THE DESIGN-BUILD EDITION

Through an Owner’s Eyes

Why DFW International Airport EVP Khaled Naja chose design-build for the DPS building, pp 8-9

Value for the GC

See how JE Dunn SVP Chris Peck finds success with design-build, pp 10-11

Looking to try design-build?

Read Barbara Bryson’s advice for firms looking to avoid paralysis by analysis, pp 22-23

DFW Airport’s DPS office 2019

TDSpirit

Featured

AUGUST 19, 2019

Hear More from your Trusted Partners

TD has partnered with Valerie Sokolosky’s “Doing it Right” podcast to discuss key topics in today’s construction industry.

Keep up with TD at valerieandcompany.com, or watch on YouTube, @valerieandcompany

HIGH-RISE COLLABORATION AT THE LINK

Evers Kreuger Powell MacDowell

Kaizen Development Partners’ Derrick Evers, Balfour-Beatty’s Eric Kreuger, BOKA Powell’s Don Powell, and TDIndustries’ Harold MacDowell discuss this downtown Dallas project, and how early collaboration improves value.

Recent

SEPT. 16, 2019

FARS WITH CITY OF PLANO

Helping Firefighters: FARS increase each firefighter’s ability to battle a blaze and free up manpower for more urgent tasks. Plano Fire Chief Sam Greif and TD’s Andrew Kobe discuss the advantages of this system.

MAY 3rd, 2019

WOMEN IN TRADES

JUNE 24th, 2019

FACILITY MANAGEMENT’S IMPACT ON FAST-GROWTH SCHOOL DISTRICTS

Randee Herrin talks about TD’s Women in Trades program and how women are making strides in the construction industry.

Fast-Growth School Districts: TD’s Brian Lillard, Denton ISD’s Jamie Wilson discuss integrated facility maintenance’s growth on student achievement and community growth.

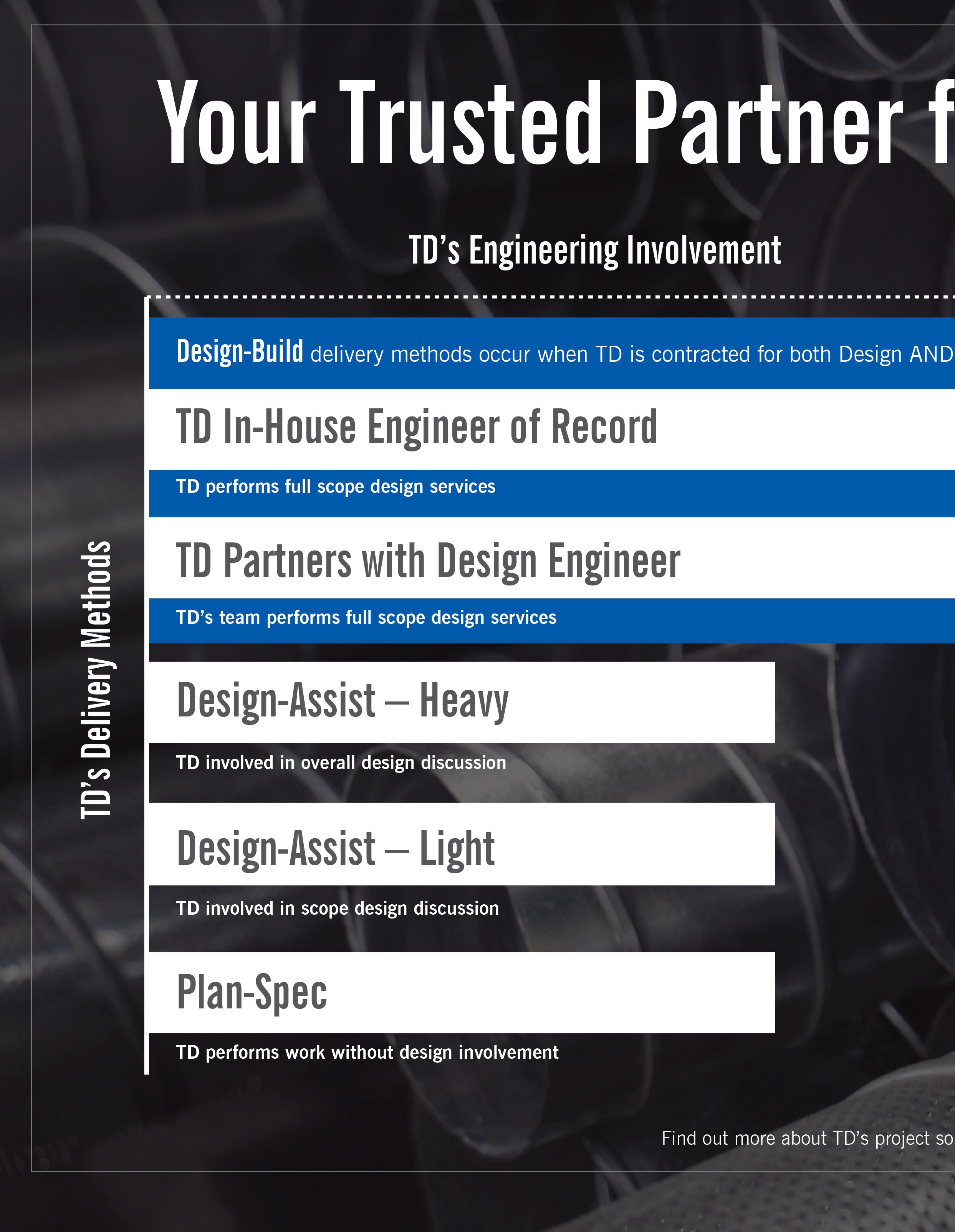

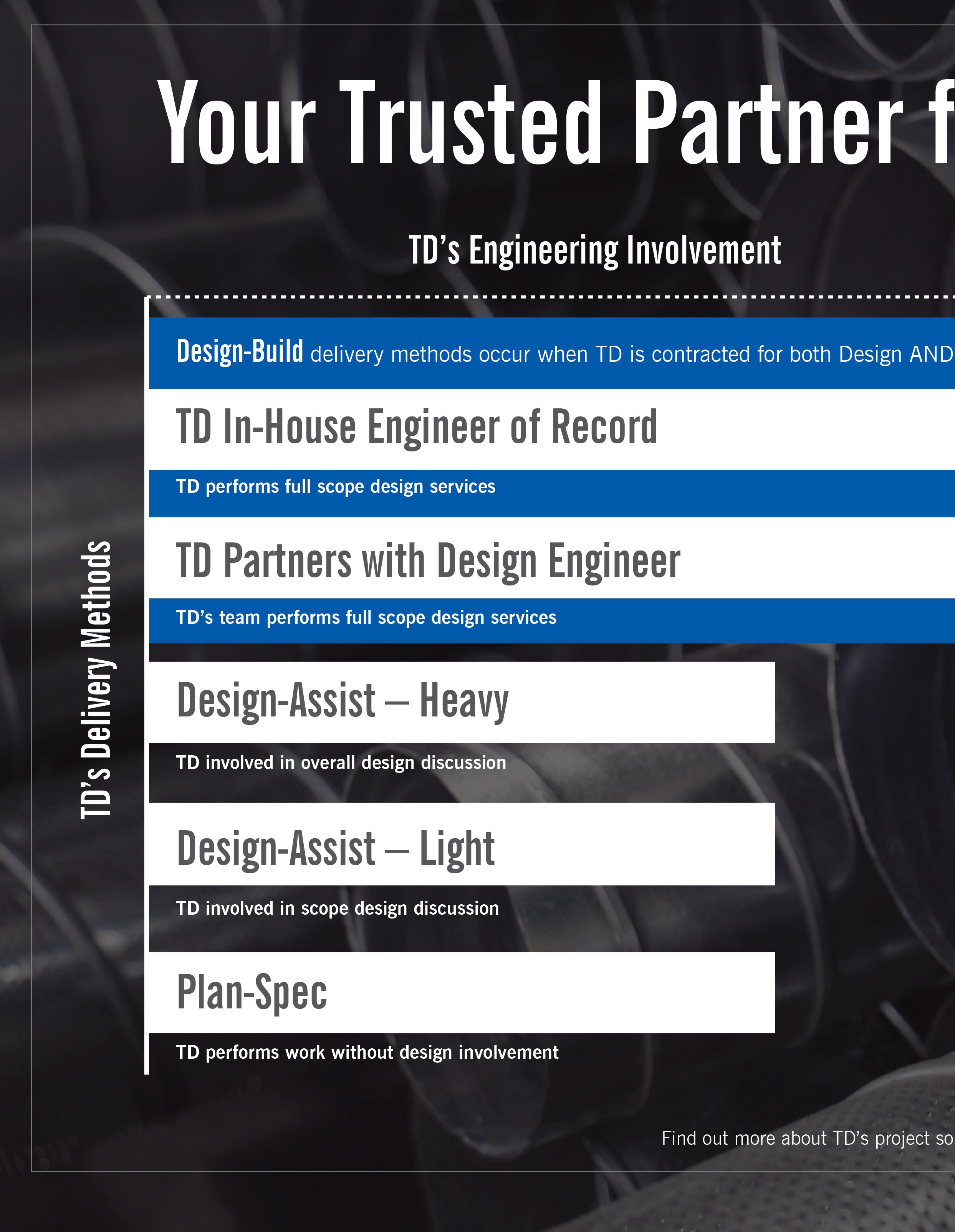

6-7 WHAT IS DESIGN-BUILD AT TD?

What owners should expect when TD is involved.

8-11 DESIGN-BUILD ON DFW AIRPORT

Design-build requires different roles for project partners. See how DFW Airport and general contractor JE Dunn describe their work on the new Department of Public Safety building at DFW International Airport.

12-13 EARLY TRADE INVOLVEMENT

See the advantages of involving a subcontractor during the preconstruction phase.

14-16 WELLNESS AND RECOVERY

See how design-build helped THR’s Mansfield facility become an Eagle award-winner.

17 ADDED EXPERIENCE IN AUSTIN

Scott Staton brings additional support to growing geography.

18-19 VALUE THROUGH ANALYSIS

See how TD’s Engineering department is finding additional value for Chandler Regional Medical Center.

20-21

FLEXIBILITY AT BP

Construction in a working office building requires balancing efficiency and tenant’s business needs. See how design-build provided adaptation.

22-23 PREVENTING PARALYSIS

See how companies can make decisions in an age of overinformation.

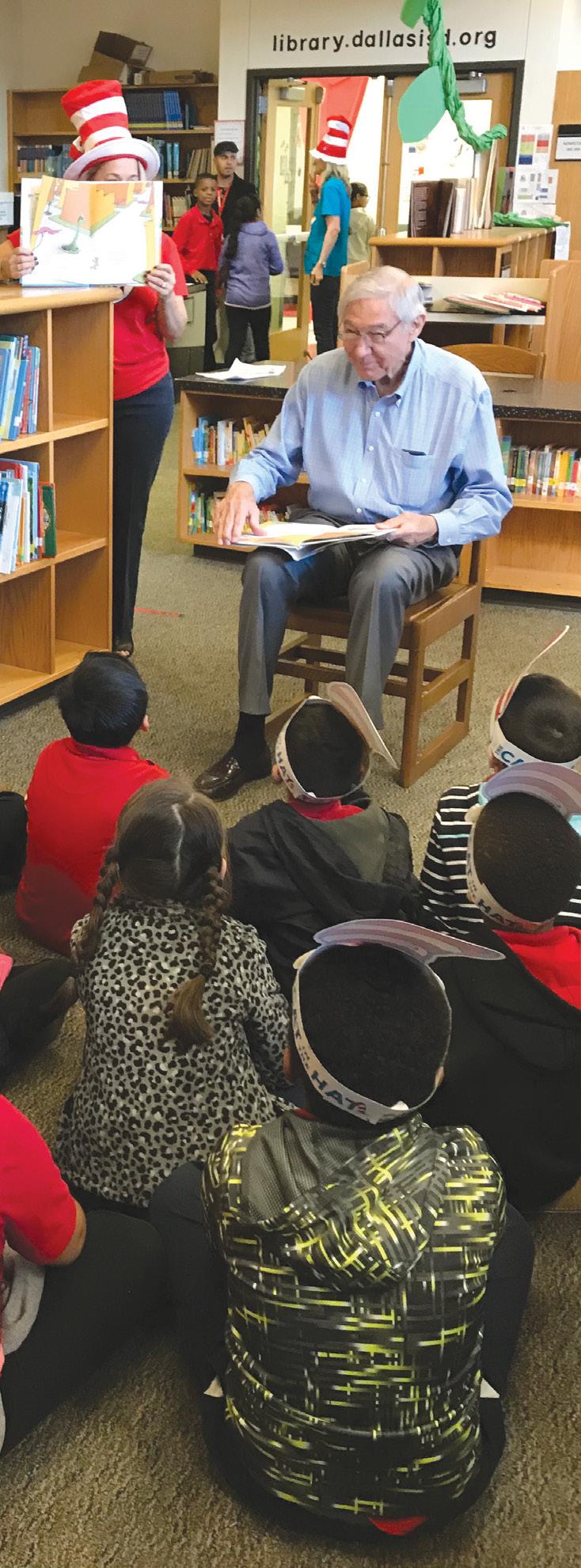

32-33

JACK LOWE’S VISION

TD continues its commitment to Servant Leadership through its work with an elementary school named for TD’s founder, Jack Lowe Sr.

THE DESIGN-BUILD ISSUE TDSpirit 3

14 20 32

8 18 CONTENTS

22

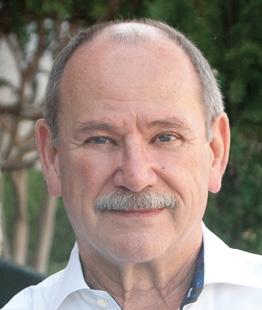

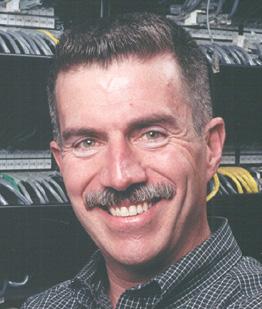

Letter from CEO Harold MacDowell

Design-build, welcome to the Southwest.

The West and East coasts have leveraged this construction mindset for years, while our region has been more invested in design-bid-build projects. Today, owners and architects are seeing great value in providing contractor experience much earlier in the design process.

Owners will spend 30 percent of their construction budget on MEP work. When an owner begins a project with a design-build mentality, experienced contractors can truly become the owner’s Trusted Partner – improving projects through speed, trust, predictable costs, and engineering excellence.

It’s no wonder that owners have spent, and will continue to spend, almost $1 trillion in nonresidential design-build construction nationwide between 2018 and 2021. In fact, a Design-Build Institute of America-funded survey shows that design-build projects are growing in popularity. By 2021, Arizona’s Mountain region is expected to grow these projects by 6.1 percent, while Texas’ region is growing at 5.5 percent.

At TD, we have always had a design-build mentality, even if the project hasn’t been contractually design-build. We collaborate with the entire project team, find value additions, and trust each team member’s strengths. It’s a natural flow from our culture. TDIndustries embraces this design-build attitude to provide exceptional advice and support to our customers’ business strategies.

In this issue, you will see how design-build strategies can inspire great results, and how a contractor’s engineering experience can improve the entire construction process from the start. You will also see other offerings, and, of course, our Partners, who are the heart of our success.

TDSpirit

THE DESIGN-BUILD ISSUE 4 Summer 2019 is a publication of Austin 2701 Gattis School Road Building “A” Suite 101 Round Rock, TX 78664 512-310-5050 Dallas 13850 Diplomat Drive Dallas, TX 75234 972-888-9500 Fort Worth 2601 Northern Cross Blvd. Suite 201 Fort Worth, TX 76137 817-306-6500 Houston 9525 Derrington Road Houston, TX 77064 713-939-1986 Phoenix Metro Area 1888 East Broadway Road Tempe, AZ 85282 480-449-7690 Richardson Process Solutions 1400 S. Sherman Street Suite 100 Richardson, TX 75081 972-888-9500 San Antonio 12700 O’Connor Road San Antonio, TX 78233 210-646-8476 Tucson 3820 East 44th Street, #416 Tucson, AZ 85713 800-864-7717 We want to thank the Partners of TDIndustries who contributed to this issue of TDSpirit. Please report any change of address, contact name or additions, contact TDSpirit@TDIndustries.com.

Carta del CEO

Harold MacDowell

Diseño y construcción, bienvenidos al suroeste.

Las costas oeste y este han aprovechado esta mentalidad de construcción durante años, mientras que nuestra región ha invertido más en proyectos de asistencia de diseño y especificaciones de plan. Hoy en día, los propietarios valoran la experiencia que ofrece el contratista mucho antes en el proceso de diseño.

Los propietarios gastarán el 30 por ciento de su presupuesto de construcción en el trabajo de mecánica, electricidad y fontanería (MEP, por sus siglas en inglés). Cuando un propietario comienza un proyecto con una mentalidad de diseño y construcción, los contratistas expertos realmente pueden convertirse en el Socio de Confianza del propietario, mejorando los proyectos mediante la velocidad, la confianza, los costos predecibles y la excelencia en ingeniería.

No es de extrañar que los propietarios hayan gastado (y continúen gastando) casi $ 1 billón en la construcción no residencial de diseño y construcción en todo el país entre 2018 y 2021. De hecho, una encuesta financiada por DesignBuild Institute of America muestra que los proyectos de diseño y construcción están creciendo en popularidad. Para el 2021, se espera que la región de las Montañas de Arizona aumente estos proyectos en un 6.1 por ciento, mientras que la región de Texas está creciendo en un 5.5 por ciento.

En TD siempre hemos tenido una mentalidad de diseño y construcción, incluso si no se acordó contractualmente el diseño y construcción en el proyecto. Colaboramos con los equipos del proyecto, sumamos valor y confiamos en las fortalezas de cada miembro del equipo. Es un flujo natural de nuestra cultura. TDIndustries adopta esta actitud de diseño y construcción para brindar asesoramiento y soporte excepcionales a las estrategias comerciales de nuestros clientes.

Respecto de este tema, verá cómo las estrategias de diseño y construcción pueden inspirar grandes resultados, y cómo la experiencia en ingeniería de un contratista puede mejorar todo el proceso de construcción desde el principio. Además, conocerá otras ofertas y, por supuesto, nuestros Socios, que son el corazón de nuestro éxito.

Our mission

THE DESIGN-BUILD ISSUE TDSpirit 5

We are Committed to providing outstanding Career opportunities by exceeding our Customers’ expectations through Continuous aggressive improvement.

THE DESIGN-BUILD ISSUE 6 Summer 2019

THE DESIGN-BUILD ISSUE TDSpirit 7

FLYING HIGH AT DFW

See why Khaled Naja chose design-build for DFW Airport’s new DPS office

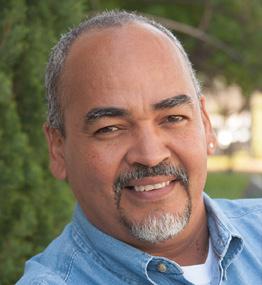

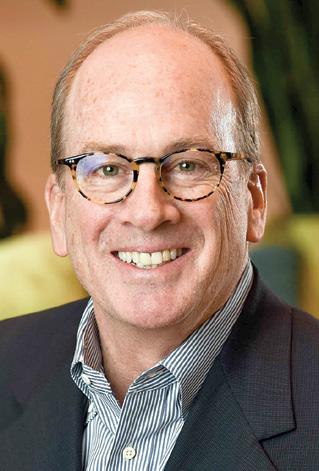

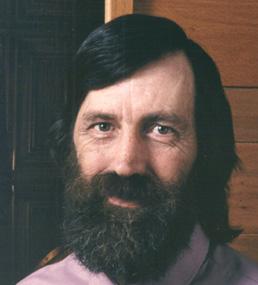

Khaled Naja, Executive Vice President for Infrastructure & Development at Dallas Fort Worth International Airport, answers how designbuild is helping create the best possible product.

01

What circumstances made this the right project to utilize design-build at DFW Airport?

We used a design-build methodology for Terminal D. What makes this delivery method attractive was that the general building requirements were known. Design-build projects are delivered

quicker than the traditional approach of design-bid-build, which was important to us since the officers and staff have been working out of the first building ever built on the airport. It was time to bring a modern, efficient facility to meet the needs of the department, as well as prepare for the future.

02

What are some key features of the new building? How will they help improve officers’ daily routines, and how will they improve safety at DFW?

I heard an interesting anecdotes from Alan Black (DFW Director of Public Safety). If you think back to the

1970s, females in the work force were traditionally in the secretarial pool. The current building was designed and built for the workforce at the time. There isn’t sufficient locker space for female officers and even restrooms are a challenge in the current building. The DPS workforce today is nearly one-third female. The new DPS Headquarters building was planned and designed for the entire expected workforce over the next 25 years.

In June 2017 representatives from DPS, corporate communications, the designbuild team, and our design, code and construction team held a workshop to understand what was important for

THE DESIGN-BUILD ISSUE 8 Summer 2019

the end user. What was surprising was that the main theme was to provide a building that was functional for their operations. They weren’t asking for crazy things, they wanted restrooms and lockers for women, men, and unisex staff. They asked to consider officers’ load; they carry a lot of equipment on their bodies daily, so they would like wider, sturdier chairs, and hooks in restroom stalls that could hold their belts. They wanted a space that they could work safely, collaboratively, and efficiently.

The single most important theme was a space they could be proud to come to work in daily. We believe we’ve delivered on these goals and more. The building was designed and built for future growth. There are several areas for meeting, training, briefing, and just quickly grabbing a cup of coffee. The building has a fitness area that can also hold defensive tactics training and quiet rooms.

03

How did DFW Airport benefit from utilizing design-build on this project?

I think the single most important benefit

was schedule. We could design and build this building in about a year. We also benefited from using a model that allowed the design and construction team to bring opportunities for better solutions.

04

Is having a single point of contact for both design and construction an advantage for an owner during a design-build project?

As an owner, you have a single point of contact and mitigate the potential for the finger pointing that can sometimes occur once design is complete and construction is underway. It’s now the responsibility of the contractor and designer to work through solutions together.

05

Design-build projects often boast faster schedules and less variance from the original budget. Did the design-build approach on the DPS Headquarters affect schedule and cost?

The schedule was one of the primary reasons the airport chose to use this delivery method and it proved to be successful. We are tracking on budget.

I think one of the reasons the budget and schedule are trending positively is because DPS leadership really took to heart the need to make decisions quickly and while there were some concessions that were made, they also made sure to prioritize their desires and needs. Their responsiveness and diligence was critical to the design build team being able to proceed as quickly as they could on the project.

06

Do you anticipate utilizing the design-build process on future projects at DFW Airport?

We never rule out any delivery approach. We are considering how this approach can be used on civil projects, like TxDOT.

07

What would you say is the best design-build advantage over designassist or plan-spec projects?

I think the collaboration is up there. Having a single point of contact is critical. Having a clear understanding of the need, a stakeholder willing and able to make decisions, and a designbuild team who communicates often is critical to the success of the project.

TDSpirit 9

NEW ROLES, NEW VALUE

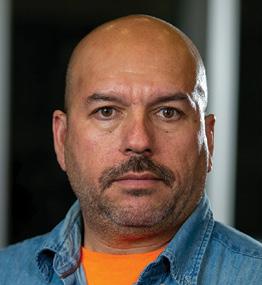

General contractor JE Dunn talks teamwork, value of design-build at DFW’s DPS project

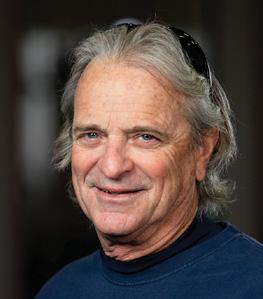

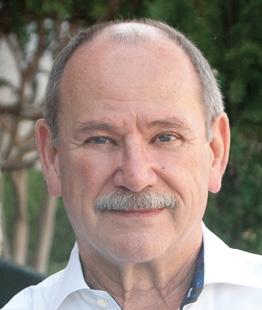

Chris Peck, Senior Vice President of JE Dunn’s Dallas branch, discusses the general contractor’s role in a design-build team.

01

Does JE Dunn have a prior history of utilizing the design-build approach? If so, on what types of projects?

JE Dunn has a long history in completing design-build projects. We have successfully completed projects of all types from Department of Public Safety buildings such as the DFW project to office buildings, warehouses, manufacturing facilities, medical office buildings, dental clinics, parking garages and many others.

Our clients have included public entities such as DFW Airport, the U.S. Army Corps of Engineers, multiple universities, the General Service Administration, along with numerous private clients.

02

Design-build projects, by their very nature, are collaborative and innovative endeavors. What were some examples of contractors (GCs and subs) and the design team providing added value through discussion and innovation?

The biggest advantage in the designbuild collaborative delivery is the ability to deliver the design in a more efficient manner. Rather than taking the normal phased approach to design with concept, schematic design, design development and construction documents our team identified what information was truly required to support construction starting early and allowing material procurement to begin.

We developed what we called a “super schematic” set of documents that allowed the team to guarantee the project GMP 10 weeks after the initial kick-off meeting. This approach of not being constrained by industry standard milestones proved

to be very successful.

The other advantage to having trade partners on board in a design-assist role with our team was the ability to make early decisions about mechanical system choices. The TD team was able to provide cost information that we could include in a total cost of ownership model that allowed DFW Airport to make a valuebased decision about the use of variable refrigerant flow HVAC system that will ultimately save the airport significant operating cost.

03

How does the role of a general contractor change on a design-build project?

The biggest change in design-build for the general contractor is the management of the design. On Construction-Manager-atRisk (CMAR) or traditional bid projects, we are working together with our design partners but we are not in control of the schedule or coordination.

THE DESIGN-BUILD ISSUE 10 Summer 2019

With design-build you need to be in tune with all team members, whether it is the architect or one of their consultants or the trade partners installing the work, as the design-builder you are ultimately responsible and accountable for all members of your team.

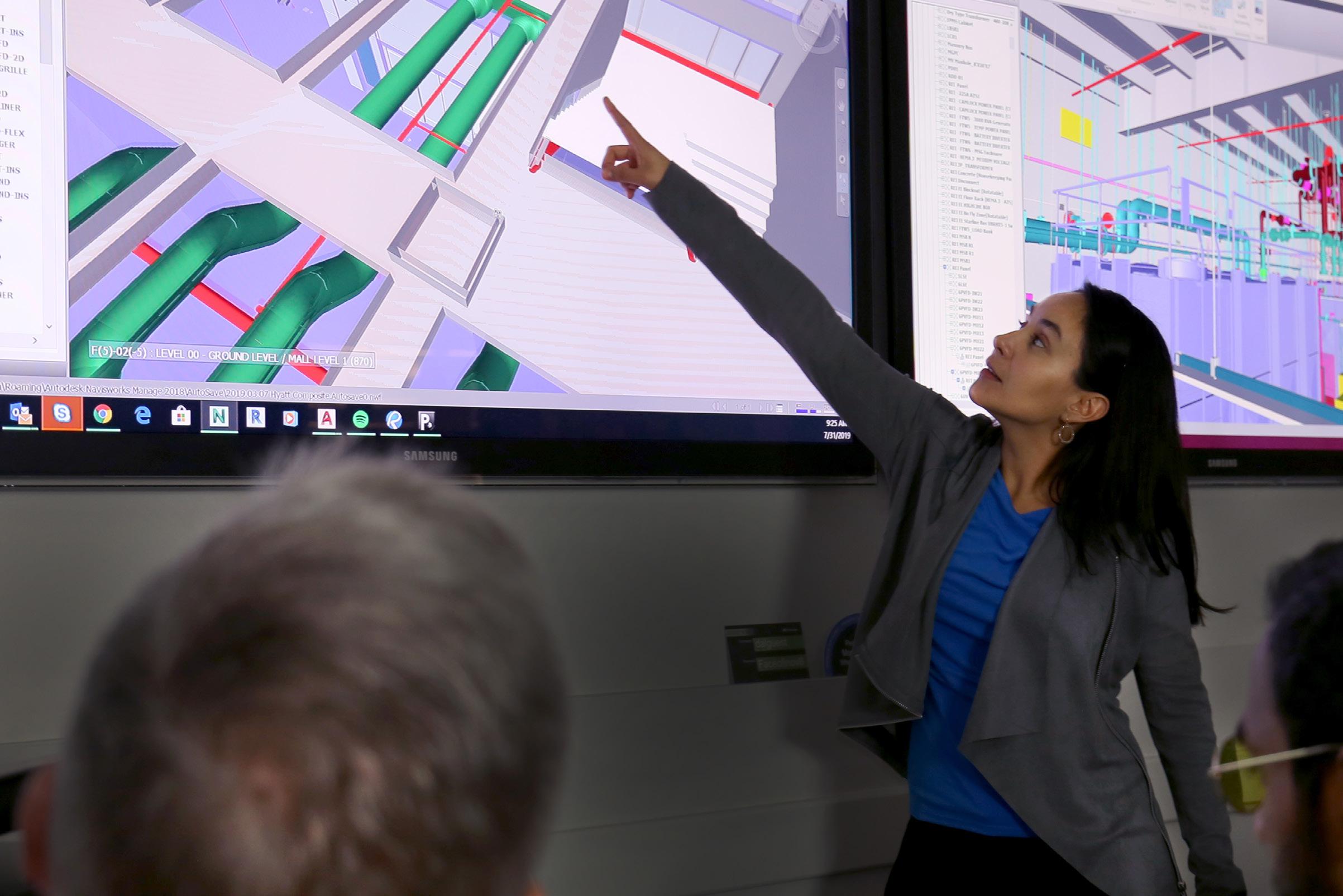

04

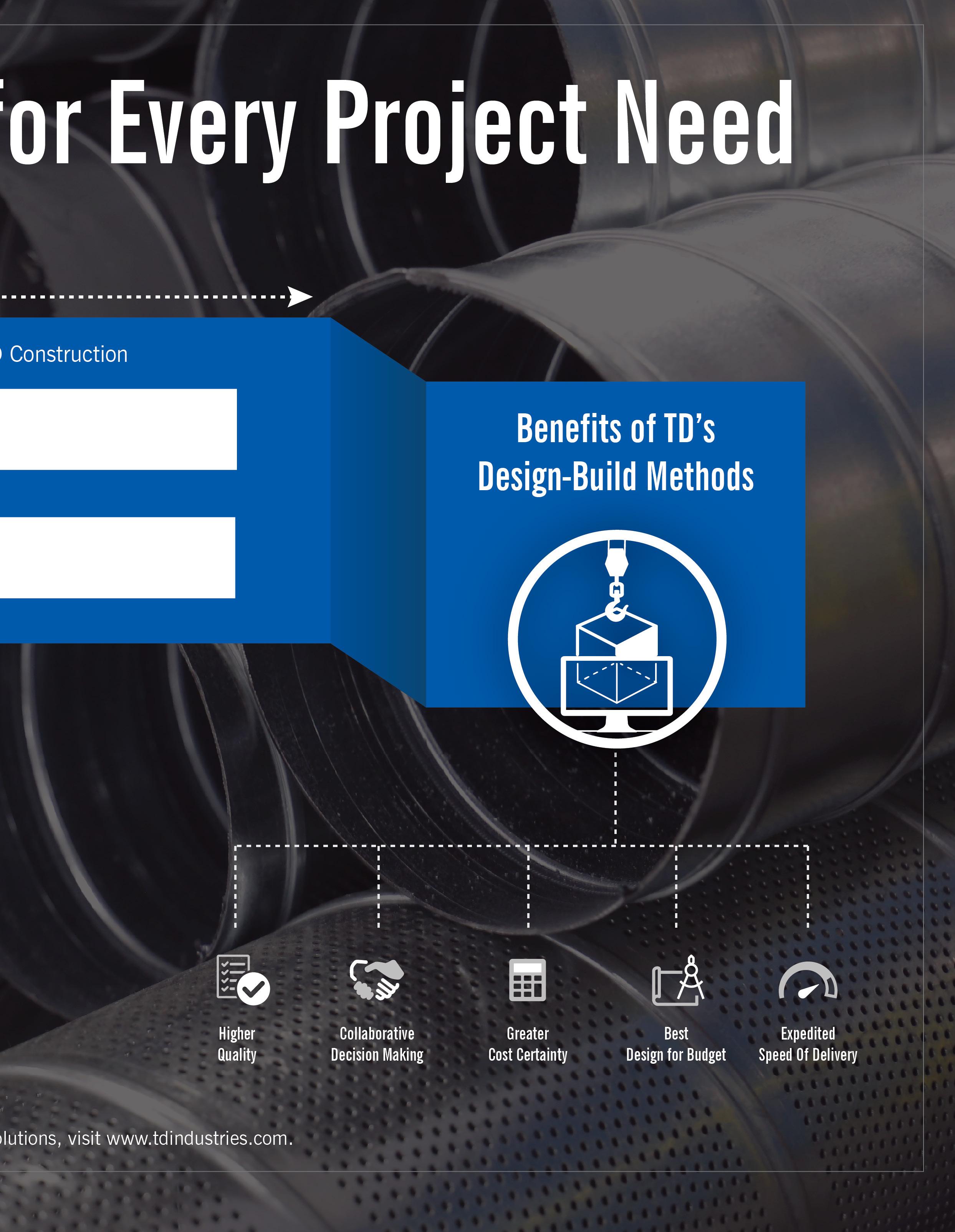

Building Information Modeling (BIM) and Virtual Design and Construction (VDC) techniques are essential to designbuild projects. How did these tools help move the DPS project forward?

The use of BIM and VDC continue to make the construction of our projects more efficient in the installation. The ability for team members to have coordinated things virtually allowed the work to flow extremely smoothly.

05

Can you discuss the natural tension that may exist between the contractors and design professionals on a design-build project? Is this tension productive and how do you manage it?

This natural tension is a good thing; we are all working hard to ensure that the client is provided with the best possible project through a painless process. The only way that we know how to manage the process is through constant open communication. The issues that arise and create tension are normally from a lack of trust or understanding of the financial aspects of the project. We provide complete transparency with our budgets and estimates, which allow our

design partners to understand how they can provide the best possible solution for the dollars allowed.

06

What advice would you give to other general contractors considering the pursuit of design-build projects at DFW Airport?

I would tell them that it is way too difficult and they should probably avoid it at all cost – just kidding!

Design-build delivery requires certain skill sets and behaviors from project participants that are different from designbid-build or CMAR delivery. The designbuild team leader must understand the design process and have the ability to manage the overall design-build team.

Additionally, a successful design-build contractor needs to have experience with early engagement of trade partners to maximize the target value design approach. Understanding that pro-active engagement of the various DFW Airport stakeholders is a must. To be successful, a designbuilder must make sure that they are communicating with all stakeholders for the project. DFW airport includes many entities that have a stake in the project.

Each of these groups needs to be engaged to understand how the project will be executed and how the process may be different from the normal process, and that the overall outcome is to provide the best possible product for them, the end client.

07 For a general contractor, what are the advantages of pursuing a designbuild project?

Design-build delivery offers cost and schedule advantages over traditional delivery methods, such as design-bidbuild and CMAR. Design-build allows the reduction of design schedules through better alignment of design and preconstruction activities without compromising the iterative process of design.

From our perspective, design-build is a more collaborative process resulting in better budget control that can foster fasttrack delivery of the construction phase. Being able to offer solutions that are faster, more cost effective with better cost certainty is a differentiator for a contractor with a design-build acumen.

08 Are there any other thoughts regarding design-build which you would like to share?

The architecture, engineering and contractor community is moving rapidly toward project delivery solutions that will deliver buildings faster and cheaper. The design-build process, due to its collaborative nature, leveraging technology and prefabrication for instance, makes this goal more attainable than traditional delivery methods.

TDSpirit 11

SPEAKING THEIR LANGUAGE

Why cross-party communication is crucial on today’s projects

Your last project was a headache. You selected the best architect and contractors, but the schedule ran long, costs grew throughout the project, and now your annual maintenance expenses are more than you expected.

What went wrong? The answer is simple: a failure to effectively negotiate between design intent and installation/ constructability issues. That’s why early collaboration is critical.

In traditional builds, team members are sometimes unable to step outside their responsibility zones to increase value for the project. For example, consider an executive and architect looking at floor plans. The executive might decide he wants to swap his corner office for a

meeting room closer to the rest of his employees. It’s a simple change for the architect, but it will require additional changes in ductwork, diffusers, and controls on each conditioning zone for the MEP contractor. That has a cost, and without early, detailed discussion between design and contractor segments in a design-build group, the costs may be significantly higher than necessary

Including contractors in the design process can be advantageous in avoiding unintended consequences.

That’s why early collaboration between engineers and construction teams is critical to avoid a scope gap, to maintain a budget, and to streamline the schedule.

“The combination of e ngineering knowledge and construction experience applied to problem solving simply generates better outcomes than either team working in isolation ,” said Engineering Vice President Justin Bowker. “Challenges must be approached addressing all of the owner’s project requirements including quality, budget, and schedule.”

Here are a few ways a contractor can enhance projects through early involvement:

Apply field experience: Historically, architects do a great job solving the big design issues for owners; however, small cost and efficiency gains sometimes aren’t discovered until construction teams join the project. Large-scale

THE DESIGN-BUILD ISSUE 12 Summer 2019

rooftop installations which require helicopter lifts have a cost and schedule impact during the summer because those crews are fighting wildfires.

VDC/BIM management: When all phases are discussing changes to the building model, the contractors can identify the impact on their upcoming tasks immediately. Construction teams can reroute labor until the issue is solved, holding off rework and driving down overruns.

Full life-cycle thinking: The construction process is just the front end of decades spent in your building. TDIndustries has business units dedicated to service, maintenance (120 million sf under contract), and renovation, including one arm that monitors data from more than 70,000 tons of central plants.

Broader options: Contractors coordinate directly with vendors and, when included in decision-making, can provide solutions adapted to specific equipment capabilities, find savings, and use in-house experience to install systems as the manufacturer intended.

Many contractors also use prefabrication, assembly systems, and modularization to lower costs and increase quality. In most cases, these strategies are more cost effective – especially when tailored specifically for unique pieces on the jobsite.

Better decision-making: Traditional builds can sometimes leave coordination and implementation until late in the construction schedule. By that time, deadline urgency eliminates many options. Concise and transparent decisionmaking process documentation allows all stakeholders to understand the factors to consider resulting in better decisions with fewer changes later in the process.

“In today’s fast-paced construction environment, it’s imperative that we communicate quickly and effectively,” states Bowker. “The complexity of today’s construction projects requires teams to be structured in a way that encourages collaboration.

“Design-build is the best structure at delivering predictable outcomes and reducing risk to the owner.”

THE DESIGN-BUILD ISSUE TDSpirit 13

THR WELLNESS

Stringent requirements call for effective solutions.

THE DESIGN-BUILD ISSUE 14 Summer 2019

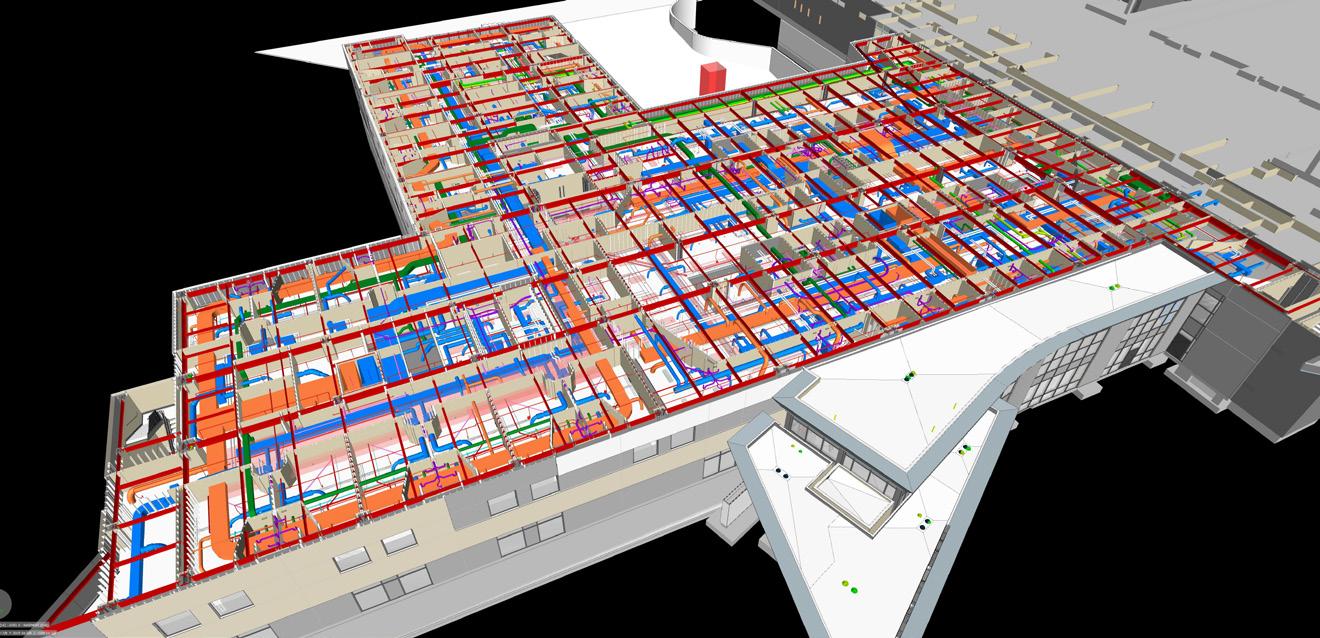

Design-build projects, by their very nature, require intense collaboration, efficiency, and flexible technologies to succeed.

TDINDUSTRIES AND OTHER project partners used all three to great effect at Texas Health Resources (THR) Recovery and Wellness Center in Mansfield. THR chose design-build to produce a premier facility on a fast-track schedule starting with a simplified, shorter design period with continuous approach to target value design.

“Using design-build and the strength of our engineering team, we were able to provide the most efficient and cost-effective mechanical system design to meet THR’s stringent requirements,” said Project Manager Richard Bain. “We used Lean processes to stay organized and keep the project on schedule, and our engineers’ healthcare experience brought added value to THR.”

The recovery and wellness center is a completely voluntary-admission addiction recovery facility. THR envisioned a facility that didn’t look or feel like a traditional treatment center: one with premier, high-end finishes and aesthetics that evoke a feeling of calmness and wellness.

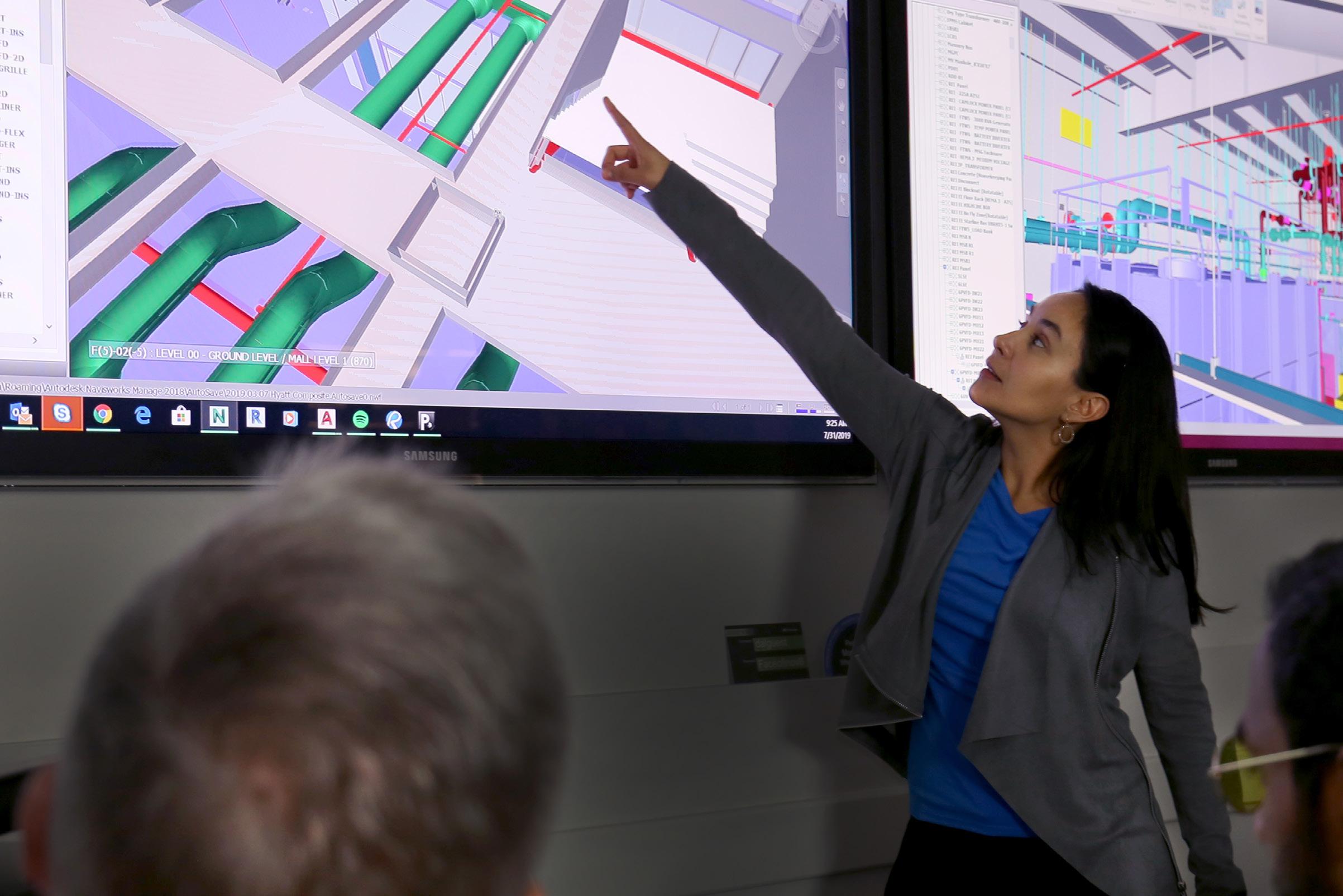

TDIndustries served as both the engineer of record and mechanical contractor. TD, The Beck Group, Beck Architecture, and electrical contractor Morley Moss placed their offices nearby to encourage communication and discussion, and weekly meetings allowed for new ideas and improvements to the building information model.

The completed 3D BIM layouts of the project enabled the team to optimize the use of prefabricated assemblies, minimized re-work and increased the overall efficiency of the construction

THE DESIGN-BUILD ISSUE TDSpirit 15

The engineering and VDC departments helped find solutions for several challenges including:

• A variable refrigerant flow heat recovery system to increase energy efficiency

• Connecting multiple buildings to necessary systems

• High ceilings in the lobby area with glass for natural light and high-end wood finishes

• Tight corridors and ceiling spaces

• Breezeway plumbing and beams

• Almost invisible air distribution systems in the lobby

• Guest room pods: Two of the four situated above the breezeway on the second floor

• Underground angles in relation to the unique structure shape

• Subsoil drainage that resulted in $50,000 savings

• Proactive efforts to reduce exposed ductwork in the indoor gym

Lean construction methods were equally important. The entire project was pull-planned from start to finish, and TD’s Lean experts conducted an onsite class for every trade involved. This substantially increased the efficiency of the project. Each team also performed 1-week plans and 6-week lookaheads to stay on top of upcoming tasks on the job.

All three – collaboration, building information modeling, and Lean processes – are prime examples of a design-build project done correctly.

“This project required intensive collaboration with our group, the

owner, and key subcontractors,” Beck senior project manager Mike Kraase wrote in a letter to TDIndustries. “TD’s expertise and dedication to utilizing Lean principles aligns very well with our philosophy and we are grateful for having TD as a true partner for keeping jobs on track.”

Awards Won:

• ABC EIC Eagle, only sub-contractor to receive both design/build and productivity awards

• AGC Outstanding Construction

• ASA Platinum

• TEXO Distinguished Building

Key statistics:

Building Size: 77,000 sf

TD’s scope: Design, Construction of HVAC and Plumbing systems

Duration: 14 months

Piping installed: 32,200 lf (plumbing); 16,100 sf (HVAC)

Ductwork installed: 66,000 lbs

Amenities: Four guest wings, café, full kitchen, twostory lobby, indoor basketball court, fitness studio, massage studio and movie theater

Project partners: The Beck Group (GC), Beck Architecture, Morley Moss (electrical)

Key TD Leadership: PM Richard Bain, SVP Matt Terry (P.E.), Superintendent Randy Smith, ME Fred Henke (P.E.). APM Rebecca Wiltz

THE DESIGN-BUILD ISSUE 16 Summer 2019

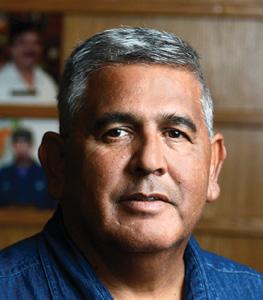

SCOTT STATON

New operations manager enhancing Austin projects

TDINDUSTRIES WELCOMED NEW Project Manager Scott Staton to the company’s Austin Construction division in 2019. As TD increases its design-build foothold, Scott and his decadeplus of related design-build experience will be a valuable addition to the company.

Scott has spent his career on both the East Coast and West Coast, where he was responsible for overseeing complex design-build projects for Amazon, Gilead Sciences, Genentech, and the Pac-12 Network; as well as higher education work at UC Berkeley and federal work at the Pentagon renovation. He estimates 98 percent of targeted work was design-build, including around 50 or so projects he worked on.

Seeing the design-build benefits first hand, Scott predicts this kind of work will become more familiar in his new region.

“Design-build increases the speed of construction, it increases everyone’s understanding of the job, and it removes most of the conflicts between parties,” Scott said. “You offer much more value to owners and you tend to find more mutually beneficial projects for everyone involved.”

A proponent of modular construction, Scott encourages others to think outside the box and find creative solutions to common and uncommon issues. He recalls the Pac-12 Network TV studio project included renovating two floors of an existing building, requiring strict detail on how the duct

and water were built, to keep the sound at a minimum. A large amount of equipment needed to be temporarily relocated to the roof, which an existing station was already using. Scott’s team found a solution through prefabrication and shared utility racks.

Looking to the future, Scott has sights on increasing TD’s position in Central Texas through the design-build method.

“I look forward to helping grow our presence in the Austin market and making TD the contractor of choice for any mechanical or plumbing needs,” Scott said. “My goal is to bring new ideas and a fresh perspective to Austin.

THE DESIGN-BUILD ISSUE TDSpirit 17

CHANDL ER REGIONAL

Advantages Of Early Design-Build MEP Involvement

Experience is invaluable when tackling a multimilliondollar project. As with all similar ventures, the earlier those voices can be heard, the better.

It only makes sense to include the contractors who will be doing the physical installation during that phase. Dignity Health did just that at Chandler Regional Medical Center in Arizona, which is in the midst of an expansion.

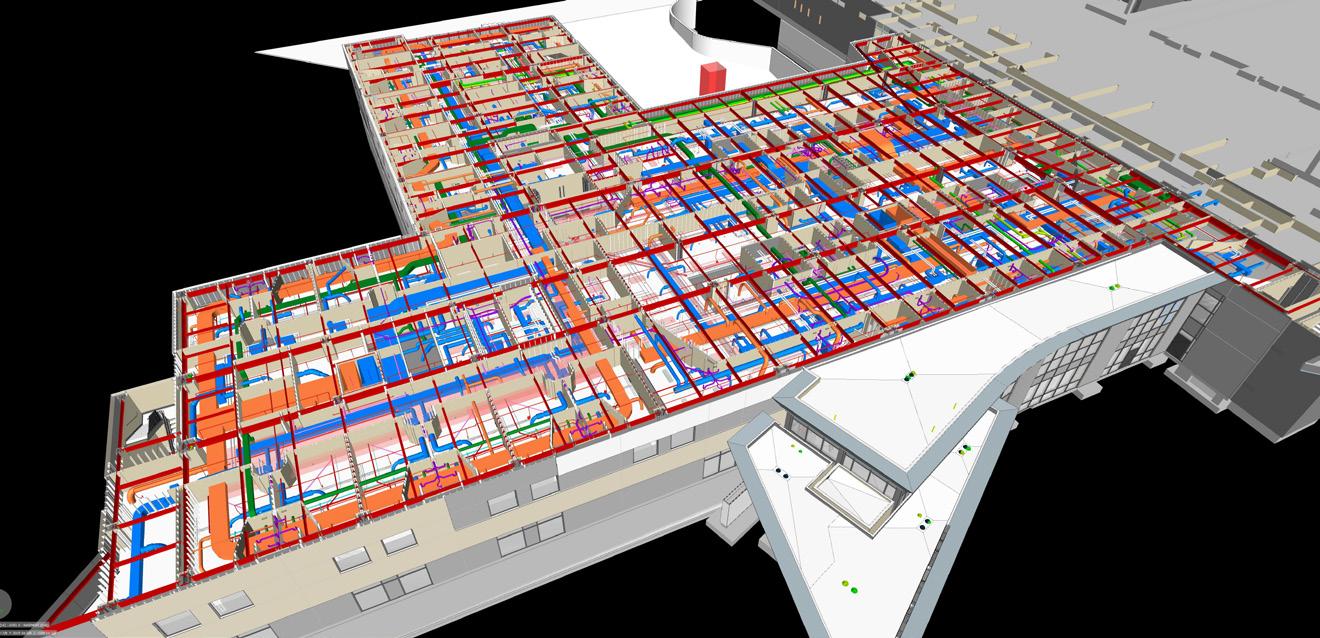

“It is a spatially tight MEP project, and requires a high level of expertise,” said Engineer Ardas Sabuncuyan. “We have the HVAC and plumbing design and installation knowledge that traditional design teams often do not own, so we’re all working together to accommodate compressed schedules.”

TD is producing advanced coordinated models prior to permitting, which allows fabrication and construction to begin faster and speeds up the entire project. With an aggressive

THE DESIGN-BUILD ISSUE 18 Summer 2019

design schedule, engineering firm WSP partnered with TD on engineering efforts. WSP knew that TD had the experience to ensure the schedule and constructability remained at the forefront. TD is working with Devenney Architects and the rest of the design team to pull-plan the entire design effort from schematic designs through permitting. To streamline the design process, TD’s engineering and VDC coordinators work in the same Revit model with the design team, allowing simultaneous design and coordination.

The result is a design at construction documentation level that is spatially coordinated and constructible. This allows the design schedule requirements to be met, while also producing a model that could go straight into shop drawing and fabrication drawing production.

That kind of work product would not have been possible without the early involvement and collaboration of the trade partners.

TD’s experience in design-build hospital construction is helping with:

Helping owner make smarter decisions: TD submitted several A3s to encourage

collaboration with multiple trades, allowing for smart decisions on chiller selection, shower-valve configuration, and pharmacy ceiling system.

Coordinating construction documents: Working with a design engineer, TD created the conceptual design and virtual, coordinated documents for permit. This eliminates the traditional double work of completing these separately, while saving money and reducing time.

Solving space crunch with constructible plans: Functional plans for floors with multiple architectural challenges were designed, while keeping installation in mind. The design, VDC, and field teams created typical MEP strategies for each floor to ensure consistency and installation ease.

Saving costs through prefabrication: Knowing its manufacturing capabilities, TD has designed the mechanical and plumbing systems to fully use prefabrication and equipment skid options.

Finding additional value through coordinating design: A plan to standardize the plumbing in patient

restrooms, as well as med-gas and dialysis ports on the headwalls was recommended to the customer, which improved installation schedules.

Mitigating future risk: TD is modeling the future underfloor sanitary piping on the shell level 5 to ensure that the level 4 overhead will accommodate future expansion.

Reducing RFIs: Design-build projects shift work-order changes from expensive end-stage costs to the design team, reducing project cost and duration. This process reduces the number of 2-3 week RFIs and replaces them with 3-day model revisions.

Perhaps the greatest advantage is having this input up front with cost in mind.

“Before the first shovel hits the ground, we have an open-cost model, submittals, and buyout packages ready,” shared Engineer Doug Rohrer. “With the designbuild model, we can work with vendors to kit typical rooms, identify and prefab typical components, and schedule labor more accurately. The owner knows what they’re getting and when they’re going to get it.”

Fast Facts

Size of project: 220,000 sf

TD’s scope: Mechanical, plumbing, and med-gas systems

Anticipated completion date: Early 2021

Amenities: Cardiac rehab rooms, PACU (post-acute care) and Thoracic patient rooms, ORs, central sterile, pharmacy, shell space

Project partners: Dignity Health, McCarthy Building Companies, engineer

WSP, Devenney Architects

Key TD leadership: Engineers Ardas

Sabuncuyan (P.E.), Doug Rohrer (P.E.), and Fred Henke (P.E.); Superintendent Doug Wallace; SVP of Operations Jay Layton

THE DESIGN-BUILD ISSUE TDSpirit 19

FAST, EFFICIENT PROJECT AT BP

Collaboration helps renovation stay flexible

For TD’s Houston construction team, being part of the BP office design-build project helped solve problems and the decision-making process in a faster and more efficient manner.

The collaborative workspace project included two entire floor buildouts (16th and 17th floors at 22,000 sf per floor) on BP’s Westlake campus in Houston. From start to finish, TD

ran an eight-man sheet metal crew, a two-man plumbing crew and a two-man piping crew on this 26-story building. Substantial completion was achieved in mid-June.

A project like this often involves constant changes, including the scope of what certain areas are intended to be and occupancy fluctuations. Design-build can help with those changes, offering an insider point of view and the ability to

have instant, offline conversations with engineers. A standard project would require going through the typical chain of command and the general contractor, which could take 2-3 weeks.

“That is an advantage,” said Michelle Reyes, TD Project Manager. “We can strategically figure out items and conflicts prior to presenting them to the entire teams – including the owner and architectural teams.”

THE DESIGN-BUILD ISSUE 20 Summer 2019

Work on the 16th floor of this building presented its own challenges: executives are using the 15th floor. Any construction noise often led to work shutdowns.

To avoid this issue, the TD crews switched operations to a nighttime schedule to achieve productive work. TD also assembled the ductwork offsite to reduce onsite noise. It was shipped flat from TD’s Dallas manufacturing operations to TD’s Houston assembly shop, and then shipped assembled to the job site. This eased delivery coordination, which normally required 48 hours’ notice to the owner, BP.

Another challenge included lifting 38,500 lbs of duct work to the 16th and 17th floors from the loading dock, which is part of a basement-level area that has been under construction due to Hurricane Harvey flooding. TD had to coordinate deliveries of 18 wheelers of ductwork with all other contractors on site.

“Being that there are now two projects nearly complete with the same Rogers O’Brien (Houston) team, these designbuild projects have established an outline,” Reyes said. “Having that history, the only modifications are building owner-suggested or required. That is the best advantage, knowing

Fast Facts

the expectations and construction standards to be expected.”

Of course, this project wouldn’t have been possible without some key teams, including Phoenix Insulation, who was recently named TD’s Houston Hard Hat Award Recipient.

The general contractor for the project is Rogers – O’Brien and the architect is PGAL, both of whom have successfully worked with TD in the past, across different types of projects and in other branches.

Thank you to these valued teams.

Size of project: 44,000 sf (two floors) and 496 occupants

TD’s scope: Mechanical and plumbing systems

Completion: Summer 2019

Project partners: Phoenix Insulation (TD’s Houston Hard Hat Award Recipient), Rogers-O’Brien, PGAL

Key TD leadership: Project Manager Michelle Reyes, Superintendent Chad Hubenak, SVP Ronell Peters; engineers Esmeralda Morales (P.E.) and Jeff Farley (P.E.)

TDSpirit 21

DECISIONS MAKE A DIFFERENCE

7 ways to prevent project paralysis

By Barbara Bryson, associate dean, University of Arizona

Congratulations! You have been selected for an amazing design-build project. You are also excited about the team. Both the contractor and the architect are known for collaborative practices, and the owner is known to be a good and thoughtful leader on projects. This should be a positive experience … if only everyone will make decisions when they are supposed to.

Nothing can be more powerful than a project where decisions are made quickly and effectively, yet, we have all seen great projects fail because decisions were mired in the quicksand of debate, insufficient information, or, simply, lack of will. Nothing can be more frustrating.

What can a sub-contractor do to change or even prevent decision paralysis occurring? Here are seven decisionplanning strategies you can use even if you don’t have a great team or a great leader with which to work:

1. Earlier the better - Make every effort to discuss decision-making at the start of the project. Creating decision norms, frames, and tools will serve every team member and will prevent misunderstandings.

2. Yours, mine, and ours - Make it clear to your team what decisions you believe are your decisions to make, what decisions aren’t yours to make, and how you want to handle decisions that have multiple stakeholders. Try to push decisions to the ideal, most effective location in every team. Discuss strategies to make sure that decisions quickly flow even if you are not sure who owns the decision.

3. Lean In – The best Hypertrack (not fast-track) decision processes encourage teams to schedule all significant decisions at the beginning of a project and to schedule who will need to be included in those decisions. This process is like creating a Lean Pull

THE DESIGN-BUILD ISSUE 22 Summer 2019

Schedule for decisions. Even if your entire designbuild team does not buy into this strategy, you can lead with your decision pull schedule. This way, you have informed the whole design-build team when you will be making crucial decisions to keep the project on track.

4. Be decision-ready – Once you know when decisions will be made, even if it is just for your own work, you can plan to prepare decision-ready information. This often means informing the rest of the team of the information they need to prepare so that your decisions can be made. Recognize that decision-ready information means that you inform the contractor and the owner of all costs related to a decision when that decision is being made. Revealing a hidden cost later does not help the team, and it does not help you.

5. Ask…don’t tell – When you aren’t in a leadership position on a team, it is sometimes tricky to raise new ideas. The best way to bring others around to your way of thinking is to ask thoughtful questions about when and how decisions will be made on a project.

6. Explain the downside – The best value you can provide when a client or team is tempted to delay a decision is to explain the consequences of delay in that moment. The consequences must be tangible and quantifiable. Merely saying it will cost more won’t

cut it. Stating that a delayed decision costs $1,000 per day will get an owner’s attention.

7. Stay on it – The most successful teams recognize that projects can go wrong in a moment. When surprises occur, find ways to help your team make corrective decisions quickly. Setting a team norm that states that you will never leave a meeting without getting the project back in budget and in schedule helps with that discipline.

Remember that decision-making is an essential element to success on any project. It requires discipline and focus. Even though the owner and the contractor will be responsible for most decisions, you can help lead your team to better, more successful decision-making practices.

Barbara Bryson is the associate dean for research and academic affairs at the University of Arizona. A former architect, Bryson has led construction efforts at the University of Miami and Rice University. She co-wrote “The Owner’s Dilemma: Driving Success and Innovation in the Design and Construction Industry.” She is also a member of TD’s board of directors.

THE DESIGN-BUILD ISSUE TDSpirit 23

THE DESIGN-BUILD ISSUE 24 Summer 2019

THE DESIGN-BUILD ISSUE TDSpirit 25

TALKING SAFETY

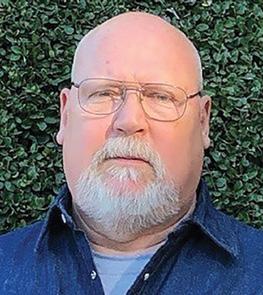

Q&A with Arizona Safety Manager

Chuck Schmidt

01

How did you get involved in safety?

“I was looking for a new career. Residential construction was on a downward trend in 2008-2009, and I started learning safety functions at my prior job, just to make myself more valuable. I really learned the true value of being safe. It was easy for me to fall into it. TD picked up a big project that required onsite safety. I was looking for an entry in safety, and they gave me a shot.”

02

What kind of Safety training do you lead?

“My main focus is on new hire safety orientation. I really think that we can continue implementing a good onboarding experience by setting safety expectations up front, letting new Partners know what kind of safety culture we have at TD, and that we need you to buy into it. I really try hard with new hire safety orientation, and I know all our other safety managers are doing the same.”

03

What are some important traits of a safety leader? How have some of your safety leaders inspired you?

“They need to lead by example. I think we need to practice what we teach. Joe Lindsay was my safety manager when I started. I had taken some classes and had my previous experiences, but Joe was a great mentor. He didn’t just quote standards, he really thought about what was the best way to keep workers safe and taught that through real-world examples. I try to follow that lead that I got from him.”

04

How do you create effective safety training and get people to adopt a safe culture?

Simply quoting our rules and regulations and writing citations is not the best way to get buy in. I like that we apply heavy use of lessons learned. We communicate and share information. Using those examples and showing the reasons WHY we are requiring these steps. It makes our message much more effective. Real

THE DESIGN-BUILD ISSUE 26 Summer 2019

examples and sharing lessons learned goes the furthest in getting Partners to buy in to safety.”

05

Tell me about a time you or someone on your team resolved a safety issue or stopped an unsafe act.

“My team member and fellow Partner, Safety Coordinator Armando Franco, is currently on a big project of ours. He noticed dust levels were fairly high in this building and suspected the air quality was not good, and that it might be carbon monoxide.”

“Armando evaluated the building with an air monitor meter and decided everybody needed to be removed. He pulled everyone out of the building, and onsite supervision supported him in that. We were able to find the source of the carbon monoxide poisoning in the building. It turns out that iron workers running equipment in one of the rooms contaminated the whole inside of the building. Armando did a great job identifying the issue and taking quick action.”

We had another great story from our service side. Some of our plumbing technicians were called out to an apartment complex for a leaking steam pipe. When digging a hole to find the pipe and repair it, the hole reached 5 feet, which is the cutoff for where protective systems are then required. Our techs told the facility manager “We can’t go on; we need to go out and get hydraulic shoring and make this safe. It’s mandatory.” The facility manager pressured our Partners to get back in and finish the job because there are people at this apartment complex without hot water.”

“And so our Partners walked away and contacted their supervisor. I’m proud of those guys for not being bullied by the manager, or being pressured to do something unsafe.”

06

Safety is often the deciding factor for young adults when deciding whether to pursue a trades career. Do you see a generational difference in their approach to safety?

“One newer trend is that we have been bringing on apprentices from schools, and when these young students become part of our company, they already have some safety training. It seems to have been part of their curriculum. They’re very open to it and they expect it. I’m so glad to see that.“

“We didn’t always see that in the past. We saw somebody who just wanted a job. Not, we’re getting people from trade schools, and their knowledge and thoughts on safety just seem to be a little different. And that’s a very positive sign.”

07

In your opinion, what could Partners focus on to improve safety? Any trends you are seeing that cause safety issues?

“When I see incidents, it seems more times than not they happen

because we’re rushing. Everybody is so busy and working hard. But we need to ensure we slow down, plan our work, stick to our plan, and use the right tools. This leads to safe choices.”

Final Words from Chuck:

“Focusing on safety does more than just protect myself and my team on the job sites. By being educated and prepared to make safe choices, it protects everyone on a project, as well as our families, our communities, and the entire industry.

“At TDIndustries, we don’t just focus on safety because it’s required; we do it because it’s the right thing to do. We live by our core value of fiercely protecting the safety of each other.

“And it’s something I’m proud to be part of every day.”

Arizona Safety Manager Chuck Schmidt joined TDIndustries in 2011, after 15 years in the residential construction field. He leads Safety efforts for our Arizona Partners.

THE DESIGN-BUILD ISSUE TDSpirit 27

PARTNERS ON THE MOVE

Talented Partners adding new responsibilities

Steve Cunningham, Chief People Officer

New Chief People Officer

Steve Cunningham brings a diverse background and more than 20 years of human resources executive experience. He will oversee HR support of all Partners, including talent acquisition, employment, benefits, training, succession planning, safety, and more.

Ed White, President

18-year Partner Ed White, who already oversees all Arizona operations, has been promoted to President.

In his new role, he will oversee North Texas Facilities, Multifamily, and Process Solutions.

Formerly

Chris

Scott

Wesley Baker, Vice President, TDManufacturing

the Vice President of San Antonio, Wesley Baker now leads TD’s Manufacturing Operations.

Kyle Hogue, Vice President, Dallas Special Projects

Kyle Hogue assumes responsibility for Dallas Special Projects.

Lauren Turner, Vice President, Dallas Service

Formerly the Vice President of Manufacturing, Lauren Turner now leads Dallas Service.

Chris Brown, Senior Vice President, Arizona Special Projects

Brown adds prefabrication, purchasing, fleet, and warehouse to his duties.

Scott Roan, Vice President Preconstruction and Business Development

Roan, Senior Vice President, now leads TD’s Preconstruction and Business Development team.

Jay Layton, Senior Vice President, Arizona Construction and Service

Wesley Baker, Vice President, TDManufacturing

the Vice President of San Antonio, Wesley Baker now leads TD’s Manufacturing Operations.

Kyle Hogue, Vice President, Dallas Special Projects

Kyle Hogue assumes responsibility for Dallas Special Projects.

Lauren Turner, Vice President, Dallas Service

Formerly the Vice President of Manufacturing, Lauren Turner now leads Dallas Service.

Chris Brown, Senior Vice President, Arizona Special Projects

Brown adds prefabrication, purchasing, fleet, and warehouse to his duties.

Scott Roan, Vice President Preconstruction and Business Development

Roan, Senior Vice President, now leads TD’s Preconstruction and Business Development team.

Jay Layton, Senior Vice President, Arizona Construction and Service

THE DESIGN-BUILD ISSUE 28 Summer 2019

Jay Layton leads Arizona Service in addition to his Arizona Construction duties.

PARTNER MILESTONES

THE DESIGN-BUILD ISSUE TDSpirit 29

20 20 20 20 20 20 20 15 15 15

Frank Byrd, Dallas Construction Guy Albanese, Risk Management

Mark Boykin, Dallas Construction Ray Jackson, Dallas Construction

Darwin Pierce, Process Solutions Rick Duncan, Dallas Special Projects Doug Wallace, Arizona Construction Rudy Camarillo, Multifamily

Jason Cinek, Dallas Construction Jose Garza III, San Antonio Construction

Mando Gonzales, Multifamily

Michael Hancock, Dallas Construction

Matt Johnson, Dallas Construction Pete Kessler, TDManufacturing Glen Krahn, Houston Construction Phillip Richmond, Dallas Construction

Randall Seargeant, Dallas Construction Vernon Smith, North Texas Facilities

Max Wagner, Dallas Special Projects Nelson Campbell, Dallas Service Jason Cano, Process Solutions Marcos Carbajal, Dallas Construction Jason Carmona, San Antonio Service Stephen Cavalier, Houston Service

Francisco Gandara, Process Solutions

Mark Hull, Fort Worth Construction

Jaime Lara, Houston Construction

Tomas Limon, Austin Construction

Lance Richey, Dallas Construction Gregory Roberts, North Texas Facilities Luchi Rusek, Marketing Chuck Swallow, Dallas Service

Andrew Streeter, Dallas Construction Arnoldo Villarreal, North Texas Facilities

Brett Ballard, Austin Service Chris Castillo, Dallas Construction

Gary Christensen, Arizona Construction Osmin Escobar, Houston Special Projects Isidro Flores, Houston Construction Oscar Flores, Houston Service

April Garza, Houston Service Cheryl Gray, Austin Construction

David Gulledge, Fort Worth Construction

Scott Hartmann, Dallas Construction

15 15 15 15 15

Stacy Lining, Dallas Construction Peggy Martinez, Dallas Construction Terry Priddy, Dallas Construction Joe Putnam Jr., Dallas Construction

THE DESIGN-BUILD ISSUE 30 Summer 2019 5 5 5 5 5

Christopher Rogers, Fort Worth Construction Kimberly Boehm, Houston Service JD Bennett, Dallas Special Projects

Dee Brodie, Dallas Construction Robert Chavez, San Antonio Construction

Janet Galdamez, Houston Service Brandon Holland, Fort Worth Service Andrew Kobe, Process Solutions

John McRae, Austin Service Jason Morris, Process Solutions

Victor Nolazco, Houston Special Projects

Jose Olivas, TDManufacturing Jose Oquendo, Process Solutions Jose Rivera, Process Solutions

Rudy Reyes, San Antonio Construction John Ruiz, San Antonio Construction

Mario Ruiz, Process Solutions Jo Sheppard, Corporate

Kevin Smith, Dallas Service Patrick Tullous, Dallas Construction Alma Villanueva, TDManufacturing Thomas Vines, North Texas Facilities

Yahya Alresetmawi, Austin Construction Adrian Atkins, Houston Construction

Freddy Balam, Dallas Service Loryn Beck, Houston Service Tim Berry, Dallas Service

Rabon Bowen, Austin Construction Noe Carreto, Arizona Construction

Miguel Chapa, Arizona Special Projects

Mark Christensen, San Antonio Construction

David Coburn, Multifamily

Robin Culp, Austin Service Tommy Crawford, Dallas Service

Danny Cruz, Houston Construction Edelberto Espinosa, North Texas Facilities

Julio Espinoza, Houston Facilities David Flagg, Dallas Service Jake Foster, Dallas Construction Cathy Freeman, Fort Worth Construction

Abraham Garcia, TDManufacturing Jacob Garcia, Austin Construction

Pedro Gonzales, San Antonio Construction Domingo Gutierrez, Information Technology Joseph Hinzman, Fort Worth Service

Nicole Hogan, Arizona Construction

Christopher Jones, Houston Construction Steven Josephson, Arizona Special Projects

Corey Kashuba, Process Solutions

Lynne Kempf, Dallas Service Rodney Lines, Safety

Michael Luera, Austin Construction

Carlos Lopez, Austin Construction

Felipe Martinez, Dallas Construction

Gary Martinez, San Antonio Construction

5 5

Amanda Moguel, San Antonio Construction

Not pictured

10 years

Tonya Lang, Accounting Bronco Juarez, Dallas Facilities

5 years

Moises Matos, Houston Construction

Larry Newsom, Houston Construction

Edgar Fernandez, Houston Construction

Jose Vasquez Gutierrez, Houston Construction

Arizona Superintendent

Pedro Ibarra: A true Servant Leader, the 5-year Partner took pride in teaching apprentices.

Former Dallas Senior Superintendent John Hogan: The retired 41year Partner John was an exceptional mentor and made major contributions on high-profile projects.

Former Pipe Shop Manager Jerry Harper: A retired 38-year Partner, Jerry was an experienced leader in the manufacturing shop and was always one of the first to arrive. All three will be greatly missed.

Melinda Salinas, Houston Service

Gary Walker, Dallas Facilities

Wesley Dunn, Dallas Facilities

Rene Molina, Houston Construction

THE DESIGN-BUILD ISSUE TDSpirit 31

5

5 5 5

Carmelo Moreno, Houston Facilities

David Moreno, Arizona Construction

Blaine Morgan, Fort Worth Construction

Matt Morton, North Texas Facilities

Eric Norman, Arizona Service

Matt Norton, Arizona Special Projects

Bryan Pense, North Texas Facilities Alde Plata, Houston Construction

David Prather, Houston Service

Josh Roden, Dallas Construction

Ernesto Rodriguez, Dallas Special Projects Francisco Rodriguez, Houston Facilities

Denny RodriguezFlores, Fort Worth Construction

Crystal Seiler, Support Services

Chris Sellers, Dallas Special Projects

Randy Smith, Fort Worth Construction

Ivan Staats, Information Technology

Diron Thomas, Arizona Construction

David White, Dallas Construction

Marcus Wicker, Austin Construction

Blaine Willbanks, Fort Worth Construction

James Williams, Houston Facilities Luis Zamora, Austin Construction

5 5 5

Dallas Multifamily 47

Dallas Major Projects 35

Dallas Multifamily 29

Dallas Construction 33

Dallas Core Operations 30

Dallas Information Technology 22

TDManufacturing 22

Dallas Facilities 24

RETIREES Phillip English

Dwain Rainey

Lucinda Scholinski

Terri Covert

Gail Stephens

Mike Murphy

Modesto Alfaro Dallas

Steve Franklin

43

Bob Lowe Dallas

Construction

41

Donald Bland Arizona

Construction

36

Chris Bailey Houston Service

Construction 26

Drew Yaggy Dallas

Multifamily 26

Drew McFaul Denver

In Memoriam

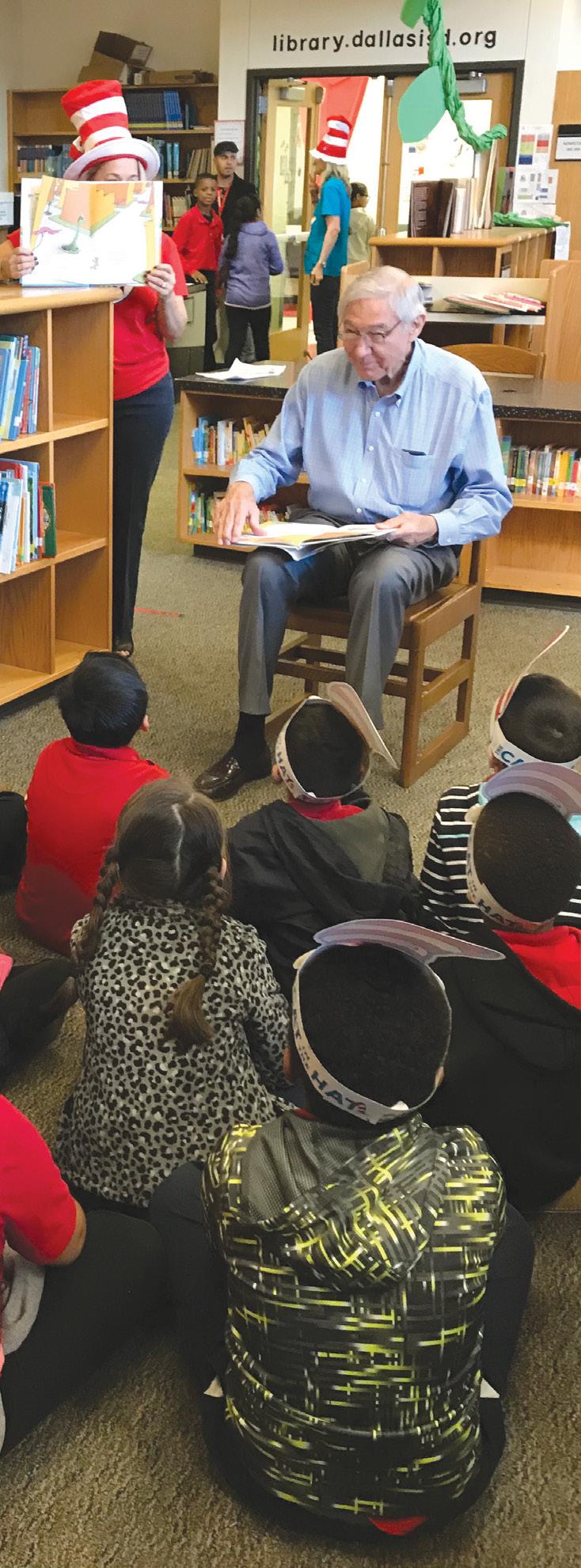

CONTINUING JACK’S LEGACY

TDPartners committed to Dallas ISD partnership

When Jack Lowe Sr. created Texas Distributors in 1946, his goal went beyond earning a good paycheck. He was hoping to improve the Dallas community, too. In the 70-plus years since, that company has grown into employee-owned TDIndustries, which continues the mission through its work with Jack Lowe Sr. Elementary School.

In 2007, Dallas ISD honored TDIndustries founder Jack Lowe Sr., for his many contributions to local education by naming one of its elementary schools after him. Jack and a group of gentlemen throughout Dallas created the Dallas Alliance Education Task Force in the 1960s-70s to help integrate the district. This plan was adopted almost word-for-word by the United States federal courts.

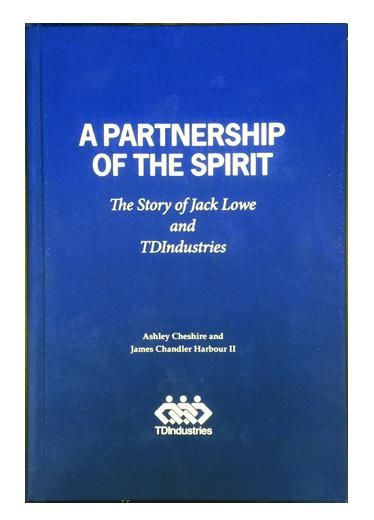

“He was the only one I know who could have gotten it done,” Field Scovell said in the corporate biography A Partnership of the Spirit. “I didn’t think that at the time, but the more I saw it progress and saw the things that he was doing, I don’t think we could have been in anybody else’s hands.”

Recently, along with the help of key vendors, the TDServes committee updated a memorial to Jack Sr. The committee painted, redesigned, and installed new artwork in the main lobby, along with new mission and vision signage in the office. TD will continue to make improvements to the school over the course of the next few years.

TD and the Lowe family have long been proud supporters of Jack Lowe Sr. Elementary and the important work the school does for children in the Vickery Meadow neighborhood. In addition to this recent work, Partners have assisted with donations benefiting both students and teachers, taken part in educational initiatives such as Read Across America Day, and helped in various teacher appreciation events.

“The artwork at Jack Lowe Sr. Elementary is stunning,” said Jack Lowe Jr., former TD CEO. “We’re really proud to have a school named for my father. Principal Sandra Barrios has done an unbelievable job turning both that relationship and the school around. Thank you to our TDPartners for your contributions to Jack Lowe Elementary. TD has always encouraged volunteering and making a difference.”

THE DESIGN-BUILD ISSUE 32 Summer 2019

Leading the second-most impoverished school in the district has certainly come with challenges for Barrios, but they haven’t kept Jack Lowe Sr. Elementary from earning a 2019 Blue Ribbon School award.

“We couldn’t be prouder of this phenomenal tribute to Jack Lowe Sr. We now have the great privilege to invite and keep our guests in a welcoming environment,” she said.

TD has several upcoming projects planned for the school. Interested Partners and sponsors should contact Marketing Assistant Samantha Camp at Samantha.Camp@TDIndustries.com.

To learn more about the school, visit its website: www.dallasisd.org/lowe

To read more about Jack Lowe, Sr. and his work with desegregating Dallas ISD, order “A Partnership of the Spirit” online on Amazon.

THE DESIGN-BUILD ISSUE TDSpirit 33

IN THE NEWS

ABC National Safety Pinnacle Award

Associated Builders and Contractors (ABC) honored TD with the Pinnacle Award, one of the top safety honors in the nation. The award is for TD’s commitment to fiercely protecting the safety of all Partners. To be eligible for this honor, TD first had to obtain platinum gold status in ABC’s STEP Safety Management System.

San Antonio Partner Earns Red Cross Award

Charlie Miffleton, who was featured in the previous TDSpirit, received the Red Cross Certificate of Merit for his role in saving his team Partner from choking. Charlie performed the Heimlich maneuver, which he learned from Safety Manager Rodney Lines.

Magazine Features Employee-Owned Culture

Employee-Owned America profiled TD in February’s issue, showing how a Servant Leadership culture leads to a profitable ESOP for all Partners.

DPR Awards TD Safety Honor

General Contractor DPR began a new onsite safety program, and named TD its crew of the month on a datacenter jobsite. “The entire TDIndustries team has done a great job leading and mentoring the crews that are onsite every day,” DPR said.

Frost Tower, Texas Scottish Rite-Frisco Projects Earn TEXO Awards

TD performed design-assist services for mechanical and plumbing processes at Texas Scottish Rite-Frisco’s 347,000 sf medical facility, keeping in mind its likely growth into a hospital in the next decade. Frost Tower is Fort Worth’s first high-rise building in 20 years and the first Class AA-plus in 10. It includes 250,000 sf of office space and 45,000 sf of amenity floors.

THE DESIGN-BUILD ISSUE 34 Summer 2019

San Antonio Wins Regional Award for Hospital

TD earned first place in the $2-10 million category for its work on HCA/ Methodist Healthcare’s Stone Oak Hospital. TD renovated and expanded 27,000 sf dedicated to operating, prep/recovery, decontamination, and anesthesia care. In addition, TD installed two new air-handlers (renovating a third), a water-cooled chiller package, roof drains and nozzles, and more than 50 plumbing fixtures.

2020 Women on Boards Names TD a Winning Company

The advocacy group, which is pushing for all boards to have 20 percent female representation by 2020, recognized TD for having three women on its seven-person board. In 2018, only 17 percent of board seats nationally were held by women, and a quarter of public companies in the U.S. have no women directors. The year 2020 also marks the 100th anniversary of when the 19th Amendment was passed.

TD Remains on Contractor’s Book of Giants Top 10 List

TD checks in at No. 8 overall, improving its revenue by $26 million in 2018, and increasing three spots in piping to No. 4 nationally. TD is No. 3 nationally in HVAC at $303 million, No. 2 nationally in plumbing at $183 million, and No. 4 nationally in piping at $126 million. For the second straight year, Contractor ranks TD No. 3 in the Southwest – and No. 3 in Texas.

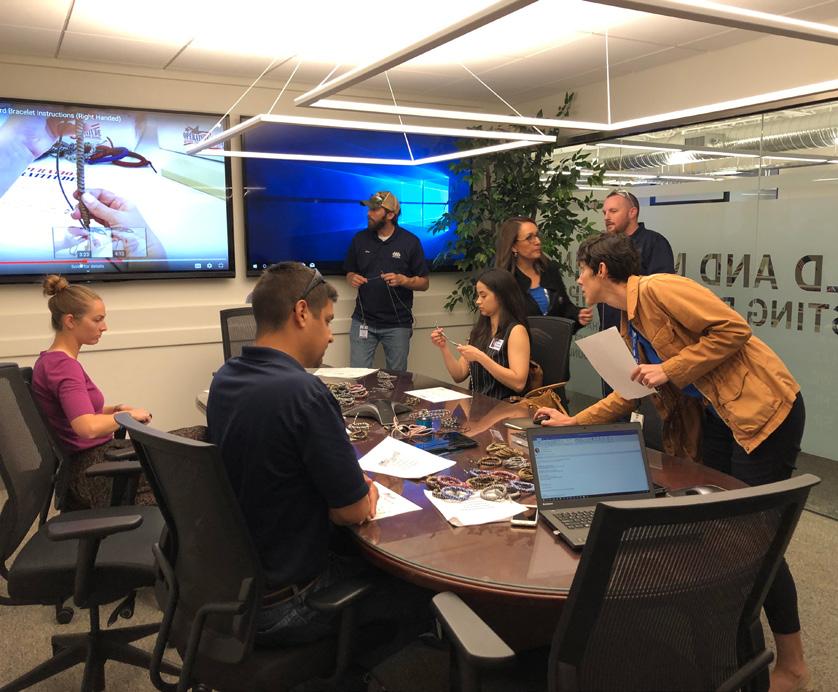

TD Supports Military Through Operation Gratitude

TD partnered with Operation Gratitude, a nonprofit group that provides care packages to deployed troops, new recruits, and veterans. TD donated 500 pounds of supplies and assembled 600 survival bracelets. The supplies include toiletries, batteries, snacks, weather-appropriate accessories, and comforts from home.

Students Find Careers With TD

TD held its latest skilled-trades “national signing day” ceremony in Phoenix. These events honor and celebrate high school seniors who have chosen a career in the skilled trades. Three TDPartners were present to welcome a few new faces from the East Valley Institute of Technology.

THE DESIGN-BUILD ISSUE TDSpirit 35

Forget what you know about facility maintenance, Visual Intelligence is changing EVERYTHING.

Receive photo and video confirmation of maintenance work to understand the reasoning behind our repair suggestions, or use it to plan for capital investments. To learn more, visit tdindustries.com/visual-intelligence-maintenance-reporting

Diplomat Dr. Dallas, TX, 75234

13850

Wesley Baker, Vice President, TDManufacturing

the Vice President of San Antonio, Wesley Baker now leads TD’s Manufacturing Operations.

Kyle Hogue, Vice President, Dallas Special Projects

Kyle Hogue assumes responsibility for Dallas Special Projects.

Lauren Turner, Vice President, Dallas Service

Formerly the Vice President of Manufacturing, Lauren Turner now leads Dallas Service.

Chris Brown, Senior Vice President, Arizona Special Projects

Brown adds prefabrication, purchasing, fleet, and warehouse to his duties.

Scott Roan, Vice President Preconstruction and Business Development

Roan, Senior Vice President, now leads TD’s Preconstruction and Business Development team.

Jay Layton, Senior Vice President, Arizona Construction and Service

Wesley Baker, Vice President, TDManufacturing

the Vice President of San Antonio, Wesley Baker now leads TD’s Manufacturing Operations.

Kyle Hogue, Vice President, Dallas Special Projects

Kyle Hogue assumes responsibility for Dallas Special Projects.

Lauren Turner, Vice President, Dallas Service

Formerly the Vice President of Manufacturing, Lauren Turner now leads Dallas Service.

Chris Brown, Senior Vice President, Arizona Special Projects

Brown adds prefabrication, purchasing, fleet, and warehouse to his duties.

Scott Roan, Vice President Preconstruction and Business Development

Roan, Senior Vice President, now leads TD’s Preconstruction and Business Development team.

Jay Layton, Senior Vice President, Arizona Construction and Service