Hydrema road-railerHigh-spec Kubota ● Hire show review ● DJB/Cat truck history ● Piling rigs EARTHMOVERS New JCB 2.5t mini MAY 2024 NUMBER ONE FOR ALL THE LATEST PLANT & MACHINERY NEWS SIZE MATTERS: CHOOSING AN 18-TONNER Crossover weight between common site excavators OWNER-OPERATOR £4.50 MARKET GUIDE NEW TECHNOLOGY FIRST EXAMPLE OF THIRD GENERATION ELECTRIC COMPACTS LONG REACH EXCAVATORS

Experience total confidence through the quality and reliability.

Cat machinery, combined with Finning’s 90-year heritage, ensures you can buy with total confidence.

Facing up to any challenge, Cat excavators and equipment are guaranteed to deliver exceptional performance, unmatched versatility, and excellent fuel efficiency. Simple operation, outstanding durability and the latest safety and technology features will help you take your business to the next level.

Get in touch to find out about our world-class customer support, warranty packages, fuel usage promise and attractive resale values, all supported by a range of options through Cat Financial.

Talk to us on +44 (0)1543 461 410 or visit www.finning.com/confidence and find your confidence.

© 2024 Finning (UK) Ltd. and Finning (Ireland) Limited are part of the Finning International Inc group of companies. All rights reserved. © 2024 Caterpillar. All Rights Reserved. Cat®, CATERPILLAR®, LET’S DO THE WORK®, their respective logos, ‘Caterpillar Yellow’, the ‘Power Edge’ trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. Finning (UK) Ltd. Watling Street. Cannock, Staffordshire WS11 8LL. Finning (Ireland) Limited, 2 Grand Canal Square, Dublin 2, Ireland.

Editor Graham Black

Editor@EarthmoversMagazine.co.uk

News Editor Kyle Molyneux

Sub Editor Paul Carter

Advertisement Sales

Richard Cosgrove +44 (0) 20 8639 4416

Sales & Marketing Manager Richard Cosgrove

Administrator Martin Attis

Publishing Director Paul Cosgrove

EARTHMOVERS is published by

Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent BR3 5JS. +44 (0) 20 8639 4400

www.EarthmoversMagazine.co.uk

Info@EarthmoversMagazine.co.uk

Subscriptions

Earthmovers subscriptions

Trinity House, Sculpins Lane, Essex, CM7 4AY, England. +44 (0) 1371 853 632

earthmovers@escosubs.co.uk

Newstrade

If you have any difficulty obtaining Earthmovers from your newsagent please contact Seymour Distribution, 5 East Poultry Avenue, London EC1A 9PT.

+44 (0) 20 7429 4000

Repro

Design & Printing Solutions Ltd, First Floor, Unit 45C, Joseph Wilson Industrial Estate, Whitstable, Kent CT5 3PS.

Printing

William Gibbons & Sons Ltd., 26 Planetary Road, Willenhall, West Midlands, WV13 3XB.

Copyright

Sundial Magazines Ltd 2024. All rights reserved. Reproduction in whole or in part is forbidden except with the written permission of the publishers.

ISSN 1743-0372 Sundial Magazines Ltd. Registered in England No 4134490.

Conditions for advertising

All advertisements are accepted subject to the publisher’s standard conditions of insertion. For a copy of Advertising Terms & Conditions, please write to Paul Cosgrove at Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent BR3 5JS.

Australian subs sales agent

Greg McNiece, Rally Badges, PO Box 9, Tatura, Victoria 3616, Australia. +61 (0) 3 5824 1734

www.twitter.com/ EarthmoversMag

The next issue of EARTHMOVERS magazine is available on 3 May

Full steam ahead

It has been a busy start to the year, with a wave of new batterypowered compact kit launched on to the market and fullsized electric excavators also being trialled in the UK. Talking of emerging technologies, an autonomous articulated dump truck is currently working in the China clay pits of the south-west, and National Highways is looking at intelligent compaction systems.

Such next generation tools of the trade are going to transform the productivity of the industry. They will also lay a foundation to attract the next generation of employees, who will not necessarily be spending their days driving a dump truck or a roller. Instead, they will be driving a computer screen in the offi ce, working alongside colleagues from the fi rm’s survey, plant maintenance and management units, on a fully connected site.

In addition to such strategic changes in the industry, there is much that is being done with current off-the-shelf technology to improve site productivity and safety, in particular the widespread adoption of GPS systems and more sophisticated hitches, such as tilt-rotators.

Yours till next month

Graham Black, Editor

MAY 2024 EARTHMOVERS 3

2024 Issue 241 Hydrema road-railerHigh-spec Kubota Hire show review DJB/Cat truck history Piling rigs EARTHMOVERS New JCB 2.5t mini NUMBER ONE FOR ALL THE LATEST PLANT & MACHINERY NEWS SIZE MATTERS: CHOOSING AN 18-TONNER Crossover weight between common site excavators OWNER-OPERATOR £4.50 LONG REACH EXCAVATORS MARKET GUIDE NEW TECHNOLOGY FIRST EXAMPLE OF THIRD GENERATION ELECTRIC COMPACTS

May

WELCOME PHOTO CREDIT: EOGHAN DALY

CONTENTS

County Wexford-based operator’s latest mount, a Komatsu PC170-11.

A round-up of the latest news from the earthmoving and associated machinery industry.

When it comes to compact construction equipment the future looks electric.

Young operator’s latest Kubota midi includes an Engcon tilt-rotator.

Finnish firm introduces thirdgeneration

20-tonne wheeled excavator that is a factory-built road-rail machine.

We report on a wave of new JCB compact construction equipment.

Brassington Moor Quarry’s latest generation 70-tonne class excavator.

Birmingham’s Operator Skills Hub is a dedicated plant training facility.

Burnside Plant’s new pair of Volvo compact radius excavators at work.

Recycled aggregates are being used on London’s gas and water mains repairs.

Graham Black introduces our review of factory-built long-reach excavators.

JCB’s mighty 4CX backhoe is the perfect tool carrier to erect utility poles.

Two time-critical Cawarden demo projects on the university campus.

49 PLANT HIRE LIEBHERR RENTAL

55 RECRUITMENT OPERATOR SKILLS

HUB

59 PILING VOLVO-MOVAX COMBOS

64 RECYCLING TERRAFIRMA PIPELINES

66 MARKET GUIDE LONG-REACH EXCAVATORS

71 PLANT HIRE POLE ERECTOR

75 SITE VISIT LOUGHBOROUGH UNIVERSITY

4 EARTHMOVERS MAY 2024

ISSUE NUMBER 241 May 2024

7 OWNER-OPERATOR PHELIM KELLY

FEATURES

11 NEWS

21 SHOW REPORT EXECUTIVE HIRE

27 OWNER-OPERATOR JACK DICKSON

31 PRODUCT LAUNCH AVANT

electric compact loaders. 37 OPERATOR FEEDBACK HYDREMA MX20G

43 PRODUCT LAUNCH JCB

16 59 64 49

UPFRONT

TAIL END

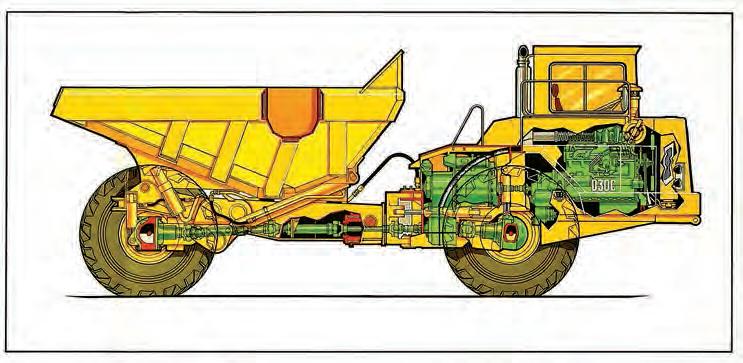

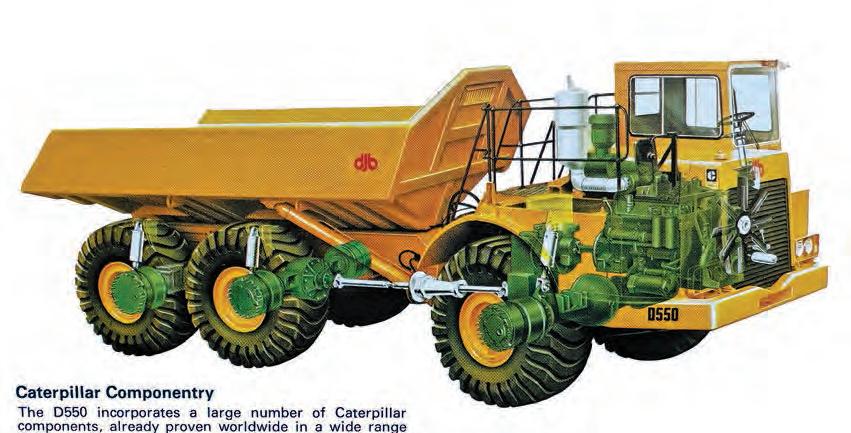

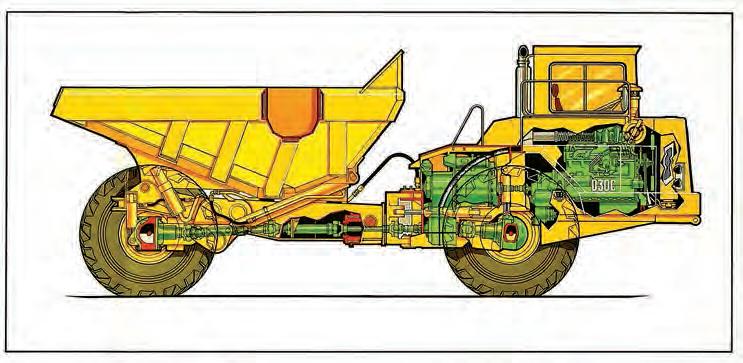

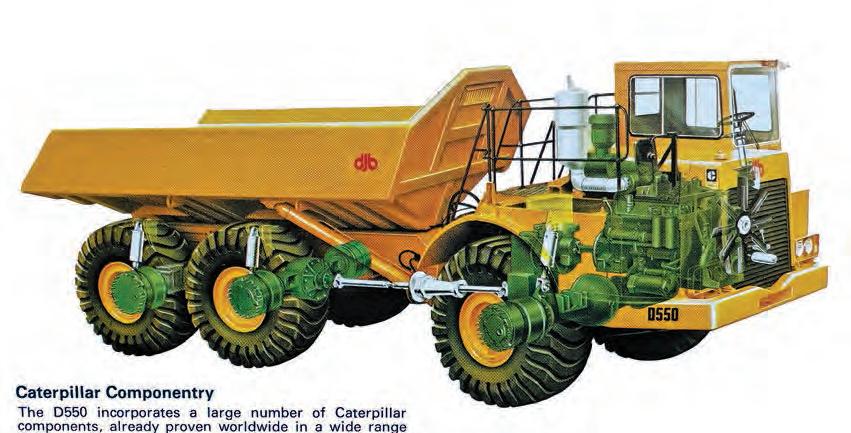

78 PLANT HISTORY

CAT

ADT ORIGINS

Insight into the history of Caterpillar’s range articulated dump trucks.

84

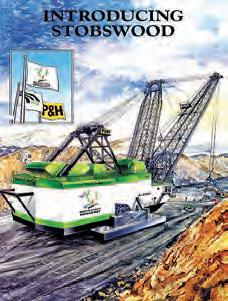

EXTREME MACHINES

P&H 757

Europe’s largest dragline is now at work on a coal site in North Dakota.

91 INTERVIEW STEELWRIST

In conversation with Stefan Stockhaus, the company’s president and CEO.

92 NEXT MONTH

Here’s a taster of just some of the exciting features planned for the next issue.

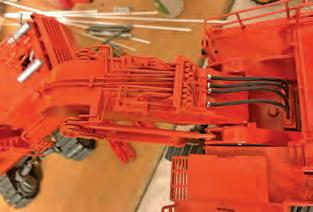

96 PLANTMOBILIA O&K CUSTOM BUILDS

EARTHMOVERS reviews unique scale models of O&K mining excavators that once worked in the UK.

98 PICTURE POST

Got any interesting or unusual pictures of earthmoving men or machinery? WIN £20 for our ‘Pic of the Month’.

MAY 2024 EARTHMOVERS 5

71 78 84 SUBSCRIBE & SAVE! –TAKEOUTANANNUALSUBSCRIPTION £12.00(UKDON’TMISSANISSUEANDSAVEUPTO SEEONLY)INTOTHEBARGAIN! PAGE 88 96 66

Register now! Sign up for your free visitor ticket at hillhead.com/register Email: hillhead@qmj.co.uk Phone: +44 (0) 115 945 4367 Join the conversation @Hillheadshow#hillhead2024 25-27 June 2024 Hillhead

| Derbyshire | UK The UK’s largest Quarrying, Construction & Recycling Exhibition

Quarry Buxton

MIDDLEWEIGHT

CHAMPION

Eoghan Daly reports on the experiences of County Wexford-based Phelim Kelly with his latest mount, a Komatsu PC170-11 excavator

Some 18 months ago, Ballycarney, County Wexford-based owneroperator Phelim Kelly found himself with an aging but reliable excavator, but made the decision to upgrade to the latest generation of machine. He ended up with a Komatsu, the first he had operated during a lifetime in plant. However, at around 18 tonnes, it continued Phelim’s belief in the advantages of operating a cross-over machine between standard 14- and 21-tonners.

BACKGROUND

Phelim’s 45-plus-year involvement with plant started at the age of 17, operating kit in his father’s plant hire business. He then began running his own Hymac hydraulic excavator, initially with a 580C followed by

Inset and right: County Wexfordbased owneroperator Phelim Kelly continues to run a single excavator, his current mount being a Komatsu PC170-11.

a 580D, before moving to the more technically advanced 141 model.

He recalls; “Everyone was saying Cat excavators like the 215 were the best in their class at the time. Based on this, I changed from Hymac to Caterpillar, first with a 215 and then on to a 215C and finally a 215D. They were well-built machines, but with the Perkins engine they used were a bit underpowered for their size, which made them a bit of a let-down, but they still managed to get through a lot of work.

“Back when I was running Cats, I would usually replace them every five years, but when the recession hit, I was running a Case CX160B. I held on to it longer than normal and in the end it had worked over 20,000 hours. It had a bit of wear in the usual places, but was still a great machine and had never let me down, which was why another Case machine seemed the best option.

“The new Case E series was just coming on stream but they weren’t in a position even to give a quote and were uncertain of the delivery timeframe. I wasn’t prepared to wait, which led me to look at other options, including the Komatsu PC170-11 from McHale Plant Sales, which then had a six-month delivery time.

“THEREISNOPOINTTYINGBIGMONEY UPINEXTRAPLANTANDNOTGETTING FULLUSEFROMTHEM”

MAY 2024 EARTHMOVERS 7

OWNER-OPERATOR // PHELIM KELLY

“THEKOMATSUDEFINITELY ISAHIGH-CLASSMACHINE TOOPERATEANDIWOULD HAVENOTHINGNEGATIVE TOSAYABOUTTHECAB”

“An excavator in this size class is ideal for an operation like mine. It provides a machine that is still not overly big for working in confined places and is easier to transport between sites. It has much greater digging power than a 14-tonne class machine and can get through bulk digging like a 21-tonne excavator, without being under any pressure and remains economical to run. I have been working with machines of this size class now since the Cat 215s and view it as being a working model that has proven itself over many years.”

CONFIGURATION

As the Komatsu PC170’s undercarriage is just shy of 4m long and its track gauge 1990mm, with 700mm-wide track shoes the 18-tonner has a firm stance, while exerting less ground pressure and occupying a smaller footprint than a 21-tonner. Komatsu certainly has not scrimped on the undercarriage, as each track frame features two top rollers, seven bottom rollers and a central track guide, in addition to

8 EARTHMOVERS MAY 2024

Above and below: This PC170-11 is configured with a heavier counterweight and a long dipper stick. It sits on a 4m-long undercarriage shod with 700mm track pads.

the normal idler end track guides.

One result of its beefy-looking undercarriage is that the PC170-11 is a relatively tall machine, the clearance under its counterweight being just 30mm short of the larger PC210-11 model. In view of this, and wanting to use the longest 2.9m dipper stick available, Phelim ticked the option box for a heavier counterweight. At 3250kg, it is half a tonne more than the standard component, but results in better stability when making full use of the working equipment. He chose a Geith quick-hitch, a brand he has used since his time with a Cat 215D.

SITE VISIT

Phelim undertakes excavation and groundworks for one-off houses, but his bread-and-butter work comes from a loyal customer base within the local farming community, for whom he undertakes farm building construction, land reclamation and drainage projects.

We met him on the Ballyhamilton Farms estate near Enniscorthy, working on an extension to a grain store, which required an extensive reduced level dig. Once topsoil had been stripped, the site was to be excavated in two levels. The first metre or so was subsoil, of which Phelim obtained a heaped bucket on every cycle. The tip area was just a short distance away, the excavator keeping the drivers of two tractor and dump trailer combinations busy.

Below the subsoil was a layer of rock, which was not a particularly high density at first. However, as Phelim got deeper, he had to use a ripper attachment on the excavator to fracture the material.

He continued, “I have always heard good things about Komatsu excavators when it comes to digging power and this one definitely has not been a disappointment where breakout force is concerned. It also has great speed and is very well balanced and smooth on the levers.

“At first, I thought fuel consumption was a bit high, but over time it became clear that it wasn’t, based on the amount of work it is able to get through. Obviously on lighter work it is very efficient and in tough going it will burn more diesel, but it is a great machine and really has that extra bite when you need it in hard digging.”

The British-built PC170-11 is powered by an ultra-low emissions four-cylinder Komatsu engine rated at 90kW. It is a torque rich powerpack that is mapped to work lower down its rev range, for better fuel economy. Undertaking intensive excavation work at the time of our visit, the PC170-11 was consuming 12.2 litres per hour, which is reasonable considering the progress it was achieving.

Phelim continued, “The Komatsu definitely is a high-class machine to operate and I would have nothing negative to say about the cab design or layout. The machine has just passed the 1400 hours service recently, in just under a year’s operation, which has been completely without problems, so everything remains positive.”

CONCLUSION

Over the decades, Phelim has resisted the temptation to expand his business. He is content being an owner-operator, delivering quality over quantity. He owes much to the loyalty of his client base, with whom he maintains a continuity of work.

He concluded, “There is no point tying big money up in extra plant and not getting full use from them. I have never regretted not expanding machine numbers over the years and believe the single machine owner-operator approach is one that has always worked for me, so why change it?

“I am always working within a 20-mile radius of Ballycarney, which brings constant work my way. Now with a new machine, which has been very reliable so far, I have no reason to regret making the change to my first ever Komatsu excavator.”

// PHELIM KELLY MAY 2024 EARTHMOVERS 9

OWNER-OPERATOR

Right and below left: The British-built Komatsu is a well-equipped machine, which has proved to be totally reliable over its first year of work.

A LONG WAY TOGETHER

EARTHMAX SR 41

No matter how challenging your needs, EARTHMAX SR 41 is your best ally when it comes to operations that require extraordinary traction. Thanks to its All Steel radial structure and the special block pattern, EARTHMAX SR 41 provides excellent resistance against punctures and an extended service life. In addition to long working hours without downtime, the tyre ensures extraordinary comfort.

EARTHMAX SR 41 is BKT’s response to withstand the toughest operating conditions in haulage, loading and dozing applications.

www.kirkbytyres.co.uk IMPORTER FOR THE UK

Tel: +44 0151 728 4171

bkt_enquiries@kirkbytyres.co.uk

Discover the BKT Radial Range

NEWS WORLD’S FIRST ELECTRIC SIXTONNE DUMPER

ecalac has introduced its all-new eMDX batterypowered site dumper, the first electric hauler to offer a capacity of six tonnes. Equipped with a 75kWh pack, Mecalac claims it will provide at least eight hours of operating time from a single charge and, with its raid recharger, can be ready for another day’s work after being plugged in for four hours.

THIRD GENERATION STEELWRISTS

s we go to press, Steelwrist has launched its third generation of tilt and rotate hitch technology, which includes the new XTR20 tilt-rotator and XR series of rotating couplers, together with redesignated tilting hitches, the XT range. Further details in the next issue.

A round-up of news stories in the plant and machinery construction industry ant

JCB-LEICA MACHINE GUIDANCE DEAL

As we go to print it has been announced that JCB and Leica will offer factory-fitted Leica 2D and 3D-ready semi-automated excavator control systems. This will initially be offered on their 22-tonne class X Series excavator for UK customers, before being rolled out across the range and to other regions.

Moredetailsinthenextissue,whichincludesthelaunchofthe370X excavator.

NEW BOBCAT ROTO-HANDLERS

obcat has launched a new range of rotary telehandlers, covering lifting heights from 18m to 39m and providing lifting capacities from five to eight tonnes. Those models with lifting heights up to 26m are powered by Deutz engines, the larger models by Volvo powerpacks. A key feature of the new range is their pressurised ROPS & FOPS protected panoramic cab, which offers great visibility, clearly inspired by cabs used on cranes.

Market note: With more than 4500 examples sold in 2023, the total global market for rotary telehandlers continues to grow, but a whopping 85% of these sales are made to European customers. The only other notable market is the USA, which takes 10% of total production.

MAY 2024 EARTHMOVERS 11

M A B

NEWS wrist gy,

As fac con Ser ran Mo exc

KRAMER DASH 8 LOADERS

Kramer has launched the Dash 8 series of compact wheel loaders, the 8085, 8095, 8105, 8115, 8085T and 8095T models, providing bucket tipping loads from 3650kg to 4250kg. The standard build for the range includes a 55kW/75hp Deutz engine, but the 8105, 8115 and 8095T models can be specified with a 74.4kW/100hp powerpack.

NEW HOME FOR LIEBHERR

ELECTRIC WHEEL LOADERS

fter roughly 10 months of construction, Liebherr has commissioned a new assembly hall, within its giant factory at Bischofshofen, for the manufacture of battery-electric compact wheel loaders. Over €2.2m has been invested in the 1000sq.m facility, which has been designed and laid out with the help of virtual reality technology.

The firm’s first electric loader, the L507E model, has started to roll off the line, which has a production capacity of 500 battery-electric wheel loaders a year.

CATS CROSS WATER

Located at Glensanda on the shore of Loch Linnhe in south-west Scotland, Aggregate Industries operates the largest granite quarry in Europe. Caterpillar distributor Finning supplies the site with machinery and support services, which can be a challenge at times. For example, the phased delivery of their latest batch of 18 machines, which includes a dozen Cat 777 haul trucks and large 992 wheel loaders, together with a D9 dozer and a model 16 motor grader. Organised by Finning Glasgow, the transport arrangements include having to navigate narrow and twisting Highland roads, before being loaded on to a barge for the last part of the journey.

SCOTTISH OPERATOR

CHALLENGE

Hosted by Morris Leslie, the final of the Scottish Plant Operator Challenge will take place during the Working Vintage Plant Weekend on 27 July, at Errol Airfield in Perthshire.

The Scottish Plant Operators Association’s Callum Mackintosh said, “Last year was the inaugural Scottish Plant Operator Challenge and I was proud to be part of it. Once again, colleagues across the plant industry have stepped up to make this event happen. I’m delighted to join Morris Leslie and James Currie on the organising team.

“We are on a mission to present an even grander spectacle in 2024. Our vision is to create a platform that not only celebrates the prowess of skilled operators, but also serves as a dynamic stage to unveil the latest innovations and equipment that define the forefront of the plant industry. It all starts at ScotPlant, so if you think you’ve got what it takes then come along and give it a go!”

The overall winner will receive a cheque for £5000, together with exclusive rewards from the event sponsors.

NEWS

A

12 EARTHMOVERS MAY 2024

EXCAVATOR EXPERTS

SUBSIDISED MACHINE DEALS AVAILABLE NOW

TAKEUCHI offer an extensive range of proven high performance excavators with more than 20 models from 1 to 15-tonnes.

Always the operator’s favourite, you can trust a Takeuchi to excel in every weight class.

IMITATIONS DON’T COME CLOSE CONTACT

Reliable and dependable, we set the standard for excavating excellence.

Designed and manufactured in Japan, TAKEUCHI deliver precision engineered excavators that outperform year on year.

TALK TO THE

YOUR LOCAL DEALER TO COMPARE THE DIFFERENCE

COME SEE US AT THE CONSTRUCTION EQUIPMENT EXHIBITION

SELF-POWERED SCALPER SCREEN

Stuart Partners has invested in a Sandvik QE342e dual-fuel scalper from dealer Retec for their recycling operation in Exeter. It features a heavy-duty, high-speed 4.7m x 1.45m screen, and the machine is powered either by its internal diesel engine or from an external electrical supply. The company has been granted planning permission to build a new

gasification plant on site, which will incinerate waste to produce electricity. The plan is to power the Sandvik and the site’s main wash plant from this renewable source. In the meantime, the scalper screen, powered by an external generator, is being used to separate out larger fractions of the waste stream, the remainder being the main feed to the wash plant.

NEW UNDERGROUND LOADER

omatsu has introduced a new WX11 load-haul-dump underground mining wheeled machine. With a heavy-duty driveline and redesigned working equipment to provide high breakout forces, it has been specifically designed for hard rock applications.

MAGNI ROTATING TELEHANDLER

agni’s new RTH 8.39 rotating telescopic handler further extends their range of eighttonne capacity machines, alongside the 8.27, 8.35 and 8.46 models. The new machine is a redesigned 6.39 model, but offering larger capacity.

M

UK DEALER NEWS

The Molson Group has been awarded the distribution rights of XCMG excavators and wheeled loaders in Scotland, through Molson Young Plant Sales.

Sany has announced a change of dealer in the north-west of England, with the appointment of TDL Equipment.

Ausa has signed an agreement with Warwick Ward to distribute its site dumpers, rough terrain forklifts and compact telehandlers throughout the north-east of England and Yorkshire, together with the south-east region.

Boss Plant Sales has been appointed by Thwaites as the new distributor for London and Oxfordshire.

Sunward has appointed two further dealers to its UK network. Based at Insch in Aberdeenshire, Crowmec will also cover the Highlands and Islands, in addition to Perthshire and Morayshire. Based at Binfield in Berkshire, Golf and Turf Equipment will also cover customers in London and in parts of Surrey and Oxfordshire.

Kubota dealer PV Dobson has opened a new branch in Washington, Tyne and Wear, where the site includes workshop and parts storage spaces, together with considerable yard space.

NEWS 14 EARTHMOVERS MAY 2024

K

IS GOING PREMIUM

CASE’s response to the growing premium business market is an additional step forward in terms of global performance. The new Wheel Loader 651G comes with cutting-edge enhancements, as new reinforced frame, axles, and new direct-mount rehandling buckets.

Contact your CASE dealer NOW

651G

The Cornwood china-clay quarry in Devon, operated by Sibelco, is piloting the introduction of autonomous articulated dump trucks (ADTs). This follows long-term trials of the system by manufacturer Bell and technology specialist Xtonomy, to create an autonomous B40E ADT.

The hardware includes radar sensors, high-precision GPS, multi-channel communication systems, together with lots of on-board processing power. The result is a resilient navigation system that dynamically plans the ADT’s route, and

predictively controls the vehicle around the entire quarry site.

Autonomous quarry dump trucks have the potential to significantly reduce accidents and near misses during the haul cycle. They can work long stints without interruptions and with no drop-off in performance, all while achieving a consistently accurate tip. This allows the quarry to introduce more effective working patterns, tailored to improve productivity.

AUTONOMOUS ADT IN DEVON

aggregates sector must embrace technology as a way of continually delivering improvements.

Dr Christian Riedel, the CEO of Xtonomy, said, “Supporting the quarrying sector through the appliance of automation platforms is a key commitment for our business. Expectations and needs are changing, as the industry looks to transition to a future where improved efficiency, better safety and targeted environmental considerations are key priorities.”

The haul is undertaken, time and time again, in the same fuel- and time-efficient manner, which also results in reduced and extended component life.

FEEDBACK

Ben Uphill, operations director for Sibelco’s Kingsteignton cluster of quarries, said, “We envisage many benefits from having access to this sector-first autonomous ADT solution.

The minerals &

South African-based Bell chose UK dealer Chepstow Plant International to pilot the development and introduction of this technology, who in turn brought their client Sibelco into the equation.

Chepstow’s MD, John Corcoran, said, “We are delighted to be involved in this exciting and UK-first collaboration. One that is focused on a next generation adventure, to ensure UK quarries continue to maximise operational efficiencies and remain competitive. It is important that stakeholders come together in this way to drive advancements and support the industry’s future prospects. We are sure that this pilot project will both deliver progress, as well as further challenges, both of which will provide the pathway towards the ultimate goal.”

We hope to bring you further details of this innovative development in a future issue.

16 EARTHMOVERS MAY 2024

SPECIAL NEWS REPORT

Above, inset and below: An autonomous Bell B40E articulated dump truck is being piloted at Sibelco’s Cornwood china-clay quarry.

JOIN US AT NEED MORE INFO? OUR TEAM IS HERE TO HELP! 01491 834666 — HYUNDAI-ENGINES.CO.UK THE SAFE CHOICE FOR TOUGH ENVIRONMENTS. HIGH POWER DENSITY, FUEL EFFICIENT DIESEL ENGINES FOR ALL YOUR OFF-ROAD, MOBILE & STATIONARY APPLICATIONS.

5

TIER 4 FINAL CERTIFIED.

RANGE 16KW

TO 100KW

INDUSTRIAL ENGINES JOI PROVIDING THE POWER FOR YOUR IDEAS RS 30587 EMS783590

STAGE

AND

POWER

(22HP)

(135HP).

SPECIAL NEWS REPORT

LIVE TRIAL OF INTELLIGENT COMPACTION

National

Highways is trialling a high-tech compaction management system on the A303 road project in the south-west of England

Anew compaction technology has been trialled by National Highways on the A303 road upgrade scheme between Sparkford and Ilchester. Caterpillar’s new intelligent compaction system is a key development in its own right, but also represents a big step towards autonomous rollers.

Mounted in a Cat roller by dealer Finning, the system is being trialled on a machine being used by contractor Galliford Try. It is intended to speed up and improve the quality of road construction, together with other environmental, cost and safety benefits. Using 3D mapping and a sophisticated sensor system, the system ensures that the right level of compaction is achieved first time and spots any uneven areas that could cause settlement issues.

National Highways’ Claire Hamar said, “We are constantly exploring new ways to design, build and maintain our roads and are committed to making connected and autonomous plant the norm in construction.

“A huge positive that we discovered in the Intelligent Compaction trial was the improved efficiency and environmental benefits, as work did not need to be repeated so, thanks to the reduced fuel use, we had reduced carbon. Not only is the work completed more quickly, saving resources and taxpayers’ money but, most importantly, it improves safety and reduces risk.”

The compactor unit is fitted with Cat’s machine drive power and compaction meter. They allow the operator to set the target depth and compaction level, and to pre-set the drive functions so the roller is automated and operates within the required parameters. This ensures the task is completed safely and eliminates the need for a ground worker to be on site during the compaction process.

Finning’s Jonathan Davies said, “Technology increases performance and operational efficiency, with reduced fuel consumption. Cat soil compactors have two types of sensor that measure the ground stiffness as well as an accelerometer base system, which is common in the industry. This is complemented by a rolling resistance system that works

particularly well in cohesive and clay-like material, which is common across the UK.

“Without the use of such technology, the only way to be sure of the compaction level across a site is through random testing, which can cause delays on site and safety issues.”

Galliford Try’s Jon de Souza said, “We were delighted to be able to demonstrate our commitment to innovation through the collaborative delivery of this research trial. We believe that connected and autonomous plant has the potential to transform construction over the coming years, improving safety and productivity while reducing carbon emissions.

“We look forward to continuing our work with National Highways to trial this technology across our infrastructure delivery.”

18 EARTHMOVERS MAY 2024

Left, above and inset: Using 3D mapping and sophisticated sensors, the right level of compaction is achieved first time around, without the need for frequent manual checks.

When work gets tough Develon delivers more Now enjoy a unique 5-year warranty with our DX17Z-7 & DX19-7 Mini-Excavators please visit: eu.develon-ce.com Visit us at EXT5 F002

As Nick Drew reports from Coventry, when it comes to compact construction equipment the future looks electric

INNOVATIVE MERLO

An eye-catching machine on the Merlo stand was the Cingo M12.3-EVO Handler 400, a pedestrian-controlled tracked telescopic handler. It offers a maximum lift capacity of 400kg and a maximum lift height of 3.4m, all in a machine with an overall width of 1000mm.

Attracting a healthy 2000 of the UK hire industry’s top decision makers, the 17th Executive Hire Show took place at the Coventry Arena in mid-February. The focus of attention was on a new generation of battery-powered mini-excavators, site dumpers, tracked spider cranes, telehandlers and the like, together with electrical energy production, storage and distribution systems. This reflects what is going to become a £multi-million market for the UK plant hire sector, as clients and main contractors increasingly demand working methods with lower environmental impact.

Event director Chris Moore said, “I would

like to extend a special thank you to our sponsors, The Hire Exchange and the Hire Association Europe (HAE), for their invaluable support. Their contributions played a crucial role in the success of this year’s networking event, helping to bring the hire community together. We’re grateful for their partnership and look forward to continuing to work together to advance the hire industry.

“This year’s Executive Hire Show was fantastic, with an unprecedented amount of deals done. The atmosphere was electric, and it was evident that our focus on innovation and sustainability resonated with both exhibitors and visitors.”

AN ELECTRIC ATMOSPHERE REVOTRUCK RAMP-UP

Also gracing the Merlo stand was the electric EWorker 25.5-90 telescopic handler. Its traditional lead-acid battery pack is capable of delivering a range of up to eight hours. This compact rearwheel-steer machine offers a maximum load capacity of 2.5 tonnes, a maximum forward reach of 2.6m and a maximum lift height of 4.8m.

Located just up the road from the Coventry exhibition centre, the Mecalac factory is ramping up to start production of the unique Revotruck, which features a cab that can rotate through 225 degrees. It offers superb visibility when hauling, the key to further improving site safety, while also allowing the operator to face the swivelling skip during discharge. The Revotruck will be available as six- or nine-tonne capacity models, both powered by a 55kW (74hp) Perkins engine driving a hydrostatic transmission.

SHOW REPORT // EXECUTIVE HIRE MAY 2024 EARTHMOVERS 21

JCB PRODUCT LAUNCH

The day before the show opened, exhibitor JCB launched a raft of new products, details of which are elsewhere in this issue.

XCMG ELECTRIC SCISSOR LIFT

xhibitor Genesis Equipment Sales is the sole UK distributor of XCMG access equipment. On show was a XG1012AC battery-powered model, which has a rated load capacity of 450kg, suitable for carrying two people to a maximum working height of 10m.

ELECTRIC TRACKED SPIDER CRANE

Looking like it had just come out of an edition of Thunderbirds, this tracked variant of the Unic spider crane was on display on the GGR Group stand. Providing far more mobility away from a hard and level surface that its more familiar wheeled counterpart, this tracked version can still fit through a standard double doorway. It provides a maximum lift capacity of 2.9 tonnes, a maximum lift height of 8.8m and a maximum working radius of 8.41m. Power comes from a 48v DC battery, which can be recharged from a 110v or 240v supply.

E

22 EARTHMOVERS MAY 2024

NEW GREENEY-GREY MINI

ans of red and grey Takeuchi compact excavators were probably a little confused when they stopped by their stand, as the star attraction was sporting a new two-tone grey livery. The two-tonne TB20e model is the first of a new generation of zeroemissions, battery-powered mini-excavators, which will be in the same paint scheme. As so many small battery-powered minis have been introduced over the last few years, it is easy to forget that, with their tethered model, Takeuchi was at the forefront of the development of electric-powered machines. This possibly gave them a valuable insight

into electric-powered hydraulic systems, machine hydraulics being Takeuchi’s speciality.

Adding a state-of-the-art battery system to the equation, the TB20e offers a working time of eight hours from a single charge when working at 65% load. Another distinguishing feature of Takeuchis are quirky design elements that are extremely practical. Not content with offering the option of a fast charger, which is capable of fully charging the TB20e in two hours, it is designed so that it can be carried on the mini’s dozer blade, accompanying the machine as it moves from job to job.

COMPACT ASPHALT PAVER

irtgen exhibited the Hamm HD12eVV battery powered tandem drum vibratory roller, which offers a working width of 1.2m and weighs 2755kg. However, the star of their stand was the UK debut of the Vogele Mini 500 compact mini asphalt paver, a battery version of which is due for launch later this year. The transportfriendly, one-tonne Mini 500 offers working widths from 0.80m to 1.80m.

BOBCAT PORTABLE POWER

Taking pride of place on the Bobcat stand was the latest version of their E10E battery powered mini, one of the first electric-powered compact excavators available. However, in many ways, the highlight of their stand was the PA7.4 generator-compressor, which represents the first sight of a new range of Bobcat branded portable power products.

The simple and robust-looking PA7.4 can be configured to a customer’s needs, e.g. with an 8.5kVA generator to power the latest generation of fusion welding equipment, as used in the utilities sector of the market. It can also be used to power lights and hand tools, together with providing compressed air at 4cu.m/min (140cfm) at 7bar.

F W

On the rise in the UK and Irish market, Sunward’s display included the popular 2.5-tonne SWE25F mini-excavator and the SWL 3230 skid-steer loader. SUNWARD SKID-STEER MAY 2024 EARTHMOVERS 23 SHOW REPORT // EXECUTIVE HIRE

RIDE-ON ELECTRIC HAULER

Staffordshire based Tufftruk showcased their range of Truxta pedestrian-controlled site dumpers, including the new battery powered EB800 BENDie model, which offers a 800kg payload.

ALTERNATIVE BATTERY TECHNOLOGY

Sany presented several new products for the UK market, including the all-new SY26C and SY35C miniexcavators.

They also showcased their SY19E electric mini, which is powered by a lithium iron phosphate battery pack. When it comes to the use of battery-powered construction equipment, Sany’s Chinese home market is a few years ahead of the rest of the world. For example, we are beginning to see the first 20-plus-tonne electric excavators in Europe, many of which are already proven products in China.

China is also the global hub for the development and production of automotive battery packs, which is a rapidly maturing industry. Lithium iron phosphate (LiFePO4) technology provides several key advantages over the more common lithium ion battery packs. It does not require the use of the rare mineral cobalt, which brings a string of advantages. But what marks out LiFePO4 batteries are their durability and a lower cost to manufacture. They provide the user with a more stable battery pack over a longer lifetime, less prone to environmental conditions and are less picky about what and how they are being recharged.

The Lithium iron phosphate battery pack in the Sany SY19E is designed to provide a lifespan of up to 3500 full charge cycles, equating to at least a decade of typical work. Featuring a single automotive standard charging socket, the machine can be fully recharged from a 240v domestic outlet in nine hours, or by spending 2.5 hours on a 360v industrial supply, with just 90 minutes needed on a DC fast charger.

n addition to their Solar Pod, AJC Power Solutions showcased their Battery Pod, which can store electrical energy from multiple sources and automatically channel it to where it is needed when demand is high. The five-model range provides storage capacities from 30kW to 250kW.

24 EARTHMOVERS MAY 2024

ON-SITE ENERGY STORAGE

I

HIRE

SHOW REPORT // EXECUTIVE

UPGRADE TO THE ULTIMATE.

KX085-5: THE 8-TONNE STANDARD

The ultimate in operator comfort, efficiency, and high productivity.

Talk to your Kubota dealer today to find out more.

The Kubota KX085-5 is equipped with a host of built-in operational and safety technologies as standard, including engine auto-stop, intuitive control systems, an integrated rear-view camera and much more. Add a new ultra-quiet, spacious cab, and it all adds up to our most productive 8 tonne mini excavator ever.

www.kubota.co.uk

OWNER-OPERATOR // JACK DICKSON

VERSATILITY IS THE KEY

Paul Argent reports on a young owner-operator with a high-spec Kubota midiexcavator, which includes an Engcon tilt-rotator

Last year Jack Dickson (22) became the proud owner of the first Kubota KX085-5 compact excavator in the UK configured with a two-piece boom and Engcon tilt-rotator. Jack hails from the Lake District where his family run a caravan and holiday park. He has spent countless hours helping with the maintenance and redevelopment of the site, but his dream is to build up the work for external clients.

He started out with a Kubota KX080-4A midi, which now has 3600 almost trouble-free hours on its clock. When the

new Dash 5 model was announced, he immediately inquired as to its price and availability with his local dealer, PV Dobson at Kendal, who Jack and his family have been doing business with for years.

Jack said, “I had heard some very encouraging reviews about the increase in performance and productivity from the Dash 5. While the older machine was still doing fine, I just wanted an upgrade with a two-piece boom to increase my versatility.”

Part of the thinking was that a higher-spec machine would help

“THETILT-ROTATORISABIGFINANCIAL INVESTMENT,BUTIENVISAGETHATITWILLPAY FORITSELFINJUST12MONTHS”

MAY 2024 EARTHMOVERS 27

Above and inset: Already running a Kubota KX080-4A midi, Jack Dickson upgraded to a KX085-5 complete with a two-piece boom and Engcon tilt-rotator.

to obtain more work, but, as things turned out, there was an influx of jobs, as Jack explains, “We agreed a deal with Dobson for a trade-in on the older machine, but with additional contracts being secured, we decided to keep the Dash 4A for a while longer.”

TILT-ROTATOR

While the new Dash 5 Kubota comes with improved hydraulics, increased cab comfort and a variety of other improvements, Jack was particularly attracted to the option of a two-piece boom, as he also wanted to fit a tilt-rotator. The combination of these two features has given him a bigger boost in productivity than he ever imagined. He said, “I already

Below: Having cut his teeth on the family’s Lake District holiday park, we met Jack Dickson and his new

midi-excavator on a long-term inner-city job.

although I do have a few more extras I want to add when I have the time.”

had a standard tilting ditcher on my old machine, which just opened up a raft of possibilities. I thought that the tilt-rotator would take that a step further when in fact it’s given us a huge leap instead.”

While the choice of base machine was almost a given, Jack took the time to look at all the tilt-rotators available before making his decision, adding, “They all have their pros and cons, but it was the recommendation of Jack Hull by Dobsons that swung it for me. Jack specified the Engcon EC209 for us and fitted it all prior to delivery from the dealer. The machine was ready to go to work when it landed,

At the time of our visit, Jack was waiting for his breaker and grab to be converted to work with the Engcon EC-Oil headstocks, which are fitted to the top and bottom of the tilt-rotator. In addition, he was expecting the imminent delivery of a brush attachment.

SITE VISIT

While much of Jack’s work centres round the Lake District, one of the first major projects for the new Kubota was in the centre of Bradford, where he is working on a long-term project from ERH Contracting. ERH is undertaking the installation of district heating pipes through the city centre. They will be used to distribute hot water to heat public and civic buildings, eventually fed by a waste-to-energy plant currently under construction. The twin steel pipes are insulated and coated in impact- and wear-resistant plastic before being buried almost 2.5m below

28 EARTHMOVERS MAY 2024

Left, above and above right: The Kubota midi, configured with a triple articulated boom and equipped with a tilt-rotator, proved to be ideal for this pipeline project in central Bradford.

Kubota

OWNER-OPERATOR // JACK DICKSON

Bradford’s busy streets and pavements. Its compact dimensions and the incredible working envelope provided by a tilt-rotator on three-piece working equipment make the Kubota midi the ideal machine to undertake this work.

“THETILT-ROTATORISA GREATADDITION,ITNOT ONLYMAKESOURLIVES ONTHEGROUNDEASIER, BUTALSOSAFER”

Jack commented, “With the two-piece boom fully extended I can easily reach the bottom of the cut, but also having the ability to curl it in tight means we don’t need a full road closure in which to operate. I can also sit outside of the line of the cut and still dig a flat-bottomed trench thanks to the Engcon.”

We met Jack and his high-spec Kubota in Bradford as he was excavating around an

existing 600mm water main. Under the watchful eye of his banksman, Jack was able to carefully remove the material from round the HDPE pipe. As the trench stays open for a few days to allow the pipe crew to do their thing, Jack was cleaning the sides of the excavation to allow him and his banksman to install lightweight piles, to ensure the excavation stayed safe.

Careful and considered movement of the bucket saw Jack clean the sides of the trench and, having the ability to rotate the bucket any way he wanted, there was very little work left for the banksman Richard to undertake with a shovel. Richard said, “The tilt-rotator is a great

KUBOTA KX085-5

With its triple articulated boom (TAB) and the full-spec Engcon tilt-rotator, this KX085-5 now tips the scales at a shade over the nine-tonne mark. It is powered by an in-house engine rated at 66hp that features a diesel particulate filter (DPF) with a service interval of up to 6000 hours.

The noise level in the Dash 5 cab has been reduced to 72dB, which also now features a new full colour 7in LCD control screen. With an easy and intuitive jog dial, Jack is able to navigate through the control system’s various functions with ease, including the ability to adjust auxiliary hydraulic flow rates. He can also use the control system to programme the LED lights to remain on for a short while after the engine has stopped, allowing him to leave the machine with the benefit of illumination. Another nice touch that Jack has discovered is the new blade float function, which allows easier and quicker grading of material.

addition to the machine, it not only makes our lives on the ground easier, but also safer. We don’t have to be using a pick or a shovel to dig round services, as Jack just spins the bucket round and does it so much quicker and easier.”

Jack concluded, “I have a range of buckets to use with the machine, but the Scandi-style Engcon bucket is ideal for this project. It’s the perfect size for the trench, lightweight and will dig through the harder material with ease.

The tilt-rotator is a big financial investment to make, but what we are able to do with it and the added productivity gains, I envisage that it will pay for itself in just 12 months.”

Below left and below right: Compared to the Dash 4A model, the KX080-5 brings a host of upgrades, especially to the cab interior and, more importantly, to its hydraulic performance.

MAY 2024 EARTHMOVERS 29

30 EARTHMOVERS MAY 2024

PRODUCT LAUNCH // AVANT

“UPTOHALFTHE COMPACTLOADERS WESELLCOULDBE ELECTRICINAS LITTLEASFIVE YEARS’TIME”

THIRD-GENERATION ELECTRIC KIT

As Nick Drew reports, the family-run Finnish manufacturer Avant has introduced its third-generation battery-powered compact loaders

Back in 1997, Finnish compact wheel loader manufacturer

Avant developed the MultiTec, its first battery-powered machine. It was pioneering R&D work, but the technologies available at the time, particularly the batteries, were not up to the job and the project was cancelled.

Fast forward to 2017 and with the availability of modern AC electrical components Avant launched its e5 and e6 electric models, of which over 700 examples have been sold to date. They were the first compact loaders in the world to use lithiumion batteries. Broadly speaking, the industry is now using similar technology to roll out a wide range of compact electric equipment.

DIVERSIFICATION

Compact construction equipment producers will increasingly be procuring batteries, competing on the global market with much higher volume on-road vehicle manufacturers. Just like a diesel engine, the battery pack is the single most expensive component in any item of compact construction equipment. Securing a supply of such components is critical, but with a continued dramatic increase in global demand, the cost of battery packs remains frighteningly high.

Since Avant was established in 1991, it has manufactured 90,000 compact wheel loaders. On average, 33 machines roll off the assembly line every day, 90% of which

are exported. Jani Käkelä, son of company founder Risto Käkelä, claimed, “According to our predictions, up to half the compact loaders we sell could be electric in as little as five years’ time.”

Against this background, in 2022 it was decided to establish Avant Power, to develop and manufacture battery packs for compact construction equipment. The cost savings associated with local, in-house production will be reflected in the price of electric Avant products, giving them a competitive edge. It also gave Avant the opportunity to develop battery packs specifically suited to such a rugged application, complete with a superior heating and cooling system better suited

MAY 2024 EARTHMOVERS 31

Left and above: Avant has launched two compact electric loaders featuring the firm’s in-house produced, high-tech battery packs.

“OURBATTERY

TECHNOLOGYWILL BRINGMANY BENEFITSANDWE WILLBEABLETO RESPONDTO STRONGGROWTH INTHEFUTURE”

to working on snow clearance duties during the harsh Scandinavian winters.

The new Avant Power operation was established in a purpose-built, state-of-theart facility next to the main factory at Ylöjärvi. The new firm’s chief operating officer, Mikko Piepponen, explained, “We have invested heavily in product development and we also have partners with world-class expertise. The exceptional solutions in our battery technology will bring many benefits to our customers and we will be able to respond to strong international growth in the future.”

POWER PACK FEATURES

Production of lithium-ion battery packs at Ylöjärvi began in January this year, and operations are currently being ramped up to produce a projected 700-plus units next year. Two 44v lithium-ion battery packs are available, rated at 13kWh and 27kWh.

Like the majority of automotive power packs, these are constructed from individual 21700 lithium-ion cells, in this case the nickel-manganese-cobalt variety (see panel), which look like a larger version of an AA battery. They are assembled into 360-cell modules, comprising two modules in the smaller capacity battery pack and four in the more powerful version. In automotive applications, the common

way to regulate the temperature of such battery packs is to sandwich cooling/ heating plates between the layers of individual cells, but Avant’s design is radically different. With the 360-cell modules fastened inside the green battery pack, the housing is filled a non-conductive coolant, which Avant calls OptiTemp. With this immersion thermal management technology, there is far greater control

available to the system’s digital brain to heat or cool the battery modules as required, including during recharging. In addition to the latest generation of multi-level protection sub-systems for the battery pack, this advanced thermal management system helps to extend both the battery’s range and lifespan. The battery packs come as self-contained units with a cluster of electrical connections.

32 EARTHMOVERS MAY 2024

Above and right: Both machines offer a lift capacity of 900kg and 30lit/min auxiliary hydraulics. The e513 is fitted with a 13kWh battery pack, while the e527 gets 27kWh of stored energy.

NEW PRODUCTS

The first compact loaders to feature Avant’s OptiTemp batteries are its new e513 and e527 models, which offer a significant increase in operating time over its original e5 and e6 machines. Equipped with the larger 27kWh battery pack, the e527 offers an operating time of six hours, double that of its predecessor, or it can travel on the road for 21km on a single charge, a 60% improvement in range.

The e513 is basically the same machine, but equipped with the smaller 13kWh battery pack, for which a single charge provides a range of 3hrs or 11.4km. This variant is aimed at less intensive applications, such as livestock, equine, greenhouse or DIY applications. Both machines offer a lift capacity of 900kg, an auxiliary hydraulic system capable of delivering oil flow of 30lit/min and, with the telescopic boom, a maximum lift height of 2820mm.

Both loaders have an on-board 3kW charger, which will take under three hours to fully recharge the smaller battery pack, while the e527 will spend over 5.5 hours hooked up to a domestic electrical supply. For professional use, a 400v/16a external charger is available, which slashes recharge times to 1hr 10min and 2hr 20min, respectively. Only available for the larger battery pack in the e527 model, a 400v/32a fast charger is also offered, which cuts its full recharge time to just over an hour.

PRODUCT LAUNCH // AVANT

FIRST IMPRESSIONS

With plenty of snow piled up from clearing the factory’s car park, there was a selection of new Avant loaders available to try out. I opted to spend time in an e527 model fitted with a toothed loading bucket, an attachment configuration not usually seen on small compact loaders.

These new electric loaders look like Avant’s diesel-powered 500 and 600 models, with the rear half of the chassis containing the engine or battery pack. Access to the seat is straightforward, a step up while grabbing the canopy frame and swing into position. This example was configured with a rear screen surround, which offered some protection from the elements, while the option of a fully heated cab will be offered in due course. I was delighted to discover that the PVC-covered seat in this canopy/ rear screen version was heated.

What I like about these machines, whether diesel- or electric-powered, is that they are simple to operate. Forward or reverse drive is selected by two pedals down on the right-hand side. A hand throttle is located just behind the joystick controlling the loader arm and attachment. Eight rocker switches, also on the operator’s right, control the machine’s lights, parking and master lock and boom float. One of these switches controls the machine’s working mode, which offers fast and slow settings, in addition to the default eco mode.

EDITOR’S COMMENTS BATTERY TECHNOLOGY

Lithium-ion type batteries have been with us for a long time, but the components used in smart phones and laptops are not suitable for upscaling for use in an electric vehicle. This is partly due to the weight, size and cost of the resulting battery pack, but also due to limitations of such battery technology’s operational and recharging performance, together with their projected lifespan. What changed all this was the development of different Lithium-ion chemistries, particularly the composition of the battery’s cathode, the metal that gathers and transmits the energy within the battery. The top three types of modern cathode are nickelmanganese-cobalt (NMC), nickel-cobaltaluminium (NCA) and lithium-iron-phosphate (LFP). Compared with a decade ago, these types of batteries are cheaper to produce, lighter and have a higher power density.

Avant uses NMC battery cells, an American technology that features a cathode with a high nickel content and offers an extremely high energy density, you can pack a lot of power into a kilo of NMC batteries. This is currently the most successful of the three alternatives that comes at a premium price, but it is also a battery technology that requires a relatively high degree of digital supervision, particularly its temperature. A similar product is NCA batteries, which is the Japanese technology used in Panasonic cells, their biggest customer being Tesla’s USA operation.

The new kid on the block is the LFP, often called LiFePO4, battery, produced and widely used in China. They may not have the energy density and other performance metrics of rival technologies, but they have two things going for them. The cathodes are made from common elements, mainly iron and phosphor, so they are cheaper to produce than their rivals. In addition, it is an incredibly stable battery chemistry, requiring relatively little in the way of digital supervision.

MAY 2024 EARTHMOVERS 33

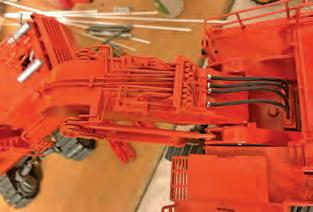

A module of 360 battery cells is assembled. Two of these modules are used in the 13kWh pack, while the 27kWh battery gets four modules containing a total of 1440 cells.

“THEYHAVETHE

HYDRAULICOUTPUT, TRACTIONANDWORKING ENVELOPETOUNDERTAKE AMULTITUDEOFTASKS”

FACTORY TOUR

Avant has invested €10m in its highly automated compact loader factory, with a recent large extension to increase production equipped with robot welding, cutting and bending machines. One example is the German-built Trumpf TruBend 5130 bending machine, which subjects a laser-cut piece of steel to a series of highly accurate bends, to produce a finished component.

Although some manual welding is still undertaken, increasingly this is being undertaken by robot welding machines. There are eight robotic welding stations for the major frame components alone. The completed loader frames are then sent through the site’s semi-automatic powder coating paint facility, before heading to the assembly line.

As we toured the factory, autonomous forklifts were scanning barcodes on the components, then moving them to where they were required. It’s absolutely incredible to see these units trundling around the floor space, occasionally stopping when they encountered the odd rogue trade journalist blocking their path.

An updated multi-functional display monitor is fitted to these new models, offering feedback on battery status, temperature and the loader’s power consumption, in addition to the usual machine functions, including setting the output of the auxiliary hydraulics.

FIRST DRIVE

Based on previous experience of Avant machines, I selected the hare position on the throttle, but with the machine set to eco mode, which would provide more than enough speed and power for my liking. I initially took it for a spin around the car park, to refamiliarise myself with how these quirky little machines react.

With the cab mounted on the front half of the articulated chassis, it can feel a little bit strange at first, but you soon get used to it, together with the advantages of the fixed view along the centrally mounted single loading arm. Even in its eco setting, I found the machine to be extremely lively and fast. I probably should have reduced the throttle input, but by this time the banks of snow beckoned.

Two electric motors are fitted, one for drive function and the other for the

working equipment and steering. Such electric motors instantaneously produce their maximum torque, providing a thrust of momentum as I ploughed into a heap of frozen snow, prompting an initial spell of wheel-spin.

I then decided to put the bucket teeth to good use, to break up the snow by using them in a downward action, which enabled me to grab a full bucket load.

The machine features a telescopic boom that extends outwards by 600mm. It is operated by a small lever, which is my only criticism of the otherwise straightforward controls. Taking your hand off the loader control joystick to operate this lever makes it a bit of a disjointed operation. I would like to see the boom extension controlled by a roller thumb control on the joystick. With an overall width of 1130mm and a length of 2610mm the machine is well balanced when working, and a travel speed of 10kph makes it no slouch. The inside turning radius is less than a metre, and the outside radius 2050mm, so it’s a highly manoeuvrable piece of kit. As with all electric machines, it is super quiet in operation, with just a few squeals to be heard while in use.

34 EARTHMOVERS MAY 2024

Inset above and above right: Components are delivered to the relevant part of the assembly operation by autonomous fork-lift trucks, which scan the part’s barcode.

Right: The manufacturing side of the factory is highly automated, including cutting, bending and welding metal to form structural components.

Left, below and below right: The Avants are simple to operate and with this articulated machine being just 1130mm wide and 2610mm long, it is extremely manoeuvrable and surprisingly quick.

PRODUCT LAUNCH // AVANT

CONCLUSION

Operating the e527 compact wheel loader/tool carrier in the snow was lots of fun, but don’t be fooled, they are not toys. They are incredibly quick and nimble machines, which have the hydraulic output, traction and working envelope to undertake a multitude of tasks, thanks to the 200-odd attachments available from Avant.

These latest electric versions take the concept to a new level, with an immediate surge of torque available from the power pack.

Located in the Pirkanmaa region to the west of Tampere, Avant’s compact equipment factory at Ylöjärvi is truly state of the art. The facility features a host of automated and robotic processes, undertaken in an unusually clean environment.

After an extensive period of R&D, Avant Power’s new operation is up and running, producing battery packs for the assembly line next door. Looking to the future, there will be a huge demand for such advanced batteries, which could offer a plug-‘n’-play solution to many applications.

MAY 2024 EARTHMOVERS 35

36 EARTHMOVERS MAY 2024 THE TOUGHEST RANGE OF RADIAL OTR TYRES BUILT TO WORK WITHOUT STOPS LDSR 300 HTSR 400 MGSR 200 www.yokohama-atg.com CONSTRUCTION SEATING FOR DETAILS OF YOUR LOCAL STOCKIST PLEASE VISIT WWW.UNITEDSEATS.COM UNITEDSEATS.COM Off road seating manufacturer TREAT YOUR SEL TO A NE W

OPERATOR FEEDBACK // HYDREMA MX20G

“DESIGNEDFORHEAVY LIFTINGTASKS,ITHASA REARSWINGRADIUSOF JUST1839MM,THE SHORTESTIN

COMPACT DUCK RUNNING ON RAILS

Eoghan Daly reports from Finland on a compact radius, 20-tonne wheeled excavator that is a factory-built road-rail machine

ail contractors working on the UK and Irish networks seem to favour a small number of manufacturers to satisfy their needs for road-rail excavators. Their Finnish counterparts adopt a different approach, using a far wider selection of base machines and factoryproduced road-railers. They all require additional engineering to operate on Finland’s 1524mm-wide gauge rail network, not the common 1435mm gauge used in most of Europe.

RWe visited Riihimaki railway station in southern Finland to see a Hydrema MX20G Rail excavator run by contractor Verkkoviikarit Oy. Our aim was not only to receive feedback on the capabilities of this

factory-built road-railer in this application, but also to take a closer look at the underlying short-tailswing 20-tonne wheeled excavator, which is a rarity on these shores.

BACKGROUND

In 2022, Danish manufacturer Hydrema revamped its dealer structure in Finland with phenomenal results. Sales of construction equipment have taken off and Hydrema products have also made a positive impression on the rail sector.

Verkkoviikarit is a major construction company in Finland, whose rail division runs a considerable fleet of specialised equipment, including several Hydrema road-rail excavators. In addition to rail

decommissioning, maintenance and construction projects, the scope of their activities includes dedicated electrical works and installing automation systems.

When not working on rail projects, the road-rail excavators and their highly experienced operators are kept busy on a variety of other tasks, which will inevitably include snow-clearing duties during the winter months. To get the most from this investment in people and machines, in true Nordic fashion the base machines are to an extremely high specification.

With 11 tracks and six platforms, Riihimaki is an important rail hub both for passenger and freight trains. The station, which has evolved considerably from its humble

ITSCLASS”

Left and inset: The triple articulated working equipment on this Hydrema MX20G Rail excavator provides a reach of 8.8m, to which must be added the reach of the tilt-rotator.

MAY 2024 EARTHMOVERS 37

“THELIFTINGPOWERANDSTABILITYAREINADIFFERENT CLASS,IDON’TTHINKTHEREISANYTHINGTOMATCHIT”

origins way back in 1862, is run with Scandinavian efficiency. The same is expected from their chosen contractors, to carry out their assigned duties in a safe and efficient manner, without unplanned disruption to the busy train timetable.

FIRST IMPRESSIONS

This Hydrema MX20G Rail excavator was the latest addition to the Verkkoviikarit road-rail fleet. At the time of our visit it was six months old and had clocked up 900 hours. It has remained trouble-free over this time, apart from a fault with the auto-greaser mechanism, which had been retrofitted by a third party.

Weighing in at 20,500kg, the MX20G is the largest dedicated road-rail excavator produced by Hydrema. Despite being designed for heavy lifting tasks, it has a rear swing radius of just 1839mm, the shortest in its class. It is powered by an ultra-low emissions four-cylinder Cummins engine rated at 129kW, but provides its maximum torque of 780Nm at just 1500rpm. It drives a ZF two-speed hydrostatic transmission, which in turn drives ZF axles.

The hydraulic system serving the upper carriage produces a combined oil flow of over 400 litres per minute. This is able to power heavy-duty rail attachments while simultaneously allowing smooth and precise slewing and movements of the working equipment, while an independent circuit powers travel movements. This version

features a hydraulic steering lock-up system, activated while the machine is running on the rail line.

As you would expect in this application, there are a variety of auxiliary hydraulic lines plumbed along the triple articulated boom (TAB), which provides a reach of 8.8m.

At the end of the dipper is a directly mounted Engcon tilt-rotator with an integrated gripper, which feeds attachment position data to the excavator’s 3D GPS machine guidance system.

OPERATOR FEEDBACK

The operator of the MX20G was Jari Huotari, who has spent a couple of decades working on rail projects. He said, “The first rail machine I operated was an Akerman and more recently a Doosan and then a Volvo 160. The Doosan had a much greater tailswing than the Hydrema, while the Volvo

needed an extra tonne of ballast on top of the standard counterweight.

“The Hydrema is the best machine I have used on rail work so far, as it is very compact and extremely stable, allowing me to make full and safe use of its lifting capacity. Hydraulic performance is also in a different league to other machines. This is very important for a rail machine, since we often use many different attachments that require high oil flow and put big demand on the system.

“There is plenty of engine power with this machine and it remains very economical. The previous Volvo I operated was much thirstier on fuel compared to this Hydrema. It is really economical in digging, but on road travel it does use slightly more.

“The MX20G Rail may be very much on top of any application it is expected to work in, but it is also very much an operator’s

38 EARTHMOVERS MAY 2024

Below: The MX20G Rail remains a versatile wheeled excavator, but is factory-built with heavy-duty rail wheels and other kit to allow it to operate on the local rail network.

machine. In the time I have been using it, I have found it a pleasure to operate from every point of view.”

This factory-built road-railer features 650mm-diameter steel rail wheels with individual disc brakes in each of the rail wheel hubs. The design of the rail gear units allows the machine to work in both low and high rail modes. In high mode, there is 100mm of clearance from the rail line.

The rear rail apparatus incorporates a coupling for a rail trailer, together with a frame to mount an extra-wide bucket. Jari commented, “The bucket linkage on the rail gear is a big benefit, as it allows me to carry tools and other things to the work area down the line. This bucket also has S hitch brackets, which allow it to be used on the boom. This kind of versatility is important in any work, but especially on rail work.”

IN THE CAB

Despite the 20-tonner’s extremely compact slew radius, the cab dimensions are generous, particularly legroom from the well-appointed seat. While a comprehensive control console extends down the offside of the cab, the main operator interface is the 10in all-singing, all-dancing control monitor, which also displays the output from a multi-camera system. The standard build includes Hydrema’s telematics system, providing remote data monitoring of the machine’s health and current workload.

Jari said, “I really like the Hydrema’s big cab, as there is really good space inside. Everything is nicely positioned and the seat gives a very high level of comfort. It is possible to make many different adjustments, so the joysticks sit exactly at the right position to suit what works best for every operator.

“The joysticks are very sensitive, some may say they are too loose, but over a 12-hour shift this is much better, making the machine a pleasure to operate. Having travel and steering on the joystick is also a big advantage and certainly something that should be on every machine.

OPERATOR FEEDBACK // HYDREMA MX20G

“Overall visibility is very good. The only one thing that is difficult is the view to the right side when the boom is in the outward position, but that is to be expected and is unavoidable. It is compensated for by the 360-degree camera system view that gives a very clear real time image on the screen of everything that is going on around the machine, making it really very safe.”

MAY 2024 EARTHMOVERS 39

Above, left and below: Operator Jari Huotari highly rates the new Hydrema road-railer, praising its lifting power and stability, together with its large cab.

OPERATOR FEEDBACK // HYDREMA MX20G

LIFTING & TRACTION

For working on the local rail network, this excavator is fitted with the latest Prolec safe load indicator and slew/height limitation system, which is said to be easy to use and delivers fast set-up times.

Even though the system keeps a watchful eye on lifting operations, the machine’s capabilities are extremely impressive, as Jari remarked, “Lifting power and stability are in a different class, I don’t think there is

Below: The rail sector uses some weird and wonderful attachments, some are unwieldy like this one, some power hungry, and some a mixture of both.

Below inset and below left: Access to the powerpack is via a large electrically powered offside gullwing panel, and all key components are reachable from ground level.

anything to match it. Taking a full bucket over the side to the next railroad you see so much stability. When lifting rail track, it is so powerful out to full reach it really is a first class performer. The machine works the same, whether it is three tonnes on the end of the boom or nothing.

“What we appreciate in rail work is the traction a rail machine can deliver, as everything is pulled by the wheels. In winter I use a 4.5-metre plough on snow clearance and the machine just powers on with it.

“The whole machine lighting package is excellent as the location of the boom lights make a real difference to night-time working. When I am cutting the bushes below embankment level, the three lights positioned round the stick are ideally placed to light up the work without shadows. Even though this may seem like something obvious, many other machines do not get

their light placement correct.”

Putting aside the performance of the underlying machine and its rail bogies, perhaps this is the most impressive aspect of the Hydrema: how they have got the little details right, to make the operator’s life easier.

40 EARTHMOVERS MAY 2024

“INWINTERIUSEA4.5-METRE PLOUGHONSNOWCLEARANCEAND THEMACHINEJUSTPOWERSON WITHIT”

Europe’s Largest Independent Retreader THE ENVIRONMENT YEARS OF SAVING TYRES BUILT TO CONQUER ANY TERRAIN Come visit us at: Scotplant – 12th Avenue Number 2 Hillhead – Stand W19

Expander® lightens the workload of pin maintenance - in the field or at the workshop. Regardless of pivot position, wear pattern or available equipment, Expander System can be installed in the field with general tooling. Cut repair hours, simplify installation & removal and upgrade to the longer lasting pin system.

See how it works and use our pin finder: www.nord-lock.com/expander-upgrade

© Copyright 2023 Nord-Lock Group. NORD-LOCK® SUPERBOLT®, BOLTIGHT® and EXPANDER® SYSTEM are trademarks owned by different companies within the Nord-Lock Group. All other logos, trademarks, registered trademarks or service marks used herein are the property of the Nord-Lock Group. All rights reserved. nord-lock.com

FOR HEAVY-DUTY WORK.

PERFORMANCE PINS

Visit us at Hillhead 2024 – Quarrying, Construction & Recycling, 25-27 June Hillhead Quarry | Buxton | Derbyshire | UK

IGEARING UP FOR THE FUTURE

Nick Drew reports on a wave of new JCB compact construction equipment

t is shaping up to be a busy year for JCB. As this issue goes to the printers they are hosting a second major product launch of the year. It follows the introduction of a raft of new compact construction equipment early in February, in time for the Executive Hire Show.

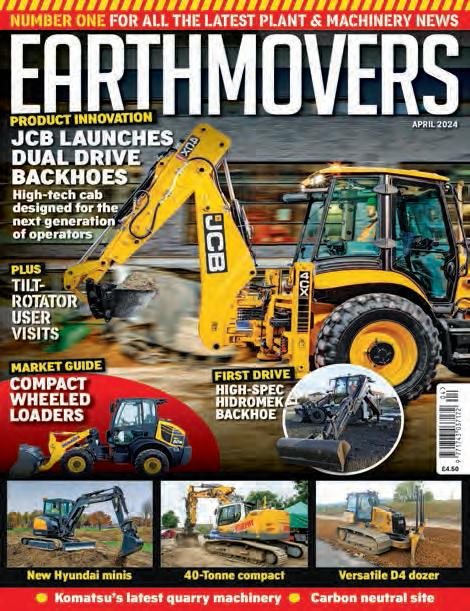

As previewed in the previous issue, the headline news is dual drive backhoe loaders, more about this later. However, this key development should not overshadow the other machines introduced to the extensive JCB range, particularly new 2.5-tonne class mini-excavators.

NEW 2.5-TONNERS

A 2.5-tonne class mini-excavator – the largest that can be towed within a 3.5t gross weight limit – is the workhorse of many a crew, both in conventional counterbalance and, increasingly, in zero-tailswing configurations.

JCB’s 8026CTS model has been a popular machine in the weight class over the years, particularly within the UK plant hire sector. However, it was showing its age, as was its stubby sibling, the 8025ZTS, which have now been replaced by the new 26C-1 and 25Z-1 models. The conventional 26C-1 tips the scales at 2675kg, while the zero-tailswing 25Z-1 model weighs 2550kg. Both have an overall width of 1500mm and feature no fewer than nine integrated trailer tie-down points.

First impressions of the new minis are that they appear dynamic and stylish machines, in keeping with the overall design of JCB’s larger compact excavators. Like their larger counterparts, they feature pressed steel bodywork that can withstand the odd knock, ideally suited to the hire sector.

MAY 2024 EARTHMOVERS 43

PRODUCT LAUNCH // JCB

“FIRSTIMPRESSIONSOFTHENEWMINIS ARETHATTHEYAREDYNAMICAND STYLISHMACHINES”

Inset and below: In time for the Executive Hire Show in Coventry, JCB launched a variety of compact construction equipment, including 2.5t minis and another electric site dumper.

As is the engine, an ultra-low emissions 18.4kW (24.7hp) Kohler, which does not use AdBlue and does not have a diesel particulate filter. Daily checks and routine servicing look easy enough, as filters and check points are readily accessible in the engine compartment.

“INTHEDIG,THEZEROTAILSWINGMININEVER

The lift-up bonnet extends almost the entire length of the offside and opens to reveal the battery, battery isolation switch and radiator cap, together with the hydraulic tank and its filter. Nicely positioned at the front is the diesel tank filler cap, providing excellent access for those who top up using 25-litre drums.

JCB’s high-tech working equipment bushes help to push out greasing intervals

to the 500-hour mark, again ideal for plant hire. The new minis feature improved boom and arm geometry over their predecessors. They also come with a high-flow double-acting auxiliary hydraulic circuit as standard, delivering 48 litres/min for powering attachments such as flail mowers and planers.

I wanted to spend time on the new zero-tailswing 25Z-1, which offers a maximum dig depth of 2824mm. In addition to a supplementary counterweight, the example available on the demo plot was fitted with the shorter 1100mm dipper arm, but a 1300mm option is available, which is likely to be the most popular configuration for the UK market.

Below: The 2550kg zero-tailswing JCB 25Z-1 mini-excavator is joined by the conventional tailswing 26C-1, which tips the scales at 2675kg.

IN THE CAB

The 26C-1 and 25Z-1 share the same cab structure, for which a canopy variant is also available. The canopy saves a little weight over the full cab, important when getting close to a 3.5t towing limit. In addition, utility contractors often prefer this configuration, as they are constantly getting off and on the machine during the course of their work.

The roll-over and tip-over protected cab is spacious enough and offers plenty of legroom, however, as is often the case with smaller minis, there is no space behind the seat for storing a lunch bag. A cab heater is the standard fitment, with a full air-conditioning package on the factory options list.

All-round visibility is excellent and it’s good to see that flat glass is fitted, which is a lot less expensive to replace when damaged. I especially liked the 66/34 split front screen. This horizontal windscreen split configuration has been used on and off

44 EARTHMOVERS MAY 2024

FALTEREDONCE,ITWASNICE ANDSMOOTHTOOPERATE ANDHADPLENTYOFPOKE”

PRODUCT LAUNCH // JCB

throughout the industry for decades, but I still feel it’s a great feature. It is easy to use, the larger panel being moved up in the roof out of harm’s way, while also offering uninterrupted forward visibility into a trench.

The cab interior has a touch of JCB’s X-Series to it, but a lot simpler and more user-friendly. Most of the control buttons and function switches are located on the offside console, easy to use and selfexplanatory in design. There are a couple of cubbyholes and that all-important cup holder. Five adjustable air vents are located around the cab, four to the front and one to the rear. Those who like a bit of fresh air will be delighted with the double opening offside sliding window arrangement.