ADVANCED MANUFACTURING CENTRE

SHAPING THE FUTURE OF MANUFACTURING

AS THE FIRST OF ITS KIND IN HONG KONG, ADVANCED MANUFACTURING CENTRE IS REGARDED AS A FUTUREPROOF SMART FACTORY AND THUS A DRIVING FORCE IN THE RE-INDUSTRIALISATION OF HONG KONG AND THE COMMERCIALISATION OF INNOVATION.

BEYOND THE INDUSTRIAL AGE 04 / THE VISION 10 / CONSTRUCTION 2.0 MEETS INDUSTRY 4.0 14 DESIGN FOR THE FUTURE 21 / EXCEPTIONAL REACH 26 / DIGITISATION 36 SEAWATER DISTRICT COOLING SYSTEM 41 / ONE TEAM, ONE GOAL 44

BEYOND THE INDUSTRIAL AGE

Hong Kong is advancing with confidence into an era of industrial excellence in which new standards are being set in production and manufacturing through the application of innovation and technology.

This new chapter parallels the worldwide emergence of Industry 4.0, with the HKSAR Government envisaging the re-industrialisation initiative in the Chief Executive’s Policy Address of 2016, while also revitalising traditional industries through the use of new technologies and developing advanced manufacturing.

Re-industrialisation not only builds on Hong Kong’s strong capabilities in research and development but also stimulates demand for more and a shift in new directions, while providing a fresh impetus for economic growth and creating quality jobs.

The HKSAR Government’s data shows that many entrepreneurs have expressed interest in investing in smart production, while within industry there has been proactive upgrading of production lines towards Industry 4.0. This drive in the private sector demonstrates the sound basis of the HKSAR Government’s promotion of re-industrialisation – and the results are emerging.

01

4 | BEYOND THE INDUSTRIAL AGE

One of HKSTP’s key aims is to attract new manufacturing to the city, adopting innovative technology and requiring highly-skilled labour to enhance the competitiveness of Hong Kong’s manufacturing industry

At the centre of the HKSAR’s revolution is Hong Kong Science and Technology Parks Corporation (HKSTP), which has a long-term commitment to providing value-added services for the technology, and research and development sector in Hong Kong. One of HKSTP’s key aims is to attract new manufacturing to the city, adopting innovative technology and requiring highly-skilled labour to enhance the competitiveness of Hong Kong’s manufacturing industry.

HKSTP is driving many initiatives, including the recent rebranding and repositioning of the HKSAR’s three industrial estates at Tai Po, Yuen Long and Tseung Kwan O as “INNOPARKs” providing high-potential sectors like advanced manufacturing with plenty of specially designed spaces and facilities with a view to fostering high-tech smart production.

The nine-storey Advanced Manufacturing Centre (AMC) in Tseung Kwan

O INNOPARK is the latest in a series of projects developed by HKSTP. While AMC was conceived, designed and purpose-built, it was preceded by Precision Manufacturing Centre, a factory building refurbished into a manufacturing base for precision products that opened in Tai Po Industrial Estate in 2017. They are to be followed by Microelectronics Centre in the Yuen Long INNOPARK, scheduled for completion in 2023.

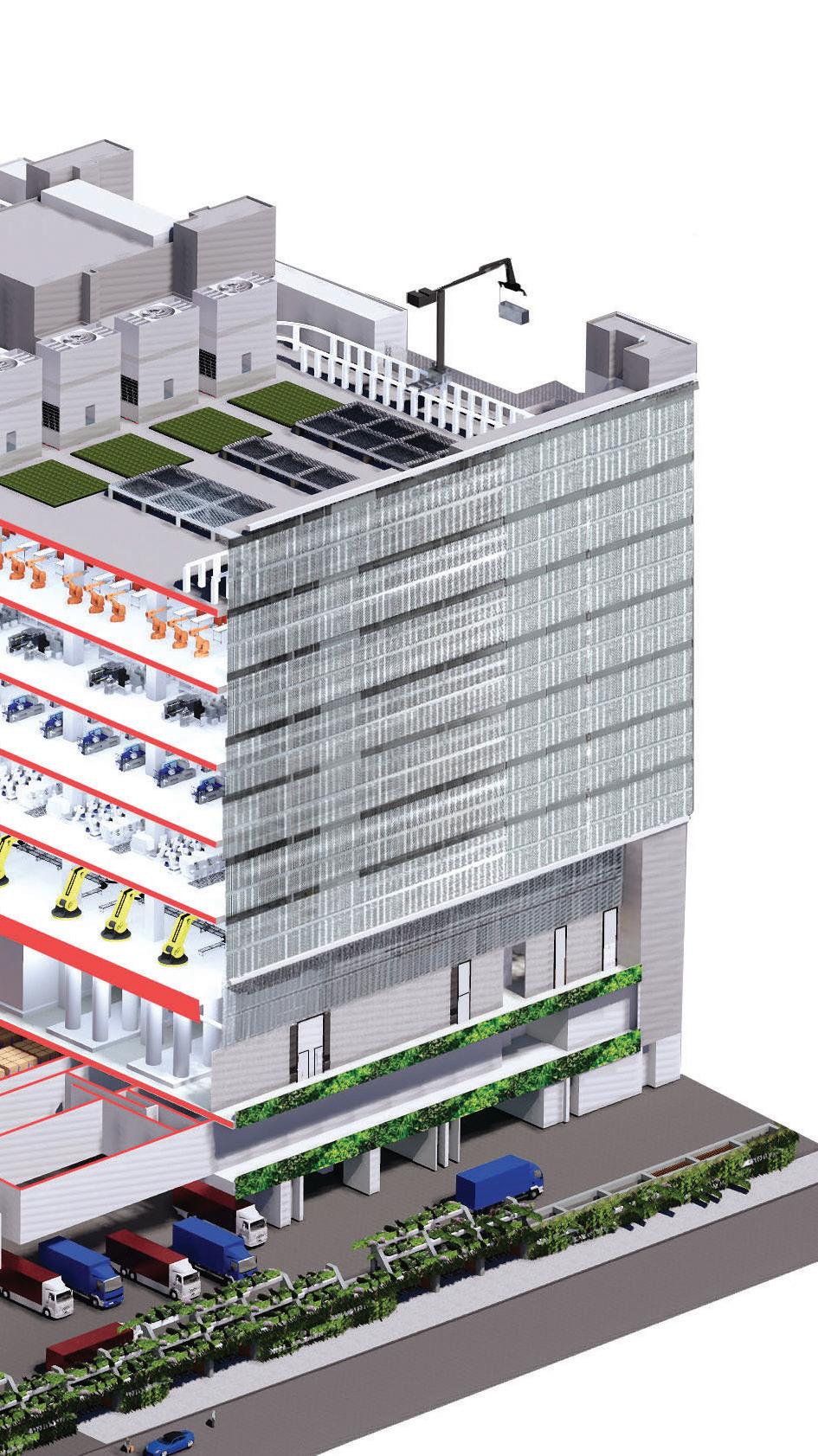

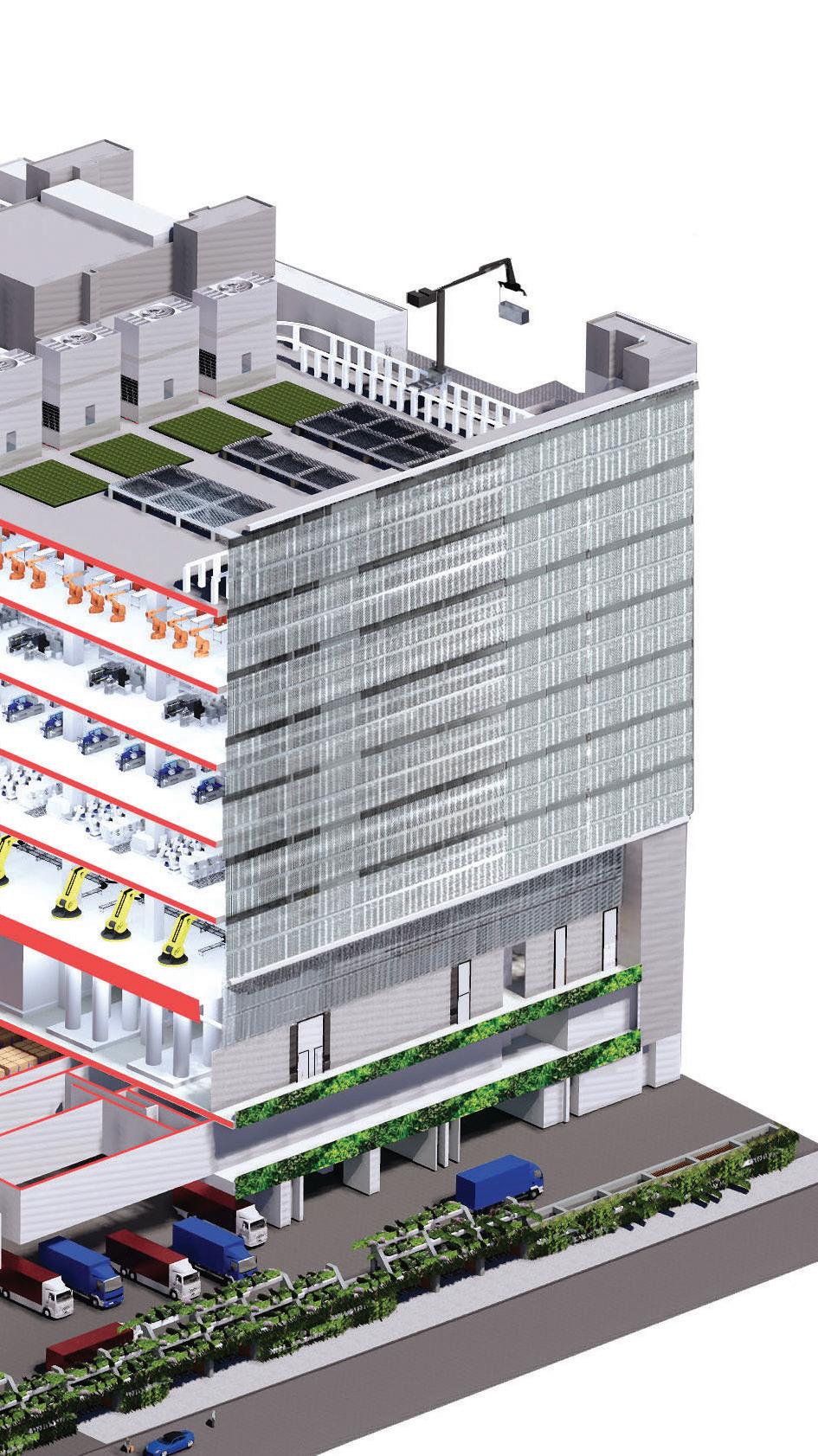

As the first of its kind in Hong Kong, AMC is regarded as a future-proof smart factory and thus a driving force in the re-industrialisation of Hong Kong and the commercialisation of innovation. It showcases how Hong Kong has responded to the emerging need for digital-smart factories in a multi-storey environment for multiple tenants involved in advanced industries. Its tenants include those in the robotics electronics, medical and biomedical engineering, smart electronics and optical equipment, and the semiconductor sectors among others.

The project will benefit many industries by providing advanced and scalable manufacturing facilities to fit the needs of present and future tenants.

BEYOND THE INDUSTRIAL AGE | 7

It is also HKSTP’s objective to bring in new industries as well as open up job opportunities for highly skilled workers, especially among youth. AMC will be important to the corporation’s continuing effort to further advance Hong Kong into a regional innovation and technology hub.

Inherent in the design of AMC is flexibility and resilience, allowing it to provide companies of different sizes with scalable, efficient and serviced manufacturing space, and to assist them in embarking on technological innovation and adding value to a high degree.

AMC puts Hong Kong’s long-standing reputation of quality and trust into smart production and advanced manufacturing processes, making the city accessible for innovators who demand world-class excellence.

AMC will be important to the corporation’s continuing effort to further advance Hong Kong into a regional innovation and technology hub

BEYOND THE INDUSTRIAL AGE | 9

AMC is the first fully-fledged project in Hong Kong’s drive towards fulfilling the Industry 4.0 ideal. As such, its aims are to bring into Hong Kong new high-skills industries and with them opportunities for a highly skilled young labour force. Equally, it is to support advanced and future manufacturing.

In the context of HKSTP, AMC can complete the value-added chain by adding its manufacturing facilities to the research and development strengths of HKSTP.

For all that, a building of technical complexity and great flexibility is necessary. These key properties, along with its scale, set AMC apart from a traditional, purpose-built factory building.

Essentially what HKSTP commissioned was a completely new type of building in Hong Kong, one without precedent. It could not look to its Hong Kong Science Park Phase 3, an office and laboratory building, its Data Technology Hub (DT Hub), an office building, or its InnoCell, which is a dedicated accommodation centre designed to foster interaction and collaboration among its residents. Each, no doubt, is a specialist building in its own right and the focus of critical, innovative research and development work.

The AMC is a smart industrial project built for low-volume and high-mix production to enable INNOPARK tenants to manufacture prototypes without needing to cross the border to mainland China. So, at the same time, AMC is helping to reignite the spirit of local manufacturing.

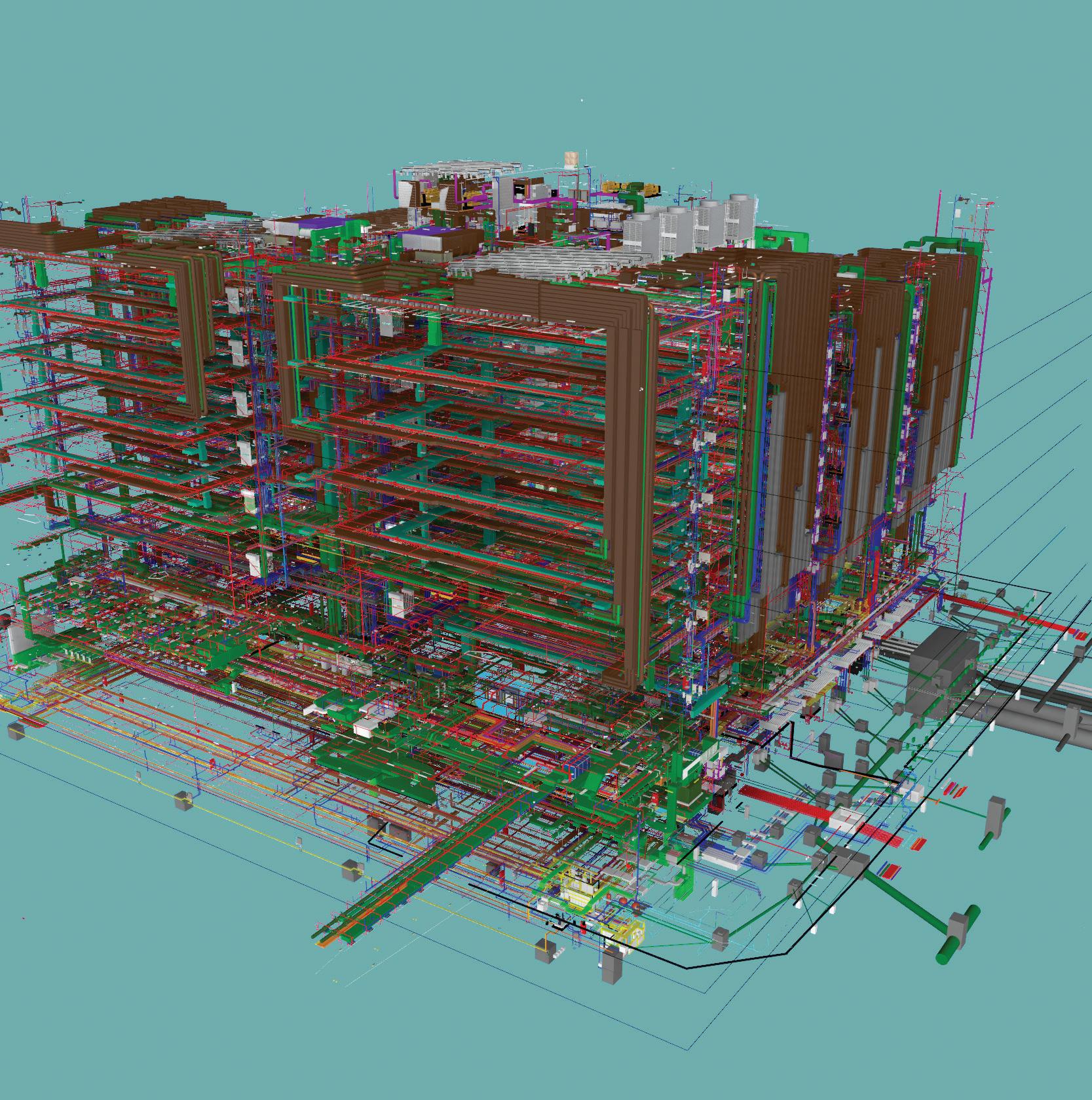

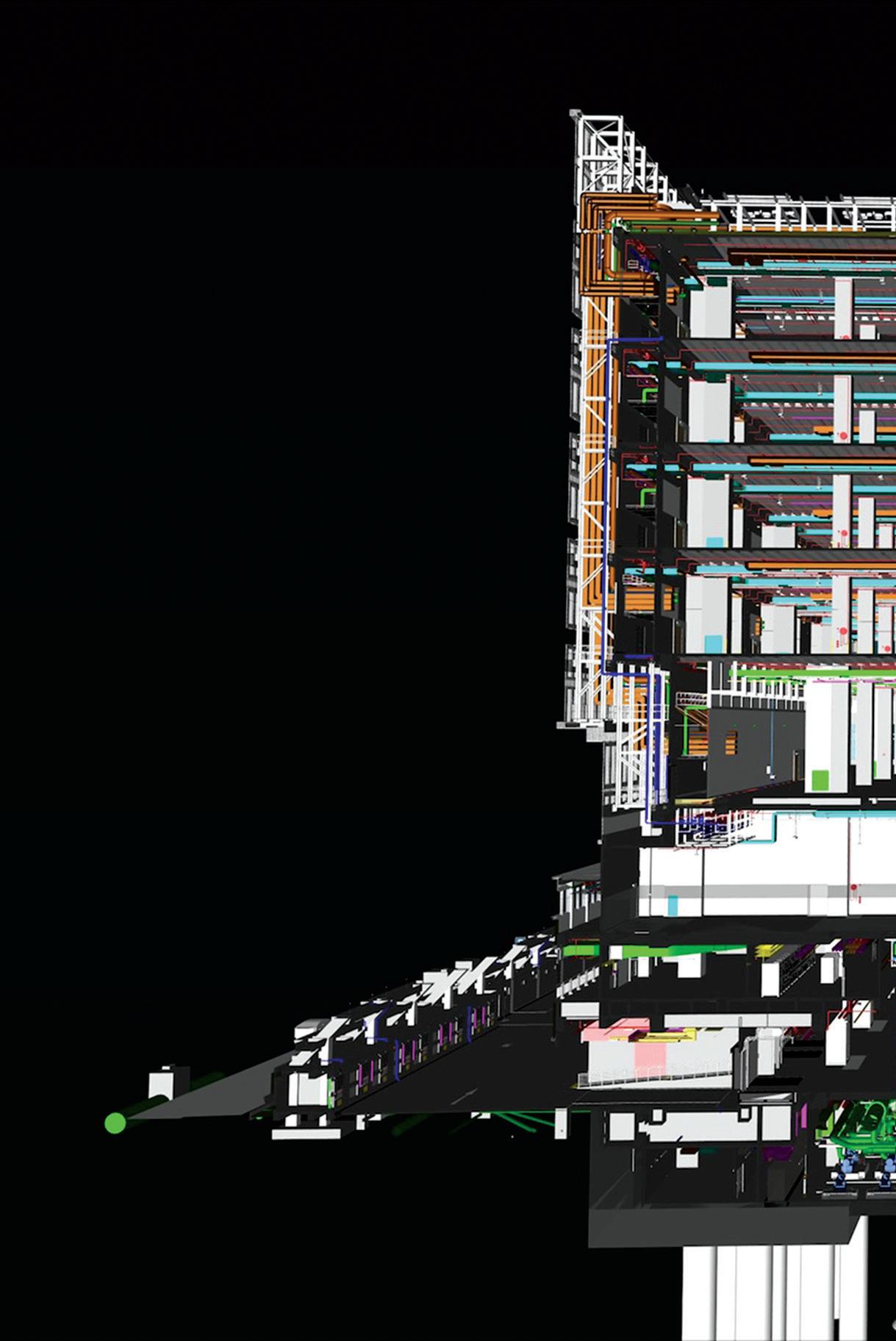

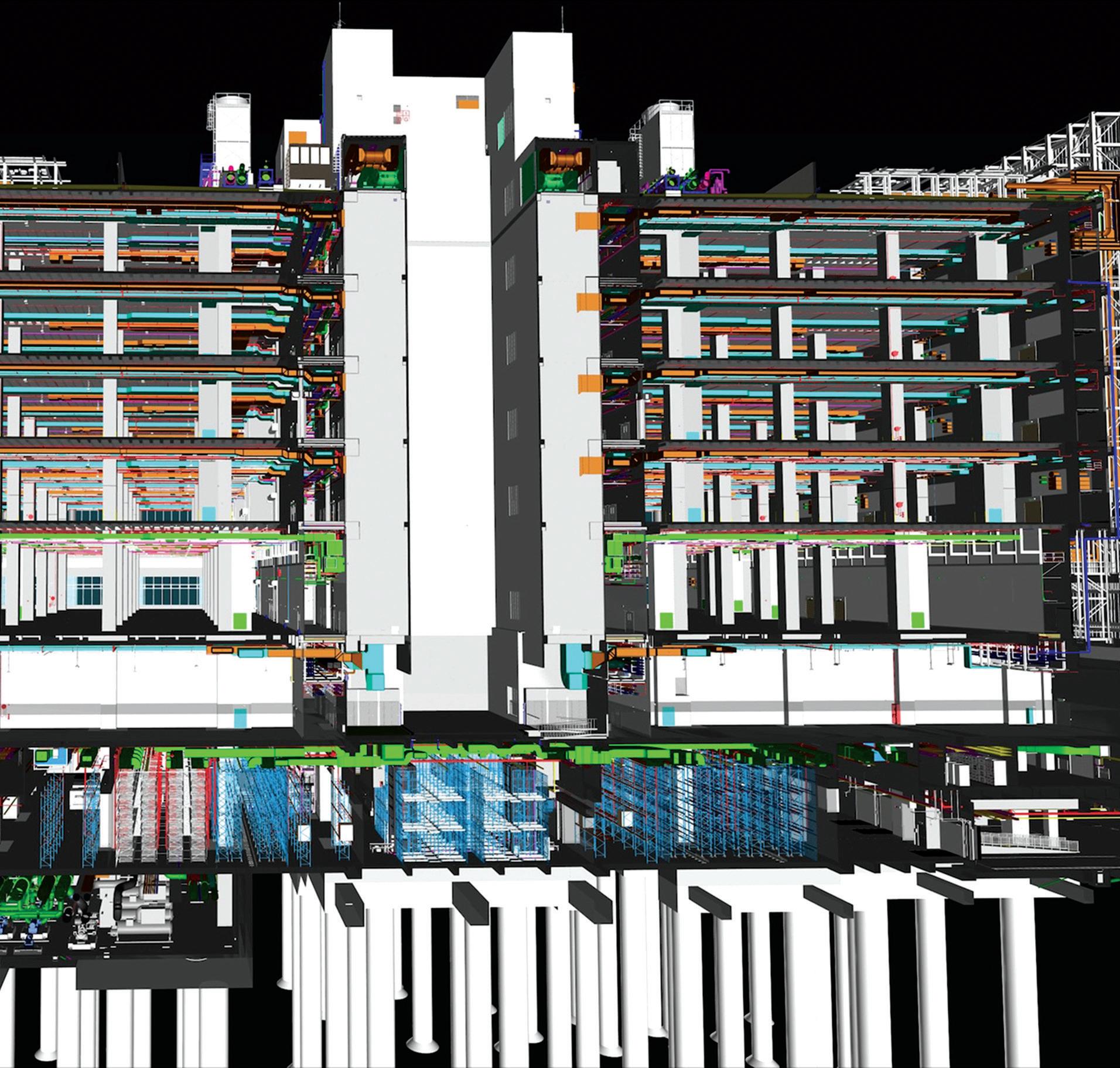

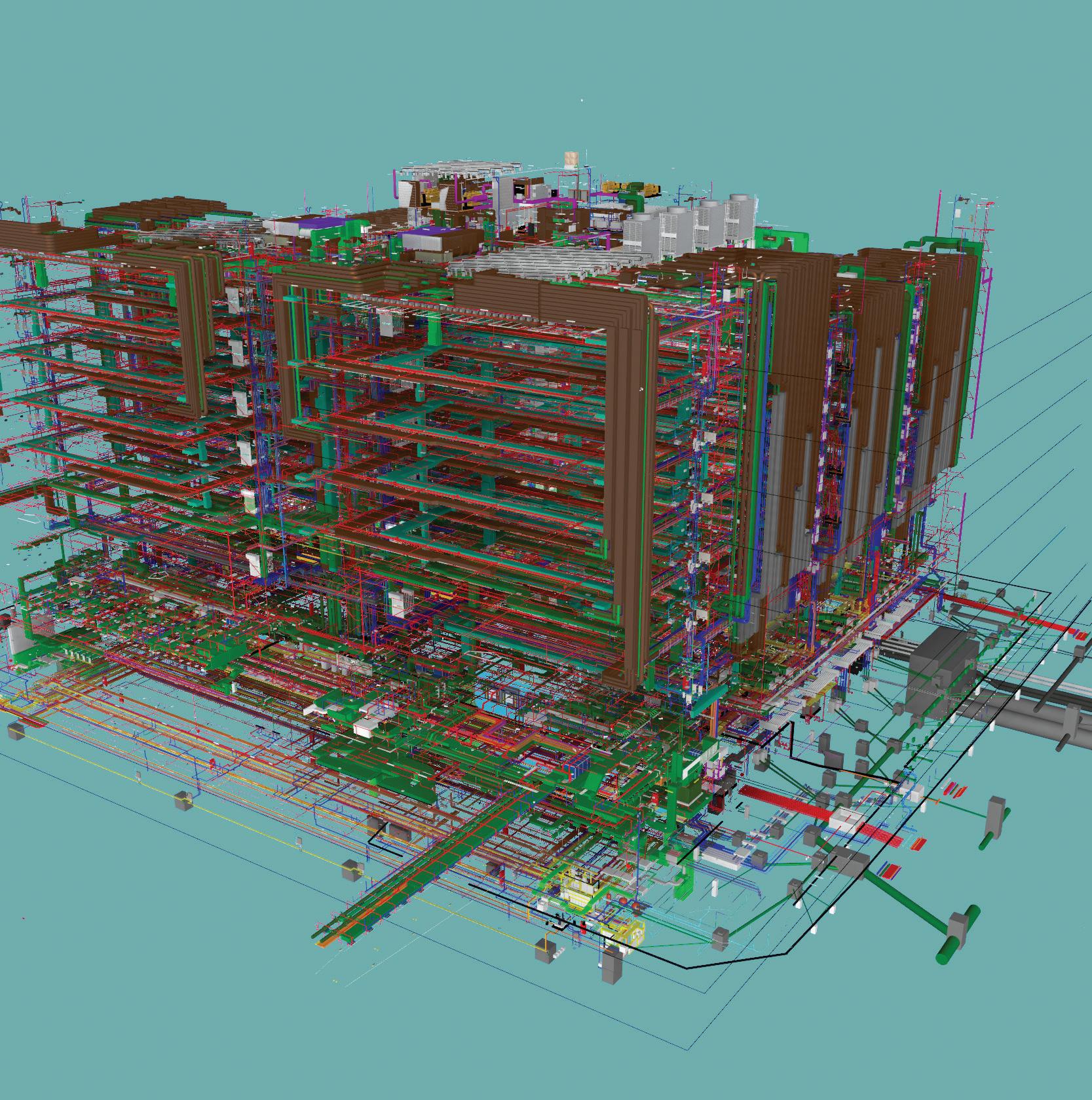

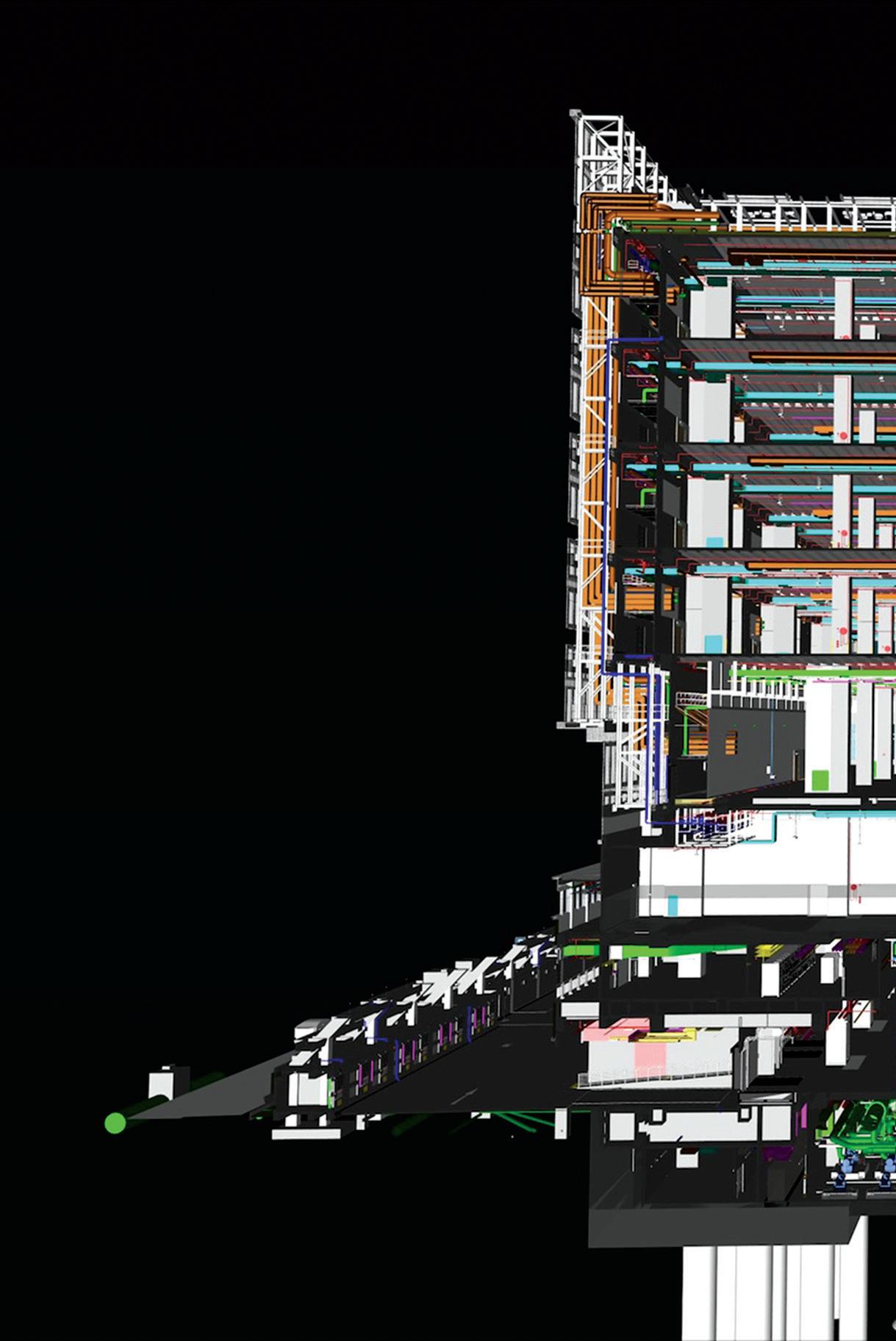

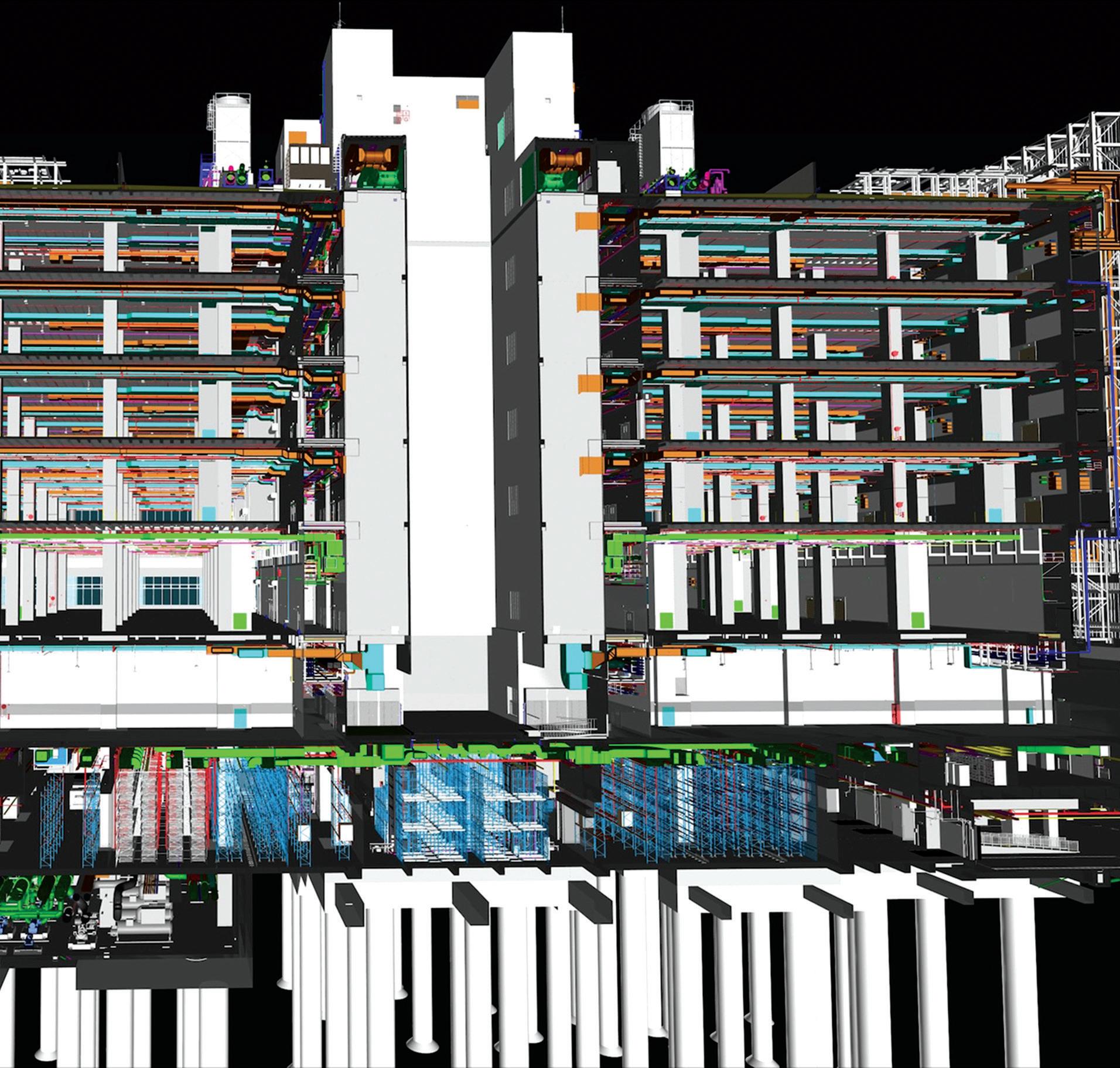

Fittingly for a pioneering project, innovation has been implemented at every stage of the building’s design and construction, and will have a hand in its long-term management. This has been possible by the application of Building Information Modelling. BIM was at the heart of planning and construction, and it allowed for greater efficiency in managing the building’s services through interactive controls that could respond in real time to live environmental changes, minimising energy wastage in daily operations and delivering a greener, more sustainable smart factory.

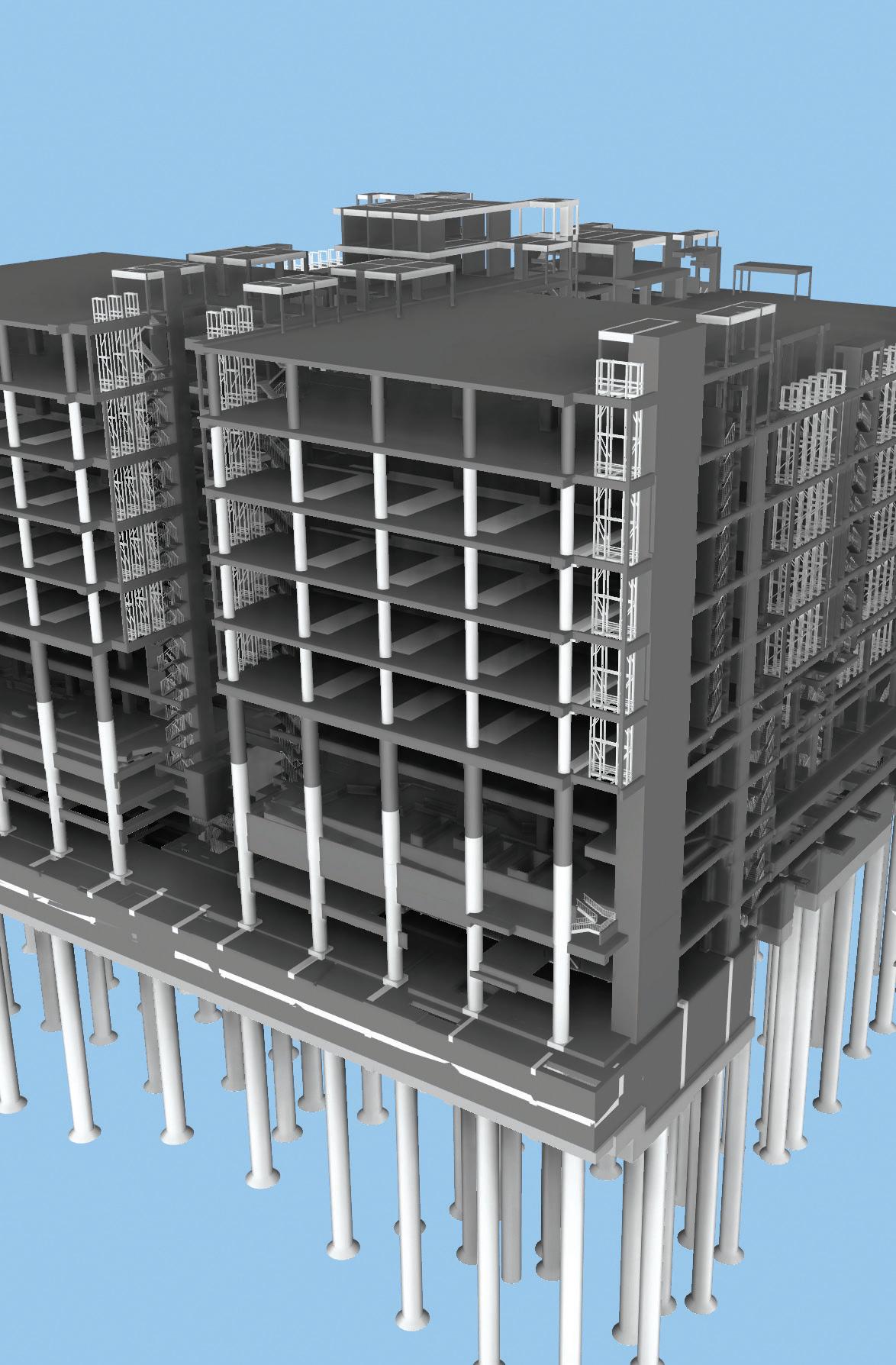

The AMC project with over 100,000 square metres of gross floor area has involved the construction of a nine-storey block, with a two-storey basement. A seawater district cooling system (SDCS) forms part of the air conditioning system in AMC, and will be extended to adjacent properties in the INNOPARK. The district cooling system is a long-term, cost-effective and environmentally friendly solution for temperature control.

The architects’ design brief was specific: AMC was to be developed for special manufacturing and production needs, to meet as many custom requirements as there may be from tenants. Tenants may come from five focus industries – devices and equipment for medical health and hospitals, biomedical engineering devices, implants and equipment, smart electronic and optical equipment, smart sensor fabrication, semiconductor advanced packaging as well as robotics electronics and smart power devices for smart city application. Thus, the AMC building features high headroom, heavy floor loading, and is equipped with anti-vibration technology

02 THE

10 | THE VISION

VISION

AMC

is the first fully-fledged project in Hong Kong’s drive towards fulfilling the Industry 4.0 ideal

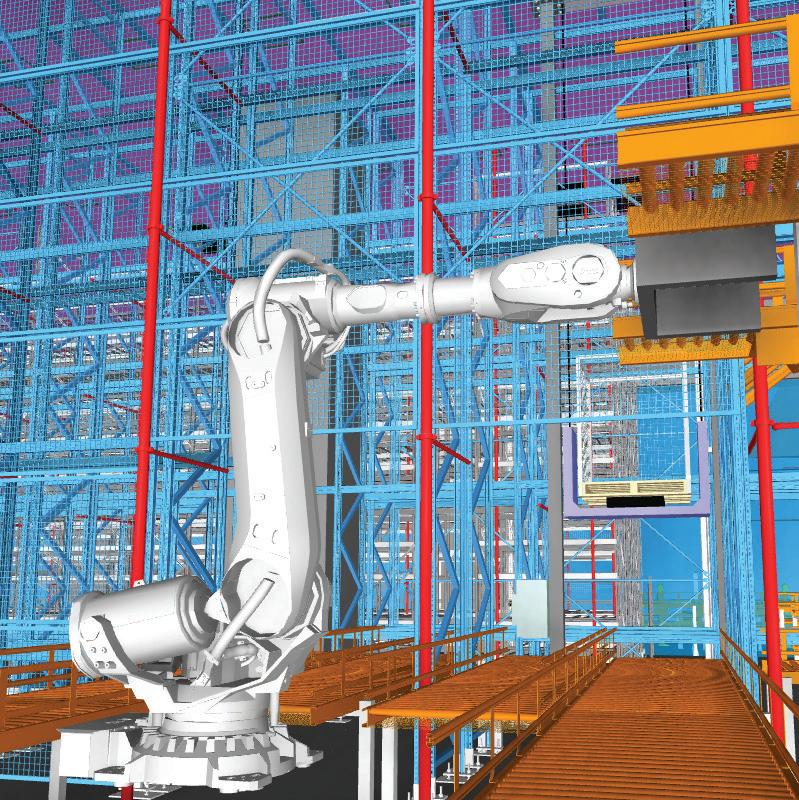

and efficient cooling that can be tailored to each user’s differing needs. In the Industry 4.0 era, automation of logistics and supply chain visibility are critical, and AMC provides all of these, with shared economical and logistical systems available for small to medium-sized factories.

According to HKSTP Chief Project Development Officer Simon Wong, it took four years to develop Industry 4.0 from concept to reality, and it is expected to last from 50 to 100 years. He mused, “AMC does not stand alone. A double-storey bridge connects it to DT Hub across the road and symbolises the synergy between these two HKSTP projects. While DT Hub is well equipped to house tenants’ data on-site, AMC is more comparable to a huge

machine specialising in manufacturing pilot products. In other words, DT Hub is a control centre or a computer’s CPU to the AMC’s 3D printer, sending orders across the bridge to realise ideas in the manufacturing centre. Prospective tenants have already leased space in both DT Hub and AMC.”

In Industry 4.0, it is expected that customers and suppliers will establish closer relationships through data made available on the internet. What’s more, prototypes always need certification and, with an eye to the future, AMC may well see its way to opening up tenancies for certifiers, so that new ideas can be devised, realised and approved all under the same roof. After all, this cradle not only has eyes on local but international tenants.

12 | THE VISION

HKSTP Project Director Carrie Chan contended, “AMC is key to fulfilling our objective of re-industrialisation, so the concept of Industry 4.0 is an important part of the DNA of AMC. Also embedded in its erection are the principles of Construction 2.0, the HKSAR Government’s drive to bring the construction industry into the future through focusing on innovation, professionalism and revitalisation. These qualities resonate in Industry 4.0 and all are exemplified in the construction of AMC. As the building itself is already unique, and captures the users’ requirements and advancements in manufacturing, users’ experience and feedback on AMC will help us plan for AMC 2 in order to meet further demands of our tenants for advancement. For sure, we want a big leap forward from AMC to AMC 2 instead of just a copycat.”

Stakeholders unanimously expressed excitement and felt privileged that they had been involved in a project that is a beacon for the future. Although it was a steep learning curve, the journey ultimately empowered them, and took their skill set and expertise to higher levels.

THE VISION | 13

CONSTRUCTION 2.0 MEETS INDUSTRY 4.0

With the construction industry facing challenges such as an increasingly ageing workforce, high costs, lack of innovation and site safety incidents, the Chief Executive of the HKSAR announced the launch of Construction 2.0 in her Policy Address in 2018 with an emphasis on industry changes required across three key pillars: innovation, professionalisation and revitalisation. It is hoped this will move industry to the next level and beyond. Over the past few years, the Development Bureau has been proactively driving these three pillars to raise the productivity and skill levels of industry by the wider use of information and technology, and modular integrated construction (MiC). For instance, the speedy completion of the quarantine centre at the Lei Yue Mun Park and Holiday Village amid the covid pandemic won applause.

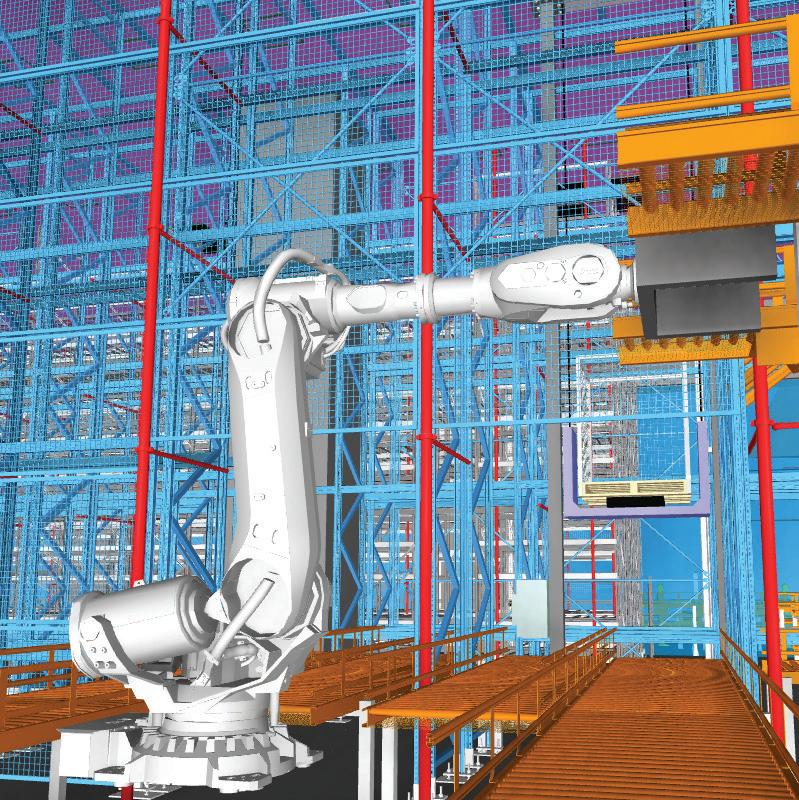

Industry 4.0, a concept that first hailed from Germany in the early 2010s, is no longer a buzzword and considered a direction for the government to promote re-industrialisation. Under Industry 4.0, the manufacturing process will evolve to a higher level of automation where the physical world of industrial production merges with the digital world of information technology, forming cyber-physical systems. With the continuous exchange of data within computers and networks, cost-effective production of customised products could be achieved and new business models developed autonomously. Key elements of these concepts include big data, cloud computing, IoT (internet of things), autonomous robots and AR/VR (augmented reality/virtual reality).

03

14 | CONSTRUCTION 2.0 MEETS INDUSTRY 4.0

The manufacturing process will evolve to a higher level of automation where the physical world of industrial production merges with the digital world of information technology, forming cyber-physical systems

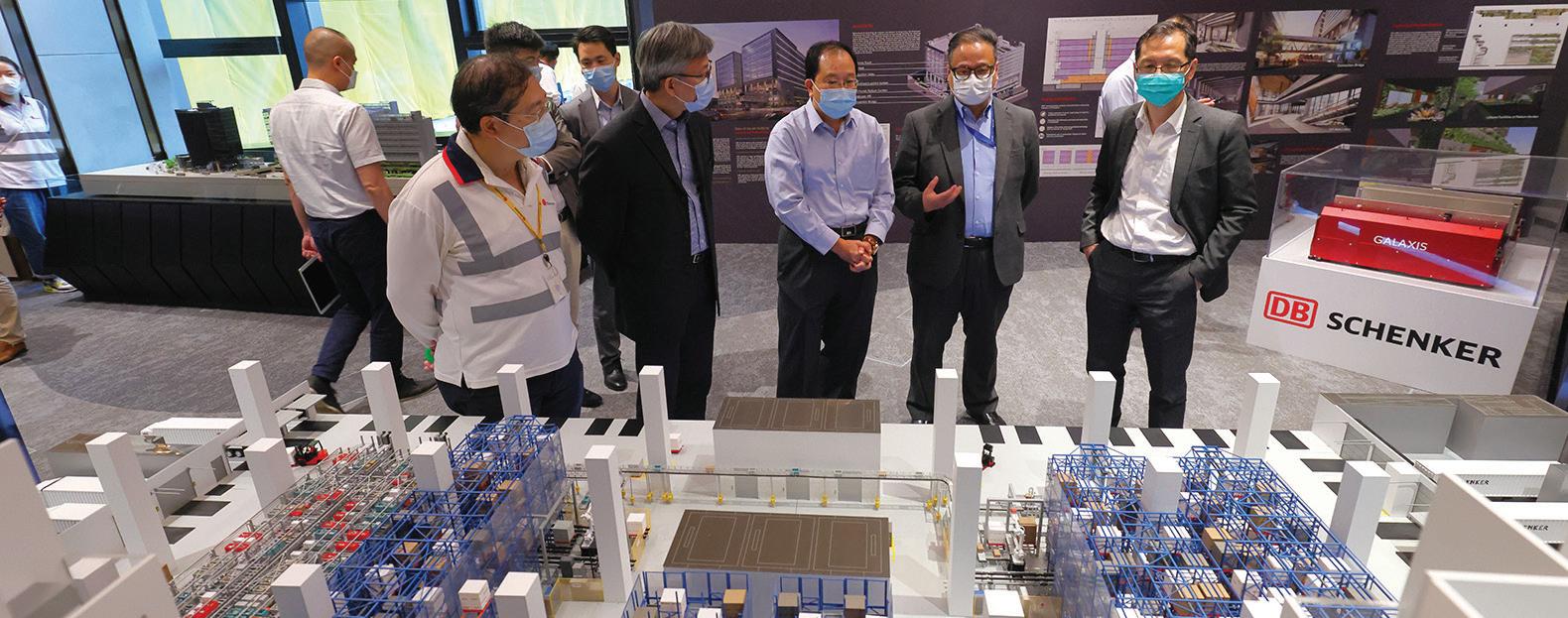

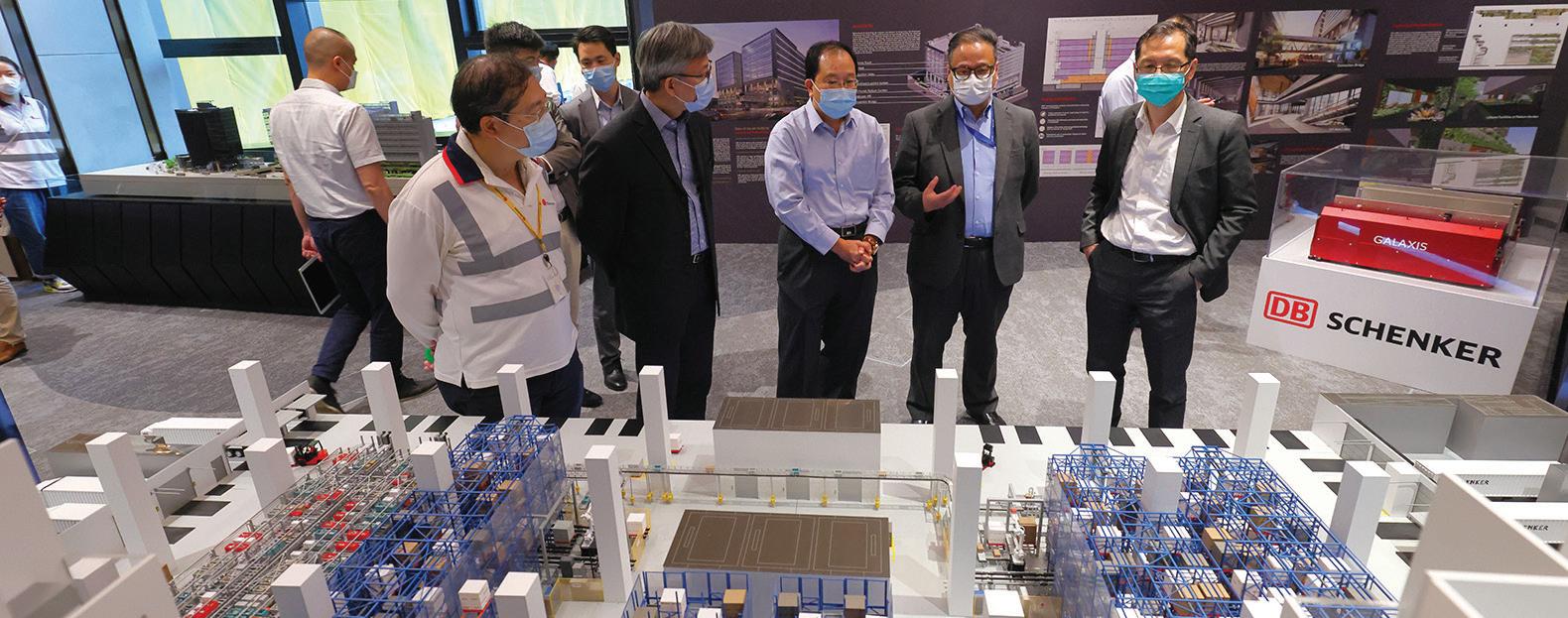

As a pilot project for Industry 4.0 in Hong Kong, AMC is also the first and only building adopting Construction 2.0 simultaneously. According to HKSTP’s Chief Project Development Officer Simon Wong, when key parties met on the 27,000 square metre site of the AMC building before construction began, everyone felt the spark that gave birth to this industrial masterpiece, which people can touch and see today.

Mr Wong mused, “Indeed, both concepts sound very similar with some of the elements overlapping, i.e., construction digitalisation and prefabrication. Given its mass scale of over 100,000 square metres of gross floor area with many repeated items of construction, we emphasised digitisation and off-site manufacturing to address challenges, i.e., ageing labour and the shortage of a skilled workforce. That’s why our digitisation started from day one of construction with data stored properly for the optimisation of services. Our precast beam and curtain wall were prefabricated at factories in mainland China where automated functions like robotic arms are equipped to ensure quality. Afterall, Construction 2.0 and Industry 4.0 are inseparable, and need to walk hand in hand to shorten construction time, reduce manpower and enhance safety on construction sites.”

Obviously, this trend is new for the industry as well as for the consultants on this project such as Meinhardt (C&S) Ltd Managing Director Adam Choy. It was a fresh learning curve and he realised that the concepts were integrated into modern technology i.e., BIM, the AR technique, concrete sensors, cloud services with an innovative design approach and construction methods such as Design for Manufacture and Assembly (DfMA) and MiC, which continuously enhanced quality, safety and sustainability.

Mr Choy contended, “The use of the MiC [Toilet] having freestanding volumetric modules (with finishes, fixtures, fittings, etc.) manufactured off-site and then transported to the site for assembly was impressive with proven immense benefits like improved site safety, more efficient and better quality control,

CONSTRUCTION 2.0 MEETS INDUSTRY 4.0 | 17

shortened construction periods, less construction waste, less demand for on-site labour, less disturbance and nuisance to the neighbourhood, etc.”

Lead architectural consultant, Wong Tung & Partners Ltd, assisted in making AMC Industry 4.0 ready by adopting many of the suggested methodologies and innovations such as DfMA, modular design and BIM. Examples include the 75 percent adoption of DfMA and precast double tees. Director Amy Ho said, “Construction 2.0 is a set of clear goals that involves changing society’s mindset towards the construction industry. We have adopted a lot of the suggested methodologies and innovations such as DfMA, modular design and BIM. We are also very intrigued by the idea of making AMC Industry 4.0 ready. Industry 4.0 refers to this new Industrial Revolution phase that we are in now. We focus heavily on interconnectivity, automation, machine learning and real-time data for the production of goods.”

Revitalisation as a key pillar of Construction 2.0 stresses reinvigorating the appeal and benefits of joining the industry to attract and nurture a growing number of young and energetic talent to the workforce. Hopefully, success stories like the AMC building demonstrate the appealing prospects for young and highly skilled talents to make the construction scene bigger and brighter.

18 | CONSTRUCTION 2.0 MEETS INDUSTRY 4.0

DESIGN FOR THE FUTURE

Constructing an industrial building of this type from the ground up was non-existent in Hong Kong. It’s been an innovative, difficult yet rewarding journey because HKSTP and Wong Tung & Partners Ltd devoted an immense effort to ensure a future-proof design. In the beginning, HKSTP’s project team not only conducted various overseas site visits and inspections in Singapore, Germany, South Korea and Japan for best practices and tips on Industry 4.0, but also sought local advice through internal surveys with about 30 potential tenants on what they look for and their production requirements in an AMC. It took the team several months to grasp what to build. Meanwhile, it solicited support from the Japanese industrial architectural design consultant – Nikken Sekkei Ltd (NS) – and the project team visited NS’s office in Japan. NS played a key role as a design leader and established a design direction for the AMC project based on its track record and engagement with a broad range of clients from globally renowned leading companies to small enterprises, which utilise advanced technologies.

INNOVATION GATE

This design idea symbolises the opening of opportunities that lie ahead in the future; the Innovation Gate also celebrates the transition to a new era marking the industrial revitalisation movement in Hong Kong. The city is home to many highly skilled professionals, but lacks advanced manufacturing industries. The hope is that on one hand this production environment would lead young talents to stay and develop their careers in the city. On the other hand, it would lure homegrown entrepreneurs to partially or wholly relocate operations from overseas.

Benchmarked against Industry 4.0 standards, AMC has been developed to become the driving force in the re-industrialisation of Hong Kong and commercialisation of innovations. It is a pilot project showcasing how to respond to the emerging trend of smart factories in a multistorey environment for multiple tenants in advanced industries, such

as medical and biomedical engineering, smart electronics and optical equipment, semiconductor, robotics electronics, etc. They consist of scalable manufacturing and prototyping of technologically innovative, high value-added, high-mix and highly customised production. It fits small to large companies adopting advanced processes.

THE SMART FACTORY

AMC is designed for maximum flexibility to cater for future tenants of various sizes in advanced manufacturing industries. For most companies, they will require specific manufacturing conditions to facilitate production of their innovations. To set the parameters of provisions in the design, the team provided the basic elements required by many industries as standards using the industrial architectural design consultant’s greatest common denominators (GCD) approach. Finally, the architectural design reaches the buildable stage and complies with local regulations. For instance, the 12m grid span and the maximum 15kPa floor-loading capacity on a typical floor and 25kPa on heavy production floors enables flexible production line layouts with heavy equipment. The beauty of having a simple structural bay system allows for easy expansion and layout changes to suit any client’s needs over time. Indeed, the 12m grid span is already beyond standards in Japan where it is normally 6m or 8m in common buildings. Exceptionally high ceilings mean the storey height of 8m on a typical floor provides adequate headroom for the installation of robotics and clean rooms.

Moreover, it is designed for maximum flexibility with high standards of reducing the severity of vibrations – known as Vibration Class B according to the handbook of the American Society of Heating, Refrigerating and Air-Conditioning Engineers – in the 12m grid molecular production area providing between 15kPa and 25kPa of floor-loading capacity. The large floor plate is enclosed in a concrete structure and cladding panels to maintain its thermal comfort, with FM2 (free movement category 2) floor finishes

04

DESIGN FOR THE FUTURE | 21

providing a stable environment for the high-precision works required of focus industries. The Eco Well at the centre of the building and MEP (mechanical, electrical and plumbing) balconies on the east and west elevations serve as a functional distribution of MEP services to the roof from production units or for ventilation and chemical treatment tanks on the 1/F and basement.

The building removes a major stumbling block for advanced manufacturing – that of the prohibitively high cost for low-volume production – by providing shared services, i.e. the Logistics Centre, so that partner companies can focus their valuable resources on their core productions. Additionally, a communal workshop functioned as a facilitator to help budding businesses get off the ground by offering equipment and facilities to conduct prototyping and small-batch manufacturing. It’s also a space where people can gather and freely converse to pave the path to creativity.

CHALLENGES

Since AMC was a pilot project with multiple tenants, the team had to prove to the stakeholders and the decision-makers the reasons for the spatial requirements and the building services system requirements to exceed previous and current parameters in Hong Kong. Also, this atypical design with high headroom was a

hurdle in terms of obtaining general building plan approval under Hong Kong’s stringent system. Therefore, the team had several rounds of Buildings Department submissions to show how this unique multi-tenancy building could cater to diverse industries and ultimately permission was granted.

The industrial architectural design consultant is experienced in advanced technological factories – single-use and owner type, but not multi-storey with unnamed tenants, so it could only share what these industries’ users needed in space and requirements. In the end, a GCD approach was adopted to be able to cater for most future tenants. This was demanding because there were no local precedents, so the team had to review and assess requirements garnered from five focus industries to make calculated assumptions in setting the design criteria. The industrial architectural design consultant led and guided the team to build an Industry 4.0 factory.

Given the tight programme, key milestone dates were set by HKSTP to meet schedules. For instance, meetings were held to seek approval for basic concepts (the grid, MEP balcony, etc.) and the schematic designs (façade/interior design). At the tender stage, the consultants worked hard to issue a main works tender within two months and the impact of COVID-19 led to closer

22 | DESIGN FOR THE FUTURE

coordination with the contractor to work out different remedial proposals to meet the milestone dates.

At a glance, the spirit of advanced manufacturing is instilled from inception to the design, construction and operation of the AMC building. After weathering the storms, the team successfully implemented all the advanced features as planned in the concept stage. This building can be fit for use for decades to come.

EXCEPTIONAL DESIGN FEATURES

The hard work reaped dividends as AMC was honoured with third place in the Rethinking the Future Awards 2020. These prizes are awarded to the trendsetters and pioneers dealing with the global challenges head-on with innovations that inspire the next generation. It proves that AMC is truly avant-garde and a forward-looking project. Some examples of the building’s exceptional design features are:

17M GLASS WALL ENTRANCE LOBBY

As 90 percent of the building is for factory use, the main entrance lobby is one of the few areas visible to the public. It is therefore framed by one of the largest distinctive single-piece 17m-tall glass façades. The perforated panel ceilings are filled with LED lightboxes, which are programmable for thematic lighting to create

a special ambience or to respond to the external environment like the sunset or a rainy day.

FM2 FLOOR FINISHES

The industrial concrete floors are constructed to the highest practical standards of FM2 where the floor finish is specified for AMC. FM2 provides a high standard of floor surface for the stability of high-level racking, ASRS (the automated storage and retrieval system) and a carton shuttle at the Logistics Centre. Furthermore, the floor surface is also a critical factor in the performance of highlift materials equipment and for high-precision manufacturing

LOGISTICS CENTRE (COMMUNAL WAREHOUSE)

AMC operates a communal distribution centre and warehouse on the G/F with a dynamic scheduling system to move goods to and from partner companies at appointed times, and on-demand storage in the warehouse. The Centralised Logistics System with IoT offers an inventory of materials deliveries and finished goods. The system is managed by a third party logistics (3PL) partner with the provision of web-based control of the Warehouse Management System. A 3PL partner can provide a lean logistics system for “just-in-time delivery” without wasting valuable space on stockpiling materials.

DESIGN FOR THE FUTURE | 23

It believed AMC...would become a platform for the generation of highvalue products...as a master model, “Industry 4.0 HK version”

CONTAINER HOIST

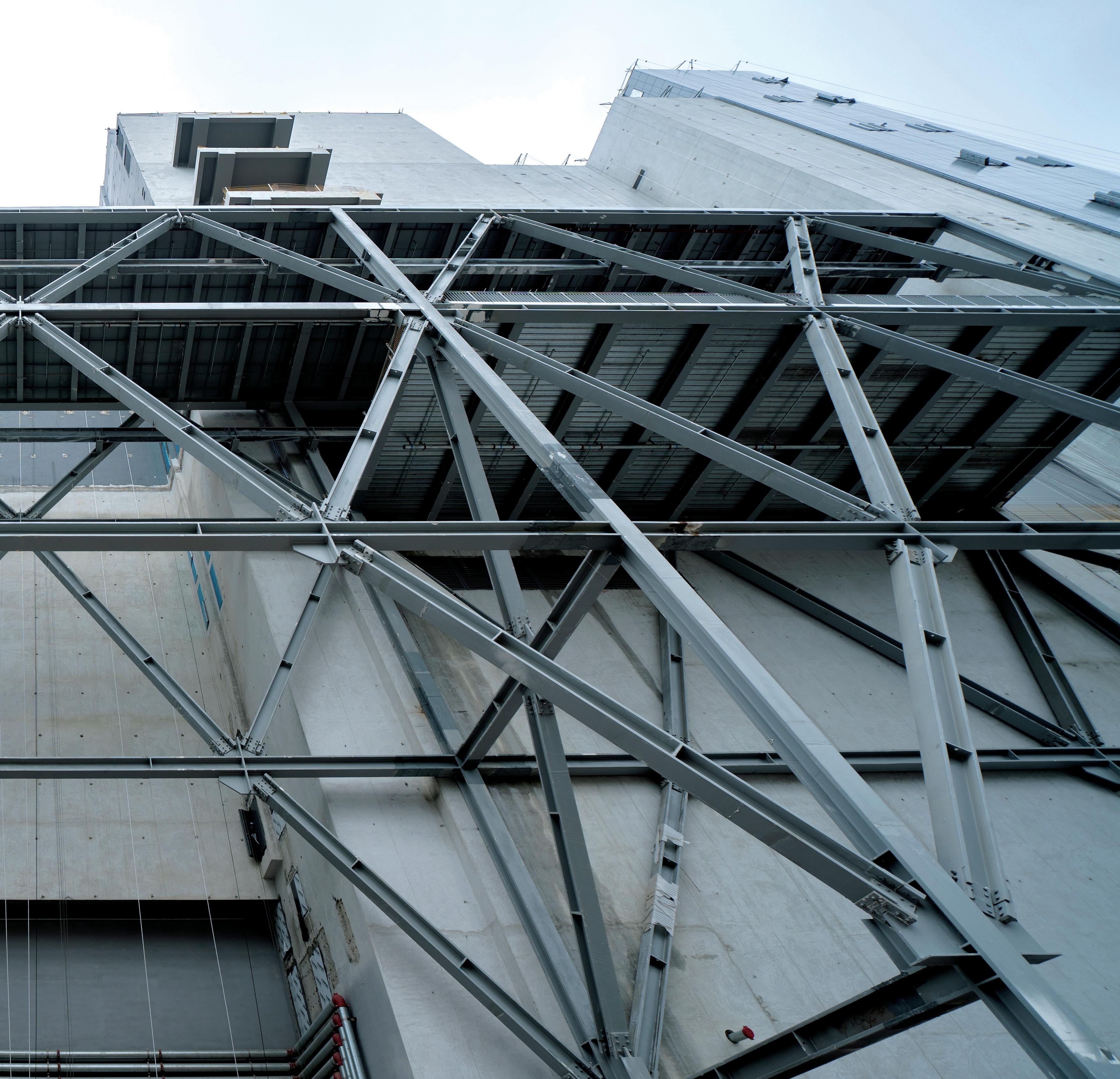

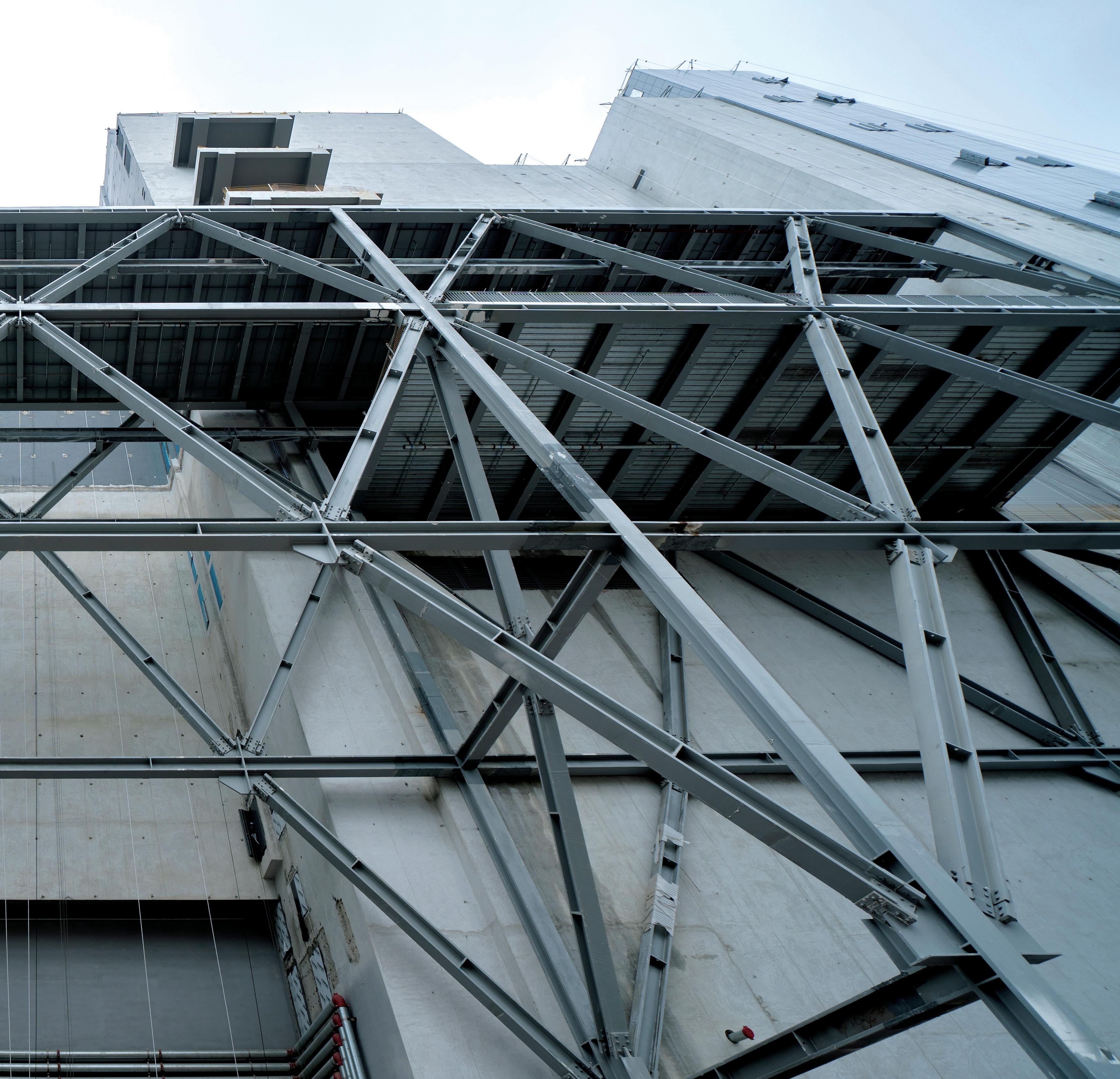

Heavy production units can be accommodated on the 2/F where the floor loading is strengthened to 25kPa. The tenant here has the privilege to use the container hoist for material delivery/ dispatch with the 40-foot containers being lifted directly from the lorry arriving at AMC at the Logistics Driveway on the G/F. The steel structure of the container hoist is detached from the main building’s concrete structure to mitigate vibration transfer to the production floors above.

ENGAGEMENT OF NIKKEN SEKKEI LTD

Industry 4.0 is a new standard for buildings and only a few projects had been completed worldwide by the time this Hong Kong project started in 2019. The engagement of the industrial architectural design consultant was aimed at tapping their experienced understanding of the rationality and economy required in industrial facilities as well as their familiarity with approaches to achieve flexible designs to adapt to future changes in a multi-storey industrial building for multiple tenants in AMC.

To integrate Industry 4.0 in the project, NS put forward key elements such as multifunctional production equipment that could be downsized, and the number of workers, space and energy consumption could be minimised. Flexible layouts for equipment and lean production of required quantities at set times became feasible. The functional arrangement of vertical logistics and building services by the use of common MEP spaces are specially designed for multi-layering of production spaces. Most importantly, to cater for common and conflicting requirements, modularisation of spaces was introduced. As the backbone of AMC, shared logistics would cover production on all floors.

The industrial architectural design consultant had not been able to visit the construction site due to COVID-19, so site photos and regular progress reports were provided. Still, it believed AMC was a real space in the cyberspace era and would become a platform for the generation of high-value products not just as hardware, but also as a master model, “Industry 4.0 HK version”, allowing for synergy among tenants.

DESIGN FOR THE FUTURE | 25

EXCEPTIONAL REACH

Main contractor Gammon Construction Limited is renowned as a construction industry leader in innovation, and dedicated full support and resources to maximise the concepts of Construction 2.0 and Industry 4.0 in this project. As a result, the use of innovation tools had been front and centre as they were manifested widely by the owner, consultants and contractors on-site to enhance productivity and efficiency throughout the life cycle of the project.

DFMA AND MIC APPROACH

Using the Design for Manufacture and Assembly (DfMA) approach and Modular Integrated Construction (MiC) not only standardised the construction sequence, but also provided significant advantages to the works in terms of safety, quality and delivery of the programme.

The main contractor employed DfMA mainly for structural steel and façade works, MEP service modules and the precast double tee concrete slab. This resulted in an achievement of 75 percent offsite prefabrication of the structural steel works, 75 percent off-site modularisation of the MEP works, and the MEP balcony was even 100 percent prefabricated in a bolt-and-nut approach to reduce working at height. With 27 percent of the reinforced concrete superstructure produced in an off-site factory, by using the precast double tee concrete slab, it saved 5 percent of the challenging programme time and reduced the labour resources required on-site.

The innovative method of using a precast double tee slab on a typical floor with a weather-controlled environment, saved time on the overall programme, reduced 60 percent on-site in-situ concrete work, ensured safety enhancements and reduced 15 percent the demand for site labour.

To mitigate the risk of time delays and ensure security of the construction programme, the main contractor used a modular

05

26 | EXCEPTIONAL REACH

approach for the SDCS plant rooms including duct work, pipe work, headers, and chilling-pipe accessories. About 75 percent of SDCS plant rooms are modularised, while the same integrated MEP modular approach has been used for the FS pump room. Moreover, the ground floor toilets have been delivered as freestanding integrated modules with finishes, fixtures and fittings for a right-first-time approach.

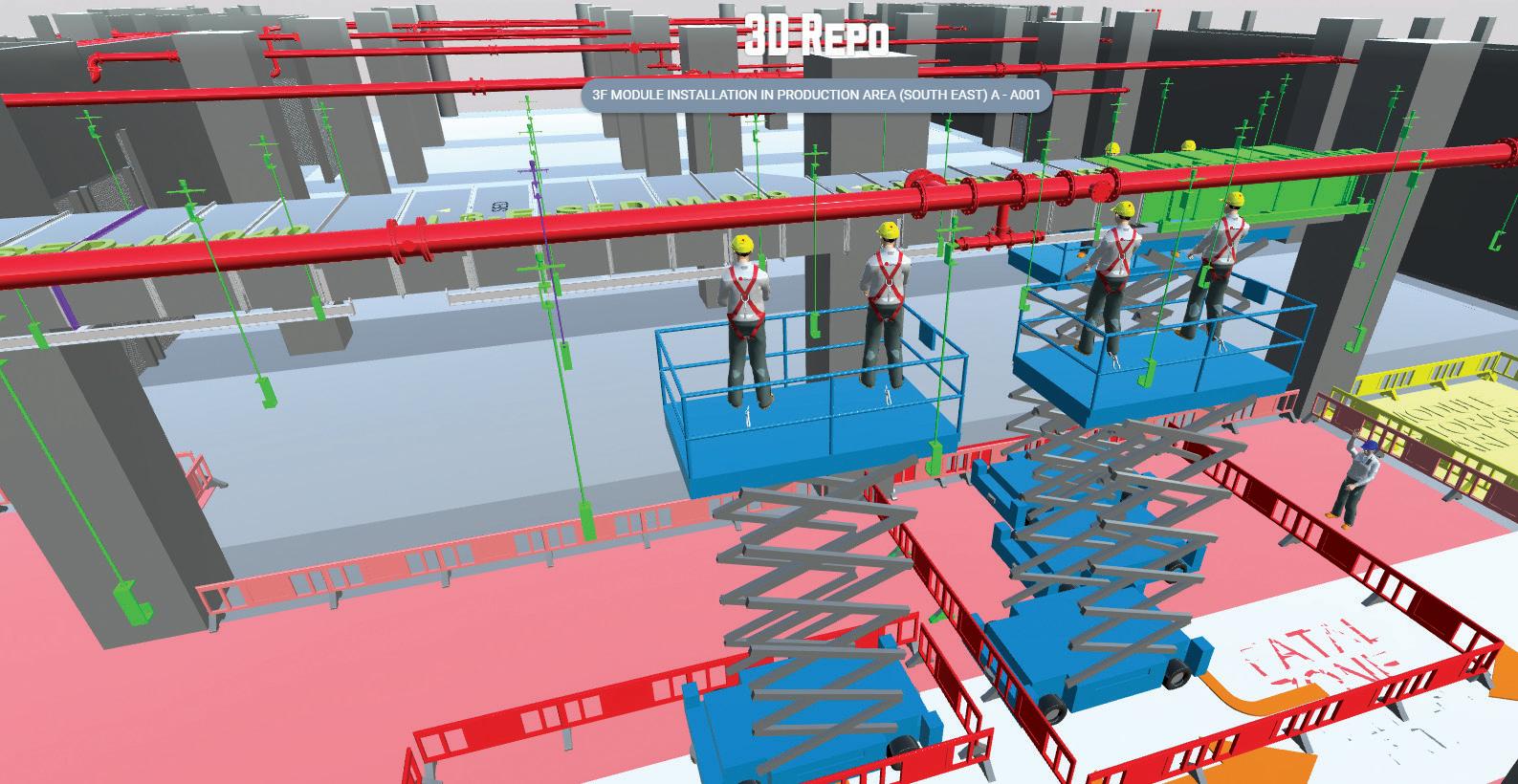

MIMEP

Another notable innovation is the adoption of the multi-trade integrated mechanical, electrical and plumbing (MiMEP) approach in the smoke extraction plant rooms on the 8/F and rooftop. The “One Team” approach made the second genuine application of MiMEP possible in Hong Kong. MiMEP embraces three key principles: off-site prefabrication, multi-trade integration and module maximisation, and “plug and play”. Therefore, all MEP materials and equipment were pre-assembled off-site, including all the cable wiring works, which is the “plug and play” function. Advantages resulted in on-site time savings of 30 days and reduced labour on-site. It is hoped MiMEP will be widely used industry-wide in the future to tackle the shortage of skilled manpower and an ageing workforce.

Moreover, QR codes for M&E modules were created so they could be traced from the time they were fabricated in the factory till they were transported on-site for installation. The MEP team could even monitor whether the right modules and workmanship were used before directing it to the correct location in the Flying Factory and then to the AMC site.

To support the construction programme, a 2,800 square metre

Flying Factory was established in the vicinity of the AMC site, allowing integrated MEP work to commence earlier by removing dependence on site access and providing greater flexibility in planning work. The use of the Flying Factory also meant all modules were produced in Hong Kong for better quality control and keeping to programme deadlines. This also improved safety on-site by reducing the amount of labour and simplifying disassembling procedures, thus the quality of the work was enhanced via a mass production approach and greater control of activities in the off-site fabrication yard.

EXCEPTIONAL REACH | 27

GAMMON’S IN-HOUSE INNOVATIONS

One of the many Gammon in-house innovations is software tool, i720, enabled on-site or off-site commissioning, inspection and handover to speed up and streamline processes. Thanks to the above-mentioned technologies teams were able to reel in any lag in the project’s programmes, i.e., the M&E peak period saw 900 to 1,000 staff on-site.

CONCRETE SENSOR

The use of sensors to monitor the strength of concrete development at an early stage saved time. A sensor inside the concrete obtains real-time strength assessments and this data is sent and stored in cloud services. It significantly reduced the time spent on cube tests on-site.

ENERTAINER

In a first in Hong Kong, the “Enertainer” is a mass battery comparable to a mega powerbank of about 6m to 7m long. Two sets of enertainers were deployed in AMC to fuel high-peak electricity demands of heavy plants and equipment like the tower crane and material hoists, which are traditionally powered by diesel. That was considered not environmentally friendly even though biodiesel fuel could be used as an alternative.

SAFETY HELMETS

Smart helmets leveraging on the use of IoT technology provided data like worker location and body temperature to the project team. If the wearer had tripped or fallen at work, it could detect and send automatic alerts. This smart helmet could integrate worker location with site demarcation to provide automatic notification and alerts should the wearer accidentally enter prescribed fatal zones.

In fact, the proudest moment for Gammon Construction Limited Director Sammy Lai was when he saw how innovations were chosen and applied to AMC, and their installation for the first time. He contended, “Of course, project completion definitely excites me, but witnessing the journey of new ideas evolving from scratch till their successful application to benefit day-to-day operations is a sense of satisfaction. AMC as a cradle for new innovation, pushed by an open-minded HKSTP, enabled us to make the most of this opportunity for trial and error. Frankly, the list of innovations

28 | EXCEPTIONAL REACH

continued after numerous trials, testing and improving of initiatives had taken place on-site i.e. the first-of-its-kind “Enertainer” – a mass battery storage system ideally suited to peak-demand equipment on construction sites. Whereas true MiMEP modules are initially adopted in multi-trade projects with many different elements, even control panels and cables are already included to enable the ‘plug and play’ format.”

BUILDING SERVICES | DESIGN FEATURES

The building services provided for tenants of AMC befits the project’s ambitions as an Industry 4.0 pioneer. Among its many remarkable future-proof design features are the MEP balconies. These are mechanical, electrical and plumbing units attached to the building’s external façade, one for each production unit to connect their own service pipes to shafts that lead up to the roof for air treatment and down to the water treatment plant. In this way, major polluted substances were treated properly before leaving the building.

The MEP balcony frees space that might otherwise be taken up with piping: ducts are run between units and MEP balconies in trenches underneath a raised floor system, which also provides the flexibility to accommodate future tenants that may well have different piping requirements.

There is a centralised logistics facility on the ground floor from which all goods and materials are retrieved, stored and delivered automatically. Fourteen cargo lifts are interfaced with automated guided vehicles (AGVs) through advanced communications technology, such as a 5G network, to collect, receive and dispatch goods for tenants.

Each level incorporates logistical floor space that is the exclusive domain of AGVs and other person-free machines, with 4m wide aisles allowing ample room for two-way traffic. This keeps the movement of machines and humans separate: people have their own 1.5m-wide corridor that runs alongside the MEP balconies.

Security into and within AMC is advanced, with a range of access controls. There is a choice for the ground-floor entry, access cards or palm recognition, while a destination control system is used in the lifts.

EXCEPTIONAL REACH | 29

M&E SERVICE PROVISIONS

AMC provided designers with many interesting challenges, but one in particular tested their ingenuity: they had no idea who would be its tenants. Without any specific user requirements at the early stage of the project and any number of possibilities in the future, the team turned to the Japanese industrial architectural design consultant to set parameters for the building services.

NS used the GCD benchmarking process to identify common infrastructure among surveyed industries and devise “standard provisions”. From there, they estimated requirements for heating and cooling, fresh air, water consumption, electrical loading, and how to make the best use of the centre’s spaces to ensure their flexibility to accommodate future tenants and any projectspecific equipment they may have to install. A typical floor is equipped with two built-to-fit chiller plants, so chilling capacity and operations can be tailored to meet tenants’ requirements and future expansion. Should the need ever arise, the eighth floor and roof are equipped with additional cooling plants, generators and air exhausts, while MEP areas on the first floor and basement are set aside for flexible support facilities such as watertreatment space.

Additionally, there are dangerous goods storage rooms for up to 50 tenants, an IoT network supported by a dark-fibre system to connect tenants to nearby data centres, and 396 rooftop photovoltaic panels and biodiesel generators to generate supplementary electricity as well as a rainwater collection system.

CHALLENGES

The question of how the MEP systems could be integrated with new techniques and technologies well and truly tested the MEP team, especially as there were more than 5,200 MEP modules. Around 75 percent of the MEP material used in AMC was produced by the DfMA tool.

Factory near the AMC site, to produce mechanical and electrical items like pump sets, valve sets and modules for engineering quality assurance and quality control.“

There were other obstacles to overcome. The logistics centre and AGVs work on two different systems, leaving the M&E team to come up with an interface to enable them to talk to each other to give the droids free rein, like automatically moving up and down in the cargo lifts.

Last but not least was the SDCS, not only for its complexity but also for the need to keep its major aspects free from disturbing road traffic and other businesses in the park during construction. The seawater system has greater flexibility than a traditional district cooling system allowing it to provide each of the myriad tenants with the particular cooling demands they require, now and in the future. Seawater, which is free, plentiful and reliable, cools traditional chilling plants in the basement of the building. Water is pumped from Junk Bay through a series of pipes specially laid using the pipe-jacking method, which required two shafts to be bored instead of an open trench. This reduced the environmental impact from dust as well as disruptions such as traffic jams and affecting existing utilities below and above ground.

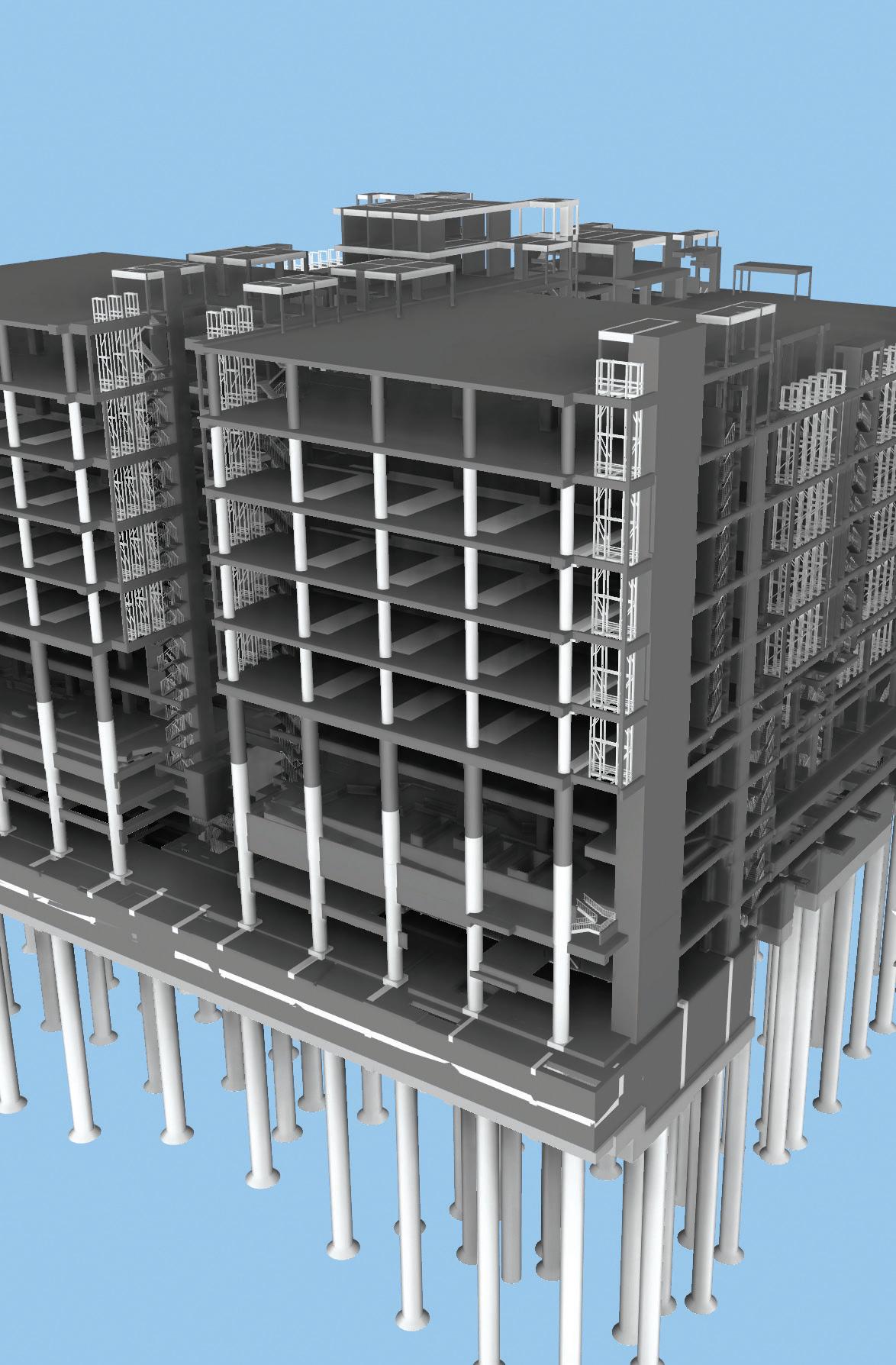

STRUCTURALLY SOUND

Hong Kong’s first Industry 4.0 manufacturing centre for multiple tenants from many different industries is big enough and solid enough for them all. AMC is 67.5 metres, or nine floors, tall with two basement levels. It has a gross floor area of over 100,000 square metres.

The second floor alone sets the AMC’s structure apart from other buildings: it has heavy load capacity with extra-high ceilings in response to a special request for heavy-duty machinery with headroom of over 10m.

HKSTP Project Director, E&M, M.K. Liu said: “My team was constantly having to think of new ways to improve efficiency. The BIM system was great for this. We could produce shop drawings directly from it, and fabrication drawings for DfMA were created with our own BIM team and then sent directly to the manufacturers. We also made good use of an on-site Flying

The factory’s smart structure reflects the design requirements for the flexibility to tailor make spaces. For instance, the standard structural grid was set with columns in a 12m x 12m grid with 8m-high ceilings. This is the most cost-effective distribution to allow for any equipment, large or tall, and special production conditions that may be needed, such as built-to-fit clean rooms.

30 | EXCEPTIONAL REACH

The second floor alone sets the AMC’s structure apart from other buildings: it has heavy load capacity with extrahigh ceilings in response to a special request for heavy-duty machinery with headroom of over 10m

This grid pattern allows for the large floor plate to be subdivided into units to suit various sized companies and different levels of production all while maintaining optimal traffic efficiency within the building. The structural loading for a typical floor is set at 15kPa.

Each floor must be able to control vibration and deflection to minimise any disturbance of highly automated and highprecision production, and assembly lines. As such they have been built to high standards: a structural design to achieve Vibration Class B (velocity within 25μm/s per second) and a vibration assessment in accordance with the AISC Steel Design Guide 11 – Floor Vibrations Due to Human Activity. Moreover, the operation of robots demanded that the floor be laid to stringent flatness tolerances of FM2.

Engagement exercises with potential tenants resulted in an understanding that there would be the occasional need for

32 | EXCEPTIONAL REACH

special conditions beyond the standard parameters set for the building, specifically high structural loading to suit certain operations. The second floor was set aside for heavy production units. To accommodate heavy machines, such as robotic arms, expected from future tenants, the floor has a loading of up to 25kPa and headroom slightly over 10m, 2m higher than other floors. Additional reinforcement was put in place along a 5m strip of the floor slab at Grid X4 and Grid X11 to cater for exceptional loads, to a maximum of 120kPa.

Owing to the time constraints of the project, consultants went the extra mile to save time. For instance, Meinhardt (C&S) Ltd put in more time and effort at the planning stages to come up with 17 structural schemes and scenarios from which HKSTP could choose.

Moreover, a system formwork was used to construct the building: it saved time and work on-site, and eliminated the need for extensive falseworks especially for work at height.

Innovative methods like the MiC and DfMA were used to standardise the construction sequence. Of particular note was the main contractor’s recommendation to complete the precast of the double tees in mainland China, assemble the prestressed beams to build the floors, with late-casted topping to achieve the FM2 standard, and to closely space the tee beams (1m c/c) to control the deflection and provide sufficient mass to limit the floor vibration: all of which reduced the column sizes and number of piles, required less demand on in-situ concrete, produced less wastage – and resulted in better quality outcomes overall.

GOING GREEN

With a slew of innovative and green features, the project aims to achieve the “Gold” rating for BEAM Plus Certification. Even before its completion, AMC had already scooped awards and industry recognition, among them a Certificate of Merit from the Hong Kong Awards for Environmental Excellence 2020 given by the Environmental Campaign Committee. It was also selected

to be in the Hong Kong Green Building Council’s Hong Kong Report on the State of Sustainable Built Environment 2020.

AMC has among its key and diversified green and sustainable features:

SOLAR ENERGY

On the roof, 396 photovoltaic (PV) panels have been installed to produce 130MWh of electricity per annum. The solar energy will be converted and connected to an electricity grid for direct use to power equipment in AMC.

RAINWATER

A 27 cubic metre basement water tank to store rainwater collected from the roof. The water will be filtered and used for irrigation on the gardens, saving 4.1 percent of the annual consumption of approximately 6,440 cubic metres.

BIOFUEL

The generators, powered by Biofuel B-100, will kick in to provide backup electricity to non-FSI equipment when the normal power system fails. Since this environmentally friendly fuel consists of vegetable oil and does not contain diesel, its use eliminates by-products of smog, ozone, and sulphur emissions. The flues from the generators will also contain less poisonous carbon monoxide and particulate matter than generators that burn diesel fuel.

ELECTRIC VEHICLES

A 100 percent electric vehicle (EV) charging system is provided in the carpark.

Wong Tung & Partners Limited Director Ms Ho said the consultant team was constantly pushing the envelope in reviewing specifications for innovative materials and then seeking statutory approvals. For instance, AMC is equipped with many innovative and green features such as a rainwater storage system, PV panels, an EV charging system and an SDCS that is also used by surrounding sites in the INNOPARK.

EXCEPTIONAL REACH | 33

“As this is a smart factory, we took a big leap in controlling pollution,” Ms Ho said. “We used natural resources to save energy and reduce carbon emissions. We also continued the spirit of ‘Innovative Advanced Manufacturing’ into the construction process by adopting a precast structural system, MiC and by taking advantage of the Flying Factory to prefabricate MEP components. By doing this, we minimised the transporting of raw materials to the site, hence reducing CO2 emissions, and facilitated the efficiency and accuracy of the construction process. The pipe-jacking tunnelling method minimised pollution and disruption to traffic during the installation of the seawater district cooling system.

“Apart from these, we designed cascading landscaped hills at the eastern and western sides of the site. These cascades, made with vertical green wall systems, will contribute substantially to a quality green cityscape in the neighbourhood and give shelter for bicycle parking, while also hiding future tenants’ dangerous goods stores.”

Continuing with this theme, AMC is not just a manufacturingoriented building because of its connection to nature and the outdoor environment are also among its special features. Designers have placed a communal garden on the first floor, carpeted richly with all kinds of plants, providing an urban oasis for AMC users and the public alike. On the northern side, the garden and podium garden link seamlessly with the pedestrian bridge, connecting AMC with DT Hub, and provide a continuous planted open deck that stretches into the communal garden. It also allows users from the north site to gather and share facilities in AMC, creating a community hub for the area.

SUSTAINABLE CONSTRUCTION

In addition to AMC’s many sustainable features – smart factory future-proofing, Industry 4.0 standards, an automated logistics centre and robotic systems – smart construction through the use of DfMA must also be incorporated. DfMA was adopted in the structural works, external façade and the E&M installation, thereby minimising the transport of raw materials to the AMC site and resulting in the overall reduction in CO2 emissions and a more efficient and accurate construction process. By using system formwork and precast double tees to construct the typical floor slabs, it saved on the use of 220 cubic metres of timber and reduced on-site labour.

The precast double tees and MiC also contributed to reducing wastage on-site, while the early use of concrete sensors to monitor the strength of setting concrete significantly decreased the need for cube testing. With the AMC site adjacent to data centres and other sensitive buildings, traditional pile driving was rejected for the necessary deep excavations. A silent piler was proposed to install the sheet piles, and its use diminished vibrations, noise and ground settlement during construction.

CONSTRUCTION HURDLES

In addition to the pressure of a tight schedule imposed on the AMC construction programme, all the key stakeholders said COVID-19 was one of the biggest obstacles to construction, testing plans to their very limits.

Not least was the enforced shut down for several days for the site to be disinfected. Consultants were also kept away from their offices and working remotely put a strain on efficiency.

The closure of the border to mainland China brought more tests, squeezing the supply chain of materials since many components and DfMA items like the double tees and the curtain walls were prefabricated in Guangdong province. The result was a knock-on effect on site works.

Moreover, the work being done in mainland China could not be inspected in person to ensure its quality, until the Buildings Department stepped in. The department was able to clear the way for live inspections via the internet. There were initial glitches with the internet, setting up WiFi connections, and with software and the quality of the cameras, but these were ironed out early on and the system worked smoothly. The cameras scanned double tees, zoomed in on details of formwork and were invaluable tools in ensuring standards were being met.

Another significant hurdle had to be confronted early during the tender stage of the foundation: a change was made to the basement layout. There was additional pressure to meet the time constraints on the designs for the ELS and submissions to government authorities for approval. Consequently, to save costs on the basement’s construction, the consultant team employed different techniques. It would use open cut with a grout curtain

34 | EXCEPTIONAL REACH

on the east and west sides of the basement, and open-ended sheet piles on the north and south sides. The Geotechnical Engineering Office of the Civil Engineering and Development Department also imposed conservative design parameters in its approval. In spite of it all, the civil and structural consultant was able to obtain statutory approval on time and before the foundation works tender was awarded.

The consultants deserve every praise in their drive to work with contractors in order to meet all milestone dates: it is truly the can-do spirit in action, a fine display of resilience and adaptability by the entire team in the face of multiple challenges.

AMC’s atypical designs along with specifications requiring versatility had consequences on the bureaucratic front. It took longer to obtain statutory approval and necessitated coordination with many government departments. Take the 8m headroom for its typical floors as an example. This is a rare request; the standard floor height is about 3m or 4m. The Buildings Department scrutinised the application carefully and the project team lobbied

for months before receiving the green light. The consultants had to demonstrate the actual needs of the building and could do this only by referencing cases overseas.

The consultants had to build a model and devise a notional design of the factory. The nature of the building – a smart factory – meant AMC would have a lower occupancy rate than normal factories in Hong Kong and the consultants had to convince different government departments of its viability before being granted approval.

Another example of diligent liaison occurred over a 17m-tall glass curtain wall at the main entrance. The Buildings Department expressed concern about its stability and the system devised for attaching it to the building structure. The request to add diagonal bracing and a horizontal tie rod to the glass wall would have upset the design’s intent and spoilt its appearance. In the end, the original design was approved after close liaison between the civil and structural consultant and the Buildings Department made it clear that the wall would be stable.

EXCEPTIONAL REACH | 35

DIGITISATION

Unlike conventional construction projects with ample lead time, AMC had no such luxury afforded it for completion. To resolve this issue, the main contractor implemented “integrated digital project delivery” for which centralised and shared BIM formed a pivotal centrepiece, along with other digitised tools such as a Common Data Environment (CDE) and untethered BIM mobile apps for use within the construction site without internet connection etc., to enhance management and reporting efficiency by providing real-time progress for on-site activities. It was also believed that the adoption of these new technologies would also help attract young people to join the construction industry.

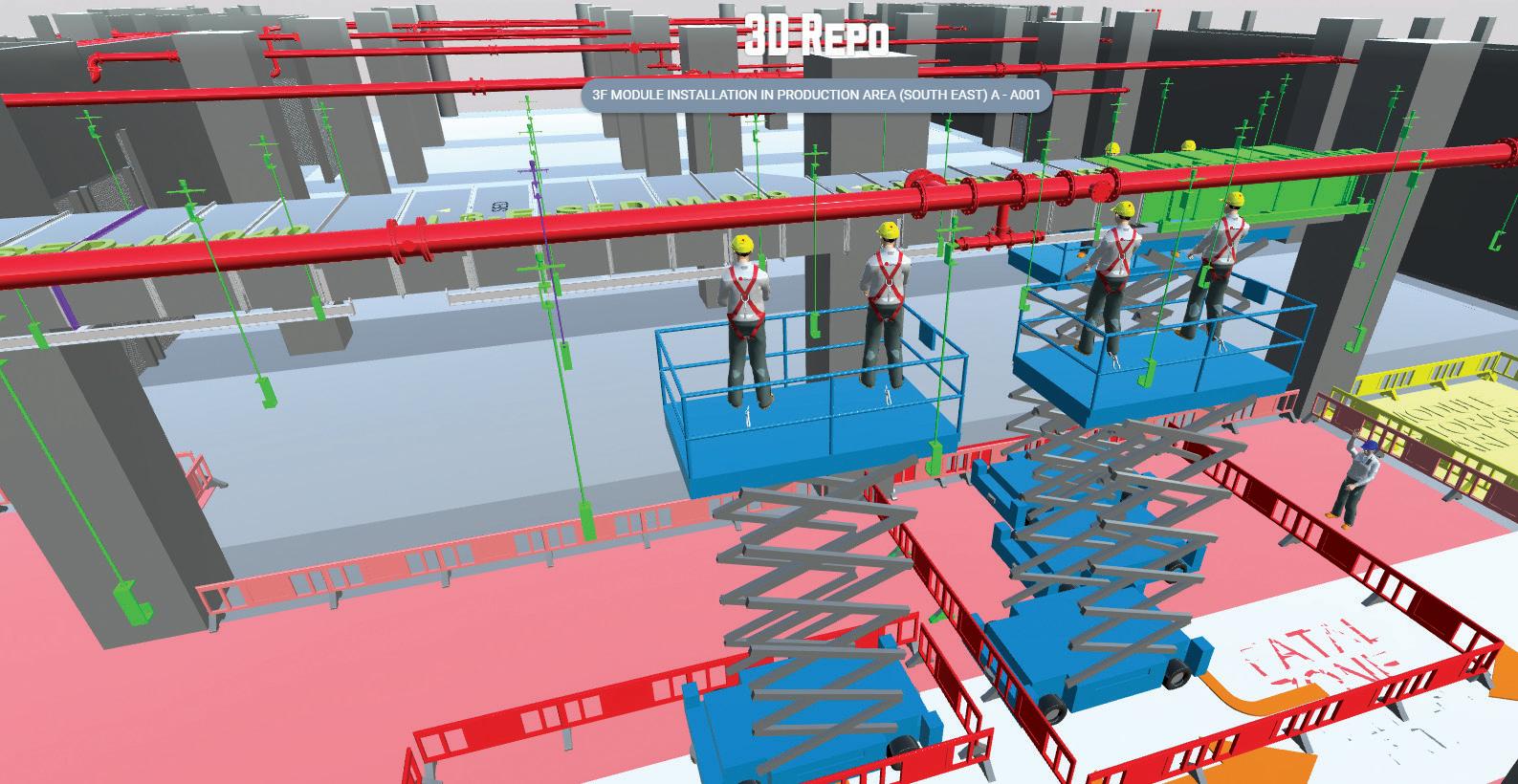

FROM 2D TO 5D

BIM simulations have been used at all levels from design coordination to the supervision of different works, i.e., site inspection, safety training and critical operation. There were altogether eight BIM teams in this project, from subcontractors to the main contractor and specialty equipment vendors, with each team’s professional skills central to the coordination of BIM and system integration.

According to Gammon Construction Limited Director Sammy Lai, their BIM applications went beyond the simple 2D view of drawings and plans, with 3D modelling, 4D programming and scheduling, and 5D focusing on costing projections. Although BIM has been widely adopted within the industry, the main contractor extended its application to an even broader and deeper level of use. The implementation of a CDE, for example, was a single source of truths platform that allowed stakeholders to always be able to collaborate on the latest 3D models among multiple BIM teams to accelerate design coordination. In this project, the main contractor also investigated facility management (FM). These were factored into AMC, so HKSTP could smoothly incorporate the building asset information into future FM items.

Mr Lai said, “Laser scanning supplemented the BIM model, which was updated to ensure accurate representation of existing conditions, allowing the team to check for and ratify any clashes between ELS works and prominent designs at an early stage. And mapping of an alternative ELS dismantling sequence also reduced clashes by 50 percent, greatly minimising

06

36 | DIGITISATION

the need for flame cutting inside the enclosed basement. In addition to using BIM for visualisation or design coordination, we went deeper by generating fabrication drawings directly from BIM. Shop drawings were produced directly from BIM and fabrication drawings of DfMA were created with our own BIM team instead of manufacturers. With the aid of BIM, our fabrication and production time on MEP modules had been shaved by two months. The application of 5D BIM had helped to verify the records and quantity of interim payments throughout the construction, collectively saving time for both the contractor and the QS team because they did not need to cross-check the amount.

“BIM mobile apps even brought BIM models to the construction site via cloud technology. CDE adoption was kind of a no-brainer, the advantages were almost instant such as 30 percent in time saved on engineering for site coordination. Also, stakeholders had no hesitation in exchanging drawings and, therefore, this ensured that the latest information was shared among members of both the project team and BIM teams. On top of sharing information, BIM 360 could be integrated with various software and mobile apps. These allowed BIM to become more adoptable in many different situations, in particular, on-site coordination and workflows embedded in a CDE.”

Originally, it had not been required in the contract for the project team to use 5D BIM in AMC, but it decided to go the extra mile. To the quantity surveying consultant, the 5D BIM model made this project a different ball game. Rider Levett Bucknall Ltd Managing Director Ling Lam said, “Traditionally, we would go to the site and complete an evaluation as well as assess how much work had been done followed by office paperwork and/or calculations, so a high degree of inaccuracy was possible. The 5D BIM cycle meant quantity take off, a measurement by BIM like estimating the costs, payment evaluations and assessment of cost payments. We used BIM to process payment evaluations and work out the amount of work done on an interim basis. By using technology, we obtained information with just a few clicks like how much work had been completed, say, over the past four weeks. The model was also connected with the payment, so we could quickly work out the value of work done and reduce the chances of miscalculations and disagreements with contractors. BIM is a single source of truth so you can’t cheat, lie or misinterpret.”

Ms Lam also appreciated other benefits such as reducing abortive work or reworks and the digital workflow greatly minimising the generation of hard copies. She said, “One key benefit of using BIM is to do clash analysis at the design stage. Traditionally, various disciplines will do their own work and, when putting drawings

38 | DIGITISATION

together, they discover things that are not coordinated and certain details will clash with others. Through BIM, you can visualise where the clashes are before going to tender. So at the design stage, this analysis of concurrent work will dictate where the clashes are so the design consultant will be able to fix them before incorporating it in the tender drawings. As contractors will price on tender drawings, if clashes are not removed at this point eventually the contractor will request extra payments to fix discrepancies incurred in the drawings. On the flip side, BIM also helps consultants lower their risks and eliminate a lot of disputes before they occur.”

The pioneering BIM initiative and achievements deployed at AMC earned the recognition of Construction Industry Council (CIC) BIM Achievement - BIM Projects 2020 as well as the Autodesk Hong Kong BIM Awards 2021.

A GLIMPSE OF DIGITISED TOOLS

As a key driver of digitisation, Gammon also rolled out various digital tools to reel in any time lags on the tight programme schedule. One of the many self-developed digital solutions is its in-house mobile application Inspecto. As a digital solution for site inspection and workflow processes between the client, consultants and contractors, it digitalises the RISC form and fully complies with the digital works supervision system requirements of the government. Comprising

a mobile app, dashboard and proactive real-time alerts, it shortens the inspection turnaround time, creates fewer disturbances onsite, and keeps reliable and consistent records for further reference. The inspection records are encrypted with blockchain technology to ensure secure storage of the content and this key information is not easily lost when compared to the previous practice of using handwritten documents. This means easing the workload so inspectors can easily plan ahead the schedules at a glance.

Other ready-built solutions like HoloBuilders enabled the team to capture 360° photos using mobile apps to record construction conditions and store this data in the cloud, so engineers could review and access information anytime and from anywhere, saving a visit to the job site. As a result, it led to better control and adjustments in the progress of construction, and the ability to check both quality and safety remotely. Moreover, 3D Repo created a cloud-based platform for BIM, while digital workflow by STAMP also assisted the team to oversee the progress of off-site manufacturing. Dalux combined BIM and AR, helping the team inspector compare BIM models with on-site conditions on mobile phones even without an internet connection on the construction site. By using digital sensors to monitor settlement, the project team had access to realtime data that reduced potential risks to the public and enhanced quality control of work.

DIGITISATION | 39

It is 40 percent more efficient at rejecting heat than air-cooled heat rejection systems; it does not pollute the air or produce noise that can affect adjacent buildings

SEAWATER DISTRICT COOLING SYSTEM

By their very nature, every project undertaken by HKSTP has been forward-thinking, requiring high-technology and innovation, and Advanced Manufacturing Centre is no exception. Within the AMC building, the environmental requirements of the many and varied tenants – and the unknown requirements of future tenants –meant the need for a special cooling system.

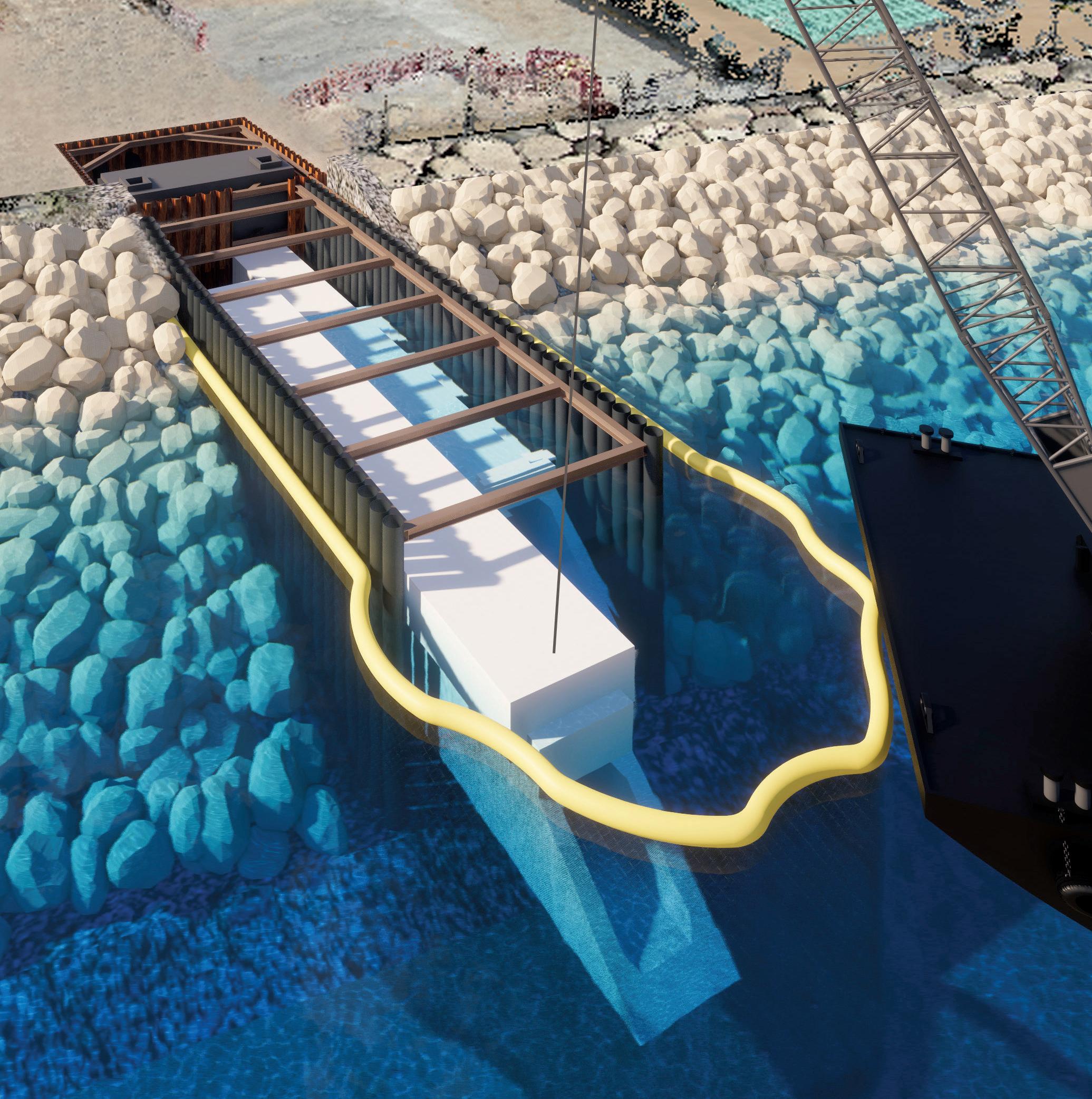

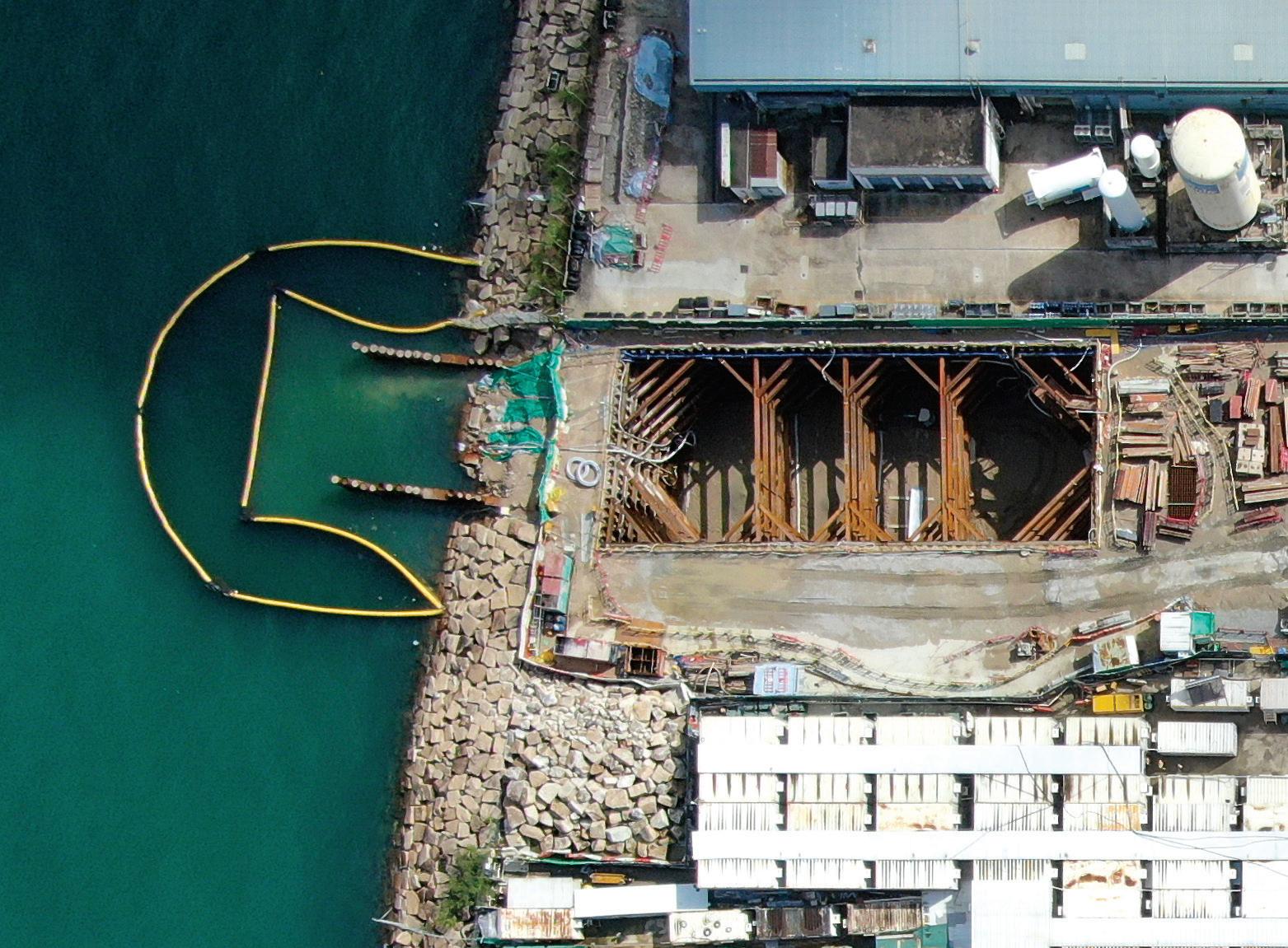

With the Tseung Kwan O INNOPARK being on the shores of Junk Bay, it made good sense technologically and for sustainability to employ a seawater district cooling system (SDCS), rather than erect a dedicated freshwater cooling tower for AMC.

It also made sense from the standpoint of one of AMC’s most important features – that it is future-proof. The seawater system has a greater flexibility than a traditional district cooling system allowing it to provide each of the myriad tenants with the particular cooling demands they require, now and in the future.

The SDCS uses seawater – free, plentiful and reliable, which are key advantages over freshwater cooling towers, especially as air-conditioning uses half of the building’s energy. The seawater cools traditional chilling plants in the basement of the building. Water is pumped from Junk Bay through a series of pipes specially laid, according to Wong & Ouyang (Building Services) Ltd Director Lai Chi-hung.

Mr Lai said, “Seawater has other advantages: it is 40 percent more efficient at rejecting heat than air-cooled heat rejection systems; it does not pollute the air or produce noise that can affect adjacent buildings, both benefits that cannot be overstated in the context of the INNOPARK. In addition to these environmental advantages, the SDCS achieves economies of scale. On a typical floor of the AMC building, built-to-fit chiller plants supply cooling needs as required; beyond AMC, the seawater system supplies cooling

to other buildings already up and running, such as DT Hub, and will be able to cool new buildings in Tseung Kwan O INNOPARK that come on line. Its design also gives it the flexibility to sell extra capacity.”

The SDCS can be seen as a manifestation of Hong Kong’s drive to re-industrialise and commercialise innovation to advance sustainable development in the project’s challenges. A highly technical and complex system, the SDCS pushed the project team, consultants and the main contractor to their very limits, requiring them to come up with innovative approaches to complete the job.

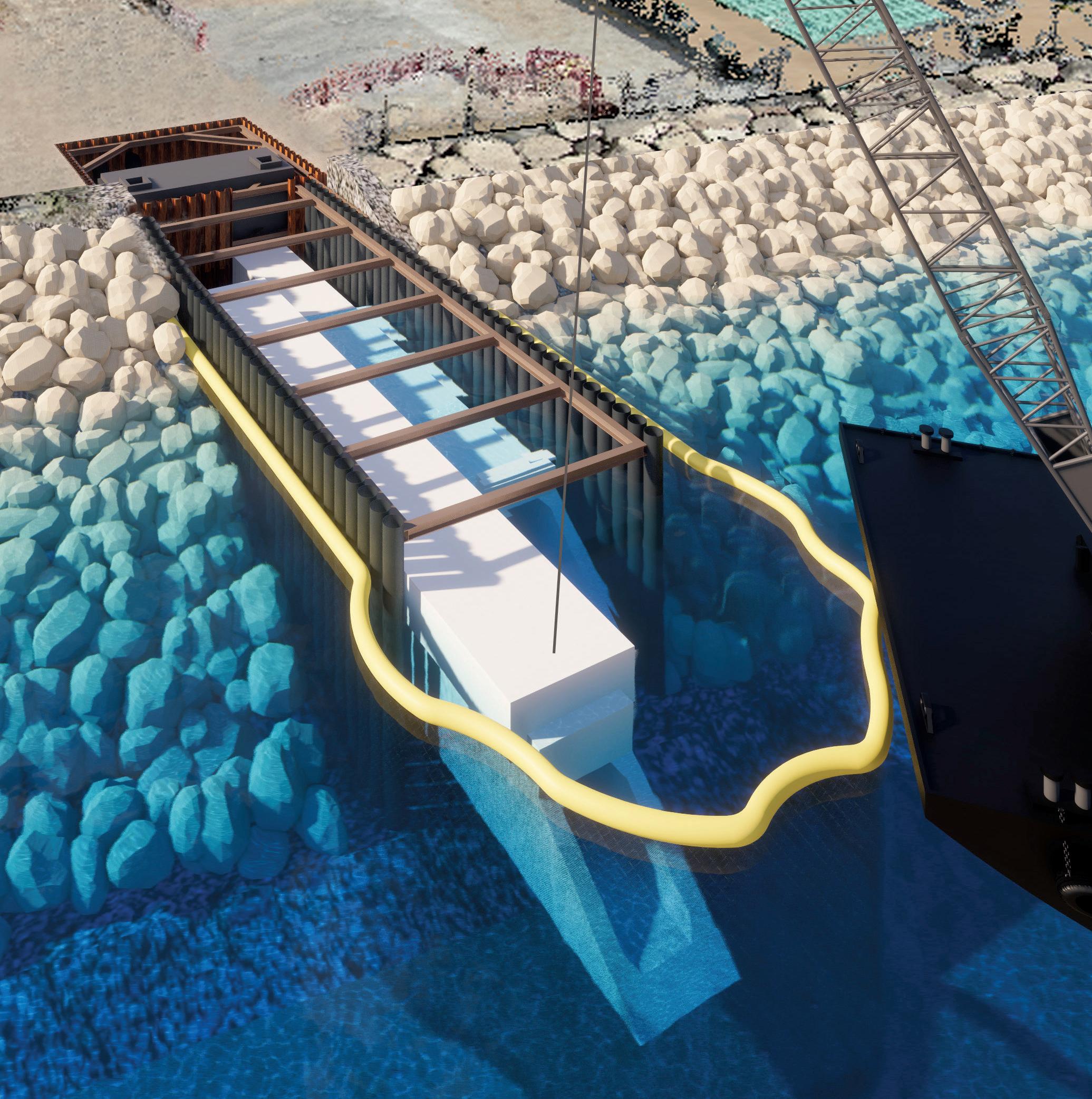

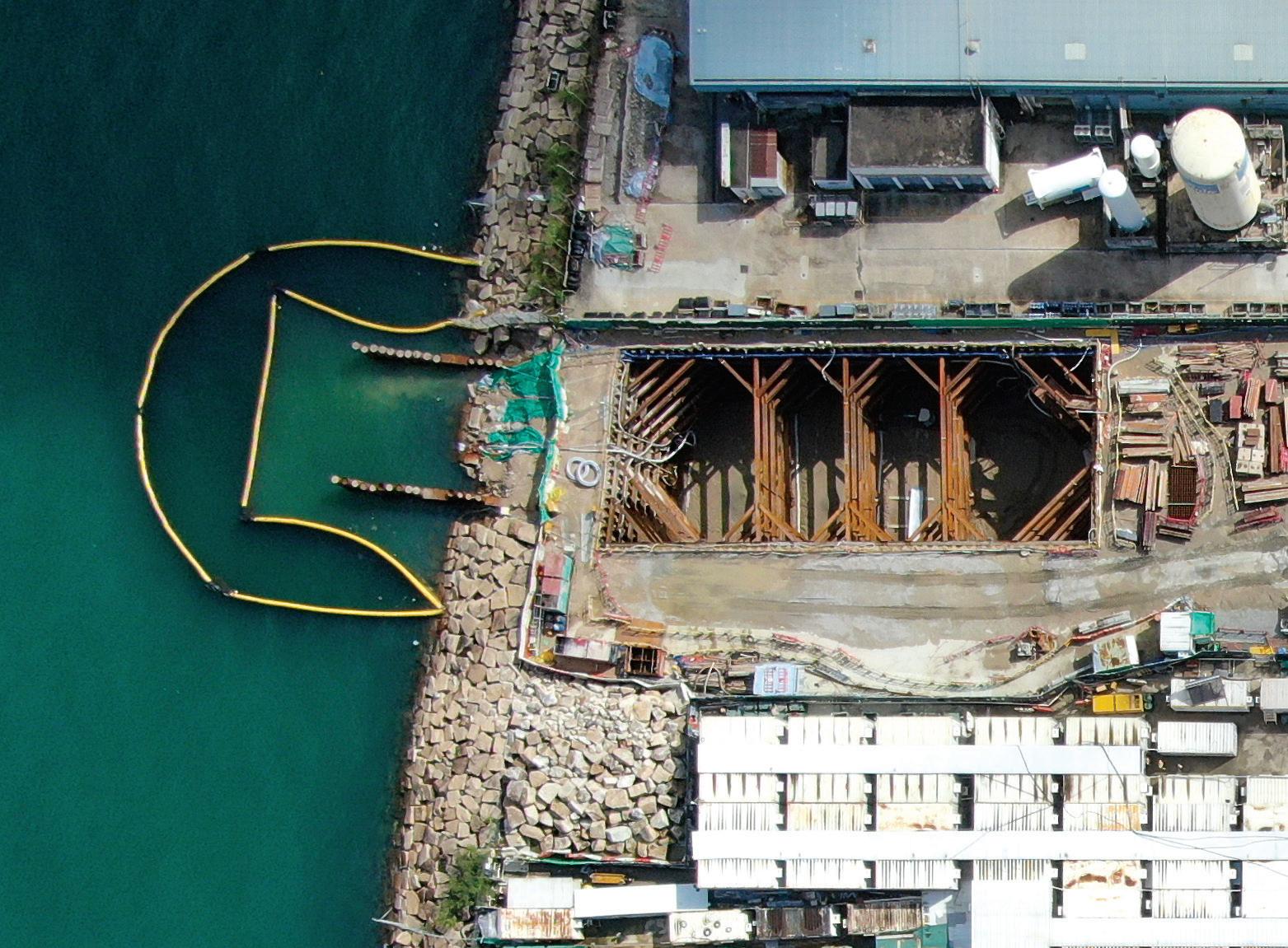

The original plan was to dig an open trench for the pipe works, but that would have meant excavating 200 metres of road along busy Chun Yat Street, causing traffic jams and affecting existing utilities below and above ground. These disruptions were avoided by adapting a tunnelling method usually used on large civil engineering projects, but rarely on buildings: pipe jacking.

Two shafts were excavated at either end of the pipe works. A mini tunnel-boring machine was lowered into the first shaft, from which it began to excavate, laying pipe behind it as it was jacked forward. On reaching the second shaft, the tunnel-boring machine was removed, leaving behind freshly laid pipes ready to be connected to chilling units and pumps.

This method was quicker – it cut several months off the construction programme as a whole – it had a minimal effect on traffic and utilities, and generated less dust, noise and other effects that would have otherwise come from open excavation.

At the sea end, the team was restricted by the small site, and had to take care to maintain the integrity of the seawall and stability

07

SEAWATER DISTRICT COOLING SYSTEM | 41

of adjacent structures. To build the seawater intakes and outfalls, it involved modifying the existing seawall and, in the limited space, the team likened it to microsurgery, keeping their work strictly to the area that needed to be changed. A pipe pile wall was installed around the relevant section of the existing seawall, the rock armour removed and a precast culvert fitted.

The team’s solution – having rejected traditional in-situ concreting – required no significant marine excavation, leaving the seabed as undisturbed as possible and it also required fewer workers.

The use of BIM helped greatly in every step of the design-andbuild process. This smart technology proved critical on many fronts from coordinating the design, ensuring the compatibility of different sections to creating safe delivery and installation of major components of the building, including the chiller pump room, and the chilled water and seawater pipes.

The project also faced challenges as clearances had to be obtained from different government departments including the Marine, Drainage Services, Water Services, Environmental Protection and the Geotechnical Engineering Office of the Civil Engineering and Development Department. In addition, since the SDCS works at Tseung Kwan O were in many ways pioneering, involving numerous innovations, just as many approvals had to be secured. These hurdles would be of great benefit in the lessons they would hold for future contractors with similar plans.

Of course, the decision to proceed with seawater cooling was thoroughly supported through detailed consideration from the very beginning by the quantity surveying consultant. Rider Levett Bucknall Ltd Managing Director Ling Lam said, “We applied lifecycle costing as part of the design evaluation and judged the balance of upfront costs to the recurrent costs of operation, maintenance and replacement well in favour of the latter. We worked with the design team to calculate both capital costs and operational expenditure as well as the payback period for each of the various systems. We evaluated the many contractual options and advised HKSTP that for maximum value it was best for the SDCS to be designed and built under one contract and operated under a separate one.”

42 | SEAWATER DISTRICT COOLING SYSTEM

The use of BIM helped greatly in every step of the design-and-build process. This smart technology proved critical on many fronts

ONE TEAM, ONE GOAL

The construction of AMC benefited from Gammon’s “One Team” approach. For instance, it was separately awarded the foundation works contract before clinching the main works contract for AMC. Therefore, an instant synergy with their colleagues carrying out the foundation works and the superstructure construction allowed earlier possession of areas and advance preparation of organisational work, delivering programme certainty. This meant a seamless handover and site control. Its competent civil works team adopted a rare pipe-jacking method for the SDCS, and they installed the link bridges with three modules in two nights.

Externally, as the main contractor, Gammon, played a facilitator role via its in-house digital tools to pull the owners and various consultants to work together. Gammon Construction Limited Director Sammy Lai said, “For instance, we extended assistance to some consultants, who may not have been that well-versed in BIM and offered facilitation, no matter whether it was downstream or upstream, of such an advanced method. Moreover, we collaborated with consultants in the design process to check whether ideas were buildable or how to improve the feasibility of the design and coordination, so it’d be more practical in the building process.

“Our dedication in R&D gave birth to many in-house innovative digital solutions to improve productivity. We are pleased to have the ultimate support from our client, which openly invited our team to test as many innovative ideas as possible. All the lessons learned from AMC were also shared with the industry and among the trade’s peers pushing industry development and the advancement of society to tap more young talent and high-calibre people to construction.”

44 | ONE TEAM, ONE GOAL

08

From the outset, HKSTP Chief Project Development Officer Simon Wong and his team had committed to building AMC differently, frequently going off the beaten track by employing innovative methods. He said, “It’s not easy to take a new path. Of course, this couldn’t have been successful without Gammon, which shared a similar pioneering spirit with us from day one. Kudos to its strong team and willingness to invest in resources, especially for treating AMC as a cradle for the real-life testing ground of their creative ideas.”

HKSTP Assistant Construction Director Louis Yung had solid faith in Gammon, which played a pivotal role in this project. He said, “AMC involved different parties in this job, so communication was the key. Gammon acted reliably and proactively to break through all communication barriers. This resulted in building trust and pulling parties together. Moreover, they committed resources and the full support of Construction 2.0, i.e., proposing the precast double tee method, a younger team with a higher percentage of female staff as well as promoting the best practices of AMC at industry seminars.”

The experience of the project team backed by the main contractor’s extensive in-house resources as well as consultants at the top of their field provided fully integrated support for this project. They shared a common goal to set standards and also met scheduled programmes within the budget. Meinhardt (C&S) Ltd Managing Director Adam Choy recalled, “During the peak period, the resident engineering team had six people on-site. Moreover, we arranged a design liaison engineer full-time onsite to solve all design or construction matters with other related parties immediately until the end of the project, so a lot of the issues were addressed on-site.

“When talking about effective teamwork, for example, the client wanted to further increase the headroom in the lobby area during construction and different parties contributed their professional expertise to provide the best solutions. Wong Tung & Partners Limited then reviewed if it was possible to squeeze the ceiling zone. Meinhardt (C&S) Ltd had to check if the beam depth could be reduced so the structural opening for the pipes could pass

ONE TEAM, ONE GOAL | 45

through. Then, Wong & Ouyang (Building Services) worked on the possible alternative routing of services. Then maintain and check the quality.”

To put forward the project, the design had to be viewed and judged by the client to ensure the direction of AMC was correct. That’s why Wong Tung & Partners Ltd had to meet and answer any questions raised at meetings once every few months until decisions on the design were firm. Director Amy Ho recalled, “They were very supportive as the project would be something that would make Hong Kong great. We spent a lot of time on developing the GCD in the beginning, with meetings to verify a good design followed by the government’s approval on higher headroom, so eventually at the tender stage, we only had two months to complete all drafts/ graphs required for the tenders and that’s very challenging for all consultants.”

From the owner’s perspective, HKSTP Project Director Carrie Chan also highlighted the importance of team work when members hailed from various disciplines. “Working as a team, we shared a common goal to meet the programme deadline and budget with quality standards. Sometimes, we had different opinions with our consultants and encountered versatile issues in respect of quality. Hence, a lot of discussions and dialogue were conducted both with

consultants and contractors to solicit solutions as well as to resolve differences in opinions,” she said.

On top of that, the active participation from HKSTP’s directors, committees’ members, and management as well as government officials will not be forgotten in this innovative project in Tseung Kwan O. Sincere gratitude and thanks must be extended to their collective involvement in designing AMC as well as providing invaluable comments and support.

After several years from its inception to reality, AMC stands as a beacon for the future of the industry in Hong Kong. Hats off to the whole team’s concerted effort, which successfully achieved a common goal from the beginning to the end. They created something innovative and unique that will be a catalyst to propel the city’s industrial and manufacturing development. Afterall, it’s also because of HKSTP’s vision, which had the foresight to enact many firsts, paving the way for the future by constructing this ninestorey building to realise the advanced possibilities of the adoption of Construction 2.0 and Industry 4.0. Certainly, AMC leads the way, but this future-proof smart factory’s story will not end here as HKSTP sets out to take an innovative approach to build many more firsts that the industry will employ in decades to come as well as drawing new and young talent.

46 | ONE TEAM, ONE GOAL

Building 5E, 5 Science Park East Avenue, Hong Kong Science Park

48 | BEYOND THE INDUSTRIAL AGE

5/F,

hkstp.org