FORUMSubmarineTelecoms

Submarine Telecoms Forum is published quarterly by WFN Strategies, L.L.C. The publication may not be reproduced or transmitted in any form, in whole or in part, without the permission of the publishers.

Submarine Telecoms Forum is an independent commercial publication, serving as a freely accessible forum for professionals in industries connected with submarine optical fibre technologies and techniques.

Liability: while every care is taken in preparation of this publication, the publishers cannot be held responsible for the accuracy of the information herein, or any errors which may occur in advertising or editorial content, or any consequence arising from any errors or omissions.

The publisher cannot be held responsible for any views expressed by contributors, and the editor reserves the right to edit any advertising or editorial material submitted for publication.

© WFN Strategies L.L.C., 2004

Contributions are welcomed. Please forward to the Managing Editor: Wayne F. Nielsen, WFN Strategies, 19471 Youngs Cliff Road, Suite 100, Potomac Falls, Virginia 20165, USA.

Tel: +[1] 703 444-2527, Fax:+[1] 703 444-3047.

Email: WNielsen@SubTelForum.com

General Advertising

Tel: +[1] 703 444 2527

Email: Advertising@SubTelForum.com

Designed and produced by Ted Breeze

Exordium

Welcome to the 14th edition of SubTel Forum!

We’ve shaken off the wine-induced hubris from Monaco, rested up from too many late nights, and are now set to resume course.

Two distinct groups seemed to emerge at SubOptic: the first forecasted continued industry gloom; the second saw fair skies with new activity. What I found interesting was that in my unofficial poll taken around wine bars and dining tables (just doing my job), both groups seemed diametrically opposed.

That begs the question: How can we ever move forward if we can’t even agree on our relative position? To that end, STF and SubOptic are conducting our 2nd annual pulse-taking, asking you to spend a few moments to describe your thoughts, concerns and hopes for our market. We will publish these results in the Autumn.

In this issue George Krebs details Alcatel’s vision, and Antoine Lécroart examines emerging submarine cable markets. Frank Cuccio spotlights recent marine recovery operations. Jim Bishop examines cable jointing, and Michel Chbat and Herve Fevrier discuss allRaman transmission technology. In addition, we begin a multi-part serialization of From Elektron to ‘E’ Commerce, covering the industry’s first 150 years, and Jean Devos returns with his ever-insightful observations.

Good sailing,

Wayne Nielsen

Alcatel and Pirelli Enter Mutual Acquiring Arrangement

Alcatel and Pirelli announced today that they have signed an agreement regarding their respective submarine telecommunication businesses.

www.subtelforum.com/NewsNow/ 9_may_2004.htm

Alcatel Wins Iran Oil Platform Project

Alcatel has announced that it has signed a multimillion US dollar contract to provide a fully integrated communication solution to equip, before end of 2006, an onshore gas plant and three offshore platforms of the South Pars gas field in Iran.

www.subtelforum.com/NewsNow/ 21_march_2004.htm

A synopsis of current news items from NewsNow, the weekly news feed available on the Submarine Telecoms Forum website.

ASRC Joins with Gulf Fiber

Arctic Slope Regional Corporation’s wholly owned subsidiary, ASRC Communications Ltd, an Alaska Native Corporation (ANC) has announced that it has joined with Gulf Fiber, LLC to construct, operate, and manage a secure, reliable subsea telecommunications fiber optic cable network in the Gulf of Mexico.

www.subtelforum.com/NewsNow/ 14_march_2004.htm

Bahrain Takes Steps to Protect Submarine Cables

In a measure designed to stop the damage to Bahrain’s international communications cables, representatives from the port authorities, coast guards and Fisheries Directorate met with Batelco officials to finalize agreed protection measures.

www.subtelforum.com/NewsNow/ 21_march_2004.htm

BT Announces New Europe-Singapore Link for Business Users

BT has announced that European companies could now communicate more quickly with their operations in the Asia Pacific region due to the completion of its new direct link between London and Singapore.

www.subtelforum.com/NewsNow/ 25_april_2004.htm

BT Exec Challenges Industry to Pull Together

BT executive board member, and chief executive officer of BT Global Services, Andy Green, called for the information and communications technology (ICT) industry to pull together and rise to the challenges of today’s connected world.

www.subtelforum.com/NewsNow/ 11_april_2004.htm

Cable Ship Written Down

Cable ship owner James Fisher & Sons reported annual profits that were below market forecasts due to the decline in the building of new submarine cable systems. As a result, the company has written down one of its cable ships to scrap value. www.subtelforum.com/NewsNow/ 14_march_2004.htm

Caldwell Marine Awarded Cable Supply Contract

Caldwell Marine International has been awarded a Turnkey Submarine Cable Supply Contract by the Orcas Power & Light Cooperative (OPALCO) of Eastsound WA. Caldwell will also supply and install a submarine repeaterless telecom cable and install an OPALCO supplied submarine cable. www.subtelforum.com/NewsNow/ 16_may_2004.htm

FT, Alcatel Form Strategic Partnership

France Telecom and Alcatel have announced the signing of a Memorandum of Understanding (MoU) for the joint development of Next Generation Network Architecture.

www.subtelforum.com/NewsNow/ 11_april_2004.htm

Global Crossing Facing De-Listing

Global Crossing received a Nasdaq Staff Determination on April 29, indicating that the company’s common stock does not comply with the filing requirements for continued listing. It will be delisted unless the company requests a hearing with a Nasdaq Listing Qualifications Panel..

www.subtelforum.com/NewsNow/ 9_may_2004.htm

Global Crossing Hires Accountant for Review

Global Crossing retained Deloitte & Touche LLP to review cost of access liabilities, expenses and related internal control, and Grant Thornton LLP to evaluate procedures and its determination regarding restatement of financial statements. www.subtelforum.com/NewsNow/ 9_may_2004.htm

Global Marine Wins ntl Maintenance Contract

Global Marine Systems has announced another contract win for their Guardian Total Maintenance Solution. ntl has signed up the cables they own in the Irish Sea to this unique maintenance service. www.subtelforum.com/NewsNow/ 21_march_2004.htm

Great Eastern Group Awarded Multi Year US Navy Support Contract

Great Eastern Group of Fort Lauderdale, Florida and its team was recently awarded a contract for support services for all phases of naval ship and shipboard weapon systems acquisition. www.subtelforum.com/NewsNow/ 25_april_2004.htm

MCI Sells Embratel Stake to Telmex

MCI and Telefonos de Mexico, S.A. de C.V. (TELMEX) have entered into a definitive agreement to sell MCI’s investment in Embratel Participacoes to TELMEX for $360 million in cash.

www.subtelforum.com/NewsNow/ 11_april_2004.htm

New World, CANTV Sign Capacity Agreement

New World Network, Ltd., the principal owner of the Americas Region Caribbean Optical-ring System (ARCOS), has announced a capacity services agreement with CANTV, the leading provider of telecommunication services in Venezuela.

www.subtelforum.com/NewsNow/ 25_april_2004.htm

NEC system to link Indonesia and Malaysia

NEC has signed a contract with PT Telekomunikasi Indonesia and Telekom Malaysia Berhad for the supply of an optical fiber submarine cable system linking Indonesia and Malaysia.

www.subtelforum.com/NewsNow/ 16_may_2004.htm

PRIMUS Pays Off Debt

PRIMUS Telecommunications Group has repurchased and retired approximately $23 million principal amount of its 12.75% senior notes due 2009 and has repaid the entire outstanding balance of approximately $10 million principal amount on its Canadian financing facility.

www.subtelforum.com/NewsNow/ 11_april_2004.htm

PTC Seminar and Exhibition to be held in Tianjin, China

Tianjin, People’s Republic of China, will be the venue for the PTC Mid-Year Seminar and Exhibition 2004 at the new Hua Tian Software Building in Tianjin’s Hi-Tech Industrial Park. www.subtelforum.com/NewsNow/ 16_may_2004.htm

PTC’05 Call for Papers and Presentations

The Pacific Telecommunications Council is now accepting proposals for PTC’05, the Council’s 27th annual conference.

www.subtelforum.com/NewsNow/ 16_may_2004.htm

Santec Releases a 40mW High Power Tunable Laser

Santec, a leading manufacturer of fiber-optic components, sub-systems and optical instruments is pleased to announce a new, high power tunable laser, the TSL-210H.

www.subtelforum.com/NewsNow/ 16_may_2004.htm

SAT-3/WASC Cut

According to reports, the SAT-3/WASC cable has been severed 35 kilometers off the Nigerian coast.

www.subtelforum.com/NewsNow/ 14_march_2004.htm

SingTel, IBM Announce Data Center Deal

IBM Singapore and SingTel have reached a longterm data center lease agreement to provide next generation computing for clients in Asia Pacific . www.subtelforum.com/NewsNow/ 9_may_2004.htm

Telkom SA Touts African Submarine Cables

Telkom SA Limited will talk about its experience in building and operating a world-class telecoms network at Africa Telecom 2004 in Cairo this week.

www.subtelforum.com/NewsNow/ 9_may_2004.htm

Tyco Selected to Provide Media Transport on TGN Transatlantic Cable

Tyco Telecommunications, leading provider of international wholesale capacity, services and telecom equipment space on the Tyco Global Network, announced a contract with BBC Technology, a subsidiary of the British Broadcasting Corporation, for high capacity Trans-Atlantic optical bandwidth.

www.subtelforum.com/NewsNow/ 16_may_2004.htm

TeliaSonera Contracts Tyco for High Bandwidth Communications Between Europe and the US

Tyco Telecommunications, a leading provider of international wholesale capacity, managed services and telecom equipment space on the Tyco Global Network (TGN), announced today that it has signed a contract for a 10Gb/s Trans-Atlantic Wavelength

with TeliaSonera International Carrier, the leading carrier of Internet Protocal (IP) traffic in the Nordic and Baltic Sea regions.

www.subtelforum.com/NewsNow/ 16_may_2004.htm

T-Systems, TI Sparkle to Jointly Deliver IP VPN for Carriers

T-Systems’ carriers’ carrier division, International Carrier Sales & Solutions (ICSS), and Telecom

Italia Sparkle SpA (TI Sparkle), a subsidiary of Telecom Italia SpA., announced that both carriers are now in a position to develop a joint approach to the market for wholesale IP VPN solutions.

www.subtelforum.com/NewsNow/ 14_march_2004.htm

WFN Strategies Awarded US Navy Support Contract

WFN Strategies, as a part of the Great Eastern Group team, was recently awarded a contract for support services for all phases of naval ship and shipboard weapon systems acquisition.

www.subtelforum.com/NewsNow/ 9_may_2004.htm

International Submarine Cable Systems Map 2004 Edition

SubTel Forum and T Soja and Associates are making available the industry’s first comprehensive worldwide submarine cables map in over three tumultuous years.

• Accurate and detailed picture of the world’s major existing and planned submarine cables

• Landing point references on the Caribbean, Atlantic, Pacific, Mediterranean, Asian and SubAsian coasts

• Color distinguished cable routing of all major operational or under construction systems

Available laminated for wall mounting and mark-ups, or in electronic form, the Submarine Telecoms Forum International Submarine Cable Systems Map is today’s “must-have” system planning resource.

pdf Version$350 inc shipping

Printed and Electronic Versions$465 inc shipping www.subtelforum.com/catalog/maps_279992_products.htm

call +1 703 444 2527

Submarine Telecoms Industry Survey

SubOptic and Submarine Telecoms Forum magazine are co-sponsoring the second annual Submarine Telecoms Industry Survey, the results of which will be shared online and published in an upcoming issue. One lucky responder will receive a free laminated copy of the 2004 edition of the

Submarine Telecoms Forum International Submarine Cable Systems Map, which was developed by Submarine Telecoms Forum Magazine in conjunction with T Soja and Associates, presenting the industry’s first comprehensive worldwide submarine cable map in over three tumultuous years.

Please take a moment to respond by printing these pages and sending by mail or fax to: WFN Strategies

19471 Youngs Cliff Road Suite 100, Potomac Falls Virginia 20165 USA

Fax [1] 704 444 3047

1.Which best describes you?

Academic Management

Marketing Other

Engineer/Project Manager

2.What best describes your business?

Cable owner System Integrator

Marine Surveyor Other

Cable Installer/Maintainer

3.How would you rate the content of Submarine Telecoms Forum magazine?

Excellent Unsatisfactory

Good Poor Satisfactory

COMMENTS_____________________________

4.How would you rate the content of NewsNow and the STF website?

Excellent Unsatisfactory

Good Poor Satisfactory

COMMENTS_____________________________

6.Did you attend SubOptic 2004?

Yes No

COMMENTS_____________________________

5.Would you like to see any particular changes in Submarine Telecoms Forum or News-Now, or other information services?

7.What did you find the most stimulating and relevant topic to be discussed at SubOptic?

8.If you did not attend, why, and do you have any immediate thoughts on what would change your mind for SubOptic 2007?

Continued on next page

9.Are business conditions improving or getting worse?

13.How has the type of project you handle changed over the last three years?

10.Are you optimistic or pessimistic about the future? Optimistic Other Pessimistic

11.Does your current business performance indicate that we are still in an industry recession?

14.In your opinion, what does the industry most need?

The following prices are for digital reprints of editorial pages from Submarine Telecoms Forum magazine, without alteration. Page size is 8-1/4" x 11-3/4" on 28lb paper stock. Shipping cost is in addition to reprint price.

12.How have client requirements changed over the last three years?

For the fifteen organisations that make up the Executive Committee, and our host organisation Alcatel, the answer was a very welcome surprise . . . it worked, and all of you who attended and contributed produced a great result during the deepest and most prolonged slump in the industry’s history.

The spirit of SubOptic lives on and the 2004 Conference not only proved that the objectives and constitution are sustainable, but that the event is truly embedded in the culture of our industry. At the end of the event, we all had to pinch ourselves to think back to the previous year when cancellation was a very real option. In particular, the EC and Alcatel took a very brave decision, which in hindsight seems obvious, but in reality was difficult and risky. In the end, over 600 registrants passed through the turnstiles and, barring some well understood difficulties with hotels, the majority of you seem to have got a lot of value and pleasure out of the conference programme and social events.

Now, Wayne Nielsen has asked John Horne and myself to reflect upon some of the key themes during the four days. As committee bureaucrats, we shall probably have a biased view but, please, letters to the Editor, not SubOptic. I am sure Wayne will welcome the debate.

So how was SubOptic 2004 for you?

Reflections on the Monaco event from Alan Robinson and John Horne

As administrators, we certainly never got down to the Irish Bar, which is where the real SubOptic took place, but we were able to enjoy some of the splendid hospitality laid on by the Monaco Government, the SubOptic EC and hosts of a number of private parties, all unfortunately packed into too short a time scale. And I suppose our first theme that we shall be working on for 2007 is that a number of you have indicated that the conference is expensive. On the surface, the registration fee is higher than some of our commercial competitors, but please remember that SubOptic is inclusive of a number of extras, including the social programme, which many other conferences do not even bother to organise, let alone fund. The programme is more broad and varied, and the speakers more informed on specialist subjects, which are unlikely to even get a booking at other events. And, of course, it is non-profit making.

Key themes in the conference followed a familiar line - geographical regions were in different states of development, so there is not a “one model fits all”. There is over supply in manufacturing and, in particular, Atlantic capacity. Pricing has been irrational and unpredictable, leading to a loss of confidence and an unwillingness to take risks. Everybody wants and

There is a long Alan Robinson was Vice President of Global Operations Engineering Services (GOES) for Cable & Wireless, responsible for strategic investments on behalf of C&W.

He is a Master Mariner and joined BT in 1976. He has since held positions in Sales and Project Management, before being appointed BT Marine’s General Manager for the Asia Pacific region, based in Singapore.

On his return, he took up a position of Director of International Sales with the newly combined BT and C&W cableship fleet in C&W Marine.

Alan was appointed Managing Director of Network Services in 1997 and Director of Capacity Management in January.

way to go before infrastructure investment returns to an unexciting, low risk business, where the risks are shared by operators, and are understood to be manageable rather than entirely speculative. As we wait for this to happen, new technology is coming into the market to enable us to sweat current assets. But, inevitably, supply and demand will have to come back into balance. And we know that the demand side is certainly not in decline.

Specific answers to many of the industry’s problems were not in plentiful supply.

Funding for future developments is still a key issue. The “bottom fishers” are out, and assets will continue to shift ownership.

But this is only clearing up the debris. Developing areas of the world still need broadband capacity, but at much reduced costs. The need for telecom operators to continue to own infrastructure rather than to have access still looms as one of the most complex and unanswered questions. I think, though, that the conference got close to agreeing that we are looking at the economics of unglamorous utilities.

And, finally, amidst the natural networking of SubOptic, the new Poster Session seemed to fit and gain credibility from presenters and audience alike. Less time on the feet for presenters, more space for posters, and the promised liquid refreshment have all been noted, and we shall rework the model for 2007.

John Horne has been involved with the development, planning, and implementation of Submarine Communications Systems since 1969. In the 1980’s he was responsible for the development activity, which supported the introduction of BT’s first optical fibre submarine systems. He later took responsibility for Project Managing the major International Transmission Centres at the heart of BT’s Digital Transmission Network. He left BT in 1996 and has since worked as a Consultant.

At SubOptic 2001, he was one of the ViceChairmen of the Papers Committee and took on the role of Secretary to the SubOptic Executive Committee, the body which provides strategic management to the SubOptic series of International Conventions.

needs a return to an orderly market, but this will need further difficult re-structuring and re-balancing. The models for a future investment are still unclear, and the pressure on operational costs is as extreme as it has ever been.

And, during the entirety of the conference, there was a wonderful buzz of enthusiasm and camaraderie.

Jean Devos encouraged us all to make more of SubOptic and ensure that we build on all the hard work and short history of the organisation. We shall work on

this and, with your help and enthusiasm, keep building the structure and benefits for 2007.

For a conference that nearly didn’t happen, it was a very satisfying result for us - and we hope it was for you too. Things can only get better!!

Emails to the Editor

Dear Industry Colleague,

I can confirm that Pro-Bank now has 18 registered candidates based in 4 different countries. The service has been promoted within Submarine Telecoms Forum - visit: www.subtelforum.com/ 16_march_2003.htm. Submarine Telecoms Forum is an excellent publication - if you do not receive it, visit www.subtelforum.com and sign up!

Best Regards, Graham Marle, Qualtrack Ltd

Another good edition.

John Graham, ITG

I enjoy reading Submarine Telecoms Forum.

Donald Dean President, DMM International Inc.

Re: NEWS-Now

Good show, mate.

C.F. Chamberlain, Esq.

EXECUTIVE FORUM

Georges Krebs

COO, Alcatel

Submarine Networks

Georges Krebs started his career with France Telecom participating in the installation and maintenance activities of the cableship fleet. He was also in charge of managing new projects for the company such as the TAT 8 and TAT 9 projects.

He joined Alcatel in 1988 as Engineering Manager for Alcatel TCC in Australia and was later promoted to Vice President of the Asia Pacific region, responsible for the marketing of submarine cable systems in that region and based in Singapore.

He returned to France in 1997 as Line and Marine Operations Director of Alcatel Submarine Networks. In 2002, he was in charge of the Sales & Projects Department within ASN. Since 2003, he has been Chief Operation Officer.

QArebusiness conditions improving or getting worse, and are you optimistic or pessimistic about the future?

AAfter three difficult years, business conditions are now stabilizing. The business conditions vary significantly from one telecom segment to another. Some segments such as mobile telephony, broadband ADSL or IP networking, are enjoying solid growth whilst other segments, such as optical networking remain cautious even if some more positive signs have recently appeared.

I am optimistic about the future because the use of telecommunications services is growing very rapidly. The main drivers of this growth can be synthesized in:

The growth of mobile services is very solid in all countries, especially developing countries where the flexibility of mobile networks is helping to increase very rapidly phone penetration rates; Broadband internet is picking up in several developed countries and it appears to become a fundamental platform of services that is shaping our future way of life; broadband penetration rates are still very low in most countries, thus providing an enormous business potential; The convergence of services (broadband internet + video on demand + voice) is becoming a significant reality, increasing drastically the competition between incumbent operators and cable TV and internet providers. The need to develop and

adapt existing networks to meet these new challenges is generating innovations and big business opportunities in a more competitive environment. If incumbent operators don’t adapt, they may simply disappear.

These are some of the reasons for being optimistic about the long term prospect of the telecommunications sector.

QWhatdo you see as the short term and long term health of the international telecoms industry?

AThe growth factors listed above apply to the national telecommunications industries primarily. Of course, the phone penetration and broadband Internet growth will have a positive impact on the international telecommunications as well, but the size of this impact will depend on economical and cultural factors.

Some of these factors can be identified with:

Globalization - a key trend, together with the growing penetration of the English language as an international communication tool;

Growing international trade;

All forms of delocalisation and international division of work;

Population migrations all around the world;

Internationalization of sporting and cultural events;

Networking of all sorts (Research Institutes, Universities, Cultural Centers, etc…)

Most operators say that they experience double digit international traffic growth frequently nearing levels of 100 % per year. This traffic increase is primarily related to the growth of the Internet and it is expected that higher broadband penetration will further fuel that growth.

When the WDM technology was introduced in 1997, the capacity transmitted over a fiber was 4 x 2.5 Gbit/s; today, some systems could be operated at 105 x 10 Gbit/s.

Investments in further technology developments are currently limited but we know that the potential is there to very significantly further increase fiber transmission capacities.

As a result, it can be assumed that future traffic growth, however large it might be, will be primarily covered by fiber transmission capacity increase. This means that the number of submarine cable systems will remain relatively small, typically between 2 and 4 cables over each route. If this is the case, the growth in the number of cable kilometers will be limited and there will be no need to significantly develop manufacturing, installation and maintenance facilities in the future.

The situation should be different for the manufacture of terminal equipment as it will grow largely in proportion with the growth of traffic.

QWhat are your customer profiles for submarine networks and what are they key requirements?

AOur Customers are primarily the incumbent telecom operators and the new mobile operators.

In the long term, our Customers will be the successful global telecom operators, concentrating on mobile or on broadband services or both. They already require and will increasingly require networks working as transparent multi services platforms down to the subscriber level.

QFrom

your perspective, what is the state of the submarine telecommunications market?

AAlthough background demand for bandwidth has consistently increased, even during the downturn in the submarine systems market, it is expected that in most regions the demand for upgrades to existing systems will resume before any significant demand is seen for new systems. With the clear exception of the Sea-Me-We 4 route, in most parts of the world we have yet to see these upgrade orders which are likely to be the first indications of demand for new installed capacity.

QWhatdo you think the submarine industry would need?

AThe submarine cable industry needs to further be re-organized and we should see things happening in the next few years. Ideally the submarine industry would benefit from a return to a market stability that existed prior to the deregulation. Of course, the industry has always been cyclical and there is no reason to believe that cycles will disappear. Because submarine cable systems will deliver always more capacity in a single cable, it will be increasingly necessary to share this infrastructure among a large number of users.

Our culture . . . our future

Working out solutions for our business is now your job. I would like to share with you my strong convictions. I do not expect everybody to agree with my statements or to share all of my views. I do not actually exclude the possibility of me “preaching the desert”.

But, please understand where I am coming from: I am a great believer in people, people leadership; in people responsibility. Leaders carry more weight than all the theories and the words in “ism”, the laws of the economy, etc.

We are responsible for the situation in which we are, and it is now up to us, I mean to you, to invent the Future.

by Jean Devos

A preliminary remark: It seems that we have not yet recovered from the bubble. The suppliers who signed the SMW4 contract last week do not seem either happy or satisfied. 20 years ago; two such simultaneous projects such as Smw4 and Falcon, 2 Europe-Asia cables, would have saturated and satisfied the full industry for 2 years and would have made this conference a place of exuberance instead of this depressed atmosphere!

No, definitively not; our Submarine cable activity is not a business like any other business. This is a very specific business.

Two reasons: Our environment and our mission!

Our environment is extremely demanding, does not accept mediocrity, and does not forgive easily.

Our mission: We have a mandate from the world community to provide the world with an adequate infrastructure; giving all the countries a chance to develop. As such, we hold a huge responsibility,

collectively and individually. Each of us works for its own company’s success and bottom line, but equally each of us plays a citizenship role.

We are supposed to build and manage the global network in a responsible manner, optimising the investment costs.

Our predecessors have properly achieved this mission in a very frugal manner.

Within the constraints of the period, key peoples managed to move our business forward on a cooperative mode. Each period was marked by a new culture, which came as a new layer: Pioneer, Engineer, and Planner.

But more recently, the deregulation came like spring after a very cold winter; an explosion of initiative, newcomers, new ideas, and new opportunities; an irresistible wave!

The new culture brought by entrepreneurs and investors swept everything. Our community of engineers failed to avoid the excesses of the hypercompetition. Our mission was forgotten!

The crash of our industry could have been easily avoided. We have dug our own grave, through the behaviour of nobody else.

Had we not lost contact with the reality of the international traffic, our only real driver, our god, we would have equipped the world with just what was needed, without throwing away billions of dollars through the window or in the water!

Look, for an instant to the suppliers, how they behaved during that mushroom period. Not only did they come in with the most powerful technology, which in itself would have been enough to satisfy the demand, but they also invested heavily in new

Jean Devos , Past President of SubOptic, was formerly Senior Vice President of Sales and Marketing for Tyco Submarine Systems Inc., and previously Director, Submarcom and Director Marketing and Projects for Alcatel Submarine Networks.

Jean is currently with Submarcom Consulting, is a member of Don Quixote and a director of Axoim.

manufacturing capabilities and new ships (340,000Km!).

At the same time they accepted cutting their prices down and they brought project finance and took many other project risks. They have more than contributed to a virtual market, to unnecessary projects. And all this without any profit!

Why all this? The suppliers were suddenly convinced that they could not rely anymore on the incumbent’s carriers, their traditional customers, for their future. The trust was gone.

An example: Had Tyco not been rejected from the supply process of both Japan-Us and TAT14, the traditional SSI market, Tyco would never have come with their TGN (I was there). For similar reasons Alcatel injected a lot of vitamins in carrier’s carrier projects.

Look now at the cable owners’ side: They also could have behaved in a more reasonable manner. Here in reality, we have suffered from a fundamental mismatch between carriers and carrier’s carriers. This community decided to rely on the law of the market, in other word the law of the jungle to decide the outcome – no sensible communication between the two camps. Here also a terrible lack of Trust. The carriers were not in position to accept a clear separation between operators and cable ownership. Example: SAC and SAM could easily have been co-built. PC1 and Japan-US should have been a co-build. But there was no trust among the players and some egos were just too inflated.

If you bear with me and accept my point that there was no absolute determinism in all this but most often management attitude, you need to agree with me on the fact that we should now endeavour to

influence our future! Nothing is written. We need to reinvent ourselves! We need to decide on our future culture. Make sure we have the right one. Let me try to help.

We need a stable business:

No bubble anymore: A continuous process without these huge surges followed by deadly abysses. We need then to adjust permanently the network to the real traffic needed. No over building.

To achieve this we need some auto-regulation process. This can only come from our own attitude, behaviour, and our own culture. We need to drive this activity like one drives a car or a truck, one foot on the accelerator (competition/innovation) and one foot on the brake (cooperation/sharing).

L & G, believe me our good steady future relies on our ability to implement the concept of Coopetition , a smart combination of a necessary competition and a necessary cooperation.

We definitively need competition . . . but:

We need competition between the suppliers to bring the best products, services, prices etc. Competition between cables on the same route needs to offer choices of route of access, of costs.

But these competitions need to be understood as competition between athletes, not like killing wars. Athletes do respect each other, because they need each other. Your competitors are your best assets. Fight hard to be the best one not to be the last and only one in the field!

Competition will ensure that we have the very best players in the field, but these players need to cooperate. They need to accept other’s mere existence, and accept the need to share the activity with them each time it is feasible. Ownership should be shared; building should be shared. Not for ethical reasons, but for efficiency reasons, in an effort to ensure the long-term viability.

We also need a good spirit of cooperation between owners and suppliers. They need to know each other, to respect each other and to develop healthy contractual and working arrangements. Contracts need to be good for both.

To carriers / carrier’s carrier:

I am not naïve, and I do not underestimate the concept of competition. But I would hope that you would hesitate in the future to consider an investment in an infrastructure as a gun! If your competitor is real, I like to think that your best option is to co-build with him.

We have seen the negatives of both situations: The North Pole (glaciations) and the equatorial jungle (exuberance). There must be a way to establish a Mediterranean climate.

There is only one tunnel under the channel and there is not often three bridges crossing the same river in parallel !! I am not sufficiently close to the facts, but I know for sure that 20 fiber pairs (20 terabits potentially) between India and SEA is not today the right answer. There must be a better way!!

Now if you plan to build a cable and then need to select suppliers, please do it in a fair and clear

manner. You are fully entitled to enter in a direct deal with the supplier of your choice. It could be the best solution for your project. This method is good since this will force the suppliers to position themselves in the race to get your attention and this will establish the partnership type of relation we need.

On the other hand if you choose to enter in a tender process, it has to mean a fair chance to all suppliers who deserve to be evaluated on their real merit. Please do not request the impossible by taking advantage of your buying super-power. Negotiate fair prices and conditions. 15 % penalty for lateness is not the best way to get your project on time. . . but it could be the best way to kill both your supplier and your project.

And if you request a very short delivery do accept offers from supplier’s consortium.

Now for the suppliers:

You are a group of 4 to 5 suppliers; some big some smaller. Please accept this. This is what the market wants.

Be reasonable in your ambition. Establish your production and associated capability to satisfy a reasonable market share. If there is, say, 4 suppliers on the market and your targeted market share is 3035%, this is a healthy ambition. If your target is 60%, this is a war declaration, which will be detrimental to our community.

As said before, work hard to bring the very best product, services, the best cost. But stay in your field. Do not bring solidity to a weak project. No more vitamins, please!

Be careful, competition is like wine: In reasonable quantity it is a good, exciting, stimulant. In large quantity it makes you sick and can bring you and others to death.

I also invite our analysts, consultants, traffic forecasters, to bring their contribution to this necessary culture, to this effort toward wisdom and stability. Please keep sharpening your pencils before writing and turn your tongue seven times in your mouth before talking.

Let the pink colour in your box.

And finally, I would invite SubOptic to evolve rapidly toward being a light permanent structure with a new mission: being the submarine cable business watchdog or lighthouse. I know SubOptic cannot be a real regulator with real legal power. This would be stupid. But a moral power!

SubOptic could publish statements and white papers, designed with the view of the general interest of our business. I am sure of the impact. We should feel entitled to do this since we are all victims when the train derails.

Dear friends, our future is in our hands.

It can still be very dark if we let the things go their natural trend.

But if we manage to mobilise the only resource, which can transform a desert into a Garden of Eden, I mean Trust, then we will have a good future.

Trust in each other and trust of all of us in our common future.

If you manage to rebuilt trust and come back to some humility, then you will be able to invent the new solutions that our business requires.

REAPING THE BENEFITS

using an all-Raman terrestrial amplified transmission technology in unrepeatered applications

Bridging very long and/or high-loss optical transmission links without a possibility of a repeater has long presented technical and engineering challenges, making unrepeatered systems a distinct category of optical transmission systems. A large number of unrepeatered systems have now been deployed in all parts of the world, with distances up to a few hundred kilometers and capacities of several Gb/s. Historically, the main applications of unrepeatered systems were in coastal festoons, access to or between islands, or lake crossings, all categorized as submarine applications. To that end, the designs of unrepeatered systems have been made following a “submarine link philosophy”. However, unrepeatered transmission is also part of terrestrial networks that have to deal with uneven span distributions, very remote ILA sites (generator or solar powered), exiting or avoiding expensive leased facilities and costly building additions.

In general, unrepeatered systems have to deal with two main physical layer issues: total loss and chromatic dispersion. On the operational side, the major considerations are: safety, equipment reliability, and density. Above all, cost is undoubtedly the largest differentiator among the systems. Here, we will see how the use of a proved-in terrestrial technology can be applied to submarine and terrestrial unrepeatered systems and provide a low-cost, high-density, and high-reliability system, with superior transmission performance on various fiber types.

Michel W. Chbat and Herve A. Fevrier

Xtera Communications, Inc.,

Submarine unrepeatered applications considerably differ from their terrestrial counterparts in that the former usually involves standalone links where the cable and fiber types are chosen independently of any other network, whereas the latter usually deals with a uniform fiber type throughout the network. For example, submarine unrepeatered links are implemented with a low-loss pure-silica core fiber (PSCF), while terrestrial links can have a large variety of fiber types, differing by their physical characteristics [standard single-mode fiber (SSMF), non-zero dispersion shifted fiber (NZ-DSF) types, dispersion-shifted fiber (DSF)]. An unrepeatered system should be able to support both submarine and terrestrial categories.

Raman amplification has been widely used in terrestrial and submarine systems in order to increase the overall transmission reach and/or bandwidth. Lumped Raman amplification (LRA) – also referred to as discrete Raman amplification – has been shown to enable the access to previously unused spectral windows, e.g., S-band, since the amplification bandwidth only depends on the wavelengths of the pump sources.

Distributed Raman amplification (DRA) is usually used to improve the system noise performance by effectively reducing the amplified spontaneous emission (ASE) noise contribution of each line amplifier, leading to an increase in the transmission distance.

This is achieved by allowing the operation at reduced power levels while maintaining the received optical signal-to-noise ratio (OSNR), thus also reducing the impact of optical nonlinear effects, and further increasing the transmission distance.

A tight integration of DRA and LRA has been implemented in a terrestrial amplified ultra-long-haul transmission system, leading to several important

benefits. A 100nm bandwidth system, accommodating up to 240 OC-192/STM-64 channels without the need for a parallel amplifier configuration, has been shown to operate over more than 3000km of several types of fiber.

With a gain fiber in the LRA stage of the in-line amplifiers also providing the necessary dispersion

Figure 1

compensation for the link, the line equipment cost is substantially reduced. In addition, the integrated DRA enables ultra-long transmission distances with low cost, off-the-shelf transponder technology that uses NRZ modulation and standard G.709 Reed-Solomon (255,239) out-of-band forward-error-correction (FEC).

The tight integration of DRA and LRA, along with the reduced size for the transponders, results in a high-density system, whereby a 240 x 10.7Gbpschannel terminal (with a capacity of 2.4Tb/s) is

accommodated within three 7-foot bays (see Fig.1).

Furthermore, owing to extremely low FIT values for the pump diode lasers, an innovative architecture, and the choice of the amplifier setpoints, the overall FIT of the line amplifiers is very low, close to 1000. The simple architecture of the terminal and line configuration also leads to several operational benefits, among which are the rapid channel turn-up and in-service capacity upgrade. A full system based on this technology is currently under deployment on a European terrestrial link of more than 1700km. Therefore, the all-Raman tightly-integrated LRA/DRA system is already a proved-in technology and its cost, performance, and operational benefits can be applied to unrepeatered systems.

The unrepeatered system is shown schematically in Figs.2a and 2b in its two possible implementations, using the exact same line and terminal technology as for the terrestrial system described above. The system provides the necessary dispersion compensation for the line fiber section, which is divided into pre- and post-compensation, as well as the gain to overcome the loss of the line fiber section and any non-pumped

dispersion-compensating unit (DCU). Up to 60 OC192/STM-64 channels are coupled into the multiplexing stage, and a DCU provides a part of the dispersion pre-compensation. In the configuration shown in Fig.3a, the channels are then amplified through the LRA-based booster amplifier with a gain fiber providing the rest of the dispersion pre-compensation. After transmission over the line fiber, the channels are amplified by the receive terminal amplifier, which is based on a tightly-integrated LRA/DRA. The distributed pump module of this amplifier is used to

Figure 2b

Figure 2a

provide distributed gain in the line fiber – thus effectively improving the noise performance of the system – and to increase the channel input power level to the amplifier. The LRA stage of this amplifier yields the remaining necessary gain to boost the power level of the channels. The LRA gain fiber provides a large part of the dispersion post-compensation. A second DCU provides more post-compensation and is followed by an additional amplifier that compensates for the loss of the DCU and the demultiplexer, ensures an adequate channel power level at the receiver, and provides the remaining amount of postcompensation.

The configuration shown in Figure 2a has been tested over a loss budget (excluding the DCU budget) of 57dB, by using 270km of SSMF, with a loss coefficient of 0.21dB/km. Thirty OC192 channels spanning 25nm were transmitted. All the channels had measured pre-FEC biterror-rate (BER) values below 10-12. The entire terminal for this configuration fits in less Figure 3

than one rack with 60 channels present. A photograph of a terminal with 30 channels is shown in Figure 3 and the 30-channel received optical spectrum is shown in Figure 4. For unrepeatered submarine transmission over PSCF with a loss of ~ 0.17dB/km, and considering a 3dB repair and maintenance margin, the 57dB budget corresponds to a transmission distance of 320km.

Since the PSCF has a much lower loss coefficient and an almost identical effective area than the SSMF, the pumping efficiency in the line fiber will be significantly improved, and the actual reach will be well beyond 320km.

The configuration shown in Fig.2b differs from the preceding one in that there is forward pumping in the transmit terminal, that helps boost the power level in the line fiber section and increase the “depth” of the high-power level in the line. This configuration has been tested over a loss budget (excluding the DCU budget) of 64dB, by using 340km of a mix of 300km low-loss SSMF (0.19dB/km) and 40km standard SSMF (0.21dB/km). Six OC-192 channels were used around 1578nm, with a channel spacing of 100GHz. All the channels had measured post-FEC BER values below 1012. The 6-channel received optical spectrum is shown in Fig.5. For unrepeatered submarine transmission over PSCF with a loss of ~ 0.17dB/km, and considering a 3dB repair and maintenance margin, the 64dB budget corresponds to a transmission distance of 360km. As stated before, owing to a lower loss coefficient, the reach on PSCF will actually be longer. A reach of 400km on PSCF will be achievable with a further optimization of the launched optical power.

The only two noticeable differences between the unrepeatered system and the aforementioned

4

terrestrial transmission system are: (1) the channel power level setting, and (2) the optical supervisory channel characteristics (wavelength and power level).

Aside from the high density that is shown for this unrepeatered system, several additional benefits can be noted:

First, the safety and reliability of such a system present considerable advantages over those of a system with separate discrete amplification and DRA. For

5

Figure

Figure

example, in the case of a fiber cut, the loss of signal power and OSC trigger the automatic shut-down of the amplifier in which the signal and OSC power levels are measured.

The integration of LRA and DRA within a single amplifier module ensures that both parts be simultaneously shut-down in the case of a fiber cut, thus guaranteeing the optical safety of the system. For separate discrete amplifier and DRA modules, the safety operation is compromised by the reliability of the communication cable between the two modules.

Second, benefits from the all-Raman terrestrial system also apply for the unrepeatered system: Integration of dispersion compensation within the amplifiers reduces the need for additional passive compensating elements, and subsequently the overall system cost. For example, in a 250-km PSCF link, only 50km (20%) is compensated by DCUs.

In-service capacity growth

SONET and SDH support for worldwide applications

Mix and match of OC-192/STM-64 transponders and 4:1 OC-48/STM-16 muxponders, enhancing the suitability for system upgrade

Short turn-up time

Third, adoption of a terrestrial technology for this application provides additional advantages. Three main features can be of significant impact to unrepeatered systems: Simplified and lower cost handling of festoon networks: such links can be handled with optical add/drop multiplexers (OADM)

in some of the landing points, thereby dramatically improving the overall cost of the system that would otherwise require a terminal at each landing points. For example, the same technology allows transmission over 2 spans of 240km each with an OADM at the mid-point landing site. High-quality element management system (EMS), corresponding to terrestrial network standards. This implies: (a) a feature-rich EMS for the unrepeatered link, and (b) easy integration of an unrepeatered system in the overall terrestrial / submarine network Same equipment as in the adjacent terrestrial network, thus facilitating sparing, personnel training . . .

In conclusion, the all-Raman integrated LRA/ DRA technology provides all-around solutions for operational issues that are specific for submarine unrepeatered systems. This is obtained without compromising on the transmission performance: a loss budget of 64dB (excluding DCU loss budget) on SSMF has been demonstrated, and a reach of 400km on PSCF is expected with commercially available equipment.

If need be, additional modifications to the system can be made to further increase this loss budget: G.709 enhanced FEC with improved coding gain at the same data rate, remote amplification, ... The tight integration of LRA and DRA contribute to a lowering of the system cost, improving its density (one 7-foot bay can support an unrepeatered system with 60 OC192/STM-64 channels), and enhancing its reliability and safety operation. Furthermore, applying a

Dr. Michel W. Chbat is Director of Technical Marketing at Xtera Communications, Inc. He was previously Director of Photonic Systems Engineering, leading a team of engineers responsible for the optical system requirements, design, and optical validation of the Nu-Wave, Xtera’s all-Raman ultra-long-haul transmission product.

Michel has over 10 years of experience in optical communication systems at Xtera Communications and other companies, and has published over 80 papers and book chapters on optical transmission and switching, and filed several patents.

Michel holds an Optical Engineering degree from Ecole Superieure d’Optique (France), and M.A. and Ph.D. degrees in Electrical Engineering from Princeton University.

Dr. Herve A. Fevrier is Senior VP for Sales, Business Development and Marketing at Xtera Communications. He previously led the photonics development activities of the NuWave DWDM platform.

Herve holds more than 20 years of experience at Xtera Communications and other companies where he served in many capacities.

Herve has over 100 papers and conference contributions, as well as more than 25 patents filed.

Herve graduated from the Ecole Centrale des Arts et Manufactures in Paris and holds a Ph.D. in Physics from the University of Paris.

terrestrial technology to unrepeatered systems introduces a new class of benefits such as a featurerich EMS and elimination of some of the back-to-back terminals in festoon network landing points.

500 m

Nexanswasthefirst tomanufactureand install384fiber submarinecable. Nexans hasqualifiedand installedtheirURC-1 cablefamilyforfiber countsupto384fibers.

1500 m

For furter information, contact:

Telecom:

Vegard Larsen

Tel: + 47 22 63 76 47

E-mail: vegard-briggar. larsen@nexans.com

Oil & Gas:

Jon Seip

Tel: +47 22 63 88 25

E-mail: jon.seip@nexans.com

Nexans Norway AS P.O Box 130 Økern, N-0509, Oslo Norway

Tel: + 47 22 63 88 20

Fax: + 47 22 63 74 55

US Contact: Les Valentine

Tel. +1 281 578 6900

Fax: +1 281 578 6991

E-mail: les.valentine@nexans.com

Failure

Failure was

was never an option . . .

Failure was never an option . . . Failure was never an option . . .

never an

option . . . Failure was never an option . . .

Marine Recovery Operations aboard the cable ship TYCO DECISIVE

On the afternoon of Tuesday March 9, 2004, Tyco Telecommunications (US) Inc. received a request from the Baltimore City Fire Department for assistance in locating three victims of the tragic water taxi accident which occurred on the previous Saturday. Within 15 minutes of receiving the request, Tyco Telecommunications requested and received permission from the ACMA to use the vessel and began mobilization efforts. Departing at 0800 the following morning, the TYCO DECISIVE maneuvered to the location of the accident and began a series of dives with her unmanned submersible vehicle.

For more than 20 years, Baltimore has been the home port for Tyco’s Atlantic cable ships. These ships are a landmark on the Baltimore waterfront along I-95 just south of the Fort McHenry tunnel. TYCO DECISIVE, Delivered in March 2003, is under charter from Tyco Telecommunications to the Atlantic Cable Maintenance Agreement, better know as the ACMA.

The unmanned, remotely operated submersible vehicle or ROV is operated by a highly specialized Tyco Telecom crew aboard the mother ship TYCO DECISIVE. Outfitted with highly accurate Differential Global Positioning System (DGPS) navigation aids, sonar, and camera equipment, the ship and

By Frank Cuccio

self propelled ROV are normally used for the inspection and burial of submarine telecommunications cables.

With a depth rating of 2500 meters, the 20 meter depths of the Baltimore Harbor ship channel were no problem for the Nereus ROV. Typical cable operations in the open ocean utilize the four cameras aboard the ROV for visual inspection of the seabed. Baltimore’s harbor bottom turned out to be a tangled mess of manmade and natural debris with absolutely zero

visibility. During the first 24 hours of recovery operations, the Nereus ROV was maneuvered along the harbor bottom and used her forward looking side scan sonar to identify objects of the approximate size and shape of the victims. Working in the extremely cold and dark water, Baltimore City Fire Department divers, in conjunction with TYCO DECISIVE and Nereus ROV, made a series of dangerous dives on targets identified by Nereus only to find debris. With hundreds of potential targets on the bottom of the harbor, it was clear that a miracle would be required to find the victims.

During the evening operational briefing, Tyco’s head submersibles engineer, Phil Walker, described a device called a DIDSON Acoustic Sonar that was reported to provide a near video quality image in a zero visibility environment. After several phone calls, two such devices were located. Recognizing the extreme nature of this situation, Tyco Telecommunications issued a verbal order at 5 p.m. Thursday to the MagnaPatch Company in Houston, Texas. Howard Bailes, President of MagnaPatch quickly packed his gear, boarded a flight and hand carried the DIDSON, arriving aboard TYCO DECISIVE at 2 a.m. on Friday, only 9 hours later.

With the ROV recovered and routine preventative maintenance performed, the ROV

TYCO DECISIVE

engineers were standing by when Howard arrived and immediately began the complex task of integrating the DIDSON to the ROV system. With twelve hours of integration efforts logged, system tests revealed a communication problem between the submersible and the mother ship. While efforts to resolve this problem continued, Phil Walker called on Dave Clifford, President of Prizm Inc., manufacturer of the communication circuit boards. Dave responded to Phil’s call early Friday afternoon by locating the spare boards and hand carrying them to the TYCO DECISIVE.

As additional insurance, Dave brought the circuit board design engineer, Geoff Huntington to assist with the installation and trouble shooting. These efforts paid off and after a total of 20 hours of integration efforts the ROV was ready to dive and resume the search. The DIDSON performed as advertised and provided the ROV crew with near video quality images of the seabed.

To expedite the search and focus the ROV to specific target areas, Tyco Telecommunications worked in cooperation with John DeMille from Marine Sonic Technology LTD, who provided target data from a separate side scan sonar towed from a Fire Rescue boat. The target data was electronically plotted on Tyco’s shipboard charting system, and after careful evaluation, was used to prioritize the search areas. Working in two 12 hour shifts, the Tyco ROV crews methodically searched the seabed using the ROV’s side scan sonar.

With a range of approximately 10 meters, the side scan sonar was able to identify possible targets on the harbor bottom. Once targets were identified

and classified by side scan sonar, the ROV was maneuvered closer to the target and the DIDSON unit was focused on the target. By using the broader beam side scan sonar and the narrow beam DIDSON, the Tyco ROV crews were able to rule out debris and positively pinpoint the location of the missing victims.

With the DIDSON focused on the victim, the ROV was positioned about a meter away on the seabed.

The dynamically positioned cable ship TYCO DECISIVE was maneuvered directly adjacent to the ROV umbilical. Using TYCO DECISIVE as a command center, the Baltimore City Fire Department Special Operations Dive Team and Tyco Telecommunication’s team worked together to brief divers, showing them a video of the ROV position and victim’s position. TYCO DECISIVE created a lee for the dive support boat and the ROV umbilical served as a down line for the Baltimore City Fire Department divers. This technique reduced dive time to a minimum and greatly assisted the divers who worked in the extremely cold and dark waters.

The three victims were successfully located and recovered through the combined efforts of Tyco Telecommunication’s personnel and the Baltimore City Fire Department. The parents of one victim released a statement thanking the Fire Department and Tyco Telecommunications. “We are very grateful for the recovery of Corinne and look forward to bringing her home. This brings our family a measure of closure to this tragedy and will allow us to focus on grieving for the sudden and heart breaking loss of Corinne and Andrew Roccella.”

While the tragedy of the lives lost overwhelms the technical achievement of the recovery efforts, we

Francis J. Cuccio is the Managing Director , International Construction Operations and Maintenance (ICOM) for Tyco Telecommunications. He is responsible for Tyco’s engineering and construction, cable ship fleet, submersibles, cable depots and the wet maintenance business. Frank is a former Merchant Marine Engineering Officer, and has a Bachelor Degree in Marine Engineering from S.U.N.Y. Maritime College, Master’s Degree in Industrial Engineering from Purdue University and a Masters Certificate in Project Management from George Washington University.

are proud of our accomplishments. This group of Tyco Telecommunications employees worked 24 hours per day for five days, called in I.O.U.’s, personal favors, leveraged Tyco’s vast resources, solved engineering problems, battled fatigue, and bitter cold weather to exemplify Tyco’s commitment to excellence. Speaking on behalf of the forty nine Tyco Employees aboard TYCO DECISIVE, the recovery of these victims was personal. Failure was never an option.

OFS innovates today’s major submarine networks with fibers that support longer distances and higher capacities than ever before. The results? Lower system costs and unrivaled performance.

OFS has the optical fiber to support all your emerging system design needs –

Lower dispersion management cost

Higher reliability

Greater capacity and bandwidth

To unleash your system’s full capabilities while keeping your costs competitive, choose OFS fiber for your next submarine cable project.

For more information on OFS’ complete family of fibers for the submarine market, please visit the OFS Fiber website at www.ofsoptics.com or call Tom Davis at (973) 655-1502

The versatility of telecom undersea cables in transporting large volumes of optical data and reasonable amounts of power make them good candidates for new applications offered in the oil and gas industry, as well as in the field of undersea scientific observation. In both cases, there is an ongoing evolution of how these different communities work at sea, which results in the growing need for more submarine cable networks.

New challenges for the offshore oil and gas industry

Man is key to the operation of complex systems such as oil and gas offshore exploration and production units. Prompt decisions and actions are required to limit the operational risks while maintaining efficiency at its maximum. However, new ways of operating the offshore systems are needed to either further limit the risks or decrease the cost associated with their operation. The operating risks encompass many areas such as the risk to the personnel onboard the offshore unit, the risk to the equipment and structure itself, as well as the environmental risk in case of accidental leakage.

One clear trend to mitigate those risks is to propose ways to either make the operation automatic when it is technically possible or to allow its remote control from a safer location on the mainland. In both cases, similar techniques that rely on dependable real time communications to shore are required. Remote operation, for instance, may require 2 to 10 Mbit/s of capacity whereas uploading real time reservoir drilling data to shore may require 10 to 100 Mbit/s, easily offered by optical transmission.

Emerging Markets for Submarine Cables

Antoine Lécroart Antoine Lécroart Antoine Lécroart Antoine Lécroart

Area Marketing Director

Alcatel Submarine Networks

Antoine Lécroart has been working in the submarine industry with Alcatel for over 15 years.

After being a technical project manager for the S560 submarine line terminal equipment, he was in charge of technical bidding for the first optically amplified transoceanic systems: TAT-12/ 13 and APCN. He was subsequently responsible for Product Marketing within Alcatel Submarine Networks for five years in Europe and three years in the US. Now relocated in France, he is in charge of Marketing and Sales for Emerging Markets.

Automation and remote operation are indeed required to reach the newly explored deep-water fields. These fields are deeper (500 to 3000 meters) and are further from shore (50 to 100 kilometers) compared to the previous shallower areas.

Direct drilling from the surface is no longer possible and they normally require the support of floating platform and storage facilities (FPS). This trend will further develop as these deep fields are more and more explored due to the increasing scarcity of easier-to-reach resources.

New undersea techniques capable of superior reach rely on the use of Remote Operating Vehicles (ROVs) and undersea manifolds equipped with wetmateable cable connectors. Dynamic risers or J-tubes accepting limited movement while still efficiently protecting the cable are also used to link the undersea elements to the FPS (Floating Platform and Storage). Flexibility is the key word as the submarine network evolves in time and new elements need to be connected as field coverage increases.

The almost limitless bandwidth available over optical fibers brings other benefits such as improved voice communications and better security due to extensive use of video surveillance. Indeed, a wellengineered and protected cabled solution brings unsurpassed availability for true multi-service capability that easily copes with all types of data transported, including Internet Protocol (IP), voice, raw data and video streaming. As such, a ring architecture may create the backbone of this flexible multiple client network and can complement, and eventually replace, complex solutions using different satellite or radio links (Figure 1).

Another big advantage of submarine cables is their robustness against atmospheric events such as gales or hurricanes. The antennas used for microwave or satellite links, or the structures supporting them, may be damaged or destroyed during severe seasonal weather conditions. This is particularly true in hurricane prone areas such as the Caribbean basin or the Gulf of Mexico. Microwave links may also be difficult to implement for FPS, as misalignment due to the platform movement or signal reflection and fading can cause service unavailability. Cable connections allow the continuous operation of the system during severe weather or bad propagation conditions, resulting in minimized down time.

Overall benefits for the oil and gas industry

The supply and installation of a submarine cable network may require a large initial investment but it is likely to be very safe provided the installation is performed with adequate means and measures (use of burial and other appropriate cable protections).

The cost required for a high availability communication system needs to be compared to the loss of revenues faced when the service is disrupted for long periods.

The oil and gas industry is cautious in introducing new technologies and certainly the high risks associated with the activity are a clear deterrent to experimental solutions, nonetheless, cabled

communication solutions are mature and will improve significantly the overall field productivity.

Cables for the scientific community

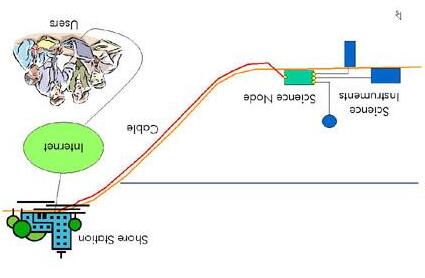

The need for continuous real time monitoring of science related parameters at sea is driving the recent interest for new sea floor cabled observatories. They will allow observation to occur over years instead of months with the possibility to use local power provided by the cable. Optical fibers enable real time communication of the monitored parameters to shore where they can be stored, processed and made available to all interested communities, using, for example, the Internet as a convenient way to access the information. Figure 2 shows a typical single node observatory. A lot of opportunities are now offered for submarine cabled networks allowing either dedicated infrastructures, such as undersea Cherenkov neutrino telescopes (e.g. ANTARES in the Mediterranean and the upcoming Very Large Neutrino Telescope), or multidisciplinary observatories able to cope with a broad range of arrays and sensors such as the MARS, VENUS and NEPTUNE programs in the Northeast Pacific and the ARENA initiative in Japan.

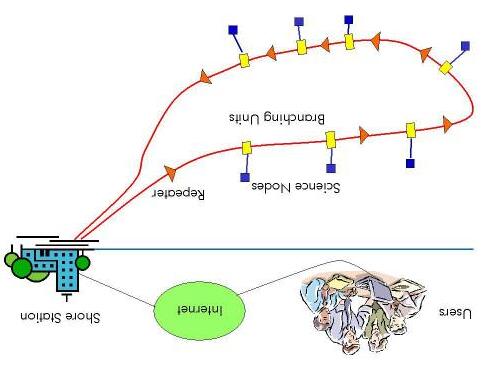

Robust architectures for large observatories

Many aspects of a telecom cable system can be re-used in cabled observatories, especially for power distribution to science instruments and for communication between the sensors and the shore. The advent of qualified deep-sea capable ROV operated wet-mateable connectors is also an enabler for the undersea cable observatories allowing to easy disconnection of parts of the undersea arrays. Large

Figure 1: Ring backbone architecture for offshore fields

Back

Haul

multiple node cabled observatories will rely on architectures allowing a separation between a very robust backbone and the area where more challenging elements will be used such as the nodes and the science instruments. The backbone will mostly be composed of standard telecom cable, Branching Units, Terminations (including wet mate connectors) and repeaters (Figure 3). It will be deployed using traditional cable ships and special consideration will be given to the protection of the wet plant as it is likely to be laid across areas that telecom systems would

normally avoid, but which are close to major science interest spots. Provided careful route selection and adequate cable protection is performed, using armoring and burial, the installed backbone will exhibit very low intrinsic failure rate over its 25 year lifetime, as seen in the telecom industry.

For the science nodes and the science instruments, it is foreseen that maintenance will be required more frequently because the inherent nature of science instruments is precisely to look at parameters in novel ways. During the expected long life of observa-

tories, mature sensors are likely to be replaced by new devices providing more interesting information. Therefore the use of wet-mateable connectors will allow smaller ships equipped with ROVs to perform most of the maintenance required at the science nodes.

Benefits to the scientific community

When compared to other devices such as moorings or “landers”, cabled systems will noticeably improve the power management and the real-time communications to shore. Power will be fed through the cable using the cable single conductor. The return will take place through the sea using an electrode at the science node. Available power for each node will be much greater than what can be provided with batteries and cell replacement will no longer be required. This high power capability will be available for the full life of the system by the use of Power Feeding Equipment (PFE) in the shore station. The optical fibers of the cable will provide high-speed broadband communication back to shore.

Although various techniques and protocols can be used, there is a clear advantage to try to standardize the interface between the science instruments and the “transport” function performed by the backbone. Today, it seems that Ethernet interfaces ranging from 10 Mbit/s up to 1 Gbit/s will allow the transport of a wide variety of data flows either coming in bursts or streaming.

Using Ethernet and IP allows the use of widely deployed data network equipment that can be combined with Wavelength Division Multiplexing (WDM) optical transport to make better usage of the bandwidth. The optical fibers also eliminate the

Figure 2: Single Node Science Observatory Principle

transmission delay for the information that will be sent back to shore the fastest way.

Conclusion - New markets with high potential growth

As for the oil and gas industry, a change in the perception of undersea-cabled infrastructures is slowly taking place in the scientific community. These industries now understand that the relative high cost of the turnkey supply and installation is necessary in order to benefit from reduced risks and increased

benefits over the full period of operation of the undersea infrastructure.

The viability of the projects will only be better as the technical solutions gets well adapted to these new needs. The potential for growth for these emerging markets is fairly substantial, as the demand is structural for each of these sectors. Although the current pace may be slow, we clearly are at the very beginning of a new era with the design and installation of the first projects but large-scale deployment will inevitably come in the future.

World 2004

The 7th annual Submarine Networks World 2004 has grown to be Asia’s most established and well-attended event by the submarine cable community. The senior level conference has evolved into THE "industry event" where cable operators, carriers and technology vendors converge annually.

Our outstanding speaker panel includes:

•Claire Paponneau, France Telecom

•Patrick Gallagher, Flag Telecom

•Bob Woog, Pivotal Telecom

•Kaz (Kazuhiro) Nishihata

NTT Communications Corporation

•Fiona Beck, Southern Cross Cables

•Stefano Mazzitelli, Telecom Italia Sparkle

•Andrew Kwok, Hutchison Global Communications

•Kamran Malik, Saif Group Telecom

•Ian Pulford, British Telecom

•Scott D. White, Azea Networks

Register now! Call our customer service hotline at (65) 6322 2700 today

Featuring more than 20 key carriers and cable operators in the submarine industry Media Partner:

Networking sponsors: Associate sponsors:

www.carriersworld.com/2004/snw_SG/

Figure 3: Multiple Node Science Observatory Backbone

undersea intelligence 22 – 24 September 2004, Grand Copthorne Hotel, Singapore

Submarine Cable Jointing is a core part of the whole undersea communications network. It has often been called a Black Art, and whole careers have been built around some apparently miniscule aspect of jointing. In recent years, a large amount of time and effort has been spent understanding the processes involved and introducing tight process control to reduce the dependence of jointing on the supernatural.

The potential applications of old or obsolete jointing techniques. IN CABLE JOINTING

involved are often traceable back to analogue cable system joints.

Marine cable jointing is not a variant of the civil engineering activity which involves the roads being dug up in busy cities at the busiest times of the year. Both types of joint involve splicing fibre, but there the similarity ends. The demands of a submarine cable joint are more extreme. First there is the sea bed pressure to contend with – joint cavities must not implode when installed in the deepest oceans. The tension and torsion that a joint undergoes during deployment and recovery require a jointed length of cable to have similar mechanical properties to the parent cable. Long haul submarine cables require DC power feed to the repeaters or regenerators. The insulating material or dielectric must form an effective waterproof seal of the joint (at sea bed pressures) as well as bonding to the cable to form an effective

By Jim Bishop

electrical insulation capable of withstanding voltages of up to 12 kV for the duration of the system life.

Marine cable jointing is not exclusively a cable ship activity. Manufacture of a submarine cable involves a significant number of consecutive processes. An ‘event’ in any one manufacturing process can cause unplanned system joints.

Planned joints are also employed during system assembly or as a transition from one armour type to another.

In the ideal world, jointing at sea and in a factory should employ the same equipment and processes, although a number of factory specific techniques have been introduced to increase the throughput of joints, in an environment where ease of equipment manoeuvrability is not a prime consideration.

Having established that jointing is an essential part of both system assembly and marine operations, whether installation or maintenance, the technologies

Moulding and X-ray techniques have changed little in principle from the analogue systems from which they are descended. Some of the tolerances and measurements quoted in specifications are often a direct conversion into millimetres of a round number in inches or thousandths of an inch. A jointer, who spliced the earliest optical submarine cables, would not have difficulty recognising the mechanical construction of a modern joint (splicing equipment excepted - which has improved unrecognisably).

The jointing technologies in use at sea today are few, and closely protected by the owners and users of the technologies. On cable ships and at dockside depots around the world, large sums of money have been invested in supporting these technologies in the form of large stocks of equipment and jointing kits.

Developing a new joint design as an alternative to established products would be an expensive project, involving the same extensive range of mechanical, environmental optical and electrical tests to meet the requirements mentioned earlier (and more). If a new joint is developed in parallel with a new cable design and qualified simultaneously, the cost can be shared

between the two activities. Over a relatively short time period the cost benefits of owning a jointing technology rather than buying into someone else’s begin to accrue and offer substantial savings.

Over the years a number of the processes involved in jointing have been developed and subsequently shelved, such as factory based processes that did not make the transition to a shipboard environment. Even complete joint designs have been shelved for a whole variety of reasons, not necessarily a result of the product not meeting the design requirements.

Are future jointing solutions hidden away in old flight cases?

These joint designs and associated processes were developed for, and used on, some of the older optical cable designs and have been qualified either in part or in full. The joint designs have often met qualification requirements in excess of those in use today.

Some of these joint designs could be readily adapted to accommodate the modern cable designs

and performance requirements, and proven using a reduced qualification programme, supported by the original qualification data and test results.

Reviving older processes is more challenging. Around the world, legislation and safety regulations are increasing exponentially in volume and becoming more stringent and enforceable. Examples of relevant directives apply to EMC or Low Voltage electrical equipment.

Typically these considerations need to be designed into a product during initial development. Not surprisingly, these regulations vary (sometimes only slightly) from country to country. This is not helpful in an industry active around the world, requiring equipment to be moved around globally.