LEADING THE INDUSTRY FOR OVER 70 YEARS IN PRINT | SPRINTER.COM.AU

NOVEMBER 2022

Women in Print: Julia Van Der Sommen People in Print: Romeo Sanuri AP’s extensive review of Printing United 2022 The key role of consumables in print

Cyber and RMGT introduce new products

Please pass on our thanks to the team for the quality and service for both prints this week. Arrived on time and in good shape which is a pleasant change from some of the jobs we have received from other places.

Kevin

Thank you for having this order completed so promptly, the print quality is faultless and the blind shipping is very much appreciated

Donna

Great job on the books - client is stoked! Thanks again for suggesting the extra laminate -it really made a huge difference! Appreciate it!

James

I just wanted to say thank you for rushing those 2 banners through for me, I really appreciate how quickly you made that happen, pretty amazing service.

Kelly

The postcards were delivered to them this morning and the client is impressed bordering on disbelief. Not sure exactly how you and the team did it all so fast but thank you.

Tom

Loving the magnetic boxes the velvet cards come in, a great way to present the card to the client.

Sarah

o ^Queen

‘CUSTOMER IS KING AT HERO PRINT’ ...AND

IT SHOWS

AUSTRALIA’S BEST TRADE PRINTER

GAINING RESULTS WITH PREMIUM CONSUMABLES: How Ball & Doggett delivers consistent, repeatable results

KEEPING PRODUCT RANGES RELEVANT IN CONSUMABLES: Currie Group addresses how consumables can be worked to their optimum

4 | AUSTRALIAN PRINTER NOVEMBER 2022 SPRINTER.COM.AU

CONTENTS ABC Copier Solutions 50 Admag 55 All Work Crane Services 10 Allkotes 10 Ball & Doggett 35 Bottcher Australia 49 CTI Colour Printer 50 Currie Group 37 Cyber (Aust) OFC, 14-17, OBC D&D Mailing Services 56 Dataflow Business Systems IBC Dockets and Forms Australia 54 Durst Oceania 5 EH Manufacturing & Alltab 52 Flint Group Packaging 23 FUJIFILM Australia 7 Gecko Sticker Signage 53 Giga Print Silverwater 57 Goldfields Printing Co 50 Graph-Pak 39 Hero Print 2, 3 HVG Graphics 13 JTS Engineering 54 Labelline 52 Lifhart 50 Marvel Bookbinding & Print Finishing 51 National Auctions 58 Periodical Press 58 Screen GP (Aust) 19 Smartech Business Systems 25 Top Line Binding 52 Advertiser’s Index To advertise call Carmen on 0410 582 450 or carmen@proprint.com.au 14-16 CYBER AND RMGT INTRODUCE NEW PRODUCTS TO THE MARKET 18 WOMEN IN PRINT: JULIA VAN DER SOMMEN 6-12

Printer’s comprehensive industry news 14-16

NEW PRODUCTS

The companies

months with the launch of a

of new products at a

of global events 18

22

24

26

34

36

38

40

41

42

43

44-48

49

50-58

20-21

ROMEO

NOVEMBER 2022

NEWS: Australian

CYBER AND RMGT INTRODUCE

TO THE MARKET:

have had a busy six

range

series

WOMEN IN PRINT: Pattern Room’s Julia Van Der Sommen builds a unique business 20-21 PEOPLE IN PRINT: Next Printing managing director Romeo Sanuri

APPOINTMENTS: Flint Group A/NZ targets growth with key hires

INSTALLATIONS: S martech equips Global Signs with robust kit 26-33 PRINTING UNITED REVIEW: All the latest technologies that were on show

Agfa 30 HP 27 Durst 31 Kornit Digital 28 EFI 32 Ricoh 29 Heidelberg 33 RMGT

POSTERBOY PRINTING: Don’t hesitate to create emotional content

THE REAL MEDIA COLLECTIVE: ’Tis the season for print

MEQA SMITH: Want to boost profits? You need a Talent Bible

DEBORAH CORN: Collaborate with your print customers

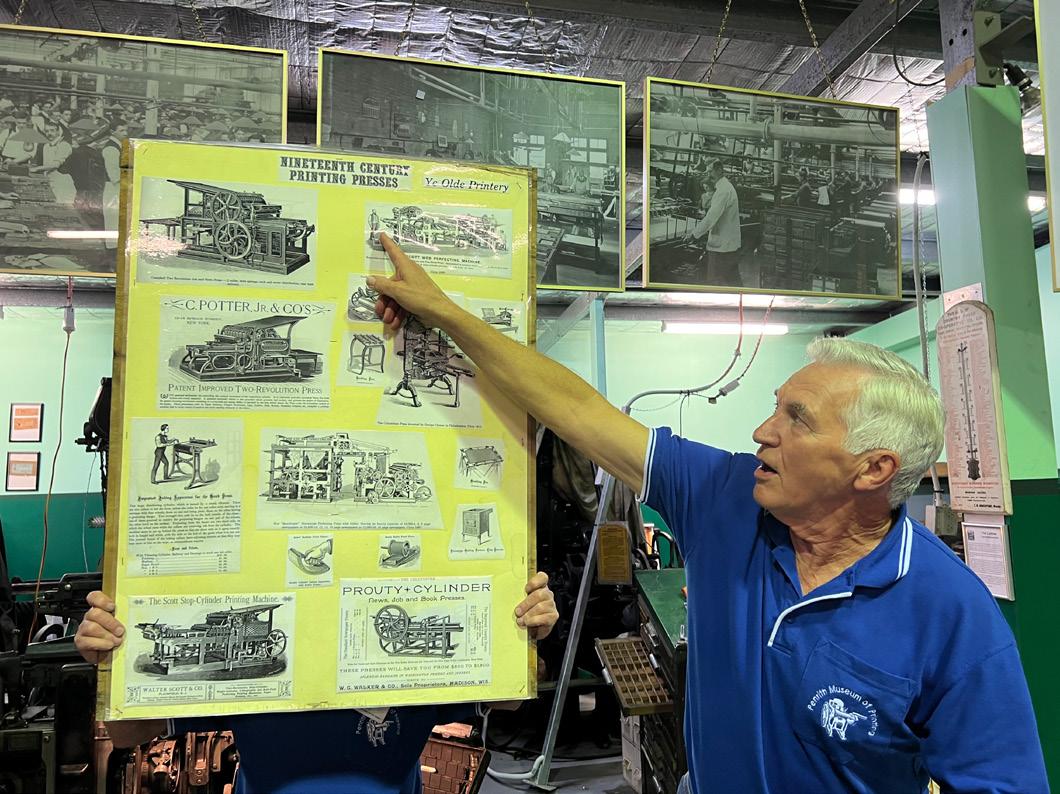

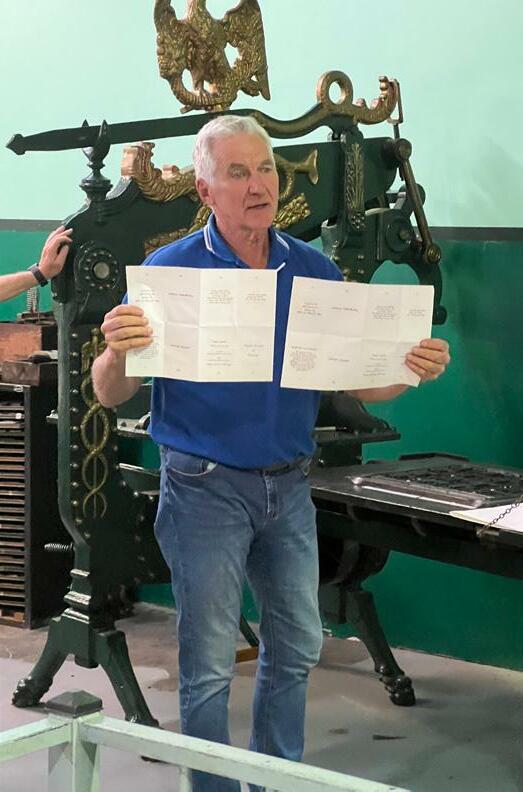

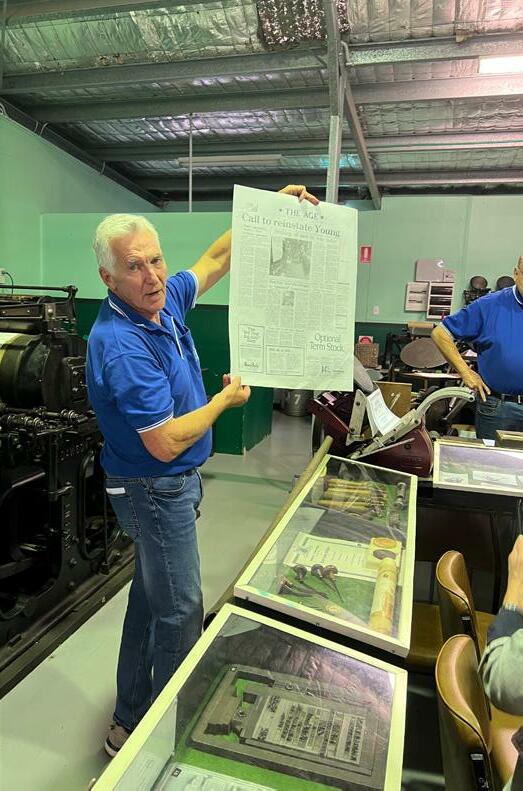

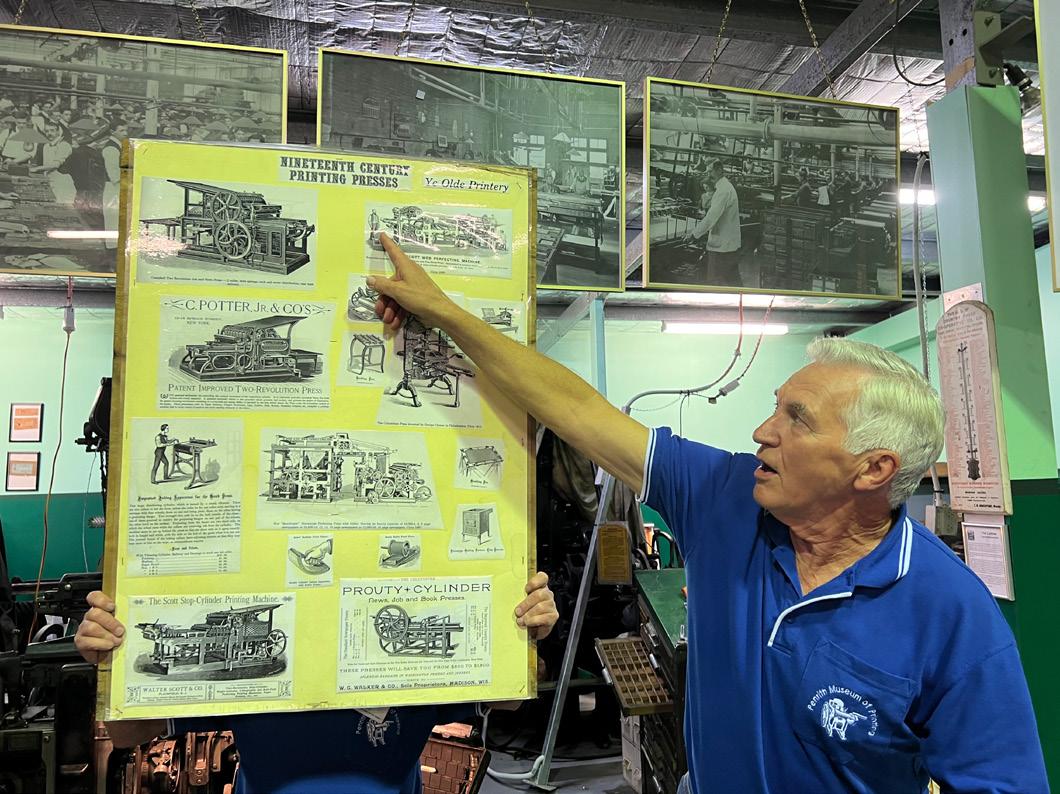

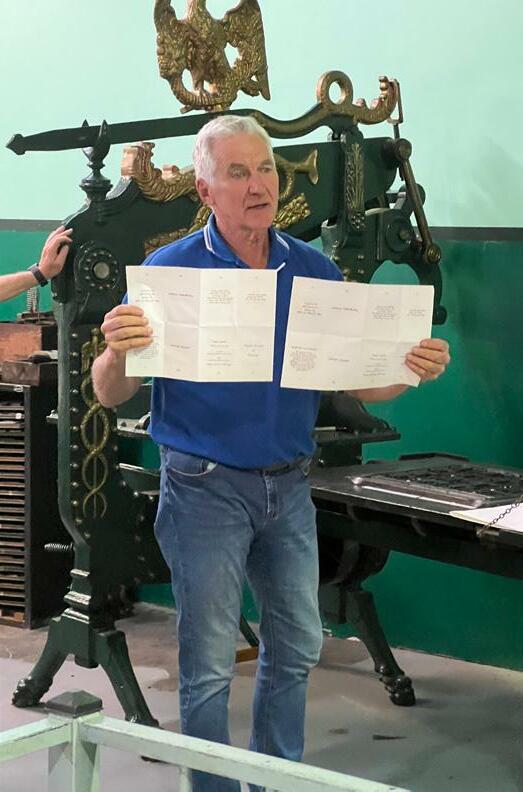

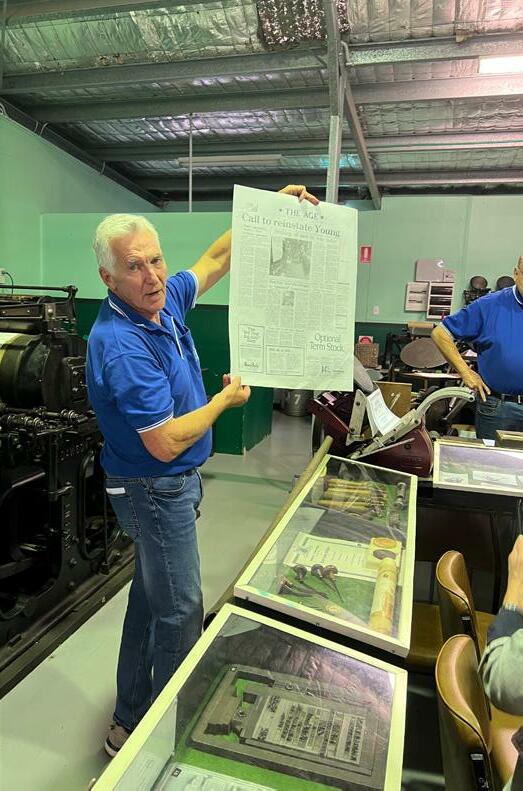

GALLERY: LIA NSW enjoys a trip to the Penrith Museum

WIDE FORMAT +PLUS: Australian Printer’s comprehensive wide format news, powered by Wide Format Online

PRINT DIARY: All the upcoming events

CLASSIFIEDS: The Australian print industry’s biggest marketplace

PEOPLE IN PRINT:

SANURI

For more information, please visit durst-group.com/p5350 PRODUCTION EXCELLENCE P5 TM The hybrid printer that elevates the efficiency in your production cycle. P5 350/HS

It has been way too long since the industry gathered, and this year was the first time since COVID where people could get together face-to-face at trade events on a global scale. Taking advantage of the opportunities that events present, many manufacturers and printers alike have travelled to these tradeshows, of which Printing United in Las Vegas was the most recent.

Printing United saw tens of thousands of attendees who share common interests, goals, and challenges convene. It was an opportunity for them to create new relationships, see new products and network with industry experts.

With over a million square feet of equipment, technology, and trends on display, attendees discovered new products and innovations to fit their business and customer needs.

This issue of Australian Printer takes a deep dive into the technologies that were on show and the potential that they present to users. Next year also promises plenty of trade events, and we look forward to seeing you there. Until then, happy holidays!

Print-related roles excluded from latest skills shortage list

By Sheree Young

By Sheree Young

The 2022 workforce update from the soonto-be-disbanded National Skills Commission has again left several print-related occupations out of the Skills Priority List with print finishing and screen printing the only print industry occupations listed as being in a worker shortage.

The Real Media Collective & The Print & Visual Communication Association are looking to change this with GM – Policy, IR and Governance Charles Watson saying the methodology used to determine what occupations are experiencing a worker shortage was not consultative enough.

Watson said the TRMC/PVCA will meet with Jobs and Skills Minister Brendan O’Connor in November to voice the industry’s concerns on vocational training and apprentice support for print. The association will also press for more consultation with the new body, Jobs and Skills Australia, which has been named to replace the National Skills Commission.

“It’s something we are not happy with and we have not been happy with the government’s response to our overtures and submissions,” Watson said of the print-related occupations being left out of the skills list.

“The National Skills Commission is going to be replaced by Jobs and Skills Australia and we are hoping to be working a lot more closely with them. We’ve been critical about the methodology that the National Skills Commission used to determine which skills are in demand. To my way of thinking, it utilised jobs that were advertised online and that isn’t the best way of finding out what is in need.

“We are going to be sitting down with Minister O’Connor in November to try and put some industry viewpoints forward as far as how Jobs and Skills Australia should operate and that it should have a lot more industry consultation.”

This year’s report found occupation shortages were most acute in professional occupations, requiring higher level qualifications and experience, and Skill Level 3 occupations among technicians and trades workers. It also found the unemployment rate fell to 3.4 per cent in July 2022 – the lowest rate recorded since August 1974 – while the demand for workers has increased rapidly.

Ai Group CEO Innes Willox said the findings reflect the skilling and recruitment challenges that employers are experiencing daily.

“Of specific concern, 47 per cent of all trade and technician occupations are in shortage, up from 42 per cent at the same time last year. The ongoing shortage of trade and technician workers has bedevilled companies’ capacity to undertake or complete a range of projects as well as business as usual activities,” Willox said.

“The expansion of trade and technician occupations on the priority list will improve access to apprentice incentives. It’s welcome, but only a small step towards the overhaul of the apprentice incentive system.”

6 | AUSTRALIAN PRINTER NOVEMBER 2022 SPRINTER.COM.AU

Australian Printer is published bi-monthly by Printer Media Group (a division of Charted Media Group and The Intermedia Group). This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken n the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication.

NEWS

The industry has concerns on vocational training and apprentice support for print

The new blueprint for wide format

A true flatbed with a unique and exceptional design.

The IF Design Award winning Acuity Prime offers high quality printing on a range of rigid and flexible media across five dedicated vacuum zones. Using our Uvijet HM LED UV inks and jettable primer, bold graphics and fine text can be reproduced with variable drop sizes from 7 to 21 picolitres for near photographic quality.

Visit acuityprimeseries.com for more information or contact your local FUJIFILM representative to request print samples and organise a demonstration.

FUJIFILM Australia1300 650 504

FUJIFILM Business Innovation Australia 13 14 12

and Fujifilm Value from Innovation are trademarks of FUJIFILM Corporation. ©2021 FUJIFILM Corporation. All rights reserved.

FUJIFILM

FUJIFILM

Avon Graphics acquires Lorimier

By Sheree Young

Avon Graphics has acquired historic Melbourne-based foil stamping and embossing specialist, Lorimier, in a move which brings together 200 years of finishing excellence together under one brand.

The acquisition was completed on 31 October with all staff to be welcomed to the Avon Graphics team, including Lorimier owner and managing director Peter Johnston, who will be staying on into 2023 to ensure a smooth transition.

Avon Graphics managing director Tate Hone said initial discussions between himself and Johnston were straightforward, open and positive, with both agreeing that the acquisition of Lorimier by the familyowned and operated Avon Graphics made good sense.

“We both felt that the time is right for further rationalisation in the trade supply marketplace, and that provided a sound basis for productive discussions which

Bobst strengthens APAC with two senior appointments

By Hafizah Osman

Bobst has made two key senior appointments in the Asia Pacific region, which includes Southeast Asia, Oceania, Japan, South Korea, India, and China, hiring Cyril Ruiz-Moise and Yasser Oweida into the company.

Ruiz-Moise has been appointed as its APAC general manager and regional business director of the printing and converting business unit.

Ruiz-Moise was previously general manager at Bobst Shanghai, a position he led with great distinction for five years. In his new role, Ruiz-Moise will lead Bobst for all machine product lines in the Asia-Pacific region.

“The Asia Pacific region is a diverse and exciting one, and an extremely important strategic region for Bobst,” Ruiz-Moise said.

greater Melbourne,” Hone said, adding that changes to the Lorimier facility are expected over time, to broaden the range of services offered from that location.

In addition, the companies’ shared commitment to superior quality, personalised service and long-term relationships means the two teams of passionate and professional staff are expected to fit comfortably into the newly expanded operation.

“It’s been great working with Peter, and we thank him for his cooperation and professionalism as we have worked through the detail of this important agreement,” Hone said.

resulted very quickly in a deal which was acceptable to both parties,” Hone said.

Hone also mentioned that the strategic acquisition will strengthen Avon’s offering for trade supply, particularly throughout Melbourne and Victoria.

“Avon intends to continue operations from Lorimier’s Heidelberg West location, in addition to our own manufacturing facility in Rowville, spreading our footprint across

“We are looking forward to welcoming all Lorimier staff to the Avon team as we put our plans into action, including Peter who has agreed to stay on into 2023 to ensure a smooth transition across all aspects of the handover.

“Together, we can now not only look back on a proud combined history of more than two centuries of service, but look forward to a future of even better and more comprehensive support to our industry throughout the Melbourne metropolitan area – and across the country.”

“We have bold ambitions to grow and expand our presence in the region, and our deep knowledge and understanding of our customers and their needs will help us to achieve this goal while helping our customers to achieve theirs.”

Oweida has been appointed as region services director of APAC business unit services and performance.

Oweida was previously head of global sales development at Bobst for three years. Before that, he was head of business unit services for the Africa & Middle East region.

In his new role, Oweida will strengthen the technical and services team in the region and ensure customers receive the highest quality expert service.

“I am very excited to be appointed in this role in a region with so much potential for economic and industrial growth. Having an agile and efficient service team in place is a vital part of our offer, and that is a commitment I can make to all our valued customers in the Asia-Pacific region,” Oweida said.

Ruiz-Moise is based in Shanghai, China while Oweida is based in Bangkok, Thailand.

SPRINTER.COM.AU8 | AUSTRALIAN PRINTER NOVEMBER 2022 NEWS

Avon Graphics managing director Tate Hone

(l-r) Bobst has hired Yasser Oweida and Cyril Ruiz-Moise

Industry collaborates again for Movember fundraising

By Hafizah Osman

Mezographic, Ball & Doggett and Arden Building have come together again this year in support of another Coles Expressled Movember project, which will run all through November.

This year 58 Coles Express sites – 16 in Queensland, 12 in NSW, 14 in Victoria, two in Tasmania, four in SA and 10 in WA – will be donning the “Your Dough will Save a Bro” decal as the company aims to exceed last year’s phenomenal fundraising effort of $366,660.

Last year, the partnership saw 27 Coles Express sites across Australia dressed up for the length of the programme.

The project has grown significantly since 2020, where a similar project was limited to just five sites.

Sydney building wrapped in ‘Ancient Tracks’

Indigenous art

By Hafizah Osman

Mesh Direct has wrapped a striking, large-scale artwork which pays homage to traditional Indigenous navigation and land management around scaffolding on the facade of the historic Woolworths building located on one of Sydney’s busiest intersections.

Mesh Direct said it is the largest piece of Indigenous art to ever be displayed in this way in Australia.

The artwork ‘Ancient Tracks’ was designed by 25-year-old Kungarakan graphic designer Toby Bishop. He created the impressive piece in response to an art competition call out from the City of Sydney in 2021.

‘Ancient Tracks’ was printed on a Building Wrap by Mesh Direct, with the company saying that the sheer size of the artwork meant that the printing and installation

As in 2021, the project involves the generous supply of one-way vision film by Damian Pocock from Ball & Doggett, which will be used for the window decals, while Frank Mezo from Mezographic manufactured, packed and shipped the signage as a donation to the sites.

Richard Pitcher from Arden Building installed the decals and included the future removal of the decals post-campaign as a donation.

“Arden is, once again, proud to supply all labour nationally to the 58 sites involved in this campaign, to install and remove the Movember decals in full support of Coles Express’ drive to promote more awareness of men’s health throughout the nation,” Pitcher said.

The only difference is this year’s decals were a ‘one size fits all’ measuring 2m by 1m.

This was done so that more sites could be fitted as part of the campaign for less cost.

Coles Express project manager Ian Lockwood said, “Frank, Damian and Richard are donating stock, machine time and install/deinstall of window decals across the length and breadth of the country. It is a massive donation to the cause and I am so proud to see this partnership grow and evolve.”

Mezo addressed the importance of men’s health, adding, “Supporting Movember using our industry skills adds extra value to the fund-raising efforts that Ian has coordinated. Men’s health is often underfunded and overlooked. We have had workmates directly affected by some of the issues Movember supports. So, being able to contribute by doing this is an important way for us to put something back into our community”.

“We are happy to be involved and support Movember. The COVID pandemic has highlighted the importance of mental health, in particular with men. Anything we can do to assist with funding is a great thing. Let’s hope we raise the muchneeded funds again this year and hit our target of $500,000,” Pocock said.

“The foot traffic through Sydney meant the installation had to be completed between 10pm and 6am each day, with traffic controllers on-site to guarantee the safety of everyone involved. At over 3500sqm in size, safety was certainly our biggest challenge but one we faced head-on with success.”

required for the project was nothing short of immense. Replicating the detail of the original artwork on such a large scale required particular care and attention and the wrap was broken down into eight huge panels for the installation process and to fit the scaffold.

“One only must glance upon the ‘Ancient Tracks’ artwork to understand the true scope of this job. We were presented with several challenges throughout the process of producing this magnificent piece of artwork,” the company said.

“Firstly, the timeframe was incredibly tight. Commencing the installation just prior to Christmas last year, this job rode a COVID wave as well as unprecedented rain and floods. Then, once installed, we notched winds up to 120km per hour, really challenging the integrity of the product at almost 180kg per panel.

And the nature of the artwork meant that a green approach to production was essential. As a 100 per cent carbon neutral business, Mesh Direct produced ‘Ancient Tracks’ in line with the ‘green’ brief Bishop used to create his artwork.

Mesh Direct said not only is it the largest piece of Indigenous art to be displayed on scaffolding, but it is also the largest carbon neutral wrap in Australia as far as it knows.

Mesh Direct director Andrew Doenicke said, “this was a fantastic opportunity to align our own desire for a greener city with the values bound within Toby’s incredible artwork. The two marry up perfectly and we are incredibly proud to have been part of this project”.

The artwork has been displayed since the start of the year and will remain in place until the end of the year while the Woolworths building is being repainted.

SPRINTER.COM.AU AUSTRALIAN PRINTER NOVEMBER 2022 | 9 NEWS

One of the sites dressed up for the campaign

The facade of the Woolworths building with the ‘Ancient Tracks’ wrap

Kwik Kopy Australia celebrates its 40th anniversary

By Hafizah Osman

By Hafizah Osman

Kwik Kopy Australia is celebrating its 40th anniversary this year and in line with its achievements, the company is making further plans to improve business.

Kwik Kopy Australia CEO Sonia Shwabsky, who recently took on the role in March, said, “We’ve got big plans for the future. We just reached our first milestone, which was delivering a new brand campaign that is going to lay the foundations for the business moving forward”.

This purpose-led brand transformation involves the release of its biggest-ever national marketing campaign that will build on its entrepreneurial spirit.

“Kwik Kopy has the power to transform businesses, not-for-profits, individuals, and communities, and we take that

Kwik Kopy Australia CEO Sonia Shwabsky

Kwik Kopy Australia CEO Sonia Shwabsky

www.allkotes.com

responsibility seriously. In the power of print in all its forms, there is no substitute for the tangible, tactile and emotive connection that print can provide, she said.

“So, through this campaign, we’ve set the scene by informing everyone as to what we do, and will continue to build on our legacy.

“Moving forward, we’re about to embark on a large strategic process to redefine our vision, growth plans and cement what the business does for its customers. Personalisation, serving customers by addressing their challenges and needs, and bringing their ideas to life is what we do; it’s not just about having a transactional relationship.”

According to Shwabsky, this strategic process will involve the alignment of approaches across its franchises. Its positioning of being a trusted business partner will be amplified across its channels with a focus on sustainability.

“We take responsibility for our impact on the environment and are committed to a sustainable future. We are proud to say over 80 per cent of our franchises have achieved Sustainable Green Print Industry Certification,” she said.

“This means that we have processes in place to recycle our waste and safely dispose of any chemicals. We offer sustainable options and support our customers with the transition to adopting new sustainable solutions.”

It also involves bringing on new franchises across Australia and setting up new sites, revamping its technology stack such as its back-end data architecture and infrastructure, as well as launching a new website that offers more of its B2B e-Commerce functionality.

It has also introduced a brand book to ensure that messaging, processes and values across all stores are the same.

SPRINTER.COM.AU10 | AUSTRALIAN PRINTER NOVEMBER 2022

NEWS E: ben@allworkcranes.com.au E: ben@allworkcranes.com.au Complete factory relocations: Specialising in a wide range of machinery from Engineering, Metal Work, Printing & Packaging Providing a full rage of services including: 3 Machinery handling 3 General crane hire 3 Forklift hire and transport 3 Packing and unpacking of containers Established 7 years. Serving a wide range of customers we pride ourselves on punctuality, reliability and customer satisfaction. All aspects of printing machinery

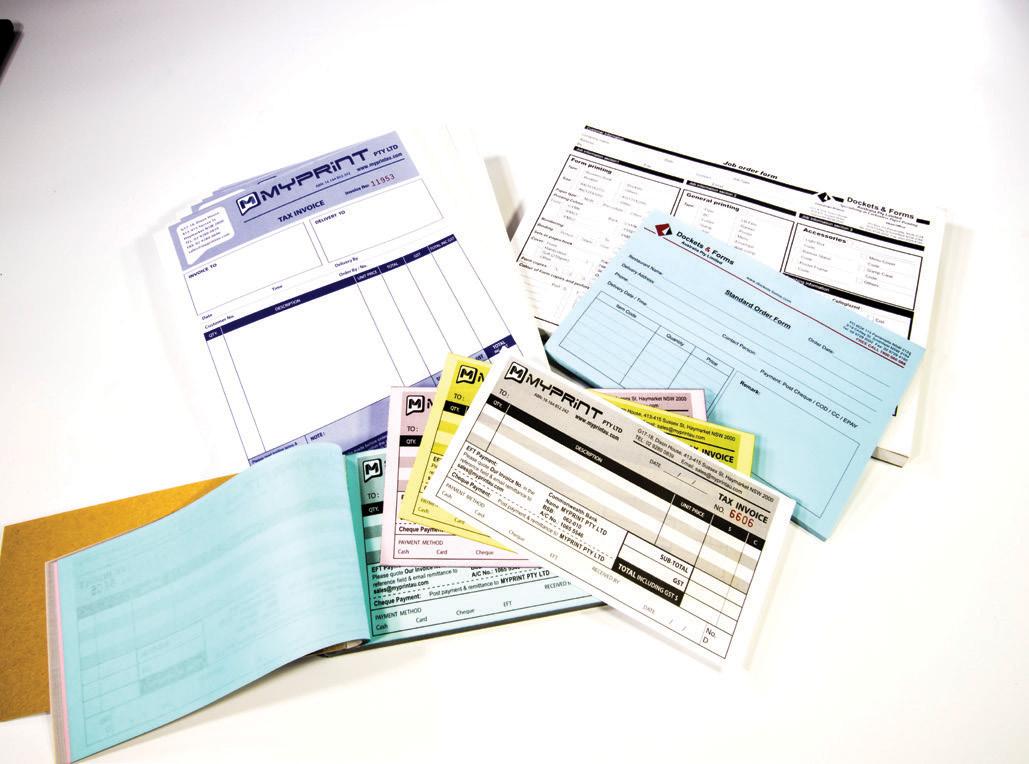

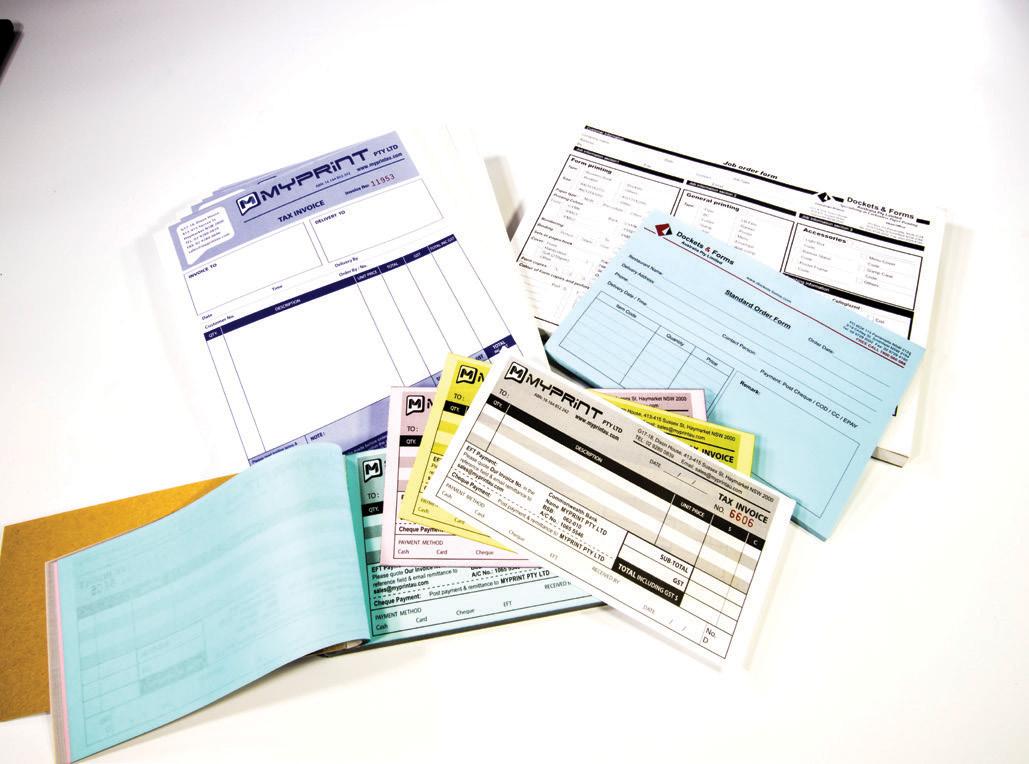

Fotobase Group buys Autobond machine from Graph-Pak

By Hafizah Osman

South Australia-based Fotobase Group has purchased a high-end Autobond laminating machine from Graph-Pak as the company looks to improve its speed to market performance. The first-time Graph-Pak customer said it selected the Autobond Mini 53 TPH M model as it is a premium, high-speed laminating machine that provides stellar results and consistent performance for decades of use.

The Autobond Mini 53 TPH M is a quick make ready, thermal laminator designed specifically for half size offset, and digital format applications. It has a modular design to add options such as a perfector, automated stacker, in-line UV coating, or in-line magnet production, or an in-line foiling machine. It runs at a maximum speed of 50 m/min and sheets are laminated top and bottom in one pass.

Fotobase Group CEO Jason Gentle said, “Speed and efficiency is always front of mind in our business – and we selected the Autobond as it is a remarkable machine. It opens the doors to increase our turnaround potential.

Out of Home grows by

in Q3

By Hafizah Osman

The Out of Home (OOH) industry has announced an increase of 43.7 per cent on net media revenue for the third quarter of 2022.

According to the Outdoor Media Association (OMA), its net media revenue for the quarter was $244.6 million, up from $170.2 million for the same quarter in 2021.

Digital OOH (DOOH) revenue accounted for 62.5 per cent of total net media revenue yearto-date, an increase over the recorded 57.6 per cent for the same period last year.

Year-to-date net media revenue sat at $725.3 million, an increase from 26.5 per cent on 2021 and sitting behind pre-pandemic 2019 by 2.8 per cent.

OMA CEO Charmaine Moldrich said, “Quarter three sees the industry almost on par with prepandemic revenue, only .8 per cent down from 2019. This continued growth is in line with our projections for recovery. Driving our success is

“Having the Autobond machine will allow us to compete in certain spaces more effectively, given the speed at which this machine can run.”

Jason mentioned that the company bought the machine as it had simply outgrown its existing infrastructure and needed a new laminating machine to evolve and grow.

Graph-Pak managing director Tom Ralph said Fotobase needed a long-term solution for its laminating, but as a bonus the machine it ordered has the capability to laminate magnets from a reel to the printed sheets, then sheet them online.

“Speed to market performance, build quality, reliability, and robustness are just some of the qualities of this machine. The magnet application is an extra feature that Fotobase Group will massively benefit from,” Ralph said.

ACCC launches “greenwashing” online crackdown

By Sheree Young

The Australian Competition and Consumer Commission (ACCC) announced it is conducting two internet sweeps to identify misleading environmental and sustainability marketing claims as well as fake or misleading online business reviews.

Around 200 companies are on the ACCC’s hit list with the review looking at a range of targeted sectors including energy, vehicles, household products and appliances, food and drink packaging, cosmetics, clothing and footwear.

“As consumers become increasingly interested in purchasing sustainable products, there are growing concerns that some businesses are falsely promoting their environmental or green credentials. Misleading claims about products or services undermine consumer trust and confidence in the market,” ACCC deputy chair Delia Rickard said.

our concerted effort as an industry to launch new research and tools into the market.

“To-date in 2022 the OMA has launched a raft of tools making easier to plan and buy Out of Home campaigns. This includes the Neuro Impact Factor (NIF), a qualitative metric which goes beyond attention to measure the impact of Out of Home campaigns. The NIF is part of the upgrade of MOVE which allows for the measurement of digital campaigns; both metrics are supported by industry-wide standards.

“These initiatives, and the building of the new measurement platform MOVE 2.0, have undoubtably spurred the raft of new members, with eight so far this year, bringing us close to representing a 100 per cent of the industry.”

“This sweep forms a core part of our work in actively monitoring for ‘greenwashing’ in the market and industries, and will help inform what steps businesses can take to improve the integrity of their environmental claims.”

Rickard said the ACCC, “won’t hesitate to take enforcement action where we see that consumers are being misled or deceived by green claims”.

The ACCC is also targeting fake or misleading online reviews and testimonials.

SPRINTER.COM.AU AUSTRALIAN PRINTER NOVEMBER 2022 | 11

Fotobase with its new Autobond Mini 53 TPH M

NEWS

OMA CEO Charmaine Moldrich

close to 50 per cent YoY

Platypus Print buys Ovato’s packaging business

By Hafizah Osman

was favourable due to it having some good equipment, highly skilled staff and customers in industries where we have less of a presence,” he said.

Lusch confirmed that Ovato’s packaging business will soon come under and be branded as Platypus Print Packaging.

Queensland-based Platypus Print Packaging has purchased the packaging business of troubled catalogue and magazine printer, Ovato.

The move comes following the entire business of Ovato entering voluntary administration in July with its administrators, FTI Consulting, issuing a call for Expressions of Interest to make a bid for Ovato, or parts of it.

In August, the Australian Competition and Consumer Commission (ACCC) approved IVE Group’s proposed $16 million acquisition of parts of Ovato, which didn’t include its New Zealand businesses, nor its packaging business in Brisbane or its printing operation in Cairns. In September, IVE Group completed its acquisition.

A spokesperson for FTI Consulting, confirmed that a sale agreement with Platypus Print Packaging has been signed, but the terms and conditions of the sale remain confidential.

Platypus Print Packaging general manager Aaron Lusch said the company purchased Ovato’s packaging unit to further build on its business.

“Ovato packaging is a good business that has had the challenge of being a small unit within a much larger company. The business purchase decision

As the Ovato packaging unit is in Queensland, it will continue to operate from the existing site in the short-term with key equipment being moved to the Platypus site in December 2022 and January 2023.

“All the plant and equipment owned by the Ovato packaging business will be sold to Platypus under the terms of sale. We plan to retain most of the equipment except where the cost to get the equipment up to our standards is excessive,” Lusch said.

“Platypus will also be engaging the Ovato packaging staff. The Ovato packaging business has some of the most skilled tradespeople in the industry so we will be looking at various ways to retain these skills where we can.”

According to Lusch, having the Ovato unit under the Platypus banner will increase its folding carton manufacturing capacity and allow it to realise the synergies of the two businesses.

“Platypus’ focus is folding carton manufacturing and so we expect to unlock the full potential of the Ovato packaging business by combining the strengths of the two businesses,” he said.

“The Ovato packaging business has had some manufacturing constraints over the past couple of months and so there is a backlog of work for us to get through. Once we do, we expect it to be business as usual for customers, suppliers, and staff.”

SPRINTER.COM.AU12 | AUSTRALIAN PRINTER NOVEMBER 2022 AMCOR NOV 2021 14 15 16 17 18 19 NOV 2022 NEWS CORP NOV 2021 20 25 30 35 NOV 2022 ADOBE NOV 2021 200 300 400 500 600 700 NOV 2022 APPLE NOV 2021 120 140 160 1.6 2.0 NOV 2022 KOENIG & BAUER NOV 2021 10 15 20 25 30 35 NOV 2022 UPM NOV 2021 25 30 35 40 NOV 2022 NEWS: BUSINESS

Amcor 17.62 1.69 19.03 14.63 IVE 2.22 0.50 2.54 1.38 News Corp 26.56 5.86 35.04 21.89 oOh!media

0.78 2.01 1.04 Redbubble 0.54 3.69 4.40 0.53 Adobe 299.83 332.54 699.54 274.73 Apple 143.86 5.40 182.94 129.04 Canon 22.01 3.36 25.79 21.00 Fujifilm 45.52 31.73 83.57 44.66 News Corp 16.75 0.28 24.75 15.17 Xerox 15.28 0.34 24.14 13.06 Agfa 3.02 0.70 4.16 2.86 Heidelberg 1.23 0.81 3.14 1.10 Koenig & Bauer 12.28 13.42 32.65 10.76 Metsa Board 8.38 0.04 10.49 7.09 UPM 34.64 3.98 36.61 24.85 NYSE (US$) ASX (AUD$) DAX (EURO) PRINT STOCK WATCH: SEP 01 TO NOV 01 Price Price Price Change Change Change Year High Year High Year High Year Low Year Low Year Low

1.20

(l- r) Platypus Print Packaging’s Tom Lusch, Aaron Lusch and Tim Lusch

THE MOST SUSTAINABLE PAPER BOARDS FOR DIGITAL PRINTING

OUTDOOR VARI ANT.

OUTDOOR VARI ANT.

ADDITIONAL THICKNESS 2.4 MM. CANVAS-LOOK.

OUTDOOR VARI ANT.

ADDITIONAL THICKNESS 2.4 MM.

ADDITIONAL THICKNESS 2.4 MM. CANVAS-LOOK.

CANVAS-LOOK.

3.8MM PLUS NEW THICKNESS 2.4MM.

THE MOST SUSTAINABLE DISPLAY BOARDS FOR SCREEN AND DIGITAL PRINTING.

THE MOST SUSTAINABLE DISPLAY BOARDS FOR SCREEN AND DIGITAL PRINTING.

ADDITIONAL THICKNESS 2.4 MM. CANVAS-LOOK.

All products in the DISPA® range are made of FSC ® -certified paper (FSC ® C127595) and are completely recyclable – simple and inexpensive disposal as waste paper

THE MOST SUSTAINABLE DISPLAY BOARDS FOR SCREEN AND DIGITAL PRINTING.

DISPA® display boards provide optimal flatness and dimensional stability yet are still lightweight

THE MOST SUSTAINABLE DISPLAY BOARDS FOR SCREEN AND DIGITAL PRINTING. All products in the DISPA® range are made of FSC ® -certified paper (FSC ® C127595) and are completely recyclable – simple and inexpensive disposal as waste paper DISPA® display boards provide optimal flatness and dimensional stability yet are still lightweight Equally high level of rigidity – lengthwise and crosswise – is one of the main advantages over corrugated cardboard

All products in the DISPA® range are made of FSC ® -certified paper (FSC ® C127595) and are completely recyclable – simple and inexpensive disposal as waste paper DISPA® display boards provide optimal flatness and dimensional stability yet are still lightweight

Equally high level of rigidity – lengthwise and crosswise – is one of the main advantages over corrugated cardboard

Outstanding printing results – the structure of the core does not show through

All products in the DISPA® range are made of FSC ® -certified paper (FSC ® C127595) and are completely recyclable – simple and inexpensive disposal as waste paper DISPA® display boards provide optimal flatness and dimensional stability yet are still lightweight Equally high level of rigidity – lengthwise and crosswise – is one of the main advantages over corrugated cardboard Outstanding printing results – the structure of the core does not show through

Outstanding printing results – the structure of the core does not show through

DISPA® THE PERFECT SOLUTION FOR:

RECYCLABLE

Equally high level of rigidity – lengthwise and crosswise – is one of the main advantages over corrugated cardboard

DISPA® THE PERFECT SOLUTION FOR:

DISPA® THE PERFECT SOLUTION FOR:

DISPA® - THE PERFECT SOLUTION TO REPLACE FOAMBOARD, SCREENBOARD AND CORFLUTE:

Indoor promotion campaigns

Indoor promotion campaigns

Indoor promotion campaigns

Hanging, ceiling-mounted signs

Outstanding printing results – the structure of the core does not show through

Hanging, ceiling-mounted signs

Hanging, ceiling-mounted signs

Display and POS/POP applications

Display and POS/POP applications

Display and POS/POP applications

DISPA® outdoor – for short-term outdoor applications and signage

DISPA® THE PERFECT SOLUTION FOR:

DISPA® outdoor – for short-term outdoor applications and signage

Indoor promotion campaigns

Hanging, ceiling-mounted signs

DISPA® outdoor – for short-term outdoor applications and signage WWW.DISPLAY.3ACOMPOSITES.COM

Display and POS/POP applications

DISPA® outdoor – for short-term outdoor applications and signage WWW.DISPLAY.3ACOMPOSITES.COM

OUTDOOR VARI ANT. Available from our distributor: www.hvggraphics.com.au

Available from our distributor: www.hvggraphics.com.au

Available from our distributor: www.hvggraphics.com.au

distributor:

Available from

100% RECYCLABLE.

WWW.DISPLAY.3ACOMPOSITES.COM

100% RECYCLABLE.

our

100%

100% RECYCLABLE.

WWW.DISPLAY.3ACOMPOSITES.COM

hvggraphics.com.au P 1300 851 033 100% RECYCLABLE.

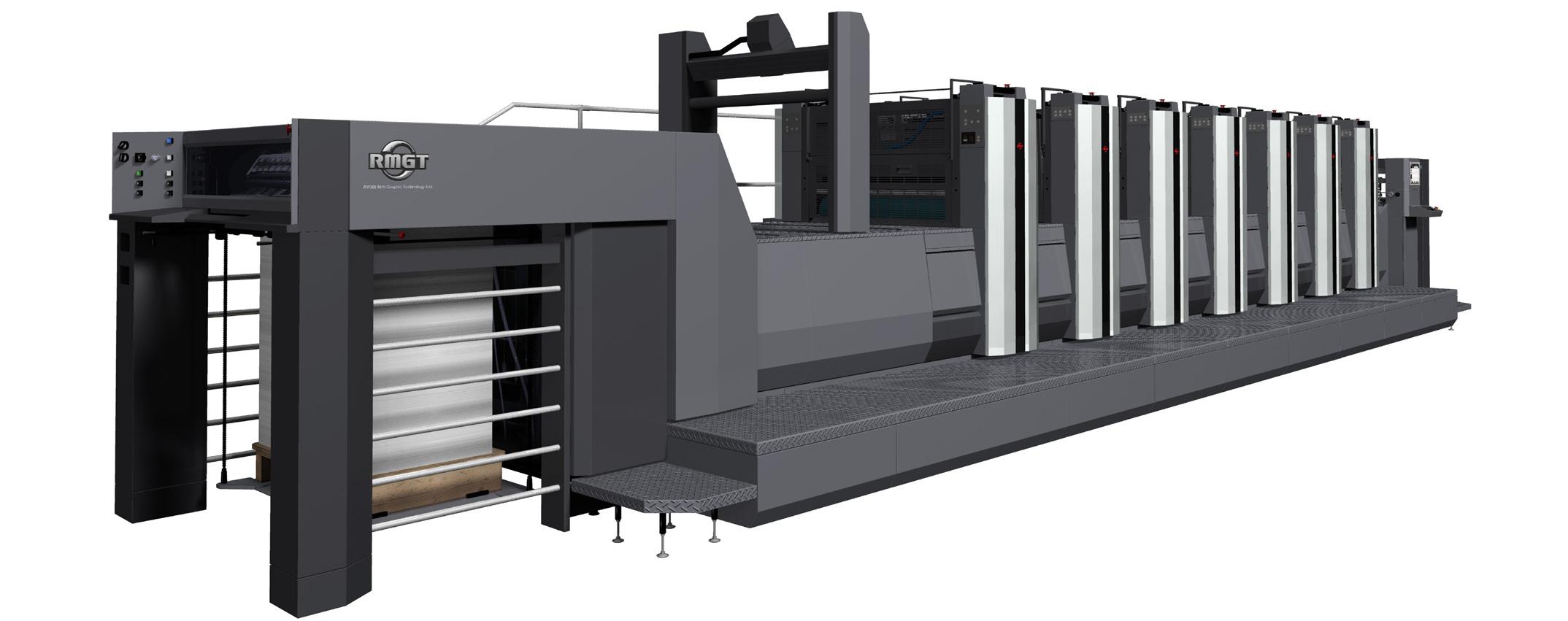

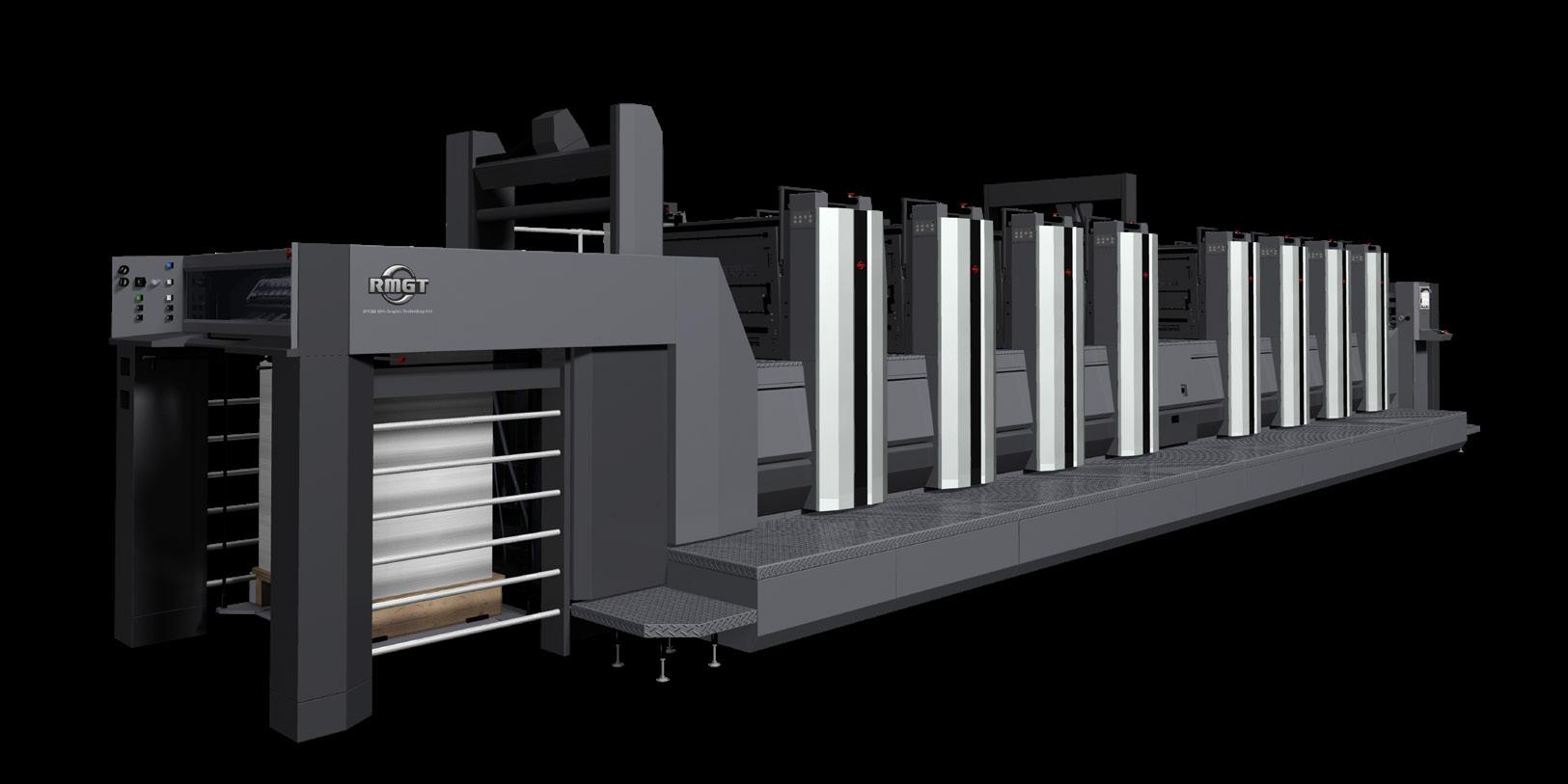

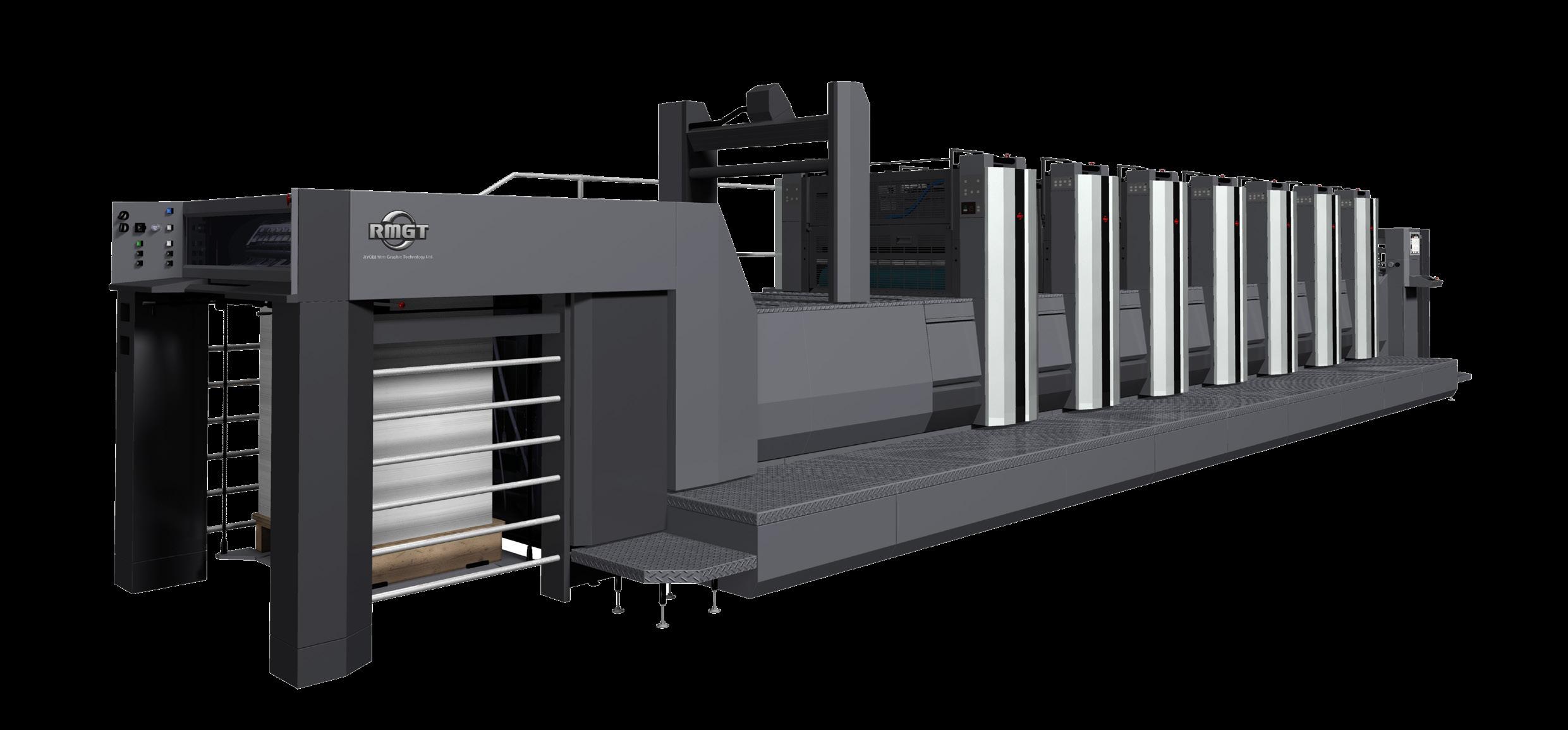

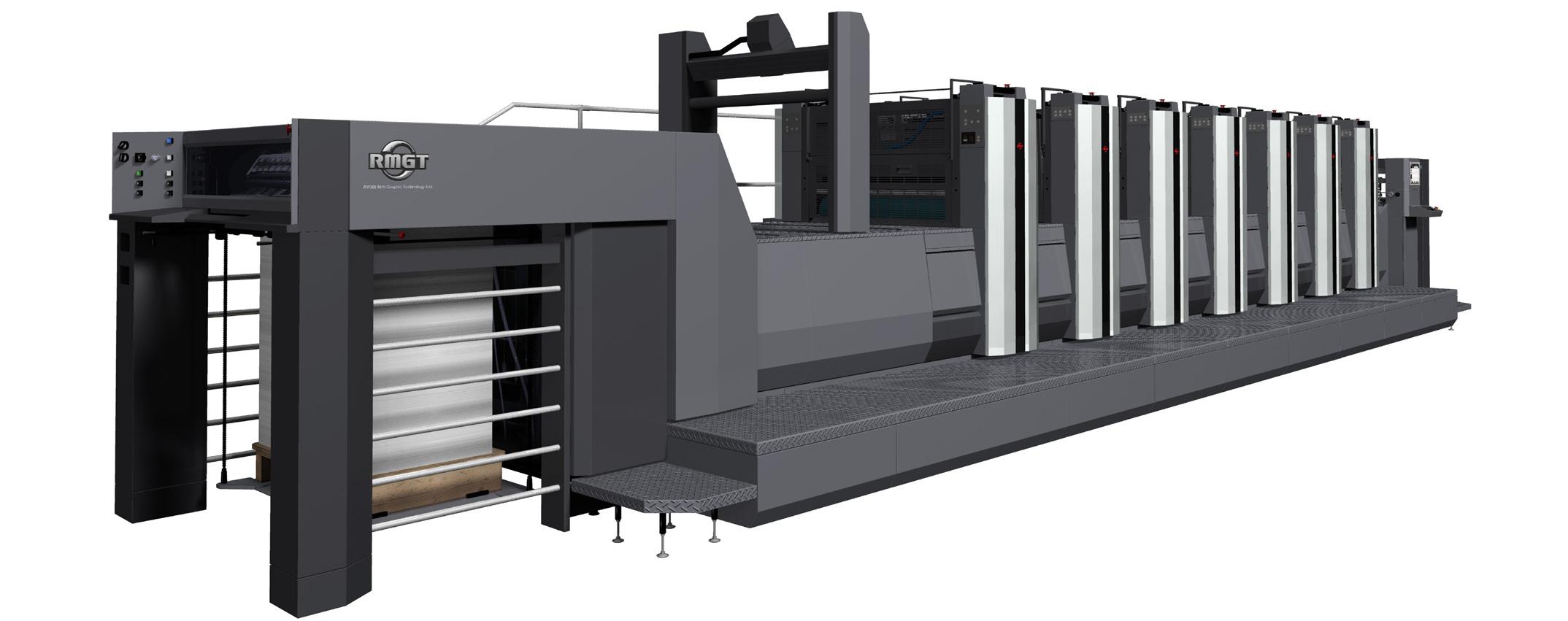

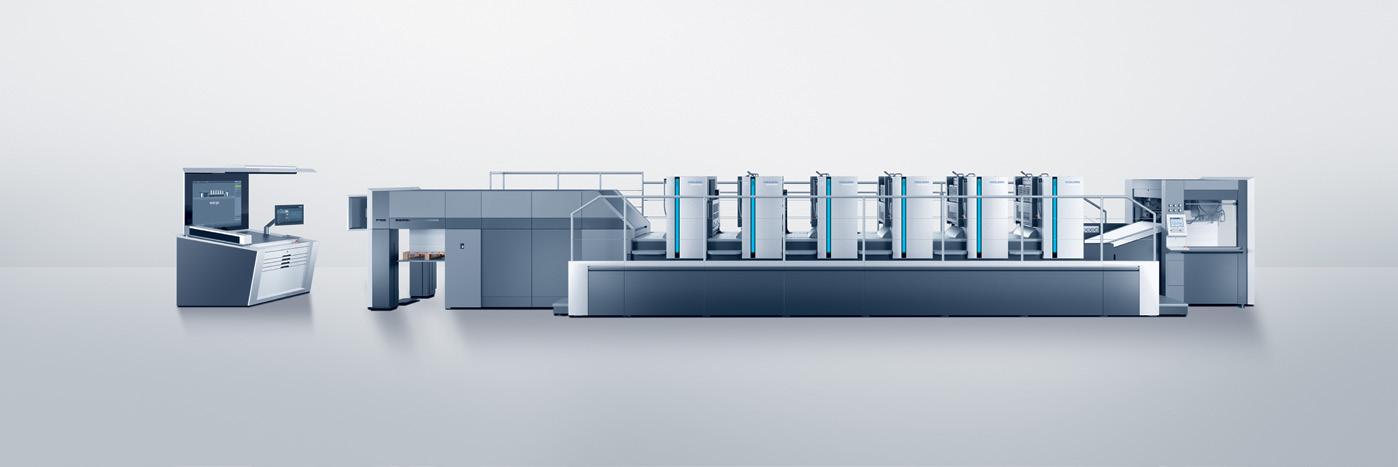

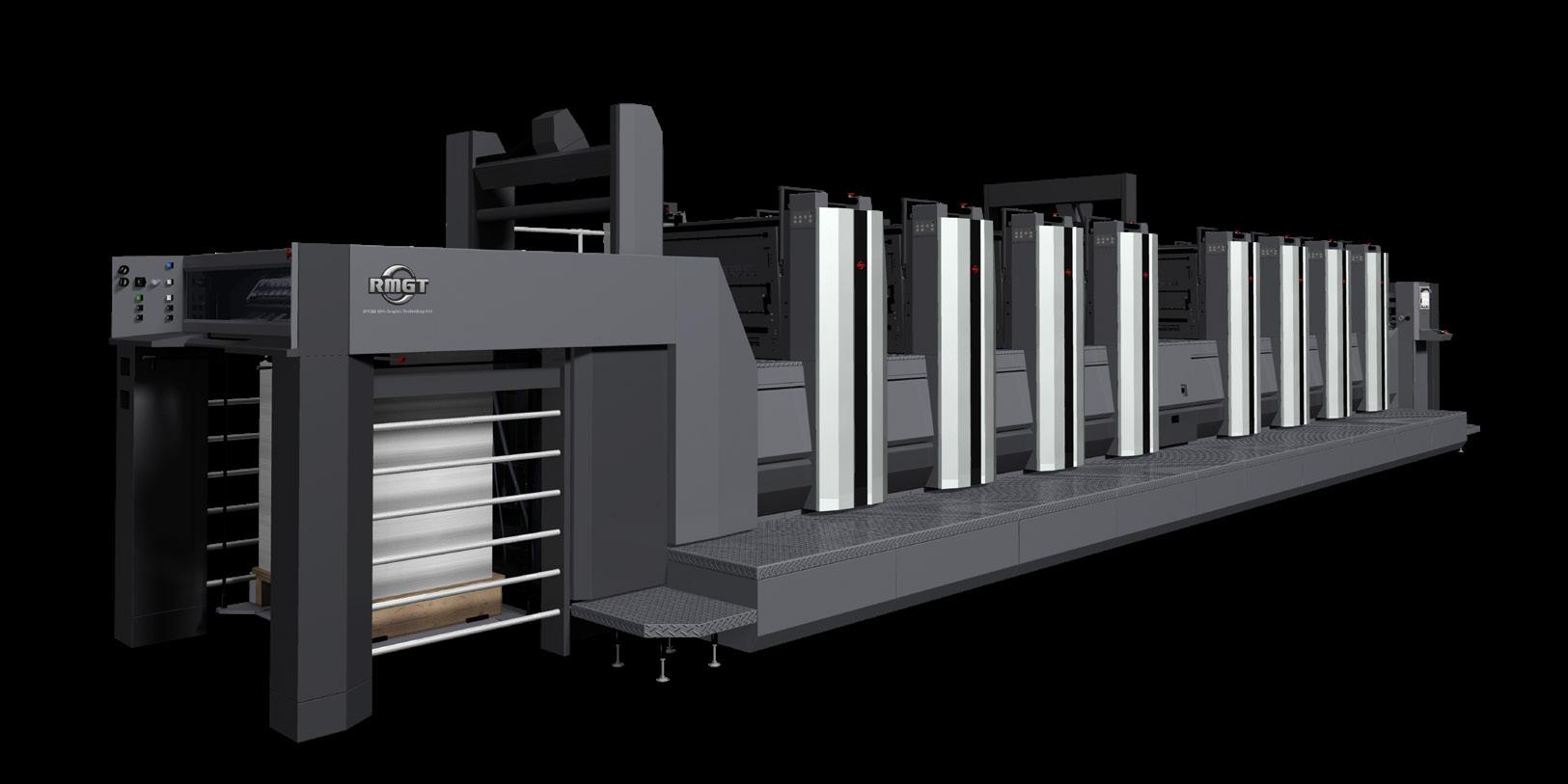

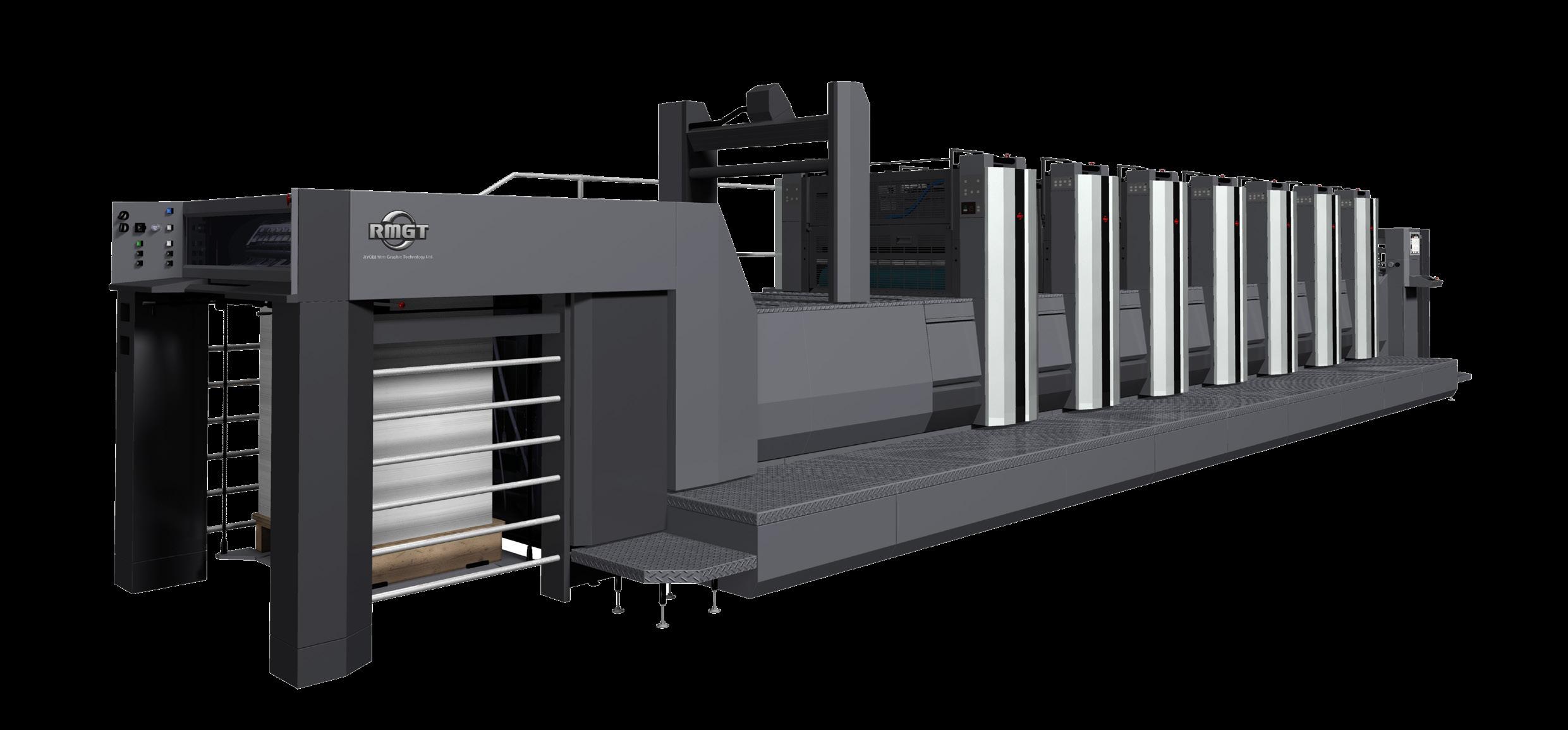

The RMGT 970ST-6 with coater for packaging printers

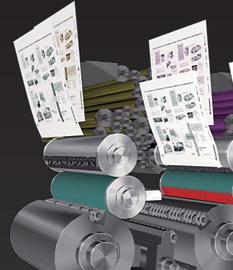

Cyber and RMGT introduce new products to the market

Cyber and RMGT have had a busy six months with the launch of a range of new products at a series of global events

Cyber and RMGT are on a growth trajectory as the companies have launched new products over the last six months, following a series of global events. These products have spurred a lot of interest in the market, resulting in greater sales.

The companies took to Indoprint 2022 in Jakarta, Indonesia in September and supported a series of Open Houses in Japan and Malaysia to show their latest kits, which garnered plenty of attention from attendees.

At the Cyber Open House in Malaysia, Cyber launched the new RMGT 970 series, which is an A1-plus size multicolour offset press, and showcased a number of other RMGT presses and Horizon machines.

With the offset market seeing rising global demands for presses offering greater productivity and cost performance, RMGT produced this machine as it saw a trend towards enhancing production capacity by enabling offset presses to handle a wide range of paper sizes.

The press now has new features that aim to help print service providers improve business. Some of these features include advanced automation and laboursaving mechanisms to assist the operator, short make-ready times to ensure high productivity and instant drying perfection for quick turnarounds.

It also features improved printing stability from thin to heavy stock and varnish coating and special printing for higher added value.

The 970 model is based on a blend of R&D emanating from the 920 series and its 1050 series presses. The range offers versatility, durability, and advanced automation, according to Cyber A/NZ managing director Bernard Cheong, who added that the range will further improve profitability of users.

“RMGT has been combining the two founding companies’ strengths of energysaving designs that incorporate new ideas with high-precision manufacturing technology and highly durable construction for long-term use,” he said.

“The new RMGT 970 has many advanced features based on the 920/940 presses, known for their superior quality and productivity. The new 970 model incorporates the latest technologies in addition to many features found on the flagship RMGT 10 series.

“In the face of rising paper and printing supply costs, the RMGT 970 is perfectly positioned to meet the needs of the times by handling the most popular A1-plus paper sizes used around the world.”

The machine is built for a maximum of 650mm by 965mm sheet size. The series can handle a comprehensive range of

print jobs, such as multi-page materials, displays and packaging.

Cheong said the 650mm by 910mm model is a popular format in Australasia, giving print service providers the ability to generate output without the need to trim. It also has a benderless plate clamp, feeder and delivery operation touch panel, along with other automation features.

“Users are moving to the SRA1 format to stay lean and profitable. The SRA1 format can do both shorter runs and long runs at the volume end of the market, so it’s a very versatile solution,” Cheong said.

Cyber also launched the new RMGT 970 ST5 CC SLD press at its Malaysia Open house. The machine is a five-colour printing machine with LED UV plus coater.

It aims to provide high-value printing such as chemical embossing and metallised paper printing.

Installations in Australia

Meanwhile, the RMGT 970PF-8 LED with PQS-D and Smart Assist Printing, which was scheduled to arrive in Australia in the third quarter of 2022, has been installed at CMYKhub’s Brisbane production centre, with Cheong saying that the machine has yielded many benefits for the business.

The RMGT 970PF-8 LED with PQS-D and Smart Assist Printing isn’t the only recent

SPRINTER.COM.AU14 | AUSTRALIAN PRINTER NOVEMBER 2022 COVER STORY

local installation by Cyber Australia. It has also installed the 920ST-5, the 750PF-8 + coater LED, and 790PF-4 machines from RMGT in the last six months.

A company that has been a customer of Cyber Australia for more than 16 years is Spot Productions. The company has purchased a range of machinery from Cyber Australia over the years, including seven RMGT presses that includes the first 920PF-10 LED installed in the A/NZ region about three years ago. It has also purchased from Cyber several folders, die cutters and finishing gear.

In the last six months, Spot Productions added to its fleet the RMGT 750PF-8 + coater LED, as well as the RMGT 790PF-4 machine, dramatically expanding the company.

Spot Productions managing director Simon Carmody said, “When we decided to expand the business 16 years ago, we had a wish list of machinery that we required to take our business to the next level. We sought expressions of interest from the major machine manufacturers and Cyber came to us with the best deal, the best options and the most support.

“When we installed the 920PF-10 LED, we needed speed to market, quality and automation. With the ease of printing with LED UV, we were able to create applications in just one pass, with no spray powder. We could use the machine to print on a variety of substrates and it made the printing process so much easier and certainly a lot quicker.

“We also recently added on the RMGT 750PF-8 + coater LED and the RMGT 790PF-4 to our portfolio. With this investment, we have three printing presses side by side, which bolsters our growth plans. Having three presses beside each other and printing two sides at once was a major goal in Spot’s expansion plans, which we have now achieved.

“With the changing landscape in the print industry, there are plenty of opportunities for us to do more. I invested in a 3,500 square metre shed to cater for our growth, which we’ve just about moved into now. I also bought the adjacent one to it, which has a space of 3,000 square metres, which I’ll expand into as well at some point.

“As a business, today, we’re 50 per cent to where we want to be. And Cyber has been a supporter of ours over the years – and continues to be as we grow – and that’s the reason we’ve stayed loyal to them as well.”

Growth, with an eye on the region

Cheong said 2022 has been a busy time for the business in Australia. According to

Cheong, Cyber and RMGT have aligned their goals for the region, to offer their collective customers nothing short of quality when it comes to printing.

“These solutions feature labour saving automation, quality control features, and IoT capabilities which are increasingly becoming important for offset in a digitised world,” Cheong said.

“The machines are designed to bring out the best in their operator, in turn, making the company profitable. The early adopters of these technologies have been reaping the rewards and will continue to grow their businesses. It is a no brainer in choosing offset technology.

“We aim to have an industry where customers are prosperous, relaxed and

invigorated to work by using Cyber’s machinery. RMGT’s corporate message of Irodori, which means colouring the world together, reflects our desire to establish a relationship of trust with our customers and everyone in the printing industry.

“RMGT offers the global market a widerange of printing equipment and services based on unique and original technologies to create this Irodori society.”

Cyber has also got an eye on infiltrating the Southeast Asian region. Indoprint 2022 was one of the global events that Cyber exhibited at in recent times.

Cheong said the company is increasing its efforts in Indonesia as based on the statistical development of the country’s economy. Data shows that in 2050, it

SPRINTER.COM.AU COVER STORY

AUSTRALIAN PRINTER NOVEMBER 2022 | 15

The RMGT 970PF-8 with PQS-D and SAP installed in Australia

The Cyber team at the launch of the RMGT 970 series

The crowds in Cyber’s showroom in Malaysia, Kuala Lumpur

will be the fourth largest economy in the world just after China, India and America.

“The printers in Indonesia do not focus on export, but the country has a very big domestic demand. That’s why all eyes are on Indonesia now,” he said.

“Moreover, more than 50 per cent of the Indonesian population is under the age of 30 – this is the strength of the domestic economy. Indonesia has skilled workers in many fields, and there are high export opportunities and the vast availability of natural resources.

“The printing industry in Indonesia will get extraordinary opportunities and we must prepare ourselves to be more competitive in the market.”

The Vietnam market, on the other hand, is seeing lots of foreign investments, even from China according to Cheong. As such, the company is also increasing its efforts in this country.

Cyber Vietnam recently installed its first RMGT 1060ST-5 in Vietnam at the end of September. The 1060 is the latest model to be launched in the country.

During the pandemic, Cyber also installed several RMGT presses in Vietnam, including: the 1050ST-6, two machines of the 1050ST-5 and the 920ST-6+C.

An Open House in Tokyo

A key focus for Cyber and RMGT is sustainability. In disseminating the message of its benefits to customers, Cyber supported RMGT’s Open House, named Eco-print 2022, which took place at the RMGT Tokyo showroom for two days in July.

“Under the theme of discovering the new businesses with the latest eco-friendly printing, we collaborated with many printing material suppliers to introduce applications for eco-friendly printing

materials, such as paper, inks, as well as know-how on eco-friendly printing,” Cheong said.

At the event, paper suppliers and RMGT presented a session about sustainable development goals (SDGs) supported by the companies. On the other hand, the RMGT 970ST-5+CC+LED-UV was demonstrated by using biomass ink and eco-friendly paper, proposing environmental load reduction printing by LED-UV.

The RMGT 1050ST-5+LED-UV was also demonstrated with waterless LED-UV for ink reduction and environmental printing by UV and concentric screening.

“Concentric screening is a multi-tone screening process that involves mixing with halftone dots which are divided to suppress ink coverage on halftone dots and reduce ink consumption by five per cent to 25 per cent,” Cheong said.

“The demonstrated biomass inks, ecofriendly paper, and LED-UV showed customers how to achieve prints with reduced environmental impacts using the RMGT 970ST-5+CC+LED-UV.

“In this process, the eco-friendly paper was made from non-edible rice, where about three to five per cent of rice was used in the make of the paper. And to get the texture of rice paper, double-sided instant-dry printing with a straight mode was used on the LED-UV feature of the 970PF-8 machine.

“RMGT also showed off the specific features of the 970 series, highlighting reduced costs such as a 30 per cent reduction in installation space compared to the B1 sized machine, and a 34 per cent saving in its power consumption.”

Waterless printing using specific ecological conscious materials, such as waterless UV ink with waterless plate

and concentric screening with halftone dots was demonstrated.

“It was a successful event and a very useful opportunity for all related suppliers to talk about their sustainability initiatives. Approximately 50 visitors participated in the event and learnt something from each other,” Cheong added.

Productive flexibility shown off at Hiroshima

Cyber also supported another of RMGT’s Open Houses in August – this one was at RMGT’s HQ showroom in Hiroshima.

“For two days, RMGT held an Open House event for the B1 sized RMGT 1060LX model. This latest printing machine incorporates various new technologies and functions to reduce printing make-ready time, as well as improve productivity, print quality control with PQS-D (I+C+R), and operability,” Cheong said.

“The press is thin and thick paper printing compatible, and was introduced through a technical explanation and printing demonstration.

“We also showed the operational demo of the automatic guided vehicle (AGV) named Nipper that saves labour between the material transporting processes and showed how the sheet pallet is automatically transferred to the next postpress process after printing.

“In addition to having the customer directly review the printing machine, we deepened their knowledge through the exchange of opinions with RMGT technical staff who also addressed any challenges that they raised.

“All of these events show the direction that RMGT and Cyber are taking. The new machines that we have introduced are tailored to the needs of today and tomorrow, and we will continue to provide the market with premium products and exceptional service.”

SPRINTER.COM.AU16 | AUSTRALIAN PRINTER NOVEMBER 2022

COVER STORY

Spot Productions’ Simon Carmody and Cyber Australia’s Bernard Cheong

Spot Productions’ Simon Carmody with the RMGT presses at his premises

CONGRATULATIONS TO ON YOUR NEW PRODUCTION CENTER RMGT 920PF-10 (5/5) LED-UV A1-SIZE OFFSET PRESS RMGT 750PF-8 (4/4) + COATER LED-UV B2-SIZE OFFSET PRESS RMGT 790PF-4 (2/2) B2-SIZE OFFSET PRESS www.cyber1976.com sales@cyber1976.com Singapo re - Tel: (65) 6272 8936 Thailand - Tel: (66) 2 682 3411-4 Malaysi a - Tel: (60) 3 7955 1668 (Kuala Lumpur) Tel: (60) 7 598 0771/2 (Senai, Johor) Indonesi a - Tel: (62) 21 2555 8924 Vietna m - Tel: (84) 9 0938 9468 Sydney : 38 V ictoria Street, Beaconsfield, NSW 2015 Australia Tel: (61) 2 9318 0099 Fax: (61) 2 9318 0399 New Zealan d : Unit 22, Ground Floor, 6 Ken Browne Drive, Te Rapa, Hamilton 3200, New Zealand Tel: (64) 7 949 7722 - Rob Crough 0423 337 788 - Peter Erskine 0432 663 322 - Alan Strugnell 0418 955 512 - Paul Hilleard (64) 21 191 6548 Sydne y Melbourne Brisban e Pert h - Greg Knight 0411 338 855 New Zealan d THANK YOU FOR 16 YEARS OF PARTNERSHIP AND LOOKING FORWARD TO MANY MORE TO COME

Building a unique business

Melbourne-based Pattern Room is not your average business. It bridges the worlds of printing and fashion, combining the work of the textile industry with dye sublimation and direct-to-garment (DTG) printing. In short, the company offers a catalogue of more than 200,000 patterns, many of which are the common styles custom printers might want.

At the helm of this distinctive company is its director, Julia Van Der Sommen.

“My career has been a journey. Since I was very young, I sewed my own clothes and with a creative, but numeric mind, found myself in pattern making roles for several well-known labels. This resulted in me starting a pattern making and development business, Sample Room,” Van Der Sommen said.

“But then I grew increasingly aware of the frustrations of people, especially in the custom sportswear industry, who struggled to get patterns for the styles their customers needed.”

This was the catalyst for Van Der Sommen to create Pattern Room – a catalogue of digital clothing patterns that are created and tested by her team.

“For my entire career I have seen myself as being in the textile industry, but Pattern Room has us working mostly with printers – dye sublimation and DTG. The team is constantly working on bringing more to the catalogue, so that you can get Ai and DXF files in less than 48 hours,” she said.

“From there, it is a case of applying graphics, printing, cutting, and sewing.

Traditionally the biggest challenge is getting access to digital patterns in a timely fashion and which work. We think Pattern Room will solve that challenge.

“It is a shift in my thinking from Sample Room, but the industry has been so welcoming. In my 30-year career, I have seen huge advances in digital printing which has changed the game in fashion. Now, there isn’t a need to have to print 300m as before with rotary or screen printing, which allows people to create unique products.”

Technology has been the biggest driver for Van Der Sommen’s business. She said the constantly evolving technology in printing machinery and inks has made it easier to access amazing print capabilities. Advancements in fabrics and paper have also supported its growth.

“Sure, there are some tech changes but nothing, until now, which has challenged the norm. More importantly, our clients aren’t afraid of new technology,” she said.

“I am passionate about showing that the technical side of developing product is just as rewarding as the design roles in the industry. There is so much for people to learn so I hope the way I talk about the process, our workroom and the success we have in our business will inspire people to consider the technical roles in our industry to be a great career choice.”

Van Der Sommen believes in supporting people in having strong career pathways and in achieving their career goals.

In her career, she said she found it hard to progress because she did not know

how, so now takes the time to nurture her team in their goals.

“It is important that we create training opportunities and support for our staff so that they can grow in their careers but also have guidance if anything is out of their reach. For me, this extends beyond career growth into personal growth,” she said.

“I have also always been an advocate for mentoring young women. But it is not possible to mentor young women if they are resistant to enter the industry in the first place. This is something that I have turned my mind to increasingly of late – how do we make the industry more attractive for young women to work in?

“This can only be done through guided career pathways, training, having more inclusive workplaces and flexible working. There is plenty of scope for change and now is the time to make those changes.”

Van Der Sommen said in her career, she found it hard to find mentors, which is one of the reasons why she has stepped up to help others.

“I found it very hard to find good mentors as in my line of work, there are not many women running businesses or challenging the conventional. I observe people from afar and carefully watch how they operate and act,” she said.

“I also look to women in other industries that have an entrepreneurial spirit and the courage to act on big ideas. I am inspired by people who look at problems in a different way and are willing to take chances and trust their instincts. I translate that to my own career and business.”

SPRINTER.COM.AU18 | AUSTRALIAN PRINTER NOVEMBER 2022 WOMEN IN PRINT

Pat tern Room director Julia Van Der Sommen

Labels, Flexible Packaging High Volume Digital ComputerTo-Plate Automated Workflow SCREEN Truepress Jet 520HD with SC inks – the digital inkjet press that prints superb colour on standard offset stocks. SCREEN Truepress Pac 830F Digital flexible packaging using aqueous inks across 830mm web. SCREEN Truepress Jet L350UV SAI digital label press. Up to 7 colours inc. white. 60 m/min across 350mm web. SCREEN PlateRite 8600NII New generation 8-page thermal CtP with fiber laser diodes. Up to 32 B1 plates/hour. SCREEN GP Australia Pty Ltd Tel: +61-(0)2-9016-3400 • Toll Free: 1300 305 118 • sales@screenaust.com.au • www.screenaust.com.au

Creating anything but ordinary solutions:

Romeo Sanuri

With a mission to seek out the latest digital printing technology, Next Printing managing director Romeo Sanuri explains what makes the company tick

As one of Australia’s leading large format digital printing companies, Next Printing is committed to the highest standards of visual communication. The result is in the work that is produced, that is both inspired and inspirational. AP spoke to its managing director Romeo Sanuri about the company’s solutions and future plans.

Q: What is the history behind Next Printing?

Romeo Sanuri (RS): Next Printing started in 2004, with Photo King as its parent company. The owner of the company was my uncle, along with his two other business partners. But when they saw a decline in the photographic market

– with the advent of digital cameras – they revised their strategy to grow the business in different areas, such as advertising, which was always done through print back then. I joined the company in 2003, just before we set up Next Printing. It was an interesting start for us, without any prior knowledge of large format printing.

Q: How did you grow the business from that point on?

RS: We initially worked with a lot of signage companies as we thought that was the quickest way to grow our business. We printed for companies like Signarama, Sign Wave, and a few other agencies. We also wanted to be at the forefront of the next big thing, so in 2004, started with

flatbed printing and UV technology when the market was still using solvent. But at that time, there were some bigger flatbed printing businesses that had made a name for themselves, so we eventually scaled down to focus on indoor applications that required very quick turnaround times and high-quality prints. That led to us entering the cosmetic, fashion and exhibition spaces, which now makes up 40 per cent of Next’s work.

Q: What sorts of products and solutions does Next Printing produce for these customers?

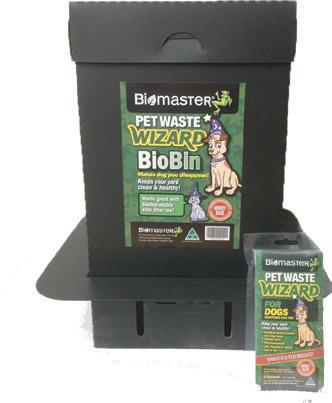

RS:: About eight years ago, we decided that we wanted to do better for our environment. We invested heavily in people and research to identify sustainable solutions. What started simply as an initiative has become our main purpose. Our customers are now becoming increasingly conscious about recycling and sustainability. As a result, we have been recommending the use of ReBoard (an eco-friendly engineered paper product) in which we specialise. Many of

SPRINTER.COM.AU20 | AUSTRALIAN PRINTER NOVEMBER 2022 PEOPLE IN PRINT

Nex t Printing produced solutions internationally for XeroCon in London, New Orleans and Sydney in a few months ago

The W+ Playground project Next Printing created for Westfield

Nex t Printing managing director Romeo Sanuri

our projects combine Re-board with envirofabrics and other paper-based products.

Q: What is fuelling Next Printing’s upward momentum?

RS: It is two things – sustainability and the growth in labels. Sustainability, because it is becoming more important to a lot of clients who want something that has less impact on the environment. The last time we were at FESPA, we connected with a company called Carbon Quota which has developed a mechanism that can assess the environmental impact of print matter including displays and activations.

Together with them, we can educate the market about what carbon emissions within the printing industry look like and how we can improve them. Today, non-sustainable approaches can produce 10 times the carbon emissions of more sustainable options.

The growth of labels is also a focus for us. We started our labels division, Next Labels, in 2020 and this has resulted in good growth for the company. We previously acquired a small labels business called Rentons Labels, and last year also acquired another label company that was looking to exit the market. We have brought all these businesses together and

since 2020, the company has grown about four times from what it was. We intend to further expand it in the near future.

Q: What is the most memorable and unique project that Next Printing has worked on?

RS: There are a few unique and memorable projects we have produced. In retail, one of the most memorable ones was for a women’s clothing company –Jigsaw, which is no longer in Australia.

At the time the business commissioned this project, because the brand is UK based, it wanted to include some of the iconic British landmarks in its ‘pop-up’ project –think along the lines of a massive ‘pop-up’ greeting card. We had the Big Ben ‘pop up’ which we produced using different materials and blew it up in scale, in 3D to 2.4m. That project won us a global FESPA silver award in point-of-sale.

Some other projects that were unique are those we have produced with Sephora – as it has been a client of ours since 2018. At that time, sustainability was very low on its radar but since becoming an early adopter, using our sustainable print solutions for its Press Day events, it has become par for the course.

Q: What is your short-to mediumterm vision for the company’s future?

RS: With businesses still recovering from COVID, our short-to medium-term plans involve ensuring that the business can go back to where it was – not so much in terms of revenue, but with regards to performance instead. We understand that profit is one of the keys to making our business sustainable, but in order to do that, we need to perform. And for optimum performance, we need to attract good talent. That has been our focus for the last six to 12 months.

Medium-term, we want to grow the labels side of our business. That entails a bit of focus on using marketing as our driver to bring in more clients. We intend to use the expertise of our recent acquisitions to support this strategy. The machines we own are new and cutting edge with a higher capacity.

Q: What is your assessment of business requirements for print in 2023?

RS: I always go back to the importance of sustainability. Sustainability can carry a slightly higher price tag. We need to educate clients that it is possible to be sustainable without breaking the bank. We want our customers to be brands that have an environmental purpose. We will continue to educate them on the long-term benefits of sustainability and how they can build affinity with their own clients by showing that they care about their future. Data continues to show that customers will choose to buy from brands that support the same causes they do.

Q: What can the market expect from Next Printing in the next few years?

RS: In the next few years, on the large format side, Next Printing aims to continue to look at areas where we can make more of an impact in the marketplace. One of those areas is collaboration with brands and how we can align with their corporate values. This is quite a big challenge in a lot of companies as logistics is an issue.

I also want to expand our business to include more international projects with our local customers. This is something that we were given the opportunity to do this year with accounting software company Xero at its Xerocon 2022 events in London, New Orleans and Sydney earlier this year.

The company wanted something green and sustainable across all three locations. As the global lead for this project, Next Printing successfully executed it, which included over 200 custom booths made from Reboard – this was a first of its kind in the world.

SPRINTER.COM.AU AUSTRALIAN PRINTER NOVEMBER 2022 | 21 PEOPLE IN PRINT

Working with Next Printing, Sephora has adopted sustainability into its Press Day set-ups

The Jigsaw Big Ben and St Paul’s Cathedral project produced by Next Printing

Flint Group A/NZ targets growth with key appointments

One of the largest suppliers to the printing, packaging and labelling industries worldwide, Flint Group, has put A/NZ on its radar with the appointment of key personnel, taking the number of its local team to about 120 people.

The company recently promoted Paul Lamberti to the role of A/NZ general manager earlier this year following the retirement of Thorsten Schauer, who headed that role previously.

Prior to taking up this role, Lamberti was the A/NZ director of commercial, publication and sheetfed (CPS) inks at Flint Group, where he oversaw the business producing web and sheetfed inks to the local printing industry and the manufacture of coldset, heatset and sheetfed inks.

“I’ve been with Flint Group for over 20 years. I have a science and business background and started with the company as a technical manager in 2002. I then progressed through several commercial roles with the business and ran various business units within Flint Group before being appointed to this role,” he said.

The company also recently named David Mitchell as its new key account manager of narrow web in Australia and appointed Grant Tychsen to a newly-created role –New Zealand narrow web sales manager – in September.

Tychsen had many years of experience working in South Africa before he moved to New Zealand five years ago. Some of the companies he has worked for include Liquid Colours, Huber Group, Damar Industries and Cambridge Steel Fabricators and Engineers.

As for Mitchell, he has had several years’ experience in print having worked for Maxcess International as its sales director and customer service manager.

“Grant’s sales and technical experience lends itself very well to his new role. He is a good fit for our New Zealand market as it bolsters the commercial component of New Zealand,” Lamberti said.

“David has a lot of sales experience within the narrow web print market. His understanding of the narrow web market,

and his sales experience will assist Flint Group in providing growth for our business.

“Our plan is to execute our strategy, which is to grow our business in the Australian and New Zealand market, especially within our packaging business. So, the recent hires and appointments are key to the development of this strategy.”

Lamberti added that the company hires people with diverse experience, talent, and ideas to achieve business objectives.

“At Flint Group, we invest in people, and we look for long-term employees that understand and work with the Flint strategy. This is to deliver premium products and services to the to the print markets in Australia and New Zealand,” he mentioned.

“We encourage continuous learning and creative thinking, we promote team-based problem-solving, and we recognise and share successes. Continuous improvement drives performance and supports our aspiration to achieve excellence.”

With compliance and sustainability high on the company’s agenda, Lamberti said this will be central to Flint Group’s longterm engagement.

“A continuous improvement culture helps to reduce our current and future environmental footprint. Making progress on our sustainability journey would not be possible without the dedication of our employees,” he said.

“We strive to stay ahead of evolving regulations on chemicals, packaging and labelling. Over the years, we have maintained a strong focus on building and consolidating our sustainability culture. We have taken some important steps to reduce our environmental footprint, and we only partner with trusted suppliers who adhere to our high standards and uphold rigorous human rights and environmental standards.

“We’ve also globally launched a lot of sustainable products recently. Our customers are looking for innovation to offset inflationary costs, as well as solid partnerships. This will result in the needed stability in the market, especially with the ongoing disruptions to supply chains.”

According to Lamberti, Flint Group A/NZ will also focus on new product development, which includes the digitisation of the business.

“This means providing our customers with digital service solutions. We recently launched Flint Link, which is an app for our customers to do business using this program,” he said.

“We also have our global Colour Centre, based at Flint Group Poland, which we work with to support our customers through various digital packages like our Vivo Colour Solutions.

“We are here to partner with our customers and provide them with value-added solutions. The industry can expect stability with Flint Group and our dedication to our customers is and will remain unparalleled.”

SPRINTER.COM.AU22 | AUSTRALIAN PRINTER NOVEMBER 2022 FLINT GROUP HIRES

Hires David Mitchell and Grant Tychsen, and promotes Paul Lamberti in A/NZ as the company continues to support further growth in the region

Grant Tychsen, Flint Group’s New Zealand sales manager

David Mitchell, key account manager of Flint Group narrow web in Australia

Paul Lamberti, Flint Group A/NZ general manager

Smartech equips Global Signs with robust kit

Global Signs has improved on its speed to market and environmental efficiency after it purchased two HP Latexes and a Neocut 2516 from Smartech

Lagana mentioned that the service support from Smartech has been second to none.

“There are many resellers of HP machines, but we found Smartech’s technicians to be the best in their field. I’ve been around print since I was young but when it comes to the technical side of things, you need that support. And that’s where Smartech carries itself exceptionally as it has some good technicians,” he mentioned.

“They’ve also got colour specialists who’ve helped us get rid of colour inconsistency; we’ve got colour management across both the Latexes now.”

Moving forward, Lagana expects these machines to support Global Signs as it heads down a growth path.

NSW-based company Global Signs has purchased several machines from Smartech Business Systems over the past six months, alleviating challenges that it was facing previously and transforming its business.

Global Signs owner Joseph Lagana said the company initially invested in a HP Latex 700W from Smartech Business Systems around the middle of this year as it needed a machine that produced quality results while being environmentally friendly.

“Our business has evolved from being a vinyl plotter many years ago to expanding into wide format – predominantly servicing retail, and more recently moving into the online space also,” he said.

“Increasingly, over the last few years, we were being asked by clients about our printing processes and how environmentally friendly they were. Our industry is quite notorious for being the opposite – from its use of solvent inks and plastics, even through to some of the installation processes.

“So, one thing we could never get was the green process of printing. That got our minds ticking, because we wanted to be more conscious of the environment but also have a solution that was safer for our staff to operate. This drew us to HP and its Latex range.

“After we used the HP Latex 700W, we found that the results we were creating were

of better quality. It also allowed us a much better print process and was greener. It was a big change for us, but a positive one.”

Lagana said the business had a lot of options at that price range but picked the HP Latex as it is the only Latex flatbed in the market and seamlessly worked with its Onyx workflow system that it had in place since it started operating 15 years ago.

Not long after installing the HP Latex 700W, Global Signs wanted to take advantage of the growth opportunities that presented themselves and further boost the company’s productivity. It then invested in a HP Latex R1000 and Neocut 2516, also through Smartech, at PacPrint.

“This investment just skyrocketed our productivity. We decided quite quickly to go with the R1000 and the reason we ended up with the Neocut was because we said we wouldn’t buy another flatbed without a cutter. We never had an automated cutting system and used to outsource this work, which resulted in us losing speed as we were always relying on someone else to do it for us,” Lagana said.

“HP is ahead of its time with its technology and is the benchmark for any serious business. It has spent a lot of money on R&D, and has perfected its Latex machines. The R1000 gave us roll-to-roll and flatbed capabilities, and the Neocut has added to that as well. It has been a huge, positive change for our business.”

“We’re trying to grow the business and we’ve got our eyes on the next 20 to 30 years, not just tomorrow. My aim is for Global Signs to be one of the biggest wide format printers in Australia. And to survive today, especially with labour being scarce or costs being extremely expensive, you need machines that can deliver on productivity,” he said.

“So, we need to be smart with how we purchase equipment and make sure that we take the right path.”

In addition, Lagana said Smartech will continue to be its trusted partner.

“We’ve always had them as our main supplier; our relationship will continue as it always has. Going down the HP route will help them and help us in the future,” he said.

“Looking forward, whether it’s an additional machine or a larger one, I foresee that relationship with Smartech to be there.”

SPRINTER.COM.AU24 | AUSTRALIAN PRINTER NOVEMBER 2022 INSTALLATIONS

Global Signs’ Joseph Lagana with the Neocut 2516 machine

The HP Latex R1000 gives Global Signs roll-to-roll and flatbed capabilities

Lagana with the HP Latex R1000 (l) and HP Latex 700W (r)

Large Format Printers & Finishing Equipment

Designed for Today’s Market

NeoCut-2516

Flatbed cutter

Automate your cutting and creasing solutions with the Neocut 2516 (2.5m x 1.6m). Automatic flatbed cutting machine for rigid and flexible substrates. Features include Auto roll feeder, Automatic contour recognition, and Jwei cutting program. Optional extras include high frequency router and OptiScout Software.

Suitable for: cut paper card, coated paper, PVC, special paper, corrugated paper, grey cardboard, honeycomb paperboard, ABS , PVC , EPE, EVA , light box pieces, KT board, posters, light boxes, display racks, personalized signs, flags, banners, car stickers, magnetic stickers, billboards.

HP Latex 700w

Grow your business with high-value, profitable jobs and high-productivity printing with white ink. All while at the same time as improving your sustainability edge. Produce the highest value jobs, robust, smart, and productive printing, sharpen your sustainability edge with HP Latex.

Suitable for: Banners; Displays; Exhibition and event graphics; Exterior signage; Indoor posters; Interior decoration; Light boxes - film; Light boxes - paper; Murals; POP/POS; Posters; Textile; Vehicle graphics; Window graphics; Stickers.

HP Latex R1000

Help grow your business by printing high-value jobs on one device with white, rigid and flexible. The HP Latex R1000 Plus Printer allows you to transform rigid printing in ways you never thought possible..

Suitable for: Signage: indoor, flat, backlit, thermoformed; Decoration: wall coverings, window decoration; Vehicle decoration: fleet graphics, wraps, decals; Textile: soft signage, front lit, backlit; POS and Packaging: corrugated displays, short-run customised packaging, prototyping.

ebusiness@smartech-aust.com1800 422 349 smartech-aust.com SMARTECH Business Systems

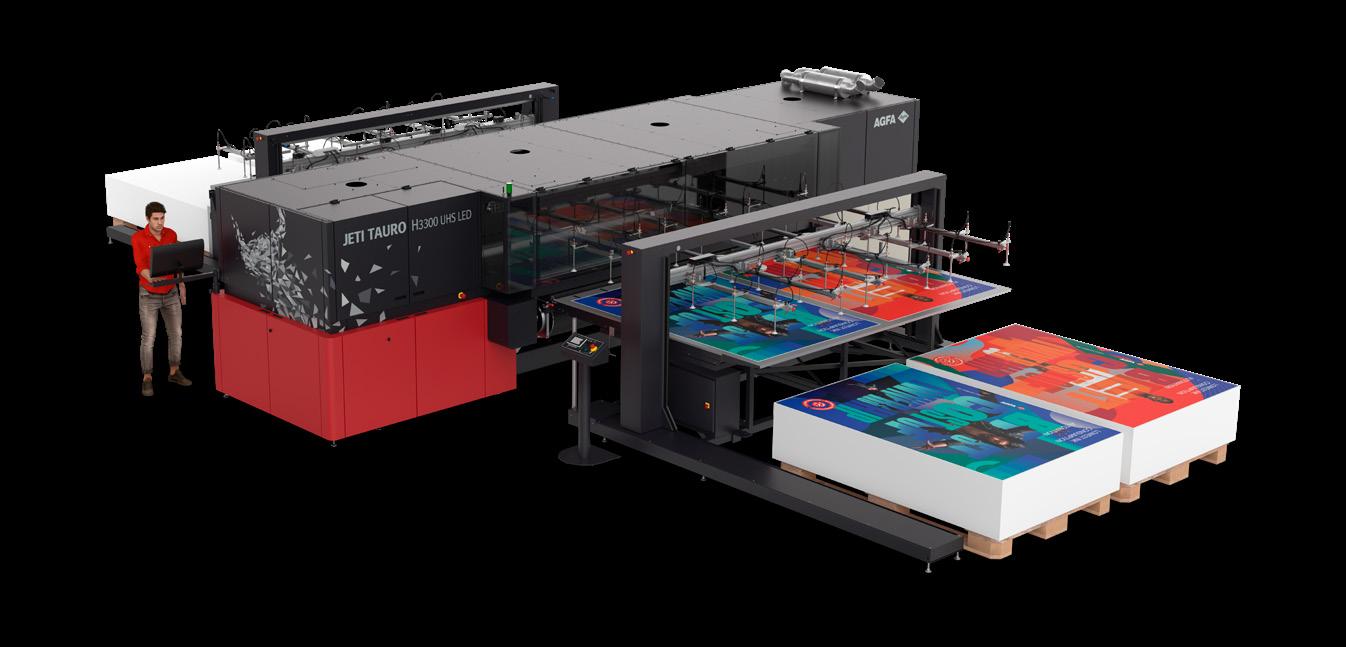

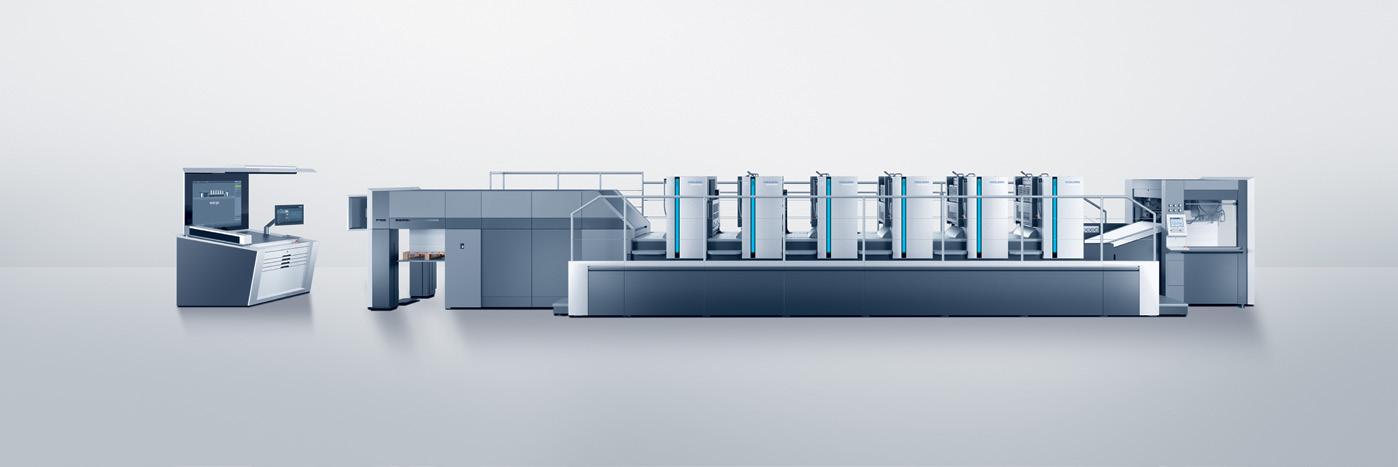

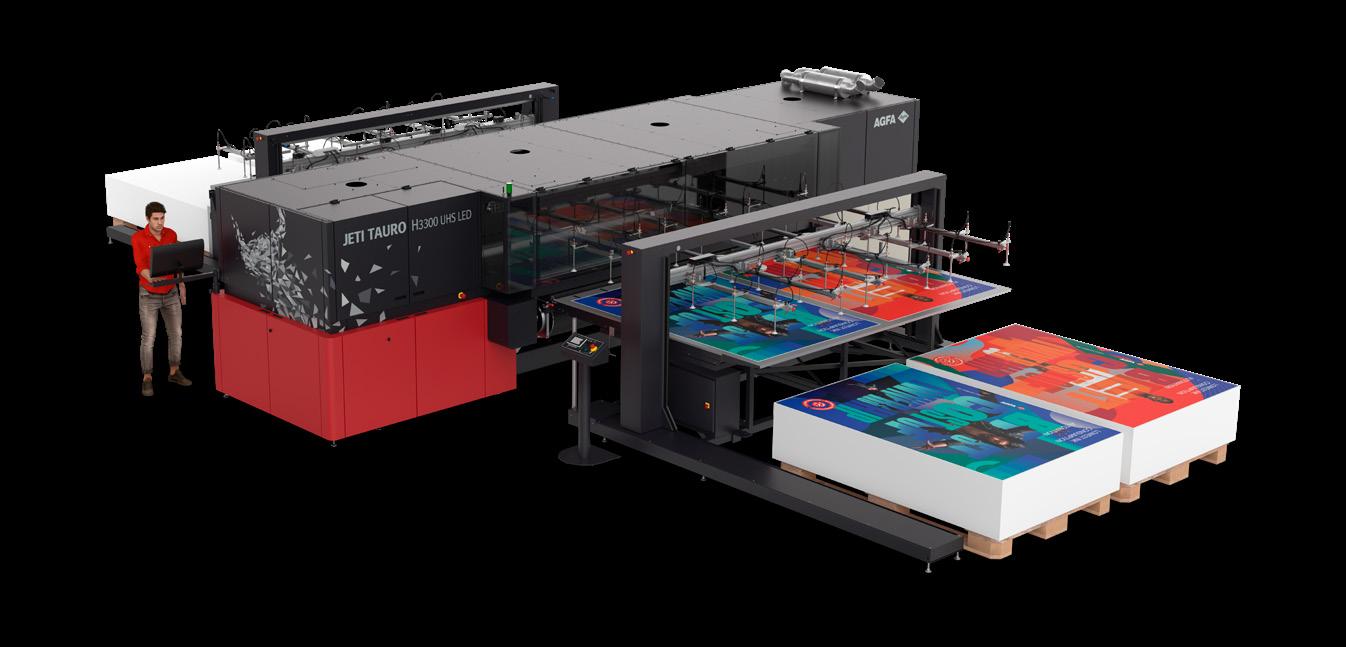

Agfa showcases next-gen tech at Printing United

At the Las Vegas exhibition, Agfa had a range of its largeformat inkjet printers in action, as well as several software solutions for inkjet and offset printing on show

high-quality long-runs with consistency and reliability.

“We are committed to the digital printing industry, with solutions for both sign and display and industrial applications. Visitors that were looking to step up their game dropped by our booth to explore our offering and we believe they found the solution they were looking for,” Agfa director of industrial inkjet Tom Cloots said.

Agfa also showed two of its Pinnacle Product Award winners at the booth, the first being the Avinci CX3200, a 3.2m dye-sublimation printer.

This roll-to-roll printer prints directly on a wide range of polyester-based media, as well as on transfer paper. It lets users create vibrant, high-quality prints on polyester-based fabrics up to 3.2m wide, to be used for a broad range of indoor and outdoor soft signage applications, as well as interior decoration.

“A rich colour gamut with deep blacks and vivid reds makes this printer the perfect solution for making retail banners and other instore advertising,” Agfa textiles business manager Mike Horsten said.

Agfa took to Printing United again this year with an offering that is bigger and bolder than it has ever done before. It showed a broad range of its large format inkjet printers, as well as several software solutions for inkjet and offset printing.

After the announcement that Agfa won five Pinnacle Product Awards this year –four for the Jeti Tauro family and another one for the new Avinci CX3200 dyesublimation textile printer – it was clear that Agfa is a force to be reckoned with. Agfa is the first digital inkjet company to win five awards at one show.

Agfa global business manager for Interiojet Mike Horstern said, “Our inkjet solutions have won five Pinnacle awards from the Printing United Alliance. This is testament to our dedication to deliver innovative technology with superior performance and reliability.

“We see great possibilities for our inkjet solutions in Australia and New Zealand, especially in the big population centres where there is a lot of retail going on. Textiles is a growth market and the Avinci has good possibilities.

“At Agfa, we are a full service provider. We build the inks, the machines and the

software. On top of that, we have great international service. Agfa has a great heritage in software; you can build high end workflow into your systems. For us, covering everything is important. These big presses are major investments and our machines have high uptimes that is extremely important these days.

“We also have a heritage in offset and we have translated those offset attitudes into inkjet as we look to get an equal offset quality on inkjet. But most importantly, we have an honest relationship with our customers.”

Agfa had several of its presses on display, including those from Inca Digital Printers, the UK-based manufacturer of flatbed inkjet printing technology that Agfa acquired in May of this year.

The OnsetX3 HS was showcased with a full-fledged robot feeding system. This printer can produce 600+ full sized boards (1600mm by 3200mm) per hour – or 1440 m²/h – in an amazing quality.

The OnsetX3 HS features three CMYK ink channels plus the choice of white or orange, sitting at the pinnacle of productivity. With this printer, users of analog screen-printing lines can take the digital route, confident they can print

“The new Avinci inks finally allow you to have perfect solids, accurate spot colour mapping and smooth tonal rendering that is particularly noticeable in skin tones, at high printing speeds. Through the process of dye sublimation, soft signage prints look amazing and are produced sustainably. In addition, they are easy and efficient when it comes to transport.”

Finally, the Jeti Tauro H3300 HS with varnish was shown for the first time in the US. The high-speed UV LED wide-format inkjet hybrid printer is capable of printing full flood varnish at 75 m²/h, and can be used to print on a range of rigid and flexible media.

Producing detailed prints up to 3.3m wide at up to 600 m2/h is possible thanks to the unique UV LED curing technology of Agfa’s signature high-pigmented UV inks and the smart colour management features of the Agfa Asanti workflow software.