RIDING THE TIDE

The man behind ScaffFloat’s success: An exclusive interview with MD Toby Budd

ALSO FEATURING: HMS VICTORY, THE SCAFFOLDING TRANSFORMATION OF HISTORY’S MOST FAMOUS SHIP

Scaffolding gets smarter: Avontus set to take the industry to the next level

64

REGULARS

6 NEWS ROUNDUP Working at height regulations face the scrap, NASC launches SG4:22, construction workers and scaffolding instructors are needed, plus much more.

12 COMPANY NEWS

A rundown of company news from within the industry, featuring Millcroft and JMAC.

17 EVENTS & AWARDS

Star-studded NASC Annual Ball & Awards 2022, plus Scaffolding Championships news.

18 INTERVIEW

Daniel Norton hears how ScaffFloat’s Toby Budd is making a splash in the access system world.

23 INTERVIEW

David Brown, the youngest ever NASC President, on his vision for transforming the scaffolding sector.

FEATURES

26 SOFTWARE

With a focus on software development, Daniel Norton discovers the Avontus Designer program and Avontus Viewer

30 26

app; Carl Sharley reflects on a decade of SafeTime®; and ScaffPlan’s Simon Boyes takes a look at laser scanners and point cloud data.

36 WOMEN IN CONSTRUCTION

Des Moore discusses diversity and inclusion in the scaffolding industry.

42 THE BUSINESS

Billy Jones on 50 years of Millcroft; Chadderton’s Rose System Scaffolding; and Ideal Scaffolding of Surrey.

52 PRODUCTS & SERVICES

Pilosio’s revolutionary Flydeck system, Altrad’s LIFTBOT, and ScaffFloat’s new access solution for bridges, piers and other structures over water.

57 SYSTEM

Layher UK unveil its sweet new TwixBeam, and UK System Scaffold Hire explain how to refurbish a bridge over the M5 – without closing the motorway.

62 PROJECTS

This issue we focus on the HMS Victory at Portsmouth’s Royal Navy Dockyard and Salford Cathedral in Manchester.

for Scaffolders

SUSPENDED SCAFFOLD

Installing a suspended scaffold over water?

PARTNERSHIP WORKING

Hire a ScaffFloat to your customers.

Access: We can supply you with a ScaffFloat pontoon, with propulsion and skipper if needed, to give your scaffolders a safe and stable platform to work from.

Payload: The ScaffFloat has a payload of several tons to store tube, clips, beams and boards.

Transport: If there is limited access next to the project, we can load gear up or downstream and then transport it to and from site.

Height: Build a scaffold platform up from the pontoon to give you access to the underside of the structure. Full stability assessment provided.

Adding

We provide: 1) The floats, engines, mooring lines, anchors, safety pack and other equipment 2) The on water management & RAMS 3) Qualified skippers & crew if necessary 4) Designs and certification 5) Stability assessment 6) Licences and permissions

You provide: 1) The relationship with the client 2) You invoice your client 3) The scaffold and if needed labour for the mob & de-mob 4) Local knowledge

Proven: This is now a well tested business model and we are always looking for forward thinking scaffold companies to work together with on projects.

Welcome

Happy New Year to you and thanks for reading this latest edition of ScaffMag! We are thrilled to bring you another jam-packed, full-on, and, once again, informative issue. Over the following 70-plus pages, you will find an array of articles and features that will provide you with invaluable information, inspiration and insights to help you to stay ahead of the curve in this incredible scaffolding industry.

Although 2022 was yet another year of uncertainty and turbulence, with inflation, the cost-of-living crisis and the dreaded skills shortage, our industry and the wider construction sector will still face many difficulties and formidable challenges this coming year. Despite this, our great industry is incredibly resilient and will continue to grow and evolve. One such business that’s going places and making waves in the industry – quite literally – is our cover story on ScaffFloat. We speak to its founder, Toby Budd, in a Q&A about its success and plans for the future on page 18.

Now, more than ever, staying informed on the latest industry advancements is essential to help scaffolding businesses overcome challenges and succeed. That’s why, in this issue, we’ve dedicated a significant portion of our coverage to exploring the progress in technology and scaffolding software by speaking with some of its leaders. On page 26, we find out that Avontus, one of the leading scaffolding tech companies, has something significant in the pipeline and is about to launch multiple new features and upgrades to its flagship design program and viewer app. Meanwhile, on page 30, digital inspection firm SafeTime is celebrating 10 years in business; we caught up with its co-founder, Carl Sharley, to reflect on the past decade.

Also in this issue, we have focused on the role of women in construction and how it massively benefits a business both financially and culturally, as Des Moore explains in his detailed piece on the subject on page 36. Elsewhere in this issue, we look at some outstanding heritage projects from PHD Modular Access at HMS Victory and IBN Scaffold Access at Salford Cathedral. Plus, much more...

Happy reading and stay safe!

Daniel Norton – Editor dan@scaffmag.com

EDITORIAL

Editor Daniel Norton

T 01472 476024

M 07776 218831

E dan@scaffmag.com @ScaffMagDan

Features writers

Grahame Anderson

Richard Trenchard

Design

Demot Rushe

Dermotrushe.co.uk

CONTRIBUTORS

Billy Jones - Millcroft Scaffolding

Des Moore - TRAD Group

Gary Griffiths - UKSSH

Simon Boyes - ScaffPlan

ADVERTISING

Manager Jessica Norton

T 01472 476024

M 07776 218831

E jess@scaffmag.com

PUBLISHED BY ScaffMag Ltd

Office G8

The Enterprise Village

Prince Albert Gardens

Grimsby

DN31 3AT facebook.com/scaffmag

twitter.com/ScaffoldingNews

Working at height regulations to be scrapped

Working at Height Regulations are expected to be scrapped by the government at the end of 2023 unless ministers in Westminster can be persuaded otherwise

❖ Following the UK’s exit from the European Union, the government plans to eliminate the Working At Height Regulations, along with over 2,400 other laws and regulations by the end of 2023. This is part of the government’s sweeping policy changes called the Revocation and Reform Bill.

The Bill, which is currently being passed through Parliament, seeks to remove EU-derived laws that remain on the UK statute book following Brexit.

Working at Height Regulations is just one of the many laws entwined with the EU to be removed. Other laws are Manual Handling Operations Regulations and Personal Protective Equipment at Work Regulations.

REPEAL CAMPAIGN

In an effort to save the Work at Height Regulations, the Access Industry Forum (AIF) is urging all members of the

industry to support its campaign.

The AIF said: “No one was calling for the repeal of the Work at Height Regulations. There was no campaign for reform; no one said it was unfit for purpose or burdensome. In fact, the guidance has been simplified over the years. There has been no consultation, no parliamentary scrutiny. The issue is simply that they originated from an EU directive, so are being swept up in this mass clear-out of regulations –despite extensive UK stakeholder consultation taking place before they were created and being an established UK law for almost two decades.

“If the Retained EU Law (Revocation and Reform) Bill passes, the whole lot will automatically be axed on 31 December 2023 unless the government takes action to save individual regulations.”

AIF has submitted written evidence to the House of Commons Public Bill Committee, which is now considering the Retained EU Law (Revocation and Reform) Bill.

It also united the 10 principal trade associations and federations involved in work at height: ATLAS, EPF, FASET, IPAF, IRATA, Ladder Association, NASC, PASMA, SAEMA and WAHSA.

SUPPORT THE CAMPAIGN

The AIF is asking many in our sector to urgently write to their MP to ask them to push for the Work at Height Regulations to be assimilated into UK law and excluded from ‘sunset clauses’ within the EU Law (Revocation and Reform) Bill.

Chair of the AIF Peter Bennett OBE said: “I’m in no doubt that the Work at Height Regulations have saved lives and if this legislation cannot be rescued from the scrapheap, it’s workers who will pay the highest price of all.”

NASC LAUNCHES SG4:22

❖ The NASC has launched SG4:22: Preventing Falls in Scaffolding Operations. This long-awaited, core NASC safety guidance document provides industry best practice for fall prevention when erecting tube & fitting and now also includes system scaffolding.

In addition to its 60 pages of detailed scaffolding sector analysis and safety guidance, SG4:22 includes 95 key figures and illustrations that provide the reader with a deeper understanding of its flagship safety guidance.

NASC ePortal users are able to download this document in PDF format now. However, SG4 user guides are due to be available in A6 booklet form in the near future. For now, the NASC states that current SG4:15YOU booklets can still be

issued to scaffolders – along with briefings on the main changes to SG4 –until SG4:22 booklets become available later in 2023.

“SG4 has long been one of the most important documents in the access industry,” Acting NASC Managing Director, Dave Mosley said. “As such, it is imperative that it receives a thorough review every five years. Since its introduction, it has gone a very long way in helping make our industry a safer place – for NASC members and non-members alike. It is a must-have document for anyone involved in working at height, scaffolding and access.”

225,000 extra workers needed

Construction workers are still in high demand despite economic uncertainty, according to new data

❖ New figures in a report from the Construction Industry Training Board (CITB) reveal that in order to meet UK construction demand by 2027, almost 225,000 extra workers will be needed. If the projected growth is met by 2027, there will be 2.67 million construction workers in the UK.

The CITB’s annual Construction Skills Network (CSN) report also shows construction output is set to grow for all nations and regions; however, a recession is expected in 2023 with slow growth returning in 2024, the report says.

The report highlights that construction is expected to remain a sector where there is demand for workers despite the current economic uncertainty. As a result, recruitment, training, development and upskilling remain major priorities for the industry for 2023 and beyond.

“The latest CSN report clearly shows that despite current economic uncertainty, recruiting and developing the workforce remains vital to ensure the industry can contribute to economic growth,” says Tim Balcon, CITB Chief Executive. “We know the next 18 months won’t be easy; however, I remain inspired by the construction industry’s resilience shown in the pandemic and throughout 2022.”

Scaffolding instructor numbers set to rise

❖ CISRS is providing 16 qualified scaffolders with the opportunity to switch careers and pass on their knowledge to the next generation as scaffolding instructors. In particular, the training body is seeking scaffolders in the following UK regions, which have been identified as having a higher need for scaffolders than others. CISRS is seeking scaffolders located in Wales, south-west, north-west, Midlands, north-east (Humberside/north Yorkshire) and south central (Hampshire, IOW, Berkshire, west Sussex, Buckinghamshire, Oxfordshire, Surrey).

It is without a doubt that these 16 scaffolding instructors will play a significant role in assisting the newly elected NASC President, David Brown,

in his mission to boost the number of scaffolding workers and upgrade their skills.

CISRS Scheme Manager and NASC Managing Director David Mosley said: “CISRS will be making all efforts to ensure that these regions get the additional instructor numbers that they need. We have already met with several centres that are fully on board, looking to recruit, train and retain the potential new instructors.

“Qualifying a new scaffolding instructor can take a considerable time. We are very grateful to CITB for offering this support. CISRS will work closely with the providers to ensure that all relevant training, experience and assessment is

OWNER OF ALTRAD FOUND GUILTY OF RUGBY CORRUPTION

❖ A court has sentenced Mohed Altrad, the billionaire owner of the Altrad Group, to an 18-month suspended prison sentence following his conviction for corruption related to rugby.

French scaffolding giant Mohed, worth $3.3 billion according to Forbes, has been found guilty of corruption along with French Rugby Federation president Bernard Laporte, in the awarding of rugby shirt sponsorship deals to Altrad.

In exchange for a €180,000 payment, Mohed allegedly conspired with Bernard

Laporte to become the official front-ofshirt sponsor of the French national rugby team.

As a result of the court’s verdict, the two men were convicted and Mohed received an 18-month suspended sentence as well as a fine of €50,000, while Laporte received a two-year suspended sentence as well as a fine of €75,000.

There has been no admission of guilt by either man. However, the lawyer for Mr Altrad indicated that his client will appeal the verdict, if he decides to do so.

“Mohed Altrad never intended to illegally obtain any favours from Bernard Laporte,” his lawyer said in a

given to new recruits to get them up to at least Part 1 approval status.

“Scaffolding instruction is a great career option for those who love their work in the industry but are considering a change of direction. You can continue to be involved within the sector by sharing skills and experience and maintaining high standards of training and skills to the upcoming workforce.”

Those interested in becoming scaffolding instructors should contact CISRS by sending an email to instructors@cisrs.org.uk with details of where they are located and the regions in which they would be interested in working, in order to begin the application process.

statement. “The Altrad group is neither concerned nor impacted by this ruling and Mohed Altrad will continue to invest his time and energy in management missions for his group, its employees and partners.”

Mohed Altrad became the first Frenchman to win the World Entrepreneur of the Year award in 2015. Altrad sponsors both the French rugby union national team and the famous All Blacks.

In 1985, Mohed, together with a partner, bought a scaffolding manufacturer close to bankruptcy and founded Altrad. Born into a Syrian tribe, he moved to France as a 17-year-old with little money.

As a result of a string of acquisitions over the years, Altrad has grown into an international group employing 62,000 people with a turnover of €4.5 billion.

A CITB commission has been awarded to CISRS to help fund the training and development of 16 new scaffolding instructors in England and Wales

The past, present and future of system scaffolding

TECHNICAL FAST ASSEMBLY

LAYHER:

FLEXBEAM

High load capacity, low height solution

for simplified construction of suspended and cantilevered scaffolds

• 40% higher bending load capacity

• 40% lower structural height (280mm)

• No requirement for horizontal/diagonal plan bracing

• Fast, easy, safe and systemised assembly

MULTIPLE APPLICATIONS

EXPANSION PARTS

VICTORY FOR MILLCROFT

Millcroft wins second phase of specialist scaffolding works at London Euston

❖ Specialist scaffolding contractor

Millcroft has successfully won the second phase of a multimillion-pound contract to provide temporary works infrastructure, acoustic and public protection screens, and all required access and containment solutions to support Skanska in delivering the enabling works at London Euston; to facilitate the construction of the new HS2 Euston Station.

Millcroft was chosen by main contractor Skanska after the success of

their work on phase one, which will be completed over the next few months. The complex and competitive tender process, based on technical and qualitative questions and commercial scoring, saw Millcroft succeed against strong competition from multi-regional and nationwide competitors.

The enabling works, which will take place within the current Euston station, include platform containment screens that will run the length of three platforms at a height of 8m. The screens will be clad with

system modular acoustic panels and have been designed for optimum crowd loadings to provide a safety barrier between public areas and the work site. The temporary screens will be secured at their head to permanent steel beams and weighted using kentledge and bolted embedment options.

The team will also erect large birdcage structures over the live site offices, and protection decks over the back-room areas to ensure day-to-day ‘business as usual’ running of the station can take place during the removal of the roof structure.

Scaffold will be installed to accommodate other contractors on site at the occupied station, which is the sixth busiest in the UK. This will require a meticulously planned scheme of works to ensure the installation can be carried out safely 24-hours a day, and within organised block possessions. Millcroft will adhere to stringent protocols once the scaffold protection is in place to ensure safe and effective enabling works can be carried out above live platforms.

Millcroft’s skilled scaffold operatives will not only be working to deploy the scaffold, but the company will also have a dedicated managerial team and backroom staff on site throughout the works. On the encapsulation screens, they have opted for a solid scaffold system containment panel, manufactured by Layher, ensuring no single-use plastic materials will be used, as part of their commitment to sustainability.

Billy Jones, Managing Director at Millcroft, said: “We are delighted to have won the second phase in what is such a prestigious project. The rail industry is one of the specialist sectors where we can build on our core discipline of expertise in infrastructure-based works. Our experience in rail means we are equipped to answer the specific requirements as we work collaboratively with the client to offer a robust and specialist installation.

“This project strengthens our HS2 division, with the works being designed by our in-house technical team. This two-year programme will deliver core elements of one of the highest-profile rail projects the UK has ever embarked upon.”

Bright future for JMAC

There is nothing but good news from scaffolding specialist JMAC Scaffolding as they continue their path of exponential growth and continued success across the north-east. Daniel Norton reports

❖ Established in 1981, the Stocktonbased company, which employs over 170 local people in and around the Teesside area, has recently undergone an intensive management restructuring and investment programme. And it is clearly paying dividends for the firm.

According to its latest financial statements, JMAC Scaffolding, a division of the JMAC Group, has seen its annual revenue increase significantly. So much so, it has achieved profits greater than at any time in its 40-plus year history. Many would say this demonstrates that bringing in the right people for the right job has marked a major turning point for the company. And this is also a theory that is echoed by JMAC’s Ryan Payne, who holds the position of Operations Director at JMAC Scaffolding, as he explains: “When I joined the business in January 2022, Luis and I set about reshaping the management structure and organisation chart for the scaffolding division.

“I brought in a contracts manager and

supervisor I have worked with in previous businesses, as well as bringing back a senior manager who had moved down to London for a couple of years, which has given us a strong and stable management team operationally enabling us to deliver on a larger scale.

“Week by week, our reputation has grown thanks to the drive and determination of our operations team. The estimating and marketing strategies we have developed have been instrumental in improving our turnover and profitability by identifying the type of clients and the type of work we want to do as a business,” says Payne.

EYEING INDUSTRIAL OPPORTUNITIES

Currently, JMAC has a diverse portfolio of works and offers industrial scaffolding services to a variety of clients. Still, this thriving business is now looking to build and expand on its existing industrial scaffolding service and bolster its order books further. As part of these efforts to broaden its reach

and increase efficiency, JMAC has decided to invest £600,000 in Layher’s latest lightweight scaffolding system.

“Layher is a family-run business with a similar ethos to us,” says Payne when asked why they chose the Layher

system over others.

“We have great contacts within Layher with Heath Brown, who has always been very helpful and accommodating to our needs and has assisted in coming up with solutions on various projects.”

In the firm’s view, implementing the lightweight system on industrial projects will provide “large efficiencies in programme delivery, load capacity of platforms, and a number of labour savings. And JMAC is already seeing the benefits and reaping the rewards of its new system after using the lightweight kit on a project at Navigator Terminals as Payne explains: “We have just erected a Designed Splay Scaffold on a 58m-diameter tank on Navigator Terminals (North Tees), which also included the purchase of Layher gap cover plates – I believe this is the first time the new lightweight system has been used with the gap plates and the job looks fantastic.”

In order to further expand its

industrial portfolio, JMAC plans to make more Layher investments in the coming years, as its industrial portfolio continues to grow.

WHAT’S NEXT FOR JMAC

Through pure determination and hard work over the years, JMAC has grown to become one of the largest family-run and owned scaffolding contractors in the north-east. But what’s next for this forward-thinking business? “Myself and Luis are very similar in terms of our ambitions,” says Payne.

“JMAC currently employs over 170 local people in Teesside and that is something we are incredibly proud of; however, the senior leadership team want to strive for more. 2023 is going to be a really exciting year as we expand JMAC Industrial Services and look to invest further, both into our infrastructure and our fleet, to ensure we maintain our capabilities in line with the growth of the business. “The future is bright, the future is Orange!”

THE NASC ANNUAL BALL & AWARDS 2022

Scaffolding community celebrates at star-studded NASC Annual Ball & Awards 2022.

Some of the leading scaffolding firms and members of the scaffolding and access industry came together in London recently for the NASC Annual Ball & Awards 2022, the largest black-tie awards event to date for the national scaffolding trade body.

Over 740 guests gathered at the Westminster Bridge Park Plaza Hotel for a night of celebration and recognition for the industry’s top performers.

The event, themed ‘Think Sustainability’ in line with NASC President David Brown’s objectives, kicked off with a drinks reception followed by a three-course meal and live entertainment, featuring online viral sensation Troy Hawke as the Master of Ceremonies and a surprise appearance by award-winning children’s novelist David Walliams as the host for the awards.

The NASC Awards recognised the best in the UK scaffolding and access industry, including Apprentice of the Year, Health & Safety, Innovation of the Year, President’s Award, and Project of the Year

Scaffolding championships goes global

Several teams from around the world, including the UK, have signed up for the third Scaffolding Championships.

This year’s growing scaffolding competition in Vilnius, Lithuania, has attracted 13 teams of scaffolders from around the world to participate.

While entries for the 2023 Scaffolding Championships are still open, the event organisers, The Baltic Scaffolding Association, have announced that teams from Australia, Mongolia, and now the United Kingdom have registered to compete.

Previous years have seen mostly

European teams go head-to-head in a series of timed system scaffolding build-offs using the Layher Allround system. Last year’s event, which saw defending champions Hotrema retain its champion status, proved popular with those attending and those watching online. More than 120,000 people from around the world tuned into the event’s live steam on YouTube and its social media networks.

The Scaffolding Championships will be held on 26– 27 May 2023. Teams of scaffolders from countries currently registered are Lithuania, Sweden, Finland, Denmark, Ireland, Poland,

in small, medium and large categories. A full list of winners and runners-up can be found on the ScaffMag website.

Acting NASC Managing Director Dave Mosley said, “It’s been another fantastic NASC Ball and Awards. The event grows year-on-year and has been established as a real highlight in the scaffolding and access industry calendar.”

The NASC Annual Ball & Awards 2022 celebrated the industry’s achievements and recognised the hard work and dedication of its members. Congratulations to all the winners and nominees.

Mongolia, Australia, Bulgaria and the UK.

A spokesperson for The Baltic Scaffolding Association said: “Although last year’s Championship was very popular, we didn’t expect so much interest for our event this year. Its grown so much that we have had to expand it to allow the registration for three extra teams to a total of 15.

Our 2023 Championship will again be live streamed with translation for those who cannot attend, but this time we are expecting to make it more interesting and interactive for viewers.”

MAKING

It is no secret that Cornish start-up ScaffFloat has certainly made waves in the scaffolding industry since it launched its safe floating scaffold access system in 2020. For a Q&A, ScaffMag’s editor, Daniel Norton, catches up with Toby Budd, founder and managing director of ScaffFloat to find out how it all came to be

DN: Toby, thank you for taking the time to talk to our ScaffMag readers and for taking the time to answer our questions. What inspired you to come up with the idea for ScaffFloat in the first place?

TB: A few years ago, we were working on a project to build a folding workboat that would fit in a shipping container. We decided to make our own plastic floats for this, and it was during the design process that my father-in-law asked me to make a netting framework over his fruit bushes to keep the birds out. I figured scaffold and key clamps would be easy to use, so I looked on Facebook Marketplace and

found a scaffolder down west selling up his business. I drove down and spent a couple of hours chatting with him about beams, tubes and clips. I had never really looked at scaffolding components before and remember being impressed with the low massproduced cost and versatility of the components. I was towing the trailer load of scaffold back up the A30 when I joined the dots and had the idea to make pontoons with scaffold. We moved quickly and launched the first prototype, a 16m x 6.4m ScaffFloat, a few months later after filing a patent and trademark.

DN: Can you tell me about your first job with ScaffFloat?

TB: A local marine contractor, KML, was working in the Port of Felixstowe to demolish an old ‘dolphin’. This required access to the steel piles that supported it. Initially, they tried a modular plastic pontoon but it moved around too much in the waves and contractors felt it was unsafe to work from. We mobilised a horseshoe-shaped 4m x 4m ScaffFloat that could fit around the pile. With a dropdown deck section behind the pile, this gave them 365-degree access to the pile from a much more stable platform. It did a great job and stayed for several months. It was a really good first test in the real world.

DN: Since you started your business, how many projects have you been able to deliver?

TB: Well over 50 now. I think in total we have now delivered over 5,000 hours of safe floating access to contractors around the UK.

DN: The idea of ScaffFloat sounds awesome, but what is the business model for the company?

TB: Our floats are available only for hire, and we are very strict about this, even though people constantly ask if they can buy the floats. We do this to maintain control over how the system is used. We make sure that every project has a proper design and stability assessment, and that we have overseen or checked the RAMS. Safety is one of the things our customers like most about ScaffFloat. Therefore, it is vital that we maintain our track record, and to do this we need to retain some control.

DN: I noticed your ScaffFloats are equipped with engines. How did this come about?

TB: Putting propulsion on ScaffFloat was a turning point in the business and now 80% of our ScaffFloats go on hire with outboard engine pods. This adds a huge amount of value to what ScaffFloat can do, and once onsite these workboats are incredibly useful.

WAVES

We now use high-thrust 60 hp Yamaha four strokes which meet all the latest emission standards and are very fuel-efficient. We tend to run them as a pair for redundancy and manoeuvrability and can get just under a ton of bollard pull from them for towing and pushing. Like wind farm transfer boats, we also rely on ‘pushing on’ as a method of holding position while contractors work from ScaffFloat. This is normally much safer than using lines, particularly in any wave action.

DN: So, do you operate overseas as well?

TB: Yes, but not properly. We have floats in Australia, Malta and Cyprus but we have not had the time or resources to develop our international offering properly. We get very regular enquiries from overseas, particularly from Europe, the Middle East, Australia and New Zealand. At the moment we don’t have the framework to push ScaffFloat overseas, and this is one of my priorities this year because the demand is there for sure.

OPPOSITE: Toby crashing through the waves while driving the 8x4 workboat; navigating through a canal lock system.

DN: Can you tell me what kind of regulations you operate under?

TB: We operate under a range of regulations; for the marine side it is the MCA, PLA & IMO which cover manning, safety equipment, stability standards and minimum freeboards. Most of TG20:13 and other scaffold regulations are not relevant to what we do, but we do use elements of it for things like edge protection. For lifting, we use Lloyd’s Register Code for Lifting Appliances in a Marine Environment and all our cranes are LOLER tested. To assess the structure, if needed, we use EuroCode EN1993-1-12005 & DNVGL-T-0378 and also refer to BS5975:2019 for temporary works. On larger projects we can also offer customers an independent Cat 3 check by our partner Richter; this gives our customers reassurance that we have taken a safe and prudent approach to our design and planned method of works.

We have also always been able to satisfy any of our customers’ structural or safety questions. This includes the Royal Navy, BAE systems, Network Rail, Port of London Authority, MCA, numerous harbour authorities and harbour masters including QHM (Now KHM), Canal & River Trust, the Environment Agency and numerous principal contractors like Volker, Dyer Butler, J Murphy, Amco Giffen, Laing O’Rourke, Balfour Beatty and Story & BAM.

DN: What is your approach to working with scaffolding contractors?

TB: We have a really good relationship with a number of scaffolding companies around the UK and over half of our jobs are delivered in partnership with them. Initially, we had the concept of ‘approved installers’, where scaffold companies could hire the floats from us and then build and hire on the pontoons. However, this did not work. We quickly realised customers wanted much more than just a pontoon. They wanted our marine experience to manage the floating element of their project. Now, most of the work we do includes personnel, extra equipment like engines and winches, and the management of that part of the project.

So now we work with scaffold firms in two ways:

1) Bridge Scaffold – We provide floating access, normally from a self-propelled ScaffFloat with a skipper, for them to install a suspended scaffold under the bridge. We can carry the scaffolders and a couple of tons of boards, fittings, beams and

tubes onboard and position the ScaffFloat right under the bridge. This saves the scaffolders a significant amount of time compared to if they built from one end. 2) Your Customers – If a scaffolding company has a customer that needs a floating solution, we can work together with them to deliver a ScaffFloat. It is a great partnership because they have the relationship with the customer and also provide scaffolding and help assemble the ScaffFloat. We bring the floats, engines and other equipment, and once on hire we can run the floating element of the project.

We are always keen to speak to scaffolding companies who would like to work with us.

DN: It seems to me that you have a pretty good handle on your marketing.

TB: Yes. We get that a lot, which is nice. I have a strong background in simple marketing that works, but the reality is that we can and will do much better in this area going forward. Our website has not been updated for almost a year. We are in the process of setting up a CRM, newsletter and sales process. We also run no SEO, PPC or outreach. We have just been too busy. The only thing I have worked hard on is LinkedIn, which has been invaluable for us, especially in lockdown. Luckily the product has done very well selling itself. We have grown as much through customers’ positive endorsements and referrals as anything else, which is really pleasing and encouraging. It is abundantly clear already that ScaffFloat is doing a great job of providing a long-needed solution to the well-known problems associated with floating-access works. The surprise so far is just how big the gap is in the market that we are addressing.

DN: Can you tell me how safe ScaffFloat is?

TB: Safety is the cornerstone of what we do. We provide a number of services but the core of what we do is getting contractors access to the work they need to do, and then keeping them safe while they do it. Whether it be cutting, drilling, welding, electricals, coring, surveying, scaffolding or painting, we want the workers that operate from ScaffFloat to be able to work efficiently and safely, and as they are normally used to working from land, a big part of what we do is taking care of them when they work afloat.

DN: What does the future hold for ScaffFloat?

TB: In the medium term, the big focus is on developing processes with particular emphasis on

developing our marketing, sales, project management systems and SOPs, thus ensuring that the business is well-equipped and resourced to continue its scale-up. We have a great team of dedicated professionals that have enabled us to get this far in such a short period of time. However, in the near future, we plan to expand the team in all of these specialist areas to ensure that human capacity doesn’t become the limiting growth factor. We are also working towards various accreditations including ISO 45001.

Long term is a very tough question because, given how busy we currently are, it’s proving difficult for me to lift my head up out of the day-to-day to really take a view of where we will be beyond this year’s growth. But if I am being honest with myself, I suspect we will ‘outgrow the pot’ we are in within the next year or two. I really love innovation and solving problems, and in some ways I have reluctantly learned to do the business bit. At the moment, we are pumping in value with lots of exciting ‘firsts’ planned for this year, but after that, I suspect the business will shift, become less of a start-up and more of a mature business where it’s about photocopying services and designs and growing to the next level. We have some strong IP and patents and so the future commercial possibilities for our innovative business are clearly very significant.

DN: Last but not least, do you regret anything?

TB: That’s a good question. No. Well, hindsight is a wonderful thing, and I am sure I would do some things differently, but I am not one for regret. Mistakes are an inevitable and valuable part of the innovation process. You minimise them, fix them, learn from them and move on. Every day is a school day and we’re on a steep learning curve. I don’t know what this year will hold. However, if I look back in our wake and what we have done in the last 12 months, I suspect it’s going to be busy. January revenue is already up tenfold on last year.

OPPOSITE: 8x4 ScaffFloat with skipper under the Millenium Stadium in Wales; under a rail bridge in Belper giving access to Crossways Scaffolding to install suspended scaffold under the bridge; with twin outboards being launched by the Port of London Authority on the Thames.

“We plan to expand the team in all specialist areas to ensure that human capacity doesn’t become the limiting growth factor.”

Have you heard of PERI UP Scaffolding?

Leading from the front

We speak to David Brown, the youngest ever NASC President about his background, his plans for NASC and his vision for transforming the scaffolding sector

David Brown, the youngest ever NASC President, is bringing fresh vision and leadership to the scaffolding industry. In this exclusive interview, we delve into Brown’s background, his plans for NASC, and his vision for transforming the scaffolding sector.

Experience counts for plenty, but fresh life helps industries prepare for brighter futures. The new face of the National Access and Scaffolding Confederation seems to have both bases covered.

Appointed to NASC President four months ago, David Brown might be the youngest ever organisation head, but his resume speaks volumes about why he’s the perfect fit. With a career stretching back to the age of 17, he joined Richardson Projects Ltd. as a trainee quantity surveyor in 2003, and quickly went on to achieve an ONC in Construction, HND and then degree in Quantity Surveying, while gaining in-depth knowledge of the sector working on-site.

With all aspects of construction susceptible to economic fluctuations, in November 2010, as the fallout from the financial crisis continue to wreak havoc globally, ROK collapsed. Brown’s father, Nigel, stepped in with the offer of a temporary job at IBN Scaffold Access Ltd. 12 years and several promotions later, he’s still in the sector, and poised to lead from the very top.

“My age is one of the first things people make a comment about. It’s a huge positive for the NASC that the Council made the bold decision to vote for me and give me the opportunity to be NASC President. It shows that the NASC is evolving and modernising. We’re moving in the right direction now to shake off the negative image some in our industry have towards the NASC,” says Brown, quickly pointing out this new position is no “job for the boys” or pre-retirement swan song. He’s also keen to clarify that, from where he’s sitting, the idea of breathing new life into scaffolding is partly a misnomer.

“The scaffolding industry is full of unbelievably talented individuals and has numerous vibrant forward thinking companies constantly producing amazing projects for their clients. So in this instance I don’t need to breathe new life into the industry,” he continues.

“What I want to do is highlight the skillset that is in our trade, I want to promote the careers that are available within scaffolding and how young people leaving school, college or university should be seriously considering coming to work within it.”

Nevertheless, he’s understandably excited about the prospect of an evolving NASC, with a new managing director also drafted to continue moving things forward. Fresh blood, as he calls it, can help provide more support to members, and mobilise the organisation itself to tackle one of the biggest issues facing the sector — skills shortages. Initiatives introduced so far include a series of grants, with £150 paid for each new starter member firms recruit, £200 for every newly qualified

scaffolder, and £250 per newly qualified advanced scaffolder qualifying for a CISRS card.

Beyond this, each new Supervisor Card issued offers a £500 reward, and companies can also claim £175 for successful completion of a CISRS System Scaffold Product Training Scheme. The same amount is available for basic scaffold inspectors that progress to advanced level with the systems endorsement. Meanwhile, the opportunity to change the outward facing image of the industry is another the new president wants to seize.

“The perception of the scaffolding industry needs updating and transforming the most,” says Brown. “The message during my term as president will be that scaffolding is an industry full of talented and highly skilled individuals. We are able to design, erect and dismantle the most amazing of projects that enable our clients to undertake their works. We are a highly trained trade. With the support of CISRS, our scaffolders receive excellent training. I can’t think of another trade on site that is as highly trained as ours.”

IT’S A HUGE POSITIVE FOR THE NASC THAT THE COUNCIL MADE THE BOLD DECISION TO VOTE FOR ME AND GIVE ME THE OPPORTUNITY TO BE NASC PRESIDENT. IT SHOWS THAT THE NASC IS EVOLVING AND MODERNISING.”

Sustainability is key to HAKI’s strategy for long-term growth.

We are committed to being a pace-setter for sustainability in the workzone safety industry and are working towards being carbon neutral. By 2030, we’ll aim to have reduced our direct greenhouse gas emissions by 50%.

Find out how we could work together at: haki.com

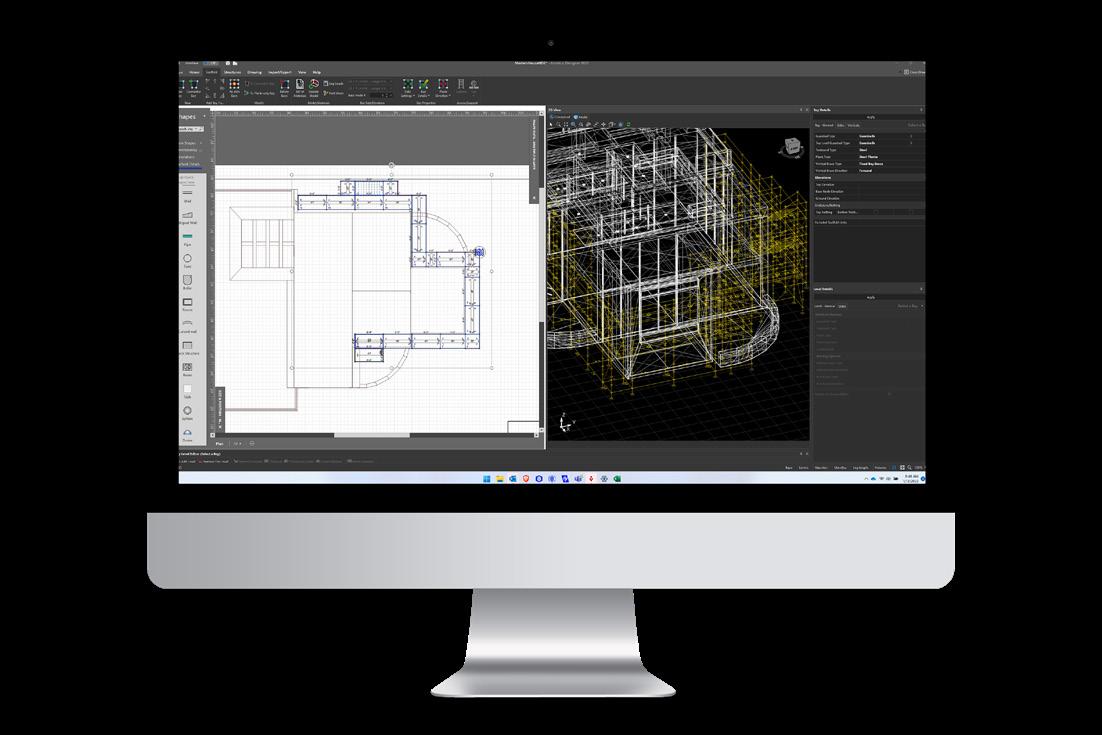

VISUALISING THE FUTURE

Avontus, one of the world’s leading scaffolding tech companies, is about to launch and deploy an array of new features and major upgrades to its flagship design program Avontus Designer and its Avontus Viewer App. ScaffMag’s Editor, Daniel Norton, discovers that this isn’t the only change coming...

If you ask any scaffolding business owner worth his salt, he will tell you that ensuring a scaffold is erected properly and safely from the get-go is only ever possible if everyone involved fully understands the design. Whether that be an extremely complex multimillion-pound scaffold involving many scaffolders or a simple scaffold structure around a building or house. Both the visualisation and communication of the project and design to the workforce, and moreover the paying customer, are fundamental to a successful and profitable scaffold project.

Safety is paramount in our industry and the design of scaffolds can play a huge role in ensuring that structures are compliant and safe for all users. But unfortunately, even the safest design can turn into a total nightmare when the actual scaffolds are being based-out and erected, due to miscommunication between customers and contractors. When there is a gap between the design and the build, problems can arise. When these issues are not pointed out and discussed before the build, valuable time and resources are wasted to make the necessary changes and modifications. This can, in turn, ultimately eat away at your bottom line.

Since 2002, Avontus, one of the biggest names in scaffolding software, has been providing contractors and scaffold business owners all over the world with digital solutions to solve such problems.

“We believe it is critical to a successful scaffold project for

all stakeholders to be on the same page when it comes to a solution. If a still picture speaks a thousand words, an interactive experience offers a million!” Avontus’ CEO, Andrew Smith, told us.

Avontus delivers a portfolio of high-tech tools to estimate, design and visualise projects by bringing scaffold designs to life in full 3-D, virtual and augmented reality by using a standard desktop or laptop computer, enabling any person with basic scaffold knowledge to deliver conceptual designs within a day of starting to use Avontus Designer.

AVONTUS DESIGNER & VIEWER 2023

With no intention of slowing down or resting on its laurels, Avontus continues to innovate and advance its next-gen software. As a result, the company is about to release a brand-

new version of its core product, Avontus Designer 2023, along with its Avontus Viewer App that comes with a number of cutting-edge innovative tools and features that will enhance the user’s experience.

Avontus Viewer delivers visualisation of the Avontus Designer project in augmented reality (AR), virtual reality (VR), and 3D on a mobile device and desktop. And furthermore, designed scaffolds can be shared with customers through a simple in-app sharing function, or via a fly through in YouTube.

“We always look to push the envelope with scaffold design, and we think Avontus Designer 2023 will not disappoint,” says Smith when asked about the upcoming update and features. “In addition to the greatly improved 3D import and export functionality we have rebuilt Avontus Designer to provide performance enhancements, and a platform to allow for the inclusion of future scaffold types.”

“Avontus Designer can import and export complex 3D models such as BIM (IFC) and DWG, and display the complete model to allow users to design a scaffold suitable for the project requirements. Following design completion, Avontus Designer projects can be viewed and shared in Avontus Viewer,” Smith said.

MAJOR NEW PRODUCT COMING SOON

Smith revealed to ScaffMag that its innovation team has been really busy developing a brand-new product to add to its portfolio of digital offerings for contractors that will ‘change and disrupt’ the communication of scaffold requirements on a construction site.

Set to be called Avontus Site, this brand-new scaffold management software application, which is expected to be released later this year, will provide scaffolding users with an easy way to manage scaffolds.

Designed for both mobile devices and desktop computers, it will provide a platform for easy communication between owners and contractors, thus reducing the volume of communication and instead concentrating the information into one easily accessible source.

Smith said: “Avontus Site will allow a scaffold company to better manage scaffolds and scaffold projects, allowing for total accountability and control with the easy-to-use map-forward platform made for scaffold teams on every job site.”

WE ALWAYS LOOK TO PUSH THE ENVELOPE WITH SCAFFOLD DESIGN, AND WE THINK AVONTUS DESIGNER 2023 WILL NOT DISAPPOINT.”

SafeTime®, the digital inspection company that revolutionised the scaffolding industry, has reached a significant milestone after 10 years in business.

ScaffMag’s Editor, Daniel Norton, caught up with SafeTime’s Co-Founder Carl Sharley to reflect on the past decade

Unless you have been living under a rock for the last 10 years, you will have no doubt heard about or seen SafeTime’s slick Inspect7® device on countless construction projects up and down the country. This clever visual tagging device launched in 2013 and helped revolutionise the industry in how contractors record critical scaffold inspections, improving safety overall.

For many forward-thinking scaffolding contractors, the traditional, outdated tagging system now seems like a distant memory. Gone are the days of manually filling in scaffold tags and reports every week for each and every structure in the contractor’s portfolio of works. SafeTime’s Insect7 device does all that and more. For instance, the device simplifies the process of digitally tracking, recording and reporting all the necessary scaffolding information in real time, meaning users can now instantly access vital information at the touch of a button.

Time waits for no one

Impressive stuff, right? But SafeTime hasn’t been a one-hit-wonder, just sticking to its Inspect7 device; over the years, the business has moved forward and diversified into other industries with an array of new products. The company now stocks inspection devices for virtually everything and has even had “queries from farmers about tagging their cattle”!

As you can see, SafeTime continues to be a company to watch. Now with a fully diverse range of products, over 20,000

customers across the globe and a top safety award in the bag, SafeTime is bossing it in every sense of the word! This Londonbased company has become a global leader in digital inspections, but how did it all get started, and where did the idea come from?

According to SafeTime’s co-founder, Carl Sharley, the light-bulb moment came when he and his work colleague, Brendan Morrissey of Artel Scaffolding Ltd, were “working on a complex scaffolding project in Central London”. The project required more than 1,000 scaffold inspections each week.

“When undertaking the audits, it became apparent that using traditional tagging systems and pen and paper to be 100% compliant was virtually impossible. We both agreed that a digital system would be the future,” Sharley said fondly.

“Following on from my conversation with Brendan, later, I shared the idea with Clint Hickmott over a few beers. We all agreed the three of us would set about creating SafeTime and give it a go,” he said. Having just come up with the initial idea and attempting to take it to the next level in creating a business, it would have been incredibly difficult for the trio in its early days. But what experience did the group have before the inception of SafeTime?

“Unlike other software companies in the construction industry, we all have a construction background. The founders all come from the construction industry, which is why I think the product has been such a success,” explained Sharley.

“Brendan is the owner and managing

director of Artel Scaffolding Ltd and other construction-related businesses. He has over 40 years of experience in the construction and communications industries.

“Clint and I have a wealth of experience from the industry’s commercial side and were previously quantity surveyors for some of the largest construction companies in the world.

The three of us collectively bring a unique combination of technical expertise and business acumen to our company. We are well-respected in the industry for our professionalism and attention to detail,” Sharley added.

TEN YEARS AT THE TOP

This year marks an exceptional year for SafeTime as they celebrate the massive achievement of 10 successful years in business. But, as with all companies along the way, there must have been both high and low points in SafeTime’s history, right?

When asking its co-founder this question, Sharley recalled one of the most stressful periods in the company’s history. Apparently, there was a massive increase in sales for the company in one year compared to what had been forecast for its Inspect7 devices. “We were only two days away from having zero stock to meet demand. All hands were on deck, and we got through it without affecting a single customer,” he said proudly.

“The low points of running any business are the stress and pressures that come with making important decisions and being responsible for the success or

failure of the company. We all share this pressure every single day.”

Sharley said on the subject of high points in SafeTime’s history: “Taking a product that we prototyped in my basement to the mass market, where it has been used by multinational companies worldwide, is still mind-blowing.

“And winning the CHSG Beaumont Safety Award in 2013 was fantastic, and it gave us confidence that our product was being accepted and championed by our peers,” Sharley added.

LOOKING FORWARD

In keeping with SafeTime’s commitment to innovation and always looking forward, over the course of the next few months and years, the company is set to release some incredible new software, including an application called TempWorX. SafeTime’s designers have been working hard to bring this new online management tool for all temporary works in the construction industry to market.

The program, according to SafeTime, has been designed to be able to handle the entire BS 5975. It will ensure that all works on-site are designed, checked, constructed, inspected, loaded/used, adapted, maintained and dismantled in accordance with the British Standard. And, better still, it will seamlessly integrate with Inspect7 inspections.

“We believe this will change the industry just as much as the original Inspect7 product did. But let’s see what happens in the next 10 years,” Sharley concluded.

TAKING A PRODUCT THAT WE PROTOTYPED IN MY BASEMENT TO THE MASS MARKET, THAT’S NOW USED BY MULTINATIONAL COMPANIES WORLDWIDE, IS STILL MIND-BLOWING.”

SCANNING FOR OPPORTUNITIES

Has there ever been a better time to be in the scaffolding industry than right now?

The answer is probably yes, with materials and labour shortages at critical levels and businesses struggling to keep up with the work demand, it can be easy to think of everything as doom and gloom. Not to mention how many businesses are forced into bankruptcy and subcontractors are left with nothing.

It seems more and more people are leaving the industry to find another job in a less risky area. But whether you’re in the scaffolding game, a hairdresser, doctor, lawyer, or owner of a corner store, everyone is facing new challenges in the era of living alongside Covid.

While things may feel like they are getting harder and harder, the silver lining is that we are amidst the biggest evolution the scaffolding industry has ever seen!

Take a moment to think back to how much scaffolding has evolved from when the pyramids were built back in 2500 BC, to now, the mid-2000s.

Yes, we have more advanced modular systems and yes, we have higher-grade steel, which is lighter, but I’d be surprised if there were a scaffolding company in the world with zero tube and fittings in their kit.

Now just let that settle in for a second and consider how much we have progressed in the 4,500 years since they used timber and twine to build the pyramids. The only real change is that now we use less tube and fittings and more modular systems.

On the flip side, take scaffolding materials out of the equation and look at how the construction industry has

changed more in the last 10 years than the prior 4,490 years combined.

As the world looks to reduce carbon emissions, along with the worsening labour crisis, there is more and more pressure to find ways to reuse existing infrastructure rather than bring in the bulldozers and start all over again.

Working with old infrastructure to rejuvenate and reinvent comes with its own challenges. The most common obstacle is that the infrastructure is generally old and often has very little information.

I seriously doubt the Ancient Egyptians used 3D models when building the pyramids, and similarly (though not quite as old), the structures I’ve worked on – I’ve struggled to find useable design information.

There may be dated drawings, but they’re often near useless, as the structures have largely been modified without changes being recorded in the drawings. That, or there may be a ton of site obstructions that cause downtime or a host of other last-minute design changes.

These two factors can cause so many problems when you’re trying to design and complete the works. How many times have you got to a site and thought “Oh %$* it doesn’t fit” or “What the hell is that doing there?” The reality is that you can stand there all day with a tape measure, and never get it right.

Unless you can reach every surface and physically measure across them, it is difficult to get the drawings totally accurate. This affects whether you have the right materials on site and if your team knows exactly what goes where. A lot of

Simon Boyes, Director of Benchmark Scaffolding & Founder of ScaffPlan, shares insight into the use of laser scanners and how point cloud data in scaffold designs can significantly improve accuracy, reduce downtime and limit rework across scaffolding projects

OPPOSITE: The Trimble X7 “is an absolute beast of a machine,” according to Simon Boyes.

BELOW: Scans from the 3D laser scanner are accurate and highly detailed.

the time I’ve found a few millimetres in a design adds up and can be a make or break when you start the build.

This all changed for us the day we invested in our first 3D laser scanner. In the time it takes to pull out a pen and paper and take measurements, we already have a structure fully laser scanned and recorded in high-definition 360-degree photographs for our designers and engineers to use.

I can, without hesitation, recommend the Trimble X7 which is an absolute beast of a machine. It has accuracy of 0.6m at 80m range and there is nothing that this thing misses. When importing the laser scan data (also known as point cloud) into your scaffolding design platform, you can literally count the leaves on the trees – it is that detailed.

Yes, all laser scanning machines are expensive and to most people they seem scary and hard to use but they couldn’t possibly be any simpler. You literally set up the tripod, the machine will self-level and all you need to do it press the start button.

Once the scan is finished, you can easily import the point cloud data straight into your design program and away you go – check with your software provider that they have this function (or move to one that does). In most instances you also save time by not modelling the structure because the point cloud allows you to clearly see what is what.

You don’t need a university degree or a PHD to operate these things and given the time and money that it saves you, they will pay for themselves in less than 12 months. I’ve got a couple now and can honestly say that it has taken the guesswork out of all

my projects and saved our team countless hours where there could’ve been delays from incorrect materials or measurements. It’s also skyrocketed productivity; when the crew arrives on site, they already know exactly what goes where.

So much technology is becoming available to scaffolders, and it really is an exciting time. Not only is it improving efficiencies on so many levels, but the accuracy of these technologies is having profound impact on improved worker safety and effective collaboration across multi-disciplines.

This is only the beginning, with more and more uptake of scaffolding businesses using new technology, we can expect to see worldwide industry changes, for the better.

ALL LASER SCANNING MACHINES ARE EXPENSIVE AND TO MOST PEOPLE THEY SEEM SCARY AND HARD TO USE BUT THEY COULDN’T POSSIBLY BE ANY SIMPLER. YOU LITERALLY SET UP THE TRIPOD, THE MACHINE WILL SELF-LEVEL AND ALL YOU NEED TO DO IT PRESS THE START BUTTON.”

EASIER. SAFER. SMARTER.

As an industry-leading provider for scaffolding and construction safety products, TRAD UK has always championed innovation. Our extensive range sets new standards for access equipment and safety systems.

Our efficiency and safety is matched by the highest levels of service delivered by our experienced team and nationwide support network of depots. So it’s easier than ever to find the right solution for your project.

Building a brighter future: Women in construction

Des Moore has supported diversity and inclusion in the TRAD Group and across the scaffolding industry since he became Managing Director of TRAD Scaffolding some 25 years ago. He is convinced that it has undoubtedly made businesses stronger, opened people’s eyes to new ways of working, challenged preconceptions and allowed us to tap into a much wider range of skills and talents. And that’s not all...

The focus of this article is about encouraging more women into scaffolding, construction and other trades or disciplines that are seen as traditionally ‘male’. I’ve had conversations with many people in our industry – of all genders – who say that the important thing is to get higher numbers into the industry in general. I absolutely agree with that, and I’ll be writing about that later this year. But I’m starting with this area because I believe it needs to be addressed first.

WHY AM I WRITING THIS ARTICLE?

I’m not on a ‘crusade’ or jumping on a bandwagon. I think anyone who knows me, knows that’s not the kind of person I am. What I do know, because I’ve done it, is that bringing women into a business benefits that business and everyone in it both financially and culturally.

When I became MD of TRAD Scaffolding, the company employed women in administrative roles only. I didn’t see why this

had to be the case, so I employed some women as credit controllers and trained them to be surveyors. I also encouraged women to apply for senior positions, addressed the salary imbalance and gave everyone a say – right across the business. I wanted to build a truly inclusive culture in TRAD – something that I’ve taken into my current role as CEO, by putting specific initiatives in place to ensure greater balance across the company. And it’s something that I’ll continue to promote in any future roles I have.

There’s definitely been a considerable improvement since I started working in management. There are a number of companies now that employ women in a range of roles, setting a great example to the industry. We are facing a significant skills shortage across scaffolding and construction, and so we need to continue our drive to make sure that everyone is welcome, encouraged, developed and retained.

A BETTER MIX

It’s important to embrace difference. Why would you want to keep new initiatives, ideas and suggestions out of your business?

It’s far better to expand the mix. It helps you to build your thoughts and opinions from a wider basis – bringing diversity of thought and approach to your business.

What is the ideal? It’s where a business is pretty evenly balanced and hires for talent, creativity and skills rather than with blinkers on. It’s a straightforward argument. In work, we are all equal and we should treat people the way we would like to be treated and give them the opportunity to follow their chosen path.

All people are equal – my wife, Debbie, would say that she is more equal than me, but that’s my problem!

Debbie has always been football mad. When she was younger, she was out every day, playing football. She loved it and she wanted to play more. So, she got her dad to write to Crystal Palace to ask about playing opportunities there. A letter came straight back saying, pretty bluntly: “Women don’t play football.” It said to her that the thing she loved was not for her – and perhaps never would be. What a massive change there has been since then – and rightly so. There’s no room in any industry for such an outdated attitude – and yet it still exists in some places.

LYNN WAY, COMPANY SECRETARY AND FINANCIAL DIRECTOR, CHRIS SEDGEMAN SCAFFOLDING

Lynn is well known in the industry, having recently served as President of the NASC. She is delighted by the growing community of talented and enthusiastic women in scaffolding and construction, and has some clear ideas on what still needs to be done.

“I think things have improved considerably since I started in the late 1990s. Women need to see that it is possible to get to the top of the industry; senior leaders need to show there is clear career progression and support women to be ambitious. I was lucky that my brother supported me in this way.”

Lynn has often been the only woman in the room –that was certainly the case when she sat on her first NASC committee in a contracts role. “People no longer assume I’m the secretary and instead listen to me as an equal. When talking to or representing the NASC, I feel completely included within the construction community. And particularly within the NASC, we are seeing more women coming forward – something that Des Moore started promoting as President and I have continued. The motivation for continuing this needs to come from the executive team and also from the members.”

Lynn has a pet hate, however: inappropriate PPE for women. “If you go through a PPE order book, you’ll find it nearly impossible to buy PPE that’s appropriate for women – although I am now starting to see that some PPE in the catalogue has a ‘woman’ icon next to it. This isn’t just about being comfortable at work – it’s about personal safety too.”

Des’s wife, Debbie was football mad, playing outside everyday and had aspirations to play for Crystal Palace.

And what about general equality? “Things are definitely getting better, but we need to ensure equal pay for the same work being done. This is an ongoing issue in the industry and something that needs to be tackled. There’s absolutely no reason to pay a woman less for doing the same job as a man. I have been lucky to be treated equally at Chris Sedgeman Scaffolding, but I’m sure other women have not. However, I have noticed a lot more women at meetings, and contacting me on LinkedIn. There’s a fantastic community of women in construction, all doing great and valuable work, and it’s an industry I’m proud to be part of.”

LYDIA CHARD, BUSINESS DEVELOPMENT MANAGER, STAR SCAFFOLDING LTD.

Lydia joined the construction industry in 2014. “Growing up, playing with dolls, make-up and all things glittery, I never imagined myself in construction,” she says. “But I couldn’t imagine being in any other industry now!”

Lydia joined Star Scaffolding, where her dad is a director. She did some temporary work before going to university but enjoyed it so much that she stayed in the business rather than taking up her place. She started as a trainee estimator, gained her CSCS card and Scaffolders Inspectors card and is Strike and Smart scaffolder trained. As Business Development Manager, Lydia’s currently studying for a degree in Business Management and has plans to do a Master’s.

“Times are changing,” says Lydia. “Even since I started eight years ago, I am seeing more and more women in construction. Generally, I have been welcomed into the sector. I think you have to believe in yourself, your knowledge and your opinion – speak up and be confident.

I’ve found the industry, especially the NASC, is doing its utmost to support, welcome and encourage women.”

During her short time in the industry, Lydia has become a member of the NASC marketing board, and a member of the ASITO training board, receiving an award for taking on the most Kick-starters in the sector. She’s currently leading a returning-citizen scheme at Star Scaffolding, which she says is one of the most rewarding things she has ever done, and recently made the top 100 women in construction, as voted by the NFB.

“We can definitely do more to promote the variety of positions in the industry. As well as being on the tools, there are roles in health and safety, management, quantity surveying, accounting and designing, for example. I think it’s also important to show that there are career-progression opportunities – you can earn a really good salary in this industry. And we need to keep sharing success stories. It was great to have Lynn Way as the President of the NASC, and I hope to see another woman in that role before too long – especially as we approach its 70th anniversary!”

SIX FOCUS AREAS

When I was preparing this article, I put out a poll on LinkedIn to see what people thought we could do to encourage more women into the industry. The responses were pretty evenly spread:

Some people asked if women could work on the tools or had the right strengths to be in the scaffolding business. My reply is that our industry is about far more than being on the tools. Of course, that’s our core business, and if women want to work on the tools, they should be able to – and they should be made welcome and part of the team. But that central work is supported by estimators, surveyors, supervisors, health and safety experts, contract managers, project managers and more. All these opportunities should be open to everyone.

Of course, it’s important that anyone working in our industry

said we needed more visible role models

said we needed to educate careers advisors

think that management investment was most important

think that company cultures should be more inclusive

19% 23% 27% 31%

has on-site experience – they need to be given opportunities to work on site alongside project managers to pick up the rudiments of whatever trade they are involved in. You need to have an appreciation and knowledge of how trades work before you take on operational and management roles. So, it is up to organisations to make sure they make this part of their development programme.

In fact, this is one of the biggest barriers to women gaining senior positions in the industry. Most managers come from the tools, so if women haven’t had any exposure to the practical skills, they simply don’t know enough to win those positions. It’s something we need to tackle head on, making sure that those opportunities exist, so we can level the playing field.

WHAT DO WE NEED TO DO?

There are six main areas where I think a greater focus will help to recruit not just more women, but more people across the board:

• Ensure that there are role models across the industry, both female and male – not just in the top jobs but in as many disciplines as possible. Give people the confidence that our industry is a good place to build a long-term career.

• Encourage and support mentoring programmes – this is an area where both men and women can benefit from sharing experience and advice – and it helps to keep people in the industry.

KYM AUST-HOWLETT, THE GENERAL MANAGER MARKETING & COMMERCIAL AT SAMOA RUGBY UNION

“My career started when I was 17, leaving Australia to live in Japan as a model.

I mention this as its relevance to my career has been profound. It started my love of travel and ease of living overseas and understanding very early on how to adapt to different cultures.

“I started my career in rugby not long after returning to Sydney. Through the

• Educate the educators – careers advisers, schools and colleges often have restrictive views of the ‘trades’ – it’s often just about the people doing the visible work. It often completely neglects all the other job opportunities that we have to offer. We need to get out there and make our case.

• Change perceptions – many women think that working on a construction site isn’t for them. We need to work on the perception and image of the industry across the wider population, so that women feel this is a valid career choice option.

• Challenge behaviours and lead by example – where behaviour of any type is unacceptable, we should challenge it and demonstrate how we would like things to be. This is part of the responsibility of leadership.

• Think about our cultures – do we pay the same, offer equal working conditions, flexibility, development and more to everyone? If not, why not?

The Altrad Group is a proud sponsor of several rugby union teams, including the All Blacks and their international women’s team, the Black Ferns. We also support Australian club Western Force, and their women’s team. So, we’re aware of the huge strides that have been made in a very traditionally male sport. That’s one of the reasons it’s been fascinating to talk to Kym Aust-Howlett, the General Manager Marketing & Commercial at Samoa Rugby Union.

leadership of a new CEO, rugby had to make changes to be sustainable and operate as a successful business. So, I was appointed the first female and youngest general manager in Australian Rugby at the Waratahs. I knew being appointed so young that I was going to have a task with gaining respect, so said I was six years older than I was!”

Kym says it took nearly two years to get any form of respect in the sport. There was a lot of resistance to her appointment, but she focused, worked hard, studied for an MBA and built a record of commercial success. “I have so many stories about the issues I faced,” she says. “At the core of them is men asking how a woman can know and understand rugby. But I found that when I delivered the commercial results they wanted, the resistance eased.”

From there, Kym moved to New Zealand and then back to Australia to pursue TV work alongside commercial consultancy. When Covid hit, she was offered the role as General Manager Commercial for Samoa Rugby Union and now bases herself in the northern hemisphere.

“I love this role – it’s making a difference to a rugby nation that has had limited commercial and marketing resources in the past. Being able to represent young women making a difference in sport is challenging and competitive, as you’d expect – only the best survive!”

Kym’s faced issues that are common for women as they move into leadership roles.

“When I first started as General Manager, I’d have leaders of

organisations start talking to my male team members, thinking they were the GM. It always amused me when the penny dropped and they realised it was me who they were about to negotiate with – the back-pedalling was just gold –and those deals were often some of my best. This problem has pretty much gone away as I have grown my presence in the sport – but it’s a common issue in male-dominated businesses and it needs to change.”

Kym says the key to her success is three-fold:

“Have a great mentor – mine opened doors and opportunities that I couldn’t have found on my own. Once you’re able to, offer yourself as a mentor to other women as they start out on their career journey.”

“Embrace your points of difference. On a commercial level, there’s definitely a difference in the way women negotiate compared to men. Don’t try to be a bloke – use your talents to deliver great results.”

“Create strong relationships and partnerships. Business is all about

people and if you want to succeed commercially and as a leader, you have to pay attention to those relationships.”

“There are definitely a lot more female voices in leadership roles and at the table,” Kym points out. “There’s a better understanding that women look at business through a different lens and that gives a wider breadth to conversations, strategies and discussions – women add diversity and that adds value.”

THE BOTTOM LINE

There’s some research that suggests that companies with diverse management boards are more profitable. However, when you dig more deeply, it’s not about sticking a range of people on a board and crossing your fingers for more profit. The companies that perform better have a healthier culture – and that is reflected in who holds senior roles. Companies that are more inclusive, have a positive culture and welcome difference are likely to have more productive employees, deliver better results and are, therefore, more profitable.

This is about much more than just employing some token women or bringing in quotas that are relatively meaningless – it’s about having a fair and equal approach to running a successful business.

For example, I have always paid the same salary for the same

job and frankly, why wouldn’t I? Of course, there’s a need for flexibility to consider maternity leave and childcare needs –but again, we should be offering this flexibility across the board. And the more we pay attention to helping people achieve a sensible work-life balance, the better the business becomes.

IT WORKS IF YOU WANT IT TO WORK

I employ men and women in the same roles, on the same salary. I expect the same productivity and results from each – the job is the job – but perhaps delivered differently depending on circumstances – and that’s how it should be. If we don’t pay attention to our employees, we will lose them, along with the years of development we have invested in.

This approach applies at all levels. This means a mix of ages, genders, ethnicities, cultures and skills. How can we genuinely

“There’s no doubting that women generally have better social and empathy skills. They see things from a different perspective and can be more likely to speak up when they think something is wrong.”

work with a diverse range of people in our businesses if we have the same old people and cultures at the top? For clarity I’m not referring to myself here!

I genuinely feel that TRAD has benefited hugely from employing more women at all levels. There’s no doubting that women generally have better social and empathy skills. They see things from a different perspective and can be more likely to speak up when they think something is wrong. It’s interesting that a significant number of construction and subcontract trades have very autocratic management styles. Often, as a result of that, the men in the business don’t speak up when they see a problem or have a different view. My experience is that women always will.

Emotional intelligence can make a positive difference to team dynamics and customer relationships. It can also help hugely in commercial negotiations, as you can see from Kym’s experience above.

It’s not rocket science. As an industry that needs to grow and attract new talent, we should be encouraging everyone to consider scaffolding and construction as a serious career choice. Women account for around 50% of the population. There are no clear statistics for the number of women in the construction industry – although figures range from 13% to 28%. And we have even less evidence for the percentage of women working on the tools, which I’d estimate to be less than 5%.