Via Mantova, 65 - 43122 Parma, Italy

Tel. +39 0521 490211 - Fax +39 0521 243701

info@zacmi.it - www.zacmi.com

ZACMI: Advanced solutions for the food and beverage industry

ZACMI is an Italian industrial company based in Parma specialized in the design and production of filling and seaming machinery for the food industry. The Company, founded in 1954, has a solid history of success in its field.

ZACMI’s mission is to offer innovative and technologically advanced solutions to satisfy the customers’ needs and improve production efficiency.

The strength of ZACMI’s highly skilled team lies in its vision into the future, engaged on a daily basis to provide the highest-level service for its customers.

Machinery and solutions

ZACMI has developed top quality solutions in terms of applied technology, as a result of constant long-term research and testing with the help of a highly specialized R&D department.

Due to its expertise in manufacturing filling and seaming machinery, ZACMI also has the competence to design and produce entire processing lines.

Filling

ZACMI offers a vast range of ultramodern filling machinery.

ZACMI Piston Fillers are designed to accurately dose liquid or semi-liquid ingredients, guaranteeing the uniform distribution of the product with an extremely high filling precision and the total absence of dripping, using a patented product dosage method.

ZACMI Vacuum Fillers ensure an airtight filling, thus preserving the products’ freshness and quality. This filler offers the perfect solution in topping up containers that have been pre-filled with solid product or for the total filling of thick products into the containers.

ZACMI Telescopic Fillers are ideal for a rapid and accurate filling of bottles, cans and other containers, reducingwastetoaminimumwiththemaximumefficiency.

The special design and the choice of specific instruments make this Telescopic Filler reach the highest standards in filling accuracy to satisfy all customers’ needs.

ZACMI Monoblocks perfectly integrate the rinsing, filling and closing phases into a single compact solution, to guarantee a higher production yield, whilst optimizing space.

Seamers

ZACMI also distinguishes itself for its innovative seaming solutions. The specific design facilitates cleaning and maintenance, reducing handling costs, with a completely washable Wash-In-Place system, the ZACMI Clean Design Seamer satisfies the strictest hygiene standards set by the food industry.

On the other hand, ZACMI Vacuum Seamer exploits a new technology that preserves the integrity of the filled product, eliminating the risk of contamination and extending its shelf life.

Furthermore, ZACMI seaming machines offer a wide flexibility of configuration, adapting to the specific needs of the customer, guaranteeing a high-quality productivity. Processes

Apart from filling and seaming machinery, ZACMI also supplies complete solutions for crucial food industry processes, such as pasteurization.

The machines are designed to provide an accurate thermal disinfection, eliminating harmful bacteria and micro-organisms, without jeopardizing the organoleptic characteristics of the product.

ZACMI’s avant-garde technology application, ensures the maximum energy efficiency and conformity to the strictest food safety standards.

ZACMI offers high quality machinery, but also engages in providing a full and reliable service to its customers.

The ZACMI team of experts, supplies technical support, personalized consultancy and a complete range of after sales service assistance, including preventive maintenance and spare parts supply.

This strongly customer-oriented approach, assures that ZACMI customers obtain a continuous and reliable support, saving time and workforce.

ZACMI has continued for decades to satisfy the requirements of the sectorial companies worldwide, with its innovative solutions, competence of its work team and constant commitment to customers with its after sales service,improvingproductionefficiencyandinternationally establishing its place as a trustworthy point of reference.

For further details please visit the website:www.zacmi.com

Via dell’Artigianato IV^ Strada, 6 - 35020 Candiana (Padova) Italy Tel. +39 049 95 99 935

info@zmatik.com - www.zmatik.com

Z.matik, cutting-edge technology for bakery and pastry shops

Z.matik has forty years of experience in the production of machines for bakeries and pastry shops, in particular of manual dough sheeters, croissant groups, work tables, planetary machines and cutting rollers in Aisi 304 steel.

From this year the company began a real revolution, but always maintaining tradition. It starts with the manual table top and floor standing sheeters that are much more compact and ergonomic.

The modern style and cutting-edge materials are captivating even the most demanding customers.

The mechanics maintains some key points, but is also renewed, allowing the customer less maintenance and greater resistance. The goal is to

make this range even solider and more intuitive, thus facilitating the operator especially in routine cleaning.

The new dough sheeter is good for multiple applications: from pastry shops to hotels, catering, etc. The existing options have been made even more advanced, for example the thickness detector, which allows you to calibrate the lowering of the calibrating cylinders to exactly check the thickness of the dough. Now this accessory counts a lot of digital display larger, in color and very accurate in reading.

Z.matik is certified according to the TÜV SÜD - ISO 9001 quality system and complies with all standards for food contact. Finally, each product is sanitized before packaging, in order to guarantee the customer greater safety of use.

Piazzetta Osvaldo

de

Bortoli,

Vimco, your unique partner for the secondary packaging

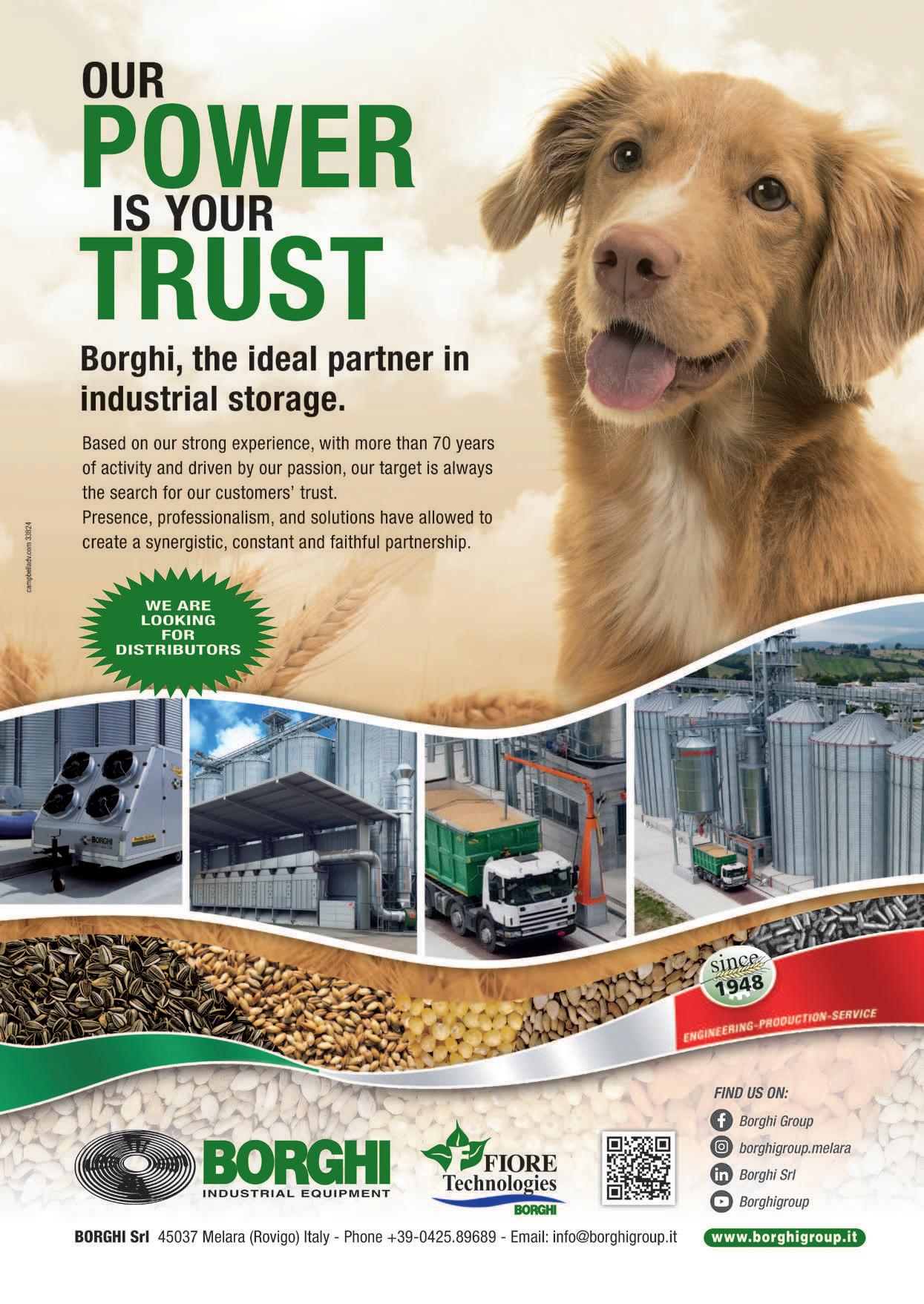

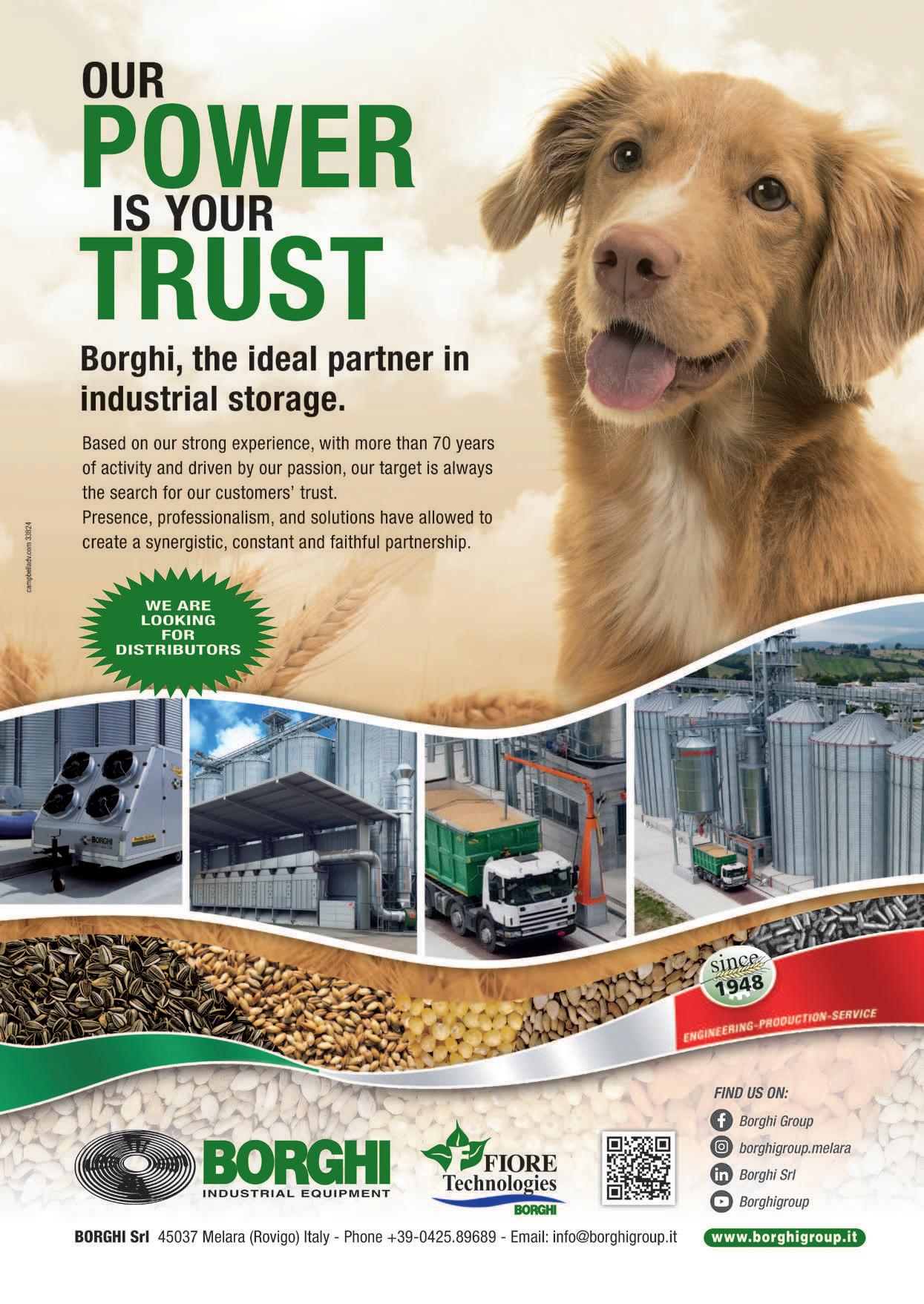

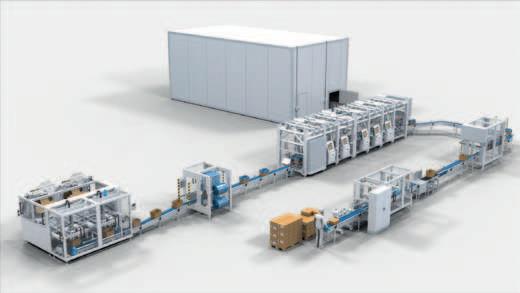

The company know-how and the ability to provide custom-made solutions, let Vimco be a turnkey partner for complete lines. Vimco, born in 1980, is a vibrant, dynamic and flexible company whose core business focuses on the engineering and manufacturing of complete lines in the secondary packaging, end of line equipment and robotic solutions for the food and non-food industries.

All machines’ components are manufactured and assembled in-house in order to allow an efficient, well-controlled, internal work-in process flow aimed to supply reliable and durable solutions to customers worldwide.

The company’s know-how and ability to customize tailor-made solutions and turn-key systems represent a “unique” asset customers can take advantage of, making Vimco a reliable, qualified packaging partner.

An experienced technically skilled team leads Vimco to be an eclectic, versatile company, capable to offer customers a good variety of top-class solutions across all food market segments with an after-sales service up to the tasks and customers’ expectations. Vimco mainly operates in food sector,especially bakery,confectionery,dairy,ready meals, grocery,snacks,petfoodandcoffeebusinesscategories.Themachines’portfolioincludes forming, closing, lidding, cartoning, sleeving, robotic loading systems, monoblock units, end of line and complete solutions.

The company is riding sustainable business practices and represents a good venue to help customers to pursue automation in an eco-friendly environment.

Why Vimco?

• Wide range of standard and customized machines for cardboard packaging.

• Innovative systems.

1 - 22073 Fino Mornasco (Como) - Italy Tel. +39 031 92 95 39 vimco@vimco.it - www.vimco.it

• High flexibility in designing and project management.

• Machines studied and developed in relation with the features of the product/packaging.

• Customer-focused and service-focused orientation.

• Immediate after-sales service.

• Preventive maintenance service of the machines to guarantee the proper operation in their entire lifespan.

• High-quality products and performances thanks to the use of high-tech components.

• Highly skilled and specialized R&D department.

Via Vivare, 425/B - 47842 San Giovanni in Marignano (Rimini) Italy

Tel. +39 0541 955276

info@universalpack.it - www.universalpack.it

Advancing sustainable solutions for singledose packaging

Universal Pack, a leading manufacturer of packaging machines and automated lines for single-dose solutions, promotes environmentally conscious practices in the food industry. Their scientific approach ensures packaging technologies are compatible with compostable and recyclable laminates, maintaining efficiency and reliability.

Fortheplanet:Compostableandrecyclablepackaging

Universal Pack’s relentless research has led to optimized machinery design for packaging with compostable, recyclable, and recycled laminates. Using Life Cycle Assessment (LCA) to measure environmental impact, our holistic approach includes every step of the packaging machinery production process. Collaborating with global film suppliers and major multinational companies, Universal Pack provides turnkey solutions for the production of sustainable packages.

Global partnerships

To achieve the best results in sustainable packaging, Universal Pack has been working hand in glove with international film suppliers, multinational customer corporations and University research centers. This tightknit collaboration allows each stakeholder to contribute their expertise and benefit from the know-how of others to achieve the desired outcome. For example, the customer brings their initial requirements, the film supplier develops a compostable or recyclable laminate, Universal Pack

tests it on its machines in order to optimize the packaging process, and the University contributes their know-how at every stage of this process.

Universal Lab

Each project begins with a careful personalized analysis of customers’ products and laminates, in order to optimize the design, efficiency and reliability of the machinery. For over 30 years, Universal Pack Laboratory has been lying at the core of project management and design review, as the whole engineering process is always backed up by science principles used to meticulously analyze various aspects. As a result of many years of experience, Universal Pack is not only

packaging experts at your service, but also a team of experienced packaging scientists.

The company

Universal Pack, with over 50 years of experience and 8,000 systems in 150 countries, is a leader in designing VFFS machines and automated lines for single-dose packaging, such as stick-packs, 4-side-seal sachet and cartons.Currently,the company is focusing on packaging with compostable, recyclable, and recycled materials, and integrating systems into Industry 4.0 environments.

Via Vivare, 425/B - 47842 San Giovanni in Marignano (Rimini) Italy Tel. +39 0541 955276 info@universalpack.it - www.universalpack.it

Tekno Stamap designs, develops and manufactures dough-processing systems and machinery for bakery and pastry industries.

Founded in 1982 by Antonio Baldovin and Remigio Dante, Tekno Stamap straightaway stood out in the market of mechanical equipment for the food industry; over the years, it has enriched its offer with dough sheeters (manual or automatic) and planetary mixers, still today constituting the core of the company’s production. More recently, Tekno Stamap’s range of products has been further integrated with croissant machines and make-up lines for bread, pizza and pastries. This is what allows Tekno Stamap to provide its final clients (mainly resellers and producers from large restaurant services) with the dough-processing equipment required by their activities.

Tekno Stamap manufactures internally almost all machine components, thereby actually establishing an autonomous production line: the design, development and assembling phases are entirely carried out within the company’s plants with significant advantages, among which the possibility of maintaining a highly competitive quality-cost ratio. Innovative design, state-of-the-art technology and top-notch

quality are the factors completing the offer of a by now global brand

For more than 3 decades now, Tekno Stamap has been writing its own history of success, both at a national and international level. Born as a Vicenza-based firm, it has nowadays become an affirmed global reality, with branches in Europe, Japan, South Africa, Asia and North and Latin America. The client can find in Tekno Stamap a dynamic, autonomous, reliable, flexible, and technologically advanced commercial partner and a thriving business as well.

Tekno Stamap has gained a significant share of global market thanks to its expertise, state-of-the-art technology and attention to the client’s needs. The company’s mission statement is to constantly improve the offer of appliances, all the while maintaining high quality and technological standards and investing in research and development of the production process. Tekno Stamap aims at becoming an international benchmark in the sector of professional doughprocessing machinery for the bakery and pastry industry.

Tecno Pack means technology, experience, service in flow and pillow-pack packaging, primary and secondary.

Market leader Tecno Pack provides all the technology your company needs: from small electronic packaging machines with manual loading, right to complete plants.

Skilled trade team, experienced technical department, in-house production of mechanic parts, accurate material selection, excellent production team and after-sales assistance for the world over, enable Tecno Pack to propose machines and plants that are thought as “tailored suit” and broadly recognized as cutting-edge technology by Gruppo Barilla, Nestlé, Pavesi, Kraft, Baxter, Chipita, PepciCo, to name some but a few.

Speed, flexibility, modified atmosphere, shelf life, integration of the packaging into the corporate system, are the issues that Tecno Pack deals with enthusiastically every day and that gives it new evolution leaf of live.

IFP Packaging is a sound benchmark in heat-shrink film wrapping technology. At the end of 2011, it became part of Tecno Pack SpA group, thus beginning a new course of greater technological, commercial and industrial development.

Electronic continuous wrapping machines built on fully cantilever structures, and high performance, high reliability, sanitization, versatility and customization are just some assets of IFP Packaging’s offer.

Automatic loading systems, bundling machines of any size, complete end of line systems are fully customized by the company’s skillful and versatile technical department. Adjusting the state-ofthe-art technology upon customer’s peculiar requirements is IFP Packaging’s main goal. Moreover, the company also proposes the market its sturdy and versatile wrapping machines, standard built, for a quite interesting quality-price ratio.

General System Pack continues evolving and implementing its range of machines and automation flow-pack dedicated. 30 years of continuous development have turned this company into a world leader able to study, produce and install machines from horizontal single flow-pack packaging to fully electronic machines and complete packaging lines for any kind of product.

General System Pack introduces its GSP 50 EVO model to package a broad range of products thanks to full control of brushless motors and reduce time for change of format down to the minimum.

High speed, controlled atmosphere, full automation of the entire primary, secondary and end-of-line cycles are carried out ordinarily by applying the highest state-of-the-art mechanical and electronic technology.

Via Lago di Albano, 76 - 36015 Schio (Vicenza) Italy

Tel: +39 0445 57 56 61 - Fax: +39 0445 57 56 72 comm@tecnopackspa.it - www.tecnopackspa.it

Via Lago di Albano, 70 - 36015 Schio (Vicenza) Italy

Tel: +39 0445 60 57 72 - Fax: +39 0445 58 03 44 sales@ifppackaging.it - www.ifppackaging.it

Via Lago di Albano, 82 - 36015 Schio (Vicenza) Italy

Tel: +39 0445 57 62 85 - Fax: +39 0445 57 62 86 info@gsp.it - www.gsp.it

Via Mastri Cestai, 2 - 12040 Corneliano D’Alba (Cuneo) Italy

Tel. +39 0173 61 05 64 - Fax +39 0173 61 94 94

tecno3@tecno-3.it - www.tecno-3.it - www.beantobarmachine.com

For two generations, TECNO3 has been technical partner of the best confectionery companies

• Production of fat creams (from dosing and mixing to the finished product)

• Continuous dosing and mixing (for the characterisation of chocolate, compounds, fat creams and pastes)

TECNO3 is an Italian entrepreneurial reality, a reference point for technological innovation in the confectionery industry to provide complete industrial solutions for:

• Cocoabeanprocessing (fromcleaningtoalkalinisation)

• Nut processing (from cleaning to dried fruit paste)

• Chocolate production (from dosing and mixing to conching)

• Melting of loaves of fat, anhydrous and hydrated butter, chocolate and cocoa mass

TECNO3’s competitive strength is research and development, based on a deep understanding of production processes to continuously increase the value of its plants, focusing on the needs of the food industry to design, engineer and deliver turnkey plants based on new technological knowledge.

Headquarters: Tecno3 S.r.l. – Corneliano d’Alba – Italy

TECNO3 optimises business performance for long-term value creation and more efficient process management:

• Reorganisation of the production layout in a Lean Transformation path to significantly reduce delivery times

• Strengthening the Tecno3 team to ensure a high rating thanks to industrial know-how and the ISO 9001 certified quality system.

• Integration of Lean Thinking principles to continue to raise the level of products and services offered, maximise plant performance and achieve excellent results

• Use of SAP software, a technology that fits seamlessly into business process management to achieve a significant increase in production efficiency

TECNO3 is committed to improving processes and enhancing the characteristics of the final product:

- Ensuring plant reliability

- Significantly reducing the amount of product required for recipe changes

- By streamlining processes thanks to continuous processing

- Facilitating the disassembly and sanitisation of equipment

- Optimising space with company-wide solutions

- Reducing consumption and promoting energy savings

- By providing a test area where the production cycle can be reproduced

- By respecting the nutritional and organoleptic properties of raw materials through to the final product

- Favouring increased and optimised productivity

Every day TECNO3 works to create innovative, inspiring and enjoyable technologies for everyday life around the world; it operates and exports to 5 continents and 30 countries.

Tecno3 Switzerland

Tecno3 USA INC

Via Mastri Cestai, 2 - 12040 Corneliano D’Alba (Cuneo) Italy

Tel. +39 0173 61 05 64 - Fax +39 0173 61 94 94

tecno3@tecno-3.it - www.tecno-3.it - www.beantobarmachine.com

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (Bergamo) Italy

Tel. +39 0345 40 400 info.smipack@smigroup.net - www.smipack.it

Continuous innovation to meet a changing market Food and non-food companies, influenced by a strong trend towards product diversification, need very flexible and efficient packaging machines to reach high levels of competitiveness.

Present on the market since 1997, SMIPACK (a company part of the SMI Group) is one of the main producers of packaging machines worldwide.

SMIPACK designs and manufactures a wide range of manual, semi-automatic and automatic packers that provide thousands of customers all over the world with smart solutions capable of meeting their requirements in terms of competitiveness, production efficiency, operational flexibility, energy saving and ease of use.

Tradition and innovation: the basis of a solid business reality

Year after year, the story of SMIPACK features a sequence of projects and initiatives combining passion,commitment, research, customer support and above all continuous innovation, factors that have allowed the company to grow

In the modern and functional SMIPACK headquarters in San Giovanni Bianco (Bergamo), all design, assembly, sales and after-sales activities are performed

in terms of sales turnover, product range, international presence and surfaces occupied.

Today SMIPACK proudly looks back at the year 1997, when it started its activity with the production of L-sealing machines from the S range, that in only two years reached stunning results.

Research and development of new packaging machines still characterize the activity of SMIPACK, which invests significant resources every year to develop new technologies and launch on the market increasingly

innovative and competitive products, designed for easy use by the operator and for the optimization of the packaging operations.

FW series for flow pack packaging

An example of SMIPACK continuous evolution is represented by the flow pack packers from the FW series; an extremely versatile, flexible and cost-saving solution, suitable for any type of food and non-food products. SMIPACK offers a wide range of flow pack machines, including several models, even for the entry-level sector.

Main advantages of flow pack packers by SMIPACK:

• high efficiency and production speed: depending on the model chosen, the FW packers meet production requirements up to 200 products/minute

• versatility: products are packed in packs made of simple or coupled flexible material

• high customization possibilities: the FW range is equipped with several standard devices which make it the ideal solution for any packaging need, ensuring a great quality/ price ratio

• compact structure: machines suitable for any packaging line

• accessibility and ergonomics: all models adopt solutions that optimize the manmachine interaction, guaranteeing easy access to any part of the machine and improving performance in terms of ergonomics

• subsequent easy maintenance

• advanced technology: the FW range adopts cutting-edge solutions that ensure high performance and high safety standards

• wide operational flexibility: packers suitable for a wide range of products, even with irregular shapes and small sizes, which arrive at the machine loose (single pack) or grouped (multipack)

• easy management even for less expert operators, thanks to the innovative FLXMOD® control system, equipped with an operator interface with PC panel and color touchscreen display

• advanced control system inspired by Industry 4.0 principles

Customer-oriented company

Thanks to the trust of an even higher number of customers and the collaboration with an extensive network of partners, SMIPACK is nowadays well known in the world for the quality of its machines, for the development of innovative packaging technologies and for the constant attention to customers’ satisfaction.

Today the installed packers in the world are 87,000. Thanks to an annual production of about 4,000 units, designed and produced in Italy, the company is among the world leaders in its sector and throughout the years has become a reference point for a growing number of companies operating in the food and non-food industries.

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (Bergamo) Italy

Tel. +39 0345 40 400 info.smipack@smigroup.net - www.smipack.it

In an increasingly competitive and demanding market, SMIPACK plays a key role in ensuring its direct presence on the main international markets, in order to offer a highprofile, well-organized sales and technical assistance.

A wide range of products to meet the 4.0 Factory

Innovation and advanced technology have always been distinctive elements of the packers produced by SMIPACK, to such an extent to significantly contribute to their huge success on the market thanks to key aspects including process automation, ease of use, operation flexibility and reduced maintenance.

SMIPACK machines are designed to offer all the advantages of IoT (Internet of Things) solutions for data and information exchange through 4.0 Factory supervision and control systems.

Via Piazzalunga, 30 - 24015 San Giovanni Bianco (Bergamo) Italy Tel. +39 0345 40 400 info.smipack@smigroup.net - www.smipack.it

Via A. Tomba, 15 - 36078 Valdagno (Vicenza) Italy

Tel. +39 0445 43 15 76 - Fax +39 0445 43 95 88 info@sitecsrl.it - www.sitecsrl.it

144 Blue OLED

For over 25 years, Sitec has been synonymous with excellence and reliability in the field of professional timers and temperature controllers for the baking and pastry sector. We are pleased to introduce the new 144 Blue OLED electronic timer, a technological evolution that retains the appreciated features of the original 72X144 timer while enhancing it with a modern design and innovative functionalities.

Main features

This new model has been designed to meet the modern needs of the baking world by improving user interaction and simplifying use. The new setup includes a single dial supported by a high-resolution 2.42-inch Blue OLED

display, which allows for more detailed visualization of the various functions thanks to its high contrast.

Optimal control with physical buttons, not simple touch

The timer is specifically designed for dough mixers with two or three working times. The dial, equipped with 11 LEDs, allows precise and intuitive adjustment of the desired time. Four additional LEDs indicate the movement of the bowl and spiral, while an alarm signal LED ensures immediate control over the work cycle.

Exclusive features of the new model, standard for all mixers, whether equipped with inverter motors or not

• Improved design and user interface

The display is accompanied by three ergonomic buttons that facilitate the setting of times and various timer functions, even when wearing gloves

• TR backward time management for perfect dough optimization

This function now allows managing the reverse rotation time (TR) during T1 time. The bowl, which normally rotates forward, can now rotate backward for the TR time before resuming forward rotation to complete the remaining T1 time and then proceed to T2 time.

• Up to 10 stored and editable recipes

It is possible to set and automate the working times for frequently used doughs, with the ability to store up to 10 customized recipes, ensuring significant time savings and quality assurance.

New features available for mixers with inverter motors, thanks to an additional card

• Ability to control motor speeds, ensuring greater flexibility and customization of recipes

The optional card features two 0-10V outputs for controlling the bowl and spiral inverters and two inputs for managing any alarm signals (FAULT), allowing the machine to be paused and the alarm reset if necessary.

• Dough temperature display

The timer is setting to control dough temperature via a 4/20mA current loop input, to which the probe (not included) can be connected.

• RS422/485 interface for future expansions

The expansion possibility with the RS422/485 interface paves the way for further developments and future integrations, ensuring that your investment remains at the forefront of technology.

Conclusion

The new timer 144 Blue OLED from Sitec is the ideal choice for professionals in the baking and pastry sector who are looking for a cutting-edge product that is easy to use and capable of significantly improving work quality. Thanks to its innovative functionalities and intuitive design, the timer 144 Blue OLED offers superior performance and precise control, making each processing step more efficient and reliable. Choose excellence and innovation. Choose Sitec.

Via G. Fabbri, 9 - 47034 Forlimpopoli (Forlì Cesena) - Italy Tel. + 39 389 6145402 info@silosrevolution.com - estero@silosrevolution.com www.silosrevolution.com

Silos Revolution is a company specializing in the design, development and customization of Raw Material Storage, Conveying and dosing systems for the food, chemical and pharmaceutical industries. Silos Revolution puts the customer’s needs at the first level and then tailors on them what will be the customer’s tailor-made system.

Dealing with particular and unique systems, there can be no copy and paste. Each system is different because the requests of the individual customer are different, only the gained experience on how to deal with certain particular ingredients that can be a game-changer.

This technical conception of work combined with the availability and flexibility of the company’s engineers and technicians has initiated important collaborations with large Italian and foreign groups.

On the company website you can find all storage solutions for powders, granules and liquids suitable for all needs, from the most economical fabric silos to monolithic stainless-steel outdoor silos to thermo-conditioned tanks. Bag emptying systems for bags up to 1 ton or bag emptying systems of 25-50 kg conclude the range of products dedicated to powder storage.

Indicate the precision in the dosages of individual ingredients you would like to have, and Silos Revolution will build the appropriate system to guarantee those accuracies. Silos Revolution micro-dosing systems guarantee accuracy of +/- 5 grams per individual ingredient.

Special production processes such as:

- Flour disinfestation

- Flour cooling

- Powder mixing stations

- Powdered sugar

- Inverted sugar are designed and sized ad-hoc so that they can be integrated into classic storage facilities.

Each system is managed by industrial PLC, and if the customer wishes, we can supplement the supply with management supervisors open to dialogue with existing systems and remote assistance.

Ifyoualreadyownarawmaterialstoragetransportanddosing system, but you are not satisfied with its performance, Silos Revolution can safely solve your problems and guarantee you the production you set out to achieve.

Choose to be free is Silos Revolution’s slogan, come and find out how!

Via Artigianato, 85 - 25030 Torbole Casaglia (Brescia) Italy Tel. +39 030 2650488 - Fax +39 030 2650143 info@sigmasrl.com - www.sigmasrl.com

Sigma started its activity in 1974 as one of the most important European manufacturers of mixers. Sigma production consists of:

Pastry machines

Planetary Mixers. Different lines characterize the production of planetary mixers for craft and catering:

• Best Mix, a line with mechanical speed variator from 10lt to 80lt

• Chef line with electronic speed variator (inverter) from 7,5lt to 60lt

• Powermix planetary mixers for industrial use from 60 up to 160lt, with motorized bowl lift and descent, total tool disengagement and programmable control panel

• Aeromix with a worldwide patented system. With their outstanding speed ratio,they offer the best results in terms of quality when used for making emulsions, mixtures and dough for pastry-making and food preparations. What makes them truly unique is the combined use of three special tools in the production of the mixtures. The range of machines for pastry also includes:

• Sheeters

• Electric cookers

• RF300 grinding machine

• Twin-arm mixers

Pizza machines

Worth of special mention the “Sprizza” cold spreading system, a machine that reproduces the manual skills of a pizzaiolo as closely as possible by imitating his unrivalled delicateness with a cold working process, and the rounding cutter Dr 1411 to cut and round 800/1000 portions of dough per hour, from 150 to 650 gr with 2 different cutting groups.

The portfolio is completed with:

• Spiral mixers Silver Line with removable bowl in the following models: 80,120,160,200,250, 300 kg of dough capacity.

• Spiral mixers Super Premium with removable bowl

• Spiral mixer bench model Tauro from 12 to 40 kg dough

• Screw rounder Sfera for dough ball from 30 to 1000gr

• Vertical sheeter T50

Bakery machines

The production of spiral mixers is composed of different lines, such as:

• Benchtop spiral mixers Tauro for kneading from 12 to 40k g of pizza dough. Available with fixed or removable bowl

• Red Line spiral mixers with fixed bowl of capacity from 60 to 280 kg of dough

• Green Line with fixed bowl, able to save around 20%25% energy compared to the traditional mixers

• Self-emptying spiral mixers available in models of 80120 - 160 - 200 - 280 kg of dough, able to automatically empty the dough onto a table or into a divider

Other kinds of machines to complete the range:

• Bowl lifters

• Feeding hoppers

• Hexagonal dividers

• Squared dividers

• Bun dividers

• Conical rounders

• Moulders for wrapped bread and baguette

All the Sigma manufactured equipment complies with EU safety and hygiene directives. Today, Sigma is present in over 100 countries in the world through its 500 regular dealers. The attention paid to its customers and constant commitment to innovation have always distinguished the Sigma’s philosophy.

Since 1982

Satinox has been manufacturing perfectly welded stainless steel bowls for more than 30 years. They are made by hands to fit the machines used to knead and mix dough for the bakery and pastry sector as well as for the chemical and pharmaceutical sector.

The company was founded in 1982 and since then it has been a strong believer in the value of manual metalwork fabrication.

All bowls are made by expert and specialized workers, able to manufacture robust, versatile and long-lasting tailor-made products.

Satinox can count on a team that works together with passion and professional expertise, uses high quality materials and is continuously fine-tuning its metal fabrication and welding techniques.

In fact technical expertise and knowledge go hand in hand with the quality of the materials and the ability to turn traditional artisan metalwork fabrication into expert joining technique.

From project development to product manufacturing careful examination of any special production needs is definitely essential to find the ideal solution to optimize bowl performance, and consequently machine performance.

Strict compliance with the drawings, the painstaking attention to tolerances along with machining precision guarantee tailor-made products of any shape and size.

Diameter: from 240 mm up to 2000 mm

Customized height

Thickness: from 2 mm up to 8 mm

Bottoms available in high thickness

Upper ring: plate or round bar

Customized flange

Discharging bolt, auto discharging system

Diameter: from 400 mm up to 1400 mm

Customized height

Thickness: from 2 mm up to 5 mm

Upper ring: plate or round bar

Customized flange

Diameter: from400 mm up to 1400 mm

Customized height

Thickness: from 2 mm up to 4 mm

Upper ring: plate or round bar

Customized flange

BOWL FOR PLANETARY MIXER

Capacity:

Electrically

Optionals: product discharge valve, washing discharge valve, brackets

Diameter: from 900 mm up to 2000 mm

Customized height

Thickness: from 4 mm up to 6 mm

Upper ring: plate or round bar

Customized flange and bolt

Diameter: from 700 mm up to 1500 mm

Customized height

Thickness: from 2 mm up to 4 mm

Upper ring: plate or round bar

Optionals on demand

Diameter: from 220 mm up to 1700 mm

Customized height

Thickness: from 1,5 mm up to 2 mm

Truncate Conical, Truncated pyramid

Upper ring: plate or round bar

Customized flange

BOWLS FOR PRALIN CANDY MACHINE, CHOCOLATE MELTER, CREAM COOKER

Diameter: from 250 mm up to 1500 mm

Customized height

Thickness: from 2 mm up to 3 mm

Entering round ring

Optionals on demand

Via Sempione, 82 - 28053 – Castelletto S. Ticino (Novara) Italy

Tel. +39 0331 92 20 86 sales@robox.it - www.robox.it

ROBOX, since 1975, has been developing and producing axis controls, programming languages and development environments ideal for robotics and for “motion control” in general.

The multiplicity of programming languages (structured text, ladder, object blocks) and the wealth of libraries make learning the Robox systems easy for any willing child with the right foundations in electronics and IT provided by Italian higher education.

Robox controls can manage any application, thanks to the variety of fieldbuses on which they communicate, including Ethercat, CANopen, profibus and modbus.

The current flagship product of Robox S.p.A. it is the RP-2 controller, a Robox branded brain with ARM A9 processor that can manage up to 32 interpolated axes. RP2 has gained an important place in robotics and industrial automation in the most varied types of machines, such as flowpackers, fillers, cappers and case packers.

In recent years, the demands for safety in systems and the appearance on the market of many Safety devices have pushed Robox towards the integration and interfacing of these elements and protocols. After the fruitful use of Phoenix safe I/O, Robox has entered into a collaboration with BBH, a German company that has been dealing with security for more than 30 years.

The combination of Robox motion controllers and BBH safety PLCs offers OEMs operating in every sector the possibility of achieving functional safety requirements (SLS, SLP, ...) also for TCP.

The Robox / BBH combination has also found an important application in the AGV sector, where Robox has been operating successfully for decades and has gained experience in all the most used guidance systems: guide wire, laser guidance, inertial guidance, magnetic guidance and natural driving (SLAM).

The integration between control systems and drives has also significantly increased. On the hardware development front, we mention the RID20-E drive which replaced the RID20 drive. We remind you that RID20 is a drive designed to be installed directly on the motor; 14 years after its birth, a

redesign was carried out - the RID20-E - to take advantage of the technical developments during these years. RID20-E is available in a version suitable for direct installation on the engine (shuttle configuration) and in a version suitable for being placed in the immediate vicinity of the engine (nearby configuration). Thanks to the integration with the motor,RID20-E is suitable for use in all multi-axis applications that require drastic reductions in size and wiring, such as applications in the beverage, food and packaging sectors. www.robox.it

The breakthrough innovation in processing systems

Roboqbo is on the market since more than 40 years and is one of the leading companies worldwide for food processing system manufacturing. Roboqbo manufactures Qbo, a versatile processing system capable to cook, cool down, concentrate, refine and vacuum-process any food product. Qbo is a complete, compact and patented transformation system that integrates different machines into a single process.

Via Mazzini, 1 - 40010 Bentivoglio (Bologna) Italy

Tel. +39 051 892483 - Fax +39 051 893 162 www.roboqbo.it - info@roboqbo.com

It’s an all-in-one system that lets you introduce all of the ingredients in one step. This is a radical break with old methods,bringing down the number of stages to one single uninterrupted cycle. It’s a one-for-all system because it meets the needs and demands of whoever uses it, and because it can be adapted to multiple fields of application. Qbo can replace traditional equipment such as dough kneaders, stand mixers, stoves, cookers, ball mills, cylinder mills, pasteurisers, concentrators, candying machines, emulsifers, turboemulsifer mixers, tilting frying pans, mills, granulators.

The revolutionary technology and the wide range of models from a capacity of 5 to 860 liters, make Qbo an essential ally for those operating in the food industry, as it meets all production needs.

Thanks to its extreme versatility, Qbo is ideal for sectors such as pastry, confectionery industry, chocolate, ice cream, gastronomy,catering, food processing, ready meals and dairy

It is a technological tool available in its 4th generation with a large 10.1” touchscreen display as well as an easyto-use interface with advanced control functions of the production process and automatic cleaning.

Made of Inox Aisi 316L., Qbo comes with a microserrated blade knife, bowl scraper, speed control, PLC and software, pressure cooking and cooling system, automatic steamjet cleaning program to clean concealed parts and the lid, pneumatic extrusion to deliver the product and automated ejection system for fluid and semi-fluid products, ingredient loading hopper from the lid, inspection window

with glass wipers, lighting inside the bowl for direct control of the process, complete vacuum system, automatic bowl tilting movements, opening and closure of the lid, steam generation, compressor, USB port for updates and technical support.

Qbo is perfect for all professionals and for anyone who is constantly looking for the highest quality without compromising on creativity,full efficiency and technological innovation.

Popping machine RP-EVO: Re Pietro’s innovation for the production of cereal cakes and no-fried snacks

Popping machine RP-EVO is the press of the latest generation manufactured by Re Pietro Srl to produce both cereal cakes and no-fried snacks, products that following a worldwide trend are having a constantly increase in demand. With this new press, the highly innovative attitude of Re Pietro Srl is setting new standards in cereal cakes and snacks production, by offering one solution that will revolutionise and simplify the manufacturing of these products. In fact, once the mould has been chosen and installed, the popping machine RP-EVO transforms the cereals and/or the micro-pellets into fragrant cakes or crunchy snacks. Its efficiency and flexibility allow to have a wider range of products, using one press only. Nowadays these products not only are appreciated as healthy alternatives to conventional bread, but they are also valued for their versatility by professionals and consumers: they are perfect as carbs supply during meals, as crunchy snacks for a quick bite or as fancy decorations to dishes and desserts.

You may wonder how many moulds and which shapes can allow you to produce both cakes and snacks with the new press. Round big and small, round with ridges, triangular or square, hexagonal and rectangular just to name a few. But Re Pietro can also produce customised moulds based on the customers’ requests.

Popping machine RP-EVO – focus on

Structure in nickel coated steel, certified food contact material, electric panel in stainless-steel with a side rotating and swivelling touch screen control panel set at eye’s level for easier use.

Equipped with a hydraulic system that produces the high pressure needed for the expansion of the cereals or micropellets turning them into fragrant cakes or crispy snacks. The volumetric dosing is carried out by a pneumatically operated feeding plate. The moulds which shape the popped cakes and snacks are made by hardened steel coated with titanium nitride, to guarantee solidity and a long-lasting life, and to prevent

Via G. Galilei, 55 - 20083 Gaggiano (Milano) Italy Tel. +39 02 90 85 025 info@repietro.com - www.repietro.com

the sticking of the products on the moulds. The moulds, as well as all the parts that get in touch with the products, comply with the MOCA specification for food processing machines as per Reg.No.1935/2004 CE (MOCA compliance).The upper and lower moulds are heated by cartridge heaters separately controlled by thermoregulators. Each press has got its own PLC (Siemens S7-1200) and 7” control panel. From the HMI it is possible to set up each production phase, to save the recipes and check any malfunctioning thanks to its efficient diagnostic system. Popping machine RP-EVO is another milestone in the production of Re Pietro Srl, where the manufacturing of food processing machines and plants has always been approached with an eye to innovation and development, relying on 90 years of solid experience. In fact, the company, surrounded by paddy fields in the southern outskirts of Milan, celebrates this year the 90th anniversary of the great intuition of its founder Mr. Carlo Re, who saw the potential of rice and its processing. Without forgetting the incredible added value of the Made in Italy quality.

PND: A new system for processing pineapples in Taiwan

The pineapple offers an increasingly segmental product, which lends itself to both fresh consumption and other types of processing.

PND, a leading manufacturer of fruit-processing machinery, is working tirelessly to install a dedicated pineapple processing plant in Taiwan by June.This system, which can process up to two and a half tonnes per hour, employing a

Via Brancaccio, 11 - 84018 Scafati (Salerno) Italy

Tel. +39 081 850 93 68 info@pndsrl.it - www.pndsrl.it

total of only 9 operators, is composed of two machines: the PL4D peeling-coring machine and the SS8 cutting machine. The intuitive, user-friendly, manual-feed, semi-automatic PL4D peeling-coring machine has a productive capacity of 24/28 fruits per hour. The double-adjustment product and blade rotation enable all fruits to be peeled, even if they are uneven and irregular, achieving a 55% yield, without affecting their nutritional and organoleptic integrity. The machine is equipped with two conveyor belts; one for the peeled product and one for the rejects, with inspection and product certification counters, and a reject chute. Its foodgrade stainless steel structure also guarantees maximum durability and hygiene in the processing area.

Aligning perfectly with the PL4D, the SS8 universal segmenting and cutting machine guarantees the production of 40 fruits per minute.This is a semi-automatic machine, which enables quality cutting, in various shapes (slices,wedges,cubes,depending on production demands) and sizes, made possible by the option to replace cutters and plungers. The operator only has to load the fruit, as the automatic mechanism pushes it through the cutters, producing the desired form, which is then collected on the appropriate output belt for packaging.

While one of the first systems in Taiwan, this is not an innovation, as the pineapple production lines have already been tried and tested by several customers around the world (Australia, Europe, America, India, Asia and Africa);

in fact, PND boasts more than 170 of them for peeling pineapples and melons.

With impressive versatility, ease of use and integration into production processes, effective and fast maintenance and customer care, it not only reduces costs, but also improves results. Thus PND, with its tailor-made processing lines, has succeeded in winning the trust of industry technicians and customers alike, who appreciate its machines as irreplaceable business partners.

You can visit the websitewww.pndsrl.it to consult the machinery catalogue and view the equipment lines available, as well as the international trade fairs in which the company will take part.

For further information: info@pndsrl.it

Omag, your partner for primary and secondary packaging for over 50 years

Since 1973, Omag has been designing and manufacturing customized packaging machines for the packaging of powdery, granular, liquid and solid products in sachets and single-dose stick-pack dedicated to the food, cosmetic, chemical and pharmaceutical sectors. The product range is very wide: starting from limited size packaging machines useful for laboratory tests or new product launches to complete packaging lines for high productivity.

Dedicated technologies for the food sector

Omag’s offer for the food sector consists of a wide range of packaging machines - horizontal or vertical, continuous or intermittent motion - according to the customer’s specific production needs. In fact, packaging machines can be equipped with different dosing systems for powdery, granular, liquid and pasty products, combined with robotic counting systems, cartoning machines and a wide range of optionals such as markers, smart cameras, sensors, etc. At the technological level, issues concerning technology and augmented reality remain focal points to which much of the R&D investment is devoted.

In addition, Omag is testing and implementing predictive maintenance processes on packaging machines: thanks to IoT technologies, remote control and machine interconnection, in the very near future it will be possible

Via Santi, 42/A - 61012 Gradara (Pesaro e Urbino) Italy Tel. +39 0541 950854 commerciale@omag-pack.com - www.omag-pack.com

to constantly monitor the performance and status of packaging machines, receive specific information on individual machine components so as to intervene more effectively at the customer’s premises and zero in on the risks of downtime.

Customer at the center: Omag as a reliable allaround partner

An important novelty concerns secondary packaging:Omag used to supply complete lines by working with partners, while now,thanks to continuous investment in research and development and favorable tests on different prototypes, Omag is finally able to offer a complete 360° solution, from primary to secondary packaging

Omag wants to be a reliable partner for the customer, able to offer a complete,easy-to-use and intelligent solution that allows monitoring all parameters and intervening - even

remotely - to solve any anomalies. In this way, production is continuous, downtime is minimized, and losses are minimized.

My-O: new Omag’s dedicated customer portal

With the aim of offering the best customer experience, the brand new My-O portal was launched in recent months. This is an online reserved area and accessible to Omag customers that allows them to consult the documents of their machines and lines, from certificates to machine manual, from electric and pneumatic schemes to spare part list, organized by contents and by machine models.

In addition, customers can view the 3D of the machine making easy the spare parts offer, in a secure way and with the 24-hours support of the Service Omag.

Visit www.omag-pack.com to be always update with the latest news and events.

Via del Santuario, 41 - 12045 Fossano (Cuneo) Italy

Tel. +39 0172 69 25 79 - Fax +39 0172 69 25 78 info@vdlolocco.com - www.olocco.eu

Olocco Srl has been manufacturing valves and components for pneumatic conveying and metering since 1950. Its valves are used in the feeding, unloading and pneumatic conveying of any kind of product in grain or powder, in the food, chemical or plastic industry, with low, average, high-pressure lines. Olocco’s commitment has always been characterized by constant research from design to production of valves and accessories, ensuring the manufacturing of products at the top technical specifications, quality and safety. In recent years, the production department has undergone a profound renovation with the commissioning of new machining centres equipped with the most modern, flexible production systems, with high levels of automation for the handling of pieces, pallets, tools. New milling, boring and turning

centres have produced a great increase of internal manufacturing capacity and brought our quality standards to ever-higher levels. During the last years, despite the difficult situation caused by the pandemic, Olocco has been able to complete the construction of the new office building and assembly department. All this demonstrates the will to grow and bet on the future.

In 1997,Olocco Srl obtained the quality certification UNI EN ISO9001:2015 and afterwards certified most of its products according to ATEX Directive 2014/34/EU. In 2007, it so started manufacturing rotary valves in accordance with EN15089:2009, the European Standard that describes the general requirements for explosion isolation systems. Olocco Srl is also able to guarantee the food compatibility of the materials used in the manufacturing of any valve, in compliance with the provisions of EC Regulation No.1935/2004 concerning materials and objects in contact with food products (MOCA), and the EC Regulation No.2023/2006 on good manufacturing practices.

Due to the increase in demand for stainless steel components, the manufacturing of a new range of rotary valves, “UPH”, entirely built in AISI316 stainless steel, with unified round flanges according to UNI PN10 / DIN2576 standards, in the sizes from DN150 to 300 and flow rates from 3 to 37 litres/rev, is at an advanced stage. These valves will be also available in the quick disassembly version with extraction bars, “SMD”, typically to ensure the safety of the operators, to facilitate cleaning and general maintenance, inspection tasks or where rapid cleaning times are requested. A fully disassemblable rotor gives the possibility to clean it separately and remove any deposit. In advance inner surfaces can be completely polished and blended to meet the strictest hygienic standards in food, chemical and pharmaceutical industries.

Via Massarotti, 76 - 26100 Cremona - Italy

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92 info@ocrim.com - www.ocrim.com

The company OCRIM, headquartered in Cremona, is globally renowned as a reliable partner for the construction and supply of milling, feed, and cereal processing plants, as well as end-of-line plants. Its commitment in research, customer care, training and communication has always been an incentive for innovative and productive teamwork.

In Cremona, Ocrim boasts two large sites, due to the ever-increasing insourcing of processing: The original headquarters in Via Massarotti, which houses offices and parts of its production factories, and the premises at the industrial area of the city for some important production and logistics departments, and not far, there is also the Milling Hub created jointly with Bonifiche Ferraresi, is meant to strengthen Italian agro-food supply chain by offering food industries without milling plant the chance of using a customized plant, as well as the technical and technological knowledge of OCRIM team.

Turnkey projects are one of OCRIM’s strong points, supplied in tailor-made solutions, increasingly welcomed by international customers who decide to rely on a single partner who can guarantee a high professional level and respect programmed time. OCRIM is an irreplaceable partner also for the supply of machines only, and in milling plant upgrade/modernization.

The FBC department designs and manufactures end-ofline plants for palletization and packaging of bags and other packing, supplied turnkey and personalized upon customer’s requirements. Today, it is fully integrated in OCRIM and further piece to complete the industrial chain, which means internalizing all processes, thus

guaranteeing a traced, controlled, and certified Italian Made product.

OCRIM’s versatility and seriousness have been further highlighted at the beginning of 2024, thanks to the acquisition of the company SIMA of Treviso, specializing in storage system design and construction for more than thirty-five years. All that grounds on shared values, such as honesty, reliability, team feeling and availability, and above all, attention to Human Capital.

OCRIM has always been an attentive and well-prepared supplier of storage plants,and this partnership adds further and crucial element not only to“The ItalianAgri-Food Chain Choice”, of which OCRIM is one of the main players, but also to the increasingly complete production chain.

OCRIM’s reliability is also evidenced by an important agreement reached with Italian company Molitecnica Srl, to build nixtamalized flour plants for tortilla, snacks and chips production.These products are mainly part of Central and Southern America’s food culture, but also highly appreciated and consumed all over the world. OCRIM will supply its process machines for these plants, thus guaranteeing high performance in line with the targets set. With the goal of supplying long-lasting milling plants and efficient high-quality services, OCRIM proposes increasingly innovative solutions in terms of sanitation, reduction of energy consumption, maximization of technological results of the plants, and reduction of operating and maintenance costs down to the minimum.

In fact, as for strategies and management related to maintenance and improvement of technological results, OCRIM has introduced the Modular Mill Concept, an innovative technology that enables stopping some parts of the grinding section, for any reason (ordinary and extraordinary maintenance, or else), while letting another run, thus granting uninterrupted specific production. This solution is chosen and highly appreciated by many customers thanks to the benefits it generates.

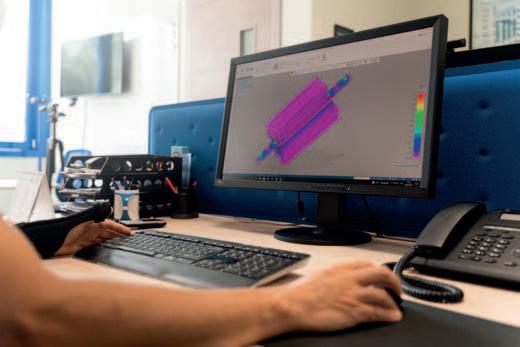

As far as automation is concerned, OCRIM plays the role of direct reference, thus avoiding external bodies for the study and implementation of plant management systems. The general automation package @mill, which includes many application packets, the innovative @rollermills, which enables controlling the mills remotely via tablet, and the Immersive Reality are futuristic solutions created to improve and simplify the work activities of those in the milling sector.

Inaddition,OCRIMalsooffersitscustomerscomprehensive support with its innovative Service, and its customers can be granted specialised after-sales technical support in real time, and can easily and quickly require their own. This state-of-the-art approach to customer service sets this company apart in the milling industry, offering timely and customised solutions for every need.

OCRIM also excels in terms of training and higher education, in fact,thanks to the extensive training experience of OCRIM International School of Milling Technology, active since

1965, and in line with the Milling Hub initiative, the Milling Hub Masterclass training hub has been established. This hub enriches the training with an innovative perspective. Access to the Masterclass is reserved to previously trained technicians only, with proven expertise, as to guarantee a high-degree training. 360° advanced training focusing on the knowledge of seeds, through cereal and pulses processing, to finished product sales.

On account of this corporate positive development, OCRIM’s R&D department is committed to experimenting new strategies and state-of-the-art projects can be broadly acknowledged as unique in the milling sector and in full harmony with the innovation the company has been experiencing. The partnership between OCRIM and some prestigious Italian universities is further strengthened, broadly contributing to get valuable results for the milling sector in general.

OCRIM’s communication instruments mean to finetune the corporate language to the new trends.

The company boasts considerable visibility through both national and international sector publications, via its LinkedIn and Instagram profiles, and three Internet websites: the corporate website www.ocrim.com, one dedicated to the company’s museum www.ocrimcore. com, one dedicated to the blog www.ai-lati.com, strongly wanted by OCRIM as a real information provider for the entire The Italian Agri-Food Chain Choice chain, and therefore for its member companies.

In 2020, the company’s media department was greatly and successfully developed with the start of highly technical-scientifical Webinars into the milling world. Yet, the real novelty arrived at the end of 2022 with the new format O-News Live, a TV news hosted by three OCRIM employees, whose stage is the new O-Theatre, a space that OCRIM strongly wanted for events like this, as well as for meetings with customers. In addition to this, OCRIM also continues offering its customers tailored solutions featuring customized machines, participates in events such as “Wheat, flour, and …”, and welcome its guests at O|HOUSE, a historic residence in the center of Cremona, and at O|FARMHOUSE,a farmstead typical of the Cremona area, renovated and inaugurated on occasion of the company’s event “Wheat, flour and …” 2022). Those are the events and projects created to provide a close-up view of a company that is continuously and constantly evolving.

Via Massarotti, 76 - 26100 Cremona - Italy

Tel. +39 0372 40 11 - Fax +39 0372 41 26 92 info@ocrim.com - www.ocrim.com

Superior – the compact mill by OCRIM

Superior is a compact mill representing a strategic and smart investment that offers safe and versatile productive solutions for an excellent final product.Pre-assembled at OCRIM warehouse, Superior reduces the costs of a dedicated multi-level building and bureaucracy expense for urbanization works, and offers high energy performance for reduced production and management costs.

Meant for customers with different entrepreneurial courses,Superior is suitable for people approaching the milling world for the first time as well as for those who want a compact plant to extend or diversify their offer, without revolutionizing their industrial production.

Create in the 1950s, Superior is a state-of-the-art engineering icon that has highly contributed to OCRIM’s industrial development internationally.

The mill offers the possibility to personalize its technical, technological, and design equipment, with four different solutions available: Passion, Natural, Gold, and Style. Back to OCRIM home in a futuristic shape, from the technological and design points of view, Superior has generated great interest and significant demand, as to persuade OCRIM to create dedicated Internet website (www.ocrimsuperior.com) and e-mail address (info@ ocrimsuperior.com) for information and request, accompanied by a as well as a brochure that fully conveys the elegance of this compact mill.

OPARTS: Ocrim’s world is just a click away OCRIM launched the innovative platform www.oparts-shop.com, an e-commerce portal with interactive catalogues where spare parts for milling plants can be bought.

The entire website has been designed with the customer in mind.The aim is to ensure the best user experience in terms of ease of navigation, speed, and intuitiveness. The is available worldwide and allows customers to directly purchase milling products 24 hours a day via certified international payment circuits.

The portal is structured in two parts: a B2B e-commerce platform for the immediate and direct purchase of milling plant articles, and a customised section for loyal customers with interactive catalogues. In the latter area, the user’s machine catalogues are uploaded for browsing, with the minimising the chance of error when searching for a specific component.

Thanks to this portal, with just a few clicks, the user can choose and order the spare parts he needs for his machine, by selecting them directly from the table and order, and also find dedicated promos in the “My Area” and keep track of requests and orders at all times.

For more information visit www.oparts-shop.com or e-mail to info@ocrim. com for more details and to receive a brochure about this service.

Founded in 1926, Novacart is the biggest company operating the full-cycle production of paper and cardboard products for confectionery and food sectors, with production of millions of moulds and boasting branches all over the world.

Novacart has always stood out for the quality,sustainability, and versatility of its products, registering more than 100 patents out of the will to develop solutions able to fully meet market’s requirements, from craft confectionery to industrial.

Novacart’s experience in the food and confectionery industry enables offering tailored solutions and an allround service, to meet specific requirements and particular needs; The R&D laboratory is at the customer’s disposal to select the best material and design ad-hoc products, from mould creation to the supply of automatic spraying lines.

Some Novacart products for the industry, and don’t call them packaging!

NTS baking trays are the Novacart’s international patent ideal for automatic spraying lines: A system of trays with cups in paper or cardboard suitable for oven high temperatures, freezing and food fats. They do not need to be buttered before use and require shorter baking temperature and times. In addition, the trays also feature hatches for easier cutting of the portions for packaging. Tulip Cups and cases are made in paper resistant to high temperatures in ovens up to 220°C, freezing down to -40°C, and they do not need to be buttered. Cases and Tulip Cups can be used in industrial environments: Inserted in classic metal pans, in reusable cardboard supports, and in automatic spraying machines.

Baking methods and PM moulds are in corrugated microwave paper resistant to baking temperature to more than 220°C.The design of Novacart baking moulds is wellfinished and elegant, studied to enhance the product, and makes any additional presentation element superfluous.

Zona Industriale - 73043 Copertino (Lecce) Italy

Tel +39 0832 931184 / 935458

info@newplast.eu - www.newplast.eu

Founded in 1984, New Plast is a national and international leader in the production of innovative, sustainable and eco-friendly packaging for:

• Food Industry and non

• Packaging resellers

• Hypermarkets and cash & carry.

Manufacturers of high-quality vacuum pouches, New Plast bags are ideal for professional and domestic use and are suitable for storing fresh and processed foods such as meat, cheese, fish and vegetables.

New Plast vacuum pouches are made from up to 11 layers in PA/PE that provide a high barrier, extend shelf life and ensure food preservation and hygiene.

The wide range, available from stock in over 150 sizes and different thicknesses, ranges from smooth and embossed to cooking vacuum pouches.

In addition, the company is able to satisfy any customer requirement, including the possibility of private label production.

New Plast boast also the production of BOPP and PP bags, square bottom bags and compostable bags.

Moreover, it converts multi-purpose baking paper for professional market, silicone-coated on both sides, fully recyclable and biodegradable.

The high quality of production, customers satisfaction, workplace safety, energy efficiency, environmental

protection, the compliance with the Good Manufacturing Practice (GMP) are the core values of New Plast business. In compliance with the requirements of BRC Global Standard, New Plast scrupulous traceability system tracks every raw material in all the phases of the production process, ensuring the quality and the integrity of its products from manufacturing to customer satisfaction. Indeed, its production department is staffed by trained and competent personnel who ensure the quality and the integrity of the products.

New Plast exhibits at the most important international trade fairs, such as Pack Expo Chicago, Pack Expo Guadalajara, Iba, Innovation Packaging Birmingham, Gulfood, IFFA, ProPack Africa, Fachpack, Scanpack and Qazpack in order to keep up with the market, learn about new consumer trends and retain new customers. Understanding, meeting and solving customer needs is New Plast philosophy.

For New Plast, every milestone represents a new starting point!

Zona Industriale - 73043 Copertino (Lecce) Italy Tel +39 0832 931184 / 935458 info@newplast.eu - www.newplast.eu

Via Virginio, 252 - 50025 Montespertoli (Firenze ) Italy

Tel. +39 0571 671661 - Fax +39 0571 671636

info@moelsrl.com - www.moelsrl.com

Moel® is an Italian company located nearby Florence, specialized in the production of PVC based plastic films

Located in the Tuscan countryside in an area of 15,000 sqm and with yearly capacity of 7,000 tons of stretch, cling and shrink film, Moel srl is leader in the production of flexible packaging films for food and non-food wrapping. Decades of experience in flexible packaging film production allow this company to offer a large range of high-quality films.

All films manufactured by Moel Srl are extremely performing, very easy to use and are the result of long experience and technical knowledge gained in the sector of flexible packaging.

Moel Srl production is guaranteed through extremely accurate checks during the several steps, from the early arrival of raw material to the final delivery of the goods to the customer. Moel R&D department follows and checks day by day the outcoming production, certifying the highquality standard of the rolls.

Almost half Moel’s capacity goes to export market, that’s why this company is well-trained in export procedures. It delivers the goods all over the world, such as in Europe, Asia,Africa, DROM-COM countries, etc.

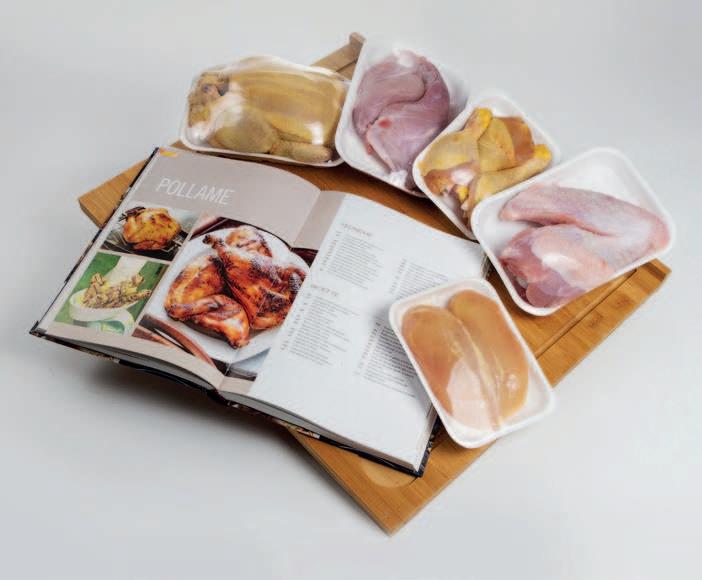

Stretch and cling films manufactured by Moel Srl are destinated to the food sector packaging: Fresh meat, poultry, fish, fruit and vegetables, ready meals and more. The high stretchability, self-adhesion, memory effect and antifog properties are the main features.

AllMoelfoodcontactfilmsarerecyclableandmanufactured in compliance with EU REG. 10/2011.

Shrink films PVC based and polyolefin based manufactured by Moel are destinated to non-food and food packaging sectors. The unbeatable shrink speed at low temperatures permits a higher productivity with energy saving. Transparency and brightness typical of these films assure an excellent product presentation.

Last February 2023, Moel Srl also got ISO 9001:2015 certification.

If you are looking for a long-term reliable partner, Moel is at your complete disposal!

Via Virginio, 252 - 50025 Montespertoli (Firenze ) Italy Tel. +39 0571 671661 - Fax +39 0571 671636 info@moelsrl.com - www.moelsrl.com

Via Martin Luther King, 12 - 35010 - Curtarolo (Padova) Italy

Tel. +39 049 96 24 258 - Fax +39 049 96 23 823 info@me-foodsolutions.com - www.me-foodsolutions.com

Millennium Engineering redefines the food industry

These years have brought the company recognition for its expertise in stainless steel processing, primarily focusing on AISI 304 steel. The company’s exceptional precision in metal sheet and tube laser cutting, punching, welding, and bending has been pivotal in forging significant partnerships for the manufacturing of food machinery. Their cutting-edge systems cater to various stages of food processing, including deep-freezing, cooling, leavening, pasteurizing, and conveying. With over 25 years of extensive research and development, ME Food Solutions has proven itself to be an innovative and dependable company. Additionally, its global distribution network, adept at facilitating the parent company’s ventures in the international market, attests to the company’s esteemed reputation.

ME is glad to offer customers the most suitable solutions for the entire factory line, starting from components preparation and finishing with packing and storage. A wide range of solutions for freezing, cooling, leavening, pasteurizing, and conveying are available. All systems are designed with the aim to provide customers with the best solution improving their business in terms of quality, safety, and hygiene. Every system is designed considering mechanical and thermodynamical aspect and considering the special features of the processed food.

Bread and bakery products have always held a special place in our lives. They are not just food items, but symbols of tradition, comfort, and nourishment. From the crispy crust of a freshly baked baguette to the soft texture of a warm croissant, bakery products have the power to evoke memories and bring people together.

In the bustling world of bakery production, precision and efficiency are key. ME Food Solutions understands the importance of quality bakery products in our daily lives. That’s why it is dedicated to providing the best services in the food industry market to help its customers produce the finest bread and bakery items.

When you choose ME Food Solutions,you can be confident that you are receiving the best equipment designed and

manufactured by its team of experts. Engineer Luca Priore leads the design process, working closely with the Technical and Development Departments to ensure that each installation meets the client’s specifications. Within a few months, the equipment is ready to be tested and put into operation, allowing customers to create the best bread and bakery products possible.

So, if you want to take your bakery production to the next level, choose ME Food Solutions. With its high-quality equipment and dedicated team, you can be sure that your customers will enjoy the finest bakery products every time. Let ME Food Solutions help you make delicious bread and bakery items that will leave a lasting impression on everyone who tastes them.

From the initial design phase to the installation and operation of the equipment, ME Food Solutions will be by your side to ensure that everything runs smoothly and efficiently. Its experienced team is always ready to provide support and assistance, making sure that your production process is optimized for success.

Once the work is completed and the equipment is up and running, ME Food Solutions offers a convenient service that allows its clients to remotely control and monitor the entire production process. Through innovative technology clients can access real-time data and insights from anywhere, allowing them to manage their bakery operations efficiently. Consequently,this feature gives you the flexibility to manage your production line from anywhere,providing you with realtime data and insights to make informed decisions.

With ME Food Solutions, you can trust that top-quality equipment is provided and advanced solutions offered to enhance the efficiency and productivity of your bakery production. Let ME Food Solutions help you take your bakery business to new heights and achieve success in the food industry market.

Millennium Engineering, a leading manufacturer of spiral conveyors for the food industry, delivers cutting-edge solutions built on a deep understanding of technological processes and customer needs.

Complete control, uncompromising quality: Unlike most competitors, Millennium Engineering designs and

manufactures its own conveyor belts.This not only ensures exceptional quality at every stage but also provides comprehensive knowledge of material properties and characteristics, unattainable for those relying on third-party components.

Unmatched flexibility and adaptability: Utilizing an external drive instead of a traditional drum mechanism unlocks unprecedented possibilities. Millennium Engineering constructs spiral conveyors in a variety of shapes and configurations, perfectly tailored to each customer’s unique requirements and production specifics. Strength and reliability redefined: At the heart of Millennium Engineering’s conveyor belts lies the Genoa chain, boasting 25% greater strength compared to counterparts used by competitors. This guarantees uninterrupted equipment operation under heavy loads and extends the lifespan of the conveyor system.

Three-in-oneefficiency: EngineersatMEFoodSolutions,a division of Millennium Engineering, have developed a unique spiral conveyor configuration featuring three independent belts moving within a single housing.This unlocks previously unimaginable possibilities for food manufacturers to optimize and accelerate their technological processes.

Millennium Engineering represents:

• Cutting-edge technology: In-house belt production, innovative design solutions.

• Personalized approach: Flexible conveyor configurations tailored to individual customer needs.

• Unsurpassed reliability: High-strength materials, extended service life.

• Maximum efficiency: Unique solutions for production optimization.

Choose Millennium Engineering, choose the future of food production!

MIllennium is already conducting large projects in Arab countries. One of the major projects is a collaboration with Salalah Mills Co.

High efficiency in a packaging line is the primary objective of any project manager, when he begins the design phase. In the present days packaging machines have reached performance levels that were unthinkable just a few years back, but as much as a single machine can be efficient, the overall result when you put all the pieces together can be extremely different.

The first result of a Google search with the keywords “Buffering System” is a Wikipedia page on the pH balancing system of the blood that is needed by the human body to maintain the proper functioning of the metabolism.

A packaging line behaves in a very similar way, the different machines need to be connected to each other by an efficient circulatory system and that is able to balance the operating differences that may exist between them. Conveyors represent this circulatory system and are too

Via G. di Vittorio, 3 - 20826 Misinto (Monza Brianza) Italy Tel.+39 02 96720176 - Fax: +39 02 96720215 info@mhmaterialhandling.com - www.mhmaterialhandling.com

often underestimated in the design phase with dramatic results on the final efficiency of the line.

Buffering systems,ensure that the packaging line operates smoothly and efficiently. They are able to compensate for any variations in the speed or performance of individual machines, preventing bottlenecks and ensuring that the entire line operates at maximum capacity. Some kind of buffering systems should always be present in the packaging line, as they can have a significant impact on the final throughput of the line. Providing consultancy in the identification of the correct solution and subsequently supplying the machines to the customer is exactly the core business of M.H. Material Handling Spa, an Italian company that has been operating in this market for almost forty years now, being founded in 1986.