ADVERTISING PUBLICATION

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION

In cooperation:

PUTTING CIRCULAR ECONOMY INTO PRACTICE Circwaste project makes circular economy concrete

The magnet of a large generator is worth recycling page 8 Map-based service shows the quantity and location of biomass page 10 Golli service has a new feature that reduces product waste page 12

The former CEO of the OP Banking Group

Reijo Karhinen:

“We are facing a huge change”

2

An Independent Supplement by Mediaplanet

IN THIS ISSUE:

EDITORIAL

2 Editorial: Finland is becoming a leading country for circular economy 4

Let’s use our natural resources wisely

Reijo Karhinen: Companies are facing a huge change

6 Sampaanalanlahti minimized climate emissions in industrial construction 7 A new digital marketplace for surplus materials from construction 8

The aim is to make Finland a model country for circular economy. Succeeding in that depends a lot on business development.

The rising price of rare earth metals prompted the idea of recycled magnets

More use of biogas in transport in Central Finland

A food waste reduction roadmap is prepared in in Southwest Finland – a unique project on a European scale

12

The popular Golli delivery service has a new feature

Challenge Prize – a recognition for those working with circular economy

Environmental education path introduces young people with more sustainable patters of consumption

13

Collaboration provides support and expertise to regional administration, businesses and residents

14

The revision of the Waste Act speeds up the transition towards a circular economy

15 Regional monitoring of the circular economy is developed in co-operation with businesses, municipalities and other stakeholders The government subsidy for projects in the circular economy

Publisher: Finnish Environment Institute (SYKE) Publication date: 14.9.2020 Editor in Chief: Leena Rantajärvi (SYKE) Editorial Committee: Tuuli Myllymaa (SYKE), Hanna Savolahti (SYKE), Leena Rantajärvi (SYKE) Editorial staff: Tarja Sinervo, Anna Kuronen, Laura Vasile (Mediaplanet) Layout: Emmi Hanninen (Mediaplanet) Cover Photo: Kai Widell (SYKE) Project graphics and logos: Satu Turtiainen (SYKE)

facebook.com/Resurssiviisaus @circwaste Please recycle this magazine

PHOTO: KAI WIDELL

10 Map-based service shows the quantity and location of biomass

ADVERTISING PUBLICATION

M

ainstreaming circular economy is one of the top priorities of the Finnish government. The aim is to find solutions to the over-consumption of natural resources, to combatting climate change and to preserving biodiversity, and doing all this in a way that creates both prosperity and new sustainable business, in which economic growth is less and less linked to the use of natural resources. The transition to circular economy Tuuli Myllymaa Project Leader, The requires a systemic change that starts CIRCWASTE project, with product design, covers the design Finnish Environment of production processes and extends to Institute a new kind of consumer behaviour. What is problematic in terms of sustainability are cheap, short-lived and low-quality products produced at the expense of natural values from virgin natural resources and under unethical working conditions. Finland has the opportunity to be a pioneer in sustainable product and service design and production. The recipe is clear: we need high-quality and long-lasting products that do not have adverse effects and are repairable as well as produced from recycled materials, with low emissions, with environmentally friendly processes and in a way that does not disadvantage employees. Digitalisation has also been identified as a significant part of the solution: there is still room for many easy-to-use and time-saving service concepts that could inspire us all to try out rental, leasing and turnkey services.

Companies benefit from the Circwaste project The Circwaste project, coordinated by the Finnish Environment Institute, promotes the implementation of strategies and goals related to circular economy and waste sector. It provides information on circular economy and its development. The project involves more than 20 partner organizations. The EU will finance the project in 2017–2023 with a total of about € 11 million. A significant part of the funding goes to companies. The business partners involved in the project have been developing inventory loss and land mass management service applications, composite products made from recycled plastics, sorting technology for construction waste and utilization of industrial by-products in civil engineering, among other things. Non-project partner companies have also benefited from the funding received by the project. The project involves four municipal development companies that promote the development of companies in their area and a sustainable growth of circular economy business. For example, the region of Satakunta has achieved pioneering results in the manufacture of recycled magnets. Municipalities, regional councils, waste management companies, universities, polytechnics and research institutes participating in the project have also through their work created conditions for new businesses and increased growth in circular economy, for example by providing regional and national data on waste quantity, quality and treatment and by encouraging public actors to support circular economy through their purchases.

System level changes are needed The implementation of circular economy requires systemic changes, which are done only in cooperation with the economy. This goal is supported by the ongoing national cross-administrative Strategic Programme for Promoting Circular Economy. Changes at the system level are also supported by changes in waste legislation that are being prepared. Companies are likely to expect clarity from the reform of waste legislation, for example information on when a material no longer is classified as waste but becomes a product again. This makes it easier to use recycled raw material in products and to market products made from recycled raw materials. In addition to binding legislation, other tools that encourage to the use of circular economy have been successfully introduced in Finland. Voluntary Green Deal agreements are a lighter concept than binding legislation meaning that businesses or municipalities make an agreement with the state administration in order to promote the goals of sustainable development. The agreements include environmentally and socially significant objectives and actions, which are monitored annually. The agreements allow companies to stand out from the crowd by labelling themselves as pioneers and responsible players in the circular economy. The closure of material cycles under the circular economy has sometimes been slowed down by the limited market for manufactured recycled raw materials. We have a huge amount of process engineering know-how that should be put to use. We should be brave and make commitments on the use of recycled raw materials when manufacturing new products. That would create concrete opportunities for business solutions within circular economy and grow our reputation as a model country for circular economy.

The aim of the Circwaste project is sustainable waste management and the mainstreaming of the circular economy. The project is led by SYKE and is funded in large part by the EU LIFE programme. The project, which started in 2016, will continue until 2023. The project involves companies or municipal companies (9), municipalities or provinces (8), and research institutes (5). The Circwaste project receives funding from the EU to produce the project materials. However, the content presented in the materials only represents the project’s own views, for which the EU Commission is not responsible. materiaalitkiertoon.fi/en-US #circwaste

ADVERTISING PUBLICATION MAINOS

3

An Independent Supplement by Mediaplanet MAINOS

Pakkauksia tulevaisuutta varten Dispersiopäällystetyt pakkaukset on helppo kierrättää. Siksi ne ovatkin varteenotettava vaihtoehto tulevaisuuden kestäviksi ruokapakkauksiksi. Kun elämäntyylimme muuttuu alati kiireisemmäksi, myös mukaan otettavien ruokien menekki kasvaa. Erilaisten kertakulutushyödykkeiden myynnin ennustetaan kasvavan 2,7 prosentin vuositahdilla aina vuoteen 2040 saakka. Asiakaskuntaa tällaisille tuotteille ovat erityisesti nuoret työssäkäyvät aikuiset, joilla ei ole aikaa laittaa ruokaa, ja jotka haluavat syödä ruoan heti sen ostettuaan. Kulutustottumusten muutos asettaa uudenlaisia vaatimuksia myös pakkausmateriaaleille ja kierrätyksen infrastruktuurille. Pakkausmateriaalivalmistaja Walki, jonka missio on kiihdyttää maailmaa kohti jätteetöntä tulevaisuutta, uskoo, että yksi tärkeimmistä tulevaisuuden teknologioista on dispersiopäällystys: sen avulla pakkauksista saadaan paitsi toiminnallisia myös helposti kierrätettäviä. Dispersiopäällystyksessä pakkauksen pohjamateriaaliin lisätään erityinen vesipohjainen päällyste, jonka lävitse vesi, vesihöyry, happi ja rasva eivät pääse. ”Yleensä dispersiokerros lisätään kuitupohjaiseen materiaaliin, esimerkiksi kartonkiin tai paperiin. Walkin dispersiopäällystetyt materiaalit ovat helppo joko kompostoida tai kierrättää”, kertoo Walkin innovaatiojohtaja Annika Sundell. Walkin dispersiomateriaaleja käytetään etenkin taiteltavissa kartonkirasioissa, kartonkivuoissa ja paperipusseissa. Taiteltavat kartonkirasiat ovat monille tuttuja noutoruoka-annoksista. Vuoat sopivat esimerkiksi lentoyhtiöiden tai muiden liikennöitsijöiden ateriatarjoiluun. Päällystetty paperipussi sopii hyvin kuivaruoille, joille halutaan myös pitkä hyllyikä. Ekologisesti kestävän pakkauksen kehittäminen ei ole aina suoraviivaista, Sundell kertoo. ”Kehitystyössä tarvitaan kokonaisvaltaista otetta ja monenlaisten teknologioiden yhdistämistä. Me Walkilla pystymme auttamaan asiakkaitamme laajan teknologisen osaamisemme ja tietotaitomme ansiosta.” Lue lisää: walki.fi

MAINOS

MAINOS

Kestävästi puhtaaseen bioenergiantuotantoon

Megawatista satoihin Tarpeeseenne sopivimmat ratkaisut. Uuteen ja vanhaan. Sellutehdas, lämmön- ja yhteistuotanto. ECP Group Oy • p. +358 20 741 8350 • ecpgroup.fi

ou al Sa vu ka as u ec npu pg hd ro is up tu .e s o u/ n cir ki cfl ert ue ot

Puhtaus Savut kiertotalouden käyttöön. Takuulla. Ympäristö ja käyttökustannukset kiittävät.

tta

Kestävyys Maanantai tulee joka viikko. Ratkaisumme kestävät sen. Vuosikymmeniä.

4

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION

INSPIRATION PHOTOS: KAI WIDELL

– Combating climate change will be the main source of economic growth for the next twenty to thirty years, Reijo Karhinen says.

Reijo Karhinen (65) Working Life Professor, University of Eastern Finland CEO of the OP Financial Group in 2007–2018 Chairman of the Board of the Finnish State Development Company VAKE Oy 2017-spring 2020 Chairman of the steering group preparing the national circular economy promotion programme Member of the Sustainable Recovery Working Group Chairman of the Joint Dining Table Programme Chairman of the Central Chamber of Commerce’s Competence Committee

Companies are facing a huge change – As Finland moves towards a carbon-neutral circular economy, companies will face dramatic, huge and rapid changes. Fortunately, creativity is at its best when it is placed among constraints, says Reijo Karhinen. Text Leena Rantajärvi

ADVERTISING PUBLICATION

5

An Independent Supplement by Mediaplanet

I

t is the week before Midsummer. However, the retired former CEO of OP Bank Group is not on his forest farm on the shores of Lake Saimaa, but in the heart of Helsinki. He is heading to the Ministry of the Environment: a meeting with the national Circular Economy Promotion Programme is about to begin. Reijo Karhinen is the chair of the steering group preparing the programme. Finland’s vision is a carbon–neutral circular economy society by 2035. – The transition from a fossil to a non– fossil economy requires bold and rapid renewal by companies and society. Fortunately, creativity is at its best when it is placed among constraints, Karhinen estimates. – The use of natural resources must be on a sustainable footing. Basically, the circular economy is industrial policy. For example, the circular economy means extending the life cycle of products and returning materials for reuse. In addition, there is an increasing shift from ownership to using services.

There will be entirely new business areas According to Reijo Karhinen, a large number of companies will face a change in their business area. – There will be completely new business areas and the existing ones will die out. Businesses will have to make even drastic changes. His words are directed to those leading the companies: – Look to the future. Anticipate the future by listening to experts and young people. This will give you an idea of what your company’s new operating environment will look like and how your company can navigate in this environment. You need to understand that combating climate change will be the main source of economic growth for the next twenty to thirty years. He also urges business leaders to engage in social debate with a proactive approach. – Social media is an easy channel for this today. It is a good place to communicate about the kind of expertise that is needed in Finland in order for companies to succeed in the future. The society must be able to address the needs of companies. Karhinen emphasizes that a carbon–neutral circular economy will be here in just ten years’ time. – I am very concerned, for example, whether engineers are trained to operate in a carbon–neutral circular economy. No one in the field of technology should focus on the old, linear economy.

Anticipate the future by listening to experts and young people. Finland in a pole position According to Reijo Karhinen, economic growth must come from other sources than an excessive use of natural resources in the future. Less means more. He thinks Finland’s chances of succeeding in this change are good. – There is a big change ahead, but Finland is in a pole position. In the 1950s, Finland was carbon neutral, but now we are living beyond our means. Yes, we can adapt, because we are a high–tech country. – I am confident that the digitalization and data economy will bring new economic growth. We have both good business

expertise and digital expertise. We just need to be able to combine these skills better. We need to build a way towards a digital welfare economy where data replaces material flows. According to Karhinen, the transition must not be driven by regulation and restrictions alone, but on a business–oriented basis. – We cannot create anything new unless companies have a constant cash flow. What we need is a carrot, not a stick.

Slush was a wake–up call Reijo Karhinen retired a couple of years ago. Since then, he has been involved in many things. – Values have always been important to me. Working for a sustainable lifestyle and a sustainable economic structure is, in my view, work for future generations. He seems really excited about the challenge of moving towards a carbon–neutral circular economy, and describes the 2014 Slush event as a wake–up call for his enthusiasm. – I felt the Finnish operating environment had been gloomy. In the public debate, new things did not go through. New ideas and thinking were met with resistance. “We’ll do the way we’ve always done.” For Karvinen Slush offered a glimpse of hope: – There were a lot of young people at the event and everything was about opportunities. He started thinking about what was the group he wanted to belong to. – Do I want to be someone who gets excited and passionate about things, or someone who clings to the old ways. So he is now heading to the Ministry of the Environment. The government program outlines that a strategic programme promoting circular economy will be planned for Finland.

– We will prepare the proposal for approval by the Government this year. Ministries, research institutes, Sitra, Business Finland and a large number of companies and municipalities are involved in the preparation work.

Building a log cabin After the meeting at the Ministry of the Environment, Karhinen heads to the shores of Lake Pihlajavesi in Saimaa. – Our family will assemble another old log building in the yard of our summer house this summer – in the spirit of circular economy. It’s the tenth in a row of buildings. And this newcomer is a real gem. It’s a two–story granary from the 1820s. We will probably celebrate its 200th anniversary, Karhinen describes. Silviculture is also close to his heart. The Karhinen family is a significant forest owner. Today, Reijo Karhinen likes to call himself a forestry entrepreneur.

A national programme promoting circular economy The programme is run by the Ministry of the Environment and the Ministry of Employment and the Economy. Objectives of the program by 2035: • A carbon-neutral circular economy is the foundation of our successful economy. Our choices are future-proof and strengthen a fair welfare society. • Less is more: the use of natural resources is sustainable and materials stay in circulation longer and safer. Sustainable products and services are mainstream in the economy, and sharing economy is part of our daily life. • The breakthrough of the circular economy has been achieved through innovation, digital solutions, smart regulation and responsible investors, businesses and consumers. The Finnish circular economy is a strong player in the world and a provider of sustainable solutions in the international market. ym.fi/kiertotalousohjelma

6

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION

CONSTRUCTION EFFICIENCY AND LAND USE

Climate emissions cut to a minimum in industrial construction building Careful planning and scheduling made it possible to use the dredging spoils from sea routes and industrial by-products in the construction of an industrial area in Rauma. Text Tarja Sinervo P H OTO : R A JA L A P R O S H O P

Tuomas Suikkanen Project Manager, Ramboll

In the development of the Sampaanalanlahti bay area, part of the old bay will be transformed into an industrial storage area. The Circwaste subproject, designed by Ramboll, provided many benefits by using dredging spoils dredged from maritime shipping lanes and by–products from a nearby industrial area in the construction of the area. – The goal is to save virgin aggregate, reduce climate emissions and costs compared to traditional civil engineering, says project manager Tuomas Suikkanen from Ramboll. Virgin aggregate is an unprocessed natural mineral that is a non–renewable or slowly renewable natural resource. Often it has to be transported to construction sites from afar, in Sampaanalanlahti it would have been gravel or sand from some sand quarry. Now, there was instead dredging material dredged from Rauma Southern Seaway that could be used as backfill. The bottom of the bay consisted of a thick layer of mud and clay. It was filled up to sea level with dredging spoils. The soil was then mass stabilized, i.e. the low quality areas were reinforced by mixing a binder in order for the soil to become sufficiently firm and stable for construction. With the help of mass stabilization, soft material could be left in place, thus avoiding large–scale mass exchange.

Industrial by–products instead of cement The project also investigated successfully the utilization of industrial by–products in stabilization instead of cement. According to Suikkanen, the highest CO2 emissions – up to more than 90 percent – of the stabilization techniques used as a bottom reinforce-

When working with waste, it is important to find out the suitability of waste materials for the project and to make sure that they are available at a sufficiently early stage. ment method in civil engineering come from the production of cement, traditionally used as a binder. But by using by–products such as fly ash from a nearby paper mill and biopower plant, the use of cement could be minimized. – We managed to cut climate emissions and save costs when land and stabilizers were obtained nearby, the dredging spoils did not need any new landfills and industrial waste did not have to be transported to a landfill, Suikkanen sums up. The use of recycled materials in construction is the sum of many components. – The utilization of alternative construction solutions and industrial waste must always be considered on a project–by–project basis. Recycled materials should be available within a reasonable transport distance and in a safe and environmentally friendly manner. The utilization of recycled materials is also studied in the Finnish Transport Infrastructure Agency’s sub–project on road projects. In the project, the challenges and benefits are largely the same as in the Sampaanalanlahti project.

Other construction efficiency and land use subprojects of the Circwaste project: • Karelia is investigating the overall picture of plastic waste generation in the North Karelia region and is preparing a waste plastic recovery scenario. In addition, the project will update North Karelia’s regional waste management system and carry out legal and technical-economic studies on plastics processing. The project collects various plastics from agriculture and construction sites, and their suitability as raw materials for new products is being tested. The aim is to produce new business models related to the use of plastics that can be duplicated elsewhere in the future. Further information: Simo Paukkunen, Project Specialist, firstname.surname@karelia.fi • In the city of Pori, resource-efficient construction is promoted, and co-operation between construction industry actors related to the circular economy is being strengthened. The project organizes a cooperation network between builders, construction companies, property owners, authorities and universities. The network implements successful practices for recycling and reducing construction waste. In particular, the city supports the circular economy of building components and demolition waste through various practical measures. The construction sites selected for the project aim to achieve the required 70% recycling rate. Further information: Anu Tuovinen, Project Coordinator, City of Pori, firstname.surname @pori.fi • The waste management company Puhas Oy is developing the sorting of construction waste from its point of origin together with construction companies in the Joensuu, Ilomantsi, Kontiolahti, Liperi and Polvijärvi areas. The aim is to streamline the processes for the separation and recovery of waste materials in waste centers and to communicate effective practices to construction operators. Further information: Matti Mikkelä, Project Manager, Puhas Oy, firstname.surname@puhas.fi

ADVERTISING PUBLICATION

7

An Independent Supplement by Mediaplanet

CONSTRUCTION EFFICIENCY AND LAND USE PHOTO: GETTY IMAGES

Maapaikka.fi is a service for the delivery of clean surplus earth and aggregate materials used in construction and construction materials in accordance with the Government Decree on the Utilization of Certain Wastes in the Earth Construction.

A new digital marketplace for surplus materials from construction The new digital marketplace for earth and aggregate materials developed by Kiertomaa Oy enables environmental and cost savings. Kiertomaa Oy’s material terminal for recycling and storage of surplus stone and earth material is located in Saramäki in Turku. According to the company’s CEO Päivi Laakso, the Circwaste project has developed the regional planning of the terminal and created a digital marketplace for earth and aggregate materials.

Maapaikka.fi is a service for the delivery of clean surplus earth and aggregate materials used in construction and construction materials in accordance with the Government Decree on the Utilization of Certain Wastes in the Earth Construction. On the website, companies, communities and citizens can inform on their earth material, and search for what others have to offer, free of charge. The price, transportation and necessary documents are agreed on between the users. – The service enables more efficient recycling of earth material. Optimizing

transportation distances reduces carbon emissions and promotes the use of recycled material instead of virgin aggregates. The service is in its test phase, and will also include additional information on resource– efficient and responsible construction, such as location information on contaminated land areas. Thus, the platform promotes the implementation of a material–efficient, environmentally friendly and resource–saving operating model in the private and public sector, Päivi Laakso says.

MAINOS

MAINOS

Destacleanin auttaa asiakkaitaan saavuttamaan kiertotaloustavoitteet Kotimaisen Destacleanin tavoitteena on edistää jätelain mukaista materiaalien kierrätystä kehittämällä hyödyllisiä ja innovatiivisia kierrätysmateriaaleja ja -tuotteita. Destacleanilla on ruuhka-Suomen kattavin rakennus-, purku- ja teollisuuden jätteiden vastaanottoverkosto – Helsinki–Tampere-akselilla vastaanottopaikkoja on yhdessä Tehokierto-tytäryhtiön kanssa yhdeksän. Kierrätys- ja hyödyntämisaste on lähes 100 %. – Kaiken toimintamme lähtökohta on kiertotalous, ja meidän tehtävämme on nimenomaan mahdollistaa asiakkaittemme kiertotaloustavoitteet, toimitusjohtaja Tanja Rytkönen sanoo. Rytkönen painottaa yrityksen tekevän asiakkaiden kanssa jatkuvaa kehitystyötä,

josta rakennus- ja purkujätteiden erilliskeräyskonsepti, digitaaliset asiointipalvelut ja kierrätettävyysraportoinnit ovat viimeisimpiä esimerkkejä. – EU:n jätesäädöspaketin keskeisinä tavoitteina on vähentää jätteen määrää sekä lisätä uudelleenkäyttöä ja kierrätystä. Vaikka Destaclean on pääkaupunkiseudulla suuri toimija, on organisaatio pysynyt ketteränä. Rytkösen mukaan asioiminen on tehty yksinkertaiseksi ja nopeaksi sekä työmaille että yrityksen johdolle. – Kierrätysasemillamme saa hyvää palvelua ja vastuuhenkilömme ovat helposti tavoitettavissa. Yhden luukun periaate näkyy asiakastyytyväisyydessämme, joka on toistuvasti ollut huippuluokkaa. Viime vuonna tehdyssä tutkimuksessa suositteluasteen keskiarvo oli asteikolla 1–5 kokonaisuudessaan hyvin lähellä viittä.

Tanja Rytkönen toimitusjohtaja, Destaclean Oy 040 573 7006 tanja.rytkonen@destaclean.fi

Destaclean on nimetty monena vuotena peräkkäin Sitran kokoamalle Kiertotalouden kiinnostavimmat -yritysesimerkkilistalle. Destaclean Oy:n johtamisjärjestelmä täyttää ISO 14001-ympäristöjärjestelmän ja ISO 9001-laatujärjestelmän vaatimukset.

www.destaclean.fi

8

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION PHOTOS: PRIZZTECH OY & LUT

UTILIZATION OF INDUSTRIAL BY-PRODUCTS

Can side-branches contribute to business growth? The industry’s demand for recycled products is tough: the qualities must be almost as good as in the mainstream products. Prizztech Oy and LUT and Wimao Oy are boldly testing something new. Text Anna Kuronen Recycled magnets increase the security of supply. Most magnets are currently recycled among scrap metal, which means that only the iron contained in the magnets is recovered. Rare earth metals end up mainly as impurities in recycled iron. The idea for recycled magnets came about some 10 years ago when the prices of rare earth metals rose drastically. In Europe, ecological thinking is on the rise and companies are interested in buying recycled materials. They are also willing to compromise a bit on their power requirements. – Studies in the US have shown that recycling strong magnets is possible by pulverization. We tested it with the help of the Circwaste project, Minna Haavisto, project manager at Prizztech Oy, explains.

Demo beyond expectations Pulverization of permanent magnets is

New technology makes it possible to utilize difficult waste fractions. Professor Timo Kärki of LUT University develops composite fiber products from recycled materials in the Circwaste project. Product development is carried out in cooperation with LUT University and Wimao Oy, a provider of plastic recycling technology. – Industrial, household and construction waste are all recyclable, but waste generated from industry is relatively clean and therefore clear in terms of processes, Professor Kärki describes. The handling of waste raw material processes is straightforward, and both product safety and quality control are closely linked to them. – From the quality point of view, the

the most ecological, cost–effective and energy–efficient way to produce recycled magnets. In theory, in an optimal manufacturing process, the maximum field strength produced by a recycled magnet is two percent lower than that of a virgin magnet. – In the demo, we tested magnets with 75 percent recycled raw material and proved that it is possible to achieve theoretically defined qualities. So the most promising result came true, Haavisto says happily.

Huge potential Outside China, magnets are manufactured by only a handful of companies, but in Europe there is a great need for them. In Germany and Sweden, a large number of wind turbines will be dismantled in the near future, and their generators with magnets could be recycled in Finland, which means a new kind of business.

most important thing is to keep the physical, mechanical and chemical qualities of recycled materials good and to ensure that possible contaminants do not affect the end–products, Kärki says.

Composite fiber is versatile Legislation strongly advocates extending the life cycles of materials. For example, the recycling of construction waste in the EU countries varies between 30 and 60 percent, but Finland aims at increasing its recycling rate to 70 per cent. – Composite fiber products can be used in construction as sheets and profiles. In addition, they are used as packaging materials and transport boxes in logistics, Kärki says. Concrete lightened with composite fib-

The most profitable way to go is to recycle the magnets of large industrial motors and generators. – The most profitable way to go is to recycle the magnets of large industrial motors and generators. They produce a lot of homogeneous raw materials at once. We are happy to help companies to bring infrastructure and know–how together here in the Pori region. Neorem Magnets Oy, one of the most significant magnet manufacturers in Europe, is already here, Haavisto says.

This concept is easy to scale. er is suitable for noise barriers and traffic barriers. In consumer products, it can be found in cell phone cases and cars. – The economic potential becomes apparent especially with large volumes, for example, in infrastructure construction. This concept is easy to scale, because the infrastructure for waste collection already exists and the materials circulate well, Kärki sums up.

Other sub-projects for the utilization of industrial byproducts in the Circwaste project: • The Pielinen-Karelia Development Center, together with North Karelia’s industrial companies and municipalities, model and test sustainable utilization methods for byproducts and waste. In addition, the project will carry out four practical experiments using companies’ by-products. The aim of the project is to improve the cost efficiency of biogas plants and increase the number of plants in Finland. Further information: Jukka Nevalainen, Development Manager, Pikes Oy, firstname. surname@pikes.fi • Business Joensuu is looking for sites in the developing urban area of Joensuu where new circular economy businesses can be created. The development company has organized several successful business idea competitions. In addition, the project will conduct material flow studies, with geopolymers as one potential material flow. Further information: Terttu Kinnunen, Development Specialist, Business Joensuu, firstname.surname@ businessjoensuu.fi

ADVERTISING PUBLICATION

9

An Independent Supplement by Mediaplanet

MAINOS

MAINOS

CleverBin huolehtii täydennystilauksista – ihminen voi keskittyä omaan työhönsä Ferrometalin CleverBin on älykäs vastaus teollisuuden pientarvikkeiden varastoinnin optimointiin. CleverBin ottolaatikossa on kyse optisella anturilla varustetusta pientarvikelaatikosta, joka hyvissä ajoin havaitsee kiinnitysosien tai pienkomponenttien vähenemisen ja osaa ennalta asetetun tilauspisteen alittuessa tehdä ostotilauksen ERP-järjestelmään mobiiliyhteyden kautta. – Meillä toimitusaika kaikkialle Suomeen on vain yksi vuorokausi. Joskus sekin voi kuitenkin olla tuotannon kannalta liikaa, jos täydennystilausta ei ole saatu ajoissa, Ferrometalin toimitusjohtaja Mika Brandt perustelee. CleverBin-laatikko on suunniteltu

pientarvikelogistiikan hoitamiseen erilaisissa tuotanto- ja huoltoympäristöissä. Monikäyttöisyytensä ansiosta laatikko soveltuu käytettäväksi niin teollisuudessa, varastoissa, huoltoautoissa kuin sairaaloissa. Uuden teknologian säästöt ja hyödyt alkavat heti Uusi teknologia mahdollistaa Brandtin mukaan ennakoivat täydennystilaukset ilman ihmisen tekemää erillistä tilausta. – Asiakas voi keskittyä omaan työhönsä laatikon huolehtiessa, että komponenttien täydennykset tulevat ajallaan. Samalla tekniikalla voimme toteuttaa myös kappaletavaroiden seurantaa sekä täydennystilauksia esimerkiksi hyllypaikoille. Järjestelmän avulla CleverBinin ekosysteemikokonaisuudesta pien-

tarvikkeiden hallintaan voidaan asiakkaan niin halutessa rakentaa varsin laaja – ja erittäin kustannustehokkaasti. – CleverBin soveltuu lähes kaikille asiakkaille, ovat asiakkaan volyymit sitten isot tai pienet. Ennakoivan järjestelmän häiriöttömyys ja tehokkuus tuottavat lisäarvoa. CleverBin-järjestelmän käyttöönotto on helppoa sekä edullista, ja säästöt ja hyödyt alkavat heti. Ferrometal Oy on alan johtava kiinnitystarvikkeiden ja asiakkaiden lopputuotteen kokoonpanoon sekä asentamiseen käytettävien pientarvikkeiden toimittaja. Yritys tunnetaan Rfid-Kanban ratkaisuista sekä kyvystä virtaviivaistaa asiakkaiden pientarvikelogistiikkaa.

CLEVERBIN EDUT • Nopeus ja ennakointi • Tarkkuutta tuotantoon

• Toiminnan tehokkuus • Prosessin läpinäkyvyys

• Pienemmät varastoarvot • Virheiden eliminointi

Ferrometal Oy

www.ferrometal.fi

Tel. 010 308 11

10

An Independent Supplement by Mediaplanet

RECOVERY OF BIODEGRADABLE WASTE AND BY-PRODUCTS

RECOVERY OF BIODEGRADABLE WASTE AND BY-PRODUCTS

Efficiency in nutrient recycling and biogas production

Central Finland speeds up the production and use of biogas

Text Tarja Sinervo

Circwaste project’s sub-project is driving a transition from the utilization of virgin nutrients to nutrient recycling in grain production. An open service called Biomass Atlas has also been developed in the project. Tanks for liquid fertilizers were installed in the tractor-seed drill units, and the fertilizer was fed hydraulically to the ploughshare. Thanks to several fertilizer containers, it was possible to dispense multiple nutrients, such as nitrogen, phosphorus and potassium, separately from each other according to the needs of the plant.

For years, Central Finland has been investing in the use of biowaste. The Circwaste project has strengthened the build-up of a biogas ecosystem and encouraged to use biogas in transport.

Digital application on biomass The project has also further developed a digital Biomass atlas application created by Luke. The map-based service illustrates biomasses that are nationally available, their volumes and location. This provides information on land use, forest resources, logging by-products, arable crop production and by-products, manure, and biodegradable waste and sludge from industry and municipalities. In the project, the application data has been further processed and combined with nutrient data. The Nutrient Calculator is a tool developed by Natural Resources Institute Finland and Finnish Environment Institute SYKE for the needs of regional nutrient planning. The information is helpful when decision-makers are considering zoning, or a company is looking for a raw material, planning to set up a production facility, or thinking about where to place the processing residue. The map can be used to calculate the amount of biomass in a specific area on the map, or to view the restrictions on use and to model the effects of use on sustainable development. Part of the biomass is suitable as raw material for cosmetics, fiber, feed or nutrient preparations.

Text Tarja Sinervo The waste stream project in Central Finland has studied the biogas ecosystem composed of biodegradable waste and by–products processed in the region’s biogas plants, their recycling as well as the promotion of biogas production and use. – We have worked in our area for a long time on processing biodegradable waste and biogas, and the project has made it possible to further develop the topic. We are working to increase the production of biogas and its use in transport, says Development Manager Outi Pakarinen from the Regional Council of Central Finland. – Our study on the state of waste management in the region showed that a lot of biodegradable waste can, in fact, be found among mixed waste. Although we have had an obligation to collect biodegradable waste for twenty years already,

Separation of liquid slurry doubles the yield Natural Resources Institute Finland has tested the separation method for pig slurry, i.e. settling, which separates the dregs at the bottom containing phosphorus and dry solid matter from the nitrogen-containing liquid on the top. This method can improve the energy production in a biogas plant, as the dregs at the bottom have a high phosphorus content and energy density compared to unseparated sludge. Therefore, it clearly has more methane-production potential than unseparated liquid slurry. According to Natural Resources Institute Finland’s calculations, a plant that processes the bottom sludge could produce 67% more methane and up to 99% more net energy. Settling means also significant benefits in the fertilization of phosphorus-rich fields. The phosphorus limitation for environmental subsidy limits the amount of nitrogen that is applied with manure. The more soluble nitrogen and potassium we are able to spread and apply on fields, the less fertilizers se need. Natural Resources Institute Finland has estimated that a farm can save up to € 9,560 per year in the cost of fertilizer for 600 hectares of barley fields if the phosphorus fertility class of the fields is “good”. The separation method can be commercialized if interested entrepreneurs come forward and seize the opportunity.

Experts: Juha-Matti Katajajuuri, Liisa Pesonen, Eeva Lehtonen and Ville Pyykkönen from LUKE.

ADVERTISING PUBLICATION

in some places mixed waste contained almost 30 percent biodegradable waste. Collecting and processing it would mean that a lot of biogas could be used in transport. The most important way to increase the bio–circular economy has been to develop cooperation and communication. – People need information that motivates them to sort waste carefully. In communication, co–operation with waste plants and municipalities is important. We have also carried out various studies and launched a network to involve all actors in the region’s production and supply chain in the ecosystem.

More use of biogas in transport The use of biogas in transport has been increased, for example by encouraging municipalities to switch to biogas–driv-

RECOVERY OF BIODEGRADABLE WASTE AND BY-PRODUCTS

Reducing food waste benefits everyone Food waste is a costly issue for the society and everyone in the food system chain, from farmers to consumers. The Natural Resources Institute (Luke) investigated the causes and solutions for food waste, and the work will result in the first food waste roadmap for Finland, rather unique even on a European level. Text Tarja Sinervo

T

he Natural Resources Institute (Luke) has started a pilot project, which will outline the first roadmap for food waste reduction in Southwest Finland. In addition, a nationwide roadmap for food waste will be prepared during the autumn. A wide range of actors in the food system chain were brought together in three workshops in Southwest Finland. Representatives of primary production, the food industry, retail chains, waste management, meal services, food aid operators, the City of Turku and develop-

ment companies were present. – In the first workshop, we mapped the problems causing food waste in the region. Sector–specific challenges included distribution channels for primary production, incorrect labeling, waste, food date labels, and unpredictable consumer behavior. There was a need for more information, as well as information on store locations, a data bank on food waste, packaging sensors and a number of other issues, says Juha–Matti Katajajuuri, specialist researcher at the Natural Resources Institute.

ADVERTISING PUBLICATION

11

An Independent Supplement by Mediaplanet P H OTO : OW N P H OTO

– Sorting biowaste and driving with a biogas engine are easy ways to promote circular economy, says Outi Pakarinen. She has been driving a biogas car for almost ten years.

Other sub-projects for the recovery of biodegradable waste and by-products of the Circwaste project: • The Turku University of Applied Sciences project investigates areas and actors suitable for biogas production. In addition, training will be provided to farmers, feasibility studies will be carried out for new biogas plants, and additional information will be collected to support procurement decisions for biogas plants. The aim is that at least one positive investment decision for the biogas plant will be made during the project, and preparations related to the construction of the plant will be started during the project. Further information: Pekka Alho, Project Manager, Turku University of Applied Sciences, firstname.surname @turkuamk.fi • The Natural Resources Centre’s subproject identifies and develops the most efficient logistics and warehousing practices for the distribution of surplus food. The project will study the functioning of food redistribution regulations and food labeling with authorities and other actors. In addition, efforts are being made to identify and resolve barriers to the utilization of surplus food. Another issue to be clarified in the subproject is whether lower quality products used as animal feed can be used for human consumption.

en vehicles and by encouraging service providers to require gas–powered cars. For example, Jyväskylä’s home nursing staff is driving vehicles with biogas energies. During the project, the number of gas–powered vehicles in Central Finland has increased from 93 (Q2/2016) to 780 (Q2/2020).* – The use of biogas–driven buses has been investigated before, but no decisions were made. By participating in the European BiogasAction project through the Circwaste project, we had a chance to

Further information: Juha-Matti Katajajuuri, Senior scientist, Luonnonvarakeskus Luke, firstname.surname @luke.fi

do a study trip to Sweden in the autumn of 2018. We heard two cities’ experiences about biogas buses and received useful information, for example what the municipality must take into account when planning biogas buses. The experiences were encouraging, and a year ago four biogas buses started operating in Jyväskylä, Pakarinen says.

• The Natural Resources Center is exploring various techniques for reducing vegetable losses. The aim of the project is to create methods that minimize the by-products of vegetable processing and, on the other hand, utilize them, for example, as animal feed. The benefits of the further processing of byproducts are also being investigated. Further information: Juha-Matti Katajajuuri, Senior scientist, Luonnonvarakeskus Luke, firstname.surname@luke.fi

*SOURCE: TRAFICOM, STATISTICAL DATABASE (FIGURES INCLUDE CNG, PETROL/CNG AND DIESEL/CNG)

Ways to minimize food waste – The second and third workshops focused on finding solutions, which turned out to be not that easy at all. Some of the proposals addressed precise details, and there could be contradictions between initiatives. Individual actors and experts in the field were also interviewed for the national roadmap. – We outlined solutions for three different levels, the first of which is the social level. That means amendments to legislation, new types of incentives, voluntary agreements, taxation, subsidies and financial incentives. Voluntary commitments in the field and expanding them, as well as sensible guidance, would steer the development in the right direction, says Katajajuuri. – The second level concerns education and knowledge. In the curriculum, food loss should be highlighted more strongly. The same applies to secondary vocational schools, especially in chef training. New ways of sharing and targeting information are needed, for example a food material

flow marketplace that shares information on the locations and volumes of waste. We need a common platform where the industry, experts, science and government can work together and come up with innovations in order to further minimize food loss. – The third level concerns guidance and policy development. The starting point is to help consumers and actors in the food chain to reduce food waste. This can be achieved by improving product placement and packaging, better understanding of consumers and influencing them, branding of food waste, and own product families, certificates and food waste restaurants. The development of forecasting systems, technology and intelligent solutions provide business opportunities for companies. Investment in research, food loss monitoring and updating the roadmap are also important measures. Cooperation between all parties in the chain as well as the public sector is very important, Katajajuuri reminds.

K U VA : O M A A R K I STO

P H OTO S : G E T T Y I M AG ES

The development of forecasting systems, technology and intelligent solutions offer several business opportunities for companies.

Juha-Matti Katajajuuri specialist researcher, the Natural Resources Institute

12

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION

DIGITAL AND LOGISTICS

The Golli service facilitates the flow of information between the entrepreneur and the seller

A Challenge Prize for you? Municipalities, companies, communities or an individuals have now the opportunity to receive recognition for their work with a Challenge Prize awarded by the Circwaste project. The Prize will be awarded by the Circwaste project and a rotating electoral committee. It is awarded annually to one or more actors.

GS1 Finland has developed an additional feature to the popular Golli delivery system that monitors transport pallets and Transbox boxes in real time.

The latest award was presented to Tracegrow Oy in May 2020 in a webinar “Municipalities Implementing Sustainable Development”. The selection criteria were, among other things, that the idea reflects innovative thinking that has led to profitable business on an industrial scale. In the process developed by Tracegrow Oy, battery mass is dissolved and harmful substances are removed from the solution. The end-product is a micro-nutrient solution containing zinc and manganese in accordance with the EU legislation on fertilizers. The process does not generate harmful emissions or wastewater into the air. Tracegrow’s micro-nutrient products are sold to fertilizer retailers and fertilizer manufacturers. The product is also well suited for organic farming.

Text Tarja Sinervo

Participate: energialoikka.fi/en/ luokka/material-leap Read more about the Prize and selection criteria:: materitkiertoon.fi/fi-FI/ Ajankohtaista/Kiertopalkinto

documents related to deliveries as well as standard address labels. The information is stored and up–to–date in Golli’s cloud service. The easy–to–use service works via an internet browser on both a computer and a mobile.

P H OTO : G S 1 F I N L A N D

How to get the product to consumers smoothly and efficiently? This is one of the most important questions for an entrepreneur. An order and delivery system that is efficient and up–to–date plays a crucial role in negotiations with retailers. Sellers want to manage logistics with digital applications and smart solutions, no longer relying merely on a mobile phone or email. Big central corporations have each their own systems posing a challenge for the entrepreneur. To help with this, GS1 has developed a digital service called Golli. – Golli facilitates the interaction between suppliers and buyers, as it “talks” with the systems of all major traders, says Anu Lahdenperä, Key Account Manager at GS1. – The service forwards orders to the entrepreneur and allows easy delivery of

The new feature improves the reuse of transport platforms Lahdenperä says that in the pilot of the Circwaste project, GS1 Finland developed a new feature for the Golli service that promotes the circular economy. – Now Golli also submits information about reusable pallets and Transbox boxes used in the delivery of goods. This is done through an identification code attached to the transport pallet. The recipient immediately sees how and when the goods are coming and can prepare for it. When products are quickly available

Anu Lahdenperä Key Account Manager, GS1

REGIONAL COOPERATION NETWORK

Schoolchildren getting acquainted with the circular economy on the environmental education path Text Anna Kuronen

The City of Pori’s Circwaste subproject Luuppi focuses on environmental education and green public procurements. Various actors in the city have co–produced environmental education material extending from early childhood to secondary education. – The environmental education is composed of Recycling, Sustainable and

responsible consumption and food, and Responsible clothing. School classes’ visit programs, theme weeks and material packages for teachers are also part of the environmental education path, says Outi Aalto, project coordinator at Luuppi.

Borrowing equipment has been a hit One of the priorities in the project is to promote co–sharing and borrowing.

– We opened Liikuttamo in the main library. It is a place where you can borrow sports and outdoor equipment with your library card. Now it is easy to try out new sports, Aalto enthuses. The project also organizes dialogue discussions with students and mothers, as well as experts in youth and sports, the library and waste management. Their wishes are listened to carefully.

Other participatory sub-projects of the Circwaste project: • The City of Jyväskylä is implementing three circular economy idea competitions for local residents, of which the best ideas are implemented in practice. The first idea competition produced innovative ideas, from an appliance loan application to experiments with using garden waste for soil. In September 2019, another idea competition was held, the results of which are currently being put into practice. One of the promising ideas was the idea of an experiment in recycling water in indoor swimming halls. Further information: Päivi Pietarinen, Environmental Director, City of Jyväskylä firstname.surname@jyvaskyla.fi

ADVERTISING PUBLICATION

13

An Independent Supplement by Mediaplanet

PHOTO: GETTY IMAGES

– Up-to-date information helps goods move efficiently across transport platforms. This saves time, money and the environment, knows Anu Lahdenperä at GS1.

Other digital and logistics sub-projects of the Circwaste project: • The Central Finland Hospital District project is developing ways to make waste collection, sorting and transport more efficient at the Nova Hospital, which will open in 2021. The hospital is a pioneer in this area, as efforts have been made to minimize waste generation from the design stage onwards. Waste-specific reduction targets will be set for the hospital, and drug losses will be minimized. In addition, a monitoring system and indicators will be developed for waste management.

on store shelves, their sales time is extended, shipment volumes and times can be optimized according to consumption, and product losses can be reduced. – Now even the company that manages pallets and boxes sees in real time where the transport platforms are. In this way, they can optimize the reuse and transport of transport platforms, and if the pallet disappears, it can be traced. This is important from the viewpoint of circular economy. It has been calculated that one pallet that is leased and reused replaces proportionally nearly one hundred non–returnable pallets. In fact, 50 reusable pallets can save up to a thousand kilograms of wood compared

In the pilot of the Circwaste project, GS1 Finland developed a new feature for the Golli service that promotes the circular economy. to non–returnable pallets. – Golli’s new feature, the information flow of transport platforms, gives entrepreneurs more good reasons to use reusable transport platforms. Now even the rental time and the billing are more accurate when the information provided to the renter of the pallets is timely, Lahdenperä sums up.

Further information: Kia Paasivirta, Project Coordinator, Central Finland Health Care District, firstname.surname@ksshp.fi • In the Kangas area of the city of Jyväskylä, a district of the future will be created with functional modern waste management solutions. The purpose of innovative waste management is to encourage residents to minimize the amount of waste generated and recycle it. During the project, a method for measuring the amount of waste will be developed, as well as a billing system based on the amount of waste generated. Further information: Tanja Oksa, Project Manager, City of Jyväskylä, firstname.surname@jkl.fi

REGIONAL COOPERATION NETWORK

Together towards an efficient circular economy Text Anna Kuronen

The Circwaste project is currently ongoing in Southwest Finland, Central Finland, South Karelia and North Karelia. Each region has its own cooperation group led by ELY Centres (Centres for Economic Development, Transport and the Environment), including main stakeholders in waste management. Co-operation groups help the local administration, businesses and residents to operate resource efficiently by providing support and expertise. The aim is to increase the regional recycling rate, promote the circular economy and enable the objectives of the national waste plan to be achieved through regional road maps.

Regional road maps The regions have set their objectives in road maps and chosen the priorities by which they will contribute to the implementation of the national waste plan. For example, one of the goals in Southwest Finland is to recycle 60 percent of the biowaste contained in municipal waste, while North Karelia aims at increasing the recycling rate of all municipal waste to 60 percent. In the road map of South Karelia, one of the priorities is biodegradable and forest-based cycles, while Central Finland will focus on biodegradable waste, biogas and nutrient cycling. All actions are scheduled in the road maps. In some of the road maps, responsible parties have been designated for the measures. Progress will be monitored

through regional indicators, and road maps will be updated as the project progresses by bringing in new priorities and measures. The co-operation involves the following stakeholders: Valonia, the Regional Council of Southwest Finland, the City of Lappeenranta, the Regional Council of North Karelia and the Regional Council of Central Finland.

Pioneers have ambitious goals The pioneering network includes the municipalitie of Ii, Jyväskylä, Kuopio, Lahti, Lappeenranta, Porvoo, Riihimäki, Rovaniemi, Turku and Vantaa. These municipalities also draw up their own road maps to a circular economy, taking into account local strengths, specif-

ic characteristics and challenges. In addition to activating residents, they will start new business and build new cooperation with various actors. The common shining light for these pioneers is be among the first ones who reach the national goals. That means they will recycle at least 55 percent of their municipal waste and recover at least 70 percent of their construction and demolition waste as materials. In addition, by the end of 2020, their waste volumes will be reduced to the level of 2000.

14

An Independent Supplement by Mediaplanet

paper work and waste monitoring becomes more efficient, says Riitta Levinen. The aim is to get the revision of waste legislation before Parliament in late September or early October. According to Levinen, companies find the current system for when the waste is no longer classified as waste unclear and non–transparent. – We have received a lot of critical feedback on that. The legislative reform makes the procedure clearer. In addition, next year we will set up a working group to think about smooth practices. Stakeholders are also invited to join the group.

PHOTO: KAI WIDELL

Obligations for separate collection of bio and packaging waste will be reinforced.

ADVERTISING PUBLICATION

Companies involved in the Green deal

Circular economy is here to stay Companies’ transition towards a circular economy is accelerated both through the revision of waste legislation and voluntary agreements. Text Leena Rantajärvi

Getting rid of the paper work As part of the reform, a broader and more comprehensive digital waste information system will be established in Finland. The first thing is to develop a system based on electronic transfer documents. For example, information on hazardous waste as well as construction and demolition waste is stored in the system in the future. – In this way, companies get rid of their

Riitta Levinen Environmental Adviser, the Ministry of Environment PHOTO: SUSANNA KEKKONEN

and financing recycling and separate collection. Producer responsibility fees will also rise. Obligations for separate collection of bio and packaging waste will be reinforced for both households and businesses, service and administrative activities. – Waste sorting should be integrated into companies’ normal practices in a more comprehensive way. Companies should also think of ways to reduce manufacturing waste and recycle in a smart way, Levinen emphasizes.

PHOTO: OLLI HÄKÄMIES

– The revision of the Waste Act is at the heart of the circular economy, says Environmental Adviser Riitta Levinen from the Ministry of Environment. The targets for waste recycling will be tightened gradually every five years. For example, the recycling target for municipal waste will be 55 percent by 2025 and 65 percent by 2035. Currently, the recycling rate of municipal waste in Finland is about 40 percent. The recycling targets for packaging waste will also be tightened in the future. The reform of waste legislation is underpinned by the EU’s waste legislation. – We are now looking at what instruments and changes in legislation are needed in Finland to achieve these goals. We are also looking for ways to ensure that products are designed to be recyclable from the very beginning. Producer responsibility for packaging producers, such as the food industry and trade, is expanding. They will have broader responsibilities for organizing

Leena-Kaisa Piekkari specialist,the Ministry of Environment

Voluntary Green Deal agreements accelerate the transition of companies to a circular economy and low–carbon future. – The Green Deal has been well received. Most recently, we signed an agreement with the real estate association Rakli on the reuse of demolition materials and increased recycling, says Leena–Kaisa Piekkari, a specialist at the Ministry of Environment. She is responsible for the preparation and development of Green Deal agreements. – The agreements define the actions through which companies will promote the circular economy and low–carbon activities, and define how the effects will be monitored on an annual basis. We will follow up on the actions taken by companies and, for example, industry–specific waste volumes, Piekkari describes. Agreements have also been made with, for example, the Finnish Automobile Confederation and Finnish Environmental Industries YTP. Each company makes its own commitments. The company does not have to be a member of the association. – We will soon sign agreements on how public procurement will reduce emissions from construction sites and harmful substances in the environment of kindergartens. An agreement on the separate collection and recycling of plastic materials for packaging in the construction industry is also currently under negotiation, Piekkari says. A Take Away Green Deal is being prepared with the restaurant and retail industry with the aim of reducing the consumption of disposable plastic packaging.

The agreements will reach a concrete level – Through agreements, we usually strive for rapid changes. The time span is 5–10 years, says Leena–Kaisa Piekkari. For example, the goal of the real estate association Rakli’s sustainable demolition agreement is that the inventory of building materials and harmful substances, i.e. demolition inventory, will be widely used by the parties to the agreement in 2025. Companies get to influence the actions they need to take. – Preparing agreements has helped us to understand companies and vice versa. We have tried to find new ways of working and the most satisfactory solutions possible. The companies have appreciated the fact that the agreements are so concrete.

ym.fi/lainsaadantopaketti sitoumus2050.fi/en/web/

ADVERTISING PUBLICATION

15

An Independent Supplement by Mediaplanet

REGIONAL COOPERATION NETWORK

What’s new in circular economy? The Service Center provides help for regional monitoring The Circular Economy Service Center provides information and expert assistance in promoting the circular economy in Finland. One of its missions is to develop and enable regional monitoring.

The Circular Economy Service Center

Text Tiina Karppinen The progress of the circular economy and the development of waste management are mostly measured by national indicators. However, local decision-making and the development of the circular economy require monitoring locally. When municipalities invest in waste management by increasing the possibilities for separate waste collection or when new companies are set up in the sharing economy, the effects are first visible on a the local level. The Finnish Environment Institute (SYKE) is developing regional indicators for monitoring the circular economy. The lack of local data is a major challenge, but there is a demand for increased monitoring. Regional monitoring of the circular economy can only be developed in cooperation with companies, municipalities and other actors in the region. SYKE collects information on, for example, regional waste volumes and they are recycled, as well as on how well the circular economy is being applied in day-to-day practice in various parts of Finland. Everyday choices are key to keeping

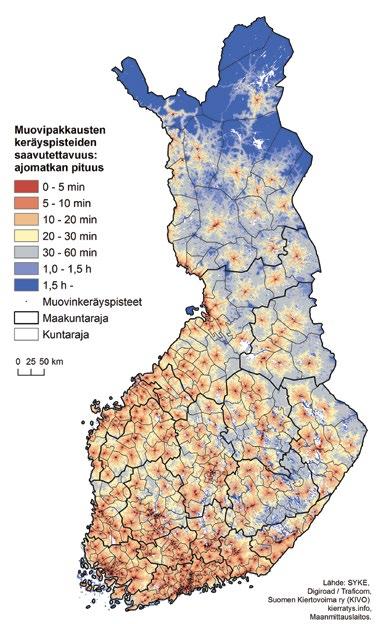

The picture shows the accessibility of regional collection points for textiles and plastic packaging waste as a driving distance along the road network in Finland. Source: SYKE, Circwaste project, 2020. the generation of waste to the minimum and sorting it efficiently. People’s concern about the environment and more ambitious targets for increasing recycling do not meet if sorting waste is difficult and collection points are too far away. Recently, SYKE has investigated how easily regional collection points are

accessible to residents all over Finland. Although the waste collection network covers almost the entire country, many of those how live in Eastern and Northern Finland have to use their car to drive to collection points for the recycling of clothing and textiles and plastic packaging waste.

• Promotes the circular economy by producing information and offering expertise (materialitkiertoon.fi) • Supports regional circular economy actors and municipalities that lead the way to the circular economy. • The Finnish Environment Institute (SYKE) coordinates the Circwaste project and the work of the Service Center. • Turku University of Applied Sciences, the Regional Council of Pirkanmaa and Digipolis Oy are co-operation partners for the Service Center • Develops indicators for the circular economy • Assesses environmental, cost and employment impacts. • Shares information on material-efficient public procurements, harmful substances, industrial symbioses, funding opportunities for the circular economy, and the assessment of material-efficiency in municipalities. • Provides visibility for the activities of the project’s core areas, sub-projects, the municipal network and companies and projects promoting the circular economy elsewhere in Finland. • Collects good practices in the circular economy on a website (energialoikka.fi/en/luokka/ material-leap)

Companies can apply for a subsidy for projects in the circular economy Companies can receive a subsidy for their investment and development projects in the circular economy. The Government approved a decree on this on 6 August 2020. The subsidy is intended to ramp up investments in the circular economy in Finland and to promote employment. The subsidy may be for technological investments promoting the circular economy, for studies and networks needed to launch investments that benefit the circular economy, and for circular economy solutions that improve employment. A total of EUR 2 million will be allocated for 2020-22. The subsidy is distributed by the Ministry of Employment and the Economy. The subsidy is available to companies

registered in Finland and, in the case of employment-supporting solutions, to public or private actors whose main purpose is other than economic activities or whose primary purpose is not to make a profit. The maximum amount for an investment project is a quarter of the total eligible costs of the project and a half of the total eligible costs for non-investment projects. The amount of a lump-sum

financing may not exceed EUR 50,000. The application must be submitted to the Ministry of Employment and the Economy prior to the start of the project. The regulation entered into force on 15 August 2020. More detailed application guidelines and forms will be available later on the Ministry of Employment and the Economy’s website.

Read more: tem.fi

16

An Independent Supplement by Mediaplanet

ADVERTISING PUBLICATION

MAINOS

MAINOS

Niemeltä Suomen puhtain muutto ja logistiikkapalvelu Muutto- ja logistiikkapalveluyritys Niemi Palveluiden kalustosta 100 % kulkee fossiilittomalla polttoaineella: kotimaisella biokaasulla, sähköllä tai Nesteen kehittämällä uusiutuvalla dieselillä. Lisäksi yritys minimoi muutosta aiheutuvat ympäristövaikutukset tarjoamalla asiakkailleen täyden kierrätyksen palvelun.

M

uuton yhteydessä yritykset ja kotitaloudet usein uusivat kalusteitaan. Lisäksi entisen kiinteistön tyhjentämisen yhteydessä varastoista ja kaapeista tulee vastaan suuret määrät vuosien varrella kertynyttä tarpeetonta tavaraa, jota ei haluta ottaa mukaan seuraavaan osoitteeseen. Mitä niille pitäisi tehdä? Niemi Palvelut on vastuullinen kumppani myös kierrätysasioissa. Kotitaloudet ja yritysasiakkaat voivat antaa ylimääräiset ja tarpeettomat tavaransa niin muuton yhteydessä kuin muutenkin kierrätettäväksi Niemelle. Tavarat päätyvät uusiokäyttöön tai myyntiin Niemen kumppanien kautta. – Kierrätämme kaiken mahdollisen jätteen. Käyttökelpoisten tavaroiden osalta meillä on koko valtakunnan laajuiset yhteistyösopimukset kuluttaja-asiakkaille Kierrätyskeskuksen ja yritysasiakkuuksille OffiStoren kanssa, johtaja (ICT ja kiertotalous) Mikko Helvelahti kertoo. Niemen kierrätysjärjestelmä kattaa kaiken kalusteiden ja toimistoirtaimiston kierrätyksestä arkaluonteisten asiakirjojen tuhoamiseen ja kierrätykseen. Tehokas järjestelmä myös säästää jätemaksuissa. Yksityisten kotitalouksien Mikko Helvelahti johtaja (ICT ja kiertotalous), varatoimitusjohtaja

Niemen ympäristöohjelman tavoitteena on saada yrityksen pienhiukkaspäästöt nollaan vuoteen 2040 mennessä.

vanhojen tavaroiden, kuten toimimattomien sähkölaitteiden kierrätys voidaan toteuttaa muuton yhteydessä, muutossa käytettävällä kalustolla ja henkilöstöllä. Se on ympäristöystävällistä ja asiakkaalle vaivatonta. – Kuusi vuotta sitten otimme käyttöön asiakaskohtaisen vastuullisuusraportoinnin eli muuton yhteydessä asiakas saa tarkan tiedon, kuinka paljon tarpeettomasta tavarasta on mennyt kierrätykseen. Olemme tuloksissa Euroopan tasolla aivan huippulukemissa, sillä saamme turhasta tavarasta jopa noin 90 prosenttia uudelleenkäyttöön, Mikko Helvelahti kertoo. Jos tavaroita ei voi enää käyttää uudelleen, ne menevät kierrätettäväksi jätelajin mukaan. Yritys hyödyntää kaiken muutossa syntyneen jätteen toissijaisesti energian tuotannossa. Niemi on myös hiljattain investoinut puoli miljoonaa euroa uusiin jätepakkaajiin. – Jotkut kutsuvat uutta

puristinta lempinimellä monsteri, mutta täytyy sanoa, että se tekee nimityksestään huolimatta hyvää työtä sille jäteosuudelle, jota ei saada uudelleenkäyttöön.

Niemellä on ollut jo neljän vuoden ajan käytössä biokaasuautoja. Biokaasu on 100-prosenttisesti uusiutuva, suomalainen polttoaine.

Jätepakkaajat eli ”monsterit”

Ympäristöystävällisiä kilometrejä

Niemi ei ole jättänyt ympäristövastuullisuuttaan vain kierrätykseen, vaan se on huomioinut ilmastonmuutoksen torjunnan myös muuttoon liittyvässä liikenteessä. Yhtiön omistamat 148 muuttoautoa kulkevat ympäristöystävällisesti, 100-prosenttisesti fossiilittomalla polttoaineella.

”Kuusi vuotta sitten otimme käyttöön vastuullisuusraportoinnin, eli muuton yhteydessä asiakas saa tarkan tiedon, kuinka paljon tarpeettomasta tavarasta on mennyt kierrätykseen.”

– Olemme ensimmäinen muuttoyritys Suomessa, joka käyttää biokaasuautoja. Koko kalustostamme jo neljännes liikkuu uusiutuvalla biokaasulla. Niemen dieselautot puolestaan käyttävät Neste MY uusiutuvaa dieseliä. Neste MY on sataprosenttisesti teollisuuden jätteistä ja tähteistä valmistettua dieseliä, jonka hiilidioksidi on peräisin jo ilmakehässä valmiiksi olevasta hiilidioksidista. Neste MY:stä aiheutuu kasvihuonepäästöjä 90 prosenttia vähemmän kuin tavallisesta dieselöljyn käyttämisestä. – Nesteen kanssa tehdyn sopimuksen avulla voimme merkittävästi vähentää muutosta aiheutuvia liikennepäästöjä, Mikko Helvelahti iloitsee. Niemen ympäristöohjelman tavoitteena on saada yrityksen pienhiukkaspäästöt nollaan vuoteen 2040 mennessä. Mikko Helvelahti kertoo ympäristövastuullisuuden näkyvän yrityksen kaikessa toiminnassa jatkossakin.