The underground soil conditions tell the story of a large flat lowlying area.

Highlights the impact of the Ciliwung river and its subsidiaries on the quality of the landscape, as a terraforming agent.

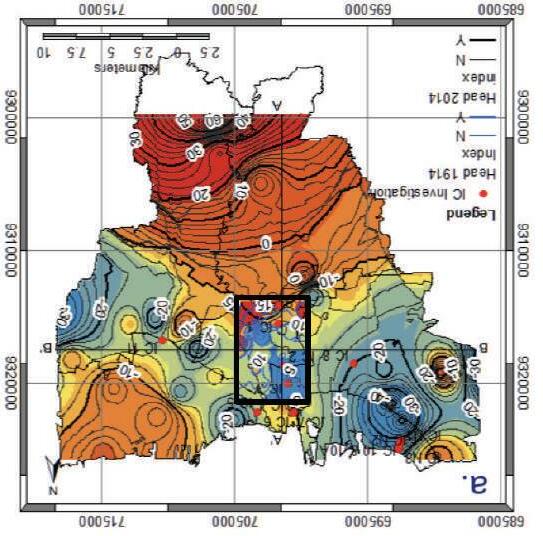

Difference in soil type does not seem to coincide with areas of drastically lowered groundwater head in West JakartaCengkareng and Tangarang.

Jakarta geological makeup

Contour lines and drainage patterns overlaid on map of surface geology show the funnel shaped basin, bound by the Cisadane (1) and Kali Bekasi (3). Rivers in the west and east, respectively

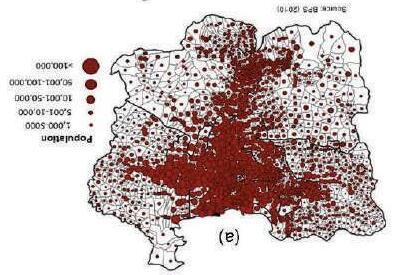

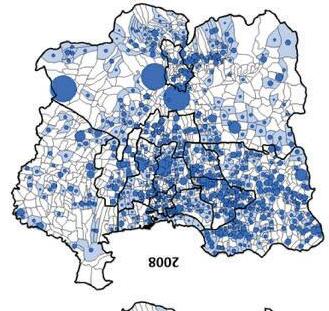

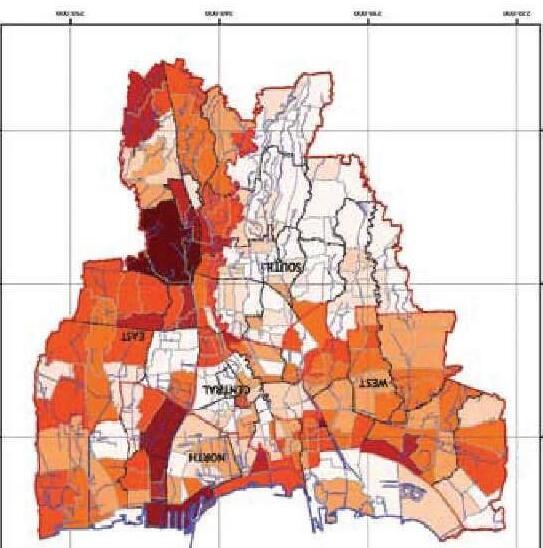

Graph (a) and (b) of Pravitasari, 2015 indicates the historic impact of the Ciliwung rivers on settlement.

Graph (e) shows the flatness of the Jabodetabek Megacity area.

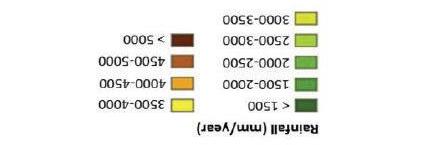

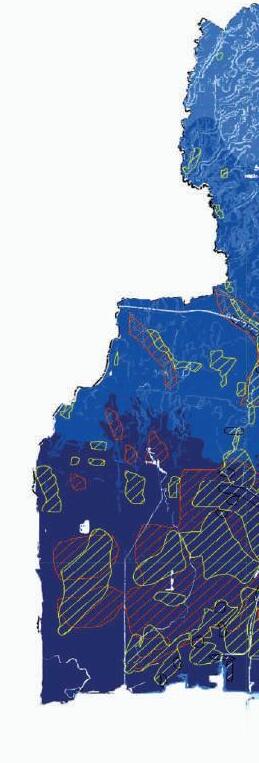

Mapping the Ciliwung river and its basin versus the areas of Jabodetabek getting the most annual rainfall, the relationship between rainfall, river flow and flooding seems to be that inland flooding is mostly caused by rivers running over.

The difference in impact of the 2002 and 2007 floods might be explained by the confluence of El Nino. The impact of the subsidiaries of Ciliwung are relevant to flooding in the southern areas of Jakarta. Flooding is less clearly distributed by natural trends in the north, other than elevation.

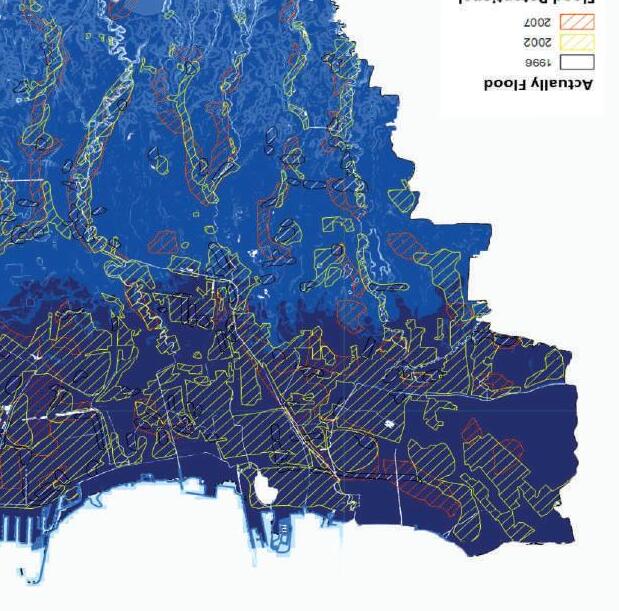

Distribution of informal settlements throughout Jakarta, compared to land classi

Many kampungs of Jakarta are not connected to piped water infrastructure. Since unregulated groundwater pumping was banned, they rely on trucks and scooters to distribute bottled water. This system is very vulnerable to flooding.

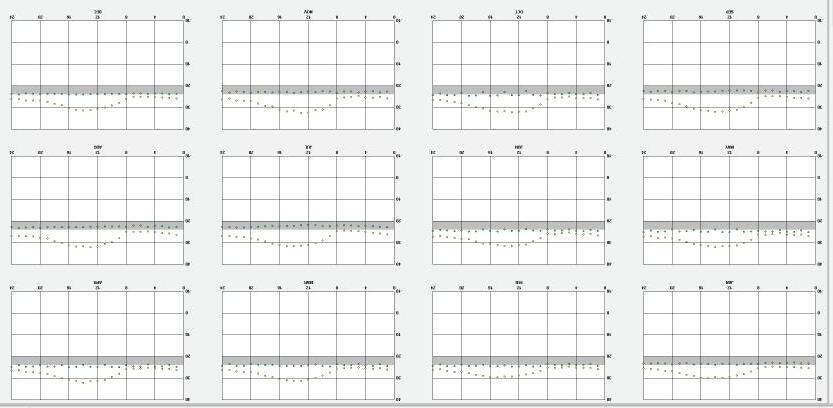

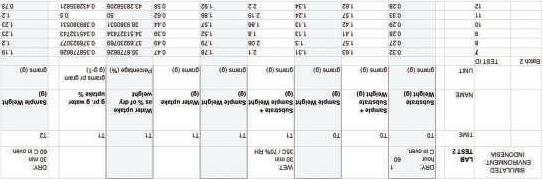

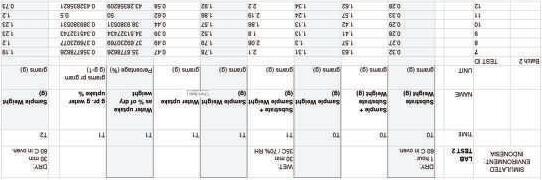

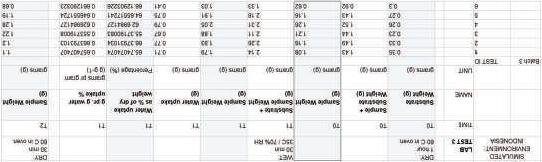

Data on weather conditions relevant to atmospheric water harvesting in Jakarta, from .epw files of local weather stations.

100% RH 2.3% of yearly - 204 hours.

>90% RH 18.27% of yearly - 1601 hours.

>80% RH 49% of year - 4331 hours.

Comparatively low solar potential (Watt hours per square meter per hour) when compared to the development context of SHPF. This is due to high average overcast ratio for Jakarta. The question is if it’s enough for generating and distributing an increase in temperature of around 25OC locally.

Traditional low-tech methods.

Emerging in it’s modern form in the 1980’s, fog catching technology, has been employed for acquiring water. Fog harvesting technology relies on specific climatic conditions being met to be effective.

Succesful projects have been developed in the highland coastal- and inland mountainous regions with high wind, where fog occurs frequently due to the natural compression of warm winds around the cold surface of inclined topographical features which create concentrations of relative humidity. This process is known as advection fog.

Using polarized fibers and polymers for netting (such as nylon, polyurathane and polypropylene) to aid with capturing and

As climate change is changing weatherpatterns all over the earth, waterstress - especially in densely urbanized areas in developing countries - is becoming a lot more common. Research into new ways to acquire freshwater from alternative sources is becoming an attractive project, to stabilize wateraccess in threatened areas and provide a greener and more accesible alternatives to traditional powerhungry methods, such as reverse osmosis desalination and conventional dehumidification.

A few actors who are making interesting progress in researching atmospheric water harvesting such as MIT and Texas university, as well as private companies such as Zero Mass Water - among many others.

As the princples are well established, the research is mainly focused on the development of specifically engineered materials, that perform well roles within atmospheric water harvesting systems, as well as how to make the systems scalable.

Whether creating a an actively (electrified) solar cycling AWH system, or a passive overnight absorption based system, the key performance/cost characteristics are:

A) Sorption and desorption rates of air vapor capturing material.

METAL ORGANIC FRAMEWORKS (MOF)

MIT / Berkeley Solar-cycling

+ Highly effective.

+ Do not degrade.

- Complicated to make properly.

- Expensive.

ZEOLITES

MIT Device Research Lab Overnight absorption

+ Cheap.

+ Do not degrade.

+ Simple.

- Not very effective.

https://www.2dmaterialsmag.com/metal-organic-framework-mof-device-that-pulls-water-from-the-air/https://news.mit.edu/2020/solar-extracts-drinkable-water-1014

B) Energy required for both heating the capture material to release the vapor or/and cooling of condensation substrate to harvest the captured vapor.

FROM ARTICLE:

“Sunlight + Air = Water. It’s a befuddling equation, but it’s at the heart of a new solar hydropanel developed by Arizonabased startup Zero Mass Water. The company’s SOURCE panels can be installed atop any building just like standard photovoltaics, but instead of just harvesting solar energy, they use the sun’s rays to pull water from the air. Each panel has the potential to draw up to 10 liters (2.64 gallons) of water per day.”

“Right now, the two-panel array costs $4000, plus installation, which runs $500. The whole system has been engineered to last 10 years, which according to Treehugger’s calculations, this averages out to about $1.23 per day, or between $0.12 and $0.30 per liter of H2O.

The hydropanels themselves consist of two different proprietary materials, one that can generate heat, and another that can absorb moisture from the air. Together they are able to condense water into an onboard, 30-liter reservoir where it is mineralized with calcium and magnesium. From there, the water can be siphoned directly to a drinking tap.

https://inhabitat.com/new-rooftop-solar-hydropanelsharvest-drinking-water-and-energy-at-the-same-time/

Described in Nature Communications in may 2022, Super Hygroscopic Polymer Films (SHPF) is a newly invented composite biopolymer. It’s high efficiency of water uptake in arid climates, aswell as it’s cheap and available material components and potential scalability make it relevant to atmospheric water harvesting all over the world.

SHPF has great vapor absorption traits (speed of absorption and absorption amount) and the energy it requires to release captured vapor is low. It achieves these properties by distributing hygroscopic lithium chloride salt molecules in a thin and highly porous fiber matrix made up of plant fibers. Material appears like a thin film, and it is produced by mixing the ingredients into a hydrogel, freezing the hydrogel and drying the material (through sublimation) in a freeze dryer.

SHPF works by taking advantage of specific chemical properties of 3 different material ingredients:

1) The emulsifying properties and the low temperature hydrophilicity-tohydrophobicity transition of hydroxypropyl cellulose (HPC).

2) The fiber strength and high viscosity, water solubility and hydrophilicity of konjac glucomannan fiber (KGM).

3) The good solubility and great hygroscopic potential of lithium chloride (LiCl).

As such, SHPF is preferable for scaling, when compared to other AWH substrate materials such as zeolites like silica gel, metal organic frameworks and pure hygroscopic salts.

Organic binding agent with low temperature hydrophiliv/hydrophobic transition.

Highly viscous organic fiber, used as emulsifyer for forming strong uniform gels.

Alkali metal salt with exceptional hygroscopic properties and great soluability.

Produced with short wood fiber from gum trees and long wood fibers from pine trees when made in european factories. Both lengths of wood fiber can be sought out in alternative species lik

Highly viscous organic fiber, used as emulsifyer for forming strong uniform gels.

Salt refinement

Alkali metal salt with exceptional hygroscopic properties and great soluability.

2 minutes

Precursor ingedrients are measured out, mixed untill even and set for 5 minutes, while the cellulose and konjac fibers form hydrogen bonds, until the gelation formation process is complete.

15 minutes

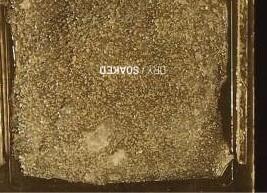

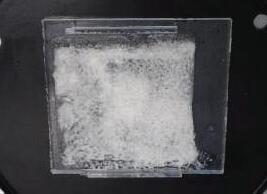

The hydrogel is poured into prepared acrylic molds. At this stage, the gel is shaped into the required surface area and thickness. The gel is set for 15 minutes to even equalize and even out.

3 hours / 15 minutes

The molds are pre-frozen at -4OC for 3 hours. It's important that the samples don't freeze solid at this stage. The Lithium Chloride dissolved lowers the eutectic freezing point of the solution. After this, the samples are rapidly frozen with liquid nitrogen bath for 15 minutes. This rapid and powerful freeze helps the water in the hydrogel freeze form small homogeneous ice crystals.

6 - 9 hours

The molds with the frozen samples are put in a lyophilizer, to remove the ice from the samples via sublimation. This is the gentlest way of removing water from the samples, and it helps maintain the pourous structure of the samples that makes SHPF able to absorb water vapor rapidly.

DEPLOY

30 minutes / 2 hours

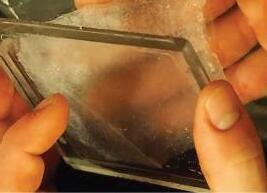

After drying the fiber matrix of the SHPF is cured and fully bonded. The dry samples are hard and brittle, but will resaturate with atmospheric moisture from ambient air over the course of 30 min / 2 hours, depending on the relative humidity of ambient air, and become soft and workable, at which point they can be lifted from the molds and deployed.

SETUP ROSKILDE UNIVERSITY

acrylic SAMPLE molds FOR POURING AND FREEZEDRYING

Mixed hydrogel precursor in acrylic casting mold

CONTROL PH-INDICATOR Range 7.5 - 9.5

precursors 01: kgm fiber + hpc cellulose microgram weight

precursors 02: licl + water USED VESSEL FOR MIXING AND SAMPLE GELATION

TOOL FOR MEASURING, MIXING, STIRRING and SCRAPING SHPF

Liquid nitrogen box used for batch 1. Stacking samples inside proved to be a terrible idea as the buttom molds got submerged and cracked after the liquid nitrogen pour or during re-heating from ambient air when pulled out of the box.

BATCH 1 FREEZING CHAMBER

~500ml Liquid Nitrogen. Lowest 4 samples and acrylic molds heavily damaged from direct exposure. Redesign freezing chamber.

SHPF MOLDS AFTER BATCH 1NITROGEN LEAKS -- FIXED WITH MYLAR INSULATION

CNC cut accyrlic molds for pouring SHPF samples. Photographed inbetween batch 2 and 3. Cracks are from material contraction and expansion due to heavy cooling. Spacers glued on with acrylic glue, to stack movlds in freezedrier.

BATCH 2 FREEZING CHAMBER

Liquid nitrogen box 2, used for batch 2 and 3. Reinforce and insulate box futher for scaling production, to slow the loss of liquid nitrogen from evaporation. Studs of styrofoam glued in place with silicone caulk to offsett acrylic molds.

When exposed to cryogenic temperatures from liquid nitrogen, the silicone caulk seal binding the styrofoam edge to the base plate contracted tore, creating gaps that leaked liquid nitrogen onto the floor.

Turns out an improvised insulation lining of mylar is an excellent way of containing liquid nitrogen in the freezing chamber.

The chemical department at Roskilde University granted access to their old

SAMPLE HOLDER

Due to the specialized elements needed for the production of SHPF, an alternative and simplified production approach was attempted for creating an SHPF material without, using a regular -25oC freezer instead of liquid nitrogen and silica gel instead of a vacume freezedryer (lyophilizer) The setup was able to surpass the eutectically lowered freezing point, but the produced samples were unviable, as they hadn’t been adequately dried after 1 week. See SCP.

Lithium chloride / water freezing point temperature.

EUTECTIC FREEZING POINT 0.88g LiCl / 10ml water 8.8% = -11OC

EXPERIMENTAL PRODUCTION: Temperature range: -20-25oC

Additive concentration [weight-%]

The samples proved viable, as they were able to perform absorption/release cycles, but the general quality of the samples inconsistent and low.

Sample 1-8 made up the lowest 2 layers in the stack of samples inside the freezing chamber. The heavy damage to these samples from being submerged in liquid nitrogen during the freeze led me to redesign the cooling setup.

Water: (H2O) 10 ml

Hydroxypropyl Cellulose (HPC) 0.1g (1 wt%)

Konjac Gluccomannan (KGM) 0.44g

Lithium Chloride (LiCl) 0.88g

After upgrading the liquid nitrogen cooling box the quality and consistency of the samples were much improved. Still a lot of heterogeneity from the manual mixing and pouring of the hydrogel precursor.

Additionally the HPC cellulose content of the samples were increased from 1g/10ml to 1.5g/10ml to give the samples additional tensile strength, based on experience gained from handling the first batch. Based on the data from Guo. et al. (2022) this should have lowered the maximum overall effectiveness of the SHPF slightly, compared to the SHPF described in their paper.

This was not the case for my samples as the absorption/ release amount was improved for batch 3, compared to batch 2, for my testing. I would attribute this to the added strength improving the general consistency of the samples produced form my setup, compared to batch 1. Batch 3 also shows slightly better release values, likely related to a higher presence of cellulose contracting from heat during the release cycle.

Konjac

MEASUREMENT CHAMBER

TESTING THE VIABILITY OF THE SAMPLES

135

246

ENVIRONMENT CHAMBERCONTROL PANEL

AIRFLOW CONTROL

AIRFLOW CONTROL

TESTING CHAMBER

HYGROTHERMOMETER

HEATING ELEMENT

HEATING ELEMENT

Samples are dried at 60oC in an oven for 60 minutes, and weighed to get their dry mass in grams. Samples are placed on a sheet of plastic for handling and mounting in frames. Sheets of plastic weighed and marked beforehand. Samples are then placed in environment chamber for 30 minutes and weighed again after to determine water uptake, measured in grams of water per grams of material (g g-1).

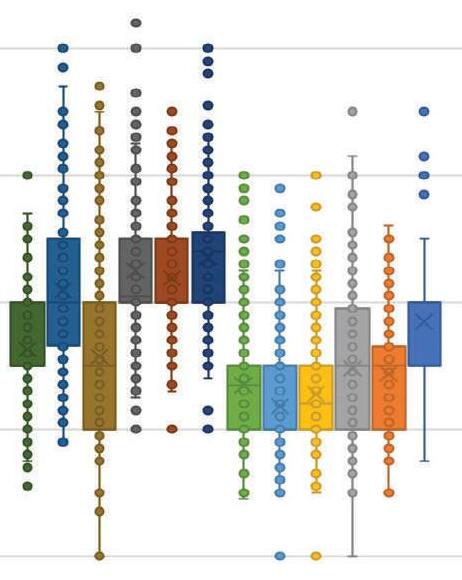

Testing the samples shows that the produced material samples were successful in cycling atmospheric moisture as intended, although at a much lower yield than the SHPF described in the original paper, when compared in % uptake of water per cycle.

The original paper demonstrates a much higher uptake of water at 0.96g g-1 in 30 min at 30% RH compared to the highest achieved absorption rate for batch 3 at 0.67g g-1 in 30 min at 75% RH. This can be attributed to inexperience with the material and the production.

PARANG pattern. One of the oldest patterns. “S” shape motions an unbroken continuity, with many interpretations. The continuity of the spirit of the ocean and it’s water, the will to never give up and the circle of life and death in all things.

Writing down family- and local history on resin coated paper lanterns, to be used in communal ceremony.

1. TIME A continuum of experience.

2. RIVER A large natural stream of water.

“Water, Air, Time - these things must flow”. A quote from the Indonesian architect Eko

Contest for celebrating special occasions with prizes handed out to those wiling and able to risk the climb.

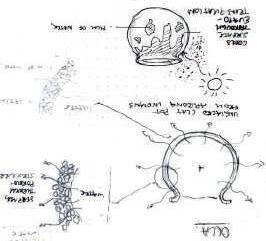

RIVER COOLING / AQUIFER RECHARGE

FLOATING BIOFILTERS DEPLOYED DURING FLOODS /

UNGLAZED CLAY POT RAINWATER “CAPACITOR”

COMMUNAL WATER CATCHMENT INSPIRED BY /

AQUIFER PUMPING FROM FLOATING BUILDING FOUNDATIONS

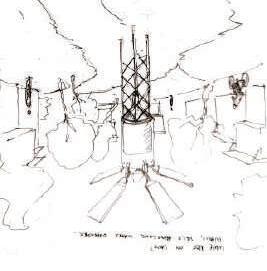

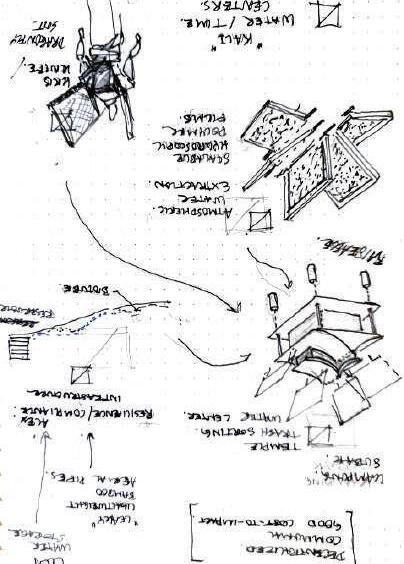

A COMING TOGETHER OF IDEAS. ATMOSPHERIC WATER HARVESTING AS A FLEXIBLE ADDITION TO EXISTING BUILDINGS.

ARTISTIC INDUCTION / SKETCHING WORKSHOP

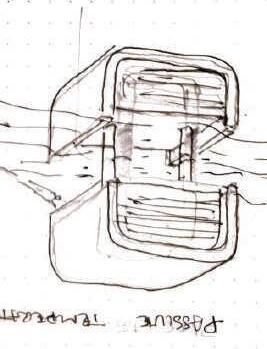

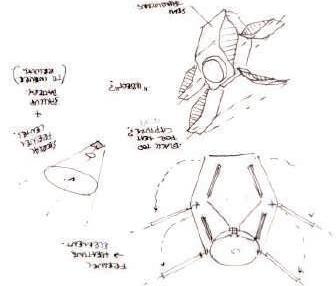

SKETCHING WORKSHOP: GIVING THE SHAPE A FUNCTIONAL HIERARCHY.

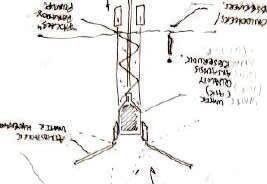

INITIAL DRAGONFLY SUIT CONCEPT SKETCHES MECHANISM SPECULATION & VERTICAL AXIS WINDMILLS FOR EXPOSING SAMPLES TO MOISTURE, WITH DRAG.

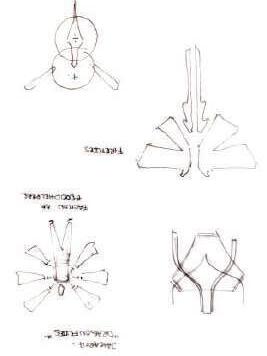

UNFOLDINGLOGO FOR SPECULATIVE “DRAGONFLY” INSTITUTION. SYSTEM DESIGN SKETCHES

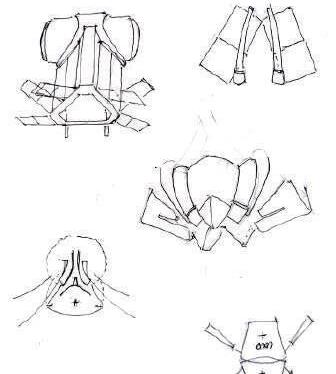

SYSTEM DESIGN SKETCHESSYSTEM DESIGN SKETCHES

Dragonflies are an intermediate keystone predatory species of insect, that regulates mosquite populations (it's nicknamed "the mosquito hawk") in wetland ecologies and is a foodsource for birds. They reproduce by laying eggs in ponds and small streams, and their presence is are known to be an indicator of clean & aerated freshwater in the local environment.

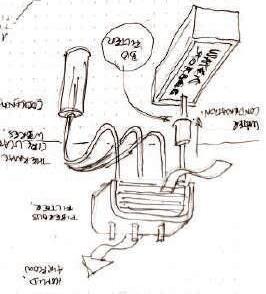

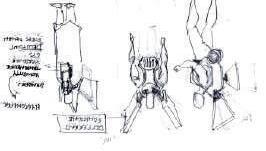

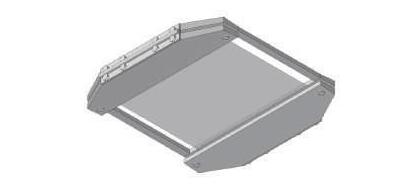

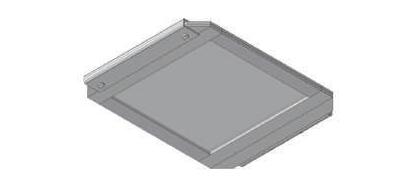

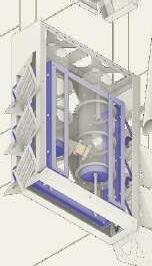

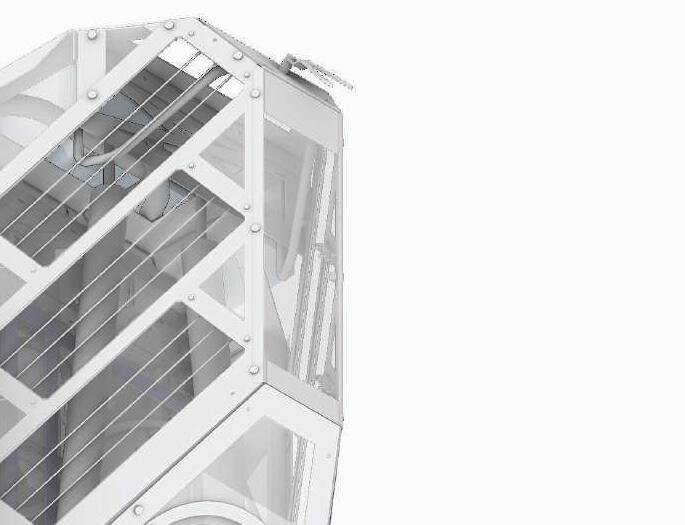

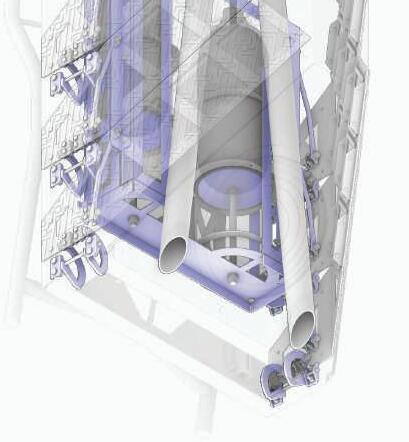

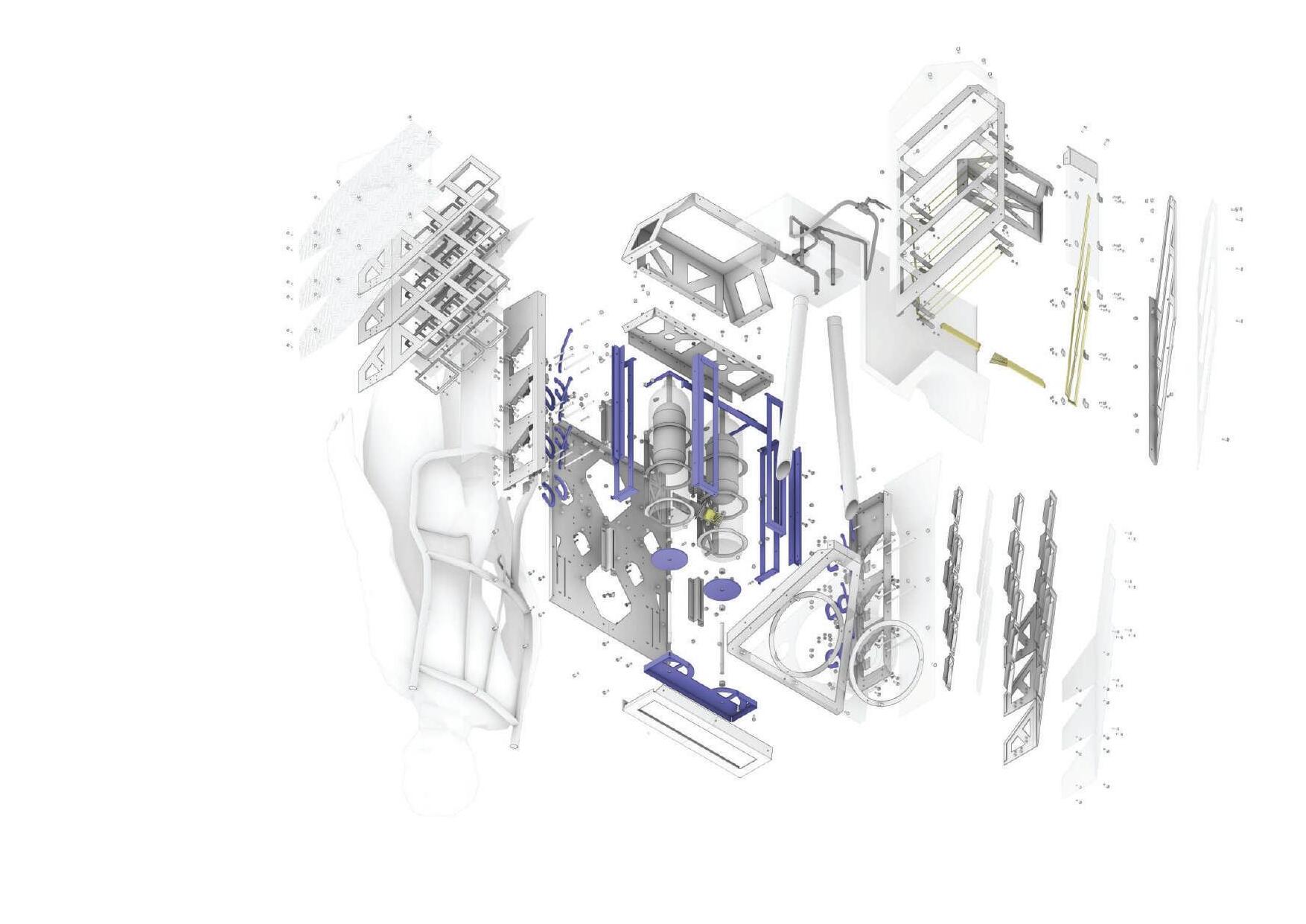

WORKING DIAGRAMS

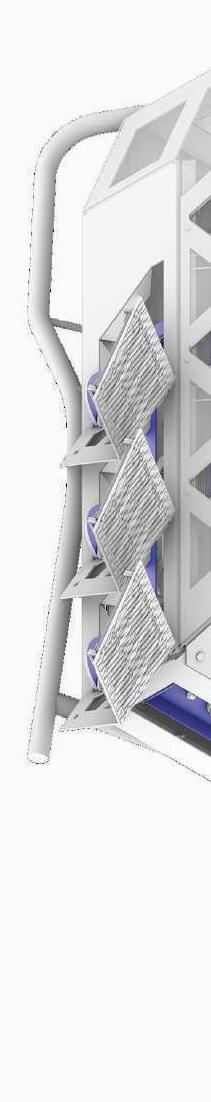

Development of the bracket system to hold the ATH samples, with a focus on the ease of manufacturing and operation.

Reducing the number of steps involved in making the bracket, as well as the tools and parts needed, yielded a design based on the bending of an upper and lower plate slotting together to fix the samples in place.

The screws needed to hold the upper and lower plate in place also fix the bracket into the wing of the prototype.

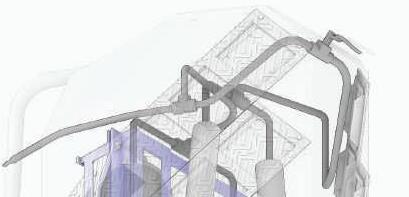

CLEARANCE MARKS

ROTATIONAL TRAVEL

LINEAR TRAVEL

ANCHORPOINTS

PISTON ARMS 1

PISTON ARMS 2

PRESSURE VESSELS TESTING

HYDRAULIC ACCUMMULATOR BICYCLE INNER TUBE

5mm thick

MOTORCYCLE INNER TUBE

HIKING WATER BLADDER

+ FORM FACTOR

+ RANGE OF SIZES AVAILALBE

+ PRESSURE THRESHOLDS

- PRICE / AVAILABILITY

+ PRESSURE THRESHOLDS

+ AVAILABILITY

+ QUALITY

- FORM FACTOR

- WEIGHT

+ PRESSURE THRESHOLDS

+ AVAILABILITY

+ PRICE

- FORM FACTOR

+ FORM FACTOR

+ AVAILABILITY

+ PRICE

- PRESSURE THRESHOLDS

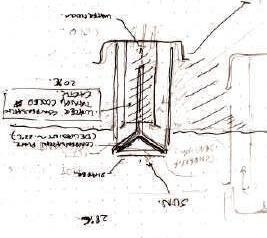

PHASE 1 COLLECTION

PHASE 2 RELEASE & HARVEST

When inflated, the expansion of air inside the volume of the pressure vessels lifts the piston assembly, which drives the wing hinge mechanism.

The wings are lightweight. Using Rhino, I found their mass to be 300 grams per wing. (without calculating the inevitable frictional resistance within the mechanical system).

The speed of closure is controlled by adjusting the flowrate of the air leaving the pressure vessels with a ball-valve.

The goal is to achieve a simple way of varying the closing speed of the sample carrying wings, to test atmospheric water harvesting material cycling intervals.

AUTO-VALVE INTAKE

PRESSURE VESSELS

BALL-VALVE HANDLE

PISTON HEAD

CONDENSATION PIPES

AIR VENT FOR THE PRESSURE VESSEL

15 cm PISTON ASSEMBLY TRAVEL LENGTH

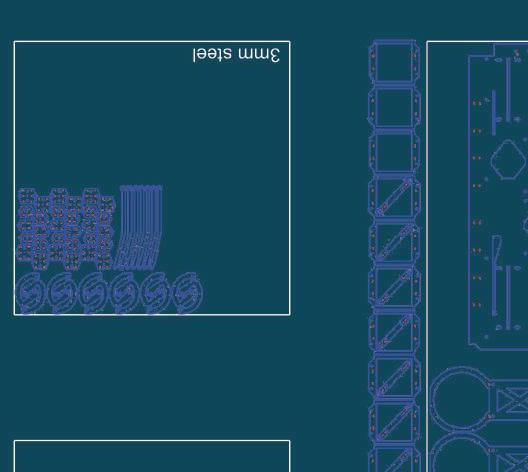

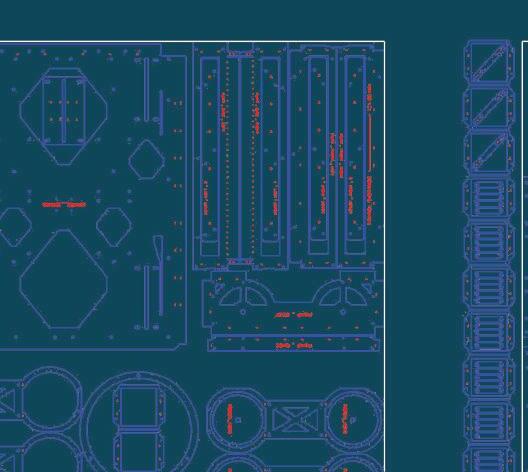

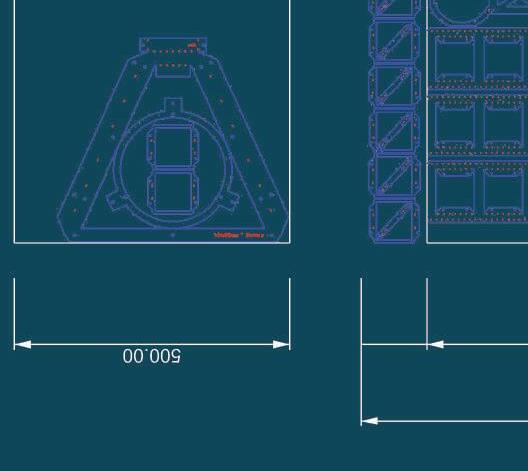

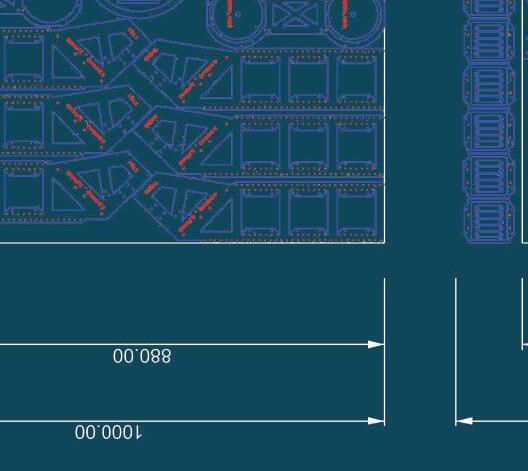

SHEET METAL BENDING LASERFILE

HOSE CLAMPS

PACKING TWINE (FLAX)

PACKING SALVE

WATER COLLECTION TANK w. FRAME BATIK WINGS (SAMPLE COVERS)

HEART COPPER HEATING PLATES w. FRAME MOUNTING BRACKETS

BERGANS ALUMINUM CARRYING FRAME

WINGS SAMPLE CARRIERS)

FRAME TOP w. MOUNTING FOR FRESNEL LENS

SEALING STRIPS FOR WINGS EDGES

DIAPHRAGM VIVAK INTERNAL CONDENSATION CHAMBER PARTITION WALL

FRAME SPINE, BASE, TOP & SIDES WITH WING HINGE MECHANISM.

WING HINGE DRIVE PISTON

RELEASE AND CAPTURE CHAMBER SIDES + FRONT

COPPER WIRE

MOBILE DEPLOYMENT OF PROTOTYPE

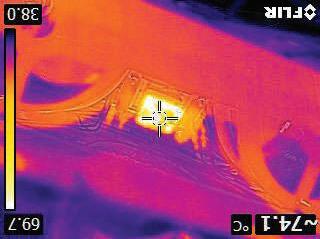

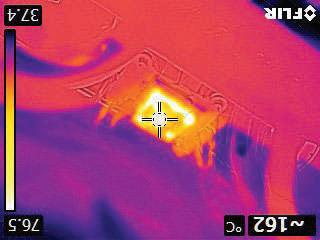

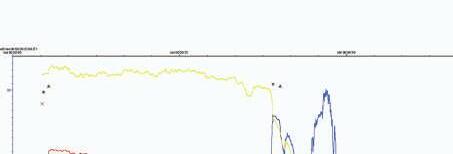

Noticably warming inside the condensation chamber, especially when closed. The temperature of the chamber is less important than the level of absolute humidity in the chamber. At 41OC / 50% RH the dew point is 28.5OC.

This is too low to be within reach for cooling with ambient air at 35.6OC. To work as intended, the heating distribution system would need better insulation to properly raise the temperature of the samples 15-20OC further, to release their captured vapor.

The 28.85 liter volume of the condensation chamber would need a further 0.015g water/liter air in absolute humidity to reliably form dew at 35.6OC. With a 13g water release potential, the SHPF could add 0.45g water/liter air. A 30 fold increase in absolute humidity, if the system is air tight.

A successful test of the saturation chamber would look like:

1) After an open phase, the chamber should hover around ambient temperature, if slightly warmed due to heat gain from the Fresnel lens and the clear plastic walls of the device, with the cooling tubes at cooler than ambient air.

2) The moisture carrying capacity of air increasing as the air is heated. As such, when the wings close, a successful saturation increase would look like an increase in temperature without a matching decrease in relative humidity.

Unexpected result: somehow airflow slightly raised temperature and the relative humidity inside the condensation tubes. My guess is that the connecting links between the tubes were made of 1/4" steel connectors. A few connectors were exposed to direct sunlight, and the thermal mass of these connectors might have heated the air going through the tube.

Predicted result: Tested with an open valve and constant airflow from a bicycle pump at 4 liter/minute, the cooling effect was tested for 10 minutes. From the graph, we see a cooling effect of 2.5oC over 10 minutes. The increase in relative humidity is not caused by an increase in air water content, but by the cooler air having less specific volume, as seen on the Dew point graph.

Susi has lived in Cengkareng all her life. She is well respected among the women in her community and speaks a little bit of English. She runs a small roadside food shop from the first floor of her house. Her husband Joyo (26) drives for Grab (a popular scooter taxi & delivery app). And is not home during the day. It's the same for all the other families in her community They have 3 young children. Two girls and a boy. Currently they can't afford schooling for any of the them.

From right:

Aman (Imam), Georgie (Export Advisor and Actor), Ronaldo (human rights lawyer) and Anthony (Anti-corruption task force leader).

The four friends come from widely different walks of life, with different ethnic, socio-economic and religious backgrounds (christian & muslim). On calm Sunday evenings they meet up at their local restaurant and have iced tea and coffee and talk about life. Sometimes they bring their wives and kids.

Nasoha

Nasoha works in one of the many local waste sorting workshops in Rawa Bengkel. He is an experienced carpenter and his primary job is assessing the quality of sorted materials for either resale or use in a workshop product. He likes to create sculptures of discarded scraps insulation foam delivered to the sorting workshops by the waste collectors. It has little to no value as is, but by his hand, the foam-sculptures get a great markup. Nasoha has two young dauthers.

Shakti grew up in Cengkareng in West Jakarta with both his parent. He wants to study IT if he can save up the money to pay of school. works as a receptionist at a local 24/7 capsule hotel with some of his friends. Social media and going to the Rawa Bengkel fishing lake with his friends are two of Shakti's favorite past times. Since mobile data is more expensive than fishing, he prefers fishing. You pay for the fish you take, so if you put them back it's free. Most people don't eat the fish here, but some do.

For residents living in informal kampungs the government is not a force that can be relied upon to solve the issues of everyday life. It is important to be a good neighbour in these communities. Abyasa, his wife and three sons know this. They Stand out as especially resourceful, even among the residents of Muara Baru. Abyasa used worked construction for many years. He was promoted and took engineering courses. Photo of Capung hanging on his repurposed water tank.

Living in informal settlements takes a lot of work. Structures need maintenance to protect from and survive rainstorms. The storms are really scary sometimes. Herni and Nadia's husbands work as waste collectors and -sorters in a government program. They take care of the kids at home with the other women living in the Rawa Bengkel landfill.

Endeh has been elected RT (Rukun Tetangga) for the 135 households of the Rawa Bengkel community for 10 consecutive terms - a period of 30 years. During his time he experienced severe floods yearly, seen houses abandoned and demolished due to subsidence and experienced the degredation of the wetlands in the area due to waste dumping. In his opinion the biggest challenges in the otherwise happy community are flooding, subsidence and unemployment.

Grew up in Rawa Bengkel and have lived there all their lives. Kris just got a job at a local convenience store. Andah is "between jobs" at the moment. Comes to the fishing pond every sunday, to hang out with friends from their childhood. Loves the community and couldn't imagine living anywhere else. Quite shocked to hear about life in Denmark, and how community and family are sometimes neglected in favour of work and education.

AEE TEACHERS:

David Garcia, Head of program

Runa Johansen, Lektor

Otis Sloan, Teaching assistant

Will Lambeth, Adjunct

Dr. Emanuele Naboni, Associate professor

Mads Johnsen & Torben Valerius, Technology Instructors.

INDONESIAN ARCHITECTURE LEKTORS & CRITICS:

BYO LIVING / Lim Masulin, David Hutama, Eko Praewoto, Paulus Bawole, Kamil Muhammad, Svetlin Petrov, Tiyok Prasetyoadi, Jacky Thiodore, Realrich Sjarief, Abimantra Pradhana,

SUPPORTING EXPERTS:

Nanna Bjerregård Pedersen, Lektor, insitute of conservation, KADK

Frederik Diness, Lektor, Chemistry Research Group, RUC

Edmont Stoyanov, Dr., General Technical Director, Nisso Chemical Europe

Endeh, Elected RT of RT 001/07 Rawa Bengkel, Cengkareng, Jakarta.

Jakarta ranked world’s most environmentally vulnerable city.

D. Karyza, The Jakarta Post, 18 May 2021.

Basin Resonance and Seismic Hazard in Jakarta, Indonesia.

A. Cipta, P. Cummins, M. Irsyam and S. Hidayati, geosciences, 2018.

Study on the risk and impacts of land subsidence in Jakarta.

H. Z. Abidin, I. Gumilar and H. Andreas, Proceedings of the international association of hydrological sciences, 2015.

River flood risk in Jakarta under scenarios of future change.

Y. Budiyono, P. J. Ward and D. Tollenaar, Natural Hazards and Earth System Sciences, 2016.

Rainfall-driven diurnal cycle of ciliwung river: overview and future prospects.

R. Sulistyowati, R. I. Hapsari, F. Syamsudin, S. T. O. Shuchi Mori and M. D. Yamanaka, Conference Paper, 2014.

Groundwater recharge and discharge processes in the Jakarta groundwater basin, Indonesia.

R. F. Lubis, Y. Sakura and R. Delinom, Hydrogeology Journal, 2007.

Groundwater Potential in the Central District of Tokyo.

T. Tokunaga, the University of Tokyo, Department of Environment Systems, 2008.

Harvesting Dew with Radiation Cooled Condensers to Supplement Drinking Water Supply in Semi-arid Coastal Northwest India.

International Journal for Service Learning in Engineering Humanitarian Engineering and Social Entrepreneurship Gandhinagar, 2011.

Fog Harvesting.

U. Nations, [Online]. Available: https://www.ctc-n.rg/technologies/fog-harvesting December 2022. [Accessed December 2022].

Solar-powered system extracts drinkable water from “dry” air.

M. N. Office [Online]. Available: https://airnews.mit.edu/2020/solar-extracts-drinkable-water-1014, 14 October 2020. [Accessed December 2022].

Scalable super hygroscopic polymer films for sustainable moisture harvesting in arid environments.

Y. Guo, W. Guan, C. Lei, H. Lu, W. Shi and G. Yu, NatureCommunications, 2022.

Handbook of Pharmaceutical Wet Granulation: Theory and Practice in a Quality by Design Paradigm.

S. I. B. Ajit S. Narang, Academic Press, 2019.

Global Hydroxypropyl Cellulose Market by Type (Low Viscosity, High Viscosity), By Application (Construction, Ink Printing, Coating, Polyvinyl Chloride, Pharmaceutical, Others) And By Region (North America, Latin America, Europe, Asia Pacific and Middle East.

DataIntelo.com, 2022.

"Thickeners: Konjac Glucomannan CAS 37220-17-0

Arshine Food, [Online]. Available: https://www.arshinefoodadditives.com/thickeners/konjac-glucomannan. CcBhBeEiwAcoMRHJzV0oRSHI1hBLaNIeTVlaaLU2R0O_html?gclid=CjwKCAiAy_Lqze7eqW5r4ygbM6Kh6ionNRoCHWIQAvD_ BwE. [Accessed 20 December 2022].

Specifications of the Konjac Glucomannan Fiber.

Nusagro 6 April 2021. [Online]. Available: https://nusagro.com/specifications-of-the-konjac-glucomannan-fiber/. [Accessed 20 December 2022].

AsiaKonjac - Konjac Supplier and Factory Indonesia.

H. H. G. Sukses, [Online]. Available: https://asiakonjac.com, 2022. [Accessed 20 December 2022].

Chemisty / Lithium Chloride.

Vedantu.com [Online]. Available: https://www.vedantu.com/chemistry/lithium-chloride. [Accessed 20. December 2022].

Lithium Chloride.

Laboratorium Discounter, ," [Online]. Available: https://www.laboratoriumdiscounter.nl/en/chemicals/a-z/l/lithium-chloride/ [Accessed 20 December 2022].

GHS Classification Criteria for Acute Toxicity.

ChemSafetyPRO, "," 06 March 2018. [Online]. Available: https://www.chemsafetypro.com/Topics/GHS/GHS_classification_ criteria_acute_toxicity_category.html . [Accessed 20. December 2022].

Production of lithium, metal grade lithium chloride from lithium containing brine.

Brown, United States of America Patent US4271131A, 18 December 1989.

Glucomannan (Konjac) Powder.

BULK.COM, BULK, [Online]. Available: https://www.bulk.com/dk/glucomannan-konjac-pulver-dk.html?view=ppc&pid=3073. [Accessed 11 . October 2022].

Home / Webshop / Varer / Kemikalier / Standard Kemikalier / Lithiumchlorid (100g)

ExperiMentor, [Online]. Available: https://www.experimentor.dk/shop/kemikalier/standard-kemi/lithiumchlorid/ [Accessed 11 October 2022].

Thermophysical Properties of Aqueous Solutions Used as Secondary Working Fluids

Å. Melinder, KTH Royal Institute of Technology, Department of Energy Technology (EGI), 2007.

The pattern of spatial flood disaster region in DKI Jakarta

M. P. Tambunan, Earth Environ. Science, 2017.

The Change and Transformation of Indonesian Spatial Planning after Suharto's New Order Regime: The Case of the Jakarta Metropolitan Area.

D. Rukmana, International Planning Studies, 2015.

Study on the impact of urbanization and rapid urban expansion in Java and Jabodetabek Megacity, Indonesia

A. E. Pravitasari, Kyoto University, 2015.

Hybrid Hydrogel with High Water Vapor Harvesting Capacity for Deployable Solar-Driven Atmospheric Water Generator

R. Li, Y. Shi, M. Alsaedi, M. Wu, L. Shi and P. Wang, Environ. Sci. Technol., Thuwal, Saudi Arabia, 2018.

Groundwater characteristics in Jakarta Area, Indonesia

M. Kagabu, R. F. Lubis, R. Delinom and J. Shimada, RISET Geologi dan Pertambangan, 2010.

Influence of groundwater extraction on land subsidence in Jakarta

Evaluating Urban Status of Informal Settlements in Indonesia: A Comparative Analysis of Three Case Studies in North Jakarta

W. S. Alzamil, Journal of Sustainable Development; Vol. 11, No. 4; 2018, 2018.

H. Hendarto and J. R. Standing, London, 2019.

“CAPUNG”

ATMOSPHERIC WATER HARVESTING