cersaie 20 23

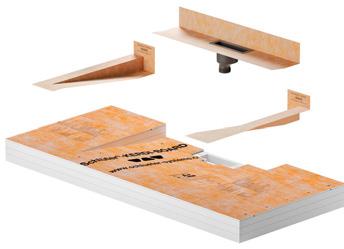

Maximum flexibility and individual design: Schlüter-KERDI-BOARD-W opens up the easiest way to a designer washbasin. The prefabricated element made of KERDI-BOARD is extremely light, can be freely cut to size and can be immediately covered with tiles. The set includes all relevant waterproofing components, the connection thread for traps and offers KERDI-LINE-VARIO drainage profiles a perfect fit. The Schlüter washbasin is suitable for installation in niches or wall ceilings and allows free-floating installation with wall brackets. schluter.com

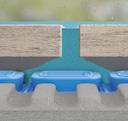

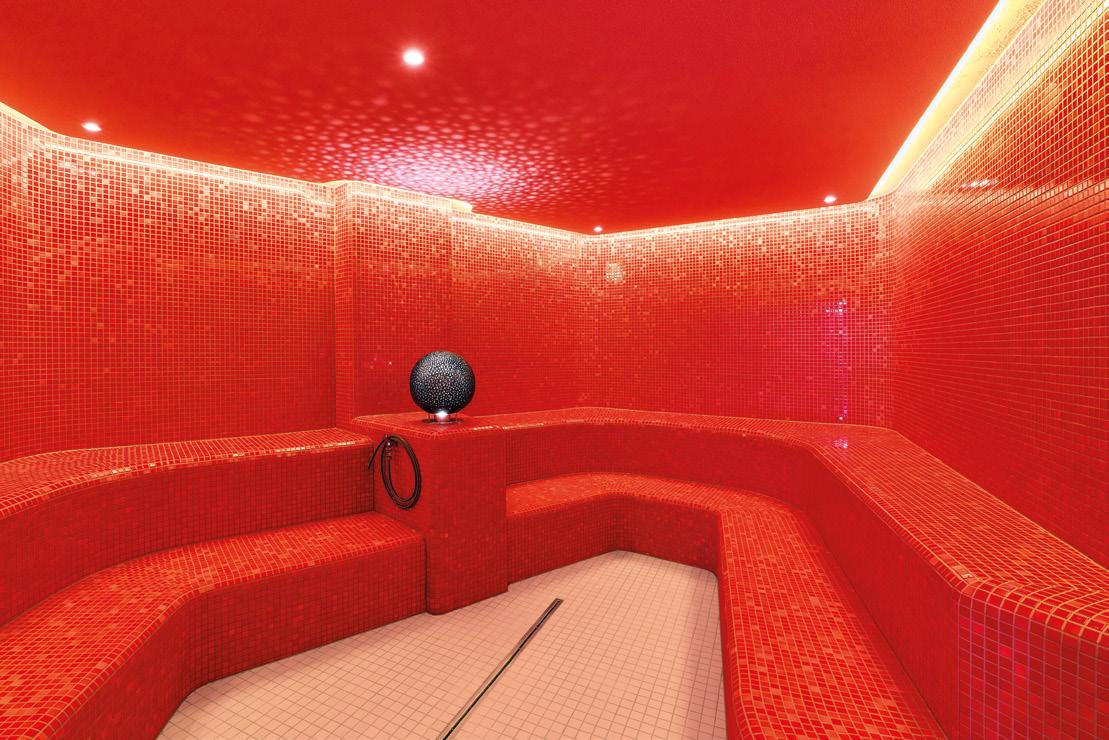

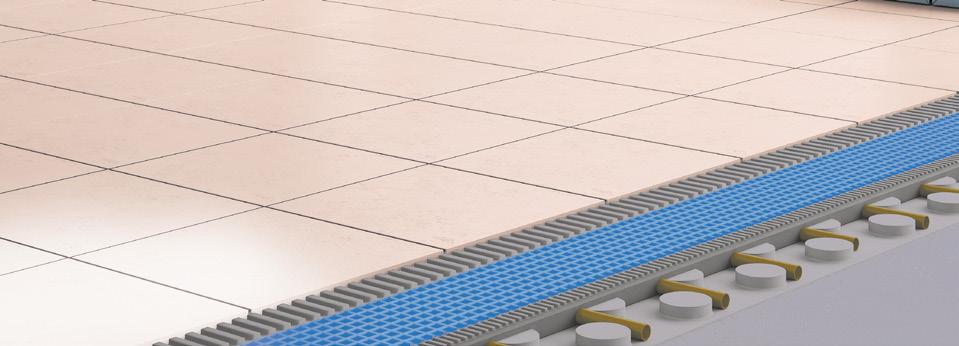

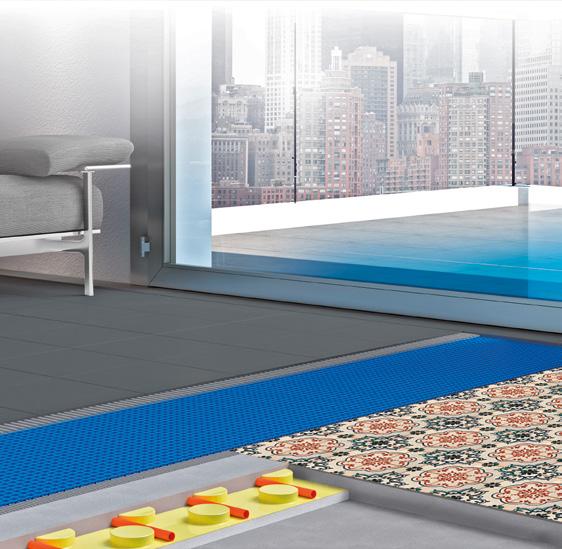

The importance of saving energy is obvious - the solution for this is on the wall and on the floor. With Schlüter-BEKOTEC-THERM and Schlüter-DITRA-HEAT-E, we have developed two pioneering surface heating systems that make energy efficiency simple. In combination with renewable energy sources, the sustainable heating systems from Schlüter-Systems efficiently and precisely provide cosy warmth on walls and floors.

schluter.com

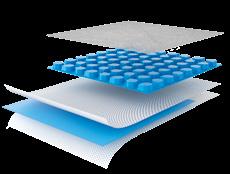

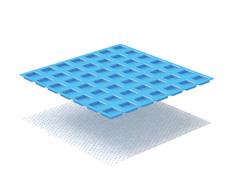

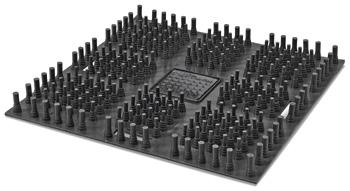

PRODESO ® HEAT GRIP 5 and PRODESO ® HEAT GRIP 8 are floor and wall heating systems with electric heating cables. Both systems are composed of a polyethylene membrane, electric cables of various lengths, a touch screen and wi-fi thermostat. The membranes, uncoupling, waterproofing and vapour management with thickness 8.5 and 5.5 mm, guarantee a correct anchoring of the heating cable. The latest generation thermostat, touch screen and wi-fi, allows personalized programming even remotely. The 5.5 mm diaphragm is also available in the adhesive version “PRODESO ® HEAT GRIP 5 STICK”.

A New evolution with the goal of flexibility, innovation and energy efficiency.

PUBLISHER:

Kairos Media Group S.r.l.

Capitale Sociale: Euro 51.400,00

R.E.A. 329775

Periodico bimestrale registrato presso il Tribunale di Modena al n. 22/17 in data 10/08/2017

Iscrizione al ROC n. 9673

OFFICE:

Kairos Media Group S.r.l. Via Fossa Buracchione 84 41126 Baggiovara (Modena) - Italy

Tel. +39 059 512 103 - Fax +39 059 512 157 info@tiledizioni.it - www.surfacesinternational.com

EDITOR AND PUBLISHING COORDINATION:

GIAN PAOLO CRASTA - g.crasta@tiledizioni.it

© 1989 Tile Italia

CO-EDITOR:

Sabrina Tassini

CONTRIBUTING EDITORS:

Sara Falsetti

Paola Giacomini

Sabino Menduni

Chiara Poggi

Sabrina Tassini

SECRETARIAT: info@tiledizioni.it

GRAPHIC LAYOUT:

Sara Falsetti

EACH COPY:

Euro 4

SUBSCRIPTION:

www.tiledizioni.it/subscription

• Italy, 1 year: Euro 50

• Abroad, 1 year: Euro 70

• Italy, 2 years: Euro 70

• Abroad, 2 years: Euro 90

L’abbonamento decorre dal mese di distribuzione. Tariffe speciali per gli abbonamenti collettivi sono disponibili su richiesta Conto Corrente Postale 20026415 intestato a Tile Edi-

zioni srl. Spedizione in abbonamento postale presso la Filiale di Modena. L’IVA sugli abbonamenti, nonché sulla vendita dei fascicoli separati, è assolta dall’Editore ai sensi dell’art 74 primo comma lettera C del DPR 26.10.72 N. 633 e successive modificazioni.

ADVERTISING:

· +39 342 092 8002

• Silvia Lepore s.lepore@tiledizioni.it · +39 345 721 8245

• Elisa Verzelloni

e.verzelloni@tiledizioni.it · +39 338 536 1966

PHOTOLIPHIE:

Vaccari Zincografica Srl

Via E. Salgari, 61 - 41126 Modena - Italy

PRINT:

Faenza Printing Industries SpA Via Vittime Civili di Guerra, 35 48018 Faenza (RA) - Italy

http://www. .com INTERNATIONAL.COM

Tutti i diritti di riproduzione e traduzione degli articoli pubblicati sono riservati. E’ vietata la riproduzione anche parziale senza l’autorizzazione dell’Editore. Manoscritti, disegni, fotografie e altro materiale inviato in redazione, anche se non pubblicato, non verrà restituito. L’Editore non accetta alcuna pubblicità in sede redazionale. I nomi, le aziende e i prezzi eventualmente pubblicati sono citati senza responsabilità a puro titolo informativo per rendere un servizio ai lettori. La Direzione non assume responsabilità per opinioni espresse dagli autori dei testi redazionali e pubblicitari.

Entire contents Copyright Kairos Media Group Srl All right reserved.

Opinions expressed by writers are not necessarily those held by the publisher who is not held responsible.

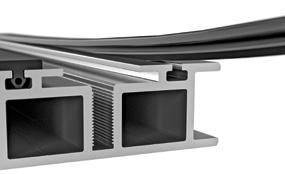

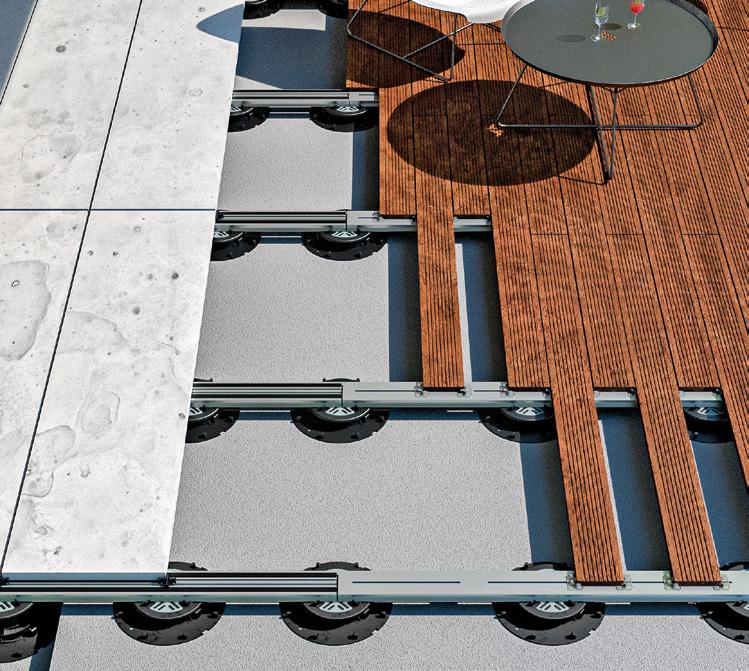

MINI SIZE, PRO PERFORMANCE.

HEIGHT RANGE FROM 25 TO 50 MM WITH A SINGLE PRODUCT THANKS TO THE INTEGRATED EXTENSION. ONE HEAD WITH DOUBLE FUNCTION: SUITABLE FOR TILE, DECKING AND RAIL.

NO MORE DIFFERENT AND NUMEROUS SUPPORTS BUT A SINGLE PRODUCT FOR ALL INSTALLATION SOLUTIONS.

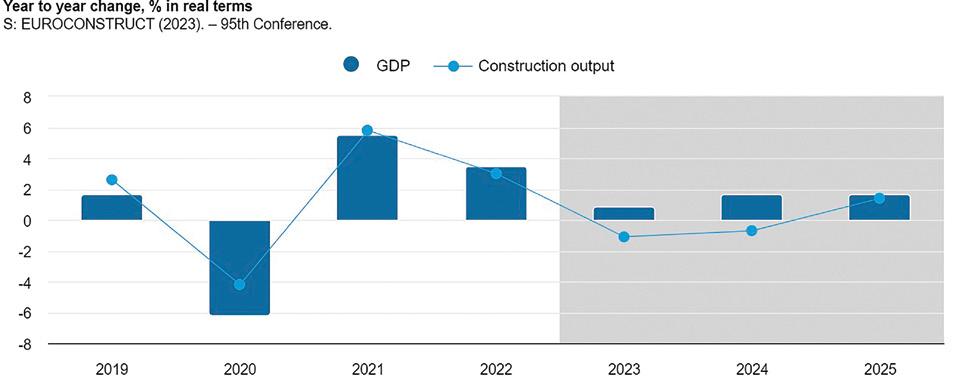

To provide a clearer understanding of how Europe’s construction sector is performing, we are publishing the overview and forecasts shared at the 95th Euroconstruct Conference, which reveal a downward revision of the prospects for the construction market.

After a record 2022, the Italian ceramic industry is also expected to see a downturn, on the basis of the figures for the first quarter of 2023, which clearly indicate the magnitude of the decline in global demand.

As we do every year, however, we are also publishing a report on Italy’s major ceramic manufacturers and the factors affecting their economic indicators, including an unprecedented focus on green investment and a look at the latest products they are unveiling at Cersaie, which always have the potential to set new trends.

Excitement is building, in fact, as we await the opening of this 40th edition of the trade show, whose new layout and cultural programme boasting major names from the world of international design confirm its credentials as an unmissable fixture for trade professionals from all over the world.

This issue’s interviews and product previews also include a selection of interesting case histories revolving around ceramic and the latest technologies for its installation.

Furthermore, in collaboration with surfacesinternational.com, which takes a 360° view of the coverings market, we publish a review of new materials for architecture and original projects, in which latest-generation coverings, in a wide range of guises, play a starring role.

Following its acquisition of Gardenia Orchidea and the French company Desvres two years ago, ABK Group is proceeding with its growth and expansion strategy.

As such, the Group recently announced the acquisition of a business division of the former Target Group based in Fiorano Modenese, complete with brands, plants and real estate in the form of a prestigious office building and a 6000 square metre factory complex (pictured). The Group will thus extend its brand portfolio with two top-end names, 14 Ora Italiana and Fuoriformato, both with a firm emphasis on design and decoration, thanks in part to their made-to-order products, which transfer artistic ceramic to large-format panels.

ABK Group is also proud to announce that its new line for the production of ex-

tra-thick Full Vein 3D slabs at the Solignano plant is now on-stream and is one of the most advanced and eco-sustainable production facilities in the world. Backed by 20 million euros of investment in research and innovation, this technological upgrade will make it possible to manufacture through-vein slabs, by means of controlled digital mixing of various coloured raw materials, giving the Group a production capacity of 13 million square metres per year.

“This progression,” explained Roberto Fabbri, Chairman of ABK Group, “will enable us to achieve the expansion that we’ve been striving for by means of substantial investments in recent years, and to set up a sales centre with showrooms dedicated to all the Group’s brands. This marks another important step towards our repositioning in the ceramic industry’s luxury segment.”

from Schlüter-Systems create new opportunities for tile installers – especially in conjunction with renewable energy sources and popular heat pumps. The company’s display at Stand A18-B17 in Hall 32 will highlight various assemblies of the thin-layer floor heating system Schlüter-BEKOTEC-THERM along with the electric floor and wall heating system Schlüter-DITRA-HEAT-E. Both generate pleasant warmth in little time due to their thin assembly and intelligent, low-energy design. At Cersaie, Schlüter-Systems will also present a new component that enables the electrical system to unfold its full potential, especially in energy-efficient buildings.

The Schlüter-Systems stand at this year’s Cersaie trade fair in Bologna will focus on intelligent system solutions for sustainable and energy-efficient heating as well as interior and exterior design options.

In times of global energy shortages, tiles are in greater demand than ever, as their excellent heat distribution qualities open up fresh perspectives for minimising energy consumption. The floor and wall heating systems

Florim publishes the 15th edition of Sustainability Report

Florim published the 15th edition of its Sustainability Report, the document that transparently describes the economic, social and environmental results achieved in 2022 and presents the objectives planned for the near future.

The document reports on a year full of new projects. Topping the list is the opening of flagship stores in Paris and Rome in addition to the other Florim spaces in the international design districts, arriving at a total of 10 by the end of 2023.

Also worthy of note is the first place earned in The Factory in the Landscape international competition promoted by UNESCO Clubs, for achieving ecological transition goals and respecting the landscape and environment.

The financial results for 2022 featured a consolidated turnover of €584 million, up more than 22%, and investments of €152 million, a significant increase compared to the previous year. Over the past 11 years €58 million has been invested in environmental sustainability measures, of which around €8 million in 2022.

With regard to the environment, in ad-

dition to the 129,388 tonnes of CO2 not emitted since 2012 (of which 18,346 in 2022), of particular interest is the launch of a decarbonisation project that envisages measuring the impact of the company’s operations in order to implement a strategy of progressive emissions reduction. In 2023 the company launched an e-mobility pilot project for the transport of slabs between the Mordano and Fiorano plants, which, thanks to the use of electric trucks, will result in the avoidance of about 560 tonnes of CO2 emissions per year. And of course we can’t forget the new 4.5 MWp photovoltaic plant in Mordano, bringing the company’s total output to 12.3 MWp of power from 64,000 m2 of installed panels. Initiatives in the area of social responsibility continue with a focus on employees and the local community thanks to the contribution of the Ing. Giovanni Lucchese Foundation. Among the most interesting activities those of the Florim Health & Training Centre for doctors, employees and the local region (started in 2021). In 2022 the company celebrated 10 years since the launch of the Summer Camp project and initiated a collaboration with the MAXXI Museum in Rome.

The impact report that the company draws up each year as a Benefit Corpo-

ration detailed the following objectives for the future: the renewal of B Corp certification, reduced consumption of water, raw materials and emissions, the installation of more solar panels and the definition of a new agreement with the Sassuolo Hospital for the benefit of employees and the local area.

As part of its drive to reduce its energy consumption and environmental impact, Brevetti Montolit recently signed an agreement with GNC, a historic supplier of blister packaging, under which it will return the cartons it uses for its packaging to their manufacturer. This virtuous cycle will cut the amount of cardboard the company uses by about 2,000kg per year, while also significantly reducing the amount of space and time it allocates to storing and disposing of it.

This latest initiative forms part of Brevetti Montolit’s environmental, social and governance programme, and will help the company achieve some of the goals it set in its 2023 Sustainability Report.

The Geberit Group posted net sales of CHF 893 million in the first quarter of 2023, an 8.9% decrease on the previous year’s figure (adjusted for negative currency effects, the decrease came to 4.3%).

These figures were positively impacted by price increases of around 12%.

The decline in volume was primarily due to the record-high figures in the same quarter in the previous year and, to a lesser extent, the now completed reduction of excess inventories at wholesalers and a slowdown in the renovation business. In some European countries, there was also a shift in demand from sanitary to heating solutions due to the energy crisis.

In total, operating cashflow (EBITDA) fell by 2.5% to CHF 296 million.

The EBITDA margin increased by 220 basis points to 33.1% compared to 30.9% in the same period in the previous year.

Regionally, currency-adjusted net sales in Europe fell by 6.0%, in the Far East/Pacific by 7.7% and in America by 1.3%. In contrast, the Middle East/ Africa region saw growth of 37.4%. All three product areas reported losses: Installation & Flushing Systems 5.8%, Bathroom Systems 4.6% and Piping Systems 2%.

Given the challenging environment facing the construction industry, the forecasts for the current year remain cautious.

However, Geberit’s management is convinced that it can continue to achieve its medium-term targets of average annual net sales growth in local currencies of 4% to 6% and an average EBITDA margin of 28% to 30%.

Having signed a joint venture agreement with the chemicals group Pidilite Industries Ltd in 2019, Litokol Spa, which has been manufacturing adhesives, sealants and special products for ceramics and construction for over 50 years, opened a new production facility in Amod in the Indian state of Gujarat at the beginning of June. On the same day that the ribbon was cut at the new Litokol plant, Pidilite took the opportunity to inaugurate two other new production facilities connected with natural stone and coverings installation products.

Litokol’s new facility in India is equipped with a technologically advanced production plant, which produces epoxy, polyurethane and other reactive two-component products for the ceramic and construction industries. Indian production will focus on Starlike® EVO, the most advanced epoxy grout on the market, developed on the back of continuous evolution and multiple international patents. On the basis of this transfer of Italian technology and know-how, Pidilite Industries is now acting as sole distributor on the Indian market, thanks to its well established network and the extension of the ROFF range, specialising in products for ceramic and construction.

Halcón Cerámicas Group, one of the global leaders in the production of ceramic tiles based in Spain celebrates 60 years with its entry into the 23rd position in the world ranking of manufacturers. With a turnover of over 250 million euros, although currently facing a difficult time for the sector and the global economy, Halcón Group faces the future by betting on technological innovation and expansion in all markets.

The significant improvements to the facilities have been a great boost for updating the product range of the Group’s three brands: Halcon Cerámicas, Emotion Ceramics, and Cicogres. Over

60% of the current range consists of high-value-added products: the company offers large formats such ascm 75x150, 120x120, 100x100, and a wide variety of polished and rectified products.

As a novelty for this new edition of Cersaie 2023, Halcón launches products with different effects and finishes, results of investment in new machinery to produce granilla effects and lappato finishes.

The strategic choice of constantly investing in technology to achieve innovative products proves to be crucial to ensure the future growth of the Group, to offer customers products with great added value and differentiate from the competitors.

Cersaie,” continues Spagni, “are the result of our commitment to offering all our customers a comprehensive range of modern ceramic coverings, made entirely in Italy, from conception to finished product, that offer technical excellence and trend-setting style.”

Italy’s newest ceramic manufacturer, formed in 2019 and based in Fiorano Modenese, is taking part in Cersaie in Bologna (Hall 25, Stand A242) with a newly designed booth and a host of new products, including marble-, stone-, wood- and concrete-effect tiles, exotic tropical foliage wallpaper patterns and much more.

Andrea Spagni, the company’s President and main shareholder, has a few specific ideas in mind as he gears up for the trade show: “We are approaching this milestone edition of Cersaie, marking the trade show’s 40th anniversary, in the wake of another year of growth, which has seen our revenues rise to 41 million

euros, from less than half that figure in our launch-year four years ago. But this is still not a destination, it is just a solid result that will encourage us to carry on pursuing our ambitious growth plans with commitment and determination.

We are still investing in the Fiorano facility and we are currently working sideby-side with our technical partners to equip ourselves with an atomisation and co-generation plant. At the same time, we are constantly working to bring our new products and new image to international markets, by proceeding with a fullscale upgrade of our product offering, so as to be able to approach the main sales channels, from major dealers to retailers, with the confidence that we are on track to achieve ever greater success.

The new series that we are bringing to

“Ghost Stories: The Carrier Bag Theory of Architecture” is an exhibition curated by Sevince Bayrak and Oral Göktaş, that the Turkish Pavilion, coordinated by the

Istanbul Culture and Arts Foundation (İKSV), co-sponsored by Schüco Turkey and Vitra, and staged with the contribution of the Ministry of Culture and Tourism and the patronage of the Ministry of Foreign Affairs of the Republic of Turkey, is presenting until 26 November 2023 at the 18th International Architecture Exhibition – the Venice Biennale.

Ghost Stories: The Carrier Bag Theory of Architecture challenges widely accepted perceptions and approaches to building, with a view to unearthing solutions that promise greater hope for the future. Özgen Özkan, CEO of Eczacıbaşı Building Products, the group to which the VitrA brand belongs, explained: “The catastrophic earthquake that recently hit Turkey highlighted the immense responsibility that falls to all actors in the construction sector. As we mourn our losses, we must give priority to preserving the past while building the future. This year’s exhibition reflects on this tragedy by calling for a new perspective on building, while stressing the need to protect existing structures and create new ones. The cycle of demolition and reconstruction not only damages nature and our heritage, it also puts severe strain on already limited resources. We urge all stakeholders to give top priority to sustainable, responsible practices. As a brand committed to these values, we are proud to support the Turkey Pavilion – an important initiative that we have been sponsoring since 2014.”

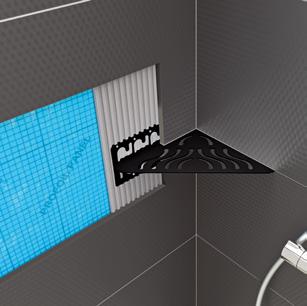

Progress Profiles, the Treviso-based company specialising in the production of technical and decorative finishing profiles and installation systems, will be taking part in Cersaie 2023 (stand A15, hall 31) to present Black Line, a range of lacquered aluminium profiles designed to complement the growing trend for

bathroom furnishings made with industrial-inspired materials.

The Black Line also features PROSHOWER PROFILE, which is designed to protect showers, bathtubs and walls, while accentuating their character. PROSHOWER PROFILE is an AISI 304/1.4301-V2A stainless steel profile with a sloping visible surface with a gradient of 2%. Ideal for floor-level showers, it protects the edges of the floor covering and decorates the visible part of the screed. Featuring a special section designed for simple, practical installation, it is suitable for use with any type of material. In addition to this model, the range includes PROSHOWER TOP DESIGN, a shower channel grille with ultra-matt finish and elegant undulating drainage slots, and PROSHELF steel and aluminium shelves. Available in different lengths, the grille can be paired with any of the vast range of Progress Profiles drainage channels, to bring a touch of dynamism to the shower tray. The shelves, available in triangular and rectangular versions, are designed as handy, spacious storage surfaces for bathroom products, to ensure maximum practicality combined with the elegance of matt black.

The range includes various other profiles in different styles, sizes and finishes, all designed to add character to other areas of the home. These include the right-angled PROJOLLY SQUARE and the quarter-circular PROJOLLY QUART, both made of AISI 304/1.4301V2A stainless steel; and the L-shaped PROTERMINAL in AISI 316L/1.4404V4A stainless steel, which is available in three different heights. These models are ideal for protecting the outer corners of wall tiles and finishing their perimeters. They can also be used as joining profiles between the tread and the riser on ceramic and natural stone staircases. Their special section and the fact that they can be used in conjunction with internal and external capsules,

joints and closure caps make them functional and versatile solutions for a perfect finish in every situation. Lastly, the F-shaped PROLISTEL CHANNEL, made of AISI 304/1.4301-V2 stainless steel, is designed to embellish ceramic and natural stone coverings and can be used as a profile for housing a glass shower screen. Its special section makes it possible to create a decorative joint that can also be used as a track for the floor- and wall-mounting of glass panels.

Grupo Lamosa’s financial results in the first quarter of 2023 were impacted by the volatile global macroeconomic environment coupled with a slackening of markets as demand returned to its normal pre-pandemic levels. Sales fell by 6% compared to the same quarter in 2022 to MX$8.3 billion (more than €421 million at the 31/3/23 exchange rate).

The San Pedro Garza García-based multinational, Mexico’s largest ceramic tile manufacturer and one of the top three global players, continued to generate the majority of its revenues (60%) in the domestic market with sales of MX$4.97 billion, down 4% on the first quarter of the previous year. However, the slowdown was most significant in export markets, where the group reported a 9% decline in sales to MX$3.33 billion in the first quarter of 2023 compared to MX$3.6 billion in the same period in 2022.

Lower revenues combined with higher costs and expenses reduced the absorption of fixed costs and impacted operating margin or EBITDA (down 20% to MX$1.82 billion) and consequently operating income EBIT (down 26% to MX$1.51 billion). Inevitably, this also impacted net income, which fell by 31% to MX$1.09 billion.

Sales in the floor and wall tile business (which accounts for 73% of the group’s total sales) contributed to the negative first-quarter result, dropping by 9% compared to the first quarter of 2022 to MX$6.05 billion (about €307 million). This business was hit by the reduction in demand in all countries in which Grupo Lamosa operates: Mexico, Colombia, Peru, Argentina, Chile, Brazil and Spain, as well as the United States.

The adhesives business, which accounts for 27% of total group sales, posted 3% growth in revenues to MX$2.25 billion (compared to MX$2.17 billion in the first quarter of 2022) following incorporation of Fanosa operations.

Despite the slowdown in business, the group led by Federico Toussaint Elosúa continued its investment plan in the first three months of the year with a total of MX$485 million (more than €25 million) invested primarily in capacity expansions and technology upgrades for its various plants and in information technologies.

In the first three months of the current year, Grupo Lamosa continued the process of consolidating and optimising the acquisitions of Fanosa and Roca Tiles that began in 2022, a truly exceptional year for the group in terms of its economic and financial performance.

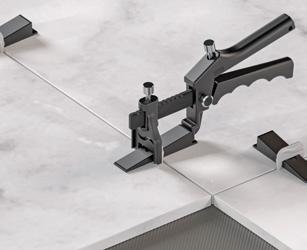

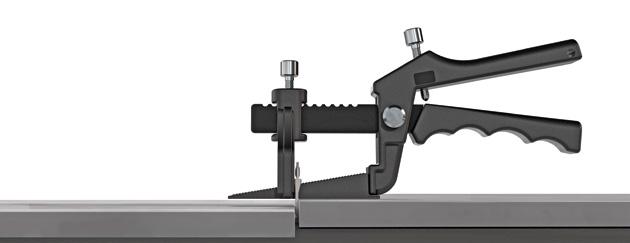

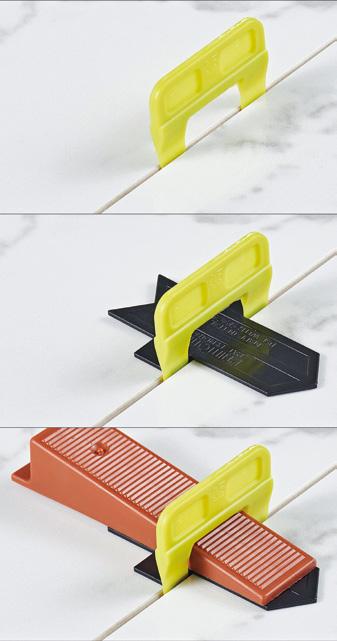

impertek presents the new LevelOut tile levelling system at cersaie

The new LevelOut tile levelling system is an essential tool for floor and wall tile installation and ensures a flat, uniform surface.

LevelOut consists of three elements: a reusable wedge with a special knurled surface, a disposable linear spacer which creates a 1 or 2 mm joint thickness when placed between the tiles, and a levelling gripper suitable for tiles of any thickness. Once installation is

complete, the levelling system is quick and easy to remove simply using a mallet or by kicking the wedges along the direction of the joint. The LevelOut system is also equipped with an optional anti-scratch disc which protects the surface from scratching during installation. LevelOut has an intuitive design that makes it easy to position each element correctly. This ensures perfect tile alignment both horizontally and vertically and guarantees a uniform end result.

To achieve consistent and sustainable growth, SOMANY Ceramics has put in place a robust expansion and investment plan in place. In last 24 months the company has invested 73 million USD and has increased its capacity by 25% capacity. SOMANY has allocated significant resources towards research and development, enabling it to continuously innovate and introduce new product lines that resonate with customers. Additionally, it is investing in advanced manufacturing technologies to enhance productivity, improve operational efficiency, and meet the increasing demand. The business decisions are centered on expanding the prod-

uct portfolio, offering a wide range of designs, textures, and sizes, and providing innovative solutions that cater to the specific needs of each target group across the world.

With a legacy of over 50 years, SOMANY Ceramics is ranked among world’s largest tile producers, manufacturing 75 million square meters annually. SOMANY exports to 55+ countries across 6 continents and has 15 modern manufacturing facilities in India. With 500+ exclusive outlets and 15,000+ dealers and sub-dealers in India, the company is a leading brand in the Indian market, winner of the “Most Desired Tiles Brand” title in India.

Apart from superior products, SOMANY is known for exceptional customer service and support, ensuring a seam-

less experience for both customers and channel partners. ADVERTISING

The continuation of the war in Ukraine and the severe energy crisis, along with the sudden changes in monetary policy, were initially pointing towards a recessionary outlook for the European economy. However, in recent months, it has

performed better than expected due to lower energy prices, reduced supply constraints, improved business confidence, and a strong labor market.

In 2022, for the European construction sector a growth of

The factors that explain the gradual slowdown in growth, leading to a contraction in construction spending levels in 2023, have been developing and solidifying over time, such as weaker momentum of the global economy, inflation, change in monetary policy direction and the consequent rise in interest rates.

The latest forecast now projects a decline of 1.1% this

3% is confirmed, within an overall expansionary economic environment. In contrast, the new forecast for the European construction sector has been revised downward, with a shift from the previous assumption of stagnation in 2023 to an anticipated

year, followed by a further contraction of 0.7% in the subsequent year, highlighting the challenging outlook for the construction industry whose expectations of recovery have been postponed to 2025.

The sharp rise in inflation in 2022, caused, among others, by the energy crisis, forced central banks to raise

reduction in volumes. Risks and uncertainties impeding the growth of the European construction market have been discussed at the 95th Euroconstruct Conference, that was held on 8-9 June 2023 in Amsterdam.

interest rates sharply and, as a result, worsened the ability to finance housing investment. Mortgage interest rates have doubled in most European countries in 2022 and tripled in Finland, Slovakia, Switzerland and the UK. According to the current forecast, total residential output in 2023 in the Euroconstruct countries will be lower than in 2022. The shrinkage is foreseen to continue for yet another year.

EC-4 countries (Poland, Czechia, Hungary, Slovakia) are predicted to witness a bigger decrease in residential construction output than the EC-15 countries (see table). Recovery for both regions of Euroconstruct might start in 2025.

The clear slowdown of economic growth will undermine non-residential construction in the next few years. In 2022, the output of total non-residential construction increased compared to the 2021 level.

Last year total non-residential construction accounted for 29.2% of total construction output across the Euroconstruct network. Growth projections for output in the field have remained the same as in the previous report (November 2022). A slight growth is forecast for this year, while growth will likely pick up marginally in the remaining period. Production output is prognosticated to exceed the 2019 pre-pandemic level in 2025.

The impact of the business cycle is smaller for civil engineering due to many long-term projects and a high share of activities financed by the public sector. Multinational funds in the EU have generally been a stabilising factor. Additionally, in economic downturns, governments often implement economic stimulus packages for the construction sector which contained maintenance and improvements of existing infrastructures as well as new infrastructure projects.

The growth rates of civil engineering works outperform the development in the building sectors and show continuous positive growth from 2021 until the end of our forecast period. The annual growth rates projected for 2023-2025 are rather moderate, though.

In a market that has been contracting sharply since 2022, the huge success of Expo Revestir last March came as a bit of a surprise. Held for the first time in

the new venue of Sao Paulo Expo, the number one trade fair for the Brazilian ceramic industry and the sector’s most important show anywhere in Latin America broke

“We weren’t expecting this degree of success, which was probably down to a number of different factors,” confesses Benjamin Ferreira Neto, Past President and now Vice President of the Brazilian ceramic tile manufacturers’ association Anfacer.“Key aspects included the novelty of the new location and the new format of the International Forum Expo Revestir (FIER+), which provided more space for new themes such as art, innovation and sustainability alongside the traditional areas of retail, architecture and design. And despite the domestic market contraction, Expo Revestir remains the event that marks the beginning of the new year in our industry’s calendar, an unmissable opportunity for professionals such as architects and distributors to get a close look at the latest innovations.”

In what is expected to be another challenging year, we discussed the health of Brazil’s ceramic industry with Benjamin Ferreira Neto and Mauricio Borges, CEO of Anfacer and Expo Revestir.

Tile International: After an exceptional 2021, Brazilian tile sales experienced a severe slowdown in 2022.

attendance records with more than 85,000 trade visitors (60% up on the previous year), including international professionals from 59 countries. The 62,000 square metre

What were the causes of this?

Benjamin Ferreira Neto: The fall in demand in the Brazilian domestic market - our most important outlet as it absorbs between 80% and 90% of our production - began to be felt as early as January 2022 in parallel with the rise in inflation (which reached 10% last year but is now falling) and in interest rates, which the Brazilian Central Bank raised to the current figure of 13.75%, the highest level since 2016. After growing steadily over the years to reach a record 902 million square metres in 2021, Brazilian tile consumption plummeted by 18.3% to 736 million square metres last year. To avoid accumulating excessive inventory, production was also reduced by around 12% to 929.6 million sqm.

Tile International: What about exports?

B. Ferreira Neto: Total exports amounted to 113 million sqm, lower than the record figure of 130 million sqm reached in 2021 but still the second best result ever in volume.

In value terms we reached $513 million, 5% more than

exhibition floor (twice the area available in 2022) was packed out as more than 300 brands presented their new 2023 collections at what has always been the first major business and networking event of the year.

in 2021 thanks to a rise in average price from $3.74/sqm to $4.53/sqm. In the United States, our largest export market, the sharp increase in transport costs made Brazilian products less competitive, resulting in a decline in sales in volume from 23.5 to 20.6 million sqm, although sales increased by 2.9% in value to US $119 million.

Tile International: What impact have the energy crisis and rising production costs had on your industry?

B. Ferreira Neto: In 2022, the cost of gas in Brazil increased by 60%, whereas electricity costs rose by just 20% due to locked-in contracts.

We were unable to pass on the higher costs to the selling price of our products because we had already raised our prices at the end of 2021 after the year’s very strong demand had depleted warehouse stocks. This year, with energy costs falling and the market still slug-

gish, we are lowering our sales prices again.

Tile International: What is your outlook for 2023?

B. Ferreira Neto: In March, Expo Revestir recorded a positive trend in orders, but we believe that this does not change the general market situation, which as I said is still slowing down. Based on the first quarter results, we are expecting to see a further contraction in both domestic and export sales in 2023 and consequently also a further decline in total produc-

tion. The Brazilian real estate market is currently hampered by very high mortgage rates, which are slowing down house purchases and consequently ceramic tile sales, but we are convinced that the recovery will begin as soon as borrowing costs start to fall. Many of us believe that signs of improvement will emerge as early as the second half of this year. In this scenario, the Lula government has also made a positive contribution by reviving the Minha Casa Minha Vida social housing programme to combat the country’s chronic housing shortage. For example, in the metropolis of São Paulo alone, the planned investment for 2023-2024 is around R$8-9 billion.

Tile International: What is your medium-term outlook?

Mauricio Borges: Despite the current situation, our

industry is strongly focused on the future. As part of a forward-looking approach, we are investing energy and resources in a ten-year programme launched by Anfacer in 2020 and based on three pillars: sustainability, competitiveness and design. In terms of environmental sustainability, the sector has already achieved some of the world’s lowest levels of gas, electricity and water consumption and is currently introducing biomethane. It is also looking into the potential future use of hydrogen. As for process and design technology, we are also well positioned to compete in international markets with innovative materials. So yes, we can be confident about the future of our companies and a market whose appeal has been demonstrated over the years by the arrival of major multinational groups, which in turn have contributed to raising the industry’s level of expertise.

Total revenues of 8.7 billion euros, representing a rise of 16% on 202 1: this is the new record reached at the end of 2022 by the Italian

ceramic industry as a whole, which comprises a total of 259 companies and 26,500 direct employees operating in the industry’s six

different production sectors, namely tiles and large-format panels, sanitaryware, tableware, refractory materials, bricks and technical

As anticipated in forecasts drawn up last December, the results achieved by Italy’s 128 manufacturers of ceramic tiles and large-format panels in 2022 show that the volumes produced and sold remained broadly unchanged, while revenues rose significantly.

Production amounted to 431.2 million sq.m – the second highest volume since 2008 – down by just 0.9% from 435 million in 2021. Total sales – 449 million sq.m (down 1.4% on 2021) – are composed of sales on Italy’s domestic market (92.7 million sqm, up 1.7%), which is still riding the wave of a vigorous upturn in construction and renovation work, and exports, amounting to 356.2 million sqm (down 2.2% on the 2021 figure of 364 million), which are among the highest volumes recorded over the past 15 years. The increase in list prices in response to sky-rocketing production costs (first and foremost energy) paved the way for Italian ceramic manufacturers to close 2022 with

total revenues of 7.2 billion euros (up 16.5% on the 2021 figure of 6.2 billion). The 2022 figure comprises 1.2 billion euros from the domestic market (up 25.6%) and 6 billion from exports (up 14.8%), which is also a record high. By the end of last year, the average selling price had risen from 10.6 euros per sqm to 12.43 euros per sqm on the domestic market, and from 14.3 euros per sqm to 16.76 euros per sqm on the export market (compared to about 10 euros and 8 euros for Spanish and Turkish manufacturers respectively).

The positive results deriving from the internationalisation of production also warrant attention: foreign companies operating in Europe and North America but controlled by Italian groups have generated revenues of over 1 billion euros.

Last but not least, investment continued to rise significantly in 2022 (up 25.6% in the wake of a 73% rise in 2021), to reach 441.3 million euros, or 6.1% of the industry’s total revenues.

ceramic.

Such is the picture that emerges from the Confindustria Ceramica National Statistical Survey

presented at the Annual Members’ Meeting on 14 June. It confirms, beyond question, the leading role played by the tile

sector, which – with revenues of 7.2 billion euros – accounts for 83% of the industry’s total turnover.

As forecast, the figures for the first quarter of 2023 have given a clear idea of the extent of the downturn in global demand, which had already made itself felt in the second half of the previous year.

Giovanni Savorani, Chairman of Confindustria Ceramica, gave his analysis of the figures, almost all of which had seen a double-digit decline: compared to the first quarter of 2022, exports of Italian tiles fell by 25% by volume and 13% by value, across all markets; the

volumes sold in Italy also fell by about 10%, while rising in value by a few percentage points.

“After the incredible performance of the first six months of 2022,”

Giovanni Savorani points out, “there can be no doubt that a return to lower values was predictable, even though the reason for the downturn lies mainly in the profound change in the global scenario, marked by sharply rising interest rates, stubbornly high inflation, the end of the post-lockdown spending spree and a dip in consumer confidence. Against this backdrop, in-

ternational competition is becoming fiercer, and the Italian and European industry are paying close attention to ensure that all exporters, including those in India and China, apply the rules of fair trade.”

The Chairman of Confindustria Ceramica confirmed that the drop in electricity and thermal energy prices was a boon for the sector, adding however that “All the structural problems are still unresolved, such as the absence of implementing decrees to increase national gas extraction by 2 billion cubic metres for the benefit of gas-hungry industries, and a reform of the ETS that is set to increase the competitive penalties faced by EU industry.”

For ceramic manufacturers, the ETS, which was formulated for the laudable purpose of facilitating decarbonisation, has proved ineffective and counter-productive in terms of environmental benefits, and actually had a regressive effect on the industry. “Current CO2 prices,” points out Savorani, are hovering around 85 euros per tonne, up from 25 euros as recently as June 2019. Even the ‘Fit for 55’ plan, aimed at structurally reducing emissions, adversely affects the competitiveness of our sector, because our production facilities have already achieved all the possible efficiency gains, and alternative technological solutions are not currently feasible.”

In this regard, Savorani confirms that testing on the electrification of production processes is already under way, but operating costs are still very high, in the same way that producing H2 is still unaffordable in terms of the electricity it requires.

Savorani believes that performance over the year as a whole is still difficult to forecast, but remains confident that things could turn around in the second half of 2023, coinciding with the upcoming 40th edition of Cersaie in Bologna.

Along with the results for the ceramic tile sector, during its annual meeting Confindustria Ceramica also presented the 2022 results for Italian producers of sanitaryware, tableware and porcelain, refractory materials and bricks and roof tiles.

The Italian ceramic sanitaryware sector (30 companies, including 27 located in the Civita Castellana cluster in the province of Viterbo, with 2,652 direct employers) produced 3.6 million pieces, generating revenues of €397

million (+7.6% on 2021), 40% of which came from exports (€156.8 million).

Refractory material production decreased to a volume of 301,000 tonnes and revenues of €373 million (-2%). This included €151 million from Italian domestic sales and more than €222 million from exports. The Italian refractory materials industry consists of 30 companies with a workforce of 1,639 employees.

Italian brick and roof tile production picked up again in 2022 to 4.5 million tonnes of products (+2.2%). The 62 companies in the sector (with a workforce of 3,000 people) generated revenues of €700 million (up from €500 million in 2021), mostly in the Italian market.

Finally, the 9 companies making up the Italian ceramic tableware industry registered a fall in both production (9,900 tonnes) and sales (9,400 tonnes). Domestic sales accounted for 75% of the total. The 2022 turnover totalled €60.1 million ).

In keeping with its annual tradition, TILE INTERNATIONAL is publishing a preview of of the 2022 REVENUES of the leading Italian ceramic tile manufacturers.

For the sake of completeness, we open with a list of Italian ceramic companies/groups with revenues

of up to 13 million euros, before moving onto the full details provided directly by the companies themselves.

The 2021 data was extrapolated from public sources and provided by MECS (www. mecs.org) on the basis of Orbis data, whereas the 2022 data

were given to the publisher by the companies concerned. The pages that follow provide a series of focus boxes on the individual companies that answered our questionnaire. This year’s questionnaire was more extensive than previous editions, with a view to providing a more

FATTURATI 2022 Copyright Kairos Media Group - div. Tile Edizioni

No part of this publication may be reproduced without the express permission of the publisher - All values are expressed in millions of euros

detailed overview of the state of the industry, with particular regard to the increasingly important issue of the Green Economy.

The focus boxes therefore only include the companies that chose to submit their data and only contain the information that they chose to

share with our readers. They do not include any companies that opted not to respond to the publisher’s request.

Two points require explanation. Firstly, we open with the results of Mohawk Industries Global Ceramics, but have left them out of the league table. Mohawk is the world’s largest

manufacturer of ceramic tiles, and has owned Marazzi Group since 2013 and Emilceramica since 2017.

Secondly, Concorde Group is absent from the list because we have no data about the group, but it is unquestionably one of the top players in the industry.

These revenues were generated through the following companies and/or brands:

(All markets) • AMERICAN OLEAN (North America)

DAL-TILE (North America)

PRODUCTION FACILITIES IN ITALY: 6

FLAGSHIP STORES IN ITALY: 4: Milan, Sassuolo

KAI GROUP (Bulgaria, Romania)

FLAGSHIP STORES WORLDWIDE: 11: Castellon, Madrid, London, Cannes, Paris, Lyon, Warsaw, Athens, Hamburg, Split, Dubai

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Co-generation plants.

ESTIMATED CO 2 REDUCTION: -29,000 tons

ENVIRONMENTAL CERTIFICATIONS: ISO 17889-1

SUSTAINABILITY REPORT: ✔ Mohawk Industry Corporate Sustainability Website > mohawkind.com/corporate-sustainability/ > 2021 ESG Report

These revenues were generated through the following companies and/or brands:

• FLORIM CERAMICHE SPA SB (FLORIM, CEDIT- Ceramiche d'Italia - FLORIM stone)

• FLORIM USA INC. (MILE@stone)

PRODUCTION: 33 MLN MQ

PRODUCTION FACILITIES IN ITALY: 1 in Fiorano Modenese (MO) 1 in Mordano (BO)

FLAGSHIP STORES IN ITALY:

EMPLOYEES:

PRODUCTION FACILITIES

FLORIM: 1 in Milan - 1 in Rome

CEDIT: 1 in Milan

N° 1,510

WORLDWIDE: Production facility and logistics centre in Tennessee (USA)

FLAGSHIP STORES WORLDWIDE: Moscow - New York City - Singapore - Frankfurt - London - Abu Dhabi - Paris - Los Angeles

EXPORTS AS A PERCENTAGE OF PRODUCTION: 73% (figure calculated on the basis of the value of direct business, excluding revenues from production on behalf of third parties)

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY:

Thanks to two co-generators with a power rating of 14.4 Mwe and 64,000 sqm of photovoltaic panels with a total power rating of 12.3 MWp, on bright days FLORIM’s systems are capable of generating up to 100% of the electricity the company needs to run its Italian facilities.

In the absence of sufficient self-generated energy, FLORIM SPA SB has been procuring electricity exclusively from certified renewable sources since 2021.

ESTIMATED CO 2 REDUCTION:

Emissions of 18,346 tons of CO2 were avoided in 2022

ENVIRONMENTAL CERTIFICATIONS:

SUSTAINABILITY REPORT: ✔

Florim has been publishing a sustainability report for 15 years

UNI EN ISO 14001 for environmental management

• UNI EN ISO 50001 for energy management

• B Corp for overall sustainability. Various product certifications.

OTHER GREEN-RELATED INITIATIVES: The Italian sites have launched a decarbonisation programme designed to measure the impact of company activities and implement a strategy of gradual emission reduction.

In 2022, the company completed a study of alternative fuel sources for vehicles for goods handling and internal logistics. A pilot e-mobility project for the transfer of large-format panels between the Mordano and Fiorano facilities has been operational since mid2023 with two 100% electric trucks powered by self-generated energy from photovoltaic panels and co-generation plants.

In late 2022, FLORIM introduced changes to its industrial processes, which involved switching all the traditional 10mm products to a thickness of 9mm, which had a major impact in terms of sustainability.

In 2020, Florim introduced Florim Connections, an innovative digital technology designed to facilitate remote communication and enable the company to reduce the amount of travelling done by its sales force, thereby reducing transport-related emissions.

NEWS:

Selected as a candidate by the Modena Club per l’UNESCO, Florim took first place in “La Fabbrica nel Paesaggio”, an international urban design and landscape redevelopment competition run by the Italian Federation of UNESCO Clubs. The jury gave the following explanation for their choice: “Despite the adverse circumstances, this latest-generation factory has risen to the challenge of the ecological transition, by minimising its impact on the landscape, in accordance with the best practices of environmental integrity sustainable development.”

These revenues were generated through the following companies and/or brands: •

•

•

FIANDRE Architectural Surfaces

Fabbrica Marmi e Graniti • PORCELAINGRES (Germany)

CERAMICS (USA)

PRODUCTION:

EMPLOYEES:

PRODUCTION FACILITIES

WORLDWIDE:

• SEVENTYONEPERCENT

Porcelaingres (Germany) - Stonepeaks Ceramics (USA)

EXPORTS AS A PERCENTAGE OF PRODUCTION: 85%

SUSTAINABILITY REPORT: ✔

ENVIRONMENTAL CERTIFICATIONS: ISO 14001

• ISO 50001

• ISO 45001

• Cradle to Cradle Certified® Silver for coverings made in Italy

• LEED/BREEAM

• GreenGuard and GreenGuard Gold for materials

• EcoVadis.

The company also conducted a Life Cycle Assessment (LCA), the results of which are published in the Environmental Product Declaration – EPD® owned exclusively by us since 2017.

OTHER GREEN-RELATED INITIATIVES: The group is developing H2 Factory™, a factory powered by green hydrogen, for the production of 4D Ceramic.

Copyright Kairos Media Group - All values are expressed in mil/€

•

• EQUIPE CERAMICAS

•

PRODUCTION: 20.3 14.3 MLN. made in Italy, 6 MLN. made in Spain (Equipe) of which

80% floor tile 20% wall tile

PRODUCTION FACILITIES IN ITALY: 7 in Emilia-Romagna

EMPLOYEES: N° 1064 of which: 36% women 60% graduates and/or specialist

Technicians New hire forecast: : ✔

PRODUCTION FACILITIES

WORLDWIDE: 4 in Spain

EXPORTS AS A PERCENTAGE OF PRODUCTION: 72%

DESTINATION OF EXPORTS AND TOP 3 COUNTRIES BY MACRO-AREA

TRENDS

ITALIAN MARKET FORECAST 2023

TRENDS

EXPORT MARKET FORECAST 2023

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels and co-generation plants

SUSTAINABILITY REPORT: ✔

ENVIRONMENTAL CERTIFICATIONS: A+ > VOC emissions into the atmosphere

Content Certificate - ISO 50001

• EPD certificate

• EU EMAS

• ISO 14001

• Recycled

OTHER GREEN-RELATED INITIATIVES: Installation of new photovoltaic panels and incorporation of electric vehicles into the company’s fleet NEWS:

The group acquired Fondovalle in October 2022.

It obtained a patent for Advance, a porcelain tile collection certified as antibacterial, antiviral and MOCA for direct contact with food. This revolutionary technology, based on a sophisticated photocatalysis system applied to ceramics, produces surfaces capable of eliminating viruses, fighting bacteria, reducing pollution and indoor dirt, and attenuating odours.

The Group has invested in R&D and upgrades relating to Industry 4.0, and made advances in its social responsibility and corporate welfare programme. Italcer took 1st place in the 2022 Sustainability Award in October 2022 and ranked among the top 100 best companies in Italy in December 2022.

Copyright Kairos Media Group - All values are expressed in mil/€

revenues were generated through the following companies and/or brands:

EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels and co-generation plants

These revenues were generated through the following companies and/or brands: • LAMINAM

PRODUCTION FACILITIES IN ITALY: 1 in Fiorano Modenese (MO) - 1 in Borgo Val di Taro (PR)

FLAGSHIP STORES IN ITALY: 1 in Fiorano Modenese (MO) - 1 in Milan (MI)

EMPLOYEES: N° 930 of which: 36,4% women

New hire forecast: ✔ information technology, sales, technical department

PRODUCTION FACILITIES WORLDWIDE:

FLAGSHIP STORES WORLDWIDE:

1 Spain

1 Russia

2 Japan (Tokyo and Osaka) - 2 Cina (Quanzhou and Shanghai) - 1 Israel (Tel Aviv) - 1 Poland (Varsavia)

SHOWROOMS WORLDWIDE: 50

EXPORTS AS A PERCENTAGE OF

PRODUCTION: 79%

DESTINATION OF EXPORTS AND TOP 3 COUNTRIES BY MACRO-AREA

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels; hybrid kilns (75% electric); 100% electric internal logistics; activated-carbon emission abatement systems; installation of tri-generation plants in progress.

SUSTAINABILITY REPORT: ✔

ENVIRONMENTAL CERTIFICATIONS:

EPD for all products (all thicknesses, all sizes) • ISO 14001 for the Italian facilities in Borgo Val di Taro and Fiorano Modenese • ISO 14064-1 on quantifying the organisation’s carbon footprint • ISO 20400 for sustainable procurement.

OTHER GREEN-RELATED INITIATIVES: Initiatives aimed at reducing processing waste and limiting water consumption in the production cycle; sustainable packaging materials and solutions; optimisation of logistics processes during warehouse picking operations, resulting in savings in the consumption of plastics.

Studies of CO2 abatement in production processes have reached an advanced stage. A patent has been filed for a new electric thermal spray-drying machine that increases efficiency and reduces environmental impact. R & D work aimed at improving body fusion conditions, with benefits in terms of energy consumption.

NEWS:

In 2022, Laminam acquired 100% ownership of Best Surface, a Spanish manufacturer and seller of of large-format coverings. The company set up a distribution centre for Laminam coverings in the Netherlands in April under the name Laminam Benelux BV. Laminam signed an agreement in late August for the acquisition of a 50% stake in the company’s Polish distributor, in which it already held a 29% stake, thus increasing its shareholding to 79%. The company completed a major investment plan aimed at increasing its facilities’ production capacity, which involved doubling the capacity of the Borgotaro facility. Laminam’s flagship IN-SIDE technology transcends the concept of back and front in ceramic tiles, by achieving complete uniformity between the body and the surfaces, even after cutting, drilling and edge grinding. With a view to promoting the welfare of its employees, Laminam launched a project called LAMINAM CARES, comprising a series of initiatives, including screening to facilitate early diagnosis of health issues, a voucher scheme for fuel and other essentials, and a discounts and concessions scheme for a wide range of services and activities.

Copyright Kairos Media Group - All values are expressed in mil/€

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels, co-generation plant and thermal recovery plant.

GREEN-RELATED INITIATIVES: The Group has brought a new Hydrogen-Ready production facility on-stream.

Copyright Kairos Media Group - All values are expressed in mil/€

Rubiera (RE) - 1 in Roteglia (RE) - 1 in Olbia (SS)

AND TOP 3 COUNTRIES BY MACRO-AREA

FORECAST 2023

MARKET FORECAST 2023

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels and co-generation plants

STIMA RIDUZIONE CO 2 : CO2 emissions fell by 20% in 2022

SUSTAINABILITY REPORT: ✗ Publication planned for 2023

ENVIRONMENTAL CERTIFICATIONS: ISO 14001 and ISO 50001 certification in progress

NEWS:

The company will completely replace its WMS system in 2023

FLAGSHIP

ITALIAN

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Co-generation plants

SUSTAINABILITY REPORT: ✔

ENVIRONMENTAL CERTIFICATIONS: EMAS

ISO 14001

ISO 14064-1

NEWS:

ISO 14021

The company became a benefit corporation, obtaining B CORP certification and Gender Equality certification. It also installed a new production machine in 2022, namely a Sacmi PH 8200 press.

Copyright Kairos Media Group - All values are expressed in mil/€

GOLD ART CERAMICA SPA

These revenues were generated through the following companies and/or brands: •

PRODUCTION:

of which: 90% floor tile 10% wall tile

PRODUCTION FACILITIES IN ITALY: 1 in Pavullo nel Frignano (MO)

€ 123.6 MLN

EMPLOYEES: N° 340 of which: 16% women 52% graduates and/or specialist technicians

New hire forecast: ✔ (technicians, graphic designers)

EXPORTS AS A PERCENTAGE OF

PRODUCTION: 58%

DESTINATION OF EXPORTS AND TOP 3 COUNTRIES BY MACRO-AREA

TRENDS

ITALIAN MARKET FORECAST 2023

TRENDS

EXPORT MARKET FORECAST 2023

ENERGY EFFICIENCY SYSTEMS IMPLEMENTED BY THE COMPANY: Photovoltaic panels and a co-generation plant

ESTIMATED CO2 REDUCTION:There was a 10% reduction in 2022 SUSTAINABILITY REPORT: ✔

ENVIRONMENTAL CERTIFICATIONS: ISO 14001 • EPD • SMETA • UNI EN ISO 14001:2015 Environmental Management System

OTHER GREEN-RELATED INITIATIVES: Class 4A office complex and showroom. The company has drawn up a Code of Ethics and appointed an ESG Supervisory Body to monitor and certify compliance with the code. It generates electricity in-house, using photovoltaic systems and co-generators, thanks to which it self-generates almost all the electricity it uses. The Pavullo nel Frignano facility is almost entirely self-sufficient.

In line with the company’s ethics, production investments are all geared towards green technology and digitalisation. The plants and machinery meet Industry 4.0 standards and allow full control and programming. Furthermore, the company selects its raw materials and packaging extremely carefully. It has also continued its efforts to reduce its emissions of CO2 into the atmosphere by using renewable energy, to maximise its re-use of water in the processing cycle and to thoroughly purify the small amount of residual waste water.

NEWS:

The company continued to grow in 2022, albeit at a slower rate due to Russia’s invasion of Ukraine and the impact this had on Europe’s economy.

The “Continua Plus” production line for large-format panels was completed, thus raising production capacity to about 2 million square metres per year. Through Winter S.p.A, one of its subsidiaries, the company acquired additional building plots, including derelict and decommissioned industrial buildings, as part of its plan to expand the Maranello logistics hub. The recent purchase also includes a building plot for logistical/industrial use, located in Via Trebbo, also in Maranello.

Thanks to these acquisitions, the company now has the space it needs for the storage and handling of large-format panels in the immediate vicinity of the production site.

The construction of a new office building overlooking Via Giardini has reached an advanced state of progress and is due for completion by the end of the first half of 2023. This will boost the efficiency of all non-production activities and the well-being of everyone who works at the site. A photovoltaic system will be installed on the roof of the building to make it self-sufficient in electricity, while the heating system will be supplied with heat generated by the kilns used to fire the ceramic.

Benefits for all workers have been maintained in the form of production bonuses and meal vouchers worth €5 per working day. The company has enhanced the technical and professional development of its staff by means of training courses aligned with the increasingly sophisticated technology used in the production process. For ethical reasons, the company does not apply unstable employment arrangements. Instead, it offers stable jobs on completion of an appropriate period of apprenticeship and training.

DESTINATION OF EXPORTS AND TOP 3 COUNTRIES BY MACRO-AREA

IMPLEMENTED BY THE COMPANY: Co-generation plant

CO2 REDUCTION:There was a 10% reduction in 2022

ENVIRONMENTAL CERTIFICATIONS: The company has obtained ECOVADIS certification. FDES and UNI ISO 17889-1 certification is in progress

OTHER GREEN-RELATED INITIATIVES: Plans are in place for the installation of a photovoltaic system

https://issuu.com/tiledizioni/docs/tile_italia_2_2023/108

With a letter of intent signed on 18 July, the Italcer Group, one of Italy’s leading manufacturers of ceramic floor and wall tiles and bathroom furnishings, has initiated the process of acquiring 100% of the Terratinta Group, a company specialising in high-end furnishing

surfaces based in Fiorano Modenese.

Under the terms of the agreement, Terratinta’s CEO and shareholder Luca Migliorini will reinvest part of the proceeds of the sale in Italcer shares, thereby becoming a shareholder alongside the group’s

Italcer now owns the Italian brands La Fabbrica, AVA, Elios, Rondine, Cedir, Bottega, Fondovalle, My Top, Tonino Lamborghini (licensed for the ceramic sector) and Devon&Devon (bathroom furnishing), plus Spray Dry (spray-dried body) and the Spanish company Equipe Ceramicas, with its four production sites in the Castellón ceramic cluster.

At the end of 2022, the Group had 1,064 employees

CEO and founder Graziano Verdi. The transaction is expected to close before the end of the year and will consolidate the Italcer Group’s position as one of the leading players in the Italian and global ceramic industry with projected 2023 sales of close to €400 million.

and produced 20.3 million square metres of ceramic floor and wall tiles and large-format panels in 2022 (including 6 million in Spain), achieving consolidated revenues of €360 million, representing a rise of 36.4% on 2021, and boosting its EBITDA to €85 million.

With the acquisition of Terratinta, Italcer now aims to significantly expand its collections with the addition of

The Italcer Group is also one of the industry’s fastest-growing players. Its growth achieved by acquisitions –Terratinta will be the eighth completed in six years – has given rise to the luxury Italian ceramic hub that was the goal of the group ever since it was formed in 2017.

four further high-end brands (Terratinta Ceramiche, Ceramica Magica, Sartoria and Micro) that guarantee high levels of sustainability thanks to the prestigious B Corp Certification recently gained by Terratinta. We spoke to Graziano Verdi about growth goals and the initiatives that the entrepreneur and his team are working on.

Tile International: Over the past 4 years, Italcer has doubled its revenues, partly through acquisitions and partly through organic growth of over 15%, which is well above the growth of the market as a whole. What objective are you pursuing?

G. Verdi: Development by the external route is a good model if it is properly managed – I am thinking, for example, of the importance of working on the integration of skills, specific characteristics and specialisations – and provided they are backed up by targeted technological investments for organic growth The two routes have always run parallel to each other in our business model, as we had planned ever since forming Italcer. Our results so far are more than satisfactory, and, as this last important operation confirms, we are sticking with this development model, with a view to maintaining the brisk pace of growth that we have achieved in recent years.

Tile International: For some time now, your plans to increase the group’s internationalization have included putting down roots in the United States, with a production facility in Tennessee. Is that still on the agenda?

G. Verdi: The American project was already under examination before we finalised our acquisition of Equipe, which therefore took priority; I can confirm, however, that an investment in the United States is still one of our medium-term goals.

Tile International: Let’s talk about your 2022 results, which reached the target you were aiming for, as well as revealing an increase in profit margins. Which parts of your strategy have worked best?

G. Verdi: There is no single element that stands out from the others in terms of effectiveness. On the one hand, we have a fully functioning team. Beyond that, I would say we have simply reaped the benefits of strategic choices that were made at the right time. I am thinking, for example, of how we dealt with the issue of raw materials from Ukraine, which we had already decided to replace in October 2021. Our partial hedging on gas has also enabled us to carry on operating with more peace of mind. Our business model, based on the specialisation of production facilities, is definitely working too. We have opted to focus on three segments – large-format panels up to 160x320cm, small and extra-small formats, and 2cm thick floor tiles for outdoor applications – with the individual production facilities serving the various Group brands. And in addition to these three types, in fact there is a fourth – the most important one – relating to the innovation of Advance, the name given to our patented antibacterial, antiviral and anti-polluting surfaces.

Tile International: Do you plan to give equal weight to strengthening your four pillars?

G. Verdi: In terms of investment, I would say yes, they

will all benefit in roughly equal measure. Large-format panels, made in three thicknesses (6mm, 8.5mm and 12mm), currently account for 10% of our total production, equating to around 2 million square metres, whereas the outdoor segment will have to grow in parallel with the increasing demand we are seeing on the market. As far as very small formats are concerned, in other words the segment covered by Equipe in Spain and our Vetto facility in Italy, we had already stepped up production last year, in response to a big increase in sales, and we intend to keep stepping it up in the years to come.

Tile International: Talking of Spain, are you satisfied with your acquisition there? And what is your view of the situation faced by the Spanish ceramic industry, which was hit much harder by the 2022 energy crisis than Italy was?

G. Verdi: We are delighted with the acquisition of Equipe. The company was not affected by the increase in production costs because it was able to offset them with higher selling prices. It is a leading player in the niche segment of small-format wall tiles, which command a high average selling price, and it closed 2022 with revenues of 80 million euros, as against 50 million in 2021, when it joined the Italcer Group. On top of the lack of public aid to help overcome the 2022 energy crisis – which definitely put the Spanish in-

dustry at a disadvantage – I think that one of the problems faced by the Castellón ceramic cluster is a lack of clear differentiation between what the many manufacturers are offering, as this generates fierce competition that inevitably risks being played out on price alone.

Tile International: Are you worried now about the sharp slowdown in global demand that we are seeing in 2023, as forecast, and that is affecting Italy’s manufacturing sector, which saw its export volumes fall by a quarter in the first three months of the year?

G. Verdi: There is a slowdown, but we can deal with it, as we have shown we can in the past, because our sector is historically cyclical. It is true that Italian industry had to reduce its output in the first half of this year, by an estimated figure of about 20%, but Spain has had to cut back even more.

Italcer closed the first quarter of 2023 with 4% growth in revenues, which is below the pace we are used to. But as I said before, cyclical trends are a constant in this sector. It is worth remembering that our customers’ warehouses were still well stocked thanks to the record purchases made in the first half of 2022, so an upturn in orders in the second half of this year is likely. Among other things, signs of recovery are appearing in the United States (where imports from Italy fell by 30% in the first quarter of 2023): by late March, US GDP had grown by 2%, which was above expectations, and

the number of new-construction permits issued in May saw its second-largest increase after years of decline. Against this backdrop, we have other factors on our side too: our continuously expanding product mix and top-notch customer service will enable us to safeguard our average selling price.

Tile International: The question of sustainability has been a central, not to say a priority item on your agenda. Could you tell us something about that?

G. Verdi: Product and process innovation and sustainability are now inseparable. Companies, especially if they are market leaders, cannot ignore either one or the other if they want to satisfy consumers, who have increasingly high expectations in terms of environmental protection.

In the last two years alone, our Group has invested over 20 million euros in sustainability. One of the most significant initiatives was the installation of three latest-generation co-generators, which give us about 33,000 MWh, out of a total requirement of 57,000. Our most recent investment is the latest-generation Sacmi “Maestro” kiln, which came on-stream at our Fiorano Modenese plant in April. It incorporates hybrid hydrogen-methane technology, so it will be possible to fuel it with an energy blend comprising 50% hydrogen, once hydrogen becomes available on a large scale, thereby saving something in the order of 1.5 million cubic metres of gas. Inevitably, we need to keep looking to the future.

Tile International: Is that also why you decided to sign a deal with Renovit, of the SNAM Group, in March, aimed at obtaining further energy-efficiency gains from of your production facilities?

G. Verdi: Yes, and it marks another major step forward for us, which advances our renewables project. We had already installed about 2 MWp of photovoltaic plants last year. The agreement with Renovit is for the supply, installation and operation of 6,800 photovoltaic panels, which will cover an area of over 18,500 square metres at our production sites, adding a total of about 3.2 MWp. This will enables us to meet over 30% of our electricity needs with energy from renewable sources. Our target, however, is to reach a total of about 10 MWp in the next two years, which equates to 2,500 tonnes of CO2eq avoided per year.

Tile International: The efforts you have made in recent years have also reaped prestigious awards, including first place in the Sustainability Award 2022 and the TOP 100 Eccellenze Italiane award. Are you pleased with these achievements?

G. Verdi: Here at Italcer Group, we currently invest over 3% of our revenues in Research & Development, we use over 50% of recycled raw materials in our production, and we are capable of recycling and recovering more than 99 8% of the waste we generate across our various plants. As well as winning these awards, which we are very proud of, our commitment to high environmental standards has also enabled us to join the “World Alliance for Efficient Solutions,” the NGO that promotes green energy worldwide and helps governments achieve their ESG goals. These results highlight how we are continuously increasing the sustainability and efficiency of our production processes, by making more efficient use of materials, saving more energy, cutting our emissions and managing our water and waste more carefully. It also helps motivate us to stick to this path and keep on improving. ✕

Tile International took part in the exclusive press preview held in Milan this summer, at the studio of the famous architect and interior

designer Andrea Castrignano. We took the opportunity to interview Stefano Storchi, Marketing Director of Cerdisa

Tile International: The real challenge is to predict future scenarios: how did you come to imagine the Group’s present?

S. Storchi: We inherited historic brands, backed by the strength of a ceramic culture that had built up layer by layer over the course of decades of intense production activity, and we asked ourselves how the product could make another major leap forward

The big investments in technology we have made in recent years are what enabled us first to imagine and then produce “our” ceramic of the future, which made its début at Cersaie 2022, when we unveiled the “Now” concept and the stand dedicated to it. It marked an im-

Ricchetti Group and the mind behind the changes blowing through the company, which are having a major impact on the

portant turning point, where our new dialectics came to life in a kind of design metaverse.

Tile International: Can we talk briefly about these technologies?

S. Storchi: The production process we call “Material Design” is not simple and requires the invaluable input of highly skilled craftspeople, but to simplify it as far as possible, I would say that “Touch to Digital – T2D” is a “glue and graniglia” technology that makes it possible to apply the glue transparently by means of digital printing and, first and foremost, to create effects with as much gloss as the glossy ink bar, but in a less in-

positioning of the brands and the bold design choices they have made over the past two years.

tense and more refined way. It can be combined with a system for dropping dry graniglia onto the product immediately after digital printing, which, of course, only sticks where glue has been applied, as dictated by the digital file.

This type of application gives the surface an endless range of three-dimensional effects, and can be centred or offset, to create macro-strokes or micro-patterns with elegant

gloss-matt effects. What’s more, the technology enables you to create brushed, satin-effect and lapped surfaces: depending on the type of processing you choose, you can give the tile very different tactile and visual attributes, which bring sumptuous effects to the surfaces involved.

The other technology that has revolutionised the appearance of our collections is the one we call “Gloss and Shine – G+S”, which has the ability to centre the ink-based graphics in relation to the gloss material, thus creating refined gloss and matt visual effects on the surface.

This technology is designed to embellish the base material: the perfect fit between the ink-based graphics and the glue-based graphics, followed by the process of scattering with fine, latest-generation graniglia, gives the finished surface considerable depth.

Tile International: So with all that fire-power, the only limit is your imagination…

S. Storchi: Exactly! We wanted to free ceramic from the confines of merely replicating other architectural materials, mainly wood and natural stone. We wanted to go the extra mile and have a real impact on our customers with a material that still offers the excellent performance of porcelain tile but is also a powerful medium for narrative.

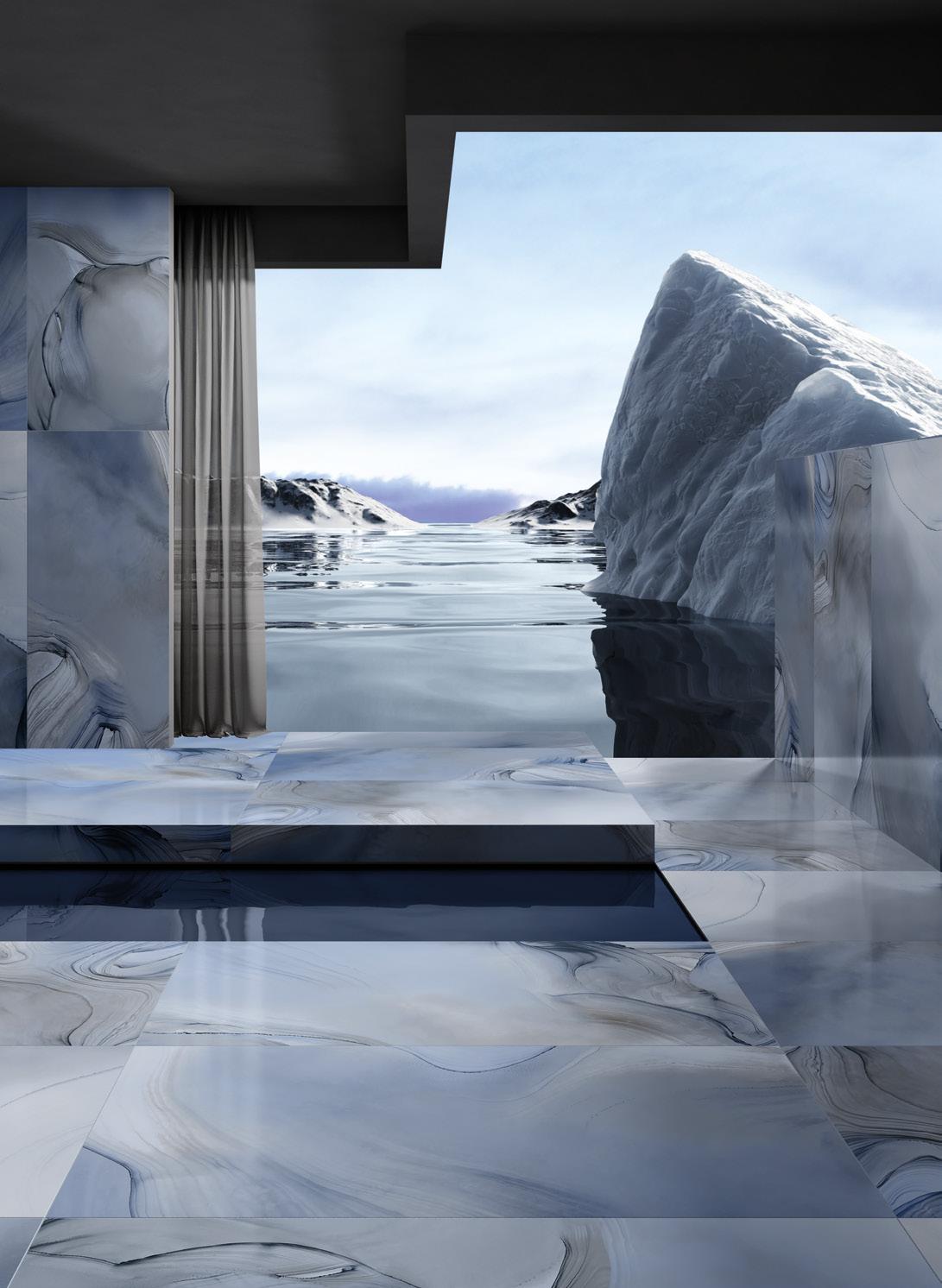

We drew inspiration from nature in its broadest sense – from the elements – and we took the challenge to its furthest extreme… and that’s why, at Cersaie 2023, we’re presenting a river of crystal clear water, with the installation “SYN”. In this context, we’ve deliberately used nothing but ceramic: the entire panorama is saturated with material, which becomes architecture and narrative itself. The collection that enabled us to achieve this ambitious goal is “Fluids,” which features graphic movements created by the winding pathways of inks applied seemingly at random, but in reality controlled by human ingenuity through the empirical use of artificial intelligence. The result is a showcase collection that recalls both the hypnotic fluidity of a liquid such as water, and the iconography and chromatic vividness of liquid crystals. So nature and technology form a perfect symbiosis, for a consummate creative synthesis and an aesthetic rooted more in science than in the craft of artisans. The result is so contemporarily artistic that it expresses itself in all its visual strength through large formats and an extremely bright and deep surface.

Tile International: Ceramic is going back to its true essence: it’s no longer a “sheet to print on” but a continuously evolving creative medium in its own right.

S. Storchi: Yes. It’s a return to the past, but it’s full of all-new meanings, which we’ve summed up as “Synthetic Nature”, where the word “synthetic” is used in

the positive sense of compositional, innovative, creative, free from conventions and preconceptions, full of possibilities for experimentation and shaped by people for people.

An ancient material that people have been making since the dawn of time because of its plasticity, durability and scope for decoration, it is re-appropriating its expressive potential while embracing a solid green philosophy. Suffice it to say that our collections contain an average of 23% of recovered material, which enables us to put something like 5,000 tonnes of processing residues per year back into the production cycle.

What’s more, our close attention to design and technology means that our collections complement each other in terms of formats, colours and surface finishes, giving designers the maximum compositional freedom. The ultimate expression of this freedom is the “Cross” surface finish, which is blazing a new trail in the ceramic industry. Thanks to the use of special nano-graniglia, it can be used equally well as a floor or wall covering, indoors or outdoors, enabling designers to create perfect visual continuums, with no compromises in terms of cleanability, tactility or slip coefficient.

Tile International: Technological innovation, a revolution in product philosophy and unconventional design of trade show spaces. This is a major repositioning of the brand. Could you tell us something about that?