BIGGER ON COMFORT SMALLER ON FOOTPRINT clarksusa.com

Every season we design, not to t in but to stand out. With a commitment to luxurious comfort and artistic style, we strive to make high-quality shoes that feel as good as they look.

So beautiful and comfortable. e leather is soft and supple and molds to your feet. I will be ordering another pair in a di erent color. Highly recommend!

-Sheila S.

H.H. BROWN SHOWROOM

10 Times Square | 7th Floor

New York, NY 10018

Contact Linda Grosser for more information: GROSSERL@HHBROWN.COM

“

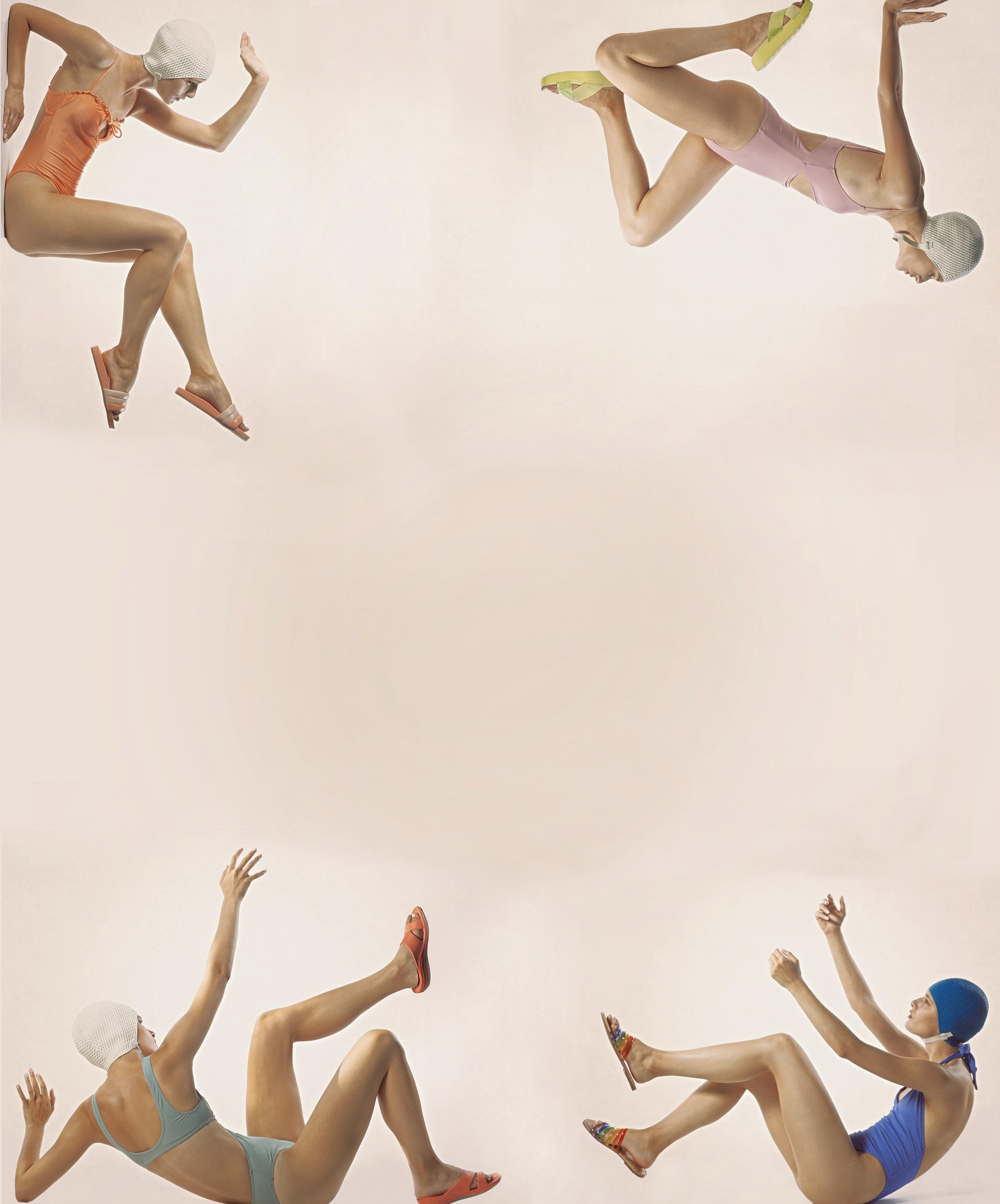

FEATURED: IWA

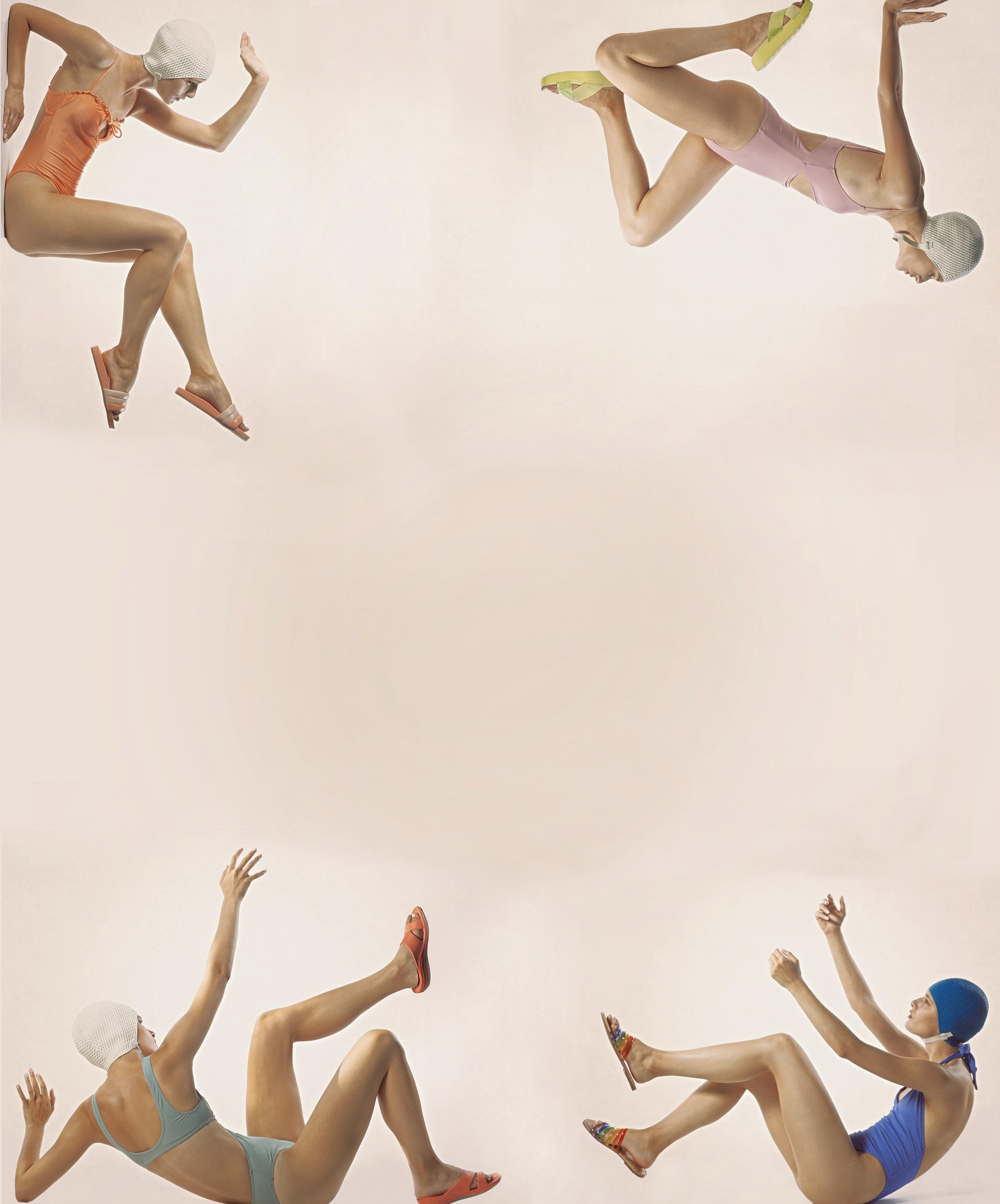

On cover: Holo Footwear slip-on mocs with 100 percent recycled quilted nylon uppers, EVA midsoles, and rubber soles. This page: Dr. Liza lace up made of locally sourced Brazilian leather; Wilding sneaker with organic cotton/linen upper, hemp/ flax fleece removable insole, and partially recycled sole made of synthetic rubber, silica, and cork.

Photography by Jamie Isaia; fashion editor: Kathleen O’Reilly; models: Charlotte Walker/Supreme Management, Anthony D'Alessandro/Crawford Models; makeup: Maya Ling Feero; photo assistant: Rebecca Steighner; styling assistant: Sarah Frey; production assistant: Eileen Viglietta.

APRIL/MAY 2023

Belinda Pina Publisher

Greg Dutter Editorial Director

Nancy Campbell

Trevett McCandliss Creative Directors

EDITORIAL

Kathy Passero Editor at Large

Kathleen O’Reilly Fashion Editor

Ann Loynd Burton

Contributing Editor

Melodie Jeng

Marcy Swingle

Contributing Photographers

ADVERTISING/ PRODUCTION

Noelle Heffernan

Sales Director

Laurie Guptill

Production Manager

Kathy Wenzler

Circulation Director

Catherine Rosario Office Manager

Mike Hoff Digital Director

WAINSCOT MEDIA

Carroll Dowden Chairman

Mark Dowden President & CEO

Steven J. Resnick

Vice President & CFO

OFFICES

ADVERTISING/EDITORIAL

One Maynard Drive Park Ridge, NJ 07656 Tel: (201) 571-2244

Advertising: Belinda. Pina@Wainscotmedia.com

Editorial: Greg.Dutter@ Wainscotmedia.com

CIRCULATION

Kathleen O’Reilly

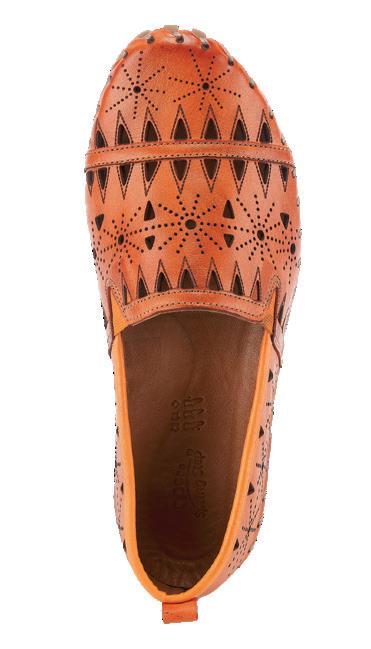

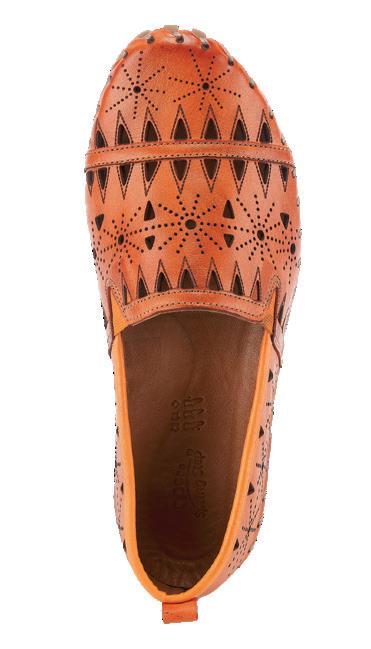

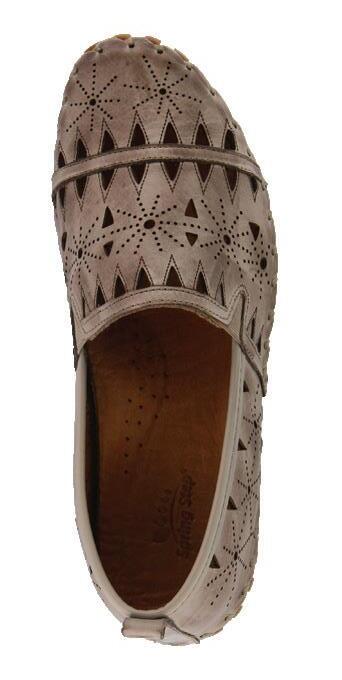

Dummy Naot leather mules

One Maynard Drive Park Ridge, NJ 07656 Tel: (201) 571-2244 Circ@Wainscotmedia.com

2 footwearplusmagazine.com • april/may 2023 PAGE 26 4 Editor’s Note 6 This Just In: Cape Town 8 Green & Heard 19 A Note to My Younger Self 22 Trend Spotting: Blush 24 Trend Spotting: Deck Sneakers 38 Shoe Salon 40 Last Shot 12 Triple Play Ayelet Lax Levy, president of U.S. Operations for Naot, is rolling out a bevy of initiatives with the goal tripling sales within three years By Greg

26 Natural Beauty Eco goes easy with everyday versatility and breezy styling.

Dutter

By

FEATURES DEPARTMENTS

FOOTWEAR PLUS ™ (ISSN#1054-898X) The fashion magazine of the footwear industry is published monthly (except for bimonthly April/May and October/November editions) by Wainscot Media, One Maynard Drive, Park Ridge, NJ, 07656. The publishers of this magazine do not accept responsibility for statements made by their advertisers in business competition. Periodicals postage paid at Mahwah, NJ, and additional mailing offices. Subscription price for one year: $48 in the U.S. Rates outside the U.S. are available upon request. Single copy price: $10. POSTMASTER: Send address changes to FOOTWEAR PLUS, P.O. Box 8548, Lowell, MA 01853-8548. Publisher not responsible for unsolicited articles or photos. Any photographs, artwork, manuscripts, editorial samples or merchandise sent for editorial consideration are sent at the sole risk of the sender. Wainscot Media will assume no responsibility for loss or damage. No portion of this issue may be reproduced without the written permission of the publisher. ©2008 by Wainscot Media. Printed in the United States.

• 4 WIDTHS • ORTHOLITE® INSOLES • WOMEN’S & MEN’S SIZING ULTIMA FALL 23 propetfootwear.com 800-877-6738

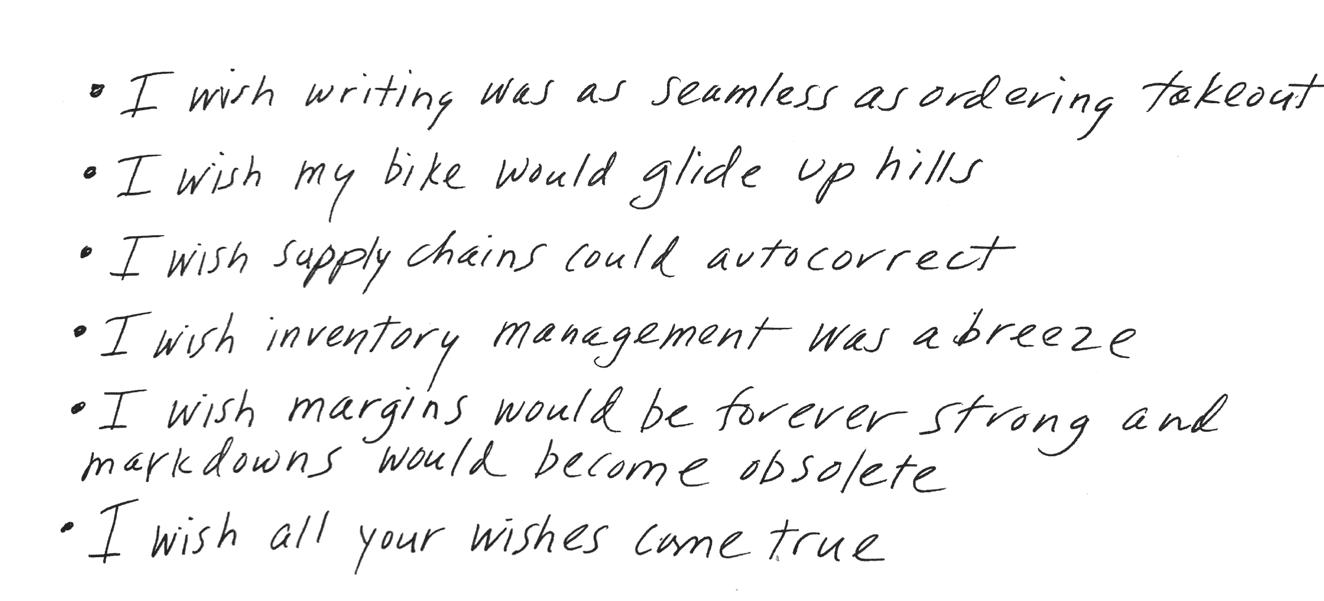

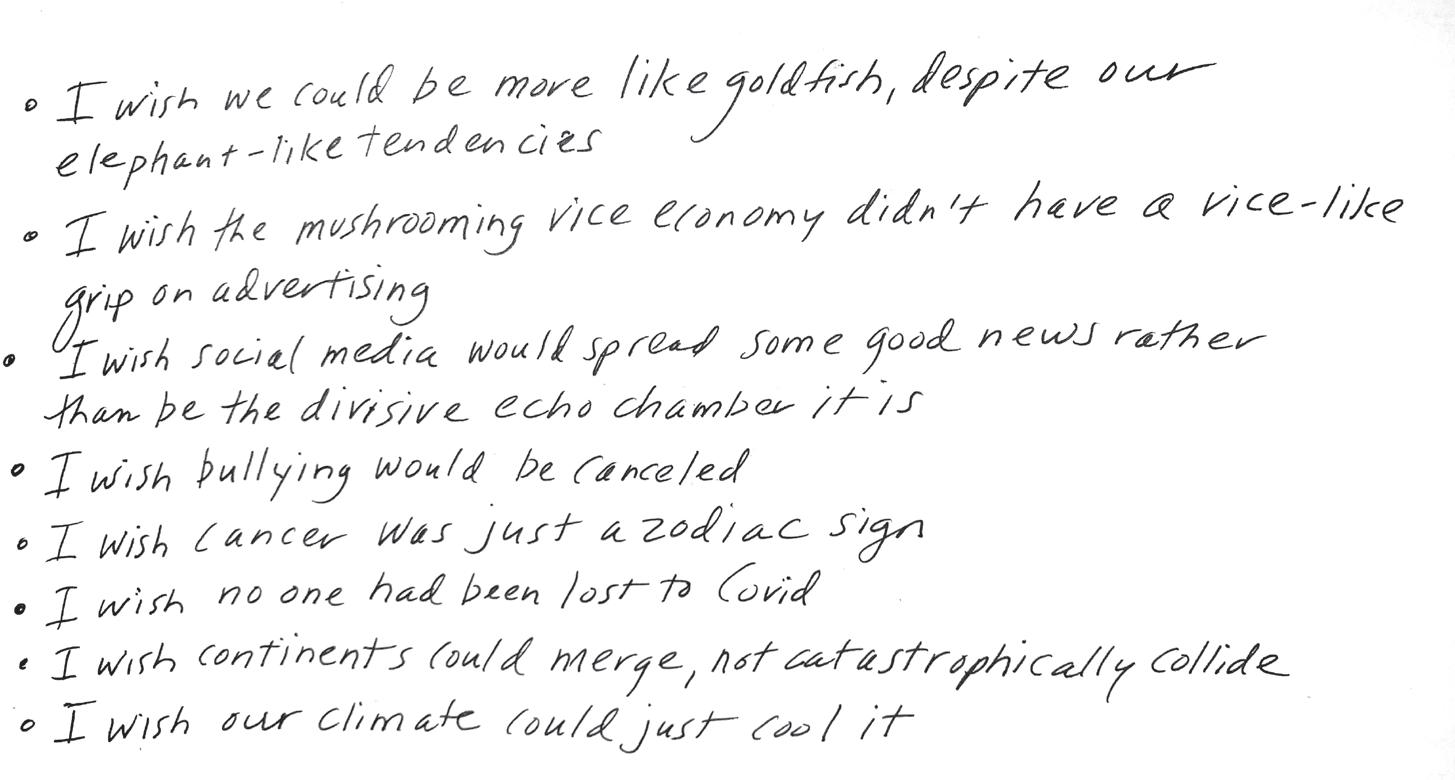

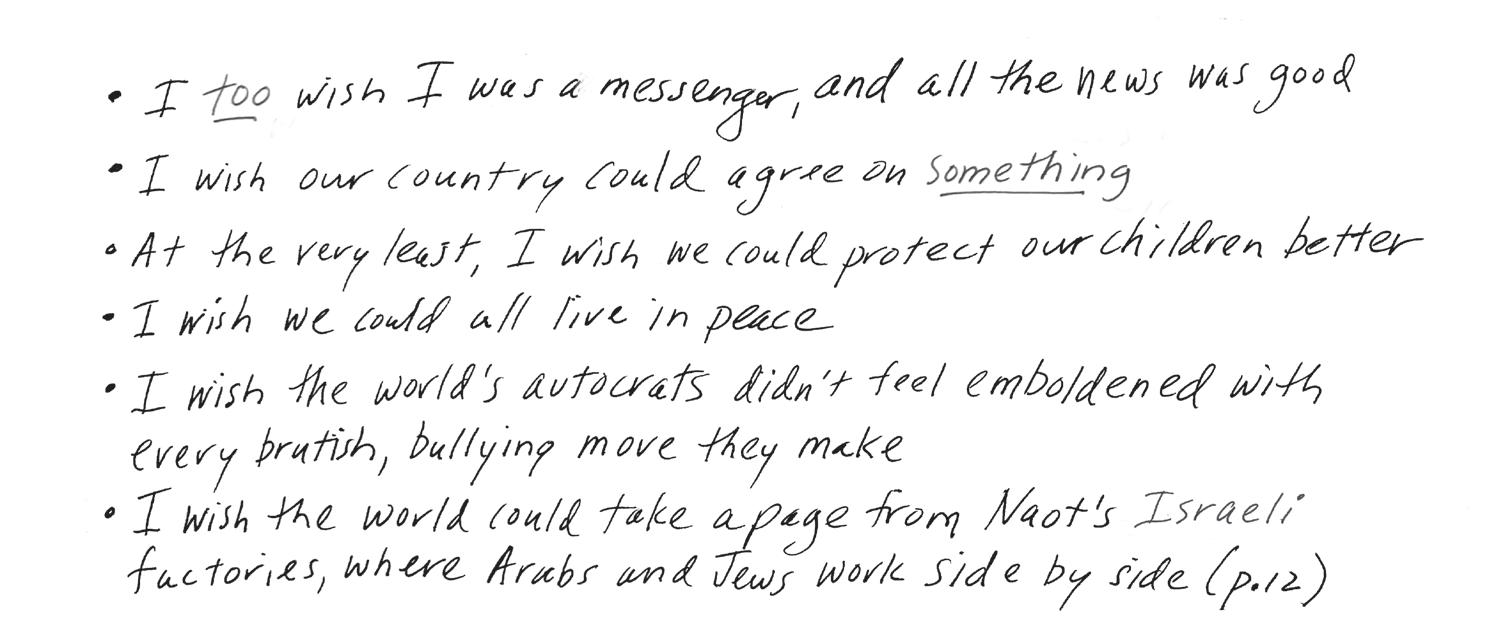

wishlist

What could be more fitting for our Sustainability Issue than to emulate one of pop culture’s most iconic eco warriors? Like the visionaries and leaders featured in the following pages, Pearl Jam’s Eddie Vedder is committed to leaving his mark on the world without leaving a massive carbon footprint behind. In fact, his band’s most recent album (Gigaton, released in 2020) was a nod to pressing environmental issues. But his earlier hit, Wishlist, is the inspiration for this month’s column.

Greg Dutter Editorial Director

Greg Dutter Editorial Director

EDITOR’S NOTE Better Man

4 footwearplusmagazine.com • april/may 2023

Cape Town Cool

South Africa’s “Mother City” embraces eclectic streetwear.

6 footwearplusmagazine.com • april/may 2023 THIS JUST IN

Photography by Christina Fragkou

Ecco Marks

60th Anniversary in Eco-Friendly Style

Two brand classics receive green upgrades.

THEY BECAME HITS when they debuted decades ago and have remained in Ecco’s line as perennial top-sellers. So how does one make the Soft sneaker and Cozmo sandal even better? How about green upgrades.

To celebrate the Danish brand’s 60th anniversary this year and ongoing commitment to sustainable design, the two classic styles have been reimagined in a special-edition, three-silhouette capsule. The highlight is a new bio-based, LYTR outsole (made of 40 percent castor beans), making them the lightest Soft and Cozmo versions to date, not to mention ones that are longer lasting, feature improved cushioning and shock-absorption, and are easier to clean. In addition, the Soft 60 (SRP: $200-$220) features Ecco’s new DriTan bio nappa leather, which greatly reduces water use during production, are 100 percent metal- and chrome-free, and fully compostable.

“Ecco was sustainable before the consumer even knew what sustainability was,” says Tom Berry, CEO of Ecco US. “Our anniversary package provides a great platform to celebrate this journey.”

Felix Zahn, product director of Ecco US, says the LYTR soles are based on critical foaming/PEBAX technology. “It sounds very technical, but in simpler words it’s an expanding closed-cell foam, which we’re combining with our no break-in Fluidform injection manufacturing process,” he explains. “This combination allows our construction to preserve the natural contours of our foot shaped lasts plus adding all the benefits that comes with the critical foaming.”

Specifically, Zahn cites the reduction in weight and added cushioning as product highlights. “The Soft 60 sneaker is around 60 percent lighter than the original Soft 7,” he says. “In addition, internal tests show an improvement in rebound and shock absorption by 40 percent. These are significant boosts.” Zahn adds, “Improving weight, cushioning, and shock absorption while leaving a better carbon footprint is a fantastic combination, which is very much aligned with our Danish design principle of ‘less is more.’”

Doing right by the planet, Berry says, is just how Ecco rolls. “Because sustainability has long been an important part of Danish culture, this capsule came natural to us,” he says. “We’re showcasing two iconic franchises (SRP for Cozmo 60 is $120-$130) while celebrating the sustainable principles of Danish Modernism and Ecco innovation.” That combination, he notes, includes timeless style, quality, truth in materials, and long-lasting comfort and durability though Ecco’s Fluidform, DriTan, and LYTR innovations. “The combination of these principles and innovations—along with our vertical farm-to-foot production model—presents a powerful and authentic sustainability story that we’re excited to share with consumers during our 60th anniversary,” Berry says. “Our anniversary is both a celebration of where we’ve been and of our journey still to come.”

Values Proposition

Sanctuary, the lifestyle brand with a conscience, aims to put its best foot forward.

SANCTUARY, A LICENSE of Highline

United, entered the footwear market in early 2020 on the heels of its strong lifestyle reputation built in women’s apparel. Creators Ken and Deb Polanco launched as a pants brand 23 years prior and have steadily expanded into other categories fueled by a unique combination of laid-back California cool and effortless New York attitude. The result: modern, timeless fashion. The brand has also built a strong following based on its commitment to lessening its carbon footprint whenever possible, which strongly resonates with its target audience.

Similarly, Sanctuary footwear is aimed at a fashion-savvy, but not a trend chaser-type of customer, says Christine Fuchs, president of sales/design for Highline United. “That

Sanctuary’s Bigtime Loafer 2.0 mules feature chrome-free napa leather and recycled rubber outsoles.

includes the eco-conscious shopper who appreciates the sustainable story behind every one of our shoes as well as our recycled packaging.”

Sanctuary’s eco-friendly footwear efforts, dubbed Smart Creation, include the use of low-impact fibers such as linen and Tencel that use 20 times less water than cotton, are non-toxic, and leave behind minimal waste and emissions. Additional eco-friendly

8 footwearplusmagazine.com • april/may 2023

GREEN & HEARD

>39

Hold the Foam!

OrthoLite teams with Novamont to create Cirql, the first circular foam material solution at scale.

SHOE MANUFACTURING HAS inherently been a dirty business, especially when it comes to the use of man-made EVA materials commonly found in athletic footwear. That foam-like material pollutes landfills for millennia. And every year, in the U.S. alone, consumers throw away more than 300 million pairs of shoes, 95 percent of which end up in landfills. There must be a cleaner alternative.

Enter: OrthoLite Cirql, the world’s first circular foam material solution. OrthoLite spent the past several years in deep dive mode to develop this sustainable, 100-percent biodegradable foam cushioning alternative. Now the Amherst, MA-based company is teaming with Novamont—a leading developer, producer, and designer of biodegradable and compostable bioplastics and biochemicals—to bring Cirql to the masses through OrthoLite’s 500-plus footwear brand partners and factory stakeholders beginning the second half of this year.

Essentially, two leaders in their respective fields are joining forces to revolutionize manufacturing and create a global solution for environmental improvement across a footwear industry currently valued at around $400 billion. It’s a big deal.

“It comes down to one word: trust,” says Glenn Barrett, CEO and founder of OrthoLite. “We chose to partner because both companies are trusted organizations with trusted teams that have successfully grown and created expansion by delivering trusted solutions for decades. Now, we’re combining that power to drive the most important innovation for both companies to date: OrthoLite Cirql.”

Based in Novara, Italy, Novamont is a 33-year-old entrepreneurial technology company with a track record of pioneering change and soil health through its circular biomaterials, says Barrett. The company has developed low-impact, certified biodegradable, and compostable solutions with multiple end-of-life options for agriculture, food service, packaging, and organic waste collection. Barrett believes the partnership will result in a cornerstone solution that will drive design and production of more sustainable/circular footwear going forward, starting with midsoles. “Footwear is a very large consumer product segment with incredible reach and influence,” he says. “We’re excited by the potential of this partnership because it combines Novamont’s proven biopolymer with our clean foaming process to yield a game-changing sustainable materials solution to the footwear industry. Our global teams are so fired up to deliver—at scale—the world’s first sustainable and circular footwear materials that will enable our 500-plus brand partners to meet their climate-friendly manufacturing and product goals.”

OrthoLite Cirql is free from forever chemicals and responsibly sourced from non-GMO raw materials derived from plants and synthetic biodegradable materials. It can be returned to the production cycle using low-energy, advanced chemical recycling to help keep materials in use or returned to nature through selected industrial composting methods and processors. Using existing and new closed-loop, take-back, recycling streams for

footwear, scalable end-of-life management will involve collaboration with footwear brands and the waste management sector. OrthoLite Cirql will also help prevent the accumulation of persistent microplastics because the particles in it biodegrade just like cellulose and other natural polymers do. What’s more, extensive testing reveals Cirql to be as good or better than EVA in terms of performance and durability.

“Brands are extremely excited about what OrthoLite Cirql offers to the marketplace, and how it effectively addresses the need to eliminate the use of toxic or hazardous chemicals and materials currently used in the manufacturing process,” Barrett says. “OrthoLite Cirql will help drive the industry towards true circularity.”

To that end, Novamont developed a material for OrthoLite Cirql’s chemical-free foaming process, in which the biopolymer pellets are melted and mixed with liquid nitrogen under extreme pressure. The unique injection-molding process results in incredibly efficient cycle times that reduce energy consumption and create a finished part with no downtime, polymerization, or waste.

“Novamont has always based its model on the development of

2023 april/may • footwearplusmagazine.com 9

GREEN & HEARD

>11

Natural Instincts

Pedag doubles down on its sustainable production and products.

THE GERMAN COMPONENTS company

Pedag is upping its sustainability efforts, which span product, packaging, solar panels (recently installed at the company’s headquarters), and electric company cars. Even the logo imprinted on the millions of insoles the brand sells annually has gotten an eco-friendly makeover.

Pedag’s logo had long featured a gold foil imprint design on its leather and cork insoles, a process that involved printing the pigment on plastic sheets and created lots of manufacturing waste with every stamp. “Now we do a hot-stamping logo without any gold foil,” says Thomas Timm, CEO of Pedag. “We underline the natural characters of the leather and cork, and we’re also reducing waste in our manufacturing process.”

The more sustainable logo is just one of many ways the 68-year-old company is seeking to lessen its global footprint—without sacrificing quality, comfort, or performance. Another involves environmentally friendly packaging. Pedag had switched to renewable carbon paper several years ago, but the team saw a way to get even greener. “We still had quite a lot of plastic packaging in our line,” Timm explains. “So now our insoles packaging is made of completely renewable carbon boxes, and the plastic hooks are 100 percent recycled materials.”

It’s another win-win scenario, as the new packaging is consistent across all categories and showcases the product better. “Before, we had different packaging based on fashion, outdoor, comfort, and athletic sectors,” Timm says. “We now have one design, which adapts to the different channels of distribution via category-specific point-of-sale lifestyle photography. The product is the hero, consumers recognize the brand more easily, and it’s easier for the retailers to merchandise. We now have a homogenous customer journey.”

In truth, Pedag has been driven by sustainable design principles since its inception in 1955—long before consumers cared about such things. “We’ve always sought to make a good product that’s good for people, because natural materials feel much better against the skin,” says Ivan Komashinskiy, president of Pedag USA, noting that these materials are part of the

company’s DNA. “They’re moisture-absorbing and good for the body’s microclimate, and step by step we realized these materials are better for the environment as well.”

Even so, both Timm and Komashinskiy believe consumers buy Pedag insoles and shoe care products over competitors’ because of the quality-price ratio first and foremost. Eco-friendly attributes tip the scales further in the brand’s favor. “The beauty is our products are priced below the leading brands that are made in Asia and from synthetic materials,” Komashinskiy says. “For example, our flagship insole products, made from vegetable-tanned cowhide, retail for $40, while synthetic competitors start at $50—and we offer 60 percent margins.” Not surprisingly, he reports strong sales of late in the U.S. “The last few years we’ve seen doubledigit growth and have doubled revenue,” he says.

“Our brand story resonates very well, especially among independent retailers.”

Looking ahead, Pedag will continue to build on its sustainable foundation. Timm is proud to report that solar panels will soon enable the company’s factory to produce its own electricity. “It marks a big step for us in reducing our carbon dioxide output in manufacturing,” he says. “In fact, we’ll produce more electricity than we need, so we’ll sell it to the surrounding area.”

Pedag is also in the process of transitioning its cotton surface insoles to bamboo—an abundant, renewable material that is far less labor intensive than cotton and doesn’t involve using suppliers in China’s Xinjiang province. The bamboo terry material will be made in Spain. Moreover, the company is addressing the industry’s dirty little secret: harmful adhesives. “They’re harmful to the environment, workers, and consumers,” Komashinskiy says. “That’s why we only use solvent-free, water-based adhesives, and while it takes a longer time to set and thus adds cost, we don’t compromise on that aspect.”

The same goes for the materials used in Pedag’s shoe care collection of waterproofing agents, cleaners, and conditioners. Renewable raw materials include lanolin, carnauba, and beeswaxes. The eco-friendly collection is biodegradable, free of solvents and fluorocarbons (PFCs), and safe to use indoors. Even Pedag’s shoe trees and brushes are manufactured in a carbon-neutral way. The wood is regionally sourced in Germany, while items made with plastic consist of recycled materials.

Being green isn’t easy, but Pedag is committed to adhering to the three guiding principles of its founder, Hartmut Schelchen: Produce in a resource-saving way, use natural materials as much as possible to create healthy products, and always remember the human being is the center of attention. While that resource-saving production philosophy stemmed from a postwar economy of scarcity, it has taken on new relevance in the age of climate change. Thus, Pedag’s sustainability mission continues. “It’s impossible to be 100 percent sustainable, and there isn’t a final destination on this journey, but we’re always learning and trying to improve our efforts,” Timm says.

10 footwearplusmagazine.com • april/may 2023 GREEN & HEARD

Pedag’s new hot stamp logo process greatly reduces waste; the Viva Summer insole combines a natural bamboo terry upper and cushioning made of sisal fibers.

continued from page 9 products conceived as true catalysts for change, which are capable of activating much greater systemic effects than the product itself, and not as mere substitutes for traditional ones,” says Catia Bastioli, CEO and founder of Novamont. “Our philosophy has always been to avoid the problems of pollutant accumulation in the environment, and the fruitful collaboration with OrthoLite, a company that is also committed in finding solutions and not just products, allows us to bring our approach to the footwear industry for the first time.”

Of course getting to scale takes time. Cirql was officially introduced last March and, over the past year, OrthoLite has invested heavily in educating and creating awareness in the industry before the official launch. Change is never easy, and at this scale it’s exponentially more challenging. How would Barrett grade the company’s efforts so far? “I’d give us an A+ on building awareness and generating interest,” he says.

The commercialization path for any innovation can also take unexpected turns that impact the go-to-market strategy, and Cirql is no exception. “We experienced many of the same supply chain–related challenges that everyone experienced over the past couple of years, and scaling from a lab to repeatable production trials presented challenges,” Barrett says. “What we’re most proud of is how our team has persevered through all this. The demand for Cirql is overwhelming, and we anticipate that all of our brands will adopt it once we officially launch.”

The initial goal is to roll out Cirql in collaboration with OrthoLite’s key partners. Cirql will be exclusively available to brands that support its core business. “The key is to deliver on our promises and to provide worldclass service to both the brands and their T1 partners,” Barrett says. “So, as we activate production together with our brand partners, delivery, service, and support will be critical to our mutual success.”

Looking five years out, Barrett says the growth plan is aggressive but within reach. “We remain confident that these goals will be achievable based on the initial demand from our OrthoLite brand partners,” he says. “And with brands looking for a more sustainable solution compared to the traditional plastics utilized across all parts of the shoe, Cirql checks those boxes.”

In many ways, Cirql is a logical next step for OrthoLite, founded 26 years ago with insoles containing rubber from recycled tires. The company’s goal is to achieve zero waste by 2025—a significant move toward pollution reduction and the regeneration of natural systems, which are central tenets of circular, sustainable solutions.

“From day one, OrthoLite has delivered sustainability stories unlike any other component supplier, and today we have the largest portfolio of eco-technologies to support all categories, applications, and price points in footwear,” Barrett says. “From product to our processes, we’ve been synonymous with comfort, performance, and sustainability.”

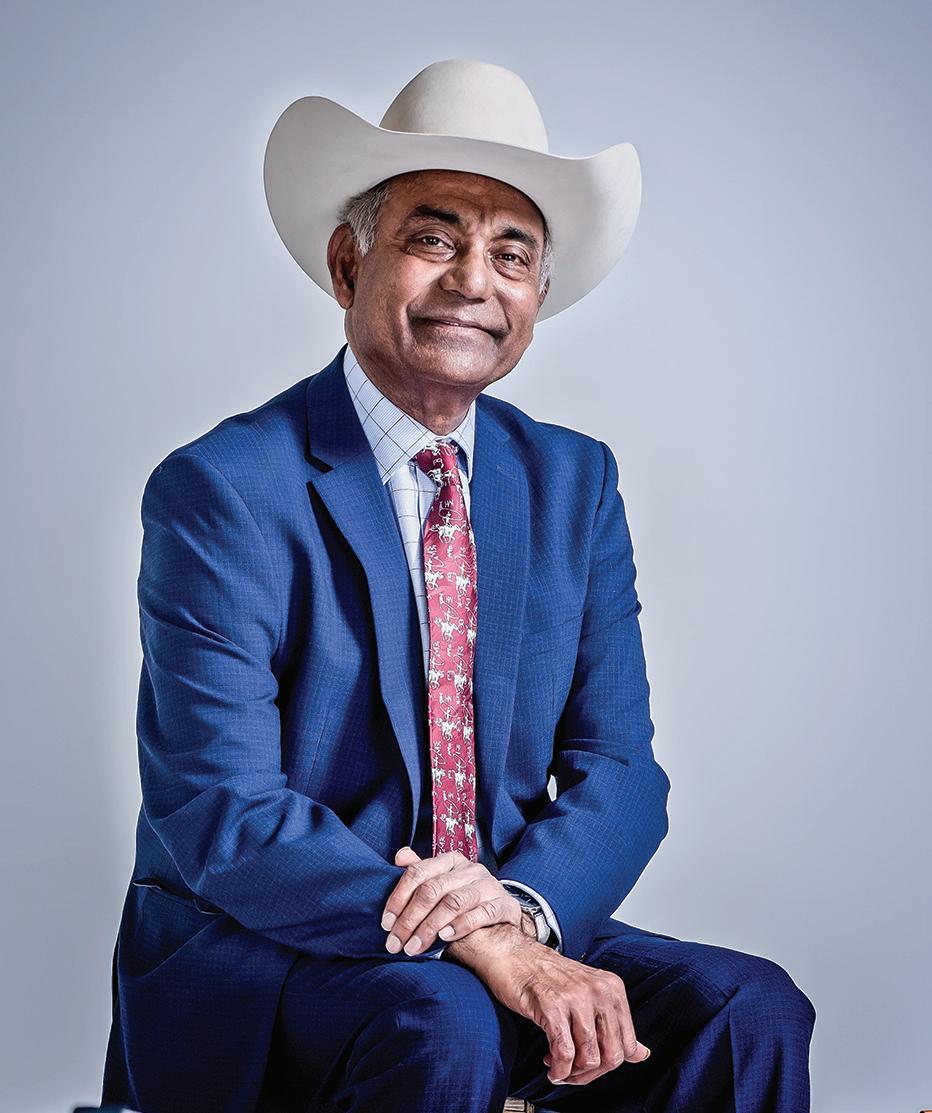

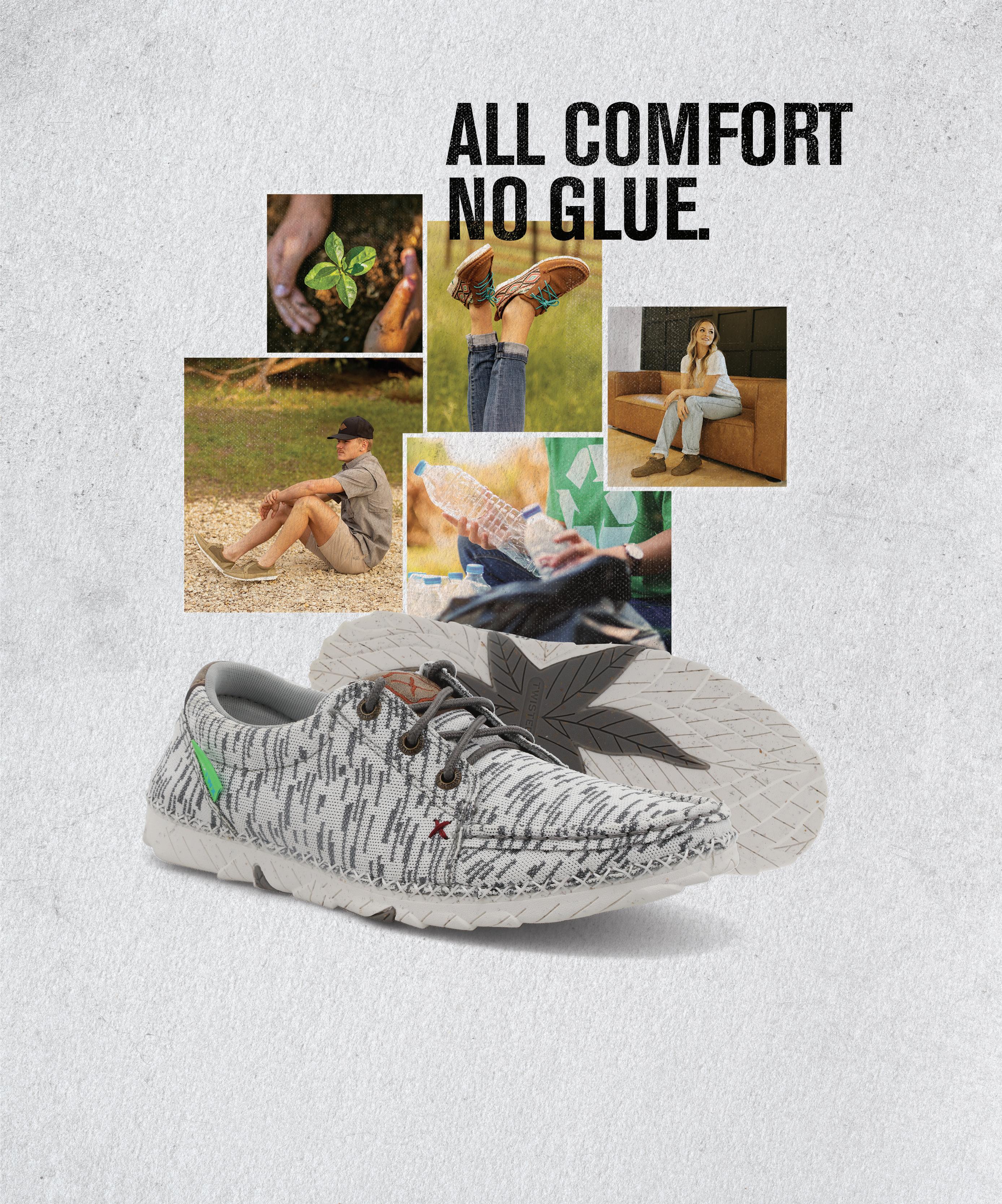

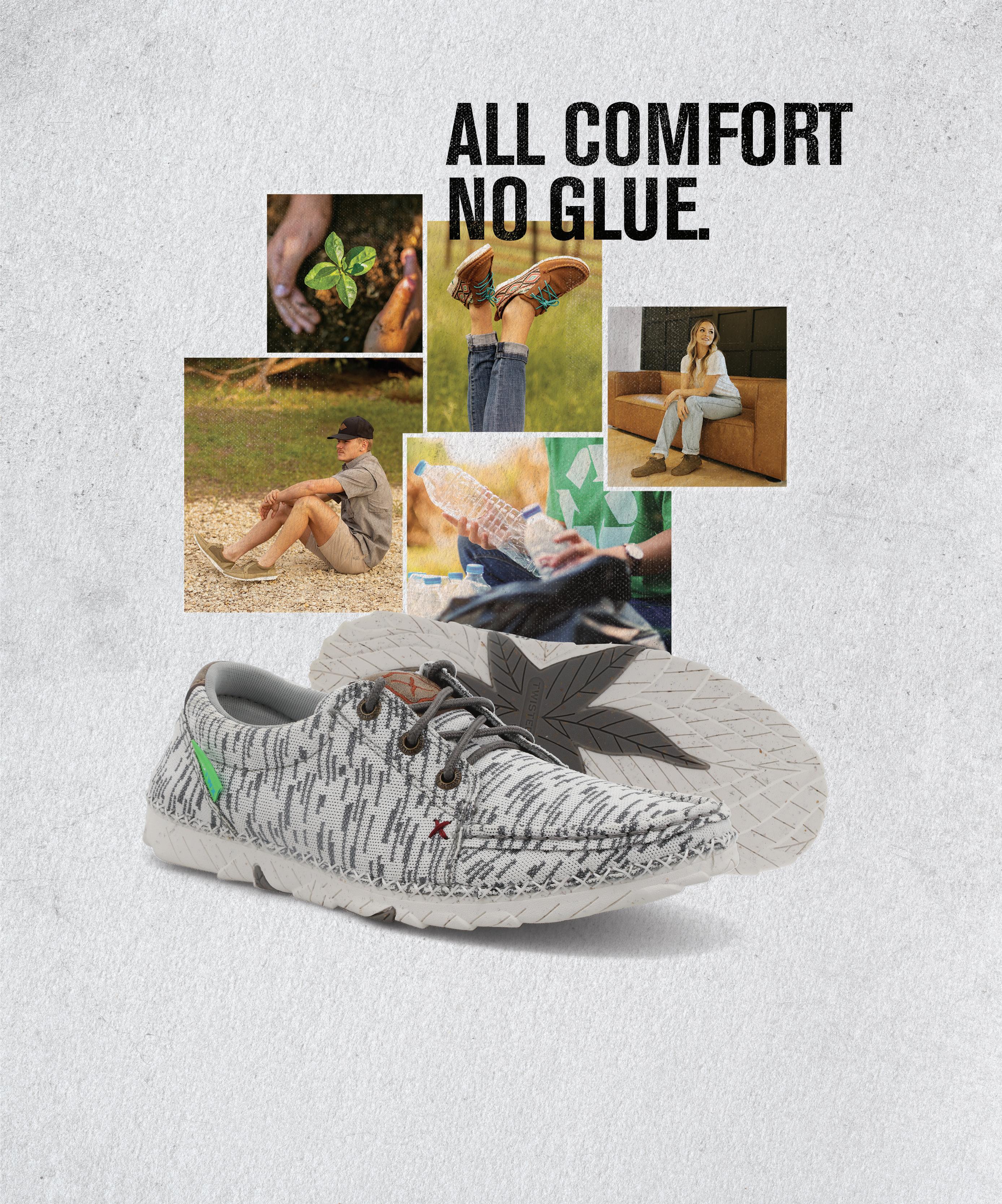

Grinding to a Greener Future

Twisted X aiming for circularity with grinding program.

MOST SUSTAINABILITY EXPERTS consider circularity the holy grail of manufacturing. In simple terms, it means producing zero waste. That is what Twisted X Global Brands (Twisted X, Wrangler, and Black Star) hopes to work toward, beginning this fall—once its state-of-the-art grinders get fully up and running at partner factories in the Americas and, this January, at its Decatur, TX, headquarters.

CEO Prasad Reddy can’t wait to start throwing mounds of PU, EVA, rubber, end-of-life footwear, and (potentially) textile waste into the grinders and turning that trash into shoes. “This is a totally new play for us where we are removing waste from landfills in a different way than we’ve done before,” he says. “For example, with Zero-X we removed harmful glues from the process, but here we are truly going to remove factory waste. This is full circle because we are not contributing to factory waste; we are grinding and upcycling into other industries and offerings.”

The yet-to-be-named program could be used across the company’s brand portfolio, primarily in casual styles. “What we’ve tested so far doesn’t compromise on comfort, and the durability is good, but it isn’t quite as durable as a rubber sole used for work wear,” Reddy says. “So, the material will lean more toward use in casual comfort styles at the start.”

As for how much waste Twisted X hopes to redirect from landfills, Reddy says the more the merrier. “At this moment we don’t have an estimate, but we feel the impact is going to be huge,” he says, noting it depends on how many pairs are sold. That aside, the grinding process bodes well on how much waste can be repurposed as it essentially squishes it down to approximately 1/20th of the original volume. “The first round of our process is expected to save 90 percent in volume of waste going into landfills. Then it can be reground even further,” he says. “The first round can be used in variety of footwear profiles, while grinds from round two can be used in flip-flops only, and round three grinds can be used by other companies for products like doormats, gym mats, and cushioning filler in sofas and automotive seats.”

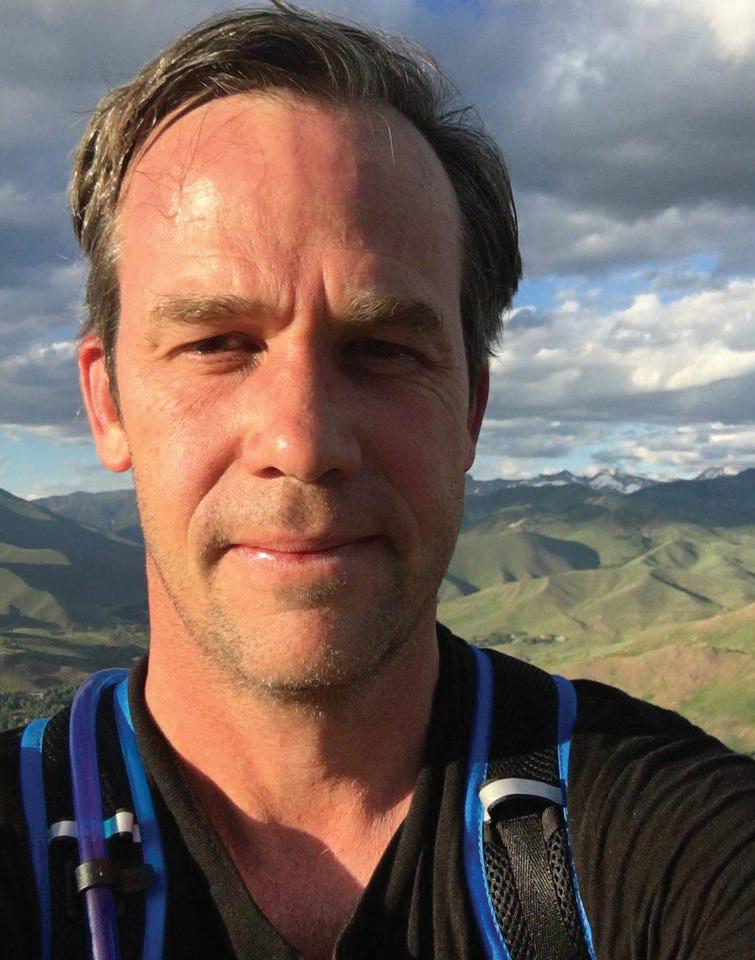

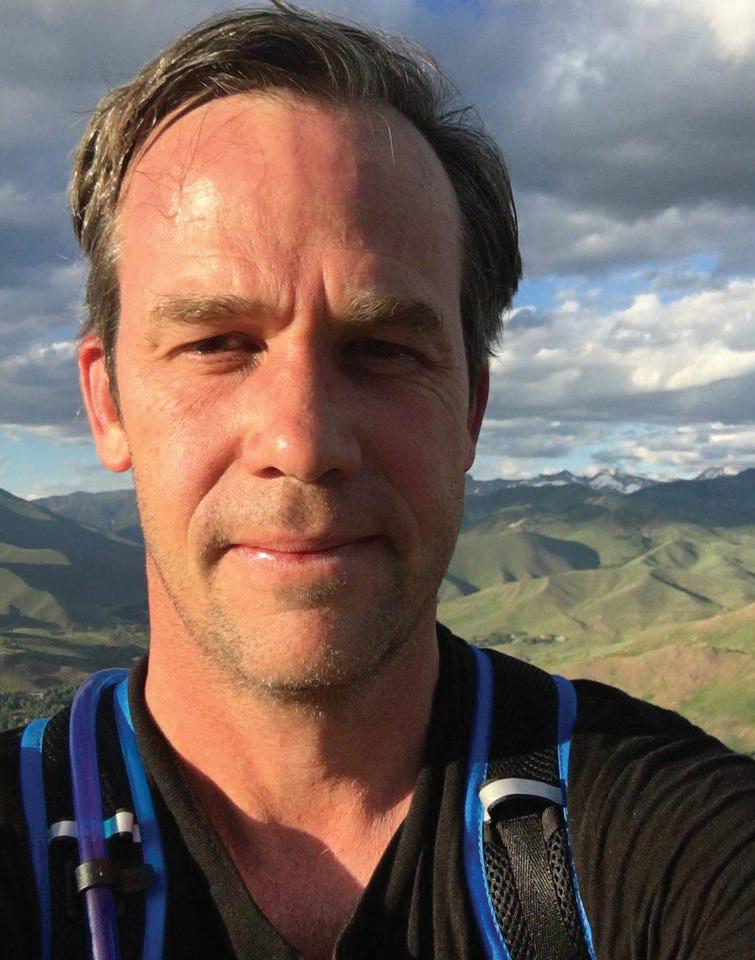

Prasad Reddy, CEO, Twisted X Global Brands

The ability to keep regrinding and repurposing waste is what has Reddy most excited about the program’s long-term potential. “It’s not single use. This is a full circular initiative,” he says. “The next level up will be using the grindings for the entire shoe. So, zero waste is where we’re headed.”

2023 april/may • footwearplusmagazine.com 11 GREEN & HEARD

Q&A

BY GREG DUTTER

TRIPLE PLAY

Ayelet Lax Levy, president of U.S. operations for Naot, is rolling out a bevy of initiatives with the goal of tripling sales in three years.

FIRST: YOU GOTTA believe. Second: You must have the plans and team in place to attain your goals. Third: The timing must be right. Ayelet Lax Levy, president of U.S. operations for Naot, has gotten two out of three right since she took the reins from her father, Steve Lax, in December 2019. Timing has been the stumbling block for Naot. When the pandemic hit, it put the entire industry in survival mode. That meant Lax Levy’s grand plans—designed to triple U.S. sales within three years—had to wait.

“I had a lot of great intentions and expectations going into 2020—like rolling out a new branding campaign and introducing shop-in-shops to increase brand awareness that would drive consumers into our retail partners,” Lax Levy says. “There were a lot of technological and marketing aspects that were also put on hold because, basically, the world was put on hold.”

The wait is finally over. Lax Levy is once again going full throttle on the job she has yearned to do since taking the helm. The expectations remain equally great. “Starting this year through 2025, we’re going to really push all those plans we had fully into place, which includes rolling out our new branding campaign this month (complete with new logos, tagline, and influencer marketing programs) and having our new ERP system become operational on June 1.”

Lax Levy’s game plan is both consumer-facing and backroom. It represents a changing of the guard but doesn’t completely abandon how business was (successfully) done under the previous regime. It’s a compromise between what works and what Lax Levy believes can be improved. Such seamless generational handovers are rare, but this one is working well so far for Naot’s U.S. division.

Take the company’s new website, for example. It was a more involved process than usual because Lax Levy had to find a way to adhere to her father’s parting directive that Naot would never compete with its retail partners by selling DTC. But Lax Levy knew a simple informational website wasn’t enough in this day and age. Naot reached a middle ground by

cherry-picking nine of its longtime retailers (the 10th is its Soho flagship, which opened last fall) to service orders made through the site.

“It’s a marketplace. Whoever can fulfill the order gets the sale,” Lax Levy explains, adding that the site has been performing extremely well. “Because of the volume one of our retailers has been doing through our site, they were able to hire back two employees in their warehouse. Sales on our site overall have quadrupled.”

Lax Levy has also updated the company’s marketing strategy, introducing influencers into Naot’s recent campaigns. Her dad, who still doesn’t have an Instagram account, was thumbs-down on using them, but she saw big potential to reach new

12 footwearplusmagazine.com • april/may 2023

Our Zero-X™ collection features a revolutionary and eco-forward stitching method that eliminates the need for glue in the production process. A unique, multi-layered technology that keeps the planet and everyone on it at the forefront. Learn more at twistedx.com/zero-x

Copyright © 2023 Twisted X Inc. All Rights Reserved.

TM

audiences—and to do so cost effectively. “When we opened our Soho flagship, we backed it with an influencer campaign that drove traffic into the store right away,” Lax Levy reports. “One influencer in particular promoted our new knee-high boots, and within days we had people come in requesting that style. So, the right influencers and social media agencies can produce meaningful results.”

Then there’s the ambassador program, which debuted last year. Naot chose 10 influencers from around the country as brand ambassadors. But Lax Levy felt that the old norm of featuring young, flawless models was limiting and unrealistic, so the company scrapped its previous beauty-driven campaigns in favor of a more inclusive approach, which now extends to all of its brand marketing. “We chose a range of ethnicities, body types, and ages,” she says. “I want my daughter to believe whatever she looks like is great. I also believe changing from a very model-esque advertising approach to featuring authentic women is a way to connect with a much broader audience of potential customers.”

Other aspects of her father’s approach to managing Naot haven’t changed a bit, starting with how the company treats its retail partners. Naot does whatever it takes to meet their needs. This ranges from not selling DTC to being as flexible as possible with inventory management, a top concern among retailers as supply chain disruption continues to wreak havoc on deliveries. Naot’s approach is a refreshing contrast to that of competitors who offer no flexibility on terms regardless of how late a shipment is. “We’ve never said, ‘We’re late, but it’s your problem,’” Lax Levy says, noting instances where orders expected for July arrived in January. “Vendors still expect them to accept it without any concessions, whereas our team always calls to let our customers know if a shipment might arrive a little late and to see whether they still want it or if there’s anything else we could provide instead.”

Flexibility and willingness to compromise in an increasingly rigid industry landscape are serving Naot well. Lax Levy is forging a path by blending new and old school managerial techniques to reach her goal of tripling sales in the next three years. She says the division is already off to a roaring start in 2023—and that’s before the new branding campaign debuts in May. Indeed, the best is yet to come.

“Our plans are just starting to come to fruition,” Lax Levy says. “It’s been a three-year journey, but we’re all really excited about the future.”

How’s business?

We’re having good problems. Business is significantly up, and we’ve asked our factories to almost double capacity, but that’s really hard to do. So, the main goal for the rest of this year is to try and get enough shoes shipped to meet demand. It’s as simple as that, and I try to never disappoint our retailers. That’s why we’ve been flying in three shipments

per week, because I’d rather make a little less on a shoe and get it to our stores on time. But we’ll get there on increasing production. In the meantime, our shoes are selling, so we can’t really complain. This first quarter, for example, is the best sandals season we’ve had in a long time. There are about six styles that we can’t keep in stock. So, again, it’s good problems.

What do you attribute this success to most?

Multiple reasons. One: I think we just have some very good designs. Two: Naot has always been known as a good travel brand, and I think the huge rise in travel post-pandemic is helping fuel a massive increase in our business. I mean, our family tried to book a trip recently, and we couldn’t get in anywhere. So, a lot of people are traveling, and they

They want to wear a cute, little heel. What’s also interesting is that a lot of consumers saved over the pandemic. So even though there’s inflation, they’re willing to make that investment in their wardrobes. That said, we’ve held pricing throughout most of the pandemic. It hasn’t gone up nearly as much as our competition, and that’s also helped our sales. Four: The hybrid work trend fits with many of our styles, which crossover well from casual to office settings.

Are you able to meet the growing demand within your existing factories?

We’re actually in the process of expanding our factory base, but not in the Far East. We’re aiming to do something closer to our Israeli base. We plan to announce that in June. In the meantime, we’ve been ramping up production in or existing region

OFF THE CUFF

What are you reading?

Tomorrow, and Tomorrow, and Tomorrow by Gabrielle Zevin. It’s a gaming industry plot and a New York Times Best Seller. It’s fun.

What was the last movie you saw? We have a rule in our house where my kids are not allowed to watch a movie until they’ve read the book. So, now that they’ve finished the Harry Potter series, we’re on a Harry Potter movies kick.

What might people be surprised to know about you? I wake up at 5:30 a.m. every day. Our factory base is in Israel and their workday starts seven hours before ours does, but I also wake up then to just get life going.

What is the best piece of business advice you’ve ever received? To always come up with three outcomes for

everything: best case, worst case, and middle of the road. It came from our former CEO, who was with us for a long time. It’s been very helpful.

Who is your most coveted dinner guest? If I could, Ruth Bader Ginsburg. She was such an interesting woman. Talking with her about her life and learning how she got to where she did would be fascinating.

What is your favorite word? Absolutely. But it’s also one of the two or three words that I’m told I say too often.

What is your least favorite word? Like. It’s annoying. But, like, I grew up in the ’90s, so...

What is inspiring you right now? The people who’ve been protesting in Tel Aviv. Almost a half million came out recently.

want comfortable shoes. Three: In general, consumers are moving beyond their pandemic practices, but they don’t want to give up on the comfort that many of them discovered during that time. And Naot offers great comfort and style which, of late, involves a desire for slightly dressier looks. That’s probably why our heels, like our Innovate sandal, have been blowing out. Women are going out to dinner and attending events again. Even those who were more cautious are now out and about.

I’m inspired by their determined ability to stand up for democracy.

What did you want to be when you grew up? A famous singer, which obviously didn’t work out.

What was your first-ever paying job? Filing for my dad in our Yaleet (U.S. distributor of Naot) o ces when I was 14. That was back when we actually had filing cabinets. It was a very important task, mind you.

What was your first concert and best concert? My first was the Moody Blues in the early ’90s. My parents were into that music and took me along. The best was Paul McCartney. Billy Joel came out for a few songs. They both had so much energy. It was so inspiring.

What is your motto? Always find the good.

as best we can, including having opened three facilities in the area recently. But there’s only so much production that we can do there. We’ve maxed it out. Again, it’s a good problem to have.

When do you expect to have increased production capacity in place?

I’m hoping by August. But there are lots of variables in play. Looking at the best case, worst case and middle of the road scenarios, I’d say we’re in

14 footwearplusmagazine.com • april/may 2023 Q&A

J U L Y 2 8 - 3 0 , 2 0 2 3 REGISTER TODAY! S A N D I E G O C O N V E N T I O N C E N T E R

ASHOWCASEOFFOOTWEAR'SFINESTBRANDS

pretty good shape. We’ve tried multiple ways to increase production already, although not all of them have worked. For example, we tried a new supplier for buckles, but then they went about of business. Fortunately, we have plenty of plans in play. If only 20 percent of them come to fruition, then I think we’ll be able to increase production capacity at some point this year.

How much have the supply chain issues impacted Naot?

We’ve been affected in multiple ways, and still are. The industry’s supply chain issues overall haven’t been solved at all. For example, a lot of our stitchers, which we contract out to small factories in the West Bank, closed during the pandemic. So, we had to find alternatives. Same goes for our buckle supplier that we partnered with in Spain. Then he shut his doors, and we’ve had to find someone else. There’s a lot of that going on throughout the industry. Like, one of the biggest tanneries in Italy closed last year, and while it wasn’t our main supplier, a lot of those who did use them have switched to our suppliers, and that affects our business. Basically, there are less suppliers overall, and everyone is competing for the remaining ones throughout the supply chain. As a result, those suppliers are charging more, and that affects our business as well.

Sounds like a never-ending nightmare. It is. The good thing is we own our own factories. We weren’t impacted by the shutdowns in China. In fact, we never shut our factory doors once throughout the pandemic. Even if we couldn’t product shoe X, we found ways to produce shoe Y because we had enough of those materials on hand. We found ways to keep our business going, and that certainly has helped us. And while our shipping costs have gone through the roof, it’s not the same as Far East costs. As a result, we’ve definitely grabbed some shelf space because other brands couldn’t deliver.

Still, knowing what you know now, would you have preferred to skip the pandemic and taken over at the start of this year?

I might have waited a year or two. (Laughs) But I’m so happy, for starters, that we were able to keep my dad home throughout that time. I didn’t want to jeopardize his heath by having him think he needed to come into the office and help. We achieved that—and we never shut down. Our distribution center stayed open the whole time. So did our main office. We rotated three teams: two that were in the office while one worked from home. If anyone got Covid, we’d rotate the other team in. And those few employees with underlining conditions never had to come into the office. Our IT department did a great in

getting them up and running at home.

Would you say this year marks your real start as president, whereas the previous three years was a crash course in survival?

I think so. The past three years have been a lot of “what’s going to happen next.” But I’ve always had the mindset of planning for best case, worst case and middle of the road scenarios. Be prepared for anything, basically. That’s how we got through it, and continue to do so. At least now, though, we can look forward more clearly and with more enthusiasm. We have a little more confidence in forecasting our business. Even though there are still supply chain issues, we’re used to them. Whereas, in 2021, I don’t think anyone was prepared for those issues and everybody was impacted greatly.

It’s been a managerial baptism by fire for you. It sure wasn’t what I initially envisioned the job to be. On that note, I think one of the key reasons we were able to navigate through all this disruption so well was because we never lost contact with our retailers. Our reps stayed on the road the whole time. If we expected retailers to be in their stores, then we wanted our reps alongside them and our offices open. That was very important, because retailers were on the front lines of all this and were forced to adapt to all kinds of changes. They were facing people with masks, no masks, dealing with customer quotas, outdoor fittings, curbside pickups, etc., etc. So, we just tried to do the best that we could to be there alongside them to help them through it. Because, at the end of the day, if they weren’t going to still be standing on the other side of this pandemic, then there would be no industry left, basically.

How might have that experience changed how you manage Naot now?

I’m not rushing things as much. For example, our ERP system was supposed to go live in March and now it will be June. Our rebrand was also supposed to launch in March and now it will be in May. I tend to give myself short deadlines, but I’ve learned that it’s better to get things done correctly rather than quickly.

To what extent is Naot’s rebranding effort going to be different than it’s been?

Pretty different. It will include a new logo, tagline, and marketing deck that will give us a more uniform look worldwide. It’s under the guidance of our CEO Moshe Marie, who came aboard in November 2021, from Nestlé Nespresso. He’s phenomenal. That brand became one of the best-selling coffee brands in Israel, which was not an easy market to break into. We also hired Inbal Oren, our first chief marketing officer,

Q&A

about eight months ago. We really are envisioning tripling the size of Naot mainly through increased brand awareness.

And you can achieve that within Naot’s current distribution?

I think the distribution we have now is great. We’re not looking to open up every store. I don’t think that would be good for the brand, or our retail partners. I think we can achieve that growth primarily because our current customers love our shoes. They often buy multiple pairs. One recently purchased her 130th pair. Our retailers say we have a cult-like following, and customers keep coming back for more. The other reason is Naot in Israel is like Coca-Cola in terms of brand recognition, and I think it has big potential in the U.S. Just by increasing our brand awareness in what is such a bigger market provides us an enormous growth opportunity.

Might this growth extend beyond Naot’s core customer base?

We’re not looking for 16 year olds, necessarily. I don’t think that’s our market. Then again, with TikTok, you never know what might catch on. That aside, I believe that there are many women in our core customer base who still don’t know our

Q&A

Naot’s first flagship store opened in Manhattan’s SoHo neighborhood last fall.

brand. The growth there could be tremendous. Whereas a lot of companies might have a good brand, but the product is lacking. I believe we have a phenomenal product, and we just have to build the brand around that.

Planning to triple Naot sales mainly within the existing distribution must be music to your retailers’ ears, no? Well, our overall goal is to send more customers into their stores asking for Naot. It’s one of the reasons why we sell through retailers on our website, because we believe that’s another way to drive traffic into their stores. And while our online channel is growing, we strongly believe in brick-and-mortar. There are multiple reasons for that, including the fact that shopping online can be overwhelming. Sometimes there’s just too much choice and uncertainty, and it’s just easier to go into a store to make a purchase. Plus, those stores help communities thrive, and we believe that is very important. I think that, over the course of the pandemic, a lot of consumers also rediscovered the importance of supporting local stores. We’re seeing a resurgence in shopping in downtowns and strip centers. And let’s be honest, who’s going to sponsor the Little League team if there aren’t any local businesses left in town? It’s not going to be some online conglomerate.

Along those altruistic lines, where do matters of sustainability lie in importance for Naot? One of the cool aspects about Naot is sustainability, as well as diversity, have always been very important aspects of our company. It wasn’t like, all of a sudden, these are cool talking points and we need to figure out how to make them fit into our mold. Those concerns have been built into the company from day one. For example, our factory is located on a kibbutz and the staff includes Druze, Christians, Muslims, and Jews hailing from around the world. We have men and women of all different ethnicities and religions working side by side in our factories, and have for years. It’s part of our ethos. Certainly, there’s more that we can do, and we’re always looking for ways to improve. As technology improves matters of sustainable design, we’re trying to change as well. So, maybe a glue that we’ve used is replaced by a more sustainable alternative. On that note, we’re certainly looking at expanding vegan line.

Why, exactly?

There’s a growing demand around the world for such goods, particularly in Israel. I think that trend will continue to expand greatly in the U.S. as well, especially among younger generations. They’re seeking more sustainable options across their purchases. Leather production leaves behind

a huge carbon footprint. These consumers want an alternative. For example, we can’t keep our Okahu vegan slip-on moc in stock. It happens to be a great-looking shoe, but I think the vegan aspect is a huge plus and represents a direction the market is heading. We’re also looking at socially responsible ways of producing shoes, even though we pay working wage rates in Israel. We’re also continuing to help refugees around the world. Unlike a lot of brands, we donate unsold merchandise to homeless and battered women shelters, rather than sell them for pennies on the dollar. We donate tens of thousands of pairs annually. We also just donated about 3,000 pairs to earthquake survivors in Turkey, as well as to survivors of last summer’s Florida hurricane. In the U.S., we always donate through a local retailer, because we believe they know that community better and know which agencies are best to get our shoes to people in need. For instance, in Naples, FL, we worked with Peltz Shoes. Our PR got multiple TV stations to cover the donation, which was made in their parking lot. They received great recognition among the local community.

What keeps you up at night, besides your kids?

The state of the world. I wish I was handing my children a better world than the one we have right now. I wish that we were not as divided as we are. I wish that we were heading toward a better world. While social media can do a lot of cool things with communication and learning, the bad side is how divided it seems to make us all. That’s what keeps me up at night: How do we fix this world for our children?

What do you love most about your job?

I’m super-passionate about my job—to the point my kids think I’m always working. But I love what I do. Ironically, my dad always pushed me to do something different, and I did work in advertising for a while. But I always made excuses to tag along with him to shoe shows in Milan and Vegas. I just loved being around this industry. I really love shoes. I love looking at new products and working with designers. I love watching how what you’ve been working on with the team in the sketch stages comes to fruition. I love how it all comes together. And let me just say, I think we have a phenomenal team—the best in the industry. I enjoy working with great people. We have a super-warm culture where everyone genuinely cares about each other. Our Israeli team is also a phenomenal group of people who are working to make our company great but also the world a better place. Whether it’s donations to good causes, helping protect the environment, or working with refugees, Naot is a vehicle to do good. I love that. •

Q&A

LIVING IN THE FLOW STATE

Serial entrepreneur Philip Curry, CEO of Astral, reflects on an epic career ride in the outdoor industry.

TO MY EIGHT-YEAR-OLD self, hopping along boulders in the whitewater behind our home in the mountains of North Carolina: You’ve discovered the flow state! Embrace this wonderfully present mindset peacefully while in a very risky environment. Pursuit of this epic feeling will guide your life for decades.

It begins, at age 13, when Uncle Doc takes you on your first whitewater trip with the Nantahala Outdoor Center (NOC). You step into the Nantahala River and become forever hooked on whitewater kayaking. The experience also pulls you into the alternate universe of NOC. You’re captivated and inspired by the large community of guides living there, impressed by how responsibly they live in the wild. Though you don’t know it yet, this trip will guide you to a career using and building equipment for wilderness athletes. Enter with full abandon!

Of course, there will be a few curves in the river of life. In your teens, you move to Charlotte. The new environs awaken you to the beauty of cultural diversity, and you revel in the wild turbulence of youth. You’ll wander and thrash, and experiment and crash. While your soul craves a return to that flow state, this period kindles a deep appreciation for culture, commerce, and music—all of which will play critical roles later in life.

At 15, you get a job selling outdoor equipment at the SouthPark Mall. It’s a job you’ll hold—and love—through high school. You devour the latest product information and training offered by brands about how their technical gear is made and how it elevates people’s experiences in the great outdoors. Take note: Very few people buy climbing ropes. Most buy light hiking shoes, book bags, and a plastic sweater by Patagonia. (More on that company later.) What really moves consumers to buy are color, texture, surprising functions, and brand allure. Pay attention, kid. The details of which products sell are everything

After high school, you spend 1990 living in that alternative flow state. (Today, people call this a gap year.) You take jobs guiding kayaks in the Caribbean and rafts on the Chattooga River. You spend your free time kayaking the Narrows of the Green in North Carolina, then considered the hardest section of whitewater in the country. You live in a van, become a vegan, and get into Zen meditation. Celebrate this short-lived period of minimalism, because your life is about to get a lot more complicated—in good ways. This is when you become acutely aware of the shortcomings in outdoor gear, especially lifejackets. A seed is planted.

Before that takes root, however, you enroll in the former Asheville Farm School, a.k.a. Warren Wilson College, to major in anthropology. Here, you develop a deep love for organic agriculture and cultural anthropology. Despite your father’s urging, you avoid taking business classes. I recommend you rethink that.

Three years later and with just $7,000 in funds, you launch your first business, Lotus Designs, making life jackets for kayakers. The office/ factory/warehouse is your cramped basement apartment. Fortunately,

you’re 22 and have the stamina to handle the endless days and nights a startup requires. Still, it’s hard work, the currents are swift, and there are unexpected dips and twists. But like any accomplished kayaker, you find a way to navigate the tumult. Within a couple of years, Lotus Designs grows exponentially, having moved out of your basement to a factory near Asheville, NC, with 50 employees! You’re now married and have had your first kid! Life is good! But slow down a bit.

In 1999, you sell Lotus Designs to Patagonia. You’re now free to wander. After a couple of months traveling, you settle down south of the Sawtooth Range in Idaho, where you discover the backcountry. It lights up your world. You fantasize about becoming a pool boy/snowboarder for the rest of your life. But hot tubs are gross, and the fertile soil of Appalachia beckons. You decide to go home and put that college degree to use by starting a farm!

You’re now 28, holding 80 acres with the intent to support your family the old-fashioned way. You dig deep into biodynamic farming principles and various cultivars of blueberries, leveraging hydraulic implements and tending Jersey cows. You love working outside—and the entrepreneurial challenge of filling a void in the market. Time spent on the farm teaches you huge lessons about the nature of nature. These will guide you through the next decades of your career, because as much as you love farming, it’s not what really gets your tractor humming.

In 2002, you make a family decision and launch Astral, an outdoor company committed to building the best-performing products for wilderness athletes in the least toxic, lowest-impact way. You love creating a company where cool, creative people work together to benefit soil and water. Astral grows rapidly and wins awards for our paradigm-changing footwear designs, including our Super Sticky G.ss outsoles, the stickiest-ever rubber for wet rocks. We’ve also basically eliminated toxic PVC foam from the life vest industry and invented breathable life jackets.

Seven years into this gig, you’re 35 years old and have moved well beyond another startup phase. Yet you’re still working 16-hour days, six days per week, which is no way to live. After reading lifestyle guru Tim Ferriss’ books, you decide, in 2009, to delegate everything and move to Vietnam! There, you open Astral’s product development and quality assurance office. Life is again very good. You love everything about living in Vietnam, except for the road level pollution.

Astral has come into its own as a quality brand with purpose. You adhere to the lessons learned during your retail days: The finer details of a product are what sells. So, stay the course—even during rough patches when you find yourself smoking ciggies every day and thinking you may have lost your mind. My advice, as your now 51-year-old self, is whenever you feel like that, get back to the river and rediscover that flow state.

2023 april/may • footwearplusmagazine.com 19

you on the river, Philip A NOTE TO MY YOUNGER SELF

See

Design Intervention

First off, Holo Footwear’s new Troy collection doesn’t look like the typical hiker. The palette isn’t dull brown and dreary black, nor is the collection of mid-height boots (and one low-cut style) overbuilt with heavy leathers, bulky overlays, and needless bells and whistles. To the contrary, the Troy is a less-is-more, athletic-inspired, clean look that Holo CEO and Head Designer Rommel Vega says ushers in a fresh alternative to a stale shoe wall. Hence the name Troy, which is in reference to Greek mythology’s Trojan Horse.

“Troy means Holo has shown up with something really different,” Vega says. “As a newer brand, we wanted to target the burgeoning athleisure hiking space. So, we’ve created a clean, super-lightweight, versatile hiking boot that offers all the support, traction, and comfort needed to go on a hike, or a walk around town.”

A strong test run at REI and Nordstrom this past fall convinced Vega that the collection has big potential as the Grand Rapids, MI-based

company expands distribution, beginning this fall, at Scheels and other select retailers. “It’s been performing really well,” he reports. “It’s one of our best sellers, and it’s sitting right next to the Merrell Moab and Keen Targhee. Customers immediately see how different the Troy is—our recycled knitted uppers in striking colors, 60 percent recycled rubber outsole, and Honest Foam midsole for all-day comfort.”

Vega attributes the Troy’s success, in large part, to the design team’s ability to know when to say when. “Oftentimes designers don’t know when to put the pencil down,” he explains. “Whereas our emphasis is on including everything you need but nothing beyond that. Designing a shoe is not a drawing contest; it’s about solving problems.” Over-designed products, Vega says, can lead to unnecessary costs that are passed on to consumers. “Just putting more stuff on a shoe can also be offputting to a lot of consumers,” he says, noting that the SRP for the Troy is $100 and $95 for the low-cut version. “They’re turned off by brands that take themselves too seriously, because not everyone is going to Kathmandu to hike the Himalayas. They’re just looking for something that looks and feels good that can be worn from the local trail to the bar, or as an everyday shoe.”

That everyday versatility is Holo’s sweet spot, according to Vega. “We aren’t trying to be a top-of-the-mountain company,” he says. “Our focus is on being sustainable and attainable, making sure we don’t over-design, yet the durability, traction, and fit are great.”

A key part of Troy’s alternative hiker recipe is the popping unisex color palette of Sundown red, Moon off-white, and Absinthe green. “We didn’t include black and brown on purpose,” Vega says. “The shoes pop on the shoe wall—consumers are picking the boots up because the colors are so rich and vibrant.” Vega notes that

Moon is one of the most popular colors. “Who ever thought a white hiking boot would be a top seller?” he laughs, but the dirtier it gets, the cooler it looks. “It shows you’ve been out doing stuff. You’re telling a story about where you’ve been and what you’ve done.”

Troy’s target demographic is men and women 25-35 years old. Or, as Vega says, the consumer who grew up wearing sneakers. “Troy has a cool sneaker feel; it’s not the Hummer of boots. It’s faster and lighter—more like a Tesla.” He likens it to the gasoline car, which “was only good until the electric car came around. The Troy feels and looks like that.”

Vega, who has been a footwear designer for nearly 20 years (stops have included Merrell, Keen, and Columbia), knows of what he speaks. In fact, he longed to infuse freshness into the category even in his early days. “I’ve always wanted to design something younger, faster,” he says. “But it always came down to the organization saying this was working and let’s not disturb it.” He believes brands can talk themselves out of potential great ideas because of that approach. Not anymore. Vega is the boss and Holo’s foundation is product-first. “Holo leads through the lens of product, and our team believes that product is king.”

Holo is also nimble and quick. “I can make the decisions if we need to change, and we can move fast,” Vega says. “We like to zig when everyone else zags, because we must offer something different—and better.” This requires researching what the market opportunities are and what’s not being done, then creating something new. That’s the best way for Holo to get on the shoe wall. “Retailers and consumers don’t want or need more of the same,” Vega says. “Holo’s entry into the market is lightweight, colorful, clean, made responsibly, and at an attractive price point.”

Vega is excited about Holo’s future. The brand is expanding distribution into Canada this fall, then Australia and New Zealand in Spring ’24. The race is on. “We’re going to continue to press on the gas,” he says. “We’re young and ambitious. We’re not going to slow down.”

SPONSORED

Behold the Troy hiker by Holo Footwear, a clean, green upstart shaking up the outdoor space.

The Troy collection’s palette is a fresh, attention-grabbing alternative that pops on shoe shelves.

Take the trails less traveled. Explore the streets with no name. Return with scuffs and stories to last a lifetime. www.holofootwearinc.com H O L O FOOTWEAR

Get Dirty.

Pastel pink pleases the palette.

22 footwearplusmagazine.com • april/may 2023 TREND SPOTTING

Valentina Rangoni

Nisolo

Qupid

Sanctuary

YOU’RE BLUSHING

FOR MORE COMFORT STYLES Style FUSARO Springfoot wear springfootwear.com | 800.962.0030 | Follow us

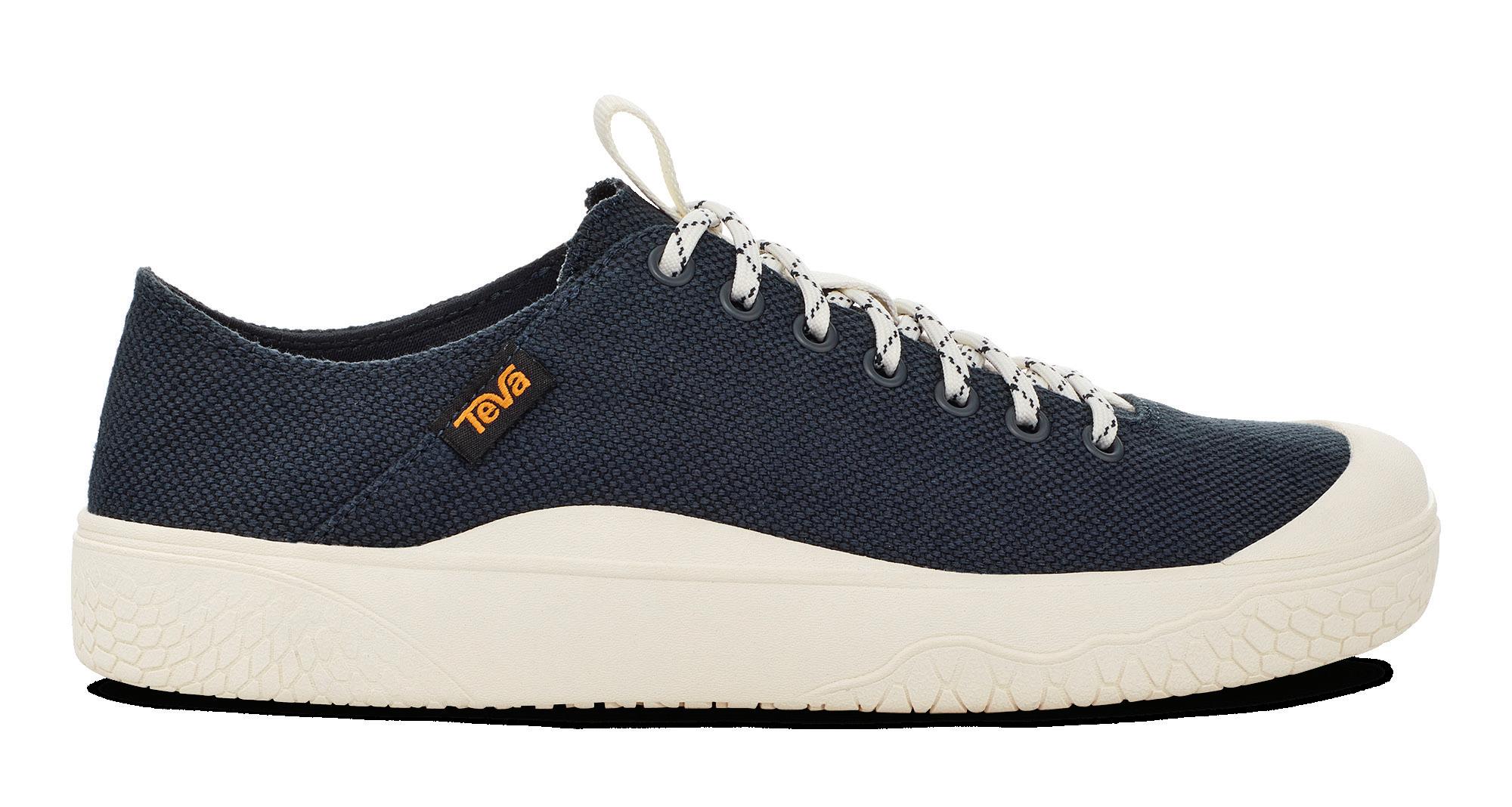

DECKED OUT

The classic sneaker silhouette rises to any casual occasion.

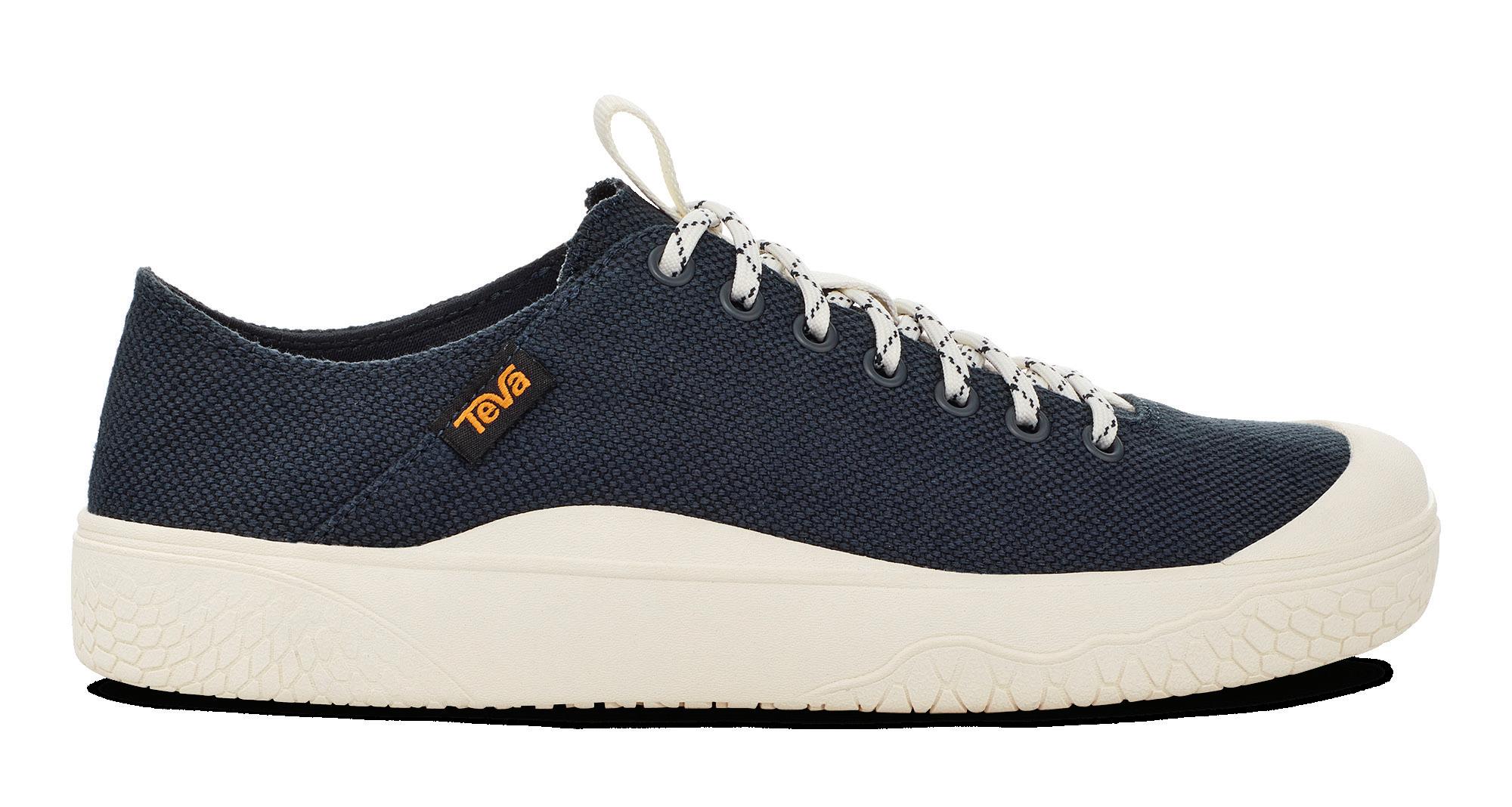

24 footwearplusmagazine.com • april/may 2023 TREND SPOTTING

Ecco

Wrangler

Teva

Twisted X

powered by your friends at Footwear Plus Strategy + Content + Design We specialize in award-winning custom content and marketing programs tailored to grow your business. www.footwearplusstudio.com contact: Belinda Pina | 310-633-3454 belinda.pina@wainscotmedia.com brand announcements - design - digital and print magazines photography - fashion shoots - look books - catalogs - email marketing - web development - consulting - partnerships

Toms slip-ons feature uppers made of upcycled cotton scraps and wood pulp from sustainably managed forests.

2 8

Psudo slip-ons feature breathable recycled plastic uppers. Opposite page: Rugged Mary Janes with corn base recycled mesh neoprene uppers and r

ecycled

EVA midsoles by Jambu

29

Vegan-friendly sneakers with removable cork/latex footbeds by Naot Opposite page: Twisted X wedge sole boots feature Blend85 footbeds made with 85 percent recycled foam and ecoTweed linings made of recycled plastic bottles; Earth Shoes laser cut slipons feature water-based adhesives and cork footbeds

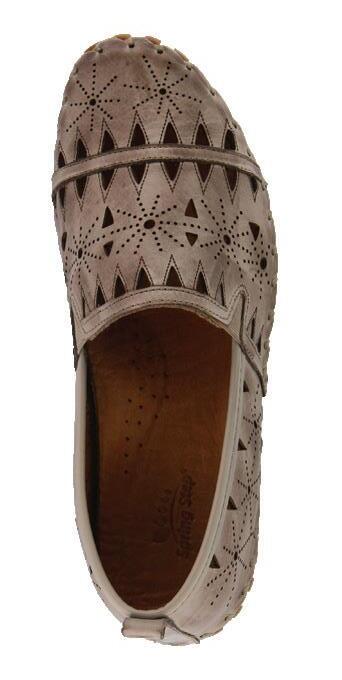

Vegan-friendly sneakers with removable cork/latex footbeds by Naot Opposite page: Twisted X wedge sole boots feature Blend85 footbeds made with 85 percent recycled foam and ecoTweed linings made of recycled plastic bottles; Earth Shoes laser cut slipons feature water-based adhesives and cork footbeds

Sanctuary hikers with linen/ Tencel uppers use 20 percent less water than cotton and reduce waste and emissions. Opposite page: French and Vietnamese army-inspired jungle boots feature 100 percent recycled polyester canvas uppers and waterproof membranes by Astral

33

Teva mocs with 100 percent recycled polyester ripstop uppers, 50 percent recycled EVA midsoles, and 50 percent regrind rubber outsoles; Wallabee boot made of woven recycled eco suede, recycled polyester laces, and natural rubber crepe outsole by Clarks

34

Sneakers made of form-fitting recycled plastic bottle knit uppers by Avre Opposite page: Merrell waterproof mocs feature 100 percent recycled mesh footbed covers and 50 percent recycled EVA footbeds.

Fashion editor: Kathleen O’Reilly; models: Charlotte Walker/ Supreme Management, Anthony D’Alessandro/Crawford Models;

makeup: Maya Ling Feero; photo assistant: Rebecca Steighner; styling assistant: Sarah Frey; production assistant: Eileen Viglietta.

37

The Recycle of Fashion

Meet Nicola Masolini, founder of RE49. The visionary designer is finding purpose in repurposed materials, using them to create one-of-a-kind wearable works of art.

By Greg Dutter

By Greg Dutter

Portraits in design: Nicola Masolini and repurposed styles by RE49.

HEY SAY ONE man’s trash is another man’s treasure. That’s the basis of RE49. Founder/designer Nicola Masolini has made it the brand’s mission to produce limitededition shoes using recovered, reused, and regenerated materials that would otherwise likely end up in landfills. Examples include fabrics from furniture, umbrellas, and regatta boat sails that Italian beach resorts often toss into the trash at the end of each season. Denim waste is another example.

“We search for authentic and iconic materials with great storytelling aspects to them,” explains Masolini, a fourth-generation shoemaker. “Our mission is to repurpose discarded objects and transform them into precious works of art that are to be worn with pride, because RE49 shoes are a message of love to our planet.”

Masolini introduced RE49 in 2019, but the concept was actually much longer in the making. In fact, the story stretches back to the days of his greatgrandfather, who reinvented the family business after WWII when he was forced to use the only materials available to his factory at the time. “He understood that he had to adapt,” Masolini says, noting that his grandfather used recycled fabric scraps and discarded military uniforms. “I’d like to pass on that wisdom, because alone you don’t go anywhere.”

While RE49 launched just before the pandemic and faced many unexpected hurdles, Masolini believes the consumer climate is now more receptive to his brand’s eco-friendly ethos. “We’re pioneers in this new field of footwear design, which young people are quite interested in, as well as middle-aged consumers, who increasingly understand the need to make more sustainable fashion choices,” he says. “Our shoes enable people of all ages to tell a profound and authentic story that helps spread the green word.”

RE49’s range of men’s and women’s casual styles (SRP: $300-$500) currently includes oxfords and chukka boots. In addition to repurposed fabric uppers, sustainable materials include insoles and linings made of recycled microfiber or cotton terry towels recovered from hotels, while outsoles are made of recycled tires. New for Fall ’23 is the Urban collection, a collaboration

with Dinamica by Miko, which produces a suede-like microfiber that is made with recycled polyester and used by leading car makers. RE49 is using the manufacturer’s production waste. “United we stand, divided we fall,” Masolini says. “Our companies share the same values, and we’re both committed to sustainability and circularity.”

Masolini believes RE49’s future is bright. The company is focusing on expand-

38 footwearplusmagazine.com • april/may 2023

ing into the North American and Asian markets this year, where he sees a growing customer base in the new sustainable luxury footwear space—one that advocates reducing extraction of raw materials because there are plenty of fabrics to recycle and convert into fashion items. “People see the beauty of our shoes, as well as the beautiful message we’re spreading to the world,” Masolini says, noting that its shoes are handmade in Italy. “RE49 shoes have soles and soul, which is for the good of consumers today and for generations to come.”

Who is the RE49 customer? They’re in search of something unique, which is difficult to find in the world of shoes. They want shoes that stand out and are worthy of conversations with friends. They want to be proud that their shoe choice contributes in some way to the sustainability of our planet.

What are some signature design aspects of RE49? Definitely our stitch processing, in addition to our unique materials such as sails, denim, deck chairs, and beach umbrellas.

You’re living proof that you can, in fact, go home again. How gratifying is that? When I left home to go in search of new work experiences, I never thought I’d return to my family’s business. But having worked across the industry for years and seeing how so many big brands create a financial structure that is based on inexpensive product sold at 15 times the value and that lacks an authentic brand story, I realized the value of my family’s factory in Italy. I also worked with many companies in this linear economy, and I’ve seen the excesses and production waste with my own eyes. The only solution, I believe, is to change to a more sustainable approach, which is a circular economy. That’s why I returned to my family’s business: to create something unique and that I can be proud of. Something that gets people talking, is simple, and yet pierces the hearts of customers.

To quote Kermit the Frog, it’s not easy being green. So why go through all this trouble? Kermit is the most intelligent and “human” of Muppets. So maybe he was on to something all along? Nowadays, I believe being green is the duty of every human being. We must all do our part to lessen our global footprint for ourselves and future generations.

Who are some designers you admire? There are so many. I love Trippen’s designs, which we produce in my family’s factory. I’m also in love with the clean esthetics of Tom Ford, Armani, and Versace. And while RE49 is not producing heels currently, I’m in love with some of the most architecturally wise women’s styles being produced today.

What’s the best business advice you’ve ever received? “Look to the past to give something more to the future.” That came from my grandfather. Fashion is always about looking for something new, but knowing how to get the best out of the historical experiences of others can be a source of important ideas.

What is your first shoe-related memory? I grew up immersed in my family’s workshop and have many great memories. For example, playing with the leather rolls and other upper materials. I’d repurpose scraps into Robin Hood and Peter Pan hats. Also, I’ll never forget many of the faces of the people who worked there. They used to play with me while I hid among the various shoe trolleys. Then there are the various smells that every shoemaker knows. I keep all these indelible memories in my heart.

What do you love most about designing shoes? Being able to express myself by creating a product with great meaning. I also love that people wear our shoes with pride and tell others about our unique story—one that provides a valuable service to our planet.

continued from page 8

materials include stretch fabrics made from recycled post-consumer plastic bottles, chrome-free leathers and suedes that are gold rated by the Leather Working Group, bio-oil Memory Foam insoles made from forestry waste, toe box and counter pockets made from fishing nets recovered from the oceans, and recycled fabrics. “We also recently developed a sneaker outsole comprised of a coffee grind and corn starch polymer,” Fuchs says, noting the SRP is $89-$139 for sandals and shoes, and $149-plus for boots.

Sanctuary walks the green walk, which Fuchs believes is rare in the footwear industry.

“Several well-known brands tend to use just one sustainable component—like a recycled fabric upper—and then over-advertise the eco-friendly aspects of that shoe,” she says. “Sanctuary, on the other hand, dives deep in to making as many, if not all, parts of a shoe as green as possible, and we include traceability and certification.” The exec adds, “What good is one recycled component if the rest of the shoe is made of plastics and harsh chemicals? Our slogan is, ‘We value nature,’ which we truly live by, inside and out.”

Still, to quote a certain well-known Muppet, it’s not easy being green. So why go through all the trouble? Fuchs believes it’s simply the right thing to do. Being green, she adds, becomes habit-forming—in a good way. “The idea of being more sustainable has become ingrained in our team’s way of acting. We’ve transformed our daily practices within the office—like doing away with plastic water bottles and other single-use plastics, recycling paper goods, etc.—and our factories are also following similar practices, along with reducing the amount of electricity and water use whenever possible.” Fuchs adds, “Small, daily changes add up, so if the idea of helping our planet is something you truly believe in, it’s not so hard ‘being green.’ After all, it’s the only planet we have!”

While debuting at the onset of the pandemic brought challenges, Fuchs believes there’s been a silver lining. Namely, learning the art of scaling back. “Long gone are the days of massive overdevelopment,” she says. “A tighter focus within design and a smarter approach to managing deliveries and inventory have been building blocks for us.” Fuchs reports the past year has been successful. “We’ve brought in new key accounts, have seen an increase in sales overall, and have had more significant reorders, which helps establish our core, year-round styles.”

On that note, Fuchs says Sanctuary’s game plan going forward is more of the same: stay focused on emerging trends, incorporate new eco-friendly practices and materials, grow U.S. sales, and expand internationally. “Sanctuary is a bicoastal brand that caters to a woman’s work and weekend needs,” she says. “Thus, inclusivity as well as sustainability will remain at the forefront of our designs.”

2023 april/may • footwearplusmagazine.com 39 GREEN & HEARD

Sanctuary loafers feature Bio Oil Memory Foam insoles.

Recycled materials transform casual kicks into statement fashion pieces.

LAST SHOT Tread Lightly

Sustainable Soles

Minnetonka

Naot

Veja

40 footwearplusmagazine.com • april/may 2023 PHOTOGRAPH BY NANCY CAMPBELL

Clarks

STEP INTO

The OrthoLite® X Series delivers customized elasticity to meet the growing demand for even higher levels of rebound and energy underfoot. With the option for good, better, best offerings, the OrthoLite X Series elevates the game in comfort and performance. ortholite.com

Featuring Aetrex orthotic support and memory foam cushioning for superior comfort

Featuring Aetrex orthotic support and memory foam cushioning for superior comfort

Greg Dutter Editorial Director

Greg Dutter Editorial Director

Vegan-friendly sneakers with removable cork/latex footbeds by Naot Opposite page: Twisted X wedge sole boots feature Blend85 footbeds made with 85 percent recycled foam and ecoTweed linings made of recycled plastic bottles; Earth Shoes laser cut slipons feature water-based adhesives and cork footbeds

Vegan-friendly sneakers with removable cork/latex footbeds by Naot Opposite page: Twisted X wedge sole boots feature Blend85 footbeds made with 85 percent recycled foam and ecoTweed linings made of recycled plastic bottles; Earth Shoes laser cut slipons feature water-based adhesives and cork footbeds

By Greg Dutter

By Greg Dutter

Featuring Aetrex orthotic support and memory foam cushioning for superior comfort

Featuring Aetrex orthotic support and memory foam cushioning for superior comfort