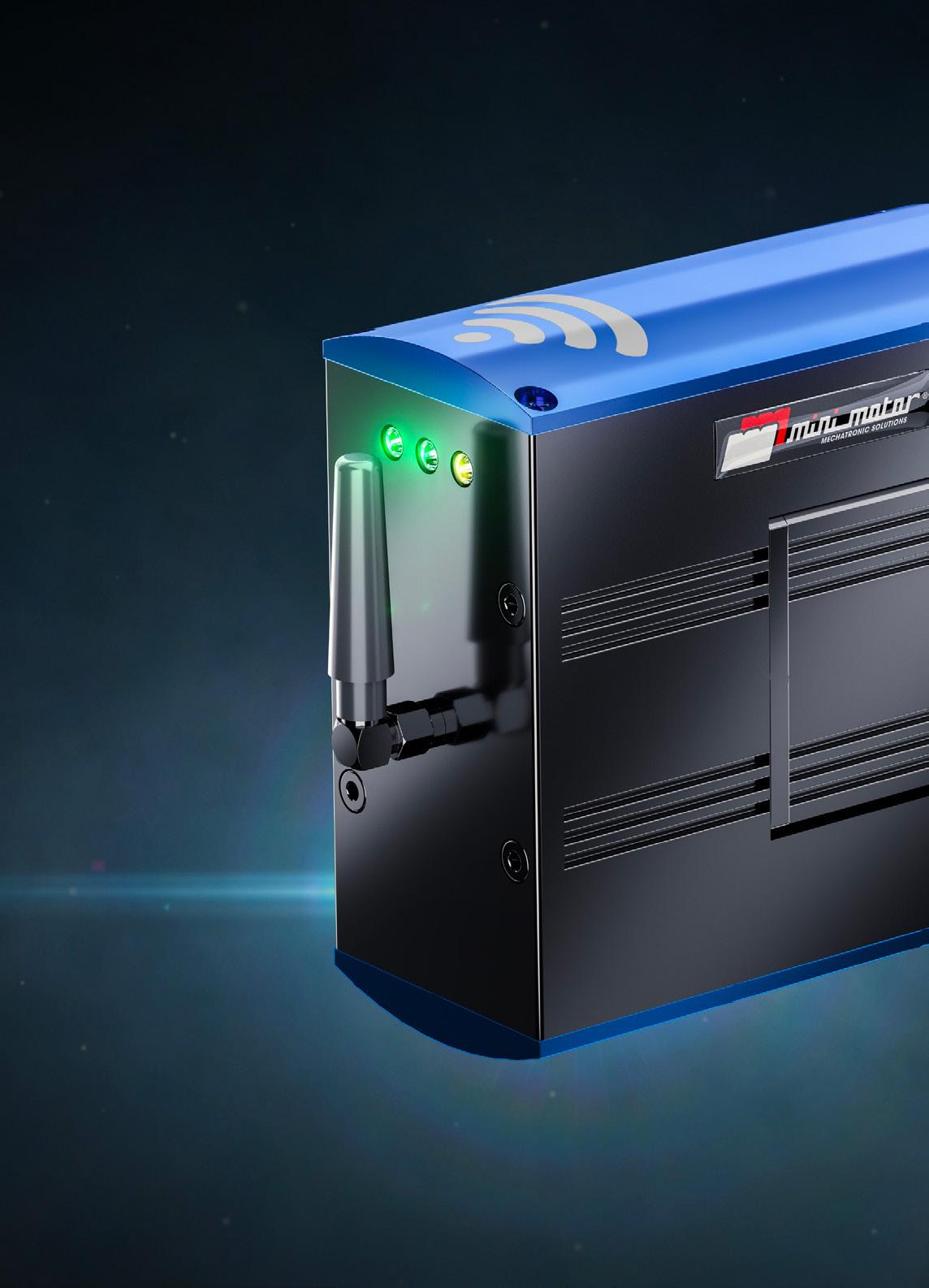

motors@oem.co.uk +44 (0) 0116 284 9900 www.oem.co.uk FULLY WIRELESS NETWORKED SMART MOTORS ARE COMING... Contact the Motors Team at OEM Automatic to find out more

INEOS AUTOMOTIVE AT THE 2023 GOODWOOD FESTIVAL OF SPEED: GLOBAL DEBUTS FOR ALL-NEW GRENADIER QUARTERMASTER AND HYDROGEN FUEL CELL DEMO

Following the start of series production of the Grenadier 4X4 last year, INEOS Automotive will made its mark across this year’s Goodwood Festival of Speed (13 - 16 July).

The All-New Grenadier Quartermaster, a double cab pick-up variant of the awardwinning Grenadier, will make its global debut on Thursday 13th July. This will be shortly followed by a very special appearance on the famous hillclimb with some familiar Goodwood faces to celebrate two 75-year automotive anniversaries - motorsports at Goodwood and the Belstaff Trialmaster Jacket that lends its name to one of Grenadier’s trims.

Also making its first ever public appearance is the Grenadier Hydrogen Fuel Cell (FCEV) Technology Demonstrator, which will show how well-suited the zero emissions technology is for a future

long-range 4X4 off-roader.

Both the Grenadier Quartermaster and FCEV Demonstrator will be showcased in the First Glance Paddock and will be driven up the hillclimb route on each of the four days of the Festival.

In an exciting exclusive for Goodwood Festival of Speed, adventurous visitors will be able to get behind the wheel of the Grenadier Station Wagon on a challenging off-road course at the Goodwood Halnaker Chalkpit neighbouring the main event site. Hundreds of slots are available throughout the four days of the Festival for those wanting to put the 4X4 through its paces.

24

Lantek Reports Impressive Growth with 24.9% Increase in Turnover

• The Basque multinational’s turnover has exceeded 35.3 million euros, reaching 32,000 customers worldwide.

• Lantek’s expansion plan includes a strategic commitment to R&D that continues to drive the launch of groundbreaking products. International growth defines the position of the group which has nearly 400 employees worldwide and a 58% increase in the recruitment of STEAM profile women.

Lantek, a multinational company with more than 32,000 registered customers supported through 21 offices in 15 countries, has announced its global financial results for the 2022/23 financial year, concluding on June 30, 2023. The company has achieved a remarkable 24.9% surge in sales, resulting in a turnover exceeding 35.3 million euros.

“This financial year has been a pivotal period for Lantek as we continue to strengthen our position as a leading company in our sector,” said Alberto López de Biñaspre, Lantek CEO. “Dedication to the industry and our customers remains steadfast, even in times of uncertainty. We are proud of our team’s efforts to develop pioneering products that empower both Lantek and our customers to succeed in various industrial projects.”

The company’s global market vision has recently been increased by the creation of Lantek Australia, serving

customers operating in both Australia and New Zealand.

Recruiting STEAM talent

As part of Lantek’s strategic commitment to digitalizing the industrial metals sector, the company has made significant progress in its growth plan and is on track to employ nearly 400 professionals globally. The company is committed to nurturing STEAM talent with a global perspective and international reach. Women in STEAM recruitment have represented 58% of that talent during the past financial year.

A commitment to innovation

With a steadfast commitment to innovation spanning over 35 years, R&D has been an enduring component of Lantek’s success. Supported by a vision of global technological leadership in the sector, the company’s close collaboration with over 140 leading machine

tool manufacturers worldwide exemplifies its dedication to driving transformative advancements through cutting-edge software solutions.

To this end,Lantek’s R&D team has doubled within the last two years.

As part of Lantek’s strategy for technological leadership, Lantek actively participated in the aiXia collaborative project, aimed at establishing a secure and reliable infrastructure for AI federated services and is associated with the Basque Artificial Intelligence Centre (BAIC). Collaborating with this respected Basque Country organization for AI, further demonstrates its commitment to the development of talent while upholding ethical and regulatory AI standards.

Through these initiatives and strategic alliances, Lantek remains at the forefront of promoting technological advancements, spearheading transformative innovations in the industry.

26

27 Category Title to go here 29

INEOS AUTOMOTIVE ACQUISITION BRINGS SPECIALIST VEHICLE CONVERSION CAPABILITY IN-HOUSE

• INEOS Automotive has acquired Botswana-based specialist vehicle conversion business

• Kavango Engineering becomes ‘INEOS Kavango’ following the acquisition

• Grenadier conversions planned for conservation, safari, filming and healthcare roles

• Acquisition galvanises Sir Jim Ratcliffe’s vision of the Grenadier playing a key role in conservation activities

• Lynn Calder, CEO of INEOS Automotive, said, “We are thrilled to welcome the Kavango conversion experts into the INEOS Automotive team, expanding the capabilities of both companies to better serve these specialist use cases worldwide.”

INEOS Automotive has acquired Botswana-based Kavango Engineering, one of southern Africa’s most respected and established vehicle conversion specialists. The business has been renamed INEOS Kavango.

Ideally located in Maun, northern Botswana, at the gateway to the Okavango Delta, INEOS Kavango’s 5,000m2 premises includes extensive fabrication and assembly facilities. Its highly skilled 70-strong workforce completes around 200 conversions a year. Members of the team that founded Kavango Engineering will remain involved in the business.

INEOS Kavango will expand its current activities to encompass ground-up conversions and ongoing maintenance of Grenadier Station Wagon and Grenadier Quartermaster pick-ups for a wide range of use cases. These include extensive specialist modifications for the conservation, safari, antipoaching, veterinary, primary healthcare and film production sectors. To accommodate future business growth, land adjacent to the existing INEOS Kavango site is earmarked for further development that will double the scale of the operation.

As a proof of concept, in late 2022 INEOS Kavango created a Safari Grenadier from a donor production prototype vehicle. Engineering modifications were minimal, centering on a slightly raised ride height, and relocating the Station Wagon’s roof-mounted switchgear to the centre console. The original roof has been replaced by a lightweight roll-back canvas top with foldable windscreen and the usual tiered seating has been added to maximise passengers’ views.

“This acquisition will help INEOS Automotive realise the vision of INEOS chairman Sir Jim Ratcliffe for the Grenadier to play a key role in critical conservation and environmental programmes worldwide,” says Lynn Calder, CEO of INEOS Automotive. “Bringing the Kavango team in-house also means it can work closely with our engineering and manufacturing teams to optimise processes to supply conversion-ready vehicles so we can better serve these specialist use cases worldwide.”

Charles van Rensburg, CEO, INEOS Kavango said: “Botswana is recognised as a global leader in conservation, and we will continue to support its work and that of

other countries and organisations across Sub Saharan Africa. In addition, there are a broad range of opportunities across other sectors that always need durable, capable off-road vehicles with purpose-built bodies to perform specific roles. Our objective is to sustainably grow the business over the long-term. That means developing a broader portfolio of services, adding further highskilled jobs and diversifying the local economy to the benefit of the community.”

28

29

XYZ Machine Tools streamlines medical device development

ATL Technology in Cardiff is a specialist manufacturer of medical devices, particularly energy-driven surgical devices.

These are used in minimally invasive surgery and use low voltage, high current RF energy waveforms to seal, coagulate, dissect, vaporize, resect, or mobilize tissue. Typical applications are in urology, gynaecology, and arthroscopy.

As a company committed to delivering tailored products for specific medical applications, ATL Technology collaborates closely with surgeons throughout the design and production process. To ensure rapid development and timely completion of projects, continuous prototyping plays a crucial role. This approach is essential due to the stringent requirements for quality, repeatability, reliability, and cleanliness inherent in medical device development.

ATL Technology in Cardiff utilises two toolrooms to produce prototyping tooling, jigs, fixtures for production, specialized inhouse machinery for assembly and disassembly, and spare parts to maintain the special-purpose production assembly line.

The Research and Development toolroom initially adopted the XYZ SMX 2500 bed milling machine in 1997. Over time, its capabilities have expanded with the addition of a 660 HD vertical machining centre, a 1340 lathe, and an XYZ 500 LR vertical machining centre featuring linear rail technology.

Meanwhile, the Maintenance toolroom utilizes an RLX 1630 lathe, an XYZ 1500 manual turret mill, and an XYZ RMX 2-OP, which specializes in machining light alloy and plastic parts from stock materials. The recent acquisition of an XYZ 500 TMC in March 2023 further highlights ATL Technology’s

30

longstanding investment in XYZ machines.

Stephen Green, Process Development Engineer, highlights the advantages of the XYZ 500 TMC, stating, “The XYZ 500 TMC has a larger working area. This enables us to machine bigger mould tools, jigs, and fixtures in-house, which we were previously subcontracting. It has more power, a 12k spindle— which is ideal for small tools—and through tool coolant. This makes it easy to machine tool steels for injection mould tooling and electrodes for die sinking. It is also good at deep hole drilling, delivering faster material removal rates. With subcontracting, it took many weeks to deliver a tool. Now we can produce an entire tool within a week, or a single part to repair a production line breakdown within 24 hours.”

For ATL Technology, the ability to rapidly produce prototype parts— using metal injection moulding sintering techniques from 17PH powder with an ABS substrate—is crucial. The quick iteration and lifecycle testing of prototypes play a significant role in refining

product designs to meet the specific requirements of health professionals while ensuring manufacturability.

The XYZ 500 TMC’s ProtoTRAK® control provides ATL Technology’s engineers with a convenient way to program parts directly in the workshop. Additionally, CNC programs for prototype parts are mostly generated offline in Autodesk FeatureCAM from CAD models supplied by the Product Development team. The ProtoTRAK® control allows engineers to verify the program, enabling them to review and correct any errors before machining begins.

Ashley Gardiner, Toolroom Technician, emphasizes the machine’s versatility, stating, “90% of our work is one-off, small batches or spares, and the 12 tool pockets on the 500 TMC are sufficient for most of our needs. With this machine, we have increased our capacity to rapidly develop new devices and keep our production lines operating. Generally, we are looking for ±50 microns. With the TMC, we can achieve ±10 microns and, using the

probe on the machine, we can also do in-process checking to ensure the part is correct before we take it off.”

To accommodate the XYZ 500 TMC in the Maintenance Toolroom, XYZ Machine Tools had to dismantle the machine entirely to fit it through the door. The technicians from XYZ Machine Tools then meticulously reassembled and tested the machine to ensure its functionality, accuracy, and reliability. Overall, the machine’s adaptability and XYZ Machine Tools’ reliability have made the partnership invaluable to ATL Technology.

In conclusion, the integration of the XYZ 500 TMC has significantly enhanced ATL Technology’s medical device development capabilities.

The ability to rapidly prototype, create specialized components inhouse, and achieve high precision has allowed ATL Technology to stay at the forefront of medical device innovation, ensuring the delivery of cutting-edge products to meet the needs of healthcare professionals.

31

Owl Autonomous Imaging 3D Thermal Sensor Named a 2023 Best of Sensors Award Winner

Owl’s new HD thermal camera sensing technology and AI software will enable the automotive industry to meet the NHTSA’s new mandates for pedestrian safety at night.

Owl Autonomous Imaging, The smartest choice for the road ahead, today announced it has been named a winner in the Optical and Camera category of the 2023 Best of Sensors Awards for 3D High-Definition Thermal Ranger Camera with Computer Vision. The awards program is presented by Sensors Converge and Fierce Electronics and honors the best in sensor technologies and the sensor ecosystem, people and companies.

Throughout the world, government agencies and industry organizations are in the process of developing and implementing automotive safety regulations that will force vehicle makers to adapt new safety and night-time driving technologies that are much more effective than those in use today. Owl’s Thermal Ranger™ combines the latest Thermal Camera hardware and AI technology that not only can “see” warm objects like humans, animals and bicyclists on the road, but can also classify them as to what they are and how far away they are, enabling the vehicles to automatically hit the brakes or steer around them.

“Pedestrian safety, especially for night-time and urban driving, is THE critical milestone for the automotive industry’s next-generation vehicles, and we are honored to be recognized by Sensors Converge & Fierce Electronics for the impact of the problems we seek to solve” says Chuck Gershman, CEO & Co-founder of Owl Autonomous Imaging.

Submissions were judged based on the value to the marketplace, the impact of the problems it solves

or issues it addresses and the uniqueness of the design.

Charlene Soucy, Senior Director, Technology – Sensors & Electronics said, “Congratulations to the individuals, teams and technologies on their award wins. Each year we are continually amazed at the

innovations and achievements the award winners have created. This year, the winners have outdone themselves with their innovations and perseverance. We are excited to honor them as the best of the best in the industry.” More

32

info at www.owlai.us

New laser distance sensor measures up to 270

metres with measuring frequency of 40 kHz

Precision sensor supplier

Micro-Epsilon has introduced a non-contact laser distance sensor that measures distances up to 270m with a resolution of 1mm.

The sensor measures reliably even on difficult surfaces such as dark, structured or weakly reflecting objects. Without any special adaptations to the target, the sensor has an impressive range up to 125m. Adding a reflector to the target extends the measuring range to 270m.

Designed primarily for outdoor use, the new optoNCDT ILR1171-125 laser distance sensor measures 20 times faster and is more cost effective than its predecessor, the optoNCDT ILR1191. Due to the timeof-flight principle, a larger infrared laser measurement spot and a measuring rate of up to 40 kHz, high energy pulses are achieved, enabling stable measurements with very good signal quality. Even in poor visibility conditions such as smoke, fog, steam and rain, the sensor provides accurate measurements. The sensor is resistant to ambient light up to 50,000 lux.

Protected by a robust IP67 die cast aluminium housing, the optoNCDT ILR1171-125 is suitable for a wide range of applications, from transport, logistics and conveyor systems, to the monitoring of buildings, cranes and wind turbines.

The sensor can be used in ambient temperatures from -20°C to +60°C.

In terms of its technical performance, the sensor provides repeatability of <25 mm, resolution of 1mm and linearity of < ± 60mm, resulting in stable measurements and good signal quality. The sensor’s small footprint (25 x 46 x 81mm) and weight (140g) allows it to be easily installed in narrow or restricted spaces.

The optoNCDT ILR1171-125 can measure on static and dynamic targets and is easy to integrate into existing systems. The sensor provides continuous measurement output via a 16-bit, scalable, 4-20mA analogue output or via RS232/422 serial communication. Two digital switch outputs are available for simple process monitoring and a trigger input provides opportunities to control when the sensor takes a reading.

For more information on the optoNCDT ILR1171-125, please visit www.micro-epsilon.co.uk/sensors/ optoNCDT-ILR1171-125/ or call the Micro-Epsilon sales department on +44 (0)151 355 6070 or email info@micro-epsilon.co.uk

33

KEB drive controllers make servo pumps more efficient

Performance, pump protection and high precision control without compromise –all this is provided by the servo pump control function integrated in KEB Automation’s drive controllers. In combination with KEB’s DL4 and TA series servo motors, they can also save energy.

By controlling the pump drive, pressure and flow can be optimally adapted to the requirements of servo-hydraulic machines at any time. This is the case, for example, in injection moulding machines where cycle times are key. Here, the COMBIVERT F6 drive controller and S6 servo drives from KEB come in. With the precise and high performance solution for pump control, they ensure continuous control, as well as faster cycle times, to increase the productivity of injection moulding machines.

Another goal of the control: the hydraulic valves are to be protected and the service life of the pump is to be extended. For this purpose, there are various parameters in the firmware of the drive controllers whereby the lifetime and availability of the injection moulding machines can be significantly increased.

Designed for high requirements

Various features that have been specifically integrated into KEB’s drive controller firmware are proving useful in practice. “Among other things, we have considered ‘anti-cogging’ in our solution,” says Michael Schulz, application engineer at KEB. “This enables KEB’s

inverters to equalise disturbing cogging torques, which are systemimmanent in permanent magnet motors. The result is significantly improved concentricity on the motor axis. In combination with the notch filter from the Wizard, which serves to avoid resonances in the hydraulic circuit, the result is highly precise and very good control of flow and pressure. Furthermore, there is the additional feature that the PQ control can be switched on and off by setting a bit. The user therefore has a regular KEB drive in place. This can lead to cost savings.”

Basically, the choice of servo pumps is always a sensible idea when hydraulic systems are confronted with highly dynamic or highly constant control requirements. These include various areas of plastics processing, hydraulics and bending presses, but also applications in the field of lifting technology. Here, according to Schulz, the stability of the KEB system and the performance of the software solution are particularly evident in the control of pressure and flow.

For more information, please visit www.keb.co.uk

34

35 7 Custom Cut Technical Materials - FAST! No Tooling Charge Fast Manufacturing Technical Support Quality Assured Thermal Interface Materials | Tapes & Adhesives, LED Optical Materials | Sealing Gaskets EMI Shielding | Electrical Insulators info@materialsdirect247.com | www.materials-direct.com Materials to Protect Your Electronics INSTANT PRICING, ORDER ONLINE TODAY! www.materials-direct.com

36

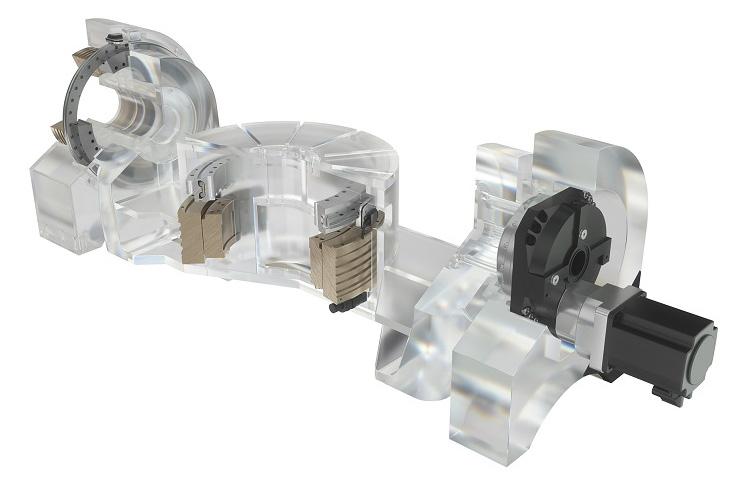

NSK to show live ball-screw condition monitoring at EMO

NSK is the only manufacturer to offer a complete development and supply service for the essential parts that machine tools require, including high-precision, highspeed ball screws.

However, the company also helps customers to apply novel technologies that support extended product life and the potential deployment of predictive maintenance strategies. Therefore, central to the display on Booth C42 in Hall 7 at EMO Hannover 2023 (18-23 September) will be a live demonstration of a condition monitoring system developed by Brüel & Kjær Vibro (B&K Vibro), a member of the NSK Group. Involving a pair of NSK ball screws, this fascinating exhibit provides a compelling reason to visit the booth.

The live demonstration will centre on the VCM-3 condition monitoring system (CMS), produced by Brüel & Kjær Vibro, a member of the NSK group and one of the leading worldwide suppliers of condition monitoring solutions for rotating machinery. Specifically, the VCM-3 plus vibration sensors will showcase proven credentials for monitoring linear motion equipment such as NSK ball screws. The system, based on compact, cost-effective, cutting-edge technology helps turn vibration data into real business value.

On a wider level, the VCM-3 provides automatic machine fault detection and diagnostics, adding a new dimension of healthcare awareness to machine shop assets. Users do not require any previous diagnostic expertise: the system uses specially defined measurements that not only facilitate the early automatic detection of developing faults, but also give a diagnostic indication of the fault type and its severity.

The VCM-3 is simple and fast to configure. A built-in OPC UA server enables seamless integration of VCM-3 data to DCS, SCADA, data

historian and other systems. The system is also expandable using other components of the broad B&K Vibro solution portfolio to provide plant-wide condition monitoring.

Ball screws will of course be a core technology on the NSK booth. Making its debut appearance in Europe will be the company’s nextgeneration ball-screws for highaccuracy machine tools. Offering reduced motion errors and no ‘second glitch’ phenomenon, these new ball screws help enhance the surface finish of workpieces, in turn reducing or eliminating the need for secondary polishing/burnishing operations.

Another ball screw on the booth will be the NSK low-temperature series. Features include 45% less friction loss (heat generation) in comparison with conventional systems at the same rigidity. Also making its European exhibition debut at EMO will be the company’s HFT series for high-load drive applications, which offers up to two times longer life than conventional ball screws.

Further NSK ball screws on the booth will include the S-HTF range, which takes advantage of NSK’s proprietary Tough Steel to help combat high loads and contamination.

NSK will also shine its EMO spotlight on linear guides, including the

new DH/DS long-life series. With a world-leading dynamic load rating, the DH/DS delivers over twice the running distance of the company’s conventional NH/NS series. NSK will also present its proven RA series roller guides featuring highly dustresistant seals.

The company is world-renowned for its bearings and EMO will provide the European launch pad for NSK’s ROBUSTDYNA ultra-high speed, high-load capacity angular contact ball bearings. Ideal for machine tool spindles, these ground-breaking new bearings feature bigger bearing balls to increase maximum load capacity by up to 15% in comparison with the previous-generation solution.

A further major introduction at the show will be NSK’s ROBUSTGRD grease for high-speed spindle bearings, which improves seizure resistance and reliability in coolant environments.

The booth will also showcase NSK’s SURSAVE (TSR) bearing cage for angular contact ball bearings that deliver energy savings, high speeds and reduced vibration during use on machine tool spindles. A range of various NSK super precision bearings and highspeed motor bearings will round-up the showcase for machine tools, alongside thin angular contact ball bearings for robots.

37

More precision, dynamics and efficiency: Schaeffler presents new drive solutions

• New solutions for direct-drive swiveling rotary tables, bearings with integrated angular measuring systems and precision gear units

• Spindle bearings for every application

• New automation solutions with exceptionally rigid, backlash-free, precision gear units and drives

Just as in other industries, rising energy and material costs, as well as a shortage of skilled labour have become increasingly important for the machine tool sector. Schaeffler is meeting these challenges with new automation solutions that offer even greater dynamics, precision, energy efficiency, and

longer machine operating times. To address these needs, Schaeffler is presenting a comprehensive array of product and system solutions at the EMO 2023 trade show, which takes place September 18-23 in Hannover, Germany.

As Ralf Moseberg, Senior Vice President Industrial Automation at Schaeffler, explains: “The machine tool industry was remarkably quick to recognise these current developments as an opportunity, and responded accordingly. Within this context, customers are

particularly focused on reducing electricity, air, and lubricant consumption along with increased domestic sourcing. Investments are geared toward optimising machine service life and capacity utilisation, as well as being able to use production equipment more flexibly with the help of new automation solutions. Robots and cobots –especially with respect to ROI –along with the development and application of new technologies such as direct-drive systems, play a key role here.”

38

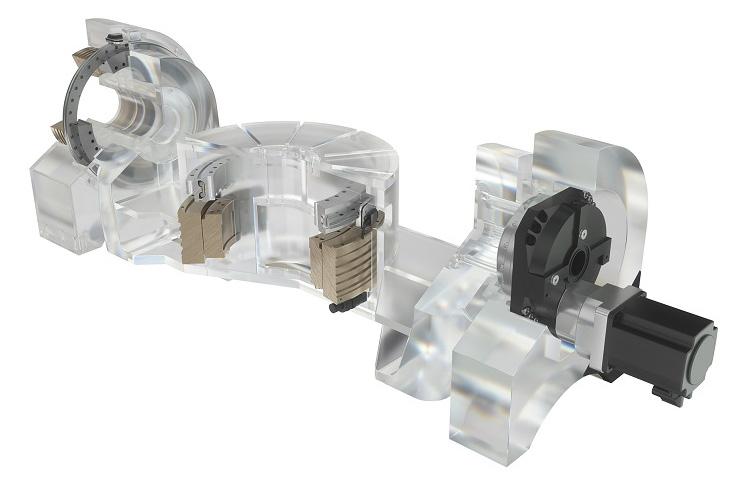

Innovative drive concept for swiveling rotary tables

An attention-grabbing exhibit at the Schaeffler booth in Hannover is a direct-drive swiveling rotary table (SRV- and RKIB-series motors). On one side, a direct drive with a YRTCMA-series axial-radial bearing is utilised to drive the swiveling rotary table. In this case, “MA” designates the inductive, absolute value angular measuring system that has been integrated into the bearing. The other side, for demonstration purposes, features an innovative, newly designed drive for pivoting axes: a PSC precision planetary gear unit with a servomotor. The torsional backlash of just 0.1 arc minutes, which remains constant over the device’s operating life, makes it possible –for the first time ever – to dispense with a second drive for tightening and eliminating the backlash. The exhibit positions the two solutions across from each other, enabling them to be readily compared and discussed.

Spindle bearings for every application

Schaeffler will also present its expansive spindle bearing portfolio at EMO 2023, which consists of axial angular contact ball bearings with small, medium, and large balls, as well as cylindrical roller bearings. With this range of high precision bearings – for which various rolling bearing steels, cage designs and ceramic rolling elements are also available ¬– Schaeffler can offer the right bearing configuration for virtually any turning, milling, or grinding spindle. A particular

highlight of this product range is the VCM series, which features medium-sized balls combined with Vacrodur high-performance steel. These bearings enable spindle manufacturers to design extremely robust and high-performance products.

Precision gear units and drives

Unique to the market and a technological highlight: Schaeffler’s RT1 precision strain wave gears – also optionally available as the RT1-T featuring seamlessly integrated torque sensors – as well as PSC precision planetary gear units with automatic backlash compensation. With these precision gear units, a variety of automation solutions can be implemented in an extremely broad range of applications such as cobots, machine tools, welding positioners, rotary indexing tables, tube bending machines and many more. Both types of gear units will be on display at EMO 2023 in milling heads for light machining tasks.

By adding a motor, feedback system and optionally integrated controller to its RT-series precision strain wave gears, Schaeffler is now also able to offer individually configurable precision drives. This allows manufacturers to concentrate on their core competencies when developing their machines, without having to forgo customised precision drives.

More information on EMO and Schaeffler here

39