Scan to know more

Scan to know more

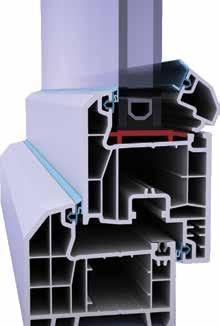

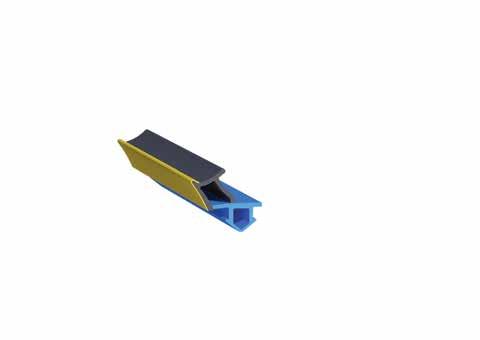

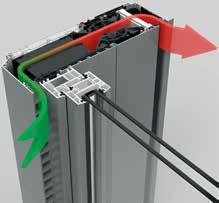

Lingel - Panzer - Glazing 14 mm

Recommended for P6B as per EN356

LPG 18

Lingel - Panzer - Glazing 18 mm

Recommended for P7B as per EN356

LPG-X

Upgrade your existing Lingel security glazing to LPG performance

LINGEL SAFE BOX hardware

to upgrade your existing Lingel window Recommended for RC2 and RC3 as per EN1627-30

LINGEL SAFE BOX hardware

for your new state of art

Lingel - security - window recommended for RC2 & RC3 as per EN 1627-30 LSB 1 LSB 2

Lingel Provides Masterpiece Windows Where Every Component Is Merged To Perfection

Volume 7 | Issue 3

March - April 2021

PUBLISHED BY

F & F Media and Publications

C-55, Okhla Industrial Area, Phase - 1, New Delhi-110 020

T: +91-11-40623356

CO-FOUNDERS

Syed Ahad Ahmed Amit Malhotra

TECHNICAL PANEL

Mahesh Arumugam Director

Meinhardt Façade Consultants

KR Suresh

Regional Director Axis Façade Consulting

EDITORIAL

Renu Rajaram renu@wfmmedia.com +91 9312864830

Shefali Bisht editorial@wfmmedia.com

DESIGN & CONCEPT BY Prashant Kumar

MARKETING & OPERATIONS

Kapil Girotra kapil@wfmmedia.com +91 9560925255

SUBSCRIPTION & CIRCULATION

Devagya Behl support@wfmmedia.com +91 9871151112

Mukesh Kumar mukesh@wfmmedia.com +91 9560088995

RNI: DELENG/2014/57870

10 Intelligent and Adaptive Façade Design

Ar. Gurpreet Shah, Principal Architect, Creative Group

14 Tribute to an Unsung Hero - The Window

Aparna Nair, Specification Manager - Middle East, Saint Gobain –SageGlass

18 Podium Designs

Ar. Harish Gupta, Principal Architect, Habitat-n-skins

21 Need for Skylights & Effective Fenestration

Ar. Milind Pai, Principal Architect, Milind Pai – Architects & Interior Designers

26 Glass for Fenestration & Cladding

Ar. Aayush Chaudhary, Founder, ACad Studio

30 Face to Face

Interview with Ar. Naresh V Narasimhan, Architect & Managing Partner, Venkataramanan Associates

44 Cover Story

Innovative Glass & Glazing Solutions for Façades & Fenestrations

68 Interview

Shailesh Ranjan, Head – Business Planning & Operations, Asahi India Glass Ltd (AIS)

71 Use the Right Kind of Glass & Glazing on Façades & Windows

Ar. Harish Gupta, Principal Architect, Habitat-n-skins

74 Interview

PV Varghese, CEO, Glazing and Metal Works Division, Sobha Ltd

78 Industry Speaks

Interview with A.R. Unnikrishnan, Managing Director - Glass Business, Saint-Gobain India Private Limited

94 Project Watch

Fundermax Corporate Office, Bengaluru

Cover image courtesy: Venkataramanan Associates (Project - Cummins Technical Centre Pune, India)

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

Architecture is shaping us in ways that we haven't even realised. During the testing times of pandemic, buildings play an outsized role in stemming the tide of a pandemic and in keeping sanity. Whether it is for providing ample, clean airflow to decrease the presence of contagion or for occupant comfort and wellbeing, architecture can and should do its part.

Over the years, architects have leveraged the use of exquisite building materials to create building masterpieces. However, no other material has come to match the elegance of glass as a building material.

Who wouldn’t like to sit next to those huge glass windows and work, which connect us to the outside world and play a great role in retaining mental health? If spaces can be purposefully designed, they can assist in driving away the negativity created by infectious diseases, including COVID-19.

The present situation will surely change the way we consider designing and building the spaces we need in the future. Architecture has been relegated as a passive backdrop, but if it is deployed as an active agent in the fight against the coronavirus pandemic, we can recapture trust over our public spaces and solve problems.

This issue of the WFM is largely on Glass and Glazing, a significant topic considering that most of the urban buildings are recoganised by their glass façades. The edition features many informative articles and interviews on its theme. Over 15 experts are giving their views in the cover story on cuttingedge glass and glazing technologies and materials.

Do read the interview with Ar. Naresh V Narasimhan, Principal Architect and Managing Partner, Venkataramanan Associates, a stalwart in the field of architecture, has designed many landmark buildings.

We had the opportunity to converse with one of the most prominent leaders of the glass industry – Mr. A.R. Unnikrishnan, Managing DirectorGlass Business, Saint-Gobain India, who explains his company’s products and services, the challenges faced by the industry during the pandemic, and the future of the glass industry in India.

Glass has a variety of properties and uses that present architects with a whole new range of possibilities. This can be seen in many of the projects featured in this edition as case studies.

I am sure this edition will be of your interest as a learning aid. Look forward to hearing your comments and suggestions.

Please do take care and stay away from negative thoughts…. There is always light at the end of the tunnel.

Renu Rajaram renu@wfmmedia.com

Nature by its foreface offers enormous resources to support the comfortable existence of the dwellers, therefore understanding the principles of nature, abiding by them, result and reflect in maintaining the equilibrium and balance between nature and human interventions. The philosophy of evolution justifies its cohesive adaptability on environmental grounds by subtly being interdependent, yet individually significant. Nature is self-healing and has the power to recover from any kind of natural destructions. It is the interference of mankind that caused an imbalance and irregularity in the rhythmic functioning of nature. Humans built shelters for their protection with the resources being drawn from nature. Until the point where 'dependence of nature for resources' became 'exploitation of nature for resources', the equilibrium was very well maintained between nature and mankind.

"Understanding the nature and choosing materials for buildings rapidly helps in the energy conservation and therefore reduces the carbon footprints and develops a netzero environment."

- AR. GURPREET SHAH

NATURE IS THE MOTHER OF ALL CREATION!

The shape of a camel exclaims to be a good example to understand the creation of nature based on the sustainable features and factors. A camel in a desert carries a huge amount of water for days together. The potential to retain water in a camel's body is designed by Mother Nature in such a way that it could sustain its life in the desert. Similarly, a cactus has a spherical shape with minor thorns. The spherical shape distorts the heat/ light radiations along its surface, for, the spherical shape gives a smooth surface to equally distribute heat over the

surface of the cactus and transfer it to the ground. Hence, the water is retained in the central nucleus of the cactus. With these simple examples from nature, it is evident that human interference is what causes discomfort in the systematic cyclic process of nature.

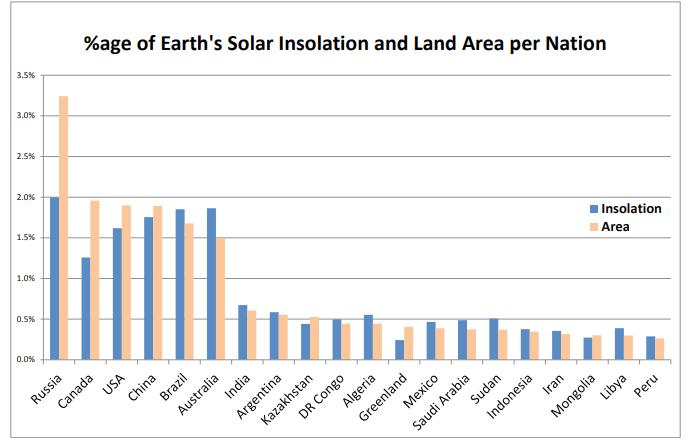

However, mega structures and massive infrastructures do not seize to flourish with the need to withstand the bloating population. Having stated this, it is bilaterally understood that there are no realistic limits to restrain the growth of buildings across the globe. Considering a building, the key function within the spaces directly reciprocates the design of the whole building, on both interiors as well as exterior faces. The materials, predominantly façade elements of a building plays a vital role in the level of comfort and sustainability of the building without harming the surroundings, causing degradation. India experiences an unequal and non-uniform distribution of resources. Subsequently, this has led to an unsustainable pattern of production and consumption of materials for construction. Therefore, in order to avoid excessive demand in a particular region for materials, again leading to the exploitation of nature, conventionally practiced and exercised methods of material application could be considered. India stands 7th in the world in the

list of countries receiving the maximum solar radiation annually. Hence, it is very essential to utilise the abundantly available solar energy without letting it cause discomfort through the passive heat gain. One of the key elements of saving solar energy is the solar panel. Mega structures of corporate set up that acquire a lot of electrical energy to function monotonously in all seasons, could involve the usage of solar panels on its façade.

Considering the aspects of aesthetic look of the building, usage of solar panels all over the surface of the façade undeniably affects the aesthetic beauty. Hence, combinations of materials like solar panels, glass and climber plants could be introduced to increase the probabilities in the scope of façade design to serve the aesthetic touch. Glass, vegetation and solar panels exhibit totally different properties,

hence, a glass could be used in the areas where only light/heat gain is necessary. In the areas where the building is subject to openings, plantations could be ornamented with, for, it enhances both the aesthetic beauty as well as the air quality. Similarly, in the areas of solar panels, the heat energy could be stored and used for mechanical cooling of the internal spaces. By proactively designing the façade of a building with such mixtures of materials, the dependence on nature is relatively brought down. It is a mainstream practice to caste the solar panels above the roof surface to absorb the solar energy. This nevertheless is a proven concept, but, replacing the element of solar panels on the rooftop with green plantations could reduce the heat gain in the building. The green roof helps in the passive cooling of the building by retaining atmospheric humidity. Therefore, the solar panels may subjectively be used as a cladding material along with the glass.

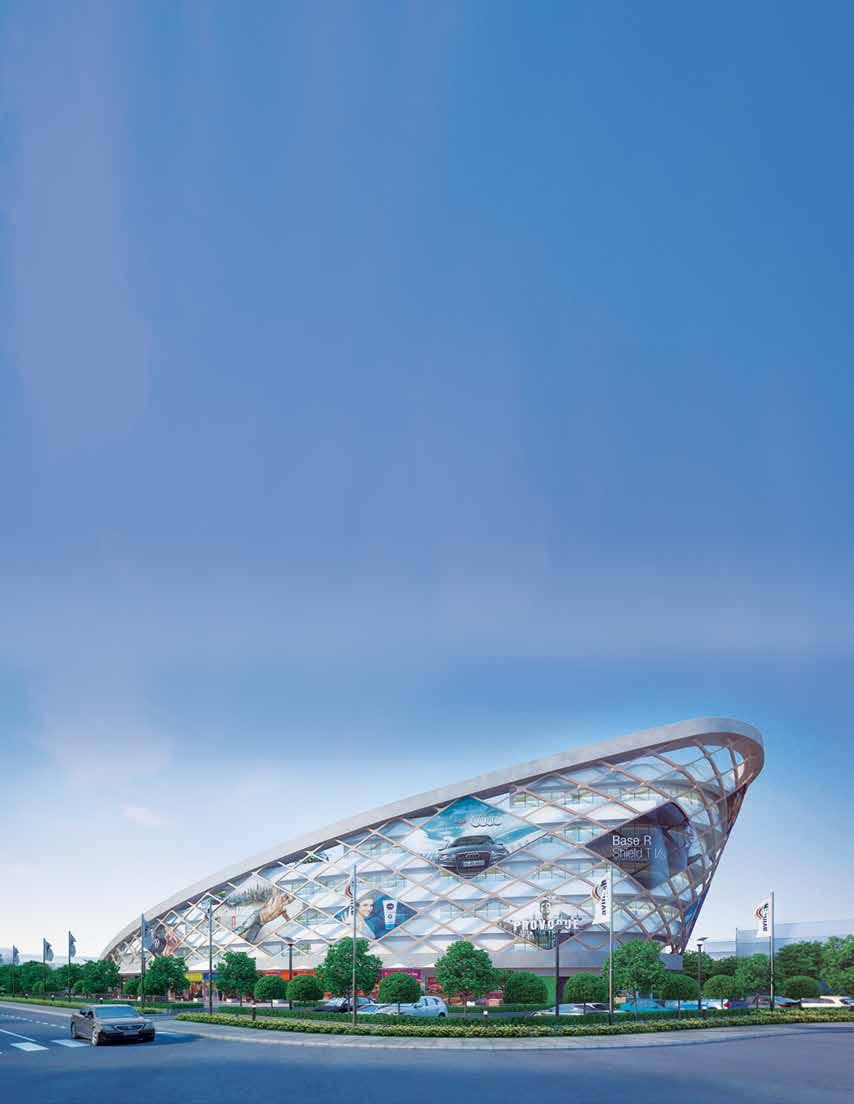

In the Avinash Times Square Mall, Naya Raipur, A permeable façade is designed which induces wind circulation and

Solar Panels that are used in the DPI Campus, Chennai (Creative Group, Delhi)

eventually helps in reducing the temperature inside the building. Direct sunlight infiltrates through the pergolas on the top, minimising the need for artificial lighting during daytime.

Such experimentations might give a holistic approach towards sustainability, green space development and reduces carbon footprints for the futuristic constructional activities. The future of habitation completely lies in the premeditated and experimental measures implemented now, so as to cater to the needs in a sustainable way. Design means, not only the internal spaces of a building but also the very façade that communicates with nature and the public equally.

I strongly believe in the philosophy of Prof. Charanjit Shah, "The built form should not be treated as a mass of brick and concrete but as a living organism. The built form needs to breathe and be embodied in the environment."-Says Ar. Gurpreet Shah.

AR. GURPREET SHAH Principal Architect, Creative Group

Ar. Gurpreet Shah, Principal Architect and Urban Designer, Creative Group has valuable insight into the allied aspects of airport design and development - construction and design of brownfield and greenfield airports, passenger facilitation technologies, safety & security, etc. The firm Creative Group is a distinguished architecture & design firm based in New Delhi. Established in 1970, the firm has 4+ decades of experience in delivering award-winning projects across commercial, institutional, aviation, mass-transit, housing and residential sectors. The firm has to its credit some of India's most modern airports in Chennai, Goa, Raipur, Vadodara, Shirdi, Agartala, Itanagar and Diu, intermodal Hubs for Gujarat Metro, India’s largest convention centers, master plans for net-zero townships, sustainable housing complexes, state-of-the-art shopping complexes, schools and education campuses among others.

In the most recent times, we have all at some point been left feeling boxed up thanks to the pandemic. While we can all choose to ride out of social isolation to “normalcy”, we cannot ignore the importance of how windows have played a crucial part during our lockdown. In most countries, people have sung to each other in unity, and to propel mental wellbeing –through windows. One particular social media group started a trend

called “View from my Window” which united millions of people from all over, where they shared pictures of their view- thereby enabling members to travel virtually. Well, let’s say – we were all “connected” through a glass pane. We chose windows as means of communication, be it by giving a standing ovation to front liners or singing out to each other in unison. Our doors may have been closed during the pandemic, but our windows were open.

All of this goes on to show how fenestration openings are not just a part of the design, but they are a part of occupant wellness. Windows work with you constantly to improve the indoor quality.

ENERGY-EFFICIENT OR HEALTHY BUILDINGS?

It is imperative for us on the construction platform to start thinking deeply about the materials being used. As the

world is moving towards smarter ways of functioning, we need to adapt our façade into the smarter as well. To think about it, our weather conditions outside are ever-changing. We pass through different seasons, and we need to move towards façade solutions that adapt to our external environment.

From the very beginning of architecture, man has sought to bring sunlight into his buildings and thus was born the window. For centuries, buildings have been designed in clever ways to maximise the admission of daylight, for that was the only source of light. However, in the last century or so, with the advent of electric light, building design has changed to create deeper floor plates and interiors solely lit with electric light. As a result, in the last century, access to daylight has declined in our built environment.

In recent years, we have come to notice that many of the green-certified buildings are actually not any more efficient. This has led to the initiation of energy performance verification requirements of the as-built designs. In parallel, the push for increased energy performance in buildings has also given rise to significant debate about the role of windows, and more importantly, the amount of glass that should be

used (Wilson 2010; Shuttleworth 2008). Windows are often seen as the weak link in a building because of their lower insulation performance and higher solar heat gain compared to a solid wall.

The window-to-wall ratio debate within the green codes especially is leading to a dichotomy between providing acceptable window area for daylighting and views and achieving energy-efficiency

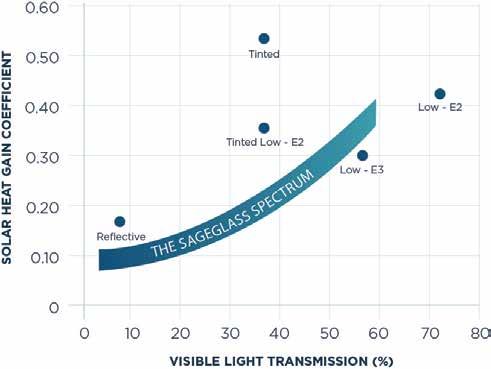

targets, all while providing occupant visual and thermal comfort. This is a major challenge for “green building” design as is pictorially represented in Figure 1.

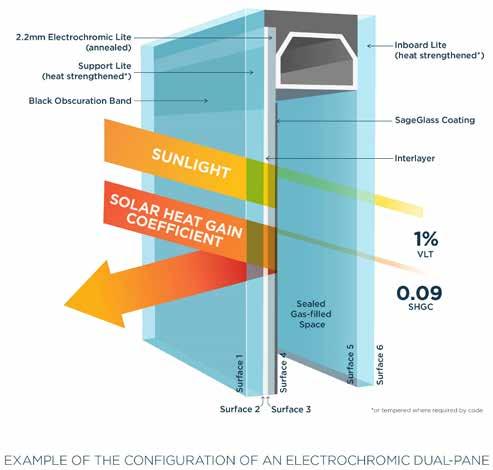

We say that the world is at our fingertips! Indeed, yes and now with our electrochromic glazing solution, which can, at the touch of a button, with a swipe in a mobile application, or with a higherlevel command from a building automation system, modulate its solar heat gain coefficient (SHGC) and visible light transmission over a wide range, stopping at points in between (e.g., a range of 60% to 1% in visible light transmission and 0.41 to 0.09 in SHGC), can provide an elegant solution to this problem (see Figure 2). EC glass saves energy in all climate

zones by providing passive solar gains during heating seasons, minimising cooling loads during cooling seasons and providing maximum daylight harvesting potential, replacing the use of electric lights with natural light in all seasons. Additionally, because products today can achieve transmissions of 1%T or less, they can control glare without using blinds, thus preserving the view and connection with the outside in contrast to mechanical alternatives, which block or mar the view. Studies have shown that 1%T is required to be able to control the glare (LBNL 2006; Kelly et al. 2013).

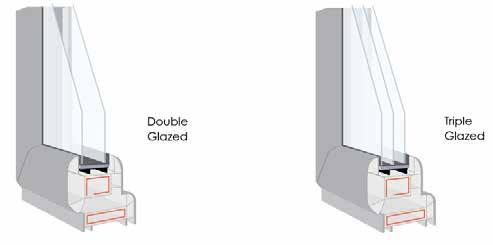

EC coatings can be cleanly integrated into a double or triple glazing unit just like traditional

coatings (see Figure 3), and different exterior aesthetics can be achieved by adding tints or another coating to the exterior glass pane. The ability to modulate the sun’s light and heat provides the designer with a controllable heat and light valve for the building; the amount of light and heat coming into space is tuned depending on the exterior environmental conditions and the needs of the occupants. By dynamically controlling the light and heat flow, significantly more energy savings can be captured than when using a static façade solution as well as providing enhanced occupant comfort whilst maintaining exterior views. As a result, the use of EC glass provides an architect with the

ability to design with more glass, thus providing the needed access to daylight and views without energy or comfort penalty.

Because of the ability to dynamically control the heat flows into a building, EC glass can provide additional architectural freedom because more glass can be used, especially on challenging façades, without energy penalty. For example, in a recently commissioned villa in Dubai hills, United Arab Emirates, the architect was able to add a grand window element to the entrance area, without compromising on the energy efficiency criteria. Mr. Divya Golash from Al Shandagha Architects has felt that dynamic glazing has provided the required efficiency as well as keeping the design intact - “The most important benefit is that the glazing is dynamic, so we can switch it to the tint level that we want to achieve. Our external conditions are not static, the weather and sun change dynamically, so why not have a dynamic glazing solution? We need to have more adaptable and sustainable solutions such as SageGlass in the market. Also since we have the glazing at a height, we had chosen glazing for the area, for ample natural light to come in, without the heat entering into space. So this would save a lot of energy and HVAC consumption could be lowered”.

The impact of being able to design with more glass without energy or comfort penalty should not be underestimated. In the Middle East, we are often faced with the challenge of having

A recently commissioned villa in Dubai hills, United Arab Emirates, the architect was able to add dynamic glazing to window element, without compromising on the energy efficiency criteria

buildings that have a high WWR, but then because of the intensive heat transfer, the HVAC consumption is skyrocketing. Glass is a key architectural design tool and provides significant design flexibility for architects. Sustainable design standards and codes recognise the need to use glass to provide occupants with access to daylight and views, because of the positive impact that it has on people’s health and well-being, yet doing so often requires compromising energy performance and at times occupant thermal and visual comfort especially with the weather condition around. Dynamic glazing can relieve the constraints enforced on designers by static building envelopes when balancing architectural design with occupant comfort and energy efficiency. The improvements

in EC glass aesthetics and functionality described herein clearly demonstrate that EC glass can provide an elegant façade solution that achieves both the competing goals of strong energy performance and access to daylight and views, without compromising occupant thermal and visual comfort or the aesthetics of the façade design. The ability to maintain architectural design freedom while still providing an energy-efficient AND comfortable building is invaluable. This value will continue to increase as energyefficiency targets rise and as the importance of creating peoplefriendly workspaces is further appreciated.

(Research credits : Ryan Park and Maure Creager)

APARNA NAIR

Specification ManagerMiddle East, Saint Gobain – SageGlass

Aparna Nair is an architect, working as specification manager for SageGlass by Saint Gobain, handling one of the most innovative glazing solutions for the Middle East markets. She is a firm believer of the fact that using the right kind of glass is a key contributor in energy savings. She along with the team together strives to eliminate the need for blinds and other shading solutions thereby encouraging uninterrupted views. (aparna. nair@saint-gobain.com)

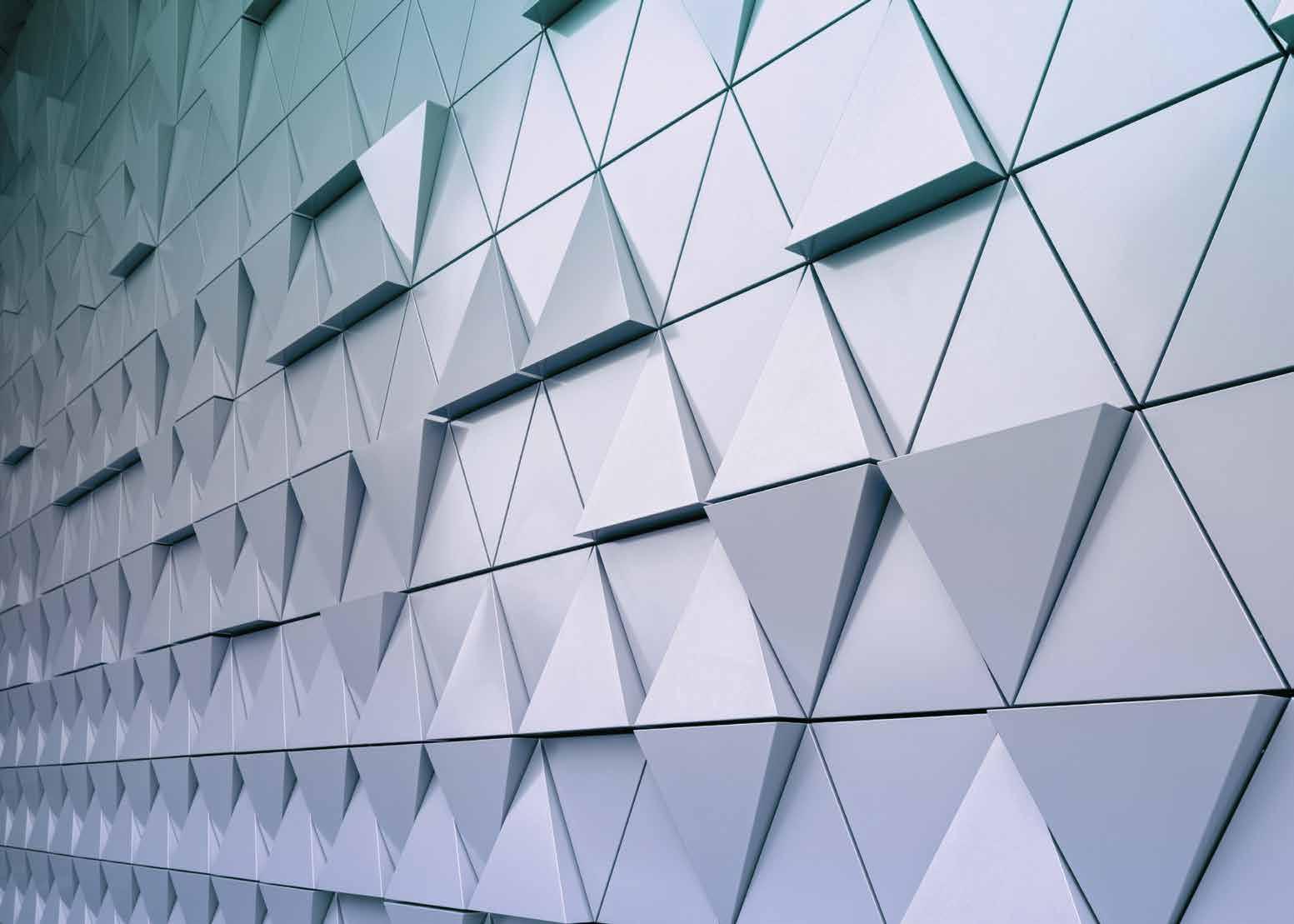

High-rise building façades have their own set of challenges of wind and execution difficulties and that narrows down the options for what you can and cannot do. But at lower heights there is immense scope to be innovative and let the ideas go wild.

Some very interesting technologies and materials are used to decorate podiums with very creative designs. The architecture is usually treated differently for the tower which is visible from a far distance and differently for the podium which relates more with the street views on which

Some very interesting technologies and materials are used to decorate podiums

they stand and blended to form a homogenous massing. The podium is almost like a personnel identity to the building and that is primarily the reason most architects do not replicate a podium façade design. What they want is to be unique in every way and this paves the ground for innovation in façade with shapes, sizes, treatment, material choices, dynamism of design, technology, etc.

One of the most popular design trends that can be seen in building designs today is how parking podiums are designed. Podiums are generally 3 to 8 or 10 floors which mainly house the services, recreation, entrance lobbies and car park. The buildings in many such cases start after the podium which usually has a very different architecture. Since the human eye level experiences the podiums as the first introduction to the building, the designers give a lot of importance to the lower levels of tall buildings. These zones will usually have partial glazing for the habitable areas and the entrance lobbies and the rest of the area are designed as naturally ventilated in conformity with planning requirements for parking areas.

The correct selection of glass, façade materials and system is primary to a good façade which must strike the right balance between aesthetics and cost. What leads to such a façade that not only is striking, innovative, long-lasting and cost optimised? Today the façade industry is moving so fast in innovation that it is very difficult even for many leading architects

to keep track. Any designer who designs a building must be armed with the knowledge of the façade, materials, fabrication method and erecting method before integrating it in their project. Often it’s easier said than done.

There is a very high amount of innovation that goes into such façade designs. Designers need to explore the length and breadth of the globe to innovate and source materials and fabrication technologies. The design needs to be treated like a sculpture and

clients must come to terms of understanding that such types of works are dependent on a huge amount of experimentation and innovation as these are not standardised systems. Often the budgeting team makes the mistake in the allocation of funds for these areas and compromises are not always in the best interest of the project. One needs to keep an open mind for innovation to happen and allow the designers some free hand to create a landmark that will be cherished for a long time.

AR. HARISH GUPTA Principal Architect, Habitat-n-skins

An Architect, Civil engineer with an MBA in marketing management, Ar. Harish Gupta has journeyed for nearly three decades in the construction industry. Flagging off his career with Pheroze Kudianwala in 1990s, he moved on to India Bulls, Glasswall and others, designing and project managing many landmark buildings. With nearly 15 years as a consulting entrepreneur he now heads his company Habitat-n-Skins offering services under architecture, various verticals of façade design, town planning, project management and audits. His company strategy is to ensure clients give repeated opportunity to work and that is the single motto that drives his team and him to ensure quality projects delivered and client satisfaction achieved.

Buildings are the largest users of energy, and are also our greatest opportunity for energy conservation and

protection of the environment.

In the past few years, the rapidly growing energy needs have raised a global concern over continued depletion of energy resources

followed by their negative impact on the environment. The major objectives for contemporary façade design are the strategies and technologies that allow us

Skylights are light transmitting elements filling building envelope openings which form all or a portion of the roof of a building's space for daylighting purposes. Skylight types include, roof windows, unit skylights, tubular daylighting devices (TDDs), sloped glazing, and custom skylights. Uses include:

• Daylighting elements used to allow direct and/ or indirect sunlight via top-lighting.

• Ventilating the room with an opening skylight allows the cooler air to be drawn indoors and circulate, while warmer air rises and escapes.

• Sustainable building — passive solar heating, and with operable units; ventilation for passive cooling and fresh air exchange. Hence, this increases the natural light and a variety of physical and psychological benefits. Skylights help to not only bring new life to a room but also improve our health and happiness as well.

to maintain our satisfaction with the interior environment while consuming fewer of the resources.

Ventilation and daylight can be provided via windows or glazed doors, as well as via skylights and other forms of top lighting. These glazed openings are collectively referred to as "fenestration." While fenestration refers to the design, construction, or presence of openings in a building, they are extremely important and can also tip the balance between a high-performance and lowperformance building.

The style, placement, construction and materials used are all important features in giving a building its character, environmental interaction and climatic optimisation. This impacts the buildings' energy efficiency by affecting cooling loads, heating loads and lighting loads. Hence, the importance of these aspects of building construction cannot be underestimated. Therefore, the field of fenestration has seen a rapid development in recent years and its importance is widely understood by builders, architects and also the manufacturing industry. While, skylights can make a major

contribution to energy efficiency, ventilation and comfort, this system can be installed in both existing and new homes. As per architects, skylights are an excellent source of natural light: they can admit more than three times as much light as a vertical window of the same size, distributing it evenly, saving energy and improving the visual comfort levels.

Talking about ventilation, skylights can also uplift the ambiance of internal spaces that might otherwise require supplementary artificial ventilation, especially in situations like windowless rooms. They allow additional flexibility in architectural design. Even under overcast conditions, the use of skylights can ensure spaces which are predominantly lit by natural light, with little or no supplementary artificial lighting required.

Hence, along with ventilation, the visual comfort also is strongly affected by the skylight location, shading and glazing materials. But, well-designed skylights can give a proper ventilation and visual delight too. Also, there are types of skylights available for this purpose which is why it’s important to note that ‘opening skylights’ are mechanical and able to be opened and closed, whereas ‘ventilated skylights’ are passive – they are fixed in a ventilated position. Both are great for ventilating the space. Unlike fixed skylights, opening skylights gives one the ability to

release the hot air that gets trapped inside in the summer. Ventilating the room with an opening skylight allows the cooler air to be drawn indoors and circulate, while warmer air rises and escapes.

Particular attention is given to daylighting while designing a building when the aim is to maximise visual comfort or to

reduce energy use.

Basically, this is the practice of placing windows, skylights, and reflective surfaces in such a way that the sunlight (direct or indirect) can provide effective internal lighting. In tropical environments, however, the placement could be done in a way to avoid the harsh direct sunlight glaring into the interior environments.

Daylighting forms the

cornerstone of sustainable, highperformance design for skylights. The availability of daylight is dictated by the conditions of the sky at a given point in time; which is mostly controlled by the density of cloud cover. Ar. Milind Pai states, “When conducting daylighting analysis, it is important to design for a range of conditions. This means making sure to analyse a range of sky conditions, not just a bright and clear sky. It's unlikely that these conditions will be true for every hour of every day. A good analysis will consider bright and clear sky as well as an overcast sky”. Hence, mainly the effective delivery of daylight depends on the following factors:

• Sun altitude

• Relative occurrence of overcast vs sunny weather

• Season changing

• Levels of air pollution and haze

• Roof aspects and designs

• Shading from trees or neighbouring structures

Strategic use of daylight can reduce the energy demand. Daylight also improves people's comfort and productivity.

A skylight can admit more than three times as much light as a

vertical window of the same size and one can reduce energy costs by installing energyefficient products.

In addition, daylight offers opportunities for natural ventilation and, if properly integrated with the electric lighting system, it can provide tremendous energy savings. These advantages of daylighting translate to higher performance in places like institutes, recreational centres, etc. In commercial buildings, electric lighting accounts for 35-50 per cent of total electrical energy consumption. Highperformance fenestration features include double glazing, low-emissivity coatings, and blue/green tints. These have become a very important means of energy conservation in modern construction to reduce both thermal losses and solar gains. It's a good idea to understand the systems and know what energy performance ratings we need for the windows, based on the climatic conditions and designs.

Skylights are important elements in passive solar home designs, which use solar energy at the site to provide heating, cooling, and lighting for a house. Passive solar design strategies vary by the building location and regional climate, but the basic window opening guidelines remain the same. Selection, orientation and glass size contribute to maximise solar heat gain in the winter and minimise it in the summer.

‘Even when we can’t use daylighting, good lighting design can reduce energy use significantly’.

As a final bonus, when we have skylights, we will have unexpected masterpieces throughout the home or office. Artistic shadows will cast themselves on the walls, and overcast days will accent different areas when the sun is out and the sky is clear. Cascading lights will touch and calm the surroundings of the space and will relax one’s living environment in that space and create a Zen-like feel.

MILIND PAI

Principal Architect, Milind Pai – Architects & Interior Designers

Milind Pai established the firm Milind Pai – Architects & Interior Designers in 1988, after graduating from Sir J.J. College. The core purpose since the inception of this firm has been to ‘inspire creativity’ that turns dreams to reality. Since then the design firm has evolved into a dedicated team of professionals committed to designing excellence and offering comprehensive service in the field of architecture, interior designing and project consultation. Today, they are a multi-specialty firm undertaking projects in commercial, residential, institutional, health and hospitality interiors. The team is driven by a passion for excellence pursuing them to improve and innovate in all areas and every stage of design development while staying abreast with the latest in technology to ensure consistent high-quality work. In this firm, the architects and the interior designers work in close collaboration with other experts, including engineers, graphic designers, artists, sculptures, landscape designers, lighting and acoustic specialists. Besides Mumbai, they have executed projects in almost 30 Indian cities and 3 international cities of Dubai, Muscat and Singapore.

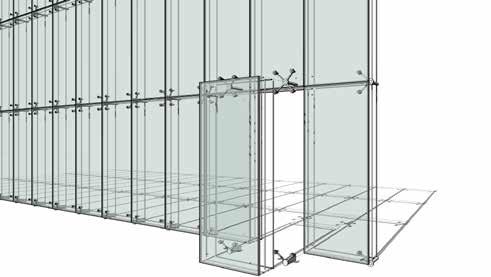

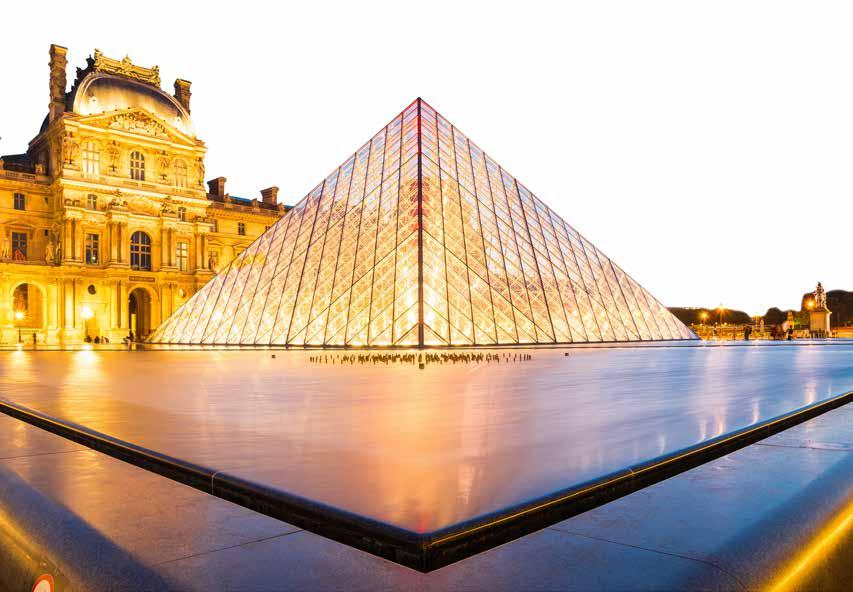

THE SYSTEM:

• Patented curtain wall system

• Long spans

• Elimination of horizontals

• High transparency

• Complex geometries

• Versatility

• Superior thermal performance

• Jumbo glass sizes

• System material options: aluminum, glass, & timber

Glass is a versatile material that has been used in architecture for a long time. It is due to its transparency that glass is used in spaces to create partitions without barriers. It can connect the places without the use of concrete and bricks and also let light pass through. This helps the colours and the design to show, so the use of artificial electric energy is used less during the day, and the sunlight or moonlight carries into space.

Out of all the materials, glass is already used in most of our homes. The use of glass in home decor is rarely thought of as decorative and is thought to be more utilitarian.

Glass can come in several forms from the glazing, to countertops and decorative walls or even cladding and fenestration.

Glass fenestration refers to the installation of glass windows and doors and also use glass to make the building energy efficient. The use of glass starts with understanding the building requirements and selecting the optimum type of glass and its processing. With the logical and correct selection, glass can be a very useful and friendly material by providing optimum daylight, energy efficiency, sound insulation, comfort, and wellness, while being

safe from injuries to human beings. An incorrect selection can result in just the opposite by being a source of excessive heat gain or loss, glare, discomfort, and risk of injury from the glass.

Thermal insulation: If the priority of the building design is to insulate the interiors, then the usage of solar control glass products is recommended. The solar control glasses help in solar heat gain and offer high levels of natural light to provide comfortable and pleasant environments to live and work in. These types of glasses are not necessarily coloured or textured, though these are available to suit the aesthetics of the building.

Sound proofing: Laminated glass with soundproofing qualities can be used for fenestration. It can help to keep unwanted noise and vibrations at bay. This is also known as acoustic insulation. Another technique to achieve acoustic insulation is with doubleglazed glass in which vacuumsealed inner spaces and some gases affect sound insulation and provide acoustic stability.

Safety and security: Glass is also one of the safe materials to be used from a security point of view. Toughened glass or fire-rated glass provides a great degree of protection. Toughened glass is a type of safety glass that should give you an idea that it’s the safest choice for residential as well as commercial buildings. On a rare occasion of breakage due to some harsh impact, toughened glass breaks into harmless circular chunks instead of breaking into sharp jagged shards. This reduces the risk of incurring injuries,

thereby making the toughened glass less dangerous than ordinary glass. Moreover, these circular chunks can easily be swept by a broom and then thrown into the garbage without the fear of any sharp shard causing injuries.

Glass fenestration is aesthetically pleasing: Glass when used as a facade material, makes the building look more beautiful. It not only allows natural light inside the building but also ensures comfort while providing more design flexibility to architects and interior designers.

Glass cladding in decorative or coloured glass is a practical and cost-effective alternative to tiling, painting, and other forms of decoration. Glass cladding can provide a striking, easily maintainable wall surface that is ideal in a wide range of commercial interiors and exteriors. Enameled glass is used in most glass claddings especially in hotels, big commercial buildings, and hotels.

There are two kinds of glass cladding popularly available, these are:

Glass cladding in the decorative or colored glass is a practical and costeffective alternative to tiling, painting, and other forms of decoration

Curtain walling: Typically curtain walling systems are comprised of a lightweight aluminium frame onto which glazed or opaque infill panels can be fixed. This framed wall prevents any weather from penetrating through to the building.

Rainscreen cladding: As the name suggests, this kind of glass cladding prevents significant amounts of water from penetrating the wall construction. Rainscreen cladding is part of double-wall construction that can be used to form the exterior walls of buildings. Open joints between the panels allow a circulating air layer to be formed between the hung panels and the thermal insulation, which is mounted directly onto a building structure.

The primary difference between the two types of glass cladding is that curtain walling is usually the whole building envelope, while rainscreen cladding is just the outer protective layer of the envelope.

To conclude, glass fenestration and cladding is a popular choice for modern architectural designs. It is sustainable, aesthetically pleasing, and weatherproof. The choice of fenestration and cladding is an ultimate decision based on the purpose and the function of the building. Not only for external use, but glass is also a great choice for usage in the interiors of buildings. The versatile material is an excellent choice for all kinds of fenestrations, claddings, doors, windows and skylights.

AR. AAYUSH CHAUDHARY Founder, ACad Studio

Aayush Chaudhary is the cofounder and principal architect of ACad Studio, Gurugram. Founded in 2019, ACad Studio is an architectural firm that provides the best solutions in all formats. A graduate in architecture from Sushant School of Art and Architecture and a post-graduate in construction management from the City University of London, Chaudhary has a rich career as an Architect for over 7 years. He has handled prestigious architectural projects in London for various clients and is now practicing in India with an aim to introduce global best practices in architecture. His extensive list of clients includes OYO Hotels, Carrier Midea India, etc. ACad Studio comprises young, passionate and self-motivated architects, interior designers, contractors, site/project managers and developers.

“Innovation has Always been Fundamental to Our Practice”

V NARASIMHAN Architect & Managing Partner, Venkataramanan

Naresh V Narasimhan is a practitioner and leader with over 35 years of experience in architecture and urban design. He is best known for his association with Venkataramanan Associates - an awardwinning architecture firm based out of Bengaluru, which saw a meteoric rise under his leadership.

In addition to his architectural practice, his contribution to urban development as an urbanist, activist and creative entrepreneur has been far-reaching. As co-founder of Bangalore Agenda Task Force (BATF), co-founder of MOD Institute - an international collective of urban designers, researchers and curators and founder of Numa Bengaluru, a co-working space and business accelerator, Naresh has fuelled a variety of progressive causes in the city. He also regularly advises government agencies on infrastructure development.

Naresh studied architecture at Manipal Institute of Technology, followed by further education at Harvard Institute for International Development. His interests range from studying the startup ecosystem, open data and institutional development to cinema, art and popular culture. Naresh is also a prolific speaker who has been invited to lecture at several national and international events.

In a candid interview with WFM Media, Naresh talks about his practice and its growth, on his ongoing projects and a few of his milestone achievements, selecting apt materials for façades, sustainable and energy-efficient elements of façade design, and much more.

Please tell us about your practice and its growth over the years?

Over the five decades since its founding, Venkataramanan Associates (VA) has built a formidable and growing knowledge base in architectural design and design-build processes. P.K. Venkataramanan set a strong foundation for much of the work that the firm is now so well known for, such as the Raman Research Institute (RRI), multiple buildings at the Indian Institute of Science (IISc), as well as several office buildings and housing projects. Since then, the firm has diversified into multiple sectors and expanded its presence in India and abroad. VA is now responsible for a wide range of work spanning Research and Development facilities, specialised manufacturing, IT business parks, public and institutional buildings, corporate offices and Real-estate developments.

All of VA’s work is based on a deep understanding of the transformative impact of architecture. Our ability to design high-quality buildings is fuelled by an earnest appreciation of visionary ideas. Innovation has always been fundamental to our practice –exploring better methods of space making and the usage of the latest materials and technologies. Our architects carry out in-depth analyses of site, feasibility studies, sustainability studies, and we use several new-age technologies such as augmented and virtual reality to create a spatial experience. This sets apart VA’s approach to design. Architects, especially now, have a responsibility to design buildings that respond to the emerging global concerns regarding the use of energy and resources.

Tell us about a few of your ongoing projects?

We have a wide range of ongoing projects, each catering to a different scale, complexity, expertise, and

sector. Some of the notable ones include – HPCL Campus, Presidency School, IISc IDR Campus, Prestige

et al.

There are many glazing materials available in the market. How do you choose the apt one for your project? What are the criteria?

Glazed façades are known to be one of the most glamorous components of buildings today. Nowadays, improvements in glazing technology have made it possible to render different types of glazing for any specific surface, but in doing so the project might end up being more complicated than necessary. Therefore, it is essential to assess the realistic needs of the façade - its climatic suitability, aesthetic appeal, load on the built form and energy efficiency.

How would the façade design and other elements of the façade help the building to be energy efficient, at the same time provide a better interior environment?

The new trend in façade design is leaning towards reviving vernacular materials in modern form while harmoniously blending them with composite materials. Architects now understand the significance

of sourcing relevant materials found within a certain radius to be vernacular and hence truly

sustainable. This outlook coupled with sustainable construction processes weaves in sustainability at the early onset of a project.

One of VA’s award-winning projects, Lupin R&D Centre uses materials that are locally available, eco-friendly, and ensures that nature is preserved and unharmed. High energy-efficient glass is used to maximise daylight and minimise heat gain. In addition to this, the façade design maximises on the locally available natural stone with low embodied energy and recycled high-pressure laminate as cladding material.

What are your views on future façades technologies and materials?

In the last century, all the major experiments in building envelopes were focused on aesthetics and environmental protection. Future evolution will shift from façades being just an envelope to them participating in structural functions as well.

Key attributes of the façade of Lupin R&D Centre

THERMAL COMFORT: Being a laboratory building, the interiors require high lux levels (minimum 500 lux), without compromising on the views to the outside. To comply with the requirements, the façade utilises large glass surfaces to harvest maximum daylight and provide unhindered views to the exterior. High-performance glass [PPG Solarban (6 mm Clear REF + 12 Air Gap + 6 mm Clear)] was selected for the façade, which provided a high VLT of 70 and a low u value of 1.5 W/sqm-k. In

Additional elements such as deep steel Pergolas, stainless steel mesh has been aesthetically incorporated as the second skins, to reduce thermal gain

addition, heavy shading with deep pergolas and SS mesh second skin are added. Vertical fin elements

The façade utilises large glass surfaces to harvest maximum daylight

clad in HPL Trespa further cut off incident sun rays.

ACOUSTICS: To ensure recommended indoor sound levels (35db as desired by the client), the design combines 24mm IGU and a well-designed aluminium profile with an EPDM gasket sealer.

WIND RESISTANCE: Entire façade system is designed for a wind load of 150 kpa.

FIRE SAFETY: Fire stop joint spray is used to prevent the spreading of fire. Also, the material used meets LEED requirement for indoor air quality credits.

• The building façade uses extensive amounts of glass to harvest maximum daylight. Additional elements such as deep steel Pergolas,

Project: Lupin R&D Centre

Location: Pune

Architect: Venkataramanan Associates (VA)

Land area: 19 Acres

Built-up area: 330,000 sft.

Project completion: 2016

stainless steel mesh has been aesthetically incorporated as the second skins, to reduce thermal gain.

• Vertical fin elements downsize the low-angle sun and prevent glare.

• Reinforced concrete form finish wall on the front façade obstructs view into the service areas.

The Green Leaves project for BASF required redeveloping an existing building into a world-class research facility. The new innovation campus is a collaborative space

housing scientific and technical laboratories, modern offices, a full-scale auditorium, a cafeteria, and other employee amenities. The structure follows an open plan, offering interactive spaces

to encourage communication and collaboration amongst the users. The interior spaces follow a contemporary style with minimal lines and burst of colour, defining the various spaces within the

The design on BASF Green Leves project is based on a deep understanding of the transformative impact of architecture - exploring better methods of space making and the usage of the latest materials and technologies

building envelope. A glassroofed central atrium lends insular spaces on every level with animated balconies looking inwards. Designed to achieve LEED gold rating, the building incorporates several sustainable

features such as a secondary façade to minimise solar heat gain, energy-efficient LED lights, rainwater harvesting, a reflective roof with photovoltaic panels, and a windmill to generate renewable energy.

Project: BASF Green

Leaves Project

Location: Mumbai

Client: BASF

Architect: Venkataramanan Associates

Completion date: 2014

Completion date: March 2017

As a global leader in engines, Cummins demanded the architecture of its new research facility to be a carrier of the brand’s high standard of excellence

Cummins Technical Centre India is planned on a 16acre site, which is part of a larger 67-acre campus owned by

Cummins in Dahanukar Colony, Pune. The existing site included a research & development building complete with test cells,

laboratories, and offices. The design brief stressed demolishing all but the test cells.

As a global leader in engines,

The external façade of the building reflects Cummins’ vision and follows a futuristic approach, pertinent to the high-tech environment

Cummins demanded the architecture of its new research facility to be a carrier of the brand’s high standard of excellence. Keeping with the requirement of retaining the test cells, the entire facility was planned as one cohesive unit encouraging movement across departments. The test cells were thus designed at the core of the building, while offices and laboratories surround them.

The external façade of the building reflects Cummins’ vision and follows a futuristic approach, pertinent to the high-tech environment. Featuring a 120,000 square-foot VS1 façade of glass and terracotta, the geometrically complex wall is the largest faceted wall in the world. Concrete columns form a structure of slanting surfaces on the façade,

QUICK FACTS:

Project: Cummins Technical Centre - India (CTCI)

Location: Dahanukar Colony, Pune

Architect: Venkataramanan Associates (VA)

Land area: 16 Acres

Built-up area: 740,000 Sq ft / 68,687 Sq m

Commencement of the project: 2011

Completion of the project: 2018

with grey tile cladding on the support and strips of glazing in between.

The main reception area is expansive enough to accommodate the movement of up to 2000 people at a time. An information desk, an experience center for visitors, rooms for vendor meetings, visitors’ lounge areas, a small pantry, and restrooms are some of the facilities provided in this area. A canopy, made of aluminium composite panels and clay tile cladding, covers the main reception area. The main reception and the two southern receptions to the facility have air-locked entrances freeing the environment of dust and sound.

Green spines run across the building, adding a touch of natural freshness, and form an integral element of the building. These spines are landscaped at the ground floor level and pedestrian walkways are planned around them. Skylights further grace this atrium and the rest of the office with ample natural light. The duality of a dynamic exterior façade coupled with minimalistic interiors is reflective of Cummins’ corporate social image and value.

Glass has made its way as a wonder material and deep inroads in the building industry. It has revamped itself hugely and the industry has broken the conventional fears and norms of breakage, safety, security and several other factors and

addressed them head-on. The technological innovations in glass and glazing have helped and rewarded the industry with substantial growth in volumes and adding diversity and versatility in usage.

Façade glazing contributes to the aesthetics of a building and

reduces the visual and physical weight of a building. It presents design opportunities to architects, where they can explore different geometric configurations and shapes of glass with customised module design and its assembly. Architects are still exploring its creative applications.

DWAYNE SLOAN

Director Principal Engineering, Built Environment, UL

RAJAN GOVIND Director, BES Consultants

NILESH GANDHI

Principal Architect, Meta Design

The building façade refers to the outside or the external faces of a building, relating to the origins of the word meaning “facia” or “face”. Over time, the term façade has grown to also refer to the external layers of the complete building structure as well. Window glazing, or more commonly referred to as window glass, used in façade construction are a key element of the building envelope, says Dwayne Sloan, Director Principal Engineering, Built Environment, UL. Window glazing is an essential material used largely to encapsulate the perimeter of the building.

A window can also be called the eye of the building. Window or glazing refers to similar functions, but generally differentiated based on their scale or sizes, says Rajan Govind, Director, BES Consultants. The window serves several functions and protects occupants. Furthermore, the window gives characters and aesthetics to the building. Hence it is an important component of the building.

Nilesh Gandhi, Principal Architect, Meta Design too agrees that windows are super critically important as the eyes of the structure since they are the ones through which the building relates and interacts with the external environment. He adds: “direction,

specifications, wall to window ratios popularly called WWR, define natural light, heat, ventilation, insulation that are lifelines for building efficiency”.

Ar. Gaurav Goel, Founder & Principal, Studio Parametric Curiosity adds that window/façade glazing provides a weather shield to the interiors of a built structure, also protection from the exterior environment elements like temperature, sound and wind control. Glazing is a part of a wall or window, made of glass. Strong, durable and highquality glazing offers many benefits to commercial properties, points

Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates: “Homes window glazing is more energy-efficient, saving you money on heating bills. Good quality windows will also make it easier to regulate the overall temperature of your building,” he adds.

According to Jatin Shah, Managing Director, Technical Due Diligence (India) at Colliers, Glass, the primary element, is selected based on various functional and aesthetic criteria to meet the overall engineering requirements of a project. “Right from the project concept stage, a suitable methodology should be laid down by stakeholders to understand implication and influence of available façade options. Effect of window type/glazing system design is not only driven based on codal requirements or cost of the system, but also includes investigation based on parameters like safety, lighting, acoustic, thermal, fire, durability, life cycle, maintenance and buildability with the right detailing,” adds Shah.

The glazing and its framing must be functional and possess performance attributes including, but not limited to visibility, aesthetics, physical security, thermal, structural, UV protection,

fire protection, ease of installation, resistance to air infiltration and resistance to water penetration, adds Sloan.

Right glass helps to achieve a superior indoor environment and reduced HVAC loads, observes Rajiv Balaggan, Sales Head - Architectural Glass India, Pilkington Glass India Pvt. Ltd. He lists a few important factors that need to be kept in mind while selecting the right/perfect glass:

• Geographical location & type of structure

• Correct glass/glass combination unit

• Interior & exterior appearance

• Energy efficiency

• Acoustic property Façades and windows play a great responsibility to be efficient by choosing the right kind of glass. First get the basics right that the building is designed for the climate and context, advises Ar. Balaji Gunasekaran, Associate Director, Katerra Design. Next, the building is oriented well to achieve the passive

Sharing the example project - Solus Office at Bengaluru, a mid-range commercial office project of about 60,000 Sq ft and located off JC road, Ar. Balaji Gunasekaran, Associate Director, Katerra Design says that this project was challenged initially to go for single glazed units as a cost factor. Then the clients were explained about the importance of energy savings by using double glazed units - reduction of OPEX cost with all design excel sheets supporting the data. “Since the client was practical, and we did a mock-up for smaller furnished office space with different glass units of SGU & DGU to analyse the virtual benefits. Thus the client understood the importance of energy savings with the live reading and energy savings and finally gone with Low E glazing in façades”, explains Balaji on selecting the right façade.

design. Glass must be sensibly chosen on following major factors to achieve maximising daylight, negating solar ingress, minimising glare, enabling ventilation, points out Balaji.

There have been numerous innovations since glass was understood as a building material. Current innovations have improved the security performance of brittle glass as a material. Based on different chemical treatments and manufacturing processes, different security glasses are available, says Ar. Goel.

Safety glass is considered to provide safety in the event of breakages, and less prone to inflicting injury when it breaks, notes Govind and Gunasekaran. It also includes glass that is manufactured for more strength and fire resistance. Safety glasses are mainly used with two layers of glasses sandwiched with an interlayer. In some cases, monolithic tempered glasses (thicker glass panes) shall be used for safety, however monolithic tempered do not provide adequate safety as compared with laminated glass units, hence they should be used with care, adds Govind.

Tempered glass (also known as toughened glass) is made by heating annealed glass uniformly and then cooled rapidly by blowing air uniformly onto both surfaces at the same time by a process known as air quenching. This process alters its brittle breakage pattern. These glasses, when broken fall into smaller pieces rather than big pieces as in the basic float glass which is dangerous to the building user. Tempered glass is about four times stronger than a lite of annealed glass. Tempered glass can resist the forces caused by heat, wind and impact. While breaking, it shatters into small cubes, reducing the likelihood of serious injury on impact. Therefore, it qualifies as a safety glazing material. The tempered glass helps reduce the possibility of

thermal/mechanical breakage. It has been mandated to use tempered glass worldwide.

Tempered glass is pre-stressing glazing to ensure that the glass has certain physical properties by prestressing the glass, says Matt Schumann, Industry Manager, Building Materials, UL

Wired glass is made by feeding a welded wire net into the molten glass just before it enters the rollers. The wire does not add to the strength of the glass, but it does hold the lite (a cut piece of glass) in the window sash if it shatters. Wire glass is used in fire-rated windows and doors because it meets most fire codes. However, wired glass use is limited in many places as it does not meet impact safety standards, adds Schumann. Wired glasses are used in the olden days, currently, it is not common, says Govind.

Laminated glass is a glazing fabricated from multiple layers bonded together with an adhesive to create a single panel. Lamination is used to create glazing with higher security against forced entry and to provide bullet resistance, says Schumann.

Laminated glass is used in safety glazing applications. However, it has many other applications, such as burglar resistance, sound reduction, sloped glazing, skylights, and space enclosures. Laminated glass can be used to reduce the transmission of solar energy, control glare, and screen out ultraviolet radiation.

• Tempered Glass is used in buildings for unframed assemblies (such as frameless glass doors), structurally loaded applications, and any other application that would become dangerous in the event of human impact. Building codes in the United States require tempered glass in several situations, including skylights, glass installed near doorways and stairways, large windows, windows which extend close to floor level, sliding doors, elevators, fire department access panels, and glass installed near swimming pools.

• Wired Glass is exclusively used on service elevators to prevent fire ingress to the shaft, and also why it is commonly found in institutional settings which are often well-protected and partitioned against fire.

• Laminated Glass, remains intact when broken, it is also great for overhead glazing in buildings. Due to their noise insulation properties, laminated glass can also be used at hotels, airport terminals, recording studios, etc. You can use it either in windows, roof lights, canopies; overhead glazing, domes, skylights, and glass lift walls.

(Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates)

Laminated glass is made by placing a layer of Polyvinyl Butyral (PVB) between two or more glass lites. The PVB can be clear or tinted. The laminating process can be performed on clear, tinted, reflective, heat-strengthened, or tempered glass. If the laminated glass breaks, fragments will remain stuck to the interlayer, typically of PVBl, ethylenevinyl acetate, or thermoplastic polyurethane, between its two or more layers of glass, eliminating the risk of injury, adds Balagan and Deshmukh. Because of its unique safety feature, it is being used more in architectural applications now.

Safety conditions under which a glass behaves when subjected to various impacts determine the type of glass to be used, says Shah. The glazing material is treated or is combined/fused with other materials to meet such performance criteria.

National Building Code 2016 defines various parameters are critical locations at which a

Pooja Crafts Office in Hyderabad by Katerra Design: Laminated glass Glass canopy

toughened or tempered safety glass and locations under which a laminated glass should be used. The thickness of such usage depends on span, loading conditions and various other factors. Primarily as defined in NBC 2016, it is recommended to use laminated glass for all horizontal or sloped glazing, for glass railings and where the sills are less than 750mm and fall height is greater than 1500mm. For fall height less than 1500mm and sills less than 750mm, tempered or toughened glass should be used, advises Shah.

Out of several materials used for façades, glass is being one of the widely preferred. Glass

Testing and certification by UL

UL 752 is a test Standard for Bullet-Resisting Equipment and is used to evaluate resistance to different levels of ballistic attacks. The term “bulletresisting” signifies that protection is provided against complete penetration, the passage of fragments of projectiles, or spalling (fragmentation) of the protective material to the degree that injury would not be caused to a person standing directly behind the bullet-resisting barrier. These applications are intended to protect against robbery, holdup, or ballistic/armed attacks such as those by snipers. UL 972, is the Standard for safe, burglary resistant glazing material. These products are clear, translucent, or opaque glazing material intended for indoor and outdoor use principally as a substitute for plate glass show windows or showcase panels. The material is intended to resist burglary attacks of the “hit and run” type.

Principal Engineer, Security and Life Safety, UL

manufacturing technologies are evolving quickly, and innovative products achieve high performance and energy efficiency. Furthermore, it offers comforts like natural lights, and protections against extreme weather. Building façades of ecofriendly buildings are achieving much higher performance through modern materials and

construction techniques, thus able to contribute sustainably and achieve the highest level of green building ratings, says Govind.

Glass is made of abundant natural raw materials like sand, soda ash, cullet (broken glass), etc., and it is a fully recyclable material. Glass recycling helps in saving energy as cullet melts at a lower temperature than other raw materials, says Balaggan. Glass also used to generate renewable energy.

According to Ar. Gandhi, glass has higher performance, speed of execution, but it comes at a cost of higher embodied energy. Hence a justified analysis and exploration and due diligence are required while opting for glass on façades and fenestrations. DGU glasses that

Characters of glass-like transparency, masking, the ability to fabricate, adaptability, etc. highlight its suitability for structures. It is sound insulating, heat-reflecting, heat absorbent, nonabrasive, weather-resistant and incombustible. By understanding the building requirement, optimum basic glass is selected. With the logical and correct selection, it can be very useful and friendly material. An incorrect selection can result in just the opposite by being a source of excessive heat gain or loss, glare, discomfort and risk of injury from glass.

The primary function of glass is to provide daylight and visibility through it or transparency. Visible Light Transmission or VLT is the most important parameter of glass and higher VLT will result in higher daylight but also higher energy transfers and glare. The designers often consider that a higher VLT means higher transparency and end up with the wrong selection.

Transparency is dependent on the colour rendering index, reflectivity and illumination levels inside v/s outside. A glass of VLT as low as 10% is also quite transparent if viewed independently and not in contrast or simultaneous comparison with a higher VLT glass.

Other than light and energy, the factors like strength, safety, acoustics, etc., should be considered to evaluate the processing needs of glass. It will be useful to bring a method to the selection process which is easily understood by all the stakeholders and steers them to a common approach.

The National Building Codes 2016 has introduced a new section 8 of ‘Glass and Glazing’ under Part- 6 ‘Structural Design’. The code covers almost all design aspects of glass and glazing. It explains various types of glasses as well as processes and defines the methodology of selection as well as drawing the boundaries of certain limitations.

Right from the initial project evaluation stage, a suitable methodology that incorporates the implications of the use of glass materials and their influence on the performance of the building shall have to be looked into.

Design requirements, including aesthetic considerations and client-specified requirements such as security and maintenance, are to be considered. Effect of design on cost such as the initial cost of glazing (specification of glass; glazing method; access for initial glazing; work schedule; protection during construction); effect of glass material on capital; running cost related to building heating/cooling, lighting and ventilation; and maintenance cost of glazed areas (access for cleaning and re-glazing) should be considered as well.

(Ar. Prashant Deshmukh, Founder & Principal Architect, Prashant Deshmukh Associates)

provide insulation reduce the overall HVAC loads and requirements. Glasses manufactured with higher SHGC, help in the reflection and non-absorption of heat conductive to the envelope. If the glass is used in locations where it is not required as a functional element, it will add to the absorption and heat gain of the interiors.

One of the vital environmental factors is the thermal performance of glass. This can be enhanced by layering glass into different arrangements in its assembly or by coating it with materials to reduce its ability to transfer heat indoors., says Ar. Goel.

Shah points out the need for the careful and planned use of glass by control of solar gain and UV while maintaining performance parameters. It helps to reduce dependency on artificial light. Further, when glass breaks, it remains safe and stable and releases no harmful chemicals into the soil. So even if the glass is not recycled, it does minimal harm to the environment. Additionally, glass has the GRAS designation (Generally Regarded As Safe) from US Food & Drug Administration, adds Shah.

Ar. Gunasekaran too agrees that glass is sustainable since it is a fully recyclable material that provides great environmental benefits such as contributing to mitigating climate change and saving precious natural resources. Other than saving energy, glass is also used to generate renewable energy through solar-thermal and photovoltaic applications and wind turbines, which largely profit from lightweight reinforcement glass fibers, he adds.

Glass provides natural light into buildings which enhances the living and working conditions of the occupants. Studies show that glass in buildings, through all these benefits, contributes to people’s well-being and improved health conditions.

Types of glazing are generally called based on their visual and construction methods, explains Govind.

Visual-based Category:

• Structural glazing caters to more transparency with lesser frames or obstructions called frameless or bolted or spider glazing.

• Cable or suspended glazing refers to a supporting structure that uses a tension cable system against structural frames.

• Curtain walling refers to framed constructions such as windows, commercial building façades, etc.

According to Balaggan, structural glazing is a more specialised job of fixing perfectly uniform large glazed surfaces with silicone. In this system, glass is fixed to

support which is attached to a structural element of the building. This system can be used with any type of glass, even DGU. Structural glazing can be used to create huge glass installations with minimal obstruction, says Ar. Deshmukh.

Structural glazing refers to a method of retaining the glass in a window, storefront or curtain wall, points out Gunasekaran. Instead of the edges of the glazing being captured in a pocket of the framing and secured in place with gaskets, the structurally glazed glass is retained on one or more sides by an adhesive, normally silicone. Structural glazing is one of the fastest-growing and most innovative forms of glazing.

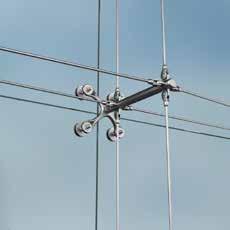

Spider glazing or bolted glazing and fin supported glazing are types of structural glazing.

o Frameless or bolted or spider glazing: According to Ar. Deshmukh, spider glazing acts as a structural support for any high-end exterior designs. Structural support for the spider glazing can be taken from the structure of the building and for the larger elevations. Spider glazing is generally installed in areas where maximum visibility is required. Glazing with steel tubes as a vertical backup supporting structure called bolt glazing /spider glazing.

Skytech Office project by Katerra Design at Bengaluru: Structural glazing In this project, complete glass façade is Unitised Structural glazing system manufactured at the factory and assembled at the site which reduces the façade construction time by 30%

Explaining it further, Balaggan adds that in the bolt/spider glazing system, the glass is fixed at points with specially designed bolts and steel plates rather than a frame. This is the less obtrusive alternative of glued-on structural glazing. Spider glazings are the most transparent structurally glazed systems used, agrees Gunasekaran. Silicone sealants between the joints are like other structurally glazed systems, but have far less obstructed views looking from the inside out and vice versa due to the elimination of vertical and/or horizontal aluminium mullions. This system is often used for the main entrance elevation of big structure, double lobby, atrium, skylights, canopies and elevator enclosures.

o Fin supported glazing system: Glazing with laminated glass fins as a vertical backup supporting structure called fin supported glazing. This system, says Balaggan, offers unique and

transparent façades especially if the low iron glass is used. Glass fins can be suspended from above or rested on the structure below. Maximum heights can be achieved with this system. Spider and Pin fittings are usually bolted on the side of the fins and steel shoes and connector plates keep the fins in place. This type of glazing is considered good for projects with height and required less obstructive view. Fin systems are also designed with bolted joints. Fins represent the earliest form of structural glass façade.

Glazing with stainless steel tension rods as a vertical backup supporting structure called cable glazing/ suspended glazing. It could be considered a type of structural glazing.

o Cable glazing system can use both vertical and horizontal cables from the boundary structure to act as a support for bolted glass panels. These high tensile cables or stainless steel rods to impose loads of the façade on the main structure. A

surrounding frame is built with cables brought across it and those cables are pulled tight and locked in a place, explains Balaggan and Ar. Deshmukh. This is mainly used for huge entrances, skylights, etc. This decreases the amount of solid structural elements visible on the project.

o Suspended glazing system is used for very high glass panes to avoid flexing and buckling due to self-weight. It absorbs the movement of the building. Single glass panes are suspended using tongs, which press on both sides of the glass.

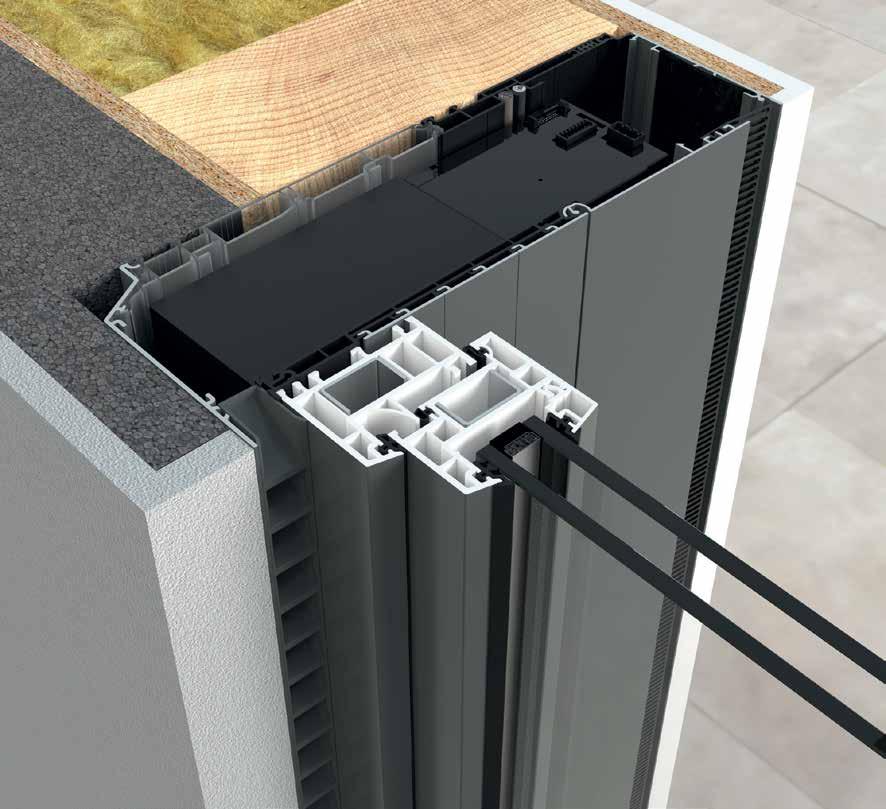

The curtain wall system is an outer covering of a building and generally not resting on the concrete structure and just connected to it, adds Balaggan.

Curtain walls are not structural and they are only able to carry their own weight, observes Ar. Deshmukh. They are thin and lightweight, and an affordable option for a building’s exterior casing, he adds.

According to Gunasekaran, curtain walling is a vertical building enclosure that supports no load other than its weight and the environmental forces which act

Façade glazing can be categorised into many types based on their assembly and construction tectonics.

Structural Glazing: Structural glazings are glass assemblies that are attached to the structural system of a building like its slabs and columns using adhesives like silicone. These systems give a flushed appearance on elevation with the impression of continuity without frames. Generally, a big glass elevation with neat adhesive joints is visible in such systems. These form a large part of institutional and commercial architecture.

Spider Glazing: This is a type of flushed glazing that is devoid of frames. Glasses in this glazing system are held together with building structure along with 2- or 4-way spider SS bolts. Eventually, the joints between glass modules are filled with silicone sealants or gaskets in such systems. Suspended glazings are used in large retail and commercial façades where a larger footfall of people is expected along with high safety standards.

Fin Supported Glazing: This assembly comprises vertical tempered glass fins for support along with horizontal glass modules fixed to these fins using specific bolt connections. This glazing can be useful for Stone fronts, taller elevations, or areas where the external wind pressure is of vital concern.

Cable Glazing: These are glazings that use tension cables or rods to transfer façade and external loads to the structure of the building. Due to these tension cables, the frame area decreases and the façade become lighter and more transparent. These glazings can withstand higher wind loads without a big frame structure. They can be used in larger retail and commercial areas.

Curtain Wall: These are glass assemblies that span like a curtain between floor slabs of a building. Their assembly consists of frames in which glass modules are assembled to construct a full glass wall. These systems are non-load-bearing and have to support their own weight along with the external wind pressures.

(Ar. Gaurav Goel, Studio Parametric Curiosity)

upon it. A curtain wall is defined as a thin, usually aluminium framed walls, containing infills of glass, metal panels, or thin stone.

Glazing for fenestration products was originally built with a single pane of glass installed into the products for many years, says Dave Stammen, Principal

Engineer, Building Envelope, UL Through research and improved manufacturing processes, the use of double-pane and even triple panes of glass in an insulated glass unit (IGU) were developed and installed in window systems, which allowed for providing an air space between the panes of glass, thereby greatly improving the thermal performance such as heat loss reductions, when filling the

space with inert gases such as argon or krypton. New developments in the use of vacuum glazing, which creates a vacuum in the air space between the panes of glass, now allow greater improvements in thermal performance when compared to the original standard double-glazed products. Also, using double or triple glazed IGU’s will provide improvements with the overall acoustics or noise reduction of the finished fenestration product, adds Stammen.