The railroad passing through Corona, California, has bolstered the local citrus industry for an entire century, earning Corona the nickname “Lemon Capital of the World.” However, that same rail infrastructure that connected Corona to the rest of the world also divided it from itself as it snaked through the very center of the city. For drivers on McKinley Street, long waits for freight and passenger trains to clear the gradelevel crossing became customary. In 2018, the City of Corona began the environmental and final design phases to build a new bridge over the railway and the open-channel drainage canal that runs beside it.

The project engineer, Biggs Cardosa, decided to go big with American steel. By spanning the entire 291-foot gap over the railway, canal, and access roads, any conflicts with the drainage

canal were eliminated. Utilizing a lightweight steel span meant that the bridge could be constructed adjacent to its final location and then lifted into place, minimizing railway disruption. In this case, an arch design was the perfect solution. Using interlaced “network” suspenders to support the deck reduced moments imposed on the arch ribs when compared to vertical suspenders, allowing the arch ribs to be lighter, more slender, and more aesthetically pleasing.

Initial designs included wide-flange X-bracing between the arch ribs, but those members were switched to parallel 22x22x7/8” Jumbo HSS members from Atlas Tube due to their ease of constructability and cleaner aesthetics. Atlas Tube’s 100% domestic Jumbo HSS helped engineers avoid the obstacles presented by wideflange beams, and its near-immediate availability provided the benefits of closed sections without fabricating additional built-up boxes for the structure.

Thompson Metal Fab (TMF), with 85 years of history in oil and gas, marine structures, and transportation, fabricated the geometrically complex structure. Walsh Construction, the largest bridge builder in the country, would self-perform the steel erection. TMF’s expertise was critical as the project included several heavy weldments with complex geometry, especially at the joint where the arch rib connects to the tie girder. According to TMF, Atlas Tube’s Jumbo HSS made a difficult job simpler.

Atlas’ domestic Jumbo HSS was not the only innovation that made the bridge a reality. While the tie girders were large enough to allow ironworkers to reach the interior of the bolted splices, the arch ribs, tie beams, and support diaphragms were not. A new technology, Shuriken® by Atlas Tube, was a logical answer to this challenge.

Shuriken allows the installation of A325 and A490 bolts from one side and was the perfect solution to the connection conundrum confronting the team. By mounting the nuts on the interior of the HSS and box members, splices could be bolted up from the exterior. The built-in lateral flexibility of Shuriken preserved erection tolerance, while DuraSquirt® DTI washers from Applied Bolting Technologies made accurate tensioning and inspection easy for the slip-critical A490 bolts.

All these innovations came together to give Corona a beautiful, efficient new bridge as well as a safer and betterconnected community.

atlastube.com

Scan the QR code to read the full case study. To learn more about Atlas or to discuss your design ambitions, call 800.733.5683 or visit atlastube.com

New construction architecture requires special consideration for the inevitability of future upgrades. That’s why modern construction projects need hanging solutions that are built for speed, versatility, and adaptability to ensure quick and seamless renovations.

To help meet that challenge, Vulcraft-Verco has developed the PinTail® Anchor, an innovative hanging solution that works exclusively with our Next Generation Dovetail Floor Deck, and are specifically designed to futureproof today’s construction projects for tomorrow’s renovations.

subscriptions@structuremag.org

Chair John A. Dal Pino, S.E. Claremont Engineers Inc., Oakland, CA chair@STRUCTUREmag.org

Kevin Adamson, PE Structural Focus, Gardena, CA

Marshall Carman, PE, SE Schaefer, Cincinnati, Ohio

Erin Conaway, PE AISC, Littleton, CO

Sarah Evans, PE Walter P Moore, Houston, TX

Linda M. Kaplan, PE Pennoni, Pittsburgh, PA

Nicholas Lang, PE Vice President Engineering & Advocacy, Masonry Concrete Masonry and Hardscapes Association (CMHA)

Jessica Mandrick, PE, SE, LEED AP Gilsanz Murray Steficek, LLP, New York, NY

Brian W. Miller Cast Connex Corporation, Davis, CA

Evans Mountzouris, PE Retired, Milford, CT

Kenneth Ogorzalek, PE, SE KPFF Consulting Engineers, San Francisco, CA (WI)

John “Buddy” Showalter, PE International Code Council, Washington, DC

Eytan Solomon, PE, LEED AP Silman, New York, NY

Executive Editor Alfred Spada aspada@ncsea.com

Managing Editor Shannon Wetzel swetzel@structuremag.org

Production production@structuremag.org

Director for Sales, Marketing & Business Development

Monica Shripka Tel: 773-974-6561 monica.shripka@STRUCTUREmag.org STRUCTURE

• Concrete Repair Mortars

• Corrosion Protection

• Construction Grouts

• Waterproofing

• Sealants and Joint Fillers

• Coatings and Sealers

• Epoxy Adhesives

• Cementitious Flooring Systems

• Cure and Seals

• Densifiers

• Structural Strengthening Products

• Precast

• Epoxy Adhesives

Visit www.mapei.com/us for details on all MAPEI products. Your single-source

MAPEI offers a full range of products for concrete restoration, waterproofing and structural strengthening. Globally, MAPEI’s system solutions have been utilized for such structures as bridges, dams, tunnels, highways, parking garages, stadiums and high-rises.

By Nik Blanchette, SE; Steve Heyne, SE; and Chris Warner, SE

The comprehensive rehabilitation of a Silicon Valley high school used a composite solution.

A landslide incident on a gentle slope serves as a reminder of the importance of site investigation, desk study, and checking of overall global stability.

By Matthew Fadden, Ph.D, PE; Sedona Iodice; and Gary Klein, PE, SE

The collapse of the condo in Surfside, Florida, underscores important lessons for the structural engineering community.

floor joist systems with flush-frame connections.

Way better, weigh

Simple to specify and design, steel floor joists with flush-frame connections provide performance equal to wide-flange beams—using up to 35% less steel. Lower material and installation costs while gaining impressive advantages.

By Brian Petruzzi

The concept of borrowed belief is not new, and is certainly not mine. In fact, a quick Google search brings up other articles and entire websites dedicated to borrowed belief. I first heard the term earlier this year at a physical security design conference in Dublin, Ireland. We are all familiar with presentations at conferences dedicated to softer topics —leadership, communication, and the alike. It was a particularly busy week for me, and I was looking forward to catching up on some e-mails during a presentation titled, “The Power of Borrowed Belief” by a retail coaching consultant named Louise Lally. I’m glad I didn’t.

The concept of borrowed belief is not complex—it’s quite simple. At its core, borrowed belief is about believing in someone else before they can believe in themselves. It’s often used when someone is lacking self-confidence and needs to draw strength from the positive opinions of others to move forward in a situation. It’s about actively incorporating the trust and faith others place in you to propel your own actions and decisions.

as well as planning our local awards gala. I joined the National Council of Structural Engineers Association’s (NCSEA) Young Member Group Support Committee (YMSC) in 2016 and chaired the committee in 2018. However, my engagement with SEA-MW and NCSEA came to an abrupt halt in 2019 when I made the difficult decision to pursue a career in physical security. I still saw value in SEA-MW and NCSEA, it’s just that I thought my contributions to these organizations wouldn’t be valued once I left the profession. I had a perception of the type of person who provided value, and I no longer fit the mold.

While some may be capable of offering more, we should always be able to articulate one person we are supporting and empowering—our communities will be better for it.

Borrowed belief lays the foundation for why mentorship is so impactful to young engineers or why advocacy is a critical aspect of career development. In ways, mentorship and advocacy are forms of borrowed belief, however the concept of borrowed belief is much simpler. Winston Churchill once said that “All great things are simple.” This is why the concept of borrowed belief continues to stick with me, as the simplicity and efficacy of believing in others is borrowed belief’s greatest superpower. Let me explain. Just over six years ago I decided to leave the structural engineering profession. At the time, I was a licensed Professional Engineer with nine years of experience. I was very active in the Structural Engineers Association of Metropolitan Washington (SEA-MW), helping start our local Young Member Group in 2013 and our local career fair titled The Next Step Event in 2014,

Six months later I received a phone call informing me that I was nominated for a position on the NCSEA Board of Directors. While I didn’t see it at the time, others saw value in having a 33-year-old, with nine years of structural engineering experience, who recently transitioned out of the profession, join a board whose mission is to advance the practice of structural engineering. To be honest, it still doesn’t seem plausible after reading the above sentence today. Some would call this imposter syndrome, and they are probably right. However, the power of borrowed belief is that it doesn’t matter what the diagnosis is called. Lending support and believing in others is the simple answer. Imposter syndrome, glass ceilings, inclusion & belonging—the answer starts with believing in others.

This is where I challenge each of you. Take a moment and consider the following—who are you lending belief to right now? Maybe it’s a child who doesn’t think they are good enough to make a sports team, a colleague who is struggling to keep up with rapid advancements in technology, or a parent who is resisting elderly care. No matter your age, borrowed belief is effective in both personal and professional settings to create supportive and inclusive environments. While some may be capable of offering more, we should always

be able to articulate one person we are supporting and empowering—our communities will be better for it.

For the first time in NCSEA’s his tory, both the President and Vice President of NCSEA are Professional Engineers currently supporting other pro fessions and industries. While I’m not proposing to stage a mutiny, I do believe that diversity in thought strengthens communities. NCSEA is entering its 32nd year and has never supported a stronger community of structural engineering professionals. Our diverse programming this year includes awarding student scholarships for the NCSEA Summit in New York, issuing grants to our Artificial Intelligence (AI) Team to develop an AI roadmap for the structural engineering profession, and recently hosting our first annual Executive Leadership Retreat in Napa, California. I’m grateful for the immense belief others allowed me to borrow six years ago to continue my journey with NCSEA, and encourage all of us to empower others to join their local structural engineering association or to directly join one of NCSEA’s many committees. It’s only when we find a place for everyone that this profession will reach its maximum potential. ■

Scan the QR code to watch Louise Lally’s Tedx talk titled, “The Power of Borrowed Belief” to learn more.

Robert K. Otani, PE LEED AP, is Chief Technology Officer at Thornton Tomasetti, Inc., a 1,800+ person multidisciplinary engineering and consulting firm, and founded the CORE studio, an applications development, advanced computational modeling, and R&D group at his firm. Otani serves on the Advisory Committee for Thornton Tomasetti’s firm-wide Research and Development program. He has extensive structural design and project management experience involving commercial, infrastructure, institutional, cultural, and residential structures. Over his 29-year career, he has worked on a wide variety of complex projects, including high rise buildings, long-span roof structures, sports arenas, airport terminals, major building structural renovations, and complex art projects totaling over $3 billion USD of construction. He served as President of the Structural Engineers Association of New York in 2007 and was a professor at Pratt Institute School of Architecture from 2008-2018 and Columbia GSAPP from 2009-2015.

STRUCTURE: What inspired you to become a structural engineer?

Otani: At first, I didn’t know that I wanted to be a structural engineer. In high school I did well in math and science, I worked as a carpenter during the summers thanks to my brother, and my dad was a chemical engineer, so the combination of those factors led me to civil engineering at Rutgers University.

STRUCTURE: What were some of your most fulfilling moments during your career?

Otani: I’ve worked on some iconic and very challenging buildings, so anytime one of those projects gets built successfully—as engineered and as planned—it’s very fulfilling. From a management perspective, it has been the growth and success of the CORE studio team which I helped to create in 2010 and is now over 40 people. From a mentoring standpoint, I’ve supervised many upand-coming engineers and to see them develop into very successful project managers and leaders in the firm has been fulfilling as well.

STRUCTURE: What were the biggest challenges you experienced during the various stages of your career?

Otani: Early in my career, the biggest challenge was that despite excelling in the technical aspect of engineering, I was not recognized in the firm. So, I had to learn the business aspects of the firm. From a personal perspective, I had to learn to be more extroverted and confident in speaking. To a large extent it was self-marketing. In many ways, SEAoNY helped me with that aspect when I became very active in the organization, serving on the Board and being active in the Codes, Publications, and Programs committees.

STRUCTURE: These sound like issues that many engineers face. What would be your advice to them?

Otani: My advice would be to learn as much as possible from subject matter experts early in one’s career to excel at project technical work, be observant and learn from the successful Principals

in the firm to understand what it takes to be a leader, and raise your hand for specific initiatives within the firm that will both add value and earn recognition. Finally, it is critical that every engineer knows their strengths and weaknesses and to improve their skills when needed, which is something that is important throughout an engineer’s career. We all can improve.

STRUCTURE: Our industry has advanced significantly over the past few years with the aid of technology and now the consideration of AI. What will the impact be on our industry?

Otani: The industry has evolved tremendously over my career from mainly doing our work by hand calculations, engineering design aides, and hand drafting. I did not have a computer when I started at Thornton Tomasetti in 1995! We had shared computers when I started and only a handful of engineering software to use as compared to now, where a myriad of software are available to use. In many ways this has made it more difficult for young engineers to navigate the design of a building. What we do in terms of production has changed as well with the advent of BIM, which has led to clients asking for more detail at all stages of the design process. So technological advances have been a double-edged sword in many ways. Technology has allowed us to do more, but clients and the resulting standard of care have required us to do more, as well.

STRUCTURE: What advice would you give to someone who doesn’t know where to start with integrating AI into their daily work?

Otani: With any new technology or software, the most important aspect to know is what is its capabilities—what it does well and what it doesn’t. I explain AI as “embedded intelligence” since the data/information that AI is built upon (if done correctly) is real data and smart data and the artificial part is how the AI models are trained. So, the biggest aspect of trust in AI is going to be where and how that data was created or developed and how accurate the AI model is. That level of accuracy will determine how much an

engineer can trust AI and consequently how much double checking of that information is required.

STRUCTURE: Is there anything you miss from a time without the advanced systems we have today?

With any job there will be challenges, but if you enjoy your work and related contributions to the built environment and ultimately the cities we live in, have fun solving complex challenges along the way, and remember to find fun away from engineering and the office, then that is key to work life balance.

Otani: Absolutely. In the “old” days we used to only do analysis for a subset of a building i.e. a few columns, a few bays, and a few options for lateral systems, and use our engineering skills to make judgements about the entire building system. Now many engineers model the entire building in finite element software and let the software do the work without necessarily understanding the nuances of the behavior of the building, load paths, and sensitivity of the system layouts to the overall design. I’m hoping that AI can help engineers become better engineers as opposed to technicians using software.

STRUCTURE: What might young engineers do today in response to the difficulty of navigating so many software options available?

Otani: I think it’s the engineering firms’ responsibility to both educate young engineers on “best practices” of what software to use (as well as teach engineers how to best use the software) and when during the project timeline to use the software. However, it is also the responsibility of the young engineer to know when to ask questions to the subject matter experts in the firm and engineering organization members (like SEAoNY). My most valuable engineering lessons, both technically and professionally, came from my colleagues both at my firm and from my SEAoNY colleagues.

STRUCTURE: Sounds like mentorship is still critically important. Would you like to mention a few of yours and how they helped you?

Otani: There have been so many so I’ll only mention my first mentor, I. Paul Lew, PE, RA, who was Project Manager/Senior VP of the JFK Terminal One project that I started on. As a licensed architect and engineer, Paul had a unique combination of skills as a prolific technical engineer, but he also had an aesthetic mindset where he would seamlessly communicate with the design architects. He would perform step-by-step calculations on a yellow pad in front of the engineering team to simplify an otherwise very complex problem which was invaluable to me by instilling that every engineering problem can be broken down into simpler components if you understand load path and physics. Finally, he was the only person in the office that would detail connections in 3D autocad, which in 1995 was unheard of. That level of detailed thinking, simulation, visualization and ability to share that knowledge certainly stuck with me and has become a model for me.

STRUCTURE: As a past president of SEAoNY, what accomplishments are you proud to see in the organization now, and what do you hope for the future of SEAoNY?

Otani: I’m particularly proud that when I was President, we hired a management company (Jaffe) to help manage the SEAoNY functions and to this day Jaffe is still assisting the organization. Prior to that, I had to email the organization from my work email, and it certainly is more efficient now. I’m also glad that SEAoNY

has added Sustainability and Diversity to their committees. I would hope that SEAoNY would try and get more young people involved. I’ve noticed that since the pandemic there is less interest in young engineers getting involved with organizations like SEAoNY which would help them grow and learn to be better engineers and managers.

STRUCTURE: Everyone is concerned about work-life balance. Can you share some of your tricks?

Otani: When I was a young engineer, work-life balance was not really discussed. We were rewarded for being productive and getting things done and I was one of those who worked many hours, including weekends, to do that. I don’t regret that because I became skilled very fast. However, more recently I’ve learned to balance that workaholic mentality and manage my time with the help of others in a more reasonable timeframe. One of the keys to work-life balance also is really enjoying what you do and making adjustments in your daily work to make it more enjoyable.

STRUCTURE: Do you think that working extra hard, in the workaholic mentality you mentioned, is the only way for young engineers to ultimately succeed in our industry today, or are there other paths?

Otani: No, being a workaholic is certainly not a successful longterm strategy for succeeding particularly in today’s environment. It had some benefits when I was a young engineer—working more meant learning more and being more productive but that was a different time. Today it’s important that engineers develop smarter. That is, to learn as much as possible from their colleagues and continuously develop both their technical and leadership skills.

STRUCTURE: What sorts of adjustments in your daily work has made your job more enjoyable?

Otani: I started by assessing my strengths and weaknesses and decided to focus on what I do best. Today as our firm’s CTO, my colleagues know me for software, AI, and computational tools but the reality is that my passion for advanced FEA modeling back in the mid-2000s was what got me interested in computational modeling in the first place. With the rapid pace of technological improvements, structural engineering will never be the same as when I first started and it’s exciting to be part of forming the future of our practice.

With any job there will be challenges but if you enjoy your work and related contributions to the built environment and ultimately the cities we live in, have fun solving complex challenges along the way, and remember to find fun away from engineering and the office, then that is key to work life balance.

STRUCTURE: What is the best career advice that you have received?

Otani: Charlie Thornton told me once that everybody should have a vision of where they want to be in 5 years, to work every day towards achieving that vision and to do whatever it takes to get there.

Credit is given to SEAoNY for several questions in this interview. ■

It’s time for an update to your concrete specifications.

By Michael Lyons, PE, LFA

If you are a practicing structural engineer, you are likely familiar with the idea of a concrete mix design table and concrete general notes. For many projects, these are supported with additional detail provided in specification section 03 30 00—Cast in Place Concrete. While the level of detail and amount of information included may vary depending on what type of project you find yourself working on, nearly every project involves some amount of concrete. Unlike other materials, concrete can vary significantly in performance among suppliers and is made from multiple constituent materials, each with their own ASTM standards. It can’t be defined by a single ASTM standard as is the case for steel or a species and grade from the NDS supplement as is the case for wood. Specifying concrete often seems to require a deep knowledge of multiple different ACI codes, an understanding of various rules of thumb and navigating a few contradicting opinions from contractors and peers.

Many structural engineering firms have started to update their existing concrete design criteria because of two emerging and important industry trends: performance-based specifications and embodied carbon. The goal of this article is to provide a summary of the different variables that engineers need to consider when specifying concrete and explicitly address how these variables are related to performance-based criteria and embodied carbon. A detailed reference related to these topics is provided at the end of the article which has been developed by the National Council of Structural Engineering Association (NCSEA) Sustainable Design Committee.

Performance versus prescriptive—what is the difference when it comes to concrete specifications? Prescriptive design criteria do not guarantee performance, but often have historic precedence or are backed up by research indicating a correlation to performance. Engineers rely on these based on this historic precedence even though the concrete industry is constantly evolving. Procedures for production are different, materials are more advanced, and our ability to collect and report data has significantly increased. A common example of prescriptive design is limiting the water content in a mix to achieve adequate durability of the finished surface, reduce long term shrinkage, and ensure a quality mix. Another is specifying a minimum slump to ensure the concrete is placeable and consolidates well, or a maximum slump as a limitation on excessive water content.

Prescriptive specifications are when an intermediate or proxy value is being specified with the intention that it will correlate or lead to the desired performance. They are one lingering example

in many structural drawings where engineers are still specifying the means and methods of the contractor.

Performance-based specifications are when the desired results are specified directly. Using the same examples noted earlier, slump and max w/cm ratios are replaced with shrinkage data. As engineers, we do need data for a performance-based specification to be successful, which is often a drawback. We may need data that the supplier doesn’t immediately have and that will increase the lead time for mix design submittals and concrete placement. The sophistication of a supplier is potentially highly variable within a given market and especially between different size markets and regions. Additionally, the industry does rely on prescriptive based requirements when there are not time-proven and reliable performance-based metrics available, such as the durability requirements outlined in ACI 318, Chapter 18.

Performance-based specifications are when the desired result or performance characteristic of a concrete mix design are specified directly without dictating the method by which the mix supplier must use to achieve the required performance. They inherently allow for optimization by the ready-mix suppliers, allowing the responsibility for performance to shift to the entity that can affect the change.

The National Ready Mixed Concrete Association (NRMCA) has advocated for this idea through their Prescription to Performance Initiative (P2P), which began in 2002. The initiative was developed to educate suppliers and engineers on the benefits of movement towards performance-based specifications. They highlight the incentive it creates for concrete suppliers to innovate. It rewards them for decreasing variability in their test data and increasing the performance of their materials. Along these lines, it inherently supports reducing embodied carbon, even if it wasn’t being tracked or stated as a goal on a project.

Historically, a variety of different variables have been specified for concrete mixes by structural engineers. A non-exhaustive list is shown in Table 1. Included in the table for reference is an indication whether the variable is primarily performance-based or prescriptive in nature and the variable’s impact on the embodied carbon and cost of a mix, i.e., does specifying a higher value for the variable tend to correlate to an increase in embodied carbon or does it have an inverse relationship (or “it depends”)? For prescriptive properties, a performance-based property that can be substituted is indicated.

Cement Type Prescriptive N/A N/A

Slump Prescriptive

Max W/CM Ratio Prescriptive

Max Nominal Coarse Aggregate Size

Exposure Class Prescriptive and Performance components

C150,

of

Shrinkage, Compressive Strength

to 0.6 Shrinkage, Compressive Strength

F1, F2, F3 S0, S1, S2, S3 W0, W1, W2 C0, C1, C2

Durability Testing

Shrinkage Performance It Depends N/A 0.04% to 0.08% N/A

Global Warming Potential Performance

SCM Replacement1 Prescriptive

Durability

1: SCM = Supplementary Cementitious Material; 2: Testing may be performed based on ASTM C1202, AASHTO T358 or ASTM C1876; 3: Noted as decrease due to the embodied carbon and cost of lightweight concrete commonly exceeding equivalent strength normal weight, due to the production of the aggregate used; 4: Greater strengths can be achieved with high performing (HPC) or ultra-high performing (UHPC) concrete

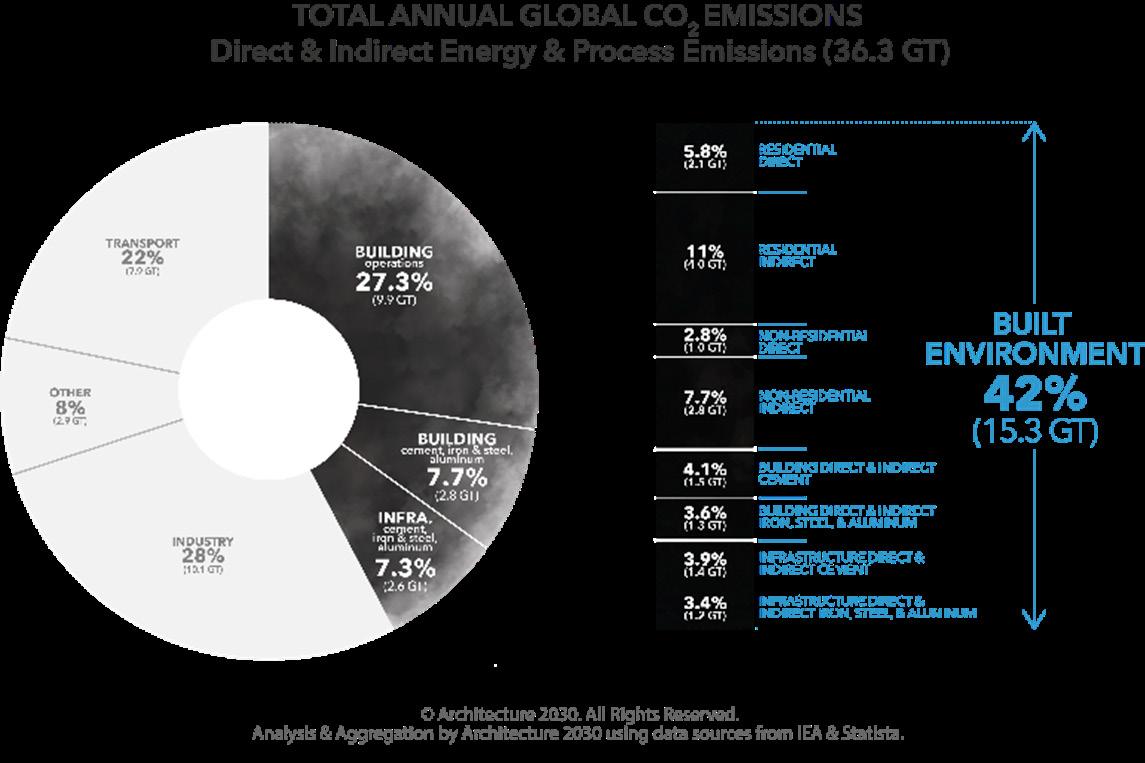

Concrete producers and specifiers have another variable that they must consider and balance along with structural performance, durability, place-ability and pumpability: embodied carbon. Both globally and domestically, buildings are responsible for 35% of greenhouse gas emissions. While a large portion of these emissions are the result of building operations, embodied carbon has been gaining more and more attention as a smaller but significant portion of the problem (Fig. 1). With the focus on embodied carbon increasing, both the structural engineer and the concrete industry should be strategizing on how to make reductions and learning how to appropriately respond to the demands of architects and building owners. Many are realizing, if it wasn’t

clear already, that this is a complex and difficult issue to solve. The concrete industry is responsible for as much as 11% of global and 1.5% of domestic greenhouse gas emissions. For perspective, the steel industry is responsible for 8% globally and 2% domestically and the airline industry is around 2.5% globally. Two primary reasons have led to the concrete and cement industry being at the center of the embodied carbon discussion. The first is that the production of ordinary portland cement requires both significant energy (heat) and involves a chemical reaction that results in direct

An environmental product declaration (EPD) is what a material supplier will typically provide to demonstrate conformance with a global warming potential target. These traditionally provide the user with environmental impact category data, including global warming, for cradle-to-gate scope (all emissions occurring up to the point that the concrete leaves the ready-mix plant and starts to travel to the project site). An EPD is a form of life cycle assessment (LCA) with a specific goal and scope defined by a product category rule (PCR) that allows for comparison between concrete mixtures from different suppliers with a reasonable amount of confidence. Specifications should require Type III third-party verified EPDs conforming to International Standards Organization (ISO) 14025 and the current concrete PCR (NSF PCR for Concrete, Version 2.1).

CO2 emissions (process emissions). The second and more important variable is the volume of concrete that the built environment requires. A commonly referenced statistic is that concrete is the most consumed man-made material on earth, or alternatively, the secondmost consumed material after water. The built environment has become dependent on the use of a large volume and uninterrupted flow of concrete and each unit of concrete delivered to a project site is contributing greenhouse gas emissions to the atmosphere.

Approximately 90% of the emissions associated with concrete come from the production of cement, with the remainder from other constituent materials and transportation and placement during construction. For this reason, most reduction strategies involve reducing the amount of cement or exploring alternative cements, pozzolans, and supplemental cementitious materials (SCM). Prescriptive approaches to reducing the emissions of concrete typically involve requiring the cement quantity to be reduced or requiring a minimum amount of SCM use. A project may choose to balance performance and embodied carbon by specifying a range of SCM content, with the lower end of the range attempting to reduce embodied carbon in a prescriptive way and the higher value ensuring reasonable performance and strength gain is provided by the mix supplier for the contractor. It should be noted that it has been shown that an SCM specification requirement does not directly correlate to a reduction in embodied carbon but may be a strategy for projects without the necessary data to implement a global warming potential limit. The best way to ensure a project meets a desired embodied carbon

AND EASILY

ACCORDANCE WITH CODE REQUIREMENTS.

DEWALT DESIGN ASSIST (DDA) is a no-cost/no-fee state-of-the-art

that streamlines, automates, and optimizes your concrete anchoring

standards to choose from, a comprehensive library of anchors, numerous

and a wide range of design tools, simplify your design process with DEWALT Design

BASEPLATE THICKNESS CALCULATOR

(FINITE ELEMENT ANALYSIS TOOL)

This tool discretizes the baseplate into elements to calculate and check the thickness to determine when the plate is sufficiently rigid. A heat map is generated to highlight the distribution of the stresses on the plate.

target is to specify global warming potential targets for each class of concrete. This concept is relatively new for the industry and typically requires some amount of education for the design and construction team to successfully implement. Like other performance-based criteria, it also requires data to be submitted to the structural engineer by the mix supplier to ensure conformance. The availability of this data (see sidebar on page 14) has been growing exponentially but is still a new concept for some suppliers and may not be available for every mix. A significant amount of lead time may be required if you are targeting a significantly lower value than the national or regional benchmarks as established by the NRMCA. There are inherently two components to specifying a global warming potential target. One is transparency and data, creating the information engineers need to understand what the emissions are for a mix and inform decision-making. The second is to push the industry to develop lower-carbon emitting solutions. We should be leaning on the innovativeness of the supplier to produce new mixes both with the tools and materials they have available and looking for new materials and procedures to meet the demands of project specifications.

To meet an embodied carbon goal, along with performance and life safety criteria already demanded of suppliers and contractors, it becomes even more essential than ever to allow flexibility and control for the ready-mix supplier through an overall performance-based approach to the concrete specifications.

The best way to achieve an embodied carbon goal, or other project requirements for your concrete scope, is through the use of performancebased specifications. They allow for specification of a direct measure of embodied carbon: a global warming potential limit supported by an environmental product declaration. For detailed supplemental information on all the concrete mix design properties discussed in this article, refer to the Performance-Based Concrete Specification Guidance: Concrete Class Table published on the NCSEA website by the NCSEA Sustainable Design Committee. Take this document and start to have discussions with your project teams. Better yet, start having conversations with your local concrete suppliers about their capabilities when it comes to low embodied carbon concrete. For the ideas proposed in this article to be successful, it requires increasing our ability to specify the appropriate tests and trust the data that we receive. It also requires suppliers to understand the testing requirements and early communication among all stakeholders to optimize mixes and perform additional testing as required to meet the needs of the specification without resorting back to traditional prescriptive based approaches.

Using the code provisions as intended, without any additional factors of safety, will result in structural designs that inherently meet the stability safety objectives.

By Jaspal Singh Saini, PE

The methodology for analyzing and designing building structures using specified loads and load combinations in the International Building Code (IBC) and ASCE 7 Minimum Design Loads and Associated Criteria for Buildings and Other Structures has undergone significant evolution over the years. Structural engineering practice has progressively transitioned from traditional allowable stress design methods to reliability-based strength design methods. The updates in IBC and ASCE 7 aim to allow a consistent set of load combinations throughout the entire design engineering lifecycle. For assessments related to overturning and sliding stability, irrespective of the building risk and seismic design categories, seeing a factor of safety of 1.5 has been a norm for structural engineers throughout the U.S., particularly for those accustomed to traditional approaches. Design coordination with geotechnical engineers in the building industry who typically follow allowable or working stress design practices and require a minimum factor of safety of 1.5 for soil slope stability failures under sustained loads may also reinforce this opinion. Despite the well-intentioned nature of the IBC and ASCE 7 code revisions, they are often misinterpreted/misunderstood when evaluating the stability of structures against overturning and sliding.

Sections 7.2.9 and 7.2.10 of ASCE 41-23 Seismic Evaluation and Retrofit of Existing Buildings require that the minimum factor of safety of 1.0 shall be used for the overturning and sliding checks for seismic evaluation of existing buildings; ASCE 41-23 commentary clarifies that these requirements are “consistent with prevailing practice specified in current codes for new buildings”. Furthermore, Section 5.3.5 of ASCE Report Seismic Evaluation and Design of Petrochemical and Other Industrial Facilities mentions that the minimum factor of safety for overturning and sliding stability checks for seismic loads shall be 1.0 for petrochemical and other industrial facilities and recommends using the alternative allowable stress design (ASD) load combinations in IBC. However, quantitative structural stability requirements in IBC (2024) and ASCE 7-22—the codes of record for analysis and design of new building structures—are only provided in IBC Section 1807.2, which stipulates that the retaining walls shall be designed to produce a stability factor of safety (called safety factor in IBC) of 1.5 for nominal [or service] loads. Does this mean that new building structures are exempted from the global structural overturning and sliding stability checks, and have IBC and ASCE 7 always been silent on the required factor of safety for stability calculations for new building structures? The answer is obviously no for both questions. IBC (2024) Section 1605.1.1 states

that “where overall structural stability … is being verified, use of load combinations specified in Section 2.3 or 2.4 of ASCE 7, and in Section 1605.2 shall be permitted”. ASCE 7-22 Section 1.3 requires that the building structural systems “… shall be designed and constructed with adequate strength and stiffness to provide structural stability …” and “… designed to resist forces caused by earthquakes, wind, and tornadoes, with consideration of overturning, sliding, and uplift …” However, these standards do not provide any explicit requirement for the required factor of safety for these checks for new building structures. A quick review of the evolution of building codes shows that ASCE 7 used to contain explicit stability check requirements just a few decades ago, but those requirements were removed with the migration from the allowable stress design approach towards the reliability-based strength design methods.

ASCE 7-95 Section 2.4.4, applicable to load combinations for allowable (or working) stress design for service level loads, required that “Buildings and other structures shall be designed so that the overturning moment due to lateral forces…does not exceed two-thirds of the dead load stabilizing moment… The base shear due to lateral forces (wind or flood) shall not exceed two-thirds of the total resisting force due to friction and adhesion...” This ASCE 7-95 provision meant that a minimum factor of safety of 1.5 was required for service level loads. Similar requirements were not explicitly included or deemed necessary

either in ASCE 7-95 Section 2.3 pertaining to load combinations for strength design or in the UBC-1997.

The code updates in ASCE 7-98 revised Section 2.4.4 to remove the above requirement but added two new allowable stress design load combinations involving 0.6D+W and 0.6D+0.7E, where D, W, and E represent dead loads, wind loads, and seismic loads, respectively, to supplement the existing D+W and D+0.7E load combinations; it is noted that basic wind loads were at service level and basic earthquake loads were at strength level in ASCE 7-98. The intent of these changes was that the use of 0.6D implicitly provides a factor of safety exceeding 1.5 for service level lateral loads when using the allowable stress design method. The commentary to ASCE 7-98 noted that these new load combinations are to “eliminate inconsistency in the treatment of counteracting loads in allowable stress design and strength design and emphasize the importance of checking stability.” In principle, these provisions have remained the same until now, with the only change occurring in ASCE 7-10 when the wind loads were defined to be at strength level, thus, necessitating the redefinition of both strength design and allowable stress design load combinations involving wind loads. Additionally, ASCE 7-22 now includes tornado loads (W T ) in addition to wind loads. IBC standards since their inception have also followed the framework of UBC standards with no specific quantitative requirements for stability checks of building structures except for the retaining walls, as noted earlier.

IBC (2024) and ASCE 7-22 prescribe two sets of load combinations, one for the strength design and the other for allowable stress design. Different material design standards, such as American Institute of Steel Construction (AISC), American Concrete Institute (ACI), National Design Specification (NDS), and The Masonry Society (TMS), permit the use of different design approaches (Fig. 1). Specifically, AISC, NDS,

and TMS for structural steel, wood, and masonry design, respectively, allow design engineers to use either the strength design (SD) method (called load and resistance factor design [LRFD] in AISC and NDS) or the allowable stress design (ASD) method, noting that AISC uses the “allowable strength” design method that is not formulated on traditional allowable stress based design practice though uses the allowable stress design load combinations in IBC and ASCE 7. However, ACI 318 now exclusively adopts the strength design method for concrete design and includes the strength design load combinations consistent with those in IBC and ASCE 7. In this article, the term “strength design” encompasses LRFD, and the terms “allowable stress design” and “allowable strength design” are collectively referred to as ASD. The current building codes aim to provide a comprehensive framework using either design approach, allowing structural engineers to conduct complete design evaluations, including structural stability, using either the SD or ASD method. The load combinations in IBC (2024) and ASCE 7-22 reflect this framework to lead to similar though not identical design outcomes using the two design approaches.

Based on the author’s opinion, typical design engineering firms for building structures have generally adopted the use of SD methods though some designers still prefer using the ASD methods. However, the soil checks to verify the adequacy of the subgrade supporting the buildings are typically performed for service conditions using demands based on allowable stress design load combinations irrespective of the method used to perform the design of the structural system. ASCE 7 Section 12.13.5 now includes the necessary design requirements that allows using the strength design method for soil checks and is permitted by IBC Section 1605.1.1, but this approach is still catching on in the building industry. Therefore, for analysis of the building structures, both strength design and allowable stress design load combinations are generally used and become necessary for concrete structural systems if the geotechnical capacity is based on allowable stress design.

The designers typically perform the analyses for all applicable load combinations in IBC and ASCE 7 and use the enveloping results from

the strength design load combination set and allowable stress design load combination set for various design checks. Absent any direct discussion on this topic in IBC and ASCE 7, many designers misinterpret that the traditional code intent of minimum factor of safety of 1.5 for stability for service loads applies for all allowable stress design load combinations. However, an important though unstated design objective of the building codes is that the strength design and allowable stress design load combinations involving 0.9D and 0.6D, respectively, implicitly provide a minimum factor of safety to ensure structural stability when subjected to lateral loads. Alternatively, performance-based design procedures may be used to meet the target reliabilities defined in ASCE 7 Section 1.3.1.3. For the building structure depicted in Figure 1, the structural analysis and design (including stability checks) for the wind (or tornado in ASCE 7-22) and earthquake load effects with the factored loads shown in Figure 2a for SD method and Figure 2b for ASD method implicitly meet the traditional minimum factor of safety requirements for stability. For seismic stability evaluations, the vertical load effect, not shown in Figure 2 for simplicity, shall be appropriately considered. As mentioned earlier, IBC Section 1807.2 requires the traditional minimum factor of safety of 1.5 for overturning and sliding stability of earth retaining walls for service level loads, which correspond to 1.0D+1.0H. The same objective would be automatically achieved by checking the stability of the retaining wall for the allowable stress design load combination 0.6D+1.0H or strength design load combination 0.9D+1.6H, though noting that the design of the different structural elements and soil bearing checks may still require analyses using both sets of load combinations.

The load combinations in IBC and ASCE 7 for the structural analysis and design of building structures have evolved over the years and are intended to produce a consistent design whether the strength design (SD) or allowable stress/strength design (ASD) methods are utilized. The traditional practice of maintaining a minimum factor of safety of 1.5 against overturning and sliding failures is only meant for situations where the evaluations are based on service level (nominal) loads, such as design of retaining walls. The building codes do not specifically address factors of safety against overturning and sliding failures since the appropriate application of either strength design or allowable stress design load combinations inherently result in a stable structural design configuration; additionally, ASCE 7 provides the target reliability for stability evaluation for use of performance-based design approaches. Therefore, there is no need to apply an additional factor of safety beyond those implicit in building code requirements and, if used, will result in overconservative and inefficient designs. ■

ACI 318-25 anchoring provisions reduce conservatism, clarify usage, and account for the effects of reliability and redundancy, plus major updates to breakout calculation of reinforcing bar groups have been added.

By Kenton McBride, Ph.D, PE

"Anchorage” in concrete is a broadly used term that can refer to concrete members, including pre-stressing anchorage devices, connections between concrete members via reinforcing bars, and connections between steel and concrete members via steel anchoring elements. While these various anchorage types possess common principles in force transfer, they have traditionally been treated as mutually exclusive in code provisions.

The American Concrete Institute’s ACI 318-25, Building Code Requirements for Structural Concrete, introduces major changes to the anchorage of steel-to-concrete and reinforcing bar connections. In addition to updates to factors within existing equations, steps toward recognizing the commonalities between steel/concrete and concrete/ concrete anchorage in "Chapter 17: Anchoring to Concrete and Chapter 25: Reinforcement Details" have been made.

This article focuses on major changes relating to anchorage in ACI 318-25 Chapter 17 and Chapter 25. Changes to Chapter 17 address inefficiencies and reliability concepts, while changes to Chapter 25 include new bridging provisions to Chapter 17 in the treatment of concrete breakout failure.

ACI 318 Chapter 17 provides design requirements for anchorage between steel and concrete members. The scope of Chapter 17 includes cast-in headed anchors, post-installed mechanical and adhesive anchors, and shear lugs. Failure modes incorporated into Chapter 17 for shear and tension design checks are summarized in Table 17.5.2. Section 17.8 addresses interaction between tension and shear failure modes.

This section examines five major changes to the design provisions:

Change 1: Updates to safety factors.

Change 2: Introduction of a beneficial overturning moment term.

Change 3: Beneficial separation of concrete and steel failure modes in interaction equations.

Change 4: Permissible use of new Chapter 25 factors for use of existing reinforcement.

Change 5: Clarifications on use of reinforcing bars as anchor reinforcement.

In addition to the five technical changes presented, clarifying editorial changes have been made throughout Chapter 17.

In ACI 318-19, the strength reduction factors, ϕ, for anchorage are defined in Chapter 17 in contrast to other Chapters whose ϕ factors are housed in Chapter 21. The Chapter 17 factors were primarily separated to address product-specific sensitivity and reliability characteristics via

an “Anchor Category” assignment from qualification.

In ACI 318-25, ϕ factors have been moved to Chapter 21 to be consistent with the remainder of the document. Anchor Category adjustments and the supplementary reinforcement condition have been decoupled from ϕ and separated into a new modification factor, ψa. All equations relating to concrete failure modes for post-installed mechanical or adhesive anchors have now been changed to incorporate this additional ψa factor. Finally, a new distinction between redundant and non-redundant fastenings has been made, providing a capacity benefit for fastenings that are considered redundant. Commentary on the redundancy of anchors is provided in a revised R17.5.3, which states that “Redundancy may be assumed where it can be shown that failure of a single anchor or anchorage point does not result in loss of position retention or progressive collapse.” While every case will require engineering judgment to determine whether a fastening is redundant or not, an example of a redundant fastening might be a line of single-point fastenings of a pipe to a ceiling where failure of any individual anchor does not result in progressive failure of nearby anchors or failure of any other component in the load path. Another example in a group of anchors might be demonstrating that failure of any individual anchor will not cause failure of the anchor group, the base plate, or any components within the load path.

Table 1 provides the new anchor-related ϕ factors in Chapter 21 in ACI 318-25. Table 2 compares the outputs of the new ϕ∙ψa product for concrete tension failure modes in ACI 318-25 compared to the equivalent ϕ factor in ACI 318-19. It can be observed that the ϕ∙ψa product for redundant connections in ACI 318-25 is roughly equivalent to the ϕ factors in ACI 318-19, while the capacities of non-redundant connections are reduced by 10 to 15 percent. Table 3 compares the safety outputs between the two code editions for concrete shear failure modes.

1. New Anchor-related Factors in ACI 318-25 Chapter 21

Table 2. Comparison Between 2019 and 2025 Safety Factors for Concrete Tension Failure Modes in Chapter 17

Table 3. Comparison Between 2019 and 2025 Safety Factors for Concrete Shear Failure Modes in Chapter 17

*Supplementary reinforcement factors do not apply to pullout strength in ACI 318-19, but do apply to pullout strength in ACI 318-25.

Chapter 17 Change 2: Introduction of a Beneficial Term to Account for Compression Due to Connection Overturning Moment

ACI 318-25 introduces a new strength-increasing factor, ψcm,N, in Section 17.6.2.7 for concrete breakout in tension to account for the positive influence of the compressive toe of an overturning connection moment. While the behavior described by this factor is related in principle to a concrete strut, it does not function the same because the anchorage condition includes an unconfined concrete surface that does not produce the same triaxial stress state as a strut within a concrete mass. The new Equation (17.6.2.7.1) is provided below. 2 1.5h z 1.0

Figure 1 (left) illustrates the variables included in the calculation of ψcm,N and Figure 1 (right) shows the influence of the ratio of the internal lever arm to the embedment depth of the anchor group.

Chapter 17 Change 3: Beneficial Separation of Failure Modes in Interaction Equations

ACI 318-19 conservatively simplifies the interaction between tensile and shear failure modes by determining the governing tensile failure mode

and the governing shear failure mode and combining them into a single interaction equation. By reducing all failure modes to a single interaction equation, ACI 318-19 allows for the possibility that a governing concrete failure mode interacts with a governing steel failure mode. A flowchart of the interaction between tension and shear in ACI 318-19 is shown in Figure 2.

However, it is well understood that concrete failure modes only interact with other concrete failure modes and steel failure modes only interact with other steel failure modes. Recognizing that concrete and steel failure modes behave separately and also recognizing that a simplified interaction calculation is not necessary to simplify the design process, ACI 318-25 separates interaction into three equations, one for concrete failure of individual anchors, one for concrete failure of anchor groups, and one for steel failure. By separating steel and concrete interaction, unnecessary conservatism is removed, producing more efficient designs in many cases. A flowchart of the interaction between tension and shear in ACI 318-25 is shown in Figure 3.

The use of the new Chapter 25 Eq. (25.4.11.2) is permitted to be used for calculation of tensile breakout capacity of anchors in the new Section 17.1.9 of ACI 318-25. See the “Change 1” section of Chapter 25. When

using Eq. (25.4.11.2) in a Chapter 17 design, the following notable requirements and restrictions apply:

• The k c factors used for the determination of N cpg are the same as are used for Chapter 17 design in contrast to the higher permitted k c factors used in the Eq. (25.4.11.2) design.

• The factor relating to concrete cracking, ψc,N, is permitted to be greater than 1.0 in accordance with Chapter 17.

• Factor ψa is determined in accordance with Chapter 17. The “distributed reinforcement” term N srg cannot be used in combination with the “anchor reinforcement” provisions of Chapter 17.

The anchor reinforcement provisions in ACI 318 Chapter 17 permit concrete breakout calculations to be omitted and replaced with steel

calculations of special reinforcing bars when those bars comply with the geometric requirements of Section 17.5.2.1. Two clarifying technical changes are made in the use of reinforcing bars as anchor reinforcement.

Section 17.5.2.1 is now split into two subsections 17.5.2.1.1 and 17.5.2.1.2 for anchor reinforcement meant to intercept tension and shear breakout, respectively. In both subsections, a clarifying component (b) states that anchor reinforcement legs must be parallel to the direction of the applied load. New Section 17.5.2.1.3 further clarifies that where anchor reinforcement meeting the requirements of 17.5.2.1 are not oriented parallel to the load, only the parallel component of the reinforcing bars is permitted to contribute to the strength calculation of the anchor reinforcement.

A new Section 17.5.2.1.4 states that the shear friction calculations of Section 22.9 cannot be used in the design of anchor reinforcement. This translates to the prohibition of the use of shear friction calculations to replace concrete breakout calculations in tension and shear.

Anchorage of reinforcing bars typically applies to the connection between two concrete structural members, e.g., between columns and foundations. This section examines two major changes to the design provisions: Change 1: Design requirements for breakout of reinforcing bar groups Change 2: Updates to hooked-bar and headed-bar development length equations

Other changes to Chapter 25 not expanded upon within this article include updates to coupler qualification and classification requirements and editorial changes throughout the chapter.

ACI 318-19 Section 17.1.6 states that consideration of breakout of reinforcing bar groups is required. However, it does not provide solutions for determining the breakout capacity that incorporate the proper safety levels for the problem of reinforcing bar groups, leaving all such consideration to engineering judgment.

ACI 318-25 introduces a major expansion to the provisions for breakout of reinforcing bar groups by providing explicit equations in new Section 25.4.11 at a safety level corresponding to existing Chapter 25 development length equations. Equation (25.4.11.2) provides the basic expression for the breakout capacity of reinforcing bar groups, incorporating a concrete contribution term, N cpg , and a steel contribution term, N srg

N cpg is calculated using the breakout equation in Section 17.6.2 with the following modifications:

A ϕ factor of 0.90 is assigned to the breakout capacity, in contrast with lower ϕ factors for Chapter 17 design. The author infers ψa =1.0 in this calculation (see Chapter 17 Change 1).

The concrete effectiveness factor, kc, is permitted to be taken as 35 for straight reinforcing bars and 40 for hooked and headed reinforcing bars OR Eq. 17.6.2.2.3 is permitted to be used with an additional increase factor of 5/3.

The cracked concrete factor ψc,N is always taken as 1.0, as the kc factors above already incorporate the uncracked concrete condition. The uncracked concrete condition is accepted in these provisions because reinforcing bar anchorage includes longer embedments than shallow anchors that are much more affected by bisecting cracks.

N srg is defined by ACI 318-25 Eq. (25.4.11.5) and applies to “distributed reinforcement” with the following properties illustrated by Figure 4:

Distributed reinforcement does not have a larger diameter than the anchored bars, is headed or hooked at the embedded end, and is oriented parallel to the anchored bars within the area Ac,eff

Spacing of distributed reinforcement is no greater than 0.25hef for N rg>2.5Ncbg and no greater than 0.5hef for N rg≤2.5Ncbg

Distributed reinforcement extends over 90% of the embedment of the bar group and terminates beyond the embedded end of the bar group.

In ACI 318-25 Equation (25..4.11.5), ρt is the average reinforcing ratio within the potential breakout surface; Ac,eff is the area defined by dimensions in both directions not exceeding 0.75hef from outside anchors and the distance from those anchors to the edge of the concrete, whichever is less, as illustrated in Figure 4; and f y is the nominal yield strength of the distributed reinforcement.

Hooked and headed reinforcing groups are subject to the breakout calculation requirements described in the Change 1 section above. In addition to the newly required breakout calculation checks, both of the basic equations for development length have changed as described in this section.

ACI 318-19 conservatively increased the development length of hooked bars in comparison to ACI 318-14 and prior editions. ACI 318-25 has refined the hooked-bar development equation to return to the same basic development length equation as ACI 318-14, but incorporating adjusted modification factors, including a new modification factor for size effect.

2019 ,, . min f f din r 86 50 ' dh c ye b oc , m } }} } =

2025 ,, min f f din86 55 ' dh c ye b s cc r , m } } }} = eo

Red text indicates a change from the preceding version. Blue text indicates a reversion to 2014 usage.

ψe Epoxy (1.0 to 1.2)

ψc Cover (0.7 to 1.0)

ψr Confining reinforcement (0.8 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

ψe Epoxy (1.0 to 1.2)

ψr Confining reinforcement (1.0 to 1.6)

ψo Location (1.0 to 1.25)

ψc Concrete strength (~0.7 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

ψe Epoxy (1.0 to 1.2)

ψs Size (1.0 to 1.5)

ψcc Cover (0.7 to 1.0)

ψr Confining reinforcement (0.8 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

Table 5. Progression of Headed-bar Development Length Equations From 2014 Through 2025

ψe Epoxy (1.0 to 1.2)

ψc Cover (0.7 to 1.0)

ψr Confining reinforcement (0.8 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

ψe Epoxy (1.0 to 1.2)

ψp Parallel tie reinforcement (1.0 to 1.6)

2019 ,, . min dt f f dd in86 75 ' c ye bb po c 15 , m } }} } = eo

2025 ,, . min f f dd in86 90 ' dt c ye po c bb 15 , m }} }} = eo

Red text indicates a change from the preceding version.

Table 4 shows the progression of the hooked-bar development length equation from 2014 through the 2025 edition. The headed-bar development length has retained its structure from the 2019 edition but has been shortened by approximately 17% by increasing the constant term in the equation’s denominator. Table 5 shows the progression of the headed-bar development length equation from 2014 through the 2025 edition.

Anchorage provisions in ACI 318 Chapters 17 and 25 have been significantly updated in the 2025 edition. In Chapter 17, several changes have been

ψo Location (1.0 to 1.25)

ψc Concrete strength (~0.7 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

ψe Epoxy (1.0 to 1.2)

ψp Parallel tie reinforcement (1.0 to 1.6)

ψo Location (1.0 to 1.25)

ψc Concrete strength (~0.7 to 1.0)

λ Lightweight concrete (0.75 to 1.0)

made to reduce conservatism, clarify usage, and provide direct accounting of the effects of reliability and redundancy. In Chapter 25, a major new requirement has been added to account for the potential breakout of reinforcing bar groups while also updating the basic development length equations for hooked and headed bars. While the subject of anchorage still remains disjointed between Chapter 17 and Chapter 25, some common elements have been bridged in this newly published document. ■

Kenton McBride, Ph.D, PE, is Director of Codes and Standards at Hilti North America. He is a member of ACI committees 318-B (Anchorage and Reinforcement), ACI 355 (Anchorage to concrete) and the president of the Concrete and Masonry Anchor Manufacturers Association (CAMA).

The comprehensive rehabilitation of a Silicon Valley high school used a composite solution.

By Nik Blanchette, SE, Steve Heyne, SE, and Chris Warner, SE

Homestead High School is in the heart of Silicon Valley, California, and has produced notable alumni like Steve Wozniak and Steve Jobs. With great innovation in its DNA, the school required an inventive, surgical retrofit to two of the campus’ original buildings, which consist of concrete masonry unit (CMU) walls with precast concrete floor and roof framing. ZFA, the SEOR for the project, identified these buildings as seismically deficient, particularly the floor and roof diaphragms, and assisted the school in pursuing state funding towards seismic strengthening. These large, heavy buildings warranted a creative approach to improve performance without adding significant seismic mass or replacing substantial elements. At the same time, low ceilings, poor ventilation, and limited natural light hindered the function of the space; a rehabilitation served to drastically improve the users’ experience day-to-day while also dramatically increasing the seismic resilience of the buildings. Originally constructed in 1962, the campus comprised eight stackedbond CMU-framed one-and-two-story buildings with precast concrete tee-beam floor and roof framing. The walls are fully grouted, steel reinforced, of various thicknesses: 8, 12, 16, and 24 inches; stackedbond is defined as aligning mortar joints from course-to-course in lieu of offsetting them (i.e. running bond). Eight-inch walls are reinforced with a single layer of reinforcing, both vertical and horizontal, whereas

thicker walls are reinforced with a double layer of rebar. Tee-beams are either 24 or 36 inches tall, reinforced with a mixture of prestressing strands, deformed bars, and welded-wire reinforcement. Heavy walls and heavy beams generate significant seismic mass, which can lead to poor seismic performance when coupled with non-ductile concrete & masonry detailing. The original scope of the rehabilitation was four of the buildings: A, B, C and L (Fig. 1), however only A and B have been modernized thus far. Buildings A, B, and C are two-stories, and L is one-story. Building L was an addition to the original campus, but it contains similar detailing to the previous structures. Bringing these buildings up to current code performance was no small task.

In 2006, California voters approved Proposition 1D to fund critically seismic deficient public-school buildings throughout the state; allocation of funding is organized through the Office of Public School Construction (OPSC) with the Division of the State Architect (DSA) reviewing and approving construction documents, including eligibility for the funding. This program is defined as the Seismic Mitigation Program (SMP). SMP provides matching funds and is a phenomenal option for school districts to improve the resiliency of their building stock for seismic hazards.

First, SMP requires an Eligibility Evaluation Report (EER) to establish qualification for the program. Qualifying buildings exhibit a critical

seismic deficiency that is expected to result in local or global collapse in the design earthquake event. Utilizing ASCE 31-03, Seismic Evaluation of Existing Buildings, DSA created a straightforward approach to screen vulnerabilities severe enough to warrant state funding: soft story, captive columns, wall anchorage deficiency, etc. The EER involves brief calculations to support the assertion of seismic deficiency. When completed, the EER is submitted to DSA for review and approval.

Buildings A, B, and C contained the same critical deficiency—inadequate concrete tee-beam flange interconnection for diaphragm action. At the roof, concrete tee-beam flanges, with no topping slab, acted as the diaphragm (Fig. 2). Without a topping slab, force transfer relies on welded connections between adjacent precast tee-beams. These connections consist of a piece of rebar welded, one side, to rebar embedded in adjacent beams (Fig. 3). This results in a one-sided weld that is dangerously subject to prying, which could be due to transverse loading, contraction and expansion, and/or differential prestress cable relaxation. Additionally, there is no positive attachment between the tee-beams and the perpendicular shear walls. At the floor, there is no positive attachment between the topping slab and the shear walls or collectors—load transfer between the horizontal and vertical Seismic Force Resisting System relied on concrete “blocking” panels physically

interlocking the team beam stems on top of the collector line. Of course, there are other seismic deficiencies; however, those deficiencies are not considered per EER to be something that would result in local or global collapse.

Following eligibility confirmation, an important decision for the school district is rehabilitation or replacement. If the estimated retrofit cost is equal to or greater than 50 percent of the replacement cost, then the district can obtain funding to replace the existing building with new construction. To preclude inflating the comparison cost, DSA reviews the scope of the proposed retrofit to confirm it’s the minimum amount of work necessary. If rehabilitation is the selected direction forward, the next step is the Evaluation and Design Criteria Report (EDCR).

Second, the EDCR is the designer’s opportunity to define the design criteria for the structural safety aspects of the rehabilitation project, establishing a baseline for preparation of the construction documents. Due to the dramatically different approaches available to retrofit a building, the EDCR serves to coordinate between stakeholders and DSA before the design begins. The EDCR has several key areas: potential seismic deficiencies, both structural and nonstructural; design criteria; data collection, which includes condition assessment and material testing; and geological hazards, which includes soil effects like liquefaction as well as ground shaking. A critical decision at this point is choosing between ASCE 7 Minimum Design Loads and Associated Criteria for Buildings and Other Structures and ASCE 41 Seismic Evaluation and Retrofit of Existing Buildings. Using ASCE 7 for the retrofit design requires compliance with prescriptive detailing requirements of the material reference standards, which is not typically feasible for decades-old concrete, steel, and/or masonry structures. ASCE 41 was utilized for this project due to that reason.

An EDCR is required for each building individually: a total of three were prepared for this project. The EDCR specifies what Performance Objective the project will be retrofitted to, which is in accordance with California Existing Building Code (CEBC) Section 317.5. For Risk Category III structures, DSA specifies BSE-2N and BSE-1N Seismic Hazard Levels and Limited Safety and Damage Control Performance Ranges, respectively. DSA reviews and approves the

EDCR—the next step is the construction documents. Identified in the EER, the concrete tee-beams were the main culprit for poor seismic performance; various elements of the diaphragm required strengthening: out-of-plane wall anchorage, diaphragm shear & flexure, and in-plane shear transfer between diaphragm and shear wall. Several options were evaluated to improve the diaphragms: concrete overlay, horizontal steel truss, and composites. Adding new concrete would add seismic mass, which would exacerbate other seismic deficiencies. Steel would weigh less than concrete but the complicated steel connections would be costly. Composites, like Fiber-Reinforced Polymer (FRP), offer a lightweight solution to strengthening existing concrete. FRP typically consists of carbon or glass fibers combined with a liquid polymer material, such as epoxy. Simply put, adding strips of FRP to concrete acts like adding rebar, which can increase flexural strength, shear strength, and/or confine elements to improve ductility. DSA requires the approval of Alternate Design, Materials and Methods of Construction (AMM) request for the use of FRP. The engineer submits the proposed condition; a description of the requested alternate for various topics like suitability, strength, fire resistance, et cetera; and supporting documentation like preliminary calculations and manufacturer’s information. One initial discussion point with DSA was unidirectional versus bidirectional fabric.

FRP fabric typically comes in either unidirectional or bidirectional weaves. As the name suggests, the difference is the orientation of the fibers. Unidirectional fabrics have fibers primarily oriented in one direction; whereas, bidirectional has primary fibers oriented in two orthogonal directions. Unidirectional fabric is a great solution for flexural reinforcing because the tension forces are oriented in one primary direction. Bidirectional is a good option when forces may occur in more than one direction, like in diaphragms. However, overlapping orthogonal layers of unidirectional fabric can achieve strengthening in those orthogonal directions as well. Ultimately, diaphragm strengthening utilized overlapping layers of unidirectional fabric due to high demands.

At the interface of the concrete diaphragm and the CMU wall, in-plane shear transfer was deficient. Bidirectional fabric in an

added scrutiny to the FRP strengthening because ACI 440.2R-17 Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures specifies that FRP materials and specific applications are to be qualified by tests. Simpson Strong Tie (SST) is the Manufacturer of FRP solutions that was the basis of design for this project, and they had not previously tested CMU-to-concrete FRP connections. To address this condition, SST performed testing at their research and development lab in Stockton, California, to substantiate the capacity of the connection (Fig. 4). SST addressed DSA comments on their test setup and results; DSA approval would not be possible without their participation. Testing was in accordance with AC125 Concrete and Reinforced and Unreinforced Masonry Strengthening Using Externally Bonded Fiberreinforced Polymer (FRP) Composite Systems, which is the basis for ICC-ES approval. SST fabricated five specimens to recreate a segment of the existing CMU wall and concrete diaphragm, to which the proposed FRP connection was added. Installation of FRP matched project specifications, such as the surface preparation and the paste radius to smooth out the right angle between wall and diaphragm. Load was applied cyclically to the concrete stem, with a push-pull cycle of one kip-per-second load rate. Per AC125, load reversal was applied at increments of 25% of the anticipated ultimate failure load. Per ASCE 41, the lower bound strength calculated from the test results was the average maximum strength minus one standard deviation. For one layer of bidirectional fabric, 12.5 inches wide, this was 4.8 kips per foot of capacity, which was only a six percent reduction from calculated capacity. With shear transfer resolved, the next problem to solve was collector forces.

FRP solved a great number of challenges in the seismic retrofit of these buildings; however, another solution was utilized for strengthening of collectors and in-plane shear transfer in some locations—steel (Fig. 5). Steel was a viable option for collectors specifically due to their isolated locations, which allowed for localized swaths of material; unlike the diaphragm that involved the entire area of the floor. FRP was considered for collector strengthening but the enormous seismic mass of the buildings produced such large collector forces that steel was more economical. Steel plates, field welded together to allow

the Contractor to select their splice locations, were anchored to the existing collectors with screw anchor bolts at 24 inches-on-center, to provide strengthening in both compression and tension. Similarly at transverse walls, in-plane shear strengthening was achieved using bent steel plates bolted to the diaphragm and connected to the wall with screw anchor bolts. In addition to the dramatic structural upgrades, nonstructural improvements were a crucial piece of this project. Nonstructural connections to tee-beams warranted extreme scrutiny to avoid prestressing strands. Typical prestressing strands sweep from full depth at supports to the bottom approximately 25 percent at midspan with around 1.5 inches of clear cover, leaving little room to embed fasteners. A product relatively new at the time to receiving ICC-ES approval, Hilti HDI-P TZ drop-in anchors were extensively used due to the incredibly shallow hole depth – ¾ inch. In most nonstructural anchorage conditions, like cold-formed steel wall framing or folding partition support, the drop-in anchors allowed installation without locating the prestressing strands due to the lack of conflict. Nonstructural components like mechanical, plumbing, and/or fire protection warranted a screw anchor connection due to the larger mass; screw anchors required coordination with prestressing strands to ensure none would be cut. New penetrations through tee beams were another item that required close coordination. Vertical penetrations through tee beams were carefully located to avoid existing connections and incorporate with new FRP strengthening. Incorporating nonstructural anchorage into the structural drawings added scope of work but ultimately helped preclude unfortunate surprises in construction. These rehabilitated buildings, standing at 62 years old, offer a phenomenal learning space for the campus. SMP provided matching funds to achieve this work, which was a tremendous opportunity for the school district to maintain the original form of the campus while achieving current code equivalent building performance. FRP demonstrated itself as an incredible solution to mitigate critical seismic deficiencies while not adding burden to any other structural elements—a key aspect of retrofitting heavy buildings. ■

A landslide incident on a gentle slope serves as a reminder of the importance of site investigation, desk study, and checking of overall global stability.

By Hee Yang Ng, PE