Volume 7 | Issue 4

May - June 2021

PUBLISHED BY

F & F Media and Publications

C-55, Okhla Industrial Area, Phase - 1, New Delhi-110 020

T: +91-11-40623356

CO-FOUNDERS

Syed Ahad Ahmed Amit Malhotra

TECHNICAL PANEL

Mahesh Arumugam Director

Meinhardt Façade Consultants

KR Suresh

Regional Director Axis Façade Consulting

EDITORIAL

Renu Rajaram renu@wfmmedia.com +91 9312864830

Shefali Bisht editorial@wfmmedia.com

DESIGN & CONCEPT BY Prashant Kumar

MARKETING & OPERATIONS

Kapil Girotra kapil@wfmmedia.com +91 9560925255

SUBSCRIPTION & CIRCULATION

Devagya Behl support@wfmmedia.com +91 9871151112

Mukesh Kumar mukesh@wfmmedia.com +91 9560088995

RNI: DELENG/2014/57870

10 Façades have a Cultural Context

Ar. Suneet Paul, Author/Architect/Academician, Architecture+Design

14 Sustainable Buildings - Role of Façades

Aayush Chaudhary, Principal Architect, ACad Studio

18 Simulating Moisture Control in Resilient Building Envelopes

Mansi Dhanuka, Senior Architect, Environmental Building Designer, Jacobs; Niharika Kishore, Program Manager – Sustainability, Amazon

24 How to Select Glass for Buildings

Rajan Govind, Director, Façade Specialist, BES Consultants Pvt. Ltd.

28 AAC - An Efficient Material for Building Façades

Rajdeep Chowdhury, Biltech Building Elements Ltd.

32 Latest Technologies and Solutions for Safe and Efficient Façades

Ar. Sathish Desai, Principal Architect, Creo Concepts Architects

39 Expert Speaks

Interview with Mr. Sanjay Pant, Bureau of Indian Standards (BIS)

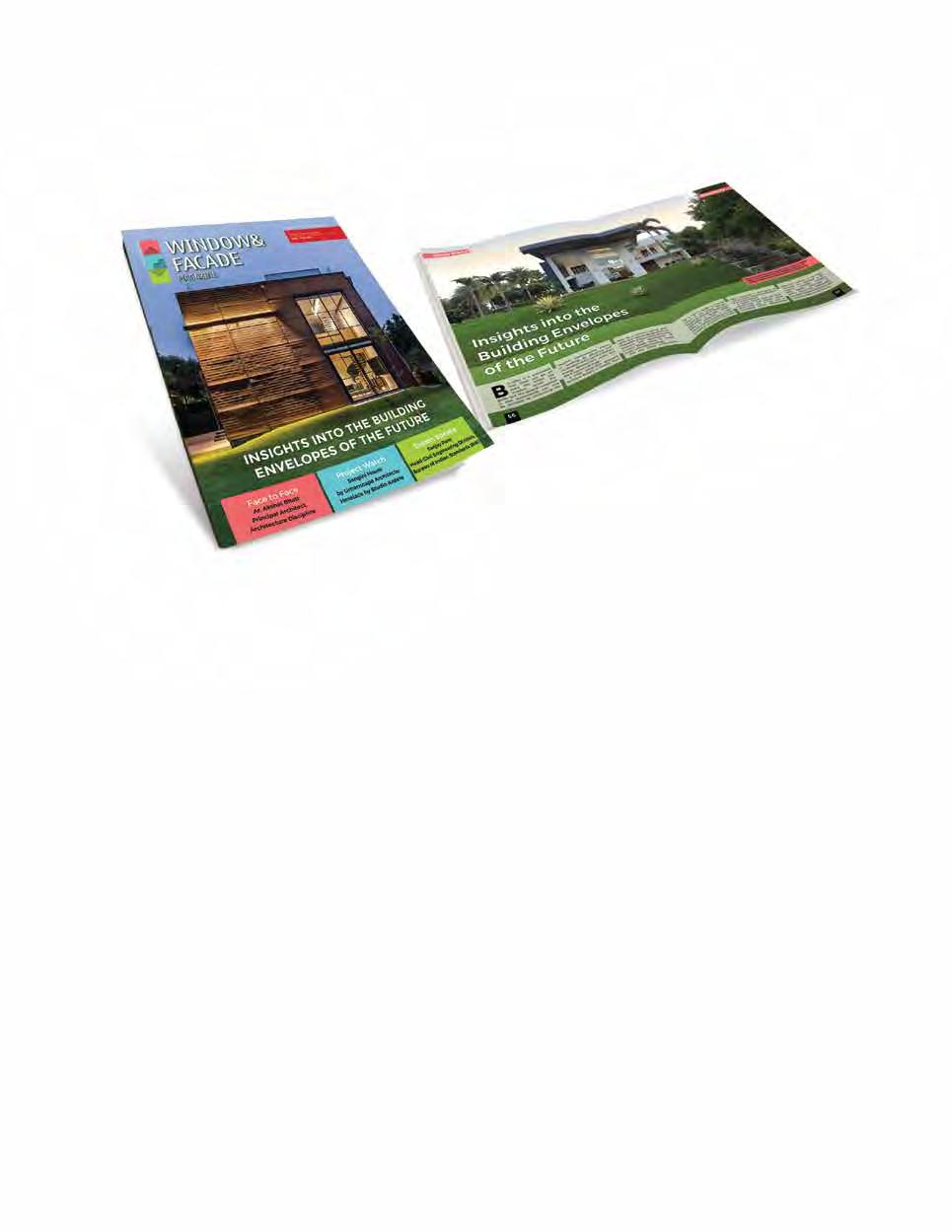

44 Face to Face

Interview with Ar. Akshat Bhatt, Principal Architect, Architecture Discipline

58 Cover Story

Insights into the Building Envelopes of the Future

74 Interview

Ar. Sarabh Marwah, Principal Architect, Sarabh Architects and Consultants

Ar. Shashirekha, Chief Architect, Space Studio, Chennai

82 Industry Speaks

Interview with Mr. Pranesh Chhibber, Country Director, Canadian Wood

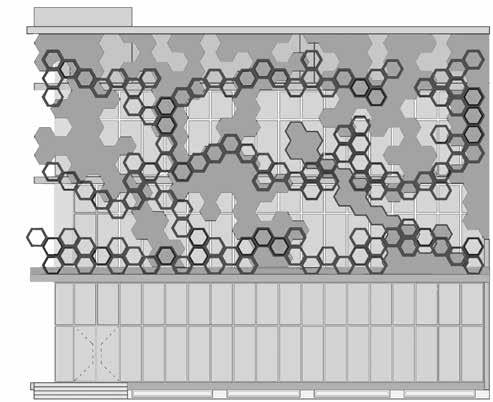

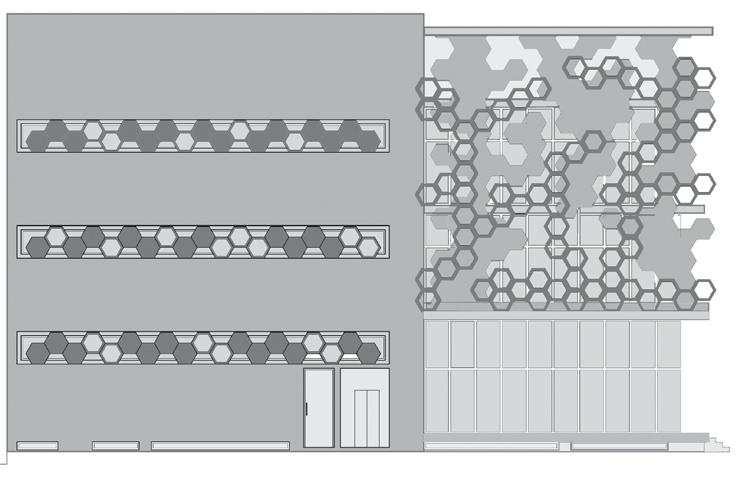

94 Project Watch

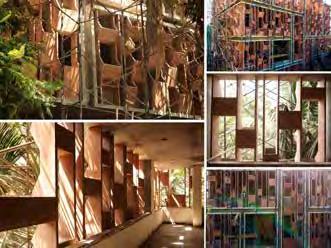

Hexalace, Mohali, Punjab by Studio Ardete Pvt. Ltd.

Sangini House, Surat by Urbanscape Architects

Cover image courtesy: Courtesy: Ar. Akshat Bhatt, Principal Architect, Architecture Discipline; Project - Palm Avenue, Vasant Kunj, New Delhi

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www.wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

I write this note with a sense of reflection, gratitude and pride.

Almost 9 years have gone by since we published our first magazine and it is close to one year since we started the initiative WFM Community – A networking platform connecting architects, builders, engineers, consultants and other industry members to share their knowledge and skills, and to discuss their concerns. As I look back, we had many wonderful associations, and moments to cherish and we are thankful for the contributions, collaboration and commitment of each and every one associated with WFM Media and WFM Community for always being poised to step forward in the service of the industry.

It speaks to the strength of our small team and the legacy of all the wonderful work done in the past 9 years, before and during the pandemic. We were able to create an impact in a seamless manner, through our publications, webinars and other knowledge-sharing means, with the industry members despite the constraints imposed by the pandemic. While we learn from the past, we have always believed it is up to us to create “new beginnings”.

It is amazing to see how our activities have pivoted to the virtual and online mode and the fabulous response we received for the same. It is precisely these qualities and efforts that have led us to not just survive but thrive these past few tough months. It has been our vision and goal to keep our industry on the center stage through our activities, and facilitate the well-being of all the members. In standing together, we stand tall and we stand free- free from worry and free from anxiety. I am confident that our team will continue its efforts in this direction. We are soon to announce another initiative for the benefit of the AEC industry.

This year began with hope, the hope of putting 2020 behind us with the wisdom of the learnings from the pandemic. “On the other side of fear, lies freedom”. The worst hopefully is behind us and I look forward with hope that the end will soon be near and around the horizon, lies the new dawn of happiness and freedom.

Renu Rajaram renu@wfmmedia.com

Historically, the visual aesthetics of the external façade of any structure was always as significant as the achieving of the appropriate functionality indoors. Glimpse back and you would realise the humungous thought, efforts, skills and details through exhaustive labour that the ancient churches, temples, mosques and other institutional structures displayed on the exterior. There was a representation of the cultural context. It was a matter of prestige and pride to make them iconic to evoke the ‘awe and wow’ factor amidst the viewers. In the olden times, rulers and regimes have often used the representations on the façades as symbols of strength and power. And this is very evident

when viewing our heritage of palaces, forts and parliament houses. They ejaculated a grandeur of monumental scale, an emotion for art through meticulously detailed materials, a love for

voluminous indoor spaces and a sensitivity to create harmony with nature through meticulously designed gardens and parks. There are so many examples to qualify this point — Taj Mahal (Agra, India), Red

Fort (Delhi, India), Mysore Palace, (Mysore, India), Amber Fort (Jaipur, India), Hagia Sophia (Istanbul, Turkey), St. Peter’s Basilica (Vatican City, Italy), Palace of Westminster (London, England), Harmandir Sahib Gurudwara (Amritsar, India)the list is endless. All these became symbols of regality for the era they belonged to. And this penchant for classy and expressive exteriors of a building, carried through all ages.

As we observe, the focus of architecture in the earlier centuries was primarily for the rulers/royalty/ elite/rich. Exclusive design and imagery were really not for the

common man. It is the ingenuity and the love for a cheerful living that led to houses for him have colourful façades with art/folklore/ graphics surface on the exteriors bringing in playful tones. All these efforts were essentially selfgenerated by the citizens to bring in a cheer in their everyday life. The state had very little role to play. It was only in the nineteenth century that we observe a shift in approach to architecture when all across, society went through sociopolitical changes. Democratic rights came to the forefront and the era of kings/rulers/

dictators steadily gave way to wider participation of the citizens in governance which brought his interests to the forefront. Modernism in architecture brought a metamorphosis to the physicality in architecture. Architecture façades became more focused on so many other issues other than being iconic. Movements like the ‘Bauhaus’, ‘Deconstruction’ and such others brought in fresher perspectives to architecture. Ever since, there has been no looking back.

The last years of the twentieth century and the beginning of the twenty-first one have indeed been revolutionary in design and architecture. With the industrial era, the prefabrication thrust and engineering evolutions as a strong base, the architects got a strong impetus for heading towards an experimental approach. Never did the exterior renderings of the buildings see so much of diversity. It was as if Buckminster Fuller’s belief “You never change things

fighting the existing reality. To change something, build a new model that makes the existing model obsolete,” was pursued to the hilt. Yes, visualising architecture truly took a new mold.

Post-modernism, globalisation – have all been contributory to this revolution. With prosperity on the rise, came a change in values, lifestyle and cultural preferences. Technology on a fast-track, the architects and the construction industry lapped up the advancements in further evolving ‘trendsetting’ skyscraper concepts. In fact, in India, it is accomplished architect Hafeez Contractor who is known to be the pioneer in focusing on the façades as a major element of his architecture of high-rises. With innovatively restructured materials such as glass, steel, aluminum and more new-age ones being available, today the usage of vocabulary like panel-framed façade, steel and glass skin, double-layered exterior, etc. is in vogue. Contemporary façade design has become so specialised that for some projects, the clients prefer having specialist façade-designing architects.

Contemporary architecture, more so with the learnings from stay/work from home in this Covid-19 pandemic, has on priority, addressing concerns for the deteriorating environmental, energy-consciousness, the rapport of the inside-outside… This ideally should be a phase of designing green façades keeping ventilation procedures/acoustic insulation/ solar appropriation high on the agenda. Well-known Bombaybased architect Sanjay Puri has taken a lead here. There is a fair amount of research ongoing towards adaptive façade technologies. It becomes so important to recollect masterarchitect Frank Lloyd Wright’s

words, “Study nature, love nature, stay close to nature. It will never fail you.” Whether a small-scaled project or then a large one, the attempt at all levels needs to be for alternatives that are climateappropriate. In the India context, eminent architects like Raj Rewal, Christopher Benninger, Manit and Sonali Rastogi, Sourabh Gupta, Brinda Somaya, Gurjit Singh Matharoo - have all evolved form and used material very contextually in their architecture. This becomes evident in the treatment of the façades of their structures. World over, there is a growing realisation that contextualised architecture relating to the cultural idiom would always find a sync with the end-user and the public at large.

It is no doubt heartening to note that as we progressively climb the ladder with technologybacked tools in design, we have simultaneous activity which is equally energized in reinterpreting

contemporary vernacular. The vernacular has always provided a strong link between us humans and the environment. The flame has been kept burning high in this zone by Indian architects like Yatin Pandya, Ankur Choksi and Amrish Arora, Sanjay Prakash and others who have innovatively utilised and brought to the forefront elements from traditional vernacular. They reincarnate the design basics of the past in the present context and reinforce Finnish architect Alvar Aalto’s thought that “Architecture belongs to culture not to civilisation”.

This period in Indian architecture is of course an exciting one with a more aware and exposed client and with the architects and designers creatively responsive to modernday demands from architecture. Aesthetics in design would always keep churning and get redefined with time and context. And yes, the other day during a chat with a fellow colleague on this subject of architecture façades then and now, she commented, “the façades of the yesteryears were more emotive, expressive and responsive – more feminine, while nowadays they are definitely rugged, brazen, often indifferent – more malelike.” It left me pondering if there was any truth in her statement.

SUNEET PAUL

Author/Architect/Academician Architecture+Design

Author/architect/academician

Suneet Paul is the former editor-in-chief of the magazine - Architecture+Design. Apart from his professional writing, he has also authored a couple of books- short stories. Exploring culture and art has always been close to him.

Façades play an important role in regulating natural heat generated by the sun.

Sustainable façades can be defined as elevation designs that promote the use of green materials and conserve energy. Sustainable façades reduce the energy consumption of buildings, ensure thermal comfort, visual effect, acoustic, and improve air quality. It is a new approach to maintain the integrity of the building for future generations.

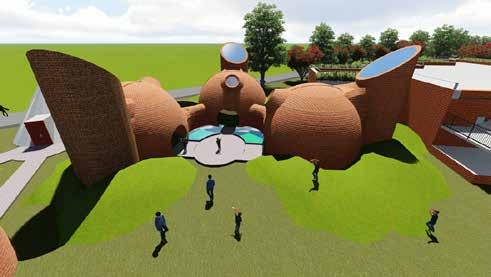

Green façades or vegetative walls are designed by aiding the growth

of green climbing plants upward and across the front portion of the building. The green façade impacts the overall building thermal performance. Designing the green façades is a nice choice but do we know about materials best suited for building green façades?

Before designing the elevation, various parameters are studied to ensure the comfort of living. The various parameters are:

The temperature fluctuation - All the sides of the buildings have a different temperature range due to the absorption of solar radiation.

The green façade affects the absorption rate. The green materials absorb light and heat energy which keeps the temperature low. The façade support system also makes the compressed air layer around the walls when stems are immature. This is very similar to the dry-clad approach. The effects of green buildings result in 1.4ºC cooler in summer and 3.8ºC warmer in winter.

The difference in surface temperature - The surface temperature of bare walls and vegetative walls differ during

summer. In green façades cover, the green leaves which provide shading and even prevent from gaining heat from the building system. This results in calculating the average bare wall temperature that comes out 5.5ºC higher. The maximum temperature is 15.2ºC higher.

The relative humidity temperateThe back part and the front area of the building have a different rate of relative humidity. The evaporation and transpiration of water droplets from leaves causes an increase in the humidity and gives cooling in summer. This results in 7% higher humidity in summer and 8% lower in winter.

The sustainable building façades are designed by following the various steps. The approaches to designing sustainable buildings are:

Climate considerations - Air conditioning of buildings is always required, and it can be reduced if building design minimises the overheating of buildings. This can be achieved if the building design minimises or eliminates the glazing towards the west side, reducing the heat gain during summer and afternoon. In hot climates, the glasses and windows are oriented towards the north or shaded by vertical fins. No passive solar needs are required. If possible, the doors and windows should open to the opposite side of the building to enhance cross-ventilation.

Building orientation - The most important factor in the implementation of green façades is the orientation of the building. The optimum orientation is a key factor in the reduction of energy consumption. It improves the overall

energy efficiency. It is proven that if green façades are used as a second layer in the southeast or southwest orientation, it results in maximum energy-saving in coastal cities.

Façade material properties - The material used in the building should possess minimum heat transfer coefficient and minimum embodied energy during construction and installing framing. The façade design should have maximum thermal resistance which prevents buildings from heating. Apart from thermal resistance, it should also possess thermal insulation properties like sound insulation.

Wall assembly - Wind velocity and hot weather conditions in regions are not suitable for having a single gaze because the building absorbs an immense amount of heat. So Double glazing is preferred to bear the wind load on the building. This can maintain the embodied energy of the building material used. This can reduce the peak heat and cooling loads.

• Remove air pollutants - The people living in the urban areas experience maximum health

issues due to diminishing air quality in urban environments. Small-sized particles penetrate deeply into the alveolar areas and lungs which further becoming dangerous to human healths. As a solution to the problem, green façades are introduced. The plants and their associated growing substrates effectively aid in cleaning the air and produce cooler ambient temperatures. Green walls impact positively urban areas in many ways: mitigating air pollution decreasing surface temperature. Vegetation is considered a particulate sink because of the plant surface which acts as a source of turbulence which increases the turbulent diffusion and influences PM diffusion. Green walls are an appropriate tool to reduce PM via deposition without disturbing the air exchange between the street canyon and the air above it. The vegetation has helped with ambient air pollutant removal.

• Reduce noise/acoustic - In urban areas, the exposure to noise pollution increases due to the expansion of transports, residential areas, and

infrastructures. This exposure results in a negative impact on human health; it disrupts work and sleeps productivity. The hard surfaces of street canyons reflect sound and increase the urban ambient noise. The plant structures absorb noise instead of reflecting between buildings. The plant absorbs noise due to the mechanical vibrations in plant elements induced by sound waves which convert sound energy into heat. The Thermo-viscous boundary layer at plant surfaces reduces sound, and sound energy is effectively reduced by the interference caused by sound waves. The presence of soil-like substrate interferes between the source of information and ground reflected contribution. This effect is known as the Acoustical Ground Effect. The different parts of the plant absorb sound at different frequency ranges as leaves produce a sound absorption effect in the high-frequency range and wooden parts like branch stem and twigs produce an effect in the midfrequency range.

Apart from the abovementioned benefits, green façades also offers various benefits like; reduce urban temperature, thermal benefits, improve biodiversity, attenuate rainwater, increase productivity and creativity, improve the sense of well-being, health benefits.

To conclude, with the reduction in energy resources and increase in cost every day, the primary focus is kept on building systems to conserve energy. intelligent façades came up with a solution that provides heating and cooling, produces its energy. Though many types of research are carried out about using of energy requirement in the building system. The energy-efficient building envelope consists of the use of optical properties of glass, double façades to control the air circulation, insulating materials, etc. The concept of green building in the construction sector has reduced the waste of resources, the resource utilisation improved, improves the living standard of people, and most important the symbiotic relationship of man and nature.

AAYUSH CHAUDHARY

Principal Architect, ACad Studio

Founder of Acad studio, Ar. Aayush Chaudhary has done his Bachelor’s in Architecture from Sushant School of Art and Management, and after that, he completed his master’s in construction management from Cass Business School, London. At the early age of 16, going to construction sites with his father always mesmerised him. That’s where he found his passion for architecture. He has rich experience in the architecture industry in India and the UK. Ar. Chaudhary has won various awards at graduation Level, and master’s level. He is currently one of the emerging names in the architecture industry at a very young age of 25 years.

ACad studio is one of the most promising architecture firms in India. The motivation behind the firm since its inception is to ‘Inspire Creativity’ and uplift the level of the Indian construction industry. ACad studio has evolved into a devoted team of experts focused on offering comprehensive service in the field of architecture, interior design, and project consultation.

People spend 90% of their time inside a building - be it our homes, offices, schools, colleges, workplaces, etc. This makes it imperative to make buildings healthy and improve our health, comfort, and productivity through operational and design strategies.

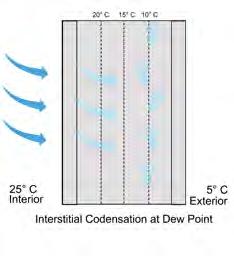

Imagine it’s a hot day outside, you take out a cold can of soda from the refrigerator. Within a few minutes, water droplets form on the can – this phenomenon is called condensation. The temperature at which condensation begins is called the dew point. Psychometric

charts can be used to predict this dew point temperature. This brings us to this article –simulating moisture control in resilient building envelopes. A similar situation occurs in the building envelopes – the outdoor temperature is 5ºC and the indoor temperature is being maintained at 25ºC. There will come a point when air diffuses from the warm interior of a building to the cool exterior and reaches its dew point within the construction of the building, turning water vapor into droplets. This is called interstitial condensation.

Building interstitial condensation can cause mold growth, staining, corrosion, the poor performance of insulation, damage to equipment and electrical failure. It may affect the integrity of building materials and structures. Mold and mildew within buildings leads to increased concentration of organisms such as bacteria, termites, insects, etc.

Another major issue caused by this is “Sick Building Syndrome” which started during the energy crisis of the 1970s. Designers increasingly began to employ methods to reduce energy consumption to increase energy

efficiency in buildings. This led to building designs including weatherstripping doors, insulated double or triple pane windows, increased insulation and building wraps without testing the impact of these additional insulation materials on the dew point of the wall sections.

Some thumb rules to mitigate condensation are:

• Vapor barriers to be located on the warm internal side of the construction in cooler damper climates

• Ensuring buildings are adequately ventilated

• The thickness of insulation to be carefully selected meeting various building codes

There are many ways to measure the condensation risk beforehand using innovative software and technology.

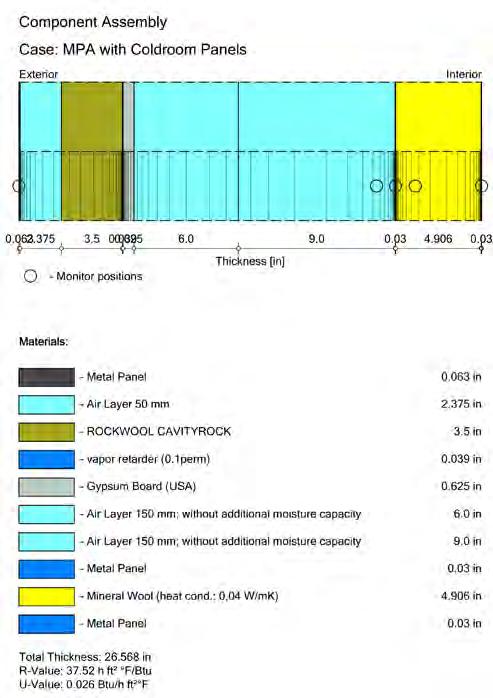

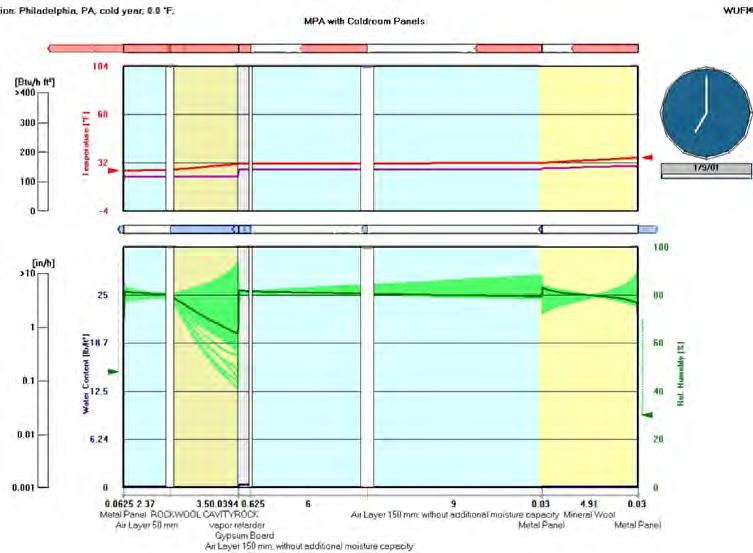

USING WUFI TO MEASURE CONDENSATION RISK DURING EARLY PHASES OF DESIGN

WUFI is a software capable of calculating heat and moisture transport in walls and other multi-layer building components

exposed to natural climatic conditions. WUFI takes the following components into account to assess condensation risk:

• Materials assembly (construction and material parameters) including R-value, thickness, type of material, conductivity, etc.

• Building orientation, inclination, and height

• Surface transfer coefficients (comprising of the surface transfer properties for the exterior and interior surface)

• Initial conditions (initial distributions of moisture and temperature)

• Calculation period/profiles (duration of simulation)

• Outdoor climate (pulled from weather files loaded into the software)

• Indoor climate (interior environmental information from the HVAC systems)

Several databases are available globally for determining building material parameters. In addition, WUFI has the capability to create project-specific materials and determine the overall R-value of the wall section. Monitor position is the location at which the temperature of the external assembly is measured. At the beginning of a project, testing multiple monitor positions for each wall section is recommended to find out the weaker points.

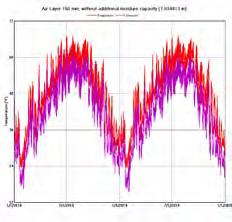

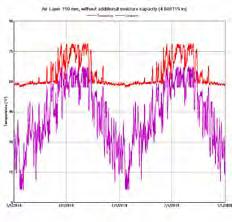

The graphs of Figure 3 portray the monitor position temperature and the dew point of the assembly at a specific location and time. This graph is an important tool to understand the simulation by providing information on when the test assembly will fail and have condensation. When the

temperature through the wall section (red line) intersects the dew point of the assembly (purple line), condensation will occur. Ideally, the temperature should always be more than dew point at all points to prevent condensation. Special care must be taken to

understand the location of the monitor position. For example, if the monitor position is outside of the vapor barrier and the temperature line intersects the dew point line, then this condensation does not pose a risk for building degradation since it will be drained out.

The first step during this analysis is to identify the numerous scenarios that could pose a condensation risk. For this project, the design team tested more than 20 different sections throughout the exterior façade of the building.

Figure 3 shows the Temperature vs. dew point graph for the rain screen façade and modular construction system at the cold room on the south wall of the building. The monitor position for this graph lies within the air space between the two constructions. As shown in the graph the air space will have condensation

over a period of time, degrading the building materials around it.

While testing other wall sections, the project team saw this problem occurring only at one location outside the cold room wall. The wall section at the cold room mechanical space on top of it did not show any possibility of condensation. This proved that the exterior rain screen façade was well-

designed to mitigate condensation and the low temperature of the cold room was causing this issue. This issue was the genesis of another idea – ventilating the cavity with the same temperature as the cold room mechanical spaces, which will prevent the air space from getting cold enough to reach the dew point temperature. To check the feasibility of the idea, the ventilated cavity

solution was tested out in different joint conditions around the cold room. Even if more insulation was added to the building, the ventilated cavity at the cold room did not show any signs of condensation.

In summary, the project team was able to find a deficiency in the composite wall system of the cold room through simulation, provided a viable solution in the form of the ventilated cavity which would prevent improper moisture intrusion and demonstrated the results of this new design through simulation.

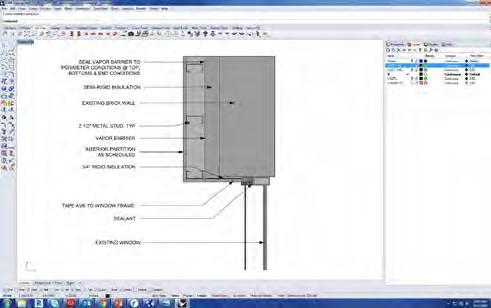

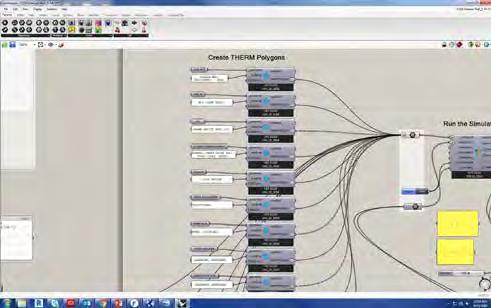

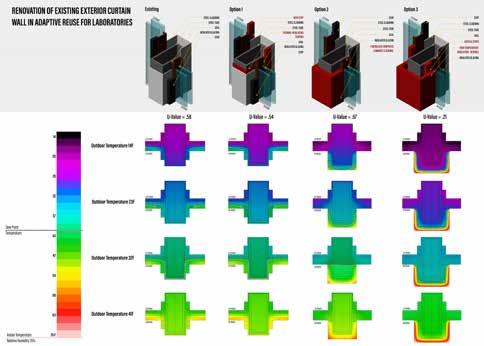

Ladybug tools in collaboration with Therm (LBNL) allows testing of noncontinuous wall sections, involving multiple materials. Drawings in these software are customisable and help determine the thermal bridges of the assembly. On the other hand, Therm provides a range of building materials for running the analysis and also provides an option to create new materials.

The simulation is a simple 4-step process and uses Rhino, Grasshopper, Ladybug tools, and Therm:

Step 1: Import the section detail from AutoCAD/Revit or Draft it in Rhino. Ensure all materials are closed poly surfaces. Alternatively, create a parametric model within grasshopper and test multiple iterations.

Step 2: Assign materials to surfaces in Grasshopper from default Therm materials or create your own.

Step 3: Import climate data from weather file to create external boundary conditions and input internal boundary conditions such as set point temperature, relative humidity.

Step 4: Run the simulation. Ensure that the legend and colors are assigned such that all options have the same parameters.

Figure 8 is a comparative representation of different window sections and the effect of environmental factors on them, in a historically significant mid-century modern building. It portrays window section options in isometric view and envelope heat transfer through those options at different winter month temperatures. It also depicts the risk of condensation in each option with effective U-Values of construction. This analysis was aimed at understanding what happens to renovated laboratory spaces in an existing building, whether differing humidity levels would lead to condensation, and how to reduce energy loss through the exterior enclosure while maintaining the minimal vertical mullions. Rhino was used for modeling and rendering the mullion detail sections, while Therm combined with Ladybug-Honeybee for envelope heat modelling and condensation

risk analysis. Post-simulation was done using Photoshop and Bluebeam. The study shows the different options in one graphic for ease of comparison between environmental factors and visual aesthetics.

Both case studies help us understand the importance of such analysis and the capabilities of the software used. Ladybug tools are preferred when analysing complex wall section details since they are flexible and can test multiple transitions in materials. Ladybug tools are open source and available to all for use.

On the other hand, WUFI is considered appropriate for early design stages and multi-season analysis since it is easier to use and provides dynamic results, although cost can be a deterring factor.

MANSI DHANUKA LEED AP BD+C Senior Architect, Environmental Building Designer, Jacobs

NIHARIKA KISHORE LEED AP BD+C, EMP, Fitwel Ambassador Program Manager – Sustainability, Amazon

Mansi Dhanuka is currently practicing as a Senior Architect and has a Master's in Environmental Building Design from the University of Pennsylvania. In her 4-year experience in the building industry, she has worked on various project types on schematic design, design development, construction documentation, LEED documentation, and construction administration phases in India and the United States. (mansidhanka21@gmail. com)

Niharika Kishore holds an undergraduate degree in Solar & Alternative Energy and a graduate degree in Sustainable Urban Planning from the University of Illinois at Urbana-Champaign. She has 5 years of experience in sustainability consulting and energy. (niharikakishore.10@ gmail.com)

Lingel - Panzer - Glazing 14 mm

Recommended for P6B as per EN356

LPG 18

Lingel - Panzer - Glazing 18 mm

Recommended for P7B as per EN356

LPG-X

Upgrade your existing Lingel security glazing to LPG performance

LINGEL SAFE BOX hardware

to upgrade your existing Lingel window Recommended for RC2 and RC3 as per EN1627-30

LINGEL SAFE BOX hardware

for your new state of art

Lingel - security - window recommended for RC2 & RC3 as per EN 1627-30 LSB 1 LSB 2

Lingel Provides Masterpiece Windows Where Every Component Is Merged To Perfection

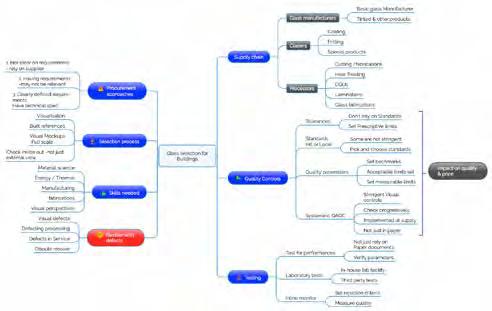

Glass selection is an art of designers which requires vast knowledge on wide spectrum of skills varying from material sciences, energy impact, fabrications, practical aspects, etc. Glass specialists must have in-depth knowledge in wide range of aspects so that they can advise architects and clients for right choice of glass selection.

With the introduction of numerous products that comes to building construction on every day

basis, the designers should have global connect with international expertise, familiar with other regions, up to date on latest trends and technologies. These skills may lead to help the clients and the architects to find the right glass for their buildings and be proud and pleased with their right choice of glass once building completed.

Floods of technical jargon but know how to wade through these without just carried away by the supply chain claims and marketing.

Good knowledge is needed in the whole selection process right from design, performance, energy efficiencies, reading data, comparing, and evaluating various products. This will help and ease the glass selection process which greatly helps building architects and owners.

Just from a small handy sample, an experienced glass specialists could visualise the overall impact of glass on a very large scale. This will help to communicate to other stakeholders to go for right choice of glass for their buildings.

Good understanding on performances, limitations, visual characteristics of glass products, etc. helps in selecting right products. Glass experts can use latest tools and technologies such as advanced simulations, visualisations, optimise natural daylights, achieve energy efficiency, thermal comforts, and arrive at appropriate glazing designs and glass specifications. Final glass selection shall be done based on detailed analysis, not just on thumb rules or assumptions or hearsay from marketing.

With any amount of experience, designers face challenges on a variety of aspects such as

• Insight on how glass industry works

• Understanding the products

• Getting lost with supplier’s specifications

• Are the product comparable (having similar characterizes)?

• How to check i.e., specification Vs actual supply

“Inexperienced procurement, have to deal with Defects & Failures”

Good knowledge on manufacturing, international standards, acceptable tolerances, glass processing and fabrication techniques, help to manage on ground problems and achieve the expected results. Ability to control the outcome with the strong technical and practical knowledge is often very critical in glass finalisation process. Following flowchart illustrates some key aspects, impact overall quality and output.

Although it may look like a simple

selection process, glass selection requires significant experience and skills in various disciplines which comes with a deeper level of dedication. This is not just a documentation or checklist process, one can just tick off all the boxes. It is a highly sensitive subject as it involves the architect and the client, sometimes may lead to upset someone in the process if the outcome is not satisfactory. That said, the right strategy and a systematic approach with rich experience will greatly help in this process of selection of the right glass for façades and fenestrations.

RAJAN

GOVIND Director, Façade Specialist, BES Consultants Pvt. Ltd.

Rajan Govind has more than 27 years of international experience within the façade industry. He has served more than 11 years at Arup. With structural engineering background, Rajan has gained working experiences in regions such as Asia, Middle East and Australia. He has successfully delivered several prestigious projects with integrated façade designs, involving 3D design, complex engineering and building integration. He is a Certified SGMM (Singapore Green Mark Manager), which enable him to understand sustainable design requirements. He has delivered several large projects including Mondeal Heights, The Park, Brigade Tech Garden, Pan Pacific Hotel (Singapore), ASPTM Hospital (Vietnam), etc. Govind has taken various efforts to adopt technology to improve the efficiency in design and construction aspects.

❷ Installation: e ortlessly simple. Maintenance: not needed! The system adjusts itself and compensates for tolerances.

The building industry consumes maximum fossil fuels and contributes most to global warming. Over usage of conventional building materials not only causes global warming but also adversely affects natural resources. The façade is one of the most important contributors to the energy consumption and comfort parameters of any building. So the use of efficient façade material has a big role in optimising the requirement of operational energy and other

functional parameters desired in buildings.

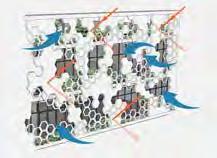

This paper presents a unique building material named Autoclaved Aerated Concrete (AAC). AAC is a building material which consists of various sized elements that form a complete building system. E.g., walling blocks, reinforced wall & roof panels can be made out of AAC.

AAC is also recognised as a Green building material and is used commonly for the buildings conforming to TERI–GRIHA, ECBC and IGBC–LEED rating systems.

No other single building material can provide such a wide range of benefits like lightweight, thermal insulation, high productivity, increased carpet area, etc. offered by AAC.

With the increase in housing demand, the use of sustainable green buildings materials has become a necessity. The benefit of using Green materials are generally expressed under three broad categories, i.e., environmental, economic, and health safety benefits. AAC materials provide all these benefits to the users.

AAC has been utilised as a building material throughout the world for more than 80 years. It was developed during the early 1920s at the Technical College in Stockholm, Sweden. Since then, it has been used commercially in the construction of industrial, institutional and residential structures throughout the world. In India, AAC has its presence for last more than 40 years. Government PSU M/s Hindustan Prefab Limited (HPL), known to be the first in India to produce AAC and subsequently various companies like Biltech Building Elements Ltd., Ultratech, JK, HIL, et.al has also started manufacturing AAC. At present, there will be more than 100 units (in different capacities) producing AAC in India.

AAC is manufactured using various raw materials – ground silica sand or fly-ash, quicklime, cement, gypsum, and aluminium powder. Input materials are tested, graded and weighed as per process

BENEFITS OF AAC BLOCKS AS WALLING MATERIAL:

• Structural saving: The oven dry density of AAC varies from 450 -650 kg/cum. While compared with conventional materials AAC induces one-half to one-third less dead load in the structures resulting in substantial savings in the structural cost.

requirements and then conveyed in a programmed sequence into a batch mixer. This mixture is poured into huge moulds of appx. 6 m in length. In the mould the raw material mix in slurry form is allowed to rise and set. The material in the green stage is then trimmed and cut to shape and size and loaded into autoclaves. In the autoclaves, the material is steamed at 11 bar and temperature of appx.180°C for 8 hours. Once autoclaving is over, the material is unloaded, palletised and sent for dispatch.

TECHNICAL SPECIFICATIONS:

RELEVANT BIS STANDARDS:

BIS - 2185 (III) – 1984: Specification of AAC block

BIS - 6041 – 1985: Construction of AAC block masonry

BIS – 6072 & 6073: Specification of AAC reinforced products

BIS - 6441 – 1972: Methods of test for autoclaved cellular concrete product

Density (Oven dry)

Compressive strength

Thermal conductivity (K Value)

Resistant to fire

Drying shrinkage

Design gross density

• Speed in construction: AACbased systems shall provide better productivity and time benefits over conventional construction due to a reduction in the number of joints in the wall masonry and avoidance of any shuttering for flooring jobs. AACbased systems also require almost nothing pre-curing and post-curing activity.

• Operation & maintenance benefits: AAC-based systems shall provide a major saving in energy costs due to reduced air-conditioning load vis-à-vis conventional construction. The thermal conductivity of AAC material is on an average of 0.16 W/ MK which is 4-5 times better than concrete and clay products.

A high-rise building in

Values

450-650 Kg/Cum

Minimum 30 Kg/cm2

0.162 W/mK (avg)

2 - 6 hrs depending upon Thickness

0.1 %

850 Kg/Cum. (appx.)

• Transportation benefits: Because of lesser dead load, more material can be shipped in a single trip i.e., 9 M Ton capacity truck can carry 12 cum of AAC Block in comparison to 5 cum of clay bricks.

AAC reduces environmental impact considerably during manufacturing and construction stages. AAC products are considered "Green building material” because of the following features:

• Raw materials consist of recycled industrial wasteUp to 60% of the raw materials used in AAC manufacturing process is industrial waste i.e. Fly ash.

• Non-polluting manufactureAutoclaved aerated concrete manufacturing is a closed-loop process. Clean steam is only released into the atmosphere.

• Resource efficiency - The end product approximately contains 80% of pores and 20% mass. Thus 5 parts AAC are produced from just 1 part of raw materials.

• Low energy consumption throughout the life cycleThe total energy consumption to produce AAC is 1/3rd of that of many comparable building materials.

• Healthier indoor air quality - AAC products do not offgas and do not promote the growth of mildew and mold.

AAC blocks qualify for Green ratings because of the following attributes:

• Minimum use of water during

construction - lesser prewetting and post-curing

• Reduces energy load –because of high thermal insulation properties

• Less embodied energy –Waste content (Fly ash) is 5560%

• Regional material –Availability of AAC within 500 km

• Indoor environment quality

– NIL VOC

With the increase in electricity demand, conservation measures are required to be introduced and enforced to curtail the energy requirements in buildings. ECBC code of practice for energy conservation in buildings sets several requirements to limit the peak loads for space cooling.

The enforcement of limits (voluntary) on the thermal resistance for exterior walls

gave way to the introduction of AAC as an efficient material that can provide the requisite thermal Insulation without any other specific thermal insulating material. AAC, being a lightweight material, provides useful thermal inertia because it possesses an advantageous combination of mass, thermal conductivity, and specific heat properties. Just for e.g, AAC blocks of 300mm thick with two coats of plaster offer thermal transmittance factors (U Value) of appx. 0.47 W/m2k which is very close to the desired level.

AAC meets favorably most of all the parameters mentioned below, desired in efficient building material.

Sl. No.Proposed parametersWeightagePerformance of AAC

1Recycle content 10Yes

2Embodied energy 10Low

3 Rapidly renewable 5Not outstanding, OK

4Locally available material10Yes

5Functional life period 10Good

6 Capital cost 10 Medium

7 Maintenance cost 10Less

8Construction waste management 5Very less

9 Fly-ash content 10High

10Reduced weight 5Yes

11Reduced time of construction 5Yes

12 Toxicity/ indoor air quality/ safety 10Yes

Some of prestigious projects where AAC blocks have been used in huge volume for their construction are:

Emmar MGF CWG Village at Delhi, ITC Office at Gurgram, Indira Paryavaran Bhavan at Delhi, WIPRO office at Gurugram, FORTIS hospital at Delhi, T3 – Airport in Delhi, SD Corpn in Mumbai, and various CPWD and PWD projects across India.

CONCLUSION:

While designing the façade of a building considering various functional aspects like stability, thermal insulation, durability,

T3 – Airport, Delhi

weathering resistance, workability is very important. The façade materials have to perform in all types of climatic conditions throughout the life cycle of the building.

AAC because of all its inherent properties and its excellent resource efficiencies will score very high over all other substitutes. AAC has good workability and because of its large size/lesser joins ensures minimum thermal bridging affect which is a very important parameter while planning façade materials.

AAC integrates very efficiently with all other masonry products like thin bed joining mortar, rendering products like skim coat can be applied directly on AAC. All these Dry Mx materials are energy efficient and environment friendly. AAC has immense potential to become the most credible green and efficient façade building material.

RAJDEEP CHOWDHURY

Senior Management Personnel, Biltech Building Elements Ltd.

Having 23+ years of experience in the building material & construction Industry, Rajdeep Chowdhury has good networking with various national nodal agencies to promote usage of sustainable building materials and technologies in India. He has experience in various aspects of the business including formulation of business plans, brand building, development of sales strategy & structuring commercial transactions. Rajdeep has developed various techno-commercial proposals, reports pertaining to the usage of lightweight concrete, fly ash utilisation and prefab construction. He has presented technical papers and keynote lectures in various national-level seminars. He has done B Tech in civil engineering and has an advance diploma in marketing management. He also completed many specialised courses relevant to the industry. He is a life member of the Indian Building Congress & IGBC, and Indian Concrete Institute.

Building envelope forms a critical component of our built environment. This is the medium that communicates with nature around. Lighting, ventilation, thermal comfort and safety are the attributes, in addition to aesthetics that have challenged architects since the beginning of

civilisation. Insulation from heat, cold and noise, indoor air quality, longevity and maintainability are primarily contributed by the fenestration set-up or façade of the buildings.

This article is an outcome of my personal search for solutions,

and I hope that this serves as a simple reckoner to architects while designing, to assess possible solutions for building envelope, façade and fenestration.

Establishing an unhindered connect with nature possibly is the most desired design element for all architects.

Collapsible or sliding - folding

mechanisms of a wide variety for near 100% opening are now possible, thanks to technological advances and material choices. Bugs, bad weather, burglar and bullet resistance (rarely though) are further considerations that at times contradict the design outcomes envisaged. Minimalistic narrow stiles and rails are preferred, minimising the interference with views outside.

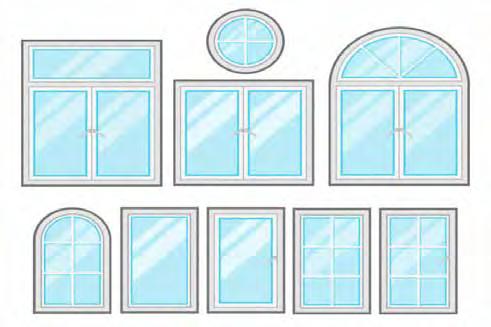

Elements of design that usually excite us all are window seats, corner windows, wrap-around (wall to roof) windows that turn into skylights, retractable roofs/atrium covers, operable skylights, clearstory windows, monitor windows, picture windows and the list goes on.

A variety of glasses are in the offing – clear, textured, coated, tempered, laminated and multiple panes with vacuum sandwiched between panes provide choices to achieve the desired intent.

Some design solutions that excite me in particular for the potential they hold are - second

skin building envelope, transitional spaces (neither fully enclosed nor open) ventilated façades, 3D printed façades, tensile fabric on façades and parametric façades.

We notice a big surge in hardware technology for a variety of operations like sliding, sliding-folding (bifold or collapsible), tilt and turn, top-hung or awning, casement, pivoted sash (vertical or horizontal), lift and slide mechanism, fixed or picture windows, louvered both mechanical and automated and so on.

Most of us are familiar with IR sensor-operated automatic glass doors at storefronts that reduce aircon leaks and maintain indoor air temperature optimally, providing much-needed touch-free entry. Many other technological innovations have found their way into our lives and projects such as electronic security with the use of

video door phones, access control devices of various types, motorised curtains, blinds, louvers & awnings. What is new?! Profile integrated electronics with motors, chain operation using actuators to open and close windows including sensor integration for automatic opening and closing of windows (smart climate control) are new entrants into the Indian market.

My inquisitiveness about technology in the building industry has led me to discover the following in recent times:

•

Glazing (Alternative to Spider Glass Fins)

This system is a hybrid of the spider glazing system and uses wire ropes/ cables to support the glass structure of the spider system instead of the conventional glass fins. Glass fins in spider systems limit the spans and are also pricier. The cable system thus effectively manages wind loads and enables larger span frameless glazing possibilities. Cable truss system and tension rod system are further variations of the same concept that come in handy while designing large span glass structures.

• Electrochromic Glass (Smart/ Dynamic)

Electrochromic glass (smart glass or dynamic glass) is an electronically ‘tintable’ glass used for windows, skylights, façades, and curtain walls. Electrochromic glass can be directly controlled by building occupants or managed by integration with building automation. Users can operate automatic control settings to manage light, glare, energy use and colour rendering. This glass when used improves occupant comfort, maximises access to

daylight and outdoor views, reduces energy costs and provides architects with more design freedom.

Electrochromic glass is a smart solution for buildings in which solar control is a challenge, including classroom settings, healthcare facilities, commercial offices, retail spaces, museums, and cultural institutions. Interior spaces featuring an atrium or skylights also benefit from the use of smart glass.

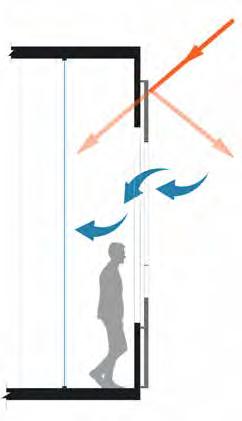

• Window Integrated Ventilation System

Window profile integrated ventilation system with a multistage air-cleaning filter is developed especially for residents

of large cities and metropolitan areas with air pollution. Healthcare and hospitality properties where operating windows are a rare occurrence can benefit from this innovation. This technology efficiently frees the air of particulate matter and other components troublesome to health including removal of the smallest particulate matter in intense smog. A sensorcontrolled valve injects outer air as needed to ensure the optimal air quality in the building at any time.

• Automation & Electronics in Hardware (Profile Integrated)

Concealed actuator technology consisting of an actuator fitting and profile system is new to us

in India. For various opening types and sizes, this electronic profile integrated system can be adopted, to automate and operate the windows.

When integrated into the building automation system, the very quietrunning fittings series fulfills a wide range of requirements in terms of energy efficiency, convenience, and security for commercial as well as residential projects. A variety of automated ventilation functions such as night-time cooling, crack ventilation or timed ventilation save on energy costs, ensure a pleasant indoor climate, and can be easily combined with fire protection requirements (smoke extraction, NSHEVS). Natural Smoke and Heat Exhaust Ventilation System (NSHEVS) is a critical standard in the fire safety of high-rise buildings.

• Solar PV Integration in Glazing For architects who wish to integrate Solar PV Panels over building façades and roofs, there are now solutions that offer clear glass having photovoltaic properties that use nano and microparticle technology to internally diffuse, redistribute, and reflect elements of the incoming light towards the edges of the glass panel, where it is collected by monocrystalline silicon-based PV modules. The PV modules are placed into a circuit, which is optimised to harvest energy rays coming from multiple directions even when cloudy. The systems also offer tinting and automation integration options. About 30 Watts of power per square meter of area can be harnessed with this innovation.

• Bug and Burglar Protection without Grills

Obstruction-free framed views are favourites of all architects. The need

for such fenestration means the absence of grills and safety shutters. Solutions for such use cases are two in my view. Tamper-proof glass which is essentially toughened and laminated pane (bulletproof glass as we know it) and tamper-proof mesh developed using Australian Technology, which serves as both bugs and burglar protection screen providing near clear visibility without the need for safety grills.

Bureau of Indian Standards has specified many parameters and standards to assess glass and glazing products, some of the many aspects cover the following: Energy performance, safety & security, Smoke and Heat Exhaust Ventilation (SHEV) and indoor lighting requirements. Products and systems for fenestration that are now available in India, manufactured overseas, follow their respective stringent standards.

Durability, ease of maintenance and environmental impact also is computed for comparison and benchmarking. This is a vast subject usually neglected and needing more awareness among professionals.

Passive solar design principles when followed in tropical climates (like in India) ensure a significant reduction in energy usage. While using glass as a building material, U-value, low emissivity properties & SHGC (Solar Heat Gain Coefficient) are factors to be considered. Multiple panes with vacuumsealed layer/s, solar PV integration in glazing, electrochromic glass (smart/dynamic) are solutions that come in handy to minimise energy usage provided context and costs permit.

Sleeker sections, darker frames, wide frame or panoramic visibility, window walls (floor to roof windows) are trends that are always in vogue. Solutions for every kind of need and application are now available. Easy operation hardware, thermal and acoustic insulation and a variety of glazing and automation solutions are accessible to us today and technology are advancing further. This article intends to provide a ‘memory list’ such that a needed solution may be sought through a bit of search and research by coprofessionals.

AR. SATHISH DESAI

Principal Architect, Creo Concepts Architects

Ar. Sathish Desai brings with him a passion for design, both at the macro and micro levels. Be it ‘planning, architecture, or product design’ - functional aesthetics, minimalism and sensitive detailing elevate his spirit. He started his career as an architect in Pune in the year 1994. Later he moved to Gayathri and Namith Associates (GNA), Bangalore, where he did a wide range of architectural and interior design projects in a tropical context working with the various climatic zones of India.

In 2013, Sathish founded Creo Concepts Architects to service architecture, interior & space design, and product design domains. Creo, a team of enthused young professionals, is based out of Bangalore, presently engaged in housing, institutional, commercial, retail and social projects spread across the country.

Lingel Windows and Doors Technologies, a premium fenestration brand that offers complete fenestration solutions, based out of Rajasthan, opened its first experience centre in Jaipur last week. Architect Tushar Sogani, Principal Architect, TSDPL was the Chief Guest for the occasion. Lingel’s experience centre, situated at Crystal Mall - Jaipur, has a great variety of fenestration solutions for its customers. Lingel is famous for many of its landmark projects, one of these is the famous Ashram at Pali.

Speaking on the occasion, Dr. h.c. Mario Schmidt, Managing Director, Lingel Windows said, “This was a much awaited

showroom. Due to the pandemic, we were unable to open it earlier. We hope the people of Jaipur will visit to check out our latest collection of designer doors which are available in various options and other customised solutions. We have been selling windows and doors for 15 years in India and have all company owned showrooms in all major cities across India”.

Ar. Tushar Sogani, Principal Architect, TSDPL said, “The company has a wide array of beautiful solutions of international finesse and sections to offer. Lingel is also a member of UWDMA. The company has specially catered to the demands of Indian customers with provisions of grills, various coloured profiles and

technological sound windows and door profiles. We wish them a great start and a good future ahead.”

Lingel recently celebrated 15 glorious years in India. This German brand can boast of completing many unique and challenging projects across India. The brand is well-known for its quality, aesthetics and after sales services. The brand is known for its innovative product portfolio, to name a few Lingel Smart-Li, Lingel 6.0 Aluminium windows, Glass conservatories, LSB and LPG Secure window solutions.

For more details on the products, E-mail: mario@lingel.in; Contact number: +91 9870273743. Website: www.lingelwindows.com

TECHNAL® is a part of Hydro’s Building Systems Division whose business focuses on aluminium extrusion-based solutions. It is a pioneering international specialist in architectural aluminium construction systems that are designed to inspire contemporary architecture: façades and curtain walls, doors, windows, sliding doors, balustrade and verandas.

TECHNAL® has recently inaugurated their new showroom in Bengaluru on the occasion of the 25th anniversary of Hydro Building Systems in India.

The showroom was inaugurated in the presence of Ar. Mohan BR, Partner - Architects Inc. and Chairman - The Indian Institute of Architects, Karnataka Chapter. Ar. Mohan was very appreciative of TECHNAL®'s innovations and initiatives, like Palmares, the architectural competition for budding architects. He also commended on Hydro’s

commitment to sustainability. The ceremony was showcased online and was attended by TECHNAL®'s colleagues and customers from across the globe. The inperson event witnessed a limited number of attendees due to the implementation of necessary covid guidelines.

Henri Gomez, President, Hydro Building Systems made an encouraging introductory speech for the showroom reveal, discussing the evolution of Hydro's involvement in India. He mentioned, “Our first day as Hydro Building Systems in India was close to 25 years ago, with our first European colleague to India started proposing and showing our product offering.” He also mentioned that they started with Domal, the first ever architectural aluminium system to be offered in the Indian fenestration market and since last few years the focus has been on TECHNAL®, as a new step in product and technology with the highest standards of innovation. Gomez also expressed his happiness for the fantastic journey TECHNAL® has had.

The ceremony was also graced by the presence of Sam Robinson, Managing Director, Hydro Building Systems (South Asia), and V Gurumoorthy, General Manager

of Sapa Extrusion India Private Limited, under whose leadership this spectacular feat of the showroom launch was achieved right from conception to execution and the final launch.

Esha Sharma, MarCom Manager demonstrated a tour of the showroom which hosts 22 product lines of Technal - from corner free bi-folding doors to minimalistic panoramic sliding doors to unitised facades befit for high rise construction.

TECHNAL®'s new showroom displays a space for innovation, novelty, creativity, quality and sustainability. Whether you are an architect shaping the world, a contractor developing the ultimate portfolio, or a customer wanting to enhance your living space, the showroom exemplifies a space to realize architectural visions collaboratively.

For more information about the showroom and pre-book a visit as per Covid guidelines, contact: Esha Sharma, esha.sharma@hydro. com

Address: 2nd Floor, office No. 209, No. 29, Prestige Meridian, M.G Road, Bangalore 560001, Karnataka. India.

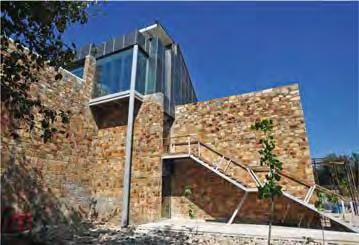

Innovation Glass India Pvt. Ltd. announced the recent completion of the Cummins Technology Center in Pune, India, which broke ground in 2013. The new technical campus was designed by Venkatraman Associates. Cummins, which has technical centers in 30 countries around the world, designs and manufactures diesel and other alternative fuel engines. The company’s forward-thinking and innovative work is manifested in the stunning architecture of the new campus, which features the world’s

largest faceted wall—made possible by VS1.

VS1 is a patented curtain wall system that uses a blade shaped mullion and cast aluminium fittings to support insulating or monolithic glass. This simple kit of parts offers users an unprecedented level of flexibility while eliminating transoms and fitting hardware from daylight openings. After an international bidding process, VS1 was selected over conventional solutions as the system of choice for the Cummins façades.

Alternative approaches would have used a more costly steel and drilled-glass approach. The feature façade of the Cummins Technology Center is a 120,000 sq. ft VS1 wall. VS1's proprietary radial fittings make possible the complicated geometry of faceted

façades at unprecedented value. The folded texture of the façade is accomplished with up to 70-foot VS1 mullions featuring multiple mitered bends with concealed splice plates. Other systems would have required horizontal members, but VS1 managed the extremely complex façade geometry without them. The typical detail at the transitions is a 25mm butt joint visually communicating true "folds" in the glass. VS1 also accommodates multiple cladding panel types incorporated into the same façade, the CTC façade features a pattern of laminated "terracotta" glas s, clear glass, and ceramic tile panels.

VS1 canopies protrude from the façades to shelter the entryways. The mullions, which support panels of glass with a frit to prevent solar gain, are on the top of the canopy, creating a flush surface to those entering.

The new center’s 2,000 employees enter the building through allglass VS1 vestibules, which are a unique feature of VS1 lobby façade installations. 3/4" aluminum portal plates frame out sliding and swing doors. Roof plate frames above the vestibule connect to internal vestibule wall portals to create a minimalist "glass cube" aesthetic. Within the building, spine-like VS1 "green" skylights draw natural light into several inner courtyards. Standard VS1 mullions support IGUs with a dot frit to decrease solar gain.

The one-way mullion framing visually eliminates 50% of the metal normally associated with a skylight, resulting in a much more transparent solution. VS1 allows the installation of "flat" glass skylights with slopes of only 1/8" per ppt (3mm per 30mm).

For more information on the product, visit www.innovationglass.com

“BIS has embarked upon a major exercise of development of performance tests and performance-based specifications for doors and windows”

Sanjay Pant has more than 30 years of experience in diverse areas of civil engineering and buildings. Out of the above, about 26 years of experience in the field of standardization in various civil engineering areas such as cement, cement concrete, cement matrix products of various types, various flooring/roofing/ walling, other building materials, prefabricated construction, structural safety, safety in construction, constructional practices and management, buildings & facilities for persons with disability, planning and housing, National Building Code of India (NBC), water

harvesting, energy conservation, sustainable development, etc. He is also n expert in the field of quality control, quality assurance

and third-party certification for various products used in Civil Engineering and building construction applications, including certification of building materials.

In an interview with WFM Media, Mr. Sanjay Pant talked about the need for creating benchmarked specifications, standardisations and certifications for fenestration products, systems and installation methods. He also explains the role played by the National Standards Body of India, the Bureau of Indian Standards (BIS) in the development of performance tests and performance-based specifications for doors and windows.

How important is it to create benchmark standardization of technical specifications for window /door products, considering manufacturing and installation?

With large-scale construction of buildings, particularly the housing stocks, a substantial number of doors and windows are being installed. Further, in view of high rises being the order of the day, quality and performance are receiving more and more importance.

Do we have Indian standards for doors, windows and façades in place?

As the National Standards Body of India, the Bureau of Indian Standards (BIS) has formulated a series of standards on various types of doors, windows and door frames including for their test methodologies. Standards have also been formulated on door installations procedure. Also, standards have been brought out, namely IS 16231 (Part 1 to 4):2019 on use of glass in buildings including glass façade in buildings covering methodology for selection, energy and light optimization, safety against fire and wind loads, and safety-related to human impact.

Most of the products in the markets are imported and are certified by agencies abroad. How far have BIS progressed in specifying standards for doors and windows and façade materials?

At present, there are around 450 units that have opted for BIS certification against various types of doors and windows. Of course, this number is bound to increase substantially in time to come. In order to meet the challenges of the future, BIS has embarked upon a major exercise of development of performance

tests and performance-based specifications for doors and windows. With that, the BIS certification of these products is sure to grow by leaps and bounds, meeting the aspirations of the users for their current and futuristic demands.

The BIS standards will ensure quality, environmental and safety concerns as per the global benchmarks to facilitate fair trade and enable the availability of the right quality of products. It will also hinder the imports and use of cheap and sub-standard scrap in India. Then why is the delay in finalizing the standards? What is the hindrance?

As already mentioned, an ambitious exercise of development of performance-based standards has been taken up by BIS under the aegis of its Doors, Windows and Shutters Sectional Committee, CED 11. The project involves the development of Indian standards for the testing of doors and windows against the performance requirements of wind loads, water tightness, air tightness and sound insulation.

Simultaneously the standards on aluminimum doors and windows are being revised to incorporate the latest profiles and technological developments. At the same time, new standards on uPVC profiles and doors and windows therefrom

BIS has embarked upon a major exercise of development of performance tests and performance-based specifications for doors and windows

are being drafted. All these involve work of a highly meticulous nature with in-depth study of the practices the world over. Additionally, it is important to take into consideration the interest of MSME and build consensus on various provisions of the standards. The work is going on, on a war footing, and the draft standards would be released soon for public comments.

Notwithstanding these, it is also worth sharing that BIS has already

With the development of Indian standards, the entire paraphernalia for the window system would be in place shortly, augmenting the testing, production and supply of quality window systems duly certified by BIS

covered a comprehensive chapter on glass and glazing in the National Building Code of India 2016: Part 6 Structural Design, Section 8 Glass and Glazing. This chapter covers : a) Structural stability and safety,

b) Energy efficiency, c) Visual comfort (light transmittance and reflection),

d) Fire protection, e) Sound insulation, f) Air infiltration (wind pressure, stack pressure, fan pressure), and

g) Water penetration (covering static, dynamic and cyclic pressures).

Quality control of the fabrication process is important, considering the key factors including checking the thickness of the profile, gasket selection, hardware selection and fitting, glass selection and fitting, etc. How is BIS planning to certify the products along with proper installation guidelines?

BIS has developed separate standards on glass, hardware, etc. and more such standards are being developed to complement the efforts of the available standards. These are certifiable standards, and in fact, we foresee a spurt in BIS certification of all these products in near future.

I understand that the only test done for uPVC profile in India is “determination of the resistance to artificial weathering”. This is the minimal and basic test that can be done. Also, there are only one or two testing agencies to do this in India? Though the use of uPVC window is surging, why is the delay in implementing standardised testing, specifications, finalisation of standards and certification?

As already mentioned, the preparation of Indian Standards is going on, on priority, and soon taking along all levels of industry as well as the user segment, draft standards would be issued for public comments, to be duly finalized and notified thereafter, including for uPVC profiles covering tests such as heat reversion, impact, heat aeging, weldability, Charpy Impact apart from weathering test. The testing facilities are already available in some of the institutions and are going to be further spread to other research and testing institutions with the availability of the standard for the product and its certification.

In the case of window systems too, no standard is specified yet concerning wind load/ water tightness/fire resistance, etc. There are no specific standard tests or testing agencies. Most of the available products are following European standards and testing methods. What is the way forward?

As already discussed, while NBC 2016 does cover these tests, with the development of Indian Standards the entire paraphernalia for the window system would be in place shortly, augmenting the testing, production and supply of quality window systems duly certified by BIS.

In the process, the quality testing and certification of components of window/door/façade systems including glass, hardware, cladding material used, etc. are

very important. How to bring about an integrated certification of the final product?

BIS already has standards on glass for use in building façades. Recently a new standard on aluminium composite panels sheets has been finalized and would be available shortly. BIS would be too happy to serve the industry as well as consumers through its BIS certification scheme to help provide certified quality products. The certification of façade materials, window profiles, doors and windows, and their hardware would together provide a comprehensive system to fulfill the need of the industry, consumers, technology and economy in this area.

Most of the aluminium scrap across the globe is finding its way to India. This is definitely affecting the quality of aluminium products available in India and will go against the certification and standardisation effort. What is your take on this?

The Indian standards on aluminium raw material for making doors and windows sections require certain quality parameters to be met, and as such no inferior material that is unable to fulfill requirements

will be permitted. Furthermore, the final products would also be tested against performance tests thus allowing only quality finished products to be certified and used in works.

Please brief on the role played by the associations like uPVC windows and door manufacturers association (UWDMA), glazing society of India, Aluminium Association of India, etc. in the process of certification?

There are three specialized Working Groups constituted under the Door, Windows and Shutters Sectional Committee, CED 11 of BIS dealing with

(1) aluminium doors, windows and sliders

(2) uPVC profile and uPVC windows

(3) performance test methods. UWDMA, Glazing Society of India (GSI), AAI and various other industry representatives are involved in and contributing to the cause of standardisation in these areas quite actively.

I thank WFM Media and Window and Façade Magazine for this opportunity to share my views and development in this topical subject of standardisation in the area of doors and windows.

“Architecture can be Bold, Edgy, and Progressive”

Akshat Bhatt is the Principal Architect at Architecture Discipline, a New Delhi-based multi-disciplinary design practice he founded in 2007. His work, spanning varied typologies from residential and retail interiors to large-scale public and commercial assignments and spread across the length and breadth of India, highlights the emergence of an architectural expression that is contemporary, yet rooted in a critical understanding of regionalism. The outcome of every commission at Architecture Discipline is determined by a series of design processes, from full-scale mock-ups to longterm material investigations, which strive to develop programmatic and technical flexibility. As a result, all buildings are integrated from conceptual framework to tactile experience.

AR. AKSHAT BHATT Principal Architect, Architecture Discipline

Over the last sixteen years, Bhatt has taught at three architecture schools in New Delhi, actively engaging with the city’s academic community. He is currently engaged in many critical commissions for large-scale public spaces and on the refurbishment of heritage buildings.

We spoke to Ar. Akshat Bhatt, Principal Architect, Architecture Discipline on his practice, design principles, latest projects, innovative façade materials and technologies, and much more. Here is the excerpt from the interview:

Frit-printed glass covers the façade of the Discovery Centre, Bengaluru

Please tell us about your practice and its growth over the years?

Our practice, Architecture Discipline, is based in New Delhi and our expertise spans across many multidisciplinary fields from residential and retail interiors to large-scale public and commercial projects. Our projects are spread across the length and breadth of India and we attribute this growth to our thorough design processes, from full-scale mock-ups to long-term material investigations, which strive to develop programmatic and technical flexibility. When we started in 2007, our goal was to stay true to this process and we have indeed followed through, continuing to reinvent ourselves for now and the years to come.

The firm’s work has been critically acclaimed in India: multiple Indian Institute of Interior Designers (IIID) Awards, an NDTV DAA Architect of the Year Award (2013); citations from Alliance Francaise (2012), Architectural Digest India (2015), the National Gallery of Modern Art (2015); a felicitation by the Government of India (2015), the ID Honours award (2020) and the AD100 award for the 100 most

influential Architects and Interior Designers in India (2020).

What inspired you to become an architect?

I was thirteen years old when I saw an architect’s drawing board for the first time. I was fascinated by everything on it and not in a deep philosophical sense — at that age, it was a contraption that could move in all directions, with tools, tackles, and really cool coloured stationery. But, in my second year of architecture school, I saw a rooftop extension in the library by the design studio Coop Himmelb(l) au, which made me realise that architecture can be bold, edgy, and progressive and that there is more to it than block-work and

organic settlements.

Before I studied architecture formally, I was already studying music and it gave me an insight into how to use a universal language to create a regional or personalised expression. What any subject or formal education does is that it allows you to post-rationalise and strategise things that go beyond your intuition. Of course, your first reactions and the strongest ones are always intuitive but formal education allows you to rationalise it and build upon it further and definitely helps you to get out of sticky situations. So, if you study the rules of the competition and the tools and devices available to you while doing something including the value system, it allows you to

find answers very quickly without a hit-and-trial approach which essentially reduces waste, in terms of time and material.

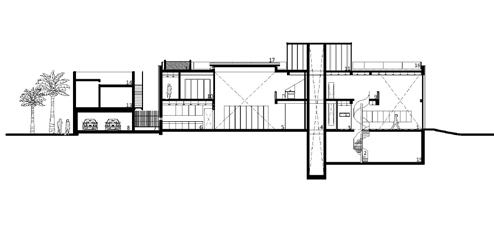

Could you please talk about a few of your ongoing projects?

We are developing a series of modular primary clinics for the Government of Delhi, built of repurposed shipping containers. The Mohalla Clinic is a fully furnished, prefabricated unit that can be easily installed with minimal construction in dense urban regions.

We are also currently working on the following residential projects:

i. A house in Vagator, Goa made out of mass timber

ii. A modular prefabricated concrete farmhouse with a timber brise soleil in Delhi

iii. A residence for American Diplomats at West End, Delhi

iv. Adaptive re-use of a 15,000-sq. ft Art Deco villa at Jor Bagh, Delhi

There are many façade materials available in the market. How do you choose the apt one for your project? What are the criteria?

As a practice, our approach is grounded in longevity — we design open-ended, adaptable frameworks with large, well-serviced and well-lit floors – spaces that can be used for multiple activities in the short term and offer the possibility for a long lifespan along with a variety of longterm uses. The same values extend

to our material choices, with a high emphasis placed on reusability and modularity.