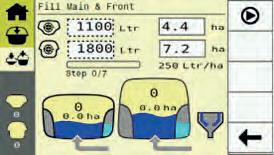

The Leeb CS mounts to the tractor’s 3-point linkage to form a compact and manoeuvrable unit that is ideal for smaller fields. Active boom control system is a unique feature in this class, while continuous cleaning system CCS Pro, the induction tank and the 25cm nozzle layout are available for the new Leeb CS. HORSCH.COM

Unique BoomControl active boom control system with 3-point linkage

2200 litre tank offers high efficiency and extended working

One-sided or partial folding to reduce working widths

HorschConnect for simple data transfer

TOGETHER FOR A HEALTHY AGRICULTURE

ACTING EDITOR Graeme Kirk

editor@farmmachineryjournal.co.uk

ART DIRECTOR David ‘Spike’ McCormack

DESIGNERS Sarah-Jane Mortimer, Claire Trent

RETOUCHER Linda Duong

ADVERTISEMENT SALES Alex Cronin 020 8639 4406

ADMINISTRATOR Martin Attis 020 8639 4409

PUBLISHING DIRECTOR Paul Cosgrove 020 8639 4401

CONTRIBUTING WRITERS AND PHOTOGRAPHERS

Eoghan Daly, Nick Drew, Tom Hunt, Tom Laight, David Laley, David Pullen, Terry Richardson, Mick Roberts, Howard Sherren, Ken Topham, Katherine Weir

Farm Machinery Journal is published by

Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent, BR3 5JS

TEL 020 8639 4400 FAX 020 8639 4411

EMAIL info@farmmachineryjournal.co.uk

WEB www.farmmachineryjournal.co.uk

SUBSCRIPTIONS

Farm Machinery Journal subscriptions

Trinity House, Sculpins Lane, Wethersfield, Braintree, Essex, CM7 4AY

TEL +44 (0)1371 853634

EMAIL farmmachineryjournal@escosubs.co.uk

NEWSTRADE

Seymour Distribution

2 East Poultry Avenue, London, EC1A 9PT

TEL 020 7429 4000

REPRO

Design & Printing Solutions Ltd

Unit 45C, Joseph Wilson Industrial Estate, Whitstable, Kent, CT5 3PS

TEL 01227 770034

PRINTING

William Gibbons & Sons Ltd

26 Planetary Road, Willenhall, West Midlands, WW13 3XB

COPYRIGHT

Sundial Magazines Ltd 2024. All rights reserved. Reproduction in whole or in part is forbidden without the express permission of the publisher. ISSN 2055-043X Sundial Magazines Ltd. Registered in England no. 4134490.

CONDITIONS FOR ADVERTISING

All advertisements are accepted subject to the publisher’s standard conditions of insertion. For a copy of advertising terms & conditions, please write to Paul Cosgrove at Sundial Magazines Ltd, Sundial House, 17 Wickham Road, Beckenham, Kent, BR3 5JS

Farm Machinery Journal is available on the second Friday of each month

to Farm Machinery Journal, the monthly magazine dedicated to modern agricultural equipment.

I ended this column in the February issue with praise for the NEC for being warm and waterproof – and thank goodness that’s the case! I attended the second day of LAMMA 2024 at the exhibition centre near Birmingham and was met with a temperature of -5C and frost on the ground on the short walk from my hotel to the show.

Once inside, however, and with my heavy coat in the cloakroom, the exhibition halls couldn’t have been more comfortable for a day taking in the sights and sounds of what is now undoubtedly the UK’s leading farm machinery event.

I hadn’t been to LAMMA since the rst NEC event in 2019. Back then, frankly, I wasn’t impressed. Something about the layout just didn’t work; the large NEC halls felt sparsely populated and the excitement of, say, Agritechnica or SIMA was missing.

This time, however, I had no such complaints. There was a new level of professionalism, and time, money and e ort had clearly been put into the layout of the stands in the hall, and the building and presentation of the stands themselves.

Whatever the investment involved, there’s no doubt that this year it paid-o for the organisers and exhibitors alike. Visitor numbers hit a record 40,000-plus and there was a real buzz about the event that suggested business was being done. That can only be good news for British farming.

Graeme Kirk Acting editor

We’re in Dorset to see a contractor who’s happy with his Krone BiG X 980

A round up of the latest stories from across the farm machinery sector

We’re on a Derbyshire pig unit to see its 2023 New Holland T6.180 tractor

We meet the owner of the first RT ProArm JA2122T telescopic hedgecutter

We’re in the driving seat to form a view on the Bobcat L95 wheeled

We look at the technology used by overseeders to rejuvenate grassland

We outline the main players in the UK’s mounted crop sprayer market

An Irish contractor running a 2009 Claas Cougar 1400 self-propelled mower

Farmer JF Tomlinson & Co runs

but e ective

FMJ report from the 2024 LAMMA Show at Birmingham’s NEC that proved to be the event’s most successful edition yet

We’re in Wales to meet the owners of a 2022 Major 3100LGP slurry tanker

The first part of a new series on the history of high-horsepower tractors Technical

How today’s hybrid tractor tyres can help reduce soil damage in wet fields 73

Everything you could possibly need to know about tractor front axles

All you need to know about buying the classic John Deere 6400 tractor

Farm machinery auction sales at Lower Hall Farm and Ford Valley Farm

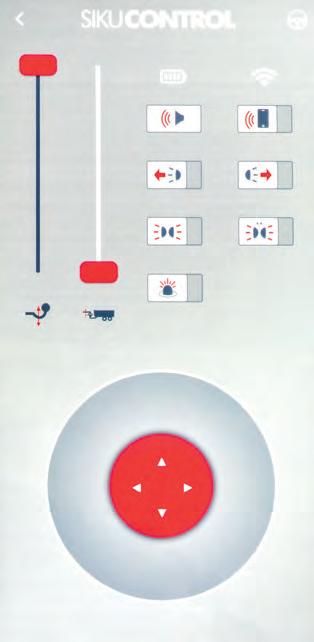

All the latest models that wouldn’t look out of place in any miniature fleet 98

A look at some of the lesser-known tractor brands at this year’s LAMMA Show

Dorset contractor Philip Trim took delivery of the UK’s first Krone BiG X 980 in spring 2023. FMJ found out why he opted for the brand and what the machine brings to his business

WORDS AND IMAGES KEN TOPHAM

rone launched the BiG X 980 in the UK at LAMMA 2023. The machine wasn’t a revolutionary new design but a model that filled a gap in the widebody forage harvester range. The larger BiG X 1180 still sits at the top of the heap as the most powerful machine on the market, but the 980 looks a good choice for cost-conscience operators.

KThe BiG X 980 is something of a wolf in sheep’s clothing. It shares the V12, 24-lit Liebherr D 9512 motor used in the 1180 – unlike its predecessor, the BiG X 880, that was powered by a Liebherr V8. This gives it a trick up its sleeve; if you find you need a few more ponies under the bonnet, you can rent them.

“A machine with this horsepower made sense for us, with the potential to pay for the extra power if needed”

The power output can be increased to that of the 1180 by buying a block of hours, and it’s only used when needed, so it won’t necessarily be exhausted in one go. These “XtraPower” hours are purchased through the Krone owner/operator portal and can be used straight away – it’s easier than ordering a takeaway. Adding 100hp for 10 hours costs about £29/hr, while 250 hours of 200hp extra costs about £37/hr.

Although owner Philip Trim hasn’t needed the extra power so far – 2023 yields haven’t been stellar – he wanted this additional forager, which joins a Claas Jaguar 970 already in the fleet – to be in the 1,000hp bracket.

“We could see an increase in maize growing for energy production, so a machine with this horsepower made sense for us, with the potential to pay for the extra power if needed,” he says.

First Impression // Krone BiG X 980

Krone BiG X 980 Engine Liebherr

D9512, max power

979hp, max eco power 600hp

Chopping drum

36 knives

Headers

XCollect 900-3, EasyFlow 300 and XDisc 620

Annual output

1,400ha maize, 600ha wholecrop

All of Krone’s current widebodied 80 Series machines have XtraPower available except the rangetopping 1080 that isn’t marketed in the UK anyway. Arguably, the smart money is on the 980 as it offers the potential to have the output of an 1180 when you need it, and the fuel economy of a 600hp machine in EcoPower mode when you don’t.

Philip Trim is a first-generation contractor who started out his business with a round baler and one tractor. Things have escalated somewhat since and he now runs two forage harvesters and 21 tractors, as well as some HGVs for bulk haulage.

The operation’s forage harvesting service caters to dairy and beef customers, and with a growing energy production base on Philip’s doorstep, running two forage harvesters has become a necessity. Chopping 6,000ha/yr between the two high-output machines is fairly manageable, and a large part of the workload is providing 30,000t of forage to an anaerobic digestion (AD) plant. This was instrumental in

“The crop flow is excellent, always smooth in di erent crops; with varying chop lengths, you can definitely see the benefit of the six feed rolls”

the decision to run the Krone as its 36-blade cutting drum has the flexibility to run one cylinder and either a full set of blades for maize or a half set for grass. An optional Variloc drum pulley that has an internal reduction gear further increases the chop lengths to give the customer the best material for their application.

Philip chose the 36-blade unit for maximum flexibility; it offers a 3-17mm theoretical chop length with a full set of knives and 6-34mm with half a set. The half knives are accompanied by blanking plates to protect the knife carrier surfaces. These should see out a few sets of knives, as they clear the shear bar by quite a distance. This configuration currently suits the demands of stock farmers, but can be changed by adding a full set of grass knives if the customer’s nutritionist recommends short-chop feed.

Chopping grass at 12-15mm is the norm for most of Philip’s customers, as is high-volume additive.

“We’ve tried to get them to change over to low-volume, but they’re not keen,” Philip says. “We use a bulk tank mounted at the rear of the 980 that’s fairly easy to fill, and the auto-shut-off

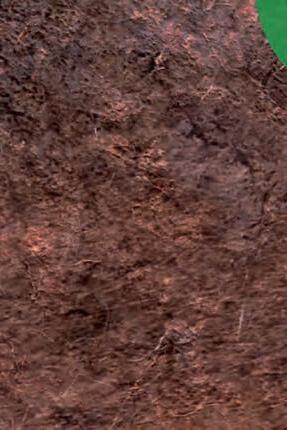

Main image: Pictures don’t do justice to this dip; tractors of every brand were struggling, but the BiG X strode up.

In the BiG X 980 the Liebherr engine works from 600-979hp with the potential of 200hp more.

Operator pros and cons

+ Feed of crop is excellent in all crops

+ Blow and adjustment are very useful

+ Visibility to trailers to the side or behind

– Noise level in the cab is higher than Claas

– No hands-free option for CB radio

– Fuel tank could be larger

and application rate system works the same as using the BigX’s built-in tanks.

Wholecrop is part and parcel of contract foraging these days and the 980 is equipped with Krone’s XDisc direct cut header that is available only with a 6.2m working width. Running a full set of 36 knives for the job, a separate crop processor takes care of the smaller grains.

Maize knives are installed after the

summer harvest is finished, and Philip has been impressed by the results.

“We like the sample; there are very few unchopped leaves, which is what digester customers prefer as big pieces of leaf end up floating and affect the reaction in the AD plant,” he says.

Most of the digester ration gets chopped at 5mm that’s comfortably in the range of the 36-blade drum. Of the 1,400ha of maize Philip’s team harvests, the BiG X does the lion’s share because of the quality of the sample.

Kevin Evans is the usual pilot on the BiG X and is a Claas convert, having used the Harsewinkel-made machines in the past.

“We use the crop sensor more in maize as we supply an AD plant that wants to know what the quality of the crop was when it was harvested”

“I really like the Krone,” he says, “it feeds really well, and the adjustable blow feature is brilliant. Cab visibility is excellent, although it’s a bit noisier in the cab compared to our Claas.”

Having almost completed a full season with the BiG X when we caught up with it, Kevin has given it a good test. He has been particularly impressed by the VariStream crop accelerator that boosts the 980’s ability to swallow lumps in grass.

“You can see the lumps, particularly when the crop is short, and they just flow through, it’s very good,” he says. “The overall crop feed is one of the 980’s strengths. The whole machine seems very well tuned-in, and the

crop flow is excellent, always smooth in different crops with varying chop lengths. You can definitely see the benefit of the six feed rollers.”

The XCollect 900-3 header has been available for a few seasons now, updating the stationary knife Krone was known for. It has a rotating blade that is hung from a gearbox, unlike other disc-type headers where the drive is below the cutting surface, leaving only skids and crop guides below.

Top right inset: Maize for biogas is usually chopped at 5mm, and the sample has been well received by customers.

Below inset: The XCollect header has high-speed cutting discs and shatter the stubble effectively.

One of the drivers for a spinning disc system is the corn borer beetle that likes to make its home in the stubble after harvest. Thankfully UK growers haven’t seen this pest yet. But, the spinning disc does smash the stubble noticeably more than the original endless chain and knife method, which should aid decomposition. The only notable downside is a slight increase in fuel consumption.

Having used the EasyCollect and XCollect, Kevin praises the newer model.

“It works very well, and seems comparatively lighter row-for-row than other maize headers I’ve used,” he says. “The discs are very robust,

and if you do catch a stone and bend the tip of the cutting edge, you can tidy it up with a battery grinder and carry on.”

The 980 is fitted with Krone’s EasyLoad automatic trailer loading solution that was taken from a previous Krone forager operated by the business. Fitting the camera pod under the spout was the biggest job when preparing the new machine for work. The system employs a 3D camera array and can follow trailers alongside or behind the forager with programmable strategies for loading.

The system did take a bit of dialling-in on the latest forager as it had been set up from the factory on a

Krone 880 that was previously in the fleet.

“It works well while the load is below the sides, then you have to top it off manually,” Kevin says. “The output of the machine outpaces the loading camera, and you can end up with crop on the floor because it doesn’t move fast enough.”

Crop analysis has become commonplace on forage harvesters lately, and it’s particularly important for

energy producers that buy-in or grow their own forage. On the contract growing side of this equation, dry matter at harvest and crop readiness will be easy information to extrapolate from the recorded data.

“We use the crop sensor all the time in maize,” Kevin adds. “The AD plant we work for wants to know what the quality of the crop was when it was harvested, while the tonnage is also useful to record for bought-in crop and a customer’s own maize.”

ACKNOWLEDGEMENTS Thanks to Philip Trim Contractors for its time and assistance with this feature

Above: The EasyLoad system was swapped from the previous machine.

Left: Philip runs a bulk additive tank, but still uses the machine’s automatic application functions.

Left: Philip says the XCollect gives a good result with a clean cut whether the rows are followed or crossed.

Above: The EasyLoad system was swapped from the previous machine.

Left: Philip runs a bulk additive tank, but still uses the machine’s automatic application functions.

Left: Philip says the XCollect gives a good result with a clean cut whether the rows are followed or crossed.

Deere & Company has announced it has entered into an agreement with Ellon Musk’s SpaceX to provide cutting-edge satellite communications (satcom) services to farmers. Utilising the Starlink satellite network, the solution will allow farmers facing rural connectivity challenges to fully engage with precision agriculture technologies.

The partnership, an industry first, will enable John Deere customers to be more productive, profitable and sustainable in their operations as they continue to provide

food, fuel, and fibre for their communities and the growing global population.

“The value of connectivity to farmers is broader than any single task or action,” Deere’s Aaron Wetzel said. “Connectivity unlocks vast opportunities that were previously limited or unavailable.

“For example, throughout the year, farmers must complete tasks within extremely short windows of time. This requires executing incredibly precise production steps while coordinating between machines and managing machine performance. Each of these areas are

enhanced through connectivity, making the entire operation more efficient, effective, and profitable.”

The satcom solution will connect both new and existing machines through satellite internet service and rugged mobile satellite terminals. This will fully enable technologies such as autonomy, real-time data sharing, remote diagnostics, enhanced self-repair solutions, and machine-to-machine communication, all of which help farmers work more efficiently while minimising downtime.

“John Deere has led the agriculture equipment industry for more than two decades with satellite-based precision guidance technology,” Deere’s Jahmy Hindman said. “Now, we’re bringing satellite communications service to the farm at scale so farmers with cellular coverage challenges can maximise the value of connectivity to their operations. The satcom solution unlocks the John Deere tech stack so every farmer can fully utilise their current precision agriculture technology in addition to the new innovative solutions they’ll deploy in the future.

The satcom solution will initially be available through a limited release in the United States and Brazil starting in the second half of 2024.

In celebration of 50 years of its iconic Jaguar forage harvester, Claas of America has introduced special equipment packages on various models. And while all 2024 Jaguar foragers are considered anniversary editions, all models ordered with the optional Operator Comfort Package will receive a special 50th-anniversary graphics and accessory package (pictured) at no additional cost.

The Jaguar line paved the way for an unprecedented success story in the self-propelled forage harvester segment when it launched 50 years ago in Germany, and it has been a leader in the category ever since. Featuring many innovations over the years, the Jaguar attained not only a worldwide reputation but also world market leadership with more than 45,000 units built.

The Fendt Rotana 160 V Combi baler/wrapper is now available with film binding and a variety of features that enable it to produce 30 more bales a day and save up to 3m of film for every bale. The new model also features a quick-change system for film and net rolls as well as a ‘Speed’ tailgate function.

“Film binding is already available for the fixed-chamber, baler/ wrapper combi machines,” Fendt’s Ed Dennett said. “To offer variable-chamber baler operators the same advantages, this technology has been transferred to these models of the Rotana.”

Using only film, the Rotana 160 V Combi reduces the air between the bale and the film. This reduces feed losses caused by mould formation and also protects the bale in freezing temperatures.

“Two gathering arms, and a shaft binding system specially

developed for the variable presses, guide the binding material into the baler chamber,” Mr Dennett said. “The shaft formation also protects the film from damage. An electro-magnetic brake controls the pre-stretching of the net or film according to the binder and its roll diameter.”

Only one waste material is created with film binding, and film is typically much less contaminated and, therefore, easier to recycle. Usage is also reduced compared to net, and Fendt’s new film binding system can save up to 3m of film/bale.

The arrangement of the rolls on a magazine enables a quick change between film and net. This allows operators to quickly switch from silage to hay or straw bales.

This new model benefits from a faster ‘Speed’ tailgate capable of baling up to 30 more bales/day than the previous Rotana.

Kuhn Farm Machinery has introduced a new flagship FC 13460 RA trailed mower conditioner aimed at users requiring increased mowing capacity and e iciency from a wider trailed machine.

The FC 13460 RA features a 12.4-13.4m cutting width, allowing operators to benefit from reduced fuel consumption and lower soil compaction due to covering a wider area with each pass. It also has well-known features from current Kuhn machines, such as Lift-Control and the Optidisc Elite cutterbar.

Kuhn’s grassland product marketing specialist, Rhodri Jenkins, said the increased output from running a wider width should be a key consideration for users this season.

“The FC 13460 RA o ers significantly higher output from a single machine handling large areas and operators can expect a 25-30% wider cut on each pass than a mounted triple mower combination,” he added. “Across a single season, the savings in fuel, labour and time are considerable.”

The FC 13460 RA uses Kuhn’s proven Optidisc Elite cutter bar featuring Fast-Fit quick knife system to reduce downtime. The mower has 12 discs on each unit, with improved crop flow and an increased knife overlap to ensure all crop is cut. A greater distance between the discs allows improved crop flow to the rear of the mower and away from the cutting area. Disc skid linings and Triple 5 knives are standard.

Central to the design is an innovative frame that o ers constant ground pressure control through the Lift-Control suspension. The weight of the mower is spread between the tractor’s drawbar and the mower’s axle, with flotation tyres helping to further protect the soil. Users can adjust bed pressure during work.

25 years experience

Applies all small seeds, Avadex granules, cover crops and slug pellets

Powerful hydraulic fan

Garmin GPS control system

200l or 400l hopper

Configure the spec to suit your needs

12m/15m boom available

Dual hopper option

Excellent service and spares support

T Bunning & Sons is returning to trailer manufacturing after a 13-year break in production. A new four-model range will be built at the firm’s factory at Gressenhall, Norfolk.

The reintroduction of the trailer line has been driven by increased customer demand, and will maximise output from a

6,840sq.m factory expansion that has been completed during the past two years.

“We’ve been asked by existing Bunning trailer customers for several years to start production again, and our recent factory expansion has allowed us to streamline the build process with cutting-edge technology,” the company’s sales director, Chris Druce, said. “We’ve improved some

The new Vogelsang XSplit slurry separator is claimed to be the first to produce material with a dry matter content of 40%. The screw press machine is, therefore, capable of producing separated dry matter that’s suitable for bedding.

Vogelsang’s separation specialist, Andrew Hayhurst, said he expected farming grants to be a key to unlocking the benefits of slurry.

“By separating slurry, farmers can reduce the volume being sent to storage and improve the nutrient value of the slurry that is stored,” he added. “Dry matter can subsequently be used as a soil conditioner or a cost-e ective and sustainable bedding material.”

The XSplit is designed and engineered to be both economical to run and easy to maintain. The drive is arranged on the solid matter outlet side, which gives the XSplit an excellent cost-benefit ratio with no need for an extra shaft seal. This reduces both the cost of spare parts and the time required for maintenance work.

key areas of the trailer that will please old and new customers, and we’re delighted with the final product.”

The new range is based on the old design but has been improved and modernised in certain areas and features a completely new tailboard. Four models will initially be available in 14-, 16-, 18- and 20-tonne formats.

Kubota North America unveiled its vision for 2030 at the world’s biggest tech event, CES 2024, showing a novel autonomous farm vehicle.

The company’s New Agri Concept is a fully electric, multipurpose unit that will bring autonomous technology and AI together to provide solutions for small-acreage growers. Key technologies highlighted include: automatic data collection, real-time monitoring, AI identifying potential issues, automation addressing labour challenges, water management automation, and a data platform enhancing productivity.

The fully electric New Agri Concept is designed for flexibility and to support a wide range of tasks. The vehicle’s six independent drive motors and a standard three-point hitch allow it to use many existing implements. Fast charging, from 10% to 80% in less than six minutes, allows flexibility by not constraining customers with long charge times that reduces vehicle downtime.

The well-known UK importer of Vervaet machinery, J Riley Beet Harvesters (UK), is celebrating its 30th anniversary in 2024.

Company founder Jeremy Riley, who left the business in 2022, was heavily involved with the establishment of six-row self-propelled sugar beet harvesters in Great Britain. He set up the company, where he was joined by Peter Smith and David Oakley, in 1994 to import Vervaet harvesters from The Netherlands. Vervaet’s 17t harvester was the go-to machine for British farmers and contractors for more than 20 years.

The German Agricultural Society (DLG) will present its new FarmRobotix feature at this year’s DLG Feldtage event taking place at Erwitte, Germany, on 11-13 June.

An international platform, FarmRobotix will o er farming experts a comprehensive overview of the latest developments in robotics, artificial intelligence (AI), automation and digital solutions in crop production.

FarmRobotix has been established to meet the needs of farmers, manufacturers, start-ups and suppliers of technology for a comprehensive and practical overview of farm robotics that will aid decision-making for farmers and o er impetus for product development.

Agricultural machinery auctioneer Che ins has reported total farm machinery and plant sales of £71 million in 2023, a £23 million increase compared to the previous year.

Demand for top-quality, low-hour machinery remained strong, and good examples were sold at a premium as buyers looked to the second-hand market for sound financial investments and a significant saving on buying new.

The Che ins team conducted 51 sales during the year, made up of 34 on-site farm or dealer dispersals, 12 monthly Cambridge Machinery Auctions and five Vintage sales – the same number as 2022.

Farming in Pakistan is booming as the country targets higher crop production to meet staple food requirements. This has had a knock-on e ect on tractor sales, with the number of locally assembled models sold doubling in the six months to the end of December 2023.

Massey Ferguson is the largest domestic manufacturer and it produced 15,258 tractors in the latest half-year compared to 7,430 in the same period of 2022.

Another familiar name, Fiat New Holland, assembled 8,325 tractors compared to 6,664 in the previous corresponding period.

Spearhead Machinery has appointed Scot Agri as its new dealer throughout the North and East of Scotland in a strategic move to strengthen sales activities. The brand says it has only scratched the surface in terms of what it has to o er Scottish customers.

Tyre maker BKT and Europe’s Tractor of the Year (TotY) awards organisation has renewed its partnership for another four years. The managing director of BKT Europe, Lucia Salmaso, and TotY president Fabio Zammaretti signed the new sponsorship deal.

Bailey Trailers has raised more than £36,000 for Breast Cancer Now by ra ling a special pink TB2 15t model that’s the first and only of its kind. The free prize draw was run in conjunction with Bailey’s UK dealers, and the winner was Ripon-based farmer and contractor Charles Waudby.

The Thompson family has run Ford and latterly New Holland Tractors for more than 30 years on its 100ha pig farm situated in the picturesque Moss Valley. FMJ visited to see the unit’s latest fleet flagship, a 2023

Oliver Thompson is a fifth-generation pig farmer who currently runs Povey Farm and Moss Valley Fine Meats with his parents, Stephen and Karen, full-time farm worker Sam Wainwright and their dedicated butchery team.

The business is situated in the beautiful surroundings of the Moss Valley on the border with South Yorkshire and Derbyshire, close to the city of Sheffield. The farm is home to 220 Large White and Landrace cross sows plus their offspring, while 100ha of arable land is used to grow feed wheat in rotation with winter barley and oilseed rape.

The Thompsons also run an

award-winning onsite butchery, Moss Valley Fine Meats, that produces more than 25 different varieties of sausages, pork pies and cooked hams. The operation also includes hog roast and catering facilities, while they also supply cuts of meat to the general public, restaurants and hotels, and are the only pig farm to have been awarded the “Made in Sheffield” mark.

For more than 30 years the Thompsons have remained loyal to Ford and New Holland tractors supplied by Platts Harris and more recently Russells from its Darley Dale depot.

“We’ve always maintained an excellent working relationship with

Above: The T6.180’s slimline steering column is simple to adjust and features a conveniently positioned shuttle lever.

the team at Darley Dale, most of whom have been there since the early days of Platts Harris,” says Oliver. “They’ve always provided us with an excellent trade-in deal on new tractors, and when we’ve encountered any issues its service and back-up has been second to none.

Below: The Thompson family has been running Ford and New Holland tractors supplied by Platts-Harris, and latterly Russells Darley Dale depot, for more than 30 years. This 2023 New Holland T6.180 Dynamic Command is the most recent addition to its fleet.

“Fortunately, other than the occasional minor niggle, we’ve never encountered any serious problems with the Ford and New Holland tractors we’ve operated during the past three decades.”

The Thompson family has run a whole host of compact six-cylinder New Holland tractors including a 100hp TS115 and a 127hp T6050 Delta that came equipped with New Holland’s 24-speed Dual Command transmission.

More recently, Oliver and his father Stephen, along with full-time farm

worker Sam Wainwright, have operated a high-specification 2012 New Holland T6030 Elite alongside one of the first 154hp T6.155s to be retailed in the area back in 2012.

The T6030 Elite was purchased as an ex-demonstration machine and was powered by a 6.7-litre six-cylinder turbocharged and air-to-air intercooled FPT NEF engine fitted with New Holland’s Engine Power Management (EPM) that boosted the 4.9t tractor’s horsepower up to an impressive 152hp. The Thompson’s T6030 Elite was also equipped with the 16F/16R Electro Command semi-powershift transmission that provided a top speed of 40kph.

“The T6030 Elite had a fantastic power-to-weight ratio and was very manoeuvrable too,” says Sam Wainwright. “It was ideally suited to pulling a New Holland 570 small square baler and flat eight bale sledge up some of the Thompsons steepest fields in the Moss Valley.

“The Elite specification Horizon cab was comfortable to spend a long day aboard and was loaded with lots of useful creature comforts including New Holland’s Comfort Ride cab suspension and additional work lights.”

“Since arriving at Povey Farm, the Thompsons’ new T6.180 has clocked 250 trouble-free hours”

Prior to commencing harvest last year, the highly regarded T6030 Elite made way for Oliver and Stephen’s newest fleet flagship, a 2023 New Holland T6.180 Dynamic Command that has now taken over most of the T6.155’s frontline tasks.

“In the past, we’ve normally part-exchanged tractors every three to four years,” explains Oliver. “However, when profit margins began to tighten within the pig industry, we chose to hang onto the T6030 Elite and T6.155 a little longer.

“Both tractors have served us well, and by the time we decided to move on the 11-year-old T6030 Elite last year, it had only clocked 3,300 hours and remained in excellent condition. This enabled us to obtain a decent trade-in price against our new T6.180 Dynamic Command.”

Since arriving at Povey Farm, the Thompsons new T6.180 has clocked 250 trouble-free hours with Oliver and Sam at the controls. It spent most

of summer 2023 corn carting, before moving onto spraying duties with a 1,200-litre Hardi sprayer equipped with 24m booms.

In between last Autumn’s inclement weather, the T6.180 also completed its fair share of slurry spreading with the farm’s 8,000-litre Marshall tanker, applied fertiliser with a Sulky twin-disc spreader and carried out all of the winter drilling with the Thompson’s immaculate mid-1980s 4m Bamlett drill.

This spring, the T6.180 will be expected to complete primary cultivation work with a set of trailed Ransomes discs, and share powerharrowing duties with the older T6.155 that’ll now play a crucial supporting role to its more

Left: Oliver and operator Sam Wainwright have been impressed with the specification and layout of the T6.180’s quiet 69dB(a) and spacious four-post Horizon cab.

Above: The T6.180 comes equipped with a 218-lit capacity fuel tank and a 31-lit AdBlue tank, as well as a useful factory-fitted toolbox.

Left: Oliver and operator Sam Wainwright have been impressed with the specification and layout of the T6.180’s quiet 69dB(a) and spacious four-post Horizon cab.

Above: The T6.180 comes equipped with a 218-lit capacity fuel tank and a 31-lit AdBlue tank, as well as a useful factory-fitted toolbox.

Below: The T6.180 comes equipped with the SideWinder II arm rest that features the IntelliView IV touch screen and CommandGrip joystick. The smaller advanced loader joystick is used to shift up and down through the 24 speed Dynamic Command transmission.

powerful and advanced younger brother.

“Since it arrived on our farm, I haven’t been able to fault its performance, reliability and efficiency,” says Oliver. “It’s the quietest and most comfortable tractor we’ve ever owned, and has more than enough power for tasks we will use it for. I’ve become a huge fan of New Holland’s Dynamic Command gearbox too.”

“It’s the quietest and most comfortable tractor we’ve ever owned”

New Holland added the six-cylinder T6.160 and flagship T6.180 tractors to its T6 range in November 2018. The four-cylinder turbocharged T6.145, T6.155, T6.165, T6.175, and T6 Methane Power make up the rest of the current range.

The Thompson family’s T6.180 is powered by a six-cylinder turbocharged 6.7-lit NEF engine developed by New Holland’s sister company FPT Industrial. It complies with Stage V emissions regulations; it produces 175hp at a leisurely

2,200rpm and 740Nm of torque at 1,500rpm.

“It’s an incredibly quiet and efficient engine that’s never overly stretched on any of the PTO-driven implements we currently own, even when working in our steepest fields,” says Oliver.

The four-post

increased number of options to match the correct gear to any given task without having to change ranges as often.

Below: Fifthgeneration pig farmer Oliver Thompson and farm worker Sam Wainwright have been impressed with the New Holland T6.180’s performance and reliability since it arrived at Povey Farm in July 2023.

Power is fed to the ground through New Holland’s award-winning Dynamic Command semi-powershift transmission that was first announced in 2017 and made available on the T6 range the year after. Dynamic Command was introduced by New Holland following an extensive customer research programme to sit between its four-step semi-powershift Electro Command transmission and its Auto Command CVT unit.

Moss Valley Fine Meats

Location Lightwood, North East

Derbyshire

Cropping 100ha of feed wheat, barley, spring and winter oilseed rape

Livestock 220 Large White and Landrace cross sows plus offspring

The Dynamic Command transmission’s 24 forward and 24 reverse ratios are arranged in three ranges of eight gears and are suited to heavy draft, PTO and haulage work. This configuration is designed to give the operator an

Dynamic Command can also be specified with 40kph or 50kph ECO modes for haulage to reduce fuel consumption. Other notable features of the transmission include steeringcolumn-mounted power shuttle, and the Dynamic Start/Stop function that enables the operator to press the brake pedal to bring the tractor a stop, and release it again to set off – all without using the clutch. This is particularly useful for loader work.

The Dynamic Command transmission also features a kickdown mode, enabling it to change down a gear automatically when additional acceleration is required. The transmission can also be set up to mimic a CVT gearbox using the tractor’s Ground Speed Management II system to automatically control engine and transmission speeds.

“It’s one of the smoothest and simplest transmissions I’ve ever operated,” says Oliver. “It’s easy to configure and provides you with precise speed control when drilling and spraying.

“The T6.180’s Transport

Power Management system, that’s fitted as standard on Dynamic Command tractors, also creates a useful flat power curve to maintain forward speed and improve fuel efficiency when pulling loaded trailers uphill.”

Oliver and operator Sam Wainwright have also been impressed with the specification and layout of the T6.180’s quiet 69dB(a) four-post Horizon cab.

“It’s been very well thought out and is the most spacious cab I’ve spent a day aboard,” says Sam.

Externally, the Horizon cab comes equipped with 12 LED work lights and adjustable two-piece mirrors, while inside there’s a movable steering

Top: New Holland’s sixcylinder 175hp T6.180 was added to the top end of its T6 range in 2018. This example is equipped with the award-winning 24F/24R Dynamic Command semi-powershift transmission.

Above: The T6.180’s Horizon cab comes equipped with New Holland’s Dynamic Comfort seat that features lumbar support, heating controls and a swivelling back rest.

column, sun visor and New Holland’s Dynamic Comfort seat that features pneumatic lumbar support, a swivelling back rest and two-stage heating controls. A leather buddy seat is also fitted as standard.

The Horizon cab also comes equipped with the SideWinder II armrest featuring the CommandGrip joystick that provides Oliver and Sam with various linkage controls as well as a forward/reverse shuttle rocker switch and controls for setting up the Headland Turning Sequence II management system.

Alongside is the advanced loader joystick that incorporates the T6.180’s transmission up and down buttons, alongside the controls for a front-end loader. The Thompsons specified their SideWinder II console with mechanical remote hydraulic levers rather than the higher-specification electro-hydraulic paddles.

“Despite appearing old fashioned, the hydraulic levers fall easily to hand and aren’t cumbersome to use at all,” says Sam.

The Thompsons T6.180 is also equipped with the 26.4cm IntelliView IV touchscreen performance monitoring terminal that incorporates New Holland’s Precision Land Management (PLM) telematics.

“I’ve really enjoyed analysing the

tractor’s performance through the Intelliview screen,” says Oliver. It’s easy to navigate and provides you with a lot more detail and feedback on the tractor’s behaviour, enabling you to make informed adjustments to improve its efficiency on the move.”

The T6.180 is fitted with a 3.2t capacity front linkage and a Category 3 rear linkage capable of lifting an impressive 7.9t.

“The tractor’s front and rear linkages are well made and haven’t been under any great stress,” says Oliver. “They provide ample capacity for all the implements we use with the T6.180 each day.”

Oliver and Stephen anticipate keeping the T6.180 for four to five years and have been very impressed with its performance, comfort levels and reliability so far.

“It’s a fantastic mid-range tractor loaded with lots of useful tech that’s not overly complicated to use,” says Oliver. “Its compact size is ideally suited to the confines of our yard and the narrow tracks that link most of our land together, while its 6.7-litre engine provides us with plenty of power to negotiate our steepest fields in the Moss Valley safely and efficiently.”

ACKNOWLEDGEMENTS Thanks to Oliver Thompson and Sam Wainwright for their time and assistance with this feature.

We visit Mike Collins Agri, the contractor running the first RT ProArm hedgecutter conceived and built in Ireland by RT Sales WORDS AND IMAGES EOGHAN DALY

Being the first purchase of any newly introduced machine often attracts a degree of hesitation with a tendency to wait until the longer-term performance and reliability aspects of its design are established. However, for County Cork-based Mike Collins Agri, being the first to purchase the all-new Irish-designed and manufactured RT ProArm from RT Sales wasn’t viewed as having any element of risk thanks to the innovative features it presents coupled with the considerable experience of the team behind its development. As one of the few machines on the market developed by end users, the RT ProArm was subject to considerable advance testing and much design refinement before its official launch last year.

With prior knowledge of the machine’s looming introduction, Mike Collins

had deferred his hedgecutter purchasing to coincide with the availability of the RT ProArm. This decision was based on his early assessments of the initial machines operated as part of its designer’s contracting operation, followed by a period of operation of a prototype machine that left a lasting impression.

Impressive prototype

“I’d tested the prototype and was really impressed by it,” he says. “At that point, I was looking for a replacement for my ArboCut hedgecutter and waited until the RT ProArm machine became available. It was delivered in August 2023 and I’ve already worked it for more than 450 hours. During that time, it’s been first rate and I can’t fault its design or performance in any way.”

Not only was Mike the first

purchaser of a production RT ProArm machine, he was also the first to put RT Sales’ JA2122T telescopic boom model into service.

Presenting individual thinking when it comes to the design features adopted, the RT ProArm presents many unique traits, which is deeply suggestive of how the company is eager to innovate instead of mirroring existing manufacturers’ designs. This has led to the emergence of a machine with several groundbreaking features starting with the process of mounting the hedgecutter on the host tractor.

“RT Sales is eager to innovate instead of mirroring existing manufacturers’ designs”

RT ProArm JA2122T

Working reach 6.7m

Head type 1.2m flail Flails 24

Head rotation

Unlike other hedgecutter designs that necessitate the inconvenient fitting of brackets to the host tractor’s main frame, which depending on the tractor’s design can be a difficult and in many ways awkward task, the RT ProArm adopts a totally different

240 degrees Controls Proportional electronic joystick

Operating weight (including head) 1,530kg

Power requirement 70hp or more Oil tank capacity 180 lit

patented concept that involves the replacement of the pickup hitch’s hook by a specially designed anchor block for two adjustable stabilising links that contribute to anchoring the hedgecutter to the tractor in a stable fashion.

With this anchor block fitted to the host tractor, it’s merely a case of attaching the hedgecutter to the three-point linkage and tensioning the stabilising links to the appropriate level before raising the hedgecutter clear of its support legs, which are then easily removed. By linking the hedgecutter to the tractor via the pick-up hitch, it draws stability from the strongest point of the rear of the tractor, while the low set anchoring position also contributes greatly to

Left: Immense thought has been invested in boom construction, geometry and hose routing to ensure long-term service.

Right: The electric canbus joystick controls all machine functions and has a very user-orientated profile for ease of use.

Below: The machine presents a compact transport position and doesn’t impede rearward visibility during road travel, especially towards the outer side.

reducing the centre of gravity. This approach also means the hedgecutter is easily mounted on any tractor within the owner’s fleet.

Stabilising system

just a case of mounting the control joystick to the armrest in the cab and the machine is ready for work.”

Below: The machine presents a compact transport position and doesn’t impede rearward visibility during road travel, especially towards the outer side.

“The build quality of the machine shows real strength without being too heavy”

“The design of the stabilising system for mounting by using the pick-up hitch works very well and means the RT hedger can be mounted on any of our tractors not just the 2005 registered Valtra T120 it’s most commonly paired with,” says Mike. “My other Valtra tractors have Dromone pick-up hitches and the lads at RT provided me with an anchor block to suit this design on to which the stabilising arms are linked. Then it’s

Nevertheless, it’s not just an alternative mounting arrangement and the added flexibility it brings that set the RT ProArm apart from others as its design has a range of other fundamental differences in many key areas. A theme of maintaining simplicity and the use of proven easily accessible components runs through the machine, while the essential durability of construction in the areas that matter most is ever evident.

Mike Collins Agri Location Freemount, County Cork Main activities Mowing, raking, baling, slurry spreading, reseeding, low-loader work and hedgecutting

“Looking at the build quality of the machine, it shows real strength while it still isn’t too heavy,

The hydraulic valve chest is identical to that

a

Below inset: The stabilising system is unique to RT and requires no brackets on the tractor chassis. Instead, a special anchor block is fitted to the hitch and two stabilising arms linked to it and tensioned to pull the hedgecutter down to the strongest part of the host tractor.

this particularly impressive build strength are the mainframe and boom base, while the boom itself reflects a sensible design with positive hose routing evident. However, the real test of the machine is in its cutting capabilities and the performance of its hydraulics to deliver effective operation and oil-cooling properties.

proving it has durability in the right places,” says Mike. “The Valtra T120 it’s normally mounted on isn’t a big or overly heavy tractor and is still capable of working very well with this hedger despite its impressive reach.”

Among the areas benefitting from

Looking in greater detail at the machine’s hydraulics, the system centres on a proven gearbox that propels the hedgecutter’s main pump and secondary hydraulic pumps. Hydraulic oil is pumped through a high-pressure filter and into a PDG valve chest that’s controlled by the electric canbus joystick from the tractor cab. The system’s return line from the head goes through a radiator with a thermostatically controlled fan with

RT Sales, the company behind the RT ProArm hedgecutter range, has more than 20 years’ experience of the operation of such machines as part of its contracting operation, RT Hedge and Tree Cutting. From its base just outside the County Kerry town of Castleisland, founders Johnny Reidy and his son-in-law Padraig Teahan run a sizeable fleet of hedgecutters working for local authorities, landowners, utility companies and forest owners. Its experience of hedgecutters also extends to a sales role as it has been a dealer for the Irish-built ArboCut range of machines for many years. Through this considerable engagement with the industry, RT Sales has amassed much practical experience of running machines from various manufacturers and became aware of the shortcomings and inadequacies of a range of design features. This experience was put to good use when it came to designing and building its own machine with a range of innovative new features. With the testing of initial prototype machines ongoing for more than four years, it’s clear that consideration has been given to this vital development aspect. As the first units sold now begin to prove their long-term e ectiveness with early users, RT Sales is concentrating strongly on extending its range of machines with active product development underway to ensure it can o er a complete range of machines to cater for every operator’s needs from smaller farmer-orientated units right up those for the most demanding contractor.

In addition, the company founders believe a hedgecutter should be more versatile than just completing hedge and verge-cutting operations based on the relatively short operating season imposed on their use in most applications. Consequently, they’re exploring the possibility of developing other attachments that can be used to broaden their application range and transform a seasonal machine into a unit with year-round uses.

With the company devoting its energies towards product promotion, testing and future development, manufacturing is completed by County Kerry-based Torc Precision Engineering. It has built considerable experience in steel fabrication and precision engineering since it was established in 1979, and this shines through in the quality of the RT ProArm.

oil subsequently fed back to the 200-litre tank before passing through another filter on the circuit. All components that combine to make up the system are sourced from a proven local source, Cork-based Hi-Power Hydraulics, with the valve block assembly being identical to that used on McHale balers. In addition, the valve block can be controlled manually from outside, bypassing the control joystick, allowing the boom and head to be folded to the transport position in the event of a problem such as a wiring malfunction – a feature applauded by Mike.

“My first season has been very successful with the RT ProArm”

“The machine is very simple and a lot of things have been thought of in its design that shows the people behind it have hands-on experience with hedgecutters,” he adds. “It could be a big advantage if there was ever a problem with the machine by being able to fold the boom and head and move it back to the workshop for repair.”

Intuitive design is also reflected in the machine’s flail head that has a cutting width of 1.2m. Since the bearings are located on the outside, the rotor facilitates a full bank of 24 flails, instead of the usual 22, to achieve the

cutting width. Having the bearings on the outside also provides immediate and direct access for replacement. In addition, the rotor is secured by just five bolts that ease the process of its removal should repair work be necessary.

Mike uses F10 flails instead of the more aggressive F14, but remains impressed by the machine’s results, which he puts down to the head design.

“I like the fact it will be easy to work on if there’s a problem in the future,” he says. “But it also performs very well whether handling light or heavy material.”

Another factor that assists in the user-friendliness of the machine is the contoured in-cab joystick selected for use with the RT ProArm hedgecutter. Its profile ensures it gives a positive grip while it requires minimal effort to receive a response when contrasted with servo joysticks. Two thumb rollers are integrated into the upper face of the joystick with one activating head tilt while the second fulfils slewing motions of the boom. A click diverter button switches head tilt motions to control of the telescopic extension.

Mike’s RT ProArm JA2122T telescopic boom hedgecutter has performed flawlessly during its first six

Above inset: Reassuringly strong construction and high levels of workmanship are manifest in the machine’s build quality.

Right and above right: The head gives a full 1.2m cutting width and employs 24 flails instead of the more normal 22. This is made possible by positioning the bearings on the outside, improving access considerably.

Below: Mike Collins using his RT ProArm JA2122T hedgecutter on a 2005-registered Valtra T120 that has worked in excess of 20,000 hours on its original engine.

months of operation with this County Cork contractor.

“My first season has been very successful with the RT ProArm, and I can honestly say there’s nothing I would change about its design as it’s a first-class machine to operate and can get through work at a great pace,” he says. “What’s even better is being able to buy a quality Irish-built machine made by people who know the demands of contracting through their involvement with the job.”

EXCLUSIVE OFFERS EXTENDED WARRANTY PROFESSIONAL TRAINING PERSONAL ASSISTANCE

*Unlock exclusive perks! Scan the QR code for members-only access to product promotions, and a 2-year warranty extension on new radial Trelleborg agricultural tyres. Stay ahead with custom training and get personalised advice to maximize your Trelleborg tyres. Register now for a world of benefits! *

As ever-increasing global demand is likely to top US$6 billion in the next few years, compact wheeled loaders may be relatively small in stature, but are big business. Traditionally, the market has been largely driven by the needs of European customers, but their popularity is spreading, particularly in North America. Extremely versatile machines, they’re either used with a bucket and/or pallet forks on general loader work, or as a tool carrier to host a range of hydraulically-powered attachments.

Bobcat’s first in-house designed and built compact wheeled loader –the high-spec 5.1t/68hp L85 – was launched in 2021. In 2022 the firm

“Even with an overflowing bucket of heavy clay at full height, the new bobcat L95 remained stable”

introduced the L75 Value model, weighing 4.6t and powered by 55hp engine, equipped with the same 0.80cu.m bucket as the L85.

At Bobcat’s most recent Demo Days

event in the Czech Republic, the company previewed its largest compact loader to date, the L95 Premium, a 5.4t unit powered by a 75hp engine. With an operating weight of 5.4t and offering a rated bucket tipping load of almost 3.4t, the stylish Bobcat machine, which is at the heavier end of this category of compact equipment, certainly looks the part.

Access to the falling object-protected (FOPS level II), air-conditioned cab is easy, as the door is vast, or rather the doors. There’s an offside door of the same proportions, handy if the operator wants to speak to anyone on that side, but with steps and handrail provided only on the nearside. For those who prefer to keep one or both doors open, they fold back and lock into place, well protected from any accidental damage.

With no joystick, a flip-up armrest and an adjustable steering wheel, there’s little to hinder access into the flat-floor cab from the traditional left-hand side of the machine. An orange-topped compartment, conveniently located to the left of the seat, opens to reveal a surprisingly large storage box.

The first thing that struck me was

how much glass there is. Both large doors are made from a single pane, which makes for excellent visibility to the sides. The front screen is slightly curved back, which I discovered allows a much better view of the bucket when it’s fully raised, without the need to lean forward.

The fully adjustable, air-suspended seat features an integrated multifunction joystick on the right, which rises and falls with the operator, as the seat is doing its job when the machine is travelling over rough terrain, to ensure full control at all times.

The complex-looking joystick turned out to be easy to use and, above all, comfortable to operate. Raising the loader arms and tipping the bucket is performed by the industry standard joystick control pattern. The direction of travel rocker switch is located on the front of the joystick, operated by your index finger.

The top of the joystick has buttons for: the diff-lock; low- and high-speed travel; the loader arms’ float function; and auxiliary hydraulic flow control. To the operator’s right there are three banks of soft-touch switches for a multitude

of functions including: lights; windscreen wipers; flashing beacon; and the heating element in the seat.

Engine speed can be controlled by a rotary hand dial that’s part of Bobcat’s smart Flex Drive feature. Intended to speed up the operation in certain applications, it features an engine auto-idle function. However, I opted to use the traditional foot throttle.

Simple cab

I really loved the simplicity of the cab, which is all very clean-cut, workmanlike and user-friendly. The 5in display screen is minimal, but extremely practical and doesn’t obscure the operator’s vision. It also doubles as the reversing camera

screen, which is automatically engaged when reverse is selected. A familiar jog dial, as we so often see in excavators, is used to access the various menus, including the ability to alter settings such as auto ride control and hydraulic oil flow. Having settled in the cloth seat,

“With global demand likely to top six billion dollars, compact wheeled loaders are big business”

adjusted it and the armrests, and popped on my lap belt, it was time to give the machine a bit of a workout. A key is used to initially start up the machine, thereafter, red and green buttons on the right-hand console are used as a quick and easy way to stop and start it.

This recognises that in many applications for a compact loader, the operator will frequently dismount, typically to assist those working on the ground.

The 75hp compact loader has a two-speed, electronically controlled hydrostatic transmission that provides a maximum road speed of 40kph, although on the demo ground I was only ever going to need first gear.

The bucket position indicator on its cylinder lets you know that it’s level. The L95 displayed plenty of grunt and breakout force as I drove the bucket into the pile of dirt, then curled it back as I powered forward to retain the material. Selecting reverse on the joystick, the feed from the rear camera popped up on the screen, but the view through the large rear window was good and required very little effort.

Below: The huge door provides easy access into the cab and can be locked back, out of harm’s way if required.

Below right: Bobcat’s latest compact wheeled loader is the L95, a 5.4-tonner powered by a 75hp engine, due to go into production anytime now.

Over the course of this workout, I was impressed with the ride quality and the overall stability of the machine. Even with an overflowing bucket of heavy clay at full height, the new Bobcat L95 remained stable. The layout of the controls and the good visibility from the seat contribute to a comfortable and relaxed operating experience.

The L95 is a lively machine, quick, nimble and powerful, at the larger end of the compact wheeled loader scale. I would be quite happy to spend a few shifts on, and couldn’t fault it in any way.

These larger machines follow the conventional wheeled loader layout of cab and engine on the rear part of the articulated chassis, with the loader arms on the front section. It feels more grown up and logical to operate than some of the smaller compact loaders, where the cab is mounted on the front section of the chassis, which is fine, but can take some getting used to.

Assisted by two gas struts, the stylish, rear one-piece bonnet raises up to reveal superb access to all the engine components. This example was shod with the much-applauded Michelin XMCL 400/70R20 tyres, but di erent options are available to suit various applications across many segments of the market.

The loader arms feature twin lifting rams neatly located on the inside frame, together with the single ram for the bucket tipping function that forms part of a classic wheel loader Z-bar linkage. The demo machine sported a larger than standard 1.0cu.m bucket, mounted on Bobcat’s Power Quick-Tach attachment pick-up system. This has been redesigned to simplify and protect the hydraulic connections from any potential damage. It can be used to share Bob-Tach attachments with wheeled and tracked skid-steer loaders.

The standard-flow auxiliary hydraulics are designed to power attachments such as a multi-function bucket, a broom and a sweeper. This example was fitted with high-flow hydraulics with quick-connect couplers mounted on the inside of the nearside loader arms. This provides 100 lit/min at 225 bar to feed oil-hungry attachments such as planers, flail mowers, cutting wheels and snow blowers.

The Tomlinsons bought this 90hp John Deere 6300 new in 1996 to replace a 1983 two-wheel-drive Ford 6610. Originally used for drilling, it now completes all of the business’ baling with a 2019 New Holland BC5070.

“The 115-150hp New Holland and Case IH tractors we run are reliable, economical and easy to maintain”

The Tomlinson brothers farm 200ha of heavy clay land in North Nottinghamshire with a trio of modestly powered six-cylinder Case IH and New Holland tractors free from technological wizardry and touch screen terminals. Farm Machinery Journal travelled to Beckingham to find out more about their fascinating fleet.

WORDS AND IMAGES DAVID LALEY

You’d think farming some of the heaviest clay land close to the River Trent would demand a significant amount of horsepower to make the most of it. However, the Tomlinson brothers, who grow 200ha of oats, barley, wheat and beans at Wood Farm, near Beckingham, are proof that you don’t necessarily require a sledgehammer to crack a nut.

Robert Tomlinson and his older brothers Mike and John currently run a bog-standard 175hp Case IH Puma 150 as their front-line tractor that’s used to complete all of their ploughing and cultivation work alongside a pair of modern classic 132hp and 115hp

New Holland TM125 and M115 tractors.

“We’ve learnt over the years that the heavy land we farm tends to be less forgiving on more advanced higher horsepower models at the top end of manufacturer’s tractor ranges,” says Robert. “Their components are designed to work at faster speeds approaching their maximum tolerances at higher temperatures leading to poorer reliability.

“We prefer to run rugged entry-level models equipped with large-capacity, low-revving, six-cylinder, normally aspirated and turbocharged engines at the lower end of their power scale matched to simpler transmissions and hydraulic systems.

“Although they’re not loaded with the latest creature comforts, the

Above: The Tomlinsons’ 300hp New Holland CX5090 has little trouble harvesting 200ha of oats, barley, wheat and beans each year on their ring-fenced arable unit in North Nottinghamshire.

115-150hp New Holland and Case IH tractors we run are reliable, economical, easy to maintain and provide us with sufficient horsepower to establish our arable crops successfully with a wide range of mounted machinery.”

The Tomlinsons began farming about 80 years ago when Robert’s grandfather John, a coal miner by trade, invested in a smallholding near Mansfield Woodhouse, Nottinghamshire. He then moved his family to a larger farm at West Bretton, near Wakefield, before having the opportunity to purchase Top Farm near Beckingham in 1959, which he ran with his son Fred.

Above: This 132hp New Holland TM125 Classic arrived new at Wood Farm in 2002 to replace a temperamental Track Marshall 155. It’s now clocked 9,000 hours and still carries out its fair share of cultivation work.

Shortly afterwards, the Tomlinsons purchased a 60ha farm near Epworth, North Lincolnshire, that remained in their possession until 1967, when they sold it to fund the purchase of Wood Farm that was situated next door to Top Farm at Beckingham.

“My father Fred wanted my brothers and I to grow up on the same ringfenced farm together, and ensure we could all make a living from the land in the future,” says Robert. “The combined hectarage of Top Farm and Wood Farm has provided us with an immense amount of stability over the years, and we’ve been able adapt our crop rotation and diversify the business successfully without treading on each other’s toes or falling out.”

Fordson and Ford tractors were the preferred choice at Wood Farm during the 1960s and 70s, with the vast majority of them coming from local dealer Harris of Epworth.

“The first tractor I can recall operating was a late 1950s Fordson Dexta that we still use on the farm for spreading slug pellets,” says Robert. “During the 1970s we also ran a trio of 67hp Ford 5000s before they were replaced with a pair of more modern 78hp Ford 6600s equipped with Q cabs.

Below right inset: Robert Tomlinson enjoys maintaining and operating the simple rugged tractors and equipment he runs with his older brothers Mike and John on their 200ha

“In 1983 we bought a new Ford 6610 followed by our first larger six-cylinder tractor, a two-wheel-drive 95hp International 955XL supplied by Platts’ Doncaster depot. This tractor remained on our farm for 18 months before it was swapped for a similar 956XL that we still own and use for hedge cutting.”

Below: This basic-specification

Case IH Puma 150 arrived at Wood Farm new in 2018. Its main roles are ploughing, power harrowing and pulling a 2.5m Watkins Tri-Till one-pass cultivator.

During this time, Wood Farm was home to a suckler herd and the Tomlinsons also diversified successfully into road haulage, purchasing their first lorry, a Leyland Clydesdale, in 1980. The cattle were sold off in 1985 as their transport business, known as JF Tomlinson & Co,

continued to expand. Robert and his brothers currently run three DAF, Iveco, and Scania rigid and articulated lorries that carry out bulk haulage work within the agricultural sector.

In 1986, the Tomlinsons purchased their first six-cylinder, four-wheeldrive tractor, a 110hp Massey Ferguson 2640, to complete all their subsoiling and ploughing. This was joined in the mid-1990s by a much rarer 112hp articulated Massey Ferguson 1250 that remained on their farm until 2018, when it was traded in against a new Case IH Puma 150.

“The 1250 was a lovely tractor, but we only really used it for two years before retiring it to our collection of classic tractors because we were concerned our heavy land might cause a serious component failure to an incredibly rare and desirable tractor,” says Robert.

In 1996 the Tomlinsons ageing two-wheel-drive 1983 Ford 6610 was replaced with a 90hp four-wheel-drive John Deere 6300 supplied new by RBM-Agriculture at Clarborough. The 6300 completed all of the Tomlinsons drilling with a trailed Massey

Right: John Tomlinson says the 1999 New Holland M115 he operates is ideally suited to the 4m KRM Sola 799 tine drill they acquired in 2010. arable farm in Nottinghamshire.Ferguson 30 until 2010, when they invested in a much heavier and wider 4m KRM Sola drill.

Nowadays, the 12,000-hour 6300 carries out all of the family’s spraying and also powers a 2019 New Holland BC5070 baler each summer to produce several thousand small square haylage and straw bales for customers throughout England and Wales.

The Tomlinsons also briefly operated a reconditioned Track Marshall 155 yoked to a six-furrow Dowdeswell DP1 plough that suffered from a litany of driveline problems and was swiftly disposed of in favour of a 2002 New Holland TM125 Classic equipped with a 132hp 7.5-litre six-cylinder turbocharged PowerStar engine.

“We purchased the TM125 Classic new from Platts-Harris and it’s been one of the most impressive pulling tractors we’ve ever ran,” says Robert. “The 7.5-litre PowerStar engine provides you with an enormous amount of torque backup when operating PTO-driven implements, while its closed-centre hydraulic system and 6.8t capacity rear linkage is ideally suited to most of the heavier mounted cultivation kit we run.

“We originally used the tractor with a four-furrow Lemken reversible plough and a 3.5m Maschio power harrow, before we bought a wider 4m Kuhn HR last year to run behind our more powerful Case IH Puma 150 CV. It has now clocked 9,000 hours and still completes its fair share of primary cultivation work, discing, subsoiling and corn carting.”

Following the business’ decision to invest in a new 4m wide KRM Sola tine drill in 2010, the Tomlinsons required an additional longwheelbase six-cylinder tractor to lift and pull it. They found just what they were looking for in the shape of a 1999 115hp New Holland M115 in the yard of former Fiatagri dealer Lyons of Gainsborough, where the drill was also sourced.

“It was originally a terracottaliveried tractor, but the dealer had struggled to sell the tractor so he decided to replace and repaint all of its panel’s blue in a bid to make it more appealing to potential customers and increase its resale value,” says Robert. “It still has the original brown interior, and I recently acquired a terracotta bonnet so I can return it to its original livery one day.”

The 9,000-hour M115 is powered by a normally aspirated 7.5-litre PowerStar engine that’s matched to New Holland’s 40kph 18F/6R Range Command partial powershift transmission.

“Its rugged hydraulics and long wheelbase make it the ideal tractor for lifting and pulling the KRM drill across either cultivated or ploughed and power harrowed seedbeds, while the Range Command transmission is very smooth,” says John Tomlinson.

In 2018, the Tomlinsons’ modern classic New Holland tractors were joined by a new Case IH Puma 150 purchased from local dealer Farmstar near Doncaster. The Puma became their frontline ploughing, powerharrowing, and primary cultivations tractor and is equipped with an almost identical 18F/6R transmission that’s fitted to the older M115.

The Puma 150 is powered by a 6.7-litre six-cylinder turbocharged FPT NEF engine that produces 150hp as standard and boosts up to 175hp at just 2,200rpm when required. The Puma’s Category 3 rear linkage is capable of lifting an impressive 8.3t and features three mechanical remote valves.

“It’s a very basic tractor inside and

out, but does everything we require of it reliably and efficiently,” says Robert.

“There are very few electronic systems that can malfunction on the tractor, nor are there any unnecessary and complicated screens or terminals to get confused by.

“It’s a brilliant ploughing tractor and handles our five-furrow Lemken reversible plough with ease and is also ideally suited to operating our new heavy-duty 4m Kuhn that arrived in spring 2023. It’s also the only tractor we own capable of maximising the capability of our 2.5m Watkins Tri-Till one-pass stubble cultivator on our heavy land.”

All three of Robert, Mike and John’s frontline tractors are fitted with standard-size wheels and tyres so they can all be used to plough in-furrow when necessary. In order to spread their weight over a wider

Above and above inset: Despite being repainted blue during its lifetime and fitted with a blue seat the M115’s original brown interior trim remains intact.

Right: The Tomlinsons five-straw-walker New Holland CX5090 combine is powered by a 6.7-lit six-cylinder turbocharged FPT NEF engine matched to a three-speed hydrostatic transmission. It also comes equipped with an 8300-lit grain tank and a 6m header.

Left inset: This 1999 New Holland M115 had its original terracotta livery changed to blue by dealer Lyons of Gainsborough, hoping to make it more appealing to potential customers. Robert hopes to return it to its original colour scheme.

surface area, they’re equipped with dual wheels when cultivating, power harrowing and drilling during the autumn and spring.

“Aside from 4ha we own in Beckingham, all of our land is ring-fenced between Wood and Top Farm, so there’s no issue with keeping our frontline tractors on dual wheels

“Dual wheels are fitted to the tractors for cultivating, power harrowing and drilling”

The Tomlinsons replaced an old, trailed Massey Ferguson 30 drill in 2010 with this new KRM Sola 799 tine drill from dealer Lyons of Gainsborough, which also supplied the family with the second-hand New Holland M115 that lifts and pulls it.

JF Tomlinson & Co

Location Beckingham, Nottinghamshire

Cropping 200ha oats, wheat, barley and spring beans

Frontline Fleet

● 2018 Case IH Puma 150 CV

● 2014 New Holland CX5090

● 2012 Manitou MLT627 Turbo

● 2002 New Holland TM125

● 1999 New Holland M115

● 1996 John Deere 6300

when they’re busy cultivating and drilling,” adds Robert.

Harvesting is currently carried out by a 300hp five-straw-walker New Holland CX5090 combine equipped with a 6m header and 8,300-litre grain tank that was bought new in 2014 from Platts Harris’ Tuxford depot.

“We bought it to replace an ageing 190hp New Holland TX62 equipped with a 5.2m header,” says Robert. “It was the first new combine we’d bought since my parents purchased a Ransomes Crusader in 1971.

“From the late 1970s, we began running second-hand New Holland combines, starting with a 105hp 1530 before this was swapped for a more modern 116hp 8060 in 1983. We then ran a 155hp New Holland TX32 equipped with a 4.5m header prior to the TX62 arriving in the early 2000s.

“Our CX5090 is significantly more comfortable to operate compared to the TX62 thanks to its larger Discovery

III cab that’s well laid out and provides you excellent visibility.”

Materials handling at Wood Farm is carried out by a Manitou 627 Turbo telehandler bought new in 2012 to replace an old Manitou rough terrain forklift that remains in the fleet today.

The 627 is powered by a 100hp four-cylinder turbocharged Perkins 1104C matched to a bulletproof four-speed torque converter transmission.

“Like all of the equipment we run, the Manitou isn’t the most advanced or sophisticated telehandler, but it does everything we ask of it on daily basis reliably and economically and, like all three of our frontline tractors, it’s simple to maintain and operate.”

ACKNOWLEDGEMENTS Thanks to Robert, Mike and John Tomlinson for their time and assistance with this feature.

Above: The M115’s front linkage is equipped with 450kg of weights to help keep its nose on the ground when lifting the fully loaded KRM Sola drill. Above: John Tomlinson is pictured applying fertiliser in spring 2023 with the M115 and an Amazone ZA-M 1001 twin-disc spreader.

LAMMA 2024 didn’t disappoint, with the return of big names and lots of new equipment on show. Visitors flooded the halls on both days, keeping exhibitors reassuringly busy

WORDS AND IMAGES KEN TOPHAM AND MICK ROBERTS

After a few of the big manufacturers took a LAMMA break, it was great to see some more of these brands back at the show. CNH made a splash, bringing the new CR11 combine. JCB also populated a good area with kit. There were more than 40,000 visitors over the two days, and the halls were busy.

After Agritechnica, the worry of slim pickings of new machinery to look at were quickly subdued. There were lots of new machines and innovations. UK and global companies made the show great, putting plenty of effort in to engage with visitors and press alike.

We can’t not mention the big-bang items. Massey Ferguson and Valtra brought their new flagship tractors to LAMMA, the first UK showing of these AGCO machines. Fendt didn’t bring a 600 series over, but instead wrapped a Gen 7 720 in gold, to celebrate 50 years of Fendt in the UK.

The vibe around the halls was very positive, with busy stands

throughout the two days. After a bit of post-Covid lull, LAMMA seems to be back, bigger than ever. We’ve tried to show a balanced range of equipment, there were new offerings to satisfy almost every size and type of UK farm.

Back with a bang, JCB previewed a new high-reach loader, the 542-100. It’s ideal as a straw contractor’s machine, with 9.8m of reach and 4.2t of lift. The new loader will be offered in the familiar specs: AgriSuper with 130hp; AgriXrta at 150hp; and AgriPro with 170hp and a 50kph option.

Not just a bulked-out existing loader, the

new machine has a redesigned chassis and is fitted with wider axles to improve stability. The new loader can be fitted with air brakes, a pebble guard on the top of the roof and a windscreen guard. A weighing system is also optional, connected to LiveLink to document the day’s work. JCB also had its new bale grab fitted to the 542-100. This features an integrated side-shift of 100mm.

The latest model from Polaris is the XP Kinetic, an electric side-by-side that may appeal to operations where the vehicle is used in a business where short work periods are the norm and it returns to

base often so it can be plugged-in ready for the next job.

Built on the same chassis as its fuel-based stable mates, the Kinetic can carry 567kg in the rear box, and tow 1,134kg. There are three user-selectable drive modes: Eco+, Standard and Sport. Batteries come in 14.9 and 29.8 kW options.

The model is an addition to the rest of the range as Polaris understands that diesel or petrol engines still offer the most practical solution for many farming businesses.

Last autumn, Case IH launched the Quadtrac 715. The uprated model received a larger engine and is now fitted with the Cursor 16 power unit. The rest of the tractor has been uprated to cope with the increased output. The drive wheels are larger so that six drive lugs are engaged. The undercarriage is longer and the idlers are now bolt-on modular units.

The transmission has upgraded to take more power, as has the three-point hitch, which no longer derates the engine if in use. The fuel tank and AdBlue storage have also seen increased capacities; the DOC pack has been reduced in size.

As well as the obvious aesthetic change, there are improvements throughout the Quadtrac including lighting rails on the side of the cab.