Peak Processes

9/19/2023

Heather Crowell, Natasha Drennan, Jeff Sink, Brett Eiffert

Heather Crowell, Natasha Drennan, Jeff Sink, Brett Eiffert

9/19/2023

Heather Crowell, Natasha Drennan, Jeff Sink, Brett Eiffert

Heather Crowell, Natasha Drennan, Jeff Sink, Brett Eiffert

● 9/19 – Christmas Gift toYou

● 9/25 – Complete Leadership Schedules for Oct, Nov and Dec

○ Use the Planning Calendar your DLshared with you for key shifts

● 10/30 – Write two weeks schedules – Nov Wk 3 & 4

● 11/13 – Write two weeks schedules – Dec Wk 1 &2

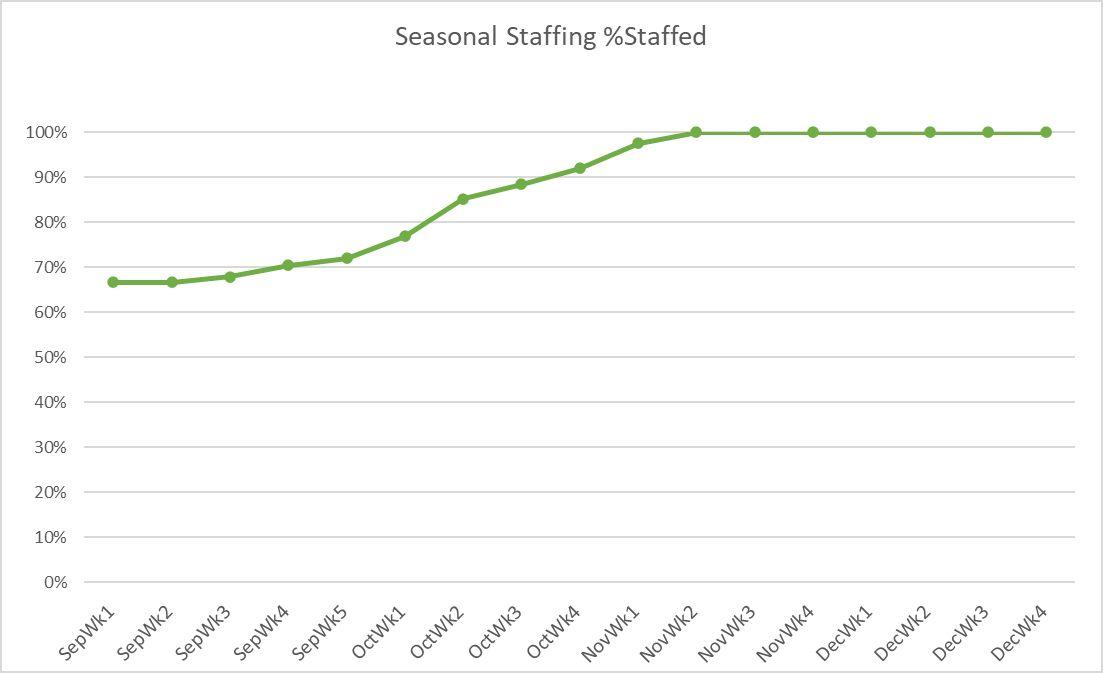

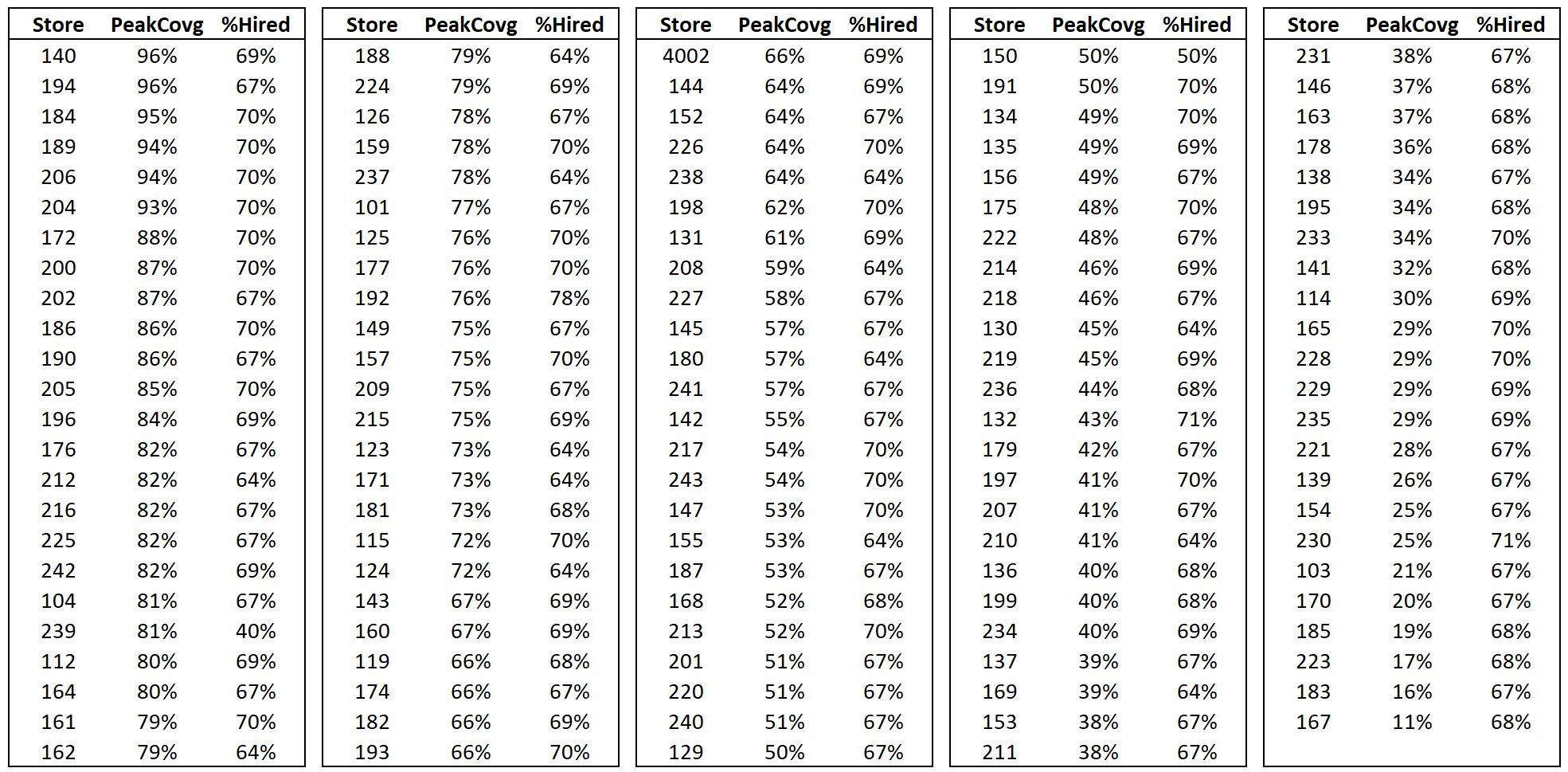

● Peak Coverage measures how well are we covered for our 20 highest traffic hours for the week

● Goal is to get to 90% or better

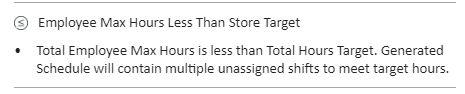

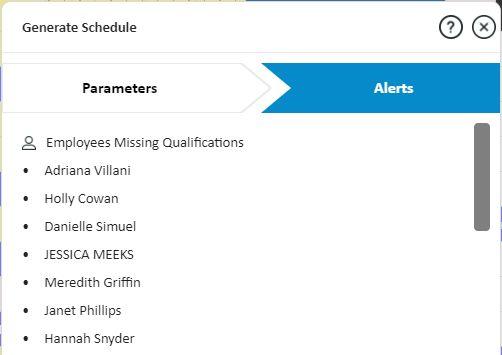

Unassigned Shifts are where you need coverage but no one has the qualifications or availability to cover

● Qualifications tell StoreForce what associate can work where

● New Hires always come in without any assignments

What does this alert tell you?

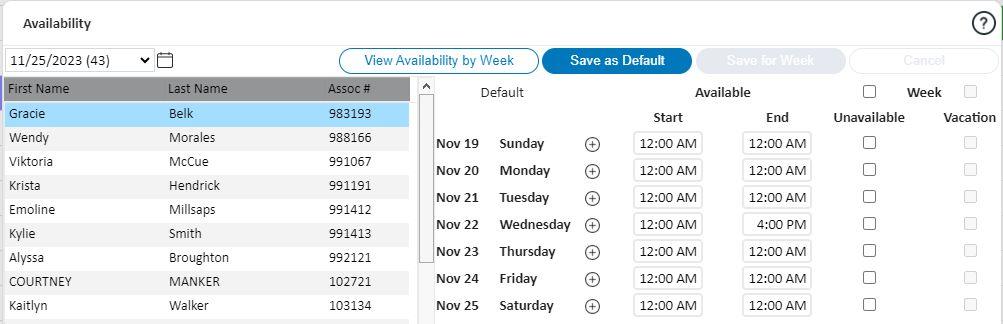

● Availability tells StoreForce when the associate can be scheduled

● Below is an example of FullAvailability: 12:00am - 12:00am 7-days a week

● To mark unavailable for the day, check the “Unavailable” box

● To limit a day, you can change the start or end time

● Availability can be saved as the new default or temporary “Save for Week”

Make sure these are correct before generatingplease email me when you get your store hours

Week History Pattern

Nov Week 4

PreviousYears (same week)

Dec Week 1 TY/LYBlend

Dec Week 2 TY/LYBlend

Dec Week 3 TY/LYBlend

Dec Week 4 Date Based

Dec Week 5 Date Based

Jan Week 1 Date Based

Keep these as wide as you can

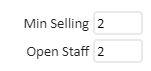

● Minimum selling is what will be scheduled the slowest segment of the week

● Max selling is Black Friday limits

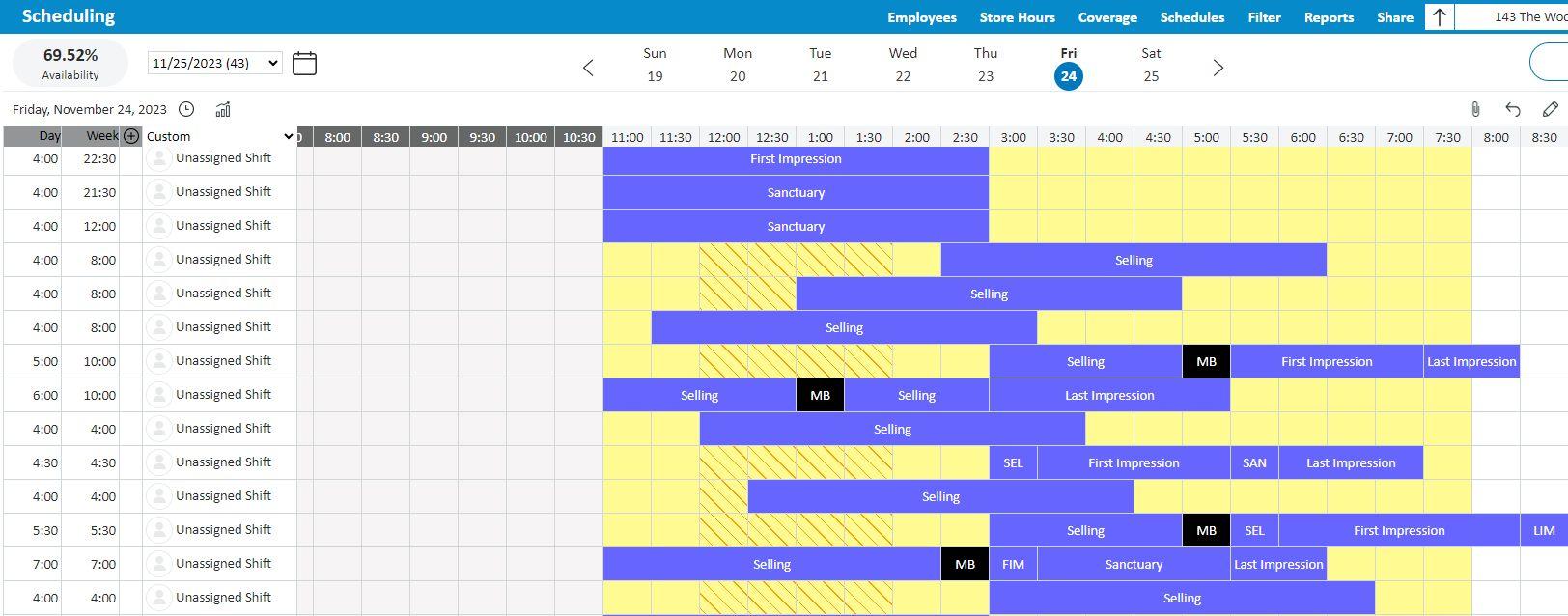

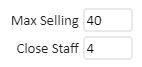

● Let the tool work for you

○ We want the dashed yellow line and red line to overlay

● Rerun Recommended Coverage and the schedule for Week 43 schedule as often as you’d like to see the impact on your Peak Coverage score

● Use the StoreForce resources on Milo - get associates enrolled in Employee Self Service (ESS)

● Be disciplined with your processes and non-selling hours

● Unrelated!!! - 68% complete on the ITReadiness survey

Key Receipts & Dates:

Stockroom Organization

“Heart of the House”

● Receiving Christmas statements for the set of FS: 1000 units avg. store vs. 300-400 LYin store by 10/15

● Kait Cup inventory at peak: 550 units avg store

● Cloud Boots (stored in the box): 300 units avg store

● Socks: 1800 units avg store

● Beauty will be back at the end of October/beginning of November

● Buying deeper vs. more CC’s

● November week 1 will be the highest week of receipts vs. Nov weeks 2&3

There will be more inventory to manage than LY, coming early than LY, and we will have more backstock than we did LY.

Effective Staffing & Scheduling:

● Stock Captain in place that has the availability to flex to shipment drop times

● PTmerch roles filled in stores with the position

● Brand Reps that are cross trained in processing and product placement

● Training that includes productivity and efficiency: having a well trained team that can move with pace and efficiency to get product to the floor on 24

Effective Organization of the Stockroom:

● Clear home for all departments with labels

● Clear stock processing area that includes a place for processing racks

● Clear place for shipment to be stacked when it’s dropped

● Clear home for bags/boxes/tissue

● Break area for the team

● Beauty placed by item not scent

● Clear bins for beauty not cardboard boxes (partner with DL on ordering)

● K-cups by color/style

Hanging Backstock

● Organized by dept then customer choice and in size order (NOT by color)

● Use waterfall hangers when possible to condense and save space

● Key items like dresses on the lowest bar

● Use a garment rack (found on Amazon: partner with DL) and add pegboard.

● This will be an easy place for processing as well as easy roll to the floor for placement and replen.

Shoe Backstock:

● In Bins by style

● Can carry bin to the floor for easy replenishment

● Cloud Boot backstock: remain in boxes and can be stacked in the same way as bins are shown here

● Facing with size out

● All tags tucked

● Folded by style and in size order

● Fold majority of sweater backstock: fold 100% of Chenille program

● Denim folded with tags tucked and joker out by style and in size order. Labels with the style are a key to success here

● No cardboard boxes with beauty or anything in it, clear bins with labels only

● Peg board area to store any back stock of Christmas

Ornaments

● Socks housed in bins by style with labels for easy replen

● Have a home for these items and the ability to flex seasonally (Christmas will bring ornaments, etc)

● Can hang sling bags on a peg board or use a belt hook to hang them on a bar

Things to store in offsite:

● Extra visual tools/fixtures that are not currently used

● Excess bags/boxes/tissue (non-holiday packaging)

● Extra SFS supplies

● Non-merchandise items that are not frequently needed and can be easily brought to store when needed

● Minimize the back and forth as much as possible

Getting the product to the floor for our guest is key to driving leverage and providing a world class experience.

Having the stockroom set up for success is step one, now let’s talk about replenishment.

Replenishment tips and Expectations:

● Have a team of BR’s (size based on volume, partner with DL’s) trained on stockroom flow and replenishment expectations.Teach them the homerun items and priorities for replenishment.

● Schedule replenishment during peak hours: in the last 2 hours of your peak segment have your replenisher on so that they can replenish based on real time sell through.This is separate from your runner that is handeling go backs.

● Closing team must understand that the expectation is to replenish based on sell through before leaving each night. BOD that is closing must walk all homerun items to ensure full size runs and replenishment is executed.

● Utilize your tools:

○ Geiger/RFID

○ Personality Chart

○ Homerun item guide

● VASL/FTMerch/OASLpartner together to staff and oversee this team and the execution of replenishment

● Use “Dog House” Shelving to create more space:

○ Stack empty large shipment boxes with flaps removed sideways to create shelving

○ Use these to store key items like sweaters in back stock

● Use high bars where you have them to store waterfall hanging product

● Evaluate your space and make a stockroom map now

○ Keep in mind what’s coming vs. LY: you will need more space for statements and accessories/beauty

○ Solve to the challenges: get creative

○ Plan what is going into offsite and how it will be transferred back as needed

● Use binning to help solve space constraints

○ If you have extra clear bins, use them to house accessories and/or a key program like a sweater.Always label your bins clearly.

● Purge: Make space by purging any unused/old items (partner with VDL/DL)

○ Old window elements that can be discarded

○ Unused/not in good condition binning (get approval before discarding)

○ Fixtures that are no longer used or you have an access of (may be able to rehome to another store)

● Teach your stock team what behaviors they need to adapt with the change in deep buys vs. additional CC’s:

○ Do not prep 100% of an item for the floor, prep 1-2 size runs and backstock the remainder

● Have back of house team in place by 10/1 that is fully trained by 10/15

● Have an owner of the back room: OASLwhere applicable, or assign a leader

● Get Creative: plan ahead for space challenges and create plansA,B,C

○ Have a stockroom map

● Plan what is going into offsite and minimize the trips to and from

● Schedule effectively for efficient processing and flow to floor

○ Have team there after shipment drops to minimize down/dead time

● Keep stockroom neat, clean, and organized daily

● Purge any unneeded items to create space

● Educate your entire team on what’s coming, what to expect, and stockroom standards and maintenance

● Peak week for receipts is Nov week 1: schedule and plan accordingly

Expectations:

● There is a well trained team in place for the stockroom at peak by 10/1

● There is someone on the leadership that owns the stockroom and holds team accountable to the maintenance of it

● Stockroom is 100% deep cleaned, organized, and mapped by 10/1 (use this weeks fall cleaning to get this done)

● There is a plan in place to ensure product is processed and to the floor within 24 throughout peak season and stockroom is kept neat, clean, and organized