ISSUE NUMBER 76 | FALL 2022 | PM40024961 | $6 issue The PASSIVE HOUSE THE PUTMAN FAMILY YWCA Community neighbour combines energy efficiency and affordable housing THE KEN SOBLE TOWER EnerPHit transformation lights the way to new retrofit model 825 PACIFIC STREET ARTISTS HUB New residential space provides public amenity and top performance SOLO HOUSE Off-grid design a learning experience for larger projects

2 SABMag - FALL 2022

Centre Jean-Daigle – Edmundston, NB

GENTAS

façade interior

+ exterior ABCP Architecture © Photos

: Stephane Groleau

endless POSSIBILITIES 1-866-591-7021 EngineeredAssemblies.com info@engineeredassemblies.com G-Ext® exterior decorative panels brings compelling aesthetic and nearly limitless design possibilities to next-generation architectural claddings. With its smooth and non-porous surface, G-Ext® decorative panels are easy to clean and it takes longer to accumulate dirt and thus they are easy to maintain. Exterior Decorative Panels

SABMag - FALL 2022 3 6 10 12 15 16 21 28 33 40 46 News & Products Insurance Pricing for Mass Timber Buildings A comparison to concrete/masonry Builders are going to shape the future. Here’s how. Habitat For Humanity House A pilot project for modular, affordable housing The Ken Soble Tower EnerPHit transformation lights the way to new retrofit model The Putman family YWCA New community neighbour combines energy efficiency and affordable housing SoLo House Off-grid design a learning experience for larger projects 825 Pacific Street Artists Hub New residential space provides public amenity and top performance Hockey, Peacekeeping and HFO Carbon reduction innovation in closed-cell foam insulation Interview with Graeme Stewart Transforming one of the largest EnerPHit projects to date NEXT ISSUE WINTER 2023DON’T MISS WWW.SABMAGAZINE.COM For more about the articles in this issue! FALL 2022 21 16 28 8X on the Park LEED Gold tower makes rigorous commitment to detail Embodied Carbon in Buildings Vancouver puts theory to practice The 2023 Directory of Products and Services for Sustainable High-Performance Building Our annual Special Supplement … and more

4 SABMag - FALL 2022 THE HELIO BUILDING, a landmark of the West 5 community in London by Sifton Properties, is Canada’s fi rst mixed-use, multi-unit residential high-rise building to target net-zero energy. lbidner@inlinefiberglass.com 1.866.566.5656, ext. 226 CALL US TO DISCUSS YOUR NEXT PROJECT! Inline is honored to be part of the Sifton Properties experience where we were given the opportunity to work with the renowned Architect Firm of Diamond Schmitt Architects and master builders EllisDon where striving for a higher performance building envelope drives energy costs lower, occupants’ comfort higher and making a positive impact on our community’s future. Inline is onboard and helping to make it work! SPONSOR C A NADIAN GREENBUILD I N G AWARDS 2022 Architect: Diamond Schmitt Architects; Owner/Developer: Sifton Properties Ltd; General Contractor: EllisDon.

VISIT

Publisher Don Griffith 613-421-7588, dgriffith@sabmagazine.com

Editor Jim Taggart, FRAIC 604-874-0195, architext@telus.net

Senior Account Manager Patricia Abbas 416-438-7609, pabbas@sabmagazine.com

Graphic Design Carine De Pauw cdepauw@sabmagazine.com

Cadieux, lcadieux@sabmagazine.com

FROM COMMODITY TO COMMUNITY

In the run-up to municipal elections in British Columbia, voter surveys have confirmed that 40% of voters identify housing, homelessness and poverty as their greatest concern. Already a deeply entrenched problem in Vancouver and the Lower Mainland, this issue now transcends all demographics, ages and genders throughout the province and is grounded in the increasing unaffordability of housing everywhere.

With approximately 23,000 people experiencing homelessness in 2019, and 20% of renters spending over half of their income on housing and utilities – a figure that far exceeds the 30% considered ‘affordable’ by most lending institutions. These figures of course fail to recognize those people who have lost the battle and are sleeping in cars, tents or on the street.

Many of the candidates seeking election are promising to increase housing supply, reduce permit costs and shorten processing times; others are promising to ‘clean up’ the streets by introducing new bylaws to prohibit sleeping overnight in public places. For whatever reason, all of these measures ignore the root cause – the profound and growing income inequality we are now experiencing across Canada.

The latest figures from the Parliamentary Budget Office (which provides independent and non-partisan financial and economic analysis to govern ment) indicate that the top 20% of Canadian families have almost 75% of the country’s total wealth; the middle 40% have almost 25% of that wealth; and the bottom 40% Share the remaining 1%. While this disparity is less than that in the United Kingdom or the United States, it does make Canada the sixth worst in terms of income inequality among 17 peer countries with similar GDP per capita. Among those countries, it was New Zealand Prime Minister Jacinda Ardern, who first acknowledged publicly that ‘affordable housing is one of the greatest failures of Capitalism’.

The increasing concentration of wealth has emphatically debunked the neo-liberal myth that ‘a rising tide floats all boats.’ At best, it will create an Ark of sorts for the elite. Our salvation lies not in the tweaking of outdated policies and protocols, but in a wholesale reimagining of an economic system that has transformed housing from a community asset for everyone to a commodity exchange exclusively for the privileged few.

Jim Taggart, FRAIC Editor

SABMag - FALL 2022 5

www.sabmagazine.com

Subscriptions/Change of Address Lyse

Printed on EQUAL Offset paper. ISSN 1911-4230 Copyright by Janam Publications Inc. All rights reserved. Contents may not be reprinted or reproduced without written permission. Views expressed are those of the authors exclusively. Publication Mail Agreement #40024961 Return undelivered Canadian address mail to: Janam Publications Inc., 81 Leduc St., Gatineau, Qc J8X 3A7 Subscription prices for print [taxes extra] CANADA USA INTERNAT'L 1 year [4 issues] $28.95 $39.95 $84.95 2 years [8 issues] $50.95 $69.95 $148.75 3 years [12 issues] $74.95 $104.95 $219.85 order print or digital: https://sabmagazine.com/subscribe/ Published by www.janam.net 81 Leduc St.,Gatineau, Qc J8X 3A7 Dedicated to high-performance building SABMag is a proud member and official media partner of the Canada Green Building Council. Member Canada Green Building Council

photo: Roy Grogan

The RAIC Climate Action Engagement + Enablement Plan (CAEEP) Steering Com mittee is actively engaging the inter-pro fessional community in a collaborative and meaningful process to amplify and accelerate climate action by the architec tural community and within the built en vironment sector. The Steering Commit tee expands on the values outlined in the RAIC strategic plan, focusing specifically on counteracting climate change and miti gating the impacts of the climate crisis on people and communities.

The RAIC Climate Action Engagement and Enablement Plan is a national dialogue on accelerating design and construction for human, climate and ecological health. The underpinning principles for this plan include:

1. Embedding reconciliation in the ap proach by upholding the Principles of the

United Nations Declaration on the Rights of Indigenous Peoples

2. Embedding social justice in the approach

3. Adopting an ecological model of climate action communication in engagement

4. Employing a participatory and deliberative process

5. Employing best practices in climate communications including framing for hope and empowerment

6. Focusing on holistic health, human health, climate system health and ecological systems health

7. Embracing a multi-sectoral approach

8. Being regionally informed and internationally aligned

To enact change, human interventions across a complex ecosystem is needed.

The Climate Action Engagement + En

ablement Plan will focus on three key areas that shape the practice of architecture and in turn the built environment: education, practice, and advocacy.

The committee is supported by three working groups comprised of over 30 vol unteers, who together are developing a shared vision to inspire transformation as it relates to climate action.

Recent activities - At the 2022 RAIC Virtual Conference on Architecture, the CAEEP steering committee, alongside the RAIC Committee on Regenerative Environments, hosted two events, focused on significant discussion on climate change.

We encourage you to explore these re sources to learn more- RAIC Podcast on Architecture, Inspiring Commitment and Engagement to Climate Action, Towards a Climate Action Plan. raic.org

Correction: Anne of Green Gables Visitor Centre

In the article about the Anne of Green Ga bles Visitor Centre in the SABMag Sum mer issue we neglected to mention that the firm of Vollick McKee Petersmann & Associates Ltd. was the site design lead consultants on the team and responsible for designing and/or coordinating all exte rior site design aspects including building

siting, entry plazas and pedestrian linkag es, entry driveways and parking layouts, as well as all landscaping and various exterior visitor amenities.

The firm also specified/designed restora tion of site construction and civil services impacts. SABMag regrets the omission.

The PV pilot project, which began con struction in early 2021 with funding from Natural Resources Canada and Alberta Innovates, involved installing 1,900 so lar photovoltaic panels atop CF Chinook Centre spanning 53,000 square feet, ap proximately the size of three professional hockey rinks. Not only are those panels generating electricity, they are exporting excess energy back to the grid – a first for specialized secondary networks which supply power to dense urban settings in cluding downtown Calgary.

Most parts of Calgary's electrical system are capable of two-way power flow and customers are eligible for credits for elec tricity they export back to the grid. Up until now, that hasn't been possible for custom ers in high-density areas like some shop ping malls and downtown. ENMAX Power will continue monitoring and reviewing the results of the pilot this year with a goal to make the technology more available to customers on the secondary network going forward. mediaroom@enmax.com

PHPP is an easy-to-use, energy efficiency tool made for architects and planning ex perts.

Thousands of users have already benefit ted from this planning tool’s reliability and ease-of-use. While retaining its well-known Excel format, version 10 of this software now has a simpler look and an online flip book to replace the printed manual.

Explore new features and worksheets, in addition to revised external tools to facili tate data entry with secondary calculations. For returning users: upgrade your version 7, 8 or 9 PHPP at a discounted price!. www.passivehousecanada.com

6 SABMag - FALL 2022

NEWS RAIC Report

The Passive House Planning Package (PHPP) essential to PH design process

ENMAX Power and Cadillac Fairview's solar pilot project at CF Chinook Centre paves way for increased customer choice and lower carbon future

First digitally-printed cork tile provides more options for traditional, sustainable floor

Calgary-based Opus Floors has introduced Naturcork, the first, 24” x 36”, 8mm thick, digitally- printed, glue-down cork tile.

Designers have always appreciated the features and ben efits of traditional cork flooring but, when the “cork look” isn’t desirable, it limits its use.

Glue down cork floor tile has been in use for over 100 years, and at one time, had a strong presence in institu tional and hospitality settings.

With this introduction of digital printing technology on cork tiles, the market is no longer limited to the expected look of a cork floor, opening the door to wider use of this natural flooring product.

FPInnovations’ new Modelling Guide for Timber Structures will facilitate analysis and design of mid- and high-rise and long-span structures

FPInnovations has launched its new Modelling Guide for Timber Structure intended to facilitate the construction of taller and larger wood buildings. Developed in collabora tion with more than 100 experts from 13 countries, the Guide comprises a wide range of practical and advanced modelling topics, including key modelling principles, methods, and techniques specific to timber structures, modelling approaches, and considerations for woodbased components, connections, and assemblies.

It also provides analytical approaches and considerations for timber structures during progressive collapse, wind, and earthquake events.

Free downloadable copies can be obtained via web.fpinnovations.ca/modelling. Hard copies can also be ordered via FPInnovations’ Amazon library.

SABMag - FALL 2022 7

Sticks to Concrete Without Primer Fentrim 430 grey®

Visit SABMag's

of

Sustain-

Cat egory

LiteZone® Glass Inc.

Up to R17 for a window (in cluding glass and frame).

Up to R19.6 centre of glass. 60 year life. Award Winner for 2016 “CaGBC Product of the Year”.

VETTA Building Technologies Inc. triple-glazed wood windows and doors; High performance, Passive House and FSC certified; German steel hardware; All custom-made to your shape, size, colour specifications; and High grade anti theft and acoustic barrier performance.

Aqua-Tech Sales and Marketing Inc.

Provides the market with high efficiency products. LEED v4 Category for new construction for energy performance.

Daikin Applied

Designs and manufactures technologically advanced commercial HVAC systems for customers around the world. Our goal is to deliver superior air quality and energy efficiency to every solution with innovation in ad vanced technology, IoT, and next genera tion compressors.

ELKAY

Elkay filtered ezH2O bottle filling stations reduce lead and other harmful par ticulates, putting cleaner, healthier water within every one’s reach.

Artech Ceiling

Specialties

Provider of Lindner Metal Ceilings and Baffles for that “Over the Top” pop. Ideal for boutique areas, atriums, offices and schools. Also proven ceiling radiant for maximum LEED comfort and sustainability.

Century Wood Products Inc.

Operating since 1997, Century Wood Products re claims historic wood from vintage buildings for re storing or replicating that which is old, and to add character to new designs. We offer custom-milled antique solid wood floor ing, reclaimed timber and mantels, and antique hand-hewn and re-sawn boards for cabinets or millwork.

Dulux Paints

Operates the largest net work of company-owned paint stores across Canada. Our highly experienced team of account represen tatives provides specification and on-site support and we have the scale to deliver outstanding services to help you meet any of your design challenges

Fantech Specifying made simple.

models and CSI 3-part specifications make it easy to spec quality residen tial and commercial ventilation products providing a healthy indoor environment where people live and work.

Klimatrol Environmental Systems

Call Klimatrol now for assis tance on your next Radiant Floor Heating/Cooling or Snow Ice Melting project. Use our experi ence and products to select and specify a system that would provide years of com fort, energy savings and low maintenance.

Mitsubishi Electric Sales Canada Inc.

Designed specifically for the Canadian HVAC market, City Multi water-source sys tem provides optimum occupant comfort while substantially minimizing installation costs and energy consumption with it’s 2-pipe VRF technology.

Forbo Flooring Systems

Creating better environ ments… this statement re flects the mission and values of Forbo Flooring. From the indoor environment to the natural environ ment, Forbo’s products and services com bine design and functionality in world-class flooring solutions.

MAPEI Inc.

Over 375 products certified under SCS Global Services Indoor Advantage™ Gold for low VOCs, qualifying them for LEED v4, the WELL Building Standard, and the Living Building Challenge. MAPEI also provides environ mentally responsible products and trans parency through Environmental Product Declarations (EPDs), Manufacturers’ Inven tories (MIs) and more.

Acuity Brands

A market-leading industrial technology company. We design, manufacture, and bring to market innovative products and services that make the world more brilliant, productive, and connected including building management systems, lighting, lighting controls, and emergency lighting applications.

NTI Boilers

The NTI High Output Combi System offers the perfect bal ance between an on-demand combi boiler and a boiler with an indirect. All the advantages of a combi plus the advantages of a tank: Versatile, Easy to Install and Peak Performance.

RadiantLink

Connect your forced air heat source to RadiantLink. We create comfort, address in door air quality and reduce your carbon foot print. Infloor heating and passive infloor cooling is affordable with the RadiantLink system. Proudly made in Canada.

8 SABMag - FALL 2022

Directory

Sustainable Products and Services for

able, High-Performance Building [sab magazine.com/product-directory] where products are organized by Product

and by LEED Category. Examples of featured listings include: NEWS FOR SUSTAINABLE, HIGH-PERFORMANCE BUILDING CANADIAN DIRECTORY OF PRODUCTS AND SERVICES 22 sabmagazine.com/product-directory

BIM

AQUATECH™ delivers the market with high efficiency products. LEED v4 Category People. Solutions. Value.

SABMag - FALL 2022 9 DUXTON Windows & Doors 204.339.6456 duxtonwindows.com The future is FIBERGLASS Super low U-values Tough frames Beautiful aesthetics Passive house applications SHOWN HERE Fort St. John Passive House Low Hammond Rowe Architect RENU Engineering Inc. WCPG Construction Ltd.

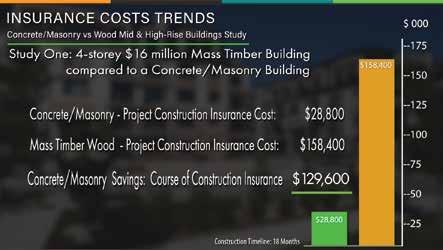

INSURANCE PRICING FOR MASS TIMBER BUILDINGS COMPARED TO CONCRETE/MASONRY

By Frank Came

By Frank Came

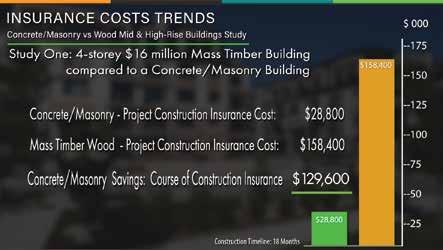

It has long been known that insurance costs for wood frame buildings are higher than the rate for comparable structures built with masonry, concrete, or other non-combustible materials. The cost differential could be seven to ten times higher for low to midrise wood buildings.

Questions have arisen as to whether the same pricing differential exists for ensuring taller buildings constructed with more advanced engineered wood products such as cross-laminated timber (CLT) or glue-laminated timber (glulam) are promoted as being more robust and more fire-resistant than concrete or steel.

Tall mass timber buildings, some approaching skyscraper heights, have been constructed in various parts of the world to demonstrate that building with wood can be faster, less costly, and more envi ronmentally friendly than comparable concrete or steel structures.

Extensive research has been undertaken to test the real-world performance of these structures in terms of resistance to extreme weather events and their ability to withstand fire or water dam age in times of emergency. In several jurisdictions, fire and build ing codes have been adjusted to accommodate the greater use of engineered wood products in the construction sector.

And while efforts have been made to have mass timber reclassified for insurance purposes as a building product distinct from conven tional wood frame construction, insurers have been doubtful about moving in this direction.

While it is accepted that tall mass timber structures repre sent a distinct segment in the construction market and that new technologies are involved, from an insurance perspec tive, the risk factors are viewed as higher than for buildings constructed with concrete or steel.

Recent research in the Canadian construction sector sug gests insurance the costs to insure tall wood buildings could range from five to seven times higher than for comparable structures built with non-combustible materials. Not only are premiums higher, but securing full coverage for mass timber structures is more complex, as underwriters are reluctant to assume total exposure to the risks involved.

The simple fact that wood burns and will continue to do so until extinguished introduces safety and property protec tion issues that must be accounted for. Despite tests dem onstrating that mass timber walls and beams provide fire resistance performance comparable to concrete or steel is of little consequence to underwriters.

Allowing a building’s occupants time to escape is essential, but from the underwriter’s perspective, the question is what happens beyond that escape window. Will the fire extend through compartment walls, service ducts or other spaces and consume different parts of the building, adding to the extent and costs of property damage? What measures are in place to extinguish fires, not simply contain them?

Case study one

A four-storey $16 million mass timber building constructed over 18 months. Coverage was priced as a wood frame project. The rate was 5.5 cents per $100 value per month ($8,800 per month x 18 months) which results in a total pre mium of $158,400 for Course of Construction insurance. By comparison, coverage for that same project if built with concrete would be at an estimated rate of .01 cent per $100 value per month ($1,600 per month x 18 months) totaling $28,800.

10 SABMag - FALL 2022

SPONSORED BY FRANK T. CAME AND ASSOCIATES

Case Study Two

This case involved a $120 million concrete build ing project which was insured at 1.1 cents per $100 value per month for 18 months for a to tal premium of $237,600. A comparable mass timber building insured at 5 cents per $100 value per month for 18 months would cost over $1,080,000. For the mass timber comparison, however, it is unlikely that one would get a 5 cents rate on such a large project, especially since it would need several insurance companies to participate in the project to fill the full $120 million project limit. Currently, very few firms par ticipate in the wood frame construction industry let alone mass timber. Of those firms that do par ticipate in wood projects, only a few would be comfortable with a 5-cent rate.

These issues are difficult to quantify, and the gold en rule of insurance is that you cannot insure what you can’t quantify. Factors influencing the pricing differentials go far beyond the combustibility is sue. Mass timber buildings involve new technolo gies in building materials and designs, as well as just-in-time construction methodologies and skill sets that are not as widespread as conventional construction methods.

While underwriters will look at combustible void protection, fire suppression and extinguishment measures, they will also look at water exposure risks not only from fire fighting but also from flood and extreme weather perils. Indeed, water dam age remains the most significant risk factor affect ing insurance pricing, followed by risks of damage from fire, extreme weather events, or other inci dents such as earthquakes.

Other factors considered are the scale of the build ing and the extent of material damage to property or from business interruption exposure; design features that could affect access or egress and the spread of water; and the location of the build ing relative to first responders’ capabilities. Also considered by underwriters are the track records of building contractors or property managers in building construction and post-construction op erations.

The high costs to repair, remediate, or deconstruct wood structures partially damaged by fire or wa ter are of particular concern to insurance provid ers. While masonry and concrete structures are relatively easy to assess, processes to verify the structural integrity and other features of mass tim ers are costly, time-consuming, and sometimes inconclusive.

The fact that wood building projects are more vulnerable to all these risks has prompted some insurance companies to vacate or severely limit their involvement in the wood frame or mass timber markets. This is why most wood construction projects require multiple insurers, each limiting their risk exposure.

Risk exposure policies of the world's major reinsurance companies are also influenced by losses arising from natural or artificial disasters. In ‘harsh mar ket conditions, local insurance companies have little flexibility to circumvent these industry-wide policies, which contributes to the need for many insur ance companies to be involved in providing coverage for tall wood construc tion projects.

To sum up, insurance is based on indemnifying against risks. Risks and un certainties are not the same. Uncertainties stem from a lack of knowledge, and reducing risks involves reducing those doubts. Pricing insurance cover age is based on the probability that certain risks will not occur.

The more significant the chances that such risks will happen, the higher will be the premiums. In this regard, ensuring tall mass timber structures cur rently involves more uncertainties than conventional construction. Hence premiums will continue to be higher.

Mass Timber Buildings are a niche design practice in today’s construction market, but they are evolving. The trend in several countries suggests more tall timber projects will rise over the next decade. What the next genera tion of projects will look like depends on what designers and other industry stakeholders can and will do to resolve the insurability and the many other issues discussed in this article.

Download the Full Study at: https://www.edchats.ca/fullstudy

References: The findings are an update of research undertaken by Globe Advisors in 2016 entitled Study of Insurance Costs for Mid-Rise Wood Frame and Concrete Residential Buildings. Frank Came was the Project Director for the original study.

SABMag - FALL 2022 11

FRANK CAME, PRINCIPAL, FRANK T. CAME AND ASSOCIATES, AN INDEPENDENT CONSULTANCY BASED IN BRITISH COLUMBIA.

BUILDERS ARE GOING TO SHAPE

THE FUTURE. Here’s how.

By: Chris Ballard

We are pleased to participate in the Passive House issue of SABMag. Builders, and the building industry, have a crucial role to play in the struggle to adapt to and mitigate the effects of climate change, and I foresee that Passive House is going to play a big part in addressing that struggle.

Our built environment is a major contributor to climate change. In large urban areas, emissions from buildings contribute over 50 per cent of green house gas (GHG) emissions, and over 30 per cent globally. As governments set ambitious targets to reduce GHGs, builders are going to be increasingly called upon to deliver higher performance buildings.

At the same time, Canada is grappling with a national housing crisis. In Ontario alone, the provincial government has promised no less than 1.5 million new homes by 2031. We know we can’t build our homes to previous standards because of climate change – and governments at all levels are beginning to insist new buildings be built to increasingly high-performance standards. Still, it’s those on the ground — architects, contractors, skilled trades and developers, as well as lenders — who will ultimately become the gatekeepers for better, low energy consumption builds.

Industry players are key to educating homeowners and the public as to the standards that will deliver on the promise of high-performance buildings that achieve net-zero or near net-zero carbon without relying on carbon off sets or renewable energy add-ons. We see “green” standards everywhere, and there are numerous claims as to the efficiency of each.

While I’m not here to make claims for or against other standards, I will say that “green washing” is a major problem — and not just our industry. Still, it is an issue we need to address head on, and tackle collectively, through education and verification.

There are, currently, enormous burdens on our power grids. As extreme weather events esca late, our cities and towns face ever greater risks of blackouts and grid failures. We need to enter this into the equation and build homes that will reduce those burdens by ensuring cooling and heating loads are minimized through good design and construction. We need buildings that can keep people safe and comfortable at home, even in the event of power outages, or extreme heat and cold. Passive House provides one such solution. The alternative is stark. Take, for instance, the horrify ing situation arising from B.C.’s 2021 heat dome, which caused the deaths of 619 people.

People in our industry are often stymied due to the very simplicity of the Passive House standard, be cause it advocates for passive energy consumption — through airtight building envelopes, superior ventilation, and other passive conservation tech niques. Buildings that consume far less to heat and cool than the average home, rather than more, can be a difficult concept to grasp, but that is precisely what Passive House delivers.

12 SABMag - FALL 2022

Photos left to right: The Putman Family YWCA, 825 Pacific Street Artists Hub, and the Ken Soble Tower, all Passive House projects profiled in this issue of SABMag.

We now have nearly 50 years of science-driven data to back up these claims, and Passive House has been recognized as the standard to meet for affordable, high-performance buildings.

And, as our industry moves further into discussing the role of operational carbon and embodied carbon, Passive House is like wise evolving. The Passive House community can employ a new PHRibbon tool that helps calculate embodied carbon over the life of the building, a tool which also models future increases to average temperatures.

Passive House Canada is likewise poised to support the build ing industry, as financial institutions and governments more and more make investment decisions based on Environment, Social and Governance (ESG) policies of the developer, and of its de sign, engineering and construction companies. Passive House is perfectly suited to address the “Environment” in ESG, and we would be delighted to explain how.

Resilient buildings which keep people safe and comfortable should be the norm, not the exception, and that is precisely where I want to leave this thread. As builders, you have enor mous power to transcend building policies and their real-world impacts. Get educated. If you haven’t already been trained and certified in Passive House, I urge you to do so. If price is an is sue, know that government grants are available, and we offer competitive pricing for Passive House members.

Become an advocate of better buildings. Educate your clients, your manufacturers, and your government. Insist on high perfor mance projects that live up to their promise — not just in five years, but in 25 or 50. Finally, I urge each of you to simply build better. We’ll all feel better, and live better, for your efforts.

www.passivehousecanada.com

SABMag - FALL 2022 13

CHRIS BALLARD IS A FORMER MINISTER OF BOTH HOUSING AND ENVIRONMENT AND CLIMATE CHANGE FOR ONTARIO, AND IS CURRENTLY THE CEO OF PASSIVE HOUSE CANADA, A NATIONAL NON-PROFIT PROFESSIONAL ASSOCIATION THAT ADVOCATES FOR HIGH-PERFORMANCE BUILDINGS USING THE PASSIVE HOUSE STANDARD.

14 SABMag - FALL 2022 Custom Made for Net Zero & Passive House Builds Leading Canadian supplier of high performance triple-glazed, alu-clad wood windows & doors photo: @habitstudio vettawindows.com @vettawindows 416 234 1033 Proud to help Ken Soble Tower in its ground-breaking Passive House certification, achieved partly through our AlphaGuard™ liquid applied roofing system. www.tremcoroofing.com 1-800-363-9879 Tremco Roofing is part of Tremco Construction Products Group 1/4tremcosabmag.indd 1 2022-10-19 1:51 PM SUBSCRIBE TO THE SABMAG E-NEWS https://sabmagazine.com/newsletter Subscribe to the SABMag monthly e-news to stay informed of news and events in Canadian sustainable design, of new releases of SABMag and the CAGBC FOCUS publications, the Canadian Green Building Awards, and more.

HABITAT FOR HUMANITY HOUSE

A pilot project for modular and sustainable affordable housing

By Joe Scrocco

The Willowdale Street house in the County of Brant came about from a telephone call which Makers (https://makers.to/), a Toronto-based Producer col lective, received from Habitat for Humanity asking for help with a campaign launch in the Brant Norfolk region. In response Makers went further by creating Project Upstart, a modular and sustainable affordable housing system in collaboration with Habitat for Humanity, the County of Brant, The School of Architecture at Waterloo and architectural firm PH43, who specialize in Passive House design.

SPECIAL THANK YOU TO:

Many skilled and knowledgeable volunteers and these companies:

- Better Bin Company for garbage disposal and recycling/repurposing

- Ark Electric - Hunter Plumbing and Excavating

- East Elgin Concrete - Simple Life Homes

- Jackson Roofing - Turkstra Lumber - Town & Country - Fantech

- Moduloc Fencing

- Franke Kindred

- B.N.C. Crane Service

- CleanShot

- Home Depot

- AMA Drywall

- Ferrell Builders Supply - Fraser Locksmith

- Grandbridge energy - VerBeek kitchens

- VETTA Windows

The design utilizes prefabricated components for much of the construction. This approach lowers the cost of materials and sim plifies the building process for Habitat volunteers, who are mostly non-trades people.

The placement of the house on the Brant County lot was care fully considered to maximize the seasonal solar gain, and to use the sun strategically to heat and cool without the need of air conditioning. With an airtight and thermally efficient envelope, along with high-efficiency appliances, heating demand should be reduced by up to 75% for an energy bill of between $11 and $25/month.

The Upstart house on Willowdale Street is a pilot project for the Habitat Heartland Ontario Brant-Norfolk Chapter; a chance to try a new building process and learn from the experience. It’s also the first time Habitat for Humanity has built to Passive House standards in Canada.

The home sits close to the Grand River and the Brantford Conservation Area on a 1,000-square metre lot. Its location in a residential neighbourhood, within walking distance to schools, parks, and a grocery store, helps a family become part of the community around them.

Such low demand will allow the home to be powered by electric ity while still reducing the overall operating cost of the house significantly. Should PV modules be installed in future, the lower energy demand means a significantly smaller solar array.

The walls are double stud 2x8 and 2x4 construction; the panels include cellulose insulation. In future projects blown-in cellulose (an 80% post-consumer recycled newsprint) will also be used in other areas throughout the home. Either way, the wall assembly far exceeds standard building code practices while also creating a healthier, more comfortable and quieter interior.

JOE SCROCCO IS DIRECTOR OF BUILD SERVICES, HABITAT FOR HUMANITY HEARTLAND AND BRANT NORFOLK CHAPTER.

SABMag - FALL 2022 15

THE KEN SOBLE TOWER

EnerPHit transformation lights the way to new retrofit model

1

1. The renovated tower offers a built example to improve dramatically the performance of the thousands of similar apartments across North America. The AlphaGuard™ liquid-applied roofing system by Tremco Roofing helps to maintain the integrity of the building envelope.

By Graeme Stewart

By Graeme Stewart

The project is not only the first such retrofit in North America but, at 18 storeys and more than 7500 m2, it is one of the largest EnerPHit1 certified projects in the world. In the Canadian context, it is also arguably the most successful to date in meeting the goals of the Federal government’s National Housing Strategy Repair and Renewal Fund.

The modernization of the building has rein stated 146 units of affordable seniors’ hous ing, while reinvigorating community spaces and outdoor gathering areas, enabling agingin-place throughout, and barrier-free living in 20% of suites.

1EnerPHit is the Passive House standard for retrofits, a rigorous European certification for net-zero-ready construction focused on occupant health and comfort. In meeting this standard, the total annual heating demand is less than 25kWh/m2 and the total annual primary energy demand is less than 155kWh/m2, as per the Passive House energy model.

16 SABMag - FALL 2022

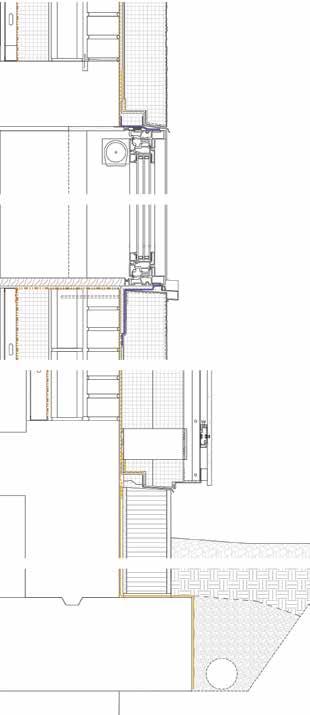

SABMag - FALL 2022 17 3 2 2. The tower location on the Hamilton waterfront. 3. The original tower built in 1967. Ground floor Floor plans 1. Main entrance 2. Transformer room 3. Moving room 4. Electrical room 5. Boiler room 6. Vestibule 7. CACF 8. Office 9. Lobby 10. Mail delivery 11. Garage room 12. Universal WC Rooftop solarium Typical floor plan 1 2 34 5 6 7 8 910 11 12 13 14 15 16 17 18 19 19 20 21 22 23 23 24 24 2424 24 24 13. Recycling 14. Community room 15. Laundry 16. Storage 17. Community garden 18. Accessible terrace 19. Green roof 20. Solarium 21. WC 22. Garage room 23. One bedroom 24. Studio

4 Background

The Ken Soble tower was originally constructed in 1967 and by the start of this project had fallen into a state of disrepair and was uninhabitable. One of the considerations at the outset of this project was whether to demolish the existing structure and build new, or to complete a retrofit and restore the building to a ser viceable condition, consistent with today’s standards of durability and performance.

Ultimately, the team decided to retrofit which extended the life of the existing building’s cast-in-place concrete frame and part of the existing masonry envelope. The environmental impact and embodied carbon of the original construction were not wasted, nor unnecessar ily duplicated in a new building. Through the Passive House level retrofit, the ongoing operational carbon emissions were drastically reduced and will support an extended service life.

Retrofit Strategies

Operational carbon reductions are achieved using a high-performance envelope, with nearly twice the insu lation value required by Code, drastically reducing heating and cooling demand. The envelope upgrades include R-38 effective over cladding, passive-house cer tified windows and air sealing details to achieve 0.6ACH @50Pa airtightness.

4. Deterioration of the existing brick-clad envelope was remediated prior to the addition of a new façade which con sisted of a fluid-applied air barrier, an Exterior Insulation and Finish System (EIFS) comprising 6” (150mm) of noncombus tible mineral wool insulation, and a synthetic stucco finish.

5. The finished façade with new Juliette balconies. EJOT® CROSSFIX® stainless steel thermal clip brackets in the facade system help to maintain thermal performance.

Modernization diagram 146 units of modernized affordable seniors’ housing Reduction of greenhouse gas emissions Designed for a changing climate 20% of units barrier free

5

The project also focused on improving daylight, views, and fresh air. The existing window openings were enlarged to provide expansive views from each suite. New fiberglass, triple-glazed windows are operable in tilt and turn modes and allow generous outside air and passive ventilation. To control solar heat gain, low SHG coatings were applied on the south, west and east-facing windows; and metallic-backed low-emissivity roller blinds were installed.

To improve ventilation, an innovative best-in-class system of direct suite ventilation, exhaust, filtration, and heat recovery was installed, ensuring clean and fresh air. The Energy Recovery Ventilators are complete with MERV-13 filters to remove airborne pollutants. Interior comfort modelling was conducted using projected 2050 climate data to ensure healthy and comfortable environments in extreme summer and winter conditions. In winter, models demon strate that the robust envelope can maintain indoor temperature for

days following a power outage—as compared to the four hours required by the Ontario Building Code.

The building can accommodate future on or off-site renewable

loads. The total Energy Intensity

the completed retrofit is 70.3kWh/m2/year, which is an 84% reduction over the pre-retrofit measured data.

SABMag - FALL 2022 19

four

electrical energy generation to offset grid

for

Wall detail 1. AWB Flashing 2. Polyurethane Z-Girt 3. Silicone Transition Strip 4. Fiberglass Window 5. Roller Shade 6. Vapour Barrier 7. Helical Tie 8. Fiberglass Angle 9. Galvanized Steel Girt 10. Cladding clips 11. AWB Flashing 12. Polyurethane Thermal Break Z-Girt 13. Concrete-Board Faced XPS Insulation 14. Drainage Plane 15. Fluid Applied Bituminous Waterproofing 16. Weeping Tile 1 2 3 4 5 7 8 3 9 10 11 12 13 14 15 6 6. The modernisation included new landscaping to improve outdoor amenity space. 6 PROJECT CREDITS OWNER/DEVELOPER City Housing Hamilton ARCHITECT ERA Architects GENERAL CONTRACTOR PCL Constructors LANDSCAPE ARCHITECT ERA Architects ELECTRICAL ENGINEER Nemetz & Associates MECHANICAL ENGINEER Reinbold Engineering STRUCTURAL ENGINEER Entuitive Corp COMMISSIONING AGENT CFMS West Consulting Inc PASSIVE HOUSE CONSULTANT JMV Consulting PASSIVE HOUSE CERTIFIER Herz & Lang Gmt BUILDING ENVELOPE CONSULTANT Entuitive Corp PHOTOS Doublespace Photography SABMag - FALL 2022 19

Achieving the EnerPHit certification required the combined knowledge and collaboration of the entire design team. The most important decision was the selection of low-embodied energy, highly durable and highly insulating building envelope materials (including mineral wool-based EIFS rather than the typical foam-based products). Materials were selected based on long-term durability and their overall lifecycle cost, both monetary and in terms of carbon footprint.

Conclusion

The decision to retrofit the building, rather than build new, gave the project a significant carbon benefit from the outset, although the overall impact was uncertain. The situation became clearer when subsequent modelling indicated that the embodied carbon deficit created (had the original building been demolished and replaced with a new one) would have taken 180 years to recover through operating energy savings alone. Clearly, retrofitting existing buildings has a significant role to play in the creation of a low-carbon future.

GRAEME STEWART IS A PRINCIPAL AT ERA ARCHITECTS.

7. Interior comfort modelling demonstrated that in winter the robust envelope can maintain the indoor temperature for four days following a power outage—as compared to the four hours required by the Ontario Building Code.

8. The existing window openings were enlarged for improved natural lighting and views. New Passive Housecertified fiberglass, triple-glazed windows with operable tilt and turn modes maintain envelope performance and allow generous ventilation.

Dynamic thermal comfort through cooling

R38 Effective Envelope

Glazing with a low Solar Heat Gain Coefficient

Low emissivity interior shades

Ceiling fans to circulate air within units

Lightly tempered air delivered through a centralized ventilation system

Decentralized cooling ‘boost’ through a Variable Air Volume

activated by in-suite controls

20 SABMag - FALL 2022

0 1 2 3 4 5

7 8

0.

1.

2.

3.

4.

5.

Unit

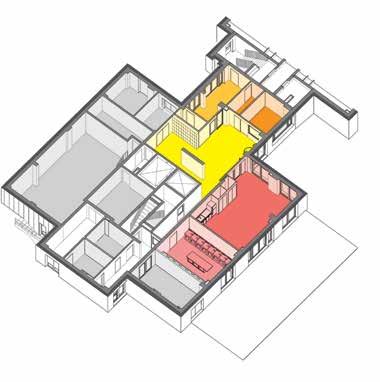

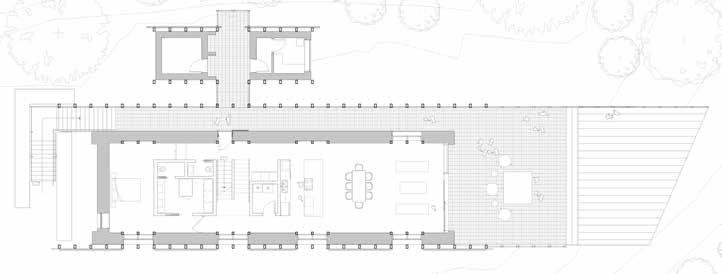

1. The south elevation. During the design and construction process, the energy performance of the building was assessed to ensure that it would achieve Passive House certification, which provides 90% thermal energy savings and reduced greenhouse gas emissions of nearly 40%.

THE PUTMAN FAMILY YWCA

New community neighbour combines energy efficiency and affordable housing

By Irene Rivera and Esther Van Eeden

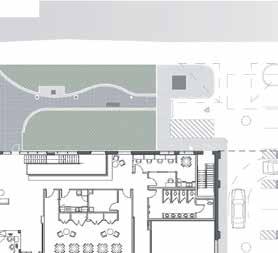

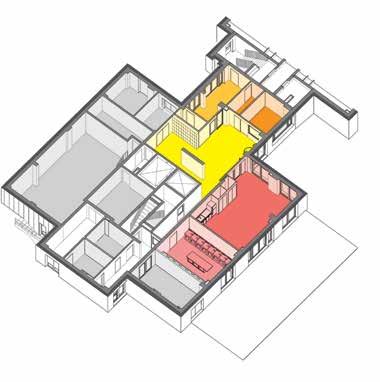

The Putman Family YWCA is Hamilton’s first affordable housing residence for women and children. The six storey building comprises four floors of apartment units above a ground floor and basement podium that opens to a community garden on one side. The interconnected ground and basement levels provide community services to residents and the greater community, while the. sixth floor provides community and amenity spaces for residents.

Of the 50 apartment units, 15 were reserved for women living with developmental challenges. Priority for all units was given to women from marginalized and Indigenous communities who have experi enced domestic violence and homelessness.

Designed to fit naturally into the city’s artistic Crown Point commu nity, the building breathes new life into the disused site of YWCA’s swimming pool. Using local materials and manufacturers where possible, the project aspired to reflect the tradition and aesthetic of Hamilton as a Steel Town. The brick clad podium mirrors the scale and materiality of the surrounding buildings and creates a tangible, visual connection between the streetscape and the community pro gramming offered by the YWCA.

SABMag - FALL 2022 21

1

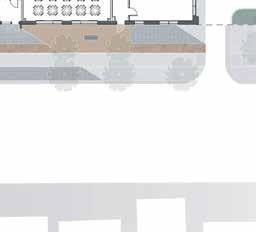

Site plan N

1. Resident and community reception

2. Open seating area

3. Senior's centre

4. Community centre auxillary space

5. Administration

6. Multi-purpose

7. Community garden

8. Long term bicycle storage

9. Moving and receiving

10. Elevators

11. Parking

12. Resident entry

13. Community entrance

In 2021, rent prices in Hamilton skyrock eted more than 14%, leaving many with the impossible choice of either paying for shelter or paying for food. Hamilton’s waiting list for social housing is over 6,000 people. Women face unique bar riers in securing safe and affordable housing and are the most vulnerable to homelessness. Safe and secure hous ing provides a haven for many women and children, where they are protected from abuse and given the ability to start dreaming of a brighter future.

The decision to pursue Passive House certification is consistent with that of other providers of supportive housing across the country, as it significantly reduces operating costs, while provid ing a high level of indoor environmental quality for residents. These attributes align with the YWCA’s core mission to provide comfortable, healthy, secure, resilient, and safe housing for women.

Construction Approach

The YWCA wanted a robust building constructed of a secure material that would signify strength and a place of safety for the community they serve. They also wanted to create a build ing whose material expression reflected its location in a historic manufacturing town. Cast in place concrete was initially considered, but discarded in favour of precast when the manufacturer dem onstrated it could meet all the design requirements with the added benefits of precast construction.

22 SABMag - FALL 2022

02 46 10

8 6 2 3 5 4 19 12 13 13 1110 2

SABMag - FALL 2022 23 2. The Putman Family YWCA meets the organization’s core mission to provide comfortable, healthy, secure, resilient, and safe housing for women. 3. The building is a prefabricated total precast concrete construction, including the exterior finishes as seen with the “corduroy” dark slate textured precast concrete finish on the north and west elevations. 4. The building recovers 85% of its heating and cooling from the ERVs, which also provide constant HEPA filtered fresh air for a high level of indoor environmental quality. 3 4 PROJECT CREDITS CLIENT YWCA Hamilton ARCHITECT/ARCHITECTE Kearns Mancini Architects Inc. STRUCTURAL ENGINEER RJC Engineers CONTRACTOR Schilthuis Construction Inc. PASSIVE HOUSE CONSULTANT Kearns Mancini Architects Inc. PRECAST CONCRETE SUPPLIER Coreslab Structures (ONT) Inc. PHOTOS Simon Tingle, Craft Architecture Photography (photos 1, 3 and 5), Industryous Photography (photos 2, 4 and 6) DRAWINGS/ DESSINS Kearns Mancini Architects Inc

Principles of

Energy recovery ventilator

heat

In addition to the psychological benefits offered by concrete, it is an extremely durable material that provides superior defense against material degradation caused by weather and other bio logical conditions. A further benefit was that the Hollow core prestressed floor elements allowed for a much lower depth to span ratio, minimizing the volume (and hence weight) of concrete per unit of floor area.

The unique total precast system satisfies thermal, airtightness and structural criteria whilst providing a robust, aesthetic façade in one factory-built component. Additionally, using a precast concrete system from a local manufacturer reduced the use of traditional formwork, auxiliary elements, and eliminated waste.

In turn, factory prefabrication reduced erection times and required only a single crane and a flat bed truck. As a result, truck idling, traffic congestion, construction site emissions and site lighting requirements were all reduced; as were noise, pollution and other environmental impacts on the surrounding community.

Prefinished

Sloped

caulking

High

Resilient

Precast

evelope

Precast

Precast

Self-adhered

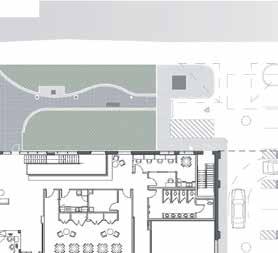

24 SABMag - FALL 2022 Scale: Project number: Drawn by: Checked by: Project : Drawing Title: Ref. Number: 1 : 10 PCO#17 18−022 AG RS Parapet Typical Detail A: Roof to wall junction Detail B: Floor slab to wall junction 1. Stale air exhaust on top level 2.

(ERV) with heat exchanger 3. High performance window 4. Solar

gains through glazing 5. Vertical supply and return air circulation 6. Fresh air intake on top level 7. Supply and extract air in each suite 8. Thermal bridge free junction 9. Continuous air tight layer and thermal insulation building envelope

Passive House 8 7 6 2 1 3 4 5 9 A C B

parapet flashing secured to continuous locking strip on the front and back and over termination bar on the backside Continuous locking strip Overlay board

air barrier membrane

insulation: 2% sloped to drains: thickness varies Base layer insulation Vapour retarder layer on primer surface to carry up onto concrete parapet 200mm and

back 15mm onto base insulation

concrete wall structure

concrete slab roof structure; seal all joints with air barrier membrane tape Panel

and backing Backer foam

strength non-shrink grout Self-adhered air barrier membrane tape behind baseboard

baseboard 9mm resilient flooring

concrete hollowcore slab

5.

SABMag - FALL 2022 25 5

The west elevation. The building orientation was determined by the site location, height

and

program area required. Triple-glazed windows were sized according to their orientation using passive design strategies. Detailing to maintain the thermal performance of the envelope includes the use of SIGA tapes Fentrim 430 grey around the windows, Fentrim 230 grey on

the bolt

connections,

Fentrim 20 (or IS20) at building

envelope joints, and Wigluv on the ground floor and on the elevator roof. Detail C: Ground plane/slab/wall junction Blind side foundation waterproofing membrane Armatherm insulation Exterior pavement Precast concrete panel Stainless steel flaching with backing for expansion concrete anchor Aluminum flashing caulked into reglet Brick finish from formliner in precast concrete panel Panel caulking and backing Backer foam High strength non-shrink grout Self adhered air barrier membrane tape behind baseboard Resilient baseboard 9mm resilient flooring Self-adhered air barrier membrane Precast concrete hollowcore slab

Building Performance

The building recovers 85% of its heating and cooling from the ERVs, which also provides constant HEPA filtered fresh air. The building’s total energy use is 130 kWh/m2/year based on a treated floor area of 3,463m2 totalling 233,782.7 kWh/a. The building recovers 85% of its heating and cooling from the ERVs, which also provides constant HEPA filtered fresh air.

The Passive House Planning Package (PHPP) is divided into residential and non-residential components. The breakdown is:

• YWCA residential (2,485m2) 70.7 kWh/m2/year;

• YWCA non-residential (978m2) 59.4 kWh/m2/year.

Internal heat gains from electrical sources add heat to the space. Any additional heating and cooling that may be required is provided through variable refrigerant flow (VRF) heat pumps.

The building is airtight and low tech, its orientation having been deter mined by its location on] site, its height and the program space required. Windows were sized optimally according to their orientation using pas sive design strategies. High efficiency ERVs (energy recovery ventilators) are used to meet the minimal heating and cooling requirements, Heat demand is 14.85 kWh/m2 and cooling demand is only 7.45 kWh/m2 based

on the treated floor area. As the energy use inten sity (EUI) and emission factor from hydroelectricity is so low it takes very little to offset any emissions from this building.

Life-cycle performance was considered for all build ing components and systems, with the precast concrete structure having an anticipated 100-year service life. The high quality construction required to achieve Passive House performance also con tributes to durability. Some of the other materials have a 50-year warranty. However, should user needs change, the precast concrete system, being demountable, reusable, and having a high loading capacity, lends itself to alteration

26 SABMag - FALL 2022 6

6. The new building occupies the site of the former YWCA swimming pool and was designed to fit into the city’s artistic Crown Point community.

IRENE RIVERA IS AN ASSOCIATE ARCHITECT, AND ESTHER VAN EEDEN IS DIRECTOR OF HIGH PERFORMANCE BUILDINGS, BOTH WITH KEARNS MANCINI ARCHITECTS IN TORONTO WITH KEARNS MANCINI ARCHITECTS.

SABMag - FALL 2022 27 QUALITY GUARANTEE ENERGY EFFICIENT MADE IN CANADA JELD-WEN ® IS PROUD TO BE THE 6X ENERGY STAR ® CANADA MANUFACTURER OF THE YEAR FOR WINDOWS & DOORS, WITH BACK-TO-BACK WINS IN 2021 & 2022. AWARD-WINNING ENERGY EFFICIENCY Visit jeld-wen.ca to view our full line of ENERGY STAR® certified products.

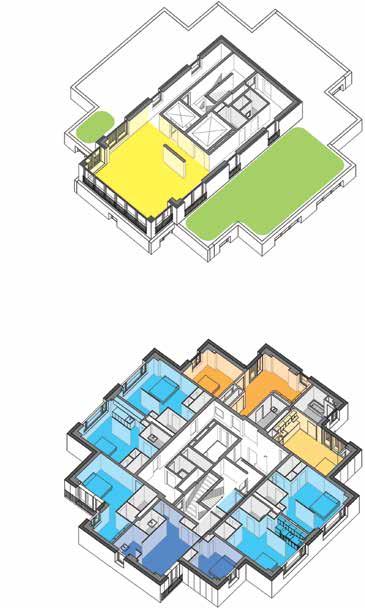

SOLO HOUSE

Off-grid design a learning experience for larger projects

By Aik Ablimit, Alysia Baldwin and Cillian Collins

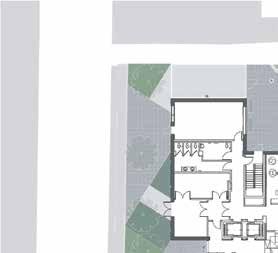

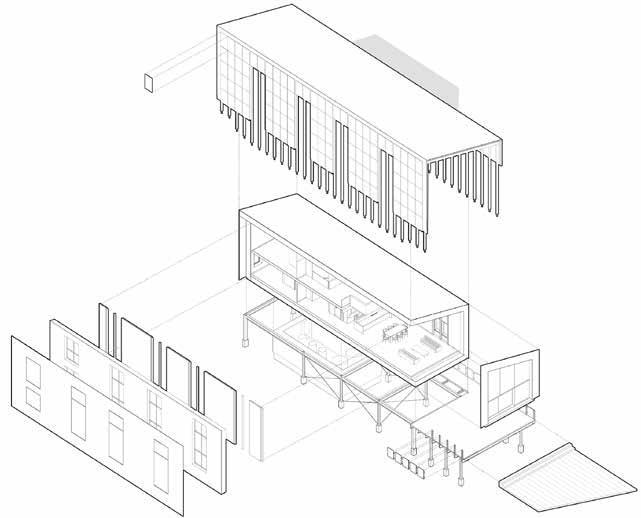

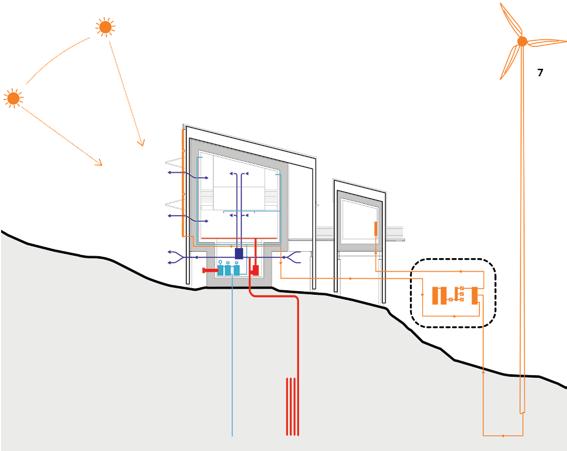

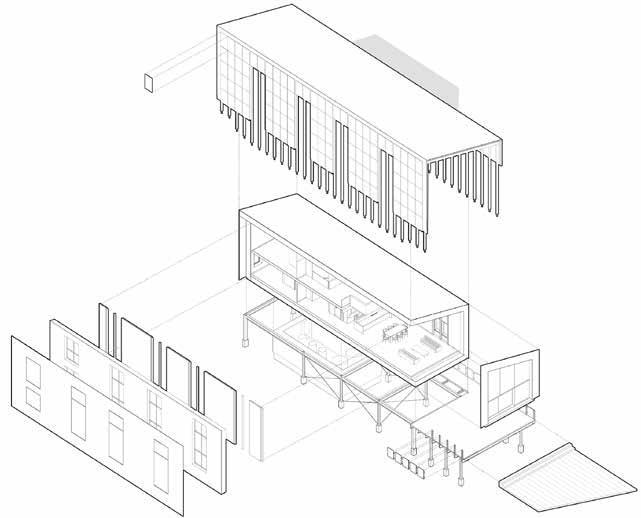

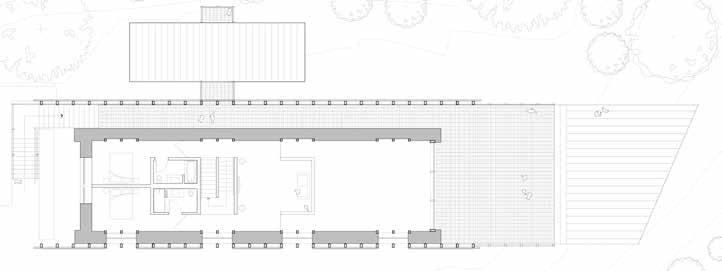

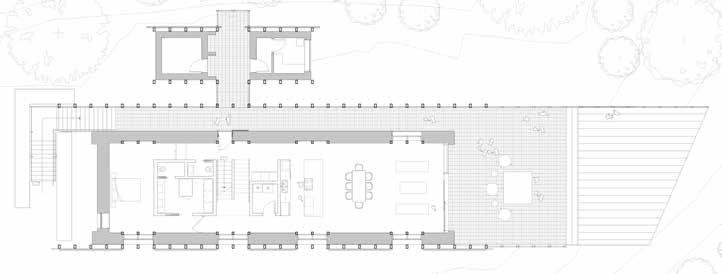

SoLo house is a 380m2, self sufficient, off-grid home with a 40m2 ancillary building, sitting lightly on a forested knoll overlooking the spectacular Soo Valley north of Whistler in the Coast Mountains of British Columbia. Reflecting the client’s expressed intention to 'set a new benchmark for environmental performance, health and well-being’, SoLo is not a typical alpine home.

Rather, we designed a prototype that demonstrates a unique approach to building off-grid in a remote environ ment where every choice has consequences. Challenging conventions in both aesthetics and construction, the pro totype acts as a testing ground for low-energy systems, healthy materials, prefabricated and modular construc tion methods, and independent operations intended to inform the approach to larger projects.

28 SABMag - FALL 2022

1

Living Design

Natural Ventilation

High Efficiency HRV

Well

Geothermal

Battery Storage

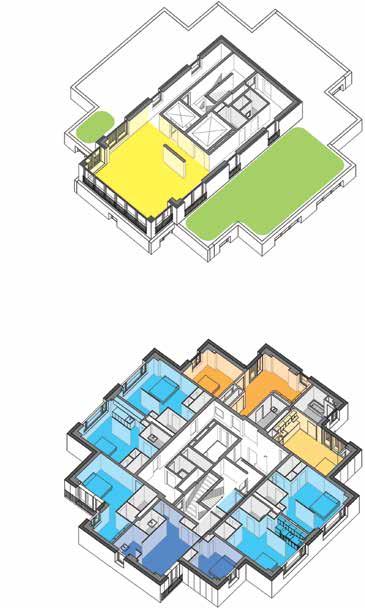

Turbine

The house includes living space and a master bedroom suite on the main level; linked to a sauna and storage space in the adjacent ancillary building. The upper level includes two more bedrooms and two bathrooms.

Given the valley’s extreme climate, it was critical to have an ‘enclosure-first’ approach to ensure energy efficiency and outstanding comfort. With the goal of Passive House certification, we devised a two-layer solution to the enclosure: an outer heavy timber frame acting as a shield to resist the weather, and the heavily insulated inner layer acting as the thermal barrier.

To ensure the house functions with exceptional thermal performance and air tightness, we conducted detailed thermal modelling of each weather condition. With the addition of double-height glazing opening the home up to the valley’s incredible views, SoLo has achieved

Low Energy Building Certification.

Setting the home on a light structure above the uneven terrain minimized site disturbance.

The remote location of SoLo House in the Coast Mountains of British Columbia.

SABMag - FALL 2022 29 2

PHI

1. PV 2.

3.

4.

5.

6.

7. Wind

1 2 3 4 5 6 7 1.

2.

Building systems

As an ‘off-grid’ home, a number of sys tems are required for operational inde

With the goal of eliminating fossil fuels and combustion, we incor porated a photovoltaic array and a geoexchange system, with a hydrogen fuel cell for backup energy storage. The fuel cell is used when there is no winter sun or when peak use exceeds

Although it reduces efficiency, the site’s topography, along with the snow accu mulation in winter, led us to mount the 32kW array vertically on the south façade.

Complementing the home’s solar gen eration, we provided future provision for wind power. In addition, the house col lects and treats its own drinking water and processes its waste water.

30 SABMag - FALL 2022 Building assembly 1. Standing seam metal roofing 2. Glulam columns 3. 19mm x 140mm 4. 1070mm x 1700mm PV modules 5. Steel structure platform 1 2 35 6 7 8 9 1110 6. Dowel laminated timber (DLT) 7. Mineral wool insulation 8. Weather barrier 9. Passive house certified curtain wall 10. Glass guard 11. Timber deck addition 3 4

pendence.

battery capacity.

3. Prefabricated modular building elements delivered to the site enabled quick erection and minimized building site waste. 4. The envelope consists of two layers: an outer heavy timber frame to resist the weather, and the heavily insulated inner layer acting as the thermal barrier.

Gabion retaining wall

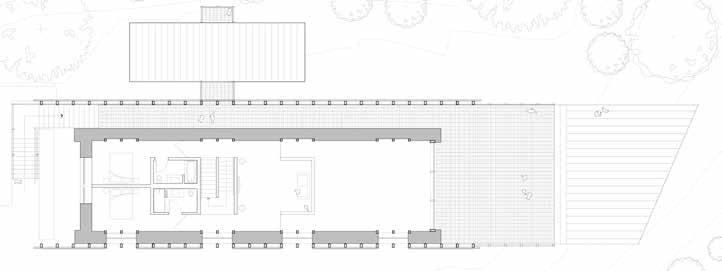

Exterior stair

Covered platform

Storage

Sauna

Belvedere

Entry

Master bedroom

Master bathroom

Powder room

Laundry room

Kitchen/dining

Living space

Outdoor deck

Timber deck

Bedroom

Bathroom

Loft

Stair

Open to Below

SABMag - FALL 2022 31 1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 16 17 18 2019 Main floor Loft level floor Floor plans N Passive House Wall Assembly Partial elevation of south wall Passive House Wall Assembly 1. DLT (dowel laminated timber) 2. Air barrier - vapour permeable 3. 600mm mineral wool insulation filled between TJI supports 4. 38mm x 89mm Strapping with mineral wool insulation 5. Moisture/weather barrier 6. 130mm x 128mm glulam columns 7. Support railing and clamps 8. 1070mm x 1700mm PV panel module 9. Triple-pane Passive House certified window 1 23 4 9 8 7 6 5

To address the challenges of the remote location and short seasonal construction window, we commissioned local builders to prefabricate modular building elements off-site. This enabled quick erection of the building in the summer season, while minimizing deliveries of materi als and equipment and the generation of construction waste on the site. This strategy also reduced the overall embodied carbon footprint of the project.

We minimized site disturbance by setting the modu lar prefabricated home on a light structure above the uneven terrain, reinforcing its relationship to the site as a 'visitor', and allowing nature to remain the primary focus. Contributing to the local economy, we ensured that all timber cleared on the project site fed into the local for est industry.

Simple Aesthetic / Superior Performance

The performance-led approach resulted in a building that is both authentic and unsentimental. Focusing on the essential characteristics, the home embodies a simple aesthetic through its restrained material palette and refined architectural expression. The interior features only six materials with Douglas fir celebrated throughout as both structure and finish.

With a commitment to promote health and well-being, we purposely chose materials that were reviewed against our Precautionary List rounding out our holistic approach to sustainability by eliminating harmful substances.

As a Passive House project, the goal is to mitigate energy loss and create outstanding interior comfort through building envelope performance. A study undertaken as part of the design process at our Vancouver studio focused on the role of thermal bridging on performance and its mitigation through good detailing. As a result, a detailed thermal bridge calculation protocol and workflow was developed and applied to benefit the project.

Incorporating low-energy systems, healthy materials, prefabricated and modular construction methods, and independent operations, SoLo is an off-grid home that challenges prevailing conventions in both aesthetics and construction. Our intention is to apply the les sons we have learned on SoLo to our larger projects.

AIK ABLIMIT, AIA, NCARB, CPHD, LEED AP® BD+C, RELI AP; ALYSIA BALDWIN, ARCHITECT AIBC, CPHD, LEED AP® BD+C; AND CILLIAN COLLINS, MRIAI, CPHD, LEED® AP BD+C , ARE ALL WITH PERKINS&WILL.

32 SABMag - FALL 2022

PROJECT CREDITS OWNER/DEVELOPER Delta Land Development Ltd. ARCHITECT Perkins&Will STRUCTURAL ENGINEER Glotman Simpson Consulting Engineers MECHANICAL AND ELECTRICAL ENGINEER Integral Group GENERAL CONTRACTOR Durfeld Constructors BUILDING ENVELOPE CONSULTANT RDH Building Science CODE CONSULTANT GHL Consultants PHOTOS Latreille Photography

5 6 5. The home embodies a simple and refined aesthetic with Douglas fir celebrated throughout as both structure and finish. 6. The open riser stair.

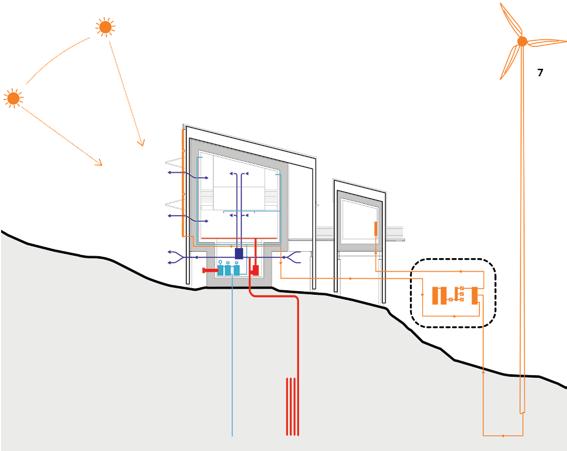

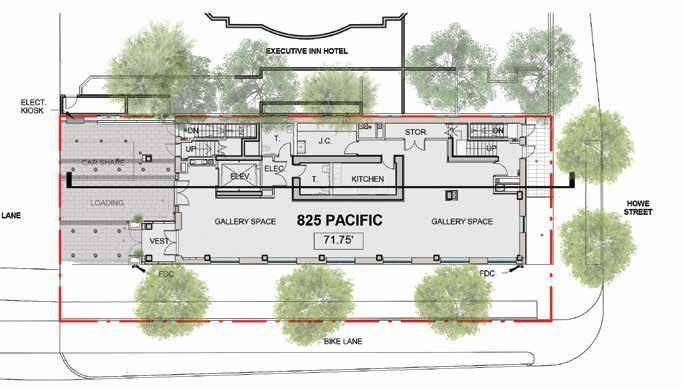

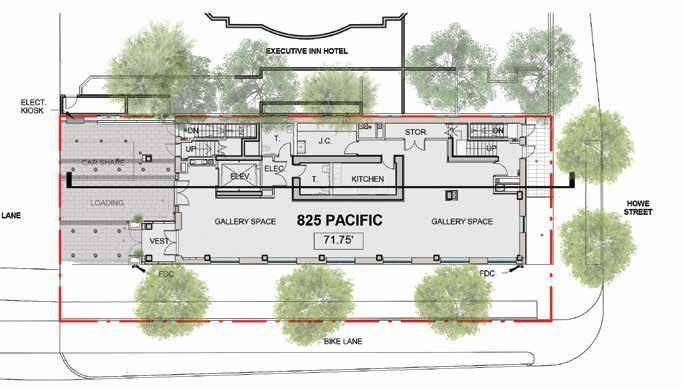

825 PACIFIC STREET ARTISTS HUB

New residential space provides public amenity and top performance

By Padraig McMorrow

production

With more than 2,000m2

exhibition

and offices, 825 Pacific provides a vital injection of dedicated artist space into the City of Vancouver. The tallest Passive House building in Vancouver, 825 Pacific represents the Community Amenity Contribution

made by the developer to the City of Vancouver, in exchange to permit the construction of rezoning an adjacent property for a high-rise residential tower. Because the City would take over the project, it was required to be constructed to the Passive House standard.

SABMag - FALL 2022 33

1 1. The just over 2,000 m2 all-electric, near-zero-emissions building offers gallery space, affordable production studios, and office space for non-profit organizations in the city.

of affordable

spaces, independent studios,

space

The seven-storey building stands next to the his toric Leslie House, one of the oldest remaining single-family homes in Downtown Vancouver. To acknowledge the small scale and cultural impor tance of its neighbour, the ground floor of 825 Pacific, which will be a publicly accessible gallery, is set back to create a small entrance courtyard between the two buildings.

This is a core and shell project, with only the washroom and storage areas on each floor enclosed; the remainder awaiting subdivision by the tenants.

The structure of the seven storey plus basement building comprises con ventionally reinforced concrete walls, columns, floor slabs and roof slab.

The stair cores located at the rear of the building provide the necessary lateral resistance.

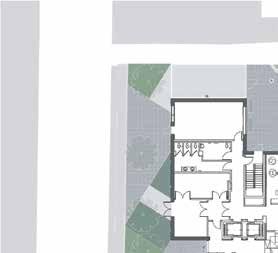

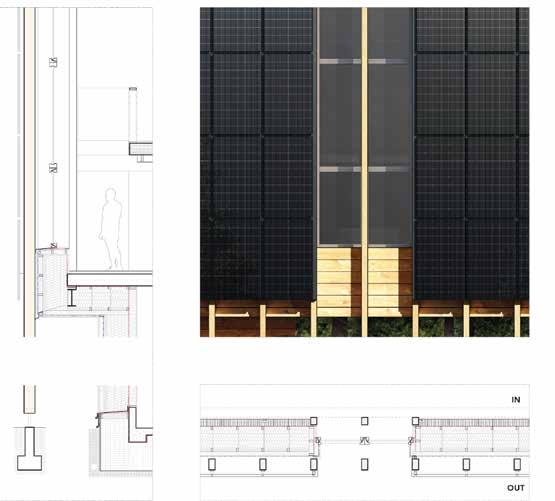

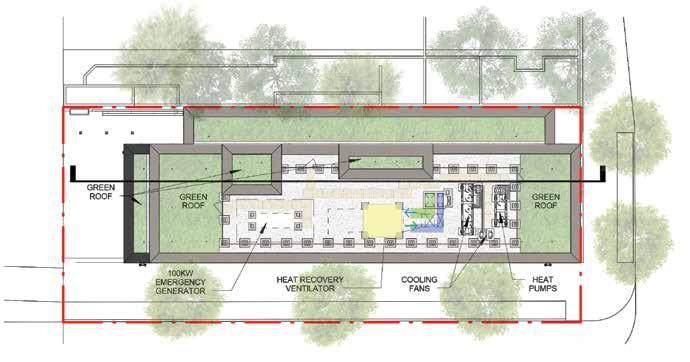

Site plan

Roof plan

34 SABMag - FALL 2022

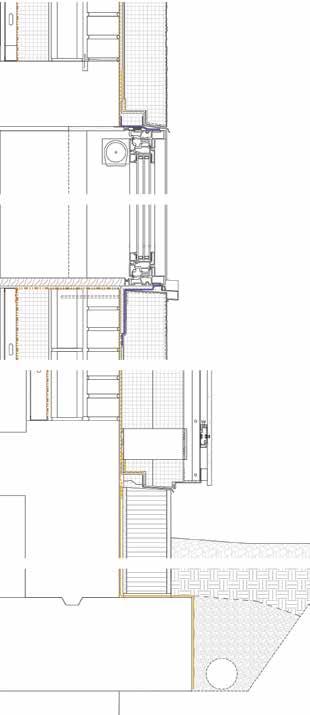

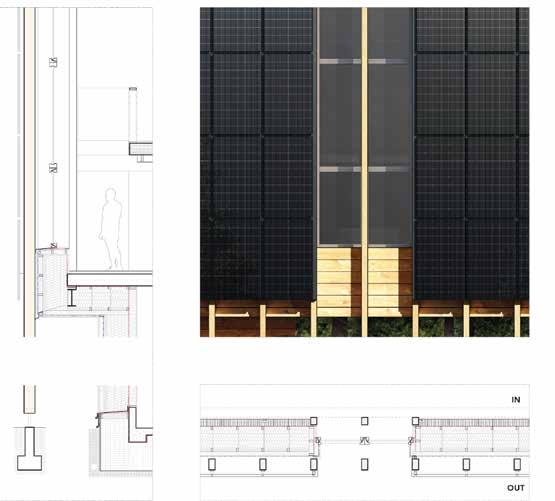

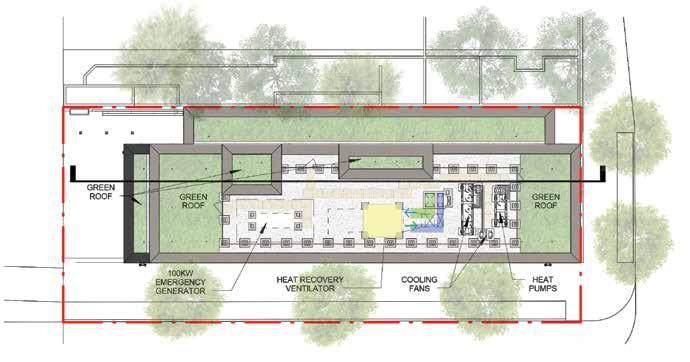

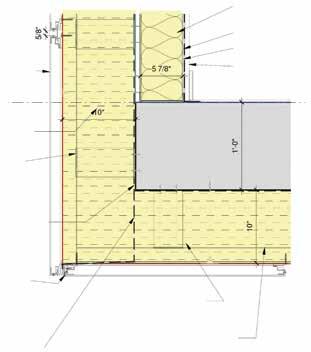

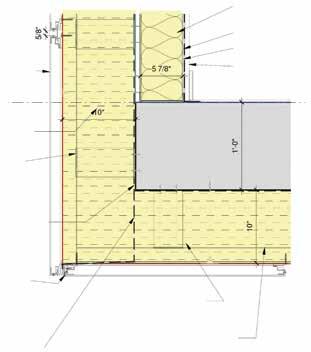

Envelope

The slab on grade and basement walls are insulated with 125mm expanded polystyrene (XPS) which provides an effective thermal resistance of R-27. The roof, with 230mm of XPS laid on the slab, provides an effective thermal resistance of R-43 for the green roof. The ground floor concrete walls are insulated with 203mm mineral wool, which provides an effective thermal resistance of R-32.

The walls of the upper floors are steel stud with 152mm mineral wool batt insulation between the studs; with an additional 203mm of continuous semi rigid mineral wool insulation, supported by the thermally broken stainless steel brackets used to secure the metal cladding.

This wall assembly provides an effec tive thermal resistance of R-44. To miti gate thermal bridging, heavy gauge studs were used to reduce the number of brackets required; together with non-metallic through wall flashings.

SABMag - FALL 2022 35 2. Three shades of metal panels create a dynamic exterior pattern, and staggered windows from one floor to another contribute to the rhythm of the facade. The overall effect is that of a pixelated beacon to attract the public. EJOT® CROSSFIX® stainless steel thermal clip brackets attach the facade to the building structure to maintain thermal performance. Building section 100 kw emergency generator Mechanical, electrical, commnications and elevator room Bike facility change rooms and showers Heat recovery ventilator Outdoor VRF condensing units for space heating/cooling Outdoor heat pumps for domestic hot water heating Hot water tank Domestic hot water piping Smoke exhaust for basement PROJECT CREDITS DEVELOPER Grosvenor Group OWNER City of Vancouver GENERAL CONTRACTOR Ledcor Group ARCHITECTS ACDF Architecture and Arcadis IBI Group BUILDING ENVELOPE CONSULTANT AND ENERGY MODELLER Morrison Hershfield STRUCTURAL ENGINEER Dialog MECHANICAL AND ELECTRICAL ENGINEER Integral Group 2

Air moisture barrier

8" thermal clip

Vertical girt supported from floor slab above to allow for deflection

Engineered continuous steel angle

Prefinished drip flashing to match metal panel PH certified universal series window

Typ green roof assembly Roof assembly

8" rigiddrainageinsulation mat

SPS roofing membrane

Air moisture barrier

Section detail at window

Aluminum composite metal panel

8" mineral wool

EJOT® CROSSFIX® stainless steel thermal clip brackets

Air moisture barrier wrap concrete slab

Drip flashing concealed

Section detail at soffit

Membrane to tie into drip flashing using mineral wool as backing

Thermal clip

10" mineral wool soffit insulation

3/4"ply window box Vapour barrier

Peel and stick air barrier continious around plywood window buck

1" semi-rigid insulation Window sill

3/4" ply window box

R22 batt insulation

SPS to underside of window stud

6" steel stud

GWB Vapour barrier

R22 batt insulation Vapour barrier 6" steel stud GWB

36 SABMag - FALL 2022

Exterior

Interior

SABMag - FALL 2022 37 CROSSFIX® creates a thermal break separating the interior of the building from the exterior. Its unique design features reduce thermal transfer through the building envelope and slows down heat transfer. Compared to competition, it achieves better R-values and results in faster ROI. www.ejot.com/crossfix CROSSFIX® increases energy efficiency Comfort, Well Beyond the Standards GET A QUOTE : nzpfenestration.com HIGH PERFORMANCE DOORS & WINDOWS Made in Canada Passivhaus Certified

The exterior wall assembly includes a transparent self-adhesive membrane that serves as both air and vapour barrier, and is adhered to water resistant gypsum cladding that has a glass matt facing. Joints were sealed with silicone. The inverted roof assem bly includes a reinforced elastomeric bitumen (SBS) membrane, torch-applied to the concrete slab.

The exterior walls include both fixed and opening tri ple-glazed Passive House certified fibreglass-framed windows, with an overall window-to-wall ratio of 18%. The insulated window units have two low-emissivity coatings, reducing the solar heating coefficient and minimizing cooling loads in summer. To further reduce thermal bridging, the windows are mounted outside the steel studs; almost entirely within the thickness of the exterior rigid insulation layer. The frames are secured at the corners using insulated mounting brackets. This assembly gives the windows an effective overall U-value of 0.89 W/(m²K).

Building Systems

As an all-electric, near-zero-emissions core and shell project, the building has a centralized ventilation system that that uses one Passive House certified Energy Recovery Ventilator (ERV) mounted on the roof. Sensible heat recovery is in excess of 86% when exterior temperatures are between -7oC and 25oC, and a latent heat recovery efficiency of 84% at -7oC and 71% at 25oC. Ventilation air is delivered from the ERV to a variable refrigerant flow (VRF) fan coil unit (FCU) on each floor.

Heating and cooling are supplied by a VRF system that allows for simul taneous heating and cooling if required in different zones of the build ing. Two rooftop condensing units serve the upper and lower halves of the building respectively; with multiple smaller units installed on each floor to serve future suites. These units have three settings, so that vari ous levels of demand can be met with the highest possible efficiency. The basement is heated with electric baseboard heaters, but is not equipped with a cooling system.

The energy consumption on each floor is measured by a separate submeter, with each system (ERVs, condensing units etc.) also measured separately. Domestic hot water for the common area washrooms and utility sinks on each floor, is heated by two low ambient temperature heat pumps mounted on the roof. These high efficiency units are capable of delivering hot water at 60oC at exterior temperatures as low as -12oC.

A final Note

Although the project was tendered using a CCDC 2 Stipulated Price contract, Ledcor had been retained on a design-assist basis to offer advice on construction details and sequencing necessary to achieve Passive House performance. Some members of the design and construc tion team also took the British Columbia Institute of Technology (BCIT) Passive house Tradespersons course. This approach is increasingly com mon in British Columbia as the virtues of collaboration in the design and construction of high-performance buildings become more apparent.

C M Y CM MY CY CMY K

PADRAIG MCMORROW ARCHITECT (IRELAND) MRIAI, CPHC, ASSOCIATE – MANAGER, ARCHITECTURE ARCADIS IBI GROUP VANCOUVER OFFICE.

3

3. The building uses an electric air source heat pump to efficiently deliver domestic hot water heating, along with space heating in the winter and cooling in the summer. A heat recovery ventilator, with a sensible heat recovery efficiency of just over 86%, filters indoor air ensuring optimal air quality.

Windows + Doors for Passive House Projects

SABMag - FALL 2022 39

Ask us how we can help achieve your airtightness, energy-efficiency and durability targets. Innotech Windows + Doors is a Canadian manufacturer of high-performance windows and doors. We deliver the product performance and manufacturing expertise required to achieve vigorous energy-based building standards.

COMING SOON: THE PEAK IN VANCOUVER, BC Passive House Multi-Family Project by Cornerstone Architecture and BOLD Construction.

Architectural Rendering by Cornerstone Architecture innotech-windows.com

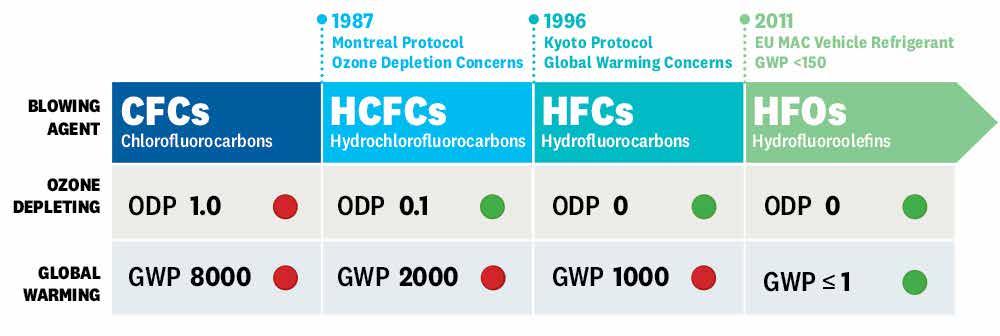

HOCKEY, PEACEKEEPING AND HFO

Carbon reduction innovation in closed-cell foam insulation

By Rocky Boyer

Canada has been a leader in two of the most important and influential global topics for the past 60 years—Peacekeeping and Hockey.

While these two subjects are still important to its identity, Canada is now emerging as a world leader in the sustainability, climate change, and resiliency movement.

Some key facts about Canada is that it has the second largest land mass in the world (9.9 million m2), is ranked as one of the coldest countries in the world, but what may come as a surprise is that Canada accounts for only 2.0% of annual fossil fuel emis sions (Figure 1).

As Canadians, we are blessed with approximately 900 million acres of forests with each 2.5 acres of forest absorbing six tons of CO2 per year. While the country benefits from the natural carbon sequestration systems, Canada’s government and its citi zens are working hard to reduce emissions even further. One of these major carbon reducing actions falls within the construction industry and, more specifically, thermal insulation.

Thermal insulation, whether traditional or high performing, all require energy and fuel to extract, produce and transport. Only when this insulation is installed in a thermal application (not acoustic or aesthetic) can the energy and carbon savings occur. I define traditional insulation as insulation that uses trapped air (batt insulation) for its thermal performance, and high-performance insulation as insulation that uses trapped gas (sprayed polyurethane foam, board stock foam) for its performance in conjunction with an air, or air/vapour retarder system.I hear all the time, although not technically correct, that “insulation saves energy!” Not all insulation reduces energy consumption when you consider products such as acoustic panels or aesthetic tiles.

40 SABMag - FALL 2022

Figure 1: Annual CO2 Emitting Countries

Insulation has the potential to save energy and car bon when installed in an application where there is resistance to the transfer of heat provided by a heat source. This article will focus on the carbon reduc tion innovation within the closed-cell foam insulation market which includes spray polyurethane foam insulation and board stock, as this is the area where we saw the biggest technological advancement in the insulation industry in decades.

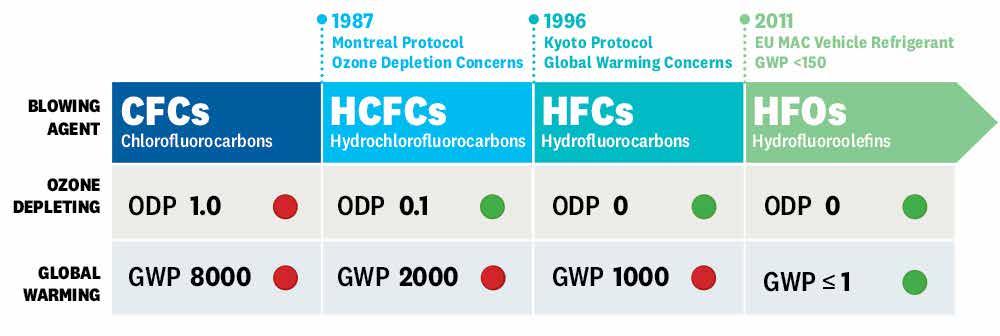

To understand the innovation and advancement in high performing insulations, we must dive into the evolution of the main component—blowing agent gases. The first-generation blowing agent gases used in thermal insulation were very effective and had high R-value potential. The downside of these agents was their negative environmental impact. The CFCs (chlorofluorocarbons) had an ODP (Ozone Depletion Potential) of 1 and a startling GWP (Global Warming Potential) of 8000. A GWP of 8000 is essentially 8000 times worse than the environmen tal impact of carbon dioxide.

In the fall of 1987, the Montreal Protocol was signed into existence. This protocol was signed by all 198 UN member states, banning nearly 100 man-made gases and chemicals from manufacturing and use. These substances were banned because of the detrimental impact to the stratospheric ozone layer.

The outcome of the Montreal Protocol on the high-performance insulation industry was a move to using HCFCs (Hydrochlorofluorocarbons) as blow ing agents to achieve thermal performance. The newly regulated HCFCs reduced the ODP from 1.0 to 0.1, however the GWP limit was still listed at a very high number of 2000 despite the drop from 8000.

Unlike the Montreal Protocol, the Kyoto Protocol was adopted in the Winter of 1997 and was designed to reduce greenhouse gas emissions and potentially curve the impact of climate change. The environmental limits for the blowing agents under the Kyoto protocol include having an ODP of zero and a maximum GWP of 1000. In the 10-year period since the Montreal Protocol, ODP was reduced from 1.0 down to zero and the unacceptably high GWP went down to a reasonable 1000.

In 2021, Environment Canada banned the use of HFCs to help with cli mate change and to reduce the impact of fluorinated gases in the atmo sphere. The new requirement in Canada stated that any refrigerant gas must have a GWP of 150 or lower. Today, the majority of blowing agents used for spray foam in Canada have a GWP of 1 (Figure 2). Board stock thermal insulation (XPS) has a GWP of less than 150 and can easily meet the strict requirements set out by Environment Canada.

Thermal insulations that utilize refrigerant gases have significantly reduced their overall environmental impact due to the new blowing agents, how ever, there are other insulation industries that have not followed suit. Traditional insulations used in both residential and commercial applica tions, such as fiberglass and mineral wool are manufactured through the energy produced from coke and/or coal, natural gas, and electricity to melt glass or rock up to 2000°C. Since the byproduct from burning of coke and coal or natural gas is carbon dioxide (GWP 1), there is no cap under these requirements due to the equivalency.

SABMag - FALL 2022 41

Figure 2: Historical use of blowing agents in thermal insulation

The benefit of using any type of thermal insulation in build ings to reduce heat transfer is that all insulations will save much more carbon during the buildings use-phase than the amount of carbon generated from manufacturing. As an industry, there must be a greater focus on the transpor tation, application scenarios, use phase and end of life of each product to have a better understanding of the true environmental impact.

EPDs (Environmental Product Declarations) are a valuable tool to assist designers in selecting singular products to fulfill their project needs, however they do not take into consideration the full system performance. A great reallife example is that closed-cell foam insulation (and some open-cell foams) can be used as a thermal layer, moisture barrier, air barrier, and a vapour retarder, whereas fibrous insulation cannot. Additional control layers such as mois ture barriers, air barriers and vapour retarders may be installed in conjunction with the fibrous insulation. These additional layers will have a significant impact on the over all carbon footprint of the enclosure due to their asphaltic, or polyethylene-based composition.

Transportation of construction materials is another impor tant area to consider. For insulation, it is quite intensive on the environment due to the consumption of petroleum to deliver these products. In addition to petroleum, there are other factors that may contribute to the overall impact, such as wear and tear on the delivery vehicles, plus the increase of delivery vehicles on roads that can cause traffic slowdowns, noise pollution, mental health risks, and the list goes on.