15 minute read

TECHNICAL TEXTILE

COVID-19: HOW ANTIBACTERIAL TEXTILE GUIDE YOU THROUGH THE DARKNESS?

NUR HANI AQILAH SALEHIN THOMAS P. S. ONG

Advertisement

In the midst of COVID-19, who would have thought this would happen. The unprecedented COVID-19. In early 2020, we were all caught off guard by an illness caused by a novel coronavirus that was first discovered in Wuhan, Hubei Province, China. Despite the fact that we are one step closer to entering the great Fifth Industrial Revolution, and the cure for COVID-19 is still being created, the war is far from over. As a result, what do we do at the very least to eliminate the virus? We ought to mitigate everything about what we wear as prevention is easier than treatment. According to a source, at room temperature, COVID-19 was detectable on fabric for up to two days, compared to seven days for plastic and metal. However, when it was exposed to high heat, the virus became inactive within five minutes.

We must adapt to the current norm in order to reduce the number of deaths and infected patients, which has crossed 124 million worldwide. To deter COVID-19, for example, the ‘new rule' that should be followed nowadays is to stop touching MEN's mouth, eye, and nose and to follow WOMEN; wash hands, obey social distancing, mask up, exercise daily, and never ignore above four lines. It is though, becoming an integral part of our lives. To adhere to the recommended procedures in order to reduce the number of sick patients. The distribution of COVID-19 cases by Ministry of Health Malaysia. Since the pandemic began to rage in early 2020, people have been concerned about maintaining their source of income, and this is not exclusive to business players, especially B2C players. Businesses who can offer their products by retail may be concerned with their sales because they are unable to open their store during quarantine. Furthermore, it may also impact the e-commerce market players due to a loss of revenue from consumers, or customers may believe it is not worth investing their money on merchandise; especially when it comes to clothing or apparel, as they might feel “what’s the point of buying a shirt for RM60 when you just sit at home?” and “why should I buy a shirt while the old shirt still can be use?” However, thanks to the nanotechnology services providers of the textile and garment industry in Malaysia, NanoTextile to save someone’s bacon in this current situation. NanoTextile offers the opportunity for business players to “invest” in functional clothing as part of their product collections, a safety and precautionary investment. NanoTextile not only has to offer in the resultant end-products in clothes design and processes; but also in business models where innovations, leading to a range of functionalities, technical offerings, and production methods. Nowadays, people and technology somehow cannot be separated, as most right now are prone to become technology-savvy. Wherever we go, we need technologies to survive. Hence, in the midst of COVID-19, it is not about the technology we hold, but the technology we wear. NanoTextile is able to make the realization of dreams, “When Fashion Meets Technology” come true. Functionalized clothing textiles are now in higher demand mainly in Muslimah fashion brand in Malasyia; precisely for antibacterial technology, which is featured in Hygienic Series; one amongst many series that NanoTextile has to offer.

Hence, the core to understanding how anti-bacterial technology works is first by understanding the meaning behind it. Anti-bacterial was classified, according to the dictionary, as anything that kills bacteria or suppresses their growth or reproductive potential. The main function of antibacterial textile is to help prevent the growth and spread of microbes from attaching tangibly on the fabric. A humid condition allows the bacterium to linger and propagate in the air roughly 45 minutes after someone sneezed. Subsequently, once

it is attached to our clothes, the embedded anti-bacterial properties help slow down the growth of bacteria by preventing the migration and microbial growth. This is further enhanced by human body sweat secretions, skin desquamation, natural particles present in the clothing fibers or on the fibers, or nutrition from elsewhere in the environment.

In a situation riddled with viruses and illnesses like Covid-19, the situation mentioned above is extremely beneficial. It is like having two layers of protection against the virus and the environment. For example, we wear a face mask that also has antibacterial properties on it. As a result, consumers would feel secure. Similarly, BioRomper, a recent start-up, debuted a single product, an antimicrobial jumpsuit. When travelling, this New York formulation was designed to avoid cross-surface contamination. It is similar to a hazmat suit, but it is more sustainable and appealing. According to L’officiel, BioRomper took five months to develop the jumpsuit as in Fig. 1, and it was sold out in just eight weeks.

Fig. 1. Bio Rompers antimicrobial jumpsuit

Additionally, anti-bacterial technology on textiles helps create awareness amongst people on the hygiene practices in clothing we wear. Nanotechnology not only shield you from bacteria and other microorganisms, it also provides the cloth with a permanent defence to combat bacteria, mould and mildew that create smell. This makes antibacterial products in textile stay fresher longer and persist, to protect against the potentially dangerous bacteria wash after wash. On a different note, in the warm and humid areas, the mould was not subject to cloth only, but it also had an effect on leather goods, mattresses, and home walls. This problem was seen in Malaysian stores as in Fig. 2. as the leather products were covered in mould after being left untouched for two months due to the strict regulations during quarantine last year. This problem also hit some of the cinemas in Malaysia as the seats and carpets had been totally ruined by the mould and dust due to poor ventilation and humidity.

Fig. 2. Mould found growing on leather products in Malaysia as businesses reopen – via thestar.my

Overall, as anti-bacterial technology on textiles is a current niche for business players in the new era of disease on Earth, it is predicted by Scott Pantel, the CEO of Life Science Intelligence, the textile market for anti-bacterial will not going into a short-term bounce at a critical juncture like this pandemic situation, but will experience longterm growth as it has been foreseen will surpass $20.5 billion by 2026. This can be seen by the anxious shoppers which makes the industrial players seek a higher level of thinking whereby hygienic clothing has been introduced. Such upgrades appeal to customers who live busy lives and as a result, affect their purchasing decisions. We do not know what will happen in the coming years, but sanitation and hygiene will always come first. Besides, with respect to this pandemic, wearers requested more for anti-bacterial textiles or apparel, such as anti-bacterial face masks, headwear, and clothing. Some individuals demanded to have a trendy but safe fabric face mask for their regular use, such as the fashion face mask of batik, satin face mask, knitted face mask and so on. Therefore, business players need to grab this chance to venture into nanotechnology in textiles. Apart from that, the commercialization of anti-microbial technology on textiles has not stopped at clothing only, but it also has been commercialized in home textile, sportswear, accessories and more. Home textile fabrics, used for home furnishing make our lives more comfortable; such as bedding, floor coverings, and towels. In addition to that, it gives us more cosiness and ease if it is embedded with anti-bacterial technology. Users or hotel management especially do not need to wash the collected towels every day as it seems to become unsustainable and waste the resources. It has been estimated in the United States by the U.S Environmental Protection Agency (EPA) that laundry accounts for about 16 percent of hotels’ water usage which can be translated to affect a significant amount of energy costs. As many hotels prefer to make the difference via conservation of water, tourists may not feel comfortable with this initiative, but with the presence of antibacterial technology, it helps to keep towels smelling better with less required washes and it will give you that “just laundered” pleasure.

Everyone feels the intensity of COVID-19, the after-effect of COVID-19, the stronger will survive and the wise one will take the chance, especially the business players. At first glance, you will see that it is not worth it to commercialize this functionalized textile or apparel; but in the long term, it will give you unbelievable benefits. NanoTextile will help you redefine your goods especially to adapt to this current situation. The need for the use of nanotechnology in this industry is motivated by the ever growing need for advanced fabrics with unique features and exceptional comfort. Hence, antibacterial technology on textiles is quite an unexceptional product in the midst of this pandemic that can give a lot of benefits and guidance to walk through the darkness of COVID-19.

AMEET KAUL

Head (Business Development), Texcoms Worldwide

Global Textile & Apparel Scenario

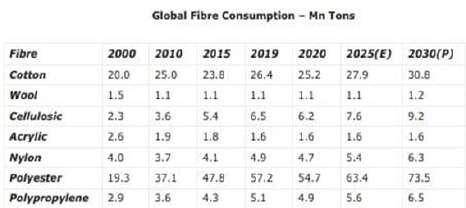

Textile and Apparel industry has witnessed significant growth over the past few decades. The global T&A trade stood at a value of 818 Bn USD in the year 2019 having grown at a CAGR of 3% over the last 10 years. Of the 818 Bn USD global trade, majority share is claimed by apparel with a total of 470 Bn USD. Fabric and yarn are the second and third largest traded categories. In terms of fibre, 2016 marked a milestone as global consumption crossed the 100 Mn MT mark and has

ANUSUYA

Research Associate, Texcoms Textile Solutions

been growing with 2019 recording consumption of 108 Mn MT. Majority of the fibre demand is met by synthetic fibres (63%), followed by cotton (25%). As per the 2020 Lenzing report, 3-4% annual demand growth is expected for synthetic fibre during the years 2019-24.

It is estimated that by the year 2030, the global fibre consumption would increase to approximately 140 Mn tons with the Man-made fibres constituting to ~108 Mn tons.

According to the Fibres Global Supply Demand report 2018 published by Wood Mackenzie, while cotton contributes only 26% of the total fibre consumption, Polyester contributes around 56%, Polypropylene – 4.9%, Nylon – 4.8%, Acrylic – 1.6% and the remaining by other fibres. The global fibre consumption growth for the period 2010 to 2020 was recorded at around 3.3% annually with the Asian countries having a higher consumption rate. The share of natural fibers, which was at 41% two decades back, has declined to around 26% now. This makes it evident that the Man-made fibres will be the mainstay for

Factors driving the growth of the man-made textiles and apparel industry globally With the increasing global population, fibre consumption is expected to rise. While the demand for cotton may also be increasing, its supply base has inherent limitations. Man-made fibres fulfil the gap and are increasingly becoming a fibre of choice.

Cost competitivity offered by MMF has also been a factor in boosting its adoption by the industry. Changing attitude towards traditional textile products and increasing acceptability has contributed to increasing consumption of MMF based textile products and apparel. As the global consumer mood shifts towards sustainability and circularity, MMF’s unlimited recyclability adds to its overall appeal. Lastly the versatility of MMF in end-use categories such as sportswear, leisurewear, women dresses, home textile, automotive, carpets and other industrial sectors makes it an ideal ‘fibre of the future’.

Bangladesh’s MMF Textile & Apparel Industry

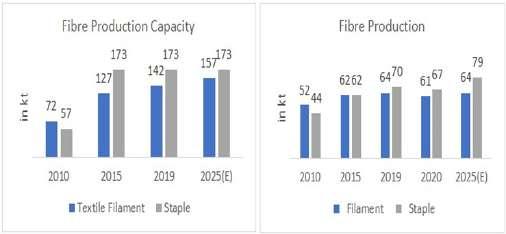

Bangladesh has established itself as a strong producer in the Ready-made garment sector with more than 4600 garment factories operating. In the spinning sector, around 430 mills are operating out of which only 27 mills are producing man-made yarn, in particular polyester. The production facilities for other man-made fibres like polypropylene, nylon, acrylic etc. are yet to be established in Bangladesh From the Wood Mackenzie Chemicals report 2018 and TTS analysis, the textile mill consumption of polyester staple fibre and filament in South Asia* has increased over the past decade. At the same time, it can be noticed that the actual production of polyester staple fibre and filament is only half of the production capacity in Bangladesh. There is still untapped potential for the production of man-made fibre in Bangladesh if it can utilize the existing resources and build on it.

MAN-MADE APPAREL EXPORTS

the leading apparel suppliers, second only to China. The growth of the Bangladesh textile and apparel industry has been tremendous owing to factors such as vast workforce, lower energy and power cost, etc. Bangladesh’s apparel exports have increased from 27 Bn USD in 2015 to 41 Bn USD in 2019 with a growth rate of 11% over the years 2015-2019 while the textile exports have seen a growth of 2% over the same period. Bangladesh’s man-made apparel exports are low when compared to the cotton apparel exports. In the year 2019, the global man-made apparel trade stood at around 179 Bn USD with Bangladesh holding approx. 5% market share. At the same time, Bangladesh market share was close to 15% in the global cotton apparel market of 199 Bn USD.

Interesting to note that Bangladesh being very strong on the garmenting part of the value chain can easily pivot to making high value garments.

Bangladesh’s Exports Share in Global Man-made Apparel Trade

Trade value in Bn USD. Categories arranged in descending order of Global trade in 2019. *BD – Bangladesh

Source: ITC Trade map, TTS Analysis

From the secondary research conducted, it is clear that Bangladesh’s share in the Global Man-made apparel trade keeps on increasing over the years. Bangladesh has established a strong presence in the category of sweaters, having a share of 11% in the year 2019.

Opportunities and Growth Potential

As the consumption of man-made fibre is increasing globally, Bangladesh needs to increase the number of factories dedicated to the production of man-made fibre textiles and apparel so as to increase its exports in this sector. Out of the 433 spinning mills in Bangladesh, only 27 spinning mills are producing man-made yarn. The production from the mills can meet only 20 percent of the national demand for the product. If Bangladesh can invest in the backward linkage of the man-made textile value chain, it has the opportunity to capture the remaining 80% of the demand. Currently, countries such as China, Viet Nam, Indonesia, South Korea, Thailand etc., are leading the man-made fibre production. The export of apparel items produced from man-made fibre (MMF) from Bangladesh has remained stuck at 20 percent for many years although the production of such garment items has crossed 40 percent worldwide, according to a study of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA). Though it is stuck at 20%, Bangladesh has the potential to pivot to the production of man-made fibre based textile and apparel thus realizing greater per unit values. The government should also ease the rules to attract FDI to man-made fibre textile and apparel production as the country has very low capacity in this segment. Recently, the Government of Bangladesh has planned to diversify the apparel export basket and strengthen its backward linkages industries by extending the tax holiday facilities for the manufacturing of man-made fibres.

According to the Chairman of BTMA, in order to utilize the tax holiday advantage to the maximum, the government should also allow importing the raw materials under a duty-free facility. Otherwise, the cost of production will be higher. This move was very much welcomed by the entrepreneurs and business leaders as this would help in attracting more foreign direct investments in the apparel sector.

Given the business scenario globally vis-à-vis the COVID-19 situation and the growing apparel sourcing diversification, the time is opportune for the industry in Bangladesh to invest in the Man-made fibre textile Industry and take the leap to up the value chain.

NEWS

India, Bangladesh underscore the need for removal of non-tariff barriers

Prime Ministers Narendra Modi and Sheikh Hasina recently emphasised the importance of removing non-tariff barriers, upgrading infrastructure and facilities of land customs stations and land ports in a coordinated manner, and harmonising standards and mutual recognition of agreements and certificates to improve trade between India and Bangladesh. Modi visited Bangladesh on the 26th and 27th of March at Hasina’s invitation to participate in the celebrations of Bangladesh’s golden jubilee of independence and the birth centenary of the country’s founder, Sheikh Mujibur Rahman.

Bangladesh has asked India to lift its current customs policy requiring the verification of certificates of origin issued by Bangladesh. In the event of a dispute between a clause of the new customs rules and the rules of origin of a trade agreement, India stated that the provisions of the trade agreement’s rules of origin would take precedence. India reiterated its request for at least one major land port on the border with the North Eastern region of India, with no port restrictions or a negative list of restrictions, for easier market entry, beginning with the integrated check post at Agartala-Akhaura. According to an official statement, the Bangladesh Standards and Testing Institute (BSTI) and the Bureau of Indian Standards (BIS) will cooperate on capacity building and the construction of testing and lab facilities. Bangladesh invited Indian companies to invest in jute mills through a publicprivate partnership, while India urged Bangladesh to end practises that exclude Indian firms from bidding on tenders issued by various government departments.