DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM FIND YOUR NEAREST THERMO KING DEALER AT DEALERS.THERMOKING.COM With E-Series, Thermo King hits the town with a new, all-electric refrigeration unit for electric light commercial vehicles. With energy efficiency at the heart of the new design, it’s built to bring out the best in electric performance, and deliver it straight to the city center. THE ELECTRIC EDGE IN URBAN AND INNER-CITY DELIVERY E–SERIES TK24-013_E-500_Print_AD_186x227_EN_Food&DrinkNetwork.indd 1 05/02/2024 14:24 ISSN: 20568355 foodanddrinknetwork-uk.co.uk FOOD AND DRINK NETWORK UK FLEXIBLE POUCH PACKING SYSTEMS Whatever your requirements -

25-27 MARCH 2024

26-28 SEPT 2023

EXCEL, LONDON, UK

NEC, BIRMINGHAM, UK

STAND H30

Visit us on Stand 331

EDITORIAL:

Akabo Media

Anuga Foodtec Multimodal

Cannon PR

Curious Heads Media

Harford Control

Montgomery Group

best in electric performance, and deliver it straight to the city center. TK24-013_E-500_Print_AD_186x227_EN_Food&DrinkNetwork.indd 1

ADVERTISEMENT SALES:

KIMBERLEY READ (Advertisement Sales Manager) GINA MADDISON

AMANDA WALMSLEY

EVELYN WOOLSTON

STUART TURNBULL - Studio Manager

RACHEL RILEY - Designer

WALTONS PUBLICATIONS LTD

46

Kimberley Read at: kimberley@ foodanddrinknetwork-uk.co.uk

or Gina Maddison at: gina@foodanddrinknetwork-uk.co.uk

foodanddrinknetwork.co.uk

08. Anuga Foodtec 2024

Shaping the future of responsible food & beverage industry

Anuga FoodTec 2024, scheduled from the 19th to the 22nd of March, stands out as a premier trade fair for the global food and beverage (F&B) industry.

DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM

05/02/2024

FIND YOUR NEAREST THERMO KING DEALER DEALERS.THERMOKING.COM

With E-Series, Thermo all-electric refrigeration commercial vehicles of the new design, performance, and TK24-013_E-500_Print_AD_186x227_EN_Food&DrinkNetwork.indd

PROCESS & FILLING 23

DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM FIND YOUR NEAREST THERMO KING DEALER AT DEALERS.THERMOKING.COM With E-Series, Thermo King hits the town with a new, all-electric refrigeration unit for electric light commercial vehicles With energy efficiency at the heart of the new design, it’s built to bring out the best in electric performance, and deliver it straight to the city center. AND INNER-CITY DELIVERY TK24-013_E-500_Print_AD_186x227_EN_Food&DrinkNetwork.indd 1 05/02/2024 14:24 DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM FIND YOUR NEAREST THERMO KING DEALER AT DEALERS.THERMOKING.COM With E-Series, Thermo King hits the town with a new, all-electric refrigeration unit for electric light commercial vehicles With energy efficiency at the heart of the new design, it’s built to bring out the best in electric performance, and deliver it straight to the city center. TK24-013_E-500_Print_AD_186x227_EN_Food&DrinkNetwork.indd 1

HENEAGE ROAD, GRIMSBY N.E. LINCOLNSHIRE DN32 9ES

02 03 NEWS NETWORK PRODUCT NEWS All rights reserved. No part of Food and Drink Network UK Magazine may be reproduced or stored in a retrieval system or transmitted in any form, electronic, mechanical or photocopying, without prior written permission of the publishers. The publishers do not accept responsibility for views expressed, or statements made, or in those reproduced from any other source. No responsibility is borne by the publishers for any errors made in any advertisement, or for claims made by any advertiser which are incorrect. The publishers cannot be held responsible for any breach of copyright arising from any material supplied. This includes copy, design and/or images. Find us on LinkedIn Copyright © 2024 All Rights Reserved. 01472 359036 Helping Wales become a zero-waste nation - Food and drink vendors across Wales get ready for new recycling law set to help make Wales a zero-waste nation. Ecofill Autoclaves: Revolutionising Sustainability in the food and drink industry The STOPP project, to produce strategies for food plastic circularity The Value of Lims in Manufacturing An article by Roy Green of Harford Control Cross and Morse: Makes conveying easy! VOLUME 24 • ISSUE 03 Produced in Europe’s Food Town SUBSCRIPTION: 12 issues - £84.00 (inc. postage) A guide to the exhibitions and events supporting the Food & Drink Industry ACCOUNTS & ADMINISTRATION: GRAPHICS DEPT: PUBLISHED BY: TELEPHONE: EMAIL: WEBSITE: TWITTER: @fdnetworkuk FOOD AND DRINK NETWORK UK 08 EXHIBITIONS & EVENTS RECYCLING LAW ECOFILL AUTOCLAVES PACKAGING & LABELLING SPECIALIST VIEW SOLUTIONS 17 Ensuring Food Safety: The role of Teknomek BST J800 Pens in Contamination Risk Prevention 31 SUSTAINABILITY 13. Multimodal 2024 The Future of Logistics Unfolds 15. Intralogistex 2024 19th & 20th March 2024 IntraLogistex innovation trail set to showcase path to business efficiency and profitability 28. Penn Packaging Produce recyclable spouted pouches economically 29. Penrhos Spirits Artisan Gin company breaks new ground with aluminium bottles Unveiling the advantages of purchasing food factory equipment via online auctions. 32 FOOD MACHINERY AUCTIONS 30 18 Streamlining Food Production: The Role of Processing Equipment in the Modern Food Industry PROCESSING EQUIPMENT 22 27 20 24 Did the social media revolution begin with Facebook Latest ‘how to’ food application videos from Silverson Machines 04 26 SOCIAL MEDIA MIXING EQUIPMENT Thermo King starts production of the new fully Electric E-500e for Electric Light Commercial Vehicles 11. Sustainable Food Factory Accelerate your Food and Beverage Plant Decarbonisation by Attending Sustainable Food Factory 2024 09. IFE 2024 Uncover the future of food and drink at IFE 2024. HYGIENE & SAFETY DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM FIND YOUR NEAREST THERMO KING DEALERS.THERMOKING.COM With E-Series all-electric commercial of the performance, DISCOVER THE NEW E-SERIES AT TKELECTRICEDGE.COM FIND YOUR NEAREST THERMO KING DEALER AT DEALERS.THERMOKING.COM With E-Series, Thermo King hits the town with a new, all-electric refrigeration unit for electric light commercial vehicles. With energy efficiency at the heart of the new design, it’s built to bring out the

14:24

1

Nuvonic Celebrates 100 Years in Business

The company has been innovating in UV technology since the 1920s and pledges ongoing commitment to customer-focused innovation

Nuvonic, a global UV technology solutions provider, commemorates its 100th year of unwavering commitment to excellence. Formerly known as Hanovia, the company has been a stalwart in UV science since its inception in the 1920s, and its century-long journey is a testament to innovation and adaptability.

Founded in Slough, Berkshire, U.K., in 1924, Hanovia started manufacturing UV lamps for medical applications. Since then, the company has consistently been at the forefront of UV science. Over the years, Hanovia evolved into one of the world’s leading UV lamps and systems manufacturers, contributing to industries such as food and beverage processing, pharmaceuticals, brewing, electronics, and aquaculture.

Over the decades, Nuvonic has undergone a transformative journey marked by strategic milestones and industry leadership. In 1981, Nuvonic became part

Union Industries improves efficiency with double Eiger Door installation at Taj Foods

Union Industries, the UK’s leading manufacturer of bespoke industrial doors, has helped food importer and distributer, Taj Foods, improve efficiency through the installation of high-speed freezer doors – the Eiger Door.

Taj Foods, specialists in frozen exotic food and prepared meals, was established in 1980 and recently expanded its cold storage at its Sheffield warehouse to meet growing demand. The project undertaken by EJM refrigeration, involved improving its energy efficiency and carbon footprint with the installation of a new CO2 refrigeration system.

The two Eiger Doors will enhance operational efficiency in the high-demand environment and will maintain consistent freezer temperatures, while ensuring unimpeded access to cold stores. Since its launch in 2002, the Eiger Door has been installed as a fast-access traffic door at major food retailers, 3PL cold storage and distribution, and frozen food manufacturers across the UK. The Eiger Door ensures that consistent temperatures can be maintained and features an innovative dehumidification system, which prevents snow and ice build-up on the door blade and frame. This feature tackles a consistent issue plaguing other door types, as the freezer encounters humid ambient air entering the cold store. Minimising downtime is also supported by the Eiger Door’s robust construction and its tried and tested crash-out and reset system. Due to the modest difference in size between Forklift Trucks and the door opening, as well as the busy nature of this freezer, this is of particular benefit at this depot when considering the long-term reliability of the Eiger Door.

Rob Howe, Union Industries’ Technical Sales Engineer, said: “The installation of the Eiger Doors at Taj Foods showcases our commitment to providing cutting-edge solutions that prioritise efficiency and reliability. Over the past 20 years, the Eiger Door has consistently proven to be a superior and effective innovation for cold storage access, overcoming challenges such as ice build-up and excessive energy use to maintain consistent temperatures. We are confident that the Eiger Door will significantly contribute to Taj Foods’ operational success.”

Anil Solanki, Managing Director at Taj Foods, said: “We were looking for a reliable door solution to fit in with the redevelopment of our Sheffield warehouse, and after reading about the success of the Eiger Door we approached Union Industries to assist us to improve operational efficiency as we doubled our capacity. We believe that the advanced features of the Eiger Door will not only enhance the efficiency of our cold storage but also contribute to long-term reliability, minimising disruptions in our day-to-day operations.”

For more information visit www.unionindustries.co.uk

of Halma plc, laying the foundation for future growth. The subsequent years witnessed important developments, such as Berson’s integration into the Halma family in 1986 and Berson’s groundbreaking introduction of the InLine model of UV systems in 1995. In 2017, Hanovia, Berson, and Aquionics united under a single management team, fortifying their position in the UV technology landscape. The year 2021 saw Orca joining Halma, further strengthening the collective expertise. In 2022, these four entities converged under the innovative banner of Nuvonic, reflecting a unified commitment to excellence. For more information, visit www.nuvonicuv.com.

Coperion develops MEGAtex cooling die for manufacturing plant-based meat substitutes

New MEGAtex S7 Cooling Die Offers HMMA Meat Substitute Manufactures Significantly Greater Flexibility.

Coperion has developed the new MEGAtex S7 cooling die for manufacturing plant-based HMMA (High Moisture Meat Analogue) meat substitutes. Mounted at the discharge of the ZSK Food Extruder, this texturizing unit gives the plant protein mass a dense, fibrous structure that closely resembles animal flesh.

For many years, Coperion has been a proven supplier of production systems for plant-based meat substitute products. With the MEGAtex S7 cooling die, Coperion has developed a new discharge for HMMA production that allows for variable width and strength as well as various textures for meat substitutes. Moreover, Coperion has equipped the MEGAtex cooling die with features that simplify handling and make both recipe and configuration changes possible with just a few quick adjustments. Coperion will exhibit the new MEGAtex S7 cooling die at Anuga FoodTec 2024 (19-22 March, 2024, Cologne, Germany) at booth B-011 in Hall 10.1.

New key technology for processing plant proteins

HMMA is a plant-based intermediate product that is primarily used for ready-to-eat meals such as vegan chicken nuggets or ground meat. It contains 50 to 70 percent water and 30 to 50 percent plant proteins with less than 10 percent fat content. In the HMMA manufacturing process, protein-rich raw materials are first mixed with water and worked into a homogeneous mass in a ZSK Food Extruder. This mass is then pressed through the MEGAtex cooling die, where the meat-like texture is formed and a solid strand is discharged for further processing.

Characteristics of HMMA quality are the product’s texture and strength as well as the length and strength of the fibers. Coperion developed this new texturizing unit in order to more precisely fulfill these quality requirements, and in particular to provide more flexibility to smaller companies, research organizations, and startups. The MEGAtex S7 achieves throughputs of 5 to 50 kg/h and can currently be combined with the ZSK Food Extruder sizes 18, 27 and 34.

“The market for plant-based meat substitutes is growing exponentially and it’s very important to us to propel this development forward with innovative technologies. With this new MEGAtex cooling die, we’re pursuing our goal of redesigning the HMMA manufacturing process with greater variability. Moreover, maximized accessibility will markedly reduce cleaning time and increase the overall profitability of HMMA production. After comprehensive tests at our Food Test Lab using various raw materials, we can confirm with high certainty that we have fully achieved these goals,” said Markus Schmudde, Head of Research and Development, Compounding & Extrusion at Coperion, clearly very pround of Coperion’s new MEGAtex cooling die.

News Network 02 | foodanddrinknetwork-uk.co.uk General

For more information visit www.coperion.com

Photo caption (L-R): Rob Howe, Technical Sales Engineer at Union Industries & Anil Solanki, Managing Director at Taj Foods.

Mijenta Announces Limited Edition Cristalino Aged

A clear spirit with the complexity of aged tequila brings new versatility to mixology

Mijenta, the award-winning, additive-free, sustainable tequila from the highlands of Jalisco today announces the release of its limited edition Cristalino, which through extensive experimentation has brought to life something truly unique and utterly unpredictable. The idea to create a Cristalino tequila was born from Maestra Tequilera Ana María Romero Mena’s passion for exploring the sensory possibilities of tequila, which for Mijenta’s latest expression, began with experimentation with Symphony barrels. With staves composed of American Oak from the forests of Minnesota, Missouri, Pennsylvania and Virginia, over the course of approximately eight months, the barrels continuously enhance the incredible richness of the tequila as new compounds develop, transform and evolve. As with all Mijenta expressions, the Cristalino packaging is fully eco-friendly.

The bottle and cork are made from recycled glass and the box is made from 100% post-consumer recycled paper.

Yorkshire Entrepreneur With Thirst For Success Launches New Independent Drinks Brand As Passion Drives New Project

Vais Founder, 31 year old serial entrepreneur, Nicky Story has declared that; “the first supermarket to stock VAIS, I will tattoo on my leg!”

Any hard seltzers in the UK are in cans - with his glass printing factory, Nicky was determined to differentiate and his premium product VAIS comes in a luxury glass bottle, that is screen printed in gold.

A 31 year old serial entrepreneur from South Yorkshire is celebrating this month, having seen an idea he had whilst on a tour of the United States, come to life - Nicky Story, CEO of Nicky Story Holdings and Founder of Supplies for Candles, which also incorporates The Soap Kitchen, Ava May Aromas and Glassprint Ltd, has branched out into a new market with his latest venture - as he brings a new drinks brand to market.

A low calorie, alcoholic hard seltzer VAIS (pronounced Vice), was born out of his own desire to replicate a drink he loved in the States, which he had struggled to find in the UK. After deciding to embark on a health kick and make more ‘health conscious decisions’, Nicky was attracted to hard seltzer drinks, but found it near impossible to find a low calorie drink that also tasted good. After trying several other seltzers on the market and not being impressed, Nicky decided to create a drink that filled this gap.

A refreshing premium fruit seltzer at 96 calories per bottle, with 100% natural flavours, VAIS comprises of alcohol (4.5% alc/vol), fruit and soda water. The initial products are Lemon & Lime / Black Cherry & Raspberry / Mango & Passionfruit. Since the start of his product development more hard seltzers have hit the marketplace - but are all in cans - Nicky, with his glass printing factory, was determined to differentiate and create a premium product in a glass bottleand this is the only one on the market.

To find

more about VAIS, please visit: www.vaisdrinks.com

in Symphony Barrels

This latest launch follows Mijenta’s release of its second batch of Añejo Gran Reserva in Autumn 2023, along with the brand’s recognitions by the International Wine and Spirits Competition (IWSC) as the Agave Producer of the Year and the overall Spirits Producer of the Year, the most prestigious recognition awarded by the IWSC.

Priced at £98.50 for a 70cl bottle Mijenta Cristalino is available to purchase from Harvey Nichols.

For more information please visit www.mijenta-tequila.com and find the brand on Instagram and Facebook at @mijentatequila.

Remedy Kombucha Becomes First No-Sugar Multipack Kombucha to Launch into Waitrose

With multipacks now growing at more than 77% year-on-year due to habitual kombucha consumption, Remedy has driven more growth within the category than all other competitors put together over the past 12 months.

Remedy also recently became the first kombucha brand to reach £8.5m in grocery in the UK, supported by continued and sustained demand from retailers seeking out healthier soft drinks for their customers, with Remedy crafted from all-natural ingredients, with no sugar and no artificial sweetener.

Remedy’s Wild Berry, Raspberry Lemonade and Ginger Lemon flavours (4 x 330ml; RRP: £5.50) are available in selected Waitrose stores nationwide and online at waitrose.com now

Remedy Kombucha, the UK’s leading kombucha brand, can today announce its launch into Waitrose - the first no-sugar kombucha available to Waitrose customer in multipack format. ...and

If you would like to see your Newsworthy articles , regarding the Food & Drink Industry, published in the next issue of ‘Food & Drink Network UK’ email:

graphics@waltonspublications.com

Your release will also be placed on our website: foodanddrinknetwork.co.uk

Product News

foodanddrinknetwork-uk.co.uk | 03

New Innovations ALL NEWS IS GOOD NEWS!

FOOD AND DRINK FOOD NETWORK UK

out

on our Social Media and online Platforms

Did the social media revolution begin with Facebook?

The origins of Facebook and how Mark Zuckerberg successfully transformed an idea into a billion-dollar business that has dominated social media networks for two decades are well documented.

However, in this article I wanted to reflect on how Facebook’s world of pokes, likes and shares hasn’t only transformed the way in which many of us communicate with others, but how it has become a vital aspect of almost every business marketing strategy.

It could even be argued that the evolution of the social media industry itself can be traced back to the day when Facebook went live.

Over the past 20 years, social media channels have come and gone; Facebook isn’t just remarkable for its longevity, but for how it has transformed the way in which businesses engage with their customers.

So, what exactly has been the secret to Facebook’s success?

It could be argued that the origins of social networking as a communications tool predate the dawn of the internet age.

February 2024 marked something of a milestone in social media history: Facebook celebrated its 20th anniversary.

Early experiments into bulletin-boards and interactive text communication using the computers of the day first began in the early 1970s. In most cases, these early experiments were limited to a small user group, largely due to the inhibitive costs of the technology.

Remember, these were the days when a computer would occupy the size of a small house, and even a home computer could cost nearly a year’s salary!

The limitations of the computing technology available meant that any forms of interactive communication between computers required technology out of reach of the typical home computer user.

That changed in the 1990s with the advent of the internet age. Suddenly, it was possible to transport yourself to almost anywhere in the world at the click of a button. You didn’t need a PhD in computer science, and even someone with very limited computing skills could quickly learn how to surf the internet.

Connecting to the internet in the early 2000s was a very different experience to that of today. Less than half of Britain’s households were connected to the internet; the vast majority were reliant upon dial up connections.

04 | foodanddrinknetwork-uk.co.uk

Where did the Revolution start...?

The limitations of the connection speeds meant that downloading images could be a painfully slow experience, and when it came to video and music, although it could be done, it was not a quick process!

However, one solution would soon change all that: broadband. As fibre-based connectivity reached more areas of the UK, householders quickly liberated their landlines and consigned dial-up modems to the history books.

Offering lightning-fast connectivity speeds, in most cases more than 100 times faster, the stage was set for a social media revolution.

The dawn of the social media age

One of the first companies to harness the power of the internet was AOL. Unlike many of its competitors, AOL saw potential in building online communities, not simply providing access to the internet and email.

The communications strategy AOL embraced concentrated on making its software as accessible as possible. For quite a long period of time it was almost impossible to pick up a magazine without a CD-ROM falling out of it containing the latest incarnation of the AOL platform.

After installing the software, suddenly computer users were transported into a brave new world – one that didn’t simply provide internet access but offered the chance to become part of a brand-new community… all for the approximate sum of £15 per month.

rekindled. Within a year of its launch, the site was attracting 2.1 million visitors per month and was even blamed for an increase in divorce rates!

The platform was sold to ITV for £120 million. Friends Reunited had generated a membership of more than 15 million members with over a million paying subscribers. Despite the success it achieved, and the rolling out of the brand into music compilation tapes and even TV shows, Friends Reunited failed to find ways of keeping its audiences engaged, and by 2016, the school reunion was over forever.

Perhaps one of the primary reasons for the failure of Friends Reunited wasn’t the online communities it built so successfully, but the combination of its subscription model (latterly dropped) and an inability to keep users engaged.

But, as The Washington Post noted, the failure of Friends Reunited could also in part be attributed to the rise of Facebook: “Like many social networks that aren’t Facebook, Friends Reunited’s decline was almost certainly triggered by the success of Mark Zuckerberg’s online empire, which leaves little need for other reunion-type sites.”

The young pretender

Although Facebook certainly benefitted from advances in both technology and connectivity, it’s important to remember that in 2004, the platform was only available to a small number of students at Harvard. According to The Guardian, within just 24 hours the platform had received 1,200 sign-ups. The first month saw half of the university’s undergraduates sign up for the new service.

The AOL platform combined news and information on a wide range of subjects, but where it really distinguished itself from the competition was its online communities. Equipped with chatrooms, messaging boards and even offering users the chance to build their own microsites, the platform catered for hobbies and interests covering just about any subject matter conceivable… and just like Facebook today, if there wasn’t one there to suit your tastes, a new group or chatroom could be created at the click of a button.

Early social media channels

One of the innovative features included in the AOL platform was the built in instant messenger. Launched in 1997, AIM provided opportunities to look up and chat with other members.

AOL was one of many different companies leading the social networking revolution, but most struggled to attain universal appeal. That was until a husband-and-wife team successfully captured the hearts and minds of the British public by tapping into the nostalgic memories of our school days.

The result of their work was Friends Reunited, arguably the first social media network to achieve widespread appeal in the UK. Launched in 2000 by Julie and Steve Pankhurst, the website grouped users into classes and years, allowing long forgotten connections to be

The roll out, first to other Ivy League universities, then to other universities across America, Canada and the UK also provided an opportunity for Facebook to manage its growth, ensuring that any potential glitches could be addressed before reaching the mainstream – something that was attributed to the downfall of Myspace.

By the time Facebook was made available to anyone in the UK aged over 13 and with a valid email address, the platform had amassed 12 million global users, with half a million UK accounts registered in October 2006 alone.

Hitting the mainstream

Looking back through the newspaper archives of the time, it seems remarkable just how little media attention the platform received. Writing in 2006, when examining some of the different channels available, The Daily Telegraph simply described it as, “Like Friends Reunited, but free to use”.

All that would change a year later when Prince William joined the platform. Suddenly, Facebook wasn’t just another social media platform, but one that had seemingly received royal endorsement. As it’s user base grew, businesses were quick to spot the marketing potential offered by social media. One of the UK’s earliest examples

foodanddrinknetwork-uk.co.uk | 05

Social Media

Where did the Revolution start...?

saw Cadbury respond to an outcry from the now 3.5 million strong community by announcing the return of the Wispa bar.

Where there are people, there are PR opportunities!

The return of the Wispa illustrates how brands were able to tap into public sentiment and seize the initiative when it comes to capitalising on the PR opportunities offered through social media.

Business pages, launched in 2007, also presented new ways for companies to build a new audience for their products and services, often enticing individuals to like a post and tag friends, in return for a potential reward.

Marketers were quick to spot the enormous potential of viral marketing campaigns, driven through social media. As new creative ways of engaging with audiences were developed, brands often attempted to test the boundaries of possibility.

Perhaps one of the most notorious examples of this was the shortlived, “Would you sacrifice your friend for a burger?” campaign produced by Burger King.

The concept of the campaign was a fiendishly simple one, based around the premise, what do you love more, a Whopper or your friends? If a Facebook user deleted 10 of their friends, Burger King would reward them with a free Whopper.

Designed to poke fun at the superficiality of online friendships, Facebook didn’t see the funny side of the campaign. Within a matter of days, Facebook disabled it, claiming it violated the platform.

The short-lived campaign saw 60,000 take up the challenge, resulting in more than 230,000 friendships being sacrificed in the quest to receive a free burger. You can read more about this innovative campaign here.

This campaign illustrates the way in which both effective PR and creative social media usage can be integrated together to maximise media impact. Needless to say, the campaign quickly pricked up the ears of journalists and resulted in headlines being generated across the world.

For Burger King, this resulted in a significant increase in website traffic, as well as amassing 40,000 Facebook fans.

What does the future hold for Facebook?

Social Media channels are continually evolving and changing – they always have done, and Facebook is no exception. As long ago as 2008, Britain’s love affair with Facebook has been called into question; however, I think it will continue to play an important role in social media strategies

for the foreseeable future.

Although marketers perhaps first tapped into Facebook’s ability to engage with the lucrative 18-34 demographic, the platform is no longer the disrupter that it once was. As its audience enters middle age, will evolution be enough to maintain its strong market share?

One of the main reasons companies like Facebook and Google have remained market leaders in their respective fields for such a long time is their recognition that they can’t simply stand still.

Channels such as AOL, Friends Reunited and Myspace all once held seemingly unassailable market shares, but all found themselves consigned to the history books. Will Facebook have the same fate?

Is facebook still relevant as a marketing channel?

The launch of Threads in 2023, in response to declining X (formerly known as Twitter) usage, illustrates that Facebook is continuing to keep one eye firmly on the future. Yet platforms such as TikTok have surpassed Facebook’s dominance, particularly amongst younger social media users. It will be interesting to see how Facebook adapts and responds. If parent organisation Meta can avoid repeating the mistakes of its predecessors, then I think Facebook will remain relevant to businesses both large and small, for many years to come.

There have been many new social media platforms that have come and gone since 2004, but few have captured the public imagination in the way that Facebook has. The most recent report analysing social media usage in the UK revealed that 84% of the total population are active social media users. Of those channels, the top three are all owned by Facebook’s parent company Meta.

When it comes to maximising investment in social media marketing, knowing where your customers hang out will reap dividends. This means getting to grips with understanding who is using a particular channel and why.

Perhaps what the past 20 years has taught us is that social media marketing isn’t just a fad or a passing fancy, it’s something that can be a transformational tool when it comes to driving business growth.

06 | foodanddrinknetwork-uk.co.uk

Article supplied by Cannon PR

CONTINUED FROM PAGE 05

Matthew Ridsdale Founder, Cannon PR

...connect

...Find

...the

THE RIGHT CONNECTIONS... VISIT US ON OUR SOCIALS

MAKING

places to be for the latest news across the Food & Drink industry

with and follow our thousands of readers and followers

details of our latest offers, promotions, and forward features listings or online via our website foodanddrinknetwork.co.uk OFFERS, PROMOTIONS, FEATURES foodanddrinknetwork-uk.co.uk | 07 Social Media FOOD AND DRINK NETWORK UK

the monthly launch of the magazine by clinking on the links to our online e-book ...Find

Anuga FoodTec 2024: Shaping the Future of Responsible Food & Beverage Industry

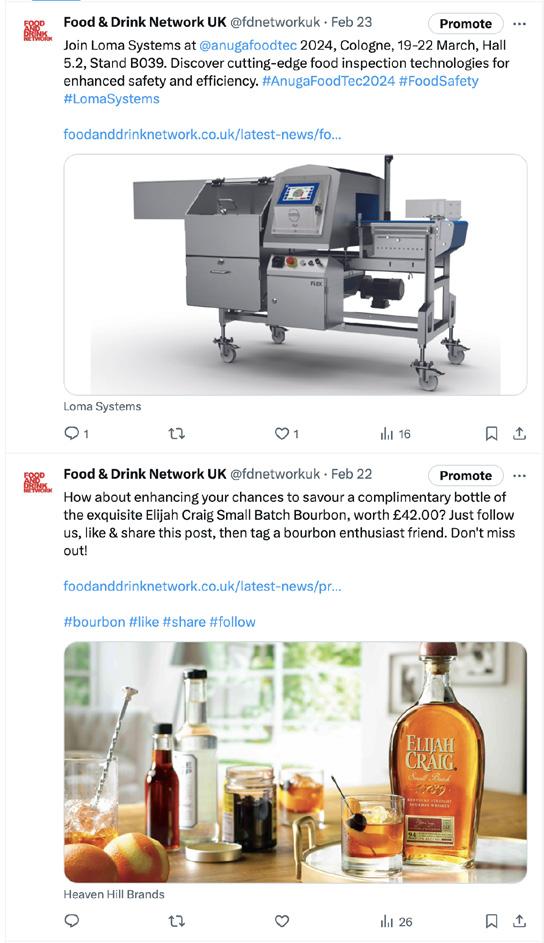

Anuga FoodTec 2024, scheduled from the 19th to the 22nd of March, stands out as a premier trade fair for the global food and beverage (F&B) industry, serving as a pivotal hub for suppliers in Cologne. Anticipating the participation of around 1,350 exhibitors, with over 60% hailing from international markets, the event draws leading global F&B manufacturers such as Nestlé, Unilever, and Coca-Cola. It accentuates the sector’s significance in areas like production, processing, packaging, food safety, automation, digitalisation, and intralogistics. “Responsibility” is the overarching theme for Anuga FoodTec 2024, spotlighting the industry’s extensive effects on global energy and freshwater usage, alongside the dichotomy of food wastage vis-à-vis hunger and obesity concerns.

Industry Significance and Thematic Focus

The fair addresses these challenges with a united approach, illustrating how innovative technologies can foster more sustainable and accountable food systems. It zeroes in on initiatives such as diminishing energy consumption, devising recyclable materials, enhancing working conditions, reducing noxious ingredients, prolonging product shelf life, and delving into alternative proteins. These endeavours are in harmony with the Sustainable Development Goals (SDGs), targeting the creation of accessible, nutritious, and eco-friendly foodstuffs.

Anuga FoodTec emerges as a forum to delve into the future of food production, underscoring the importance of energy efficiency, dependable supply chains, Industry 4.0, sustainable packaging, and alternative proteins. It presents an exhaustive survey of equipment, analytical devices, and packaging materials, addressing the needs across all F&B sectors. Unlike

other exhibitions, Anuga FoodTec spans an extensive array of solutions, ranging from cost-effective to cuttingedge technologies, offering an unparalleled chance for talent recruitment and industry networking. The final day of the fair, Careers Day, encourages students to engage with exhibiting companies, emphasising the event’s role in moulding the industry’s future.

Conclusion: A Call for Global Collaboration

In summary, Anuga FoodTec 2024 provides an invaluable opportunity for stakeholders in the F&B sector to confront present challenges, unveil innovations, and contribute to a more sustainable and responsible future. The event champions global collaboration to bolster food security, safety, and industry standards, marking a crucial stride towards shaping the future of responsible food and beverage production.

Anuga FoodTec 2024 Exhibitions

08 | foodanddrinknetwork-uk.co.uk

Uncover the future of food & drink at IFE 2024

IFE, part of Food Drink & Hospitality Week, returns to ExCeL London on 25-27 March packed with innovative new products, insightful discussions and countless opportunities to network with industry peers.

For over 40 years, IFE has been a must-attend trade event for retailers, wholesalers, hospitality professionals and more to learn about the latest new trends and products in UK and international food & drink.

With 14 exciting food & drink zones to explore, including new additions in the form of the Cheese Pavilion, the Hot Beverage Pavilion and the Fresh Produce Section, in partnership with the Fresh Produce Consortium, there are countless products to taste and discover.

In addition to thousands of delectable products from across the UK, IFE has representation from over 50 countries around the world including pavilions from Turkey, Thailand, France, Sri Lanka, China, Ecuador, Hungary and Cyprus.

The Startup Market, home to up-and-coming businesses and inspiring food & drink entrepreneurs, will once again be a bustling hub of innovation at the heart of the show, while sections such as Speciality Food, Vegan & Plant-based and the Free From Pavilion will reflect some of the most important trends in the 2024 industry landscape.

This year’s event will also see the return of the New Products Tasting Theatre, where visitors to the show can hear live pitches from startups, attend live tasting and hear from companies including Bidfood and Sysco as part of the Distributor Discovery Hours.

On the Future Food stage, visitors will have the chance to hear from leading industry figures including retailers like Co-Op and Ocado, sustainability pioneers such as Abel & Coland Rubies in the Rubble and innovative insight partners including Tried & Supplied, IGD, European Food and Farming Partnerships and Avocado Social.

Kelly Orme, Buying Manager- Community Buying at Coop, who will be taking part in a panel titled ‘Navigating the startup scene: Advice from those in the know’, comments:

“Startups are an important source of innovation and fresh ideas in the food & drink industry. I’m looking forward

to joining this panel at IFE 2024 and discussing how retailers can support and mentor suppliers as they scale and further develop their product ranges.”

Ed Ayton, Sustainability & Ethics Advisor to Abel & Cole and panellist on the session, ‘Sustainability pioneers: Global food and drink companies setting the standard’, adds: “Our team always comes back from IFE buzzing with new ideas and networks, so I’m delighted to taking part and supporting the programme this year.”

Day two of the show will see IGD curate a fascinating day of content on the Future Food stage, with sessions covering everything from economic forecasts for food & drink retail, sustainability, health, learnings international retail and an exclusive case study with a key client of IGD.

Sarah Baldock, Marketing and Communications Director at IGD, says: “As IFE’s Insight Partner we can’t wait to welcome industry to ExCeL London for Food, Drink & Hospitality Week. IGD will be taking to the Future Food stage to offer retailers and suppliers a wealth of insight to help them identify opportunities over the coming year and beyond.

“Our combined team of retail, shopper, health, sustainability and economics experts look forward to helping delegates get closer to the UK market within an international context, and our exhibition stand on the show floor will offer a space for those vital one-on-one conversations. We’re delighted to be partnering with IFE this year to help delegates get the most out of their visit. We look forward to seeing you there!”

IFE takes place alongside IFE Manufacturing, The Pub Show, HRC and International Salon Culinaire as part of Food, Drink & Hospitality Week, the UK’s biggest celebration of industry innovation. To learn more about everything happening this year, and to register for your complimentary trade ticket, visit ife.co.uk.

IFE 2024 foodanddrinknetwork-uk.co.uk | 09 Exhibitions

Sustainable Food Factory 2024 REGISTER NOW TO ATTEND DECARBON ISATI ON Sponsors correct at time of print. Attendance is free for food and drink manufacturing end-user manufacturers – delegate passes are allocated at the discretion of the organiser. HEADLINE SPONSOR EVENT SPONSORS A NEW one-day event for senior-level UK food and beverage end-user manufacturers FOR FULL DETAILS VISIT sustainablefoodfactory.live #SFFE24

Accelerate Your Food and Beverage Plant Decarbonisation by Attending Sustainable Food Factory 2024

A world-class conference programme with best-in-class exhibitors to help UK food and beverage manufacturers continue progressing towards low-carbon operations

In an era where sustainability is a business expectation, food and beverage manufacturers face increasing pressure from consumers, investors, employees and other stakeholders to improve their environmental credentials.

While factory emissions may not be the primary contributor, these Scope 1 and 2 emissions remain significant, and it is crucial factories take steps to reduce their environmental impact.

Major gains can be made through process and technology innovation to improve efficiency, reduce downtime, lower energy and water consumption, decrease waste, improve margins and create more sustainable operations.

The wider manufacturing facility can also play a role in reducing emissions through the implementation of, for example, solar photovoltaic technology.

Adopting an innovation mindset is key to ensuring the factory is best positioned to drive long-term success and remain competitive.

Sustainable Food Factory 2024 on June 12 at Nottingham Trent University will provide an unprecedented opportunity for manufacturers looking to further improve their operations and make them more sustainable.

World-class conference programme

The event offers a world-class conference programme delivered by a line-up of low-carbon experts - through presentations and interactive panel debates – to help delegates learn from peers who are successfully creating sustainable manufacturing operations.

Delegates attending the event will have access to the very latest industry thinking surrounding plant decarbonisation. The knowledge gained will equip them with practical and applicable solutions for their operations, enabling them to make significant progress towards a low-carbon future.

In addition to gaining insights into plant decarbonisation, delegates will also learn how to effectively engage and motivate their staff and foster a culture of sustainability. Employee buy-in can positively influence the operational culture, drive further decarbonisation gains and enable senior managers to address their Scope 3 emissions beyond the plant.

Collaboration and partnership Collaboration and partnership are key components of June’s event.

By working with the right solution partner, manufacturers can free up critical resources that can be directed towards core tasks and ensure they are leveraging the latest process and technology innovations to improve sustainable manufacturing outcomes.

Twenty exhibitors will be on hand to share their expertise with delegates and demonstrate their competence to be a partner of choice.

Sustainable Food Factory Exhibitions foodanddrinknetwork-uk.co.uk | 11

Sustainable Food Factory 2024 takes place on 12 June at Clifton Campus, Nottingham Trent University. More information is available at

www.sustainablefoodfactory.live

Supported by Free to Visit Including the Conference Sessions Free to attend SUSTAINABLE TRANSPORT, LOGISTICS & SUPPLY CHAIN MANAGEMENT EVENT FOR CARGO OWNERS Multimodal 2024 celebrates 17 years of bringing together shippers and cargo owners with exhibitors and sponsors who can offer products and services to help them make their supply chains more efficient and more cost effective. Visitors attend to meet new suppliers, compare new routes and modes, source new products and ideas to improve their efficiency and to network with the industry. 11-13 June 2024 NEC Birmingham UK 300 Exhibitors 60+ Conferences Digital sessions from Google Networking Drinks Party Established since 2008 REGISTER IN ADVANCE AT www.multimodal.org.uk

THE FUTURE OF LOGISTICS UNFOLDS

Bigger and better than ever, Multimodal 2024 is already smashing records with over 230 exhibitors already signed up, including industry giants such as Amazon, CEVA Logistics, DP World, Hapag-Lloyd, Kuehne+Nagel, Maersk, Maritime Transport, Malcolm Logistics and Samskip Services. With expectations to exceed 300 exhibitors, this year’s event will offer unparalleled networking and business opportunities for the 12,000+ visitors over the three days of the show.

Multimodal is the one-stop shop for shippers and cargo owners to discover ways to improve their move their goods more sustainably, efficiently and more cost effectively. The three-day show between 11-13 June 2024 at the Birmingham NEC, offers unique opportunities to make valuable face-to-face contact with new prospects and existing companies.

It’s free to visit Multimodal 2024, registering in advance is recommended, to save time on arrival, at www.multimodal.org. uk All the conference sessions are free to attend too and with 4 theatres there is something of interest to everyone.

You’ll be in great company as already registered are representatives from Sainsbury’s, Aldi, Whitworths, Nestle UK&I, Diageo, Lovering Foods, Rowan International, Bunzl Catering, Glanbia Nutrition, Crops UK, Kingsland Drinks, AB World Foods and Poundland to name just a few.

Multimodal works in partnership with the leading trade associations ensuring all aspects of the industry are served, also ensuring that relevant topics are covered in the free to attend conference sessions. Partner associations include Logistics UK, the Cold Chain Federation, the Rail Freight Group, The Chartered Institute of Transport and Logistics, the British International Freight Association, Institute of Export and International Trade, the United Kingdom Warehousing Association, and the Road Haulage Association.

A special highlight of the three days is the Multimodal Awards, which recognise outstanding industry-leading supply chain businesses and individuals. With seats for the awards always selling out, and just 200 places currently remaining, attendees are now being urged to secure their seats for the 11 June evening ceremony as soon as possible.

The 2024 Awards include some new judged Awards to continue the development and evolution of the event. The evening will be hosted by Kevin Keegan, an incredible host who brings enormous professionalism and fantastic humour. Places at the Awards can be booked at www.multimodal.org.uk/awards

The networking event you won’t want to miss! Be there for the Multimodal Mixer on 12 June. It’s a fun relaxed drinks reception open to all visitors and exhibitors, hosted by DP World on their stand in the Hall from 5pm, giving everyone a chance to mingle in a relaxed and fun atmosphere.

To find out more about attending, entering the awards, exhibiting, or sponsoring, visit www.multimodal.org.uk, or contact Robert Jervis, Director on +44 (0) 20 7384 7760 or robert.jervis@clarionevents.com

Multimodal 2024 Exhibitions foodanddrinknetwork-uk.co.uk | 13

Intralogistex 2024 Exhibitions 14 | foodanddrinknetwork-uk.co.uk www.intralogISTEX.CO.UK #ilx24 Exhibitors already confirmed include: SHOWCASING THE SMARTEST MOVES IN WAREHOUSING & LOGISTICS Registration is FREE visit the uk’S largest intralogistics exhibition • 350+ Exhibitors • 60+ Expert speakers • 8000+ Key Buyers Discover solutions in MATERIALS HANDLING, PACKAGING, ROBOTICS, STORAGE, WAREHOUSE management, BARCODE & labelling, picking & sortation, Mobile scanning, warehouse automation, transport management, safety solutions, and much more er of aceability & AUT MATI N

INTRALOGISTEX INNOVATION TRAIL SET TO SHOWCASE PATH TO BUSINESS EFFICIENCY AND PROFITABILITY

IntraLogisteX, the industry showcase for warehouse and logistics management solutions, this year includes an exciting new Innovation Trail in what is set to be the biggest and best event to date.

A true journey of discovery, the Innovation Trail provides a bespoke pathway to products and systems deemed to be the most transformative within the industry. Taking place at NEC Birmingham in March, IntraLogisteX will be accompanied by two other shows: the ever-popular Robotics and Automation Exhibition, and a highly anticipated Sustainable Supply Chain Exhibition. Together they will feature more than 350 exhibitors, 60 conference sessions and 8,000-plus attendees from across the warehouse and logistics sector. It is the year’s unmissable event for professionals and business owners in search of new ways to maximise their company’s profit through intralogistics.

Stephen Brooks, managing director of Akabo Media, said:

“The Innovation Trail is a brilliant addition to this year’s event and will encompass not only IntraLogisteX but Robotics and Automation Exhibition and the Sustainable Supply Chain Exhibition as well. It is a carefully curated highlights package for visitors looking to refine their exhibition experience. The Innovation Trail is also an opportunity to meet the brands behind the solutions set to revolutionise warehouse and logistics operations. With the Sustainable Supply Chain Exhibition also new to this year’s event, 2024 is a landmark for IntraLogisteX which businesses and industry professionals will not want to miss out on.”

Kardex, Movu Robotics, i-Mark, and Exporta are among industry-leading brands whose pioneering solutions for the

warehouse and logistics sector feature as part of the Innovation Trail at IntraLogisteX 2024. The immersive, multi-experience event, along with the two collocated shows, offers live demonstrations of cutting-edge technologies and software designed to counteract time-consuming, costly operational practices.

Visitors will discover the Robotics and Automation Exhibition to be an exceptionally enriching experience. The displays of automation are astounding and offer a tantalising glimpse of how next-generation intelligence can transform workplaces into more efficient and less demanding environments.

IntraLogisteX is meticulously crafted for personal interaction, fostering connections among industry professionals and business owners in a space tailored for generating ideas and outcomes. For the warehouse and logistics sector, the event stands unparalleled. It’s an exhilarating mix of breakthrough innovations and expert insights, as part of a packed agenda offering invaluable opportunities to engage with representatives from the industry’s most high-profile companies.

If you’re ready to be inspired, register your interest here: https://www.intralogistex.co.uk/

Intralogistex 2024 foodanddrinknetwork-uk.co.uk | 15 Exhibitions

Your expert partner in hygienic solutions

Hiding in plain sight

Protect your food against hidden contamination risks

Small items, bigger risks.

Our BST J800 pens are designed to keep your food production safe.

Helping ensure food safety throughout the food production process:

• Metal detectable and x-ray visible

• Silver ion anti-bacterial technology

• Shatter resistant

• HACCP colour coded

• EU & FDA food regulation approved

• Made in Britain.

Hygiene & Safety 16 | foodanddrinknetwork-uk.co.uk Call now on email

Ensuring Food Safety:

The Role of Teknomek BST J800 Pens in Contamination Risk Prevention

In the food production industry, maintaining the highest standards of hygiene and safety is paramount to safeguarding consumer health and confidence. From processing to packaging, every step of the production process must adhere to rigorous quality control measures to mitigate contamination risks.

Among the arsenal of tools and equipment designed to uphold these standards, Teknomek BST J800 Pens stand out as indispensable assets in ensuring food safety and preventing contamination incidents.

Unveiling the Innovation: Teknomek BST J800 Pens

Teknomek BST J800 Pens represent a pinnacle of innovation in food production safety equipment. Engineered with precision and attention to detail, these pens are specifically designed to address the unique challenges of the food industry, offering a comprehensive solution for contamination risk prevention.

Metal Detectable and X-ray Visible Properties

One of the key features that set Teknomek BST J800 Pens apart is their metal detectable and X-ray visible properties. In a production environment where metal contamination poses a significant risk, these pens provide an added layer of protection by ensuring that any accidental fragments or foreign objects can be easily detected and removed during quality control procedures. This capability not only enhances product safety but also streamlines contamination detection processes, minimising downtime and mitigating potential hazards.

Shatter-Resistant Construction

Durability is essential in the demanding environments of food production facilities. Teknomek BST J800 Pens are engineered with shatter-resistant materials, ensuring reliability and longevity even in the most rigorous operational conditions. By withstanding impact and wear, these pens minimize the risk of breakage and fragmentation, thereby reducing the likelihood of contamination incidents associated with damaged equipment.

HACCP Color Coding for Seamless Hygiene Management

Hygiene management is a cornerstone of food safety protocols, and color coding plays a crucial role in maintaining cleanliness and preventing cross-contamination. Teknomek BST J800 Pens

are HACCP color coded, aligning with internationally recognized hygiene standards and facilitating seamless integration into existing hygiene management systems. By assigning specific colors to different areas or tasks, these pens help ensure that equipment is used appropriately and that hygiene protocols are consistently followed throughout the production facility.

Silver Ion Anti-Bacterial Technology

In addition to their physical attributes, Teknomek BST J800 Pens are equipped with silver ion anti-bacterial technology. This innovative feature inhibits the growth of bacteria on the pen’s surface, reducing the risk of microbial contamination and enhancing overall hygiene levels. With EU and FDA food regulation approval, these pens offer peace of mind to food producers, reassuring them that their equipment meets the highest standards of safety and compliance.

Made in Britain: A Stamp of Quality and Reliability

Teknomek BST J800 Pens are proudly made in Britain, a testament to their commitment to quality, craftsmanship, and reliability. By manufacturing these pens locally, Teknomek ensures stringent quality control measures and adherence to regulatory standards, providing customers with confidence in the performance and integrity of their products.

In an industry where safety and hygiene are non-negotiable, Teknomek BST J800 Pens emerge as indispensable tools for preventing contamination risks and upholding food safety standards. With their metal detectable and X-ray visible properties, shatter-resistant construction, HACCP color coding, and silver ion anti-bacterial technology, these pens offer a comprehensive solution for mitigating contamination risks in food production facilities. Made in Britain and approved by EU and FDA food regulations, Teknomek BST J800 Pens exemplify excellence in design, innovation, and reliability, ensuring the safety and integrity of food products from production to consumption.

Hygiene & Safety foodanddrinknetwork-uk.co.uk | 17

BST

The

J800 Pen

ECOFILL AUTOCLAVES: Revolutionising Sustainability in the Food Industry

In the quest for sustainability, the food industry continues to innovate, seeking solutions that not only reduce environmental impact but also enhance operational efficiency and cost-effectiveness.

Enter ECOFILL AUTOCLAVES – a groundbreaking technology that is transforming the way food processing facilities operate. These autoclaves not only streamline sterilisation

REDEFINING STERILISATION PRACTICES

Sterilisation is a critical process in the food industry, ensuring the safety and shelf life of packaged foods. Traditionally, autoclaves have relied on significant amounts of water and energy to achieve the necessary levels of sterilisation. However, Ecofill autoclaves employ innovative design features and advanced technologies to minimise resource consumption while maximising efficiency.

WATER CONSERVATION: CAPTURING AND REUSING WATER

Water scarcity is a pressing global challenge, and the food industry has a significant role to play in conserving this precious resource. Ecofill autoclaves address this issue by incorporating water capture and reuse systems. During the sterilisation process, steam condensate is collected and treated, eliminating the need for continuous freshwater intake. By recycling water within the system, Ecofill autoclaves significantly reduce water consumption, minimising the environmental footprint of food processing operations.

ENERGY EFFICIENCY: HARNESSING HEAT ENERGY

Energy-intensive processes pose a considerable sustainability challenge for the food industry. Ecofill autoclaves tackle this issue by optimizing energy utilisation and minimising wastage. These autoclaves are equipped with sophisticated heat recovery systems that capture and reuse thermal energy generated during the sterilisation process. By harnessing heat energy that would otherwise be lost, Ecofill autoclaves operate with remarkable efficiency, reducing electricity consumption and lowering operational costs.

ENVIRONMENTAL BENEFITS

The adoption of Ecofill autoclaves offers a multitude of environmental benefits. By conserving water and minimising energy usage, these innovative systems help mitigate the environmental impact of food processing operations. Reduced water consumption translates to lower strain on freshwater sources and ecosystems, while improved energy efficiency contributes to greenhouse gas emissions reduction and climate change mitigation. Furthermore, Ecofill autoclaves promote sustainable resource management practices, aligning with the broader goals of corporate sustainability and environmental stewardship.

ECONOMIC ADVANTAGES

In addition to their environmental benefits, Ecofill autoclaves deliver compelling economic advantages for food processing facilities. By minimising water and energy consumption, these systems help reduce utility costs and enhance operational efficiency. Moreover, the longevity and reliability of Ecofill autoclaves translate to lower maintenance expenses and downtime, maximising productivity and profitability over the long term. With a focus on sustainability and cost-effectiveness, Ecofill autoclaves offer a strategic investment for food manufacturers seeking to remain competitive in a rapidly evolving industry landscape.

Ecofill autoclaves represent a paradigm shift in food processing technology, offering a sustainable and cost-effective solution for sterilisation processes. By capturing and reusing water and heat energy, these innovative systems help conserve resources, minimise environmental impact, and enhance operational efficiency. As the food industry continues to prioritize sustainability and responsible stewardship, Ecofill autoclaves emerge as a compelling choice for businesses seeking to align their operations with environmental best practices while achieving economic viability. With their transformative capabilities, Ecofill autoclaves pave the way for a more sustainable and resilient future for the food industry.

capture

processes but also

and reuse water and heat energy, offering a win-win solution for both the environment and bottom lines.

Revolutionising Sustainability 18 | foodanddrinknetwork-uk.co.uk Ecofill Autoclaves

Benchtop Autoclave with

autoclaves capture and reuse water and heat energy.

AMB

Ecofill

standard autoclave.

This means they need refilling less often and use less electricity than a

Astell.com

Builk Material Evaluation & Tracking Explore Harford LIMS: Call +44 (0)1225 764461 www.harfordcontrol.com Harford Laboratory Information Management Systems (LIMS) are designed to streamline and automate laboratory workflows, data management and sample tracking. Harford LIMS facilitates efficient data capture, analysis and reporting, ensuring accuracy and compliance. Materials Compliance Automated Sampling & Labelling Non-Compliant Product Monitoring Features Builk Material Evaluation & Tracking Lab Equipment Integration Track and Trace Lost Documents? Delayed Data? Human Error? Downtime? Leverage Connectivity & Collaboration between Factory Floor and Laboratory using Harford LIMS

The Value of LIMS in Manufacturing

Read how LIMS can aid Production Effectiveness

An article By Roy Green, Harford Control Ltd. March 2024

It’s frustrating to witness the frequent recalls of products in recent years, causing significant wastage, all testimony to the need for paramount control of food safety and quality. One example was the recall of four cheese products due to potential contamination with E. Coli bacteria. Tragically, one person in Scotland died from the infection, whilst 11 others were hospitalised.

Ensuring food safety and quality is crucial in the food and drink manufacturing industry. Most factories already carry out laboratory testing to assess the quality of materials, checking for compliance with specified tolerances and ensuring they are free from contamination.

Despite these precautions, a significant challenge can arise in bridging the gap between laboratory tests and the busy factory floor. This gap manifests in issues such as isolation, rejects, rework and costly product recalls, the inability to track raw materials, human errors, lost documentation, delayed data and downtime. The breakdown in communication poses a considerable risk to both the efficiency of the manufacturing process and, more critically, to consumer safety.

A Brewery’s Struggle

We visited a brewery and observed that they were encountering significant wastage and product recalls. The factory would extract multiple samples from various vessels and stages such as malting, mashing, boiling, fermenting and filtering. These samples were then taken to the laboratory for tests on factors including alcohol percentage, pH, colour analysis and clarity to ensure material quality and safety.

Everything seemed well-controlled until the gap between the laboratory and the factory floor became apparent. When the sample results were released from the laboratory, it was discovered that the sugar concentrations in the wort was too high, resulting in an alcohol percentage exceeding the tolerance limit. Unfortunately, the laboratory department couldn’t promptly communicate the failed samples to the production line, preventing operators from halting the materials in time.

As a result, the materials had already been transformed into finished products, leading to the disposal of multiple pallets of beer. At 800 cans per minute produced, it doesn’t take long to produce an impressive pile of scrap.

The occurrence of product recalls and wastages can often be avoided with the implementation of a Laboratory Information Management System (LIMS), capable of capturing data at all stages, encompassing laboratory testing across the entire production process. This way, both the laboratory department and the factory floor could track and trace raw materials, accessing laboratory test results in real-time. Early warnings could prompt necessary actions, preventing potentially large losses.

Whilst laboratory testing serves as a proactive measure to ensure food safety and quality, its full potential couldn’t be realised without the full traceability of materials.

The Crucial Role of LIMS

Laboratory Information Management Systems (LIMS) play a crucial role in optimising processes, whilst ensuring quality and compliance. Here are some key benefits of implementing LIMS:

Ensure Quality Control

LIMS facilitates real-time monitoring and control of various parameters and tolerances such as temperature, taste, colour, pH and contamination throughout the production process, ensuring product safety and quality consistency. Automated data collection and analysis help identify deviations from quality standards, enabling timely corrective actions to maintain highquality standards.

Track and Trace

Whether it’s raw materials (e.g. fish) or a group of materials that have already been transformed (e.g. fish pie), the laboratory team can track and trace materials from start to finish.

20 | foodanddrinknetwork-uk.co.uk Specialist View

Ensuring food safety and quality is crucial in the food and drink manufacturing industry. The foundation of these finished products lies in the raw materials used in the production process. Most factories already carry out laboratory testing to assess the quality of materials, checking for compliance with specified tolerances and ensuring that they are contamination free.

“ ”

Automated Sampling and Labelling

All samples can be tracked and managed from collection to analysis and disposal. The laboratory team can print labels to attach to the samples, documenting the testing process (pending, drawn, release) and the storage location. This helps reduce the likelihood of sample mix-ups, thereby enhancing efficiency and safety.

Scheduling Batches

The laboratory team can schedule batches and run separate procedures on sampling, a critical aspect of fresh products like frozen fish. For instance, upon arrival of frozen fish at the factory, the laboratory team typically has a 48-hour window to conduct tests and return the items to the freezer to prevent defrosting and waste.

Heldware

In the event that test results fall outside acceptable limits, the laboratory team can inform the factory floor to hold, and quarantine materials, whilst deciding whether to release or dispose of the raw materials at a later stage. LIMS can help capture information, conduct root cause analyses, evaluate downtime and calculate additional labour hours needed due to material failures. With this information, factories can detect batch rejections early and understand the root cause, in the hope of preventing them in future.

Workflow Automation

LIMS reduces reliance on manual processes, and minimises the risk of human error, whilst speeding up the testing processes. Whether weighing, titrating, using gas chromatography or other equipment, all results can be easily entered into fixed terminals, PCs or tablets and automatically updated in the system in real time. This eliminates lost documents, human errors and delays, fostering closer collaboration and communication between the laboratory team and the factory floor, leading to faster decision-making and improved overall efficiency.

Integrate with Existing Lab Machinery Laboratory equipment such as HPLC with multiple outputs can sometimes be connected directly to factory devices for instant data transfer, eliminating the need for keyboard entries and further minimising the risks of operator error.

Harford LIMS

Harford Control developed Laboratory Information Management Systems (LIMS) to help food and beverage manufacturers optimise the laboratory testing process and provide real-time actionable information, as stand-alone or a fully integrated part of Harford MES.

By automating tasks such as material usage confirmation, bulk material tracking and informing laboratory teams of sampling requirements, we help factories ensure material safety and quality, reduce risks and enhance efficiency.

Real-time monitoring and seamless integration of lab equipment with Harford LIMS enables proactive management of non-compliant products.

Most factories could benefit from LIMS. Contact Harford Control by calling +44 (0) 1225 764461 or send an email to: info@harfordcontrol.com.

foodanddrinknetwork-uk.co.uk | 21 Harford Control Ltd.

Streamlining Food Production:

The Role of Processing Equipment in the Modern Food Industry

In the bustling world of food production, efficiency, reliability, and quality are paramount. Behind every delicious meal, snack, or beverage lies a sophisticated network of processing equipment meticulously designed to transform raw ingredients into finished products. From steam boilers to water treatment systems, each component plays a crucial role in ensuring the smooth operation of food processing facilities.

From steam boilers to water treatment systems, each component plays a crucial role in ensuring the smooth operation of food processing facilities. We delve into the significance of processing equipment in the food industry, exploring key technologies such as fuel-fired and electric steam boilers, ancillary plant systems, and engineered solutions for water treatment.

FUEL-FIRED AND ELECTRIC STEAM BOILERS:

Powering the Heart of Food Production

Steam boilers serve as the beating heart of many food processing operations, providing the energy necessary for cooking, sterilization, and heating processes. Fuel-fired steam boilers utilise natural gas, propane, or diesel to generate steam, offering robust performance and high efficiency. These boilers are prized for their versatility, capable of delivering precise temperature control essential for cooking, pasteurisation, and other thermal processes in food production.

On the other hand, electric steam boilers have gained traction due to their cleanliness, ease of installation, and minimal environmental impact. By harnessing electricity as a power source, electric boilers eliminate the need for on-site fuel storage and combustion, reducing emissions and ensuring compliance with stringent environmental regulations. Moreover, electric steam boilers excel in applications requiring rapid start-up times and precise temperature modulation, making them ideal for small-scale food processing operations and niche production lines.

ANCILLARY PLANT SYSTEMS:

Enhancing Efficiency and Productivity

Beyond steam generation, ancillary plant systems play a pivotal role in optimising the efficiency and productivity of food processing facilities. These systems encompass a wide range of equipment, including heat exchangers, pumps, valves, and piping networks, designed to transport fluids, regulate temperatures, and facilitate material handling throughout the production process.

Heat exchangers, for instance, play a critical role in energy recovery and process optimisation by transferring heat between different fluid streams. By harnessing the heat generated during pasteurization or cooking processes, heat exchangers can preheat incoming product streams, reducing energy consumption and enhancing overall efficiency. Similarly, pumps and valves regulate the flow of liquids and gases, ensuring precise control over process variables and minimizing product waste.

ENGINEERED SYSTEMS FOR WATER TREATMENT:

Safeguarding Quality and Compliance

Water serves as a ubiquitous ingredient and processing medium in the food industry, necessitating stringent quality standards and regulatory compliance. Engineered systems for water treatment play a pivotal role in safeguarding product quality, mitigating contamination risks, and ensuring compliance with food safety regulations.

HELPING YOUR FACILITY ON THE ROAD TO NET ZERO

Our class-leading range of fuel-fired and electric steam boilers and portfolio of aftercare solutions can help with your decarbonisation strategy and put your company on the Road to Net Zero.

As a complete solutions provider, Fulton can provide your food processing facility with:

· fuel-fired and electric steam boilers

· off-grid and point-of-use solutions

· ancillary plant / engineered systems

· steam surveys

· project management

· water treatment contracts

· accredited / certified training

· installation / commissioning / upgrades

· repair / service / maintenance programmes

For further information scan the QR code, visit www.fulton.co.uk, email sales@fulton.co.uk or call the office on +44 (0)117 972 3322.

Efficient & Reliable Processing Machinery Processing Equipment 22 | foodanddrinknetwork-uk.co.uk

FBW253 - Net Zero Advertisement - FDN.indd 1 29/01/2024 10:00

Krones Process & Filling Technology

Krones at Anuga FoodTec 2024

What are the challenges faced by beverage and food producers worldwide? One is certainly ensuring security across the entire production process – because, of course, only products of impeccable quality should ever roll off the line and make their way to consumers.

What are the challenges faced by beverage and food producers worldwide? One is certainly ensuring security across the entire production process – because, of course, only products of impeccable quality should ever roll off the line and make their way to consumers. Another is sustainability, a factor that applies along the entire value chain. As we approach the end of certain finite resources, society has an obligation to do everything in its power to protect the natural environment and our planet as a whole. Of course, it goes without saying that these topics also play a central role in the vision and mission of the Krones Group, whether for new and continuing developments or for its many overarching concepts and services. At Anuga FoodTec 2024, Krones, together with its subsidiaries Steinecker, Milkron, Evoguard and HST, will be presenting plant and engineering solutions for beverage and food production. One main focus will be on showcasing customised, holistic sustainability concepts, especially those designed to save water and energy in the production process.

Integrated modular sustainability concepts

Krones plant engineering looks at a customer’s entire value chain and offers advice for recovering and recy-cling energy and water across the production operation. Steinecker and Milkron also offer a variety of ap-proaches to optimise sustainability in the production of milk and dairy products and plant-based alternatives, juices and soft drinks. Specific applications include HydroCircle, a complete concept for wastewater recycling, and specially designed heat exchanger systems or heat pumps for sustainable energy recovery.

Bioreactors for the “new food” sector

When it comes to leveraging synergies, Krones doesn’t limit itself to simply choosing solutions for customers. Instead, the company seeks to use them to develop new systems and technologies, drawing on decades of in-house expertise in process technology and plant engineering and applying it to new and different product categories. The latest example of this comes from Steinecker, whose knowledge of and technology for fermenting beer, combined with Krones’ aseptic expertise, can be adapted to accomplish the cell-based manufacturing of new food products. Steinecker’s bioreactor is suitable for both precision fermentation and cell cultivation, mak-ing it possible to manufacture new food products like alternative proteins for meat substitutes and whey and egg proteins. Krones recently launched a partnership with the Swiss startup Food Brewer, and now the two companies are testing various applications and sharing the results with other companies to develop their own recipes and trials.

visit: www.krones.com

Equipment for the production and preservation of beverages and foods

For further process technology, Krones also offers a diverse range of solutions, from the plant planning and engineering expertise of Milkron to HST’s HLI90 high-pressure homogeniser and the VarioAsept D direct-heating system from Krones right through to the broad portfolio of pumps and valves from Evoguard and Ampco, for both standard and aseptic applications. Krones is also driving security and sustainability in other filling and packaging processes. For instance, by offering filling valves specially designed for the respective final product, we are

Food and Drink Network, Sustainability, 133 x 186 mm, CC-en 02/24

ensuring the highest quality when filling milk and dairy products and plant-based alterna-tives, juices and sauces. Meanwhile, LitePac Top is one of the most sustainable packaging concepts available today for PET containers and cans. Integrated concepts and solutions are among the greatest strengths of Krones process technology and of the entire group.

Shaping the future together

It’s important to look beyond the short term, which is why Krones is working on “Solutions beyond tomorrow”. Beverage filling lines, digital services and plastics recycling: Krones’ innovative solutions combine superior performance with sustainability.

Anuga FoodTec 2024, 19-22 March, Cologne, Hall 5.1/Stand A120-D129

krones.com

foodanddrinknetwork-uk.co.uk | 23

Steinecker’s bioreactor was premiered at the BrauBeviale 2023. It holds 500 litres and is used to produce 10 to 20% biomass.

CC-en_Sustain_FoodDrinkNetwork.indd 1 09.02.2024 11:11:20

At Cross+Morse we aim to fulfil all industry demands, from the simplest to the highest level of precision required. Our objective is to offer a complete solution - not just products - to your power transmission challenges.

Cross+Morse are known in the industry as pioneers in quality standards, which is why we take our quality control processes very seriously. Quality assurance is central to our organisation with controls encompassing all aspects of design, manufacture, logistics and customer service. We are ISO 9001:2015 accredited and have been for over 20 years.

24 | foodanddrinknetwork-uk.co.uk

Cross & Morse

At Cross+Morse we have continuously invested in top of the range measuring equipment: Co-ordinate Measuring Machine (CMM), digital tri-bore gauges and micrometres which are constantly calibrated to comply with ISO standards. Our stringent inspection process guarantees that when manufacturing each operation is thoroughly inspected by either a highly trained shop-floor staff supervisor or an inspector, ensuring that manufacturing is only allowed to continue when each phase has been approved. Our hardening treatment is checked using Rockwell or a Vickers testing machine.

We review our quality procedures continuously to provide up-to-date mechanisms for ensuring conformity to the quality system; different audits are carried out on all activities in the company throughout each year.

freewheels, roller ramp clutches, combined sprag and bearing units and many more.

Cross+Morse is the largest authorised distributor and stockist for American transmission products manufactured by RegalBeloit (formerly EPT) in the United Kingdom. The range includes Sealmaster®, Browning®, Jaure®, Kop-Flex®, McGill® and Morse®.

Inverted tooth chain: including the standard SC type from 3/16” to 2” pitch and HV type from 3/8” to 2” pitch; as well as conveyor chains up to 12” width in centre or outside guide construction. We manufacture standard and special sprockets in-house for a complete drive solution.