Renewable energy systems are constantly present in today’s world. When we think about PV systems, we tend to focus on solar panels, however, systems generating clean energy are, in fact, much more complex and require using top-grade components. See below for the Panasonic range of high-quality solutions ensuring fault-free operation of entire systems.

• Inverters and their role in systems

• Polymer capacitors

• Film capacitors

• Resistors

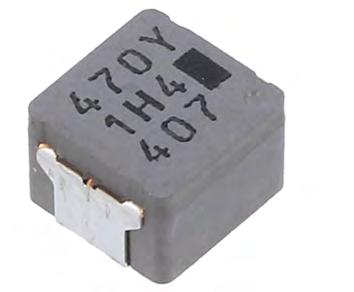

• Inductors (choke coils)

Inverter

Climate change, uncertain energy market situation, and the drive for independence – these are only some of the reasons that have contributed to a massive increase in the popularity of renewable energy solutions, the most significant of which are PV systems with solar panels at their core. However, there is much more to a PV system than just solar panels. All household appliances are supplied with sinusoidal voltage, but the panels generate DC voltage. Therefore, connecting such appliances directly to solar panels could easily lead to their damage. In order to harness the energy of the largest fusion reactor within a radius of several light

years, i.e. the Sun, it is necessary to convert the DC voltage, whatever its value, to the AC voltage, or more precisely, sinusoidal voltage of 230V.

In fact, you might say that if solar panels are the heart of a PV system, then the inverter is its brain. Inverters are used to convert and maintain voltage in a household electrical network at a constant level. Obviously, this is just a somewhat simplified description. There are inverters on the market that are capable of converting voltage from solar panels to mains voltage and simultaneously charging the energy storage which can only be supplied with DC voltage. This means that an inverter must transform DC voltage from panels into DC voltage for charging and, at the same time, convert it into AC mains voltage. It is an extremely challenging task, so the inverter designs must include top-quality components. Panasonic is definitely up to this task – its range includes numerous product series that are perfectly suitable for application in the demanding environment of an inverter’s interior.

As a rule, a PV system must be designed to operate for many years, so all inverter components must have a suitably long service life. The inverter circuit contains numerous catalytic capacitors, which are among the oldest types of such components. Unfortunately, their service life is very limited – the best case scenario assumes several thousand hours, which translates into slightly over 2 years of operation of a PV system equipped with an energy storage. It can be concluded, then, that inverters should be equipped with capacitors that can be used for longer periods. The OS-CON polymer capacitors are a solution here. They look the same as standard electrolytic capacitors, however, all the key differences are hidden inside. Due to the fact that their design includes polymers, the service life of such capacitors is a few times longer than that of electrolytic capacitors. Source

Due to the above, it can be unambiguously stated that applying OS-CON capacitors in inverter circuits is the only option that guarantees long-lasting and uninterrupted system operation.

A correct voltage value is vital, but it must also be absolutely interference-free. This requirement is best fulfilled by the ECQUA series class X2 thick-film capacitors meeting the applicable US (UL) and Canadian (CSA) safety standard requirements. Last but not least, an enclosure made of self-extinguishing plastic significantly reduces the fire risk in the event of failure. All these advantages make Panasonic thick-film capacitors suitable for mounting in any location within an inverter circuit, as they are able to filter signals at the solar panel input and eliminate peaks in DC/DC converters.

Solar inverters use dozens or even hundreds of resistors, whose main technical requirements include high voltage, high efficiency, and long operating times. The Panasonic product range encompasses several series that are perfectly suitable for such conditions. The ERJP series is a perfect solution in terms of voltage regulation and

detection, as higher operating power and resistance to voltage spikes makes it possible to use smaller resistors and simultaneously retain circuit parameters or enhance its power without increasing its size. Source

Inverter circuits also include inductors, which often operate under high voltage and current conditions, and because of that must be made of top-quality materials. The Panasonic ETQP series includes inductors which perfectly meet such requirements and are an ideal solution for the systems where high-frequency signal switching occurs. Other advantages of the ETQP series include stability and ability to operate in temperatures reaching 150°C. Application of special materials has enabled Panasonic to reduce the inductor size by 30-50%, while maintaining necessary parameters. This allows for reducing the PCB size or increasing the operating current rating while making sure that the inductor dimensions remain as desired.

Text prepared by Transfer Multisort Elektronik Sp. z o.o.

Fibre-Optics are the optimal connection technology for whenever the highest data rates and fast, interferencefree transmissions are required. We deliver quality and stability

- our high-performance optical technologies can serve a wide and demanding range of applications, whether for particularly harsh environments, high number of mating cycles, or long transmission distances.

• GOF (multimode / singlemode) and POF systems

• Fibre only and hybrid systems

• Available in four versions across most of the ODU connector range.

• Also available as a pre-assembled complete system

An enhanced Fibre Optic solution, offering highquality transmission characteristics and a high number of mating cycles. The optical performance is maintained even under mechanical stress, environmental influences, and harsh ambient conditions.

Since there is no direct contact between the contact ends, Expanded Beam connections are relatively insensitive to contamination, ensuring reliable transmission without damage. Cleaned can be done easily, but should not be required under normal conditions.

Fibre types: singlemode 9 / 125 μm and multimode 50 / 125 μm

Insertion loss: SM: < 0,35 dB (typical) / < 0.7 dB (max.) MM: < 0,15 dB (typical) / < 0.3 dB (max.)

Return loss: SM: > 60 dB (typical) / ≥ 55 dB (min.)

MM: > 45 dB (typical) / ≥ 35 dB (min.)

Mating cycles: 50,000

Sealing: up to IP 68 (when mated)

Temperature range: -65 °C to +105 °C

Lower performance characteristics, but with a higher number of mating cycles.

Fibre types: multimode 50 / 125 μm

Insertion loss: ≤ 1,5 dB

Return loss: ≥ 32 dB (multimode)

Mating cycles: 100,000

Temperature range: -40 °C to +85 °C

ODU Fibre Optic Physical Contact connectors meet all standard requirements for fast and reliable data transmission. We offer them as a ready-made complete system that includes our robust ODU connectors. The Physical Contact is characterized by very low insertion loss, which makes up to 1,000 mating cycles possible. Contacts are available as multimode and singlemode in either a straight (PC) or 8° angled (APC).

Due to the small end surface of the fibre, it is essential that the connector contacts are cleaned before each mating cycle, so as to guarantee optimum optical transmission at high data rates.

Contacts: PC (flat polish) / APC (angled polish)

Fibre types: singlemode 9 / 125 μm and multimode 50 / 125 μm

Insertion loss: ≤ 0,5 dB

Return loss: > 40 dB (Singlemode) / > 30 dB (Multimode)

Mating cycles: 1,000

Temperature range: -25°C to +75 °C

Offers cost-efficient optical connection for short transmission distances and a high number of mating cycles. Cleaning is not normally required before each mating.

Contacts: PC (flat polish)

Fibre types: 980 - 1000 μm

Insertion loss: ≤ 01,5 dB

Mating cycles: 10,000

Temperature range: -40°C to +85 °C

So, whatever the market, if you need high-performance ruggedised fibre-optic connectors or complete harness solutions, then ODU are the people you should be talking to.

Why not start with a download from our many fibre-optic catalogues

ODU-UK Ltd tel: 0330 002 0640 email: sales@odu-uk.co.uk web: www.odu-connectors.com/uk

LiftEx 2024, the flagship event of the Lifting Equipment Engineers Association (LEEA), will take place on 16-17th October 2024 at the new West Hall at Olympia in London – a great central location for a truly global industry.

The exhibition floor at Olympia will be packed with almost 100 exhibitors showing their solutions to improve productivity, efficiency and safety for end users. These will feature the latest lifting products including hoists, mobile and overhead cranes, steel chains, wire rope, winches, shackles, web slings, rigging, spreader beams, height safety and load monitoring equipment, IT solutions and more.

Crucially, your visit will contribute to improving safety with advice from experts on the LEEA stand, while free training sessions and presentations will be delivered by LEEA Accredited Training Scheme members at the ATS Seminar, which is being held across both days.

Set to be the best yet, LiftEx 2024 is supported by sponsors including YOKE, the manufacturer of lifting fittings for chain, wire rope and webbing slings; Rope and Sling Specialists, one of the largest independent

companies in the field of lifting equipment engineering in the UK; and Headline Sponsor RiConnect Inc, which offers powerful software known as RiConnect that is designed to streamline equipment management and ensure regulatory compliance and traceability.

The many networking opportunities during the event will include the annual LEEA Awards ceremony will be held at the iconic Dorchester hotel on the evening of 16 October 2024.

For engineers, LiftEx 2024 offers the perfect chance to gain vital lifting related knowledge and insights, as well as an opportunity to meet LEEA members

and discuss ways they can help achieve best lifting practice.

Registration will be open soon at the exhibition website at events.leeaint.com/liftex-london-2024.

For those interested in exhibiting, a few stands remain available. Sponsorship packages are also available for the exhibition and Awards Dinner.

Requests will be dealt with on a first-come, firstserved basis, so please contact Leah Phelps on +44 20 3488 2865 or at enquiries@L2Events.com or visit: events.leeaint.com/liftex-london-2024

Titan’s robust flowmeter technology is proving industry recommended in helping beverage manufacturers solve sticky situations. Soft drinks are typically formulated from a combination of water (which may be carbonated) and a syrup flavouring. Soft drinks manufacturers such as Coca Cola, use a twin dispense system to carefully combine and control each fluid to the exact concentration, ensuring the quality and consistency of flavour that their customers expect.

Dispense systems assure consistent and accurate measures of syrup are supplied during the dispensing of each soft drink. For low viscosity syrups or flavour additives and the diluent being dispensed alongside, both can be controlled and monitored using a turbine flowmeter. Titan’s NSFApproved 800 series and Beverage flowmeters are widely used within the food and drinks industry for this purpose. These meters are the industry proven choice of many being both effective and reliable flow sensors, with some manufacturers also using them as low-cost alternative flow switches.

0.01 to 500 l/min, using the low differential pressure across the body to drive a pair of toothed oval gears, one of which contains chemically resistant magnets.

As syrup increases in viscosity, positive displacement oval gear flowmeters are used for accurate dosing. Due to the nature of syrup viscosities – sugar free syrup has a lower viscosity than full sugar syrup for example – oval gear flowmeters can address variable viscosity fluids to measure the rate of syrup flow. Where a higher level of accuracy is required, oval gear flow meters can also be calibrated specifically for the syrup type. Dispensing equipment software is then capable of switching between multiple calibrations for an individual flow measurement device, enabling multi-syrup dispense using a single oval gear ‘syrup meter’. So, although temperature and viscosity of syrups are variable parameters, the flow rate of the syrup is ultimately of prime importance to the total volume dispensed to ensure the correct flavour is achieved.

Based on its OG2 model design, Titan Enterprises developed a syrup meter against Coca Cola’s OEM specifications for their multi-soft drink dispense machines. Manufactured in a polymer material as opposed to standard stainless steel, the syrup meter is a low-pressure, low-cost design alternative using food grade polymers. Titan’s oval gear range of flowmeters are capable of measuring flows from

Typically, separate thick syrup and water lines are necessary for soft drink dispensing systems, requiring a flowmeter for each line. However, the beverage industry is evolving fast, with dispensing machines becoming more compact and modular, and capable of adding flavours and CO2 at the point of sale rather than at the bottling plant. This lends itself to OEM designs incorporating the oval gear and turbine mechanics into one flow device designed to fit the space limitations of the customer’s equipment. Titan has developed dual-line flowmeters providing a solution that suits smaller spaces, a single unit being able to measure both non-viscous and viscous liquids side by side at the point of dispense.

“These type of product developments can translate into big environmental and financial savings for the beverage industry”, says Neil Hannay, Senior Development Engineer with Titan Enterprises. “Higher viscosity concentrate of key ingredients requires less transport, energy and CO2 when diluted at point of sale to deliver a fresh end product.” In addition to reducing transport and maintenance costs, venues are able to hold less stock, saving on storage and fridge space.

Visit Titan’s website for further information on Titan’s range of turbine and oval gear flowmeters.

To discuss a liquid flow measurement solution for your specific OEM application, contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk.

Articulated Pipework Torsion In Hoses

Rotating Cylinders

Swivel joints allow pipework to pressure 1/4” to 40” and beyond.

Vacuum to over 20,000psi.

Stock and bespoke production.

Unique bearing/seal design for longer life.

ISO 9001 CE marked where applicable.

Tel: +44(0)1663 735003

E-mail:

The organisers of the annual UK Plastics Live event are thrilled to announce the launch of Plastics Live Ireland, an expansion of their esteemed portfolio of events. Following the success of Plastics Live in Coventry, UK which runs its third event in 2025, this new addition aims to cater to the dynamic and burgeoning Irish plastics market, fostering deeper connections and promoting innovation within the industry.

Taking place 26-27 November 2025 at the RDS Arena in Dublin, Plastics Live Ireland will serve as a dedicated platform for companies to showcase their latest advancements, network with industry peers, and explore new business opportunities. The event promises to be a landmark occasion for the Irish plastics sector, providing a comprehensive forum for knowledge-sharing, business development, and industry collaboration. Plastics Live Ireland is all about making plastics parts, and as well as looking at traditional plastics processing technologies and services, also focuses on additive manufacturing, Industry 4.0 and the increasingly important area of sustainability.

Scott Colman, Show Organiser of Plastics Live, expressed his excitement about the new launch.

“We are absolutely delighted to bring Plastics Live to Ireland. The Irish plastics market has shown tremendous growth and innovation in recent years, and we are eager to provide a dedicated space for industry professionals to come together, share insights, and drive the sector forward. Our goal is to create an event that not only highlights the latest technological advancements but also fosters meaningful connections and collaborations that will benefit the entire industry.”

Plastics Live Ireland promises unparalleled, costeffective opportunities for exhibitors to present their products and services to a diverse audience of industry professionals, decision-makers, and innovators. The event will feature a range of activities designed to enhance the experience for all attendees, including

a conference including keynote presentations from industry leaders, panel discussions, and peer reviewed presentations.

By joining Plastics Live Ireland, attendees will have the chance to engage in extensive networking, gain valuable insights from experts, and explore new avenues for business growth. The event is designed to be a catalyst for innovation, providing a vibrant environment where ideas can flourish and industry challenges can be addressed collaboratively.

The launch of Plastics Live Ireland marks a significant milestone in the expansion of the Plastics Live brand, reinforcing its commitment to supporting the plastics industry across the UK and Ireland. As the premier event dedicated to this sector, Plastics Live aims to continue its tradition of excellence, offering valuable platforms for industry advancement and collaboration.

For more information about Plastics Live Ireland and to register your interest, please visit www.plasticslive.ie

The UK’s biggest event dedicated entirely to engineering, WHAT’S INCLUDED IN YOUR FREE PASS?

Join thousands of design engineers this October! Source the latest products, services and innovations available to the sector.

9-10 October 2024

Coventry Building Society Arena

ACCESS FREE SESSIONS AND WORKSHOPS

The Engineer, Eureka and New Electronics curate an informative programme for EDS covering the latest trends, opportunities and challenges for design engineers.

EXPLORE THE INNOVATION ZONE

From robotics innovation to Creative Hubb Ltd’s EOD bomb disposal suit, make sure to stop by the

COMPETE IN THE GAMES ZONE

Back by popular demand, don’t miss the immersive F1 racing simulators and games area. Get ready for even more activities, stay tuned!

STOP BY THE NTU SHOWCASE

Meet the next generation of product design engineers! Nottingham Trent University’s product design students are back showcasing their projects.

REGISTER YOUR FREE PASS TODAY

VISIT OUR START-UP ZONE

Meet the newest industry game-changers and cutting-edge advancements. Discover their products and innovative solutions.

CHECK OUT THE ROBOT HOUSE

The Robot House from the University of Hertfordshire will be showcasing their state-of-theart robots and pioneering research in human-robot interaction.

Total Automated Solutions is reaffirming its commitment to the future of engineering by actively supporting Electrical Engineering Apprentices. Within just 12 months, the company has supported York College and Leeds City College with five T-Level placement students and has recruited three new Electrical Engineering Apprentices, all from the local area.

Historically, Total Automated Solutions recruited one apprentice at a time. However, recognising the increasing need for qualified employees in their automation and control business, Company Owners Rob Iwanuschak, Kevin Chapman, and Ben Woolveridge decided to expand their apprentice intake.

In 2023, the company employed two apprentices: Jamie, a 16-year-old school leaver attending York College’s Apprenticeship course, and James, a former REME soldier in the British Army. James joined with a Level-2 qualification but aimed higher for a Level-3 in Electrical Engineering. He is attending HETA College in Hull. Both have excelled in their first year. James achieved distinctions in every category, and Jamie successfully completed his exams in record time.

Rob Iwanuschak commented, “I have witnessed both apprentices grow in their engineering skills, knowledge, and personal confidence. Jamie, a quiet teenager, tackles tasks with impressive confidence and produces excellent results. James, as an older student, has proven to be a respected team asset in the field, equally producing excellent results in his skill set.”

Looking ahead to the 2024/25 academic year, Total Automated Solutions is further increasing its apprentice intake. For the first time, they are adding two more apprentices before the previous ones are qualified. Robert, ex-military, will attend York College as a mature student. Until his course starts in September, he is providing a much-needed extra pair of hands on-site and in the workshop.

Total Automated Solutions recognises that supporting ex-military personnel in gaining professional qualifications offers a wealth of advantages to the company due to their unique attributes. These individuals bring teamwork, adaptability, commitment, stress management, and more, all of which can significantly enhance organisational performance and culture.

A new development for Total Automated Solutions, in their preparation for future growth, is the second apprenticeship to be filled by Jacob. He will begin a Degree Apprenticeship Course at Teesside University. Initially entering the company as a T-Level placement

during his second year at Leeds City College, Jacob quickly became a part of the team. Recognising his potential, Rob and the directors decided to sponsor him for a 4-Year Engineering Degree Apprenticeship at Teesside University.

Rob Iwanuschak and his fellow directors have long understood that sustaining great engineering in the UK requires qualified homegrown engineers. This philosophy, combined with the company’s growth and the evolving engineering landscape, underscores the value of both skill-based and academic engineers at Total Automated Solutions. Rob further explained, “Adding two apprentices a year may not seem a big deal, but for us it is. It’s important because, as qualified electrical engineers age out of the workplace, taking all their experience and know-how with them, we need to be prepared to replace this wealth of ability seamlessly. Additionally, we hire for the long-term, not 20 at a time and then keep only a handful.”

They underlined this philosophy by also supporting both York College and Leeds City College for T-Level

placements in engineering. A new government scheme in 2023, Total Automated Solutions have already had five T-Level students and are speaking with colleges for the upcoming year.

For the 2024/25 apprenticeship positions, the company received over 200 applicants from across Yorkshire on the UK-Gov site. While this surge in interest is encouraging for UK engineering, it was challenging to select only a couple of candidates. Rob explained, “We had to make choices that align with our current and future business needs. We remain focused on innovation and engineering excellence and are determined to nurture a strong pool of younger talent. The government initiative that supports SMEs with apprentice positions is a great asset to companies like Total Automated Solutions, enabling us to compete with larger organisations.”

Total Automated Solutions, founded in 2007, recruited its first Electrical Engineering Apprentice in 2014. Ten years later, that first apprentice, Jack, remains with the company. Over the last decade, he has progressed from the workshop to becoming a valuable site engineer, continuously adding to his skill set and taking on more responsibility. Jack stated, “The apprenticeship provided me with essential skills and knowledge, allowing me to prosper in my career at Total Automated Solutions. No two days are the same, and I enjoy working for such a forward-thinking company. Being involved in integrating customer projects makes me feel like a valuable contributor and a valued team member.”

Company co-owner Rob Iwanuschak concluded, “Jack is a testament to the success of our apprenticeship scheme, and he continues to excel in his role. It is crucial for companies like ours to blend new ideas and methods with established engineering experience to achieve ongoing success.”

On a final note, Rob concluded, “It’s heartening to see so many young people interested in engineering and that apprenticeships are once again a top choice for school leavers. Apprentices are the way forward, which can only be a win all round!”

For more information, please visit: www.total-automated-solutions.com

The PPMA Show organisers, Automate UK, have been busy planning the UK’s largest processing and packaging event to ensure it will be yet another spectacular show between 24-26 September at the NEC Birmingham.

Automate UK is excited to reveal that the well-known broadcaster, entrepreneur and writer, Gregg Wallace, will be spending a day at PPMA Show exploring the fascinating world of processing and packaging machinery, robotics and industrial vision systems as he goes ‘Inside the Exhibition’.

The show is renowned for being ‘the place to be’ for visitors, with plenty of opportunities for them to seek inspirational packaging solutions, discover fascinating new machinery, broaden their knowledge at expert talks, and engage in face-to-face networking. Visitors will walk away from the show armed with a wealth of information and knowledge that can be applied to their own businesses to streamline processes, improve efficiency, and boost productivity.

The annual PPMA Show attracts over 8,000 visitors across the three-days and includes over 350 worldclass exhibitors, comprising over 2,500 brands. These companies will be displaying their state-of-the-art products and services, hosting product launches and live demonstrations to attract the visitors’ attention. Some of this year’s exhibitors include GEA, Bizerba, Videojet, Ulma, Ishida, Beckhoff, Schur Star Systems, Ilpra, Sidel, and JBT Proseal.

One of last year’s visitors from Unilever said: “There is a good, wide range of products on show. We came to the show looking for automation partners, which is where our company is headed. We’ve visited the show a number of times and it always delivers good networking opportunities.”

The comprehensive seminar programme is one of the show’s highlights. It provides visitors with ideal opportunities to top up their industry knowledge and stay informed about the latest trends. This year’s keynote speakers are:

• Stefan Casey, Nestlé: The digital transformation of FMCG industry: How digital technology is bringing both challenges and opportunities in packaging across the whole value chain

• Jessica Sansom, Huel: The manifestations of climate change – rising to the challenge and adapting to a new normal

There will also be a panel discussion by UK Automation Forum on ‘What would make UK food businesses adopt more robots?’. The panel will consist of representatives from the food industry who will be discussing the positive impact that adopting automation can have on the sector, whilst sharing top tips and learnings that help to ensure successful outcomes.

Every year the PPMA Show organisers work tirelessly planning ways to further enhance the visitor experience through introducing new features. One of them will be a dedicated live demonstration theatre where exhibitors will grab everyone’s attention when they take to the stage to launch their new products and services.

Another new fantastic feature is a tour each day of the show for those visitors who may be new to the industry or a startup business. This is designed to increase their understanding about the usage of various machinery and what would be suitable for their business.

This year will also see the introduction of icons that will help to identify easily what sectors the exhibitors specialise in.

Automate UK will soon be launching an app for the show which will further enhance the visitors show experience. The app will offer a wide range of functions, such as the content capture which allows visitors to scan QR codes on the exhibitors’ stands to access information about their products and services.

The organisers are excited to announce that the networking reception will take place at the end of day one. This new event provides an excellent opportunity for exhibitors and visitors to connect in a more informal setting, with an array of food & drink available, along with a live performance from the wonderful Soul Brothers. The perfect way to wind down after a busy day at the show.

Collett Transport, working in partnership with IQA Elecnor Group, has successfully completed the heavy transport and installation of a 148-tonne transformer to Neilston Grid Stability Facility in Scotland

The project utilised Collett’s 250-tonne girder bridge trailer along with their heavyduty jacking and skidding equipment. Working at KGV Dock in Glasgow, Collett received the project cargo, which was offloaded from the vessel onto the quayside along with ancillary boxes. Working under CPA contract lift conditions, all port handling operations, including vessel discharge, were managed and overseen by Collett.

Prior to transportation, Collett’s Projects department conducted preliminary works, including a detailed route survey report that identified various street furniture removals as well as required civil works along the route. In addition, Collett produced lashing plans and calculations for the transformer’s transportation and liaised with Renfrewshire Council and Glasgow City Council, along with many of the councils’ subcontractors.

At the quayside, Collett assembled the girder frame and associated beams to build around the transformer, completing the 16-axle configuration. Travelling in the late evening, the 60m long truck and trailer configuration set off for the substation site, accompanied by a police escort as well as their in-house escort fleet.

Upon arriving on site, Collett transhipped the transformer from their girder bridge to a 14-axle flat-top trailer to navigate the limited site access. By increasing the girder bridge height using hydraulic suspension, the 14-row was reversed under, already loaded with a turntable. As the girder bridge was angled perpendicular to the 14-row, the transformer was loaded and turned so it aligned with the 14-row trailer.

Manoeuvring the transformer alongside the plinth, Collett’s Heavy Lift Team utilised their hydraulic jacking and skidding equipment to transfer the transformer onto the final plinth. Before final positioning, wheels were attached to the bottom of the transformer and accurately aligned with the rail tracks.

David Sanz Delgado, Project Manager, from IQA Elecnor Group commented, “This is a major milestone in our Neilston Grid Stability Project as part of National Grid’s Pathfinder Programme, Phase II. The delivery of the 148-ton generator Step-up Transformer marks a significant step forward in our journey towards enhancing grid stability and reliability.

This Synchronous Condenser will play a crucial role in ensuring a more resilient and efficient power system for years to come.

A huge thanks to everyone who worked so hard on this phase. Your dedication and effort have been instrumental in achieving this success.”

www.collett.co.uk

Optical Surfaces Ltd is a leading producer of large diameter aspheric lenses used as critical focusing optics in high-power laser research.

Aspheric lenses provide a cost-effective way of reducing the number of optical elements in a focusing system thereby making them ideal for low f-number, high throughput laser applications.

Beneficially also a correctly formed aspheric lens surface may cancel or control spherical aberration. As a result, more laser energy can be concentrated into a smaller area.

Benefiting from a uniquely stable production environment, Optical Surfaces can routinely fabricate low f-number aspheric lenses up to 600mm diameter in a range of optical glasses to optimise light gathering and focusing performance. To meet the demands of high-power laser focusing experiments - Optical Surfaces is routinely able to manufacture aspheric lenses with surface finish of 10/5 scratch/dig,

surface roughness of 1nm rms and ultra-smooth slope errors. To maintain high transmission and enable the aspheric lenses to operate at the ultra-high energy thresholds used in fundamental plasma physics research – a range of high-power laser coatings is available.

The ISO 9001-2015 approved manufacturing workshops and test facilities at Optical Surfaces Ltd are deep underground in a series of tunnels excavated in solid chalk. This provides an environment

where temperature is naturally thermally stable, and vibration is extremely low. With such stable conditions testing of all aspheric lenses becomes quantifiable and dependable. In addition to these natural advantages, the company has invested in an extensive range of test equipment and uses trusted methods to ensure accurate and reliable testing of surface accuracy, quality, and slope errors.

For further information on large diameter aspheric lenses for high power laser research please visit: optisurf.com/aspheric-lenses or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com. Large diameter Aspheric lens (courtesy: Optical Surfaces ltd)

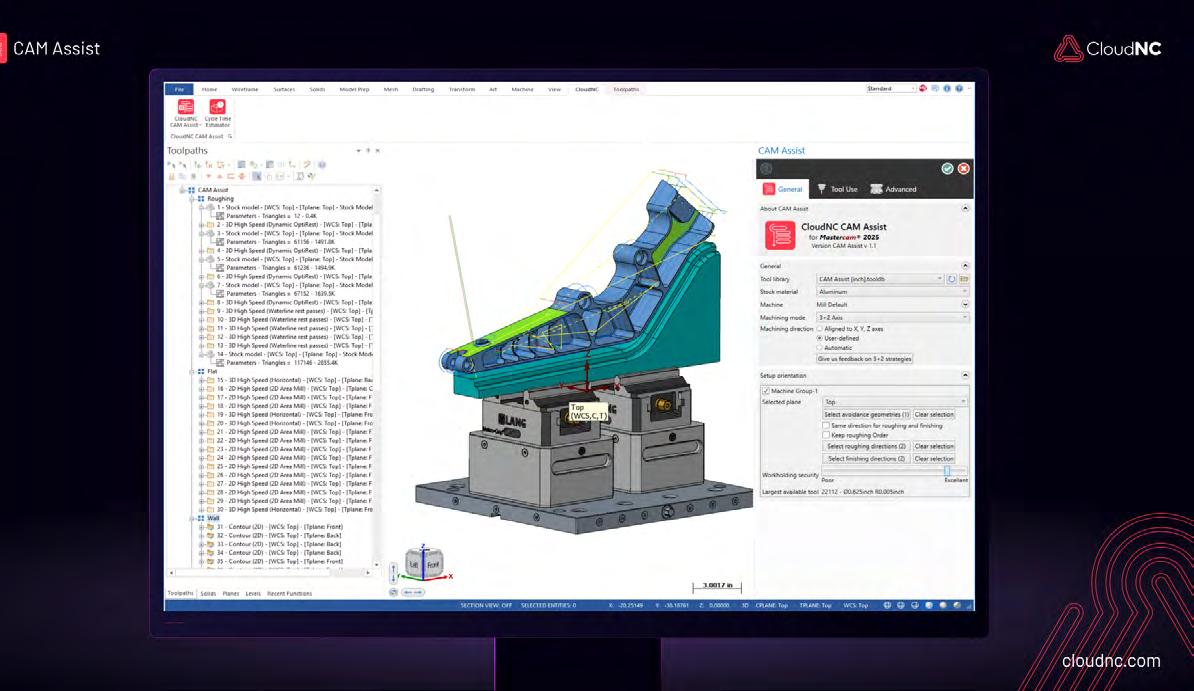

• CAM Assist, which uses AI to generate machining strategies for 3 and 3+2 axis CNC machines, is now available for Mastercam users

• The release brings the benefits of CloudNC’s CAM Assist solution to more global users, including Mastercam’s core customer base of machine shops supplying the aerospace, automotive and energy sectors

• North American manufacturing software resellers - including Shopware, CCCS and In-House Solutions – will help bring the software to Mastercam users across the US and Canada, expanding its customer base

CloudNC - a manufacturing technology company - today announces that its CAM Assist solution, which uses AI to generate machining strategies for 3 and 3+2 axis CNC machines, is now available for Mastercam users.

The new upgrade is available as an AI add-on for the Mastercam platform, one of the world’s most-used CAM software solutions, and means more machinists globally can use CAM Assist, bringing its efficiency and productivity gains to an even larger audience than before.

Theo Saville, chief executive and co-founder at CloudNC, said: “Mastercam has deep market penetration with expert machinists and workshops that serve specialist sectors, like aerospace and automotive, and our research suggests over 10% of CAM programmers worldwide have access to Mastercam. Now that CAM Assist is available to them, those users will benefit from CAM Assist’s ability to save the average machine shop over 1000 hours a year - changing the game for a large slice of the global machining sector.”

CloudNC is making the software available to North American manufacturing software resellers - including Shopware, CAD/CAM CONSULTING SERVICES (CCCS) and In-House Solutions – who will help to immediately bring the benefits of the software to Mastercam users in the US and Canada.

Bill Angsten, owner of Shopware, said: “Shopware is always looking for tools to help our customers boost productivity. To find something like CAM Assist to help automate 2D, 3D, and 3+2 Milling programming is a game changer. We’re very excited to partner with CloudNC, and look forward to saving our Mastercam customers countless hours of programming.”

Patrick Shelar, President at CCCS, said: “Mastercam has been a leader for so long because of how effective it is at making your job easier and your manufacturing process more successful. Cutting down programming and machining time as much as possible to ensure customer productivity gains is always driving Mastercam development teams.

“Now that the power of AI has boomed, it’s the natural progression to implement this into the manufacturing industry and CloudNC’s CAM Assist has arrived with the best utilization of AI technology we have seen in CAD/CAM. We are excited to bring this tool to our customers and be a part of the next evolutionary step in manufacturing.”

Neil Lang, Director of Revenue at In-House Solutions, said: “CAM Assist is poised to be the go-to AI for machinists around the world, because it effectively makes machining more accessible. We can’t wait to bring it to our Mastercam users and see the productivity gains that result from its deployment in Canada, and beyond.”

CAM Assist uses advanced computer science techniques and AI to generate intuitive machining strategies in minutes or seconds, depending on complexity, which could take CNC machine programmers hours or even days to manually create.

As a result, the amount of time it takes to program a CNC machine to make a component - a bottleneck in many factories – is greatly reduced, compared to the previous manual programming process, as is the time spent to estimate how much a new component will cost to program.

That gain enables manufacturers using CAM Assist to raise productivity and shorten lead times, while also estimating for more work, more quickly. CloudNC also recently announced the release of a new CAM Assist feature, Cutting Parameters AI, that automatically generates appropriate physics-based feeds and speeds for virtually any CNC machining scenario, in moments, resulting in productivity gains of at least 20%, and this feature is also available in Mastercam.

CAM Assist is available for Mastercam today, as well as other CAM packages, via www.cloudnc.com and via selected resellers.

TR Chai Yi Precision Fastenings

Manufacturing, now part of the Trifast plc group of companies, is celebrating the launch of its Chinese manufacturing facility in the key industrial city of Dongguan, within the Guangdong Province, capitalising on years of increasing demand in the region.

TR Chai Yi Precision Fastenings Manufacturing, now part of the Trifast plc group of companies, is celebrating the launch of its Chinese manufacturing facility in the key industrial city of Dongguan, within the Guangdong Province, capitalising on years of increasing demand in the region.

Guangdong is a vibrant world-class centre of innovation and technology, providing the perfect place for TR to produce its precision engineered screws to OEM’s and their sub-contractors, whilst leveraging its global scale on a local basis.

The new 2,800 sq. metres of manufacturing space houses 44 cold forging machines and 36 thread rolling machines producing 0.6mm to 4mm micro screws and thread forming screws, in steel, stainless and titanium, with an output of around 1 billion pieces per annum.

TR Chai Yi is proud to have achieved the globally recognised ISO 9001 certification demonstrating that TR has met the stringent criteria required for quality, safety and efficiency standards for its products and services to customers in the region. The accreditation affirms that the team is committed to providing the highest level of quality across the organisation and are continually looking at ways to improve.

Jeremy Scholefield, Asia Pacific Managing Director, comments; “We’re delighted to open this new facility and in such a renowned area, it’s such a positive move for TR as a group. Our focus is on producing competitive

products and continuing to build a strong capability in China and across the Asia Pacific region to meet market demands.

“Here in Guangdong, one of our key differentiators is our technical engineering knowledge to produce very precise and often complex components, those that are manufactured to exact measurements and mass-produced. This latest investment is key for us, as it highlights TR’s robust development in the region and our commitment to staying close to key customers here.”

The new China plant is the company’s seventh global manufacturing facility with factories now also in Italy, Singapore, Taiwan and Malaysia.

For more information, visit: www.trfastenings.com