IN THIS ISSUE

ADVANCED MANUFACTURING SCHOOLS OUTREACH PROGRAM DEMONSTRATION

ENTRIES OPEN FOR THE 2023 WELDING EXCELLENCE AWARDS

ADVANCED MANUFACTURING SCHOOLS OUTREACH PROGRAM DEMONSTRATION

ENTRIES OPEN FOR THE 2023 WELDING EXCELLENCE AWARDS

WELD AUSTRALIA CONTACTS

NATIONAL OFFICE PO Box 197, Macquarie Park BC NSW 1670 02 8748 0100

office@weldaustralia.com.au

weldaustralia.com.au

Geoff Crittenden Chief Executive Officer 02 8748 0100

g.crittenden@weldaustralia.com.au

ENGINEERING

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

TRAINING

Guy Brooks, Training Manager 0488 743 322

g.brooks@weldaustralia.com.au

MARKETING

Michelle Bignold, National Manager, Sales & Marketing 0437 106 726

m.bignold@weldaustralia.com.au

MEMBERSHIP

David Choudry, Membership Manager 0417 878 104

d.choudry@weldaustralia.com.au

QUALIFICATION & CERTIFICATION

Deniz Yalniz, Qualification and Certification Team Manager 0487 487 170 d.yalniz@weldaustralia.com.au

NEW SOUTH WALES

Arya Sharifian, Welding Engineer 0419 414 901

a.sharifian@weldaustralia.com.au

VICTORIA, TASMANIA & SOUTH AUSTRALIA

Victor Blain, Engineering Team Manager – South & West 0409 823 991

v.blain@weldaustralia.com.au

QUEENSLAND & NORTHERN TERRITORY

Ross O’Bryan, Engineering Team Manager - East 0491 491 888

r.obryan@weldaustralia.com.au

WESTERN AUSTRALIA

Mehdi Tajfar, Senior Welding Engineer 0417 044 370

m.tajfar@weldaustralia.com.au

There has been a lot of media coverage recently about Prime Minister Anthony Albanese’s $368 billion AUKUS submarine deal. This deal will see Australia source between three and five second-hand Virginia Class nuclear submarines from the United States, which are expected to arrive in the early 2030s. This will be followed by Australian-built SSNAUKUS submarines, based on the United Kingdom’s next-generation SSN design. Planned delivery of the SSN submarines is expected to commence from the early-2040s.

This is not the first time that the Australian Government has attempted to establish a sovereign shipbuilding capability. As we all know, the Collins Class submarine project was established by the Royal Australian Navy (RAN) in 1982 to

replace our UK-built Oberon vessels. In a genuine attempt to create a new submarine design and construction industry, the government-owned Australian Submarine Corporation was established and a brand new shipyard was constructed at Osborne in Adelaide.

Between 1996 and 2000 six Collins Class submarines were built at Osborne. This necessitated a whole raft of investments. Enough welders had to be trained to weld a submarine hull. BlueScope and Bisalloy had to establish manufacturing capacity for the special steels needed for the hull.

Then, the Future Submarine program was launched in 2007 with ASC to design and build a follow-on submarine fleet. However, the Australian Government scrapped this program, leaving ASC without a fleet of submarines on which to work. As a result, ASC—and Australia’s local

shipbuilding industry—has shrunk in both size and capability.

There has been some discussion in the media over whether the quality of Australian welders is sufficient to build the proposed AUKUS nuclearpowered submarines. Australia’s qualified welders are more than capable of building the new fleet.

Some pundits have stated that the quality of welding required for a nuclear submarine is of a much higher standard than that required for a diesel electric conventional submarine. However, all welding must be of the highest quality if the submarine is to meet the necessary survivability objectives—whether the submarine is nuclear or diesel powered is irrelevant.

Weld quality is critical to the structural integrity of submarines. When welds fail, often the whole vessel

Welder Certi cation AS1796/ISO 9606 – Practical Courses – Tickets 3E, 4, 7, 8G and 8F

fails. Submarines are subjected to high loads and harsh environments, and any defects in the welds can compromise the integrity of the entire structure. This can lead to catastrophic failures, endangering the lives of crew members. Welding on submarines and naval vessels must be of the highest quality, and subjected to rigorous inspection and testing.

Ensuring good quality welding is an important part of rules for shipbuilding, including Lloyds Register (1999), Det Norske Veritas (DNV 2008), the American Bureau of Shipping (ABS 1997), and the International Association of Classification Societies (IACS 2008).

DNV and IACS require that welders must be qualified to specific standards, one of which is ISO 9606. Lloyds Register requires that shipbuilders test the welders and weld operators to a suitable national standard, such as ISO 9606.

Australian welders have been certified to this standard for years now. There are over 11,500 welders on the Australian Welder Certification Register, certified to AS/NZS ISO 9606.

Whilst some welding on nuclear boats is undertaken in line with different International and Australian Standards, and utilises different materials, the quality of the weld must

be exceptionally high. Australian welders are more than capable of achieving this quality.

The biggest risk facing Australia’s nuclear-powered AUKUS submarine build is not welder capability, but the recruitment and training of enough skilled welders.

Australia is already facing a severe shortage of skilled welders. Even before the AUKUS deal was signed, Australia was looking at a shortage of 70,000 welders by 2030. So, unless we take serious precautions now, there simply won’t be enough skilled people to undertake the welding required.

We need a Shipbuilding Welding Academy to be established and funded by the Federal Government. An academy of this nature will help ensure that the defence prime contractors have access to the skilled, qualified welding professionals required to successfully deliver the nuclear-powered submarines.

It will ensure that Australia has sufficient tradesmen of the right calibre ready to commence welding of the AUKUS submarines when the time comes.

Geoff Crittenden CEO, Weld AustraliaPRODUCT ZONES

Registrations are now open for Australian Manufacturing Week (AMW2023), which will be held at the Melbourne Convention and Exhibition Centre (MCEC) from Tuesday 9 May to Friday 12 May 2023.

Organised and run by the Australian Manufacturing Technology Institute Limited (AMTIL), AMW2023 will occupy more than 10,764m2 of exhibition space at the MCEC, with over 350 organisations taking stands to showcase the latest manufacturing technologies, processes, and support services.

The AMW Future Solutions Speaker Program will be rolled out through the week: a free conference within AMW2023, covering major topics within the industry.

Tuesday 9 May: Digital and Additive Manufacturing

On Tuesday, the Speaker Program will focus on Digital and Additive Manufacturing. Markforged will reveal how Australian businesses are using 3D printing to bring manufacturing back home, RMIT will delve into metal additive research projects, and the CSIRO will speak about the research into functional materials for space, biomedical and hydrogen storage applications.

Wednesday 10 May: Women in Manufacturing

As part of the Future Solutions Speaker Program, Wednesday’s roll call of experts will expand on career pathways and opportunities open for women to advance in the industry right now. The team from William Buck will talk about unleashing the full potential of your workplace. Then a panel from SEMMA will show how women are fuelling Australian manufacturing today.

Thursday 11 May: A Celebration of Australian Manufacturing

On Thursday, the Speaker Program will showcase a range of manufacturing successes and advances happening here at home, exporting to the world. Speakers from Autodesk, Bosch, ANCA, Adobe and the Victorian Government will engage and excite attendees.

Thursday 12 May: Innovation and Research

The last day of AMW2023 will celebrate Innovation and Research in Manufacturing. The Geelong Manufacturing Council will reveal some innovative case studies from regional Victoria. We also get a look inside the Australian National Fabrication Facility and the work being done on advanced materials,.

If you haven’t already, now is the time to register online to visit Australian Manufacturing Week in Melbourne. It’s going to be the biggest manufacturing show in the Southern Hemisphere.

REGISTER FOR FREE ONLINE: australianmanufacturingweek.com.au

Weld Australia would like to welcome Stephanie Maspero to the team. Based in our Sydney office, Stephanie is our newest Qualification and Certification Coordinator.

Stephanie has a strong background in administration, with experience that spans more than 10 years. Stephanie brings her exceptional customer service skills to her role at Weld Australia, ensuring the smooth handling of qualification, certification and examination enquiries.

Stephanie started her career as a personal assistant for a family run removals business. She had wide ranging responsibilities in this role, from marketing and human resources, through to customer relations. Discovering a passion for community care, Stephanie completed a Bachelor of Community Health and took on project and service support roles at a large, aged care service provider.

Australia Needs Welders for Submarine Program, published by Asia Pacific Defence Reporter

Schools Outreach Program to be Demonstrated Next Week, published by AuManufacturing

Advanced Manufacturing Needs to be Taught

Nationwide, says Weld Australia, published by Australian Manufacturing

Time to Get Radical About Skills Crisis, published by Climate Control News

How Augmented Reality is Helping Students Learn, published by AusBiz (the in-flight magazine of Rex Airlines)

Prime Minister Anthony Albanese recently announced that the Federal Government’s $15 billion National Reconstruction Fund will now be established in law.

“Australia has all the resources that go into solar panels, batteries and other finished products. We should be making them here. And that’s what this investment is all about. It will mean more secure jobs and more world-class products made in Australia,” Albanese said. “Recognising that during the pandemic, our vulnerabilities at the end of supply chains were exposed for all to see. We’ve been very good at exporting our resources and should continue to do so.

“But where possible, we should be value-adding, creating jobs here, particularly in our regions and in our outer suburbs. And this is about manufacturing. It’s about making sure that we make more things here, that we’re less exposed to the supply chain issues which we continue to see placing pressure on inflation.”

The NRF was announced by the government in the Federal Budget for October 2022 and will invest $15 billion across priority areas of the economy including renewables and low emissions technologies, medical science, transport, value-adding in resources, valueadding in agriculture, forestry and fisheries, defence capability and enabling technologies. The NRF will be administered by an independent board making independent investment decisions. It is modelled on the successful Clean Energy Finance Corporation.

Source: https://www.manmonthly.com.au/senate-passes-15billion-nrf-bill

A group of apprentices have become the first to participate in a new training initiative at TAFE Queensland which has been specifically designed to support and encourage women pursuing careers in male-dominated industries from the get-go.

The class had apprentices from the construction, automotive, engineering, and electrotechnology trades and was comprised of 15 women in trades out of a total 24 students. The average foundation class had previously seen two to three female students in attendance.

Apprentices completing the first training block of their trade qualification have, for the last few years, been able to do so with a class consisting of their peers from a range of trades thanks to TAFE Queensland’s initiative to give young tradespeople networking opportunities outside of their own industry.

This is achieved by grouping together the foundational apprenticeship skills including units on health and safety, workplace communication, teamwork, and sustainable practices in the workplace. Now female apprentices will also be able to network with their fellow apprentices in classes with a far higher percentage of women than previously, giving them a more supportive learning environment from the outset.

The increased ratio of tradeswomen in foundation training classes was achieved by prioritising the grouping of women in trades in foundation training blocks, where usually priority would be given to the most immediate training block. Apprentices did not face any adverse implication of waiting significantly longer before the training block and were scheduled within usual time parameters.

This pilot was carried out at the largest trade training facility in the Southern Hemisphere, TAFE Queensland’s Acacia Ridge campus, which sees more than 1,000 trade students daily and leads apprentice training in Queensland for the automotive, construction, engineering, and electrotechnology industries.

An historic agreement has been signed between Australian governments and rail industry stakeholders to bring our nation’s rail network into the 21st century.

The Australian and Victorian Governments, as well as the Australasian Railway Association on behalf of senior rail industry leaders, have signed the ground-breaking Memorandum of Cooperation to make rail more competitive and interoperable across Australia.

Since federation, rail has run as a series of independent rail networks, often receiving upgrades and new technologies at different times from different suppliers. This has led to a range of critical issues impacting national rail productivity and innovation, such as:

• the use of different rail gauges, signalling systems, rolling stock and safe working arrangements, which are an economic handbrake requiring costly work-arounds

• differences in how we run trains, manage rail crew and invest in new rolling stock

• experienced rail workers being isolated to geographic areas based on these differing technologies, compounding rail skills shortages.

The Memorandum of Cooperation commits rail operators, builders, manufacturers and transport ministers to work together to make rail more interoperable, particularly for any future major rail investments. This builds on the Australian’s Government’s commitment to delivering the National Rail Manufacturing Plan, to support a nationally coordinated approach that will grow the rail manufacturing sector and create skilled manufacturing jobs.

Submerged arc welding is commonly used in industries where thick steel sheets are involved or where long welds are required.

Oerlikon offers innovative submerged arc welding solutions for pressure vessel, offshore, wind energy and pipe mills industry segments, with mechanical properties ranging from general purpose to specialised high strength demanding and critical applications.

Excellent arc performance and slag release are critical to maximise productivity, especially on thick wall narrow groove joints typically used for o shore wind tower construction.

Attend this free webinar hosted by Lincoln Electric to learn about the Oerlikon submerged arc welding consumable solutions and how to increase submerged arc welding efficiency and productivity.

Speaker: Jean-Francois Tison, Solutions Manager, Lincoln Electric

Jean-Francois is the Solutions Manager based in Kuala Lumpur, Malaysia and has more than 20 years of experience in the welding Industry – 10 years as a Research and Development engineer for Flux Cored Wire in Europe and 10 years as a senior business developer in South East Asia.

Event Details

• Date: Thursday 20 April 2023

• Time: 4pm to 5pm AEDT

• Venue: Online

Register at https://bit.ly/lenseaApr2023webinar

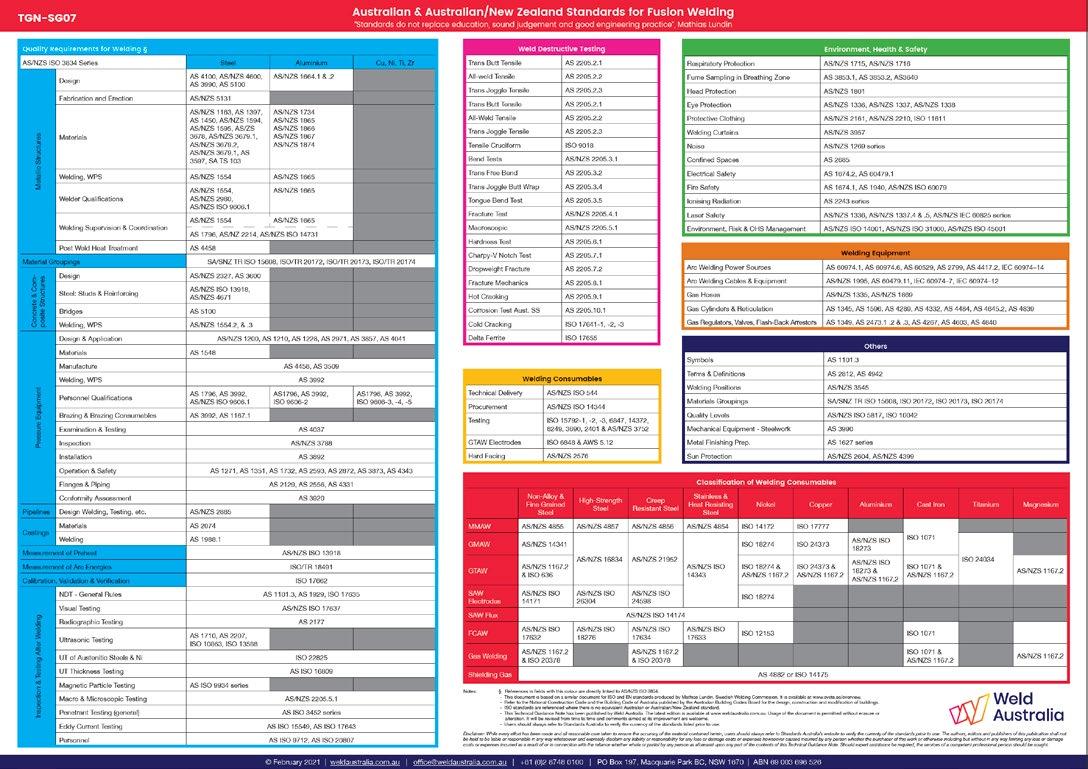

Did you know that Weld Australia makes a range of resources available to the welding industry? Some are free for anyone to download, while others are discounted or free for certain member types.

Just some of the free resources on offer include Technical Guidance Notes on topics like:

• Minimisation of Fatigue in Welds

• A Guide to AS/NZS ISO 9606-1

• Australian Welding Standards Map (see image below)

Questions? Queries? Wondering how Weld Australia can help support your business, staff or career progression?

Feel free to reach out to our Membership Manager, David Choudry, on 0417 878 104.

Weld Australia would like to welcome all our new Members who have joined recently:

CORPORATE MEMBERS

• Downer: downergroup.com

INDIVIDUAL MEMBERS

• Christopher Carpenter

• Paul Dennis

• Frank De Ponte

• Kevin Donohue

• Matthew Golding

• Jurica Kalcina

• Connor Mccallum

• Ben Popper

• Anthony Gerald Santos

• Jasbir Singh

• David Stark

• Jeremy Street

• Benoit Van Vooren

• Craig Vollmer

• James Watkins

• Jamie Watkins

• Dengxing Xue

Weld Australia’s Excellence Awards are the most prestigious event on the welding industry calendar. The Awards embody and promote the highest standards of craftsmanship, quality and professionalism. The 2023 Welding Excellence Awards are a fantastic opportunity for welders, fabricators and educators across Australia to showcase their people and their operations. Winners will be awarded in each state for each of the award categories below.

Entries must be submitted via the specific online form for each category by midnight on 15 September 2023. These forms can be found on the Weld Australia website, by clicking on the relevant red button. The Conditions of Entry can be viewed here. Before starting your entry, it is recommended that you download the Award Criteria. You will need the information outlined in the Award Criteria on hand to complete your online entry form. The Award Criteria can be downloaded via:

• Company of the Year – Fabrication

• Company of the Year – Gas & Gear

• Indigenous Company of the Year

• Project of the Year

• Welding Professional of the Year – Welding Coordinator

• Welding Professional of the Year – Welding Supervisor

• Welding Professional of the Year – Welding Inspector

• Young Trades Person of the Year

• Young Indigenous Trades Person of the Year

• Training and Education Award – Organisation

• Training and Education Award – Individual Teacher

• Ken Trevena Award – South Australia Only

The awards will be presented at events held across the country in October and November:

• Perth: Wednesday 18 October at Beaumont on the Point

• Sydney: Wednesday 25 October at Waterview in Bicentennial Park

• Adelaide: Wednesday 1 November at Glenelg Golf Club

• Brisbane: Wednesday15 November at Indooroopilly Golf Club

• Melbourne: Wednesday 29 November at Huntingdale Golf Club

Registrations for the events are not open yet. Further details will be made ASAP.

The 2022 award events sold out in record time, so be sure to keep an eye on our updates.

The Advanced Manufacturing Schools Outreach Program is encouraging kids in secondary schools across New South Wales to explore a meaningful career in the trades. With a skills deficient crisis impacting a raft of labour markets across Australia, industry is calling for the Program to be rolled out nationally.

The Program was demonstrated at a media event on Tuesday 28 March 2023 at Dapto High School. Arange of media coverage was secured, including;

• Channel Nine News

• ABC Radio Interview

• High tech trades class, published by the Illawarra Mercury

• NSW Schools Outreach Program Encourages Trade Careers, published by Manufacturers Monthly

According to Geoff Crittenden (CEO, Weld Australia), “There is no magic solution to Australia’s skills crisis. We need a radical approach. The same old approach that we’ve taken for years will not arm Australia with the skilled workers needed to deliver the record number of projects we’re seeing in industries like defence and renewables, let alone the $237 billion pipeline of government infrastructure.”

“Industry is calling out for kids with a practical bent to go into the trades. We need parents to understand that a career as a tradesperson is full of potential and a whole raft of exciting opportunities. The Advanced Manufacturing Schools Outreach Program in New South Wales is helping to do exactly this. It is helping to reverse the mindset that the only path for kids posthigh school is university,” said Crittenden. “Our STEM

Program is unique because it actually engages kids. It is hands-on, fun and educational. It is not just about studying more maths and physics textbooks. Anyone can try their hand at the welding simulators and be a star. A lot of these kids have never passed a test in their lives—the light in the kids’ eyes when the simulators gives them the all-clear is really something to see.”

Weld Australia has been working with the New South Wales Department of Education on the Advanced Manufacturing School Outreach Program to create a practical solution to the skills crisis in Australia.

The Program relies upon the use of augmented reality welding simulators to give kids a real welding experience. To date, 82 welding simulators are installed at 40 high schools across New South Wales. These simulators are used to teach students in Year 9 to develop an understanding of welding across all common processes in a completely safe and controlled environment. The technology is also being utilised by students in years 10-12 to support the delivery of Manufacturing and Engineering and Industrial Technology (Metal), as part of MEM20413 Certificate II in Engineering Pathways.

At the end of March, Weld Australia hosted an Industry Drinks Night at Cruise Bar in Circular Quay West. Sponsors by TAFE NSW, the event proved extremely popular, with over 100 people in attendance. Weld Australia would like to thank everyone who joined us for this hugely successful and popular event.

The event was opened by Geoff Crittenden (CEO, Weld Australia), who was followed by Stephen Brady (Managing Director, TAFE NSW). Attendees then heard from inspirational keynote speaker, Ben Pettingill

A focus for Weld Australia’s advocacy work in 2023 is encouraging industry to access a diverse range of people to address skills shortages—including people living with disability. Special guest speaker Ben Pettingill helped us launch this initiative.

At just 16 years of age, Ben lost 98% of his eyesight overnight to a rare genetic syndrome, Lebers Hereditary Optic Neuropathy. Running on adrenaline and shadowed by denial, Ben believed that he was just living a nightmare and that he would wake up one morning and be able to see again. He soon came to realise that this was not the case. His syndrome is incurable and he will be blind for life.

While the shock, then grief of losing one’s eyesight cannot be discounted, once Ben processed his new reality he realised that he had to make a choice that would define the rest of his life. He went on to become a construction worker. He spoke to the crowd about how there are 500,000 people with a disability looking for work, and covered practical ways to attract people with a disability.

Plus, experts from Seaberry’s headquarters in Spain were on hand to answer questions about Soldamatic augmented reality simulators and how they can help improve welder training programs.

Stainless steels are usually specified because of their enhanced corrosion resistance, high temperature oxidation resistance, or their strength. With various types of stainless steel available, there are specific welding processes and techniques that must be employed to ensure that the corrosion and oxidation resistance, and other mechanical properties are not impaired. This two day course will give participants a working knowledge of the welding metallurgy and weldability of stainless steels. Attendees will walk away with an understanding of the various types of stainless steel, and how to pre-heat, weld and post-heat treat them without introducing imperfections, causing cracking or otherwise disrupting their beneficial mechanical properties.

Dr Lippold is Emeritus Professor in the Welding Engineering Program at Ohio State University (OHU). He retired from OSU in 2016 after more than 20 years. He received his Bachelor, Master and PhD degrees in Materials Engineering from Rensselaer Polytechnic Institute. He worked at the Sandia Livermore Laboratory in California for seven years, and at the Edison Welding Institute for 10 years. Over the past 40 years, Dr Lippold has been involved in research activities designed to gain a better understanding of the welding metallurgy and weldability of engineering materials. Based on this research, Dr Lippold has published over 300 technical papers and reports and three widely used textbooks.

Course Content

This highly engaging two day course will cover the following topics:

• Introduction to Stainless Steels

• Phase Diagrams

• Constitution Diagrams

• Stainless Steels Alloy Systems

• Martensitic

• Ferritic

• Austenitic

• Duplex

• Dissimilar Welds

• Case Studies

Course Details

Registration at 8:30am on day one for a 9:00am start. Ends 3:00pm. Morning tea and lunch provided.

Melbourne:

Date: 10 and 11 July 2023

Venue: Cliftons - Freshwater Place Level 18, 2 Southbank Blvd, Southbank

Brisbane:

Date: 13 and 14 July 2023

Venue: TBC

Cost

Weld Australia Members: $1,650 inc GST Non Weld Australia Members: $1,850 inc GST

Payment is required at the time of booking. Cancellation two weeks prior to the start date will not be refunded. A certificate of attainment will be issued by Weld Australia at the end of the course.

For further information, simply contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or events@weldaustralia.com.au

Click on the buttons below, or register online via: https://weldaustralia.com.au/weldability-ofstainless-steels/

The ASME code is the American Society of Mechanical Engineers (ASME) standard that regulates the design, development and construction of boilers and pressure vessels. ASME Section IX specifies the requirements for the qualification of welders and the welding procedure specifications. This three day course in Adelaide will give participants a working knowledge of ASME Section IX, including how to comply with its requirements.

This course is intended for people who are involved in writing and qualifying welding and brazing procedure specifications, qualifying welders, brazers and operators, reviewing suppliers procedures, auditing or reviewing in-house procedures and qualifications and estimating jobs which impose the requirements of Section IX.

Welding Engineers, quality assurance personnel, auditors, testing laboratory personnel, maintenance personnel and jurisdictional inspection personnel will find this course interesting, exciting and beneficial.

Course Overview

A review of the welding processes and variables, and basic steel welding metallurgy will be conducted to provide all participants with sufficient background in welding technology to interpret and understand Section IX. The mechanics of using Section IX and how to address its requirements will be explained in a simple, straightforward manner.

Emphasis will be placed on writing welding procedures so that they contribute positively to the manufacturing process and on qualifying procedures in a cost-effective manner.

The requirements for welders and operators will be examined with particular emphasis on minimising the cost and maximising the usefulness of qualifications.

Time will be provided to address individual participant’s problems and concerns. Attendees will receive copies of the course notes covering the course’s content. Attendees must bring a copy of the current edition of Section IX. Multiple choice tests will be given for each section.

Course Details

Date: 1 to 3 November 2023

Venue: Stamford Grand Adelaide – Glenelg

Address: 2 Jetty Road, Glenelg, SA 5045

Room: Moseley Room

Time:

• Registration first day: 8:00am

• Course time: 8:30am to 4:00pm

Cost

Weld Australia Members: $3,610 inc GST

Non Weld Australia Members: $3,810 inc GST

Further Information

For further information, contact: Michelle Bignold (National Manager, Sales and Marketing) on 0437 106 726 or m.bignold@weldaustralia.com.au

Maximum capacity is 30 people. Get in quick to avoid disappointment! Click on the button below, or register online via: https://weldaustralia.com.au/ asme-section-ix-three-day-course/

Earlier this month, Mehdi Tajfar, Senior Welding Engineer, Weld Australia) attended AOG Energy in Perth. For over 40 years AOG Energy has bought the entire oil, gas and energy supply chain together as a platform for discovering innovation, capabilities and opportunities, supported by major operators, government and industry. The event was attended by more than 6,000 people from over 40 countries.

Speaking at AOG, Deputy Premier Roger Cook highlighted the need for collaboration and the right mix of energy sources as Western Australia aspires to play a leading role in moving towards a cleaner energy future. Cook emphasised the role of hydrogen and the partnership between government, industry and the research sector in establishing hydrogen hubs in the Pilbara, Midwest and South West.

Mehdi had the opportunity to spend some time with one of Weld Australia’s Premium Corporate Members, Novarc Technologies (pictured below) while there.

Bruce Cannon (Principal Welding Engineer, Weld Australia) recently presented a seminar on behalf of HERA—New Zealand’s peak body for the metals industry. An excellent event, more than 60 professionals were in attendance, and the feedback received was great.

The seminar provided practical, in-depth information to help attendees understand and interpret current and upcoming changes to AS and AS/NZS Standards. It covered the changes and revisions made over the last 12 months.

The seminar focused on the following hot topics:

• Revision of fabrication standards, such as AS 4100, AS/NZS 5131, and the bridge code AS/NZS 5100.6

• Revision of pressure equipment Standards, such as AS 1796, AS 3788 and AS 3992

• Revision of structural Standards, such as the AS/NZS 1554 series, AS/NZS 2214 and AS/NZS 1665

• An update on welding consumable standards

• An update on NDT standards

• An update on ISO Standards, including ISO 14731, the AS/NZS ISO 3834 series, and ISO 9606

• Standards policies and requirements and their influence on the revision process, including how you can get involved in the public review process

• Presentation of an innovative tool to help identify the Standards applicable to your work

Bruce’s presentation was followed by an expert panel discussion and a lively Q&A.

In conjunction with the Australian Cobotics Centre, Weld Australia recently attended the Try a Trade Showcase in Gladstone.

Almost 200 Grade 9 and 10 girls from Gladstone and surrounds gathered at CQUniversity for the event. This event brought together manufacturing, aerospace, energy, mining, engineering and construction industry businesses and stakeholders from government and education to encourage female high school students to learn about a range of careers in STEM and try out some practical activities they might encounter in STEM jobs.

Weld Australia had two Soldamatic welding simulators on-hand for students to try. Students had the opportunity to compete in a fun competition to compare welding accuracy. The Australian Cobotics Centre discussed the impact of cobots and other advanced technology on future work, asking students to think about the skills and attributes that would be required in the future to work with a cobot as a team member.

The event was organised by the Gladstone Engineering Alliance in partnership with the National Association of Women in Construction and the Queensland Government‘s Department of Employment, Small Business and Training and Gladstone Manufacturing Hub.

The Rockhampton Manufacturing Hub recently launched their Women in Manufacturing Strategy by hosting two Women Who Weld events in partnership with CQUniversity.

Twenty amazing young women with a passion for non-traditional career routes joined the team for an action-packed day where they learned valuable skills in oxy and MIG Welding.

The students got a firsthand look at the breadth of opportunities that the manufacturing industry has to offer and gained insight into what a career in the field could look like.

This event was a great way to support female students from The Rockhampton Grammar School, The Cathedral College Rockhampton, Rockhampton State High School, and Glenmore State High School by boosting their confidence and showing them that the world of manufacturing is full of possibilities for women.

Learn more about the Queensland Government’s Women in Manufacturing Strategy.

This month has seen Adam Coorey (Regional Training Coordinator, Weld Australia) provide ‘Train the Trainer’ courses for several organisations around the country.

Both CQUniversity in Rockhampton and Melbourne Polytechnic are set to introduce augmented reality into their welding curriculum. Soldamatic simulators have just been delivered to the training organisations, with Weld Australia rolling out training to their teachers, in both ISO 9606 and the use of the simulators.

Weld Australia also visited TAFE Queensland Acacia Ridge to provide refresher training to their staff.

During the training, all teachers had the opportunity to use the Soldamatic augmented reality welding simulators and learn about the role they can play in welder training.

The teachers completed training for ISO 9606-1 Qualification testing of welders — Fusion welding — Part 1: Steels, once again using the augmented reality welding simulators. The teachers also undertook a real ISO 9606-1 assessment to achieve internationally recognised welder qualifications.

The training was enjoyed by all the teachers—they all seem to be looking forward to getting students onto the simulators.

Augmented reality training systems are student-focused, allowing individuals to progress at their own pace. Welding apprentices learn and understand welding procedures and techniques through a more interactive training method, gaining hands on experience in a controlled, safe environment.

Augmented reality transforms training from boring theory and text books into high-quality interactive experiences that capture the imagination.

Weld Australia’s interactive stand at the Careers Expo in Charleville proved extremely popular with students. Students were keen to try their hand at welding for the first time using our highly interactive Soldamatic augmented reality simulators.

The Expo in regional south-west Queensland provided regional students with the opportunity to discover the diverse range of careers, education, pathways and employment available across the region.

The event included a range of workshops, demonstrations and talks to provide students with the opportunity to engage and interact with local businesses and trades to see what the workplace is all about.

EMPLOYMENT EXPO AT LANGI KAL KAL PRISON

Wednesday 3 May 2023 | 10.00am to 1.30pm

Trouble finding skilled staff? Interested in employing prisoners post-release?

In conjunction with Weld Australia, Langi Kal Kal Prison will host a Welding Employment Expo to help facilitate connections between prisoners and prospective employees.

In 2022, Corrections Victoria expanded their VET Centre of Excellence model to deliver Fusion Welding to ISO 9606 at HM Prison Langi Kal Kal. The program links prisoners with prospective employers and pre and postrelease support. These connections provide prisoners with sustainable pathways to employment and support to reintegrate to society post-release.

• Welcome from General Manager of HM Langi Kal Kal Prison

• Welcome from Geoff Crittenden (CEO, Weld Australia)

• Overview of training program from Federation University teacher

• Meet the prisoners and chat about their training and life after prison

• Tour the welding training facilities

Requirements

As per Corrections Victoria requirements, all attendees:

• Must provide proof of ID for security clearance

• Must have had at least 3 doses of a Covid vaccine

To register for the employment expo at Langi Kal Kal Prison, please email Michelle Bignold (National Manager, Sales & Marketing, Weld Australia) on m.bignold@weldaustralia.com.au

Weld Australia would like to congratulate Kitson Manufacturing Solutions (KMS), who recently achieved certification to AS/NZS ISO 3834.2 Quality requirements for fusion welding of metallic materials

Based in Parkes, New South Wales, KMS is a leading provider of integrated manufacturing, building and construction, asset maintenance and service solutions. Since 2014, they have grown from a specialist plant maintenance company to involvement in many major resource engineering projects.

KMS has built a reputation for quality and reliability backed by an entrenched safety culture, well maintained equipment and a highly qualified and experienced team who are committed to each and every project. Their services include: project management, engineering and drafting, in-house fabrication, mobile welding, pipework and poly welding, shutdown and fixed plant maintenance, civil works, and labour and equipment hire.

Questions? Queries? Need Help?

02 8748 0100 or qnc@weldaustralia.com.au

Take advantage of our advertising packages. With a multi-channel marketing approach, you can reach as big an audience as possible. Plus, Weld Australia members get a significant discount on all our advertising rates.

Diamond Package: $6,000

If you have a ground-breaking story to tell, or a brand new product or service to launch, take advantage of our ‘Diamond Package’ for maximum impact and exposure:

1. Australian Welding: 1 x full page inside cover ad

2. Weld Connect: 1 x third of a page front cover ad

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 4 x editions

4. 3 x social media posts

Gold Package: $5,000

Our ‘Gold Package’ provides great value for money, as well as fantastic impact and exposure:

1. Australian Welding: 1 x full back cover advert

2. Weld Connect: 1 x back cover advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 3 x editions

4. 2 x social media posts

Silver Package: $4,000

Our ‘Silver Package’ provides great value for money, as well as great impact and exposure:

1. Australian Welding: 1 x full page advert

2. Weld Connect: 1 x full page advert

3. Weekly Wrap-Up: 1 x right-hand sidebar advert (420px x 250px) in 2 x editions

4. 1 x social media post

Weld Australia would like to congratulate the following people on becoming newly qualified in March.

AS 2214

• Paul Gill

• Zane Patten

AS 1796 CERTIFICATE 7

• Michael Labb

AS 1796 CERTIFICATE 10

• Christopher Parker

• Selwyn Lloyd

• Zane Patten

IIW IWS

• Andrew MacDonald

• Nirajkumar Marfatia

• Robart Jacob

• Yi Chen

In conjunction with the 76th Annual Assembly of International Institute of Welding (IIW), the Singapore Welding Society (SWS) is proud to host the International Conference on Advances in Welding, Joining and Additive Manufacturing.

The Conference will be held from 16 to 21 July 2023 at the Marina Bay Sands. The event aims to provide a platform for knowledge exchange and networking among scientists, researchers and industry experts in the field of welding and joining.

Welding technologists, scientists and professionals who are interested in presenting original work are invited to submit abstracts. Topics of interest include:

• Brazing and soldering

• Mirco and nano joining

• Friction stir welding

• Linear Friction welding

• Cold spray technology

• Additive manufacturing:

• Wire arc additive manufacturing

• Laser directed energy deposition

• Powder bed 3D printing

• Laser welding

• Joining of ceramics or dissimilar materials

• Advanced arc welding or other welding processes

• Intelligentised welding manufacturing

• Numerical modelling of welding process

• Design, analysis and fabrication of welded structures

• Non-destructive testing

• Fatigue and fracture of welded joints

• Corrosion of welded joints

For further information, visit: iiw2023.com

Do you need to book an exam through WeldQ?

We’ve made the process even easier, with our new exam calendar, which can be accessed via the WeldQ homepage. The calendar includes all exam dates for 2022, making planning ahead as simple as possible. Just some of the upcoming exam dates include:

• Wednesday 19 April: IIW IWS SA1 online exam

• Monday 24 April: AS 1796 1-9 Certificate Theory online exam

• Wednesday 26 April: IIW IWI-S B6 online exam

• Thursday 27 April: National Welding Supervisor Exam Paper A

• Tuesday 2 May: IIW IWI-S (WTE S) and IWI-B (WTE B ) online exam

• Wednesday 3 May: IIW IWE EA1 and IIW IWT TA1 online exam

• Wednesday 10 May: National Welding Supervisor Exam A-B1 and B2

Kicking off on 26 April 2023, this course provides advanced knowledge of welding and inspection theory and application, including NDT, inspection techniques and procedures, acceptance criteria, identification of weld imperfections, and more. The course is conducted online over eight weeks, and then two-days of face-toface practical training. Enrol now

The course is delivered online over six live sessions. The course covers: common welding processes; welding symbols and welded joint configurations; welding defects; destructive and non-destructive testing methods; PQR / WPS and welder qualifications; and Standards. This highly engaging online course will start on 17 July 2023

A Welding Supervisor qualification enables you to improve your company’s bottom line. Welding Supervisors often make valuable contributions to four of the most important metrics in welding operations: quality, cost, productivity and safety. Not surprisingly then, this qualification can boost your earning potential and job stability. Kicking off on 18 July 2023, there are limited spots available for this course.

An AS1796 Welding certificate is by far the most well known and requested welder certification nationally. It is used in both structural and pressure equipment Standards. Delivered live online over 15 sessions, this course covers safety precautions, welding terms and symbols, preparation and set up, cutting and gouging, arc conditions, procedures and more. This highly engaging online course will start on 14 August 2023

Meet the Optrel Swiss Air: a respiratory protection system that brings clean breathing air into your environment and lets you breathe freely. Swiss Air features a ventilated half-mask made of fire-resistant material that covers the mouth and nose area completely.

Swiss Air provides respiratory protection of the highest class and ensures no passage for aerosols, smoke, particles, or viruses. With its cutting-edge breath-assisting technology and ultra-flat and light backpack design, Swiss air is the most versatile Optrel respiratory protection system suited for various industries, especially those in high-risk industries such as agriculture, construction, manufacturing, medicine, and welding.

Some of the common tasks in these industries that expose workers to hazards include:

• Dust when cutting, grinding, crushing, and polishing concrete, pavers, bricks, tiles, and engineered stone

• Asbestos-containing materials

• Hazardous fumes from welding metals

• Exhaust fumes from power tools

• Chemicals such as pesticides, paints, and adhesives

• Fumes from fumigation processes

• Microorganisms

• Fumes from medical products and pharmaceuticals

• Silica Dust from disposing of/cleaning up

Repeated exposure to these hazards may result in occupational lung diseases, which may be chronic, acute, sub-acute, and infectious, malignant, or nonmalignant. Some of the most common occupational lung diseases include work-related asthma, coal workers’ pneumoconiosis, silicosis, Chronic Obstructive Pulmonary Disease (COPD), asbestosis, and mesothelioma.

It’s no secret that workers in the welding industry are often exposed to welding fume and gases, which

can negatively affect lung health and even potentially cause severe lung diseases and cancer. Welding fume comprises various and complex mixtures of gases and particulates produced when metals are heated above boiling point. This fume is made up of minute particles from mostly consumable products.

In 2017, the International Agency for Research on Cancer (IARC)—the World Health Organisation’s specialised cancer agency—reclassified welding fumes as Group 1 carcinogens (carcinogenic to humans), from its previous classification as Group 2B carcinogens (possibly carcinogenic to humans) in 1989. The IARC also specifically classified UVR from arc welding as a Group 1 carcinogen.

As Group 1-classified carcinogens, welding fumes and UV radiation in the welding arc can cause cancer to exposed humans, specifically, workers in the welding industry. Exposure to these increases one’s risk of developing various types of cancers, including lung cancer and melanoma of the eye.

This updated classification solidifies the need for a respiratory protection system that limits and prevents worker exposure to various hazards, most especially dangerous carcinogens.

Equipped with a TH3 filter unit, Swiss Air meets the highest requirements for professional respiratory protection systems—filtering out 99.8% of all harmful particles, aerosols, vapours, smoke, or even viruses. It also features a shoulder harness for ergonomically perfect weight distribution, an infinitely adjustable headband, and a Y-hose with an adjustable neck strap and flexible hose elements, keeping the welder comfortable.

Equipped with high-tech fabric and a freely adjustable headband, Swiss Air eliminates the need for fit tests, making it the most versatile Optrel respiratory protection system available.

For more information, visit smenco.com.au

This editorial was supplied by SMENCO.

There are two fusion welding courses that adhere to ISO 9606 Qualification test of welders on Training.gov.au. This is the authoritative source of nationally recognised training and Registered Training Organisations (RTOs). These two courses were developed in Victoria in 2018 and use augmented reality welding simulators as a key component of the training.

To be awarded a certificate for the Course in Fusion Welding to AS/NZS ISO 9606 for Transition Workers, you must successfully complete seven units of competency (four core and three elective). Core units:

• Simulate fusion welding processes using augmented reality equipment

• Identify welding processes, safe welding practices and use of hand and power tools

• Interpret and apply AS/NZS ISO 9606 for fusion welding processes

• Perform fusion welding procedures to meet the procedures of ISO 96061 (Steels – carbon steels)

To be awarded a Statement of Attainment for the Course in Fusion Welding to AS/NZS ISO 9606 for Experienced Welders, you must successfully complete three units of competency (one core and two elective). The core unit is: Interpret and apply AS/NZS ISO 9606 for fusion welding processes.

For further information, contact: training@weldaustralia.com.au

Enrol in a fusion welding course through any Advanced Welder Training Centre below.

Canberra Institute of Technology cit.edu.au

81 Mildura Street, Fyshwick

Queensland TAFE Queensland tafeqld.edu.au

• Cairns Campus: Gatton, Newton, Eureka and, Wilkinson Streets, Manunda

• Townsville (Trade Centre Bohle) Campus: 763 Ingham Road, Bohle

• Toowoomba Campus: 100 Bridge Street, Toowoomba City

• Ashmore Campus: Benowa Road & Heeb Street, Ashmore

• Nambour Campus: 91 Windsor Road, Burnside

• Bundaberg Campus: 118 Walker Street, Bundaberg West

Tasmania Tasmanian Minerals and Energy Council tasminerals.com.au

13 Wellington Street, Burnie

Victoria Box Hill Institute boxhill.edu.au

465 Elgar Road, Box Hill, Melbourne

Bendigo TAFE bendigotafe.edu.au

23 Mundy Street, Bendigo

Federation University federation.edu.au

Lydiard Street South, Ballarat