Mit DILEX-F definiert Schlüter-Systems die Ästhetik der Bewegungsfuge von Grund auf neu. Die schmale, praktisch unsichtbare Bauform von DILEX-F schafft ein nahezu unterbrechungsfreies Fugenraster, während sie gleichzeitig die gewohnte Kompensation typischer Bewegungen im Fliesenbelag ermöglicht und obendrein noch folgende Vorteile bietet: Die Bewegungsfuge lässt sich bei Beschädigungen leicht austauschen, besitzt eine schmutzabweisende, einfach zu reinigende Oberfläche und ist in einer großen Farbvielfalt erhältlich.

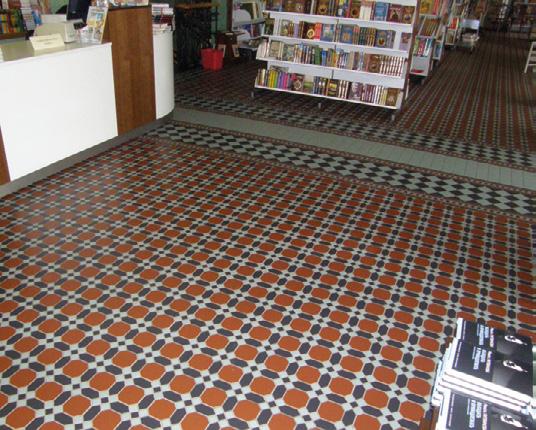

DILEX-F from Schlüter-Systems redefines the aesthetics of movement joints from the ground up. The narrow, practically invisible design of DILEX-F realises an almost uninterrupted tile joint pattern while, at the same time, enabling the customary compensation of typical movements in the tiled covering as well as offering the following benefits: The movement joint is easy to replace if damaged, has a dirt-repellent surface that is easy to clean and is available in a wide range of colours.

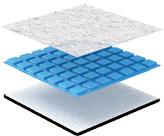

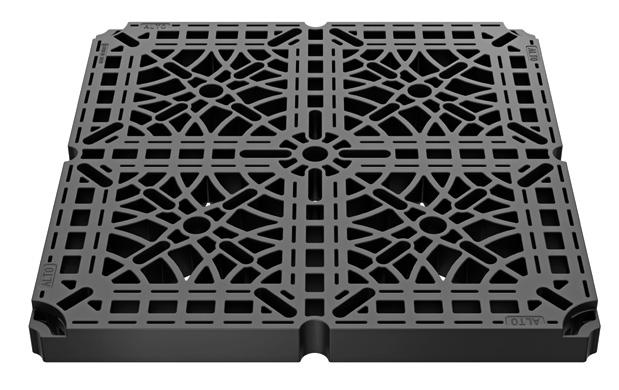

BEKOTEC-EN-F-PS

BEKOTEC-EN-FK-PS

Schlüter®-BEKOTEC-PS

Mit BEKOTEC-EN-F-PS und BEKOTEC-ENFK-PS bringt Schlüter-Systems ein neues Maß an Anwenderfreundlichkeit in die Verlegung des innovativen Klimabodens BEKOTEC-THERM. Die selbsthaftenden Estrichnoppenplatten, die zu 70 % aus recycelten Materialien bestehen, ermöglichen eine unkomplizierte, schnelle und äußerst saubere Installation. Die beiden haftenden Systeme erlauben nicht nur eine geringe Aufbauhöhe, sondern auch einen Einsatz auf vielfältigen Untergründen. Neben der Material- und Gewichtseinsparung ermöglicht die zügige Verlegung eine zeit- und kosteneffiziente Realisierung von Bauprojekten.

schlueter.de/bekotec-ps

BEKOTEC-EN-F-PS and BEKOTEC-ENFK-PS from Schlüter-Systems bring a new dimension of user friendliness to the laying of the innovative BEKOTEC-THERM thermal comfort floor. The self-adhesive studded screen panels, which are made from up to 70 % recycled materials, allow uncomplicated, fast and extremely clean installation. Not only do the two adhesive systems permit a low installation height, they can also be used on a variety of substrates. As well as saving materials and weight, the rapid installation enables the time and cost-effective completion of construction projects.

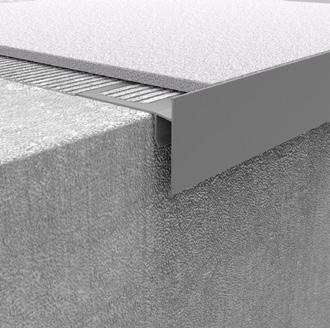

Cerfi x ® Protec is the range of perimeter profiles, designed and produced by Profilpas, for protecting and finishing the external edges of balconies and terraces.

Equipped with a section that facilitates the drainage of rainwater from the floor and preserves the outside border, they provide excellent protection from weather elements, guaranteeing a longer duration over time.

Available in aluminium or stainless steel and in different finishes, Cerfix ® Protec profiles are the best solution for those who wish to protect and finish balconies and terraces, with a focus on modern design trends.

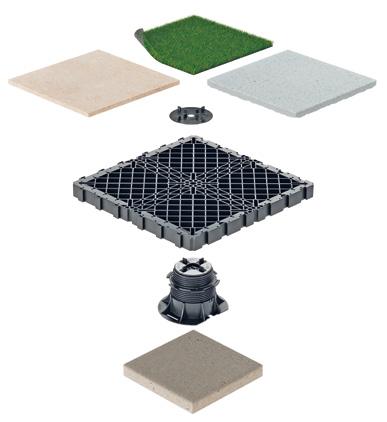

PP level DUO MAXI is the new range of adjustable supports for outdoor raised floors.

MAXI flexibility: thanks to the practical Fixed Head Ring, you can transform the tilting head, able to compensate for surface slopes up to 5%, into a fixed head, directly during installation.

MAXI strength: the new support guarantees excellent resistance to heavy loads and weather elements.

MAXI versatility: numerous accessories are available for any installation requirement, from extensions to aluminium joists, rubber mats and steel clips.

With PP level DUO MAXI the installation of the raised floor will be easy, fast and perfect.

PUBLISHER:

Kairos Media Group S.r.l. Capitale Sociale: Euro 51.400,00

R.E.A. 329775

Periodico bimestrale registrato presso il Tribunale di Modena al n. 22/17 in data 10/08/2017 Iscrizione al ROC n. 9673

OFFICE:

Kairos Media Group S.r.l. Via Fossa Buracchione 84 41126 Baggiovara (Modena) - Italy

Tel. +39 059 512 103 - Fax +39 059 512 157 info@kairosmediagroup.it - www.surfacesinternational.com

EDITOR AND CEO: GIAN PAOLO CRASTA - g.crasta@kairosmediagroup.it

MANAGING EDITOR: DAVIDE MISERENDINO - d.miserendino@kairosmediagroup.it

© 1989 Tile Italia

CO-EDITOR:

Sabrina Tassini

CONTRIBUTING EDITORS:

Sara Falsetti

Paola Giacomini

Chiara Poggi

Sabrina Tassini

SECRETARIAT: info@kairosmediagroup.it

GRAPHIC LAYOUT:

Sara Falsetti

EACH COPY: Euro 4

SUBSCRIPTION:

https://kairosmediagroup.it/en/shop/subscription-tile-international

• 1 year: Euro 20

• 2 years: Euro 35

L’abbonamento decorre dal mese di distribuzione. Tariffe speciali per gli abbonamenti collettivi sono disponibili su richiesta Conto Corrente Postale 20026415 intestato a Kairos Media Group srl. Spedizione in abbonamento postale presso la Filiale di Modena. L’IVA sugli abbonamenti, nonché sulla vendi-

ta dei fascicoli separati, è assolta dall’Editore ai sensi dell’art 74 primo comma lettera C del DPR 26.10.72 N. 633 e successive modificazioni.

ADVERTISING:

Kairos Media Group

Tel. +39 059 512 103 Fax +39 059 512 157

• Paola Giacomini

p.giacomini@kairosmediagroup.it +39 335 186 4257

Teresa Contissa

t.contissa@kairosmediagroup.it

· +39 342 092 8002

• Silvia Lepore

s.lepore@kairosmediagroup.it

· +39 345 721 8245

• Elisa Verzelloni

e.verzelloni@kairosmediagroup.it · +39 338 536 1966

PRINT:

Faenza Printing Industries SpA Via Vittime Civili di Guerra, 35 48018 Faenza (RA) - Italy

http://www. .com INTERNATIONAL.COM

Tutti i diritti di riproduzione e traduzione degli articoli pubblicati sono riservati. E’ vietata la riproduzione anche parziale senza l’autorizzazione dell’Editore. Manoscritti, disegni, fotografie e altro materiale inviato in redazione, anche se non pubblicato, non verrà restituito. L’Editore non accetta alcuna pubblicità in sede redazionale. I nomi, le aziende e i prezzi eventualmente pubblicati sono citati senza responsabilità a puro titolo informativo per rendere un servizio ai lettori. La Direzione non assume responsabilità per opinioni espresse dagli autori dei testi redazionali e pubblicitari.

Entire contents Copyright Kairos Media Group srl All right reserved.

Opinions expressed by writers are not necessarily those held by the publisher who is not held responsible.

to take a break and prioritize your well-being.

Discover how Lunar Support simplifies your work, from design to installation.

Compasso D’oro Career Award for Blu Ponti Collection By Ceramica Francesco De Maio ECONOMICS

20 European construction: recovery expected by 2025

The Italian ceramic industry surpasses revenues of €7.5 billion

Florim: a constant commitment to sustainability

Iris Ceramica Group and Edison Next produce the first large-format ceramic panel using green hydrogen

IN THE SPOTLIGHT

Kaleseramik announces new investments focused on growth Paola Giacomini

PHOTONEWS - Bardelli Group at Cersaie with “Welcome to Eden”

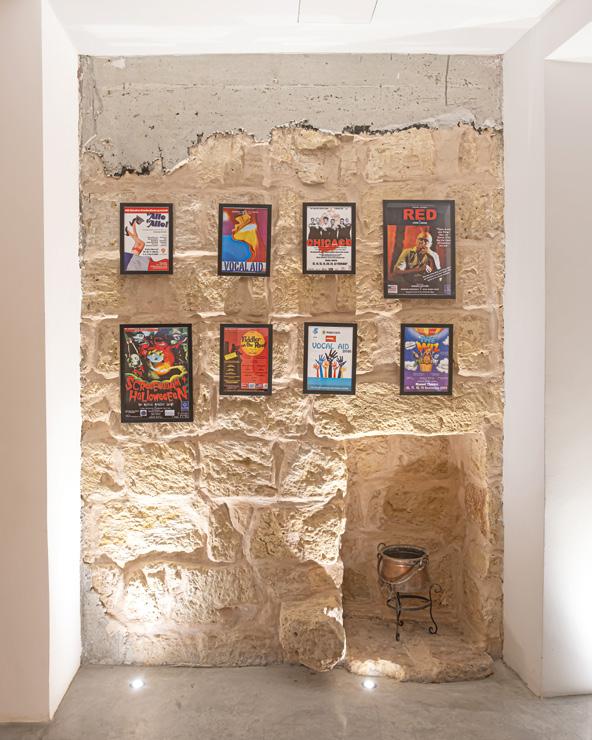

Noblesse Cocktail Bar, Vignola

Fresh Hotel, Athens

Studio 129, Modena

Unique design in a luxury villa complex in Jesolo

Mapei technique for Casa Do Vale Villa, Brazil

Eataly Restaurant in Seoul: the Hyundai Department Store welcomes Italian excellence

FOCUS ON CERSAIE 2024

WHAT’S NEW - Ceramic tiles & laying technologies

Advertiser’s list: pag. 9

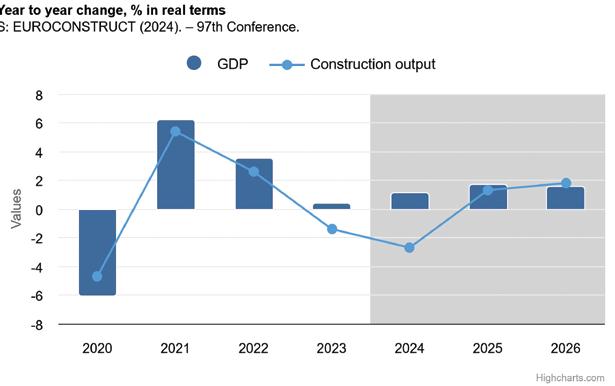

As the summer begins to fade away, we still have a few waves to surf. Because the outlook for the construction industry is not entirely calm. The experts of the Euroconstruct network, whose surveys cover 19 countries across Europe, are forecasting that, in the wake of the downturn of 2023 and 2024, the industry’s fortunes will pick up again in 2025 and consolidate in 2026. So we need to be patient.

Fortunately, Italy’s ceramic industry has succeeded in turning the waiting time into an opportunity, by continuing to make investments despite the negative growth. This is borne out by case studies of the companies that represent the driving force of the industry: Florim, for example (see page 26), invested 121 million euros in

Davide Miserendino

d.miserendino@kairosmediagroup.it

2023 (and over 270 million in the two-year period 2022-2023).

The main objective is to rationalise production lines, so as to maximise efficiency and reduce energy consumption.

It’s one of the countless flashes of brilliance that light up this industry, which never ceases to amaze, as you can see from the ideas on display in this issue of Tile International, which is renewing its partnership with the online portal surfacesinternational.com. These cutting-edge projects mark a direct path to Cersaie, an international showcase for the creative talents of the coverings and bathroom furnishing sector, where the innovative spirit needed to overcome yet another wave will certainly not be in short supply. ✕

Panariagroup was once again awarded for its sustainability projects

At the fourth edition of the Sustainability Awards – the prize by LC Publishing which recognizes the best sustainability projects – Panariagroup was presented with the award for the best performance in the Infrastructure & Construction category, among over forty competitors. In the last 20 years, Panariagroup has been distinguishing in the ceramic sector for its enduring commitment to sustainability, alongside its innovative achievements and significant milestones. In 2004, the company was the first to launch ultra-thin over-sized slabs on the market. This revolutionary product cuts down on raw materials, water, and energy during production and significantly reduces the environmental impact associated with its transport. Since 2017, the group has consistently published a Sustainability Report and is the only company in its sector to have this document certified by third parties. Since 2018, Panariagroup has remained the sole company in its sector to join the United Nations Global Compact which encourages businesses to establish a financial, social, and environmental framework that promotes a healthy and sustainable global economy and ensures everyone the opportunity to share its benefits.

In the same year, the company aligned itself with the 2030 Agenda for Sustainable Development, identifying the most significant SDG goals to address in its business operations. In 2021, Panariagroup formalised its Sustainability Plan, consisting of three pillars: People, Planet, and Prosperity. Each pillar embodies the group’s ambitious vision and the strategic approach it intends to pursue in reaching its remarkable objectives.

Building on these principles, in

September 2022 the Group launched the ambitious THINk ZERO project. After maximizing the reduction of energy, water, and raw materials in the production of its ultra-thin slabs, the company now fully offsets their residual CO2 emissions, calculating them over the course of the product’s entire lifecycle, by purchasing credits that support international sustainable mobility projects, thus offering a 100% Carbon Neutral product. The THINk ZERO project is part of a massive international communications campaign aimed at raising awareness about how choosing sustainable products and innovative installation techniques is a fundamental prerequisite for promoting increasingly environmentally conscious construction practices. Today, thanks to technological advancements in the production process, ceramic has become one of the most sustainable materials available to designers and thanks to its inherent characteristics, it allows for easier disposal after a lengthy lifecycle that can reach up to 50 years.

“We’re very proud to receive this award, a further confirmation that our commitment and our business model allow us to achieve concrete and tangible results,” commented Emilio Mussini, President of Panariagroup. “Construction is one of the sectors with the highest environmental impact. As active participants and leaders in our field, we must help to drive sustainable, attentive, and rigorous development, continuing to elevate our responsibility and our contribution to this increasingly challenging context.”

Florim opens its new Flagship store in London

Present in London since 2020, Florim has moved to 56-60 St John St, Grant House Ground floor, opening a monobrand space intended to be a meeting and dialogue place for project professionals, where to schedule appointments and educational meetings and get to know the “Made in Florim” porcelain stoneware. The Flagship, conceived with the same intent as the Milan one, offers a multifunctional and collaborative environment for designers, where elegance and quality of materials directly reflect the commitment to support and promote innovation and creativity. Inside the store, visitors can take advantage of functional tables designed to facilitate sharing and collaboration on projects.

The new store in London is the latest testament to Florim’s global expansion strategy in design districts: from the first Flagship store in Milan in 2009, followed by openings in Moscow in 2014 and New York in 2015, to Singapore in 2019, Frankfurt and London in 2020, Abu Dhabi in 2021, Paris and Rome in 2022. In 2023, after the inauguration of the pop-up store in Los Angeles, Florim moved its New York Flagship to the prestigious 5th Avenue in Manhattan. In 2024, the Milan showroom underwent a complete restyling during Design Week, and the opening of a new space in Rome is expected.

ABK Group secures €10 million order in the USA thanks to FullVein3D technology

ABK Group has won a €10 million contract for 2024 from one of the top market players in the United States. This follows the launch of its FullVein3D technology, which will be used exclusively for the production of bathroom and kitchen countertops, cooktops, tables and furniture items.

Developed at the ABK manufacturing site in Solignano (Modena), one of the most advanced facilities in the Italian ceramic district, the second-generation FullVein3D technology flawlessly recreates the veining of natural materials both on the surface and through the

entire body of the slab. By digitally mixing different coloured raw materials, this technology creates a through-vein effect with continuous graphics between the surface and thickness on 163x323 cm ceramic surfaces with thicknesses of 12 and 20 mm.

Alongside their aesthetic value, the materials also stand out for their technical qualities including non-absorbency, strength, durability and longevity, as well as their environmental benefits and greater safety for operators during the manufacturing process compared to materials such as quartz.

“FullVein3D technology is currently one of the most advanced innovations in the ceramic sector and is set to revolutionise industry and consumer standards due to its wide range of applications and its benefits in terms of the environment and health. Our success in the United States, a market known for pioneering new trends, is a major source of pride for us,” said Alessandro Fabbri, Managing Director Sales & Marketing at ABK Group.

Iris Ceramica Group unveils “ICG RenaisScience Hub” research centre

As part of the ICG LogiPack research project, funded by the Italian Ministry of Enterprises and Made in Italy, under the Innovation Agreements (2nd Call), Iris Ceramica Group is promoting the new science and technology centre known as “ICG RenaisScience Hub”, which consolidates the company’s mission to re-engineer ceramics to improve the interaction between humans and the

environment. It is a pioneering space where science is applied to ceramic to develop unprecedented projects and solutions, with a particular emphasis on the logistics and packaging system.

The Hub will explore the new paradigms of Industry 5.0, the “collaborative industry”, representing a key step in an extensive multi-year research project, whose first focus area will be the traceability of large-format ceramic panels throughout their life cycle.

Access to the Hub is limited to a team of multidisciplinary experts from within

the company – particularly Iris Ceramica Group’s solution engineers led by Claudio Bizzaglia, Project Management & Engineering Director – and a group of researchers from Polifactory, Politecnico di Milano’s Makerspace, coordinated by Prof. Stefano Maffei, Laboratory Director and Rector’s Delegate for Social Innovation. The Hub will also receive valuable support from numerous local consulting firms, with a view to studying and developing cutting-edge technological solutions designed to accelerate the technological transition towards Industry 5.0. This multidisciplinary collaboration, which the Hub will promote and coordinate, will facilitate dissemination of the results of the innovations developed, for the benefit of the entire ceramic sector. With over 800m2 of floorspace, ICG RenaisScience Hub, whose name is a clear statement of its intent to promote a scientific renaissance of ceramic, is divided into four different research areas: Training & Workshop, 3D Printing/Digital & Electronic Design, Digital Manufacturing & Making, and Factory Testing Lab. The ICG RenaisScience Hub project – like ICG LogiPack – is built on a medium-tolong-term strategic partnership coordinated by Fondazione Politecnico di Milano, the Politecnico’s organisation for promoting the competitiveness of businesses and the local area by means of innovation projects.

SINCE 1974 INNOVATIONS FOR THE TILE SETTING PROFESSIONAL

complete program of tools for cleaning, grouting, handling and more

Since day one, back in 1974, our mission has been to fully satisfy the needs of the professional tiles installer by providing him with effective and reliable tools that increase productivity while reducing fatigue.

50 Years later our mission hasn’t changed.

Find out more at raimondispa.com or visit us at Cersaie, Bologna 23-27 September 24.

raimondispa.com

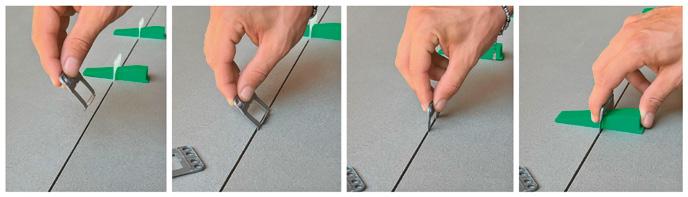

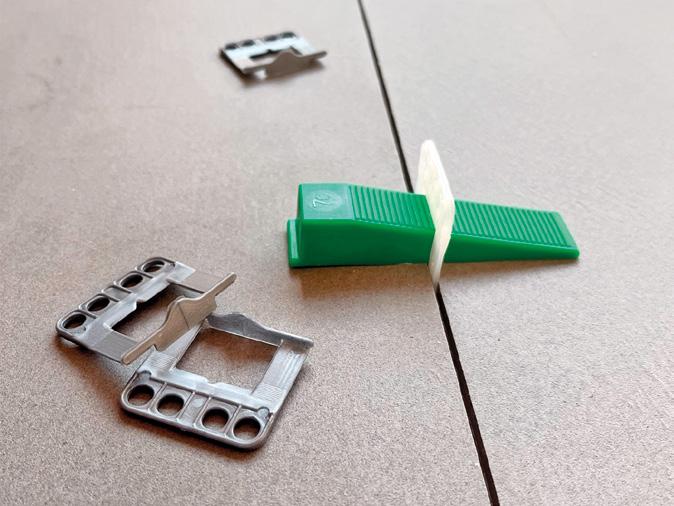

wedge & clip and screw-type levelling systems machines for cutting, mixing, floor preparation and more extensive range of large format tiles tools

VitrA presents the first almost 100% recycled ceramic washbasin

VitrA presents the first ceramic washbasin made from recycled production waste, an innovation which, according to the Life Cycle Assessment (LCA)** of the products, carried out in accordance with ISO 14040:2006 and 14044:2006, reduces the global warming potential of each piece by 30% and creates valuable resources out of materials that were once thought of as scrap.

Developed on the VitrA Production Campus in Bozüyük, Turkey, this innovative product has been designed to minimise environmental impact and underscore VitrA’s commitment to sustainability by avoiding waste, conserving re-

Mohawk Industries, Inc. has announced the promotion of Mauro Vandini as President of the Company’s Global Ceramic Segment, effective September 15, 2024. Vandini will also maintain his present role as President of Mohawk’s European Ceramic business with the support of his talented team.

“I have worked with Mauro since 2013, following the Marazzi acquisition, and I respect his deep knowledge of ceramic manufacturing, sales and marketing and his ability to drive improvements in all areas of the business,” said Jeff Lorberbaum, Mohawk’s Chairman and Chief Executive Officer. “Since we acquired Dal-Tile in 2002, Mohawk has become the world’s largest producer of ceramic tile, with manufacturing in eight countries on three continents and sales in approximately 140 nations. Mauro has built strong partnerships with our regional ceramic business leaders, and he will col-

sources and maximising the opportunities of the circular economy. Available in matt beige in various shapes, this washbasin is just the first item in a collection planned to include other products and colours. This sustainable approach to production saves about 5kg of raw materials per piece, an improvement of 36%, and 2.48kWh of electricity per piece, an improvement of 38%, due to the decreased reliance on raw materials. “These new washbasins benefit from VitrA Hygiene technology,” explains Özgen Özkan, CEO of Eczacıbaşı Building Products, “and we’re advancing our research and development efforts to incorporate recycled materials into the glazing process. With an eye on expanding our sustainable product portfolio, we’re exploring new designs and ap-

laborate with them to optimize their performance and bring outstanding design, quality and value to our customers.”

Vandini’s career began with Marazzi Group in 1983, and he subsequently worked as Marazzi’s technical director and Vice President of International Operations before serving as CEO of Marazzi Group. Following Mohawk’s acquisition of Marazzi, Vandini became the head of the European ceramic business. Under Vandini’s direction, European ceramic operations were modernized, complementary businesses in Italy, Bulgaria and Poland were acquired and a successful entry into the rapidly growing porcelain slab market was completed.

“I am honored to lead Mohawk’s Global Ceramic segment,” said Vandini. “I will continue working with our strong leaders across our regions to benefit our customers, associates and investors. As the world’s largest ceramic tile manufacturer, our focus will remain on industry-changing design, operational excellence and exceeding the expectations of

plications, from packaging to branding with new icons, all made from up to 100% recycled materials derived from our own production waste.”

our customers around the world.”

Chris Wellborn will assist Vandini during his transition to the Global Ceramic segment leadership role and will continue his responsibilities as Mohawk’s President and Chief Operating Officer, working with Lorberbaum to ensure that Mohawk’s strategies are maximizing the Company’s long-term results as the flooring industry recovers.

Energieker launches the new brand

Energieker renews its brand, the culmination of a path of evolution that, thanks to a substantial investment plan, has equipped its production plants with the most advanced technology for the production of large porcelain stoneware slabs. The renovation culminated during the summer with the inauguration of a prestigious new headquarters in the mountains of Pavullo. As of July 2024, the new brand name has replaced the previous one to all intents and purposes.

The understated elegance of the logotype expresses our company’s desire to continue on the repositioning path begun in 2018, with the aim of positioning itself as an international benchmark in high-end ceramic surfaces.

The EK monogram in the centre of the logo is coloured green, underlining the commitment to environmental sustainability and attention to the territory, essential conditions for ‘made in Italy’ products of absolute excellence, as underlined by the new mission payoff.

Lamosa sees recovery in first quarter of 2024

Grupo Lamosa saw a partial recovery in market demand in the first quarter of 2024, although not yet back to 2022 lev-

els. Sales fell 2% on Q1 2023 to MX$8.13 billion (around €450 million at 31/3 exchange rate) but were 4.9% up on Q4 2023. Some 59% of revenue was generated from domestic sales (MX$4.78 billion, down 4% on Q1 2023), while exports reached MX$3.35 billion (+1%).

Out of the Mexican group’s two core businesses of ceramic tiles and adhesives, the former was worst hit by the contraction in the construction sector, with the segment’s revenues down 4% against Q1 2023 to MX$5.8 billion, or 72% of total sales.

In contrast, the adhesive segment showed good resilience with a 3% increase in sales to MX$2.32 billion.

During the quarter, the Mexican group continued its investment plan, allocating MX$303 million (about €17 million) to the upgrading of production facilities. It also continued the process of integrating Baldocer, a Spanish ceramic company acquired in October 2023.

Gian Luca Sghedoni appointed new CEO of Litokol

Litokol, a global leader in the ceramic tile installation products sector based in Rubiera (Reggio Emilia), recently made a significant change in its top management with the appointment of Gian Luca Sghedoni as CEO. Sghedoni’s appointment was announced at the end of May by Chairwoman Daniela Cottafavi, majority shareholder and daughter of Litokol’s founder Luciano Cottafavi. Sghedoni has also joined the Board of Directors, where he will serve alongside Daniela Cottafavi and board member Elisa Pecchi.

Over its 55-year history, Litokol has achieved steady growth through its

commitment to high-quality technical solutions and in-depth expertise in innovative epoxy and polyurethane solutions for the building industry. Today, Litokol is an international group comprising eight companies located in Italy, Greece, China, India, Armenia, Ukraine and Russia. It employs around 650 people and generates global revenue of approximately €100 million.

Gruppo Romani presents Smart Tiles

Gruppo Romani launches the first Smart Tiles, so called because of the ability to interact with latest-generation home automation systems. The result of over four years of research and about 10 million euros of investment, the project was funded by Italy’s Ministry of Economic Development, due to its alignment with the policy of investing in sustainable research and devel-

opment, with the involvement of technical partners such as Sacmi, Iprel, CNR, Trebax and Studio-IOT. Originating from Gruppo Romani’s desire to transform large-format ceramic panels into intelligent modules, capable of monitoring themselves and the surrounding environment, the project concept relating to active ceramic tiles for monitoring buildings has generated two industrial patent applications, in Italy and Europe, and is blazing a trail for the future of design, for both curtain walls and raised flooring. These large-format ceramic panels have a specially designed cavity in the back to house a micro electronic control board with MEMS sensors (Micro Electro-Mechanical System), capable of transmitting the data they acquire into a cloud. As well as offering the technical characteristics set down in UNI EN 14411 and the aesthetic quality that is the hallmark of Gruppo Romani’s products, these sensor-equipped tiles enable integrated monitoring of the programmed parameters. When used in curtains walls, for example, they can measure temperature, humidity, dew level, impacts or deformation caused by seismic events. Another type of sensor, installed in floating flooring, can detect overloads, monitor the flow of people, trigger perimeter alarms and communicate with the lighting system so as to switch on lights in response to footfall. Smart Tiles by Gruppo Romani will be produced in size 120x120cm, on demand and to customer specifications.

Portobello Group resumes growth

The Portobello Group made significant progress in 2023 despite the macroeconomic and sectoral instability in Brazil and in the group’s main export markets. In the domestic market, the Tijucas-based ceramic tile group reported 3.4% revenue growth in 2022, sur-

passing R$1.74 billion (approximately US$358.5 million at the exchange rate on 31/12/2023). This growth outpaced the national average for the sector. According to data published by the Brazilian tile manufacturers’ association Anfacer, total tile sales in the domestic market fell by 5.7% in volume last year, forcing manufacturers to reduce plant utilisation rate to just 64% of the country’s total installed capacity. However, exports performed less well, with the Portobello Group’s export revenues falling by 12.2% compared to 2023 to reach R$450.7 million (a decrease of 8% in US dollars to US $85.4 million). This contraction was primarily due to a negative performance in the first nine months of the year. However, the fourth quarter showed a marked recovery of 22.9% compared to the same period in 2022, with no less than 67% of sales generated by large-format tiles.

Overall, Portobello Group posted consolidated revenue of R$2.2 billion in 2023 (at 31/12/2023 exchange rate, about US$453.2 million), broadly in line with the previous year’s performance (-0.3%), and an EBITDA margin of 13%. In the domestic market, which accounted for about 80% of total sales, the Group benefited from the strong performance of the Portobello Shop division, which posted revenue of R$917 million for the year. This marked a 12.7% increase compared to 2022 and accounted for 41.3% of consolidated revenue. The success of this business unit helped to counterbalance the negative results from the other divisions: Portobello at -6.5%, Pointer at -14% and Portobello America at -2.2%. In addition to launching the US plant, the year also saw the opening of 16 new Portobello Shops, increasing the total number of outlets to 158, of which 25 are owned by the group and 133 are franchised. Even excluding the contribution made by the new openings, the division’s sales grew by 5% in 2022. Furthermore, the strategy to strength-

en the group’s presence in the retail segment continued into the first quarter of 2024, with the number of company-owned shops increasing to 28 and the number of franchised shops falling to 128. About Q1 2024, Portobello Group saw a positive performance in revenue and an increase in market share, partly driven by the gradual recovery of the Brazilian ceramic tile market, which experienced a 3.8% growth in consumption compared to Q1 2023.

The group’s consolidated turnover reached R$525.5 million (approximately US$104.7 million at the exchange rates of March 31, 2024), marking a 7.7% increase compared to Q1 2023. EBITDA also showed an excellent performance, rising to R$81.4 million, a 62.8% increase, with a margin of 15.5%.

Domestic sales rose by 7.1% in value and 15.4% in volume, well above the sector average, while exports increased by 10.4% over Q1 2023, or 14.4% in US dollar terms, again outperforming the national figure, which saw Brazilian tile exports grow by 5.1% in the quarter. Regarding the breakdown of revenue across sales channels, exports contributed 19.4% to the total, while within Brazil, the retail segment (Portobello Shop) made up 40.5% of the group’s consolidated revenue.

Engineering and projects accounted for 21.1% and other retail sales 19%. In Q1 2024, the group’s investments totalled R$45.1 million (approximately US$9 million), representing a 47% decrease compared to the first quarter of 2023. These investments were primarily focused on Portobello America (50.4%), Portobello Shop (23.2%) and Portobello (23%).

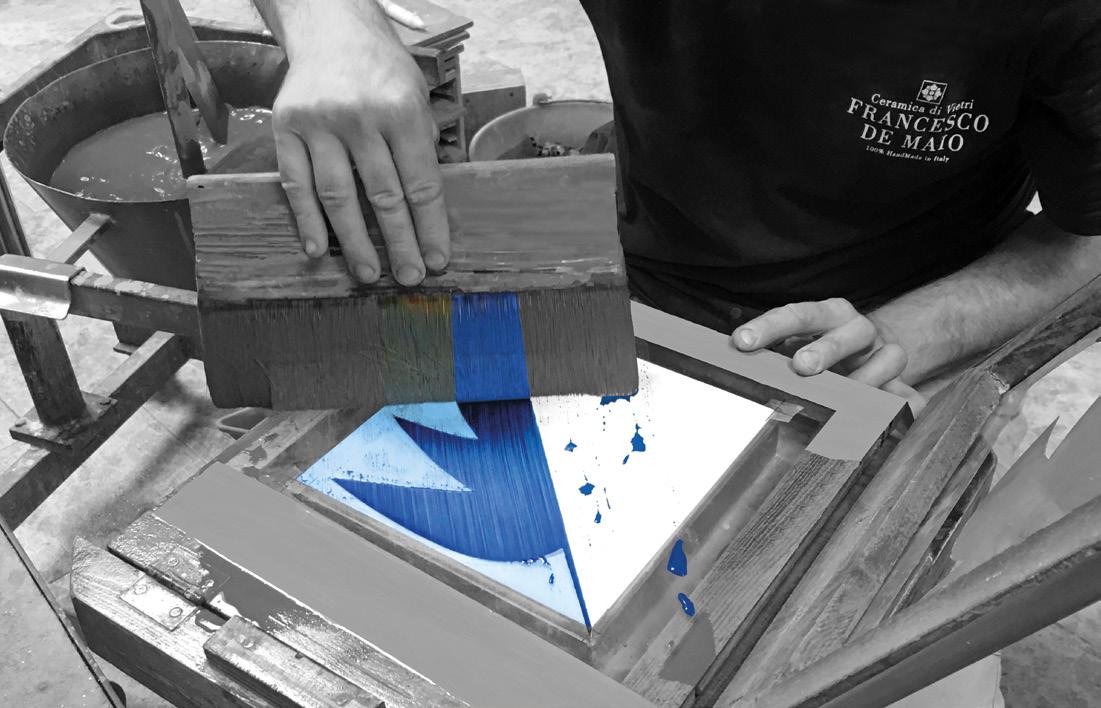

FRANCESCO DE MAIO

On the 70th anniversary of the first Compasso d’Oro Award, the Blu Ponti collection, designed in 1960 by Gio Ponti and faithfully reissued over the years by the historic manufacturer Ceramica Francesco De Maio, received the prestigious Compasso d’Oro Career Award at the ceremony held in Milan on Thursday 20 June. This award, the most prestigious in the world of design, was created in 1954 based on an idea by Gio Ponti himself and has now reached its 28th edition.

The Blu Ponti collection, consisting of 33 blue and white majolica decorations designed by the great Italian architect and designer in the 1960s, remains highly current today and has now become a permanent part of the Compasso d’Oro Collection, which gathers the most significant international design pieces from the 1950s to the present day. In 2004, it was recognized by the Italian Ministry of Culture as an “asset of exceptional artistic and historical interest” and included in the national heritage.

In addition to Blu Ponti, Ceramica Francesco De Maio holds exclusive licenses for other notable collections. These include the Puntini collection designed by Alessandro Mendini in 2018, as well as a collaboration with the Van Gogh Museum in Amsterdam for the production and distribution of a ceramics line inspired by the masterpieces of Vincent van Gogh, all meticulously hand-decorated.

The total construction output in the Euroconstruct area fell by 1.4 percent in 2023, which was slightly better than expected six months ago. The negative trend will continue in 2024 with a decrease of 2.7

percent, mainly caused by significant challenges in the new residential sector in 15 of 19 Euroconstruct countries.

A positive turning point is expected in 2025, with the positive trend

The economic outlook in the Euroconstruct area is rather mixed. After last year’s modest growth (+0.4 percent), with declines in economic output in a total of seven member states, progress is likely to remain moderate (+1.1 percent) in 2024. Growth in private consumption and exports will stay modest. Although the economy will pick up somewhat in 2025, the 2 percent

Source: Euroconstruct

continuing in 2026.

This according to the new forecasts for the European construction sectors published at the 97 th Euroconstruct conference in Stockholm on the 11th of June 2024.

mark remains unattainable from today’s perspective, given the numerous dampening factors (e.g., after-effects of the inflation shock). The most positive figures in overall economic activity for the 2024-2026 period are expected in Ireland and Hungary. At the other end of the scale, we find Italy and Germany. The dampening factors also include the continued rise in interest rates and high national budget deficits. Both are seen by the EUROCONSTRUCT partners as clear obsta-

cles to European construction activity. The limited financial leeway of the central states, as well as regional and local authorities, can have negative consequences on possible tax relief or financial injections, the provision of funding programs, or direct construction demand from the public sector.

The picture is similar for financing conditions. This influencing factor is said to have a decidedly negative effect on all main segments. The sharp rise in interest rates in a very short period has made it considerably more difficult for private households and companies to finance construction-related projects, and the situation is only slowly normalising. According to the ECB’s latest Bank Lending Survey, demand for private home loans in the eurozone has at least stabilised recently. However, corporate demand for credit weakened again until the start of the second quarter of 2024 and was still clearly in negative territory on balance. In contrast, credit requirements for house purchases by private households appear to have been handled somewhat less strictly for the first time since 2021, while banks continue to act very cautiously regarding the other forms of credit for this demand group.

The problems of recent years (e.g., interest rate turnaround, inflation, rise in construction costs) will continue to weigh on building construction, while civil engineering is expected to expand strongly in 2024. The expansion is driven by a variety of investment needs, but above all by the financial backing of governments.

Davide Miserendino

According to figures unveiled by outgoing Chairman Giovanni Savorani at the Confindustria Ceramica members’ meeting held on 12 June, the Italian ceramic industry

performed strongly in 2023, with revenues in excess of €7.5 billion, a workforce of more than 26,000 employees and an increase in investments despite the

market contraction. At the same meeting, Augusto Ciarrocchi was elected as the association’s new Chairman for the two-year period 2024-2026.

More than 81% of the Italian ceramic industry’s total revenue is generated by the tile sector, which experienced a sharp contraction last year.

The 125 companies in the sector produced a total of 373.7 million sqm, a 13.3% decline from the 431 million sqm recorded in 2022 in response to a sharp drop in market demand.

Total sales fell to 369.2 million sqm (down 17.8% on 2022, a reduction of about 80 million sqm), of which 84.4 million sqm was sold on the Italian market (-9%) and 284.8 million sqm on export markets (-20.1%).

The sector’s total revenue was just under €6.2 billion (down 14.1% on the previous year’s €7.2 billion), with €5 billion generated from exports (-15.4%; an 82% share of turnover) and €1.1 billion from domestic sales.

Despite the challenging market environment, the Italian tile industry’s vitality and competitive capacity is demonstrated by its propensity for investment, which increased by 7.4% in 2023 to €474 million, representing

The six manufacturing sectors represented by Confindustria Ceramica (ceramic tiles, ceramic sanitaryware, porcelain and tableware, refractory materials,

technical ceramics, and bricks and roof tiles) comprise a total of 252 companies operating in Italy with 26,211 direct employees and total revenues of more than €7.5 billion.

A further €1 billion is generated by factories located in Europe and North America but owned by Italian ceramic groups.

7.7% of total revenues.

As for 2024, there are signs that the decline may be slowing.

In the first quarter of the year, sales decreased by 6.7% compared to the same period in 2023, while exports to the US increased by 18.5% in volume and 12.8% in value.

Ceramic sanitaryware, exports account for 40% of total sales

The ceramic sanitaryware sector also experienced a decline in sales and consequently in production in 2023. The 29 Italian sanitaryware manufacturers operating in Italy - 26 of which are located in the Civita Casfaetano

tellana cluster in the province of Viterbo - produced 3 million pieces (compared to 3.6 million in 2022, -15.4%) and sold 2.9 million pieces with a total value of almost €350 million (-12.2% on 2022). The domestic market continued to dominate, generating 60% of revenues. The sector’s total workforce stood at around 2,560 direct employees.

The heavy clay and refractory sectors

At the end of 2023, there were 59 Italian companies operating in the brick and roof tile sector with a total workforce of around 3,000 people. Total production was down 14% on 2022 to just under 4 million tonnes, most of which was sold on the Italian market generating a turnover of around €650 million (down 7% on 2022).

The Italian refractory materials sector consists of 30 companies with a total of 1,566 employees. Production amounted to 252,500 tonnes in 2023 (down 16% on 2022), of which 47% was sold on the Italian market and 53% abroad. Total turnover fell by 7.9% year-

Source: Confindustria Ceramica

Confindustria Ceramica

on-year to €344 million, of which €137.7 million was generated by domestic sales and €206.8 million by exports.

Tableware, the smallest segment of the Italian ceramic industry, is made up of just 9 companies employing 656 people and recording a production of 9,900 tonnes in 2023 (stable with respect to 2022). Last year, finished product sales amounted to 8,800 tonnes (down 7% on 2022) and generated a turnover of €55.9 million (-7%). Here too, the domestic market is predominant with no less than 80% of volume sales being made in Italy (equivalent to 65% of revenues). ✕

Milena Bernardi

Florim, a benefit company and certified B Corp since 2020, recently published its 16th Sustainability Report. The economic, social and environmental results contained in the report testify to the group’s

INCREASED INVESTMENTS DESPITE DECLINE IN REVENUES

determination to achieve its goals and underscore its constant commitment to generating value for all its stakeholders.

“The past year will be remembered for the outbreak of yet another armed

The group’s economic profile for 2023 reveals consolidated revenues of €467 million, down from €584 million in 2022.

This downturn is linked to the general decline in demand for ceramic products, reversing the significant growth observed in the main reference markets dur-

conflict and ongoing geopolitical instability, both of which have had an adverse impact on the economy,” said Chairman Claudio Lucchese

“In this context, despite a general contraction in volumes compared

to 2022, Florim has continued to look to the future with optimism, buoyed by the outstanding results achieved in recent years. In particular, the group has continued the investment plan it initiated in 2022.”

ing 2021 and 2022. In 2023, EBITDA and EBITDA margin were impacted by both the contraction in sales and the increase in certain cost items such as energy expenditures, as well as personnel costs in the US business.

Chiara Bruzzichelli

c.bruzzichelli@tiledizioni.it

However, the downturn failed to slow down investment, which reached €121 million in 2023, totalling more than €270 million over the two-year period of 2022-2023. This marks a significant increase over the previous period and is in line with the plant renewal plan launched in 2022, focused on innovation, reducing emissions and improving product quality.

Work carried out in Italian factories, amounting to about €62 million, primarily involved the Mordano site for the continued construction of new production facilities and the expansion and modernisation of existing buildings. The work also partly involved the Fiorano site, with the construction of the new Plant 3 (covering 2,800 sqm). Additionally, at the end of the year, refurbishment began on the presses, kilns and the grinding, lapping and sorting departments at Plant 1, which produces traditional-sized porcelain stoneware. The aim of this intervention is to rationalise the production lines, achieve greater efficiency and reduce energy consumption.

Abroad, the renovation project at the Florim USA factory continued, with an investment of US $55 million during the year. This included the completion of a new 40,000 sqm warehouse and facilities for producing large-size ceramic slabs.

The group has made sustainability-related investments of €64 million since 2011, including approximately €6 million in 2023 alone.

Florim continues to open Flagship Stores in the most important international design cities.

After moving the New York Flagship store to its new location on Fifth Avenue in 2023, in 2024 the group

opened a new space in London and restyled its Milan showroom. It also plans to open a new space in Rome In Los Angeles, a new pop-up store was opened in 2023 while awaiting the opening of the new Flagship store by the end of 2024.

During 2023, Florim’s commitment to the sustainability of its business model focused on all aspects of production. At the end of 2022, the company began altering its industrial process in order to reduce the thickness of all its traditional tiles from 10 mm to 9 mm, thereby significantly improving sustainability. This innovation has resulted in the use of smaller quantities of raw materials, less water, electricity and methane gas consumption in the production process, and a reduction in CO2 emissions.

Another important environmental initiative involved the construction of a large new rainwater collection tank (350 m × 6.2 m) at the Mordano plant. Together with the existing facilities, this enabled the company to recover and reuse about 7 million litres of rainwater in 2023.

Florim continues to focus on clean energy production and to date has installed 127,000 square metres of photovoltaic panels with a power output of 12.3 MWp. Over a period of 12 years, the company’s installations (photovoltaic panels and cogenerators) have enabled it to avoid the emission of 152,845 tons of CO2, including 23,457 tons in 2023 alone. Last year, self-produced electricity covered 78% of total consumption, an achievement that enabled Florim to obtain UNI EN ISO 50001 Certification for its effective energy management policy.

Another major initiative is the Carbon Neutral surfaces project launched in 2023, focused on materials that offset the CO2 emissions generated during the production process and over their entire life cycle. In 2023, Florim sent 44,168 tonnes of separated waste (including fired waste) for recycling, equivalent to 99% of the total. When the US site is included, the average recycling rate is 87%.

Florim’s commitment to sustainability also led to the adoption of 2 electric trucks and the installation of a new high-power electric truck recharging system at both the Fiorano and Mordano plants. From June to De-

cember 2023, these trucks avoided the emission of 148 tonnes of CO2 equivalent.

In 2023, Florim continued to support employee health and wellbeing through a broad package of services, including free checkup programmes, discounts for specialist consultations and tests, free summer centres for employees’ children, distribution of fuel vouchers and much more.

It provided more than 26,600 hours of technical, digital and health and safety training throughout the year. In 2023, Florim also launched its new whistleblowing portal, accessible to employees and external parties, for reporting violations, offences, conflicts of interest, legal non-compliance and breaches of the Code of Ethics and the Organisational Model to the Supervisory Board.

The 16th Sustainability Report also outlines Florim’s goals for 2024. These include the renewal of B Corp certification; a 25% reduction in electricity consumption in the grinding department of Plant 1 in Fiorano; collection of 5% more rainwater than in 2023; the introduction of a new secondary raw material into the production cycle; the use of new water-based materials for digital decoration; the inclusion of new collections in the CarbonZero range; and the official adoption of agile working methods.

Iris Ceramica Group, a wellknown ceramic manufacturer, and Edison Next, an Edison Group company that supports customers

The production site is the H2 Factory, a new plant in Castellarano, in the Italian province of Reggio Emilia, which was completed in 2023 and is already equipped with innovative technologies and the necessary infrastructure for 100% use of green hydrogen.

The industrial process being developed in Castellarano is the first tangible result of the quest for decarbonisation that Iris Ceramica Group and Edison Next have embarked upon together. After this initial phase, the H2 Factory will be powered by higher percentages of green hydrogen produced by the bespoke, state-of-the-art plant already designed and now being built by Edison Next.

“Today we mark a major milestone,” explains Federica Minozzi, CEO of Iris Ceramica Group; “another real-world achievement that testifies to our commitment to the decarbonisation of the ceramic industry. This unique, trail-blazing and globally significant project opens up new prospects for hardto-abate manufacturing, demonstrating that it can be done.” “The test phase will enable us to finetune the production process, before moving onto the next phase, when we’ll be able to steadily increase the percentage of green hydrogen up to 50%, using the production system that Edison Next is making specifically for us. What we’re involved in is an exceptionally valuable partnership and we’re

and local authorities on their journey towards decarbonisation and ecological transition, have announced the release of the

first large-format panel made of 4D technical ceramic, using a mixture of green hydrogen – i.e. hydrogen produced using

renewable energy – and natural gas. The panel in question is 3.2m long by 1.6m wide by 12mm thick and stands out for

its four dimensions – that’s why it’s called 4D Ceramic – in which the three-dimensional nature of the material and its grain

proud that this achievement is the result of teamwork across the supply chain, which sets an admirable example of integrated sustainability. We hope that other companies will follow suit, so as to build a real system and become drivers of change both nationally and internationally.” Various preparatory activities were carried out to pave the way for the launch of this first phase, including civil works to prepare the area, the installation of the blending unit for mixing natural gas with green hydrogen, and the completion of all the necessary connections between the different machines. A 1.3 MWp photovoltaic system has also been installed, to supplement the 2.5 MWp of the existing installation.

The pilot H2 production plant, brought on-stream in May 2024 for the testing phase, comprises two temporary electrolysers with total power of 120 electrical KW, powered by renewable energy. Housed in a shipping container, the two electrolysers can produce a total of 20 cubic metres of green hydrogen per hour, thus supplying the new hydrogen-ready kiln with a blend containing up to about 7% of green hydrogen – a figure which is set to rise once the definitive plant is installed.

The aim of this first phase is to gain an in-depth understanding of how best to use ceramic slab production technology with green hydrogen, while at the same time as-

patterns, which run through the entire thickness of the slab, are complemented by a fourth dimension: sustainability.

sessing the behaviour of the material during firing. The ultimate goal is to industrialise production using green hydrogen, with complete certainty of achieving the technical, aesthetic and qualitative excellence that has always been the hallmark of Iris Ceramica Group products. 4D Ceramic, the material produced by the H2 Factory, is the Group’s flagship product, which is designed to showcase the beauty and nobility of this natural material and satisfy the demands of the high-end interior design market.

Chiara Bruzzichelli c.bruzzichelli@tiledizioni.it

Over the next few months, while the test phase continues, Edison Next will start work on installing the definitive system, which is a green hydrogen electrolysis plant with a capacity of 1 MW capable of producing around 132 tonnes of green hydrogen per year, to supply the kiln with a blend of natural gas and up to about 50% of green hydrogen. From the outset, this blend will replace approximately 500,000 cubic metres of natural gas per year, thus avoiding the emission of approximately 900 tonnes of CO2 per year into the atmosphere*

The green hydrogen production system currently being built by Edison Next has been designed to allow a further doubling of green hydrogen production, so as to supply a new 100% hydrogen kiln that is already in development. ✕ *Certification by LEAP s.c.ar.l. Laboratorio Energia ed Ambiente Piacenza

Kaleseramik, Turkey’s largest ceramic manufacturer and one of the global leaders in the industry, has a current production capacity of 56 million sqm/year across 57 production lines.

The company sells a wide range of

products under its various brands (Çanakkale Seramik, Kalebodur, Edilcuoghi, Kalesinterflex and T-One) and has an extensive catalogue spanning 1,900 types of floor tiles in 50 different sizes and 2,200 types of wall tiles in 60 sizes.

TILE INTERNATIONAL: The Kalesinterflex brand continues to be pivotal to your expansion programmes. Could you tell us more about your plans?

TIMUR KARAOĞLU: We have just signed an agreement with our longstanding supplier System Ceramics to modernise our existing Kalesinterflex slab production line in sizes 100x300 cm and 120x360 cm and to increase production capacity by 50% from 1.6 to 2.4 million sqm. The €15 million investment will be completed in two phases, the first by 1 May 2025 and

It launches around 200 new products onto the market every year.

Ever since its early years, Kale Group has been committed to adopting ever more innovative technologies, most of which are

the second by the end of next year. This investment will bring our total slab capacity to 5.6 million sqm/ year while also allowing us to improve the technical and aesthetic quality of the surfaces.

TILE INTERNATIONAL: You will also be completing another major investment this year.

T. KARAOĞLU: That’s right, we have purchased a production line equipped with Supera technology from Gruppo B&T for the production of large-size glossy glazed porcelain tiles. The new plant will replace an existing porcelain tile line and will allow us to produce 120x280 cm, 120x120 cm and 60x120 cm sizes

Delivery of the machinery and equipment will be completed within a few months and production is scheduled to start on 1 December. This $10 million investment will be financed with funds raised through the IPO we launched last year. We estimate that the revenues generated with products manufactured on this line will make a significant contribution to our 2025 turnover (between 10% and 15%).

TILE INTERNATIONAL: What are the most interesting product innovations you have developed in recent months?

T. KARAOĞLU: We have developed two main new products, both under the Kalesinterflex brand. The first marks a genuine revolution in the slab sector. Whereas Kalesinterflex has until now been available in a thickness of 3 mm, the latest technological advances have enabled us to begin producing ultra-thin panels with a thickness of just 2 mm. This also brings clear benefits in terms of sustainability, as the process uses 33% less raw materials and reduces energy consumption. The second new product is T-One, the new brand of kitchen countertops created from Kalesinterflex slabs, which are already gaining a foothold in the kitchen furnishing sector thanks to their durability, aesthetic quality, hygiene and scope for customisation.

At Cersaie, we will also be showcasing the new Kalesinterflex offerings, including the Earth Collection inspired by natural elements that won the iF Design Award 2024, as well as many other novelties from the

inaugurated during the celebrations held at the Çan headquarters on 27 July each year to mark the anniversary of the group’s foundation back in 1957.

On 27 July 2023, it officially started up its third line for the production

group’s other brands.

of Kalesinterflex slabs with a production capacity of 1.5 million sqm/year and an additional capability to produce a 160x320 cm size in various thicknesses.

This year, 27 July coincided with the announcement of a new technology

TILE INTERNATIONAL: Could you tell us about your international development strategy?

T. KARAOĞLU: Despite the difficulties, in 2023 we exported 28% of our output to 86 countries, including China.

In international markets, we aim to create long-term partnerships with reliable distributors and to reach end users by focusing on brand awareness. In terms of positioning, our strategy changes according to the mar-

investment plan aimed at supporting the group’s global growth.

We discussed this new plan with Kaleseramik’s General Manager Timur Karaoğlu.

kets, so in more developed regions we focus on delivering high-end products.

Chiara Bruzzichelli

c.bruzzichelli@tiledizioni.it

We are now a well-established brand in many countries, most notably the USA, Canada, the UK, Germany, France, Israel, Pakistan, Iraq, Kazakhstan, TRNC (Northern Cyprus), Morocco and Bangladesh.

At the same time, we are working to expand our presence in other countries in the Middle East and Africa and are stepping up the pace of store and showroom openings. By the end of 2024 we are set to open

new stores in Iraq, Morocco and Cyprus, which will join the existing eight exclusive Kale Dealers in Iraq, seven in Pakistan, two in TRNC and a project office in Kazakhstan.

In December 2023, we opened a 400 sqm showroom in Dhaka, Bangladesh with our partner Shanta Holding, followed in March 2024 by a showroom in Cologne, Germany, which also benefits from a central warehouse to ensure rapid deliveries. Both showrooms display Çanakkale Seramik and Kalebodur brand products and of course Kalesinterflex slabs, as well as sanitaryware and bathroom furniture from Kale Banyo. Germany and Bangladesh are obviously two very different markets. In Germany we face very strong competition, whereas in Bangladesh, our third largest market in Asia after Pakistan and India, we believe that Kalesinterflex can tap into the strong interest in innovative products and win significant market shares.

TILE INTERNATIONAL: In May, you also began production in Iraq.

T. KARAOĞLU: That’s right, last December we acquired a 49% stake in Al-Sadaf Porselen, one of the largest porcelain stoneware manufacturers in Iraq, and began producing Kalebodur-branded tiles on 19 May. We believe that this investment will provide us with new growth opportunities not only in the Iraqi market but across the entire Middle East. It will also facilitate sales in Iraq of products manufactured in Kale’s factories in Turkey.

TILE INTERNATIONAL: Could you give us some examples of projects Kalesinterflex slabs have been used in?

T. KARAOĞLU: Kalesinterflex slabs have been chosen for many important international projects, such as the Barcelona Metro, Bratislava Airport, the Baku Olympic Stadium, Leeds Stadium, the United Nations Building in Senegal, the Olympic Village in Sochi, the National Children’s Hospital in Ireland and the MDIS Singapore Institute.

TILE INTERNATIONAL: Could you tell us about your R&D activities?

T. KARAOĞLU: Our R&D Centre is involved in a variety of projects to support company strategies, with a special focus on sustainability and product and process innovation. It focuses on five main themes - cost, quality, efficiency, value creation and new usage segments - and in 2023 carried out 37 projects with a total

expenditure of €5 million. The R&D Centre is equipped with a series of laboratories that perform physical, mineralogical and chemical analyses of raw materials, wastewater and finished products. In recent months, the Kaleseramik R&D Centre’s laboratory became the first and only Turkish member of the European Ceramic Society (ECerS), which means it will be open to ECerS researchers, organisations requesting laboratory services for EU-funded projects, and collaborations with European ceramic research groups.

TILE INTERNATIONAL: What are your sustainability goals?

T. KARAOĞLU: Sustainability is a global priority, so it is natural that a group like ours should be keen to contribute to a more sustainable future by making strategic investments. The Kalesinterflex production line, for example, reduces carbon emissions per unit of product by 42% compared to standard production. By 2030, we are committed to significantly reducing our carbon footprint by meeting several ambitious targets. These include cutting direct greenhouse gas emissions by 25%, increasing our usage of renewable electricity to 100%, doubling our closed-loop production rates and reducing water consumption by 25% compared to 2021 levels.

TILE INTERNATIONAL: How are you addressing the digital transformation?

T. KARAOĞLU: Digitalisation of our production processes is a very important part of our technology investments. We began working on this in 2017 and have invested around €15 million over the past six years. Our Digital Transformation Roadmap aims to make the company more agile, efficient and competitive through more effective use of collected data.

TILE INTERNATIONAL: After a challenging 2023 for the world economy, what are your expectations for 2024?

T. KARAOĞLU: Projections for the global economy point to a growth trajectory, driven mainly by China, India and the United States. The development and diffusion of new technologies will also have a positive impact on the digital economy. Despite inflation and declining purchasing power, the Turkish economy continued to grow in 2023. In 2024, the measures adopted are expected to lead to a drop in inflation from the second half of the year, reviving investment and making the market less unpredictable. ✕

“Welcome to Eden” is the show-installation designed by Bardelli Group for the presentation of its latest products at Cersaie 2024. Based on a hexagonal shape that references the “Eden” collection by Appiani, it offers visitors an emotive tour of the company’s latest developments. With its palette of 18 gloss and 18 matt colours, “Eden” promotes the idea of modularity and customisation: the mosaic pieces can be mixed to create original designs to suit any type of environment.

The stand thus offers a sensory stroll through the array of shapes and colours that make up this voyage of discovery of the company’s latest highlights:

“Colorama” by Ceramica Bardelli, which includes three diversified collections of products, called Color Stick and Decor (in the Circles and Flowers versions, created in collaboration with the designer Robert Dawson, Brush and Precious) for creating an ecosystem of colour, embracing a wide range of solutions, with various large formats, textures and patterns; “Wind” by Ceramica Vogue, which draws inspiration from the power of the wind and comes in two patterns: Onde and Dune. Onde replicates the ripples caused by wind blowing over waves in the sea, while Dune evokes the geometric shapes sculpted by the wind as it blows over sand dunes. Onde and Dune porcelain listellos are made with a low-relief texture created by means of press dies and painstakingly developed, coloured glazes that give these tiles the effects typically associated with hand-crafted ceramic.

• The new “Clayborn Millerighe” variant, which is an evolution of Clayborn by Ceramica Bardelli, a collection of floor tiles whose pattern is created using “generative models” of artificial intelligence.

• “Mix & Match”, a project created to help the professional combine small and large formats in environments where ceramic colours, formats and materials dialogue harmoniously in the sign of design. ✕

Pop-style interiors and playful juxtapositions of ceramic coverings embrace a contemporary concept of mixology and set the tone for an eclectic venue steeped in character.

The historic centre of Vignola, a small town in the Modena area, famed for its cherry orchards, provides the backdrop for the Noblesse cocktail bar, where creativity joins forces with research to create a unique range of bespoke drinks.

In line with the original interpretation of mixology, the venue’s bold but welcoming interior design is brimming with character and cosmopolitan allure, underpinned by its mix&match surfaces. Enticingly sophisticated colours, designer details and vaulted, antique brick ceilings are paired with ceramic floor and wall coverings made with a mix of different Marazzi collections, to convey the unique spirit of the venue.

Interpretations of marble, wood and slate shape the

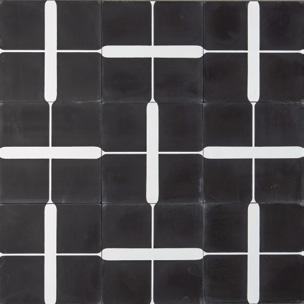

space, to create an environment whose stylistic signature is built around contrasts. The venue’s most distinctive features are its flooring and the tiling of the bar, which involve an unusual mix of Allmarble Calacatta Extra - a mainly light-coloured marble-effect porcelain tile shot through with bold streaks of grey - and Treverklife wood-effect porcelain tile, which draws inspiration from the warmth of oak and is used here in the colour Cherry.

To showcase the contrast between the elegance of marble and the warmth of wood, while maintaining the harmony and coherence of the design, both collections were supplied in custom sizes of 12.5x75cm and then laid in a herringbone pattern on both the floor and the wall. The result is an environment with a

c.bruzzichelli@tiledizioni.it

strong, dynamic, contemporary personality. The tables were made with Allmarble, in the tasteful Elegant Black variant with contrasting light-coloured vein patterns.

To emphasise the volumes, the steps of the venue –which is laid out on several levels – were made with Mystone Ardesia stone-effect porcelain tile, in the textured Cenere version in size 75x150cm, which provides

an ideal combination of contemporary design and technical performance.

As a final touch, a band of Sage-coloured Colorplay tiles installed on the walls breaks up the vertical surfaces with the discreet geometric volumes of 3D Cabochon, which draws inspiration from the facets of diamonds..

The remodelling of a hotel in a contemporary Mediterranean style

Azure, blue and turquoise are the colours of the Mediterranean, the Cyclades Islands, the sea and the ancient architecture of those places, which have always been a source of inspiration for Paola Navone. Alongside Gianpaolo Venier and Cristina Pettenuzzo of OTTO Studio, the Milanese designer has redesigned the interior of the Fresh Hotel in Athens, using coverings from the Poetry House collection of porcelain tiles created in collaboration with ABK.

The renovation project involves harmonious pairings of ancient and modern features in spaces designed to foster a relaxing, welcoming atmosphere.

The Fresh Hotel’s new look underpins a concept that celebrates its dual spirit, which is simultaneously trail-blazing and classical, in tune with the Greek capital itself, which is undoubtedly a city of contrasts.

The original modernist style of the building, characterised by concrete and glass, has been softened by the recent renovation, thanks in part to the choice of other materials, such as porcelain tile, which offers greater visual plasticity. The delicate approach to design that is the hallmark of OTTO Studio has yielded a range of spaces with an eclectic, dynamic and exceptionally contemporary Mediterranean atmosphere. The colours inspired

by air and water, the natural finishes of the coverings and the materials and craftsmanship of the decorations that reflect local traditions, are not just details but vital components that form an integral part of the overall picture.

The flooring of the glamorous, vintage bathrooms is finished with Poetry Decor Stamp by ABK and Paola Navone - OTTO Studio, an original, plaster-effect porcelain tile decorated with white glaze patterns with a hand-crafted appearance, which add a further retro touch to the environment.

The terrace also features an ABK floor covering from the extensive Poetry House collection. This time it’s the Poetry Stone outdoor series in size

120x120cm, with the Carpet Paint Ash decorative motif, whose colours and styling are in full harmony with the rest of the design. The veined-stone effect is embellished with hand-drafted patterns by the designer, which stand out for their deliberately imperfect and creative feel. In the rationale embraced by OTTO

Studio - Paola Navone, the decorations, which can be used on walls and floors alike, reassert the primacy of uniqueness and instinctive gestures as an aesthetic value, without taking themselves too seriously.

The hotel’s makeover is complemented by delicate touches such as colourful ceramic plates

on the walls, curious fish-shaped handles and iconic French lamps, not to mention the enchanting swimming pool and the terrace with a view over the Acropolis – all the right ingredients, in fact, for guests to enjoy a memorable stay with a contemporary, original and exclusive feel.

Aimed at creating an overall sense of aesthetics, functionality and sensitive regeneration, the remodelling of a photographic studio achieved complete success by combining the technology of new materials with the iconography of historic local crafts.

The building where Studio 129 is based is part of a historic jute factory to the south of Modena, surrounded by the railway and a group of old tobacco factories.

The interior, which was recently renovated to modernise it and bring it into line with the latest design standards, is a large open-plan space featuring surfaces that derive their character from the materials they are made with.

These have been showcased by exposing the brickwork of the walls and the natural grain patterns of the wooden doors through which goods used to pass.

The premises are on two levels, with large columns that support and connect two different mezzanines, delimiting the office space and the bathroom area.

The spaces are linked by a uniform and contemporary new floor, laid with adhesive over the existing flooring, which is still firmly anchored to the sub-floor.

For the new floor covering, the designers opted for large-format, slim-gauge, edge-ground porcelain panels measuring 120x120, which have the evocative appeal of old industrial-style concrete floors.

To achieve a result in line with the client’s expectations, it was essential to use high-quality products to prepare the subfloor and install the ceramic coverings. So the obvious choice was LATICRETE®, , a manufacturer of versatile, eco-friendly, high-performance solutions for the application of screeds and coverings.

The first step was to clean the existing flooring with STONETECH®, STONE & TILE

c.bruzzichelli@tiledizioni.it

CLEANER, a pH-neutral aqueous detergent. The contractors then applied an adhesion primer, to maximise the adherence of the cementitious adhesive to the glazed surface of the old tiles, which are a particularly challenging substrate for cementitious adhesive. In this case, the choice fell to PRIMER SUPERIOR, a liquid primer that can be applied with a roller and is highly effective for preparing the floor for adhesive application in just three hours.

The new large-format panels were then installed using 335 SUPER FLEX, a C2S1 adhesive that delivers first-class adhesion, while also creating the necessary

thickness underneath the tiles to compensate for unevenness in the previous floor covering.

Adhesive was applied to both the sub-floor and the back of the tiles, to ensure solid bed fixing. Levellers were also used, to prevent height differences between tiles and to ensure a perfect, even surface.

Twenty-four hours after installation, the joints were grouted with PERMACOLOR®, SELECT FINE, a quick-setting cement grout that can be coloured with water-soluble pigments.

Only in the entrance area was it necessary to remove the existing tiles, because they were poorly fixed and seriously uneven. The solution involved screeding the floor with 2261 SCREED, a ready-to-use compound of hydraulic binders pre-mixed with aggregates, which is quick-setting, making it possible to lay ceramic tiles just 24 hours after the screed has been cast. The thickness of the screed, from four to eight centimetres, ensured a uniform result without compromising the speed of execution. Once the tiles were installed, the joints were simply grouted as necessary. Thanks to the careful installation of the new coverings, the flooring looks impeccably finished and is safe, strong and capable of standing up to the daily wear and tear associated with high-footfall environmen ts. ✕

A residential complex comprising four private villas has recently been completed in Jesolo, in the province of Venice, on the Adriatic coast.

An ideal location for family-oriented tourism, Jesolo is one of Italy’s best-known and most widely acclaimed resorts because of the services it offers and its natural setting, complete with 15km of beach and a series of characteristic piers jutting out into the sea, just half an hour from Venice.

This complex of unique buildings is a perfect fit for the elegantly innovative character of the area, and features environmentally-friendly design that combines green spaces, relaxation areas and a swimming pool.

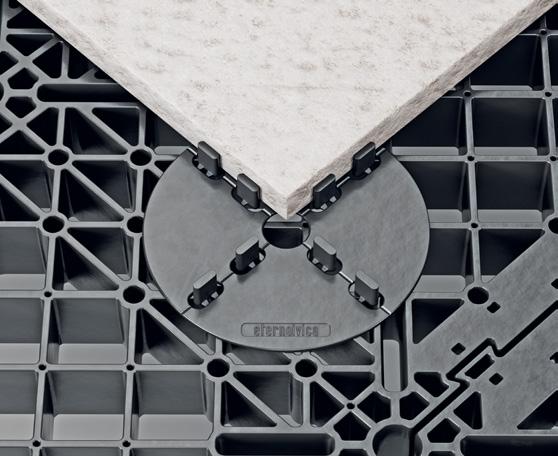

The outdoor areas of this luxurious residential complex were completed using “Grid Raised Floor System”, a raised-flooring support system that combines elegance and original design with simplicity and uniqueness

The real stand-out feature of this garden is the aesthetically impeccable juxtaposition of ceramic slabs and synthetic grass. With a surface area of 200m2, this raised floor, complete with steps and concealed drainage channels, is built on “Pedestal Prime PR2” supports.

This system is designed for the installation of raised flooring on a network of PP grids interconnected by means of dovetail fittings around their perimeters, to create a substructure capable of supporting a wide range of different floor coverings.

The system, produced by Eterno Ivica, is completed by installing the grids on pedestals from the “Pedestal System” line, whose heads snap into the slots in the corners, centre and sides of the panels.

For a more robust substructure, the manufacturer recommends installing a pedestal in the centre of the grid and along the four sides.

This premium solution can be used with the following pedestals: “Pedestal Prime®”, “Reversus®”, “Eterno SE”, “New Maxi” and “Basic SB”.

The use of the vertical perimeter profile in this project plays a key role in the aesthetic

c.bruzzichelli@tiledizioni.it

impact of the finished work, by providing a harmonious means of creating the steps that lead to the swimming pool.

This system offers maximum design freedom because it can be used with any type of covering material, from synthetic grass to porcelain tile, natural stone and decking… enabling designers to create gardens, terraces and green spaces adorned with beauty of ceramic. ✕

Situated in a panoramic position in the lush, wooded vegetated hills, the villa is located in the Vale do Vinhedos, an area inhabited by a large number of people of Italian origin. Apart from the ceramic tiles, the waterproofing and installation solutions were also of Italian origin, supplied by Mapei through its subsidiary Mapei Brasil. Before installing the tiles, the substrates in the swimming pool and bathrooms were waterproofed with MAPELASTIC SMART two-component high-flexibility cementitious mortar with high crack-bridging capacity. The large ceramic tiles (measuring 1.6x3.2 m) were installed on the façades using ULTRALITE S2 (available on the international market as ULTRALITE S2 FLEX), a one-component, highly deformable, lightweight adhesive. This product was chosen for installing large format tiles (1,6x3,2 m) on the façades due to its great deformability and to avoid any risk related to the installation on vertical surfaces MAPESIL LM was chosen to seal the joints, a neutral, mould-resistant silicone sealant, whose chemical nature deters surface bleeding or the migration of plasticising agents which would otherwise stain the stone surface.

Inside the villa, MAPEGUARD UM 35 anti-fracture, uncoupling and waterproofing mem-

brane was applied over the screed made from TOPCEM hydraulic binder. This membrane was chosen because it enables ceramic and stone tiles to be installed without having to copy the layout of control joints and expansion joints of the substrate. This also helped improving the overall heating performance of the floor. Inside the villa, the floor and wall tiles were installed using ULTRALITE S1 deformable, lightweight adhesive (now available in Brasil and in the international market as ULTRALITE S1 FLEX ZERO* with fully offset CO2 emissions). Tile joints were grouted with ULTRACOLOR PLUS cementitious mortar, which is also part of the ZERO* line, as for both interior and exterior surfaces. The expansion joints of the ceramic coverings were sealed with MAPESIL AC silicone sealant. PURTOP EASY polyurethane membrane was chosen to waterproof the roof. The product is highly elastic, versatile, and easy to apply. It was chosen due to its durability, mechanical resistance, and resistance to light foot traffic, since some areas of the roof were left exposed while others were covered with a green garden.

* CO2 emissions measured throughout the life cycle of products from the Zero line in 2024 using Life Cycle Assessment (LCA) methodology, verified and certified with EPDs, have been offset through the acquisition of certified carbon credits in support of forestry protection projects.

Large format Italian ceramic tiles cover the façades of Casa do Vale, a recently constructed villa in Bento Gonçalves in the Rio Grande do Sul state, in the southern part of Brazil.

• Period of construction: 2020-2023

• Year of Mapei intervention: 2021

• Intervention by Mapei: supplying products to waterproof substrates and install ceramic tiles on façades, swimming pools and interior walls and floors

• Owner: Lando Design

• Designers: Marlon Tondo Lando, Carolina Onzi Giovanella and Ângela Paludo

• Works direction: Carolina Onzi Giovanella

• Ceramic tile installation company: Tio Chico

• Mapei coordinators: Marcelo Saad, Rafael Mras and Rodrigo Lopes (Mapei Brasil)

“Alchemy” metallic-effect coverings by Ceramiche Caesar adorn the new Eataly Restaurant, recently opened in the Hyundai Department Store in Seoul, by the famous chain that promotes the cream of Italian gastronomic products worldwide.

Marked by a modern, cosmopolitan design that combines international style with exquisitely oriental simplicity of form, the mall is a perfect showcase for these ceramic surfaces, whose appeal is enhanced by chrome, oxidation and a time-worn, authentically crafted appearance, which is even more striking in the copper colour chosen for the restaurant’s interior.

“Alchemy Copper”, used here in size 80x80cm with a matt finish, catches the eye with its intense colours and richly nuanced variegations, which evoke the warm, aged effect and patinas that occur when metal oxidises, while at the same time offering the durability and practicality that are essential requirements in high-footfall environments.

AS EVERY YEAR, CERSAIE CONFIRMS ITSELF AS THE MAIN EVENT FOR THE CERAMIC SECTOR WITH A GLOBAL RESONANCE DUE TO THE QUALITY AND INNOVATION OF THE PRODUCTS ON SHOW, THE VARIETY OF ITS CULTURAL AND EDUCATIONAL INITIATIVES, AND THE INVALUABLE NETWORKING OPPORTUNITIES.

Five days of the International Exhibition of Ceramic Tile and Bathroom Furnishings, in which 560 brands - including manufacturers of ceramic tiles and slabs, installation systems and materials, furnishings, sanitaryware and bathroom accessories, as well as ceramic glaze and colour producers and providers of showroom services - will provide an overview of upcoming ceramic trends with novelties and innovations.

344 are the Italian and 216 the foreign companies from over 20 countries, with the biggest contingent from Spain with 138 companies and brands.

The 41st edition of Cersaie also offers a packed programme of cultural and educational initiatives. This includes the new exhibit in the Quadriportico area, now renamed “The Square”, which will serve as the central hub of Cersaie hosting the meetings in the “building, dwelling, thinking” programme. Curated by Dario Curatolo, the exhibit represents a journey inspired by last year’s Route 40 experience exploring

four decades of innovation in ceramic tiles and bathroom furnishings presented at Cersaie. It reimagines the concept of a Bologna piazza as a space for interaction, networking and socialisation.

Due to the strong architectural connotation of the fair, there will certainly be no shortage of appointments with the big names in the international design scene.