Sustainable solutions for every building.

Toge ther wi t h o ur n etw ork of partners, a rchi t ec ts, s pecifier s an d in vest ors , Schüco de li v ers tail ored pr o duct s for n ewb uil d s and r en ovat io ns, designe d to m eet in d ivi dual us er needs in all clim a te zo nes. Every one in v ol v ed is s uppo r te d with a compreh e nsi ve rang e of serv ic e s a t eve ry st age of t he c ons tructi on proces s. W ind ows, doors an d façade so lu t ions fro m Schüco mee t the highest requir e ments i n terms of design, comfort and security, whilst simultaneously reducing CO2 www.schueco.ae

“The New Year stands before us, like a chapter in a book, waiting to be written. We can help write that story by setting goals” - Melody Beattie (AFamousAmericanAuthorofSelf-HelpBooks)

We at WFM Media, are following the above quote and have set our goal to support the growth of the industry and bringing the worldwide brands and influencers together to help them expand their reach and share their experiences and knowledge.

In our last edition, we announced the launch of our virtual platform “WFM Virtual Community” built for the façade & fenestration industry - connecting architects, builders, consultants, developers, engineers, and fabricators. We have got a good response from the industry and more than 500 industry people have registered for the community till now. The platform is hosting discussions and debates on several important topics related to façade & fenestration with eminent speakers from the industry. The brands are launching their products through the WFM Community platform and architects are talking about their innovative projects. There are a lot more interesting activities are happening on the platform. You can also become a part of the WFM community, here is the registration link: https://bit.ly/3hsuTdC.

We all have seen many ups and downs in 2020 and now as we are entering into a new year, we wish you all a wonderful year ahead. We would like to extend our gratitude to the readers and contributors who have always supported us and shown their faith in us. We shall try and make sure that we will continue to do our best efforts and bring some exciting initiatives like WFM Virtual Community to help the industry and the brands to grow further.

This edition has a cover story - presenting industry experts’ opinions and views on future facades. Apart from this, there is an interview of one of the industry leaders and an eminent architect, news updates, the write-up of an interesting project by a well-known architect, and some other informative articles authored by the subject-matter experts.

Send your feedback and suggestions to editorial@wfmmedia.com. Keep supporting us.

Cheers…

Team WFM

Engineering Perspectives of Specifying Architectural Glass in Buildings

Amir Kamal Abdullatif, Executive Director, Al Andalus Holding Company

Wired Glass - All You Need to Know

Tamer Adnan Nezha, Façade Manager, Target Engineering Construction Co LLC

18

35

Interview with Urfi Kidwai, Founder & Managing Director, Gulf Rubber Industries LLC 9

45

The Overview of the Kinetic Façades

Aftab Khamisa, Design Manager, ARENA EMEA (Dubai)

Façade Challenges: A Vision of the Industry Status and Challenges Ahead

Miguel Fernandez, Senior Façade Consultant, AESG

Creating Sustainable and Efficient Façades for the Future Experts’ views on preferred material and technologies for future açades

Face to Face

Fahed A Majeed, Chief Architect, Fahed+Architects

Industry Speaks

Project Watch: Mandarin Oriental Hotel and Residences in Etiler, Istanbul, Turkey

Ben van Berkel, Founder/Principal Architect, UNStudio

Front cover Courtesy: Godwin Austen Johnson

Back cover Courtesy: Salumco

Published

Shefali Bisht shefali@wfm.co.in

Design & Concept by: Prashant Kumar

About the Author:

Amir Kamal Abdullatif Executive Director, Al Andalus Holding Company

Amir Kamal Abdullatif is an Executive Director in Al Andalus Holding Company, which is a leader in the façade field in Saudi Arabia. He manages two subsidiary companies of the group, one is specialised in the architectural glass processing and the other in fire rated glass systems. He owns a Bachelor in Civil Engineering and a Master in business administration, enabled him along with his extensive experience to add a significant contribution in many important investments and projects of the glazing industry in the region.

Selecting the appropriate building materials is an essential function of the engineers in each project, this function starts from the design stage and is being emphasised along with the project progress. Each engineering’s specialisation has its own perspective of those materials’ specifying in the project to meet the requirements according to the functional specifications of its scope. By coordination, optimisation and integration; the engineers can select the bundle of the project materials.

Architectural glass forms a significant part of the materials bundle in a building, it is used either in the external applications or in the internal applications. Curtain walls, structural glazing facets, windows, skylights and doors are glass systems used externally in the building; doors, fixed partitions and windows are examples of the internal applications. How engineers select the glass used in such systems? What are the criteria and the characteristics they build the solutions on? This is related to the functional perspective.

The first perspective is the architectural onewhich cares about design and aesthetic purposes.

The architect studies how to involve the glass’ appearance in the design concept; if he seeks a concealing concept, the highly reflective glass will be the most suitable; if he seeks the revealing concept, then the best choice will be a higher neutral glass. Also, there are many scales of reflectivity, transparency, neutrality and colours; matching the glass with the other finishing materials is a matter of art design depends on the available variety. Another thing should be considered in selecting glass types which are covering the spandrel areas, high reflective glass could be needed in this area to hide the concrete slabs and barriers, but it should be matched to the glass used in the viewing areas which might be not highly reflective. In the spandrel area, you can use single layer glass and not the double layer because you do not need a thermal and solar performance, but be careful since not all glass types can be used as monolithic and not protected by doubling.

The architect also takes the building’s function into considerations. You cannot use a high reflective glass in the residential buildings, especially the ones which have a nice view from its façades, because it will be highly reflective from inside at night. But you

Selecting the appropriate building materials is an essential function of the engineers in each project

can use the reflective glass in the buildings which are mainly used in the day and barely at night like offices or governmental buildings, and when you need to hide some concrete elements, false ceiling or any other similar elements.

The second perspective is the mechanical engineering which is related to the conditioning system of the building. In the first stage of designing a conditioning system in a building, the mechanical engineer has to calculate the thermal loads in the internal spaces of this building, and accordingly he can design the conditioning units’ capacity to meet the requirements and guarantee a comfortable ambient inside the building. This process is segmented to having the related factors of each material type used in separating between the internal and external space; one of those materials is the architectural glass.

The two main factors used in the thermal calculation are U-value and Solar Heat Gain Coefficient. U-value is the rate of transfer of heat through a structure (which can be a single material or a composite), divided by the difference in temperature across that structure. While the Solar Heat Gain Coefficient is the fraction of incident solar radiation admitted through a window, both directly transmitted and absorbed and subsequently released inward. Both factors are considered as better when they are lower since they reduce the thermal load value and consequently reduce the required capacity of the

conditioning units, and reduce both of the initial and running costs. The architectural glass takes a big percentage of the building fronts’ area and its factors are highly considered in the thermal load calculation. So, the mechanical engineer can get better performance as long as the glass is coated with solar control and thermal performance (Low-E) coatings.

The building orientation is another important consideration in selecting the architectural glass type from the mechanical perspective. This affects the volume of heat comes inside the building, according to the solar energy different paths in summer and winter. If this issue is not studied well, a huge heat volume can be gained to inside the building. Also glaring is an effect related to the solar ray’s path, the glass could pass more than required light to form an undesirable glare inside the building. Some Low-E coatings can allow enough visible light transmission to let the needed light goes on, and simultaneously, it can control the impact on solar heat gain for those façades that have long-term sun exposure. Different coatings can impact glare and solar heat gain in different ways.

I would like to mention here a practical example of evaluating a sample considering what I explained in the first two perspectives. The following procedures will help in making a decision of glass selection:

• View samples outdoors on a cloudy day

• The silver Low-E coatings should be viewed at a 40 or 50 degree angle

• Checking the glass from a distance of 3 meters

• Turning the sample over to see the reflectivity from both sides (outdoor reflection and indoor reflection)

• Inspecting the glass on the building in different lighting conditions during the day

• Inspecting the glass with a black background to simulate a window with no indoor lights

• Inspecting the glass with a white background to demonstrate a nighttime application

And third, the structural perspective of selecting the architectural glass in the building. Each component of the building could have a function of loads bearing according to its structure and location. So, the structural design and calculation are essential tasks to select the physical properties of the glass combination which is used in the façade system, the window or any other glass application. A structure supported by an aluminium framework which is made up of mullion and transom is called as a curtain wall. The mullion is a vertical support or we may call it as

a column, while the transom is a horizontal support likely to a beam. Also, the aluminium frame is used for windows and other applications and the vertical ones play the main role in bearing the wind loads and dead loads.

In our article, we concentrate on the glass design

according to the whole system structural calculation. The glass is considered one of the most vulnerable components of the building against structural loads, so it should be taken care of well in the design stage and specific fail-safe design criteria and analysis methods are required. Mainly, the glass thickness and the multilayer combinations of glass are the two considerations in such design, this to determine if the glass deflection as a result of the loads is within the tolerance or out of allowed limits in the normative standards, these limits which guarantee a safe behaviour of the glass along with forces applied on it. The glass could be single, doubled of two or three single layers, single laminated, or a combination of double and laminated glass with selected thicknesses of each layer.

Finally, there should be a high and close coordination among all the concerned engineers with different specialisation to set the bundle of criteria which leads to select the most optimal architectural glass of a building. But let us remember, there are requirements should be a must and mandatory like the physical safe structure built up of glass, and the performance which meet the calculated thermal load of the building. Other aesthetic requirements can be modified if cannot be guaranteed along with the other requirements.

About the Author:

Tamer Adnan Nezha Façade Manager, Target Engineering Construction Co LLC

Tamer Adnan Nezha is Façade Manager in Target Engineering Construction Co LLC. He has a BS degree in civil engineering and a Master’s in building materials. He has over 16 years of façade construction experience in the Middle East. Currently, he is heading up specialist façade teams and servicing projects in the Middle East. Nezha has worked on a wide variety of projects including large-scale and multiple-plot retail projects to mega high-rise projects. He has extensive knowledge of the building envelope, fit-out, curtain walling, façades, cladding, structural glazing, architectural steel, GRC in all phases (pre-design consulting phase, pre-construction phase, construction phase, operations & maintenance phase).

One of the most famous materials that are used in construction is glass. In present times, these are used a lot in windows, doors, railings for balconies and staircases, etc. The best thing about glass is it can be cut into different sizes and shapes and this makes it so much more flexible and versatile.

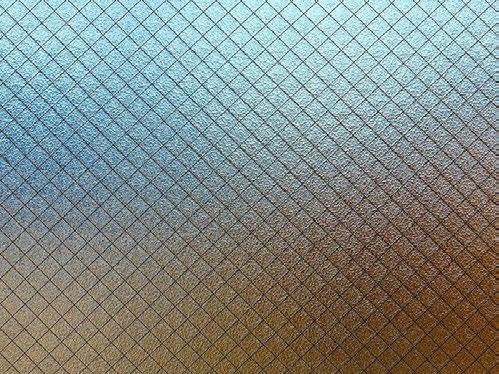

What is meant by Wired Glass?

Wired glass is being used for decades now and it prevents the glass from shattering in case of emergencies. The glass is reinforced with wire mesh during manufacture, which makes it durable, fire-resistant when compared to float glass.

It is also known as Georgian wired glass, and wire mesh works as a reinforcement. In case due to some higher impact activity the glass breaks, it is held by the wire in position. This lessens the

chances of anyone around from getting hurt. The wire mesh glass is available in diamond grids and square grids.

What are the advantages of Wired Glass?

Here are some of the main pros of having a wired glass at your home or office:

• Because of the wiring that is present in the glass, the glass is able to block fire entering into building for some time. This also offers enough time for escaping from the building and thus helps in the prevention of damage in emergency situations.

• Although it can break with impact, the fragments of glass get stuck to the wire mesh, this helps in preventing theft.

• When compared to float glass it has a much higher thermal and electrical resistance

• In comparison to different other safety glasses available in the market wired glass are less expensive, so it works like a cheaper fire and safety glass.

• These glasses can also be used as patterned and tinted glass, hence it offers an attractive aesthetic look to the property.

• Wired glass is approved by American UL standards and has a heat resistance of up to 60 minutes.

if you are looking for a clear view from your window, wired glass is not the best choice

the disadvantaGes of Wired Glass

It is important that wired glass is not installed near the areas where kids often visit as when the glass breaks it has the sharp wire and class exposed that can harm people around.

In case you are looking for a clear view from your window, it is not the best choice. The reason being the wire obstructs that view.

• These glasses are used widely in places that require nominal fire resistance such as fire exit doors

• It is used in partitions and windows of, public buildings, schools, hotels, and institutions.

• Usually, wired glass is used in windows of routes to the fire escape, this helps in increasing the time required for evacuation people in a situation of fire or other emergencies.

• Some of the prime applications of wired glass include stairwells and hallways and can be a really smart choice for installing in these areas.

• It can also be used in skylights, roofs, windows, and fire-resisting doors.

in case due to some higher impact activity the glass breaks, it is held by the wire in position

About the Author:

Aftab Khamisa Design Manager, ARENA EMEA (Dubai)

Aftab Khamisa is an architect registered with The Board of Architects- Queensland (Australia). He holds a Bachelor of Architecture from Ramaiah Institute of Technology, Bengaluru and a Masters degree in Sustainable Design from the University of Sydney. Aftab has worked in India, Australia & the U.A.E and has had the opportunity to contribute to a wide variety of projects ranging from small private residences and shops to medium scale commercial offices, residential units, institutional buildings, nursing homes, airports and also some master planning projects. While his experience before arriving in Dubai in 2013 was purely within architectural consultancies, he has taken on roles both within consultancies and contracting companies in Dubai which have given him invaluable experience across all phases of a project right from the conceptual design stage to the practical completion of projects on-site.

The environmental factors that affect the performance of a building are all dynamic and our buildings must adapt to these constantly changing climatic conditions in a sustainable way. One of the means to make our buildings adapt to dynamic climatic conditions and human needs would be to consider ‘Dynamic’ or ‘Kinetic’ façades.

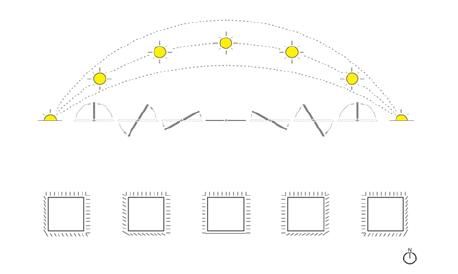

The concept of kinetic façade consists of devices mostly that move and change their forms by either internal computer control, sensory trigger or change due to climatic change conditions. (Ibrahim & Alibaba, 2019)

For most of architectural history, the focus was on creating façades through an interesting use of materials and ornamentation. These façades were primarily static, but would appear to change through the day with the movement of the sun. Over time these façades would change naturally as the materials aged with exposure to the climatic elements of wind, water, and the sun. With

advances in building construction technology, availability of newer materials and the evolution of contemporary architectural styles, the approach to architectural facades has significantly transformed. Although environmental factors have always existed, climatic changes are now being much more evident due to global warming.

A substantial share of the energy consumption in buildings can be attributed to the air conditioning in this region. Cooling buildings during summer is a major environmental problem in many Middle Eastern countries, especially since the electricity is largely dependent on fossil fuels. The building facade is critical to shield against harsh climatic conditions, thus the advancement of this system will help transform the traditional role of the facade as a filter to a more active role, which includes in some cases the integration of photovoltaic cells, to generate energy rather than just save energy.

Figure 1 (Alotaibi, 2015) demonstrates the movement of the sun and the response of a kinetic shading system that helps reduce the solar heat gain inside a building.

Modular construction and prefabrication are now being used in a big way to cater to the vast demand in the hospitality sector, however, most of the currently available prefabricated ‘POD’ solutions show little or no response to providing an appropriate shading solution in their design.

Imagine the benefits of a kinetic façade on a prefabricated/modular hotel or accommodation pod:

• Economical & Ecological Sustainability: The cooling costs in projects could be lowered when the solar heat gain is curtailed with well-shaded design, which would, in turn, reduce the operating costs and increase the return on investments of projects.

• Occupant Comfort Control: The kinetic façade could also have a manual override providing control to the occupants of the building to orient the shades as per their convenience to the views they wish to enjoy.

• Commercial Opportunity: Post COVID-19 there has been a growing demand for “Workation” which this opens up a lot of opportunities for the

hospitality sector to offer their customers a great option to work in beautiful locations all through the year, however this would be more effective if the hotel rooms provide a good level of thermal comfort throughout the year.

• Non-Wasteful and Non-Polluting: A solar-powered kinetic façade would be an efficient means to reduce air conditioning loads, causing a direct positive impact in addressing climate change. It would be a sustainable design approach that could help minimise broader environmental impacts such as ozone depletion due to the emission of greenhouse gasses because of the energy consumption of buildings.

• Prefabrication and Modular Solution: The kinetic façade could be an add-on prefab modular building element that provides an exterior aesthetic as well as a protective skin to the building while creating a dynamic facade that changes through the day with solar-powered sensors.

With numerous mega projects planned over the next decade in the Middle East, climate change is inevitable and cannot be altered, however, buildings can be! The kinetic façade technique is one of the best technological improvements in the architectural world that can be used to effectively maximise energy in buildings and adapt to provide comfort to the inhabitants with the change in time and weather.

In conclusion, kinetic façades are an effective strategy to target energy efficiency against climatic changes and dynamic human needs. A well-designed building facade needs to be much more than just aesthetics as we are now facing an increasing demand to meet more stringent ecological, social, and economic performance requirements to counter climate change. Buildings need to be responsive to the climatic context, and since the building façade is the boundary between the external atmosphere and the interior, the design and adaptability of the facade become a key factor in the development of sustainable and energy-efficient buildings. (Ibrahim and Alibaba, 2020).

Some examples of a kinetic façades:

1. Kids pod (shown in Image 1A&B): Over the windows, the CNC- routed timber is mounted onto customized, operable steel shutters. Designed in close collaboration with the builder, steel fabricator and electrician, the shutters open when Kids Pod is occupied to permit light in and views out. They close at night, glowing like lanterns, or when the rooms are unoccupied.

2. Recreation House (shown in Image 2A&B): As a compact recreation house, this project in Utrecht was built on an existing garden house with a new structure and envelope with wood window shutters. The vertical fin façade and horizontal slats rotate to be both transparent and completely closed.

3. Elysium Lot 170 (shown in Image 3A&B): Crafted with standardized materials and details to help control construction quality, this residential project occupies most of the allowable building space onsite. Interior spaces were designed with an introspective focus, both functionally

and visually. Timber was selected along the exterior that could weather naturally and open to the elements, while finishes were kept to a minimum.

4. Badehaus Am Kaiserstrand (shown in Image 4A&B): The numerous storey-high folding shutters, which constitute the façade’s outermost layer, and the sliding-glass doors behind them allow the building to be used flexibly; because the bathhouse can be opened up completely, or, on the other hand, closed and protected, for example, from inclement weather, a variety of spatial combinations are possible.

About the Author:

Miguel Fernandez, Senior Façade Consultant, AESG

Miguel Fernandez is a Senior Façade Consultant at AESG. He has started his career in façade consultancy 3 year ago in 2017. He has expended the last 10 years in Middle East working as Project Design Manager at Permasteelisa ME, developing projects on GCC region such KACST (KSA) or Coca-Cola Arena (Dubai) previously has worked in Permasteelisa Spain for 7 years where was performing the roles of Design Manager and 3D Manager.

The façade industry is facing a crucial moment, as many other industries and in particular the construction industry is in the middle of a very convulse time, affected by either global and local economic situation, pandemic or other different factors. In this article we are going through these factors and the way the façade industry is taking to overcome them.

This year has been a quite peculiar one due to the COVID world pandemic that had affected seriously all the industries, however the construction and façade in particular has reacted very fast

and adopted the required safety measures and embraced the new communication possibilities such as video calls and internet presentations, by the use of the actually available tools a good level of coordination has been maintained between the different stake holders making possible the progress of the projects.

Apart from the stationary challenges, the façade industry is affected by some other functional and structural challenges that defy the façade industry capacity to adapt. The origin of the actual challenges for the façade is diverse and interrelated, some of them come from the economic situation, some others come from the environment and climate condition and also from the design intent itself.

Façade industry as any other industry is subjected to the time and cost constraints, projects have to be executed at the establish time and in the foreseen budget, this is a primary condition, no business is sustainable without complying with this. The actual trend is going on the way of cost and time reduction and the façade is not immune to it. The façade in its role of the building envelope is the one of the most visual part of a building and its appearance gives already a very powerful impression of the building, this has a direct implication of the investment return of the project. This time and cost constrain is sometimes leading to the use of less quality materials and reduce of the installation quality. To overcome to this challenge, the façade industry has several ways to tackle, time constraints can be overcome by the correct planning of the project or by adopting façade solutions that reduce the installation time that normally is the leading factor. Cost constrains shall be considered at the early stages of the project, during the design stage all the materials need to select to avoid problems of cost in the future. Early coordination and technology integration are key tools to embrace this challenge.

Sustainability must be a goal for all the industries, for the façade as separating element between the interior of the building and the external weather conditions (sun, rain, wind…) the sustainability is part of its DNA, as we all are aware of the climate changes the façade has an essential role on the fight against it, from more efficient façade to reduce the building energy consumption to energy producing façades, we have the technology and all this possibilities need to be presented to the Architects and Developers beyond the established regulations, the aim for Net Zero buildings should be the standard to follow. Façade industry can actively collaborate on this achievement, starting from the design intent of the building, shading or building orientation, to the sourcing of materials by increasing the percentage of recycled materials, some typical façade material such aluminum profiles are obtained by very energetic process instead of recycling, local source of materials to reduce the carbon footprint, use of more efficient glazing or low conductivity materials like GPR profiles. These are some of the passive measures that can be considered, in the other hand there are also active measures focused on the obtain of clean energy from the façade itself, technologies such

as the BIPV (Building Integrated Photovoltaic), recent solutions include the use of biomass as source of power and heat integrated on the façade (Algae Bio-reactive façade). The use of electrochromic glass or active shading elements are also well known on the market.

Complex geometry façades are other of the actual challenges to the façade industry, with the surge of 3D and parametric design software the complexity of the buildings’ design and the façades has increased rapidly, the façade industry need to be prepared and be able to follow the market requirement, use of 3D and BIM software are some of the tools that the façade industry need to use generally to provide the proper solutions to a more demanding market.

The use of new materials is in close relation with the increasing façade complexity, the use of composite materials such as GRP, GRC or UHPC is giving to the architects a much bigger freedom on

the design of the buildings including the façade, the list of newer materials is large depending of the desired appearance, form metallic to stone, from wood to plastic, these materials are giving the possibility of explore all kind of shapes and dimensions of façade elements not possible

In the spandrel area, single layer glass can be used and not the double layer because you do not need a thermal and solar performance

The architectural glass takes a big percentage of the building fronts’ area and its factors are highly considered in the thermal load calculation before, is crucial for the façade industry to be aware of all the available materials and their design possibilities to be able of incorporate them into an efficient façade design.

Summary

In summary, façade industry needs to be at the state of the art of the following factors to be able to provide the solutions that the construction market and the society is demanding:

• Knowledge: Façade industry needs to invest in research to answer to the developers and architects demands

• Technology: Façade industry need to be at the latest design and fabrication technologies and materials to provide optimised solutions

• Commitment: Façade industry need to be engaged the sustainability goals and provide greener solutions

Façade industry as any other industry is subjected to the time and cost constraints, projects have to be executed at the establish time and in the foreseen budget, this is a primary condition, no business is sustainable without complying with this. The actual trend is going on the way of cost and time reduction and the façade is not immune to it. The façade in its role of the building envelope is the one of the most visual part of a building and its appearance gives already a very powerful impression of the building, this has a direct implication of the investment return of the project. This time and cost constrain is sometimes leading to the use of less quality materials and reduce of the installation quality. To overcome to this challenge, the façade industry has several ways to tackle, time constraints can be overcome by the correct planning of the project or by adopting façade solutions that reduce the installation time that normally is the leading factor. Cost constrains shall be considered at the early stages of the project, during the design stage all the materials need to select to avoid problems of cost in the future. Early coordination and technology integration are key tools to embrace this challenge.

Sustainability must be a goal for all the industries, for the façade as separating element between the interior of the building and the external weather conditions (sun, rain, wind…) the sustainability is part of its DNA, as we all are aware of the climate changes the façade has an essential role on the fight against it, from more efficient façade to reduce the building energy consumption to energy producing façades, we have the technology and all this possibilities need to be presented to the Architects and Developers beyond the established regulations, the aim for Net Zero buildings should be the standard to follow. Façade industry can actively collaborate on this achievement, starting from the design intent of the building, shading or building orientation, to the sourcing of materials by increasing the percentage of recycled materials, some typical façade material such aluminum profiles are obtained by very energetic process instead of recycling, local source of materials to reduce the carbon footprint, use of more efficient glazing or low conductivity materials like GPR profiles. These are some of the passive measures that can be considered, in the other hand there are also active measures focused on the obtain of clean energy from the façade itself, technologies such

The façade of the building has always remained the most significant from the point of view of both the designers as well as the developers. The façades of the buildings have multiple roles to play and perform several functions. It is the interface between interior space and exterior environment and plays a crucial role in heat and light exchange, thermal and acoustic performance thus providing occupant comfort. The façade of the building has to keep and maintain the balance between all the parameters that include: aesthetics, thermal comfort, managing daylight and solar heat gain, visibility, etc. With the advent of new technologies and the increasing need for occupant comfort, innovations in façade materials keep on happening.

What can be expected from the future façades? What should be the characteristics of the façades in the future? Which material can become the preferred choice to create the façades in the future? To answer all these and other important questions, we interviewed the subject-matter experts. Their views and opinions are presented in this story.

the façade of the building has to maintain the balance between all the parameters that include: aesthetics, thermal comfort, managing daylight and solar heat gain, visibility, etc.

In my opinion, the most important “tool” is to follow the basic principles of façade design with a focus on the performance requirements for each project. The role of the façade is to be fully functional and performing during the entire design life of the building. This should be delivered in the most economical manner, says michelle bacellar, technical director, meinhardt façade technology.

There is no point in using new materials and technologies if the basic principles are not well understood. Often we see “latest technology” systems installed with gaps on the vapor barriers, thermal bridges, sealed drainage points, to name a few. I guess the point that i am trying to make is that even the best systems will fail if the basic principles are missed, she adds.

Wael jomaa, façade structural manager, salumco believes that the important tool to create future façades is the modular solution, where the façade will be considered as a puzzled envelope for the building later on.

According to Michelle, any type of dynamic façade can be beneficial in “future-proofing” façades. The idea of a dynamic façade is that the building envelope can change its performance as the exterior environment changes. This concept could be applied to cover, for example, any climate changes resulting from global warming.

“The future might be related to the integrated and adaptive façade solution; however, I can see that new solutions will be integrated with the façade engineering field”, says Wael.

There are so many new technologies being developed every day, it is hard to keep up. If we take glass as an example, there is white glass that turns clear at the press of a button, clear glass that turns black, there

are even some glasses that can become tinted only at selected areas, explains Michelle. She has recently come across a new antimicrobial coating technology that claims to kill even the virus that causes COVID-19 when in contact with the surface. There are also some simple, but very smart solutions for pre-fabricated and self-adhesive membranes that can make site installation a lot more efficient and robust.

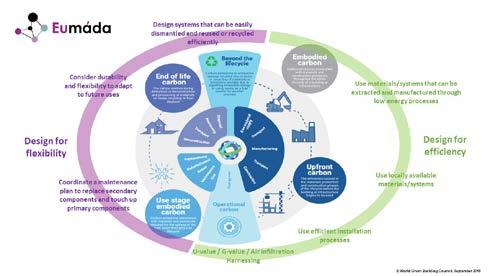

Dr. Belarmino Cordero, Director, eumada, says that the climate emergency, the raising standards of comfort, and the growing population pose serious challenges to the building industry. A transformational increase in design and construction efficiencies is necessary to be able to successfully address these challenges and is possible if we manage to leverage available technological advancements such as Building Integrated Photovoltaics (BIVPs), 3D-printing, prefabrication, or Artificial Intelligence (AI) to name a few.

Façades are no longer expected to merely limit the amount of energy consumed by a building through passive design, but also contribute to balance the energy demand through active generation. In this area, the demand for BIPV is growing thanks to their increasing efficiencies and decreasing costs.

He believes that 3D printing processes are highly

automated ensuring low costs, high speed of construction, and reduced wastage. It is a relatively young technology in the construction field and has the potential for optimisation.

Prefabrication provides flexibility for future reutilisation or dismantling of building components which is a pivotal aspect of circular, “cradle to cradle” models. Since they allow for factory QA/ QC processes, prefabricated components also serve as carriers and catalysts of other advanced technologies.

Examples of AI developments such as speech recognition, autonomous vehicles, intelligent routing in content delivery networks, or military simulations are staggering. Perhaps the building industry is not quite as developed yet. However, advancements in the software are helping automatise the design processes, improvements in computer power are allowing to process the large amount of data that is now available (from weather files to actual live information of buildings that is collected with sensors) and there are even some sophisticated examples of AI involving machine learning and generative design.

Wael says, one of the main advancements in the façade industry is the use of lightweight structures and materials to sustain very high

environmental pressure and loads.

I suppose now more than ever, the automation of entrance doors and the like will become even more popular as they bring the advantage of contactless entry, thus assisting in preventing the spread of contagious diseases, says Michelle.

Dr. Cordero notes, automation is the creation and application of technologies to produce and deliver goods and services with minimal human intervention. In façade design, CAD tools have traditionally contributed to increasing the efficiency, accuracy, and coordination, but BIM and parametric software are now taking efficiency and coordination to new levels.

Early-stage optimisation services assist to establish efficient massing configurations, considering orientation volume and positioning of the buildings in a given location and environment. This process allows to analyse how numerous configurations perform environmentally and provide the design team with the necessary performance evidence to optimise the design, he adds. Other useful parametric applications include form-finding, geometry rationalisation, or digital fabrication.

According to Wael, new techniques in architectural design based on automation, parametricity, and algorithms have invaded the design with complicated methods and applications. One of the main environmental obstacles facing any design is the allocation of fenestration, which used to be linked mainly to the design of the façade.

Contemporary windows allocation in design has started to be a more complicated issue when related to complying with certain validation environmental rating systems such as LEED. Through the use of common design strategies based on the contemporary techniques in architectural design, this issue could be achieved automatically, he adds.

Michelle says energy harvesting façades are those which have the capability of producing renewable energy. The façade can incorporate features that are used to harvest wind and solar energy. These elements could be integrated with solar shading features in the façade design. Renewable energy technologies are developing fast and I don’t think it will be long before they become a common feature in the building façades.

Energy harvesting façades are façades that

generate energy from renewable sources. They are typically used in high-performance buildings such as Net-Zero buildings where it is not enough for the façades to be efficient but they also need to actively contribute to balance the energy consumption of the building. The most common example of energy harvesting façades is Building Integrated Photo Voltaic systems (BIVP). The BIVP market is expanding

rapidly due to the increasing demand for NetZero buildings coupled with the advancements in their manufacture which is becoming more efficient and cost-effective, Dr. Cordero explains.

Daylighting is the exploitation of solar energy in the form of natural lighting indoors and it plays an integral role in minimising the energy footprint

of a building. Smart daylighting enables us to design buildings that provide comfort and energy savings simultaneously, notes Wael.

Characters of a High-Performance Façade

For Michelle, a high-performance façade is a façade that is fit for purpose and it maintains its performance characteristics during the whole design life of the building.

Dr. Cordero believes that the building envelope needs to address a long list of performance parameters that include energy and sustainability, health and comfort, safety, durability, etc. It has to do so while protecting the architectural intent, ensuring that the design is feasible and can be procured on time, within the budget, and to the required quality.

Features of High-Performance Façade

• Energy efficiency

• Fenestration

• The embodied energy of materials

• Control of heat transfer, air, and moisture movement

• Properties of façade materials and components

• Steady-state heat and moisture transfer analysis for opaque building façades

• Wind and environmental pressure resistance specially for high-rise façades

- Wael Jomaa, Façade Structural Manager, Salumco

Features of Future Façade

“I would like to see more energy harvesting façades being incorporated in the façade of large buildings. It would be great to see these technologies implemented in the design, not as an element that is distinct from the façade, but rather, as a new set of systems with which façade design can be made from”, says Michelle.

Wael would like to see the façade and its components as a structural element in design and structural analysis references, as till now, it is considered as a non‐structural element.

Interactive Façade - Advantages and Limitations

Michelle finds interactive façades very interesting as they provide an additional feature to the building, enabling the envelope to change its “look” as the façade changes. This could create a new building

appearance every day.

She believes that media façades can offer an extra advantage to the building owner, they can use the building envelope to generate revenue by selling advertisement space. Essentially, your façade becomes a billboard space that is generating revenue and additionally changes the building appearance.

According to Dr. Cordero, interactive façades are those that involve the interplay with the surrounding environment or people. When thinking of interactive façades, high-tech examples typically come to mind such as media screens, dynamic shading, switchable glazing, etc. However, low-tech features such as operable windows or manually operated blinds or shutters are also interactive façades. It is essential for comfort to design façades that enable users to maintain a certain degree of control over their environment. These simple devices allow to adjust ventilation, acoustic, temperature, or solar radiation.

The interactive façade will have to include systems that correct or moderate the performance of the glass as the outdoor conditions change, also allowing for individual occupant adjustment of the indoor comfort parameters, opines Wael. A static all‐glass envelope will not be able to give optimal performance except for a few periods during the year. Adding blinds that are irregularly controlled by occupants will not fundamentally change the performance picture. The conclusion is therefore that we need an intelligently controlled, dynamic envelope he adds.

Michelle finds glass an extraordinary material because it gives such a wide range of possibilities in the façade design in terms of performance and aesthetics.

Dr. Cordero notes that there should not be a favourite material that suits all projects. The material selection process should be specific for every project in accordance with the varying architectural aspirations, energy targets, budget, fire requirements, etc. Where possible, the material selection should take advantage of the local resources, manufacturing capabilities, and the lessons learned from local vernacular architecture.

In Michelle’s opinion, a system that is suitable for the specific performance requirements of a particular project and has been executed in the most economical manner is an efficient and sustainable system. Very often systems that are called “sustainable” are overdesigned, which, in my opinion, goes against the concept of sustainability.

An efficient building not only needs to target low operational, but also low embodied energy usage as the energy involved in the extraction of raw materials, manufacturing, transport, and construction of a building will have an earlier impact on the environment than the energy consumed during its design life, says Dr. Cordero.

Moreover, for a building to be truly sustainable, it also needs to adopt circular “cradle to cradle” fundamentals and look into its future reutilisation or decommissioning. We should be designing buildings that are flexible and can be easily adapted to what the future may bring.

Wael notes that the fenestration components (windows, curtain walls, clerestories) are significant elements of façade design, from both aesthetic and performance perspectives. They allow natural light to enter interior space but also allow heat transfer between the outside and inside. Fenestration elements affect a building’s overall energy consumption, as well as its occupants’ well‐being, health, comfort, and productivity. When choosing fenestration materials, specific properties of glass should be considered, such as U‐values, SHGC, and visual transmittance. The design of the fenestration framing system is also important.

He adds sustainable features of façades are when a building has been designed to minimise the area of its external skin. For those offices with an external façade, very high levels of thermal insulation of walls and windows help to reduce heat loss. Natural ventilation and daylight penetration are maximised.

Wael’s favourite material is glass and this returns to its chemical composition where glass is made from liquid sand. It can be made by heating ordinary sand (which is mostly made of silicon dioxide) until it melts and turns into a liquid. ... It is like a cross between a solid and a liquid with some of the crystalline order of a solid and some of the molecular randomness of a liquid.

Characteristics and Key Features of Sustainable Façades and Fenestration

The zero-energy building is the new trend and the demand for energy-efficient, sustainable, climate-responsive buildings are rising all around the world. Façade plays the most important role in providing all these features of the buildings. There is no doubt that the façade of the future will be highly efficient, adaptive, and more responsive.

Avinash Kumar Associate Partner, Godwin Austen Johnson

What are the important tools for creating future façades?

Traditionally, we have always used general rules of climatology for designing façade by assessing the solar gains. With the emergence of AI and machine learning, we will be able to analyse real time data for actual solar gains and general weather data through accurate simulations which, in turn, will allow us to design better, more energy efficient façades.

Façades in the future will be more accurate in terms of mitigating solar gains and optimising the overall views from the building providing and adding to improved occupant experiences.

What are the future opportunities for smart façades, adaptive façades & integrated façades?

Smart façades are modern façades which provide optimal thermal comfort at the same time reducing the building’s carbon footprint through a number of active measures. These can be mechanical measures, chromogenic controls or integrated photovoltaic which provide shade and power to the building.

Occupier comfort and aesthetics continue to be the main goal for us as architects. But it is equally important to lower energy consumption at the same time. Buildings in the future will move towards becoming more self-sustaining by generating a major part of electricity from façades which will offset general grid electricity.

What are the current advancements in façade & cladding technologies and materials?

With the advent of active façade technology, the façade is no longer a fixed dormant fabric. It has become a live enclosure which responds to the climate and to the occupant adapting accordingly. Glass, as an important element of any façade, has also become more energy-efficient in recent years.

Please brief about automation in façades and fenestration? What are the benefits?

The main benefits of automation in façades are the active measures to reduce solar gains and optimise the natural light inside the building without over heating or over cooling the internal environment while, at the same time, maximising views and daylight while reducing the heating and cooling loads.

This automation uses mechanical and electrical shading devices incorporated in the building fabric which work on real-time sensors and prevailing weather conditions and are activated to increase or reduce internal lighting levels accordingly.

The long term benefits have reduced operational costs of the building, better returns for stakeholders and optimal comfort for end users.

What are interactive façades, their benefits and limitations?

An interactive façade is a building fabric which reacts to real-time data generated from the building’s exteriors. A change in light or temperature engages the daylight controls which can be either mechanical or electrical shading devices. These then help balance the light and heat flow into the building, reducing the dependency on electric lights and heating/cooling of the built form.

There are, however, cost implications for the initial capital costs and the technology which tends to deter building owners who are not aware of the long term cost savings of the technology. But with time, this technology will be more prevalent with more owners making the investment.

What are energy harvesting façades? How do you see their future?

Energy harvesting façades are those which use the building components to generate energy creating a more sustainable approach to architecture.

Currently the efficiency of power generated through building integrated windmills and PV cells is low, but, as the technology improves, we will see these energy harvesting façades become more efficient in the future.

Energy harvesting will also work with self-cleaning

glazed façades offsetting much of the energy used by the built form reducing the carbon footprint considerably.

What are the key characters of a high-performance façade?

High performance façades are those which react to and work with real time data generated from the building exterior.

What features do you see or want to see in the future façade?

Personally, I believe future façades should be a lot

more sustainable with fewer solid elements and based on real time parameters. I think we will see more vertical gardens or living walls, replacing traditional glass-clad buildings to help reduce the urban heat island effect and thus the overall energy usage of the building. I also believe we will see a lot more building Internet of Things (IoT) with much more data being generated by buildings and controlling the active façade elements.

What are your views on interactive façade? What are the advantages and limitations of media/ interactive façades?

There is a promising future for interactive façades

which allow for the control of light and heat into the building balancing the interiors for maximum occupier comfort at the same time as offsetting the electricity requirement to maintain the interior environment.

What façade material is your favourite and why?

Glass and mineral board cladding materials have been my preferred choice to date. Glass has always been an important material for aesthetic reasons and for the fact that it provides good quality light within the building. Mineral boards, on the other hand, look more natural and give a minimal look to a building.

What is meant by a sustainable and efficient fenestration? What are the characteristics and key features of sustainable façades and fenestration?

Sustainable and energy-efficient fenestrations are building envelopes which are sustainable in nature and, in parallel, help reduce energy usage for cooling or heating the building. The sustainability factor comes from the material selection, its fabrication, installation and the final reuse or recycling once the life cycle is over. Care must be taken at all stages of manufacture to ensure that we keep the carbon footprint to a minimum.

“In Future, We Will Have Smart Materials for Façade to Alter thermal and climatic Response”

Fahed

A Majeed

Chief Architect, Fahed+Architects

About the Author:

Fahed A Majeed is an alumnus of Bangalore Institute of Technology, Fahed Majeed has extensive professional and academic experience having taught in architecture schools in Bangalore. Helmed by Fahed, the practice - fahed+architects - has received numerous design awards since its inception. He is one of the few charter members of the Royal Institute of British Architects (RIBA) from India. Fahed + Architects is a multidisciplinary boutique architectural practice established in 2005, with offices in Dubai, Bali and Kochi. They do master planning, urban design, architecture, interior design, product design, exhibition spaces, art installations, etc. Listed as the ‘Top 50 Emerging Practices’ and the ‘Top 50 Hot practices in Asia ‘, the practice has won multiple international awards, including The Middle East Architects Award and the Golden Leaf Award from IIA.

tell us about your practice and design approach?

Ours is a boutique practice. Our team is small and the number of projects we can possibly work on is limited. We have a presence in multiple regions - Kochi- India, Dubai- UAE, London- UK, BaliIndonesia. Now Bali primarily deals with product design and sourcing of certain specific items regarding our own projects. Our strength is we are small and have a diverse pool of architects from different regions that makes out design solutions more vibrant. We have been achieving substantial strides in terms of sustainable solutions - including having projects that are completely off the grid (for the last 10 years) to developing projects that have gone through the cradle to cradle life cycle. Every project is viewed differently as they stem from different programmatic briefs, site and desired contextual response and place making plays a key role in grounding the project.

What inspired you to become an architect?

It was my mother who inspired me. I used to aimlessly draw- with great passion- during my high school days. At that point Architecture was a very alien subject to me or our family as almost everyone in my generation was either a doctor or a dentist. I was also thinking of pursuing the same at that point. However, towards the end of 12th grade there were a series of events that resulted in a shift in thought from Medicine. I was interested in making cartoons. However, this was not a program that culminated in a degree at that point. So around that time my mother did point my possible inclination towards design and architecture. One thing led to another and finally I enrolled myself in the architecture program at BIT. Fate has been kind. At Bangalore Institute of Technology, I was extremely lucky to have Prof. Sathya Prakash Varanashi as our HOD. So

in short, it was a series of fortunate events that led me to being here. On top of everything I love creating meaningful spaces layered with life. After undergraduate I worked in Bangalore for a while and eventually planning to head to UCL for pursuing a PG in Urban design at UCL. However the same year I was awarded Young Architect of the Year by Malayala Manorama and with this project started coming in.

could you please talk about your projects featuring very innovative and different kinds of façade and fenestration designs?

Well, our practice is very new to London. So I will speak of what we have been doing in India or the Middle East. I will share a few projects that will give you details of the facade details - our core strength is working with the raw materials in developing façade systems- now this is easier in

the tropics where the temperature variation is not very drastic. In the Middle East and UK this can be challenging. Apart from this we can share what we did for a commercial building - where the entire façade is a series of siding folding windows and the whole thing can open up making the internal spaces like a huge balcony.

How do you go about choosing the material of the façade and cladding?

Well- this is very project, region, and program specific. The whole project is also influenced by the orientation we choose. So most of it is decided at the very first stroke of line while designing. We try to minimise passive absorption. We do not start or approach a project with any preconceived idea or agenda. We were once working on a project where the client had massive sources of types that were being recycled. In that case our

the complete façade of the building 900N 760N e is made up of sliding folding windows that can be opened to make the internal space a huge balcony

first thought was to see how effectively we can use their own material. At times it’s challenging, but then that’s what makes it interesting. The selection of façade material is based on the quality of life you want to achieve internally. At times you are fine with external elements passing through, at times it has to be high performance in terms of thermal gain, at times it has to have adequate thermal mass. So in short, it’s dictated by a wide range of parameters.

According to you, where is the architectural segment is heading in the Middle east?

That’s a super wide ended question- I would say that the future of this region is very promising. With the Middle East having the youngest population in the world and people traveling more than ever before the expectations are high. The education system has bought up a higher level of awareness in terms of being responsible or sustainable solutions. There is a lot of focus on human comfort.

This is not just in achieving an air conditioned space- but they are trying to bring this difference in transport, spatial volumes, quality of life, ease of doing business etc. The UAE has mandated that 25% of its construction be 3D printed. This gives a huge impetus to the 3D printing segment. So in short, they are very aggressive and optimistic.

The Middle East is perhaps one of the fastest growing economies- the changes witnessed in the last 2-3 decades is astounding. However, I think the main challenges they are facing is reconciling with their historic past. Because of the sudden surged the connection between the region and the architecture is very limited or non-existent. In addition to this most of the structures are not climate sensitive- this would obviously mean higher energy cost. So there is a higher chance of redundancy over a period of time. Apart from that

it would be good to see energy smart buildings, increasing in number- this is already happening.

What opportunities do you see for the architects in the region?

The Middle East has always been kind to outsiders. So I envisage the same to continue. The economy of late worldwide has slowed down. But over the period it will get better and obviously with that opportunity.

As an architect what sustainability means to you? How do you ensure the sustainability factor in your projects?

Sustainability for us means being responsible. This starts from the very first line you draw- in terms of orientation to the material selection. We try to see how we can use materials that have lower embodied energy and the life cycle of a material. In the tropics simple measures like adequate lighting and cross ventilation can effectively lower energy

consumption. In UAE it’s important to use the right materials be in glass or block works based on its absorption. In addition to this there are various energy modeling tools we use to make informed decisions.

What are your views on the future façade and fenestration technologies as well as materials?

I think going ahead, we are going to have smart materials that can alter its thermal and climatic response. In the next 10 years, we are going to see structures that are 3D printed and this means very limited wastage of materials.

You have won many awards for your work. could you please highlight the name of some of the prestigious awards you have won?

We have won many international awards in the field of architecture. Few of our recent wins are: ID Honors 2020 - Best Residential Interiors for ‘The Flying House’ project, “Scroll of Honour” at the

the Abwah Pavilion is a perfect example of a structure that celebrates the shape and character of the material by retaining and representing it in its purest form

11th Reality+Conclave & Excellence Awards in 2019, CWAB Awards for Noteworthy Projects in 2019Best Residential Interiors - Jaison’s Residence, Middle East Architecture Awards 2018 for the Sustainable project of the year, The International Award for Sustainable Architecture Awards 2018 by The Architecture. These are few of the awards, but the list is so long.

What is your advice for young and upcoming architects?

It’s important to be focused and work hard. There is a substantial drop in the quality of education, especially with the rising number of schools. But the reality is - life is not going to ask you which college you studied from or if your school was challenging or so on. They are going to gauge each and everyone for who we are at that point. So try not to find excuses and use your time judiciously.

“We are Making

Urfi Kidwai Founder & Managing Director, Gulf Rubber Industries LLC, Dubai

Urfi Kidwai is the founder of Gulf Rubber Industries LLC, United Arab Emirates. A unique, responsible, focused & innovative approach of URFI foresee Business endeavours that are conceptualised to maximise the market opportunity and intensify it in all economic and business cycles. He has done MBA from Bombay University and Post-graduation in Chemistry. He has set many milestones as an entrepreneur in rubber, EPDM, silicone, PVC extrusion polymer and its associated industries.

In a conversation with Window & Façade Magazine, Kidwai talked about his journey in the industry, the offerings and achievements of Gulf Rubber Industries L.L.C, etc. Here are the excerpts…

Please brief us about your Gulf Rubber Industries’ journey.

Gulf Rubber Industries L.L.C has been established as one of the pioneers of the rubber manufacturing industries in the Middle East. Our company is formed by experienced professionals who have been in this business for more than 20 years.

We are the first of its kind in the entire Middle East that have phenomenal range and capabilities of processing synthetic and silicone rubbers to manufacture profiles that comprise of multi durometer hardness, multi-material colour extrusion, profile pre-cut, TPE (Thermoplastic Elastomer), vulcanised frames, corners and various other combinations depending upon the customer requirements.

In addition to the above products, we also provide additional service to customers such as testing, analysis, design and technical support to name a few.

As a part of the ongoing commitment to excellence, Gulf Rubber Industries LLC is been recognised with the most prestigious ‘Sheikh Khalifa Excellence Award (SKEA)’, Silver category in Manufacturing for 2019-2020, and ‘Dubai Quality Appreciation Award (DQA)’ for 2020 in appreciation of the persistent distinguished efforts and commitment to quality as an ideal approach towards achieving business excellence and is committed to provide the highest quality across all the company’s business areas. By consistently providing services that meet and exceed performance beyond customer expectations. We develop customer trust to achieve strong business performance.

Tell us about your product offerings? What benefits do they offer?

Our products include extruded dense EPDM profiles, sponge EPDM profiles, neoprene, SBR profiles, silicone profiles, co-extrusion profiles, silicone compatible EPDM, TPE profiles, IDPE & HDPE profiles, vulcanised frames, moulded corners

& moulded parts, setting blocks, flame retardant profiles, self-adhesive profile, refrigerated van profiles, EPDM façade sealing membrane, rigid PVC profiles, d-fenders, wall guards, column guards, and O-rings & gaskets.

Our products are known to provide a lot of benefits to the buildings, which includes: they are extremely durable for sealing to ensure weather tight joints and provide thermal insulation for façade industry (curtain walls, frames, OEM window seals, vents, door seals and skylights)

Name some of the major projects in the Middle East in which your products have been used?

Our products have been used in many landmark projects. Some of the projects are One ZabeelDubai, Museum of the future - Dubai, Royal Atlantis - Dubai, Iconic Metro Station - KSA, 160 Folsom - USA, Regent tower - USA, Abu Dhabi PlazaKazakhstan, Mobility Pavilion - Expo 2020 Dubai, and Sustainability pavilion - Expo 2020 Dubai.

What sustainability means to your business? How sustainable your products are?

We follow all the prerequisites of LEED compliance. In addition to this, we also encourage recycling of rubber which can be used for rubber tiles.

How do you ensure the quality of your products? Do you have a state-of-the-art facility? Please brief our readers about it.

We follow very strict guidelines for our quality control. All our incoming materials are inspected intensely to match the specification required. We

do a thorough check of the rheological property of our masterbatch with the finish material in order to avoid any problem of flow and scorching of material inside the extruder. The final extruded product is checked every half an hour interval for their dimension from profile projector and keep the section for at least 6 months or as per customer requirement.

We have state-of-the art testing facilities to check all our chemicals and intermediate work in progress. GRI has the best lab in the region. We have coextrusion line, silicone line and salt bath line; from which we can produce different products which cater to all requirements of façade industry.

What are your expectations for your industry in the Middle East in the coming years? What changes do you foresee?

For our industry, it was a challenging year where we invested to upgrade ourselves in products as well as research and development in compounding. During the course of the time, we came up with different materials with coefficient value; energy saving material to save our environment.

There is a lot of development taking place in the façade industry. Since there are different types of material used in façade, we get the opportunity to design our gaskets to assure the compatibility.

What do you see as the main challenges faced by your industry?

• To procure the raw material at the right time

• Maintenance of the machinery spare parts; as

they are not available locally

• Raw material costing is another challenge as it gets affected by the oil price

• Most important is the unhealthy competition, where people reduce the prices that affects the overall product value

The COVID pandemic has affected all industries and businesses. How are you cope up with this difficult situation?

Due to this pandemic, businesses have shrunk by 20% and there is a deficit from different areas. We at GRI are currently focusing on customers in different regions, mainly for diversification.

We are making competitive formulation of the product so that we are able to compete and act

efficiently once the situation comes back to normal.

How do you see the present scenario of the construction industry for your products?

It is quite challenging, as there are lot of projects on hold and less new project are coming up. This in turn has reduced the volume business. We are meeting consultants and trying to get approval for specific projects so we can supply our material and continue to be in the business.

What are your goals and plans for the next 4-5 years?

We are planning to start our business in the US and Europe. Our strategy would be to make our factory 80% export oriented unit.

About the Author:

Ben van Berkel, Founder/Principal Architect, UNStudio

Ben van Berkel studied architecture at the Rietveld Academy in Amsterdam and the Architectural Association in London, receiving the AA Diploma with Honours in 1987. In 1988 Ben Van Berkel and Caroline Bos founded the UNStudio which is an international architectural design studio specialising in architecture, urban development and infrastructural projects. UNStudio Architectural Sustainability Platform engages all UNStudio projects from the early phases in order to ensure that the correct choices are made and that the office’s high sustainable standards remain an integral part of the design process. They make sure that sustainable knowledge and conclusions directly inform the design decisions. This involves both active and passive design tools, which have a recognisable effect on the design of the building, product or urban plan.

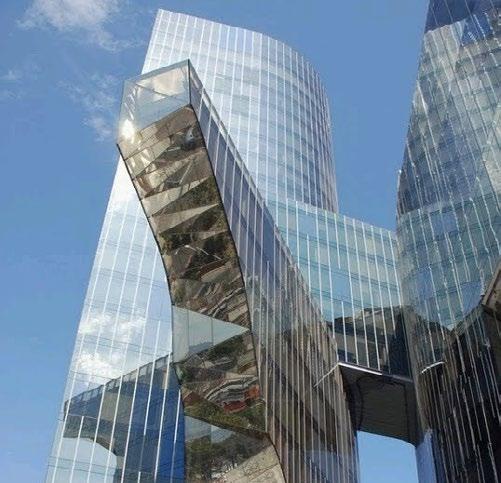

UNStudio was appointed to design the masterplan and architecture for the new Mandarin Oriental Hotel and Residences in Etiler, a prestigious residential quarter on the European side of Istanbul, located close to the city’s central business district. The 216,740 m2 development comprises three high-rise towers that merge with a lush green garden above a commercial podium with underground parking. The new Mandarin Oriental Hotel and Residences is planned to open in 2022.

The three towers within the development accommodate different living typologies. One of the towers will house the Mandarin Oriental Etiler, Istanbul with 158 guestrooms and suites and 16 serviced apartments. The remaining two towers house 251 residences at Mandarin Oriental.

The hotel will have three restaurants and bars, a selection of adaptable meeting spaces with outdoor areas and terraces, a spa and fitness centre, and both an indoor and outdoor swimming pool. The residences at Mandarin Oriental will enjoy direct access to the hotel’s facilities, in addition to bespoke resident facilities, which include two outdoor swimming pools and a fitness centre.

The commercial plinth comprises retail shops, offices and public amenities. It extends to three levels below the garden level and is accessible directly from the commercial plaza entrance at Selcuklar Sk.

With its unique topography, the beauty of Bosporus and the amalgamation of different cultures throughout the centuries, Istanbul provides its residents with a varied and rich quality of life. This new mixed-use development in Etiler reflects the contemporary lifestyle of both local and international people who want to be part of this vibrant and modern metropolis.

The site, located in the district of Beşiktaş, close to the business quarters of Levent and Maslak, is a hidden jewel within Etiler. It is easily accessible by the main axis Nispetye Cd and is within easy walking distance of Akmerkez shopping mall. The three entrances to the project are formed by the hotel lobby at the southern tip of the site closest to Nispetye Cd, the residential lobby that faces inwards for privacy, and the commercial plaza entrance along the Selcuklar Sk. A three-level parking below the commercial plinth services, in distinct flows, the residences, the hotel and the public programme.

The urban scale of the Etiler neighbourhood informs the entirety of the building perimeter. Taking advantage of the existing slope on the site, the podium appears to be partially tucked underground. This gesture not only reduces the impact of the volume at the urban scale, but also enables the lush garden area to be highly visible to the whole neighborhood, thereby adding to the quality of living in Etiler.

The design of the towers plays a key role in the implementation of sustainability measures, which begin with the massing. A sequence of passive considerations carefully curate the towers’ position, shape and form. The towers are placed on the east side of the site. This placement is the result of parametric testing with the goal to find the optimal positioning for the towers to avoid casting shadows on each other and on the garden in the afternoon hours, in addition to minimising impact on the surrounding neighbourhood. The shape of the tower footprint is also optimised to create minimum impact towards the predominant NNE wind direction, while the façade length is maximised in order to provide

all residences with the desired views over the Bosporus.

The form of the towers results in a sculpted effect with a serene yet robust expression. The towers comprise three parts that are programmatically attuned. The top floors gradually step inwards at the side with the most prominent views, in order to allow for larger penthouse terraces, whilst reducing impact at the city scale. The central levels, which form the core of the tower, host most of the residences. The lower floors establish the connection with the garden. This occurs as a continuous gesture in which the lower levels fan outwards to create the garden residences.

This ‘fanning’ approach enables the towers to seamlessly merge with the garden, as the two elements come together to provide a healthy biophilic element that increases the occupants’ connectivity to the natural environment.

The predominance of stunning views on all sides of the site became the main driver for the façade

design. As a result, a glass façade wraps around the towers, enabling all rooms, whether private or shared, to enjoy the same uninterrupted views to Bosphorus and the Levent area. A horizontal ribbon then wraps around each floor and introduces variety to the balustrade design. These ribbons, whose depth depend on the vertical positioning on the tower, become the outward horizon of the terraces. The resulting parameters that vary throughout the height of the building are: depth of terrace, height of ribbon and integration of green.

The terraces contribute significantly to the reduction of the heat load on the large glass surfaces of the towers. Aside from the terraces where a depth of 1,80m is secured to accommodate comfortable outdoor living, a continuous French Balcony surrounds the full plan, providing access to all rooms. All rooms can also enjoy natural ventilation, while apartments have the opportunity to cross-ventilate, thereby reducing the need for air-conditioning and high energy usage.

The ribbons work differently in the urban scale:

when viewed together, they present a tailored silhouette for each tower. Depending on the programme, height, unit count and layout of each floor, the ribbons respond differently in their individuality, yet as a whole, they correspond to express the entirety of the project.

To accentuate the individuality of each residence, the outline of each terrace recesses or extends in

relation to the terrace above. As a result, every resident enjoys a double-height outdoor living space: an experience of villa living in the sky of Istanbul.

The quality of living spaces also depends on the tactility of the materials that surround them. The aim of the façade design for the Mandarin Oriental Hotel and Residences is therefore to employ materials that portray artistry, wherein handcraftsmanship is evident in the quality of the design and workmanship. This is made apparent in elements produced by hand, but translated into contemporary design. Metalwork, pottery, ceramics and woodwork, become the references for the principal materials used in the project.

The anthracite ribbons are clad with glazed ceramic tiles, inspired by centuries of tradition and knowledge, in addition to a multicultural mixture of influences. The ceramic tiles are

inserted within the ribbon profiles and are cast in such a way as to catch the light differently across the course of the day. The tactility and texture of the material elevates the outdoor living experience by introducing a detail that is similar to custom designed living spaces.

Bronze details throughout the project elevate the

spatial experience and give the feeling of both tradition and exclusivity. Such details are employed in the lobby areas and in the ceiling design of the terraces. In addition, bronze panels that have been perforated with a dedicated pattern are used for privacy throughout the garden areas.