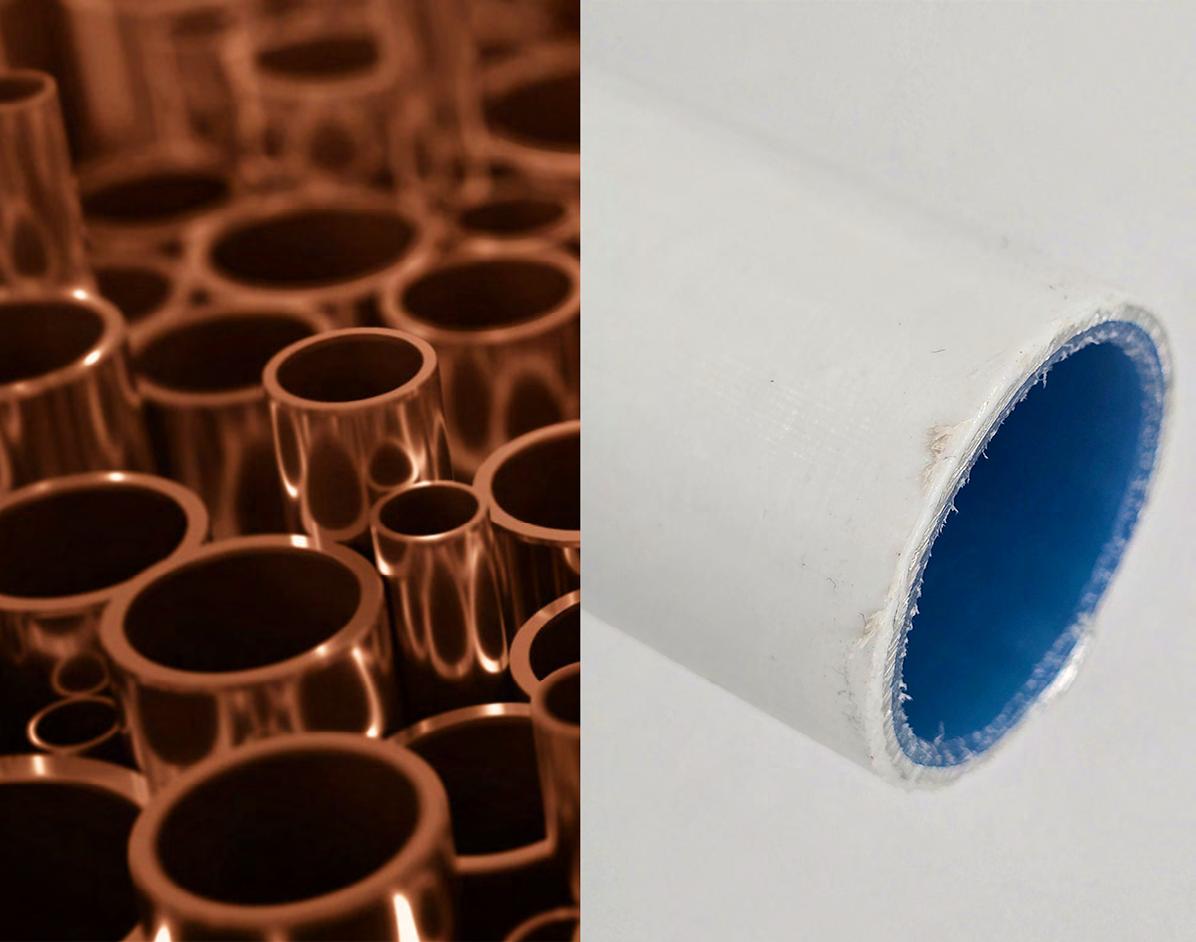

Copper has been at the forefront of the plumbing industry for centuries, but in the last two decades, new materials such as multi-layer composite pipe (MLCP) have emerged, positioning themselves as alternatives to copper in construction.

When selecting plumbing materials, efficiency, safety, sustainability and durability are key considerations. As human consumption continues to harm our environment, suppliers need to become more aware of the impact of their materials on future generations.

MLCP is marketed by plastics manufacturers as a fully recyclable product but, in reality, its multiple layers of plastic and aluminium glued together make it virtually impossible to recycle. This creates a complex degradation process of over 450 years, in which the material breaks down into harmful microplastics which poses risks to human and environmental health.

Copper, on the other hand, is a 100% recyclable material – demonstrated by the fact that since 1900, around two-thirds of the material is still used today. As a more durable material that lasts close to 80 years, coppers longevity and recyclability mean that

its carbon footprint is much less than MLCP, as well as being more cost efficient over time.

The thermal conductivity of copper also means it heats water faster and uses less energy in transferring heat than MLCP, which is predominately made from plastics with some aluminium content. In fact, copper provides 401W/mK compared to aluminium’s 237W/mK.

Furthermore, MLCP is susceptible to warping, damage and leakage when exposed to higher temperatures or used in outdoor areas. In comparison, copper’s high melting point and UV radiation resistance means it can withstand high temperatures and pressures and is less likely to need repairs over time.

Copper’s strengths also lie in its antimicrobial properties, which prevent the growth of harmful bacteria and rust, resulting in the

water from its pipes being safe to drink. Due to MLCP’s plastic content, there is a risk of the chemicals diluting the water and posing a health risk when consumed.

As MLCP is a relatively new material compared to copper piping, there is a lack of research on the potential risks of its prolonged use – whereas copper has plenty of evidence from the last 2,500 years to prove it the superior material.

With the increasing stress we put on our planet, changes such as the type of pipes we use in our buildings can make significant differences to our environment and the reduction of greenhouse gases.

To find out more, please visit: www.cuspuk.com

• UK tenants, real estate owners and developers have a new indoor mobile connectivity option for their properties following a worldleading innovation

• Global first with 4G connectivity from all four UK operators via small cells in one box with Omni Network

• Freshwave is the only provider in the UK able to provide connectivity via this approach from all four mobile operators

All the current tenants at Bloom Clerkenwell in London are now enjoying indoor mobile connectivity from all four mobile network operators (MNOs) thanks to a world first from Freshwave.

Connectivity infrastructure-as-a-service provider

Freshwave’s Omni Network delivers 4G signal from all four operators combined into a single box, something which has never been done before with small cells. It was deployed at Bloom using CommScope’s ONECELL®.

Up to 80 per cent of mobile traffic is generated indoors but building materials such as thick concrete and energy efficient glass blocks outdoor mobile signal from entering buildings, leaving people unable to use their phones seamlessly inside. This leads to frustration for users, drops in productivity for businesses and makes the workplace less appealing for everyone.

To solve this problem small cells can be deployed indoors which connect securely into the MNOs’ networks, guaranteeing the quality of service

unlike some other connectivity technologies which rely on outdoor signal. Omni Network needs less equipment on ceilings and in the comms room and less cabling and corresponding installation. This means it’s faster to design and deploy and up to 65 per cent lower cost than a traditional, legacy distributed antenna system (DAS). It’s also more energy efficient, using up to 60 per cent less energy.

Simon Frumkin, Freshwave’s CEO, said: “Mobile signal is essential in the modern workplace. We’re proud to be the only company in the UK able to offer Omni Network and are looking forward to the benefits it will bring our customers across both the public and private sectors.”

Stuart Holyoak, Director, DAS and Small Cell Business Development – EMEA at CommScope, said: “Customers need and demand coverage indoors where they use it the most and the CommScope ONECELL delivers on that demand. We’re proud to have developed such a step-changing solution to enable providers like Freshwave to accelerate connectivity for enterprises.”

Bloom Clerkenwell, managed by UBS Asset Management’s Real Estate & Private Markets business (UBS AM REPM), was the first commercial building in the UK to achieve the highest accreditations for BREEAM Outstanding, WELL Platinum, WiredScore Platinum and EPC rating A and now has another first to add to this list. The right mobile connectivity enhances the value of commercial real estate buildings and we’re pleased that Bloom Clerkenwell is on the cutting edge of developments in this area thanks to Freshwave.

Omni Network is deployed and delivered as a vendor agnostic managed service by Freshwave. It’s suited for sites from 6,000 sq ft upwards and can scale to buildings of 350,000 sq ft or more. It’s ideal for high spec environments such as premium residential or office developments and innovation-supporting settings like hospitals and research campuses. Because it connects via agreed operator technical specifications, it allows Freshwave to give their customers additional network statistics and visibility of what’s happening on their dedicated mobile network.

www.freshwavegroup.com

• New research has found that nearly one-fifth (17%) of UK industries, from renewables and telecoms to defence and transport, have received enforcement action at some point due to fixed and movable assets not meeting HSE compliance standards, with over 10% receiving an HSE fine

• Nearly 50% of organisations said that their asset data isn’t sufficiently detailed, nor updated or recorded accurately enough, to comply with the Health and Safety at Work Act 1974 and other HSE regulations that apply to their sectors

• 86% of respondents said they would like to see improvements to their asset management systems

• 42% still use paper-based methods to record, update, and store critical maintenance data, with over half using Excel

7 in 10 organisations operating in some of the UK’s biggest industries admit that they are unlikely to comply with on-the-spot Health & Safety Executive (HSE) inspection due to a lack of data proving that their fixed and moveable assets are managed and maintained to the required regulatory standards.

Nearly one fifth (17%) have received enforcement action in the past due to assets not meeting HSE compliance standards, with over 10% receiving an HSE fine.

The new research on 2,000 UK businesses, commissioned by enterprise asset management (EAM) solutions specialist, BPD Zenith surveyed organisations operating in the utility and renewable industries, including telecoms and broadband, as well as the defence, transport, pharmaceutical, and healthcare sectors.

The findings revealed that nearly 50% of these organisations’ moveable or fixed asset data isn’t detailed, nor updated or recorded accurately enough to comply with the Health and Safety at Work Act 1974 or other HSE regulations that apply to their sectors.

Latest HSE figures for 2022/2023 show that there were 60,645 employee non-fatal injuries reported by employers during this period and 135 deaths as a result of work-related accidents. The Health and Safety at Work Act 1974 legally and duty bounds companies to ensure the safe working environment for employees and third-parties, including the general public, who may be affected by an organisation’s activities. The HSE compliance standards work alongside the Health and Safety Act, designed to protect people and the environment. Penalties for failure to comply can include fines, orders for operations to cease, and imprisonment if the misconduct is found to be serious enough.

86% of respondents did acknowledge that improvements to their asset management systems

and processes are required to drive up the quality, completeness, and consistency of their data. Asset management systems are operational processes and tools that help manage the performance and maintenance of fixed or moveable assets. These assets include everything from production and manufacturing machinery to equipment found in buildings such as HVAC systems, elevators, and security doors, and any vehicles used in day-to-day operations.

42% also confirmed they still use outdated paperbased methods in part or in full to record, update, and store maintenance data, with over half using Excel spreadsheets, rather than using digital asset management solutions.

Amongst the priority improvements to their asset management strategies, 68% recognised the need for enhanced data quality, 50% highlighted improved analytics, and 46% identified a need for better systems integration with their existing EAM solutions.

Findings also identified a greater demand from organisations for improved field-based, mobile data capturing and utilisation solutions. Nearly half of all responses (47%) said recording data in the field, not being able to record data at the point of work, a lack of intuitive forms, and not having technical data and maintenance manuals at the point of use, as the biggest challenge to keep asset management

and maintenance data updated. Access to realtime inventory levels (18%) and struggling to plan, schedule, and dispatch work to multiple crafts and contractors (11%) were amongst the other challenges organisations faced.

Roger Walker, Group Head of Innovation at BPD Zenith said: “The results from this survey have been surprising in part. However, what they do identify is that 80% of these companies probably aren’t where they need to be in their asset management digital transformation journey. What they need to identify though is why. Do they have the right asset management strategy, processes and tools in place? If not, is this due to a lack of resources, either through investment in the right equipment, or software, or people, or it may be a case that data collection and analytics are not sufficiently high on their list of priorities.”

Walker continued: “HSE inspections are essential for ensuring organisations of all shapes and sizes are adopting best practices which align to the legal standards expected on health, safety and an organisation’s environmental impact in their industries. These checks can also help pinpoint where processes may be weaker and help implement measures aimed at strengthening these areas. The penalties for non-compliance can be hugely detrimental to businesses, not just financially but reputationally too.

“We work with organisations across an extensive spectrum of industries, from utilities, oil and gas, transport and logistics, and manufacturing to defence and security, life sciences and facilities management. Over recent years we have seen a growing demand for mobile solutions to support asset management amongst those organisations with large, complex and field-based estates. As well as a growing need for solutions to capture data, there is also an increasing demand for tools that support the teams maintaining these assets, whether that’s in the form of planning and scheduling tools for work order management, or intuitive solutions while they are on the job.”

Edinburgh-based risk prevention specialist, Reactec, has unveiled its busiest year ever with the filing of the company’s accounts for the year ended 31st December 2023.

Reactec’s annual turnover increased by 40.9% during the year to £5.58 million (2022: £3.96 million). In July 2022, Reactec launched its thirdgeneration wearable device, the R-Link smart watch, a multipurpose workplace wearable that informs workers of their risk environment. With an initial ability to simultaneously monitor real-time exposure to Hand Arm Vibration and provide proximity warnings when the wearer enters the exclusion zone of a hazard, it is regularly refreshed with remote firmware updates to provide additional features to the end users.

The R-Link watch, with its supporting fully integrated digital eco-system, and the powerful Reactec Analytics software, to transform the data, enables Reactec to deliver an unprecedented view of an employee’s risk environment to allow employers to refine controls and prevent future risk.

The turnover boost also reflected the growing impact of its “Safety as a Service” plan which allows clients to spread the cost of products over three years, accounting for 50% of all orders placed in 2023. Overall, Reactec’s order book grew by 50% in 2023.

Although operating costs rose by 22% to £3.92 million (2022: £3.21 million), the company posted a profit for the financial year of £66,000 compared to a loss of £360,000 in 2022.

Jacqui McLaughlin, Chief Executive of Reactec, said: “There’s no doubt that, as we make the detection of harmful vibrations and other work-related exposure more accessible, we are seeing a measurable increase in sales of our R-Link watch and our analytics programme.

“Hand Arm Vibration Syndrome – or Vibration White Finger – is a particularly cruel and debilitating condition and the detection, and early warning of harmful exposure to the vibration that can cause it, remain vital to protecting the country’s workforce.

“We have had a strong first half in 2024 and are continuing to see good sales growth. We are also encountering rising international interest, particularly from the US, which now accounts for 23% of the traffic on our website. The growth in US business prompted us to launch a US data centre earlier this month to handle the analytics for our expanding customer base there.”

Reactec’s prevention engineering approach proactively tackles common health risks in new ways, using an ecosystem of workplace wearable technology and cloud-based analytics.

The R-Link watch takes the guesswork out of monitoring exposure to vibration, allowing employers to have direct control of risk levels. R-Link monitors tool vibration in real time and alerts at-risk workers when they are close to exposure thresholds.

The R-Link watch can also warn workers when they enter an exclusion zone created by an R-Link beacon. All of the vibration exposure and exclusion incursion data is automatically presented in the Reactec cloud-based data analytics as actionable intelligence for employers to refine controls.

Custom House is a major regeneration scheme in Newham, East London. A project which Schöck has been heavily involved in from the outset; initially providing full design support and installation training. The project is designed to Passivhaus standard, so the need to effectively eliminate any risk of thermal bridging at various points of the design detailing was crucial. As Europe’s leading supplier of innovative load-bearing insulation products, this is where Schöck really came into its own – with high performance solutions for the columns, balconies and parapets. Known as the Custom House kickstart project and designed by Adam Khan Architects and Haworth Tompkins (for which they received a Housing Design Award) it is part of a wider masterplan by Adam Khan Architects. The main delivery partner is The Hill Group and the scheme overall consists of three mansion blocks, ranging in height from four to eight storeys. This first stage though will deliver

95 affordable homes, along with commercial space, community growing space, communal gardens and a high-quality accessible public realm.

The columns presented a special challenge

It is estimated that around 40% of all structural thermal bridges in buildings are caused by walls and columns; and these are calculated to be responsible for at least 10% of the heating energy loss. The recently introduced Schöck Sconnex range is a unique solution to this problem, allowing walls and columns to be directly and permanently insulated. There are three product variations, the type W, type P and type M. Specifically, the Sconnex type P is the product used at Custom House. It consists of a thermal insulation element and a reinforcement element, both of which are required to withstand the bearing load. The thermal insulation element

has a pressure-resistant support structure, made of lightweight concrete and polypropylene fibres, all in a 100mm thick insulation layer. Its performance significantly reduces heat flow, but importantly, also eliminates the need the for the traditional solution of using cumbersome flanking insulation. On this occasion though, quite apart from effectively isolating the rectangular columns from the rest of the building, there were challengingly high load requirements. To meet these demanding loads, it was necessary to incorporate multiple Sconnex type P units at the head of each column – the first time this particular design solution has been used in a UK project.

Parapets are as prone to thermal bridging problems as balconies

Preventing thermal bridging at the Custom House parapets was also a critical consideration

for such a high performance development, because as with balconies, parapets can allow conductive materials to transfer energy through the thermal barrier. Conventionally, in the majority of cases, the method of insulating parapets and parapet walls is to wrap the perimeter of the wall with an insulation barrier. However, the Schöck Isokorb XT type A used here offers a solution that is both more costeffective and more thermally efficient than conventional wrapped parapets. Its 120mm insulation thickness results in low psi-values and therefore significantly reduces heat loss – and there is no wrapping required. An added benefit being there is no risk of any additional thermal bridging through balustrade fixings. Other key factors are durability – and significantly water impermeability – so there is no risk of expensive maintenance or restoration due to waterproofing problems.

High performance solution for the concrete balconies

For the concrete balconies at Custom House the tried-and-tested Schöck Isokorb XT Type K has been incorporated to meet Passivhaus standards. The XT type K with compression module HTE-Compact and 120 mm insulation thickness, is a load bearing thermal break element for free cantilevered balconies. It is the company’s most efficient thermal break ever, offering 30% more thermal performance than the standard Schöck Isokorb T type K.

All of the Schöck products used at Custom House (the Sconnex type P, the XT type A and the XT type K) are certified by the Passive House Institute in Germany. With the Sconnex type P being the only column connection certified by the Institute. The fully compliant Schöck Isokorb range, whether for Passivhaus or standard solutions, offers the widest selection of structural thermal break solutions from any European supplier.

In the UK, the range enables projects to meet full compliance with the necessary Building Regulations (and the impending Future Homes Standard criteria where relevant). There is also the security of independent BBA Certification, which provides NHBC approval.

Contact Schöck on 01865 290 890; or for full details of the entire product range visit the solutions page on the website at www.schoeck.com/en-gb/solutions-uk

APPROVED FOR INTERNATIONAL USE: WIELAND

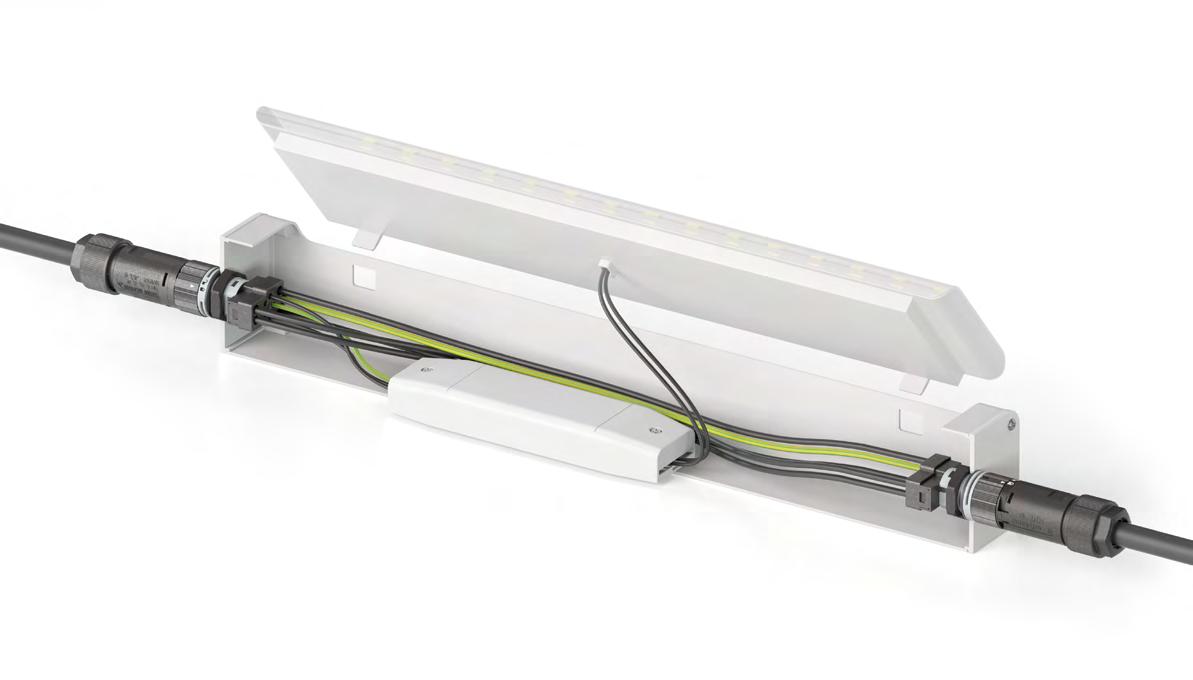

Given that no equivalent technology is available on the market, the device connection undoubtedly sets the standard for pluggability in the future.

This new product’s unique qualities are all centred on its flexible and simple assembly. This is made possible by push-in spring-equipped double conductor connections, the capacity to prefabricate the components separately, and above all the wiring’s suitability for automated systems. This implies that installations having a high protection level are much simpler and can be customised for each application.

Although MOLA® has been specifically designed with luminaire manufacturers in mind, it can also be installed in other application areas. Applications like heaters, motors, and controllers in general can also profit from this connector’s flexibility. A variety of projects and applications can be covered by MOLA® because it comes in 2-, 3-, 4-, and 5-pole versions and is designed for through-holes with a diameter of 20 mm, which makes conversion to MOLA® easier.

The modular design means that the internal cable harness and housing can be manufactured separately. An optional contact seal can enhance moisture protection, allowing MOLA® to be used in harsh environments without any problems even under the most adverse conditions.

Entirely designed and built in the Puglia plant, the electric compact wheel loader will be marketed under the CASE and New Holland brands and distributed worldwide. With this third electric-powered model in the range, CNH reaffirms the crucial role of innovation in the development of high-performance, environmentally friendly solutions that serve people and the environment.

The event also highlights the investments in advanced and sustainable infrastructure at the Lecce plant, as well as the plant’s central role globally.

Turin, 3rd July 2024

The production line for the new electric compact wheel loader was inaugurated today at the CNH plant in Lecce, Italy. The model, conceived and designed in the Puglia plant’s R&D centre, will be produced in CASE and New Holland liveries with the 12EV and W40X models respectively. From here, it will reach markets around the world, meeting the growing need for zero-emission machinery in the construction and agricultural sectors.

The ceremony was held in the presence of institutions from the Puglia Region, including Alessandro Delli Noci, Councillor for Economic

Development, and Loredana Capone, President of the Regional Council, together with the Mayor of Lecce, Adriana Poli Bortone, and CNH management: Stefano Pampalone, CNH President Construction Segment, Carlo Alberto Sisto, CNH EMEA President, Federico Bullo, CNH Head of Construction Europe, Ciro Casapulla, CNH Head of Construction Product Development, Carlo Lambro, Managing Director CNH Industrial Italia S.p.A. and Guido Moscheni, CNH CE HR Business Partner.

The new model completes the company’s range of compact electric vehicles, which already includes the two mini electric excavators produced in Cesena. CNH is thus responding to the rapidly growing demand for alternative powertrains, driven by the needs of metropolitan and municipal areas, mainly in Europe, and the requirements of sectors such as agriculture

and livestock farming, in search of highperformance yet silent and zero-emission machines that can operate safely indoors and near animals.

Lecce plant increasingly central to CNH

The Lecce plant, which recently celebrated 50 years of activity, is one of CNH’s main production centres in Italy and EMEA. It occupies 600,000 square metres and houses 7 product lines (wheel loaders, compact wheel loaders, backhoe loaders, telehandlers and motor graders) for 203 models and 4896 different configurations. Production volumes have grown exponentially, marking an 88% increase between 2020 and 2022 and a further 14% in 2023, the year that recorded the highest number of machines produced since its foundation.

In parallel with investments in production capacity, CNH has implemented major infrastructure and environmental improvements. In 2022, an investment of around €13 million (part of the Converto project, co-financed by the Region of Puglia) enabled the installation of a new advanced painting plant and a new plasma cutting machine. The former has significantly improved product quality and reduced environmental impact through more efficient use of water. The new cutting machine has increased productivity, reducing waste and maintenance costs. Furthermore, the recent adoption of a photovoltaic system covering 40% of the production area confirms the commitment to sustainability and energy self-sufficiency of the production site. Also as part of the Converto project, CNH has invested in the construction of new rooms for

testing electrified vehicles and for checking operations in extreme climatic conditions (-50° to +50°).

Alessandro Delli Noci, Councillor for Economic Development of the Region Puglia, commented on the relationship that links the plant to the territory: “This industrial complex has long been a reference point for many companies in Salento, which benefit from the allied industries linked to production and is also an important pole in terms of employment. We are happy that CNH continues to believe and invest in this important reality with products and projects of high technological content.”

The electric compact wheel loader – Italian innovation for a sustainable future

The new electric compact wheel loader, which has been successfully presented at major international trade fairs such as ConEXPO in Las Vegas and Agritechnica in Hanover, offers significant advantages in terms of low noise and zero emissions. These characteristics

make it particularly suitable for operating in closed environments, where CO2 emissions are not permitted, on night-time construction sites and in all applications that are sensitive to noise pollution. Furthermore, this type of machine guarantees high performance and lower operating costs than diesel-powered vehicles.

Ciro Casapulla, Head of Construction Product Development, explained the new electric model in detail, emphasising how innovation has always been made in Lecce, and how this, in the case of electrification, entails a paradigm shift: ‘We have not just replaced the diesel engine with batteries. We have completely revised the design, also drawing on technologies and calculation techniques typical of the aerospace sector. Firstly, by lightening the weight, removing it where it wasn’t needed, in a reasoned and calibrated way to increase performance and preserve the machine’s autonomy’.

The weight reduction, also achieved thanks to the special “lattice” boom, has led to an improvement in tipping load: a light boom means weight is shifted to the rear and therefore greater loading capacity and stability. Another important innovation, borrowed from the top-of-the-range diesel models, are the electro-hydraulic controls which, combined with the electric drive, make it possible to maximise the efficiency and the controllability of movements.

The new electric model has a range of 3 to 6 hours depending on the type of application. Recharging can be done with the domestic power socket with the standard 230V onboard charger or with the optional fast charger, which can recharge the 23 kWh lithium-ion battery from 20% to 80% in just 1 hour, the duration of a lunch break, thus enabling continuous use throughout the working day.

The new electric compact wheel loader, 100% Made in Italy, highlights CNH’s commitment to investing in technologies for the development of alternative and sustainable propulsion, while reaffirming the strategic centrality of the Lecce plant in the company’s production landscape.

Luxury Vinyl Tile (LVT) manufacturer Amtico selected Gradus’s new XT Bronze stair edgings to complement the design scheme at its newly refurbished Head Office.

The Head Office, based in Coventry, welcomes clients and professionals from all aspects of the flooring industry and an attractive, hardwearing stair edging was required for the central staircase.

The manufacturer selected XT Bronze in the BKXT5A profile in Satin Bronze finish combined with Gradus’ new metal castellated slip-resistant insert in the matching Satin Bronze finish, creating an elegant, classic look to complement the tones featured within their chosen floorcoverings on the stairs and surrounding areas. In line with recommendation within Project Rainbow and ADM, the Satin Bronze castellated insert provided an LRV (Light Reflectance Value) difference of at least 30 points between the stair edging and surrounding floorcoverings to achieve a suitable contrast.

By selecting the metal castellated insert, visitors to Amtico’s Head Office will be provided with an additional layer of safety thanks to the insert’s unique design, which extends around the entire leading

edge of the step, ensuring that foot contact is always made with its slip-resistant element when descending stairs.

Chris Newey, Gradus Sales Manager, comments:

“The key with this project was to find a balance between style and practicality, using a product that has a premium appearance while also enhancing visitor’s safety thanks to the market-leading solution for reducing the risk of slips, trips and falls on stairs.”

Christina Beedle, Executive Assistant, from Amtico adds:

“We required a stair edging system that could withstand people accessing and using the staircases daily, but it was also equally important that it provided a stylish finish that complemented the beautiful LVT flooring we had chosen for our Head Office.

“We’re extremely pleased with the finished outcome, not only do the Gradus XT Bronze stair edgings look great, but we also have the added reassurance that they have been manufactured by a company with over 50 years’ experience.”

Paul Cassell, Managing Director at PMC Flooring who fitted the stair edgings, said:

“Gradus were excellent to work with. They are always there if we need their support, from the start to the finish of each project. It was great to be able to use XT Bronze stair edgings with matching inserts – they were very easy to work with and install, and they looked fantastic once they were fitted.”

Designed for use in interior heavy-traffic environments such as retail, hospitality, leisure and commercial offices, XT Bronze offers the perfect stair edging solution, offering excellent levels of safety without compromise on style and looks.

Reducing slips, trips and falls through a selection of Interior, Xtra-grip and Metal Castellated insert formats, XT Bronze is offered in Polished Bronze or Satin Bronze channel finishes, with matching finishes also available across complementary accessories including nap trims and welded corners.

To find out more about Gradus’s range of stair edgings and flooring accessories, please download the dedicated catalogue here

Work is progressing well on the new 70-apartment extra care development in Newport.

Queenswood, located at Station Road, is being developed by The Wrekin Housing Group and is being built by Staffordshire-based Keon Homes.

Ideally situated just a ten-minute walk into the market town, the scheme will provide high quality living space and wraparound care and support for people over the age of 55.

Supported by Homes England, the £11.9m development will offer 70 one and two-bedroom apartments, all of which will be available for affordable rent to local people.

Queenswood has been designed to promote independent living in a community setting, with a care team on-site 24/7 to deliver planned care packages if needed. Residents will also benefit from a range of facilities.

It will be complemented by a café and landscaped gardens, which will also be accessible to the local community.

Simon Thompson, Director of Development at the Wrekin Housing Group said: “Queenswood will bring huge benefits to Newport and its surrounding communities. This is an exciting project that is helping meet the growing demand for older people’s housing and has created much-needed job opportunities for local people.

“Our ShireLiving brand has a strong track record when it comes to providing modern, secure and vibrant facilities that allow our tenants to enjoy a hassle-free retirement. We’re delighted to be working with Keon on this exciting development.”

Paula Reynolds, Head of Retirement Housing at The Wrekin Housing Group, said: “The Wrekin Housing Group provides affordable homes for over 28,000 people, and we’re one of the largest providers of extra care housing in the region.

“Queenswood, like all our ShireLiving schemes, gives people the provision to stay within their local communities and access services close to home. It has been designed in such a way that allows us to respond to individuals changing care needs with on-site care support.

“We’re really looking forward to bringing an extra care scheme to the Newport community giving choice to individuals to live independently while providing numerous housing and care employment opportunities.”

Matt Beckley, Head of Development at Keon Homes, concluded: “Queenswood was our first foray into the Extra Care scheme market and, thanks to the strength of our partnership with The Wrekin Group, has been a huge success so far.

Wrekin Housing Group and Keon staff outside the rapidly developing Queenswood Extra Care scheme

“Not only have we unlocked a vital piece of land for much-needed affordable older living, but we are also well on the way to completing the build ahead of the planned schedule – this is unheard of in this sector.

“There is an acute shortage of older person’s accommodation in Shropshire, and we are keen to help solve this intricate puzzle by helping to build more high-quality Extra Care schemes – starting with a second development with The Wrekin Housing Group due to start shortly in Shrewsbury.”

For further investment, please visit www.keonhomes.co.uk