Defining

Importance

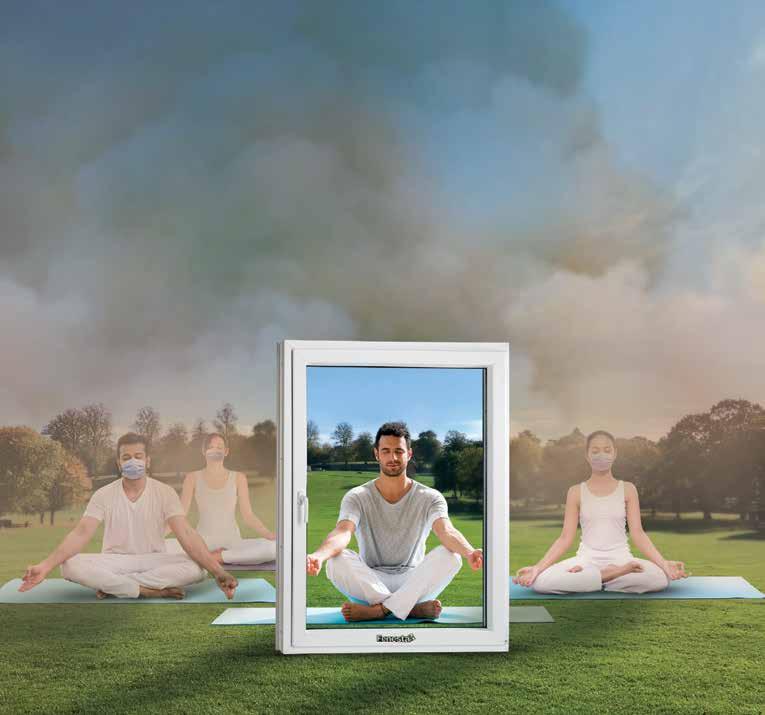

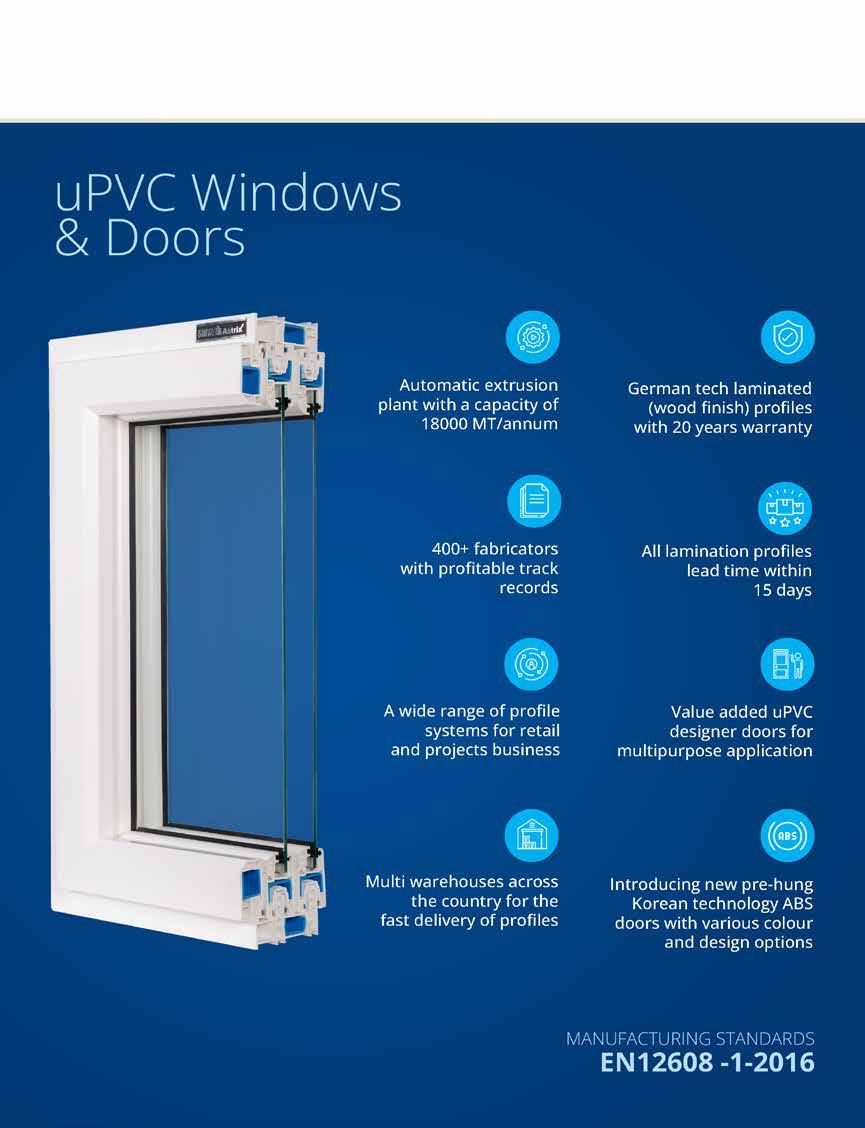

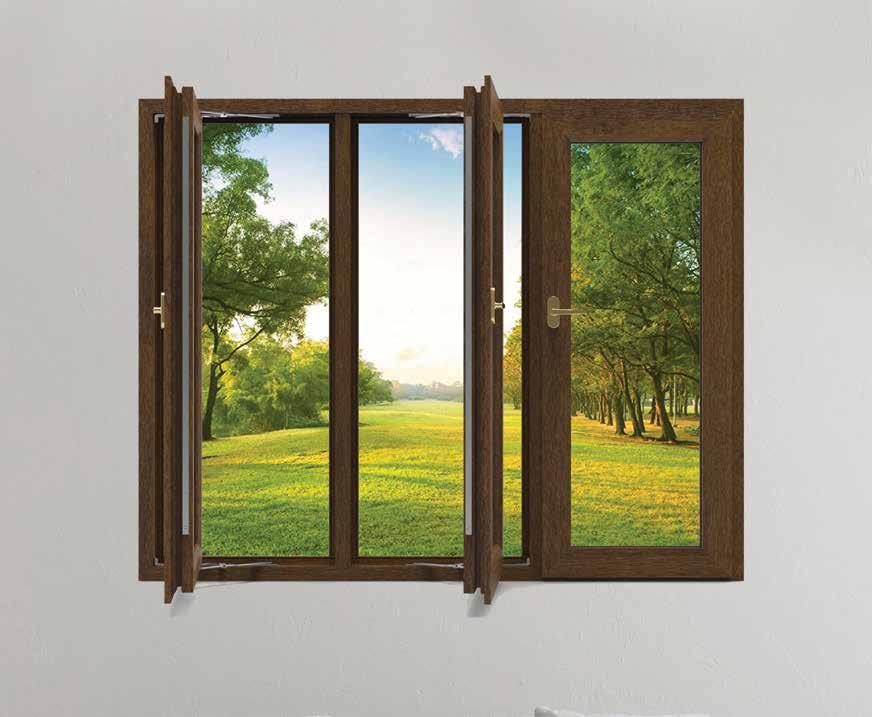

The perfect window. It is what you get when the world’s largest uPVC profile manufacturer joins forces with India’s largest. For the past 90 years, we ’ ve obsessed over our engineering and paid attention to the slightest detail. So, every window we make is perfect, and lasts for generations.

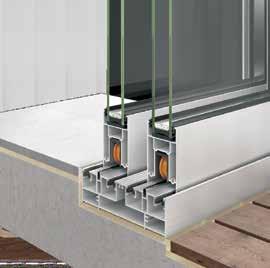

PORTAL HS with the new ECO PASS SKY axxent threshold: no barriers – no problems.

Only when the threshold height drops to zero millimetres and the sill installation is perfect does the room comfort rise to the highest level. The ECO PASS SKY axxent barrier-free threshold without incline ensures absolutely seamless passages and transitions: with fixed glazing down to the floor, an elegant grille and an e cient water drainage system. So that everything runs smoothly: www.siegenia.com Email: info-in@siegenia.com Contact: +91-99711 77168

Adress: SIEGENIA India Pvt. Ltd., Plot No. 52, Sector 37, Udyog Vihar, Phase VI, Gurugram 122 001, Haryana, India

➊ Absolutely barrier-free: 0-mm threshold without incline

➋ Perfect design and optimum drainage

➌ Preassembled and ready-to-install with the COMFORT UNIT

Inspired by Technology

ENCRAFT brings together innovation and design to create an unprecedented level of comfort and security. ENCRAFT provides you a brand new experience in the world of windows & doors. Windows extend beyond and are more than just a connector between the outside world and the interiors of your house.

Multi-locking with microventilation for sliding

Multi-locking system for sliding

fire retardant Champion Plus Top Security

Cremone for outward opening side-hung windows

Ghibo Plus

One-way device for outward opening windows

Minimal handle without rosette

Extinguishing gasket for fire rated windows and doors

Volume 8 | Issue 5

September - October 2022

PUBLISHED BY

F & F Media and Publications

C-55, Okhla Industrial Area, Phase - 1, New Delhi-110 020

T: +91-11-40623356

FOUNDER

Amit Malhotra TECHNICAL PANEL

Mahesh Arumugam Director Meinhardt Façade Consultants

KR Suresh

Regional Director Axis Façade Consulting

EDITORIAL

Renu Rajaram renu@wfmmedia.com +91 9312864830

Shefali Bisht editorial@wfmmedia.com

DESIGN & CONCEPT BY Chandan Sharma

MARKETING & OPERATIONS

Kapil Girotra kapil@wfmmedia.com +91 9560925255

SUBSCRIPTION & CIRCULATION

Devagya Behl support@wfmmedia.com +91 9871151112

Mukesh Kumar mukesh@wfmmedia.com +91 9560088995

RNI: DELENG/2014/57870

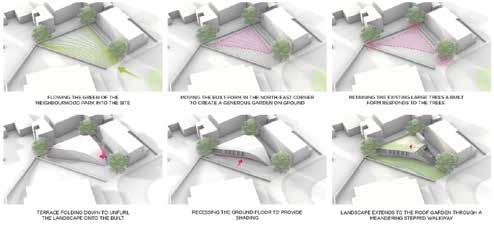

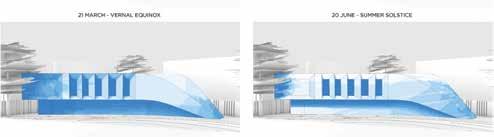

18 Architecture and Nature: How Nature Inspires Architecture?

Ar. Amit Gulati, Co-Founder & Partner, Design 21

22 Comfortable Living & Working in High-Rises

Makarand Kendre, Area Sales Manager Indian Subcontinent, Renson Ventilation NV

26 Façades: A Fusion of Materiality

Ar. Sumit Dhawan, Founder & Principal Architect, Cityspace’82 Architects

30 Future Façade & Fenestration - Role of Glass in Sustainable Buildings

Shailesh Ranjan, Head – Business Planning, Operations & Technical, Asahi India Glass Ltd (AIS)

35 Selection of Materials and Effective Cladding Methods for Sustainable, Efficient Buildings

Nitin Mehta, Co-Founder & Executive Director, ALCOI

40 Adopting High-Performance Façade Materials to Combat Climate Change

Rahul Talele, Group CEO, Kolte Patil Developers

44 Importance of Planning Facade Access in the Design Stage and the Significance of BMUs

Ahamed Hussain, Façade & High Rise Access Consultant, Director, HoistCraft Systems Pvt Ltd, Chennai

56 Facade Inspection of Older Buildings for Safety and Security

Gaurav Tiwari, Founder, Global Techniques of Architecture (GTA)

70 Cover Story

Future Façades – Designs, Materials and Technologies

94 Face to Face

Interview with Ar. Anoj Tevatia, Founding Partner, Design Forum International

106 Project Watch

l. Villa KD45, Delhi NCR, Ghaziabad, India by Studio Symbiosis

2. The Elegance of Sustainable Architecture - Biowonder, Kolkata

112 Industry Speaks

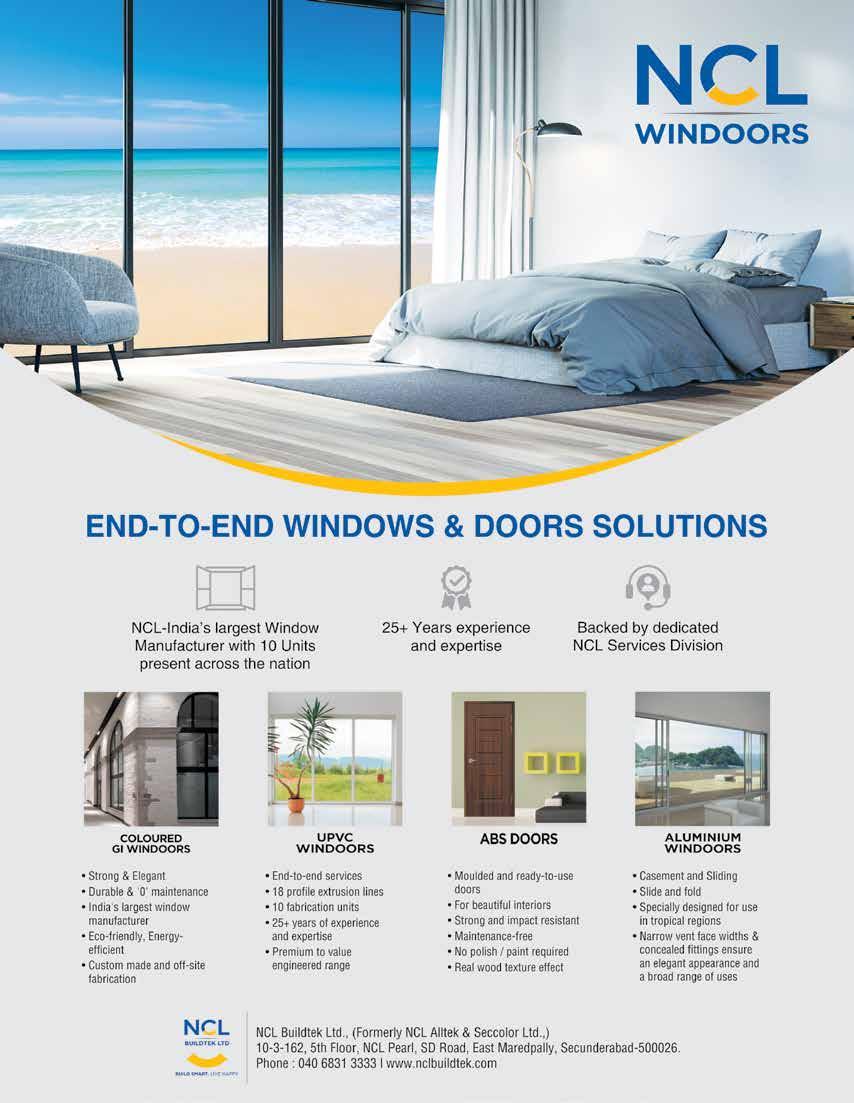

Interview with Mr. Mahesh Londhe, Head - Technical, NCL VEKA Ltd.

Cover Courtesy: Design Forum International (DFI)

Amtron office in the Tech City of Bongora, Assam, designed by DFI, is envisioned as a new-age workplace that moves away from the conventional closed work environment to incorporate flexible and co-working spaces.

DISCLAIMER: With regret we wish to say that publishers cannot be held responsible or liable for error or omission contained in this publication. The opinions and views contained in this publication are not necessarily those of the publishers. Readers are advised to seek expert advice before acting on any information contained in this publication which are very generic in nature. The Magazine does not accept responsibility for the accuracy of claims made by advertisers. The ownership of trademarks is acknowledged. No part of this publication or any part of the contents thereof may be reproduced in any form or context without the permission of publishers in writing.

WRITE TO THE EDITOR Please address your suggestions to: The Editor, Window & Façade Magazine, C55, Okhla Industrial Area, Phase – 1, New Delhi, 110020 or email renu@wfmmedia.com. Please provide your full name and address, stating clearly if you do not wish us to print them. Alternatively log on to www. wfmmedia.com and air your views. The opinions expressed in this section are of particular individuals and are in no way a reflection of the publisher’s views.

“Printed and Published by Amit Malhotra on behalf of M/s F & F Media and Publications Printed and published at Thomson Press India Ltd., B-315, Name of the Editor-Ms. Renu Rajaram”

A building is recognised by the exterior it presents. The façade gives us an instant impression of the design of that structure. The beauty of architecture forms the façade and it is where concepts unfold. Sometimes certain concepts need to be addressed, and other times they communicate for themselves. Architects have designed various types of façades over the years. Each façade indicates that the construction has something distinctive to offer.

Architecture impacts how you feel every day, which isn’t surprising considering how much time we all spend inside buildings. We spent almost 90 % of our time inside buildings, yet so many of our buildings leave us without natural light, ignoring our social, mental and environmental needs. Why should we bear with this? Solutions to this question might end up in an architectural revolution – considering design, materials, and technologies. We experience architecture today with an unprecedented immediacy, just like our smart phones and its evolution, But the change here is gradual.

Nature has served as an inspiration for addressing the world’s most challenging issues. Simulating nature is not a new concept, but it has lately been termed biomimicry. It presents the concept of “breathing skin,” like the skin of living creatures, protecting the organs and giving the body its form, shape and looks. Structures with a breathing façade are designed to breathe through countless micro apertures, helping the buildings to breathe better and improve air quality.

In the case of parametric façades, architects experiment with shapes, compute and discover solutions to establish the perfect algorithm that may provide the required performance. These concepts are influenced by geographical conditions too. They primarily evaluate how the interior of the structure will deal with environmental conditions and the changing seasons. Meticulous and scientific façades, assist in making buildings effective in adapting to environmental stimuli and delivering the best of nature to the inhabitants.

Ventilated façades are another revolutionary solution. In this case, contemporary structures use a double structure construction with a little gap between them creating an air chamber that permits adequate ventilation inside, allowing air to circulate through convection while improving the building’s acoustic and thermal insulation, resulting in higher energy efficiency and improved living conditions for the occupants.

In this edition, we are presenting many such concepts. The cover story is on designs, materials and technologies for future façades and fenestrations. Read on… and let us know your views and insights on the topic too.

Renu Rajaram renu@wfmmedia.com

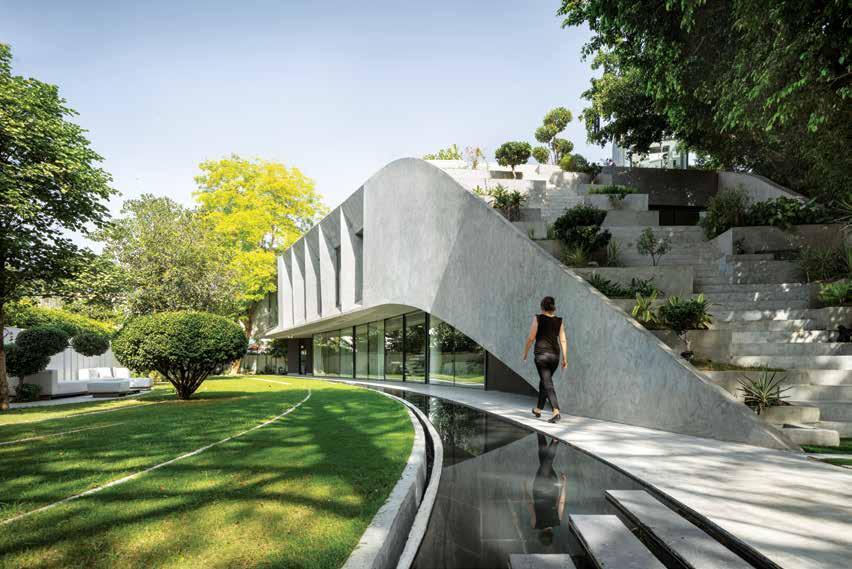

Nature has long been used as a source of inspiration for architecture. Whether from its shape, the extraction and use of its materials, or even the incorporation of natural processes in the building technologies, it is always relevant to look for relations between the built environment and nature. Today, biophilia is a thriving design practice focused on maximising our exposure to the natural environment by tapping into multisensory experiences, through inspiration from nature. Ar. Amit Gulati, Founding Partner at Design 21, shares his insights on the relationship between nature and architecture and the significance of blending nature into design.

Nature-inspired forms, known as biomorphic forms, are the representation of shapes and patterns that persist in nature. Since the

emergence of parametric design in architecture, biomorphic patterns are being largely used in building forms and façades. It is proven to create a visually preferred environment that boosts the cognitive performance of the inhabitants and helps in maintaining better mental health. Today, contemporary architecture and biophilic design have introduced more organic building forms inspired by natural elements that include plants, leaves, trees, wings, etc.

Bridge the gap between architecture and nature through the use of natural materials such as wood, bamboo, jute, cork, and clay that would also elevate the elegance of a space. Whether in the exterior building envelope or interior space, integrating natural materials brings one closer to nature, improving their overall well-being. Elements such as raw, natural wooden furniture, or

bamboo battens on the roof, instill a vibe of nature and add a personality to the space. Façade using natural and recycled materials such as clay tiles and AAC blocks create a unique visual identity for the building as well as contribute to sustainability.

Sometimes, nature can be infused into the built environment without the use of natural elements or materials. Furnishing with hues from nature is a subtle way to seed a natural aura into any space. Consider using blue, brown, or green subdued tones as they are soothing yet create a bold and saturated feeling. A great way to embrace nature is to embellish the walls using wallpapers of natural patterns. Layering all these colours and textures makes the layout look stylish while rejuvenating the mood and well-being of the residents.

Incorporating green plants is one of the most common ways of bringing nature into architecture. Green façades and roofs instinctively lend an aesthetic appeal to the buildings as well as help in improving the comfort and wellness of the occupants. Decorating the interiors with green plants uplifts the mood and promotes human well-being. It is also evident that including water features in planning avails a sense of relaxation in body and mind, a small pond or a water fountain outdoors is enough to take you to the zen mode.

With the unprecedented changes in our lifestyles, homeworking and home offices have become convenient workplaces if done up right. The new age offices are in immediate need to adapt to the changing

A more humanistic approach to design and celebrates how we live, work, and learn with nature

needs of the people and reimagine the work environment. Biophilic design is one of the ways to regain office culture. Integrating biophilic elements in the workplace has proven to encourage enthusiasm, improve physiological stress, and increase productivity while fostering connectivity.

We often get disconnected from our natural surroundings in an urban technological world. The burgeoning demand and excitement for the design have led architects and designers to trace the part of the nature-inspired design in architecture, through which buildings improve human capacity, enhance creativity and mental restoration, and expedite healing. Ar. Amit Gulati advocates a more humanistic approach to design and celebrates how we live, work, and learn with nature. Let us get inspired more by nature and create a healthy architecture for the future.

Co-Founder & Partner, Design 21

Architect Amit Gulati (LEED AP) has extensive project handling experience in architecture in Europe and India, taking overall responsibility for design and drawings, and client interactions. His professional association with International firms and time spent in Holland, Delhi, and Ahmadabad gives him a vast range of architectural knowledge. Through years of experience in large-scale projects varying from exhibitions, offices, amusement parks to a wide range of hospitality projects, Amit brings with him a detailed understanding of the management of the project, client and consultant coordination, and vendor evaluation. His design sensibilities, technical strength in CAD Software applications allow him to provide efficient design solutions and cohesive construction drawings for every space. His attention to detail ensures that his designs, especially the hospitality designs are entirely unique and awe-inspiring. Some of his hospitality projects include the Jersey Hotel, Hotels at Banaras, and many more.

Studies have shown that no less than 80% of people in high-rise office buildings or apartment buildings still want to feel like they can bring fresh air inside. But opening a window isn’t always an option in this case.

That is why High-rise Ventilation is of major importance, it makes sure that people can healthily and comfortably live and work in high-rises. Energy efficiency and aesthetics are also very important to every project developer. All of this combines into customised solutions for every type of high-rise.

Customised ventilation louvers always provide a great alternative to supply the necessary fresh air in the curtain walls

that are so often characteristic of highrises. They are aesthetically integrated and compliant with the requirements for acoustics, wind-resistance, airflow, rain, insects, security, and the possibility to regulate this yourself.

Residents pollute the indoor air by breathing and perspiring, but

their activities (cooking, showering, heating, smoking, ...) and the house itself (volatile organic compounds such as formaldehyde and terpenes) also contribute to poorer air quality. If you insulate excessively or ventilate insufficiently, you will have to deal with stale, polluted air and create a breeding ground for annoying dust mites, fungi, viruses, bacteria, moisture accumulation,

Discover how to match esthetics with functionality. With its zip blinds, RENSON® has developed the first exter nal sun screen in the world that was truly wind-tight

• Upto 12 degree reduction in indoor temperature

• Upto 35% reduction in Air conditioning tonnage

• 10 0 % retractable, motorize d, BMS controlled

• Wind -tight up to 130 k m/h thanks to ingenious zip system

• For glas s sur faces up to 22 m² (width up to 6 m and height up to 6 m)

• N o glare inside, no disturbing reflection in television or computer scre ens

• Inse ct- pro of in close d p osition

• Available in Mosquito mesh fabric as well

Kendre Makarand | Area Sales Manager India Mob: +91 98 22 912 403 india@renson eu www.renson.eu

CO2 and high concentrations of harmful gases (such as radon) are also among the risks.

Continuous ventilation is a must if you want to maximise the quality of life indoors and achieve a healthy living climate. After all, you spend 85 % of your time indoors. Ventilation helps avoid unpleasant odors, allergies and other health problems. In addition, your building or home will be protected against condensation problems and mold formation. In other words: a reliable ventilation system that does not interfere with comfort is an absolute must.

Over the course of time, a poor indoor climate can adversely affect the health of the occupants. Difficulty in breathing, dry throats, eye irritation, headaches, allergies, loss of concentration, lack of energy, or sleepiness are just a few of

the possible consequences. Therefore, it is extremely important to ensure thorough ventilation on a continuous basis.

Many people are convinced that occasionally leaving the windows open is sufficient to achieve the necessary ventilation. However, this only achieves a temporary and gives a localised effect. Moreover, one cannot achieve controlled ventilation by simply opening windows, and the result is a waste of valuable energy. In addition, open windows also bring in noise and are an open invitation to burglars and annoying insects. Continuous and controlled ventilation is your only guarantee of a healthy indoor climate. Contaminated indoor air is expelled and continuously replaced by fresh outdoor air. The home is ‘rinsed’ with fresh air, as it were.

Area Sales Manager Indian Subcontinent, Renson Ventilation NV

Makarand Kendre is working as an Area Sales Manager for the Indian subcontinent for Renson Ventilation & Sun Protection NV. He is a mechanical engineer with MBA in Marketing from Pune university. He has successfully set up distribution channels, and showroom partners for Renson across India. Presently he is responsible for the overall operations of Renson in India.

Renson started operations in India in 2015. Renson manufactures window ventilation, motorised mesh, motorised roofs, performance louvers and internal door hardware systems.

In the contemporary world, a city is nothing but a culmination of multiple clusters of built entities. These built entities have ‘forms’, the exterior. The exterior/ the façade of the building is responsible for drawings people’s attention towards it, but it also serves a bigger purpose.

The façade design of a building reveals a lot about the interior spaces. A building’s façade can convey a variety of notions about its design. It highlights the structure’s style, geographical region, materials used, and construction, as well as the period during which it was created. Other than highlighting the structure’s elevation of façade health and regulating or monitoring the interior structure of a building as architects of today it is imperative to design a façade that is sustainable, resistant to climate, has thermal and acoustics insulation, and few others.

“Façades were once used to display opulence and dignity reflected through beautiful exteriors. Conversely, when modernism approached the decoration was

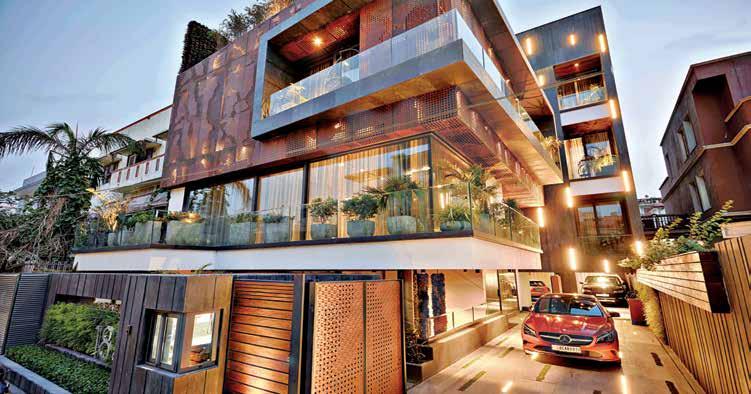

A fusion of modernity & sustainability, this building situated in Mohali is spread over a sprawling 2.09 acres, combining two plots. Carbon footprint is extremely low because of the smart sustainable features like double glazing glass, cooling tower system, rooftop garden, all these design considerations helped the building get decorated by a 5 star GRIHA rating

phased out in preference for contemporary architecture principles, and materials were completely explored as a means of expressing identity,” says Ar. Sumit Dhawan.

Working on the concept of ‘Fusion’, spread across an 8000 sqm area, this building is a 2-sided corner plot that is adept with a double-height entrance. Green wall, zinc jaali, reflective glass, and stackable parking resulting in a Platinum LEED rating have been proposed in this building

The façade was installed by omitting smaller cubes from the bigger ones providing the building with openings and punctures which allowed natural light to touch every corner of the house. A terrace in the form of a cantilever renders a floating powder-coated aluminium web, which forms to be the most dramatic feature

In regards to the environmental factors, façade design is considered an important design factor that can manipulate the indoors. Taking into consideration that in hot or humid climate concrete building structure generally generates a lot of heat whereas mud and brick as building materials would be advantageous because of their cooling capabilities. Pitched roofs are also prevalent in rainy and snowy areas, while double-insulated outside walls are common in cold areas.

Contextually speaking, indigenously obtained materials are being combined with modern materials, resulting in revolutionary aesthetics and design approaches.

Cityspace’ 82 Architects believes screen façades are becoming extremely prevalent in contemporary buildings, as light and shadow play a fundamental role. Screens provide shielding and sun protection while also adjusting the light all through the day. They work well with diverse designs and can be combined with different materials to create unique aesthetics. For instance, perforated metal façades that are typically made from steel or aluminium are a perfect cladding choice, as they offer distinct aesthetics, along with the benefits of sustainability. Because of their ability to manage heat and airflow, these façades reduce a building’s energy costs and consumption.

Sun breakers are a design element that is frequently overlooked by many designers. It’s an important concept for the environment that India experiences, and if used strategically in today’s modern construction, it’s quite effective at deflecting strong sunlight and keeping the indoors cool. Along with evolution, wooden louvres or textile products are being used to create attractive façades, which are paired with durable elements like concrete or steel. Designers can also experiment with angular façades, which can enlarge the interiors and emerge in a diverse array of forms and aesthetics.

Innovative materials are being developed to give structures a rustic but spectacular appearance. A good example is weathering steel. It doesn’t

need to be painted, and when exposed to the elements, it creates a simple yet rusty appearance that contributes to its timelessness. This allows for a gradual material transition.

Façades are also known as the building’s skin because they allow the structure to breathe in response to its surroundings, connotation, and orientation. They can be built in a variety of materials, including wood, metal, and even fabrics, to provide a unique screening for the building.

Another important key factor of modern perspectives is green design, which is becoming more widespread in buildings. Solar panels, rainwater harvesting, and vertical gardening are being used to

create buildings that have a zero-carbon impact and are self-sustaining. Solar shingle roofs can be used in conjunction with standard roofing tiles, owing to their durability. It is a sustainable and innovative choice as it serves as solar panels that generate renewable energy for the building. These solar units can be linked together into the electrical system after installation and contribute to the energy needs of the home.

On the other hand, greenery integrated into the façade is not only aesthetically pleasing, but they also keep the interiors temperate and assist in lowering total energy consumption. Though glass facades are conventional in most contemporary designs, there

are innovations with different hues and compositions of glass as well as other materials. Smart glass is a modern and trending material that enables us to actively control daylight and solar heat, improving user comfort and leading to energy efficiency in interiors. It can also filter out harmful UV radiation. In addition, transparent or translucent frame façades can be explored in a myriad of contexts.

Finally, façades are largely symbolic of a region’s unique culture and social circumstances throughout the world. Some, on the other hand, convey worldwide idioms; they are global in scope and originate for the benefit of architecture.

AR. SUMIT DHAWAN Founder & Principal Architect, Cityspace’82 Architects

Ar. Sumit Dhavan started a solitary practice directly after completing B.Arch in the year 2005 and founded Cityspace’82 Architects. His childhood passion for architecture manifested the perseverance and belief which lead Sumit to practice unconditional hard work. Firmly believing in a perfect balance between functionality and form, Sumit ensures to rationalise both, the aesthetics and functional regime of every endeavour he outlines. Having experience of almost two decades, Sumit has single-handedly nurtured this firm and given it the position where it stands today. Ar. Sumit has established his name extensively in the design industry and has found his way to renowned celebrity homes. He has done projects for politicians, bureaucrats, lawyers, the residences of famous cricketers Yuvraj Singh and Gautam Gambhir, and many more. Also, his work is appreciated by developers whom he has collaborated with including DLF, Ansal Group, Orchid, MGF to name a few. His eclectic façade style has made him a favourite amongst numerous practicing architects.

Contact: Ph.: 0124 426 7519

e-mail: cityspace82@gmail.com

Website: www.cityspace82.com

Our in-house innovation AIS Regal Select redefines your floor-to-ceiling approach with the widest range of glass solutions offered by the country’s largest glass portfolio. So you can enhance your space with slim, strong, and robust aluminum doors and windows with versatile handle options. Give your space the Regal Select touch:

The construction industry alone is responsible for 40% of the total energy consumption of the world and is projected to grow with the increase in population and housing demands. In this situation, it is necessary that the development and growth are sustainable and green in consideration to the environment around us. This is the very reason why concepts like sustainable building design, energy-efficient and green buildings, net zero building, and energy-positive development are the need of the hour. These concepts will help in reducing the building footprints on the ecological system.

Traces of fenestration in India can be found from the 3rd century where Indian architecture has given serious thought to fenestration in architectural designs. However, the usage of high-performance glazing in façade and fenestration is still at its nascent stage. At 2.1 KG per capita

glass consumption, India is currently way below the global average of 5 kg, which indicates that this Industry is at its growth stage.

Major challenges in the fenestration Industry are the lack of required infrastructure, skilled resources & technologies, and the majority of the unorganised players which are the roadblocks to the fast-paced growth of the façade and fenestration industry.

As the construction industry evolves with need, our buildings also grow and adapt. The element of design which has seen the most modification after the form of the building is the façade. Façade design evolved from being a simple wall that supported the roof and floor to one of the most important factors in terms of identity, sustainability and structural viability of the building.

Considering the building stock, the façades are very important, based on the scope of making a building green and sustainable, because of their volume and area. Researches done in the past decades have now brought us to the present concept of living façades, green façades, kinetic façades, hybrid façades, sustainable façades, etc. to amplify the energy efficiency of buildings.

Glass has been the most popular and most talked about façade element in building design since its introduction. Early modernism was a revolutionary period for the building industry, as glass and steel were used extensively in construction. Attributes like the ease of installation, lesser construction time, optimum daylight in dense cities, sleek design, easy

dismantling, and recyclability became the USP of glass as a sustainable building material. The two most breakthrough innovations in the history of glass are the introduction of laminated glass in the 1920s and coated glass products in the 1970s. While laminated glass brought the feature of safety and security, coated glass brought a revolution in making façade energy-efficient.

The green building movement started with the concept of sustainable buildings and is widely adopted by all the countries in the world. The governments have promoted the movement by creating different green rating systems and standards to follow which ensure wise use of materials, systems and processes in the construction industry. Ambitious milestones like India’s plan to become Net-zero by 2070, can be achieved only by green policies, awareness about different concepts associated with sustainability, and innovative and wise decisions. Apart from sustainability, the Government initiatives like Make in India, the launch of the Energy Conservation Building Code (ECBC 2017), National Building Code (NBC 2016), all of which promote the usage of the right building materials including glass. Regular revisions in these policies help the nations to introduce new concepts to

the standards, helping to achieve the goals faster and easier.

Being present in every building, the nature of glass is perceived to be a problem now, glass enveloped buildings are thought to be most uncomfortable, over-exposed and overheated using more active cooling methods, consuming more electricity and thus adding to climate change. The list does not restrict itself to energy consumption, the reflective nature of glass is also responsible for the heat island effect, increasing the temperatures of the immediate environment. Despite such a prevalent notion, the use of glass is still a preferred choice in large projects, futuristic ambitious skyscrapers and city developments, like the mirror city, UAE.

With the increase in demand for building stock in the world to house the

population, it became necessary that the considered development is aligned with the concept of sustainability. And with such extensive construction on the row in the future, the use of sustainable and green building materials is essential. Researchers and developers have evolved a material palette that consists of green and sustainable building materials. One of the materials is glass. Over the period of time, clear glass has evolved into performance glass, where the glass products have different performance values suited for each requirement. But, the product alone is not sufficient to bring maximum energy efficiency in a building, its wise selection of the product, well placement, and optimum shading are major factors to achieve maximum efficiency of the glass, along with ensuring thermal and visual comfort of the occupants.

The present-day market is loaded with glass products that cater to all the energy efficiency needs of the buildings. In a tropical country like India, Solar control and Low E products reduce the heat transfer into the building and further lessen the consumption of energy to mitigate the heat from the building. Coated glass also referred to as performance glass has different coatings on float glass which gives the glass its properties to become high performance by controlling the daylight, solar radiation and thermal insulation.

Innovations like electrochromic glass are gaining popularity among designers and energy professionals. The feature of the glass to respond to the external climate and manage its tint to maintain the indoor ambient environment by using a unique control system is what makes it energyefficient. Another innovation coming across is glass blocks replacing masonry as the walling material. Glass blocks are energy-efficient. in terms of both lighting and thermal comfort inside the building. Due to its translucent nature, the natural light entering the space is diffused,

reducing the need for artificial lighting and avoiding visual discomfort due to glare simultaneously. The hollow centers in the glass block provide insulation to the heat ingress. The finishing of the glass blocks with mortar joining also helps to prevent air infiltration better than windows and glazing systems.

Sustainability not only pertains to the environment but also includes the safety and security of human lives and infrastructure. Impact and fire resistance glass with increased strength and integrity provides extra protection to the inhabitants from any mishappening.

To know about the future of façades, it is important to understand the future of sustainability. The trend tells us about energy-positive development which includes surplus generation of energy on-site using renewable resources, enough for the building as well as giving back to the power grid. Since façades have a maximum area under solar exposure, they can produce more electricity using photovoltaic panels if placed on them. Using the same concept, innovations are being made to integrate photovoltaic cells with the building’s glazing system. Glass panels with BIPV can be used as spandrel glasses in the building, whereas no compromise to the view and daylight coming from the vision glass can be ensured.

Integration of glass with kinetic façades is also in the innovation stage. Optimisation of kinetic shadings to shade the façade as per the time of the day and direct solar radiations falling on it to get the best results in energy efficiency.

As it is quite clear that the future of the fenestration industry in India is very bright and the following are the driving factors fuelling the accelerated growth of the industry:

1. Organised players

2. Increase in awareness

3. Government intervention

4. Reduction in cost due to localisation

5. Fast-paced growth in the construction industry

6. Technological enhancement

While the fenestration industry is ripe for future growth, there are many challenges that can hinder the pace and disrupt the future growth path. Lack of awareness at the end consumer level about the disadvantages of the traditional windows system, no proper windows rating system, lack of sufficient façade consultants and unavailability of façade and fenestration as a separate subject in major colleges are few of many such challenges which can become the roadblock. Industry, influencers, policymakers and academia have to come together and address these issues in an organised way to clear the path for a seamless growth of the façade and fenestration industry. It will also help India in achieving its dream of achieving a net zero goal by 2070.

Head – Business Planning, Operations & Technical, Asahi India Glass Ltd (AIS)

Shailesh Ranjan is the Head – Business Planning, Operations & Technical at Asahi India Glass Ltd (AIS). He has over 18 years of rich experience in the glass industry in handling different profiles like business intelligence, product management, project management, marketing, strategy, technical marketing, business planning & operations. He has participated in various exhibitions and seminars as a keynote speaker delivering lectures on different dynamics of glass. He is also a certified green building trainer. Ranjan’s key areas of expertise are in promoting energy efficiency, net zero, and safety through the glass in the architectural segment for different climatology and type of buildings.

A view for sustainable future.

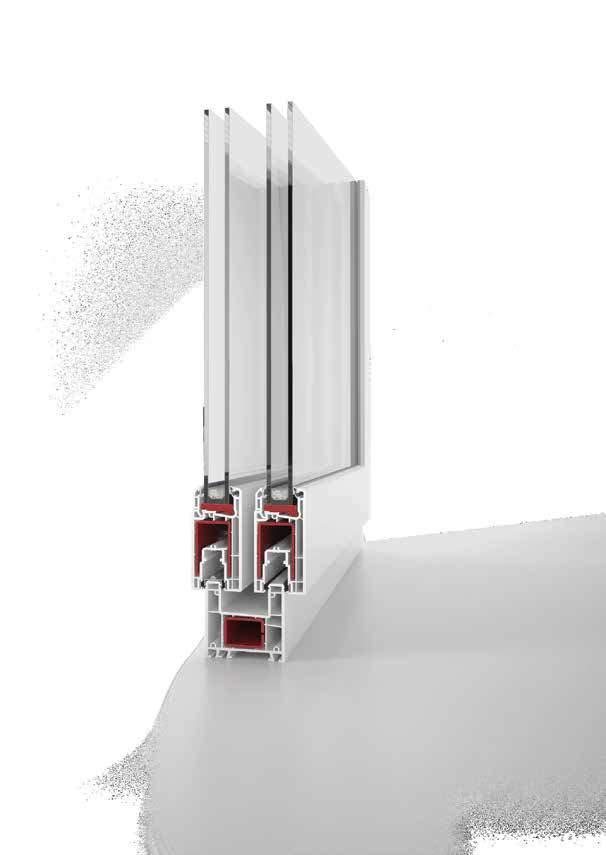

Sudhakar uPVC windows and doors are the most energy e cient systems made from advanced European technology for a sustainable product development.

Scan QR

Come and visit our latest, greatest products and witness our quality on live @

November 10th-13th 2022

ACE-TECH - 2022, Bombay Exhibition Centre, Goregaon - Mumbai

Stall No. C10a, Hall - 1

Follow us:

December 01st-03rd 2022 to download product catalogue

ZAK Windows and Doors Expo - 2022 Pragati Maidan - New Delhi

Stall No. DD1, Hall - 3

Façades serve as the structural, aesthetic, ventilating, and bracing aspects of buildings. In a highly populated country like India, it’s essential to accommodate the increasing urban densities that increase foot traffic in public areas. Urban and suburban skylines have changed due to vertical growth. A 2019 estimate claims that fenestration accounts for about 65% of the 10,000 crore rupee industry. This business is propelled by technological advancements and is mostly supported by the real estate market’s explosive demand.

How do we ensure that fenestration development is sensitive to the Indian context, follows the proper path, and keeps up with the rising demand? A comprehensive view of this advancement contains the solution to this query. Fenestration is now a crucial, practical component of places rather than just an ornament. One

can ensure a sustainable alternative by combining the appropriate fenestration technology with passive site-responsive and context-specific strategies.

1. Choosing the right material

Fenestration systems made of highquality, long-lasting materials like aluminium are anti-corrosive and malleable, which makes them perfect for various construction typologies.

Primary requirements for fenestrations should also include maximising natural light in a place and providing thermal comfort through natural ventilation. The market today offers a variety of treatments and types of glass, including laminated, tempered, and toughened glass. The most reliable method of putting these tactics into practice is selecting the proper glass type based on the above-mentioned factors. Making the appropriate decision lessens the burden on mechanical ventilation and lighting systems. Higher energy efficiency is also ensured, which is another step toward sustainability. In the long run, putting natural light and ventilation first improves public health by lowering our reliance on artificial systems.

Inherent properties of aluminium: Aluminium is a robust material that is easy to work and innovate with. It guarantees longevity and gives excellent value for its worth. In addition, it’s recyclable and consumes less energy than steel during its manufacturing and recycling process. This helps lower replacement costs of fenestration systems.

Fenestration systems made of high-quality, long-lasting materials like aluminium are anti-corrosive & malleable

Since it’s easier to install, clean, and maintain, it becomes a viable investment for hospitality spaces to save on the cost and workforce required. Besides that, aluminium can also withstand harsh weather conditions without resulting in a lot of wear and tear – making it a good fit for tropical and cold climates. Furthermore, combining this fenestration material with energyefficient glazing and a layout that optimises natural light and ventilation can result in a sustainable fenestration system that works well with the site’s climatic conditions.

Incorporating suitable materials such as aluminium in fenestration systems, accompanied by proper design and maintenance strategies, can help make more sustainable choices in the hospitality sector.

2. Processes and life-cycles

It is essential to consider the materials utilised and their life cycle, given the startling rate at which projects are produced in the Indian construction sector. First and foremost, using locally obtained, indigenous, and natural materials significantly lowers the cost. Second, materials with a longer lifespan are rigid and guarantee the longevity of construction, leading to reduced maintenance expenses over time.

Finally, the project’s carbon footprint is decreased by using recyclable and recycled components.

3. Supportive strategies

One can use architectural solutions in conjunction with the proper fenestration technology for better outcomes. For example, installing sunshades, dry-stone cladding, and vented façades can help lessen heat gain in a structure. In addition, one can get the best possible solar absorption by planning the building mass following the site’s orientation. Openable, adaptable, and user-friendly fenestration systems can produce the best results.

1. The union of smart and green buildings

Green buildings are environmentfocused, giving the utmost importance to sustainable and eco-friendly practices. Smart buildings, on the other hand, are centred around efficiency and optimising comfort for the user through intelligent, automated processes. Going forward, the union of these two concepts will take place rapidly by incorporating green practices into intelligent systems.

The fenestration industry, for example, has made efforts to integrate smart systems like better locking mechanisms and ergonomic designs into energyefficient windows and façades. These systems are developed based on indepth calculations, which results in high performance.

2. The role of renewable energy in this revolution

The passive building design is a great starting point while addressing the built environment, but in today’s hybrid world, it seems insufficient on its own. Buildings must integrate renewable energy sources from their planning

stage to the construction and postconstruction phases. Not just that, the construction industry should consider using renewable energy sources. Stakeholders can shift manufacturing products such as fenestration, furniture, construction equipment and other building materials to a greener realm by using renewable energy sources for their processes.

• Effective cladding methods

The exterior finishing technique known as cladding is analogous to a coat or an extra non-load bearing

layer. Along with making the exterior façade of the building aesthetically pleasing and decorative, it also assists in shielding the interiors from the damaging effects of the weather. The correct cladding reduces temperature variance inside buildings while also keeping the structure weathertight and economically viable. It also offers thermal insulation. Additionally, it aids in daylighting and interior acoustics improvement.

While different kinds of stone have historically been very popular, there are now a wide variety of materials available, including ceramics, aluminium

composite panels (ACP), terracotta, Corian, zinc, glass reinforced concrete panels, corten steel, concrete fibre boards, copper, fibre reinforced plastic, wood, wood composites, exterior grade laminates, glass, and LED façades, to name a few.

The fixing technology of these materials has undergone rapid change, switching from traditional wet fixing to dry systems, significantly reducing the time required for the building process.

The choice is made very carefully, taking into account the location, the weather, the neighbourhood, the type of property (residential, commercial, industrial, etc.), and other factors that might help to prepare for the material appropriately. As a result, there are now sustainable materials that are also simple to maintain, resulting in cheap maintenance costs for the structures they are used in.

• Trend-setting cladding materials:

1. Glass Reinforced Concrete: Due to the adaptability it provides and the fact that it is around 80% lighter than pre-cast steelreinforced concrete cladding, architects and engineers prefer to use glass reinforced concrete (GRC), also known as GFRC concrete, for exterior cladding.

2. Terracotta Exterior Cladding: A newer style of curtain wall system that uses terracotta panels as a decorative element is called a “terracotta façade system.” With its big format panels and practical heights that provide total privacy, it is the ideal marriage of conventional materials and modern architecture.

3. Rainscreen Cladding : To protect your core walls from moisture, the rain-screen cladding system

Intelligent façade detailing with responsive and reactive surfaces allows for the design and implementation of several options is composed of an insulation layer and cladding material that is bonded to the property using a supporting framework. To suit architectural elements, façade ends, and junctions, rainscreen cladding can readily bend and rolled. These eco-friendly cladding technologies improve thermal and acoustic insulation.

4. Solar Shingles: Solar Shingles are meant to almost seamlessly mix in with conventional roof tiles and are simpler to install than conventional solar panels. Solar shingles shield the roof from the elements, reduce energy bills, and offer a sustainable energy source.

• Intelligent cladding Intelligent façade detailing with responsive and reactive surfaces allows for the design and implementation of several options. The latest developments in designing sustainable structures are Kinetic surfaces with mechanical/ electrical designs.

Surfaces created using computational analysis in digital software allow for

the moulding of numerous materials in accordance with regional climate conditions. As a result, cladding and surface textures are simple to implement. However, they might not be economical. The intention of designing and implementing such a surface contributes to creating interactive and intelligent surfaces with a range of potential. Such materials are executed in precise formats to react to the surroundings.

Each player in the construction sector is responsible for contributing to environmental sustainability. The potential of these technologies has been revealed by research and invention. But it’s important to move forward and take the appropriate course of action.

Sustainable development is not a novel idea in the Indian context because it is firmly anchored in conventional construction techniques. However, without straying from the sustainable path, the current issue that needs to be met considers the growing technological and consumer demand.

Nitin Mehta is the Co-Founder and Executive Director of ALCOI, one of India’s leading suppliers of eco-friendly high–performance fenestration solutions. With his futuristic outlook and innovative leadership, Nitin has led the growth of ALCOI into an industry leader in the realm of premium fenestrations. Under his leadership, ALCOI has transformed into a one-stop solutions provider for the design, manufacturing, installation and servicing of precision-engineered fenestration systems in India and abroad.

An engineer by education from Punjab Technical University, Nitin integrates cuttingedge technology with his experience in the metal industry, leading the design and development of high-performance products in-line with market requirements. ALCOI is a leader in the AEC industry, with a unique product portfolio that blends aesthetics with material innovation and sustainability. Nitin has expanded ALCOI’s global presence by engaging in partnerships with international firms, carving a niche for the company and its products outside the Indian subcontinent.

Building façades have always been a significant part of the building structure for both the architect/ designer and the builder. It acts as an interface between the interior and the exterior environment, playing a crucial role in heat and light exchange, thermal and acoustic performance, structural strength and sustainability. Façade designs are well thought out to ensure the right materials and fabrication go into making the building complete and distinct while aiming to provide occupant comfort.

The objective of the façade is to maintain a balance between all the parameters that include aesthetics, thermal comfort, managing daylight, solar heat gain, visibility and very importantly the geological balance to ease global warming. With the advent

of new technology and the rising need for resident comfort, innovation in façade materials keep evolving. Façades are no more treated as a mere derivation of functions inside a building, but they also help develop a connection with nature, aiding in general wellbeing.

The atmosphere around the area and the sun path with respect to the building’s orientation are the initial guiding factors for designing a façade. The façades that attempt to adapt to their immediate environmental changes are known as intelligent façades. Massing studies for a designer or a developer then becomes important to get optimal daylight into the building to reduce solar heat gain, keeping balance in any adverse effect on surrounding nature.

The northern façade of a building help solve this problem as they provide access to ample indirect glare-free daylight without the risk of major heat gain. While the south & west façade faces require careful consideration of window-to-wall ratio, daylighting and glare studies along with the use of shading devices in the form of blinds, vertical or horizontal fins, overhangs, double façades, recessed windows, or traditional jaali. This further aids in making the buildings energy-efficient and reduces their life cycle cost.

Heat-strengthened glass on a façade is to be chosen with the right insulating value to allow maximum glare-free light into the interiors while simultaneously appropriating the solar heat gain coefficient and reducing mechanical cooling loads. This type of glass also aids in withstanding pressure and strong force from strong winds. Similarly using highly reflective materials on the roof can further reduce the heat island effect.

High-performance façades in residential buildings help maintain their performance characteristics during the whole design life cycle of the building. Some of the features of high performing façades are in offering energy efficiency to the building, wind and environmental pressure resistance for the high rises, along with control of heat transfer, air and moisture movement.

A building envelope helps address performance parameters that include energy and sustainability, health and comfort, safety and façade durability. This needs to be done while supporting the architectural intent and ensuring that the design is feasible and true to the quality.

GIGA,

The performance materials used in the GIGA project are suitable for specific performance requirements executed economically for an efficient and sustainable system. An efficient building not only targets low operational costs but also low embodied energy usage involved in the extraction of raw materials, manufacturing, transport and construction of the building.

Building fenestrations in the project further are a significant element of façade design, from both aesthetic and performance perspectives. It allows natural light to enter the interior space and also allows heat transfer between the outside and inside. When choosing fenestration materials, specific properties of glass are considered such as U-values, SHGC, and visual transmittance. Fenestration design further adds sustainable features. External façade present high levels of thermal insulation

of walls and windows to help reduce heat loss along with maximised natural and daylight ventilation.

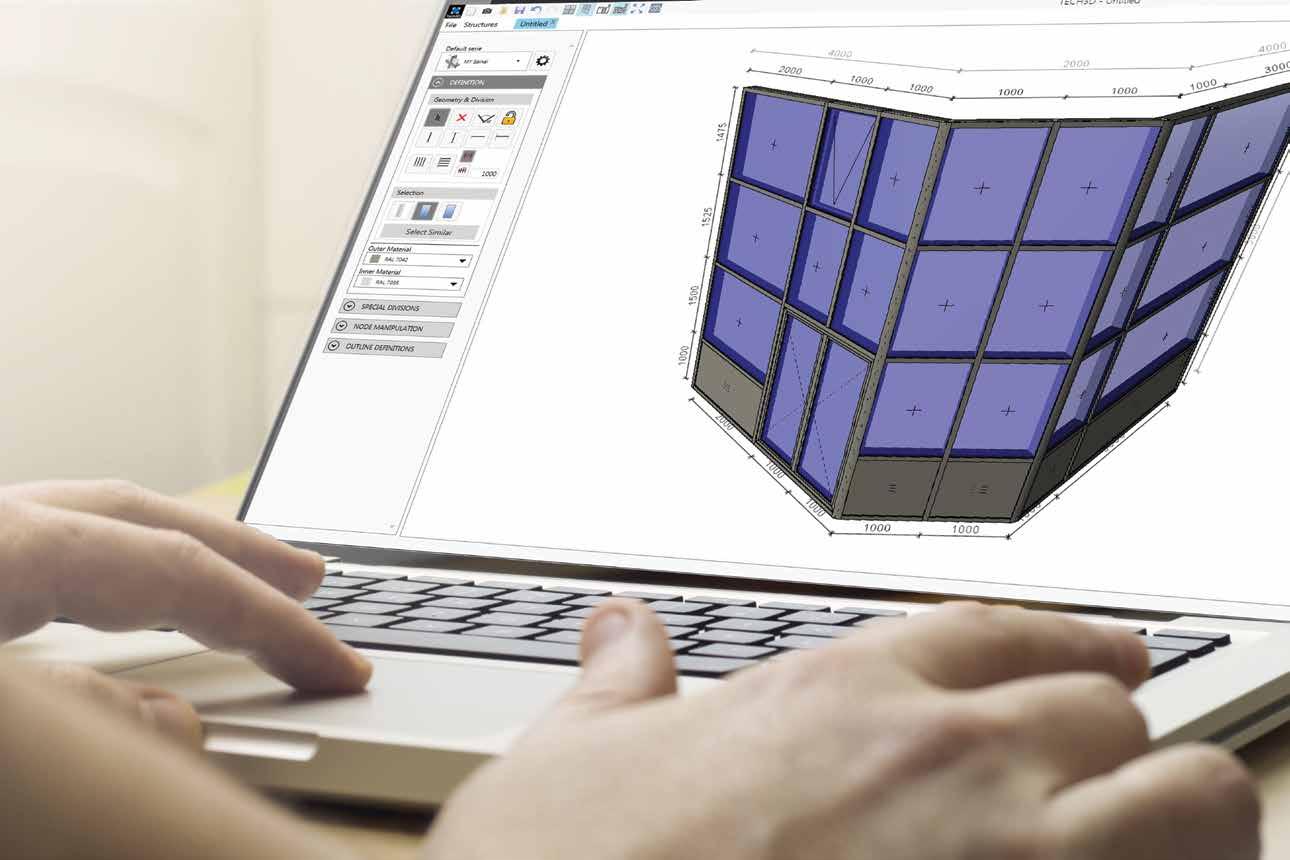

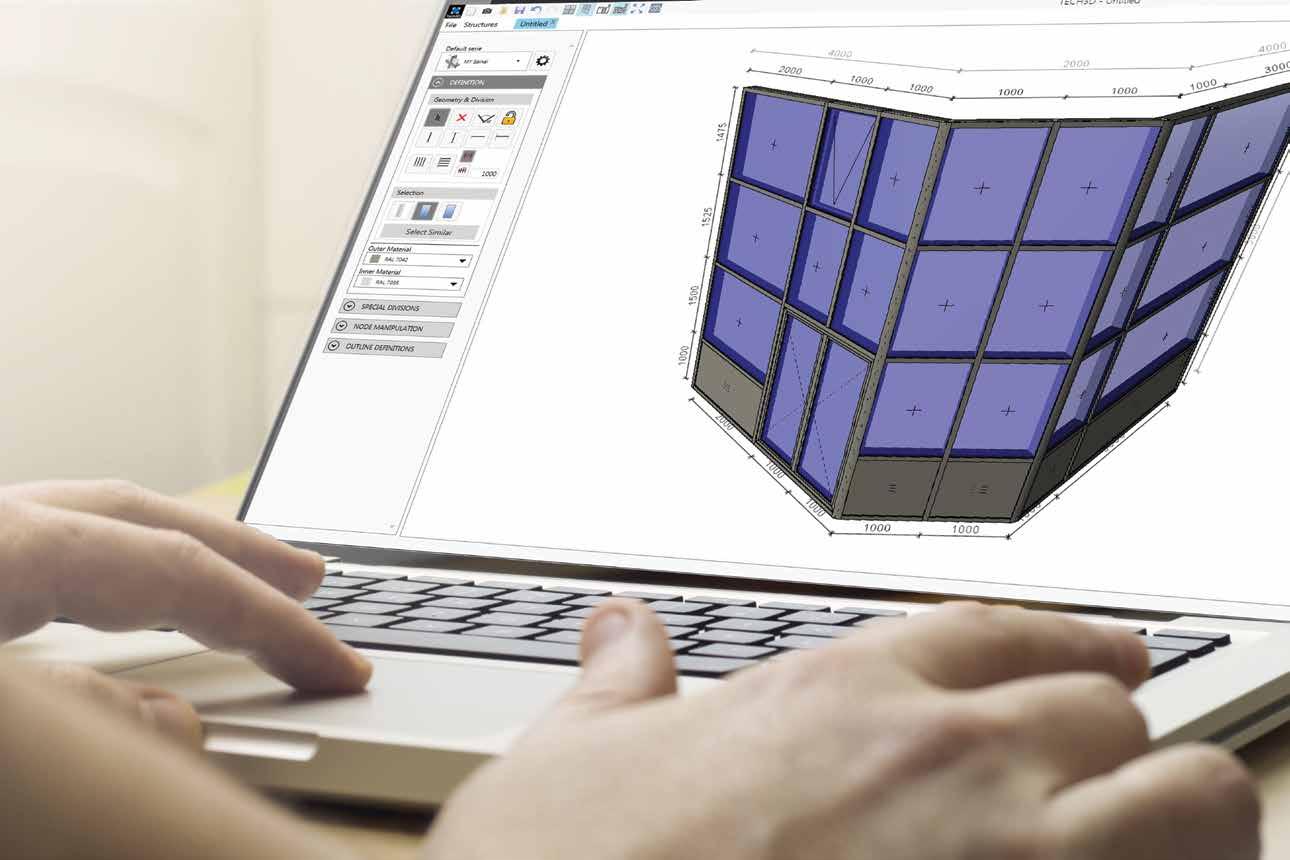

Many developers are now choosing to go with dynamic façades in the building envelopes that can change their performance with the changes in the exterior environment. This concept is being highly integrated with the façade engineering field. Software tools like CAD, BIM and parametric used in façade designs have been known to contribute to increasing efficiency, accuracy and coordination.

Early stage optimisation services help in assisting in setting efficient massing configurations, and considering orientation volume and position of a building in accordance to the location and environment. The process helps in analysing the numerous configuration perform environmentally and provide the design team with the necessary performance evidence to optimise the design.

Thoughtful façade design parameters are considered w.r.t. directions, eg. darker shade facing the south and west end and lighter shade for the north and east end as per Heat and UV calculations.

Also, IGBC parameters were taken into consideration while selecting the façade members.

Precautions were taken during the procurement of materials to meet the fire resistance parameters to avoid the spread of fire in case.

Group CEO, Kolte Patil Developers

Rahul Talele has been with Kolte Patil Developers for over a decade, having joined as Deputy Project Director in 2010. With over 14 years of experience in real estate functions spanning the entire project lifecycle, Rahul has been instrumental in driving various strategic initiatives, including the company’s entry into the affordable housing and Mumbai redevelopment markets, as well as the expansion of Life Republic Township. At Kolte-Patil Developers, he has progressed from Deputy Project Director (CMD Office - Strategy & New Initiatives) to Project Director - Mumbai (Project Strategy & BD), to Business Head - Life Republic, then to Business Head - Pune, and finally to Group CEO in September 2021. As a People’s Champion, Rahul has pushed the brand to do more for business and people. He holds an MMS in Finance from JBIMS and a B.E. in Information Technology from Sardar Patel College of Engineering in Mumbai

The envelope of every major building needs to be accessed, maintained and cleaned to an immaculate finish and appearance. This becomes all the more important when we deal with complex geometries in modern architecture, high-rise structures Power Skin enclosure and its components. With contemporary architecture growing more and more complex, accessing the building envelope has become an extremely difficult task. To access and maintain them, it is quite often necessary to have customdesigned and engineered systems in addition to the standard equipment available with the manufacturers. Barring some straightforward buildings, it requires special knowledge of the available systems options to be applied. The architects and building envelope designers need to have adequate knowledge of façade access systems available and required for their buildings which is essential for them to use the best possible choices. This article endeavours to study, illustrate and determine the importance of planning façade access systems, selection criteria and application for building façade access and maintenance

Ideally, the best stage to plan façade access requirements for a building is the design stage. Determining façade access requirements and incorporating it in the building design results in the most appropriate, functional and cost-effective result.

The following need to be taken into account in the selection and application of appropriate façade access systems for the buildings.

• Cleaning cycle requirements

• Other maintenance, frequencies and durations

• Material hoisting requirements with weights and sizes & frequency

• Architectural considerations, equipment visibility and if screening equipment from vision is required

• Provision of space for equipment and structural load bearing capacity at an available location to support equipment

• Availability of electric power supply, cleaning water supply, wastewater disposal and BMS connection if required at equipment location

The above information, which will define system requirements, need to be obtained from building designers, architects, structural designers, consultants, MEP engineers, façade engineers and facility managers.

There are instances where façade access provision is not taken into account during the design stage and considered later during building construction or even worse after construction. In such a situation following difficulties occur in most cases:

• Building may require redesign and modification to accommodate a façade access system that had not been taken into account in the original design

• The options to have an appropriate façade access system may be limited and may need to settle for an option that may be an inferior solution compared to the choices available at the design stage.

• Cost of having a façade access system may be substantially higher since redesigns and modifications may be required.

It is best to avoid this scenario.

Building Maintenance Units (BMU): These are the most commonly used systems and are roof-based, most practical, cost-effective and easy to use.

Davit System: When installation of BMU is not possible on the roof, Davit systems are frequently used, though handling and operating the davits is labour-intensive manual work. This however is not suitable for heights above 100m due to the utilisation of traction hoists and suspended electric cables, both unsuitable for heights.

Monorail system: Whenever installation of BMU or davits are not possible on the roof, monorail systems are the most frequently used system which mounts on elevations. This however is not recommended for heights above 100M due to the utilisation of traction hoists and suspended electric cables, both unsuitable for heights.

Cradle systems: There are various cradle systems, also known as gondolas and cages. These are suspended from BMUs, davits and monorail trollies for carrying operators with tools and materials for cleaning and maintenance.

Ground launched systems: When building skin to be covered is a low rise, it can be covered by ground-launched systems. Mobile Elevating Work Platforms (MEWP) is easy to use and effective. Their light-weight and compactness make them suitable to use for building exterior and interior elevations and skylights. With MEWP’s capable of operating with outrigger footing on different levels, climbing staircases and passing through narrow doorways, these have multiple applications.

Rope access system (abseiling): Whenever conventional means of human access is not possible to reach building skin, rope access is the solution we arrive at which enables vertical climb and horizontal manoeuvring for cleaning and maintenance

Traversing and revolving gantry platforms: Several types of traversing and revolving gantry platforms are being used mainly on roofs, skylights and domes. Their advantages are simplicity, effectiveness, economics and easy usage covering areas where BMU is normally unsuitable. These can be simple small manual gantries or fully powered large units. Some of the popular versions of these gantries are horizontal, inclined, curved and revolving units for exterior and interior access.

Robot Systems: Robot access systems have a trolley on a twin track system on the roof, with a hoist carrying suspended robots. The robot does automatic cleaning of building façades using vacuum cups for secure positioning on the façade. The cleaning robots are hoisted automatically by the roof trolley which carries the Robot and moves horizontally along the façade. The entire façade cleaning is programmed and fed into a control system to drive the operation automatically. The Robot cleaning system cleans the façade using purified and recycled water with minimal human effort. They cross obstacles like mullions, transoms, sunscreens, etc. covering elevations, and navigating automatically. Advantages of Robot Systems are easy usage, high-speed cleaning, cleaning water recovery, purification and recycling. These are ideal where human access is impossible or dangerous. The disadvantages include a higher cost and limited use. A robot does only the programmed operation. Does not consider an actual situation where more cleaning or lesser cleaning is required. These do not provide human access and are only for façade cleaning.

This system stabilises the suspended platform against the wind. It is mandatory to use lateral restraint systems for height over a certain limit which varies in different places as per various local standards. Relevant standards for the respective geographic region should be verified and applied.

It is important for façade and structural designers to take this into account since restraint sockets need to be installed on the elevations at the required locations taking the required loads.

The most widely used European standards EN1808 and comparative critical values of US and Australian standards are:

There are three types of lateral restraint systems.

1. Mullion Guides: The mullion guide track runs vertically on the elevations in parallel lines all around with coordinated spacing for two mullion guides to be reachable from the cradle at a time for engagement and disengagement of guides secured to the suspended cradle. Guide rollers from the cradle run into the mullion guide tracks restraining horizontal movement due to wind.

Intermittent Stabilisation System:

In this widely used system, restraint sockets are embedded on the elevations at required heights and spacings with load-bearing capacity as stipulated by the relevant standards to restrain lateral

movement of the cradle. The restraint lanyards from the cradle suspension wire ropes are secured to embedded restraint sockets. Different types of restraint sockets with quick release pins and sockets are available with different manufacturers. The most popular types are the sockets that are flush-mounted to the façade. These are generally cylindrical in shape made of SS316. Another type of restraint used sometimes is a protruding plate type that gets hooked by the restraint lanyard from the cradle suspension wire ropes. This is generally not preferred since visible by projecting out on elevation. These are normally painted to background colour for minimum visibility when an embedded restraint socket is not possible.

Creativity is ever-changing. It is a space full of diversi ed beauty and rhythm. The noble & honorable classic series & hardwares meets the needs of every hotel project & it is a business card that re ects your identity

This is intermittent stabilisation with additional independent soft rope restraint lines from the BMU down through the elevation to the reelers in the suspended cradle. This is used when suspension ropes cannot be secured to restraint anchors when cradle reach is to be extended and retracted negotiating steps and slopes on the elevation.

The selection of the right façade access systems that will suit the specific requirements of a building can be a simple task for straightforward buildings. For complex architectural structures with difficult geometries, it can be a highly challenging task to find a solution and select the right systems. In such cases, it takes a great deal of knowledge, innovation, creative thinking and extraordinary engineering skills. Façade access equipment suppliers normally provide three solutions, the most economical, the best possible and the one

that suits the requirement best. This suits sellers best since they are there whichever way the procurement process goes. It is the buyer’s prerogative to choose the right one. A techno-commercial viability check may also be required by comparing the investment in equipment and employing manpower versus subcontracting the cleaning and maintenance with hired equipment if possible.

The following requirements are to be met in the selection and application of façade access systems

• Requirements from architects, building designers, façade designers, building facility managers, consultants, structural engineers and MEP engineers as indicated earlier

• Full coverage of the system to wherever access is required

• Compliance with standards and safety regulations

• Ease of operation

• Availability of timely maintenance and timely spare parts supply

• Economy

“It is always easy to complicate a design whereas it is extremely difficult to simplify to make it easy to manufacture, install, use, maintain and sustain economically”. These words from my first design teacher several decades back hold good even today. With most of the contemporary architectures complicated already, and getting more so day by day we are left with limited choices for simplification. A sincere effort should always be made for simplification to the extent possible since a compromise is mostly not possible on performance. An ideal choice would be to endeavor to have both simplicity and performance complementing each other to the maximum possible extent. The table below gives the information, suitability and comparison of various systems for evaluation, selection and application.

When the requirement gets complex it is advisable to take advice from experts related to façade access.

The BMU manufacturer XSPlatforms had to design the façade access systems for the National Bank of Kuwait, a building with no roof and with architectural features rising high above the main building. The façade access equipment had to be developed in an all-new concept since no similar designs have ever been developed before by anyone. The iconic design and challenging construction of the building resulted in a highly innovative façade access solution. The building is being covered with three systems with one from level 52 and two from level 41 as follows:

This upper-level machine must both reach out to the crown of the building and carry a glass replacement unit in addition to the cradle system. The main challenge is that there is no roof in the building to install the machine. XSPlatforms designed a BMU that is integrated inside the building, invisible in the parking position. It will turn to its operating mode by moving out through a panel that mechanically opens and closes. When operated the machine will automatically move outwards to its working position. From this position, the operators have control of the machine and can reach any location, from the crown of the building down to level 41. The system has the following features:

• Weighing 123,300 kg, this claims to be the heaviest BMU in the world

• Telescopic base height of 38 m, BMU height 44.6 m and knuckle jib reach up to 16 m.

• Hydraulic system pumps 79 gallons of oil per minute for a hydraulic cylinder of 21 ft stroke.

• A glass replacement unit with max. load capacity of 1300 kg.

• Has 6 control panels, 4 cameras, 3-mile electrical wiring, and remote monitoring at XSPlatforms, Netherlands

The two machines on level 41 are knuckle jib slewing machines. These jibs allow the operator to position the cradle around the perimeter of the building – especially around the shape of the ribs. The systems are with a short stretch of straight tracks to move the machine close to the openings on the elevations and to take them back inside for parking. The systems at level 41 consist of 1 BMU with 2 stage knuckle jibs, another BMU with 3 stage knuckle jibs and both fitted with a glass replacement unit.

• Architects: Foster + Partners

• Number of Towers: 1

• Tower Heights and floors : 300 M (62 floors)

• Number of BMUs : 3 special BMUs

• Façade Access Systems by: XSPlatforms

• Years of construction: 2010 to 2014

Façade access systems for this iconic complex were executed by the teams of Farra and Sky Steel Systems directly managed by the author. This iconic US$15 billion governmentowned complex of seven skyscrapers n Mecca, Saudi Arabia, besides the world’s largest and Islam’s holiest Mosque, is part of the King Abdulaziz Endowment Project.

There was a space constraint to place BMUs on these towers since there was no open roof available. A 1 m wide corridor was provided on the service level under the roof to place the BMU. The space was so limited that placing BMU in that space was highly challenging. Special BMU was designed and developed by Farra

Engineering Ltd, New Zealand and Sky Steel Systems LLC, Dubai with the following features:

• Vertically opposed tracks with the upper track under the roof slab at the service level and the lower track on the floor are placed to accommodate the BMU in the service level corridor.

• No counterweights due to nonavailability of space. The track system takes the complete over-turning moment.

• Complete system squeezed into a 1 M wide space in service level corridor.

• While most of the BMU sticks out of the building during operationt,

the parking area co-ordinated and provided to hide the BMU while not in use, screened from vision.

• Special scissor pantograph cradles provided with the BMU for the cage to project into the recess to access the recessed elevations.

While working out appropriate solutions it is essential to work out the quantity of the equipment required to perform the cleaning and maintenance of systems. While material hoisting normally occurs occasionally and since there is a dedicated crane it is not included in the calculations here. The cleaning cycle time and equipment required are calculated as follows.

•

•

• Architects: Dar Al Handasa

Tower 601M

• Tower taken up for case study: Tower C

• BMU’s in Tower C: 1

• Material Hoisting: Using one dedicated crane of 2-ton capacity

• Façade Access Systems by: Design by Farra and execution by Sky Steel Systems

• Years of construction: 2004 to 2012

Ahamed Hussain, a chartered mechanical engineer, has over 25 years of experience in the façade access systems industry, and has completed over 750 projects in several countries. He has dealt with projects of various complexities and heights up to 600 m like the Clock Tower, Mecca, Saudi Arabia.

In addition to Hussain’s association with major international projects and leading façade access systems manufacturers, MEWP’s and fall protection/arrest manufacturers, he has handled many design and build projects from concept to commissioning with special focus on design and execution including specifications, standards compliances and validations. The author was also associated with many international façade access system manufacturers, collaborating with them through joint ventures. The author also has façade access systems experience, exposure, design and project execution experience from concept to commissioning. He has published many books on Façade Access Systems and Solutions.

Façade as per a layman’s term shall be the exterior of a building, even if it is not built with bricks and mortar then too forms the face of the building. The façade is the first thing people notice when they enter any building premise.

India, as a developing country, has started understanding the importance of façade inspections, and indeed, it is the need of the hour. International companies are acting as a catalyst to this process of pushing Inspection as a necessary mandate for every project under the ‘facility management’ vertical.

Inappropriate termination of façade: Termination or junction detailing has to be such that, it must not allow the structural members to be exposed, and also must be water-tight, picture shows poor installation or closure detail

Irrespective of the functionality of the building - be it a commercial building, educational, institutional, healthcare or recreational, its external condition counts.

Also, every building is different depending on its location, conceived and designed by an architect, wind load requirements, seismic zone criteria, glass grid modulation, orientation towards the solar path, selectivity of glass, project geometry, etc. hence every inspection report brings its own unique sets of challenges, associated the with overall performance of the building façade. A

Unsafe railing detail: Railings are the most neglected part of the façade wall type, unfortunately, these are also supposed to sustain Wind load and Live Load; Picture shows a typical type of installation, wherein the glass is just resting on the dead weight bracket and has no fixity visible in the holes intended

detailed Façade inspection can identify issues before they magnify as problems. Knowing what the existing and potential issues are crucial to ensuring the safety, aesthetics and value of a building, and enhancing its overall building life.

Generally, it is recommended that the façade inspection be done every three to five years even if a building is in good condition.

It’s important for building owners to understand the benefits of a façade inspection.

1. Façade inspection can identify any loose, missing, or otherwise damaged building façade elements that need to be repaired immediately or in the near term. This helps to maintain a safe building for the occupants and building users, as well as to protect passers-by on the sidewalks or roadways adjacent to the building from any potential for falling debris.

2. Façade inspection can identify more nuanced water infiltration issues or other façade deficiencies for the building owner. This allows building owners to be proactive in their maintenance efforts and eliminate small problems before they become large problems. It is much easier and less costly to replace the joint sealants on a building façade elevation, or retrofit a metal flashing over an open façade joint than to perform costly mold remediation and interior repairs related to water infiltration through the building façade.

Inappropriate locking detail: Operable panels form almost 10-15% of the overall façade area, of any given elevation, these are generally supposed to match the grid of the façade, hence are of bigger size and have to perform also for the water, air infiltration & exfiltration; the details seen in the Pic alongside is something that must always be avoided

3. Façade inspections help to reduce the liability of the building owner. By identifying building façade concerns early, the risk of falling debris and unknown water infiltration are reduced. This in turn can reduce the cost of associated insurance premiums for the property.

4. Façade inspections are an integral part of the effective facility management of any well-maintained building or facility. They help the facility or property manager have a clear picture of the capital expenditure associated with the exterior of the building. This knowledge allows for more accurate forecasting of CAPEX budgets and alleviates the need for emergency repairs.

Signs of deterioration visible to the naked eye that indicate a thorough and in-depth façade inspection by a professional is called for. These include signs such as cracks, rust stains, physical

deterioration around balconies, and displacement of stone or concrete blocks or bricks. These assessments help inform recommendations for potential energy

savings and identify areas at risk for water intrusion, prevent the risk of repetition of any issues like glass breakage, and identify the cause of glass breakage.

Generally, a façade inspection specialist or ‘due diligence expert’ will lookout for the following visible signs of deterioration:

• Drainage: Check your drains, gutters and downspouts! Dirt and debris can interfere with normal drainage paths. If the gutter is blocked, drainage can be redirected to an area within the building envelope, which could possibly be seen as leakage inside the building.

• Sealant: Cracks, detachment, penetration, change of colour, etc.

• Glass: Cracks if any chipped edge, displacement, coating damage

• Aluminium: Visual damage, corrosion, scratching on coating

• Gasket: Hardening, missing, detachment

• Sashes: Malfunctioning, lock fails, hinges stuck, fixing screws missing, loose

• Leakage: Sign of leakage, complaints from the users.

Water leakages are the most common problems faced by many of the end clients, and some of them being IT Companies, are very particular about the water ingress, the condition seen in the Picture alongside is the most undesirable one for anay office

• Screws/Rivets & Bolts: Corrosion to aluminium members, loosened screws, missing screws.

• Checking the main frame, connection gasket, weather gasket, glazing bead, bracket, anchor (to main construction), cascade drainage gasket, insulation panel.

• Air Barrier Criteria: Check for alignment of the insulation and the air barrier in the drop ceiling or soffit and seal any gaps in the air barrier. Check that the opening, drop downstairs, or knee wall doors to unconditioned attic spaces are sealed.

• Analysing the Fire Stop details from floor to floor just to restrict fire in case of aerial fire.

• Check for proper sealing between the framing and skylights, and the jambs of the windows and doors.

• Analysing the proper engagement of gaskets

in helping to determine cost-effective maintenance and repair solutions.

Visual façade inspection is a very important tool for the assessment of the physical and visual condition of a building’s facades. However, there is some uncertainty associated with this analysis, namely in the quantification of defect areas.

This study intends to present some recommendations to automate the inspection process to reduce the uncertainty related to the visual assessment, namely reducing the subjectivity related to the inspector in assessing, mapping, and measuring the defects in building facades. In this sense, the use of new technologies can help significantly in the assessment of the degradation condition of cladding and, consequently, increase the reliability of an in-service diagnosis.

GAURAV TIWARI Founder, Global Techniques of Architecture (GTA)

A detailed façade inspection is carried out for providing a detailed report to inform the clients of the best practices, mitigation measures, and short and long-term maintenance suggestions. Hence, we recommend that for enhancing building longevity, façade inspections are essential

With multi-faceted roles and responsibilities (like estimation, projects, and business development) across various companies, Gaurav Tiwari has been in the façade industry for more than a decade. An alumnus of Mumbai University with Bachelors in Mechanical Engineering. He is professionally associated with brands like Jyoti Structures Limited, Forbes & Company-Shapoorji Pallonji Group, Façade India Testing Inc, Alfaraa Infra Project Pvt Ltd. and Façade One International.

Gaurav established his dream company in the year 2020 named Global Techniques of Architecture, aiming to service the construction industry with a meticulous inspection of façades, and these inspections shall be for almost 100% of the building’s peripheral area, from the external as well as the internal side. He spearheads an energetic team and plays diversified roles for the company. He is one of the first trainers in the façade industry to be training the next generation of architects about facades at various prominent architecture colleges.