3D PRINTING & ADDITIVE MANUFACTURING INTELLIGENCE

MAG EUROPE EDITION VOLUME 30 ISSUE 1

www.tctmagazine.com

PUSHING THE BOUNDARIES

3D Systems’ technology leaders share their AM insights for the year ahead

State of the industry AM trends and M&As

Software

Creative

Sustainability, simulation & smart solutions

Applications in architecture, fashion & jewellery

RAPID PROTOTYPING

VOLUME 30 ISSUE 1 ISSN 1751-0333

EDITORIAL

HEAD OF CONTENT

Laura Griffiths e: laura.griffiths@rapidnews.com t: + 44 1244 952 389 SENIOR CONTENT PRODUCER

Samuel Davies e: samuel.davies@rapidnews.com t: + 44 1244 952 390

ADVERTISING

HEAD OF SALES TCT PORTFOLIO

Carol Cooper e: carol@rapidnews.com t: + 44 1244 952 386 SALES MANAGER TCT PORTFOLIO

Nicky Martin e: nicky.martin@rapidnews.com t: + 44 1244 952 365 SALES EXECUTIVE TCT PORTFOLIO

Andrew Cooper e: andrew.cooper@rapidnews.com t: 011 + 44 1244 952 374

PRODUCTION Sam Hamlyn

Matt Clarke

Rob Wood

We are dedicated to providing an excellent service – from rapid quote to on-time delivery – producing high-quality components at the right price. · Stereolithography

· Silicone Tooling

· Selective Laser Sintering

· Reaction Injection Moulding

· Vacuum Casting

· Water Clear Lenses

· Two Shot and Over-moulding

· Traditional Model Making

· Silicone Components

· Model Finishing

MANAGEMENT C.E.O. / PUBLISHER

(0191) 454 1900

Duncan Wood

info@amtech-rp.co.uk

www.amtech-rp.co.uk

VP, CONTENT, STRATEGY AND PARTNERSHIPS

James Woodcock e: james@rapidnews.com t: + 44 1244 952 391

SUBSCRIPTIONS

PUBLISHED PRICES TCT Europe Print Subscription - Qualifying Criteria UK & Europe - FREE US/Canada - £249 ROW - £249 TCT North America Print Subscription - Qualifying Criteria US/Canada - FREE UK & Europe - $249 ROW - $249 TCT German Language Print Subscription - Qualifying Criteria UK & Europe - FREE US/Canada - €249 ROW - €249

Subscription enquiries to subscriptions@rapidnews.com Read this and back issues for FREE on Issuu www.issuu.com/tctmagazine

3D PRINT HEADS FOR FLUID & PASTE PRINTING BPA Worldwide Membership The TCT Magazine is published bi-monthly by Rapid News Publications Ltd Carlton House, Sandpiper Way, Chester Business Park, Chester CH4 9QE, UK.

t: 011 + 44 1244 680222 f: 011 + 44 1244 671074

© 2022 Rapid News Publications Ltd

While every attempt has been made to ensure that the information contained within this publication is accurate, the publisher accepts no liability for information published in error, or for views expressed. All rights for The TCT Magazine are reserved. Reproduction in whole or in part without prior written permission from the publisher is strictly prohibited.

▪ ▪ ▪ ▪ ▪

Easy and fast integration into a 3D printer Reliable and robust print process Clean and precise start and end points Printing regardless of viscosity Very wide range of printable materials

Fluid management – all from one source: Emptying systems, treatment systems and print heads for 1- and 2-component fluids and pastes. viscotec.com

A Strong Future Stands Behind Us!

FUNCTIONAL ALUMINIUM & PLASTIC PROTOTYPES IN 1 – 4 WEEKS

AS9100 & ISO 9001 Certified • ITAR REGISTERED

email: sales@armstrongrm.com For more info visit us at: ARMstrongRM.com

• Machined Aluminium Castings One Shot Casting • Rubber Plaster Mold Precision Air Set Sand • Graphite Die Casting • RIM – Reaction Injection Molding • CNC Machining & Hogouts • Painting, Finishing & Assembly

from the editor

FROM THE EDITOR LAURA GRIFFITHS

Looking FORWARD Is it too late to wish someone a Happy New Year? It’s the first issue of TCT for 2022 (our 30th volume too!) and in the spirit of optimism and looking ahead, Senior Content Producer Sam Davies and I have been speaking to various figures within the industry to get their thoughts on what’s in store for additive manufacturing (AM) over the next 12 months (page 11), and what those mergers and acquisitions that dominated 2021’s headlines mean for the industry’s future (page 14). Supply chain remains the big one but this time around the conversation is more grounded, suggesting that while AM has proven itself in the crisis situations the last two years have thrown at us, the future will be about a more considered approach, whether it’s positioning AM as a risk mitigation tool rather than a replacement for traditional methods or finding simple (indeed, boring) applications along production lines. The year has already gotten off to a good start with the return of the TIPE Conference hosted by Women in 3D Printing in January, where we were thrilled to finally announce the finalists for our next TCT Wi3DP Innovator Award (read more about each

finalist at tctawards.com). In an industry that has historically been lacking in diversity, the event proved, to anyone in doubt, that there are plenty of different voices to be heard in this industry, and you needn’t look too far to find them. We hope we’ve conveyed that in this issue too, not least in Sam’s conversation with TIPE keynote speaker Julia Koerner (page 22). Elsewhere, we take a look at developments in software, including a recent art installation at London’s Design Museum which aims to tackle the challenge of waste using 3D printing and digital twins (page 18), and we also have a wealth of insight from AM experts on the things you need to know about one of AM’s biggest barriers: standards (page 27). Plus, we have a case study from Shell which is putting all of that into practice (page 25). It’s been a busy one already. TCT Japan returned to Tokyo shortly before this issue went to press, and it’s only going to get busier as plans continue to steam ahead for our upcoming RAPID + TCT event in Detroit and TCT 3Sixty this summer. So, Happy New Year to you. I’m looking forward to it.

30.1 / www.tctmagazine.com / 05

Your idea turned standard product within days.

®

®

Caligma

Cerion

Reliable prototyping and small series production for a toolless future.

The era of additive series manufacturing begins here.

VOLUME 30 ISSUE 1

COVER STORY

8 11

08. PUSHING THE BOUNDARIES

STATE OF THE INDUSTRY

Head of Content Laura Griffiths gathers thoughts from industry experts on emerging AM trends.

14. M&A IN AM

Senior Content Producer Sam Davies explores what the recent M&A activity means for the 3D printing industry.

22

SOFTWARE & SIMULATION

3D Systems’ CTO Dr. David Leigh and Chief Scientist Dr. 17. PRINTING SMART Brent Stucker share insights on Teton Simulation CEO Doug Kenik what they see for AM in 2022. speaks to TCT about RE Suspension’s application of its SmartSlice software.

11. AM AND THE YEAR AHEAD

8

17

18. DESIGN’S NEW DAWN

Laura speaks to the collaborators behind a new art installation created using sustainable resources and 3D printing.

CREATIVE

20

20. IS THIS THE FUTURE OF JEWELLERY?

How AM is bringing a new lease of life and personalisation to one of the most traditional forms of jewellery.

22. UNIQUE AESTHETICS

Julia Koerner opens up about her architectural and fashion design applications of 3D printing.

25

25. PRESSURE’S ON

A look at a recent certification milestone at Shell for a 3D printed pressure vessel.

27. 5 THINGS YOU NEED TO KNOW

Experts weigh in on the ‘must knows' for AM standards and certification.

EXPERT COLUMN

30

30. WHAT’S CHANGED IN METAL AM?

Industry consultant Kevin Ayers reflects on one of the major changes impacting AM adoption: price per part.

25

18

STANDARDS & CERTIFICATION

PUSHING THE BOUNDARIES 3D Systems’ Chief Technology Officer Dr. David Leigh and Chief Scientist Dr. Brent Stucker share insights on what they see for AM in the year ahead. Q: Brent, you’ve shared how you expect to see new materials designed for more rigorous use-case environments. How is 3D Systems addressing this need?

SHOWN: DR. BRENT STUCKER

Q: You both joined 3D Systems’ leadership team last year. Can you talk about any trends you’ve observed that you believe will have an impact this year? Dr. Leigh: I believe there will be key drivers that will influence the trajectory of additive manufacturing (AM). I expect many companies will not only enhance their core offering but will also broaden their portfolio to offer their customers a more complete suite of technology – and thus a complete solution - under one brand. Dr. Stucker: As AM is moving more and more towards production applications, material formulators are increasingly designing materials that are production-quality. Over the coming year, I expect we’ll see new polymer and metal materials designed for more rigorous use-case environments. I believe companies will also begin to introduce new 3D printers designed for specific applications, part sizes, or material offerings. This will result in more cost-effective solutions for production applications rather than the more generic multi-material, multiapplication prototyping machines of the past.

08 / www.tctmagazine.com / 30.1

Dr. Stucker: Over the AM industry, I expect materials that are focused on production applications, rather than for prototyping purposes, to continue to grow. For polymers, this would include materials with one or more of these characteristics: flame retardancy, high toughness, high heat-deflection temperature, high strength, more ductile, and easier to process. During the past year, 3D Systems has introduced a variety of materials to address these needs including: Figure 4 High Temp 150C FR Black, Figure 4 Tough 65C Black, Accura Composite PIV, Accura AMX Rigid Black and Figure 4 Rigid 140C Black. Q: David, as AM is increasingly used for production, what are the challenges around scaling AM and how are you delivering on that? Dr. Leigh: The challenges we are currently seeing to truly scaling AM for production applications are centred on cost and material properties. That is the cost per part at high volumes is still higher than other high-volume production applications, and AM material properties in some cases are not comparable to traditional material properties. 3D Systems is helping our customers scale AM production by focusing on end-to-end solutions. We partner with our customers to develop a custom solution for their needs and then help

integrate the entire solution and make it work seamlessly in their existing production workflow. To do this, we take a holistic view from optimising the workflow to finishing the part. Each application starts with needing the right material, and Brent addressed a handful of the new production-grade materials we launched last year alone. Additionally, we realised the value of a manufacturing operating system to integrate, streamline and automate the workflow, which is where Oqton brings tremendous value. And we also announced a

“The biggest opportunity over the coming year will be in enabling supply chain.”

COVER STORY

I also expect AM users to migrate to complete software platforms focused on AM – versus collections of individual software products. This can provide customers more functionality under one software platform rather than needing to jump around between software tools to accomplish their goals. Q: Throughout 2021, supply chain continued to be a hot topic. How do you think AM’s role will play out this year?

SHOWN: DR. DAVID LEIGH

partnership late last year with AMT that enables us to resell their PostPro industrial-scale SLS post-processing system. PostPro enables batch cleaning and smoothing of parts thus helping our customers reduce lead time and manufacturing costs while scaling their factories. Q: Brent, you’ve had a distinguished career developing software solutions. What developments can we expect to see there? Dr. Stucker: I think we’ll see improved software and machine monitoring solutions announced, such that machines will monitor their health and notify operators when things are going wrong and/or start correcting for errors automatically.

Dr. Stucker: The bottlenecks we’re seeing in automotive, aerospace, and several other industries may make it difficult for them to release as many products as they hope to do in 2022. Within the AM industry, we’re collectively dealing with our own supply chain challenges (e.g., lack of chips and components). The question I think we’re all asking ourselves is “how do we build machines in light of the supply chain bottlenecks?” I believe OEMs will look at new ways to accomplish this. For example, we could see AM machine manufacturers produce more machine components using AM itself. We can also look at this from the perspective of how AM can help to alleviate supply chain issues. Certainly, the use of AM for a host of applications is increasing, as it has been shown that it is a flexible technology that can provide on-demand solutions in a chaotic environment. I also expect more designers to begin to design for 3D printing as the production process (as opposed to designing for traditional manufacturing methods), to overcome the types of supply chain disruptions we’ve seen throughout the pandemic. By using 3D printing to produce components, the supply chain can be moved closer to home and can be more flexible to meet demand disruptions. It will be interesting to see how this impacts AM OEMs, and how we collectively look at our manufacturing processes. Q: 3D Systems has created dedicated teams to focus on specific industries and applications. Are there any emerging areas we can expect to see more AM activity from? Dr. Leigh: 3D Systems has organised itself into businesses designed to address advanced applications in healthcare and industrial markets such as medical and dental, aerospace & defense, automotive, and durable goods.

In healthcare, there is a tremendous focus on patientspecific devices. This can take the form of orthopedic implants, as well as patient-specific surgical devices and instruments. This trend is also very apparent in dental for orthodontics, prosthodontics, and implantology. And we’re seeing all of this work help propel us into the next frontier of bioprinting. This field takes “patient-specific” to a whole new level, and it has tremendous potential to change the face of patient care. For industrial applications, the pandemic allowed AM to shine in helping to stem the chip shortage through unique solutions to support semiconductor capital equipment manufacturers. We are also seeing our automotive customers making tremendous strides in using AM to deliver innovation for EVs. There are also some marvelous advancements occurring in regards to RF applications for aerospace. Q: Looking towards the next 12 months, where do you see the biggest opportunities for AM? Dr. Leigh: The biggest opportunity over the coming year will continue to be the role AM plays in enabling the supply chain. All manufacturers regardless of industry are continuing to feel the limitations of the supply chain, and we all need to think of how we meet our supply needs in a more digital way. AM has already played an important role since the early days of the pandemic, and I believe we’ll see that role expand in the coming year. All in all, there are some significant macro-economic headwinds at play as we are coming out of this pandemic. In light of that, I believe AM – as an industry – will thrive in light of those challenges. This is an industry that has shown its resilience, and it will continue to help accelerate innovation transforming how businesses operate and healthcare is delivered.

Learn more at: 3dsystems.com

30.1 / www.tctmagazine.com / 09

3D Print Production Parts in Their Thousands With the Stratasys Origin One and H350, true production-line performance from 3D printers has never been more achievable.

ORIGIN ONE | MASS PRODUCTION

Achieve industry-leading finish results with the Stratasys Origin One 3D printer using Programmable Photopolymerization technology (P3). Offering a broad range of high performance materials, this system enables parts from biocompatible medical devices to aerospace-grade components to be printed consistently and accurately.

H350 | HIGH VOLUME

The Stratasys H350 uses SAF (Selective Absorption Fusion),a new industrial-grade additive manufacturing technology that delivers production level throughput for enduse parts with excellent detail and a smooth surface finish. With quality control at the centre of volume production, the H350 offers the ability to certify your production through an established control mechanism.

To find out more about Additive Manufacturing using these technologies - or FDM, Polyjet or SLA from Stratasys - contact us NOW! UK & EIRE

THE TOTAL SOLUTIONS PROVIDER

Over 25 years’ experience helping companies reduce manufacturing and development costs.

www.3dprinting.co.uk

state of the industry

AM AND THE YEAR AHEAD Head of Content Laura Griffiths asks AM experts what’s in store for 2022.

P

ersonal resolutions, however ambitious or misguided, are standard for a January. Mine was to read a new book every week (don’t be too impressed, the second was ticked off by Britney Spears’ unofficial biography). For industry, however, January tends to be about predicting trends for the coming year, and after the two we’ve all just had, it’s good to look to the future with a big dollop of optimism. If there’s one topic that has reigned supreme following accelerated conversations throughout 2020, it’s supply chain. After AM vendors and end-users rushed to answer calls around PPE shortages and other pandemicimpacted supplies, the question since has been whether AM’s role in alleviating those problems would just be another short-lived spike on the 3D printing hype cycle or if the goodwill earned by the technology during those times of crisis would have a long-term impact. “In the second stage of the pandemic, and now in 2022, society has become more aware of the enormous social contribution of our technology - industries have seen how we can improve processes and reduce costs with our 3D printers in production lines,” Xavier Martínez Faneca, CEO at BCN3D, told TCT. “I think this situation is exceptional and transitory, and through this experience, we have all realised that it does not make sense to be producing in distant locations but that local manufacturing should instead become the norm.” Recent figures from market intelligence company CONTEXT suggest that this renewed interest in 3D printing is here to stay. Figures show a tangible impact on machine orders, and CONTEXT reports that 'almost all major vendors' at last year’s Formnext said 'new and renewed interest in 3D printing was a consequence of global supply-chain problems.' While work from home scenarios saw a surge in desktop machine

purchases in 2020, one machine segment that has remained strong throughout is the Professional class (categorised as those priced between 2,500-20,000 USD). Shipments were up not only on the previous year but +13% higher than in the same period pre-Covid, which CONTEXT believes has been driven by the launch of new products, namely lower-cost SLS machines like Formlabs’ Fuse 1. Kathy Bui, Product Lead, Engineering Business at Formlabs, commented: “In 2022, we will continue to see AM play a role in the supply chain with 3D printers becoming a manufacturer’s Swiss army knife, an adaptable tool that can keep production lines running. With in-house industrial grade 3D printers, manufacturers can fortify their business against supply chain challenges and mitigate risk rather than replacing traditional manufacturing processes. 3D printers will be used as a risk mitigation tool rather than replacing traditional manufacturing processes.” That said, the same report cautions while 3D printer shipments are on the up, the industry’s own production lines have been thwarted by the very supply chain disruptions it aims to solve. Order rates show demand is there but due to shortages in certain printer components, like many in-demand consumer-facing items from cars to PlayStation 5s, the supply chain can’t keep up. But that doesn’t mean AM can’t be an asset elsewhere, as Oliver Smith, Founder and Principal Consultant at Rethink Additive, suggests: “For every story of 3D printed rockets, there are a thousand examples of 3D printing

producing the “boring” stuff that keeps a line moving, an operator comfortable or a parts bin stocked. “Going into 2022 and beyond, expect a shift in messaging from vendors and enquiries by users from 3D printing as a production solution, towards 3D printing as a productions support solution, able to rapidly provide the “boring” components and widgets needed to keep your operations and shop floor processes moving. COVID has made “boring” cool.” That AM can’t solve all supply chain problems, not even its own, emphasises how AM adoption needs the right applications. 3D Systems, for example, has been exploring AM’s role in semiconductor capital equipment, an area the company’s CEO Dr Jeffrey Graves believes AM’s ability to facilitate “exotic machine components” will help “improve efficiencies by simultaneously producing numerous unique, end-use parts.”

30.1 / www.tctmagazine.com / 011

EVERYTHING FORMLABS, JUST FOR YOU Cutting Edge Technology from a Dedicated Supplier Advent 3D Ltd is solely dedicated to the supply and support of Formlabs' range of 3D printers. Our background in engineering and design provides a deep understanding of the requirements of these industries and uniquely positions us to help customers use Formlabs' 3D printing technologies to reduce costs, improve efficiency and reduce times to market.

Find out more about the Formlabs range, call now on 01295 672600.

DEDICATED FORMLABS UK RESELLER

www.advent3d.co.uk

state of the industry Likewise, Don Xu, Deputy General Manager and Global Business Group Director at Farsoon Technologies, which announced sales totalling more than 15 million USD during November 2021 with over 40 machines sold, believes while AM trends in supply chain will continue this year “to an extent and in certain applications,” for the vast majority of supply chain issues, we won’t see much change. Although, Xu does believe that “larger, more production- oriented applications will be a key growth area for additive in 2022.” Avi Reichental, CEO, Chairman, and CoFounder of Nexa3D, which recently introduced a new SLS system that decouples 3D printing and cooling processes to maximise productivity, says the lean towards production will lead to further micro-trends too: “The last two years have exposed a highly complex and brittle supply chain, which is top of mind for most product companies and driving CEOs to accelerate the digitisation and localisation of their supply chain with AM playing a central role with emphasis on speed, throughput, cost, and sustainability. “With more companies transitioning to volume additive production, we will experience stronger demand for larger build formats, functional materials, scaled post-processing, and full factory automation solutions that are anchored by advanced and adaptive machine learning and vision technologies for greater production consistency and yields.” Throughout each of these conversations, it became clear that if there’s an AM segment that holds the most promise and is set to be the biggest driver in said production applications, it’s material innovation, as Bui posited: “In 2022, 3D printing will grow as more innovative materials come to market to serve a variety of industries such as healthcare, dental, manufacturing, engineering, education, jewellery, audio and entertainment. In addition to evolving the existing materials to advance their affordability, functionality, and efficiency, advancements in material production will open up new markets while enabling manufacturers to reduce wasted materials and lower costs.” Speaking in a recent column for TCT, Markus Glasser, Senior Vice President EMEA at EOS, concurred: “Where historically there has been a focus on strength, production consistency and supporting a wide range of polymer and metal applications, sustainability is now the driving force for innovation. New materials are already bringing about production efficiencies in terms of the amount of material needed for an application, or production steps that require less energy.

This, alongside improved material and finished product recycling will help enable companies to achieve their sustainability goals and support the global drive to a more sustainable world.” Commenting on where such materials innovations may come from, Smith added: “Counter to the perception of 3D printing as a futuristic technology, there in actual fact has been progressively less and less blockbuster innovations year-on-year. While some interesting start-ups are refining aspects of the technology for niche applications and markets, more broad advancements in 3D printing processes have become incremental. Going forward into 2022 and beyond, the enabling and differentiating innovation in the space will be centred around materials, which in turn will drive the application space, with these materials advancements not coming from 3DP vendors, but established and specialist chemistry and metallurgy companies.” Further to that, Laura Ely, Director of Programs at The Barnes Global Advisors, says we’ll likely see more emphasis on the minutia of materials: “We also see an increased focus on what makes a good powder and how best to analyse materials. New processes to create powders are coming onto the market; for example, Metal Powder Works and their system to turn bar stock into powders without the use of gas atomisation. We’re also intrigued by a new system for solid material characterisation coming out from Exum and tools from Granutools that give new insights to solid material characteristics like flowability.”

the supply chain will die down. While impactful in some areas during the pandemic, the simple reality exists that there are a set of requirements that must be met for any use case.” Ely added: “Some realism will set in. While AM can be a tremendous stop gap to address critical supply chain shortages during crisis situations, it is not the magic pill for all manufacturing scenarios. However, we still see great opportunity; the hard work will continue to put the processes in place to use AM for spares and repairs, for expeditionary manufacturing – think 3D printing on the battlefield – and for other areas where point of use manufacturing makes good business sense.” And there are, of course, always more challenges to be solved, as Glasser noted, emphasising a topic that has seen greater attention, and action, in recent years: “In 2022, AM will become more dominant as a key route to achieving sustainability thanks to the new opportunities it creates for organisations across the design and manufacturing workflow, and the innovations that will allow it to replace more traditional production techniques.” 2022, for AM, looks set to be about incremental but impactful developments, putting what we’ve learned over the last two years into practice, and reinforcing that realism to further meaningful applications.

When we can start using the term “postpandemic” with any sort of confidence remains to be seen but for AM, there are reasons to be cautiously optimistic. In 2021, it seemed barely a week went by without news of a major AM acquisition or SPAC [Our Senior Content Producer Sam Davies has those covered over the page]. A month into 2022 and investment news remains quiet, but Smith thinks SPAC announcements will continue to be “top of the newsfeed” this year, adding that “2022 will be a good indicator for how SPACs could influence our industry long-term.” It's a similar story of pragmatism in supply chain as Cynthia Rogers, Communications ADDvisor at The Barnes Global Advisors, notes: “The noise surrounding 3D printing as the saviour of

30.1 / www.tctmagazine.com / 013

WORDS: SAM DAVIES

W

hen Stratasys’ 100m USD buy-out of Origin was quickly followed by Desktop Metal’s 300m USD takeover of EnvisionTEC in January 2021, it seemed to represent the starting pistol on a period of consolidation for the additive manufacturing (AM) market. Industry commentators had been expecting this for a while. The marketplace, many observe, has become saturated with a plethora of ‘me-too’ technologies offering the same promise and potential to address the same applications. What would follow was a wave of mergers and acquisitions (M&A). Competitors – like Desktop Metal and ExOne, Protolabs and Hubs, BEAMIT and 3T Additive Manufacturing – would merge; and the industry’s bigger fish would swallow up some of the smaller ones – say 3D Systems taking over Oqton, or Materialise acquiring Link3D. That, and more, happened. But by IDTechEx Technology Analyst Sona Dadhania’s reckoning, the 3D printing market still isn’t consolidating. And as she looks across the 3D printing space – where there are new technologies still coming to the fore – she doesn’t expect it to consolidate ‘anytime soon’ either. “While no single AM technology will be perfect, each innovative technology has strengths and weaknesses that enable AM to grow its footprint as an advanced manufacturing technique,” Dadhania expands. “Notably, these innovations come mostly from newcomers rather than longstanding market leaders. These newcomers and their technical advancements mean that the AM space isn’t yet consolidating to a small group of major players – rather, it’s growing.” Fellow market analysis firm CONTEXT is placing a significant focus on analysing such growth – parsing out acquisition growth vs organic growth and looking at the entire industry as opposed to individual companies – throughout 2022. Compared to 2020, CONTEXT recorded that +39% more industrial printers (those selling for $100k+) were shipped globally through the first three quarters of 2021, an encouraging sign of organic growth, but suggests the market still ‘recessed -6% from the pre-Covid period of 2019.’

014 / www.tctmagazine.com / 30.1

When evaluating the industry’s growth in the context of the recent M&A activity, CONTEXT’s VP for Global Analysis Chris Connery suggests there has been ‘great growth for specific companies, some of which was organic, but the better part of which was by way of acquisition.’ “Individual companies make up the total, so their individual performance is key, but we try to examine if M&A is just moving pieces on the existing chess board or if such company combinations help the industry grow,” he explains. “When a smaller company with a strong technical portfolio is taken over by a larger company with strong sales, marketing or distribution, then expectations are that one plus one can equal three – or four or five – and result in overall growth for the industry.” Indeed, when Stratasys made the 100m USD move to integrate Programmable Photopolymerisation technology into its business, Origin CEO Chris Prucha noted the company’s ‘go-to-market’ proficiencies were the most persuasive element. By IDTechEx’s calculations, this deal was just one of 40+ business combinations closed within the AM industry in 2021 alone. And while it has been many people’s assumption that the market is therefore consolidating, Dadhania points again to continued innovation, as well as external interest in the technology, to suggest otherwise.

“First, these recent M&A deals represent growing interest in AM from players outside the industry; about a quarter of these deals involved an acquiring company outside the AM space,” she says. “Second, M&A is nothing new to the AM space. Consider that 3D Systems alone acquired nearly 20 companies from 2011-2012, 30 companies total from 2011-2016. However, the growth of newcomers at the bottom has outpaced the acquisition rate of the leaders at the top, leading to overall industry growth. In our latest report, we see a very healthy growth rate of 22% for hardware revenue alone over the next five years.” To explain the rise in interest in AM from outside of AM, as well as the sheer volume of investment (IDTechEx reports 950m USD of private funding being invested in 3D printing related companies in 2021), Dadhania proffers the supply chain disruptions caused by the Covid-19 pandemic. Connery concurs, outlining such disruption has also seen machine orders increase: “The result has been the strong recognition by many end-markets that 3D printing can indeed help mitigate some of the pains they are seeing in their supply chains by pulling manufacturing closer to consumption resulting in strong sales activity leading into 2022. Such order strength then in turn makes certain companies attractive for mergers and acquisitions and/or causes investors to shift monies towards investing in AM, resulting in more public listings.”

state of the industry

In addition to the spike in M&A activity, as Connery references there has also been an uptick in 3D printing companies pursuing public listings, many of them via Special Purpose Acquisition Companies (SPAC). Essentium is one such company in the process of becoming publicly listed after combining with Atlantic Coastal. CEO Blake Teipel always intended to take Essentium public, but acknowledges the events of the last couple of years have helped facilitate the company’s next step this early. “There’s an upthrust here, a structural tailwind, to the concept of factory-focused additive manufacturing which can offer supply architectures with different solutions,” Teipel says. “That’s why we believe Essentium, and others, have been able to go public. I think the institutional investors see it too and they say, ‘okay, supply chains of the future are going to look different from supply chains of the past.’” Over the past 18 months, Essentium has joined Desktop Metal, Markforged, Shapeways and VELO3D in pursuing a SPACenabled public listing. Teipel talks of a ‘SPAC phenomenon’ whereby investors – whether they be private, institutional or public – want access to early growth stage companies. The target companies, in turn, benefit from a quick and often significant influx of cash. VELO3D CEO Benny Buller suggests, however, that ‘not all of the companies that went public, should have.’ “[What] is really important when you are a growth company is you have to have a very unique value proposition,” Buller says. “When you don’t, growth is going to be very speculative. You may be able to grow in the short term, but that doesn’t matter, because the value is based on a much bigger level of revenue that you need to grow a few years in a row very dramatically to accomplish that. And I think a lot of the companies that went

public don’t really have something unique and jumped on the wagon. “Additive manufacturing is at a place where there is a lot of expectation, but the technology today is at a point where, at least on the metal side, it’s the first time that capable manufacturing technology has been introduced, and the market will start to grow with this. But because our market share is relatively small, as we are growing, it will not show on the total market in additive manufacturing for a good amount of time. I think in the further future it will, but in the [short term] it will be hidden. There is a big gap between what the industry thinks about itself, what the industry can do, and how it’s valued.” Monitoring, recording and dissecting that growth will be the job of Connery and Dadhania, with the former suggesting that publicly traded companies are a big help to analyst organisations as their public disclosures aid them in better quantifying market trends. Whether the overriding market trend in AM will be one of growth or consolidation over the next few years remains to be seen. But one thing for certain is that 3D printing technology is catching the eye and attracting investment. Now, it’s over to the technology providers. “On one hand, [there appears to be] a clear belief amongst many major investors that 3D printing represents a long-term revenue opportunity,” Dadhania says. “That belief enables young, hot companies like VELO3D and Essentium to quickly raise funds through private investment and then through SPACs. On the other hand, many of these companies are still relatively in their infancy with a lot to prove.” EDITOR’S NOTE: As we went to press, it was announced that the merger of Atlantic Coastal Acquisition Corp and Essentium had been terminated, with the 3D printing company citing ‘market conditions.’

MATERIALISE’S CHIEF LEGAL OFFICER CARLA VAN STEENBERGEN ON THE M&A PROCESS In M&A, the first hurdle is assessing whether the target company will contribute to the achievement of the buyer’s strategy & goals. This will be evaluated on technology or business application rather than finances. This assessment is made with a business case preparation that will do a computation of the synergies postacquisition, as well as consider alternative options, before a due diligence (DD) process is undertaken to familiarise the buyer with the company, technology, management and financial reporting. Discussions in DD are aimed at getting to know the company and understanding the potential risks in order to make a correct financial valuation of the target and a validation of the initial expectations for synergies. Company culture is important for the success of the transaction will also be determined by the likeliness of the target company and its employees to find their place in their new working environment. My tips for pursuing an M&A deal: n S tart the process with the end goal in mind, and make all key team members aware of this end goal. n G o beyond the answers found in DD. Try to understand habits and operational reality. n F ocus on people & culture. In tech, M&A more often than not are a way to gain access to specific know-how which is often tied to individuals. So, spend enough time on making the transaction an added value for the target company's employees. n N ever forget, closing is not the end, closing is the start.

“The growth of newcomers at the bottom has outpaced the acquisition rate of leaders at the top.” 30.1 / www.tctmagazine.com / 015

CERAFAB SYSTEM EMPOWER YOUR DIGITAL MASS PRODUCTION

AEROSPACE

INDUSTRIAL

MEDICAL www.lithoz.com

Learn from the leaders in additive manufacturing Grow your expertise. Explore our trainings.

Your learning experience is just one click away!

Additive Minds Academy A brand of EOS GmbH www.additive-minds-academy.com

software & simulation

PRINTING

WORDS: SAM DAVIES

stronger materials’ offered by Ultimaker. SmartSlice is able to access the material profiles of the machine vendor’s extensive portfolio and factor their respective properties into its slice simulations. It means users no longer need to buy materials to try them out, just like they don’t need to print their parts to make assessments of them. “The number of slicing parameters in Cura alone is like 200 plus,” Kenik says. “Which ones do I tweak? Where do I go? You need tools to help you explore that space rapidly. You don’t want to do it manually, even virtually manually, you want to do it in an automated fashion. The software can say, ‘go in this direction, don’t go in that direction.’”

SHOWN: PISTON TRAY

I

n North Carolina, the US’s NASCAR racing capital, a manufacturer of race car components was stuck in a cycle of print a part, have it break, print a part, have it break, become extremely stressed, and then just print it solid. This less-than-ideal workflow is what Teton Simulation was founded to resolve when it came to market with its SmartSlice software platform in 2020. SmartSlice, which is available as a plug-in to slicer platforms like Ultimaker Cura, has been designed to optimise the slicing phase as companies like RE Suspension additively manufacture parts like piston trays. Piston trays, which hold the internal shim stacks and pistons for serviceable shocks, are used by race teams when disassembling, rebuilding and tuning shocks for high-performance vehicles. Before adopting SmartSlice, RE Suspension was hearing from customers that the printed piston trays were breaking. The easiest option was to reprint it solid and ship it back out. “Then we brought in our software and said, ‘look, we’re showing you on the part where it’s going to break,' which is exactly where it was breaking,” Teton CEO Doug Kenik retells the story. “Instead of changing it to solid everywhere, we just changed the print settings in a very local region where it was breaking and we saved them days of print time, which allows them to get more throughput on those 3D printers.”

“You need confidence as a user that what you're printing is what you want.” RE Suspension is said to use Ultimaker S3 and S5 machines. In its supply of printed parts for its racing team clients, RE Suspension has been looking to free up its 3D printing capacity as much as possible, while also reducing its usage and waste of material. Hence, moving away from the print, break, print, break routine was paramount. That, however, takes time. In any slicer platform there are a whole host of parameters of a printed part that can be altered, and without the requisite simulation tools, the results of which can only be determined once the part has been printed. With SmartSlice, however, RE Suspension is now able to have the numbers churned automatically in the cloud, with the platform returning a thumbs up or thumbs down response in quick time. In printing parts like piston trays and dashboard brackets, RE Suspension leverages some of the ‘stiffer and

This was of particular help when RE Suspension was moving through iterations of a rear suspension bracket prototype, which would be later manufactured via milling. Rather than printing each prototype to test its load bearing capabilities during fitment testing – the part needed to be able to support the weight of an entire rear axile while being cycled through suspension travel – SmartSlice used modifier meshes to locally reinforce the part where extra walls and infill density were needed. Achieving a thumbs up, RE Suspension could save weeks in time and more than 400 USD in cost when compared to outsourcing the machining for a metal counterpart. Moving forward, RE Suspension is intending to explore more end-use product applications with the aid of SmartSlice. When they get there, that will be job done for Kenik. “You need confidence as a user that what you’re printing is what you want at the end of it and if the printer manufacturers and the material suppliers can help supply that confidence, that creates an ecosystem where people are so successful that they want to print more,” Kenik finishes. “That’s where we are as an industry in Teton’s viewpoint. There’s a whole bunch of material innovation, there’s a whole bunch of machine innovation, but there’s a confidence issue right now where one, I don’t know where to put this, what areas it can go in, and two, I don’t know if I print it, it’s going to work. We need to continue providing these ecosystems which are providing users trust and confidence in their parts.”

30.1 / www.tctmagazine.com / 017

DESIGN'S NE L

ast year I got to attend an exhibition at the London Design Museum in the comfort of my pyjamas. No, I wasn’t testing the dress code or parameters of social etiquette, this was the product of a recent Dassault Systèmes collaboration featuring 3D printing, new materials, and a virtual twin environment that allowed me to take in a new art installation from the glow of my laptop screen. It’s called AURORA which, in addition to being the name of a striking light phenomenon, also translates to “new dawn” and is precisely what the project’s collaborators hope to inspire for the future of design. “We spent some time discussing this name, this new dawn about how we can leverage technology in the design process,” Anne Asensio, VP Design Experience at Dassault Systèmes and head of the Design Studio, told TCT from a more familiar virtual environment: a Zoom call. “It's also an optimistic view of the future. We wanted to promote our human approach to technology, and overall demonstrate where technology is not just given, but could be a great means to address those very important changes that are ahead of us.”

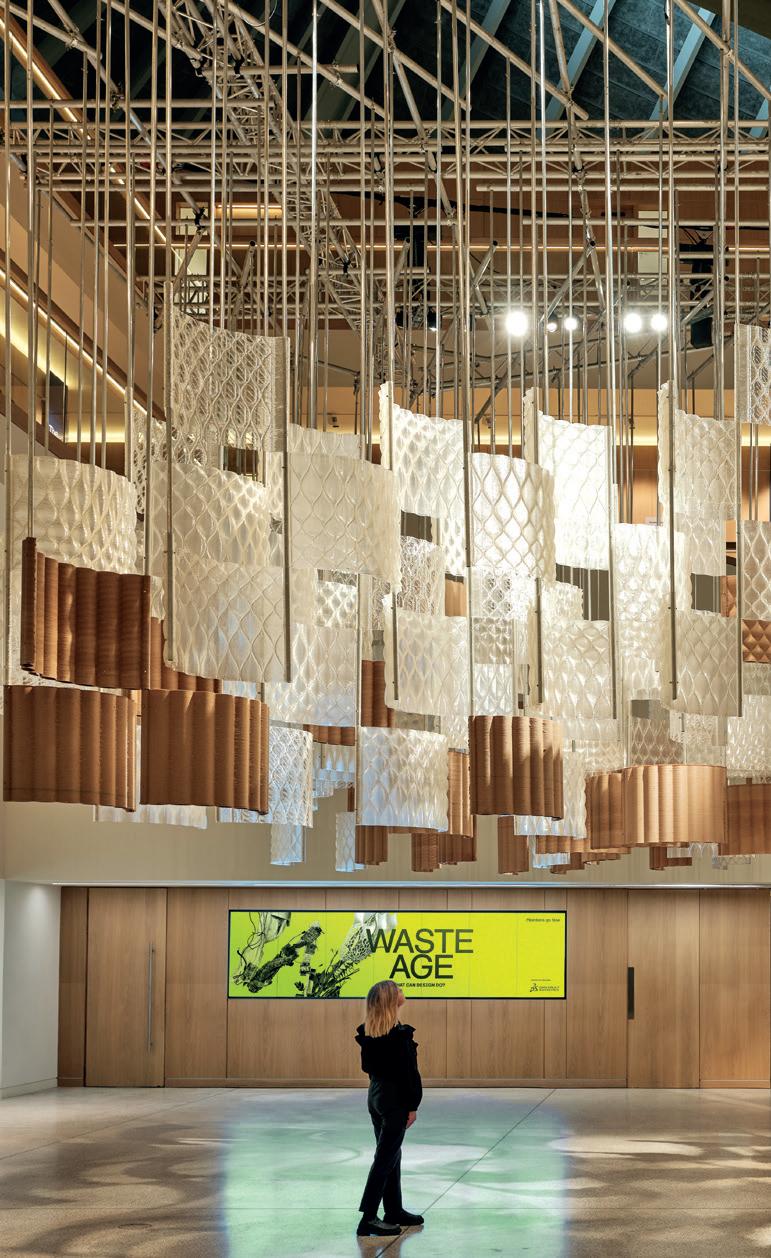

Arthur Mamou-Mani, renowned architect and AURORA designer added from a different Zoom window: “I think we both wanted to have a notion of what's next and what's after COVID? What's after this crisis?” It’s a question touching most industries as the impacts of the pandemic continue to ripple through supply chains and day to day life, but one the collaborators feel creatives and designers, given the right tools, could be uniquely equipped to answer. AURORA takes the form of a series of waves, or modules, manufactured locally at Mamou-Mani’s FabPub in London with 3D printing in bio-sourced PLA, and suspended in the air using steel tubes. It’s the third instalment from Dassault Systèmes’ Design in the Age of Experience initiative, developed within its own cloud-based 3DEXPERIENCE platform, and forms part of the Design Museum’s “Waste Age: What can design do?” exhibition, exploring design’s role in sustainability.

018 / www.tctmagazine.com / 30.1

Describing how the two came to work together, Mamou-Mani recalls how they were each “at the crossroads between tech and the circular economy,” with a need to make technology “purposeful, as opposed to just for its own sake.”

SHOWN: AURORA INSTALLATION AT THE LONDON DESIGN MUSEUM

Asensio elaborated: “It's more about collaboration, experimentation with like-minded people, looking at a very important challenge that is, in this case, waste, but it was really about creating the condition of the best collaboration.” AURORA’s modules are said to have been inspired by a dry cactus and the movement of its cellular structure. Initially designed in 3D, the team then used Dassault Systèmes’ xGenerative Design to build the larger architectural structure before creating a virtual twin experience that places AURORA within a live model of the Design Museum. It’s here where the team were able to simulate the effects of elements such a lighting and airflow to inform AURORA’s design – and also how I got the chance to visit and interact with the installation remotely. The modules were printed using a PLA made from potato starch, chosen not just because of its biocompatibility, but the ease at which it can be crushed back down and re-used for further 3D printing, taking advantage of the material’s unique aesthetics. “When it comes to working with a material that's quite new and therefore quite whimsical, the material does its own thing. If one does not adapt their own ideas to that material then it can be very challenging,” Mamou-Mani explains, pointing to a shelf in the foreground featuring an array of trials and test prints. “When we worked with the PLA bioplastic, it did its own thing, and the machine also had its own way of working. So it is kind of upside down where the machine tells us what it wants, the material tells us what it wants, and then we adapt to that as opposed to the other way around.” Using Life Cycle Assessment solutions within the 3DEXPERIENCE platform, the collaborators discovered they were able to save six tons of CO2 using this material compared to petroleumbased plastic. But this material choice, even with its clear advantages, also highlights how there’s no one size fits all solution to sustainability. “There's this big contradiction that's worth highlighting between something that's durable, i.e., sustainable, and something that you want to biodegrade, i.e., disappears,” Mamou-Mani explained. “What I like about PLA is that it sits right in the middle, it can disappear if you put it at the right conditions but it won't do it on its

own so that means that you can activate the biodegradability. Or you can let it last for a long time.” The words ‘exploration’ and ‘experiment’ come up a lot during our conversation. “An interactive experimentation of how we can achieve a more sustainable approach to life in the future,” reads the description on the Design Museum’s website, and Mamou-Mani is open about the fact that before meeting with Asensio’s team, the 3DEXPERIENCE platform was a completely new way of working for the studio, requiring a “process of discovery.” But Asensio is keen to emphasise the flexibility the platform provides for designers, and how creativity can encourage different ways of seizing the technology, resulting in new solutions to challenges. “Technology is often seen as very rigid, dogmatic, driven by a deterministic approach,” Asensio explained. “That’s not our way of doing it. We see the 3DEXPERIENCE platform as a very open, easy, collaborative virtual workshop. And it's nice to actually trigger those questions of what do we observe in nature? How can we translate that into a technological application and how can we play with it?

software / creative

EW DAWN WORDS: LAURA GRIFFITHS

SHOWN: MODULES WERE 3D PRINTED IN BIO-BASED PLA

“Sustainability is so layered - one cannot say it's good or bad.” “We have done a lot of work with Dassault Systèmes to bring basically those very competent tools, considered too complex for designers, more accessible, more agile, to actually provide this quality for any architect to actually [make] their dreams come true. We cannot make circular design processes if the designers are not part of this process. So if we are looking at a circular design, concept and intention, if you don't have a tool that allows you to actually place this concept into the same environment where you can really test, simulate and make sure that concept actually has a circularity potential well, the design stays in the concept phase.” Asensio notes the rarity of designers being able to chart the impact of their work, and the use of Life Cycle Assessment tools within AURORA’s iteration stages allowed for the team to think creatively but design with engineering intent, understanding the impacts of their design choices and how that may play out across a component’s lifespan. “Sustainability is so layered that one cannot just say it's good or bad,” Mamou-Mani said. “There

are several dimensions to that Life Cycle Assessment from water usage to transportation to the effect on your lungs when you burn it, or the toxicity of land, and what I loved about this project is we could dive deep into all these different dimensions.” Commenting on the wider impact these learnings could have, Asensio added: “This is probably going to be a little revolution. But it will not just happen by just a tool or few designers or architects doing it, it has to be framed as something that may be a new way of approaching.” Those sustainability considerations extend not only to the pavilion’s process and material choices but also AURORA’s own lifecycle.

Members of Dassault Systèmes’ design community have already begun coming up with new ways to repurpose AURORA’s individual modules to expand its life beyond the rafters of the Design Museum and drive that circular economy message even further. “AURORA is not just an installation in the middle of the Design Museum in London, it is a metaphor of the way we may build,” Asensio concluded. “If we really bridge creative thinking, original thinking and those scientific tools, we are very optimistic that we may basically change the way we live, our surroundings, our everyday things.”

SHOWN: DASSAULT SYSTÈMES’ ANNE ASENSIO AND ARCHITECT ARTHUR MAMOU-MANI WITH 3D PRINTED AURORA MODULES

30.1 / www.tctmagazine.com / 019

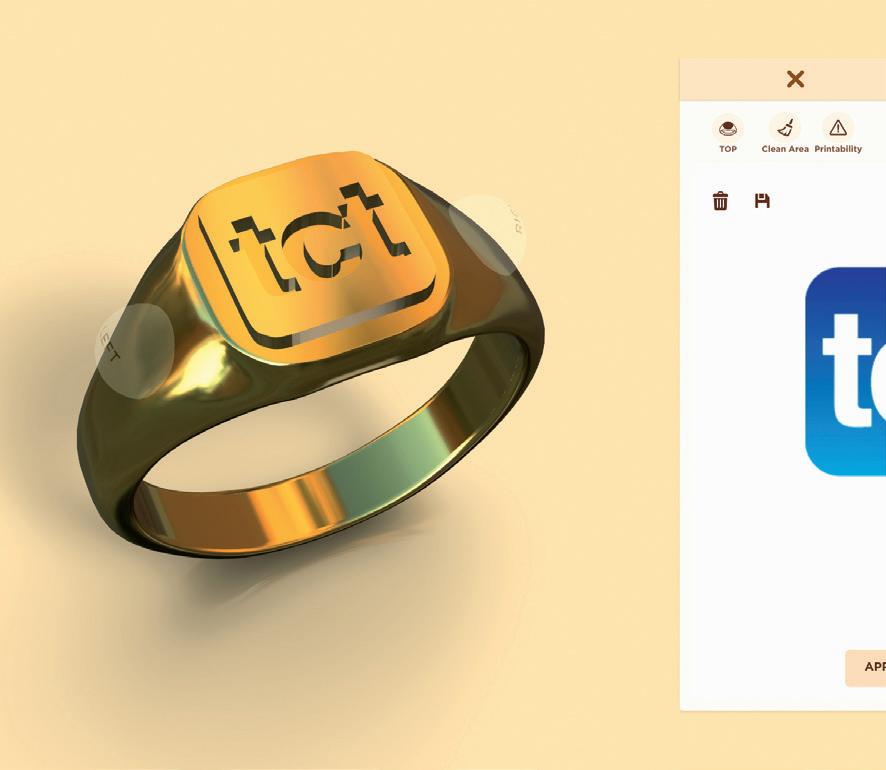

IS THIS THE FUTURE OF JEWELLERY?

Laura speaks to THEFUTUREOFJEWELRY co-founder Casey Melvin about making customised jewellery more accessible.

I

t’s hard not to feel inspired when talking to Casey Melvin. The CEO – or rather Co-CEO with sister Janine – a Princeton grad, was in law school spending a semester abroad at Oxford in 2016, where a weekend getaway to Spain ignited an idea that would change the course of their careers. “If you would have told me five or ten years ago that I would be an entrepreneur or own my own company of any sort, I probably would have said you were lying,” Melvin told TCT while recalling a trip to Mallorca that would prove formative for THEFUTUREOFJEWELRY (TFOJ), a personalised jewellery company the duo founded, that leverages 3D technologies. Searching for a memento of their summer, the sisters happened across a plain gold signet ring. It fit Melvin perfectly and they watched, fascinated, as the jewellery store owner hand etched the initials ‘CM’ on top. When they returned home to Pittsburgh, Melvin began searching for a similar ring to gift to her sister but even the few that came close were either the wrong size or too expensive. Melvin was surprised to learn that there wasn’t already a solution on the market that would deliver customisation at an accessible price point. So, they set out to change that. It was a trip to Shanghai and a visit to TCT Asia 2017 where the founders got a real sense of how

020 / www.tctmagazine.com / 30.1

3D printing could turn their vision into a reality. “It's like getting a masters in 3D printing,” Melvin said of walking that first show floor. They reached out to billionaire investor Mark Cuban, a fellow Pittsburgh native, who responded with sage advice to focus on their core product – a software platform – and to outsource their 3D manufacturing. By 2017, the co-founders had assembled a team to develop their signet ring online customisation platform, and in four short years, began shipping. The platform’s simplicity allows customers to add their initials, select from a library of designs, or upload their own image to generate a 3D model. They can then choose the shape, style, material and size of their ring (TFOJ's algorithm can automatically generate 125 sizes), and the price will adjust accordingly. Once ordered, the design is then 3D printed using a high resolution DLP process before casting into the customer’s chosen metal. Signet rings have been around for thousands of years, typically the domain of the powerful and wealthy. As time and trends have moved on, so too have the jewellery’s status, yet as Melvin discovered, even today, personalised signet rings remain out of reach. TFOJ aims to enable accessibility through not only a transparent pricing model – in which they ensure every piece is priced with the same markup, no matter the size or

material – but also with a consumerfriendly design platform, and Melvin adds: “It was really important to us that you didn't need to be a designer or have 3D modeling experience.” But that accessibility element extends to the customisation too. Unlike that first signet back in Mallorca, TFOJ wants to ensure size and fit are not a barrier for its customers. Melvin explained: “There were no ring sizes before there was mass produced jewellery, every piece was made to order. These standard ring sizes really arose in the 19th and 20th Centuries. We're going to actually do away with standard sizes so every ring can be fit to the person who's wearing it.”

SHOWN: SIGNET RING CUSTOMISATION PLATFORM

creative

SHOWN: CASEY MELVIN, CO-CEO

“Our goal is to democratise jewellery through 3D printing.”

Currently, TFOJ works with a U.S.-based contract manufacturer to produce its final products but Melvin says, as the company looks to expand, the ability to take advantage of 3D printing’s agility and localise manufacture globally is an important prospect, suggesting “the less an item needs to travel the better.” But Melvin adds there’s more that could be explored in TFOJ’s own future. Melvin concludes: “Our goal is to democratise jewellery through 3D printing – our customisation process would not be possible without the 3D printing component. And even though right now, that means 3D printing in wax and casting it, in the future that could be DMLS 3D printing into steel or into precious metal directly or in other materials that we haven't even developed yet.”

30.1 / www.tctmagazine.com / 021

UNIQUE AESTHE WORDS: SAM DAVIES

SHOWN: CRYSTAL GLACIERS

T

o me, the most important thing is that I achieve something which looks unique, so it has a unique aesthetic embedded in it, something innovative and novel, which sets itself apart from anything that we have seen before.” The standards were set more than six years ago. Julia Koerner founded JK Design in 2015 in Austria, with a new brand, JK 3D, being established last year with her partner Kais Al-Rawi. In that time, Koerner has found success in architecture, fashion design and product design, leaning on her specialities that span 3D printing, robotic technologies and computational design. Her name has appeared in this very magazine before, after she produced 3D printed garments and accessories for Marvel’s 2018 Black Panther movie, while a fashion collaboration with Stratasys and Ganit Goldstein also filled the column inches of many a 3D printing publication in 2021. Last spring, Koerner was reaching another professional landmark. Commissioned to develop two art sculptures measuring up to six feet tall, that would be put on public display in Santa Monica, California later that year, she was embarking on her very first public art endeavour. But due to unforeseen circumstances (a global pandemic; you may have heard about

022 / www.tctmagazine.com / 30.1

SHOWN: 3D STELAE SCULPTURE

it), things didn’t go exactly according to plan on her '3D Stelae' project. The plan at one time was to hand the production of the 3D Stelae sculptures to a service provider that operated large-format 3D printing systems. With the costs deemed prohibitive, Koerner then explored CNC milling, which was a little more affordable. But by the time she was ready to place her orders with a digital fabrication shop suited to her needs, they were all either closing down because of COVID-19 restrictions or swamped by the demand for faceshields and other Covid-related applications. At this point, the deadline was just months away, with the first 3D Stelae installation slated for July 2020. The only way forward was to turn to JK Design’s in-house Fused Deposition Modelling (FDM) platforms, 3D printing the two sculptures in four-to-six sections measuring around one metre tall and 30 x 30 cm in diameter. “We started printing it and it worked without adapting the geometry largely,” Koerner tells TCT. “It was so fascinating because all of a sudden we were able to print these large sections at 1.5 millimetres thick without any support material, so it’s super lightweight and the material can withstand outside environmental forces, such as sun and heat. “We started to produce this in our studio, and it was revolutionary because I realised what we can do in-house and how we can make our own products with very limited resources.”

SHOWN: HY CLUTCH

creative

ETICS

Koerner first came into contact with 3D printing at the University of Applied Arts in Vienna in 2005 and maintained an interest as she passed through the Architectural Association (AA) in London. Here, she not only met Al-Rawi, but she also became involved with the AA’s visiting school programme. This programme took Koerner and Al-Rawi to the Wadi Rum desert in Jordan, renowned for being the closest environment on Earth to that found on Mars. While there, Koerner spent a lot of time at the Nabataean city of Petra, which was once a thriving trading centre carved into the sandstone cliff faces by the Nabataeans in the second century A.D. Over time, the carved stone columns at Petra have been eroded, but would serve as Koerner’s inspiration for a project entitled Columns to Crowns. “We looked into this change over time, and we developed 25 columns which represent this change in a series,” Koerner says. “With 3D printing, you can produce unique custom elements, you can personalise, you can customise, and the idea was to showcase these morphologies in physical form.”

“There is no similar product right now on the market. It’s something really unique and cutting edge.”

Columns to Crowns was exhibited at Amman Design Week in 2019, with the work being carried out between 2014 and 2018 and the pieces being created with 3D printed PLA and acrylic tubes. It was this work that would later lead Koerner onto the 3D Stelae sculptures, advancing the research that came in Jordan and again returning to 3D printing technology. For Koerner, 3D printing is a means to push the boundaries of her creativity, reinterpreting how we typically think about products and creating distinctive pieces with unique geometries and aesthetics. It all dates back to her time at the University of Applied Arts in Vienna. “My thesis was about superhuman enticement. I was inspired by the anatomy of the human body, by biological morphologies, growth systems, and abstracting the mathematical logics, what you would find in nature into geometries, which are only possible to be 3D printed,” Koerner says. “There was a certain fascination which came along where no other fabrication technique would be able to do it.” Fifteen years on from concluding her studies, and with her JK Design and JK 3D brands progressing well, Koerner splits her time between California and Austria. On one notable return to her homeland, Koerner was invited to Swarovski’s headquarters which sits amidst a mountainous landscape in Wattens. The glass company had requested not only a keynote presentation from Koerner, but for her to also contribute to an element of its glass 3D printing research and development. “They wanted me to challenge them; how would the designers’ thought process push the technology in a certain direction,” Koerner says.

As she stood side by side with a Swarovski design team, she reinforced 3D printing’s capacity for outputting different variations of a part using the same algorithm in the same build process. This idea was manifested in a JK Design project entitled Crystal Glaciers, a series of 24 customised glass spirals that were inspired by the topology of the mountains surrounding Swarovski HQ. “With Crystal Glaciers, we wanted to showcase that across a series of these [glass spirals] there is a shift in size and scale, in intensity and the looks,” Koerner explains. “I think it had quite an impact on how they develop the technology further thereafter.” As an Austrian native, to work with Swarovski, and gain the company’s trust as an external designer, is a career defining moment and one that represented a significant shift. After years' working with polymer 3D printing, there were new size limitations to get to grips with while working with glass printing. She also had to adjust to a slower feedback loop since she wasn’t overly familiar with the glass printing technology that Swarovski are so far keeping under wraps. Crystal Glaciers was a project that primarily intended to represent Swarovski’s continued spirit for innovation, but it did a good job of highlighting Koerner’s own ambition too. Her most recent work saw a return to more conventional 3D printing techniques, but another step forward in inspiration. Manufactured with locally sourced plantbased materials, the HY CLUTCH bag features an integrated closure clasp, partial opening hinge and an interior pocket, all of which is 3D printed. Available in black, offwhite bone and transparent colours, the HY CLUTCH products are produced on-location, on-demand within a single day, before being distributed in packaging that is made from vacuum formed recyclable plastic. While meeting a prerequisite for sustainability, it also nails Koerner’s need for originality and innovation. Featuring intricate and complex organic forms that resemble the natural hymenium lamella structures found on some species of mushroom, the HY CLUTCH bag won the Red Dot Design Award for 2021 and was Long Listed for Dezeen’s Product Design and Wearable Award 2021. It is bold, it is distinct, and it meets the brief. “We’re excited about it,” Koerner finishes. “I see a lot of future opportunities with this product. There is no similar product right now on the market. It’s something really unique and cutting edge.”

30.1 / www.tctmagazine.com / 023

KimyaLab

KimyaMaterials

KimyaFactory

Characterisation laboratory Specific developments Dedicated team of chemists

Modeling & Conception 3D printing Services Support & Assistance

High-tech filaments Eco-designed filaments Customized production lines

STANDARDS

WORDS: LAURA GRIFFITHS

S

tandards remain one of the most predominant challenges in additive manufacturing (AM), particularly in those highly regulated industries the technology best serves. Speaking to TCT Magazine last year with regards to the energy sector, Shell’s 3D Printing Technology Manager Angeline Goh shared how organisations responsible for setting international standards and legislation are “still playing catch up” when it comes to AM parts, but a recent milestone with LRQA (formerly Lloyd's Register) could help to speed things along. The oil and gas giant recently worked with the global assurance provider to successfully certify a 3D printed pressure vessel in accordance with the European Pressure Equipment Directive (PED). The project, a first for the industry, underwent four stages over four years starting with the design, through to facility qualification and printing, defining acceptance criteria, and culminating last year with testing and inspection. To date, standards and legislation for AM pressure retaining parts have been lacking, and the need for regulations has generally prevented 3D printed pressure equipment from being permitted. The goal behind this project was to create a proof point that could inform the energy industry’s trust in AM for future applications. It also emphasises the “justin-time as opposed to just-in-case” method of part sourcing Goh also spoke about last year as Shell explores alternatives to the purchasing and storing of spares. The vessel has been designed for pressures up to 220 bar and was manufactured at Shell’s Energy Transition Campus in Amsterdam using Powder Bed Fusion. While this CE stamp represents a significant breakthrough for the energy sector, in a more recent Q&A with TCT, Goh says there’s still a way to go. “The knowledge and data that we have gained in this process is valuable for engaging with standards bodies and improving the sector’s trust in additive manufacturing," Goh said. "It will allow us, eventually, to further increase the scope of our inventory for just in time manufacture instead of stocking, as well as increase our scope in novel design and applications critical to our asset’s eff orts to reduce operational emissions of greenhouse gases.”

“The knowledge and data we have gained in this process is valuable for engaging with standards bodies.” Shell shared the three main challenges that arose during this project. The first was primary material approval, which meant printing test specimens alongside the pressure vessel to test and approve material properties before formal approval through the Particular Material Appraisal (PMA) process. Goh explained: “Unlike material bought in batches, tested upfront, with 3D printing, the part is created as the material is printed. Therefore, the formed material must be certified after the pressure vessel is already produced.” They also had to define inspection protocols that would catch defects caused by AM’s own “unique flaws.” This included printing a dummy vessel featuring deliberate defects and using a range of CT scanning, dye penetrant testing and other non-destructive techniques to observe hard to detect flaws. Due to those unique defects, the usual acceptance criteria for welded pressure vessels was deemed unsuitable by the certifier so the team had to model intentional flaws on the vessel's performance to help define maximum acceptable defects.

SHOWN: 3D PRINTED PRESSURE VESSEL CERTIFIED IN ACCORDANCE WITH THE EUROPEAN PRESSURE EQUIPMENT DIRECTIVE (CREDIT: SHELL)

“The sector is still lacking general acceptance criteria for defects in 3D printed pressure vessels,” Goh elaborated. “It took a lot of R&D time and effort from Shell and LRQA to be confident with the final product. Still, more data must be collected and shared by part producers for standards setting bodies to define general acceptance criteria for defects in 3D printed pressure vessels which can be adopted by certifiers in Europe and globally.” Data from this project can be utilised to support efforts to define standards for 3D printed pressure vessels under the EN 13445 - Unfired Pressure Vessels standard. Shell is now exploring the use of printing pressure-retaining parts for its own experimental installation, focusing on R&D and design and process optimisation “to improve the economy of printing critical parts, rather than large scale manufacturing.” While the company says it will have more projects to showcase in the coming months, there are no immediate plans to get more parts certified. For now, more data, and sharing of that data, is required. Goh concluded: “We hope other companies, research institutes and companies who have invested in similar research also see the value of sharing their learnings with standard setting bodies.”

30.1 / www.tctmagazine.com / 025

MAKE YOUR PRODUCT RIGHT THE FIRST TIME DESIGN WITH ADVANCED MATERIALS

When you need to combine peak performance with ultimate lightweight requirements, fiber-reinforced materials are the solution of choice – no matter what industry you’re in. From product ideation to certification, Altair solutions give you an innovative, comprehensive, holistic product development approach. With our industry-leading simulation, HPC, and AI tools, you get the power to create lighter, higher-quality, and more sustainable designs with advanced materials. With our intuitive solutions, you can beat project deadlines and deliver on performance metrics like never before. Surpass the competition and shatter expectations with Altair. Learn more at altair.com/sustainability-solutions

© Altair Engineering Inc. All Rights Reserved. / altair.com / Nasdaq: ALTR

#ONLYFORWARD

STANDARDS

AM STANDARDS: 5 THINGS YOU NEED TO KNOW

Experts weigh in on the ‘must knows' for AM standards and certification. BUILDING CONFIDENCE Andrew Imrie, Principal Technical Consultant | LRQA “In the field of AM, a ‘desire for safety’ has not been a barrier to progress to date. This revolutionary manufacturing technique has been applied overwhelmingly in non-safety critical areas, with regulators – notably in medicine and aerospace – relatively quick to adapt. However, unless standardisation progresses, the projected growth of the market is likely to stall due to a lack of confidence where AM products are used in more safety critical applications. Whether driven by regulators, standards bodies or the industry itself, the emergence of an assurance culture in AM can only build confidence in the industry. “ISO 52920 is an AM standard which will become an important part of the tender process for procurement teams. Through ISO 52920, manufacturers will soon be able to ensure that their facilities are qualified, bringing confidence into the supply chain.” A STANDARDISED APPROACH Katharine Morgan, President | ASTM International “Certification for AM is vital for the technology to get broader acceptance across different industry sectors. AM opens up a plethora of applications ranging from toys to medical to aerospace and hence requires a higher degree of quality assurance. Therefore, the reproducibility of parts with quality, safety, and consistency needs to be demonstrated and verified to gain customer confidence. Standards provide the pathway to achieve certification of additively manufactured components, and ASTM is committed to developing globally recognised and industryrelevant standards on AM. Several AM standards have been published, and AM stakeholders can directly apply these standards to streamline their certification process, both internal and external, for AM. Following a standardised approach for AM can bring down the time-to-market and respond quickly to market demands.”

MATERIALS MATTER Zehavit Reisin, VP, Head of Materials Business & Design Segment | Stratasys “With AM certification, it is important to not only consider the material mechanical, thermal and chemical resistance properties to fit a specific use case, but also the certification of the production process of the material as well as the printed part. This is particularly relevant for highly regulated industries such as aerospace, mobility and medical. For example, the Stratasys’ ULTEM 9085 material is FST compliant for aircraft interior applications. However, to supply the aerospace sector, a certificate of conformance and other documentation was required to reflect that the production process was traceable and the FDM material manufactured in accordance with industry specifications. The very same ULTEM 9085 was found suitable for the mobility sector tooling applications but needed to go through different certification tests." TEST, AND TEST AGAIN Donald Godfrey, Global Director, Business Development for Aviation and Defense | SLM Solutions “When the EASA/FAA looks to qualify printed components, their focus is going to be on performance-based data. To validate this requirement, the company printing the component must produce a certain number of test specimens at least twice (usually more) in the same 3D printing machine, meaning the machine must produce metal components that not only match design intent but also be repeatable. Specimens from both builds must be processed after build and tested the exact same way both times to validate machine repeatability. Specimens must match (at the very least) the minimal material property requirements of the component design.

the part must also be qualified. The powder chemistry, morphology, and size distribution must be repeatable over builds. The heat treat process must be verified as repeatable. Finally, the material properties of the part must be tested and shown to be repeatable.” FLEXIBILITY IS THE FUTURE Arun Ramachandran, AM Lead/SME | Collins Aerospace “AM certification is primarily about demonstrating that the part design accounts for the various sources of variability intrinsic to the AM process, and the raw material. Designing for all the possible sources of variation is expensive and impractical. One of the approaches used in the industry is to develop either a frozen or a tightly controlled process to reduce variability and build an application specific test campaign around it. While this approach can help get a part certified, it could be challenging to apply it to certify other AM applications. It may also come into conflict with the desire to realise a key value proposition of AM – flexibility, in terms of machine choices, software/hardware upgrades, part design modifications, build parameter optimisation, raw material source changes etc. It is therefore important for the industry to also advance certification approaches that allow flexibility, and scale well in the long term.”

In addition to qualifying the machine, the supply chain process and

30.1 / www.tctmagazine.com / 027

THE DIRECTORY

e | adam@agprototypes.com w | www.agprototypes.com

Metalise it… DMLS and SLS

• Fast turn around • Competitive pricing • High Quality • In-house design/development capabilities

t | 01707 391 120

3ddc.eu

Derby, Derbyshire, DE24 9FU, United Kingdom +44 (0)1332 742820 www.addqual.com

AddQual panel.indd 1

LPBF Consultancy & Digital Manufacturing Services WWW.APEX.TECH

MAG

Key services 3D Re-Engineering Inspection Qualification Digital Twin Creation Fast Make Tooling

3D SCANNING

Bureau Service | Product Sales

30/05/2018 13:38

• High Accuracy & Resolution • Reverse Engineering • Scan-to-CAD • Inspection Reports • Geomagic Software • Wrap, DX, CX, Freeform

Want to reach TCT’s independently verified audience of AM and 3D printing professionals? GET IN TOUCH

Carol Cooper | Carol@rapidnews.com TO ADVERTISE HERE CONTACT CAROL COOPER ON + 44 1244 952 386 OR EMAIL CAROL@RAPIDNEWS.COM

THE DIRECTORY

THE DIRECTORY ADDITIVE MANUFACTURING

Plassc | Nylon | Carbon | Peek | Rubber | Wax | Metal • SLA

ProJet 7000, ProX 800 Sinterit, ProX 6100 • DLP Figure-4, Modular • MJP ProJet 2500+, 3X00 • CJP ProJet 660 Pro, Z650 • FFF Omni, Funmat Pro 410 • DMP ProX Metal • SLS

01420 556755 replik8@cdg.uk.com

Not all 3D Printed Parts are Created Equal

SLS

|

SLA

|

MJF

|

SLM

|

FDM

Incremental Engineering Ltd Design, Prototype & Production Specialist HP MJF Service Bureau E: contact@incrementalengineering.com W: incrementalengineering.com

Your filament partner

Pellet based additive manufacturing solutions for both large and small products

delivering on time in full.

• Print Service • Machine Sales

maxfilament.com | contact@maxfilament.com

• Service • Spare Parts

pi-am.co.uk • info@pi-am.co.uk • 01603 891618

ADDITIVE INSIGHT

The original additive manufacturing industry podcast. Head to www.tctmagazine.com to subscribe now TO ADVERTISE HERE CONTACT CAROL COOPER ON + 44 1244 952 386 OR EMAIL CAROL@RAPIDNEWS.COM

27.1 / www.tctmagazine.com / 049

expert column

WHAT HAS CHANGED IN METAL AM - AND THE WORLD? WORDS: kevin ayers

part that I have worked with is typical. This part resembled a totem pole, characterised by very difficult to manufacture features. The traditional cost to manufacture was around 89 USD. The additive solution was 2,400 USD. Even with some enhanced performance gains, the customer would not accept the significant price increase. We were at an impasse as an industry in penetrating into mainstream manufacturing because of price per part.

SHOWN: KEVIN AYERS

A

long-time friend and colleague of mine, Angela Szerlong from SME, recently made the observation that leaders in the additive manufacturing [AM] industry have been talking for a long time about using AM for production but now she has seen that the intensity has been picking up. What has changed? Her observation and the question are relevant for today. The answer could be complicated but it is not: price per part. For some 25 years, we have pushed the applications and fought significant battles for AM to be accepted into mainstream manufacturing. Some victories were won in creating parts with enhanced performance and lightweighting, but we could never get past the most basic business barrier of cost per part. The costs of metal AM parts - mainly powder bed fusion (PBF) - were just way too high. One

030 / www.tctmagazine.com / 30.1