NEG (Non Evaporable Getter) coatings is a critical technology to maintain the ultra-high vacuum levels required in the vacuum chambers of particle accelerators, providing an efficient and low maintenance solution to avoid residual gas molecules in the beam path, that may affect the results of experimentswith photons and particles accelerated close to the speed of light.

Tekniker and AVS, in collaboration with TVP, develop vacuum chambers and coatings for particle accelerators. The implementation of NEG coatings in the vacuum chambers can help to reduce the maintenance operations related to pumping equipment and provides a betterlevel ofvacuum helping to reduce the operational costswhile improving the qualityof the experiments.

Development, characterisation and scaling-up NEG coatings for particle accelerators

Teknikerdevelops both NEG coatings, and technology and equipment necessaryto deposit them on the inner surfaces of thevacuum chambers forparticle accelerators bymeans of the following solutions:

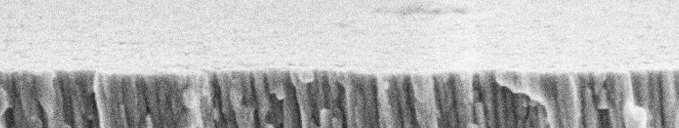

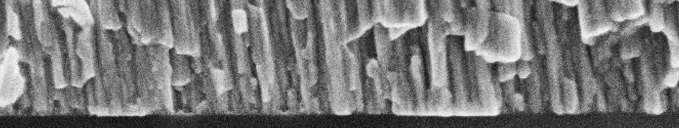

• Development and adaptation of NEG coatings to different functional requirements bymeans of deposition control to tune underdemand the characteristics of the coatings such as microstructure, composition, thickness, density, electrical resistivity, etc. on demand.

• NEG coatingswith state-of-the-art standard pumping capacities with the following characteristics:

- Activation temperature: 200ºC

-Sticking factor(H₂): 0.005-0.007

- Pumping speed: 0.21 to 0.29 l/s·cm

• Ad-hoc development of equipment for deposition and characterisation of NEG coatings,with capabilities forredesign and adaptation to scale-up according to customer requirements.

Leveraging more than 30 years of experience in the development of PVD coatings and magnetron sputtering technology, Teknikeralso offers its capabilities on design and manufacturing of equipment forcoatings deposition.

• Design and manufacturing of specialized coating deposition equipment, adapted to specific purposes and requirements.

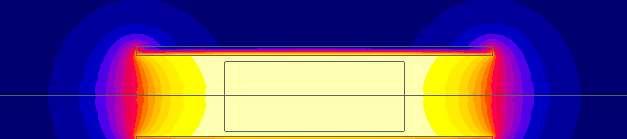

• Experience and magnetic design capabilities to adapt newsolenoids in orderto guarantee the homogeneityand intensityof the magnetic field on the magnetron sputtering processes, and therefore the homogeneityof the coatings on complex geometries.

• Design and vacuum simulation forthe deposition systems and functional characterisation supported by Monte Carlo methods.

• Design, manufacturing and ultraprecision assembly to adapt the equipment solutions to coat chambers with complex geometry.

Surfaces laboratories

Ultraprecision laboratories

Manufacturing and assemblyworkshop

Bunker for testing

Borja Coto borja.coto@tekniker.es