Tuesday, October 14 2025

Auckland

Tuesday, October 14 2025

Auckland

October event provides opportunities to learn, to connect, and to celebrate the industry.

Later this year, New Zealand Printer magazine will partner with PrintNZ and industry sponsors to present the inaugural Printing & Packaging Forum at Sorrento in the Park, Maungakiekie One Tree Hill, Auckland.

The event will run during the day on October 14 and will precede the People In Print Awards and Rising Stars of Print Awards, which will take place at the same venue.

Open to all members of the printing, labels, packaging, and signage sectors, the Printing & Packaging Forum will present a range of ideas and case studies focusing on current and future trends within the industry.

Ruth Cobb, chief executive of PrintNZ, says, “PrintNZ is delighted to work with New Zealand Printer magazine to bring the industry a one-day Printing and Packaging Forum.

“This will be a great opportunity for members to hear from industry leaders about developments across the sector, and it will provide the chance for more than just the business owners to listen and

learn. We have not held a PrintNZ Forum for a number of years and it is great to get this event off the ground again, allowing members to connect with both speakers and other participants.

“It is great that the event will then morph into the New Zealand People In Print Awards and Rising Stars of Print Awards which recognise those in the industry that have made a contribution during the previous 12 months, acknowledging the hard work that many of you do.

“We look forward to working with New Zealand Printer magazine and the event sponsors to bring you the Printing & Packaging Forum.”

The Printing and Packaging Forum will not only bring a variety of industry experts to deliver high quality presentations, it will also provide space for attendees to meet and exchange ideas and perspectives on their businesses.

Bruce Craig, editor of New Zealand Printer magazine, adds, “The message we hear from listening to industry professionals is how much they gain from talking to and listening to their peers and

experts in the sector. This is one of the major attractions for trade shows and Awards events.

“One of New Zealand Printer magazine’s sister publications, ProPack.Pro, recently hosted a one-day forum and the feedback from that event confirms the value of bringing industry members together.

“With the Printing & Packaging Forum, we will bring a variety of groups and individuals together for that purpose. This event offers you a specific opportunity to connect with people who can help you take your business to another level.

“At the end of the day, with the People In Print awards and Rising Stars of Print Awards, we can celebrate the achievements of the people in our industry and the emerging talent who will take us into the future.”

Over the next few months, New Zealand Printer magazine will keep you up to date with all the details of the event including keynote speakers, forum topics, and timings.

Brian Moore, New Zealand Printer magazine publisher, says, “We look forward to working with PrintNZ and our sponsors to deliver an event worthy of the local industry.

“The People In Print Awards and Rising Stars of Print Awards have grown year on year and have now become a regular event that industry members look forward to.

“These Awards have been held close to the beginning of the year but, with so many events in the first half of 2025, such as PacPrint and Fespa, these awards will move to October to follow the Printing & Packaging Forum. Obviously, some Forum attendees will also want to go to the Awards, so it makes good sense to dovetail them in.

“Sponsorship packages are available. Please contact me either email brian@newzealandprinter.co.nz or phone +61 410 578 876 for further information about the event.”

3 Printing & Packaging Forum: The first New Zealand Printing & Packaging Forum will welcome industry professionals to participate in a one day event in Auckland featuring guest speakers from overseas. The day will round off with the People In Print Awards and Rising Stars of Print Awards.

5 Heidelberg: As it celebrates its anniversary year, Heidelberg will tackle the challenges of the future with a clear growth strategy.

6-8 News: This month our news features: Southan Print buying Signs n Stuff; Currie Group winning a major HP award; the drupa committee planning for the next show; and much more.

22-23 Training: Torque Digital and PrintNZ have combined to deliver job placements for students interested in careers in the industry.

24 PacPrint: The May show has announced its first keynote speaker, Steven Gamble, founder of Anchor Health.

25 Kale Print: Work has begun on Kale Print’s new purpose-built premises, which will bring all its operations under one roof.

26 Business: Peter Fotiadis discusses how you can develop areas of opportunity to enhance your business.

30 Think Laterally: Mick Rowan explains the steps you can take to keep your business momentum going after taking a break.

38-40 Women In Print &

The recent Auckland and Christchurch events saw increasing numbers of women attending.

15 Introduction: Digital print is everywhere, but are you taking full advantage of the technologies and solutions available?

16 Fujifilm Business Innovation: Indigo Print has installed a new Revoria Press PC1120 and an iECHO PK4 cutting system.

18 Currie Group: The HP Indigo 120K Digital Press delivers high productivity alongside the HP Indigo gold standard print quality.

20 Konica Minolta: Chris O’Hara explores the ways that Konica Minolta has mastered advanced UV inkjet technology.

10-12 PrintNZ Helping Hand: Iain MacIntyre finds out how museums are preserving our rich print heritage.

13 PrintNZ Comment: PacPrint offers opportunities to see the latest technology, network, and learn industry trends, says Ruth Cobb.

27 Research: Smithers says the packaging print market will hit a global high in the wake of drupa 2024.

28 Durst: Matt Ashman, managing director of Durst Oceania, discusses exciting new options for labels and packaging companies.

32 Aarque Group: Roland DG has released its new flagship, the TrueVIS XP640, which delivers the highest output in its class.

34 Wide Format News: Durst Oceania adds a new team member; Summa releases its latest cutting system; and Agfa unveils the new Anapurna Ciervo H2500.

35 NZSDA Update: Mikayla Hopkins has all the latest from the NZSDA including details of the 60th Anniversary NZSDA Conference.

36-37 Sign Network: Canon Fafeita has moved from sign language to sign making.

EDITORIAL: 021 631 559

Bruce Craig, Editor - bruce@newzealandprinter.co.nz

CONTRIBUTORS: Matt Ashman, Ruth Cobb, Peter Fotiadis, Mikayla Hopkins, Iain MacIntyre, Chris O’Hara, Mick Rowan

CIRCULATION: brian@newzealandprinter.co.nz

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876

CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz

DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com

New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December.

New Zealand Printer is a member of the Printer Media Group

New Zealand: New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint

MANAGING DIRECTOR: James Wells - james@intermedia.com.au

GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

© Copyright 2025: Contents of this magazine are subject

Growth strategy aims to realise potential across printing and other businesses.

As it enters its anniversary year, Heidelberg says it will tackle the challenges of the future with a clear growth strategy.

Jürgen Otto, chief executive officer of Heidelberg, says, “To expand our market position, we are increasingly tapping into growth potential in our core business in packaging and digital printing as well as in the software and lifecycle business.

“We will also continue to expand our offering in the growing green technologies market. This includes key areas such as high-precision mechanical engineering, the automotive industry, charging infrastructure and software, and new hydrogen technologies.”

March 11, 2025, marks the 175th anniversary of the company’s founding. What began over a century and a half ago as a bell foundry in Frankenthal in the Palatinate region of Germany, has since developed into a leading global technology company and total solutions provider for print shops and packaging applications.

Growth potential

Heidelberg sees growth potential of more than €300m ($554m) in sales for all strategic initiatives by the 2028/2029 financial year, while at the same time consolidating performance and increasing efficiency.

Benefiting from the constantly growing global demand for packaging, Heidelberg says the end customer market for packaging has grown by more than 6o per cent worldwide over the past decade. In cooperation with Solenis, Heidelberg is responding to the global trend away from plastic and foil towards paper based packaging and will offer solutions for printing recyclable packaging, particularly for the food industry. The company already generates more than 50 per cent of its turnover in the packaging segment. And the trend is clearly upward.

According to market estimates, the global digital printing market accessible to Heidelberg, including service and consumables, will grow from around €5bn to €7.5bn by 2029. Heidelberg has significantly expanded its offering,

Heidelberg has helped shape the printing industry for 175 years with innovations, quality, and reliability. The company has set new standards with pioneering developments such as the ‘Original Heidelberger Tiegel’ and the ‘Speedmaster’ model series for sheetfed offset printing.

Jürgen Otto, says, “175 years of Heidelberger Druckmaschinen is a strong testimony to consistency, as well as innovative strength and thus future viability.

including through its cooperation with Canon. This will significantly increase sales of digital printing solutions. Incoming orders already confirm this from the next financial year.

Global presence

Heidelberg sees a lever for more sales growth in its strong international presence in around 170 countries worldwide, with one of the largest global sales and service networks. The company will continue to expand this internationalisation, particularly in growth markets such as Asia, the USA and emerging markets. Heidelberg has the best prerequisites for this, particularly in China, thanks to its local production and partnership with MK Masterwork. More than 85 per cent of the company’s business is already conducted outside Germany.

Another focus is on Heidelberg’s industrial business to open new product areas, markets, and industries. To this end, the company has extensive skills, expertise and resources that are currently already being used outside the printing industry, particularly in the fields of high precision mechanical engineering, the automotive industry, electromobility and hydrogen. The company is also increasingly offering its expertise and installed capacities to other companies to efficiently industrialise or manufacture their products.

“Thanks to its impressive achievements over the past 175 years, the company is looking forward to further growth in the coming years with its current market position, the expertise of its employees and global customer relationships.”

Together with customers, employees, and partners, Heidelberg is celebrating its anniversary year with numerous events and activities.

It will host a week of celebrations at the Wiesloch-Walldorf headquarters in the newly designed demonstration centre, ‘The Home of Print’. This will include an anniversary ceremony with guests from all over the world including customers, suppliers, partners and representatives from politics and society. Family days are planned for employees at individual locations. In addition, there will be an anniversary magazine in which the history of the company will be presented, and the future will be directed.

With around 9,500 employees worldwide, production facilities in several countries and regions, including China and the USA, as well as the densest sales and service network in the industry, Heidelberg is now a true global player and world market leader from Germany. Juergen Otto adds, “Our history impressively demonstrates how entrepreneurship, technical expertise and the genuine creative power of our employees can have a lasting impact on a company over such a long period of time and, far beyond that, on an entire industry to this day.”

SIEGWERK has introduced the first nitrocellulose free ink series specifically designed for surface printing on polyethylene and polypropylene packaging solutions. It includes solutions for flexo and gravure printing. Siegwerk says it developed the ink series to meet the latest packaging design guidelines. Björn Ewig, head of technology for flexible packaging at Siegwerk, says, “These new ink systems, ensure recyclate quality that meets the latest Design for Recycling guidelines without compromising on print or packaging performance.”

COLOR-LOGIC has released Volume 2 of Text-FX, which provides graphic designers with a stylised Illustrator palette of 40 text effects. It enables creatives and graphic designers to change the way they use text in various projects such as including signage, posters, and greeting cards. Mark Geeves, director of sales and marketing for ColorLogic, says, “Text-FX provides tools that enable designers to push the boundaries of creativity. Even those new to design can create stunning professional-level text effects.”

ESKO says it will bring more than 500 packaging and labels converters, brand representatives and packaging experts for its Esko World 2025 event set June 3-5 in St Louis, Missouri, USA. Joël Depernet, president of Esko, says, “For this year’s packed event, we have introduced a new format to make it easier for attendees to enhance their knowledge. Sessions include dedicated presentations, discussions and roadmap groups aimed at labels and flexibles; brands; or corrugated/folding carton conversion.”

Southan Print has acquired fellow Auckland company Signs n Stuff.

Dylan Southan, managing director at Southan Print, says, “We are excited to share that Signs n Stuff, an iconic screen-printing and signage business, is soon to be part of the Southan Print family. This partnership brings together two companies with a shared passion for quality, innovation, and service.”

Karlville and Vetaphone have partnered for corona treatment on laminators, adding the VE1H-C(C4)920 corona treater units and iPM200 generator modules to the Karlville TL800 laminator.

Currie Group supplies Karlville solutions in Australia and New Zealand. Karlville machines produce a variety of

“Since they founded Signs n Stuff in 1980, Grant and Cheryl Bavister have built a strong reputation for highquality screen printing, using both conventional, and UV ink methods for durable results. They specialise in printing on materials like powder-coated metals, acrylics, and plastics

shrink sleeves, pouches, tapes, and multipacks for the label and flexible packaging sectors,

John Price, president of Karlville, says, “It is important that every ancillary supplier matches the quality of our brand, and that includes prompt and responsive aftersales support.

“Vetaphone came with an excellent reputation from many leading manufacturers in the market. We needed a corona system that we could neatly integrate with our laminator and Vetaphone responded quickly and within budget. They are innovative and their technology fits well with our policy of best total cost of ownership.

“The TL-800 is an environmentally friendly

plus a lot of niche products.

“Grant and Sheryl have created a legacy of excellence at Signs n Stuff, and as we bring the business under the Southan Print umbrella, we are excited to continue their commitment to quality and service.

“By merging the expertise and technology of both companies, we now offer an even broader range of printing services, including materials like powder-coated metals, acrylics, and low-surfacetension plastics.

“Our expanded range of services includes screen printing, digital printing, custom signage, specialty finishes, and packaging. We look forward to continuing to serve our customers’ printing needs with enhanced capabilities and the same dedication to quality that they know and trust.”

machine, with no volatile organic compounds, odour, or any health issues, making it suitable for the food and personal care sector. It offers best time to market with minimal waste. Most of all, it is reliable, and that is why we chose Vetaphone corona treaters.”

The Vetaphone equipment treaters are single-sided and fitted with ceramic electrodes with roller faces of 920mm.

The generator has a power output of 8kW and gives accurate watt density control by following the line speed automatically. It has a zero speed switch and automatic start relay that protects the RD62UR standard blower fan that Vetaphone also supplied.

HP Industrial Print has announced its pride at Currie Group’s recognition as the winner of the APJ HP Industrial Print Marketing Excellence Award, celebrating the company’s outstanding contributions to marketing innovation and its role in elevating the print industry across Australia and New Zealand.

This accolade highlights Currie Group’s partnership with HP, which has successfully driven awareness and consideration of HP Industrial Print technology in the region. Through strategic initiatives and collaborative efforts, Currie Group has set new

HP has released two new PageWide presses. Designed for a wide variety of publishing, direct mail, and commercial print work, the T4250 HDR features fast speeds and consistent print quality, allowing customers to print more high volume, high coverage jobs.

The new HP PageWide T4250 HDR 106cm web press prints up to twice the productivity of its predecessor, the HP PageWide T485 HD, resulting in 20,000 B1 duplex sheets and over 200,000 lettersized duplex colour pages per hour.

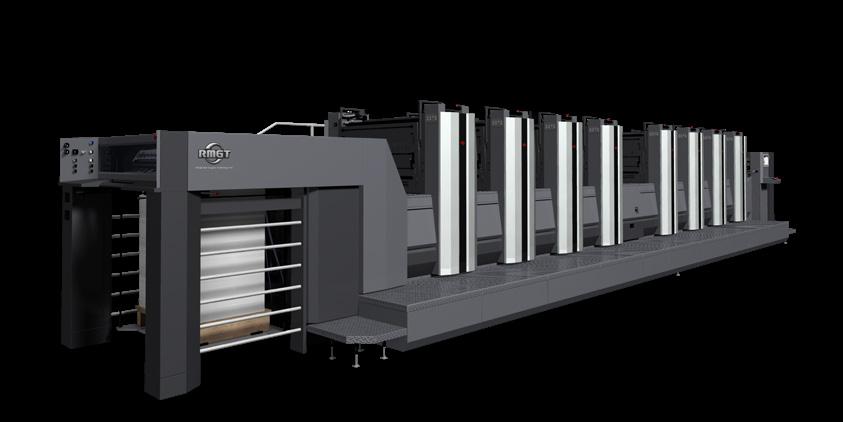

Cyber recently took a team of 12 Vietnamese printers to the RMGT headquarters in Japan. The visit forms part of Cyber’s strategy to increase recognition and promotion of RMGT products in the Vietnamese market.

After arriving from Kyoto by bullet train, the visitors were greeted by RMGT vice-president of engineering Yukio Murashige, followed by an informative

benchmarks for impactful, integrated marketing in the print industry.

Rob Mesaros, chief executive officer of Currie Group, expressed his gratitude for the recognition. He said, “This award reflects our dedication to empowering businesses with transformative marketing strategies and solutions.

“Our partnership with HP has been a key driver in showcasing the immense potential of print technology, and this recognition inspires us to continue leading the way in delivering value to the industry.”

Matt Tangey, marketing manager at Currie Group, reflected on the achievement, adding, “This recognition

Combined with HP Optimizer, the press maintains high speed and quality on coated and uncoated media with weights ranging from 40gsm to 350gsm. This press also comes with the benefits of thermal inkjet technology: eight nozzle redundancy, user replaceable printheads, automated web-wipe cassettes, and on press colour profiling.

The machine also keeps environmental sustainability in mind. HP Brilliant B70 Ink has low VOCs and reduces drying time, with up to 50 per cent less energy use than that of the T485 HD.

HP says the HP PageWide Web Press T500M HD offers book manufacturers a purpose built solution to meet their clients’ demands for shorter run lengths, tighter turnaround times, and more frequent high volume orders.

presentation from senior advisor Kohei Yatsumoto on the company’s history, recent trends, product lineup, exhibition achievements, visitor engagement, and CSPI initiatives.

A factory tour ensued, where the visitors saw the new RMGT factory 3 and diecasting factories, demonstrations of the RMGT 970PF-8 and RMGT 970ST-5, and the presentations of the RMGT 1060LX-6.

Through demonstrations of RMGT’s autonomous solution Smart Assist Printing by PQS-D and chemical embossing with skeleton transfer cylinder, the group was also able to experience firsthand how RMGT’s technologies offer labour-saving and skill-free solutions to meet a variety of demands in different applications.

from HP highlights the power of collaboration and shared vision. It represents our focus on engaging the market with meaningful initiatives that showcase how print technology can transform businesses.

“I am proud to work alongside a team and partners who are committed to helping our customers succeed.”

HP highlighted Currie Group’s outstanding marketing leadership as the driving force behind this recognition. Arnon Goldman, general manager, Asia Pacific at HP commented, “Currie Group has set the standard for marketing excellence in the print industry through strategic collaboration, innovation, and an unwavering commitment to driving awareness of HP Industrial Print technology.

“Their always-on media presence, dynamic industry partnerships, and impactful event activations, especially around drupa have not only elevated HP’s market presence but also redefined engagement in the sector. Currie Group’s ability to blend creativity with strategy makes them a true leader in marketing innovation.”

The company has designed the 137cm press to use standard offset media and impositions, allowing operators to shift between offset and digital print lines, reduce paper inventory, and streamline labour resources.

HP adds that its 305 metres per minute speed rivals offset turnaround times and throughput by producing finished book blocks of variable trim sizes that move directly to the final production stage, saving time, labour, and floor space.

With reduced paper waste at startup and between jobs with variable cutoffs, an optimised factory floor, and the complete elimination of offset aluminium plates, this press features the environmental advantages of industrial inkjet without compromising productivity or profitability, according to HP.

The sessions evolved into deep interactive experiences with guests asking detailed questions about colour sequences in printing and the effects of chemical embossing. This led to a more engaging, step by step approach, where they gained a deeper understanding of RMGT’s machines’ capabilities.

RMGT said, “Our hospitality left a strong impression, and we received words of gratitude from both our clients and our agents for the thoughtful and seamless execution of the visit.

“We hope the visit was a very fruitful one for the customers and distributors. We intend to continue working closely with our distributors and agents to actively and consistently promote such events and sales expansion initiatives.”

The drupa committee met recently and confirmed Dr Andreas Pleßke, chief executive of Koenig & Bauer AG, as chairman.

The committee also reappointed Wolfgang Poppen, managing partner of Freiburger Druck and president of Bundesverband Druck und Medien, as his deputy. Both votes were unanimous.

Dr Andreas Pleßke says, “It is a special honour for me to continue to actively help shape the development of drupa as chairman of the drupa committee. The world is changing rapidly, both in technical and political terms.

“Together with the committee we will ensure that drupa constantly develops further to also assert its pole position as a world-leading trade fair for print technologies in future and to orient the industry for the future.”

Wolfgang Poppen says, “drupa is the centrepiece of the industry, a place of innovations and technology launches. The coming months will be used intensively to further sharpen the profile of drupa’s position in 2028.”

Four new members were added to the committee. They are:

• Markus Hoffmann, executive senior vice president, Leonhard Kurz and chairman of the Printing and Paper Association (VDMA).

• Marcel Martens, general manager Industrial Print EMEA Direct, HP Indigo and PageWide, HP Industrial Printing.

• Thomas Heininger, chief executive officer MBO Postpress Solutions and chief executive officer Komori International Europe

• Peter Voigt, managing director, Perfecta Schneidemaschinenwerk

The committee has initiated its strategic process towards drupa 2028.

The organisers say drupa intensely works on an innovative concept that aims to particularly leverage new target groups in a constantly transforming industry and to promote high-calibre knowledge transfer. Alongside the proven trade fair

format, they are developing innovative formats to enable stronger networking. The focus will increasingly be on brand owners and multipliers.

A central component of the new strategy is the identification and presentation of relevant technology trends, that determine the future of the print and packaging industry. Topics such as Artificial Intelligence, automation, sustainable printing processes and digital transformation continue to be centre stage in all this.

The drupa committee says it is highly committed, with a clear vision as it prepares the groundwork for the key decisions for drupa 2028. In 12 months’ time, the trade fair will kick off its exhibitor registration again.

Founded on the first drupa in 1951, the drupa committee and its members comprise equal numbers of exhibitors and visitors. Its task is to consult Messe Düsseldorf on the conceptual and sector-relevant further development of the leading trade fair.

The committee members represent six industry associations:

• Printing and Paper Technology Association

• German Printing and Media Industries Federation

• Paper-Processing Trade Associations

• Paper Industry

• German Printing Ink Industry Association

• Flexographic Printing Association

The committee says personal dialogue with key experts and multipliers on the part of manufacturers and users in this industry is of relevance in times of ongoing change in the industry.

Print museums show dedication to rich print traditions.

Operational print museums and other related initiatives are restoring New Zealand’s rich print heritage as well as introducing next generations to historical techniques and equipment which likely would otherwise be lost in the annuls of time.

Largely run by teams of dedicated volunteers, examples include the Museum of Transport and Technology (MOTAT) Print Shop in Auckland; The Printing Museum in Upper Hutt, Wellington; the Ferrymead Printing Society in Christchurch; and the Wai-te-ata Press at Te Herenga Waka, Victoria University of Wellington.

Now proudly in operation for over 20 years, the MOTAT Print Shop’s equipment has come from a variety of sources, largely from the closure of letterpress printers and with the disestablishment of letterpress from universities and polytechnics.

Team member Alan Curtis says, “We have a variety of printing machines, from the

humble Adana, through several early Treadle machines, to the ubiquitous Heidelberg Platen and its flatbed cylinder companion. We also have an operational Ludlow and a Linotype.

“Our machines are important. However, we also prize the ability to design and compose material for them to print, which keeps our machines alive and working.”

Last year, the Print Shop team worked with MOTAT to undertake a total refresh of its working space. Alan says, “We did this to provide a better working environment for compositors and machinists, as well as for our visitors”.

“We have been immensely pleased with what we have achieved and as a result, our volunteer numbers are increasing. The

new arrangement provides workspaces for our compositors and machinists while still allowing MOTAT visitor access to see what we do.

“On our most active day, Sunday, we usually have guides with a good knowledge of letterpress to talk visitors through the process. We enjoy sharing the knowledge with our visitors, and everyone gains new knowledge and hopefully a greater understanding of historical and craft printing.”

One of the Print Shop’s latest objectives is to engage with visitors to register for ‘print experience opportunities’. We are developing these with the goal to trial the programme with MOTAT’s own team members. It will then be offered to the museum’s ‘MOTAT Mates’ – visitors who have season passes.

Alan adds, “We are also planning more formal evening and weekday classes for those who want to try their hand with a view to taking up the craft.”

Dan Tait-Jamieson, secretary/treasurer of The Printing Museum, says the organisation possesses houses both the largest printing collection and the only operating type foundry in the Southern Hemisphere.

He says, “The collection is notable for the original Albion press from The

Dan Tait-Jamieson, secretary/treasurer of The Printing Museum

Evening Post, both the Australian and New Zealand Monotype matrix libraries, items from the Government Printer, line casters, poster presses and many more.

“The Museum started in the ‘80s when letterpress was in decline and much of the equipment was either being disposed of or destroyed. Members of the trade banded together to save as much of their own history as possible and have been searching for a permanent home ever since – without which, the collection will always be in danger.

“Today, the membership is around 200; all volunteers, making it one of the larger such organisations in the world.”

At present based in an old Army storage warehouse behind Upper Hutt, The Printing Museum is currently in negotiations to acquire more suitable facilities, for which it will need to raise one million dollars in funding.

Dan says, “In late 2020, the Museum opened the Wellington Centre for Book Arts (WCBA) in the heart of Wellington. The WCBA comprises a composing room, printery and bindery, the last being a donation from Parliament’s General Assembly Library. Classes are held here and advertised on the Museum’s Meetup group.

“The Museum is about to sign off a sale and purchase agreement for a charming, industrial building in Wallaceville, Upper Hutt. Then, the more difficult task of fundraising will begin.

“We are hoping that the trade will come to the party and New Zealand will finally have its own proper National Printing Museum.”

Following the Printing Craftsman’s Club principles of “share the knowledge”, the Ferrymead Printing Society operates as a non-commercial, fully operational printing museum within Ferrymead Heritage Park.

Gary Parker, treasurer of the Ferrymead Printing Society, says, “Eight years ago the printing museum added a studio exploring letterpress printing as an art form, introducing print making and dry point printing using a range of vintage proofing presses.

“The Printing Society was first registered as a charitable organisation in 1971. We currently have 51 members, 16 of whom are children under the age of 15.”

The Printing Society consists of several different print groups. He says, “Our Junior Print Club of young children from the age of nine to 15 learn to handset their own inspirational quotes, and lino-cutting images mixing colours and printing them on our hand presses.

“We have a small bookmakers’ circle working and learning together, creating their own short story books.

“By affiliating with the ‘School of Bad Printing’, an international group of

printers, we are joining in keeping the spirit of Hendrik Werkman alive. Werkman’s work was described as ‘bad printing, his work had no structure’. We have a group of artists enjoying the challenge of making a bad impression using different forms of printing to create their art.

“There is also a small group who meet weekly, enjoying using our printing equipment, experimenting and making a range of craft products.”

In a forward-looking drive, Gary says the Printing Society is also developing external partnership initiatives. He explains, “We are working in conjunction with the Christchurch Art Gallery, holding workshops with print artists in conjunction with installations at the Art Gallery, and strengthening our relationship with tertiary education providers, keeping printing knowledge alive for future generations relearning old skills and methods of print.”

Wai-te-ata Press

Since 2016, the Wai-te-ata Press – Te Herenga Waka | Victoria University of Wellington has worked with the Chinese community to help restore a collection of distinctive Chinese movable type.

Dr Sydney Shep, the Wai-te-ata Press reader in book history/printing, says the Hong Kong-sourced tonne of lead was used to print The New Zealand Chinese Growers Monthly Journal from 19521972, the newsletter of the Dominion Federation of New Zealand Chinese Commercial Growers.

She says, “These beautifully crafted types served as a critical medium for preserving

and sharing the voices of early Chinese communities in Aotearoa.

“For the Federation, this history resonates deeply, reminding them of the resilience, innovation and determination of the growers who contributed so much to New Zealand’s horticultural legacy.

“The collection is housed in the Press’s Chinese Scholars’ Studio and represents one of the most extensive collections of Chinese traditional or full form type outside Asia.”

She adds that repatriating these distinctive types back to Wellington and putting them back into action offers an “unprecedented opportunity”.

She explains, “Victoria University of Wellington is helping to link the past with the present; language with culture; scholars with communities; and to catalyse new interest in the complexities of Chinese print history and its New Zealand stories.”

The Chinese Scholars’ Studio and Heritage Type project is supported by donations from the Chan family, the Chinese Poll Tax Heritage Trust, the New Zealand China Friendship Society and the Dominion Federation of New Zealand Chinese Commercial Growers.

She says, “The Dan and Una Laywood and Joyce Chan Residency at Wai-te-ata Press, which honours the first editor of The Monthly Journal, encourages communities to interact with the collection.

“Each year, Wai-ta-ata Press hosts Lunar New Year and Moon Festival celebrations, when keepsakes are handset and handprinted using the heritage type collection.”

The show offers an excellent opportunity to see new technology, network, and learn more about industry trends.

The rebranded PacPrint25 being held in Sydney from May 20-23 is a great opportunity for Kiwis to hop across the Tasman and have a look at the latest equipment, processes and services that our industry offers.

The event follows on exactly one year after drupa and will showcase some of the technology that was released at drupa. It is an excellent opportunity for those that couldn’t attend the German show to see the latest developments. In some cases, the 12-month time difference means that products that were released new at drupa, but not necessarily available, have now made their way to the marketplace with buyers putting them to practical application.

PrintNZ fully supports the PacPrint show and encourages Kiwis to attend as it is so readily accessible. We no longer have a New Zealand print show and with many of our New Zealand supply

companies now being owned and managed from Australia, PacPrint is a truly Trans-Tasman show that caters to both sides of the ditch.

And it is more than just a traditional print show. PacPrint will also incorporate the Label & Packaging Expo and Visual Impact which covers the signage industry. These technologies are now all a blended part of our industry, and being able to access vendors that cover literally every aspect of the print supply chain creates a one-stop-shop expo. Having the chance to look at new technology offerings can stimulate ideas and creative ways to diversify your business.

A trade show is the perfect chance to talk to multiple vendors of the same product, take the time to understand the differences between brands, and work out what would fit best with your business.

Having all the vendors in one place can save a substantial amount of time trying to assess options and allows you to make side by side comparisons. You can see the physical evidence of what it is you are looking at and what it can produce. The stands also provide ready access to technical experts which means you can learn from the people that are running

the machines, not just those that are selling them.

These shows aren’t just about technology. There is a substantial series of forums and workshops scheduled covering a broad range of topics, delivered by experts from both within the industry and externally. These can deliver invaluable insights and because they are hosted in such a targeted location there is often the opportunity to make direct contact with the speakers and follow through with them after the show. Check the programme out before you leave so you can plan to fit the ones you want to attend into our day.

Finally, take the time to network with other attendees and pick their brains. There will be a chance to attend events as part of the show so make the most of it.

In addition to vendor events, PrintNZ will host an evening for the Kiwis on the night of Thursday May 22. This is always a rousing success and with the aid of some lubrication there will be plenty of chatter about what everyone has seen, what’s the latest and greatest, purchases being considered and must-sees.

Don’t underestimate the alliances that can be formed over a few days. Our industry provides plenty of opportunities to collaborate and where better to find potential partners from both sides of the Tasman.

Utilising everything that a trade show has to offer will allow you to be better educated about the industry and in turn better support your customers.

At PacPrint25, take the opportunity to look, listen, learn and liaise.

While you might not be in the market for new equipment, it is still of immense value to know how the industry is evolving and what your competitors might be buying.

You don’t know what you don’t know, but attending PacPrint just might help you uncover some of it. Make the most of this chance. It will be two years before you get another opportunity to attend such a comprehensive show so close to home.

Digital printing encompasses a range of technologies and solutions.

Across the printing, labels, packaging, signage and related sectors, digital printing has become ubiquitous.

Digital printing does not account for the highest volume in printing, but that does not bother its proponents. Despite the continued advancements in digital print speed, and the ongoing development of hight speed inkjet technology, high volume is still not the major consideration for implementing digital solutions.

The ability to answer the demand for quick turnarounds and economically short run lengths, alongside major improvements in print quality over the past two decades, has seen digital printing machine manufacturers cement their position in the print landscape. These days, no one refers to them as photocopiers on steroids either. The flagship digital machines’ makers have long stopped calling their products printers, preferring to use the term digital presses, a moniker once reserved for analogue technology.

Where will digital take you?

The digital milieu continues to expand itself, and to expand the possibilities for printing. In the industry, digital now means so much more than just the physical press, or even digital finishing; businesses must consider digital front

ends, workflow, software, and artificial intelligence – AI.

Businesses need to commit to doing more than simply installing a digital box and waiting for the money to come rolling in. Using technology for just a few isolated jobs is not a strategy for digital success.

Turning a profit in a flat economy where consumer behaviour can change from week to week, means print businesses need to operate at an optimum level. If you expect that what worked for you five years ago to still work for you today, then you will likely suffer some disappointment.

Every issue of New Zealand Printer Magazine reports industry businesses that are achieving elevated levels of success and in most of those cases, their success has involved either new technology or new digital ways of approaching old problems.

For example, in this issue, we hear from Claire Firth, director at Indigo Print, which has installed a Revoria Press PC1120 and iECHP PK4 cutting system. She says, “You have to be pro-active, always looking to do jobs more efficiently for the client.”

Strategically speaking, manufacturing businesses of all sizes should already be integrating digital technologies into

their operations. The likes of workflow software, the cloud, automation, data analysis, and AI can play a valuable role in decision making and how businesses can plan for the long-term.

The latest, and even nascent, digital technologies can help to improve efficiency and operational capabilities. This is especially important for businesses looking to create new revenue opportunities, find new customers and scale their operations.

What prevents print, sign, labels, and packaging businesses from moving further into the digital world? Obviously, cost matters and businesses need to do their homework before any major investment.

In addition, the technology often appears quite sophisticated, so businesses can make the mistake of thinking they don’t have the necessary knowledge or expertise to implement some solutions. However, companies supplying digital solutions provide training for employees to effectively use and adapt to innovative technologies.

Another roadblock to keeping your company on track for profit is the reluctance to take on fresh ideas in the hope that if you sit and wait, you can decide later to implement advanced solutions and innovative technology. In this case, a change in attitude can make all the difference to your business. Adopting a fresh mindset can mean the difference between missing opportunities or seeing your company thrive.

This does not mean businesses should make reckless decisions for fear of missing out, and it is a fact that simply adopting new technology without a clear strategy in place to make the most of it won’t work. Instead, businesses need to create a plan to identify the areas where digital technology can make a difference and how to implement them.

Nearly all businesses already use digital solutions; even letterpress companies have a social media presence. Taking the next step in your digital growth could see you automating so much more of your workflow and inevitably, seeing a healthier bottom line for your business.

Business Innovation adds new solutions at successful Auckland print company.

Directors Claire and Steve Firth have grown Indigo Print, especially over the last 10 years, into a company that now employs 13 staff. With a reputation for honesty and transparency, the team at Indigo Print has built strong and long term relationships with clients and suppliers through taking pride in the print it produces.

Last year, Indigo Print purchased PDQ Print. Claire says, “Both companies offer digital and offset printing with Indigo also offering wide format print. We have a varied client base of direct clients as well as brokers and agencies. With the coming together of both companies and the synergies between them, we feel that we can offer our client base a wider range of products. Customer Service and maintaining our relationships with our clients is always at the forefront of what we do.”

In November 2024, Indigo Print installed a Revoria Press PC1120 and an IECHO PK4 cutting system, supplied through Fujifilm Business Innovation (FBNZ). Claire says, “The PDQ Print purchase, and the need for new technology led us to the new machines.

“The Revoria Press PC1120 enables us to offer gold and colours that we couldn’t before. It is an up to date machine in the market. The colour management is really good with excellent colour consistency. The Revoria print quality is also excellent and it is easy to use.

“The iECHO PK4 gives us the capability to produce smaller run die cut options without the need to make die tools. It also helps to keep pricing competitive.

“We produce small run packaging for clients, point of sale and, on a regular basis, paylite menu boards. Having the iECHO PK4 will speed up the process and enable us to offer clients more options.

“Our clients are looking at ways to introduce new and innovative products. The iECHO PK4 enables us to provide that without the large run volume and to be more creative. For example, its multiple blades and the ability to cut both card and paylite opens more options.

“We recently provided some ‘Mexican corn chip” shaped cards for a promo. They

were quite distinctive, and they provided a point of difference in the market. The customer did not want thousands of them, so the job worked perfectly.

“We had great training, and the machine is easy to use. Once the iECHO PK4 is set up, we can leave it to run while we get on with something else, which saves time.”

Indigo Print has a long and strong relationship with FBNZ. She says, “We have always had wonderful support through Paul Thomas and the FBNZ team. They are always available and able to answer any questions. They are also quick to resolve any issues that arise.”

It takes courage and foresight to navigate a successful path across the current economic landscape, while keeping an eye on the future. Indigo Print is working to make the most of its investments. Claire says, “The biggest challenge now is keeping sales coming through the door, especially in economic tough times. You have to be pro-active, always looking to do jobs more efficiently for the client.

“You have to invest to grow. Purchasing PDQ, installing another machine (with the Revoria Press PC1120); and investing in the iECHO PK4 cutting system means that we have more to offer our clients at the right price point.

“Our clients need to know that for what they are spending, they are getting the best value for their money, both in quality and service.”

The challenges of running a successful business do not detract from the enjoyment of producing great print. Claire says, “A great week at Indigo + PDQ Print is all jobs running smoothly, producing new and innovative print and getting great feedback from our clients.

“We have the equipment to move forward in the market and offer all print solutions at competitive pricing. In bringing our companies together we have a shared knowledge of how best to get a job done, all the while suggesting new ways to produce print.”

Gold standard in commercial print and packaging production continues with print speeds of up to 6,000 sheets per hour.

Unveiling the HP Indigo 120K Digital Press at Dscoop last year, HP confirmed its commitment “to unlocking profitable and sustainable growth for our customers”, according to Haim Levit, senior vice president and division president of HP Industrial Print. He said, “HP has been a digital transformation leader for more than 30 years, and our digital printing technology has established the gold standard in commercial print and labels and packaging production.”

Currie Group supplies HP Indigo printing solutions in New Zealand and Australia. Craig Paul, country manager for Currie Group New Zealand, says, “The HP Indigo 120K Digital Press has set a new standard for high-volume production and automation. It enables you to move your jobs from analogue to digital more intuitively and economically.

Combining analogue and digital technologies, the HP Indigo 120K Digital Press reduces human touchpoints and enables multi-press operation by a single operator.

It delivers print speeds of 6,000 sheets per hour with up to 90 per cent press availability. Designed to deliver tens of thousands of B2 sheets every day, it produces over two million B2 sheets per month.

Craig adds, “Alongside productivity increases, the HP Indigo 120K Digital Press also delivers outstanding print quality, something that HP Indigo users have taken for granted but a significant factor to consider, especially for commercial printers looking for offsetmatching print output.

“This press enables you to achieve consistent results in a hybrid printing environment with HP Indigo quality that matches the look and feel of your offset output. It optimises sheet-to-sheet and simplex-to-duplex registration, while delivering a stable colour process across all prints.

“You can also give your customers the flexibility of choice with the widest range of both coated and uncoated substrates.”

Lowering the environmental impact of printing can go hand in hand with making a decent profit. Craig says, “When

you move short jobs from analogue to the HP Indigo 120K, you can leverage the environmental advantages of the digital printing process such as eliminating aluminium consumption, reducing paper waste, and shortening makeready time.

“The HP Indigo Enhanced Productivity Mode (EPM) boosts productivity by 33 per cent; reduces operating cost per sheet; and saves 25 per cent of energy consumption per sheet while printing. The ECO 4-colour print mode option helps reduce carbon footprint by 11 per cent, allowing you to print more economically and more sustainably.

“You can also reuse imaging oil and reduce up to 35 per cent of waste with HP Indigo’s Recycling Imaging Oil (RIO) technology.”

Craig says the numerous innovations in the HP Indigo 120K Digital Press reflect the company’s continuous improvements and advancements it has made in the technology. He lists some of the major features the HP Indigo 120K Digital Press delivers:

• Prints at up to 6,000 sheets per hour.

• Generates over two million B2 sheets per month.

• True digital continuous operation that enables non-stop paper feeding; non-stop colour measurement; and continuous stacking.

• Multiple input and output paper sources allow a seamless and automated switchover process for jobs and paper on-the-fly.

• Reliable and predictable paper transport uses a robust gripper-togripper paper feed technology.

• Designed with durable parts for easy service handling

• Highly automated production with reduced press attendance allows multi-press operation by a single operator.

• AI-based technology for image

quality troubleshooting and diagnostics.

• High uptime and low service costs with AI-based predictive press care and maintenance capabilities.

• Increase press availability and end-to-end line efficiencies and reduce paper waste with advanced and automated AI-based inspection system.

• Reduce labour and turnaround time with Auto-Pallet Replacement (APR) at the delivery.

• Automated colour control system eliminates the need for manual colour tracking.

• Enable quick operator onboarding with intuitive and straightforward user interface innovations.

• The widest range of both coated and uncoated substrates.

• HD Imaging option deliver a smooth and sharp image with high LPI screens.

• The new ECO four-colour print mode option helps reduce carbon footprint by 11 per cent.

• HP Indigo’s Recycling Imaging Oil (RIO) technology reuses imaging oil and reduces up to 35 per cent of waste.

Chris O’Hara explains the advantages of Konica Minolta’s UV printing solutions.

WCHRIS

O’HARA National Production Print Manager

Konica Minolta New Zealand

ith its ability to produce highquality prints on a wide range of substrates, UV printing is changing the printing industry. This innovative technology using ultraviolet light to instantly cure specialised inks, resulting in vibrant, durable prints that adhere to almost any surface.

UV printing offers unparalleled versatility, allowing you to print directly onto an extensive range of substrates, without any requirement need for pre-coating. The possibilities for your printing projects are limited only by your imagination.

Konica Minolta has designed its range of UV printers to meet the diverse needs of digital print businesses.

Before you dive in and purchase a UV printing system, it pays to know more about the process. UV printing begins with the printer applying a thin layer of UV-curable ink to the substrate. Immediately after the ink is deposited, UV lamps emit intense light that causes the ink to solidify instantly.

This rapid curing process allows for faster production speeds and eliminates the need for drying time between printing and finishing. The result is a more efficient workflow and quicker turnaround times for your projects.

UV-curable inks are a crucial part of any UV printer. These specialised inks contain photoinitiators that react to UV light, causing them to instantly harden or cure. This process allows for rapid printing and immediate handling of finished prints, ready for immediate post finishing or shipping to the client.

Konica Minolta’s UV printers use advanced ink systems designed for

Konica Minolta’s AccurioJet KM-1e

optimal performance and colour accuracy. These inks are perfect for producing eye-catching signage, packaging, and promotional materials.

The UV light source is the heart of a UV printer. It emits high-intensity ultraviolet light to trigger the curing process in UV inks. Konica Minolta’s UV printers feature the latest LED UV lights that are more energy-efficient, produce less heat and have a longer lifespan. This technology allows for precise control over the curing process, ensuring consistent results across different print jobs.

Konica Minolta has equipped its UV printers with advanced media handling systems using vacuum suction or mechanical grips to hold materials securely in place during printing. This prevents movement and ensures precise ink placement, even on challenging surfaces.

Intelligent automation features are enhancing UV printing workflows. You’ll find smarter colour management, automated maintenance routines, and improved print queue optimisation in modern UV printers.

Whether you are a business owner, a print manager, or a graphics creative, UV inkjet printing can give you a competitive edge. Instant curing with UV curable inks reduces drying time, allowing you to move jobs immediately to post-processing steps. It also provides superior image quality, as the instant drying on paper minimises issues like dot gain, poor adhesion, and scuffing.

In addition, UV inkjet technology offers an extended colour gamut compared to other CMYK print methods, enabling richer and more vibrant colours. Whether you’re enhancing your current

commercial print services or exploring new markets, digital UV inkjet brings your ideas to life with impressive precision and colour accuracy.

Further benefits of Konica Minolta UV printing include:

• Reduced production time.

• Minimised risk of smudging or smearing.

• Reduced machine size and energy consumed compared to other inkjet technologies that require long drying tunnels that take more power to run.

• Increased overall productivity.

• Improved durability. UV ink forms a tough, resistant layer that withstands fading, scratching, and weathering, ideal for outdoor signage and longlasting prints.

UV printing offers versatile solutions across various industries and creative domains. Its ability to print on diverse substrates at high speeds, high-quality, durable results make it ideal for a wide range of applications. These include commercial and promotional items; product packaging; industrial marking and labelling processes; industrial safety signage; custom graphics and artistic projects.

UV printing offers several environmental benefits compared to traditional printing methods. It produces fewer volatile organic compounds, resulting in cleaner air and a healthier workplace for your printing staff.

The UV curing process is more energyefficient than conventional drying methods. Also, the durability of UV printed materials can contribute to less waste overall. Your prints will last longer, reducing the need for frequent reprints and conserving resources.

UV printing also allows for printing on a wide range of materials, including recycled substrates. This versatility can support your efforts to use more eco-friendly materials in your printing projects.

Please contact us at Konica Minolta New Zealand. I look forward to discussing our UV printing technology with you.

MINOLTA

More profitable business through a press that works smarter, not harder, with the AccurioPress C7100 series. You serve more customers and complete more jobs with innovative technologies that power your success.

Find out more at k konicaminolta.co.nz/C7100

Giving Shape to Ideas

Collaboration brings students into the work environment.

Supporting the industry, and the initiatives that will secure its future, has seen Auckland-based Torque Digital collaborate with PrintNZ to provide work placements for aspiring students.

Mark Bult, general manager at Torque Digital, says, “PrintNZ approached us about the opportunity to give a local student some insight into the print industry. We could see the real benefits of giving a young person the chance to see what a career in print could look like.

“The print industry has so much to offer in so many areas of career development, and hopefully an opportunity like this can steer these students in a direction to get involved in our industry.

“We often have students on board during the holiday seasons to assist in many areas of the business, most of which are not focusing on a career in print so tend to drift away at the end of their studies. If we

can find those that have a desire to follow a print career, we have a better chance at retaining them into long term positions.”

PrintNZ attends careers expos and school-based careers events to highlight the value of print and the opportunities it offers. Ruth Cobb, chief executive at PrintNZ says, “There are four parts to this equation: the young people, and sometimes their families; the company; PrintNZ; and the schools.

“We collaborate with our members to facilitate workplace visits for school staff and students, and we work with our companies, the schools, and students to then find placements to suit all parties.

“When we have students with an interest in the industry, we have one on one conversations and meetings with them, and we get them to send through their CV.

From there, we work to find the right fit for them and the company involved. We reach out to PrintNZ members to facilitate site visits, workplace experience, casual work experience, and ultimately offers of employment and apprenticeships.”

The length of the placements depends on what the school and the student and employee are looking for. Ruth says, “It could be a day a week for five or six weeks for workplace experience and NCEA credits, or it could be a fortnight of holiday work and trial placements to experience the work environment and student company fit, or full-time permanent employment.

“In the initial stages, it tends to be about experiencing a working environment and the print industry. Depending on the company they are placed at and the confidence or abilities of the student they can get quite involved in the processes on offer.”

Tharmika Annadurai, an intern at Torque Digital, is a 24 year old third-year student at Unitech studying accounting. Originally from Sri Lanka, Tharmika also works weekends as a print finisher at Torque Digital.

Tracey Bell, finance manager at Torque Digital, has overseen Tharmika’s work experience. Tracey says, “Tharmy approached us as part of her degree, which requires industry-based learning. She had to get work experience of 220 hours involving real world learning in the business and write a project on it.

“She completed a review of the company, its background, and her experience in the accounting field as well as current practices. Her work for Torque Digital included an inventory analysis.”

Tharmika says, “My sister was working here, and I approached Mark and Angela for some work. I used to work full time but then I started my studies. I had begun my degree at Unitech during the Covid 19 pandemic with lessons online.

“I have really enjoyed learning new skills and knowledge at Torque Digital, especially Tracey guiding me with things like excel skills and manual

stock systems. I have found the biggest challenge is time management with full-time studying, part-time work, assignments, tests and so on. It gets quite stressful, but I am learning.

Tracey says, “It has been a good experience for us in giving Tharmy an idea of how we operate here. She had the theoretical information from her studies but in real life, we had to work and live through it. I was nervous about how I was going to approach it. It was about taking her through each process then documenting it.

Tharmika adds, “I would definitely recommend this work experience. Torque Digital is a great place. They have such a friendly environment and everyone is so supportive.”

Perenise Taito, a year 13 student at Kelston Girls, became aware of the programme through Linden Hoverd, the PrintNZ membership coordinator who initiates the contacts for schools and the industry.

Linden says, “PrintNZ had embarked on an extensive programme of contacting schools and Kelston Girls decided to come on board. Amber Hinson head of careers at Kelston Girls suggested

Perenise might be interested in looking at workplace experience.”

Perenise says, “My family has a small screen printing business called Dynamite Screen Print based in Henderson. I don’t do screen printing, but I have done vinyl cutting and heat press work there.

“At Torque Digital, I am doing one day per week for five weeks. I have been setting up files for printing and laminating. I really like the process and watching the machines. I like watching them print the products. The biggest challenge is trying to remember the steps when I am not with someone.

“My family is glad I am doing this. They see it as a good opportunity and I do too. It is great to have the chance to try something; to give it a go; to see if I like it.

“I was nervous when I started, but everyone here has been great, and I feel more comfortable. It has also helped to think about what I should do next.”

PrintNZ is keen to see more of these placements. Ruth says, “This work is about ensuring the future of the people in the industry as well as the industry itself.

There is so much experience out there from the ‘old school’ that they need to share and hand on to the new generation. We have worked hard to educate the educators, talk to students. and engage interested parties in the whole process.

“It is interesting to notice how such an extensive and visual industry has been largely unseen by the careers people in schools. Overall, the experiences have been overwhelmingly good with careers advisors taking up the information and engaging on an ongoing basis.

“We want to be a career area of choice for students who are good with their hands or have an eye for design. Our members have been instrumental in engaging with their local schools, offering help with visits, staff to talk to students, and placements, as well as fostering ongoing relationships with their local schools to continue to look at opportunities. Whilst most of this work has been undertaken in Auckland, school visits, workplace visits and student placement and workplace experience in Hamilton, Whangarei and Tauranga are well underway. After the success that has been built in these areas, we have recently embarked on expanding this work into the South Island.

“Please jump on board and touch base with PrintNZ to show your interest. From there, we will work together to find what you are looking for and secure the print industry workers of the future.”

PacPrint25 has confirmed that Steven Gamble, founder of Anchor Health, will speak at the Industry Forum Series running through the PacPrint25 week.

Taking the stage on Wednesday May 21, Steven will lead an exploration of the role of employers across mental health and wellbeing in the workplace. He will provide an overview of Employee Assistance Programmes (EAP) and Mental Health First Aid planning, sharing actionable strategies to support employee wellbeing and compliance with increasing legislative requirements.

With workplace mental health becoming an increasing priority across the print, signage, and graphic communications industries, his experience and knowledge of the industry will deliver a relevant and essential discussion on fostering resilience, productivity, and a supportive work culture.

As the founder of Anchor Health, a leading mental health and wellbeing organisation, he has spent years educating workplaces, communities, and our industry on the importance of early intervention and structured mental health support. Anchor Health’s Employee Assistance Programme (EAP) offers confidential counselling, mental health education, and tailored support programmes designed to improve overall workplace wellbeing.

He says, “We know that a healthy workforce leads to a healthier business. By integrating mental health support into workplace culture, companies can create a thriving, resilient team while positively impacting their bottom line.”

He will outline:

• How businesses can implement an effective EAP to support employees through stress, anxiety, and personal challenges.

• The cost benefits of mental health initiatives, including reduced absenteeism, lower staff turnover, and improved productivity.

• Mental Health First Aid strategies that help managers and teams identify, support, and respond to employees in crisis.

• Real-world case studies showcasing how businesses that prioritise mental health see stronger employee engagement and business performance.

The PacPrint25 Industry Forum Series will feature an impressive lineup of expert speakers, panels, and leadership discussions covering topics that include:

• Signage innovation and best practices: Insights into emerging trends and sustainable solutions in signage.

• Business planning for the future: Expert advice on financial resilience, digital transformation, and operational excellence.

• Sustainability in print and packaging: Addressing eco-friendly printing, biodegradable materials, and energyefficient technologies.

• Diversity and emerging talent: Exploring pathways for new industry talent, mentorship programs, and inclusive hiring practices.

Kirsten Taylor, chair of PacPrint25, says, “We are curating a dynamic programme that not only highlights industry trends but also prioritises the human side of business: collaboration, leadership, and employee wellbeing.”

PacPrint25 will feature solutions designed to help businesses address their environmental impact while meeting rising consumer expectations for eco-friendly practices.

Exhibitors at PacPrint25 will present a range of eco-conscious options, from biodegradable materials and fibre-based substrates to energy-efficient solutions and more.

Kirsten, says, “Sustainability is a critical part of the future of our industry. Our exhibitors are bringing innovations that allow businesses to make meaningful environmental improvements in their operations, aligning with both regulatory pressures and consumer values.”

In addition to product showcases, PacPrint25 will host a series of panels and discussions focused on sustainability challenges and solutions to share knowledge and experiences from the signage, print and supply sectors on environmental mapping solutions.

Experts in sustainable printing will cover a range of topics, from waste management and resource efficiency to the complexities of navigating eco-certifications and regulatory standards. Sessions will provide attendees with insights into practical strategies for reducing their environmental impact, whilst minimising cost and regulatory burdens.

Kirsten adds, “In sharing our industry experiences and exhibitor innovations, PacPrint25 aims to show that eco-friendly practices are not only achievable but can also drive new business opportunities in appealing to environmentally conscious clients.

“PacPrint25 has committed to sustainable solutions, as has Sydney Showground, with a goal to achieve net zero carbon emissions by 2030 and actively working to minimise impact on the environment.

“As organisers, our banners for the show are reused for shelters, bags and sleeping requirements for the homeless or for schools and charities for craft and other uses.”

Purpose-built facility in Tauranga aligns with plans for future growth.

Kale Print has announced plans to move to a new purpose built premises.

Peter Lloyd, general manager at Kale Print, the Bay of Plenty’s biggest commercial print operation says the decision to move from its Cameron Road premises aligns with its plans for future growth.

He says, “We knew the time would come when we had to say goodbye to Cameron Road and start a new chapter in our story. Outgrowing our head office in the Tauranga CBD some years ago has seen us operating from two sites ever since. With our larger finishing equipment and paper store located in the Judea industrial estate, the team were making frequent trips back and forth several times a day to ensure jobs ran smoothly and on time.

“Essentially, we are moving just down the road, but the Tauriko Business Estate is the premier location for industry and manufacturing in Tauranga. There’s ample land ready for development, and we saw this as an opportunity to create something truly special and fit for purpose now and into the future.

“The site is situated on Kaweroa Drive, which will connect SH29 to the Tauriko

Business Estate, becoming a main thoroughfare. It will make access for freight and customers effortless.

“The new location also puts us a bit closer to our sister site, Advocate Print in Rotorua, who we collaborate with on a daily basis.”

All in one location

Kale Print’s new purpose built production facility will span an impressive 2600 square metres, housing the company’s A1 and A2 UV Offset printing presses; two digital printing presses, wide format and signage department; bindery and finishing area; paper store; as well as ample office space for administration, customer services, design studio and estimating.

Peter adds, “We will also have modern meeting spaces and a thoughtfully designed common area for team breaks and get togethers.

With work scheduled to commence in March 2025, and a move in date planned for early 2026, Kale Print has received overwhelmingly positive feedback from its customers and network regarding the news of the move. Peter says, “There is

sure to be a major roof shout. We can’t wait to share this journey with everyone.

“Bringing our entire Tauranga team together in one location will enhance collaboration, refine our workflow, and prepare us for future growth. As one of New Zealand’s largest trade print suppliers, it is crucial that we streamline our operations to maintain efficiency for our customers as we continue to grow.

“Although this is a huge milestone in the Kale Print story and there will be lots of room for growth and change, there are some things that will always remain. Our family values and culture are the foundation of everything we do. This feeds through to our quality of product and service.

“The new location will allow us to continue to provide the same level of service and quality that our clients have come to love and trust over the years while we continue to grow.

“As we have always done, we’ll keep our finger on the pulse to stay ahead of the curve, actively listening to our customers’ needs and finding innovative solutions that provide the greatest benefit to them into the future.”

He concludes, “The decision to move was not difficult as we have an incredible team that we know will lead us into the future. Our culture and team bond is our strength and the move will only see that bond increase.”

There are several areas of opportunity to deliver business improvement that enhances the value of your business – whether you choose to sell it, or not

About a year ago, one of my clients, Tom, took me aside and told me he was ready to sell his business. Tom (not his real name, obviously) had proven himself to be a very successful owner who had grown his business from scratch over many years, to a turnover of more than $20 million. Tom was honest about his motivations – the passion was waning, industry conditions were only getting tougher, and he was ready to do something different with his life.

We sat around the table in Mattingly’s Yarraville office in Melbourne, whiteboard marker in hand, capturing Tom’s key needs and scratching out the possible exit options. After the workshop, despite Tom wanting out, we all agreed it was not the right time for Tom to sell as the business wasn’t yet prepared for sale. We could do some ‘renovations’ with a defined concerted effort that would have a multiplier effect on the value of Tom’s business.

Tom’s story is not unique. Many Australian businesses are going through a period of ownership change. Part of the reason is the demographic window of long-standing business owners – the Baby Boomer generation are well within the retirement zone, well-earned, I should say, reaching completion point of illustrious careers having toiled away tirelessly at their craft. It is never forever, and this cohort are looking for a lifestyle change, to take some money off the table, and perhaps become more risk averse when it comes to business growth decisions.

Unfortunately, for various reasons, it is not often an option to pass the baton to children or family. Selling the business is the next best option.

The reality for Tom was that a year ago, he was not going to achieve the value he was after. Now, through getting the house in order and executing several key initiatives, the business has improved towards its full potential, and this will translate to higher sale proceeds.

Appoint a team to help identify, prioritise, and deliver initiatives to ensure you maximise your business’ enterprise value.

Both as a buyer and seller representative, I often come across the following pre-sale opportunities to build value in any business:

1. Can the management team operate without the owner?

A huge red flag for a buyer and common issue in small to medium business sales is the heavy reliance on the owner. If you feel your business suffers from owner dependence, it will be important to take the time to build a capable management team, and couple this with a re-design (reduction) of the owner’s roles and responsibilities. And stick to it!

2. Are customer and supplier relationships strong and operating under contract?

It is not imperative that all customers sign up to contracts but having clear and legally sound contracts provide a buyer more certainty. In the absence of contract, you will want to demonstrate customer purchase order behaviour that indicates loyalty and predictability to give the buyer comfort that the sales will not walk out the door after they have purchased the business. Likewise in relation to critical suppliers that are not easily substitutable.

3. Are the operating assets well maintained and within effective life, and is inventory on hand appropriate?

The conversation will always turn to the assets being used in the business, and whether they are reputable brands, in good working order, and ideally not needing replacement or overhaul in the near term. In terms of inventory, it is that you have exercised purchasing discipline, are realistic on the net realisable value of stock on hand and have processes to objectively assess value impact of ageing and obsolescence.

4. Do the financial statements appropriately reflect the business’ performance?

At the end of the day, you are marketing your own business to a buyer. The numbers will tell a story, but there are some steps that can be followed to best present the business’ financial position. Engaging your accountant is an obvious step, but also instituting some commercial disciplines such as improving cash collections, supplier payment terms, keeping private expenditure out of the business, and making smart capital and inventory decisions is necessary.

Aside from the main items above, there are many other areas of opportunity to deliver business improvement to enhance the value of your business – whether selling or not: operational efficiencies, simplification of IT systems, boosting organisational talent, and improving your supply chain. It is important to appoint a team to help identify, prioritise, and deliver these initiatives to ensure you maximise your business’ enterprise value.

Peter Fotiadis is a co-founder and partner at Mattingly, a boutique commercial advisory firm specialising in strategy to execution, proprietary deal flow, and commercial solutions.

The research firm expects an increased compound annual growth rate of 3.6 per cent for the US$504.9 billion packaging print market, boosted by drupa 2024

Packaging and labels are increasingly important to the strategic future of the printing industry, with annual sales now worth more than half a trillion dollars, according to research firm, Smithers.

It found that while traditional publication and graphics markets are static or in decline, rising consumption of packaged goods is fuelling growth. Smithers added this was seen at drupa 2024 earlier this year, with multiple original equipment manufacturers (OEMs) debuting new machines for printing corrugated board, folding cartons, flexible packaging and labels.