r new Quarter 2 2024 Innovations Industry News Applications Expert Opinion

Impregnation

Understanding Vacuum Pressure

MONITORING

ROTATING MACHINERY The journal from

Generative AI in predictive maintenance FOCUS ON: Condition Monitoring & Predictive Maintenance FOR THE MAINTENANCE, REPAIR, REPLACEMENT AND

OF

Brook Crompton

IP23 Cast Iron Range from 18.5kw 710kw in frame sizes 160 to 355 In Stock

New Motors

TT Electric

Full range of High Quality DC Motors from 1kw to 2000kw IP23 IP55. In Stock

Large Stocks of Electric Motor Spares Both Current and Obsolete Including:-

Brook Crompton Series 7 Steel Motor spares

Brook Crompton Series 6 Cast Iron Motor Spares

• Fan Covers

• Terminal Box Assemblies

• Endshields

• Bearing Covers

• Slip-Ring Assemblies

• Brushgear

• Carbon Brushes

• Cooling Fans

Re-Conditioned Motors

• Cage up to 1mw Ex Stock

• Slip-Ring up to 500kw Ex Stock

• D C Motors

• High Tension Motors 3.3Kv

• Geared Motors

• Two Speed Motors

• Vibrator Motors

Variable Speed Drive Specialist

Schneider Altivar Range of Variable Speed Drives from 0.18kw to 315kw available Ex Stock

Kingstown Broadway, Kingstown Industrial Estate, Carlisle, Cumbria, CA3 0HA Tel : 01228 552000 Fax : 01228 552001 E -Mail: electrics@park-gate.co.uk

87

LARGESST STOCK OF ELECTRIC MOTORS IN THE U.K.

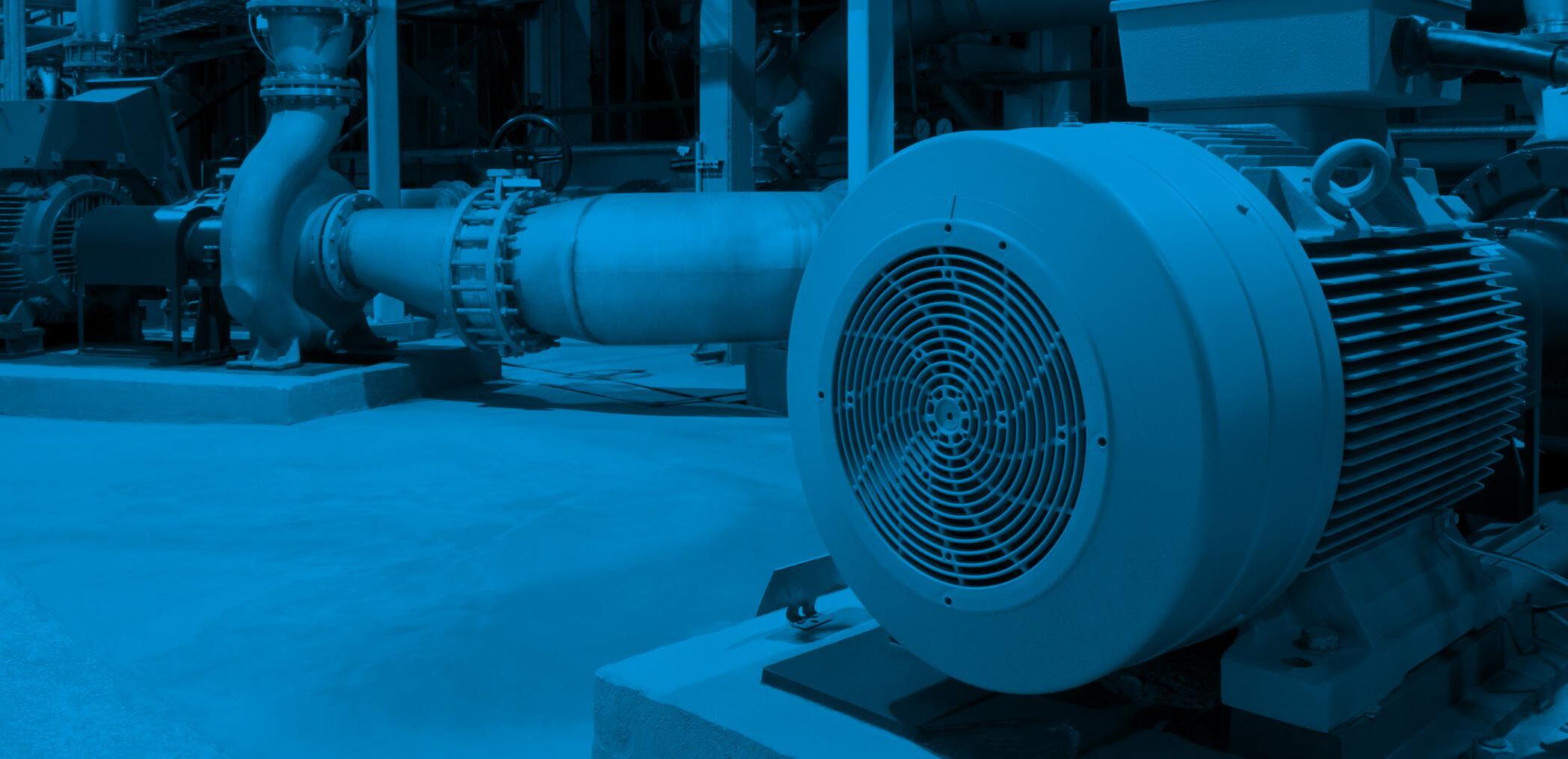

In this issue of Renew, we look at condition monitoring. As a tool to support predictive maintenance, it has come a long way in recent years, supported by advances in computing power and Artificial Intelligence (AI). And by AI, I’m not just referring to the generative AI dominating the headlines today, but rather the ability to intelligently analyse increasingly large datasets, which is fast advancing but has been with us for many years.

However, as good as condition monitoring is and may become, it can’t make a motor or generator more reliable in and of itself; it can only support effective and efficient ongoing maintenance. The quality of the product and its components remains fundamental to its reliability – when it is first made and when it is repaired.

This is why AEMT members strive to carry out their work to the highest standards. Gone are the days of throwing a motor onto a bonfire to burn off the insulation with fingers crossed; the processes that form part of a motor repair are now well controlled and guided by an internationally recognised standard which ensures the highest quality of repair, that in some cases can result in improved reliability and efficiency.

In addition, you will see on page seven of this issue that we are developing a code of practice for the Association’s members. This code will cover six key areas: sustainability, quality, stability, expertise, integrity, and safety. It aims to recognise and drive the standards upheld by the membership across their entire operations.

This drive for quality in everything we do means that the customers we support get the best service they can and makes me proud to be a part of the AEMT.

Enjoy the issue.

James Stevens, President, AEMT

Quarter 2 2024 www.theaemt.com CONTENTS 3

Renew is a controlled circulation journal published quarterly on behalf of the AEMT by Touchwave Media and G and C Media. For a copy of the magazine’s terms of control and to request a copy please email circulation@renew-mag.com The content of Renew magazine does not necessarily reflect the views of the editor, publishers, or the AEMT. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any products or processes mentioned within it. No part of this publication may be reproduced or stored in a retrieval system without the publisher’s written consent. © AEMT. All rights reserved. Editor Chris Callander chris@renew-mag.com +44 (0)1732 671123 Contributing Editor Suzanne Gill suzanne@renew-mag.com Publisher Andrew Castle andrew@renew-mag.com +44 (0)7785 290034 Accounts Touchwave Media Ltd accounts@renew-mag.com Production G and C Media Ltd production@renew-mag.com Founded in 1945, the Association of Electrical and Mechanical Trades is an International Association representing companies in the electrical and mechanical service and repair industry. AEMT Tower House Business Centre Fishergate York YO10 4UA www.theaemt.com NEWS features Condition monitoring Focus Opinion 34 Don’t ignore your motors’ lubrication 18 Understanding Vacuum Pressure Impregnation 20 Repair or replace? The environmental impact 4 Industry news 6 AEMT update 8 Product news 12 AEMT Awards update 14 Project updates 30 Generative AI enhances predictive maintenance 31 Maintenance system avoids downtime for food producer Twitter @AEMT_Updates 8 22 Delivering higher efficiency across the full speed range 24 DC motor maintenance: Tackling brush issues 26 Low voltage AC motor market performance 28 PD monitoring identifies the cause of dust contamination PEFC/16-33-254 PEFC Certified This product is from sustainably managed forests and controlled sources www.pefc.org Cover image © Houghton International 30

TRANSFORMER SPECIALIST CELEBRATES 45TH ANNIVERSARY

IN JANUARY 2024, TRANSFORMER specialist Electro-Wind Ltd celebrated its 45th anniversary. Whilst the first generation of the family-owned business started and developed it for 20 years, the next generation, its current directors, have been committed to leading the company’s growth for the last 25 years.

Since its formation, the company has evolved and grown, widening its product range in size and diversity and gaining expertise and capability along the way. The advancing product range offers bespoke transformers

from 10VA up to 2MVA in addition to AC reactors, DC rectifiers and chokes, supported by a range of associated

products, including site electrical accessories.

Over the last 45 years, the company has outgrown three different premises, and with the new addition in 2024 of a further production unit to house the significant machinery investments, its momentum shows no sign of slowing down.

Recognising the milestone, the directors have thanked all of their staff, suppliers, and customers for their continued support and are looking forward to the next exciting stage in Electro-Wind’s journey.

TOOLS FOR APPRENTICES INITIATIVE GAINS SPONSOR

ELECTROMECHANICAL REPAIR specialist, Fletcher Moorland Ltd, has gained a sponsor for its popular 'Get Tooled Up' initiative, which gives sets of quality tools to young apprentices and aspiring engineers every month.

Beta UK & Ireland, a subsidiary of the Italian specialist in the production of tools and workshop equipment for professional users, has agreed to sponsor all the tools given for 12 months, which began with ten 25-piece ratchet, adaptor and bit sets given away in the initiative's February draw.

For young engineers to have a chance of winning tools that could help them as they embark on their careers, all they have to do is look out for posts on LinkedIn carrying the #GetTooledUp hashtag and then comment or hit the like button. Fletcher Moorland randomly draws from the entrants each

month and notifies the lucky winners. Anyone who wants to nominate a young person to be entered can also do so by tagging or, if they aren't on LinkedIn, nominating them on the post featuring the hashtag.

Commenting on the initiative, Matt Fletcher, Managing Director at Fletcher Moorland, said: "Tools cost a lot of money; ask any engineer. It's particularly hard when starting out in an engineering career. You want the best tools to do your job, but getting good quality equipment costs money.

engineers in the UK. It will give a much-needed helping hand to the next generation of engineers and manufacturers.

"So I'm absolutely delighted that the team at Beta UK & Ireland wanted to support the #GetTooledUp drive to get decent-quality tools into the hands of young, aspiring, and apprentice

"Thanks to Beta's support, there will be a lot of variety in the tool giveaways this year. Plus, at the end of the year, there will be an absolutely massive giveaway, one that is not to be missed."

MILLIONS WRITTEN OFF DUE TO MRO SUPPLY CHAIN ISSUES

INDUSTRIAL SERVICE PROVIDER, ERIKS has published the Maintenance, Repair and Operational (MRO) Supply Chain report in association with the Institute of Engineering & Technology, highlighting several critical insights crucial for operational efficiency.

In the report, a direct link is made between unscheduled downtime and the operation of the engineering stores, the supply chain, and the MRO procurement function. A survey demonstrated that, in 2023, the main causes of downtime in UK manufacturing businesses were spares

availability and lead time issues.

A further revelation is that UK manufacturing businesses are collectively writing off millions of pounds of MRO stock every year. Comparisons between data collected in 2016 and 2023 show that oversight in this area has declined markedly and that stockpiling – undertaken as a reaction to Brexit, the global pandemic and, more recently, the conflict in Ukraine – has resulted in businesses tying up cash in inventory and writing that investment off as products age or go unused.

Another finding highlights the issue

of 'squirrel stores'. These occur when engineers build their own private stock of MRO equipment. While seemingly innocuous, the presence of 'squirrel stores' brings into focus the lack of trust that engineers have with their stores and purchasing teams, and the report also looks at the ramifications for the accuracy of data about a site's performance. With 55% of respondents declaring this as an issue, the report looks at the trend and suggests some potential solutions.

The report is available to download at https://bit.ly/MROreport

www.theaemt.com Quarter 2 2024 Industry News 4

Fletcher Moorland's Matt Fletcher (ctr) with Mark Pearson (left) and David Hunt of Beta UK & Ireland.

MEGGER ACQUIRES ROTATING MACHINERY VIBRATION MONITORING SPECIALIST

ELECTRICAL MEASUREMENT company, Megger Group has announced its acquisition of Diagnostic Solutions Ltd (DSL), a UK-based specialist in rotating machinery vibration monitoring and analysis within the predictive maintenance sector.

Online vibration analysis is the most common monitoring application for rotating machinery and, as such, is a good addition to Megger’s electrical motor and generator testing instruments.

carry out condition monitoring via cloud services to identify potential faults such as worn bearings or misalignment in motors and generators.

DSL’s installed wireless sensors

Condition assessment using DSL

sensors and software informs maintenance planning and reduces unplanned downtime and the associated costs, so it is a valuable tool in any industrial asset management strategy.

Commenting on the move, Damon Mount, Head of Business Development at Megger, said: “We are incredibly excited to bring DSL on board with the rotating machinery team. DSL’s vibration expertise adds extensive capabilities to our motor and generator testing range”.

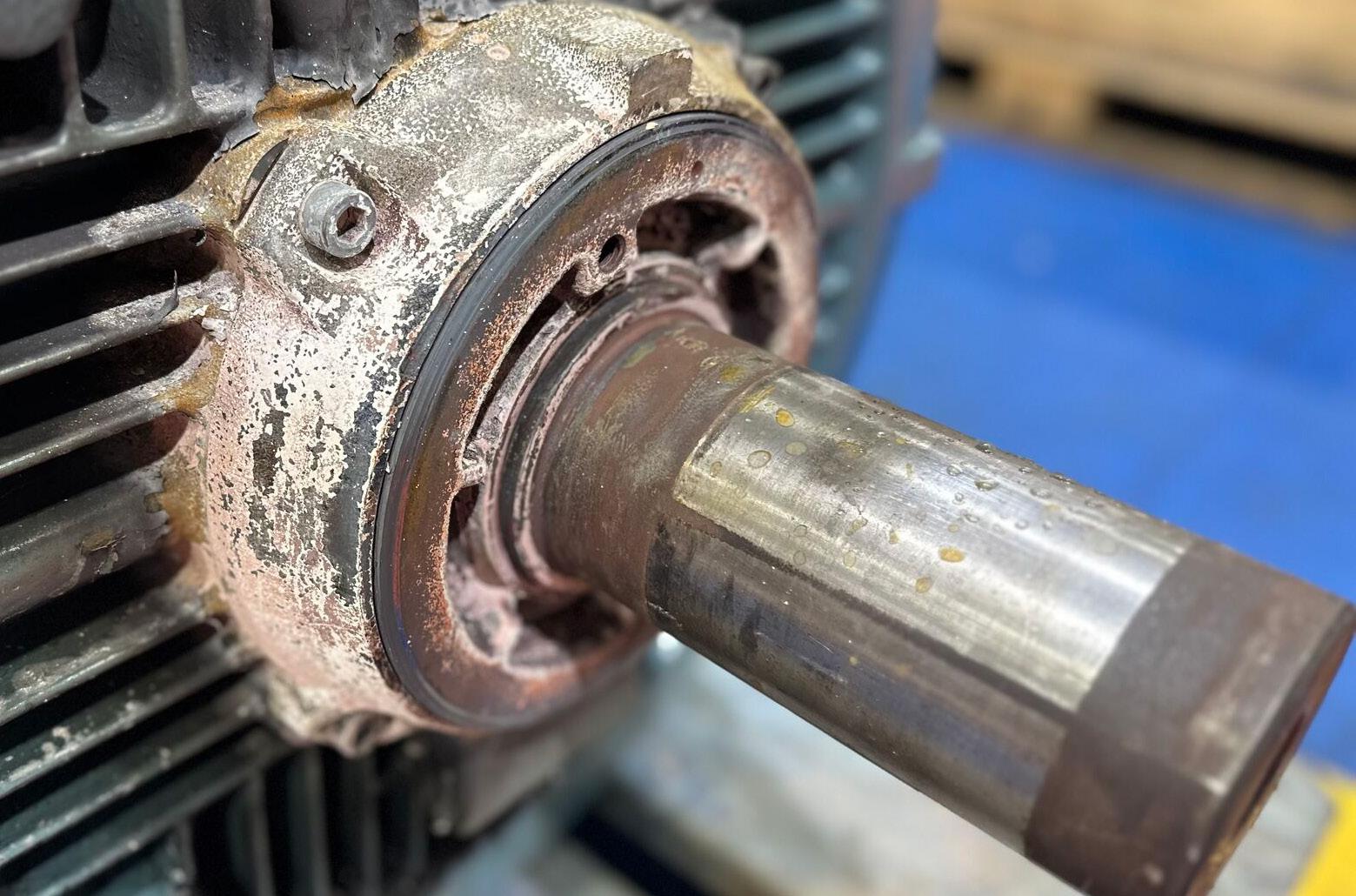

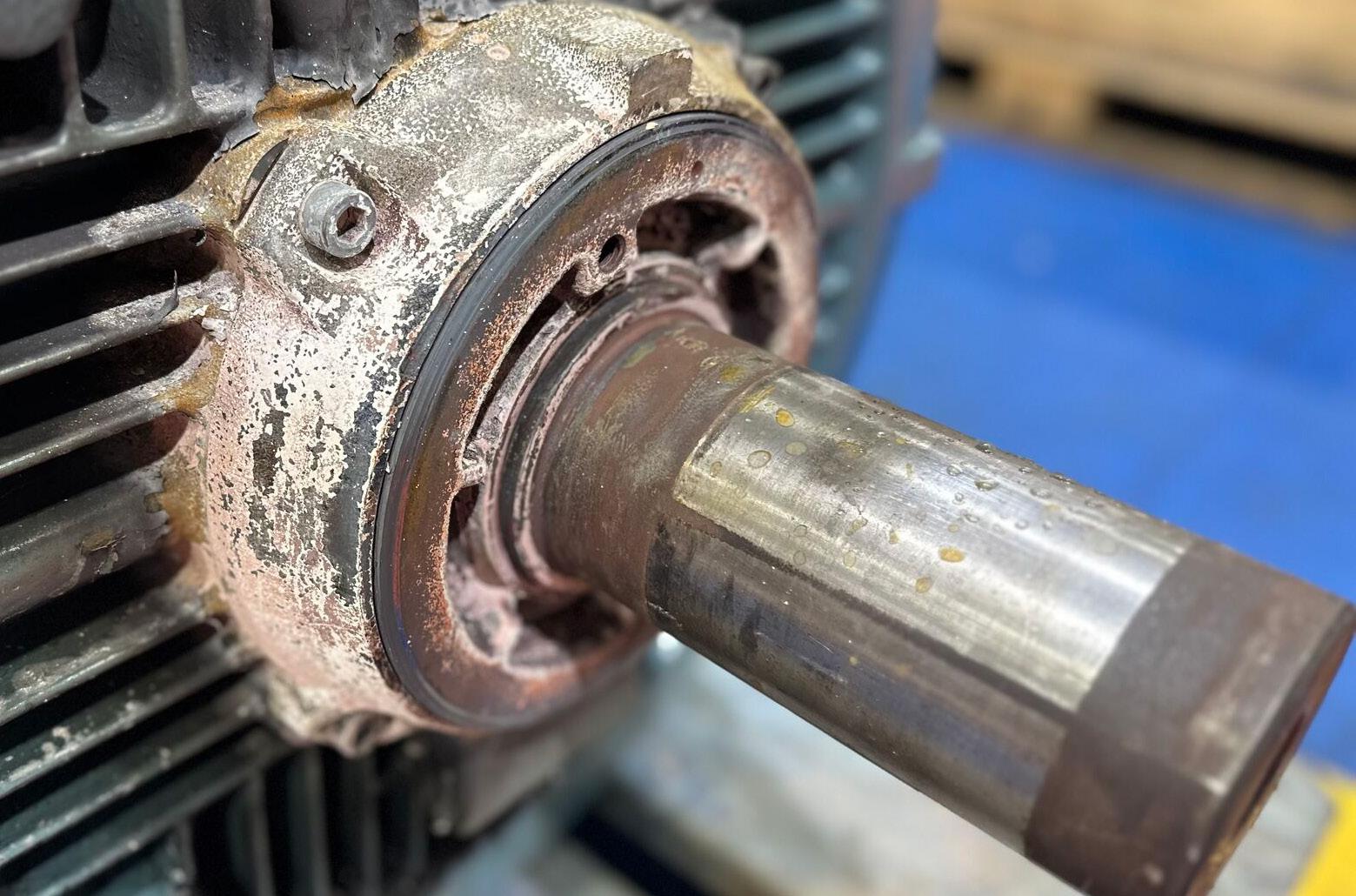

HOUGHTON INTERNATIONAL BECOMES ABB VALUE PARTNER

HOUGHTON INTERNATIONAL HAS confirmed that it is now an official Value Partner of the manufacturing and automation specialist, ABB.

The newly formed alliance means that ABB has assessed the quality of processes at Houghton International's facility and has officially endorsed them as a recommended repairer.

ABB harnesses its manufacturing and software expertise to advance electrification and automation solutions, driving towards a sustainable and resource-efficient future. Through its endorsement of Houghton International, ABB extends its commitment, providing clients with a trusted and sustainably conscious repairer based in the North East.

Michael Mitten, CEO of Houghton International, expressed his enthusiasm about becoming an ABB Value Partner: "We take pride in our endorsement from ABB, whose values of high quality, transparency, and trust align closely with ours. Being recognised as an official ABB Value Partner strengthens our belief that we are a vital asset in the industry. Our expert team has a diverse skill set capable of repairing electro-mechanical assets, now specialising in ABB motors and generators.

"We can now give ABB's customers access to motor and generator repair, including specialised services exclusively for ABB products. These

include ABB Ability, ABB Ability LEAP, and ABB Air Gap Inspector services."

To become an ABB Value Partner, engineers at Houghton International underwent exclusive training to perform specific duties unique to ABB products and protocols.

300 ORGANISATIONS UNITE TO INSPIRE A DIVERSE ENGINEERING AND TECHNOLOGY WORKFORCE

THE TOMORROW’S ENGINEERS CODE, of which the Association of Electrical and Mechanical Trades is a signatory, has celebrated an important milestone – the community now has over 300 members dedicated to increasing the diversity and number of young people entering engineering and technology careers.

United by this common goal, the collaborative community has expanded to include organisations of all sizes from across the engineering, technology, and education sectors. Aiming to collectively improve their engineering outreach programmes for young people, members

share knowledge and best practice and commit to 4 pledges to shape their engagement activities and strategy.

Cat Stuman, Senior Code Manager at EngineeringUK, which manages The Tomorrow’s Engineers Code, commented: “We’re delighted that, in just over three years, The Code has grown to over 300 members. While there is already a lot of great work being done to inspire the next generation into engineering and technology, the workforce and skills shortage isn’t something that can be solved by any one organisation on its own.

“The Code aims to drive collaboration and grow the collective impact of engineering and tech inspiration and careers activities for young people. We’re proud of what the community has achieved so far and look forward to welcoming even more members over the coming year.”

Any UK-based organisation that funds, designs or delivers engineering outreach activities, or intends to, is invited to become a signatory, which is free to do, while any organisation not meeting these criteria but supporting the aims of The Code can join as a Supporter, at code.tomorrowsengineers.org.uk

www.theaemt.com Quarter 2 2024 Industry News 5

REVISED EX REPAIR TRAINING FOR NEW AND ESTABLISHED REPAIR PROFESSIONALS

RESPONDING TO FEEDBACK FROM previous delegates, the Association for Electrical and Mechanical Trades (AEMT) has revised and relaunched its internationally acclaimed Ex Repair course for individuals involved in repairing electromechanical equipment used in potentially explosive atmospheres.

The revised course builds on the success of the Association’s Ex Theory, Ex Hands-On, and Ex Refresher courses, consolidating the learning into one new course designed for both those new to Ex equipment repair and those looking to refresh their knowledge –either online or in person.

The AEMT’s Ex repair training is in line with the IEC standard for Repair Overhaul and Reclamation of Hazardous Area Equipment - IEC BS EN 60079-19:2019, which requires that “…all personnel are up to date with the latest techniques, safety standards and regulations relevant to

explosive atmospheres.” The standard also requires that training be refreshed within a three-year timescale to ensure knowledge remains current.

This updated course brings those training in Ex repair for the first time alongside those refreshing their knowledge for the duration of the three-day course. As well as simplifying the offer to delegates and the companies they work for, the opportunity for those attending to network brings other benefits. Thomas Marks, General Manager and Secretary of the AEMT, explained: “Bringing together new and established learners brings benefits as the more experienced delegates will ask questions that would not necessarily occur to those new to the area, while those with a fresh perspective often make observations those familiar with EX Repair may not consider. So, it adds to the learning experience for both groups.”

The courses are delivered face-to-face in locations across the globe, and now online as well, to improve access and offer a more sustainable solution where suitable.

Throughout the course, delegates are regularly assessed to help the trainers ensure knowledge is retained and upon completion of the course, a certificate of assessment is issued. The AEMT is a recognised training provider by the IECEx to Unit 005, so those pursuing certified competency (IECEx CoPC) are on the right course.

Companies looking to enrol staff on a course do not need to be members of the AEMT, but those who are will benefit from ongoing support related to the overhaul, repair, or reclamation of Ex equipment.

Further details of the courses, a schedule of forthcoming sessions and details of how to enrol can be found on the AEMT website at https://bit.ly/43FJdb7

Forthcoming AEMT led Courses & Events

www.theaemt.com Quarter 2 2024 AEMT News 6

For more information or to book any of the couses listed please visit www.ex-repair.com TITLE START DATE LOCATION Ex Repair Refresher 22/04/2024 Online Ex Repair Training 22/04/2024 Online Ex Repair Training Refresher 30/04/2024 Loughborough Ex Repair Training 30/04/2024 Loughborough Ex Repair Training 06/05/2024 Online Ex Repair Refresher 06/05/2024 Online AEMT Council Meeting 09/05/2024 Hybrid Event Ex Repair Refresher 20/05/2024 Online Ex Repair Training 20/05/2024 Online Ex Repair Training 03/06/2024 Online Ex Repair Refresher 03/06/2024 Online Ex Repair Training 04/06/2024 Aberdeen Ex Repair Training Refresher 04/06/2024 Aberdeen AEMT AGM 2024 13/06/2024 TBC Ex Repair Refresher Training 01/07/2024 Kuala Lumpur Ex Repair Training 01/07/2024 Kuala Lumpur Ex Repair Training Refresher 30/07/2024 Sheffield Ex Repair Training 30/07/2024 Sheffield

UPDATE FROM THE AEMT SECRETARY

IS IT APRIL ALREADY?

This year began with a burst of activity as we deploy our strategy to recognise quality in our members' work, chart a sustainable path forward, and enhance the value we offer.

We began by forming the Codes of Practice Working Group, which has already convened twice. The clarity and consensus on our direction have been refreshing. The group's objective is to establish a framework, ensuring our members adhere to specific standards. We're drafting the new codes, aiming to present a final version to the council in May for ratification at our AGM in June. These codes will focus on six pivotal areas: Sustainability, quality, stability, expertise, integrity, and safety.

Conversations with members who may not initially meet these standards have been uplifting. The prospect of adhering to the new codes has motivated them to pursue improvements, such as obtaining ISO 9001 certification or measuring their CO2 emissions. Our goal is not exclusion but to inspire and support those who need to elevate their operations to meet these standards through the AEMT's services.

Our Net Zero Working Group has also met twice, demonstrating a keen interest in guiding the industry towards sustainability. Collaborations between members and universities are underway, promising innovative developments. The AEMT is committed to reducing our carbon footprint, particularly in our training courses, and we are currently assessing our 2023 emissions.

We continuously seek to add value to our membership. Beyond these groups' contributions, we've enriched our offerings with new tools and services. The resource hub on theaemt.com is being regularly updated with invaluable resources. This includes comprehensive guides for hazardous area repairs and leadership resources to enhance team understanding and performance. An Equality, Diversity and Inclusion hub provides support for team members who might feel excluded or are facing challenges.

Addressing recruitment challenges, we are engaging with creative agencies to launch a campaign that attracts new talent to our industry. Our goal is to foster greater interaction between members and emerging engineering talent.

Excitingly, the AEMT Training Academy is now inviting usergenerated content. This opens up opportunities for members to share lessons or webinars, reinforcing our platform as the premier educational resource for our community.

Lastly, we eagerly anticipate our next council meeting and peer networking event on May 9th, hosted by our new members, Acorn, in Rotherham. We encourage all members able to attend in person to join us for a day of valuable engagement. For more details, please visit the event's section of our website. TIMES-CIRCLE

www.theaemt.com Quarter 2 2024 AEMT News 7 BEATSON FANS & MOTORS 0114 244 99554 www.beatson.co.uk sales@beatson.co.uk Industrial fans Axial impellers Geared motors Electric motors Inverters and starters Fan balancing Repairs and rewinds And all related products and services FROM STOCK PLUS Suppliers to industry since 1928

Thomas Marks is the AEMT's Secretary and General Manager

LIQUID-COOLED IE5 SYNCHRONOUS RELUCTANCE MOTORS

THE LATEST DEVELOPMENT OF ABB’s IE5 SynRM (synchronous reluctance motor) series sees the launch of a new version that combines the benefits of ultrapremium energy efficiency with liquid cooling.

Customers can use IE5 SynRM Liquid-cooled motors to save energy costs and cut emissions in new projects or as a drop-in replacement for less efficient motors.

One advantage of the IE5 SynRM Liquid-cooled motors is that they are much more efficient than the traditional liquid-cooled induction motors and offer significant potential for upgrading with energy-saving technology.

Reliability has been improved by highly effective cooling combined with the cool SynRM rotor and cooling ribs on the bearing assembly which reduces the operating temperature of the bearings. This helps increase the lifetime of this key component and reduce maintenance needs.

The motors are robust, with tight seals

to keep out moisture, dirt and dust, and a smooth outer surface prevents dust buildup. This makes the motors well suited to demanding applications that require high power density where space is restricted, such as marine propulsion systems and thrusters. Furthermore, the motors do not need fans or ventilation, so they do not disturb the surrounding air or release heat into the local environment. This is a major benefit in processes that are impacted

by airflow, such as rubber and plastics production, and food and beverage applications like chocolate conche machines. With no fans, the motors also enhance the working environment by reducing noise levels.

The high power output of the liquid-cooled IE5 SynRM offers increased design flexibility. It can enable a machine to be upgraded to deliver a higher power output within the same footprint, or it can allow for a more compact installation footprint while still providing the same output.

IE5 SynRM Liquid-cooled motors are available in frame sizes IEC 200-315 in aluminium frames, with steel available on request. The versatile design enables the motors to provide exceptional performance over a range of powers from 37 to 710kW. new.abb.com

NEW INVERTER SERIES FOR LIFT APPLICATIONS

IN A NEW DEVELOPMENT IN passenger lift technology, motor and drive supplier WEG has introduced the ADL500 inverter series.

The ADL500 series, certified to European standards EN81-20 and EN81-50, combines the success of its predecessor, the ADL300, with innovative concepts. This new offering boasts features such as Safe Torque Off SIL3, Safe Brake Test (SBT), and the Safe Brake Control (SBC – SIL3) with EBC500 accessory, which allow operators to check motor break status and avoid any unintentional movement.

WEG has also introduced the Zero Contactors concept. Contactors are switches commonly used in inverters to switch between circuits, and this new technology removes the need for them with its Enhanced Elevator Position Control (EPC). The EPC algorithms ensure optimal comfort, direct approach, and precise floor levelling even in demanding environments. What's more, the series offers an array of energysaving solutions, aligning with the

global shift towards sustainable practices.

WEG has introduced green technologies with this latest offering, such as regeneration through the new AFE200 size for smaller elevators, a standby function for eliminating idle-state energy consumption, and energy peak shaving through rechargeable external supercapacitors to avoid spikes in consumption.

Recognising the prevalence of smart devices and IoT technology, WEG's ADL500 series facilitates seamless operator communication with the inverter. The dedicated WEG_Liftouch application for Android, IOS, and Windows platforms enables remote startup, monitoring, tuning, and alarm

checks. Whether onsite with a Wi-Fi connection or through the WEG Drives RMS (Remote Management System) portal, operators can remotely manage operations.

www.theaemt.com Quarter 2 2024

Product News 8

www.weg.net

Electrom Instruments is proud to introduce the new iTIG IV Series motor tester and winding analyzer. Smaller, faster, and lighter than ever! Now with faster automatic testing and a lightweight construction, the iTIG IV offers accurate and reliable testing in a rugged and compact case.

See what makes the iTIG IV more portable than any previous generation.

Scan the QR code to visit the iTIG IV product page for complete details.

730

720-491-3580 info@electrominst.com

www.electrominst.com www.wes.uk.com Contact Electrom’s trusted partner in the UK: Wire Electric Supplies +44 (0) 1952 208

sales@wes.uk.com +1

4kV 6-15kV

New miniaturized design! Motor Tester & Winding Analyzer

ALL NEW AUTOMATIC ELECTRIC MOTOR ANALYSER

WHITELEGG MACHINES HAS launched a new automatic motor analyser as part of its range of electrical testing equipment.

According to the company, the MTC2-R7 offers unmatched test speeds and precision, featuring allnew measuring hardware, operator software, and an ergonomic housing.

The latest technology has been applied to extend the capabilities of desktop electric motor analysers. Newly patented test functions add real benefit to both production and repair/maintenance environments, while many additional test functions can be added to extend the capacity. Different housings are available to suit mobile, workshop, automated installations, and production requirements.

The latest hardware technologies, paired with state-of-the-art .NetCore software, significantly increase the accuracy of the individual test methods and measurement speeds.

Thanks to the newly patented peak-to-peak measurement method, unsurpassed and repeatable winding fault detection is possible. This

method enables highly sensitive fault detection even in coils with very high numbers of windings connected in series or parallel.

Whitelegg also says the device can perform the world's fastest partial discharge test via the optional 50Hz pulse frequency feature. While sense of rotation is built in as standard, simply requiring an optional probe.

With all connections easily reachable and a large, bright, full HD15.6in touchscreen display, the tester is so easy to use and program that new users can be taught in minutes.

www.whitelegg.com

APP AIMS TO DIAGNOSE GREASE DEGRADATION

NSK IS DEVELOPING WHAT IT CLAIMS is a highly-accurate way of rapidly diagnosing the remaining life of lubricant grease. The company will provide the solution as a mobile app, enabling users to analyse lubricant condition on-site in bearings and linear motion systems. The company says this capability will reduce the need for grease inspection and replenishment costs, and will help companies implement condition-based maintenance strategies.

The company is currently seeking customer input and feedback ahead of launching the new app.

Existing high-accuracy diagnosis methods of grease inspection rely on laboratory analysis, but this comes at a high cost, a lack of suitability for on-site use, and a long wait for results. Visual

observation or densitometer methods are more common, but suffer from low accuracy. As a consequence, many companies replenish lubricant unnecessarily early to ensure stable operation, resulting in wasteful grease usage.

It was with these thoughts in mind that NSK decided to develop a far more convenient, cost-effective, fast, and accurate method of grease degradation diagnosis. Importantly, the new NSK app can analyse the level of lubricant degradation using just a small sample of grease. Chemical changes to the base oil and additives of the grease occur due to heat from operation and oxidation with the passage of time. These chemical changes cause the

molecular structure of the lubricant to change and absorb more shortwavelength light, affecting its colour. Grease itself starts off white when new, turning yellow or orange with use and eventually becoming black, which indicates zero remaining life. The NSK app quantifies grease by its colour to calculate its remaining life.

www.nskeurope.com

STAINLESS STEEL WORM GEAR SPEED REDUCERS

BOSTON GEAR, A REGAL REXNORD brand, has introduced the next generation of its 700 Series worm gear speed reducer. The SS700 Gen2 stainless steel speed reducer is an evolution of its firstgeneration series that has served the food and beverage industry for over ten years.

An improved domed crown curved design on the NSF-certified SS700 Gen2 eliminates virtually all pooling of liquids during washdowns. Its 316-grade stainless steel construction offers enhanced benefits in durability

and hygiene over painted, coated and aluminum alloy speed reducers. The speed reducer has an IP69K-rated stainless steel enclosure, compliant with IEC 60529 and capable of withstanding washdown nozzle pressures up to 1450psi at 4in without water ingress.

www.bostongear.com

www.theaemt.com Quarter 2 2024 Product News 10

LOWCOSTALTERNATIVETOOEM

HIGHQUALITYSPECIFICATION

SHORTLEADTIMES

CUSTOM/BESPOKEDESIGN&BUILD

MANUFACTURER’SWARRANTY

DELIVERIESTHROUGHOUTTHEUK

CREDITCARDPAYMENTORACCOUNT CREDITCARDPAYMENTORACCOUNT

MOTORMANUFACTURERS INCLUDING

SUITABLEFORMOSTMAJOR

ARFONREWINDS(PUMPS,DRIVES&MOTORS)LOCATIONS:NORTHWESTENGLAND&WALES UNIT4STADIUMCOURT,BROMBOROUGH,WIRRAL,CHESHIRECH623RN TELE:01513346808/FAX:01513461763/E-Mail:sales@arfonrewinds.com ANDMANYOTHERS

Nominations are being sought for the annual AEMT Awards

Following the highly regarded 2023 awards ceremony in November of last year, the Association of Electrical and Mechanical Trades (AEMT) has announced that the nomination process for the 2024 awards programme is officially open.

Operated by the Association of Electrical and Mechanical Trades (AEMT), the awards will again pay tribute to the skill, effort and sheer dedication of the people and businesses serving this important sector of industry. Building on its past successes, the seventh outing of this sector-specific awards scheme will again culminate in a gala presentation ceremony taking place on the evening of Thursday, November 21, at the Doubletree by Hilton Hotel in Coventry.

Centrally located for easy access from all over the UK, this venue will also host the supporting AEMT Conference – a ‘must attend event’ for all those in membership. The full programme will be announced during the summer, but its focus will again be on providing AEMT members with help and guidance on a range of topics that will be of tangible value and relevance in the development of their businesses.

Then, during the evening, the AEMT Gala Awards Dinner will bring together the electrical and mechanical trades sector to celebrate business and professional excellence. Personal endeavour, product innovation, skills training, engineering advancement and commercial acumen will again be acknowledged and celebrated in recognition of the achievements of individuals and companies operating across the maintenance and repair arena.

INDUSTRY-WIDE ENGAGEMENT

With the support of the event’s sponsors, well-deserved industry-wide recognition will be given to those businesses that excel in their commercial endeavours and, in many cases, go far beyond the call of duty to ensure the safe and efficient operation of plant and equipment within our critical manufacturing, commercial, and utility sectors.

AWARD CATEGORIES

The following nine categories make up the 2024 awards programme:

• Product of the Year – sponsored by DFA Media Group

• Project of the Year – sponsored by EMIR Software

• Service Centre of the Year – sponsored by ABB

• Supplier of the Year – sponsorship available

• Contribution to Skills & Training Award –sponsored by Sulzer

• Rising Star Award – sponsorship available

• Diversity in Engineering Award –sponsored by Preformed Windings

• Sustainable Engineering Award –sponsorship available

• Special Recognition Award – sponsored by AEMT

CALL FOR NOMINATIONS

Entries are being sought for any company, product, application, or individual involved in the supply, installation, service, maintenance and repair of industrial machinery, such as electric motors, drives, pumps, fans, gearboxes, generators, transformers, switchgear, and ancillary equipment. Individuals can put forward entries for themselves and their own company, or they can nominate others that they know merit recognition. The online entry process couldn’t be easier, so anyone wishing to play their part in highlighting engineering excellence should visit the AEMT Awards website.

CLOSING DATE

In keeping with the programme schedule from previous years, the closing date for all entries has been set at 5.00pm on Friday, September 6, 2024. So, for those wanting industry-wide recognition for a job well done, be it product innovation or project management, application knowhow, or service and repair, they should make a note of this key date.

It is free of charge to enter the awards, but the promotional value associated with being selected as a finalist is worth many hundreds of pounds. And for those individuals and companies fortunate enough to be announced as one of the winners during the charged atmosphere of the gala awards dinner, the promotional benefit is even greater.

So, what have you got to lose? Just 20 minutes spent completing the online entry form, providing the information and details that you have at your disposal, and which presents and supports your business and professional endeavours, could make you a winner in your industry’s awards programme; the gravitas and promotional exposure for which is both valuable and enduring. TIMES-CIRCLE

www.theaemt.com Quarter 2 2024 12 Awards Update

www.aemtawards.com

Easy to Use General Purpose Drive

Focused on ease of use, TECDrive provides unrivalled simplicity of installation, connection and commissioning, allowing the user to benefit from precise motor control and energy savings within minutes.

IP20

Up to 37kW

•Easy to use

• Compact & robust

IP66

Up to 22kW

•Outdoor rated

• Dust-tight

• Washdown ready

IP66 SWITCHED

Up to 22kW

•Built-in isolator, fwd/rev switch and potentiometer

Drive

www.tecmotors.co.uk enquiries@tecmotors.co.uk Tel: 01299 252990

252 990

01299

high-efficiency motors for oil pumping stations

NIDEC ASI, PART OF THE MOTION & Energy Division of the Nidec Group, has been chosen by SIOT – Società Italiana per l'oleodottoO Transalpino S.p.A., part of the TAL Group – as a partner in the TAL pipeline efficiency project that transports oil from Trieste to Austria, Germany and the Czech Republic.

This is one of the most important infrastructures for oil transport in Europe, and with its 753km of pipelines, it supplies eight refineries in Central Europe.

Nidec ASI was asked to supply 13 medium-voltage asynchronous motors. The new Nidec motors, model ET 900 V2, will have a nominal power of 3600kW, a 20% increase over the current infrastructure motors. They will be destined for the Italian oil pumping stations in Trieste, Cavazzo, and Paluzza.

Nidec was able to meet the stringent technical requirements of the TAL group and the oil industry, which demand high levels of efficiency, low starting current, high adaptability and resistance to operating temperatures, power factor

optimisation and a significant vibration reduction.

The motors are scheduled to be installed during this year. This phase, which involves working closely with the pump OEM and the TAL Group's operations functions, will be speeded up by adapting the motor's dimensions in the onshore placement and all the machine's power interfaces.

"We are enthusiastic to have signed an agreement to supply our engines for a strategic infrastructure that will continue to play such a key role in the distribution

of hydrocarbons on the European continent," said Dominique Llonch, CEO of Nidec ASI. "We have been chosen for the added value of our technologies, which will ensure the efficiency of the pipeline's pumping centres by increasing the availability and cost-effectiveness of the energy as well as improving the safety of the oil plants."

MOTOR OVERHAUL FOR STEEL EQUIPMENT MANUFACTURER

QUARTZELEC MALAYSIA HAS recently completed an overhaul and rotor refurbishment on a 11,000V, 4000kW, Chongqing Electric synchronous motor for a steel equipment manufacturer located on the East Coast of the West Peninsular of Malaysia.

The client had encountered some issues with the existing coils during operation and decided to fully replace them to avoid any further problems.

On site, the rotor and stator were dismantled and transported to the Kuala Lumpur-based workshop where the team set to work.

After initial inspections, the rotor coils were removed, and the rotor frame was cleaned, insulated and varnished.

Replacement rotor coils were provided by the client and following installation, full electrical inspections were conducted and witnessed by the client’s representatives.

Following a full rotor assembly, no load testing was successfully conducted, again, witnessed by the client and the machine was safely packaged and transported back to site for full installation.

RETROFIT SAVES THE DAY FOR BOILER CYLINDER MANUFACTURER

A MANUFACTURER OF BOILER cylinders needed a quick fix when an old Siemens S7-200 PLC broke down on a critical machine.

Westin Drives' engineers were quickly on site in Wakefield to repair the unit and have the company back in production the next day. To safeguard the machine's long-term operation, a retrofit of the PLC to non-obsolete parts was planned.

A Siemens S7-1200 PLC was selected, as this was the closest

modern replacement to the original, along with a Unified 4in HMI. Westin's technical services

engineers studied the machine's operation and prepared the new PLC program off-site to allow for a quick changeover.

The retrofit was undertaken in a morning's downtime, and the machine was back up and running in time for the

afternoon shift to continue production. The customer was happy with the service, commenting that the new program saved time on each cycle of the machine, allowing more production throughput.

www.theaemt.com Quarter 2 2024

14

Project Updates

www.nidec-industrial.com www.westindrives.com www.quartzelec.com

Why is Smart Site right for you?

Smart Site is easy to use on any smartphone or tablet device and requires very little training.

Smart Site reduces the waiting time of documents in transit. All job information is visible at the office as it happens.

Smart Site delivers accuracy. The app captures information as it happens, meaning there is less chance that something important is missed or recorded incorrectly.

Smart Site streamlines the administrative process ensuring that contracted and chargeable work can be completed in a timely fashion and invoiced with complete confidence.

Smart Site stores the history of an asset’s repair and service, so your engineer has all of the detail they need to do the job right first time.

Job (61239) Lead Engineer: GARYD Job Info Documents Assets Scheduled Labour Record Time Record Materials Record Expenses Engineer Report Record Activities Job Notes Links Photographs Health & Safety Checklists Service Checklists Obtain Customer Signature Job List 61239 Site work Service of 2 x ac motors United Performance Ltd LOOSE PAPER MILL B TONN ROAD LIVERPOOL MERSEYSIDE L34 9JB Lead Engineer: GARYD 27/02/2023 14:30 16:30 51676 Service centre Overhaul of Sewage Pump United Performance Ltd LOOSE PAPER MILL B TONN ROAD LIVERPOOL MERSEYSIDE L34 9JB Lead Engineer: GARYD 27/02/2023 08:00 10:00 60498 Site work Motor repair United Performance Ltd LOOSE PAPER MILL B TONN ROAD LIVERPOOL MERSEYSIDE L34 9JB Lead Engineer: GARYD 27/02/2023 10:30 11:30 60484 Site work Borehole pump United Performance Ltd LOOSE PAPER MILL B TONN ROAD LIVERPOOL MERSEYSIDE L34 9JB Lead Engineer: GARYD 27/02/2023 12:30 13:30 07:49 Mon 27 Feb

mobile

A

application enabling paperless service and repair

Scan the QR

EMiR Software have nearly thirty years’ experience in providing job management solutions for the Electrical & Mechanical Industry, in fact 47% of the AEMT UK Membership have purchased EMiR Software. Call us today and see how EMiR can help you – 0845 009 4588 Visit www.emirsoftware.com to book a demonstration

your engineers with an app that can: 1 Create new jobs 2 View the details of the job 3 Record the work detail undertaken 4 Adhere to ISO standards, site safety and services COMPLETE JOB 5 Review the work and gain customer sign-off

See Smart Site in action!

Code to find out more

5 Steps to Service Success Empower

MONITORING TRANSFORMERS TO GUARD AGAINST SOLAR FLARES

ELIMPUS LTD HAS INSTALLED several of Vaisala’s online transformer monitoring solutions on behalf of Scottish Power, a leading British energy provider, to carry out real-time condition updates.

In one application, the Optimus DGA Monitor OPT100 will provide continuous updates on Scottish Power’s 1000MVA auto transformer and monitor for the impact of geomagnetically induced currents on the asset.

Scottish Power is a British energy provider and distribution network operator for central and southern Scotland, as well as parts of northern England and Wales. It is also the transmission grid owner for the south of Scotland. At a key site in Scotland’s central belt, Scottish Power wanted to protect a 1000MVA autotransformer from the effects of solar flares – periods when intense high-energy radiation is emitted from the sun’s surface, causing radio and magnetic disturbances on Earth. Coupled with local geology, these have the potential to disrupt power to the magnetic circuit of transformers, leading to inefficient power transmission and significant damage to the transformers.

In order to accurately and continuously monitor the condition of its transformer, detect the effects of geomagnetically induced currents, and take proactive maintenance if required, Scottish Power commissioned the installation of the transformer monitoring solution.

The OPT100 is Vaisala’s most advanced monitoring solution and assesses a transformer’s condition by measuring for the presence of moisture and seven different fault gases in transformer oil.

“Scottish Power has a number of strategic transformers on the transmission network that require advanced condition monitoring, and we have been increasingly wary of the effects of solar flares and geomagnetically induced currents to disrupt their efficient performance,” said Keith Black, System Performance Senior Engineer at Scottish Power. “The Vaisala unit was installed because it met our current specification of online DGA devices with the addition of being maintenance free.”

An additional and key benefit of Vaisala’s

OPT100 over other transformer monitoring equipment is its simple installation process, which enabled Elimpus and Scottish Power to quickly and independently bring the unit online.

Scottish Power has been using the OPT100 since November 2017, and has benefited from greater oversight of its asset’s condition. “The OPT100 gives us the ability to track any disturbance that may occur and extend the lifetime of our transformer, as well as reducing the possibility of any unplanned outages,” concluded Keith.

www.vaisala.com

FLEXIBLE CONFIGURATED EXTRUDER MOTOR DELIVERED WITHIN TWO WEEKS

A PETROCHEMICAL PLANT operator urgently needed to replace a failed extruder motor featuring 6MW rated power, a 10kV nominal voltage, and requiring >57kNm nominal torque. Originally, the extruder was driven by a squirrel-cage motor. However, a motor with similar design parameters was not readily available on the market.

Fortunately, Menzel Elektromotoren was able to offer a suitable threephase slip ring motor. The slip ring motor design also offered significant advantages for the target application, driving an extruder, as it provides the required full torque from standstill.

MENZEL was able to quickly procure a starter for the slip ring motor and implement all necessary modifications in-house. Thanks to a delivery time of only two weeks, the customer restarted the extruder system as soon as possible.

MENZEL’s modular MEBSSL motor series is designed to enable flexible configuration for various applications and conditions. One of the most timeconsuming jobs, in the case of this extruder application, was fitting a bushing in the customer’s coupling hub and machining it from a diameter of 280mm to 240mm. In addition, MENZEL manufactured adapter plates for the motor to adjust the shaft height from 800mm to the failed motor centre height of 900mm. The replacement motor is designed with protection class IP55 and cooling type IC 611 with an air-to-air heat exchanger.

After the electric motor had undergone final tests in its Berlin test

facility, MENZEL’s motor experts also accompanied the commissioning of the extruder drive. The motor was aligned, wired and successfully commissioned on site. www.menzel-motors.com

Quarter 2 2024 www.theaemt.com 16 Project Updates

www.brookcrompton.com

Keeping industry turning every second... every day...every year

With over 110 years of technical and design expertise, Brook Crompton offers leading edge energy efficient electric motors across global markets. As the original innovator in electric motor development, Brook Crompton are trusted to power limitless industrial processes and its robust motor design drives fans, pumps, compressors, conveyors and more.

Driven by technology and innovation, Brook Crompton has one of the widest available ranges of electric motors for operation in safe areas, hazardous atmospheres and hostile environments.

The extensive range of stock can be quickly modified to suit customers’ needs and with a high level of technical support from our knowledgeable team we ensure the correct selection of motors is provided for your application.

Brook Crompton’s focus on product and service development ensures we continue to move forward to improve efficiency, offer lower cost of ownership throughout their lifecycle and to reduce environmental impact.

Contact us at: T: +44 (0)1484 557200 E: sales@brookcrompton.com

Understanding Vacuum Pressure Impregnation

VPI, or Vacuum Pressure Impregnation is a process which can be used as part of a rewind and repair of an electric motor to enhance its ongoing performance. Chris Callander gives an overview of the process, its application in electric motor repair, the benefits it delivers, and the considerations around cost versus benefit.

First introduced back in the 1960s, Vacuum Pressure Impregnation (VPI) is a process that enhances the reliability, performance, and lifespan of electric motors. Predominantly used in the repair and manufacturing of electric motors, VPI addresses many of the challenges faced in motor maintenance. Essentially, it is a method used to improve the insulation properties of electric motors by thoroughly impregnating the windings with a high-quality insulating resin under vacuum and pressure.

The process consists of several key steps. Firstly, the motor or component is cleaned and prepared, with all necessary repairs made before the impregnation process. The stator or rotor is then placed in a sealed chamber, and air and moisture are removed by creating a vacuum, ensuring that the winding is free of contaminants that could affect the impregnation quality. Then, under vacuum, the chamber is filled with the impregnation resin before pressure is applied to ensure the resin penetrates deeply into the windings and any voids. Finally, the impregnated part is cured, typically in an oven, solidifying the resin and ensuring a robust, uniform insulation system.

thermal management is critical.

ADVANTAGES OF VPI

Using VPI as part of the electric motor repair process should significantly improve the electrical, mechanical, thermal, and chemical resistance properties of the motor's windings. The impregnation process eliminates air gaps and voids, reducing the risk of insulation failure and thereby extending the motor's operational life.

By filling all voids within the windings, VPI also improves heat dissipation, allowing the motor to run cooler and more efficiently. This is particularly beneficial in high-load applications where

In addition, the resin used in the VPI process provides good resistance to moisture, solvents, and other chemicals, making it ideal for motors operating in harsh environments, such as chemical plants or outdoor installations. While the impregnation process enhances the mechanical strength of the windings; protecting against vibration and mechanical stress, which is vital for motors in applications involving high torque or frequent starts and stops.

COST VERSUS BENEFIT

While there are several valuable benefits to using the VPI process as part of a motor repair, it's not always justified. Due to the specialised equipment and materials required, the VPI process can be more expensive than traditional varnishing methods. So, for smaller, less critical motors, the cost of VPI may not be justified when cheaper repair or even a more efficient replacement motor might be a better option.

However, for motors that are crucial

to operations or have high replacement costs, VPI can offer significant savings by extending service life and reducing downtime. In environments where motors are exposed to moisture, chemicals, or extreme temperatures, VPI provides a level of protection that can prevent premature failure. And for high-power applications or motors with unique operational requirements, VPI enhances performance and reliability, making it a worthwhile investment.

CONCLUSION

By offering superior insulation quality, improved thermal management, and enhanced protection against environmental factors, VPI can extend the life and performance of electric motors. While the initial costs associated with VPI may be higher than traditional methods, the long-term benefits in terms of reliability, efficiency, and operational lifespan often justify the investment, especially for high-value or critical motors.

However, understanding the benefits and limitations of VPI is crucial for making informed decisions about motor maintenance strategies.

There are many more variables than we can cover in this article when considering whether VPI is benefical in any given scenario. One of the best ways to establish whether your motor or application would benefit from VPI is to talk to an electromechanical repair specialist. The member search section of the AEMT website allows users to search for a repair partner by categories, including location and services offered. TIMES-CIRCLE

www.theaemt.com Quarter 2 2024 Repair techniques 18

www.theaemt.com

Wire Electric Supplies Ltd • Elantas Varnish & Resins • High Voltage Insulations • Adhesive Tapes • Woven Tapes • Nomex® & Nomex® Laminates • Low & High Voltage Cables • Electrical Sleevings • Copper Wire +44 (0) 1952 208 730 www.wes.uk.com WANTED New or used, 80-100 frame Ex d and Ex de motors For Ex repair course Contact training@aemt.co.uk

comparing the environmental impact of repairing versus replacing electromechanical assets

In collaboration with electromechanical repair specialist Houghton International, Newcastle University has conducted a study to assess the environmental implications of repairing versus replacing an AC electric motor and a direct-driven wind turbine generator. The study, which focused on the impact on global warming potential and natural resource depletion, assessed three scenarios for each device – direct replacement, a repair lasting ten years and two repairs lasting five years each – and made some interesting findings.

The investigation, which formed part of an MSc dissertation titled “Using Life Cycle Assessments to compare the environmental impact of repairing versus replacing electric motors and wind turbine generators,” considered factors such as material quantity, energy consumption, transportation, and endof-life scenarios. It utilised the OpenLCA program, a software-based framework for sustainability assessment and life cycle modelling, and the Ecoinvent 3.8 database, a life cycle inventory that provides

reliable and transparent information on the environmental impacts of various products and services for a comprehensive Life Cycle Impact Assessment.

Premature asset failure prompted the investigation into three scenarios: total replacement of the asset, a repair to the asset after ten years of service, which lasted a further ten years, and a repair after ten years of service, which lasted five years, followed by an additional repair which lasted a further five years. The study’s cut-off point was set at 20 years, acknowledging the potential for the cycle to repeat indefinitely.

In the supply chain process, companies weigh factors such as cost, volume, quality control, and carbon footprint when deciding between repair and replacement options. The study’s system boundaries for inventory analysis considered inputs (raw materials and energy) and outputs (products, waste, emissions, air, water, and soil). Impact assessment focused on climate change with the global warming potential (GWP) and natural resource depletion measured as the abiotic depletion potential (ADP). It should be understood that an asset’s total

www.theaemt.com Quarter 2 2024 Circular Economy 20

cost of ownership in financial terms is often also considered, which did not fall within the scope of this study. However, a number of key findings were made that were related to the objectives of the analysis.

KEY FINDINGS

Environmental impact reduction: Repairing assets after ten years, rather than replacing them, can decrease associated GWP by 40.9% for motors and 37.4% for generators. Raw material acquisition, assembly and pre-processing have been identified as some of the most significant contributors to negative environmental impact.

Embodied carbon preservation: Manufacturing a new mechanical asset involves a substantial amount of embodied carbon in the production process. Repairing allows the preservation of this embodied carbon by extending the useful life of the existing equipment (the embodied carbon accounted for approximately 50% of GWP in all scenarios).

Energy conservation: The energy required to produce and transport a new mechanical asset is typically higher than that needed for repair. Choosing repair supports energy conservation and reduces the overall environmental impact associated with the production and disposal of mechanical assets. This aligns with global efforts to mitigate climate change and minimise the ecological footprint of industrial activities, which in turn helps organisations comply with regulations related to waste disposal and emissions, contributing to a more responsible and eco-friendly operational strategy. However, this factor needs to be considered in the context of any change to lifetime energy consumption should a replacement motor offer an increase in energy efficiency.

Circular economy benefits: Repairs using recycled components align with the principles of a circular economy, reducing discarded equipment and promoting sustainability.

Social benefits: The social benefits of implementing these responsibilities also deserve to be mentioned. By implementing a system of inspection, repair, maintenance, and monitoring, Houghton International has demonstrated its commitment to creating, developing, and upskilling a workforce with sustainable professional development opportunities essential to contributing to a circular economy.

Operational responsibility: Companies play a crucial role in environmental stewardship regardless of industry. In some circumstances, choosing repair over replacement can influence a company’s operational trajectory, showcasing commitment to positive environmental, social, and community policies.

CONCLUSION

While the benefits of repairing the assets studied rather than replacing them were demonstrated, the scenario that simulated two repairs in a ten-year period showed that the quality of a repair impacted the GWP over its lifespan. This reinforces the importance of selecting a company that carries out rewinds and repairs to the highest standards.

More details about the study can be found on Houghton International’s website, where a full copy can also be requested. TIMES-CIRCLE bit.ly/HIstudy

ELECTRIC MOTOR ANALYSERS FROM WHITELEGG MACHINES

Supporting motor manufacturing, test and repair with expertise and world beating machinery and instruments, Whitelegg can advise on the best solution for your project.

MTC2 R7 AUTOMATIC ELECTRIC MOTOR ANALYSER

Measure the motor’s performance with special analysis software to give a complete picture

MOTATEST 1 - MULTI-FUNCTION TESTER

All-purpose tester for testing electric motors and products with windings whitelegg.com Call us now: +44 (0) 1293 526 230

2 - 3KV MULTI-FUNCTION SURGE TESTER

A truly universal tester delivering truly remarkable benefits, with special test functions for DC motors

Circular Economy 21 www.theaemt.com Quarter 2 2024

NEW MOTATEST

Innovative Motor technology delivers higher efficiency across the full speed range

In an era of evolving energy efficiency standards and a growing commitment to environmental responsibility, motor manufacturer WEG has launched the W23 Sync+ motor line. Marek Lukaszczyk, European and Middle East Marketing Manager at WEG, introduces the benefits of the new PMSynRM technology.

The W23 Sync+ is a hybrid innovation that combines permanent magnet (PM), ferrite or neodymium magnets and synchronous reluctance (SynRM) motor technologies, providing higher efficiency across all speeds when compared with conventional induction motors.

WEG prides itself on staying ahead of international standards and regulations, and the quest for very high efficiency levels, now reaching IE5, was the driving force behind this innovation. That is why the IE5 W23 Sync+ model surpasses the current European Ecodesign regulation, which stipulates that equivalent new motors must meet the IE3 or IE4 standard.

As traditional induction motor technology approaches its efficiency limits, the need for alternatives has become more apparent. To achieve higher efficiency levels, electric motors must have very high inrush current levels, which demands new starters and protection systems when replacing an existing motor. While SynRM motors offer a potential solution to meet IE5, they also have shortcomings, such as a low power factor that necessitates larger drives and increased costs.

HIGHER EFFICIENCY AND LOWER LOSSES

The PMSynRM technology developed by WEG ensures a flat efficiency behaviour, boasting a

higher efficiency level for the entire speed range when compared with conventional induction motors, and a higher power factor than synchronous reluctance motors. This approach results in a lower total cost of ownership (TCO) for plant managers. The PMSynRM technology varies in the separation of electrical losses in the electric motor by employing magnets. The magnets generate their own magnetic field without requiring induction of currents. Therefore, they reduce the motor's total losses.

For example, while a conventional induction motor loses over 20% efficiency across its varying speed and load ranges,

the W23 Sync+ maintains its higher efficiency, decreasing less than 2% when the load and speed are reduced by 25%.

However, efficiency isn't just a metric for energy consumption; it extends to the operational life of the motor. The W23 Sync+ generates less heat, which leads to a longer lifespan, fewer replacements and reduced maintenance requirements. This also eliminates the need for additional cooling.

In addition, the W23 Sync+ motor line unlocks energy savings that directly impact facilities' CO2 reduction efforts. The WEG team has calculated that replacing an IE3 induction 75kW 4-pole motor

www.theaemt.com FEATURE 22 Quarter 2 2024 Motor Innovations

with an IE5 W23 Sync+ may result in a reduction of 126 tons of CO2 during the latter motor's expected lifetime of 25 years. This takes into account an operation time of 6,500 hours per year.

Development of the W23 Sync+ began in 2021and WEG's technical competence groups –spanning electromagnetic analysis, structural analysis, lamination analysis, electrical and magnetic materials, insulation materials, polymeric materials, vibration of rotating electric machines, fluid-thermal-acoustic analysis and bearing and lubrication –worked collaboratively to ensure a comprehensive approach to product development.

WIDE SUITABILITY

The W23 Sync+ is available in a range of frame sizes, from IEC 80 to 450 (NEMA 140 to 7000), and can operate over a wide speed range at constant torque without the use of forced ventilation. Speed ranges from 750 up to 6000rpm

are available, and the motor's output rating ranges from 0.75 to 1250kW, while it is compatible with a 220/380V, 230/400V, 240/415V or 400/690V power supply.

The PMsynRM motors can be used in a diverse range of industries, though they are best suited to applications with varying loads, thanks to the technology's ability to maintain high efficiency, even at partial load. The line is suitable for applications including compressors, pumps, fans, blowers, conveyors, and more.

Manufactured in Brazil and China, the W23 Sync+ motor line is globally available and backed by WEG's technical support and services.

Efficiency isn't just a metric for energy consumption; it extends to the operational life of the motor.

Furthermore, the ferrite magnet used in the W23 Sync+ is constructed from ceramic material and has a local supplier and producer. This avoids global supply chain issues and results in material price stability.

Thanks to its design, the W23 Sync+ is compact and has the same power-per-frame ratio as induction motors. For example, the IE5 variety is available in the same frame size as an IE3 motor, which makes interchangeability with existing installations smooth and hassle-free.

In the realm of electric motors, the W23 Sync+ addresses challenges posed by efficiency limits and environmental responsibility as industries strive for efficiency, reliability, and sustainability. TIMES-CIRCLE

Motor Innovations 23

bit.ly/W23Sync

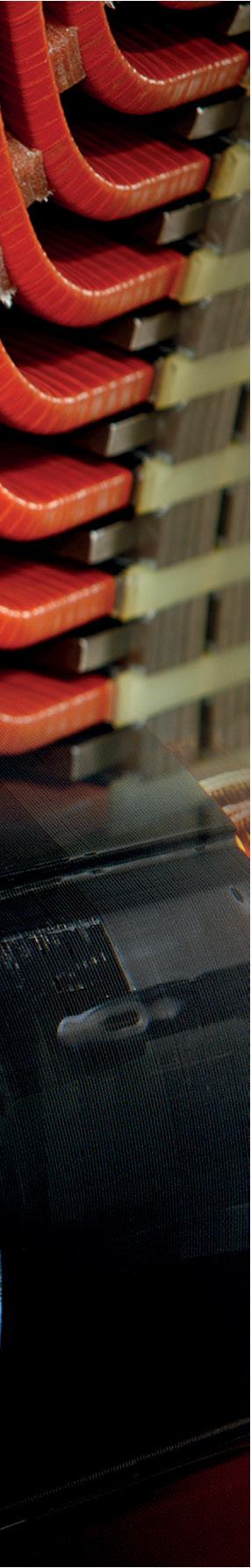

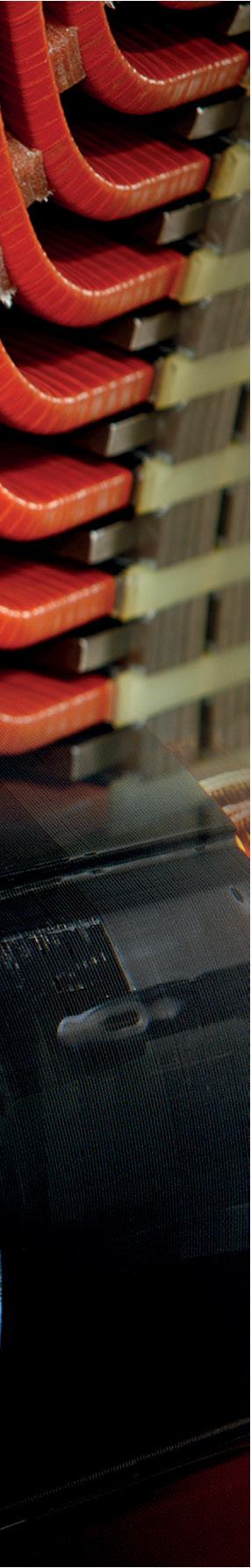

DC Motor Maintenance: Tackle brush issues

Singapore-based Maintech Engineering & Supplies looks at four common issues encountered with DC motors and outlines actions which can be taken to remedy them.

DC motors and even brushed AC motors depend on brushes for good uptime and efficiency as they provide the electrical connection between the commutator and the power source. To efficiently and effectively transmit electricity, brushes must always remain in good condition, which equates to having consistent full, flat contact with the commutator. A good maintenance regime for the brushes and commutators is key to ensuring a DC motor achieves a long service life. Still, even with proper care and maintenance, these components experience wear and tear and will eventually need replacement.

Signs that indicate when replacement may be necessary include the brush surface no longer being smooth and shiny and evidence of chipping and cracking. The brush being worn down to a quarter of its original length is another indication, as is the brush pigtail not securely fastening to the brush as it used to, or the brush not fully conforming to the commutator shape.

When it is time to replace the brushes, the motor’s manual should be consulted to verify that the replacement is of the correct dimension, grade, and type.

Let us explore the common problems that affect brushes and commutators.

GROOVING

Grooving leaves a slotted and smooth area on the commutator. It is typically caused by contamination and using brushes with the wrong grade or impurities. If this is evident, it is advisable to check whether the type of brush used is correct. Look for signs of contamination, and replace or clean the brushes if necessary.

THREADING

Threading causes fine lines on the commutator’s surface as a result of copper being shifted from the commutator to the brushes and getting embedded in the surface of the brush,

ultimately scratching the commutator. Using the wrong type of brush and contamination are also among the potential culprits of threading in DC motors, along with low brush pressure. If threading occurs, first clean the commutator and replace or clean the brushes and put them back with the proper tension.

FLASHOVER

A flashover is essentially a short circuit in a motor’s brushes due to a buildup of copper particles, dirt, and debris between the segments of the commutator. These segments are then shorted together and cause arcing between the brushes. Given how catastrophic flashovers can be, a DC motor must be deep cleaned, especially its commutator, if this ever happens. Often, cleaning the commutator will no longer suffice and a replacement is required. Lastly, the brushes also need to be inspected for damage from the short circuit.

COPPER DRAG

Copper drag occurs when copper particles are dragged to the very edge of commutator segments because of excessive vibration, brushes with insufficient tension, and abrasive brushes.

It is critical to address copper drag as soon as it is discovered since the copper buildup in the commutator segments can lead to the armature windings shortcircuiting and can potentially warrant an electric motor rewind. To address this issue, clean off the commutator’s copper flakes and then examine the brushes to see if they are of the proper grade.

CONCLUSION

When comparing DC vs AC electric motors, it is important to note that the maintenance considerations mentioned above primarily apply to DC motors. Because of the importance of brushes in DC motors and the inherent problems that affect them from time to time, regular maintenance is essential to ensure that the issues above do not fly under the radar and cause any long-term damage or catastrophic failure. Moreover, it is also recommended to always have spare brushes on hand should replacement be the only option due to excessive wear or contamination. TIMES-CIRCLE

FEATURE 24 www.theaemt.com Quarter 2 2024 DC Motors 24

www.mes.com.sg

Low voltage AC motor market performance in 2023 and beyond

Blake Griffin, Research Manager at market intelligence firm Interact Analysis, explores the performance of the low voltage AC motor market in 2023, and what the prospects are for the sector in 2024 and beyond.

Over the past three years, the low voltage AC motor market has experienced significant revenue growth, with year-over-year growth rates reaching 16.4% in 2022. While the rate of revenue growth decelerated substantially in 2023, it is important to note that much of this deceleration is due to lack of price rises.

When viewed through the lens of unit shipments, the slowdown is less dramatic. 2023 is expected to post year-over-year growth of 2.9%, down from 4.0% in the previous year. While the decline is modest, the timing and nature of the decline is indicative of what the market can expect for the near future.

Between 2020 and 2022, demand for motors significantly outstripped the production capabilities of many suppliers. As a result, backlogs increased and the benefits from a post COVID-19 surge in demand were spread across 2021, 2022, and into 2023. The market for low voltage AC motors benefited from this through the first half of 2023, however, this quickly changed during the latter half of the year.

New orders for motors saw a significant downturn beginning in June 2023, as interest rates continued to climb and projects became delayed amid economic uncertainty. This resulted in backlogs largely drying up for motor suppliers and many vendors experiencing a contraction during the last six months of the year. Consequently, 2023 went from being a continuation of above-average growth to a mediocre year.

At the start of 2023, evidence of the coming slowdown was already beginning to show. Within the US market, the Federal Reserve produces a series which tracks year-over-year percentage changes for industrial machinery production on a monthly basis. As early as February 2023, the value of industrial machinery production had begun to contract and production has continued to slide.

When you consider that approximately 70% of motor revenues are generated

through sales to machinery and equipment OEMs, this contraction has a significant impact on the demand for motors.

2024 AND BEYOND

This downward momentum is expected to continue in 2024 as the market enters the low point in its cycle, and we are expecting the market to contract by 0.7% this year. While performance varies across regions –with some still maintaining growth during the year – nearly all regions are performing below their 2023 levels. While underlying manufacturing industry performance is the core driver of this decline, we are forecasting a slight decrease in average selling price, which is further exacerbating the decline in revenues.

Prices remained steady in 2023, following two years of rapid increases. However, with a year of lower demand expected for 2024, we anticipate large customers will have stronger negotiating power with their suppliers. This is likely to manifest as downward pressure on the average sale price for the market.

With a down year expected in 2024, the question becomes: what is the expectation for 2025? Our forecast shows a return to growth in 2025, as underlying industrial machinery production increases and the price growth of motors returns to the expected 2-3% per year. Globally, over the

16 years of data that Interact Analysis has analysed, the value of machinery production has never had back-to-back years of contraction. We do not expect 2025 to be any different.

We are expecting growth to return in 2025 and remain through to the end of our forecast, as the low voltage AC motor market enters its upswing once again.

FINAL THOUGHTS

With the market cooling after a few years of exceptionally strong growth, many vendors are looking for key growth areas. Sectors where we continue to see growth above the market average are those heavily tied to government spending. Following the pandemic, many of the largest economies approved legislation aimed at improving infrastructure as a means to stimulate the economy. This had the effect of buoying the motor market during the manufacturing downturn. Sectors like power generation and water/wastewater, for example, are posting above-average growth rates when compared with the broader market. This will continue through our forecast as the allocated funds are worked through. TIMES-CIRCLE

FEATURE 26 www.theaemt.com Quarter 2 2024 26 Market intelligence

interactanalysis.com

A brief history and forecast for low voltage AC motor market revenues in industrial and commercial applications. © Interact Analysis 2024.

Call for nominations now open...

The AEMT is once again looking to recognise and reward the people, companies, projects and services that play a crucial role in ensuring our food production, utilities, manufacturing processes, transportation and other essential services are maintained and secured.

Endorsements:

“MKE are delighted to be a part of this key annual event. The AEMTs commitment to celebrating success is a welcome entry in our calendar. This year was even more special as we were nominated for three categories and won one.”

Matt Savage MKE

“What a great evening. We were delighted to sponsor the ‘Rising Star’ category and meet the guys in person and we look forward to the 2024 awards and our continued support of the AEMT members.”

Scott Edwards TEC Motors

Thursday, November 21st 2024

DoubleTree by Hilton Hotel, Coventry

The awards are a global celebration of business and professional excellence. They recognise the achievements of both individuals and companies manufacturing, distributing, maintaining and repairing industrial machinery such as electric motors, drives, pumps, fans, gearboxes, generators, transformers, switchgear and ancillary equipment.

There will be 9 categories to choose from including: Product of the Year, Project of the Year, Supplier of the Year, Service Centre of the Year, Diversity in Engineering, Contribution to Skills & Training, Sustainable Engineering, the Rising Star Award, and the AEMT’s Special Recognition Award. Make sure you enter now to be recognised as a leader in your industry.

2023 Partners:

Online Entry at: www.aemtawards.com

PD monitoring identifies the cause of dust contamination

Partial discharge measurement specialist Power Diagnostix Systems, part of the Megger group of companies, used its online partial discharge monitoring technology to identify the cause of contamination on a critical motor in a European chemical plant.

Two months after machine cleaning, drying, and repainting a critical 10kV, 6.7MVA motor, a visual inspection uncovered substantial contamination with white powder-like dust. It's very likely that this dust has a reasonable surface conductivity, which poses a risk for strong surface discharges that can eventually lead to flashover. Additionally, the core material that was not covered with paint showed relatively strong corrosion. This indicated that the machine had seen very strong discharge activities, with the produced ozone acting as a corroding agent. Unfortunately, this process is a selfsupporting cycle – dust contamination leads to surface discharge, which causes stronger corrosion, which causes surface discharge, and so on. However, this behaviour is unusual only two months after overhaul and operation.

PARTIAL DISCHARGE MEASUREMENTS

Due to the criticality of the motor for supplying power to chemical process equipment, an extended outage for shop testing and additional overhaul would have caused large economic losses and posed additional risks. The customer wished to maintain the motor's operation for seven months without a significant outage. Therefore, online PD measurements were conducted to investigate.

The ICMsystem from high-voltage

measurement specialist, Power Diagnostix Systems, was used for partial discharge measurements after installing coupling capacitors and conducting PD calibration.

Phase-resolved partial discharge (PRPD) patterns obtained with the ICMsystem, as shown in Figure 1, indicated severely thermally aged insulation and strong surface discharges, which were very likely correlated with the dust contamination. Additionally, sparking or slot discharges were indicated by a pattern predominantly found with phase V, which increases with the machine's loading. Typically, loose wedges and subsequent deterioration of the ground wall insulation and slot corona protection due to bar vibration, are the cause of this type of slot discharges.

Generally, the discharge activity with this machine was relatively strong, with the strongest surface and slot discharges measured at values of up to 20nC and 25nC, respectively. Motors of similar age and size typically show activities below 5nC when in good condition.

CONCLUSION

PD measurements confirmed that the observed dust contamination was not benign. Despite the recent refurbishment, PRPD analysis confirmed strong surface discharge activity on top of severe thermal ageing. Simple cleaning and repainting would not be sufficient to allow this machine to continue reliable operation.

RECOMMENDATIONS

The typical recommendation based on the result of this testing would be immediate rewinding or replacement. However, the customer accepted the risk with further operation since the machine needed to remain uninterrupted for approximately seven months. Therefore, Power Diagnostix recommended installing a partial discharge monitoring device (ICMmonitor portable), which would use the already-installed coupling capacitors in the termination, which remained from the service job. Partial discharge activity could then be continuously monitored for the next seven months, and increased activity could be exported via a 4-20mA signal, via alarm contacts, or via a Monitoring Web Server (MWS), which PD experts from Power Diagnostix could then access for remote support and further analysis. Of course, it was recommended that rewinding or replacement was carried out as soon as operationally feasible or if increased PD activity was observed.

Power Diagnostix also recommended investigating the source of the dust within the cooling system. Once found, the corroded material could be suitably coated or painted to avoid further contamination and a subsequent increase in surface discharges. TIMES-CIRCLE

FEATURE 28 www.theaemt.com Quarter 2 2024

28 Partial Discharge www.pdix.com