ONTARIO

Reno reimagines potential to connect with people

TRCA ADMINISTRATIVE OFFICE

Sensitive intervention gains Zero Carbon, LEED and WELL certifications

AMPED SPORTS LAB AND ICE COMPLEX

Difficult test case meets zero carbon performance

EMPOWERING TOMORROW’S BUILDING LEADERS

CAGBC Emerging Green Professionals

Welcome to Spring Thomas Mueller, President & CEO, Canada Green Building Council

AMPED Sports Lab and Ice Complex Difficult test case meets zero carbon performance

Le Phénix and The Joyce Centre Five years of zero-carbon performance Albert Campbell Library Renovation/Modernization Reno reimagines potential to connect with people

TRCA Administrative Office Sensitive intervention gains Zero Carbon, LEED and WELL certifications

Where Business and Technical Expertise Converge CAGBC’s Building Lasting Change Conference

Empowering Tomorrow’s Building Leaders CAGBC Emerging Green Professionals

Carbon Capture, Utilization and Storage An Industry Strategy for Limiting Carbon Emissions

Printed on Domtar Husky Opaque text offset paper.

Cover: The Albert Campbell Branch Library.

SITE | LANDSCAPING |

RAINWATER HARVESTING

ACO Systems

Visit our on-line Directory to see hundreds of listings of companies which supply products and services for sustainable, high-performance building. Listings are organized by Product Category and by LEED Category. Our LEED v4.1 Directory is created with the help of our partner:

Filterra Bioretention Systems/Langley Concrete Group

Molok North America Ltd.

Roth North America

Wishbone Site Furnishings

STRUCTURE & EXTERIOR ENVELOPE

Airfoam Industries

Arriscraft

Canada Brick

CAYAKI Charred Wood/ CFP Woods

CBC Specialty Metals and Processing

Engineered Assemblies

Fraser Wood Siding

475.Supply

International Timberframes

Live Roof Ontario

LP SmartSide

MAPEI Canada

N.A.T.S. Nursery Ltd.

Radon Environmental

Sapphire Balconies Ltd.

Siga

Thames Valley Brick & Tile

Tremco CPG Inc.

THERMAL, WINDOWS & DYNAMIC GLASS

Cascadia Windows & Doors

Duxton Windows & Doors

Inline Fiberglass Ltd.

Innotech Windows + Doors

JELD-WEN Windows & Doors

KALWALL

Kohltech Windows & Entrance Systems

NZP Fenestration passivhaus windows and doors

Unicel Architectural Corp.

VETTA Windows & Doors

COATINGS AND INTERIOR

Century Wood Products Inc.

Dulux/PPG

Eco Building Resource

Forbo Flooring Systems

ELECTRICAL | PLUMBING | HVAC | RENEWABLES

Aqua-Tech Sales and Marketing Inc.

Big Ass Fans

Daikin Applied

Ecopilot Real-Time Energy Management System

Fantech Canada Ltd

Mitsubishi Electric Sales Canada Inc.

RadiantLink In-wall Heating

Sharc Energy

Sloan Valve

Tempeff Inc.

Teritt Indoor Environmental

TRANE

Viessmann Manufacturing Company Inc.

GREEN DESIGN SUPPORT + PROFESSIONALS

Canada Green Building Council

Canadian Precast Concrete Quality Assurance

Certification Program

Efficiency Nova Scotia

Entuitive

FABRIQ architecture

Green Building Initiative

Save EnergyNB

I am pleased to welcome you to the Spring issue of Ontario FOCUS, part of a series of regional publications from CAGBC and Sustainable Architecture & Building Magazine.

Spring has us thinking of Building Lasting Change, our annual national conference. This year, the conference returns to Toronto on June 5-6. Our team has put together two days of compelling content exploring the business and technical sides of green building. I encourage you to learn more about our conference at cagbc.org/BLC.

Transforming buildings at scale is a massive effort which requires all players in the sector to make connections and learn to work collaboratively. I recently returned from the Building and Climate Forum in Paris, France, a follow-up event to COP28 focused on collective action in the building sector. Policymakers and industry representatives, green building councils and other organizations from across the globe met to discuss practical next steps in leveraging buildings to address climate change and promote resilience. It was a great opportunity to connect with industry leaders to understand how global developments might impact the Canadian market.

This spring also saw CAGBC’s Low Carbon Training initiative end. This program forged unprecedented national connections with partnerships between CAGBC, Real Estate Property Association of Canada (REALPAC), the Royal Architectural Institute of Canada (RAIC), the Climate Risk Institute, the Canadian Construction Association, and Building Owners and Managers Association Canada (BOMA Canada). Together we delivered low-carbon training to thousands of professionals from a broad range of backgrounds. We hope this initiative will set the foundation for greater collaboration and increased focus on capacity building and workforce development.

These activities are part of the green building community’s commitment to achieving Canadian and global climate ambitions. Our collective efforts have tangible impacts as we strive to address climate, energy, affordability, and resilience. CAGBC is the hard-working partner Canada’s building sector needs to advance on all fronts through our standards, certifications, training, research, and advocacy efforts.

I hope you’ll enjoy this new issue. In it, you’ll see also see how momentum for our Zero Carbon Building Standards continues to build. I hope to see you at Building Lasting Change.

Sincerely,

Thomas Mueller President & CEO, Canada Green Building CouncilTwo Canadian buildings are celebrating a significant milestone after celebrating zero-carbon operations five years in a row. Their achievement is marked by certification under the Canada Green Building Council® (CAGBC) Zero Carbon Building – Performance Standard™ (ZCBPerformance), which verifies zero-carbon operations over a 12-month period.

The five-year milestone was accomplished by architectural, planning and design firm Lemay’s Le Phénix Montréal headquarters, and Mohawk College’s The Joyce Centre for Partnership & Innovation.

“Achieving five straight years of verified zero-carbon performance puts these two projects in rarified air,” said Thomas Mueller, CAGBC’s President and CEO. “Lemay and Mohawk College showed tremendous vision in embracing our Zero Carbon Building standards early on, but five consecutive years of ZCB-Performance certifications demonstrates their unwavering commitment to eliminating carbon emissions and helping advance green building in Canada.”

Le Phénix, Montréal.

Located in the heart of Montréal’s Sud-Ouest borough, le Phénix is a 1950s warehouse that was abandoned before being transformed into an experimental lab for testing Lemay’s new sustainability concepts and approaches. In addition to five consecutive years of certification under ZCB-Performance, the office space is also pursuing LEED certification.

“The retrofit of the structure, as its moniker suggests, represents its rebirth: as a health-promoting, energyefficient and innovative project to inspire best practices in sustainable development,” said Hugo Lafrance, Director of Sustainability at Lemay. “The project has now achieved five straight Zero Carbon Building –Performance certifications making it a true success story about what we collectively need to do and renovating existing real estate as a priority to transition to net-zero.”

Located at Mohawk College’s Fennell Campus, The Joyce Centre for Partnership & Innovation stands out for its large solar PV canopy and for being the first institutional building to achieve Zero Carbon Building – Design certification™ in 2017.

“While The Joyce Centre for Partnership & Innovation has significantly reduced Mohawk College’s carbon footprint with five years of netzero performance, it has also been transforming thousands of students into climate champions,” said Ron J. McKerlie, President and CEO of Mohawk College. “As a living laboratory, it is nurturing a new generation of workers equipped to lead Canada to a more sustainable future. We are proud of this milestone and our college’s leadership in net-zero development in Canada and we encourage others to join us in this critical cause.”

CAGBC’s Zero Carbon Building™ (ZCB) Standards are a made-inCanada framework that make carbon the new measure of building innovation. The ZCB standards offer a proven platform for building and retrofit projects to pursue, achieve and verify zero carbon operations.

As reporting emissions and exposure to climate risk becomes more common and, increasingly, regulated, pursuing zero-carbon performance is becoming a business necessity. Addressing carbon emissions now will appeal to tenants today and protect a building’s future value. With ZCB-Performance certification, building owners take responsibility for all carbon emissions associated with energy use, refrigerant leaks and any new structural and envelope materials. The Standard recognizes the value of renewable energy and high-quality carbon offsets for any remaining emissions while encouraging energy efficiency strategies to reduce demand on electrical grids.

CAGBC’s ZCB-Performance Standard can be used by any existing building with 12-months of operational data. Projects with combustion equipment must create a fully costed zero-carbon transition plan to show how equipment will be adapted over time to achieve decarbonization, typically through upgrades that are timed to leverage normal equipment replacement cycles. Learn more at cagbc.org/zerocarbon

Fiberglass windows and doors don’t just look good they are checking all the boxes

TRCA showcase project, enveloping active and passive processes to create a comfortable living and working environment. The building is designed to meet low current and future energy demands while “conserving” its own environmental impact in its operations.

INLINE’S role is to meet the consultant’s requirements for LEED platinum, WELL Building certifications, accessibility, ease of operation, energy conservation, solar heat gain, air flow management and sustainability. INLINE is extremely proud to have been chosen to be part of this amazing project.

**These options and features must be specified, and were not part of the windows supplied to the TRCA project.

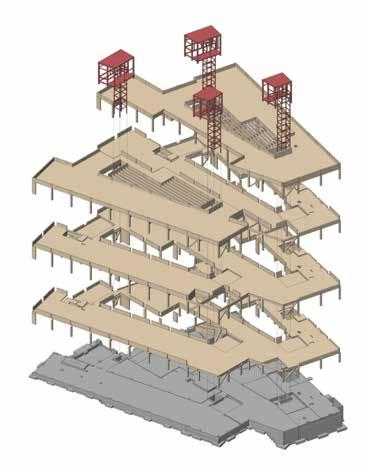

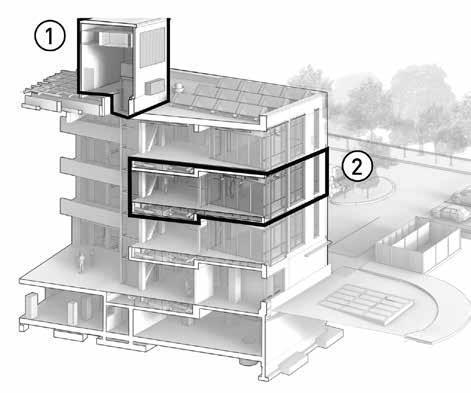

The Toronto and Region Conservation Authority (TRCA) needed a new building to consolidate its physical space and operations from multiple locations, increase its staff efficiency and improve its relationship with the public.

The more ambitious mandate, aligned with the organization’s manifesto, was to create a model development that would dramatically reduce its environmental footprint through all life cycle phases and become a living example of an environmentally responsible intervention within the fragile ravine ecosystem of Greater Toronto. Furthermore, the project was selected as a pilot Zero Carbon Building Standard development by the Canada Green Building Council and targetted high levels of certifications under both LEED and WELL programs.

ZAS Architects and Bucholz McEvoy Architects, jointly engaged to reimagine the aging TRCA’s Headquarters, envisioned the building as a link between the Black Creek ravine’s topography and the hard urban edges of (Tennis Canada) Sobeys Stadium and Shoreham Drive.

The fan-shaped form of the building is oriented to take maximum advantage of the solar exposure, with its massing rising from three storeys hidden below tops of the trees on the west ravine side, to four storeys approaching the height of the stadium to the east. The height differential is used to create a walkable rooftop terrace, one of many building amenities meant to integrate the development with the ravine.

Building off the strength of the TRCA’s educational mandate, it was important that the building design present the highest standards of sustainability and energy conservation. At the same time, the client was motivated to create an open, well-ventilated, and transparent working environment. The design team utilized an Evidence-Based Design Process which led to a highperformance, low-energy building. A variety of analytical tools and physical models were used to evaluate the performance of various strategies, guiding the design development to achieve both Comfortable Indoor Environment and Optimized Energy Systems.

Above all, this project makes a conscious effort to achieve a low-carbon footprint through all lifecycle phases, with model simulations predicting over 50% reduction in operating emissions, and over 75% reduction in embodied carbon compared to the average Toronto office building. Now that it has been Zero Carbon Building Design-certified, the project’s reported embodied carbon intensity (ECI) of 253 kgCO2e/m2 is almost one third lower than 367 kgCO2e/m2, the average ECI of all 23 buildings ZCB Design-certified by the Canada Green Building Council up to the end of 2023.

1.The main entrance. The west and south sides have charred shou sugi ban cedar. The rest of the cedar cladding consists of

Cammio Construction.

Building

PROJECT CREDITS

CLIENT The Toronto and Region Conservation Authority

ARCHITECT ZAS Architects + Interiors and Bucholz McEvoy Architects (Dublin)The

STRUCTURAL ENGINEER RJC

CIVIL ENGINEER TYLin (previously TMIG)

MECHANICAL ENGINEER Introba (previously Integral)

ELECTRICAL ENGINEER MBII

ENERGY EFFICIENCY CONSULTANT Transsolar

LANDSCAPE ARCHITECT Schollen & Company

CONSTRUCTION MANAGER Eastern Construction

PHOTOS ZAS Architects. Photo 4: Adamski Photography

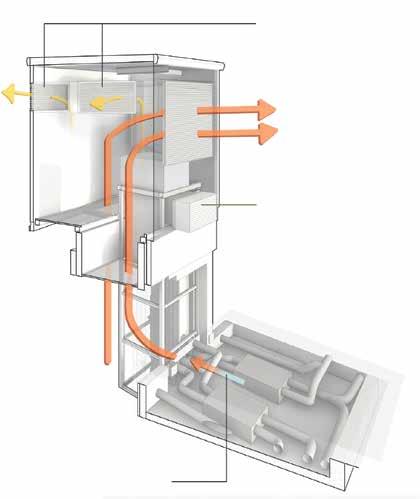

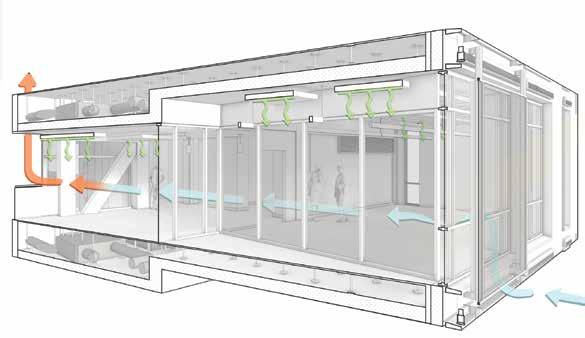

Exhaust air from atria and rooms is pulled into the solar chimney through grills.

Smoke exhaust dampers open when atrium’s negative pressure cannot be maintained. Variable speed drives to 100% to remove smoke detected by fire alarm system.

Air from spaces is pulled in and out of atria into solar chimneys

Solar chimney’s natural ventilation motorized dampers are open, allowing hot air to flow out of the building.

Radiant ceiling panels heating or cooling mode permitted under certain conditions

Motorized blinds monitored and controlled by the Building Automation System (BAS) reduce solar radiation on south facade when it exceeds 200W/m2

Where double-skin facade is not employed, operable windows are used. When ENV conditions are met, the BAS sends an indication to computers, allowing occupants to open the windows. Triplepane low iron content glazing increases light penetration while low-emissivity coating reduces heat gain.

Fresh air is drawn into the building through openings in the preheat double-skin facade.

The wood structure makes an important contribution to the low carbon footprint. The concrete structure stops at the ground floor level and steel is limited to the impressive water wall and solar chimney structures. Wood dominates the interior with exposed mass timber, wood doors, screen frames and millwork, and outside with wood cladding inspired by the nearby Black Creek Pioneer Village dwellings but carefully articulated to enhance the structure’s civic stature. Cladding on the sun-exposed facades has been strategically charred using a traditional shou sugi ban technique.

The new facility will substantially reduce operating costs, while helping TRCA deliver the best possible customer service and support and serving as a living example of green building best practices. The new headquarters will also serve as a learning centre for developers, researchers, professionals and students that will contribute to the uptake of methods and technologies that demonstrate zero carbon features and green infrastructure restoration.

To this end, the design incorporates numerous passive and active strategies and technology for renewable energy, innovative water management and integration with the ravine landscape. A natural ventilation system extended into shoulder seasons through the sophisticated use of exterior venetian blinds and glass preheat boxes on the sun-exposed facades and powered by air convection through interior atria and four solar chimneys which will reduce the use of air conditioning to only a few days per year.

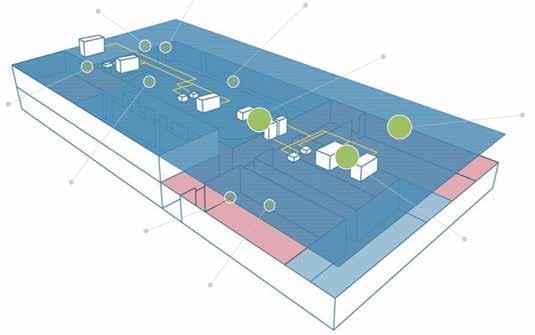

Heating energy from the open-loop geothermal system, photovoltaic panels on the roof and heat recovered from internal sources is distributed throughout the building by radiant ceiling panels and radiant floors in the atria. It is also supplied to a network of 28 decentralized energy recovery ventilators which take fresh air preheated by the four water walls and blow conditioned air into the raised floor plenum to the locally controlled floor outlets.

This promotes a highly customized use of energy and its transfer from one part of the building to another. A sophisticated building requires a sophisticated control system for the ultimate success of all climate strategies. While many building systems are controlled or monitored automatically, the building users will be educated to influence some of the building climate/comfort settings. Significantly, most of the windows are manually operated but monitored by BAS, which sends signals to staff advising when to open the windows and when they must remain closed. Similarly, the building users will have control of ceiling-mounted reverse-direction fans turned on to improve occupant comfort during extreme weather days.

The ground floor features active public spaces, creating a hub for community engagement that is embedded in the natural setting of the campus. Water is a central theme in the project with a storm water management system that collects rainwater from green roofs and rain gardens. Water is also featured inside flowing down stainless steel meshes suspended over the full height of the building in four transparently glazed water towers. The towers pay an homage to the TRCA’s mandate as guardian of our water shed resources, but also serve as heat exchangers preheating or precooling fresh air entering the in-floor energy recovery ventilators.

The project will transform the way in which TRCA conducts its day-to-day business and interfaces with the community at large, and will serve as a model of a sensitive intervention next to nature from which the development community can learn and emulate.

Get your product/service in the SABMag Directory: dgriffith@sabmagazine.com

CANADIAN DIRECTORY OF PRODUCTS AND SERVICES

Visit SABMag's Directory of Sustainable Products and Services for Sustainable, High-Performance Building [sabmagazine. com/product-directory/ ] where products are organized by Product Category and by LEED Category. Examples of featured listings include:

ACO SystemsIncreasingly extreme weather must be counteracted by more complex and sophisticated drainage concepts. ACO achieves this with intelligent system solutions which have a dual purpose: protecting people from water, and water from people. Every ACO product safely controls the water as it passes along the chain to ensure that it can be ecologically and economically reused in a viable way.

Molok® Deep Collection™ system

- An award-winning semi-underground waste containment system. Twenty years in North America and emptied by crane, Molok® containers are space saving, efficient and odour free.

Airfoam Industries

CFP Woods, Cayaki Charred WoodCAYAKI specializes in interior & exterior charred siding. Raw material is sourced and made in Canada utilizing Red & White Cedar which are two widely renowned wood species for their rot-proof, as well as insect and weather-resistant properties. The market leader in knowing how to properly char and apply a wide range of eye-catching colours and textures.

475 High Performance Building Supply - 475.Supply is a trusted source for building envelope knowledge and materials: Pro Clima airsealing, Gutex wood fiber board insulation, Lamilux skylights, Brink heat recovery ventilation, and more. Plus, download free Smart Enclosure guides today!

Canada BrickLocated in Ontario, Canada Brick manufactures an impressive selection of residential and architectural brick, including modern and traditional colour ranges and several premium finishes. Canada Brick has manufactured brick locally for 70 years and is a smart option to buy Canadian.

- Airfoam Industries is a proud North American manufacturer of high-performance building envelope products. With insulation solutions for residential, commercial, and industrial applications.

Arriscraft - Using only natural materials, Arriscraft manufactures superior stone that delivers the aesthetic and performance qualities of quarried stone. Arriscraft offers full-bed stone, thin-clad solutions and brick products, plus natural limestone quarried in Ontario.

CBC Metals and Processing/ VM Zinc - Muntz Metal, Architectural Bronze, Silicon Bronze, Coppers, Brasses, Aluminum; Stainless Steels: Satin, Hairline & Mirror; Coloured Stainless Sheet: Black, Bronze, Brass & various others. Anodized Aluminum; and CBC EZ Metal (matte finish Stainless for Roofing & Cladding). Technical service available in English et en Français.

Wishbone Site Furnishings - A recognized leader in the development and manufacture of municipal grade outdoor furniture. Using recycled plastics and metals, Wishbone products speak innovation through design that is aesthetically pleasing and functional.

Engineered Assemblies - EA imports and supplies world-class lightweight façade materials and substructure assemblies including our patented, Canadian-made TcLip™. Experts in rear-ventilated rainscreen (RVRS), EA provides design assistance with the SYSTEM2-v2 Design Guide available for download on our website.

FABRIQ architecture - FABRIQ architecture is a Montreal based firm that delivers innovative and sustainable design solutions for clients in the public and private sectors. Currently have eight major LEED projects certified or underway.

Live RoofLiveRoof is the premier pre-vegetated modular green roof system available across Canada. Regionally grown modules with vegetation specifically selected and tested for your climate by the horticultural professionals at LiveRoof. Wind uplift tested according to CSA A123.24-15. Contact us for specific rooftop stormwater management solutions.

Langley Group/Filterra - The Langley Concrete Group of Companies is the largest independent precast operation in Western Canada. Product lines dedicated to Stormwater Treatment include Oil Interceptors, Stormceptors, Jellyfish Filters, and Filterra.

Roth North America - Premier TANK. Premier WARRANTY. Premier SYSTEM. Roth North America provides water cisterns, rainwater harvesting tanks, septic tanks, and more, consisting of an inner layer of FDA approved virgin HDPE, two inside layers of PE for improved stability, plus one outer layer of black and UV-stabilized PE. Low profile, 100% watertight, and Lifetime corrosion protection.

1

By Andrew CreeseSustainability is important for businesses and individuals everywhere, and that includes the neighbourhood hockey arena. The AMPED Sports Lab and Ice Complex opened in 2016. During the initial build, energy efficiency was the main concern, not de-carbonization. At the most basic level, we simply wanted to ensure that we could make good ice for clients.

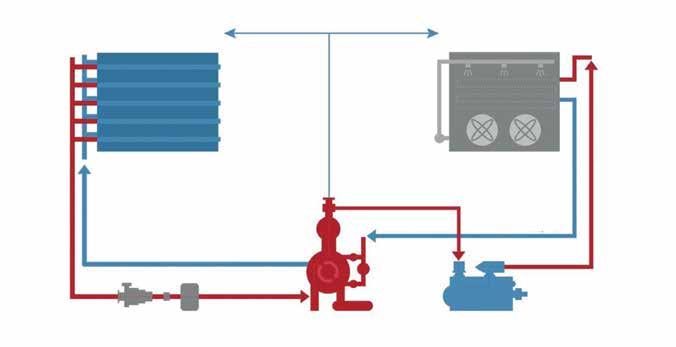

However, our partner, the multi-disciplinary contractor Modern Niagara, installed energy-saving measures that enabled AMPED to produce as much energy as it uses, effectively allowing it to operate at a net zero energy level.

The Net Zero AMPED Sports Complex is a game-changer for the way we think about buildings. AMPED is the first Zero Carbon Building –Performance Certified Arena under the Canada Green Building Council’s Zero Carbon Building Standard Program.

Back in 2019 as part of its own decarbonization strategy, Modern Niagara approached AMPED to engage with it in the challenge of making the AMPED Sports Lab the first net-zero arena in Canada (and North America, possibly the world). The impetus behind this was that arenas are historically heavy carbon emitters and experience gained from decarbonizing an arena could be applied to any type of building. The goal for AMPED was to generate energy savings of 40%. No small challenge.

Modern Niagara worked with the owners to optimize the building envelope with insulated panels for hot/cold separation while including several energy savings measures that carried an acceptable cost-benefit-analysis to the client. These included items like LED lighting, motion sensors to activate lights, low-flow faucets and showers and toilets.

The largest energy conservation measures implemented came from the electric ice resurfacer which, among other benefits, drastically reduces the dehumidification requirements and provides fossil fuel savings on an ongoing basis.

Secondly, the implementation of the De-Ox System enabled coldwater flooding for the rink. By putting the cold water through a membrane/vacuum system, the oxygen was removed from the water (hot water with its low oxygen content is used to flood) which enabled a substantial reduction in the size of the required hot water tanks and the volume of natural gas to heat the water.

Modern Niagara’s scope involved the design and installation of equipment to convert AMPED into a zero-carbon emissions building. For example, installing an Integrated Building Intelligence system that enhances modern building automation technology using advanced analytics and automatic fault detection; developing Artificial Intelligence to provide a more autonomous building while enabling demand-based service; and disconnecting the natural gas supply to eliminate future carbon cost exposure.

Other measures taken included:

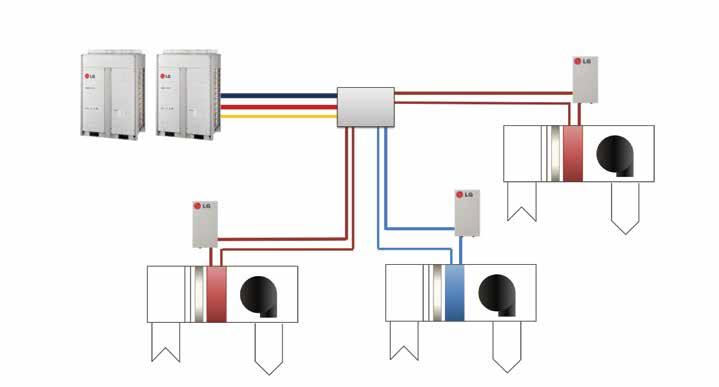

• Variable refrigerant Rooftop (VRF) units - replacing gasfired units with electrified heating and cooling and a heat recovery system

• A custom-built liquid desiccant air conditioner (LDAC)

- dehumidification eliminating emissions and improving efficiency (this was a prototype and which has since evolved to commercialization)

• Heat Pump Hot Water (DWH) - electric water heating using available waste heat

• Upgraded LED lighting and controls

• A photovoltaic array

• Optimized refrigeration plant for energy efficiency to manage compressor cycles more effectively

• Controls package to manage critical systems

• Full measurement and verification package to comply with CAGBC Net-Zero certification

As part of the project, Modern Niagara was also able to secure $250,000 in incentive funding for this project through the Climate Action Incentive Fund administered by Natural Resources Canada, and the Save On Energy program administered by the IESO for Ontario.

Such sustainable practices benefit the environment by the more efficient use of resources and reduction of waste and emissions, but often also bring economic benefits by encouraging new technologies and products which can be applied to new projects and renovations.

3. Several energy-saving measures were taken to achieve net zero energy operations, including a De-Ox System which allows cold-water flooding for the rink.

3

The Albert Campbell Branch Library opened its doors in 1971 to serve Scarborough’s diverse community. In this rapidly growing Toronto suburb, the brutalist building stood as a beacon to the community. But after five decades, the Toronto Public Library (TPL) recognized the need for upgrades to meet contemporary needs.

1.

Working with LGA Architectural Partners, TPL sought to reimagine Albert Campbell as a more welcoming hub that brings people together and is connected to the community.

Originally, TPL believed that an expansion or a replacement would be necessary. However, our careful analysis revealed that 25% of the back-of-house space could be repurposed for public use by unlocking and reconnecting the buried first floor. This approach has enabled TPL to satisfy many of its wider visionary objectives such as sustainability and placemaking.

We began by relocating the main entrance from the second to the first floor. Previously, visitors accessed the building via an upward ramp, which created a dark and underutilized ground level. By carefully reshaping the land downward to follow the natural topography of the site, we redirected the library’s main entrance to the first floor. With new windows, the entry is now intimately connected to the front landscape.

On the second level, we cut a new floor opening above the entry and removed walls, allowing visitors to experience horizontal and vertical views into the entire branch while new east and westfacing windows draw in both daylight and verdant community views. A new elevator, painted red as a nod to the previous colour scheme, visually orients visitors while providing barrier-free access to all areas of the building, particularly to the previously limitedaccess subterranean community room, and the rooftop terrace.

Beyond achieving TPL’s objective to improve accessibility, the renovation was an opportunity for us to rethink the library’s programming and create a series of more contemporary spaces that would increase the community’s engagement with their local branch. Some of these new spaces include a Digital Innovation Hub, a recording studio, a room that accommodates Indigenous smudging, an outdoor roof terrace, group study rooms, medium and large multi-purpose rooms, a learning centre, and nine allgender washrooms.

Floor plans

10. Teen area

11. Digital innovation hub 12.Dih lounge 13. A/V green room

14. Smudging/multi-purpose room 15. Mezzanine reading area 16. Study area 17. Roof garden

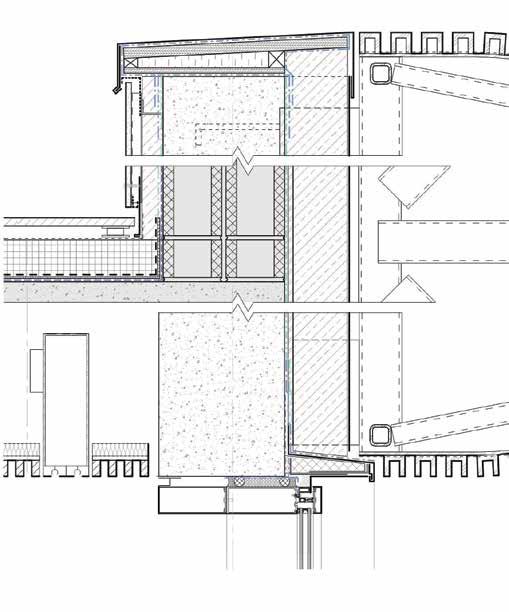

As for the project’s sustainability goals, our decision to reuse and renovate the existing concrete structure was the single most important step in limiting the project’s potential carbon footprint. Through the renovation, though, a number of other strategies were also applied to improve the building’s performance and bring it up to today’s standards.

Re-cladding the building’s exterior, for example, was one of these strategies. The exterior envelope was previously comprised of two wythes of concrete block with minimal insulation and no air or vapour barriers. To remedy this issue, we covered the existing block with a liquid-applied air/vapour barrier, R-25 insulation and fibre concrete panel cladding.

2. The before and after conditions of the renovation.

3. Visitors previously accessed the building via an upward ramp; however, the original main entrance was relocated from the second to the first floor allowing more light to the lower level.

4. and 5. One of the most powerful transformations was the replacement of the tiered metal ceiling with new slats of Douglas Fir, the new ceiling inspired by the original undulating design but with improved acoustics and a softening of the brutalist interior. New mechanical and electrical systems are concealed behind the new ceiling.

Conc infill to extend guard to obc height

New paving and green roof system on exist. terrace conc. slab

Conc infill around new windows

Ceiling “service channel” for mech diffusers and lighting

ALCBL Detail

Undulating wood ceiling: 19mm x 38mm Douglas Fir blades (8 per 305mm) on flexible backer on black fabric on tee suspension system w/ pvc encapsulated acoustic insulation

Thermally broken double glazed pre-fin. curtainwall with jam extentions

Galv sheet metal cladding under canopy on 150 semi-rigid mineral wool on liquid applied vapour permeable air barrier on new and exist. struct.

Curved canopy: 50mm x 50mm pre-fin alum channels on black filter cloth on glav perforated sheet metal on galv steel struct. on plate bracket to wall

Silicone transition strip w sealant carried to and sealed into glazing pocket, fill void w spray foam.

Fill shim space w/ closed-cell polyurethane spray foam c/w cont. backer rod and sealant both sides.

PROJECT TEAM

ARCHITECT LGA Architectural Partners

INDIGENOUS CONSULTANT Trina Moyan, Bell and Bernard LTD

LANDSCAPE ARCHITECT Aboud & Associates

STRUCTURAL ENGINEER Blackwell Engineers

CIVIL ENGINEER EMC Group

MECHANICAL/ELECTRICAL ENGINEER Enso Systems Inc

CONTRACTOR Pre-Eng Contracting

PHOTOS LGA Architectural Partners

6. The roof patio contributes to the welcoming hub objective of the library and its connection to the community.

7. Atkar North America suppled its Au.diSlat Grille of solid Douglas Fir with clear finish and FR treatment for the ceilings, and its Au.diMicro with clear finish Douglas Fir Veneer for the walls.

Exterior updates also included the addition of new window openings across all levels, allowing for more natural light to fill the lower floors and reducing the energy demands for interior lighting.

One of the most powerful transformations inside the library was the replacement of the tiered metal ceiling with new slats of Douglas fir. Reimagining the previous motif with a warm natural material, the new ceiling is inspired by the original undulating ceiling design while improving acoustics, softening the perceived harshness of the brutalist interior, and reducing the embodied carbon of the interior finishes. Hidden beneath this new ceiling, we also installed a full suite of new mechanical and electrical systems that contribute further to the building’s efficient operation.

The renovation of Albert Campbell Library demonstrates the effectiveness of reuse as a climate-conscious and advantageous strategy for addressing declining infrastructure. For LGA, the project required greater creativity and investment, but exploring how built heritage could be updated - within a more inspired and openminded approach to preservation - proved rewarding.

As a starting point, we aim to make libraries flexible and inclusive places grounded in the local community. At Albert Campbell this meant adopting a re-use mind set and reimagining the branch’s potential to connect and inspire people.

BROCK JAMES, OAA, FRAIC IS PARTNER AT LGA AND PARTNER-IN-CHARGE ON THE PROJECT.

The Canada Green Building Council’s annual conference, Building Lasting Change or BLC returns to Toronto June 5 and 6. Over two packed days, Canada’s green building sector will explore the latest developments, innovations and innovators. Tickets are available at cagbc.org/BLC.

From forums to discuss key issues, to compelling keynotes, panels, and a gala featuring the winners of the CAGBC Awards, Building Lasting Change attracts professionals from across the real estate spectrum. This year, the program offers two dynamic learning tracks covering business and technical perspectives. You can focus on one track or mix and match sessions to create a custom experience.

Dig into the latest decarbonization techniques with our Technical Pathways Track. We’ll cover successful approaches, important considerations and real-world results that drive down emissions for deep carbon retrofits and zero carbon design.

In the Day 1 Forum discussions, we’ll unveil the newest version of the Zero Carbon Building – Design Standard and dig into the meaty topic of LEED v5 with special guests from USGBC.

On Day 2, choose between session examining the benefits of combined embodied and operational analysis for whole-building life cycle carbon in MURBs or new technologies that make retrofits at scale achievable, among others.

If understanding how green building can impact your business, this track will highlight the business advantages of zero carbon buildings and their contribution to broader climate goals.

Don’t miss the Day 1 forum on Transition Planning to decarbonize existing buildings. Interested in the policy side of things? We’ll also explore opportunities for the market to support the implementation of federal green building policies and dig into the discussion on housing supply and affordability.

For Day 2, we dig into how the transition to a low-carbon economy offers both carbon-related risks (the cost of carbon, more stringent standards, and reporting requirements) and the opportunities (lower operating costs, onsite renewables, avoided costs). Our sessions will explore this from a financing and investment perspective and bring it to life with a real-world project.

Building Lasting Change keynotes will focus on how insights driven by global pressures can impacting Canada’s building sector. We kick off with CAGBC President and CEO Thomas Mueller highlighting where CAGBC is focusing in 2024. Thomas will be joined by special guests in a panel discussion on the critical trends shaping the green building sector at home and abroad.

On Day 2, JLL’s Head of Sustainability Services & ESG, Guy Grainger will share his global perspective on sustainability strategy in real estate, including the investor lens, the role of carbon and reporting standards. He’ll distill the global trends to provide insightful direction that applies to the Canadian building industry, before being joined by other industry thought leaders for a panel discussion.

Building Lasting Change is Canada’s green building conference, offering unparalleled opportunities to learn from local and global leaders in sustainability. But there’s more to experience at BLC. Take advantage of opportunities to connect with peers, build business relationships and celebrate Canada’s green building sector. Visit cagbc.org/blc to learn more.

The CAGBC’s Emerging Green Professionals (EGP) Executive Team is driven by a commitment to spearhead transformative change within the green building industry. The primary goal is to nurture the professional growth of students and young practitioners. They achieve this through educational programs, career development avenues, and networking events.

The EGP Executive Team recognizes the importance of fostering creativity and innovation within the green building sector. To achieve this, they organize dynamic design competitions that challenge members to think outside the box and come up with sustainable solutions to real-world problems. The Design Charrette competitions, taking place every fall, provide opportunity for collaborative multidisciplinary ideas at an early career stage.

Participating in EGP events unlocks a spectrum of advantages, including:

- Engaging Social and Networking Events

- Mentorship from Industry Experts

- Informative Educational Seminars

- Career Development Opportunities

- Dynamic Design Competitions

NETWORKING EVENTS:

One major advantage of being part of the growing EGP community is the opportunity to engage in social and networking events. These gatherings provide a platform for like-minded individuals to connect, share experiences, and build professional relationships. The green building industry is a changing and rapidly innovating landscape with a plethora of opportunities for collaborative work environments.

In 2024, the EGP Executive Team is creating opportunities for EGPs to meet other young professionals through relaxed social events throughout the year, and with industry professionals through our annual spring Mentorship Program.

EDUCATIONAL PROGRAMS:

The goal of the EGP Executive Team is to support the growth of green building professionals by offering educational programs that bring in experts from across the green building industry. These aim to equip EGPs with the knowledge and skills needed to make a meaningful impact in the sector. From webinars to interactive charrettes, the EGP Executive team provides a platform to empower members to stay up to date on industry trends, cutting-edge technologies, and sustainable practices. Keep an eye out for our Speaker Series Virtual Event in April!

The Emerging Green Professionals play a crucial role in shaping the future of the green building industry in Canada. As the driving force behind transformative change, EGPs embody the spirit of innovation and collaboration needed to create the next generation of green emerging leaders.

The Emerging Green Executive Team is committed to bringing networking and mentorship, education and design opportunities to young professionals. Joining the EGP community opens doors to a world of opportunities for young professionals aspiring to make a lasting impact in the green building sector.

Abiran Raveenthiran is the Vice President and Co-Founder of VxV Solutions Inc., a leading lighting controls and IoT/Ai building technology agency and integrator. He also serves as an Executive Member of the Canada Green Building Council’s Emerging Green Professionals Team.

Information: www.linkedin.com/company/cagbc-egp/

When it comes to limiting the amount of carbon emissions globally responsible for advancing climate change, the construction sector has a substantial role to play. Overall, construction is responsible for more than one-tenth of total carbon emissions around the world, and a large portion of this carbon footprint comes from the manufacturing of building materials such as cement, the second-most consumed material in the world after water.

Carbon emissions are an unavoidable byproduct of traditional cement production. This is because a core component of Portland cement – the most widely used cement today – is limestone. When this mineral is heated, the carbon trapped inside the limestone is usually released.

CCUS allows cement manufacturers to capture this carbon byproduct from points of emission within the manufacturing facilities or directly from the air. Such captured emissions can then be safely stored underground in geological formations, injected into concrete to strengthen it, or used to make other valuable products.

However, the past decade or so has seen significant advancements in methodologies for reducing carbon emissions in the cement production process. One of the most promising and rapidly growing methodologies is called Carbon Capture, Utilization, and Storage (CCUS), representing a suite of technologies designed to prevent the carbon dioxide that manufacturing processes produce from going into the atmosphere.

Several leading organizations, such as the International Energy Agency, the International Renewable Energy Agency, and the Intergovernmental Panel on Climate Change, have released long-term initiatives that rely on the expansion of CCUS to limit the global temperature rise to just 1.5 degrees Celsius. The IEA has also cited CCUS among the most cost-effective options for the decarbonization of carbon-heavy industries, many of which operate across the construction value chain.

Before outlining the specific CCUS methodologies that are gaining real momentum today, it’s important to clarify exactly how it works and the various ways it promises to lower the carbon impact of cement production.

Though CCUS has only gained widespread attention fairly recently, the technology has been achieving real results for several decades. In 1996, the first large-scale CCS project was commissioned at the Sleipner offshore gas facility in Norway. At Sleipner and Snøhvit, another leading project in Norway, over 20 million tons of CO2 have been safely stored to date.

Today, more than 30 cement CCUS projects are in different development stages worldwide, the majority of which are based in Europe. In the United States, the U.S. Department of Energy is currently conducting feasibility studies for multiple projects in California, Colorado, Texas, Missouri and Indiana, among others. However, much of the CCUS progress worldwide is taking place at the startup level, often thanks to collaborations with sustainability-focused venture capital firms.

In England, a startup called Carbon Clean has developed proprietary technology that captures carbon emissions from the flue gas that gets released through a cement plant’s smokestack. The technology is currently in use at cement facilities in several countries such as India and more recently Germany, where the goal is to standardize carbon capture and achieve cost-competitive carbon neutrality across so-called hard to abate industries before 2030.

This is just one of the myriad CCUS-related startups that has garnered considerable venture funding as of late, which reflects the increasing prioritization of sustainability in the global construction sector.

The biggest drawbacks to CCUS are the high upfront capital costs for the equipment to separate the carbon, the high energy costs of keeping the equipment running, and the costs related to transportation and safe storage of the captured CO2. According to a recent report from the U.S. Department of Energy, to cover these expenses a cement manufacturing organization would need to spend another $22 to $55 for every metric ton of cement produced.

Fortunately, in the United States, the Inflation Reduction Act offers tax credits of up to $85 per metric ton of captured carbon emissions. That’s a great start, but it doesn’t account for the additional costs of transporting and storing the captured carbon. Also, there’s the logistical issue of where to store all that reclaimed carbon if it is not reused. Companies that introduce CCUS need to have access to some kind of underground geological formation that’s capable of storing large amounts of carbon for centuries on end.

To counteract the increased costs of CCUS, many startups are developing cheaper and smaller carbon capture systems. For example, the simplified and ultra-efficient design of modular CCUS equipment is a considerable improvement over the expensive earlier systems and has the potential to make CCUS dramatically more accessible across the globe.

In addition, governments all over the world are issuing more and more grants for all sorts of sustainability initiatives in the construction sector, including CCUS. In August 2022, the Biden administration announced an investment of more than $96 million to support commercial carbon capture, utilization, and storage projects, and in Canada, the federal government launched the Energy Innovation Program - Carbon Capture, Utilization and Storage RD&D Call. Through this initiative launched in 2021, the Canadian government intends to invest CA$319 million over seven years in research, development, and demonstrations to advance the commercial viability of CCUS technologies.

Canadian start-up Carbon Upcycling is a great example of government support for the transition to net-zero emissions by 2050. Last year UK Research and Innovation (UKRI) awarded the startup £2.3 million to manufacture a climate-resilient cement alternative from waste glass and CO2 and in February 2023, Emissions Reduction Alberta (ERA) granted Carbon Upcycling CA$4.4 million for two commercial-scale projects within the Albertan construction sector.

Of course, CCUS is just one of many methodologies for reducing carbon emissions in cement manufacturing. Another strategy is producing cement with lower carbon content by replacing what’s called clinker – a key component of cement – with what are called substitute cementitious materials, or SCMs.

SCMs are typically by-products of industrial processes, such as waste from steel production or coal-fired power generation. SCMs can account for up to 50 percent of the cement that’s used to make concrete, which reduces carbon emissions from this process by up to 30 percent.

What’s more, numerous start-ups have developed their own technologies for converting waste from cement production into SCMs that can then be used by that same facility. These technologies could become particularly vital in the coming years, especially should SCMs become increasingly scarce.

Similarly, cement manufacturers can reduce carbon emissions even further by using alternative clean fuels, such as Spanish startup WtEnergy’s synthesis gas alternative, and renewable energy sources to heat the manufacturing process. In the solar energy sector, some startups have created technology capable of generating solar fuel that’s powerful enough to drive industrial processes like cement manufacturing or fuel production.

Now that CCUS and other decarbonization methods are becoming more accessible, it’s up to governing bodies to develop new policies and regulations that incentivize companies to invest in these technologies and for leading cement manufacturers to take the initiative in deploying and scaling promising start-up solutions. The Inflation Reduction Act is a significant step forward, but this is only the beginning of the incentives that manufacturers are going to need.

In all likelihood, the key to lowering the construction sector’s carbon footprint will come from uniting all stakeholders in the construction value chain around a common goal, which governments must support by fostering innovation.

ALFREDO CARRATO IS A TRAINED ARCHITECT, BIM ENTHUSIAST AND COLLEGE PROFESSOR WHO SCOUTS FOR BREAKTHROUGH DECARBONIZATION TECHNOLOGIES FOR THE CONSTRUCTION INDUSTRY. AS AN INVESTMENT AND OPEN INNOVATION ADVISOR, HE OVERSEES INVESTMENT ACTIVITIES AND PARTNERSHIPS AT CEMEX VENTURES, WITH A FOCUS ON TACKLING THE CARBON FOOTPRINT CHALLENGE OF THE CONSTRUCTION SECTOR.

1. Synhelion-solar-cement: Davide Zampini, Cemex Head of Global R&D holding the world’s first solar clinker.

2. Carbon upcycling: Carbon Upcycling's catalytic reactor onsite at cement production and ready mix facilities.