RECYCLING TRACKED CARRIER LIEBHERR L550 XPOWER HELPS MATERIAL PROCESSING OPERATION C4 MECCANICA’S INNOVATIVE COMPACT TRACKED CARRIER CLEARANCE OWNER-OPERATOR’S VERDICT ON SANY SY155U EXCAVATOR ISSUE 11 • £4.50 ALBACH DIAMANT FACTORY VISIT TOP BUYS! USED SILVATECS CONTINUE TO IMPRESS EXCAVATOR ATTACHMENTS MARKET REVIEW SWEDISH FORESTRY EXPO SHOW REPORT

EDITOR Kyle Molyneux kyle@sundialmagazines.co.uk

ART DIRECTOR David ‘Spike’ McCormack

DESIGNER Claire Trent

ADVERTISEMENT SALES

Alex Cronin 020 8639 4405

Tom Pickford 020 8639 4417

ADMINISTRATOR Martin Attis 020 8639 4409

PUBLISHING DIRECTOR Paul Cosgrove 020 8639 4401

CONTRIBUTING WRITERS AND PHOTOGRAPHERS

Paul Argent, Eoghan Daly, Dan Gilkes and David Wylie

Forestry Machinery is published by Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent, BR3 5JS

TEL 020 8639 4400 FAX 020 8639 4411

EMAIL info@forestrymachinerymagazine.co.uk

WEB www.forestrymachinerymagazine.co.uk

SUBSCRIPTIONS

Earthmovers subscriptions, Trinity House, Sculpins Lane, Wethersfield, Essex, CM7 4AY

TEL +44 (0)1371 853632

EMAIL earthmovers@escosubs.co.uk

Farm Machinery Journal subscriptions, Trinity House, Sculpins Lane, Wethersfield, Essex, CM7 4AY

TEL +44 (0)1371 853634

EMAIL farmmachineryjournal@escosubs.co.uk

NEWSTRADE

Seymour Distribution, 2 East Poultry Avenue London, EC1A 9PT TEL 020 7429 4000

REPRO

Design & Printing Solutions Ltd, The Coach House 101 Northwood Road, Whitstable, Kent CT5 2HE

TEL 01227 770034

PRINTING

William Gibbons & Sons Ltd, 26 Planetary Road, Willenhall, West Midlands, WV13 3XB

COPYRIGHT

Sundial Magazines Ltd 2023. All rights reserved. Reproduction in whole or in part is forbidden without the express permission of the publishers. Sundial Magazines Ltd. Registered in England no. 4134490.

CONDITIONS FOR ADVERTISING

All advertisements are accepted subject to the publisher’s standard conditions of insertion. For a copy of advertising terms & conditions, please write to Paul Cosgrove at Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent, BR3 5JS

WELCOME

to Forestry Machinery, the magazine dedicated to modern forestry equipment.

In recent years, the forestry industry has gained substantial importance due to a con uence of factors, including climate concerns and government policies promoting sustainable practices. This growing signi cance is driven by an increasing realisation of the forestry sector’s potential bene ts. What was once considered a modest venture for those with underutilised land, or heirs with limited farming knowledge, has now become a focal point for substantial investments, spurred by ambitious goals and opportunities. And backing them are a wealth of equipment manufacturers and dealers.

One example of a player in this evolving landscape is the forestry equipment distributor, McHale Plant Sales based in Ireland. The company has experienced growing sales of timber harvesters and forwarders since becoming an of cial distributor of Komatsu Forest equipment. The boost in forestry activity and a growing willingness among contractors to invest in equipment upgrades have led to the inclusion of McHale’s equipment in contractor eets, speci cally Komatsu 901/931XC harvester models and 845/855 forwarders. Notable clients include Cuddy Timber, Willie O’Dwyer, Tony Codd, Foley Timber, Pat Doyle, Camross, McKelvey Harvesting, and Pat Neville.

The forestry sector’s growth trajectory underscores its pivotal role in the evolving landscape, driven by environmental imperatives and ambitious agendas. McHale Plant Sales’ presence in this dynamic ecosystem re ects broader industry trends and opportunities.

Kyle Molyneux, Editor

FORESTRY MACHINERY AUTUMN 2023 3

ED’S LETTER

Satisfy your appetite for off-road machines with Earthmovers and Farm Machinery Journal –the magazines for owners, operators and contractors NEED MORE MACHINERY? Autumn 2023 Issue 11 COVER IMAGE Eoghan Daly RECYCLING TRACKED CARRIER LIEBHERR L550 XPOWER HELPS MATERIAL PROCESSING OPERATION C4 MECCANICA’S INNOVATIVE COMPACT TRACKED CARRIER CLEARANCE OWNER-OPERATOR’S VERDICT ON SANY SY155U EXCAVATOR AUTUMN 2023 ISSUE 11 • £4.50 ALBACH DIAMANT FACTORY VISIT TOP BUYS! USED SILVATECS CONTINUE TO IMPRESS EXCAVATOR ATTACHMENTS MARKET REVIEW SWEDISH FORESTRY EXPO SHOW REPORT FROM ALL GOOD BOOKSTALLS & ON SUBSCRIPTION AVAILABLE NOW John Deere’s JD18X engine comes to the 9000 Series www.farmmachineryjournal.co.uk THE POPULAR APPEAL OF DEERE’S DESIREABLE 6130M TRACTOR NOW ADBLUE FREE E cient forager FIELD TEST £4.50 FIRSTFORFARMMACHINERYOPERATORS ARE COMING TO A FARM NEAR YOU THE FARM THAT BELIEVES TWO HEADERS ARE A WHOLE LOT BETTER THAN ONE THE XERIONRECORD-BREAKING 12FROMCLAAS FLEET PROFILE BUYING GUIDE MODERN FARMING MAXXED Sunward 21-tonnerCat 994 history ● Smart compaction kit ● Huge Euclid classic dozers BATTERY-POWERED MIDI EXCAVATOR Cutting edge converted Hyundai Fast and powerful Electric Volvos at work BRITISH-BUILT SWAMP SPEC 23-TONNER BRITISH SITE VIST SMALL & MEDIUM RUBBER DUCKS MARKET GUIDE FREE!!! FORESTRY MACHINERY MAGAZINE WITH THIS ISSUE EARTHMOVERS NOVEMBER 2023 FIRST DRIVE

– A trailer for forest owners who demand a high degree of productivity

SALES REPRESENTATIVE UK/INTERNATIONAL Tom Belton 07860 951 485 tom.belton@forsmw.com

ROBSON DRIVE 4WD

C10.2

HUB DRIVE 2WD, 4WD

FORESTRY MACHINERY AUTUMN 2023 5 REGULARS FEATURES 3 WELCOME The importance of the forestry sector 6 NEWS The latest updates and developments AUTUMN 2023 CONTENTS 10 TIMBER HARVESTING SEAN RYAN FORESTRY Second-hand Silvatec harvesters 18 OWNER-OPERATOR SANY SY155U New excavator on a clearance operation 24 NEW PRODUCT POWERBULLY 9D Go-anywhere tracked dumper in action 30 WASTE WOOD RECYCLING LIEBHERR L550 XPOWER Timberpak’s high-spec wheeled loader 34 ENERGY WOOD HARVESTING RISUPETO HEAD BY REFORMET Kobelco SK140SR the perfect companion 38 TRACKED TOOL CARRIER C4 MECCANICA TMU40 Italian machine offers the best of all worlds 44 FACTORY VISIT DIAMONDS IN THE ROUGH Where Albach’s Diamant chipper is made 48 SHOW REPORT SWEDISH FORESTRY EXPO Highlights from the Stockholm exhibition 55 MARKET REVIEW EXCAVATOR ATTACHMENTS Enhancing versatility in the forest 64 USED MACHINERY MARKET HIGHLIGHTS Top equipment spots in the market CONTENTS

FORESTRY MACHINERY NEWS

FORESTRY EXCAVATOR

Hitachi Construction Machinery (Europe) has launched a new ZX135USL-7 forestry excavator designed for logging, log felling, loading and digging. Assembled at HCME’s factory in Amsterdam, The Netherlands, the excavator is equipped with a robust undercarriage and offers more ground clearance (560mm) than standard models. The short rear swing radius of 1,490mm makes it ideal for working in compact environments, says Hitachi. Operating weight is rated at 15.9 to 16.9 tonnes, and maximum digging depth is 5,760mm.

The impressive fuel economy of the ZX135USL-7 forestry excavator means that it delivers up to 9% less fuel consumption than the previous model. This is achieved with the help of Hitachi’s HIOS V hydraulic system. Fuel ef ciency can be further controlled by using the new Eco gauge, clearly visible on the cab’s multifunctional 8-inch monitor.

For added versatility, the ZX135USL-7 forestry excavator has a reinforced arm with piping for breaker or crusher, quick-coupler, as well as assist piping. A front blade is also available. Life cycle costs are reduced with the new Stage 5-compliant, 74kW engine,

which does not require an SCR system. This eliminates the need for AdBlue, lter replacements and associated maintenance. The state-of-the-art, ultra-spacious cab should make a pleasant working environment. One of the quietest in the industry, Hitachi says the ZX135USL-7’s cab reduces vibrations by 16% compared with that of the previous generation machine. The latest cab also boasts a combined seat/ console that takes up less space. Extra safety features include a xed laminated front window and OPG level 2 front guard, plus additional lights on the cab roof.

GREEN CHIP

Danish manufacturer Green Chip has taken over the rights to a woodchipper concept from Silvatec Skovmaskiner and has put the machine into production. The Green Chip CH 838 is a self-propelled chipper designed for chipping directly in the cut rows in the forest stand. The machine is equipped with a Stage 5 emissions-compliant Mercedes diesel engine rated at 230kW. There’s also a Logmer US 6-7 crane and HSM Harvester cabin. The chipper can take trees from 1 and 2 thinnings with a maximum diameter of 38cm. It has a 20m3 container with high tip up to 5m, and can tip directly into 40m3 containers. The working capacity of the chipper is up to 120m3 per hour, depending on tree size.

NEWS 6 AUTUMN 2023 FORESTRY MACHINERY

LIEBHERR LOGHANDLER

Liebherr has revamped its L 580 LogHandler XPower, improving the lift arms and the associated grabbers developed for log handling. A model of this latest generation has now been in operation for six months at the family-owned company Rubner Holzindustrie in Rohrbach an der Lafnitz, Austria. The new features of the L 580 LogHandler XPower were first tested at Liebherr’s Bischofshofen plant over a period of several months. The Liebherr special wheel loader was so convincing that Rubner Holzindustrie decided to buy it right away.

The new lift arms feature manipulation heights of up to 7m and a reach of almost 4m. Meanwhile, the 360-degree rotatable grabber with a capacity of up to 4m2 enables versatile and time-saving transportation from the storage location to the company’s own sawmill, says Liebherr.

SATELLITE POSITIONING

Komatsu’s new satellite positioning technology can be retrofitted to its forest equipment. Able to show a machine’s position to within just a few centimetres, the new system uses several satellite systems – including Galileo, the European GNSS system – to determine precise positions with precision reduced from several metres to a few centimetres.

As a result, operators can mark exact boundaries with a new ‘geofencing’ feature – a digital fence that is added when planning an area to mark out ground to be harvested from protected areas such as a neighbour’s trees, ancient monuments or charcoal pile remains. Eliminating the need to walk the forest and mark trees for felling, boundaries and specific trees can be marked digitally based on map data collected from drones or scanning.

In addition, the exact position of each felled log is available with greater precision – beneficial in the dark or when ground is covered with snow –making it easier to see the assortment found in each log pile or at the roadside.

APF 2024

Exhibitor bookings for APF 2024, the UK’s largest exhibition for the forestry, woodland, arboriculture, fencing, trees and timber sectors in the UK, are now open. The 2024 show will take place once again at Ragley Estate in Alcester, Warwickshire on September 19th to 21st.

In 2022, 320 exhibitors and over 23,000 visitors attended the event and the organisers hope to exceed that total in 2024. APF organisers say last year’s exhibitors have first refusal on their 2022 site provided they book and pay for their stand by September 30th. The remaining sites will be made available to all new exhibitors from October 1st.

FORESTRY MACHINERY AUTUMN 2023 7

SPECIALIST WACKER NEUSON

GEM Plant Sales, a construction plant and equipment supplier based in Kent, has delivered a specialist Wacker Neuson wheeled excavator to The Upper Medway Internal Drainage Board. This customised EW65 will be involved in some pioneering works on watercourses this summer.

Typically, a large, tracked machine would be used to carry out such jobs, but the decision was taken to seek a more exible tool for major excavator works, which led to the use of a wheeled excavator. The requirement was for smaller pro le machine, with large reach, and a double- jointed boom section, which while being more compact in size, did not compromise the ability to reach far sides of the banks.

In 2022, the Board’s Works Supervisor, John Davis, began speaking with GEM Plant Sales about what Wacker Neuson could offer. After several site visits to see both the larger wheeled offerings and the tracked variants, the 6.5-tonne EW65 wheeled excavator with a double boom, extended dipper, and additional Steelwrist omni-hitch was considered the best option.

After that, West Country attachment specialist Exac-One provided a tree shear and mulcher head. The tree sheer can cut up to 300mm and retain cuttings using a unique gripping arm. The mulcher head

features a xed teeth drum that activates on the use of the rotational circuit, allowing for high impact debris and brash clearance and excellent control during minor tree grinding. Completing the order was a 2m Bradshaw type bucket from Flails Direct to allow for weed and reed clearance works to be carried out. Due to the system requirements of the bucket however, additional low ow circuits had to be installed, representing a technical challenge to the build as it required multiple settings, hook-ups, and limiters.

FORESTRY TYRES

Global tyre manufacturer CEAT Specialty will debut a comprehensive range of forestry tyres at Agritechnica 2023 (November 12th to 18th). The CEAT Specialty Forestry tyre range will cover the two key segments: log skidder and forwarder harvester.

SLOPE MOWER

McConnel has unveiled the Robocut S300e, an allelectric, remote-control slope mower. Building upon the capabilities of the S300, the new S300e retains that model’s features, including 55-degree slope operation, a 150m range, and bi-directional cutting. However, with the integration of electric power, it now o ers the same high-performance level while ensuring zero emissions and reduced noise.

The Robocut S300e is powered by two Vanguard 48V lithium batteries, providing a runtime of up to 4 hours for uninterrupted operation on a single charge. Recharging the batteries typically takes around 8 hours. For added convenience, a fast-charging option is available, reducing the charging time to just 4 hours.

The Robocut S300e has a new 1.1m rotary mulching deck that has been specifically designed for electric operation. The new machine enters production later this year, with delivery of new orders expected in early 2024.

VIMEK UPDATES 870 FORWARDER

Vimek, the Swedish manufacturer of light machines for forestry thinning, has revealed an updated version of its largest and most powerful forwarder. The 8-wheeled 870.2 receives an updated colour scheme, a larger load area (increased from 2.4m to 2.6m without a ecting vehicle dimensions) with more flexible bank locations, plus three Cranab crane options. Power comes from a Cat C2.2 engine with 55kW of power.

NEWS 8 AUTUMN 2023 FORESTRY MACHINERY

“SEAN BEGAN WORKING IN FORESTRY IN 1998 WHEN HE PURCHASED HIS FIRST EXCAVATOR”

BACK FOR SECONDS

10 AUTUMN 2023 FORESTRY

MACHINERY

Sean Ryan Forestry explains to Eoghan Daly its continuing faith in veteran Silvatec Sleipner 8266 TH harvesters, both of which are equipped with Ponsse H6 heads

IMAGES EOGHAN DALY

When building a timber harvesting operation with used equipment at its core, every effort must be taken at the evaluation stage to ensure that the potential for problems is minimised. Guided by this philosophy, Irish harvesting contractor Sean Ryan of Sean Ryan Forestry believes that his choices when it comes to timber harvesters and replacement harvesting heads strike the right balance of affordability, reliability and performance.

From Sean’s base near Silvermines in North Tipperary, he has built a successful timber harvesting enterprise with vast experience attained through many years of

COVER STORY

working on afforestation and reforestation projects through his original plant hire venture, giving him valuable insight into the forest industry.

Sean began working in forestry in 1998 when he purchased his rst excavator. His interest in such operations was fostered by his father Martin’s engagement in plant hire, with a high percentage of his work already coming from forestry operations. Nevertheless, despite building a successful business around forestry ground preparation, Sean felt that a more secure future could be offered by diversifying into harvesting.

Pursuing harvesting interests led to the

purchase of a used Timberjack 1070D harvester with a 752 head, purchased privately from an Irish contractor who was in the process of upgrading in 2012. To minimise costs, it was decided to focus exclusively on harvesting, with the necessary extraction catered for by other owneroperators, currently ful lled by County Galway-based Thomas Conroy.

Before putting his 1070D to work on its initial assignment, the machine underwent a thorough appraisal and any areas identi ed as needing attention were comprehensively addressed. Deciding from the outset on the importance of maintaining a manageable scale and

TIMBER HARVESTING | SEAN RYAN FORESTRY FORESTRY MACHINERY AUTUMN 2023 11

Sean Ryan diversified into timber harvesting back in 2012.

High-flow hydraulics get the most from the crane and head.

Mountaineer model uses larger hubs to deliver tractive forces.

SEAN RYAN FORESTRY

resisting the temptation to expand unsustainably, this methodology is paying dividends as Sean returns to thin many of the forests he originally established through his ground preparation input, as he explained. “With the amount of ground preparation we had done for private growers, it showed the future potential for harvesting on these sites. This drove diversi cation into harvesting, with the rst harvester going well for me, and I then upgraded to a Valmet 901 before getting the two current Silvatec Sleipner machines.”

The common denominator of all machines run to date has been knowledge of their past history, with all being of Irish origin. With Silvatec harvesters being particularly popular among Irish contractors before the untimely demise of the manufacturer, this level of appreciation has now transferred to the used forest machine market. Despite having already worked signi cant hours, the two Sleipner 8266 TH Mountaineer harvesters sourced by Sean Ryan continue to deliver admirable productivity and satisfactory levels of reliability.

TECH SPECS

Silvatec Sleipner

8266 TH

DURATION OF PRODUCTION

2003 to 2012

WEIGHT

17,000 without head

ENGINE Mercedes-Benz

OM906 6-cylinder turbo

POWER 205kW

TRANSMISSION

Hydrostatic, based on Rexroth system

TRACTIVE FORCE 146kN

HYDRAULICS Load sensing Rexroth system

• 1x130cc crane pump

• 1x195cc head pump (2x93cc on models before 2006)

CRANE

Loglift 220V parallel 8.3m or 10m reach;

Mesera 280 as option on later models

BASE MACHINE CONTROL

IQAN

Having long since shed their original Silvatec harvesting heads, both machines now use Ponsse H6 harvesting heads, with the measurement and control computer system also changed to the Ponsse Opti system, along with the in-cab control pads,

HARVESTING

which are now of Ponsse speci cation. The initial machine was tted with a Ponsse H6 head by its previous owner, and Sean purchased the machine from Ponsse Ireland. Based on its impeccable mechanical and cosmetic condition, he put it straight to work. Running on 700mm TRS thread pattern tyres, the machine may be marginally wider than a standard Sleipner running on 600 tyres but can still work effectively in thinnings.

WORTHYUPGRADES

More recently, an opportunity arose to procure a second Silvatec Sleipner 8266 TH Mountaineer when a unit of Irish origin was offered for sale as part of the used forest machine inventory of John Deere Ireland. Identical in speci cation to the original machine with the exception of tment with narrower 600mm tyres, Sean considered the machine an ideal opportunity to acquire a second unit with a high degree of suitability for thinning operations.

To ensure his latest harvester had the same opportunity to emulate the productivity of the existing unit, it was decided to t the same harvesting head. As Sean emphasised, “Ponsse sourced an almost new H6 head for me, which had

been taken off a harvester after the customer decided he needed a larger model. This made the head more affordable and capable of delivering the performance you’d expect from a new harvesting head.”

This level of performance is a major endorsement of the Silvatec base units, which are powered by Mercedes-Benz 906 engines with a power rating of 205kW. Hydraulics are provided by Rexroth pumps, which yield 130 and 195 litres per minute of oil ow from the crane and head pumps, respectively. The machines utilise Loglift L220V parallel cranes, with later models offered with the improved performance Mesera 280 variant.

“These two machines are from 2008 and 2009, and have worked 15,000 and 16,000 hours respectively, but they still have plenty of work left in them,” Sean explained. “The main components aren’t showing any signs of wear, and so far I have only replaced the fan belt in one and an oil cooler in the second machine. Apart from a few hose replacements and normal routine servicing, they just keep going. Some of the machines had reinforcement of the centre section, but these two are still original.”

Concentrating mainly on rst and second thinnings, primarily for private forest owners, the machines are the ideal solution for these harvesting applications and still possess the operational capability to engage in clearfelling operations when required.

Nevertheless, for an owner-operator running older machines, thinning represents a far more lucrative prospect without placing the machines under undue strain, as Sean believes. “Even though I have done some clear-felling, I have no interest in

“PURSUING HARVESTING INTERESTS LED TO THE PURCHASE OF A USED TIMBERJACK 1070D”

| TIMBER

12 AUTUMN 2023 FORESTRY MACHINERY

Ponsse H6 head fitted to both Silvatecs run by Sean Ryan Forestry.

Sean’s original 8266 in first thinnings at Toorlougher, N’port.

THE

STAGE

SAFE CHOICE FOR TOUGH ENVIRONMENTS.

POWER DENSITY, FUEL EFFICIENT DIESEL ENGINES FOR ALL YOUR OFF-ROAD, MOBILE & STATIONARY APPLICATIONS.

HIGH

5

TIER 4 FINAL CERTIFIED. POWER RANGE

100KW

INDUSTRIAL

PROVIDING THE POWER FOR YOUR IDEAS O WER FO R YO UR IDE AS NEED MORE INFO? OUR TEAM IS HERE TO HELP! GET IN TOUCH TODAY 01491 834666 — HYUNDAI-ENGINES.CO.UK

AND

16KW (22HP) TO

(135HP).

ENGINES

GreenChip 838 CH Chipper

Our self-propelled 838 CH is based on Silvatec’s chipper concept; a thoroughly tested technology. Produced at our own workshop in Haverslev, Denmark.

Silvatec’s chipper is reborn

Watch our videos and learn more about our Green Chip chipper

Address: Industriparken 29, Haverslev. 9610 Nørager • Phone: +45 4019 5763 • Email: kp@greenchip.dk ® www.greenchip.dk

WWW.BMF.EE

Forest machines that are loved by farmers and valued by professionals:

• Grapples 0.15-0.37 m2

• Cranes 4.3-10 m

• Trailers 6-18 t

• Hidden hydraulic hoses

• Made of especially tough steel: My Inner Strenx® and Hardox® In My Body

• Protected oil pump

• Protected cylinders

• Tough turning house

• Powder-coated surface

• Lowered centre of gravity

• Accessible greasing points

•

M. Large Tree Services Ltd.

“Coolewell”, Church Road

Newtownabbey, BT36 6DH

+44 (0)28 9034 2838

sales@mlarge.com

www.mlarge.com

“THESE TWO MACHINES ARE FROM 2008 AND 2009, AND HAVE WORKED 15,000 AND 16,000 HOURS RESPECTIVELY”

pursuing this work exclusively as it takes its toll on machines when working on rough ground with larger tree sizes. Often, less is more, and it applies in this case as thinning on private forestry sites is our main focus.

“These machines are still capable of harvesting 50 cubic meters per day in rst thinnings, which is as much as is possible with even a new harvester,” Sean added. “With the reliability they provide, they have low running costs, which is all I can ask for, and overall I am very happy with them and hope they continue to deliver long into the future.”

JOBSELECTION

Drawing its name from the Norse mythical eight-legged horse, which was the mount of Odin, the King of the Gods, Silvatec clearly saw the machine’s eight-wheeled design as one of its chief attributes. In contrast to the current offerings from competing forest machine manufacturers, the Sleipner would have been among a minority of 8-wheeled harvester choices at the time of its introduction in 2001 when it made its rst appearance in an eye-catching pink livery at Elmia Wood.

Ultimately, production of the new machine commenced in 2003 and ran until 2012, with approximately 100 units produced. Of these machines, 20 were shipped to Russia between 2007 and 2008, with three of these remaining unsold, while one was ultimately returned to Denmark and reworked to meet European market standards.

As the successor to the 896 TH, the Sleipner took the Silvatec harvester concept forward by a number of signi cant steps, and while visually the large curved cabin with increased glass areas was the most obvious change, a host of other features made it a much-enhanced harvesting machine. Offered in a number of distinct variants, Sleipner was available in Light, Standard, Mountaineer and Boss con gurations, with each having speci c appeal to different markets and working conditions.

However, the common denominator of all four versions was the engine, hydraulics, and crane, all of which were already very well proven. Machines sold in the UK and Ireland were of the Standard and Mountaineer con gurations, with the latter units favoured because of their heavier hub assemblies and greater tractive power, which suited use on steeper terrain. Few, if any examples of the Sleipner Boss model made it to our shores. It used a hydraulic cylinder on each bogie, which pressed downward to maintain ground contact and apply the highest level of traction. The hydraulic cylinders locked completely when the machine was stationary, ensuring unrivalled stability.

TIMBER HARVESTING | SEAN RYAN FORESTRY FORESTRY MACHINERY AUTUMN 2023 15

L220V parallel crane has stood up well to the test of time.

Mercedes engine totally original despite 15K hours.

Some Sleipners had centre joint issues but not this one.

“PRODUCTION OF SLEIPNER-BADGED MACHINES WAS NOT RESTRICTED TO HARVESTERS, WITH A FORWARDER MODEL ALSO OFFERED”

Seen as a premium harvesting base unit, the Sleipner had many positives, including its terrain friendliness, stability, sheer power and oil ow. When it comes to negatives, there were clearly few. The failure of the Silvatec heads to evolve made them somewhat outdated when contrasted with those of the competition at the time.

Nevertheless, new heads were in development but unfortunately did not make it to market on time to save the nancially ailing manufacturer. In 2007, Silvatec was taken over by Russian owners

Concern Tractor Plants, and attempts to stabilise Silvatec’s nancial woes continued. A working alliance was struck up with Gremo, where the Sleipner was offered in Gremo livery and designated 1350H, with up to 10 such machines sold. Modi cations to the electrics and hydraulics by Gremo made obtaining detailed information for subsequent troubleshooting and repairs of these variants challenging. This was further complicated by the later takeover of Gremo by Ecolog. The changing ownership and partnerships in the industry added

complexity to the maintenance and servicing of Sleipner machines, making it more dif cult to access comprehensive information and support.

THESILVATECSPIRIT

Production of Sleipner-badged machines was not restricted to harvesters, with a forwarder model also offered and designated Sleipner 814 TF, available as early as 2012. Coinciding with the 30th anniversary of the establishment of Silvatec, the latest generation Sleipner 8324 TH prototype was presented in 2014. It furthered the initial variant by offering more power, a revised cooling system, and the addition of a rotating cabin function and a more powerful crane. However, by then, Silvatec had come under acute nancial strain and the machine did not reach completion before they ceased trading in 2016.

Ultimately, the machine was completed by Euromatics, which continues to offer spare parts and technical support for Silvatec machines. The company also ensures the Silvatec concept lives on through its commitment to bringing the latest generation 561 harvesting heads to the market. This product is now available, with the company run by Pol and Timmo Tuesen also working on the manufacture of a modern generation Sleipner scheduled for completion in autumn 2023.

SEAN RYAN FORESTRY | TIMBER HARVESTING 16 AUTUMN 2023 FORESTRY MACHINERY

Cab’s large glass area provides a high level of visibility.

Proudtobeworkingwith SeanRyanForestry H6HARVESTERHEAD PonsseIreland Sales:+353858514174 Alogger’sbestfriend

SEIZING THE MOMENT

Exploiting demand for estate maintenance, Alun Hughes soon found himself establishing ALH Forestry Limited and has recently added a high-performing Sany SY155U to his fleet, as Paul Argent reports

18 AUTUMN 2023 FORESTRY MACHINERY

IMAGES PAUL ARGENT

OWNER-OPERATOR | SANY SY155U

Whilst working for a contractor in North Wales, Alun Hughes saw an opportunity to offer his services to landowners requiring estate maintenance, something his employer at the time didn’t do. The purchase of a used 8-tonne machine saw Alun undertake several jobs before taking the full-time leap into running his own company.

With the estate management work decreasing and an increase in jobs asking him to cater more in forestry works, Alun looked to replace the 8-tonne machine he was running with a small timber grab and upscale to a JS130 with a larger attachment. Once this step was taken, there was no looking back and eventually ALH Forestry Limited was born.

Over the past six years, such has been the demand for his services that he now has a healthy regular client list and clients willing to wait for his services. “We started off looking to put the timber we were felling and handling in for logs or fencing, this has rapidly changed with a huge demand for biomass chips,” he commented. “This has now pushed us down the path into supplying large quantities of biomass chip almost exclusively for Jenkinsons, the largest dealer in the UK.”

CHALLENGE ACCEPTED

Whilst many companies look for the easy-to-harvest timber, Alun and his team very rarely get any of these jobs. Instead, they concentrate on the more awkward projects that demand a little more skill, thinking on their feet for ultimately higher returns. With his 13-tonne machine starting to show its age, Alun looked to the market for an upgrade. “We wanted a larger, compact tail swing machine that will allow us easier access into some of the regular sites we work on,” he explained. “I looked at several makes but some dealers never even bothered coming back to me, and if they did, they quoted ridiculous lead times and eye-watering prices even for a base machine. We weren’t asking for huge additions just proportional rollers on the joysticks and the hydraulic lines to allow us to use a grab or a tree shear.”

THIS HAS NOW PUSHED US DOWN THE PATH INTO SUPPLYING LARGE QUANTITIES OF BIOMASS CHIP”

Visiting the Arb show in Warwickshire last year, Alun happened upon the Sany stand. Looking at the SY155U on display, he enquired about a deal but was told he would have to speak to the Welsh dealer Fitzgerald Plant Services. A call to Fitzgerald put him in touch with Mid and North Wales Salesman David Rollinson who invited him up to the company’s new of ce in Corwen, just 20 minutes from Alun’s base near Denbigh. “I had the chance to try the machine out there and then, and found it to be a huge improvement over the old

FORESTRY MACHINERY AUTUMN 2023 19

ALH’s saw men Tryfan Gri ths and Arthur Cummings.

JS,” he con rmed. “It was specced as we wanted it and was available within a week or so. We looked at the components and they were the same or similar to what you nd on almost any other machine of this size. What really impressed us was the structural warranty Sany gives you. We had total con dence in both the mechanicals and the build quality to sign on the dotted line.”

The SY155U is one of the latest additions to the growing Sany product range. With an operating weight close to 16.5 tonnes, it sits above many of its peers in weight, but also in its performance in the eld. Powered by a tried and tested 4-cylinder Isuzu engine kicking out 105hp, and mated to a Kawasaki hydraulic system, Alun says the excavator has more than enough grunt for undertaking their excavation or tree handling operations. The components, like any compact tail swing machine are squeezed into the curve upper structure and whilst access is OK, any daily checks are all carried out either from ground level, or via the touchscreen in the cab.

Alun’s machine was supplied with a dozer blade, an addition that he nds incredibly handy for keeping the machine planted in some of the poorer sites they work on. “We often work with a loth of wood or greenery under the tracks and whilst the weight increase over the last machine helps, having the blade just to dig into the ground stops the machine from sliding.”

The Sany’s standard front-end equipment 20

THE SANY SITS ABOVE MANY OF ITS PEERS IN WEIGHT, BUT ALSO IN ITS PERFORMANCE IN THE FIELD”

AUTUMN 2023 FORESTRY MACHINERY

The Sany SY155U was selected for its tidy footprint.

OWNER-OPERATOR | SANY SY155U

allows a potential dig depth of over 6m, but it is the pin height of over 9m that has impressed Alun. “We sometimes encounter trees that need holding while we saw cut them. Being able to hold them higher up the trunk makes the operation far safer for us,” he explained.

ON SITE

We caught up with Alun as he and his two-man saw team were undertaking clearance works for a regular client at their pheasant shoot. The small copse had been damaged in 2021 by Storm Arwen leaving several of the large poplars and oaks either on the ground, partly broken or worse still leaning into other trees. The ground

surrounding the trees also threw up tricky issues as it required attening before the saws could enter.

Grabbing a felled tree with the Intermercato grab, Alun was able to bend over the cover plants enough to forge a path through the undergrowth. This allowed access to the trees earmarked for clearance and also revealed fallen timber which had been quickly covered by greenery and also revealed the overgrown drainage channels crossing the site.

With access gained and an area cleared to stock timber, Alun was able to start pulling the fallen timber into place allowing it to be assessed and cut into a variety of lengths depending on its nal use. “We have some

TECH SPECS

SANY SY155U (STANDARD)

ENGINE Isuzu, 78.5kW/375Nm @1,800rpm

HYDRAULICS

2x adjustable pumps, 110L/min flow

OPERATING WEIGHT 16,170kg

LENGTH 8,015mm

WIDTH 2,690mm

TRACK WIDTH 1,990mm

BLADE HEIGHT 480mm

GROUND CLEARANCE 425mm

TAIL SWING RADIUS 1,500mm

MAX. GROUND LEVEL RANGE 8,338mm

MAX. EXCAVATION

DEPTH 6,020mm

MAX. DUMPING HEIGHT 6,756mm

SWING SPEED 12.5rpm

MAX. TRACTION FORCE 124kN

CLIMBING ABILITY 35 degrees

Left: Geith hitch and grapple by Intermercato.

reasonable timber in here, especially the oak that can be sawn instead of chipped,” he commented. “We’ll pile up the material and assess whether it’s worth bringing our chipper in or transporting the material back to the yard.”

The chipper in question shows Alun’s commitment to the job and the fact that if you are going to do something, do it right. Alun has recently invested in a Heizohack chipper mounted on a Mercedes 6x6 truck. A rare site across North Wales and Cheshire (the areas within which Alun and his team regularly operate), adding this huge production machine to the eet has opened up massive opportunities for the company and now enables them to handle large

FORESTRY MACHINERY AUTUMN 2023 21

THE SANY STAYS SOLID AT FULL STRETCH EVEN WITH A GRAB FULL OF A 4M-HIGH OAK TRUNK”

diameter timber with ease. “We used a smaller chipper before, and this required the excavator to be loading it and therefore taking it off production. If we are on a large job, we now produce and chip at the same time, making the job quicker and more productive.”

Whilst handling timber on the ground is one thing, putting it there is another. Using the Intermercato grab to stabilise a tree whilst it is cut ensures there are no surprises for the team. On the softer ground, the Sany stays solid at full stretch even with a grab full of a 4m-high oak trunk. “We have been very impressed with the way the Sany handles some of the larger timber,” Alun pointed out. “It is very strong on the slew which helps us out massively when moving timber out of the undergrowth.”

TREE TACTICS

One of the large poplar trees damaged during the storm was leaning against the canopy of another tree and for the uninitiated, a quick cut with the saw would have dropped it. On closer inspection, the

trunk could be seen to have cracked vertically and could potentially have exploded when cut with devastating effect.

Alun and his team decided to push the tree back to its vertical position before putting in a wedge cut at its base. This allowed the Sany to push the tree over yet still resulted in it splitting uncontrollably, but now in total safety for the lads on the ground and Alun in the excavator.

Alun’s drive to mechanise his operations, in the process making them safer and more

productive, has seen the company expand massively in just a few short years. The Sany has performed far beyond his expectations and has opened further possibilities. “We have been impressed with the response from David and Fitzgerald,” he said. “They are very proactive, with David calling on a regular basis just to make sure everything is OK. Having their depot right in the centre of our operational area gives us peace of mind that if anything did need looking at, they’re not too far away.”

22 AUTUMN 2023 FORESTRY MACHINERY SANY SY155U | OWNER-OPERATOR

Alun Hughes, founder of ALH Forestry and his top-performing Sany.

WITHOUT LIMITS

David Wylie reports on the latest PowerBully high-mobility tracked dumpers, for which the German manufacturer is currently seeking dealers in the UK & Ireland

erman-based Kässbohrer

GGeländefahrzeug is the global market leader of snow groomers and beach cleaning equipment, sold under the PistenBully and BeachTech brands. The recent Plantworx show saw the of cial UK and Irish launch of a new generation of Kässbohrer machines, the PowerBully range of heavy duty tracked dumpers.

In 2014, Kässbohrer purchased Soft Track, a well-respected American manufacturer of specialist all-terrain, low

IMAGES DAVID WYLIE

ground pressure tracked carriers/dumpers.

Production of these machines was later moved to Kässbohrer’s main factory at Laupheim in Southern Germany, located close to their Alpine customer base.

The top-of-the-range PowerBully 18T model offers a payload of 16.6 tonnes and is powered by 310hp Cummins engine, with a separate PTO to power attachments. These large machines usually act used as a base unit to mount specialist equipment, for example a crane or an access platform. They are used extensively by utility companies in

24 AUGUST 2023 FORESTRY MACHINERY

Chassis pictured at the factory in south Germany.

South-eastern USA, to repair and erect powerline poles across sensitive wetland areas.

Of more interest to UK and Irish users are the two new smaller models, with the PowerBully 9D offering a rated payload of 7.5 tonnes and a capacity of 5.0 cubic metres. This, together with the 11.5-tonne/6.4cu.m capacity 12D model, were introduced at the bauma show late last year. They are powered by an ultra-low emission, 6-cylinder Cummins engines, with the 14.5kph Bosch Rexroth hydrostatic

transmission driving rear sprockets on an over-sized undercarriage.

The undercarriage is best described as resembling the bogie wheel track system of a military vehicle, rather than an item of construction equipment. These allow

“THE TOP-OF-THE-RANGE POWERBULLY 18T MODEL OFFERS A PAYLOAD OF 16.6 TONNES”

PowerBullys to safely tackle 60% slopes, both uphill and downhill, or navigate across a 40% side slope. It is even possible to cross trenches and, with a wading depth of 1.3m on the 18T, the PowerBully range can also operate in swampy or ooded areas. Rubber tracks up to 750mm wide offer a large contact surface area, resulting in extremely low ground pressure.

FIRST IMPRESSIONS

Next to the Laupheim factory is an impressive test track, with a PowerBully

NEW PRODUCT | POWERBULLY 9D FORESTRY MACHINERY AUGUST 2023 25

Right: Various configurations are available.

Above right: Power and traction by the bucket load.

Quality Machinery speaks for itself Visit our website for all our product information Tel: 01892 770 788 Mobile: 07836 274 164 www.marshalllogging.co.uk sales@marshalllogging.co.uk MADEIN SWEDEN wood chippers by eschlboeck.at Eschlböck BIBER Maschinenbau GmbH Made in Austria

9D dumper being available on the day of our visit. This was a pre-production model, back at the factory for an upgrade, before returning to eld trials with potential customers.

Access to the cab is via a step conveniently located on the front idler wheel, both the 9D and the 12D models share the same cab. This example of a 9D was con gured with a steering wheel, which moves just a half of a turn left or right to provide smooth and accurate steering of the tracked undercarriage. A joystick steering system is available as an option.

At 6ft tall, I found the cab had plenty of legroom to reach the single throttle pedal. Despite the engine being located just to the rear of the cab, the manufacturer claims that these dumpers have a signi cantly lower internal noise level than their nearest competitor. During my time in the cab, the Darlington-built, 6.7-litre Cummins engine was unobtrusive.

The parking brake is controlled by an easy-to-use rotary switch, with travel direction selected by a column-mounted

“THE UNDERCARRIAGE IS BEST DESCRIBED AS RESEMBLING THE BOGIE WHEEL TRACK SYSTEM OF A MILITARY VEHICLE”

control lever. With a hydrostatic transmission, there is no need for a brake pedal. Letting off the throttle a little progressively slows down the dumper, quickly coming off the throttle makes the machine rapidly decelerate. To operate the dump body, one simply presses the

unlocking button on the top of the righthand joystick and then pull it back, the two hoist cylinders raising the body quickly. To lower it, one simply nudges the joystick forward once. The options list includes a mechanical tailgate for better load retention on steep ground.

Although this example did not have the optional air suspension seat, the 9D provided a remarkably smooth ride across the ground. The cab itself is suspended, but it is the unique undercarriage, which features the largest diameter bogey wheels on the market, that must take most of the credit. Fully loaded, a PowerBully 9D dumper exerts a ground pressure of just 0.35kg/sq.cm – just under 5psi – which is around half the force of a ground worker in boots. In other words, this tracked

| POWERBULLY

FORESTRY MACHINERY AUGUST 2023 27

NEW PRODUCT

9D

Left and above inset: Simple controls; nice touchscreen.

Flatbed version would be ideal for forestry.

All service points are o ered up at ground level.

Spec it as a goanywhere crane with hooklift.

POWERBULLY 9D

BASIC SPEC

ENGINE STAGE 5 CUMMINS B6.7

POWER 173KW/235HP

MAX. TORQUE 949NM@1,500RPM

TRANSMISSION BOSCH REXROTH HYDROSTATIC

MAX. SPEED 14.5KPH/9.0MPH

PAYLOAD 7,500KG

HEAPED CAPACITY 5.0CU.M

GROUND PRESSURE (EMPTY) 0.22KG/SQ.CM (3.12PSI)

GROUND PRESSURE (LOADED) 0.35KG/SQ.CM (4.97PSI)

FORDING DEPTH 1,200MM

GRADEABILITY 60% UPHILL/DOWNHILL, 40% SIDE

dumper can operate on ground that no one could walk across.

There is a 10.4-inch LCD touchscreen, in its default view this all the usual machine information, together with a graphical representation of the live vertical and side to side angles of the machine, together with the angle of the tipping body. This screen automatically displays the output from the rear camera, part of a 360-degree multicamera system, when reverse gear is selected. The monitor can also be cycled through different screens to show machine settings and service data.

The PowerBully range is tted with a telematics system as standard, providing a remote service diagnosis function as well machine location data. All the daily service check points on the machine are accessible

from ground level with the main items, such as the oil, fuel and air lters grouped together. The cluster of fuel, AdBlue and hydraulic oil ll points are located at ground level on the front nearside of the machine.

SPECIALIST APPLICATIONS

Kässbohrer Geländefahrzeug, the global market leader in snow grooming machines, is taking a long-term strategic view of the impact of climate change. The company is

“THIS LATEST DEVELOPMENT COMES AT A TIME WHEN THERE IS INCREASING DEMAND FOR TRACKED CARRIERS/DUMPERS”

using its considerable experience to diversify into sectors of the market that are not winter sports related, including its well-established BeachTech range and the new PowerBully dumpers – a atbed version of which would be particularly suited to forestry applications.

This latest development comes at a time when there is increasing demand for tracked carriers/dumpers across Europe. In carrier con guration, the PowerBully range can be con gured to meet a bewildering range of specialist applications. As a dumper, it ensures that muck-shifting can continue all year around, no matter what the ground conditions.

Kässbohrer has recently appointed the rst PowerBully dealer in Europe, 4Me Machines, the Netherland-based Komatsu dealer.

POWERBULLY 9D | NEW PRODUCT 28 AUGUST 2023 FORESTRY MACHINERY

Optional winch driven by its own PTO pump from the PB’s powerpack.

7.5-tonne and 11.5-tonne models debuted at bauma.

HELPING HAND

Paul Argent pays a visit to a Timberpak material processing facility in Tyne and Wear, where a new Liebherr L550 XPower is used to move chips in a warehouse

30 AUTUMN 2023 FORESTRY MACHINERY

IMAGES PAUL ARGENT

“EGGER OPERATES 20 PLANTS IN 10 COUNTRIES ACROSS THE GLOBE”

The UK’s waste wood market processed more than four million tonnes of wood in 2021, according to industry body the Wood Recyclers Association (WRA). The association’s annual statistics show that the amount of waste wood processed in the UK rose from 3.82 million tonnes in 2020 to 4.17 million tonnes in 2021, with the total amount of waste wood collected returning to pre-pandemic levels of 4.5 million tonnes.

While biomass continued to be the biggest user of waste wood in 2021, representing 61% of the total amount of waste wood processed, there was also a slight increase in the quantities of waste wood being repurposed through board manufacture. One of the UK’s leading exponents of recycling waste wood back into a useable product is Austrian manufacturer Egger. The company operates 20 plants in 10 countries across the globe and produces in

excess of 10.5 million cubic metres of board products on an annual basis, which is split between building materials, ooring, and furniture production. The company operates two production plants in the UK at Auchinleck, East Ayrshire and Hexham, Northumberland where raw and melamine faced chipboard is manufactured. Whilst the material produced at both plants requires some virgin timber, a large portion of the material is produced using

WASTE WOOD RECYCLING | LIEBHERR L550 FORESTRY MACHINERY AUTUMN 2023 31

high-quality, graded timber taken from the waste industry. Reliance on a steady ow of correctly graded and suitable waste material led Egger to establish its own facilities under the Timberpak banner to receive, process and distribute material to both plants.

LONG-TERM PARTNER

Gavin Ball, Sales and Operations Manager for Timberpak in the North East and Yorkshire takes up the story. “As a recycling and reprocessing company, we have sourced the recycled material required for Egger UK’s chipboard production for over 20 years. Egger UK is the largest consumer of recycled timber in the UK wood panel manufacturing industry, so we never turn waste wood away from our recycling sites.

“THE 19-TONNE L550 XPOWER REPLACES A SIMILAR SIZED COMPETITOR’S MACHINE WITHIN THE WAREHOUSE”

“We champion the segregation of wood at source of production,” Gavin added. “This ensures we can recycle the maximum amount and protects the valuable resource of waste wood. We aim to lock carbon into the lifetime of another product and can guarantee that nothing we process goes to land ll.”

To handle the ever-increasing quantities of material being processed, Egger UK is continually investing in new material handling equipment designed to allow the material to be unloaded, graded and processed as quickly as possible. The Timberpak facility at Washington, Tyne and Wear is one of the company’s busiest plants. Material is tipped on the yard for pre-processing and segregation with lower grades of timber kept aside from the higher grades required by the Egger manufacturing plants. The material is then fed into a large chipper that quickly and effectively reduces the material to a standard grade of chipped wood. The chip is dropped from the conveyor into a dry warehouse where a new Liebherr L550 XPower wheeled

Above: XPowers are said to o er enhanced performance e ciency.

Above right: A full complement of lights aids safety/visibilty.

Below: Small camera on quick coupler sends image to display located in L550’s cabin.

loader is used to manage the storage and loading of the chips.

The company already runs several Liebherr wheeled loaders across its recycling plants and has added the 19-tonne L550 XPower to replace a similar sized competitor’s machine within the warehouse. The Liebherr has been speci ed speci cally to handle the large amounts of material being produced at the plant. Running on foam- lled tyres to prevent any punctures, the loader has been supplied with a typical material handling speci cation comprising 3.1m, straight high-lift arms carrying a high-capacity Ulrich toe-tip bucket with an 8m3 capacity.

SPECCED TO PLEASE

The design of the warehouse allows the artic trucks to sit below oor level, which requires Paul Smith, the Liebherr’s regular operator, to load each trailer with minimal lifting of the loader arms. The outgoing loader was only equipped with a standard loader arm con guration and whilst suitable for the loading of the trucks, stockpiling the material to the eaves of the building was an unachievable task meaning the building could easily ll to capacity in a very short time. The addition of the longer arms and toe-tip bucket on the L550 allows the material to be pushed into taller piles giving

32 AUTUMN 2023 FORESTRY MACHINERY

more room for manoeuvre around the building.

The warehouse contains two large storge areas where material can be stockpiled in readiness for loading on the steady ow of walking oor trailers which frequent the site delivering raw materials. Whilst the area when empty of material and machines seems to be a big space, this can easily diminish, especially with the new Liebherr running around. The XPower design of the wheeled loader allows for a shorter rear overhang compared to many competitor’s machines. Combining the shorter overhang with the loader’s impressive traction and climbing ability, Paul says he is able to push material almost to the eaves with little effort.

LIGHT IT UP

During extremely dry periods, the material coming off the chipper’s conveyor can create a very dusty atmosphere within the shed. Timberpak has speci ed a full array of LED lighting to both the front and rear of the machine. The high-capacity lights easily cut through the dust in the shed and have been bolstered by several additional safety features including a reversing radar and proximity sensor system to alert Paul of any personnel within the shed when the machine is operating. “We take the safety of anyone working on our sites extremely seriously.” Gavin commented. “A rear-view camera and a separate Liebherr Skyview 360-degree camera system adds to the safety features on the loader.”

As with any machines working in such a dusty environment, the risk of re is an issue the company doesn’t want to have to deal with, and to mitigate any potential risks the Liebherr not only has a reversable fan to blow any dust out of the cooling pack, but a substantial Ardent re suppression system has also been installed.

Paul Smith has been operating wheeled loaders at the site for several years and said that the Liebherr is by far the nicest machine he has operated here. “The cab is so quiet and comfortable, and so well laid out. Everything just falls to hand. I’ve operated the L580 XPower on the yard and that is a phenomenal machine. The L550 is just a smaller version of it. The power delivery, ease of operating, everything about it is designed to make the driver’s life easier.”

WASTE WOOD RECYCLING | LIEBHERR L550

“I thought the machine had a puncture the rst time I heard the air blow out!” Paul laughed “It’s a brilliant idea and seems typical of Liebherr to think of something like that. It’s all about the details.” The loading shovel and others in the eet have impressed the management team at Timberpak with their class leading fuel consumption, which averages between 10% and 20% lower than the competition.

EFFICIENT PERFORMANCE

Like the other Liebherr loaders and material handlers in the eet, regular servicing and maintenance are carried out by the manufacturer, which suits the Timberpak team as they are informed prior to the machine reaching the service interval and are able to plan suf cient times into their schedule for Liebherr GB personnel to attend site. “Overall, we have been very happy with the products we are taking from Liebherr. We do have some small niggles and issues which are being ironed out, but we expect these as with any manufacturer’s products.” Gavin commented.

One small but quite important addition that has really impressed Paul is the inclusion of a small camera mounted in the bottom of the quick coupler. The image is relayed to a separate screen inside the cab and is invaluable when loading the walking oor trailers allowing Paul to see inside the body at all times. An additional feature of the camera is the inclusion of a high-pressure air jet to blow dust away from the lens, allowing Paul to stay in the cab at all times.

Right inset: Paul Smith is very fond of these Liebherr XPower wheeled loaders.

Right: L550 XPower can tip loads of up to 8,300kg to 12,500kg.

Right inset: Paul Smith is very fond of these Liebherr XPower wheeled loaders.

Right: L550 XPower can tip loads of up to 8,300kg to 12,500kg.

Over the years, various approaches have been taken to the harvesting of small diameter material and clearance operations in forest management, with each having their own advantages and disadvantages.

Finnish company Reformet Oy is one of the latest manufacturers to develop an energy wood harvesting solution, and newly formed contracting operation TMI JJ Iivonen – run by owner operator Jarkko Iivonen – has put one of Reformet’s earliest production models into service.

Having worked as an operator before deciding to establish his own business, the potential to engage in wood energy harvesting, early forest management and small diameter material clearance appealed to Jarkko. With a new mechanical solution developed and tested in real life working conditions by Reformet, the ideal attachment to serve the new venture was presented by this innovative company.

BESPOKE BUILDS

Unlike most other manufacturers, Reformet designs, builds and tests equipment for speci c forest applications, initially in response to the company founder’s personal working requirements at forest level. When it came to developing the Risupeto head, Jani Karvanen created a number of working prototypes before Jarkko Iivonen put the production model into service.

The rst prototypes appeared in 2017 and 2018, and these were mounted on a New Holland E200SR reduced-swing- radius excavator. Despite being quite effective, the concept needed further re nement; the second prototype received grant aid from the European Regional Development Fund and succeeded in bringing the idea forward by a number of important steps. The nal version of the concept emerged soon after.

Deciding to base his new business around the use of one of the rst Risupeto energy wood heads, Jarkko’s initial expectations of the unit have proven correct based on the level of work he has successfully completed, something which bodes well for the future of his venture.

Jarkko considers the range of material that the unit can harvest and accumulate as being one of its main advantages. In addition, achieving impressive work rates in smaller diameter dense material is one of

UNLEASHING THE BEAST

Eoghan Daly reports on Reformet’s newly developed Risupeto energy wood harvester in the hands of Finnish owner-operator Jarkko Iivonen IMAGES EOGHAN DALY

34 AUTUMN 2023 FORESTRY MACHINERY

Jarkko set up his business with an excavator-mounted energy wood head.

“THE FIRST PROTOTYPE APPEARED IN 2017, MOUNTED ON A NEW HOLLAND E200SR EXCAVATOR”

FORESTRY MACHINERY AUTUMN 2023 35 ENERGY WOOD HARVESTING | RISUPETO HEAD BY REFORMET

The infeed rubber paddles are driven at the same speed as the cutting discs.

The positioning of the Risupeto head’s saw discs ensures low stump heights.

“I HAVE NEVER SEEN A HEAD WORK SO WELL IN SUCH A WIDE RANGE OF MATERIAL SIZES”

HOW IT WORKS

The Risupeto energy wood head succeeds in addressing the shortcomings of other working approaches, which can be time consuming. The key objective of the design was to achieve viable clearance rates in smaller material and still have an ability to handle larger diameter stems. This explains the head’s working range of 1 to 30cm diameters.

Attached to the excavator boom via a tilt-rotator hitch, the unit draws power from the machine’s hydraulic breaker

circuit. The ideal hydraulic oil flow to ensure maximum output is 260L/min; a base line figure of 130L/min quoted as the absolute minimum oil flow output from the host machine.

As the unit is swept through material, the wafer blades at the base of the attachment conduct the cutting action. Unlike a saw bar and chain, or standard circular saw arrangement, the wafer blades are not as susceptible to damage from contact with stones and as a consequence can achieve a low cutting height. Another positive is their cutting action, which does not leave a straight cutting edge on the harvested material, accelerating drying of

the energy wood while the stumps on the forest floor are left in a serrated and fractured fashion, inhibiting regrowth of unwanted invasive species.

As the cutting action is being performed, the rotating action of the upper rubber infeed flaps draw the material into the head, where it is held until a complete haul of material is attained. By tilting down the attachment towards the ground and reversing the direction of the infeed flaps, the material is quickly and e ortlessly discharged in an unbound bale on the forest floor from where it can be retrieved by the pursuing forwarder on extraction duties.

Another important feature of the attachment is the telescopic extension arm within its main structure. Even through the extension’s stroke is relatively short, it greatly enhances the head’s ability to be moved through the stand and remove material from behind remaining trees while keeping the excavator boom a safe distance away from the action and eliminating the possibility of ‘barking’ these stems through accidental contact.

While the unit is obviously most e ective in operation, the use of rubber feed paddles may be questioned by some observers. However, there is a perfectly good explanation for their use. Other

36 AUTUMN 2023 FORESTRY MACHINERY

means were explored at the prototype stage but in some cases these resulted in stem breakages especially in smaller material. The rubber feed paddles provide a more gentle handling action, while still succeeding in sweeping stems into the unit. Service life is obviously dependant on the working conditions, but the rubber feed paddles should last 1,000 hours, at which point they are easily replaced.

the unit’s specialities, as he emphasised. “I have never seen a head work so well in such a wide range of material sizes. It really has a fast work rate even in smaller material, and since there is no placement on individual stem with the blades and infeed doing the whole task, I can concentrate more on moving the head and boom through the remaining trees.”

Thanks to its compact dimensions and range of movement provided by the SMP tilt-rotator, plus the hydraulically extending mid frame of the head, accessing smaller material in between remaining viable trees is eased considerably. As Jarkko and his Kobelco worked in a delayed rst thinning of a Scotts Pine stand during the time of our visit, the round logs from the thinning action had been harvested by a timber harvester in advance, with Jarkko then commencing his contribution to the management of the stand.

Running along the edge of a main highway, the stand had become engulfed by smaller diameter birch and other species which had regenerated naturally. Advancing rapidly through the material, which presented a broad range of size classi cations, the taller material was taken down in a multiple section approach that eased the process and also eliminated the possibility of damaging the crowns of the remaining trees.

GOOD FOUNDATIONS

“An excavator base machine from 16 to 20 tonnes is recommended for this head, and with the skis tted this Kobelco SK140SRLC-5 is ideal for use here, explained Jarkko. “It is not too large for manoeuvring through the forest, it can drive the head very well, and it is stable enough to work at the maximum amount of reach.”

Placing additional ballast on the machine is the obvious way to enhance stability, but the Reformet Undercarriage Skis are a novel solution. As well as adding additional weight low down in the machine’s structure, these skis make the undercarriage more forest friendly while reducing undercarriage wear. Elsewhere, the host machine remains very much original with the exception of some steel frame guarding to the kick-out glass coupled with additional lighting for work in dense stands.

After six months deploying the new Risupeto energy wood head, Jarkko is incredibly positive about the product with it living up to his expectations and then some. Reformet’s concept is a viable alternative to previous approaches and is thoroughly deserving of its ‘Risupeto’ name, which translates from Finnish as ‘bush/twig beast’.

ENERGY WOOD HARVESTING | RISUPETO HEAD BY REFORMET FORESTRY MACHINERY AUTUMN 2023 37

SMP tilt-rotator provides maximum movement for the Risupeto head.

Above and right inset: The hydraulically extending frame design eases the head’s movement through the stand.

ONE

C4 FOR ALL

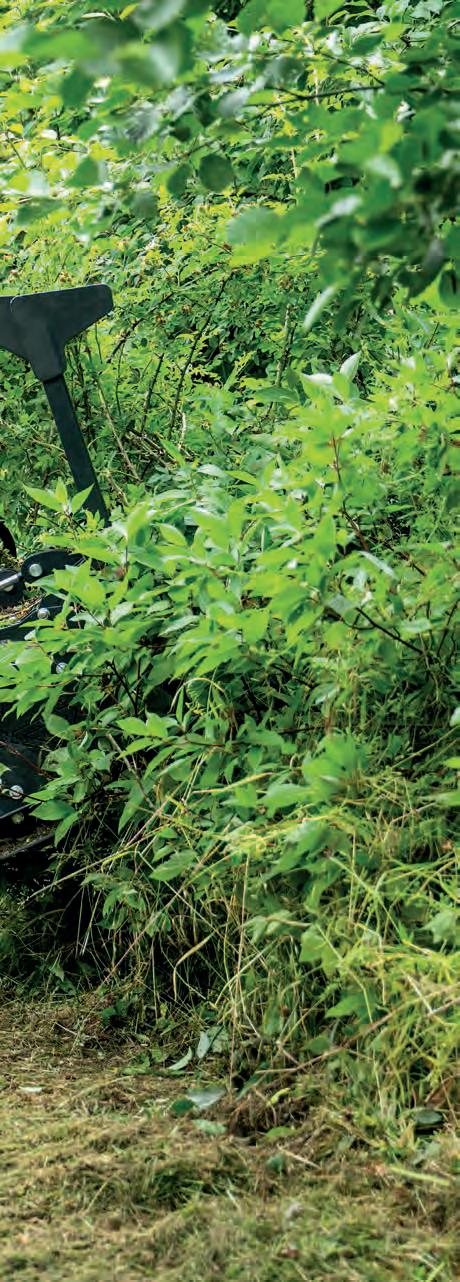

For years, the market for mulchers has been in two distinct sectors – large, cabbed models, and smaller pedestrian machines. This has recently changed with the introduction of the TMU40 from Italian manufacturer C4 Meccanica, explains Paul Argent

IMAGES PAUL ARGENT

Meccanica is no stranger to the forestry market, having already established a healthy line-up of brush cutters, shredders and mulchers designed for mounting on small agricultural tractors. The Italian company also produces a range of augers, sweeper collectors and a multi-tool system designed for use with an excavator. However, it is the company’s rst foray into producing a compact tracked carrier for use with its attachments that caught the eye of experienced dealer Arbforest, based in South Wales.

Sean Reilly, Arbforest’s Managing Director, explained, “Our initial meetings with the

38 AUTUMN 2023 FORESTRY MACHINERY

team at C4 were centred around their mulching heads, but on seeing the prototype of their self-propelled unit, we knew that there was a potential market for it in the UK. The build quality is rst-class and the idea behind the ability to use is as both a pedestrian unit and a ride-on unit made our decision to bring these machines into the UK a no-brainer.”

We caught up with Sean and his team as they were undertaking machine familiarisation works with a customer on a large country estate in the Midlands. The site had been left to grow wild for several years with small saplings, laurels, rhododendron, and other fast-growing plants gaining a foothold around the large established trees and immature trees.

“Our client’s remit was to remove as much of the undergrowth as possible to allow the

Below: Working weight of 2,080kg.

Right: High and protected seating location.

Remote control has a 100m range.

C4’S FIRST FORAY INTO PRODUCING A COMPACT TRACKED CARRIER FOR USE WITH ITS ATTACHMENTS CAUGHT THE EYE OF DEALER ARBFOREST

smaller trees to ourish.” Sean commented. “The site also contains several large shing lakes and part of the project includes removing the overgrown material away from the track sides allowing for easier access, and also do the same to the banks around the lakes to allow for safer and easier access to the shing stands. Our client was originally looking at a small tractor with a mulcher along with handwork for all of this project until we showed them the TMU40V.”

The TMU40V is essentially a compact tracked tool carrier capable of carrying a variety of C4 Meccanica’s powered attachments, but what sets it apart from other machines is its ability to swap from being a ride-on machine to an even more compact radio-controlled machine within a couple of minutes.

TRACKED TOOL CARRIER | C4 MECCANICA TMU40

HOME DELIVERY!

NEED MORE MACHINERY?

Satisfy your appetite for off-road machines with FARM MACHINERY JOURNAL and EARTHMOVERS – the market-leaders with mud on their boots!

Farm Machinery Journal

The magazine for modern farm equipment

Farm Machinery Journal is a one-stop shop for all modern agricultural equipment. The dedicated monthly magazine provides comprehensive coverage on the biggest machinery topics in farming while offering informative and in-depth features that engage and educate operators and owners. The simple easy-to-read design of Farm Machinery Journal is crammed with undiluted machinery reports picked fresh from the eld to appeal to every reader in the wide farming audience.

Farm Machinery Journal is the smart choice for every switched-on owner and operator. First drives of brand new harvesters sit alongside multimachine tests pitching the closest rivals at the hands of operators who spend their working lives at the controls of the latest farm equipment. Looking to update implements? Expert buyers guides help make every decision easier, whether looking to buy new or used. If it's found on the farm, you'll find it covered in Farm Machinery Journal.

To buy a copy or subscribe and get home delivery tel +44 (0)1371 853634 or visit www.FarmMachineryJournal.co.uk

EARTHMOVERS

The best for construction equipment

Earthmovers is the UK and Ireland’s No.1 magazine covering modern construction and earthmoving equipment. Each issue is packed with exclusive first drives, site visits, running reports, product launches, extreme machines, ground-breaking technology, and all the latest news from the industry.

Earthmovers captures the excitement of the fantastic machines that shape the world around us. All the popular types are covered – from ubiquitous backhoe loaders and huge 360-degree excavators to mighty mining trucks and tiny site dumpers.

So if you want to know what’s happening in the construction equipment sector, there’s only one magazine for you –Earthmovers.

To buy a copy or subscribe and get home delivery tel +44 (0)1371 853632 or visit www.EarthmoversMagazine.co.uk

Subscribe or buy NOW

With an operating weight of just under 2.1 tonnes without a tool, the tracked carrier is powered by a 40hp Yanmar 3-cylinder engine meeting Stage 5 emissions regulations and which is mounted inside the machine’s sturdy frame. Anyone who has used an oil-hungry attachment whilst trying to manoeuvre a machine will know that usually one of the functions dies away unless there is suf cient oil ow throughout the machine. C4 has addressed this potential issue by tting four pumps into the hydraulic circuit. One solely controls the oil to the drive system, whilst the other three all deliver a constant ow of oil to the PTO drive and auxiliary system.

A set of heavy-duty rubber tracks sit on the high-drive undercarriage and allow the machine to travel at up to 11km/h, The undercarriage design allows the TMU40 to

work on slopes of 20 degrees with an operator, and at 55 degrees in radiocontrolled mode with its tracks extended out. The 55-degree working angle is only achievable thanks to the engine being set in the chassis at an angle and having been equipped with an extra large oil sump to stop engine starvation. A variable pitch and reversible cooling fan has been tted to reduce fuel consumption and also ensure the cooling pack is regularly cleaned of ne particles to prevent overheating and potential res.

As a radio-controlled machine, the TMU40 operator has a lightweight control unit with easily identi able switches, a tough LCD screen and a pair of joysticks. This allows the operator to use the machine under low hanging branches of established trees or in situations were keeping people

OUR CLIENT’S REMIT WAS TO REMOVE AS MUCH OF THE UNDERGROWTH AS POSSIBLE TO ALLOW THE SMALLER TREES TO FLOURISH

away from potential harm is paramount. With the collapsible canopy closed, the operator station is kept clear of damage too, and ultimately this reduces the height of the machine down to just under 1.5m.

Putting the fully tested and certi ed ROPS up reveals an ergonomic and safe operator station allowing the operator to sit above the mulcher head. The remotecontrol unit is then plugged into a dedicated docking station transferring its functions for the basic operation of the machine such as travelling and powering the head onto a set of integrated joysticks each side of the operator’s seat. From this raised position the operator can easily see the entire width of the tool, down to each side of the tracks and the entire working are ahead of them.

VIEW FROM THE TOP

The site in the Midlands was ideal as it contained a landscape requiring the TMU40 to be used in both pedestrian and ride-on

TRACKED TOOL CARRIER | C4 MECCANICA TMU40 FORESTRY MACHINERY AUTUMN 2023 41

Left: Max flow on PTO is 55L/min.

Below: 1.3m wide and 2.6m long.

The TMU40 is two machines in one.

modes and also showed off the machine’s compact dimensions to widen pedestrian pathways throughout the site.

Firing up the little Yanmar engine from the remote-control unit, the TMU40 was rst set to work under some of the lower hanging branches of an oak tree. Working steadily backwards and forwards, the vegetation surrounding the tree was quickly cleared away. This task was carried out further into the small copse as more and more vegetation disappeared very quickly, leaving a carpet of green waste covering the ground. Having the canopy closed and walking behind the machine allowed the operator to carve a clear path up to each established tree.

ACCESS ALL AREAS

Pulling the machine out of the copse and experiencing a slight weep from a loose hose allowed us to get a look at the heart of the TMU40. A simple pair of catches allows the entire operator station to be raised on hydraulic struts to reveal the hydraulic heart of the machine and the offending pipe. A simple task with a pair of spanners cured the situation before the machine was readied to undertake some work with the cab up. In total, it took just two minutes to raise the canopy and x into position and relocate the remote-control unit into its docking station. The seat back was raised and the machine ready to be driven to the next phase of the project.

Using the TMU40 as a traditionally operated machine saw it quickly remove undergrowth including a short stretch of vegetation on a steep slope into a drainage ditch. Small unwanted trees were also shown the full force of the machine quickly succumbing to the TRF135 mulcher. Finally, the team put the TMU40 to work clearing the sides of an access track to the shing lakes. Taking just a couple of minutes to clear over 30m of vegetation and leaving a considerable extra width of track open showed the ability of the machine.

At just 1.3m wide and 2.6m in length without the TFR mulching head, the machine can easily t onto a small plant trailer allowing it to be moved from site-to-site with ease.

USING THE TMU40 AS A TRADITIONALLY OPERATED MACHINE SAW IT QUICKLY REMOVE UNDERGROWTH

1,350mm cutting width for the TRF135.

Above: Power comes from a 30kW Yanmar engine.

Below: Two catches secure the operator station.

C4 MECCANICA TMU40 | TRACKED TOOL CARRIER 42 AUTUMN 2023 FORESTRY MACHINERY

On site or on the farm, working in tough environments demands the durable, class-leading diesel MULE PRO-DX to make light work of the heaviest tasks.

Dependable four-stroke power from the 401cc engine combined with a 181kg load and 500kg towing capacity, plus 4-wheel drive, makes the MULE SX a true hard worker.

The innovative MULE PRO-DXT quickly changes from four to two seats that a single operator can manage in less than one minute, the vehicle of choice for many farmers, gamekeepers and grounds-care experts.

With its torque-laden 700cc CVT single-cylinder equipped engine, the MULE PRO-MX delivers all the rugged, reliable and adaptable attributes that Kawasaki’s MULE utility vehicle brand is famous for.

Dependable four-stroke power from the 401cc engine combined with a 181kg load and 500kg towing capacity, plus 4-wheel drive, makes the MULE SX a true hard worker.

The innovative MULE PRO-DXT quickly changes from four to two seats that a single operator can manage in less than one minute, the vehicle of choice for many farmers, gamekeepers and grounds-care experts.

With its torque-laden 700cc CVT single-cylinder equipped engine, the MULE PRO-MX delivers all the rugged, reliable and adaptable attributes that Kawasaki’s MULE utility vehicle brand is famous for.

CHIP OFF THE NEW BLOCK

German manufacturer Albach has achieved much in its 17-year history, developing a range of specialist machines serving the forestry, wood energy, and tree care sectors.

Eoghan Daly visits the manufacturer’s Langquaid manufacturing facility...

When we think of leading self-propelled chipper producers, the choices are far from restricted to units of Scandinavian origin, with leading manufacturers also developing productive machine solutions in many other countries across Europe. As a premium ambassador for German wood energy equipment manufacture, Albach has become a recognised force in the industry with over 600 of its machines now in operation worldwide.

Displaying a high level of pride in its product, coupled with dedication to continued innovation and progression, the company draws its name from the surnames of the founders, Alzinger and Bachmaier, which were abbreviated and merged to form the Albach name. Since its formation, the company is now controlled by brothers Franz

IMAGES EOGHAN DALY

44 AUTUMN 2023 FORESTRY MACHINERY

Langquaid factory is the production centre for the Diamant 2000.

and Michael Bachmaier, and continues to be a privately owned family-run operation, which is driven by organic growth and a passion for continual product development.

Based in the Upper Bavarian Menning region, Albach Maschinenbau GmbH & Co KG has its headquarters in Menning, which is coincidentally the founder’s home village, and provides manufacturing facilities for its Fallbach truck-crane-based tree felling units, grapple saws, and other special products, coupled with laser cutting and fabrication of machine elements in specialist manufacturing halls.

In addition to the Menning facility, Albach also has its Langquaid manufacturing facility, which is the main centre for the assembly of its Diamant 2000 self-propelled chippers. Between the two facilities, the company employs a total workforce of 200 and has an annual

Above: Line-up of machines outside the Langquaid factory.

Right: Axle of Diamant 2000 with continuous all-wheel drive.

Below right: Chassis prefabs awaiting entry to assembly hall.

“BETWEEN THE TWO FACILITIES, THE COMPANY EMPLOYS A TOTAL WORKFORCE OF 200”

turnover of €80 million (around £70m).

Recognising the market potential for a dedicated self-propelled chipper, work on developing the rst prototype began in 2004. Based on a Mouse self-propelled beet loader, the machine was designated Giga Hack, and even though subsequent machines bene ted from re nement of the initial design, the original prototype proved a success, and a bright future in the production of such machines beckoned, with the Albach company founded in 2006.