Intercomp’s RFX® HubScale360™ Wireless Scale System is the Industry’s first vehicle alignment system with selfcontained wireless scales. Bluetooth® Technology is included with all RFX® Wireless Scale Systems and securely displays live weight data from the indicator to the user’s Bluetooth ®-enabled mobile device with the Intercomp iRaceWeigh™ app installed.

Mercedes is currently a continuing and dominant force in Formula 1, but its record at Le Mans is rather more sketchy. The horrific accident in 1955 saw the Silver Arrows stay away from motorsport for decades. Then, in 1985, a Sauber Mercedes driven by John Nielsen performed a back flip over the Mulsanne hump (a feat emulated by flight officer Mark Webber and others again in 1999).

In 1988, the team was providing stiff competition to the Jaguars in Group C races but, again at Le Mans, its aero calcs were not so clever. The maximum speed on most circuits was around 200mph, but on the Mulsanne 250mph was possible. That’s a 25 per cent increase in speed, but almost a 65 per cent increase in downforce. The cars were obviously not trimmed out enough for the constant high speed and the tyres promptly exploded, causing the cars to be withdrawn from the race.

Towards the end of 1985, I took up a new post as chief engineer at TWR Jaguar on the Group C team. It was not an easy gig as one of Jaguar’s stipulations was that we use the road car V12 engine. The motor weighed over 250kg, with a high c of g and was almost as long as a Cadillac!

But Tom’s team boasted some well chosen and very talented people. Tony Southgate’s elegant and superbly aerodynamic design added to the cutting-edge engine development by Kiwi, Alan Scott, gave us a fighting chance.

By the end of 1986, we had a quick and reliable car and, come the end of 1988, the TWR Jaguar Team had delivered two world championships and wins at both the Daytona and Le Mans 24 hours.

However, after three seasons with the big V12, Tom persuaded Jaguar that a new engine was required if we were to continue winning in Group C and IMSA. A smaller, lighter, 3.5-litre, twin-turbo engine was therefore developed in house from the engine that had powered the Metro 6R4 Rally Car for the 1989 season.

The initial shakedown at Donington in February showed great promise, the turbo car instantly a second a lap quicker than the XJR9 V12 car. But two weeks, five engines and only 30 laps of the Jerez circuit later, it was clear we had a great deal to learn about turbo engines.

So the V12 cars were pressed back into service for the start of the ’89 season, and the plan had always been to run these cars at Le Mans. Over the course of the 24-hour race, the cars do a similar mileage as a whole season of F1, at a higher average speed, and (hopefully) without service.

New, smaller diameter primary pipes were dyno tested on the V12 engine and run successfully at the Daytona race early in ’89 on the 6.0-litre IMSA cars. The smooth, low-down torque was a hit with drivers and the stopwatch alike, but they would prove to be our undoing at Le Mans.

After Jan Lammers won the 1988 Le Mans race with only fourth gear, it was clear we would also be developing the gearbox prior to the 1989 race.

It consequently underwent a number of internal upgrades to reduce the operating temperature and (hopefully) prolong its life. Our partners at Castrol had their chemists working on a trick new oil that would replace the ‘go to’ American Neo gearbox oil used by most of motorsport in the ’80s.

In testing, the new oil reduced the bulk temperature of the gearbox by up to 15degC, so we felt in reasonably good shape heading for Le Mans.

I was pulling triple duty in the lead up to the race as development engineer for the new turbo car, chief engineer and race engineer for the Lammers, Tambay, Gilbert-Scott car. It was a busy time.

We had expected the turbo cars to dominate practice, with the ability to turn up the wick to gain a grid slot, so we concentrated primarily on race preparation, and it all looked quite promising.

The real race contenders were the multitude of droning Porsches, the pair of rumbling Mercedes and the howling Jaguars.

After one hour of racing, we had a car in the lead, with the rest of the pack in close company. Two of the Jags had made first lap pit stops with high tyre temperatures, indicating perhaps a puncture, but they were soon back out with a higher warning threshold on the infrared ‘heatspy’ units.

In the fourth hour, my car lost almost two laps when it came in with a broken exhaust, and one of the other cars was having gearbox issues – not unheard of at Le Mans.

By midnight, though, my car was back in the lead and was a lap ahead by 6am. Then it all started to unravel. By 06.30, my car was having its gearbox changed in the pit road (no garages at LM until the following year) and lost over 40 minutes.

Three of the four Jags suffered similar issues, and one a blown engine probably before the other problems arose.

My car eventually did a Moses (it came fourth), while the Mercedes rumbled its way to victory.

The new exhausts that had been so successful at Daytona on the 6.0-litre engine did not like the sustained high-speed running Le Mans demands on the 7.0-litre version. The heat signature and vibration nodes were obviously different, and they all cracked like eggshells on the day.

With the benefit of a long investigation and 20:20 hindsight, we discovered the new gearbox oil made a wonderful foaming agent after prolonged usage, and that after about six hours the whole gearbox casing was full of foam, leaving very little liquid oil to be collected by the scavenge pump in the gearbox sump. I’m sure you can guess what happens next.

I had carefully considered the ‘upgrades’ made to the cars that year, but unintended consequences had come into play and confirmed my mantra for Le Mans of ‘if it’s new, it will give a problem.’

It was a hard lesson learnt that day in France, but one we all learned from, and hats off to Mercedes for being there to pick up the pieces.

Unintended consequences had come into play and confirmed my mantra for Le Mans of ‘if it’s new, it will give a problem’I’m major Tom’s left-hand man… and just about to have a bit of

adisaster. This is where the term ‘the pits’ comes from

The familiar sight to spectators of F1 in 2022, a Red Bull Racing RB18 taking the chequered flag

‘We looked at the results from our initial CFD tests and made a judgement on how best to operate a ground-effect car at all the circuits’

Paul Monaghan, chief engineer of the RB18By STEWART MITCHELL AND DIETER RENCKEN

The Red Bull RB18, Red Bull Racing’s response to a set of radically new technical regulations for 2022, proved insuperable in the first season of F1’s new era. The team sealed the 2022 Formula 1 Constructors’ Championship as Max Verstappen won the United States Grand Prix in Austin, the 19th round of the 24-round season.

The Constructors’ title, paired with Verstappen’s second successive Drivers’ Championship, is Red Bull’s first since 2013 and ends an eight-year streak of domination by German manufacturer, Mercedes.

The RB18 finished the 2022 season as one of the most successful cars to date in F1, taking the chequered flag at 17 races in total – 15 for Verstappen and two for Sergio Perez.

The RB18’s concept stood out from the outset at Barcelona testing in February 2022, featuring some unique design elements, including the extended lower lip of the sidepod intake openings and the swept back rear leg on the front suspension. However, it was the car’s well-behaved driving manner that caused the most interest when it seemed to suffer significantly less from so-called porpoising than many of its rivals. This smooth introduction to F1’s new era saw it at the sharp end of the grid from there on out.

Despite Red Bull’s 2022 success, the realisation of the RB18 could certainly have been smoother sailing for the Milton Keynes, UK-based outfit. The team was forced to pull resources from the 2022 project in the latter stages of 2021 as the season came down to a shootout with Mercedes in the later races. Therefore, the personnel, wind tunnel, CFD and design resources that would have otherwise been directed toward the 2022 car remained on the 2021 RB16B, right up until the very last lap of that season.

‘The 2021 campaign dramatically affected our 2022 car development,’ Paul Monaghan, chief engineer of the RB18, freely admits. ‘With much of our capacity staying on the RB16B for longer than we had readily planned, the severe regulation changes for 2022 and finite resources we had remaining, we were worried we had damaged the development of the 2022 car going into the start of the season.

‘That said, the RB18 proved to be the ‘least-worst’ car on the 2022 grid, the result of hard work, research, design, manufacturing, and realisation of our business with our available resources. We were at least as efficient as anybody else, and we had a great car from the outset.’

As for the RB18’s overall concept, Monaghan explains: ‘During our development of the 2022 car, we looked at the results from our initial CFD tests and made a judgement on how best to operate a ground-effect car at all the circuits. We took our design route early in the development process and stuck with it to exploit the potential of the road we chose.

‘The main thing was getting our heads around the car’s aerodynamic demands. In terms of how you operate it relative to the ground, it is quite different to the 2021 and preceding cars. We knew we would run lower rear ride heights compared to the last regulation set, so the travel at the rear axle

compared to the front would be significantly less. But that reduced rear travel has compliance benefits.

‘As such, in the 2022 regime, if you’re making high aerodynamic loads on the straight, the heave stiffness must be higher than it would otherwise have been for a 2021 car. This forces your hand in some elements and forces you to carefully design for the desired compliance.’

One of the few people in F1 with significant experience with ground-effect aerodynamics is Red Bull Racing’s chief technical officer, Adrian Newey. In fact, Newey wrote his university thesis on just that subject, and his first job was chief aerodynamicist at Fittipaldi Automotive, working on the 1980 F8, itself a ground-effect car.

He would go on to design the March 82G GTP, which featured a significant hole between the front fenders that fed air to massive underbody tunnels to generate ground effect. The March 82G won two IMSA GTP titles and saw two further evolutions, namely 83G and 84G trim. This experience with ground-effect cars from early on in his career made him aware of some of the possible hazards lying in wait with F1 2022’s car with its ground-effect underbody.

Despite Newey’s extensive experience in the field, he only fed into the Red Bull technical group that created the RB18, and his design input was limited to the suspension. Nevertheless, the suspension is a critical part of the car’s platform control, and arguably the most significant contributor to a groundeffect car’s performance.

Monaghan explains: ‘Suspension proved to be the most sensitive area of the 2022 car, given that the FIA had simplified its technology with the introduction of the latest regulations and ride height control.

Of the 2022 F1 contenders, Red Bull Racing appeared to have the best overall package. Racecar talks to the team about the RB18’s development, and the effect of its recent budget cap penalty

‘We were worried we had damaged the development of the 2022 car going into the start of the season’

Paul Monaghan

This coincides with developing the suspension stiffnesses, which is paramount in this new regime.’

To put that statement into context, for 2022 the FIA changed the suspension system regulations, banning any inerters, mass dampers or acceleration-sensitive valves in the dampers, thereby prohibiting any systems or configurations that change the response of the suspension elements to body accelerations and / or angular acceleration of the rockers.

‘If you want to run the car lower to the ground, you must raise the suspension stiffnesses, which can have severe compliance side effects,’ Monaghan continues. ‘Ride height was the element of the set-up that received the most attention in 2022, but it does not come in isolation. As such, one part of the ride height vs suspension stiffness set-up wasn’t dominant over another. These cars are sensitive, so you cannot change one aspect without manipulating another.

‘The aerodynamic operation is the most critical to the fastest lap time. Still, if you get the complementary functions wrong, you will be punished by things like porpoising and driveability issues.’

The RB18 features a pull rod front suspension which allows for a lower installation for the suspension mechanisms, aiding a more dynamic, lower c of g, frontend capability. It also allows the rearwardmoving flow field path to the ground effect venturi throat to be kept cleaner, free of any disturbance that might induce unwanted turbulent flow into the floor’s venturi.

‘Ride height was the element of the set-up that received the most attention in 2022, but it does not come in isolation’

Paul Monaghan

Moreover, because the pull rod concept is a second-class lever system, its characteristics are softer than the pushrod’s first-class lever system, aiding compliance between the unsprung and sprung masses when there is a significant displacement between them.

However, when the front lowers at speed, the characteristics of the second-class lever system stiffen as it is a rising spring rate, which supports the platform as aerodynamic loads are introduced to the car’s inputs. This design is likely part of why Red Bull has suffered significantly less from porpoising

than its rivals throughout the 2022 season. The multi-link arrangement of the front suspension sees the trailing wishbone swept back and intersecting with the chassis significantly further down than the front one. This design was implemented as an anti-dive measure. Anti-dive geometry diverts the forces transmitted under high aerodynamic and braking loads away from the springs and dampers and through the suspension links to minimise disruption to ride height, limiting the rear ride height increase and the downforce loss it entails during braking.

This multi-link system sees the mechanical elements of the suspension needing to be made stiffer, and therefore heavier, than a more conventional wishbone suspension design. As proven, the benefit of platform control and compliance outweighed the weight deficit.

At the rear, the pushrod arrangement was perceived to provide stiffer and lighter mechanical installation to preserve the platform control needed to support the ground-effect aerodynamic regime. Additionally, the pushrod concept allowed tighter packaging of the suspension, keeping it free from encroaching on the diffuser exit, which aids the efficiency of the ground-effect floor and the rear beam wing interaction.

The RB18’s long rear suspension travel accommodates a variety of ride heights, allowing it to ride low at high speed, reducing drag. Despite it having a greater static ride height than much of the grid, the long rear travel, combined with a relatively soft spring rate, meant the car could settle low in such a way as to enable high straight-line speed compared to the competition.

Red Bull Racing took a different approach to the design of the RB18’s floor. Most of the cars on the 2022 grid feature a teardropshaped central section between the tunnels, providing a smooth, continuous surface on

the inside of each tunnel from the intake to the diffuser exit. This coincides with a consistent throat and diffuser ceiling angle into and out of the venturi point, respectively.

In contrast, the centre section of the RB18’s floor features a number of stepped elements on its outer wall (inside wall of the tunnels) and the roof of the tunnels also appear deeper, narrower and more sculpted in some sections along its length. The step changes of the central section, along with the varying profile to the height of the tunnels, is likely an effort to keep the tunnel volume consistent along its length to provide a steady mass flow from intake to diffuser.

‘There are multiple aspects of the floor that are weighted differently, depending on how you want to extract performance,’ explains Pierre Waché, technical director of Red Bull Racing. ‘You can be aggressive with the floor design, but you then narrow the window within which it works most effectively. Where you put the main load on the floor, which is around the centre of pressure of the venturi section, affects the overall concept of the car in terms of load distribution and aero balance.

‘The main aspect of this year’s car was the development of this, and the rest of the components were associated with that.’

The RB18’s floor design seemingly provides higher resistance to stalling the underfloor flow, compared to a floor with a consistent throat and diffuser ceiling angle into and out of the venturi point. In theory, Red Bull’s design should enable softer

suspension to work to maintain grip and compliance between the tyre and the track, with the ability to engineering the set-up to manage weight transfer where necessary.

With a stable underfloor aerodynamic regime, Red Bull could potentially decouple some of the influence of the floor on the suspension, combining the wheel travel frequency, damping ratio and weight transfer for the best spring and damper set-up for the track, which can then be optimised for the conditions more readily than its competitors.

Red Bull went on to use a variety of inlet vane and floor edge arrangements to tune the car to individual circuits throughout the season. Changing these elements alters the aerodynamic centre of pressure acting upon the front and rear axles, adjusting the aerodynamic balance of the car. This suggests the team had a very high-fidelity control of its underfloor airflow.

The result was the RB18 struggling far less with porpoising than many others in the field, and the combination of floor and suspension design is likely the largest contributing factor.

Perhaps the most significant development of the RB18, though, has been its ongoing weight reduction programme. The car began the year 20kg over the minimum weight limit of 798kg, and a number of significant elements contributed to that.

‘The cost cap influenced everything on the RB18, but it was most influential when it came to the weight,’ notes Waché. ‘Compared

to what we used in the past, plenty of parts are compromised compared to what you might do if there was no financial constraint. The resulting component is not necessarily compromised in terms of performance, but questioned in much more detail than they were before the cost cap was implemented.

‘With the cost cap in place, you must extend the life of parts, which typically sees them designed to be more robust and heavier, to make it economically effective and last longer. Sometimes we choose a material that is cheaper, which is typically heavier as well. Sometimes you don’t do development because the performance gain is not there at the cost it requires, and this balance is a big part of Formula 1 now.’

The aerodynamic loads generated by the powerful floors mean they must be stiffer, and consequently heavier, than the previous generation of cars to remain rigid. The newfor-2022 18in tyres and bigger brakes are also much heavier than the previous generation.

The RB18 struggled far less with porpoising than many others in the field, and the combination of floor and suspension design is likely the largest contributing factor

Unlike the previous generation of cars that relied primarily on the outer surfaces of the car for aerodynamic gains, the floor is now the primary aerodynamic load generating part. As such, the tight Coke bottle shapes of the previous generation cars is less prominent now

A lot of the car’s excess weight was originally toward the front, which gave the early version more understeer and made it prone to front brake locking. The weight came off via a series of upgrades throughout the season, including a new floor at Imola, re-designed brakes and the hollowing out of some components that had originally been manufactured as solid because of time constraints in the design phase. Gradually, the weight distribution moved towards the rear. This coincided with an accompanying rearward shift in the aero balance, giving greater rear stability on corner entry without affecting the initial direction change.

‘In terms of making the weight savings, there are only so many areas of the car that can be addressed to bring the weight down to the level that would make us competitive,’ Waché notes. ‘There were some ancillary components that were designed conservatively and heavier and they were easy to work on to save weight. However, this was not the goal for the start of the season.

‘Our strategy was to replace parts for mileage and put lighter ones on when we could. This was the best way to control the costs. There are some parts of the car, especially the floor, that we deliberately made heavier for reliability reasons. We knew it needed to be robust to prevent destroying it on the kerbs and so on.

‘When we saw the car in operation for the first time, it gave us the data we needed to start developing a new, lighter version. That was an easy opportunity to reduce weight.’

It is not all roses in the Red Bull Racing camp, though, as it has been found to have breached the cost cap regulations for the 2021 season, the first year of its implementation. Over the 2022 Mexican GP weekend, Formula 1 finally confirmed the team’s penalty, hitting it with a $7 million fine and a 10 per cent reduction of its aerodynamic testing allowance for the next 12 months. The FIA adjusted the strength of the penalty after its initial £1.8m overspend was amended to just over £400,000 after a tax credit had been correctly applied.

Despite this, many of its competitors are of the opinion that Red Bull has got away lightly, and the integrity of Formula 1’s budget cap has been in jeopardy throughout this process. There are many critics of the result of Red Bull’s breaching the cost cap regulations, especially as a $7 million fine is small beer for a company of Red Bull’s size. Moreover, it does not come out of its present or future cost cap, it must be settled separately.

Reducing Red Bull’s budget cap in the future somehow wasn’t an option available to the FIA under the terms of an accepted breach agreement.

The more significant damage to the team is the reduced aerodynamic testing element of the penalty, which impacts its CFD and wind tunnel programmes. This penalty is the equivalent of 1.5 finishing positions in the Constructors’ Championship, associated with the diminishing testing scale as a function of the team’s place in the championship when wind tunnel allocations are determined.

Formula 1’s new handicap system means successful teams already have less aero testing allowance than those finishing lower down. The team finishing last is given a 115 per cent baseline allowance, dropping by five per cent for each position until the winning constructor is given 70 per cent of the nominal amount within its aerodynamic testing period, of which there are six per year, each lasting around eight weeks.

Because Red Bull won the 2022 Constructors’ Championship, the development allowance would see it entitled to 70 per cent of the baseline limit for 2023. This amounts to 224 wind tunnel runs and 1400 CFD items per period. That is 16 fewer wind tunnel runs than the next highestplaced team, and 32 fewer than the third.

In CFD terms, it represents 100 fewer components than the second-place team, and 200 fewer than the third. However, because Red Bull’s penalty for breaking the budget reduces this by a further 10 per cent, it now has a reduction of 22 wind tunnel runs and 140 CFD items per period, equating to 38 fewer wind tunnel runs, and 240 fewer CFD runs during each period compared to the second-place team.

Red Bull’s testing limitation lasts for 12 months from the execution of the accepted breach agreement, October 26 2022. The penalty will impact whatever development work the team completes in the final part of 2022 and 2023 car development until the

same date in October next year, which will affect both the in-season development of the 2023 car, and the 2024 one that follows.

Red Bull indicates the effect of the penalties could be worth anywhere between 0.25 and 0.5 seconds of lap time.

‘With the limited testing allocation that we must work to from the penalty, we don’t want to burn resources on the wrong things,’ says Monaghan. ‘The car for next year will be similar because the regulations are similar, but we are using the resources we have now to develop the car in the most efficient way.

‘The wind tunnel and CFD testing deficit are connected. These are our main tools of development. The rules are set up to somewhat balance the performance of the teams across the grid as a function of the handicap associated with aerodynamic development. This system is very effective and will have a significant impact on us for next year, and the grid over the years.

‘It is very difficult to offset this handicap. We have some of the best F1 engineers in the world, but the other teams also have very effective members of their teams. We can work harder, but the others will be, too.

‘What is true is we will have to be more efficient with the resources if we are going to make up for the deficit.’

‘Our strategy was to replace parts for mileage and put lighter ones on when we could. This was the best way to control the costs’

Pierre Waché, technical director at Red Bull Racing

180 mph without moving an inch

Take cutting-edge wind tunnel technology. Add a 180 mph rolling road. And build in the best in precision data acquisition capabilities. When we created the world’s first and finest commercially available full-scale testing environment of its kind, we did much more than create a new wind tunnel. We created a new standard in aerodynamics.

The LMDh cars were on track at Daytona in December in final preparation for the opening round of the WeatherTech series. Racecar was there to see how they got on

By ANDREW COTTONThe LMDh category has been a long time in gestation but it’s finally here, and ready for competition debut at the 24 Hours of Daytona at the end of January. The cars had a final group test at Daytona early in December and, although each of the manufacturers that were present, including Cadillac, Acura, Porsche and BMW, had car-stopping problems, the teams set about fixing them in test conditions, rather than a race weekend and go into the first race with some optimism after a challenging year.

This test was the first time teams had sight of the new tyres from Michelin that will be used next year, and was supposed to be a performance test to help organisers with the Balance of Performance for the 24-hour race. However, failures of the motor generator unit (MGH) and other electrical issues, along with dramas at customs shipping new parts in, prevented much meaningful running. Following the test, teams were more concerned with making their cars run cleanly than worrying about the obvious lack of grip on cold tyres fresh out of the pits, or even what their rivals were doing.

Official times were not available from the testing, but from data available to teams it appears the Acura was fastest, at 1m35.75s, Cadillac narrowly behind at 1m35.80, Porsche 1m35.90 and BMW 1m36.35s. The cars were at similar pace over long runs, too.

Just to re-cap, the cars are based on chassis provided from a choice of four manufacturers: Dallara provides the base car for BMW and Cadillac, the Italian firm continuing its relationship with the latter that started in the DPi era of prototype racing. ORECA supplies the chassis for the Acura, again a long-standing relationship that has won big races and titles. Porsche opted for Multimatic, which was supposed to produce cars for the other VAG manufacturers, Audi and Bentley. Audi confirmed its participation but then backed out shortly before switching its allegiance to Formula 1 for 2026, while Bentley’s bid to take over the Audis was rejected by Bentley’s board in October 2022.

As none of the chassis builders are allowed to exclusively supply one manufacturer, their products are all commercially available. Lamborghini will come in 2024 with a Ligier chassis, Alpine with ORECA, while McLaren is scheduled to arrive in 2025 and is expected to choose either Dallara or Multimatic.

The manufacturers provide the engines and aero kits. This means the cars are all very different looking, with brand styling cues readily apparent in each one. They are powered by a variety of engines and only Acura has produced a brand new power unit.

Honda Performance Development, based in California, produced its 2.4-litre, twin-turbo V6 from scratch, and the company says it has very little in common with the proposed IndyCar engine that first ran in 2021, but which was dramatically dropped by IndyCar in the same week the Daytona test took place.

BMW opted for its old 4.0-litre, naturallyaspirated V8 taken from the DTM and which first raced in 2011, while Porsche went even older on its design, taking the 3.4-litre naturally-aspirated V8 from its RS Spyder that first ran in 2005, and was later used in the 918 Spyder road car.

The last power unit is that of Cadillac, which has taken over the design of its 5.5-litre V8 in house, where previously it had been prepared by ECR Engines in North Carolina.

The cars run with a spec hybrid system comprising the MGU from Bosch, battery from Williams Advanced Engineering and gearbox from Xtrac. This is designed to supplement the power from the engines, replacing the demand on the ICE with that of the electronic unit instead.

Power is limited to 500kW from either the ICE or the combination of ICE and hybrid, with deployment strategies open for the teams to choose how they want to use it.

Electronics are all supplied by Bosch, including telemetry, scrutineering harnesses and the safety systems, unlike in the DPi era when the choice of provider was open.

Teams are free to write their own software, as the ECU is not regulated, and it is up to the manufacturers to ensure the ECU is integrated into the operation of the hybrid system. This has not been easy – much of the testing and the subsequent failures have involved the demands made by the ECU on the hybrid system, which has been blamed for many days of lost track time.

The LMDh cars are performance balanced and, to help the organisers achieve parity, the cars must hit a point on the lift / drag graph in all conditions, including different ride heights and wing angles. Weight and power are also strictly regulated. Power is no longer measured by output from the engine, instead torque sensors have been introduced to monitor power at the wheels, which will make the balancing more accurate.

Minimum weights have been mandated for overall car (1030kg), as well as such items as the engine (180kg). Similarly, the location of the engine is closely monitored, which helps the chassis manufacturers design their cars to accept different engines, including in the future the new LMP2 power unit.

Tyres come from Michelin, who will provide the same rubber as in the FIA World Endurance Championship. At the Daytona race, due to the cold overnight temperatures,

a choice of two compounds will be available to teams, although IMSA has yet to determine whether the softer compound will be available for the whole race or just a 12-hour window overnight.

For the remainder of the season, Michelin will bring only one spec of tyre to each race, and it will be up to the tyre manufacturer to decide which will be available to teams on any given weekend. In contrast, in the FIA WEC Michelin will provide the choice of rubber for every race and teams will be free to use each compound as they choose.

A further change for next year is the way the sanctioning body, IMSA, deals with the energy used by each of the cars per stint. Reminiscent of the old Equivalence of Technology rule set, the body is considering limiting the energy per stint available for each car. The idea is to reduce the impact of the different choices of engine, and to retain the element of strategy. Teams will still benefit from fuel saving as they look towards the end of the race and that crucial final pit stop. This is a marked change from looking purely at fuel consumption and balancing that using different size tanks and fuel hoses.

Testing has proven to be challenging and, although each of the manufacturers claim to have racked up high mileage, all have experienced problems of one sort or another. Early testing has been hampered by a shortage of materials, and therefore components, from core suppliers as demand on such items as electronics and carbon are high due to the war in Ukraine.

According to reports from the teams, each session has been punctuated with red flags as an LMDh car has been towed back to the pits after a mechanical breakdown. The Daytona test was no different.

Teams, and crucially the suppliers, are now under huge pressure to get everything right for the biggest test of them all – a 24-hour race to kick the season off in cold overnight temperatures, followed by a 12-hour race at Sebring in March.

Early testing saw the teams use the old 29/34 tyres from the 2022 Hypercars, but the Daytona test provided a first glimpse of the all-new 2023 tyre from Michelin that has a higher bio-content than the previous generation rubber.

The shape, construction and compound will be the same across the LMDh cars in both IMSA and the FIA WEC, as well as the Ferrari and Toyota Hypercars, while for the Peugeot, which is allowed to run the same size tyre all round, the fronts will be stretched and the backs squashed to fit the needs of

predominantly front-biased car.

the

A choice of two [Michelin] compounds will be available to teams, although IMSA has yet to determine whether the softer compound will be available for the whole race or just a 12-hour window overnightAn official 3D scans the Porsche to confirm it fits within the expected parameters ahead of on-track testing The Porsche 963 suffered with a gearchange issue early on but managed to fix that and put in some longer runs on day two Bosch, Williams and Xtrac engineers were all on site for the Daytona test

Although the teams’ pre-test run plans focused on performance testing, much of the session times were used fixing niggling issues that prevented cars from extended running. None were able to complete a full stint length on track, for example, let alone a double stint. BMW and Cadillac both brought brand new chassis for their roll out, but both spent the first day in the garage waiting for their Bosch scrutineering harnesses to clear customs. They were denied permission to run without the system by the sanctioning body.

Porsche suffered a gearchange issue on the first day, having installed new components into the system, but managed to start its longer runs on the second day.

Acura has developed a complex antilag and traction control system for its turbocharged engine that sounded like a mechanical bag of nails as the car negotiated slow-speed corners. The teams confirmed codes were being re-written to help, but it took nearly two days before any meaningful running was achieved, meaning any performance testing only occurred on the afternoon of the second day.

Michael Shank’s Acura broke an MGU on the second day of testing and was unable to complete any significant running. The team was so concerned with its lack of track time that it has scheduled another test early in January, while the Wayne Taylor Racing car suffered a split header tank, though this was quickly rectified. Taylor’s team will not take part in the early January test, preferring to work towards the 24-hour race.

Throughout the Daytona test, the teams were reporting how complicated these cars are to work on. One driver commented that the controls were not integrated with each other and that, if one change was made, others have to be made in sequence to complete the process.

‘It is the most mentally draining car I have ever had to drive,’ said BMW driver, Augusto Farfus, while manufacturers confirmed it will take some time and running before customer drivers will be able to operate these cars.

For other professionals, though, the complications were not a drama. ‘The car is a completely different animal to the LMP2 cars

Throughout the Daytona test, the teams were reporting how complicated these cars are to work on

To underline the fuel efficiency with which modern racecars can be run, the 2022 BTCC required a hybrid power unit. Mated to Xtrac’s groundbreaking transmission, made available in front and rear wheel drive configurations, the system has helped provide close and exciting racing throughout the season.

I drove last year. It’s far more complicated, but to me it’s logical,’ said WTR driver, Louis Delétraz. ‘Yes, one thing leads to another, but I am comfortable doing that.’

However comfortable some drivers may be, having the systems operating separately means the teams have to hire technologically-literate professional drivers until new programmes can be written to make controlling these complex cars a more straightforward process.

The test was supposed to be one of performance running, with many teams believing they had got on top of the reliability issues that have plagued these cars from the start, but the electronics appear to be an issue, specifically getting the different elements of the system to talk to each other.

Another consequence of the lack of meaningful fast running was IMSA did not have the opportunity to accurately correlate its simulation data on track, something it

needs for the performance balancing to take place. The technical team at IMSA was confident it will get the process right as its simulation is so advanced, and says it has a good handle on what the cars are capable of, but this was the first time the cars ran on the new tyres, and the last time they will run on the Daytona track before the race week.

The BoP tables will therefore be largely based on simulation, and IMSA and the FIA and ACO are working closely together to align their approach.

In the past, the FIA’s BoP has affected the GTE-Pro class and changes have been applied retrospectively. For example, an FIA performance balancing change would rely on a prescribed number of green flag laps of the previous two races before being applied to the next race. However, that does not account for the nature of the circuit on which the change will be applied.

IMSA’s approach has been different, and more proactive. The body started to predict the Balance of Performance for its cars on the

next circuit based on experience of DPi cars. However, without that option available, it has turned to simulation experts for help.

The cars will run at Daytona at the pre-race test, the so-called Roar before the 24, one weekend before the start of the 24-hour race . That’s normally considered a fine-tuning test, and it will be too late then to make any major changes. But with teams still busy making their cars run reliably, and worrying about how their new tyres will work on a low-grip surface, it could be different this year.

Certainly standing at the International Horseshoe, it was clear that even in moderate ambient temperatures the first laps out of the pits on new tyres (unheated in IMSA for many years) are going to be difficult for the drivers. Even the front end seems to be hunting, while the option of running a lower ride height would appear to be out, judging by the sparks coming from under the Cadillacs as they passed the pits on the second afternoon while the drivers waited for pressures to rise.

Last word goes to Connor de Phillippi, driver of the BMW Hybrid V8: ‘Especially this year with where everybody is in development, I think just focusing on your own [programme] and not getting sucked into the competitive aspect, especially early in the race. It’s going to be about keeping it all together and performing at the end when it actually matters.’

The lack of meaningful fast running… [means] the BoP tables will therefore be largely based on simulation, and IMSA and the FIA and ACO are working closely together to align their approach

By ANDREW COTTON

By ANDREW COTTON

When Honda decided to continue its endurance racing programme in the US, it pulled a clean sheet of paper from the drawer on which to work. ORECA was designing an all-new prototype for the regulations and Honda Performance Development (HPD) wanted to continue its relationship with the French manufacturer.

There were options for the Californiabased company to re-use certain key elements, such as the 3.5-litre, twin-turbo engine it already had, which would undoubtedly have saved money, but with the president of the company also being the technical director, and with a reputation for innovation in racing that is enjoyed by Honda, the company embarked on an all-new, 2.4-litre, twin-turbo engine instead.

Although it shares its capacity with the IndyCar engine that was due in 2024, there was little crossover between the two, not least because the LMDdh engine had a minimum weight of 180kg by regulation, the IndyCar requirement nearly 70kg less.

Racecar sat down with HPD’s president and technical director, David Salters, at the Daytona LMDh test to discuss development of the engine for the prototype, and the decision to drop the 2.4-litre IndyCar engine.

RE: Are you satis ed with what you have seen so far at this test?

DS: You have good days and bad days. We are doing okay, but we have so much to do.

With Covid, we finished up a bit later [in our preparation] than we would like, so we are still in catch up mode. There is no point in getting too excited about it, though, you just have to get on and do your work.

RE: Hybrid integration seems to have been underestimated by many of the teams.

DS: Not by me. I have done this twice already. I worked for Ferrari [in Formula 1] for nine years [as head of engine development] to 2015, so I was fully embroiled with the KERS, and then with the hybrid V6, and it is not easy.

My admiration of IMSA has grown a lot. They have done a good job. You have to stretch yourself and, if they weren’t trying to make a big step, that would worry me

Like all the other cars at Daytona, Honda’s test wasn’t without incident, but the team is confident development of the ARX-061, and its cleansheet-of-paper engine will soon bear fruit

To fit in a racecar it needs to be too small, not cooled enough and then it is shaken to death. It is how I expected it to be. No one is doing anything wrong, it’s just a difficult thing to do.

RE: In F1 you have a large budget to develop hybrid, but here it’s a different animal as it’s private teams supported by manufacturers. DS: We have helped Bosch and Xtrac and Williams. We have tried to test everything for them on our test cell. Is it perfect? No. Could the car stop? Yes, but you have to work through it. That is what you should be trying to do.

We ran DPis for five years, so that was good, but if that carried on for another four years we would be bored. That’s not why we go racing. The fact that this is a big challenge is pretty cool. We have a hybrid, try to integrate it and we write our software in house. We had a guy yesterday who re-wrote some of the code and we put it on the car today, and that’s what racing is about. That’s why you get up in the morning. Is it going well? No, but we are not trying to cure cancer here. We are trying to make a car go around in circles, so let’s not get too excited. I might live to regret some of this, but right now my boys and girls are loving it because it is a challenge, and that is how racing should be.

The good thing about this is that while it is a lot of money, the costs are not stupid. When you look at these cars you can see the designs of the future. The cars have all this

integration, we can write our own software, and this is one of the very few series with open software architecture; maybe the only one outside F1. F1 is a bit constrained, but that’s good company to be in, isn’t it?

RE: The price of the cars has risen dramatically from what was originally intended. Reports say the Porsche is now more than $2.5 million. DS: That’s still not bad, is it? We go for quality not quantity. Yes, it is more expensive, but it is not outrageous. LMH is about a 40-million dollar car, so this is the bargain of the century when you look at it like that.

Yes, the teams must have sponsors, but I have a queue of teams wanting my car. I have no problem selling the cars. I can’t support that, though, we have our hands full doing what we are doing. There is no shortage of people who can raise the funds to run them, but do they have the skill to do that?

RE: There are rumours IndyCar programmes are paying higher wages than IMSA teams can afford. Have you come across this?

DS: We have similar problems with retention. We are based in California, which is not a motor racing hub, and we are competing against Apple, Google and SpaceX. I have lost half a dozen people to SpaceX, but I have also had people come from Formula 1 and they want to be involved in this. There is big demand at the moment.

Under Covid, the salaries went stupid. We have big challenges, but it is exciting. What I really like is that we have great engineers.

We are trying to bring on the next generation of engineers who are enthused by this, and it is down to the hybrid.

RE: Has there been frustration with the spec suppliers not coming up with some of what they are supposed to?

DS: You have to be careful with that. It is really hard to do what we are trying to do. I’ve been there. We have to work together. I wouldn’t like to be critical because this is a hard job, but I have yet to see anyone do anything complex and get it perfect.

So no, I am not frustrated. I would be if we dropped out of a race, that’s for sure, but right now it is just all working together to make it work. Pointing fingers is not the best way to motivate everyone.

My admiration of IMSA has grown a lot. They have done a good job. You have to stretch yourself and, if they weren’t trying to make a big step, that would worry me. The proof of the pudding is Porsche, Acura, BMW and Cadillac. Lamborghini is coming and we

I might live to regret some of this, but right now my boys and girls are loving it because it is a challenge, and that is how racing should be

the workin house as part of its expansion as a company

2.4-litre,

have to see about Alpine. I applaud them for taking the risk as it’s easy not to.

We have to help, because it will benefit us all. We had a component failure [in testing] –the MGU – so let’s fix it. Let’s find out why first, and then figure out what we will do.

I like the fact they committed to it, and now we all want to see it work.

RE: One of the big challenges is writing software, and many have struggled to integrate everything. Are you?

DS: We are trying to understand that stuff, and that’s cool. We have TAG 320 sat in our cars, an F1 ECU, so it’s go big or go home. We also have one of our own boxes on the car that is very fast at processing. We do that all in house, and we do our own software, so we do the powertrain control, hybrid control, energy management and vehicle control, brake-by-wire system and we have an in-house group that sorts all that out.

We also have a vehicle dynamics group, so we have our own Driver-In-the-Loop simulator, so it goes through DIL, then HIL, then here, we write code in the truck. That is the lovely bit about working for Honda, we are encouraged to do that. I get given money to do that, so I find the right people to do that, and they have Honda badges and Honda pensions.

RE: You are the only ones to have built a new engine, and it has attracted a lot of praise.

DS: Again, I may regret it, but I am president and technical director, so you want to do your best engineering job. I’ll admit I have had a few sleepless nights over it.

We already had a nice DPi engine, and so the easy choice would have been to use that, except it’s heavier and bigger, and we thought we could do better.

When you start something like this, you ask how do you make the best racecar that you can? I worked for Ferrari for nine years, Ilmor for seven years, and for McLaren. You make the lightest, most compact racecar you can. And you start with the basics – make it light and close to the ground. There’s still a lot to be said for that.

How do we make the best car we can? We have a good group of engineers. I am an engineer and have some self-respect. I’m also the president, so we decided to do the best job we could, and be proud of it.

RE: What made you decide to go with the twin-turbo V6 format?

DS: We have some brilliant vehicle dynamicists, and we did a lot of simulations to understand what we needed. We read the rule book a lot to work out what was required to make the best car. The point of making the decision on the engine came over Christmas. It’s only a 2.4-litre, and the question was can we make the power while also making it live?

One of our simulation guys went away and simulated how to make the power with the combustion loads low, so he worked all Christmas and came back on the second of January with a 100-page report. We sent all the groups off to figure out what was their best thing, and then we sat down, had a three-hour meeting and decided we would use this engine.

RE: So you didn’t sit there and think we can do this, and it will also service IndyCar?

DS: No. We knew we would have elements of the new IndyCar engine that we liked. But we also worked with our F1 guys, and we looked at the history of sportscar racing to know what the best engine was. We could use some of the bones of the IndyCar engine, but it

was an amalgamation of everything that HPD has done over the last 30 years.

We put it together and a lot of smart people did the evaluation. So, we had the core concept, that used a lot of our stuff. We then set the guys off to do the best packaging, in the most compact way we can.

Sure, there are some risks, some areas we have really gone out on a limb, but time will tell if we are right. We are always just trying to make the best engineering decisions we can.

RE: Do you use the full 10,000rpm rev range?

DS: The way the IMSA power curve is, you choose your peak, but we use pretty much the full 10,000rpm. We just tried to look at everything and make the best racecar we can. ORECA did something similar, and made a lovely racecar, and we made a lovely powertrain. We helped them with the DIL simulator, did lap time simulation and we tried to find out what we thought the best racecar was. That involved some investment, some new stuff and learning.

RE: Will you take this car to Le Mans?

DS: The teams are not the only ones who want to do it! We are here to look after racing in North America and we will focus on doing that first. After that, it’s global interest, but

There are some risks, some areas we have really gone out on a limb, but… we are always just trying to make the best engineering decisions we canThe decision to go with the twin-turbo V6 came about after a detailed simulation programme concluded the format would make the power and longevity required

that is outside our jurisdiction so it would be a decision from Honda. We will crawl, walk and then run. Let’s make sure we do a good job here, represent our brand and ourselves well, and then we will see where we are.

Would I like to go to Le Mans? Hell yes. But I am under no illusions about the challenge we face.

RE: Why was the decision taken to abandon the 2.4-litre IndyCar engine?

DS: I can only speak from a Honda perspective. IndyCar racing is great, the Indy 500 is one of the greatest races on the planet. That’s brilliant, but there needs to be electrification at some stage. That is moving along, which is good, and now it needs to move to the next step.

It is one thing making prototype stuff, another to make it race ready. There is a big IndyCar field, and trying to productionise it, it became obvious we had to work with IndyCar, Ilmor and GM, but we can’t do it all.

We are going to concentrate on the hybrid moving forward. There is only so many people and so much budget, so you have to make decisions. The priority from our point of view was to make the hybrid work, rather than the engine. It’s a difficult decision, but it is the right one.

Having some electrification and sustainability is more like the future. Just sticking with engine is not what we should be doing. Next year we have 100 per cent renewable fuel, which has 60 per cent less CO₂, so we are already on the right path. If you do some research, you will find the lowest CO₂ cycle for a road car that exists is a low-carbon fuel on a hybrid car, for road car. It costs quite a lot of CO₂ to make a battery, so at this moment a low-carbon fuel on a hybrid is the ticket.

Medium-term hybrids are great, and my company thinks the same. There needs to be an element of electrification, but you have to make some priorities and that is to move electrification and sustainability forwards. That’s the decision. We tested the engine on the track last year, it won’t be wasted.

There is a lot of open software here [in IMSA racing], but in IndyCar we want to give it more to the drivers. That is a different way of doing it. If you can improve the racing with the hybrid, that would be cool, and then that will promote itself.

Right now, the hybrid is hidden and we need to make it more visible as an energy to help you race. The first thing we have to do is create close racing. This year we set the fastest ever pole speed, so we are not doing too badly with the old 2.2-litre, but we have done a great deal of development to get it there.

This year we went two seconds a lap quicker at Long Beach, but no one talked about it. Let’s use the technology there to help the racing.

IndyCar racing is great, the Indy 500 is one of the greatest races on the planet… but there needs to be electrification at some stage. That is moving along… but it needs to move to the next stepThe decision as to whether the ARX-061 will go to Le Mans has yet

to be taken, and will come from Honda in Japanwhen it does Future development will concentrate on the hybrid, rather than the engine, as HPD believes that combination, along with a 100 per cent renewable fuel, is the way forward

Ford plans to discontinue production of its iconic Fiesta in mid-2023. This A-segment model not only won over entry-level drivers and two-car families alike, but also numerous World Rally Championship rounds. Shortly after it ends production of the Fiesta, the Blue Oval will also cease to market the Fiesta’s high(er) riding IC-engined sister, the Puma, which also enjoys WRC successes, as it switches to a battery electric range.

Given the direction the motor industry has been forced into by emission legislation, such developments are no surprise and likely to be emulated by most, if not all, manufacturers of A-segment models. As batteries add enormously to the basic weight and cost of

vehicles, sales are expected to plunge. An equivalent electric vehicle is expected to price 60 percent higher than fossil-fuelled equivalents that already provide slim margins of profit, adding pressure to manufacturers.

The bottom line for followers of the FIA World Rally Championship and its feeder series is that A-segment derivatives currently provide the core models for the WRC’s staircase, from Rally5 to Rally1. With the likelihood of model cut-backs in this sector, the very existence of the WRC is threatened unless the championship reinvents itself in something of a hurry.

Three manufacturers, including Toyota, Hyundai and Ford, are contractually committed to global motorsport’s governing

Current World Rally Championship models are being discontinued as electric mobility takes over the A-segment market. What does that mean for the WRC?

body, the FIA, throughout the current 202224 formula, but what happens after that, particularly given the accelerating changes in the automotive landscapes?

In addition to the issue facing the top class, Citroen, Opel, Peugeot, Renault, Skoda, VW are represented in lower categories, and all are also on the fast track to electrification.

Should they take the decision to also withdraw from competition such models as the VW Polo, Skoda Fabia, Peugeot 206 and Renault Clio, the impact upon the WRC’s feeder series will be significant. This in turn will affect the top category given that fewer crews will come through the lower cost ranks. In addition, manufacturer support is likely to decrease commensurately.

Clearly a rapid rethink is required. The championship’s major players, including the FIA, commercial rights holder WRC Promoter GmbH, the current three teams and some prospective entrants are, of course, totally aware of the situation. Indeed, they confirmed to Racecar Engineering during Rally Belgium in August that they are collectively investigating various solutions.

Fortunately, the current spaceframe concept whereby a percentile ‘top hat’ is fitted over the chassis in whatever shape or form a manufacturer elects provides a solid base, so the real conundrum lies in choosing the best power unit for the category.

This, though, is the hard part. For starters they face the now-standard choice of two power unit options, namely ICE or BEV. Thereafter it gets more complex. Within

these two categories there are a raft of further options such as range extenders, ICEs powered by e-fuels or hydrogen, potentially complemented by battery hybrid elements, or the powering up of batteries via standard electric sources or hydrogen fuel cells.

Compounding the issue is the point that virtually every prospective manufacturer has a different take on the energy solution of the future. Even where the stars align they are at different stages of development. Ask Ford about the future and the answer is likely electric; ask Toyota the same question and they are likely to point to the Prius hybrid or the H2 ICE-powered Yaris GR that ran selected demonstration stages in Belgium.

Hyundai would likely go with fuel cells, as would Honda were it to enter WRC, while if Audi (or another VW Group brand) joins the WRC Rally1 fray they will probably push for a range-extender solution as per the Four Rings’ Dakar entry. Then there are myriad Chinese electric-only brands who will surely one day be attracted into WRC at some level if the FIA chooses an appropriate powertrain.

There is another consideration that causes additional headaches for the decision makers. Rallies are usually staged through remote areas where the chances of finding sufficient high voltage chargers or hydrogen tanks are slim. Indeed, between their demonstration runs Toyota discreetly trucked the H2 Yaris to Brussels for gas recharging. Now consider a 20-50-strong field racing for three days solid through the wilds of Kenya, snow of Sweden or mountains around Monte Carlo.

Should they take the decision to also withdraw from competition such models as the VW Polo, Skoda Fabia, Peugeot 206 and Renault Clio, the impact upon the WRC’s feeder series will be significant

‘So far we’ve had a city car (Yaris), fivedoor hatchback (Hyundai i10) and a crossover (Puma) win this year,’ says Robert Reid, FIA Deputy President for Sport and world champion co-driver in 2001. ‘There is no reason why [the spaceframe concept] can’t be extended to other manufacturers, so I think we’ve got the basis of something [for the future].

‘By the end of this year, the target that I’ve given to the WRC people is to work out what [we need] for 2025.’ That might be an interim solution for 2025/6 followed by battery technology in 2027. Then, though, he adds another layer to the challenge: ‘There are also some manufacturers who are interested in coming now with something electric.’

The man tasked with the WRC overhaul by the FIA is the governing body’s Rally Director, Andrew Wheatley. Formerly Business Development Manager for Malcolm Wilson’s M-Sport operation which operates Ford’s WRC programme, the Briton is perfectly qualified to expand on the championship’s future plans from commercial, regulatory and manufacturer perspectives.

In an exclusive interview with Racecar Engineering, Wheatley says: ‘When you look back to 10 years ago, the talk was “Do we make it a two-litre, 1600cc; two-wheel drive or four-wheel drive?”

‘Now the opportunities are so wide you need to be some sort of mind reader to see what’s going on [in the automotive sector] and we have this huge opportunity at the FIA to be able to identify which products work best in which environment.

‘Electric was perfect for Rallycross as the events are run in heats. If you look at cross country, you have range extender, you have petrol, you have diesel, you have synthetic fuels, you have two-wheel drive, and fourwheel drive and they’re all competing in the same event. You’ve got vehicles derived from production vehicles and things derived from people’s imagination.’

The issue is, though, that cross-country marathons last for up to two weeks, whereas rally stages are short and sharp, with two cars finishing within a tenth of a second on the same stage. This year each of the three manufacturers has taken home top honours and any equivalence formula is unlikely to deliver the same level of intense competition. Thus, whatever is decided upon needs to tick all boxes, or WRC risk losing popularity.

‘If we want to try and keep that level of competition, we need to pick a technology and focus towards it,’ believes Wheatley. ‘That doesn’t mean to say that there couldn’t be different classes that could do different technologies, but at the pointy end of the competition there needs to be probably one technology. At the moment we are talking with the manufacturers that are both

the current stakeholders in rallying, and potentially future stakeholders to understand what their thoughts are.’

Wilson, who has been in the rally business as both a successful WRC driver and team owner for over 40 years, admits to genuinely not knowing the solution, pointing to the fact that ‘[Fewer] manufacturers are now producing a 1.6 IC engine that you can run in [feeder] categories. The clearest [solution] for me at the moment is probably Rally1, with what we’ve got now with this chassis, this safety cage structure.’

That implies rolling over the current regulations for another year or two, but that simply kicks the can down the road. The other issue is costs. Wilson is adamant that any WRC formula needs to reduce costs. Current Rally1 cars come in at more than 700 000 Euros, in line with the Toyota Hilux Dakar featured in the January edition of Racecar Engineering, but any new-fangled power unit technologies are unlikely to decrease costs.

That said, to delay the decision might lead to a wider the choice of powertrains available, and lower costs are likely given the present rate of change for alternate energies. Equally, WRC has to look at least five years

Racecar

‘You have to compare it to a standard GR Yaris, [and] the engine is different, there is more torque and maybe a little bit more power,’ he explained. ‘I was changing gears all of the time and it was going to rev limiter straight away, the response is good from the engine, surprisingly good.’

There was, though, a diesel-like ‘knocking’ after startup, which decreased as the four-cylinder warmed up.

Indeed, he admitted to being pleasantly surprised by throttle response, saying; ‘I thought it would be less [responsive] and lazy but it is quicker than the standard car, and there is no difference in engine braking because it is still [like] the petrol engine.’

Asked about the potential adoption of H2 in rallying and the wider industry, Akio Toyoda admitted that a lack of infrastructure was likely to be the main impediment. ‘Hydrogen or electricity, we kind of need some infrastructure,’ he said. ‘We have a hydrogen station in the only city of Belgium (Brussels), so we need some kind of infrastructure. However, if we move to this kind of power unit, if we continue with it and all the people feel the same [opinions], then we can make a future together.’

Kankunnen, though, believes firmly that hydrogen ICE is WRC’s future. ‘Rallies are too long for full electric cars plus they are very heavy and they have no noise, but if you have clean fuel like hydrogen, I think it will be the future for rallying,’ he said.

‘At the pointy end of the competition there needs to be probably one technology’

Andrew Wheatley, FIA Rally Director

is theEngineering quizzed four-time WRC champion Juha Kankunnen and Toyota President Akio Toyoda, who co-drove the car and raced one in Japan, about driving the Toyota Yaris H2 after they completed a set of stages in Belgium. The WRC has introduced hybrid technology this year, but it’s an interim solution and a more permanent solution must come soon

Mezzo Technologies is hiring a Business Development Manager with an engineering background.

Mezzo Technologies designs bespoke high-performance microtube heat exchangers for automotive, motorsports, aerospace, defence, and power generation sectors. The company is searching for a Business Development Manager with an engineering background to prepare proposal packages for a wide variety of projects and related business development activities. The successful candidate should be proficient in commercial and technical factors applied to the business of heat exchangers and will report to the Chief Operations Officer and Director of Engineering.

The role is in-house at the company's Baton Rouge, LA, USA HQ and requires travel to clients and prospects worldwide. The salary and compensation package are competitive and dependent on experience and performance. If you are interested in learning more about this career opportunity or applying directly to the role, contact us using the details below. From everyone in the Mezzo Technologies team, we look forward to hearing from you!

Kevin W. Kelly | President

Mezzo Technologies

10246 Mammoth Avenue, Baton Rouge, LA 70814

Email: kevin.kelly@mezzotech.com

Phone: (+1) 225 442 6965

ahead, yet cannot afford to be left behind through the wrong choices. But who knows, a miracle solid state 100kW battery weighing 200 kilogrammes may be on the horizon, as could be a sudden breakthrough on the e-fuel front.

Speaking to Racecar Engineering during the recent FIA Gala Awards evening JariMatti Latvala, team boss of the (double) championship-winning Toyota Gazoo WRC team, made no secret of the fact that his company’s future rally car would preferably be hydrogen-powered via an ICE engine as demonstrated in Belgium and raced in Japanese endurance events.

‘During Rally Belgium, we tested this H2 hydrogen car with Juha Kankunnen and [company boss] Akio Toyoda,’ said the Finn, himself a former 18-time WRC winner. ‘Whenever we think about sustainability, for sure we have [taken] great steps in motorsport with these hybrids and with e-fuels, but if we think about the future, and we need to think about it, I believe that hydrogen could be one option.

‘But is it ready in three four to years’ time? I’m not sure about that and I can’t give you an answer about how many years it could take, but it certainly has potential because I was myself driving on the Fuji race circuit this season with the H2 Corolla.

‘When you have an internal combustion engine which is like in a [current] rally car but it is working with hydrogen I think this is a great way to continue with a motorsport [category] which has the sounds and you have the same [sensation], with a proper engine but zero emissions.’

extending the current formula for another year. ‘There are several options for 2025,’ he admits. ‘First of all, we [could] extend the current regulations with a combustion engine and wait for a few more years to maybe give us some more time for a bigger step with new technology.’

The Frenchman believes that a ‘more efficient or more powerful hybrid system than is currently available could provide a better balance between a combustion engine and electric, like [future] Formula 1 it could be 50/50.’ But he admits some current and potential entrants would prefer to go down the full electric route sooner rather than later.

‘I guess most of the manufacturers would have interest is that right now, but we [WRC] are not ready for that in 2025. Maybe in the future or longer term, but not right now,’ he says, adding that the teams need to work with the FIA to develop even better sustainable fuels as a matter of priority.

Asked about hydrogen, Moncet references fuel cells. ‘It is an area we have an interest,’ he says. ‘Our brand is investing a lot and is quite active with hydrogen fuel cell technology, but we have as well the hydrogen combustion engine technology.’

Although the parties currently have divergent thoughts about the future of WRC, they do agree that they need more than three manufacturers. However, where does the optimum level of ‘works’ entrants lie? ‘I’ve worked for 25 years in WRC, and I’ve seen where we’ve had two and I’ve seen where we’ve had seven,’ says Wheatley. ‘For me, the

best was when we had four; five is great, because it’s an insurance.’ Crucially, he adds that when there were seven entrants, three failed to score a podium. It is vital that all teams are in with a chance. ‘Otherwise, if you haven’t got a podium finish, it’s incredibly difficult to go back and justify to your board of directors why the company is doing this.’

Therein lies the crux. Any new powertrain formula needs to attract more manufacturers and create a larger fan base, particularly among emerging audiences, via a better spectacle delivered by relevant technologies. These targets are a massive ask, but the biggest challenges facing the WRC are to achieve these targets while simultaneously reducing costs of entry and operating budgets in the face of new technology.

According to regulations a final decision needs to be taken within the next three months. The chances are therefore that the current rules are extended for another year whilst the optimum solution is sought.

Our brand is investigating a lot and is quite active with hydrogen fuel cell technology, but we have as well the hydrogen cumbustion technology

Hyundai WRC Team’s Deputy Team Principal Julien Moncet

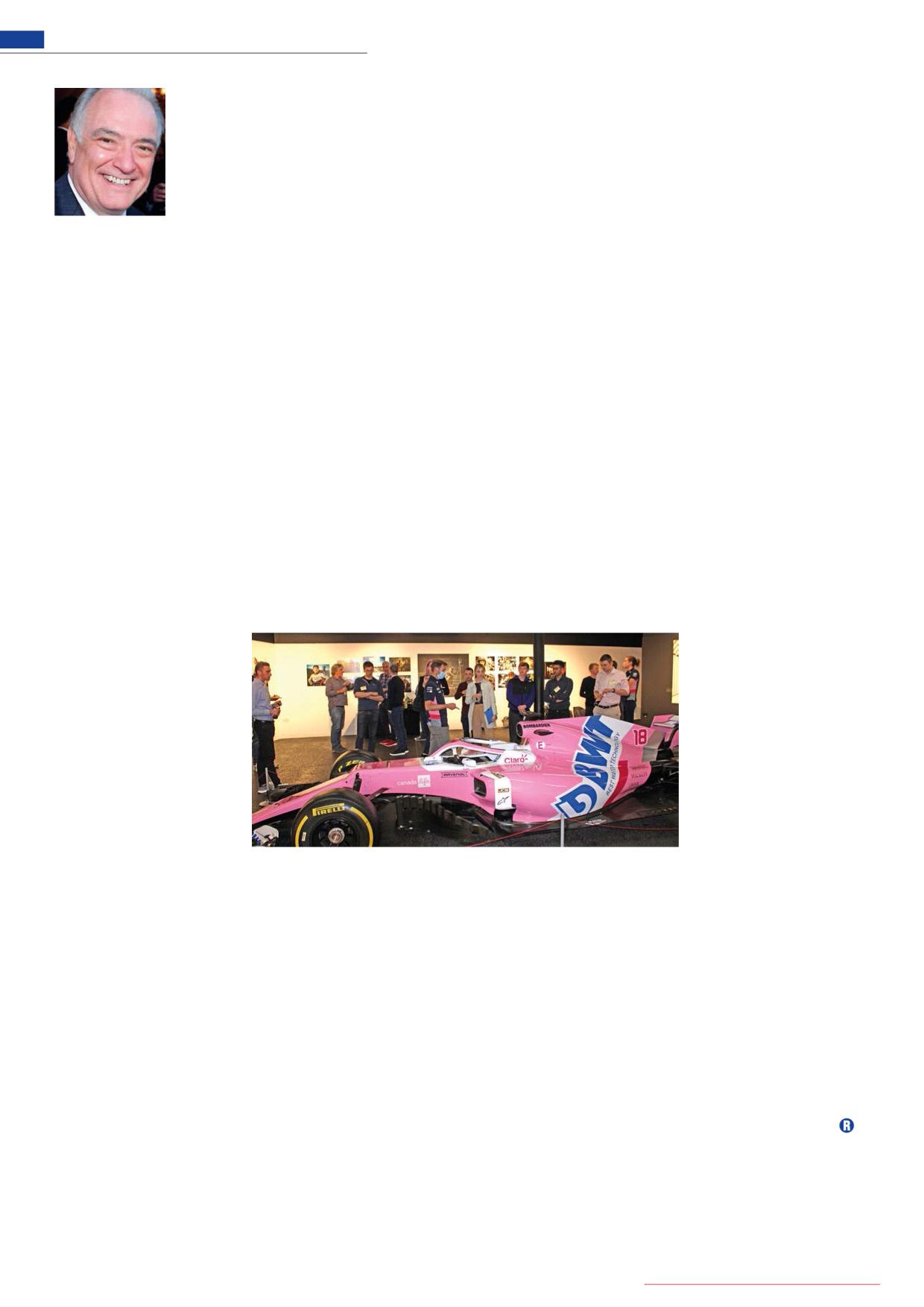

How and why a proposed budget single-seater formula has morphed into one of the world’s first club level electric racing seriesThe Formula Foundation FF-E1 made its public track debut at Brands Hatch during the Formula Ford Festival in the autumn of 2022

The pit garages on the Saturday of the Formula Ford Festival weekend at Brands Hatch in late October were occupied by cars from the Modified Ford Series, a wonderful collection of bewinged and fat ’arched Escorts and other Blue Oval favourites, all supporting the main event. Except for one garage, that is, within which sat a racecar that could not be further from a flame-spitting Sierra Cosworth in looks, concept and certainly sound. That car was the Formula Foundation FF-E1 electric racer, which was to complete a few demonstration laps in the lunchbreak.

Regular readers will be familiar with Formula Foundation, because Racecar featured its proposed entry-level racer, the RSR 001, in the V32N6 issue. For those that missed it, this was a car designed to be cheap and easy to run, the sort of thing – to use a term favoured by its builder, RSR Technology – a dad and lad could campaign successfully throughout a season of racing.

The car featured a standard, transverselymounted, 1.6-litre Ford Sigma SE engine and gearbox, which could be picked up very cheaply, even from a scrapyard, and simple, cost-effective outboard suspension. Many of the other components could be sourced at a reasonable price from local motor factors. The wheels and brake discs, for example, were from a Mini, while the single radiator was Vauxhall Corsa in origin.

The only really hi-tech element was the spaceframe, designed on CAD and constructed from T45 and ROPT CDS aerospace-spec steel, incorporating Diolen side-impact panels for extra protection.

Interest in the RSR 001 was initially very high, yet it proved difficult to sell the car in the UK. This led to a bit of an epiphany at RSR, a recognition that perhaps the days of parent/ child running a car might be over.

‘We realised that things have changed, and people don’t seem to want to buy cars and run them themselves any more,’ says Richard Huddart, who is a partner in RSR with former Formula Ford builder, Steve Wills. ‘There are plenty of kids who want to race the petrol car, but they don’t want to buy it. These days they just want to turn up and drive.’

Building a fleet of Formula Foundation cars to run a series centrally was beyond the capacity and means of RSR, and it looked unlikely teams would buy the cars without a championship to race them in. Yet it also seemed there was simply not room for another junior single-seater series on the British race calendar.

‘It’s just the commercial marketplace,’ says Greg Graham, head of formulae development at the BRSCC. ‘As a club, we understand the marketplace and what opportunities are out there, what might work and what might not. We were approached with a view to try and introduce the petrol car as a junior formula for 14 to 16-year olds.

‘But understanding how the junior market works, and how it’s governed as far as licences being issued by Motorsport UK [the British governing body], we knew that was a bit of a non-starter. So we advised Steve and Richard from RSR that this was the case.

‘However, that didn’t deflect from the fact that the car is absolutely stunning, the chassis had been built to a proper top standard and a lot of engineering expertise had gone into it.’

There was, however, another potential way, which was briefly explored in a box out in Racecar’s original feature.

‘There were a number of conversations, and somebody mentioned the electric word, and it sparked our imaginations,’ says Graham.

From there, the electric project came together remarkably quickly, helped by the fact that work had already begun on the concept – which originally was seen as just another version of the RSR 001 and perhaps an avenue to explore further in the future.

So, in autumn this year, the electric version of the car was unveiled at Croft, with the BRSCC announcing that it hoped to run demonstration races in 2023 and a full championship in 2024 – the first electric single-seater series at this level.

Since then, there has been plenty of interest ‘from credible people that want to race EVs,’ says Graham enthusiastically. ‘We wouldn’t have asked the guys to invest time, effort and energy, and also our own resources, if we didn’t think there was a marketplace.

‘And after the launch, we are hugely confident there is, and not from people that race other things, other formulae, these are people that simply want to race EV.’

This is perhaps the most interesting thing to come out of the whole project so far.

With the compact electric motor and battery box on board, weight distribution is said to be close to that of the original ICE version, although overall car weight has increased by around 50kg. To compensate, power output has increased by approximately 40bhp

We are hugely confident there is [a market], and not from people who race other formulae, these are people who want to race EV

‘It seems that there is a community of motorsport enthusiasts that have no interest in racing petrol cars,’ Graham continues. ‘So they’ve got nowhere to race. Some of them have been involved in electric karting because they chose electric karts over petrol karts, and the next step is Formula E, almost, as far as competitive EV racing is concerned.

‘That community, that marketplace, these youngsters, in general, have been getting in touch and they’re desperate to know what the next steps are, desperate to know how to become involved.

‘It’s people that want to drive an electric car, but they wouldn’t dream of driving an F4 or a GB4 or a Formula Ford,’ Graham adds. ‘They don’t want that. It seems the marketplace is going to come from people who have grown up with electric cars. Their mum and dad have an electric car, they’ve never owned a petrol car. That’s possibly a mindset thing, but it doesn’t stop them being motorsport enthusiasts.’

The car this new breed of racer will drive does differ from the original Formula Foundation offering, and not just in terms of the power source, for while safety was always a priority, things have stepped up a notch.

So, along with the existing front and rear crash structures, which go beyond FIA requirements, eight tonne-rated wheel tethers have been fitted on all four hubs and, most noticeably, a Halo has been attached – a first for a tube-frame single seater.

‘That’s one of the things we’ve instigated through Motorsport UK and the FIA, because there has never been a Halo fitted to a steel spaceframe chassis before,’ explains Graham. ‘So there isn’t a regulation, currently, that states how you test it, what the loading should be, what it should do. Motorsport UK are assisting us and we’re in constant dialogue. They are assisting us to re-define, or re-write, the rulebook. And that’s a work in progress.’

The wide nature of the original spaceframe chassis facilitated the mounting of the Halo, which is made from T45 steel, and also helped when it came to fitting the various components of the electric powertrain. ‘Fortunately, because we had a transverse engine and gearbox in the petrol car, which made the rear quite broad, all the electric stuff fits in,’ says Huddart. ‘We were very lucky in that sense.’