FUTURE TRENDS AND INNOVATIONS IN FAÇADES

Experts’ interviews on the future of façade, future materials, design trends, and opportunities

INDUSTRY SPEAKS

Experts’ interviews on the future of façade, future materials, design trends, and opportunities

INDUSTRY SPEAKS

Step into the world of architectural marvels where buildings don’t just stand tall, they inspire change. The façade of a building is not merely a barrier; it is a canvas for innovation, sustainability, and beauty. Imagine a future where every structure seamlessly blends with its environment while championing energy efficiency, financial independence, and a reduced carbon footprint.

In this era of transformation, façades play a pivotal role, bridging the gap between interior sanctuaries and the bustling world outside. They are not just walls; they’re gateways to a greener, more sustainable tomorrow.

Picture this: cutting-edge materials and designs that not only enhance aesthetics but also harness the power of nature to regulate lighting, ventilation, and thermal comfort. From dynamic shading systems to advanced cooling mechanisms, the possibilities are limitless.

But innovation doesn’t stop there. We are witnessing a renaissance in façade technology, with a myriad of systms vying for the spotlight. From modular panels to biomimetic skins, each solution offers a unique blend of efficiency and elegance.

Yet, the journey doesn’t end with today’s offerings. The horizon beckons with untapped potential, urging us to explore new materials, technologies, and design philosophies. With every breakthrough, we inch closer to a future where sustainability is not just a goal – it is a way of life.

Join us as we delve into the world of façade innovation, where creativity knows no bounds. From towering skyscrapers to humble abodes, every structure has a story to tell - a story of resilience, ingenuity, and a commitment to our planet.

So, dive into the pages of our magazine and embark on a journey of discovery. Share your thoughts, ideas, and aspirations with us, for together, we can shape a future where architecture is not just about buildings – it is about building a better world.

Enjoy the read, and don’t forget to share your feedback and suggestions at editorial@wfmmedia. com. Let’s build a brighter tomorrow, one innovation at a time.

08

20

Performance-Based Fire Engineering - Advancing Design Strategies for Complex Buildings

Max Lakkonen, Managing Director, IFAB - Institute for Fire Safety Research (Germany)

Open Cavity Barriers Investigation

Ashwant Singh (Australia), Farith Hinojosa (Bolivia), Maria Binte Mannan (Bangladesh), and Matheus Pontes Lima (Brazil)

Exploring the Role of Acoustics in Architectural Façade Design

George Xanthoulis, Senior Consultant, AtkinsRéalis

New Generation Façades: Revolutionising High-Rise Design and Performance

Sanjeev Jahagirdar, Technical Director, Integrated Quality Services & Solutions

32

48

The Acoustics of Façade and Fenestrations

Jacob Mathew, Senior Acoustic Consultant, Ramboll Middle East

Future Trends and Innovations in Façades

Experts’ interviews on the future of façade, future materials, design trends, and opportunities

Industry Speaks

Interview with Leonid Lazebnikov, CEO, Aestech

Face to Face

Interview with Tushar Sharma , Technical Design Lead, Woods Bagot (London Studio)

Front cover courtesy: Woods Bagot

Published by: F and F Middle East FZ-LLC

Founder: Amit Malhotra

Editorial: Renu Rajaram renu@wfmmedia.com

Shefali Bisht editorial@wfmmedia.com

04

15

26

42

Sales & Operations: Kapil Girotra kapil@wfmmedia.com

Subscription & Circulation: Devagya Behl support@wfmmedia.com

Design & Concept by: Chandan Sharma

Max Lakkonen Managing Director, IFAB -

Max Lakkonen Managing Director, IFAB -

Institute for Fire Safety Research

(Germany)Max Lakkonen is the Managing Director of IFAB - Institute for Fire Safety Research (Germany), bringing over 20 years of expertise to fire engineering. With a background in academia in Finland, he holds a postgraduate degree in fluid power and automation engineering. Max is a well-known lecturer, often speaking at fire protection conferences and actively participating in standard committees such as NFPA 130, NFPA 502, NFPA 750, and ITA-COSUF. He also chairs the scientific council of the International Water Mist Association and serves on the MDM Editorial Advisory Board for leading fire industry publications. Max’s strong scientific background and expertise in an accredited fire test laboratory uniquely qualify him to handle complex fire engineering challenges. Specialising in performancebased design, computational fluid dynamics, and water-based firefighting systems, Max has authored over 80 publications and holds several patents.

In modern architecture, with its evolving designs, materials, and complex structures shaping urban landscapes, ensuring fire protection poses a challenge. The integration of glass façades and other glazed structures presents both technical and commercial hurdles for designers. However, an increasingly employed solution to address these challenges is performance-based fire safety design.

Architectural advancements, environmental concerns, and the integration of renewable energy technologies like photovoltaic panels pose significant challenges to fire safety in modern buildings. Traditional fire safety standards often struggle to address these complexities, highlighting the need for a more adaptable framework. Performance-based fire engineering emerges as a viable alternative, offering a comprehensive approach tailored to the unique characteristics of each building. By prioritising safety targets through flexible and innovative solutions, performancebased design strategies empower architects and engineers to navigate the intricacies of modern architecture while upholding fire safety standards.

Performance-based design in fire safety allows for the customisation of fire protection measures, departing from prescriptive codes and standards. Widely adopted in Europe, this approach offers flexibility in addressing challenges in complex buildings where standard methods may prove inadequate, such as with glass façades.

In this iterative process, fire safety engineers and designers follow key

steps outlined by organisations like the Society of Fire Protection Engineers (SFPE) or NFPA. They commence with a comprehensive analysis including various factors such as fire risks/load, materials, occupant characteristics, and evacuation strategies. This detailed analysis covers the unique needs and vulnerabilities of each building individually.

Subsequently, engineers establish performance objectives based on the analysis findings, delineating specific targets for fire safety measures. These objectives form the basis for designing customised solutions that optimise safety while considering architectural and functional requirements.

Advanced tools such as computational fluid dynamics (CFD) simulations are frequently utilised to model fire behaviour and evaluate the effectiveness of proposed measures. Occasionally, fire testing may also be conducted. This enables engineers to anticipate fire spread, assess structural exposure to heat and smoke, and evaluate occupant evacuation in various scenarios. Additionally, the operational conditions of fire services can be analysed.

Throughout the design process, collaboration with architects, builders, and stakeholders is mandatory to ensure that proposed solutions align with project goals, regulatory requirements, and budgets.

The benefits of Performance-based design for façade and glazing design (complex buildings) can be listed as follows:

• Customised Solutions: Performance-based design enables engineers and architects to tailor fire protection measures to the specific characteristics of the façade design, considering factors such as material composition, construction methods, and unique architectural features.

• Fire Modelling and Analysis: By using advanced tools like computational fluid dynamics (CFD) simulations, engineers can model fire behaviour and analyse how different façade configurations may influence/ prevent fire spread, smoke movement, and heat transfer, enabling the identification of potential fire risks and the development of targeted mitigation strategies.

• Material Selection: Performancebased design allows for the evaluation of various façade materials in terms of their fire resistance properties. Engineers can assess factors such as smoke production, and structural integrity under fire conditions to inform material selection and fire resistance decisions.

• Integration of Active and Passive Fire Protection Systems: Performance-based design facilitates the integration of both active (e.g. sprinkler and water mist systems) and passive (e.g. fire-resistant materials, compartmentation) fire protection measures within the façade design, enhancing overall fire safety performance.

• Evaluation of Evacuation Strategies: Engineers can assess how façade design impacts evacuation procedures in the

• event of a fire, considering factors such as exit routes, accessibility for emergency responders, and the effectiveness of wayfinding systems.

• Continuous Monitoring and Adaptation: Performancebased design allows for ongoing monitoring and adaptation of fire safety measures as building use and occupancy conditions evolve over the time, ensuring that fire protection strategies remain effective and compliant with regulatory requirements.

In summary, performance-based design provides a flexible and proactive framework for addressing fire safety concerns in complex building façades. By integrating advanced analysis techniques, material science principles, and innovative design strategies, engineers and architects can create façades that not only enhance the aesthetic appeal of buildings but also prioritise the safety and wellbeing of occupants and property.

IFAB has been involved in projects where performance-based fire safe -

ty design has enabled comprehensive safety assessments of complex buildings. As many buildings incorporate automatic firefighting systems, their benefits have also been utilised in glazing dimensioning. The typical fire rating of glass depends on its ability to fulfil different fire protection criteria, categorised under fire rating classes such as E and EI.

• E Classification: The “E” classification signifies integrity only, maintaining its integrity during fire exposure, preventing the passage of flames and hot gases for a specified period but lacking insulation against heat transfer (radiation).

• EW Rating: The “EW” classification includes both integrity and heat insulation properties. It signifies that the building element can maintain its integrity and provide a certain level of insulation against heat transfer when exposed to fire.

• EI Classification: The “EI” classification denotes both integrity and insulation, maintaining integrity and providing insulation against heat transfer, preventing flames and hot gases from passing

through while restricting heat transmission for a specified duration.

E, WE and EI classifications are vital for ensuring fire safety in buildings, particularly in areas where fire resistance is very important. Architects and engineers select the appropriate fire-rated glass, based on building codes and regulations, to meet specific safety standards and protect occupants & property in the event of a fire. While EI-rated glasses are favoured for most projects due to their enhanced properties, E-rated glasses offer architectural benefits with minor compromises.

Alternative solutions have been sought as performance-based design allows for diverse technological applications. One example is using the presence of an automatic firefighting system to compensate for the limitations of E-rated glass to meet EI requirements. This approach has gained interest in projects with architectural complexities or challenges in using EI-rated glass, especially in buildings equipped with water mist firefighting systems. Water mist systems, having very effective cooling capabilities, effectively suppress fires by atomising water

into tiny droplets, extracting heat and lowering temperatures. Whether for firefighting, cooling or protecting important structures, water mist systems provide an active fire risk mitigation in fire safety engineering.

IFAB has been engaged in test programmes and result assessments for performance-based design, experimentally testing glass with firefighting systems. Figure 1 illustrates a test for a glass façade according to DIN4102, but using a water mist curtain outside the furnace/glazing to provide additional cooling and blocking heat transfer (radiation). In this specific test, normal E-rated glass fulfilled EI requirements, resisting the design temperature curve for 60 minutes without cracks. Additionally, the heat radiation limit of 15 kW/m2 was met in the fire tests, which was approved by an independent certification organisation.

Performance-based design, supported by tools like computational fluid dynamics (CFD) simulations, enables the assessment of complex structures’ fire safety. For example, IFAB conducted CFD analysis for a complex atrium in

Germany, evaluating whether glass in the atrium wall could be replaced with less fire-rated glass using sprinkler or water mist systems. The selection of a water mist system, due to its superior cooling capacity, was determined through pre-studies defining the critical temperature for the atrium glass façade as 85°C.

A comprehensive assessment, including fire load measurements and validation simulations, confirmed the effectiveness of the chosen strategy. CFD simulations demonstrated that maximum temperatures on the glass surface remained below critical values, with the activation of the water mist system effectively mitigating fire risks throughout the atrium.

The simulations were even carried out with a conservative approach defining that the mist system shall not influence the heat release rate by suppressing. Using a “Freeburn” scenario, the water mist system was challenged in the most conservative way. The maximum temperatures are shown in figure 2.

Performance-baseddesign enables the customisation of fire protection measures, departing from prescriptive codes and standards in the case of very complex buildings. Engineers conduct thorough analyses, establish performance objectives, and create tailored solutions, ensuring effectiveness across different scenarios. This approach provides flexibility in addressing fire safety concerns in complex buildings, particularly those with complicated façades. It enhances overall fire safety performance through customised solutions, fire modelling, material selection, and integration of active/passive fire protection systems. Another example is the Printing Media Academy in Heidelberg, Germany (shown in Figure 3). This is one of the oldest examples in Germany where active systems, such as water mist, were used as a mitigation method to obtain the building permit for this complex structure.

Ashwant Singh (Australia), Farith Hinojosa (Bolivia), Maria Binte Mannan (Bangladesh), and Matheus Pontes Lima (Brazil) are four promising future fire engineers undertaking the prestigious International Master in Fire Safety Engineering (IMFSE). Together, they delved into the complexities of ventilated façades and cavity barriers in an internship research project with the EU-funded Fire-Safe Sustainable Built Environment project (FRISSBE) and KNAUF Insulation. The project took place in the Slovenian National Building and Civil Engineering Institute (ZAG Slovenia) facilities where the interns blended their diverse backgrounds and abilities and worked together with several stakeholders and experts in the fire field. During the project, the interns were able to visit the R&D facilities of KNAUF insulation in Slovenia, learn about standard fire testing procedures, and perform an experimental campaign to study identified influencing parameters on cavity barriers and ventilated façades. Through their study, the interns expect to contribute to the evolving research field on ventilated façades and to the understanding of how cavity barriers perform and interact when installed in a façade set up during a fire event. Moreover, the overall exposure to the fire research and fire testing fields along with the networking opportunities and the possibility to work with fire experts have been proven very beneficial to the interns who are eager to take on future research challenges.

The façade is one of the key elements of buildings across the World. Various types can be found in various countries and regions, often fitting to specific climatic conditions at the location of the building. Among various types, one can identify also ventilated facades (VF), particularly favourable in climates where water vapor transmission through a façade and prevention of condensation in the internal façade structure is of concern.

A ventilated façade (VF) system contains an airgap layer between the inner and outer membranes of the façade system. The air in the gap flows up due to buoyancy and exits the gap from the upper part while cold air enters the gap from the lower part, providing optimal thermal efficiency and moisture removal from the façade structure. In the case of fire, the presence of the air cavity in VF systems influences the overall fire dynamics of the façade. It provides the fire a pathway to spread through the inner part of the system without being noticeable.

The design of VFs can be very complex. Each type of VF is unique in its design to some extent, and therefore the fire protection mechanisms need to be tailored to fit each scenario. It is important to consider strategies that can be useful to avoid this adverse effect, for instance, the implementation of open-state fire barriers.

The open-state fire barriers (cavity barriers), allow the passage of air during normal operating conditions. The barrier itself is always made of non-combustible materials, often of fire-resistant stone mineral wool.

In the event of fire, the fire cavity barriers are closed, to create a blockage and prevent the spread of hot gases. This blocking can be done mechanically but is more often done using intumescent coatings, which expand to block any air gaps. Intumescent coating’s expansion can only sustain its weight over a small distance, thus open state cavity barriers cannot be installed in VF with large gap widths.

The choice of materials, as well as the dimensions of the air cavity, can largely influence the performance of a VF system in the case of fire.

The materials used in the insulation layer for the inner wall of the ventilated façade, as well as the cladding material for the external walls, can be either combustible or non-combustible in nature. The choice of material influences the fire performance of the entire façade system.

The effect of using combustible materials in the outer wall mainly promotes fire spread over the external wall of the system and increases the overall flammability of the system. Moreover, the external fire spread can lead to the ignition of the inner part of the façade, if combustible materials were used in the insulation layer of the inner wall. When combustible materials are used in the inner wall (insulation layer), the main effect is again the increase of the flammability of the system. The fire behavior in the inner part can be greatly influenced by the presence of the air cavity, and thus the effects of the material of the VF system are of great importance.

However, the fire performance of the façade is not only dependent on the materials present, but also on the air cavity, configuration, and

geometry of the façade. A complete assessment of the fire performance of a façade system requires the system to be tested in a large-scale test as it is intended to be used in its end state.

Being fixed to a combustible element could cause cavity barriers and fire to spread over the façade.

Cavity barriers need to be well fixed into the structure of the inner wall to guarantee functionality. Fixing elements should withstand the actions of the fire and not lose their strength under high thermal exposure.

Several factors can influence the success of such a product. Careful testing of all parameters on several scales is required to be fully confident in the final product’s success. Some of these parameters will be driven by codes and standards, but some can be completely independent of such codes.

As well as ensuring the required performance of fire barriers, manufacturers that want to design new products for any country, need to understand the market and the restrictions imposed by codes and regulations for each country.

The following table provides an overview and overlap of the main parameters requested by Germany, the UK, Spain, and the Middle East. A colour coding has been implemented to show similarities and differences. Requirements that match completely among countries are shaded with green, requirements that partially match among countries are shaded with yellow, and requirements that completely differ are shaded with purple.

Combustibility

Cavity barrier width From 20 mm to 300 mm From 20 mm to 200 mm

Position of barriers

Workmanship -

Every second floor

Edges, gaps (including above window), and every floor above the 1st

Every floor (sector) level

Workmanlike manner or certified installer -

Every floor level at the joint between the floor and around windows and doors.

Vertical barriers should be positioned.

All stakeholders involved in the construction must be licensed and registered by Civil Defense

Type of fixation Mechanical or adhesive Mechanical - Mechanical

Fixation characteristics

Non-combustible fasteners in (vertical) distances of ≤ 600 mm OR noncombustible adhesive mortar coating the full mineral wool surface adhered to the external wall

Non-combustible materials that should be able to withstand the actions of fire, and not lose their strength

Insulation

Currently, there is no harmonised European standard for the testing of open-state cavity barriers. The Association for Specialist Fire Protection has published a technical guide (TGD19) which is currently being used by industry. A new European method for testing open-

state fire barriers is currently under development.

To analyse the identified parameters influencing the implementation of open-state cavity barriers in ventilated façades

Install cavity barriers along the length of the cavity, especially when surrounded by insulation of different fire resistance

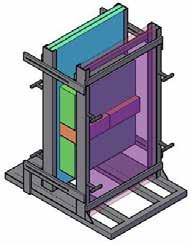

with non-combustible insulation (rock mineral wool (RMW) and glass mineral wool (GMW)), an experimental campaign was proposed consisting of bench scale tests. The general configuration of the tests is shown in Figure 1.

A testing rig was designed to simulate the conditions within a section of a ventilated façade where the barrier is placed horizontally between the inner wall (substrate) and the outer wall (cladding). The barrier is installed following the

suggested configuration of TGD 19 interrupting the layer of mineral wool insulation and under manufacturer’s guidelines.

To have a controlled environment where the testing campaign can be carried out under repeatable conditions, an SBI room was utilised. Figure 2, shows schematics of the rig with a mounted sample and a sample before being tested within the SBI room.

The heat source for the experimental campaign consisted of a propane burner with a linear configuration that fit perfectly in the middle space of the testing rig’s base. The test aimed to produce flames that were in contact with the sample’s cavity barrier to induce a high thermal load over the element. Moreover, a “flashover” like effect was sought where the flames are coming out from the window of a compartment fire and entering the cavity width of a ventilated façade.

The cavity width, air gap, and barrier height were determined according to the available product. (Cavity width: 160 mm, air gap width: 25/30 mm, barrier’s height: 75 mm)

Based on the identified trends regarding the fire resistance requirements per country in Table 1, the testing time for the samples was defined as 30 minutes in this experimental campaign. While fire resistance was not being assessed, it was considered important to capture the thermal field developed

over the sample during this time of exposure to analyse the identified parameters over a sensible time.

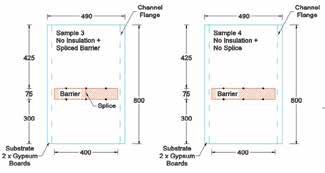

In total, 4 different samples were composed and tested in the

following order:

1. Sample 3, No Insulation with Splice

2. Sample 2, Glass Mineral Wool (GMW) with splice

3. Sample 1, Rock Mineral Wool (RMW) with splice

4. Sample 4, No Insulation, without Splice.

The chosen configuration of the samples was defined based on exposing the elements with their weakest point in a realistic setup. Thus, the first three samples were assembled with a splice in the middle which was protected with a fire stopping as per manufacturer’s recommendation. Moreover, the fourth sample did not count with any splice in order to compare the behaviour of the elements with and without a splice.

To capture the thermal field development over the samples, thermocouples (TC) type K were placed at the bottom and top faces of the barrier at different locations along the cavity barrier’s length. Thermocouples were also placed in the air gap to determine the temperature change after the closure of the gap by the intumescent. The configuration of thermocouples is shown in Figure 4 below.

Temperature measurements were registered at the top and bottom face levels of the fire barriers for the four samples. The measurements over the barrier were registered at four longitudinal locations: substrate joint (TCs 1,2,3,4,5,6), mid-body (TCs 7,8,9,10,11,12), air gap (19,20,21), and cladding joint (TCs 13,14,15,16,17,18). As expected, higher temperatures were recorded in the bottom face TCs of the barriers due to direct exposure to fire conditions. Top face barrier measurements of temperature increment were registered to be reduced at the joints (substrate and cladding after intumescent closure). However, different behaviours over the barrier were identified, and the RMW and GMW samples were the most interesting.

Figure 5 shows the TC measurements at the bottom and top face of the barrier for samples 1

(RMW) and 2 (GMW). The readings are at the mid-body location, it can be seen that the generated fire conditions in both sample tests induced a high heat transfer across the body of the barrier, although more severe in sample 2. The temperatures at the top face for this sample reached about 300 °C after 30 min of exposure which implies a high conductive heat transfer across the barrier promoted by the fire conditions of the test. This could imply a breach in the insulation performance of the element and need to be further investigated.

Figure 6 below, shows the evolution of the sample 2 test which resulted in the higher thermal exposure for the barrier due to the melting and collapse of the GMW and the fire conditions this event generated. A similar behavior was observed for sample 1. However, the thermal exposure was lower since the RMW block stayed intact.

The presence of insulation expedited the performance of the intumescent material compared to scenarios without insulation.

When comparing the two types of non-combustible insulation (Rock Mineral Wool, RMW; and Glass Mineral Wool, GMW), RMW offers a better performance. Fire resistance of RMW to fire-induced alterations ensures minimal changes in fire behaviour. Approximately 20 minutes after ignition, the lower RMW insulation collapsed due to weakened plastic fixations. Remarkably, post-test images revealed that the RMW remained structurally intact, displaying minor soot accumulation on exposed

surfaces. Contrastingly, Glass Mineral Wool (GMW) exhibited inward bending from the middle, generating eddy vortex behaviour within the flames. Ultimately, this generated different exposure conditions and higher heat transfer across the body of the barrier compared to the RMW insulation

The presence of splices and fire stoppers used as indicated by the manufacturer does not influence the behaviour of the functionality of the cavity barrier. This is an important matter as in construction, splices are used and should perform just as well as if the system did not have splices or joints in the cavity width. This also helps to mimic a more realistic setting for the openstate cavity barriers.

The insulation fixations are made of polypropylene and presented a melting behaviour during the experiments of Samples 1 (RMW) and 2 (GMW). Even with the collapse of the insulations, the cavity barrier still performed well and did its job of not allowing the passage of flames and hot gases. In a real scenario of a ventilated façade, the fall of the insulation must be investigated, as it can change the behaviour of the fire by falling and resting in a different position than the original one and even investigate the toxicity associated with the melting of the fixation.

The time of closure is deemed as the time of complete closure along the barrier’s length. Observations suggest that the intumescent reacts faster when the flames are closer to it. However, the intumescent reacts unevenly closing the locations with higher temperatures first.

Nevertheless, this does not affect its ability to close the gap effectively and within a reasonable timeframe.

In the case study, all the intumescent reacted in such a way that they completely closed the air gap, producing between 27 mm and 35 mm of horizontal expansion.

The experimental campaign presented here investigated the variables of insulation type and the use of splices within cavity barriers. The results presented provide some insight into the behavior of these variables, as well as establish some further variables and parameters that are recommended for investigation. The heat transfer mechanism, fixation material, effects of geometry, and the effect of the rain screen should be investigated in further work.

In the tests completed, rock mineral wool performed better when compared to glass mineral wool. Glass mineral wool is more likely to deform and collapse, potentially leading to issues around conduction across the cavity barrier. The extent of this conduction needs to be further investigated since it could compromise the performance of the element. The splice seems to have no significant effect on the performance of the cavity barrier if it is installed correctly.

The investigation was very limited, as no repetitions were made due to time constraints, and the system was only tested for a maximum of 30 minutes. The rig was also bench-scale and did not follow a standardized heating curve. It only aimed to replicate a direct exposure of the elements to flames. This may provide a lack of comparison to the full-scale installation of the fire barrier.

George Xanthoulis Senior Consultant, AtkinsRéalis

George Xanthoulis Senior Consultant, AtkinsRéalis

About the Author

George Xanthoulis is a Chartered Engineer with extensive expertise in acoustics and noise control. Since graduating as a Civil Engineer from the National Technical University of Athens in 2014, he has been involved in a diverse array of projects around the world, ranging from opera halls and schools to theme parks and TV studios. Currently, he holds the position of Senior Consultant at AtkinsRéalis (UK), where he oversees projects and devises innovative acoustic solutions.

In the vast and intricate world of architecture, one aspect that often does not get the attention it deserves is the acoustic performance of a façade. This element, though seemingly insignificant, plays a pivotal role in shaping the sound environment within a building. The internal acoustic conditions, largely determined by the façade, can have a profound impact on the comfort levels of the occupants, influencing their productivity and overall experience within the space.

One of the primary factors in acoustic design is the penetration of external noise into a building, also known as noise ingress. This becomes especially critical in bustling urban environments, where the levels of road noise are typically high. To address this issue, architects and designers can refer to the British Standard BS 8233. This comprehensive guide provides

valuable insights into acceptable noise levels in different types of buildings and offers reliable methods for predicting and measuring noise ingress.

In order to fully understand and anticipate the impact of noise on a building’s design, acoustic engineers often turn to outdoor 3D acoustic modelling. This advanced tool is indispensable in the field of acoustic design, enabling engineers to evaluate the effectiveness of various design strategies. With this information at their disposal, they can make informed decisions about the choice of materials and configurations, optimizing the design for superior acoustic performance.

Central to this context is the weighted sound reduction index (Rw), a single-number quantity that

encapsulates the airborne sound insulation of a building element, such as a window or door, in a laboratory setting. This value is used for selection or design purposes. It does not take into account any site particularities, such as workmanship, or how the element is connected with other elements, e.g. slabs, or junction details that can lead to sound flanking. The Rw value solely describes the main element’s sound insulation performance in an ideal, controlled environment.

Often, working alongside Rw is the spectrum adaptation term (Ctr), which provides a more accurate indication of sound insulation performance in the presence of low-frequency noise, such as traffic and music noise. The combined value (Rw+Ctr) is frequently used in specifications and regulations, offering a more comprehensive measure of a building element’s acoustic performance.

The acoustic performance of a window or façade can be significantly influenced by different glazing configurations. Architects have a range of options at their disposal to enhance the sound insulation performance of a façade. These include the use of laminated glass, which incorporates a layer of plastic for additional sound insulation; increasing the gap between glass panes; using higher thickness panes; or employing triple glazing. Each option presents its own set of advantages and trade-offs in terms of acoustic performance, thermal performance, and cost, making it crucial to consider all factors before making a decision.

Additionally, in the complex realm of façade design, internal sound transmission presents certain challenges. One such issue is flanking transmission, where sound bypasses an insulating element through paths such as mullions and transoms in curtain walls. This can pose a significant risk to the acoustic performance of a building. However, these concerns can be mitigated through meticulous design and the use of appropriate materials such as infills, or bespoke configurations, ensuring that the building achieves the desired level of sound insulation.

Striking the right balance between preventing overheating and controlling noise ingress in façade design presents an acoustic challenge. Solutions

like opening windows for ventilation can increase noise ingress. Meanwhile, keeping windows closed to limit noise can contribute to overheating. This delicate balance demands careful

consideration in the design process to ensure both thermal and acoustic comfort. This is especially relevant as net-zero building goals become more popular, making active cooling a last resort for addressing overheating. It is a fine line, but with thoughtful planning and design, it is possible to achieve a harmonious trade-off between thermal performance and noise management.

Achieving acceptable noise levels within a building is a paramount objective that requires design and execution. This is not just a matter of comfort, but also of health and well-being. High ambient noise can lead to stress, sleep disturbance in residences, and reduced productivity in workplaces. By focusing on acoustic considerations and noise control methods, ambient sound can be maintained at comfortable levels.

In conclusion, the role of acoustics in the design of building envelopes is of utmost importance. By effectively managing factors such as Rw, Ctr, noise ingress, and flanking transmission, we can create buildings that are not only aesthetically pleasing but also acoustically comfortable. This underscores the importance of involving an acoustic engineer from the early stages of design until the tendering stage, ensuring the creation of spaces that resonate with comfort and tranquillity.

Sanjeev Jahagirdar Technical Director, Integrated Quality Services & Solutions

Sanjeev Jahagirdar Technical Director, Integrated Quality Services & Solutions

About the Author

Sanjeev Jahagirdar has a strong progressive international experience in Quality Assurance and Quality Management functions with different projects/assignments. I have IRCA QMS Auditor ISO 9000, IEMA EMS Auditor ISO 14000, Welding Inspection CSWIP 3.1, and NDT Techniques RT/UT/MPT/LPT/VT Qualification. He has proven ability to provide leadership and critical interface between Contractor/ Company and Sub Contractors in resolving Quality issues in industrial/construction projects. He is well-travelled across the world and has experience working with the public and private sectors as well as a multitude of international Organisations and Third-party Inspection/Certification bodies like SGS, ABS, DNV-GL, Intertek Veloci, and Tata Projects.

Today’s high-rise buildings are shedding their static skins and embracing a new generation of intelligent systems that redefine comfort, performance, and environmental responsibility. This in-depth analysis delves into the world’s most widely installed cutting-edge façade solutions, exploring their general and specific design parameters, performance characteristics, and the materials shaping this exciting evolution. The future of high-rise buildings is being reshaped by intelligent façades, a new generation of cladding and glazing systems that go far beyond aesthetics. These dynamic systems integrate cutting-edge technologies to optimise comfort, performance, and environmental impact, setting a new standard for sustainable and responsive architecture.

• Sustainability: Minimising environmental impact through energy efficiency, resource conservation, and responsible material selection.

• Comfort: Optimising thermal and acoustic insulation, daylighting, and indoor air quality for occupant well-being.

• Thermal: Maintaining comfortable indoor temperatures through passive and active solar control, natural ventilation, and efficient insulation.

• Visual: Providing optimal daylighting while minimising glare and discomfort.

• Acoustic: Controlling noise pollution from both inside and outside the building.

• Performance: Enhancing structural integrity, weather resistance, and fire safety.

• Energy Efficiency: Reducing energy consumption for

heating, cooling, and lighting through optimised design and material selection.

• Durability and Maintenance: Ensuring long lifespan and minimal maintenance requirements.

• Safety: Meeting fire, wind, and seismic resistance standards.

• Aesthetics: Integrating seamlessly with the architectural design while offering visual appeal and flexibility.

• Climate and Context: The façade’s design must respond to the specific climatic conditions and surrounding environment. Factors like solar radiation, wind patterns, and temperature fluctuations need to be considered to optimise thermal comfort and energy efficiency.

• Sustainability: Utilising recycled and recyclable materials, minimising embodied energy, and contributing to positive environmental impact.

• Air Quality: Filtering pollutants and improving indoor air quality.

• Urban Heat Island Mitigation: Reducing the urban heat island effect through shading and reflective surfaces.

• Building Use and Occupancy: The façade’s functionality should cater to the specific needs of the building occupants. For example, office buildings might prioritise daylighting and glare control, while residential buildings might focus on thermal insulation and privacy.

• Material Selection: Material choice plays a crucial role in façade performance. Highperformance, lightweight, and durable materials like advanced glazing, photovoltaic panels, and kinetic elements are increasingly being favoured.

• Structural Integrity: The façade must be structurally sound to

withstand wind loads, seismic activity, and other external forces. Integration with the building’s structural system is crucial for seamless performance.

• Regulations and Codes: Building codes and local regulations regarding energy efficiency, fire safety, and sustainability must be adhered to during façade design and installation.

• Cladding and Glazing Systems: Material selection: Highperformance glass with coatings for thermal insulation, solar control, and self-cleaning properties. Lightweight and durable metals like aluminium and titanium for structural support. Ventilation: Integrated natural ventilation systems for improved air circulation and reduced energy consumption. Design flexibility: Modular systems allow for customisation and adaptation to diverse building shapes and orientations. Orientation: Optimising solar exposure for daylighting and heat gain control. Shading: Employing fixed or adjustable shading devices to manage sunlight and glare. Ventilation: Integrating natural ventilation strategies for improved air quality and thermal comfort. Material Selection: Choosing materials with high thermal performance, durability, and aesthetics.

• Dynamic Façades: Kinetic elements: Louvers, fins, or panels that adjust automatically or manually to regulate sunlight, temperature, and ventilation. Integrated sensors and actuators: Real-time monitoring of environmental conditions

• and responsive adjustments to the façade’s behaviour. Building integration: Seamless coordination with HVAC systems for optimised energy efficiency and occupant comfort.

Façade Performance: A Holistic Approach - Passive and Active Strategies

Passive Strategies:

• Double-skin façades: Creating a ventilated cavity between two layers of glazing for improved insulation and solar control.

• Green façades: Integrating living plants on the façade for natural cooling, insulation, and air purification.

• High-performance glazing: Utilising coatings and films to control solar heat gain and light transmission.

Active Strategies:

• Photovoltaic (PV) panels: Integrating solar cells into the

façade to generate renewable energy.

• Electrochromic glass: Adjusting the tint of the glass electronically to control light and heat.

• Automated louvers: Dynamically adjusting louvers to optimise solar control and ventilation.

New generation façades go beyond traditional passive strategies like insulation and shading. They actively manage factors like:

• Passive Ventilation: Doubleskin façades and operable louvers can promote natural ventilation, reducing reliance on mechanical systems and energy consumption.

• Active Ventilation: Integrated sensors and actuators can control ventilation systems based on real-time data, optimising indoor air quality, and thermal comfort.

• Daylighting and Glare Control: Electrochromic glazing and

louver systems can adjust to optimise daylighting while minimising glare, improving occupant well-being, and reducing lighting energy use.

Material Innovation: Efficiency, Economy, and AestheticsEfficient, Economical, and Attractive Façade Materials

• High-performance glass: Low-emissivity (Low-E) glass, electrochromic glass, and vacuum-insulated glass offer excellent thermal performance and aesthetics.

• Metal cladding: Aluminium, steel, and titanium offer durability, weather resistance, and recyclability.

• Composite materials: Combining different materials like metal and wood can achieve unique aesthetics and performance characteristics.

• Bio-based materials: Bamboo, cork, and other sustainable

materials offer eco-friendly options with good insulation properties.

The material landscape for façades is rapidly evolving, offering exciting possibilities:

• Photovoltaic Glazing: Integrated solar panels in the façade generate clean energy, contributing to the building’s energy independence and sustainability.

• Dichroic Glazing: This selective glazing filters specific wavelengths of light, allowing for enhanced thermal insulation and daylighting control.

• Intelligent Glazing: Electrochromic and thermochromic glazing dynamically adjust their tint in response to environmental conditions, providing optimal comfort and reducing energy consumption.

• Kinetic Façades: Moving louvers and panels adapt to changing sun angles and wind patterns, optimising solar heat gain and ventilation.

• Bio-inspired Materials: Selfcleaning façades with lotus effect surfaces and self-healing concrete are being explored for improved performance and reduced maintenance.

• Photochromic glass: Adapts its tint in response to sunlight intensity, reducing glare and heat gain while maintaining transparency.

• Electrochromic glass: Switches between clear and opaque states electronically, offering privacy control and solar heat gain management.

• Bio-inspired materials: Selfcleaning surfaces that mimic lotus leaves, and photovoltaic panels integrated into the façade for energy generation.

• Lightweight composites: Highstrength, low-weight materials like carbon fiber composites for improved structural performance and reduced energy consumption.

New generation façades are transforming from static elements into dynamic interfaces:

• Information Sensitivity: Sensors gather data on temperature, light, and air quality, informing adjustments to the façade’s behavior. Sensors embedded in the façade collect data on environmental conditions, occupancy patterns, and energy use, informing realtime adjustments for optimal performance.

• Communication & Interaction: Façades can display information, project images, or even generate electricity through integrated photovoltaic panels. Façades can display information or even act as interactive interfaces, engaging with occupants and the surrounding environment.

• Self-Cleaning Façades: Nanocoatings and specialised materials repel dirt and dust, reducing maintenance needs and improving air quality.

• Environmentally Dynamic Façades: Responsive to changing weather conditions and occupant needs, optimising comfort and energy efficiency. Façades can adapt to changing environmental conditions, such as adjusting ventilation rates based on air quality or providing shading during heat waves.

Beyond the focus on comfort, performance, and environmental parameters, the next generation of façades is venturing into exciting new territories:

• Self-cleaning: Nano-coatings repel dirt and grime, reducing maintenance requirements.

• Environmentally dynamic: Façades adapt to changing weather conditions through responsive materials and systems.

• Information-sensitive and communicating: Sensors and actuators collect and respond

• to data from the environment, optimising performance and interacting with occupants.

• Transparent yet photochromic: Glass that changes tint based on light conditions, providing both daylighting and glare control.

• Lightweight yet strong: Advanced materials offer high strength-to-weight ratios, reducing structural loads.

• Safe without additional processing: Inherently safe materials eliminate the need for additional safety measures.

• Energy generation: Integrated PV panels and other renewable

energy technologies power the building and beyond.

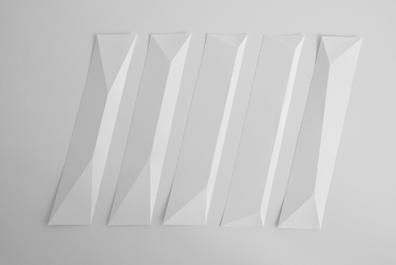

Parametric façades use algorithms to design and optimize their form and function based on specific parameters. This allows for:

• Sustainability: Minimizing material usage and energy consumption through optimised design.

• Power generation: Tailoring the façade to maximise solar energy capture and conversion.

• Vertical farming: Integrating hydroponic systems into

for urban food production.

• Balancing cost with performance remains a key challenge. However, advancements in material science and automation are driving down costs and making these intelligent systems increasingly accessible. As technology evolves, we can expect:

• Fully integrated responsive façades: Seamlessly adapting to real-time environmental conditions and occupant needs.

• Biomimetic façades: Façades mimicking natural systems for enhanced performance and sustainability.

• Hyper-connected façades: Integrating with smart building technologies for a truly holistic building experience.

• Cost-to-Performance Balance: Balancing the upfront cost of advanced technologies with their long-term performance and energy savings is crucial for wider adoption.

• Integration and Complexity: Seamless integration of diverse technologies and sensor networks into the façade system

requires careful planning and execution.

• Standardisation & Regulations: Establishing clear standards and regulations for safety, performance, and data privacy associated with smart façades is crucial.

Despite these challenges, the future of façade technology is bright. As research and development efforts continue, we can expect even more innovative and intelligent façades that blur the lines between building skin and living organisms, responding in real-time to their surroundings and creating truly sustainable and responsive high-rise environments.

The vision of a façade as a living skin, responding and adapting to its surroundings, is no longer science fiction. These intelligent systems are poised to revolutionise the way we design, build, and experience our high-rise environments. From optimising comfort and energy efficiency to fostering a connection with the natural world, the future of façades promises a more sustainable, responsive, and ultimately, human-centric built environment.

Here are some additional insights and resources you might find helpful:

• Case Studies: Explore realworld examples of highperformance façades in action, such as the Al Bahr Towers in Abu Dhabi or the 1 Bligh Street building in Sydney.

• Research and Development: Stay updated on the latest

advancements in façade technologies through organisations like the Council on Tall Buildings and Urban Habitat (CTBUH) and the International Passive and Low Energy Architecture (IPLEA) conference.

• Visualisation Tools: Utilise software tools like IES VE and Ecotect New Generation Façades: IES Virtual Environment (IESVE) and Ecotect New Generation Façades are software tools that can help architects, engineers, and designers create energy-efficient and environmentally sustainable buildings. Ecotect is a building performance simulation software that can calculate a building’s energy consumption by simulating its context within the environment. It is designed to help architects, engineers, and designers create buildings that are not just aesthetically pleasing but also highly energyefficient and environmentally sustainable.

Visualisation Tools ESVE and Ecotect are a suite of applications for building performance analysis. It can be used to:

• Test different options

• Identify passive solutions

• Compare low-carbon and renewable technologies

• Draw conclusions on energy use, CO2 emissions, and occupant comfort

• Model, predict, and verify performance throughout a building’s life cycle

• Evaluate architectural designs holistically

• Consider outcomes for enhanced daylighting status, occupant thermal comfort, natural ventilation, and reduced carbon emissions

Jacob Mathew Senior Acoustic Consultant, Ramboll Middle East

Jacob Mathew Senior Acoustic Consultant, Ramboll Middle East

About the Author

Jacob Mathew is an engineer with an honors degree in Architectural Engineering and a Masters in Energy. With over 4 years of experience in acoustic consulting, he has successfully managed diverse projects across the Middle East, Australia, and South Korea. Jacob is an Associate member of the Institute of Noise Control Engineers, the Acoustical Society of America, and an Affiliate member of the Institute of Acoustics. His project portfolio spans various sectors, including hospitality, residential, commercial, offices, mixed-use, entertainment, cinemas and recording studios. His professional ability extends to project management and client relations, showcasing a comprehensive skill set in delivering acoustic solutions for a wide array of architectural endeavours on a global scale. Jacob is currently working as a Senior Acoustic Consultant at Ramboll Middle East’s specialism team.

As cities continue to grow, the need to mitigate external noise and enhance indoor acoustic quality has become paramount. The criteria for acoustic comfort have evolved into a necessary consideration in habitable spaces. Several studies have investigated the connection between noise annoyance and both the physical attributes of sound and its impact on health and wellbeing. Noise nuisance has shown to adversely affect hypertension, increase chances of cardiovascular diseases, increases stress, and reduce cognitive efficiency in occupants [1].

An acoustically comprehensive strategy for occupant comfort in buildings often involves a multifaceted approach, incorporating design concepts, material selection, and the expertise of acoustic consultants to achieve optimal results. However, in pursuit of streamlined green and sustainable strategies, the acoustic wellbein of the users of the space often goes unnoticed. For instance, a study on indoor environmental quality (IEQ) involving 23,450 respondents from 142 buildings concludes acoustic nuisance as the primary concerns in LEED certified offices [2]. This scenario can be avoided through thoughtful consideration and a touch of creativity. It is possible to merge the objectives of sustainability and acoustics and create a facility that is both functional and sustainable.

Even in residential buildings, acoustic complaints rank among the top three dissatisfaction measures from occupant post-occupancy evaluations (POEs). Looking at the physical characteristics of sound, residents primarily express annoyance with various noise sources, including noisy neighbours,

traffic, and construction. The building envelope becomes the primary form of protection for the residents from the urban soundscape. Then, the acoustic performance of a building façade is a critical aspect to consider in providing a comfortable living space for occupants.

The Acoustic performances of façade systems are generally given in STC, OITC, R w or R w +C tr ratings. Understanding key acoustic metrics is crucial in evaluating the acoustic performance of façades.

Sound Transmission Class (STC) is a US metric that measures the ability of a material to impede the transmission of sound. Similar in most ways to STC, the R w (weighted sound reduction index) is an International Standard Organisation (ISO) metric that assess the airborne sound insulation performance of a system. Both these rating usually provide similar numbers given there are no substantial peaks or troughs in the transmission loss (TL) spectrum.

However, when specifying façade acoustic criteria, it is important to consider the extended frequency

performance of the system for appropriate design.

The outdoor-indoor transmission class (OITC) rating was created in the late 1980’s within ASTM as a standard classification in response to a perceived need for a more robust metric that adequately considers low-frequency incident sound. The OITC is usually 5 to 10 dB lower than STC. This type of noise is dominant near highways, airports, or mechanical plants. The International Standard Organisation (ISO) also provides a similar single number rating denoted as R w +Ctr. The C tr is an additional spectrum correction that focuses on low frequencies, primarily transport and industrial noise.

All these metrics are laboratory measured indices that are tested under controlled conditions. In most cases, a reduction in the range of 5-10 decibel points can be observed between lab and onsite test measurements, primarily due to flanking paths and quality of workmanship on-site.

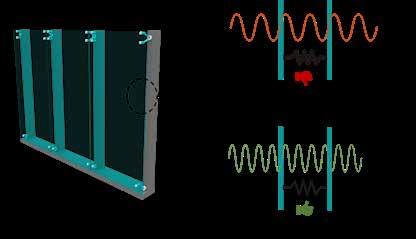

Glazing build-up is one of the key properties that determines the performance of a glazed

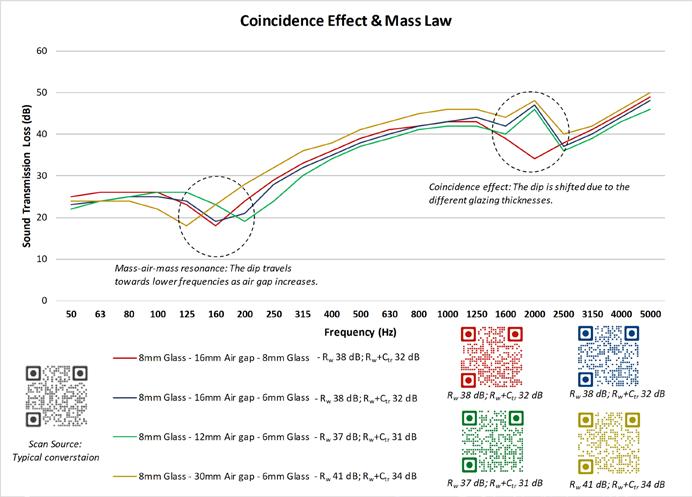

façade system. As glass is a stiff limp mass, they tend to follow the ‘mass law’ where the sound insulation performance of a system is directly proportional to its mass per unit area. Doubling the airgap is expected to give an improvement of around 3 points in R w/STC rating.

For a specific frequency, the air gap tends to reduce the performance of the system due to ‘Mass-Air-Mass resonance’ effect. In this frequency, the air will effectively act as a spring that will easily transfer noise. One of the ways to adjust this dip in performance is to increase the air gap, which tends to move this dip towards the low frequencies, away from the sensitive audible spectrum.

The materials used in the façade system, such as glass and aluminium, possess an inherent ability to vibrate at specific frequencies referred to as their ‘natural frequency’ or ‘coincidence frequency’. For glazing systems, this frequency depends on the nature of the glass, its dimension, its fittings and installation. Noise impinging on the glazing at their natural frequency range will pass through with little attenuation and will form a dip in their acoustic performance spectrum. This is known as the ‘coincidence effect’.

The coincidence effect is of particular concern since the

coincidence frequency of glass usually corresponds with the nature of high-frequency noise from traffic, aircraft, etc. If not designed appropriately, these noises can be heard through the façade system. Opting for varying glass thickness in a double-glazed system can remedy this effect to a considerable level. This will ensure that the transmission loss is flattened and spread to not occur drastically over a specific frequency.

These effects discussed above can be observed in Figure 2, along with QR codes to scan for audio files. A difference of 3 decibel points is rarely perceivable, and the sensitivity of people varies. These

audio files are provided to try to find some perceived difference in level drop from a source and also if possible any frequency response differences between the systems by the listener.

A laminated glass is a type of safety glass composed of two or more layers of glass bonded together with a transparent and flexible interlayer, typically made of polyvinyl butyral (PVB). An improvement of 1-3 points is generally expected from a typical PVB laminate system depending on the number of layers between the glass.

Furthermore, specific laminates focused on sound insulation capabilities are also developed by various glazing manufacturers that can offer an improvement of at least 3 dB or more from just a single layer of laminate & can also have specific transmission control over frequency ranges. Due to their unique nature, they are relatively expensive and are used only in specific situations if necessary. The inclusion of lamination in a glazed façade also changes its visual essence depending on the lamination thickness.

Although not as critical as a Shakespearean dilemma as the title suggests, the selection and inclusion of laminated glass in the façade requires some thought. A well-coordinated strategy with the acoustic consultant and the design team is required when prescribing laminated glazing systems. The solution should ideally maintain the visual uniformity and architectural design intent of the façade.

The performance of a building façade is usually determined by

multiple elements, including glazing, walls, windows, spandrels, and other similar components. In a composite façade, the overall acoustic performance of the system is effectively determined by its acoustically weakest insulating element. In a scenario for a room where, if around 30% of a façade area is glazing with R w /STC 35 dB performance and the remaining is blockwork of R w/STC 45 dB, the composite performance will effectively be around R w /STC 40 dB. You may expect a 1-2 point improvement by increasing the blockwork acoustic performance, but nothing more.

In reality, given the weakest element covers around 10% to 40% of the total façade area, increasing the performance of surrounding elements by 10-decibel points or more than the weakest element’s acoustic performance provides little to no improvement in the composite performance of the façade.

A façade system specimen presented for an acoustic test must include all fittings and frames exactly as how it would be constructed on-site. Separate tests of individual façade elements will not confirm

the performance of the composite façade system. If individual performances and dimensions are known, an estimated performance can be calculated using the methodology provided in BS 8233. However, this cannot validate the composite system’s performance instead of a certified acoustic laboratory test.

Flanking is the transmission of sound through alternate paths or unintended routes due to improper detailing or on-site conditions. Any fittings or fenestrations on the façade can bring down the performance of a façade drastically due to flanking even if the glazing is of superior performance.

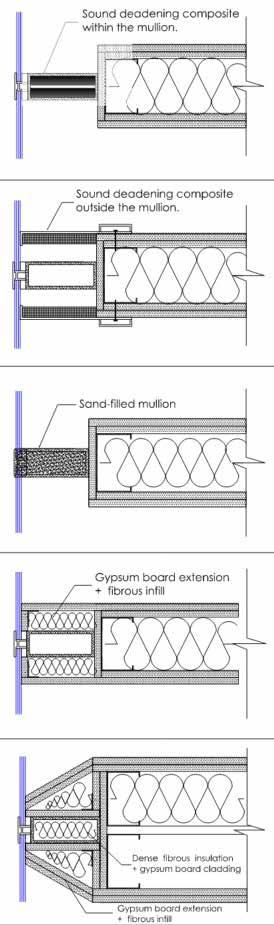

In high-rise curtain wall systems, the usual points of flanking are through mullion cavities, slab edge connections, spandrel points, cladding cavities, etc.

The first step is to identify possible flanking paths over a section detail and provide an acoustic block to the path, typically using a few layers of plasterboards & some mineral wool between cavities. This may not be a suitable option in all cases, as they

may not align with the design intent. Another solution is to provide cavity inserts in the mullions or transoms between spaces. This application has its drawbacks when considering the complexity and labour involved in actualising this on-site or otherwise. Some illustrations are provided to show possible flanking paths and good design practices to treat them.

The perimeter seals, jambs, drop seals, cavity fillers, etc that are involved in the installation and workmanship of fenestration can impact the overall performance of a building façade greatly. Applying foam, sealants, or other materials to fill gaps between the window frame and the rough opening has the

potential to effectively reduce sound transmission to a satisfactory level.

ASTM C919 focuses on the critical task of sealing small gaps between material interfaces to reduce the ease of sound transmission. The presence of a “hiss” noise or a dip in the mid to high-frequency range through the façade generally indicates poor sealing around the system.

Façade acoustics is essentially a balance of design engineering, material quality, workmanship, and acoustic expertise. Collaboration between architects, façade engineers, and acoustic consultants is essential to achieve a harmonious balance between aesthetic appeal

and optimal acoustic performance of façades. By incorporating sound insulation strategies from the conceptual stage, designers can create buildings that not only stand as architectural marvels but also provide a quiet and comfortable sanctuary amidst the urban jungles.

1. E. B. E. O. L Barregard, “Risk of hypertension from exposure to road traffic noise in a population-based sample,” Occup Environ Med, vol. 66, no. 6, pp. 410-5, June 2009.

2. C. Curtland, “Acoustics: The Biggest Complaint in LEEDCertified Office Buildings,” Buildings, 21 August 2012.

“Future Façades Shall be Seeing Rapid Integration of Renewable Energy Technologies, such as Photovoltaic Panels or

ANIKET DESHPANDE Façade Consultant, Thomas Bell-Wright International Consultants

ANIKET DESHPANDE Façade Consultant, Thomas Bell-Wright International Consultants

• As smart building technologies become more prevalent, how do you see façades integrating with these systems to enhance overall building performance?

Smart technologies today are not just prevalent but have become an integral part of our lives. With apps

controlling the lights, air-conditioning, entertainment, coffee machines, and whatnot, building fenestrations are not untouched by smart technologies today.

From integrated blinds within IGUs, digitally controlled and programmed electro-chromatic glass products, to dynamic shading devices that can change orientation, position, and location, to daring adventures where roofs and façades are designed to function dynamically to control light and visibility, façades have come a long way. All these features being connected to building automation and maintenance systems make it even more relevant today.

Apart from thermal performance, intelligent smoke and ventilation systems involving façade automation, which are triggered in case of emergencies to help mitigate fire risks elevate the building performance above and beyond the safety offered by conventional passive systems.

AI-enabled thermal detection camera-controlled fire hoses tackling localized façade fires over façade have also been experimented with, where strategically placed firefighting systems over the building face detect localized façade fires and extinguish them within critical time to avoid further spread.

• What innovative materials do you anticipate will play a significant role in the development of future façades?

The choice of materials is endless when it comes to façades. What is exciting today, is that product innovation in materials has moved beyond offering 'pretty looking'

materials to sensitive choices which helps the designers and developers meet their core principles while delivering the projects.

With the sensitivity toward the environment, leading manufacturers are offering recycled glass and aluminum products. With leading glass manufacturers finding ways to increase the cullet and system manufacturers introducing systems using up to 75% recycled aluminum, such as in the case of the Technal CIRCAL series, designers have a choice, to begin with low embodied carbon for the two major components of contemporary façade systems.

From a thermal performance point of view, the availability of high-performance glazing with low-iron glass and triple silver coatings helps designers meet their performance goals without compromising on aesthetic quality. Advancements in ceramic fritting and digitally printed glass allow designers to control the window-wall ratio without compromising on the glazed area and material pallet. Thoughtful frit patterns over façades based on the sun's path can help maximize the daylight while keeping the harsh sun away.

Laminated glass and the range of interlayers have started to play an important role in how glazing is looked at. From imparting different qualities such as translucency, color variations, acoustic performance, structural performance, and safety toward blast-proofing and bulletproofing while maintaining clear visibility, PVB and SGP interlayers are changing the way glass is used in contemporary buildings. Building integrated photovoltaic panels are also being integrated within the façade.

• What are the essential tools used in the creation of future façades?

Façade development has three crucial phases – the vision developed by the Architects, the development of façade solutions with systems that can meet this vision, and the fabrication and installation stage which makes this vision a reality. All these three phases demand different tools and different attention at every stage.

With the future of design heavily relying on parametric and generative design principles, a large set of dedicated software as well as plugins are helping

designers envision building skins that optimize environmental performance and push toward a sustainable built environment. With BIM being the industry standard and the way forward, the design information is loaded in at a nascent stage.

Façade models are then further detailed to capture the system nuances, material characteristics, and performance parameters, which can be analyzed in the larger building model to simulate the results, allowing further tuning to achieve established performance goals. Calculations for embodied carbon, impact on MEP, costing and value engineering, material optimization, and quantification can all be done within the BIM environment.

Beyond this point, the fabrication and installation discipline, popularly called the contracting world has a different set of tools that are gaining higher ground on innovation as compared to the digital counterpart. Fabricators and system manufacturers are investing in multi-axis CNC machines which can be programmed to process façade components from a simple extruded profile to a fully fabricated set of parts ready to assemble with strictest of the tolerances and high-quality control. Metal 3D printing is gaining popularity within the industry with innovative systems such as Schueco's 'Grid2Shell' and Technal's 'Tental Parametric Façades systems.

• Can you provide insights into the recent advancements in façade and cladding technologies, including materials and construction methods?

With an everchanging building landscape and a constant stream of innovative and unique design

solutions by Architects, façade and cladding materials as well as the methods of putting them together are in constant development. The industry is majorly moving toward pre-fabricated site-installed façade systems for the correct reasons, and integrating, transporting, hoisting, installing, and testing such systems is increasingly challenging. Pre-fabrication and unitization of façade systems reduce the work on site and help in maintaining the quality of façade systems at the fabrication facility. It also helps reduce the time required, as fabrication happens parallel to the construction at the site, and reduces the site-associated risks.

Given the increasing focus on sustainability, future façades shall be seeing rapid integration of renewable energy technologies, such as photovoltaic panels or solar-integrated cladding. While roofs have been engaged before for the installation of photovoltaic panels, the limited area available which is shared with other building services considerably reduces the available surface area. With the advent of HighTransparency Window-Integrated PV panels, Façades can generate energy, helping decarbonize the built environment.

• Could you share your favorite façade material and explain the reasons behind your preference?

I would love to answer that as an Architect, but as someone helping fellow designers to take their design intent to a built product, I am unfortunately not allowed to be biased for or against materials and systems and tend to choose a material or system that can achieve the best results for the proposed design intent. The projects I find interesting are the ones where the qualities and strengths of a certain material or set of materials are capitalized to achieve a thoughtful design intent.

• What features would you like to see incorporated into future façades to enhance their functionality and aesthetics?

Façade industry is dynamic and we're all learning new things every day. At an early design stage, the designers need to understand the available materials, their strengths, and their limitations. Considering available stock sizes of materials to optimize their usage at early design stages can help achieve ‘zero waste’ façades.

Performative testing and the use of certified materials in façade are equally important to ensure anticipated results. With the constant flow of attractive materials entering the market and the excitement of designers to build something unique, it happens far too often that materials that are not tested for their performance make it to building façades. Their reaction to fire, weathering, and integrity when installed within a defined façade system remain questionable and their use might unfortunately be a calling for undue events risking life and safety. Performative mock-up tests also enable designers to empirically establish the performance of façade systems and fix any shortcomings before application over the actual project.

When it comes to functionality, it is important to note that façades need timely cleaning and maintenance. It happens far too often, unfortunately, that the façade access and maintenance systems for even large projects are completely ignored and the developers just end up delivering a pretty building. Proportionate investment in appropriate BMU systems is pivotal to a functional and durable façade, which looks good and functions well throughout the building life-cycle and not just the first few months.

• How does automation play a role in façades and fenestration, and what are the associated benefits of incorporating automation in building exteriors?

Today automation by far is largely limited to home interiors, with a lot of system manufacturers now offering motorized door and window systems. As dynamic façades along with façade lighting and modern glazing materials start gaining traction, the skin systems will be much beyond a static set of materials. Buildings will be programmed to be more 'climate reactive' than 'climate-sensitive'. With the integration of automation and artificial intelligence in every aspect of our lives, façades will soon enjoy the benefits of the digital revolution with the integration of dynamic components.

• What are the key Characters of a HighPerformance Façade?

High-performance of façades is primarily associated with their thermal performance – may it be avoiding radiant heat or trapping the embodied heat within a building depending on the location of the project. While thermal performance is the key driver for highperformance façades, other aspects such as durability, fire performance, safety, air tightness, resistance against water permeability, the integrity of materials, quality of finishes, and compliance with international codes and standards – all contribute toward making a HighPerformance Façade.

Demands from façade are becoming more complex as standards keep on updating. Nations and cities are gearing up to implement stringent codes and standards addressing the performative aspects of façade systems. Façade systems employed on the projects should meet and exceed the international standards as we progress.

• In the context of climate change, how can façades be designed to withstand extreme weather conditions while maintaining their aesthetic appeal?

We have all seen faded colors of once bright-colored shopfronts around town, which were novel a decade or two ago, deformed cladding panels, dislocated louvers, and stained glass canopies with rust streaks from spider fittings. Although the aging of a building is not completely avoidable, modern materials, if chosen wisely and installed correctly, can last longer in worsening weather conditions.

It is important to choose the correct coating for exposed aluminum cladding and extrusions meeting international standards. Choice of the right hardware, fasteners, gaskets, and silicone compatible with materials in contact, bi-metallic separation, proportion of panels, and making sure the systems are designed to withstand the anticipated wind loads are a few factors that are vital while designing façade systems.

Performance glazing plays a vital role in addressing the extreme weather and innovation in high-performance glazing shall lead the path for how the industry reacts to climate change.

• As urban spaces become more interconnected, how might façades contribute to creating a sense of community and connectivity within and between buildings?

From the digital screens of Times Square, the celebratory face of Burj Khalifa, exterior green walls of Singapore, to sculpted honey-comb curved columns and canopies of Mumbai Airport, façades all over the world can define a sense of place and affect everything that happens around them.

While the experiential quality of architecture can be overwhelming through its spatial characteristics, the first relation a user makes with a building is from the exterior. Façades make the first impression on the user. With designers paying more importance to integrating interior and exterior by blurring the boundaries, building skins are becoming more permeable in nature. Designers are expecting performance glass products with higher light transmission while retaining the thermal performance. As designers continue to blur these boundaries, façades need to

be extremely flexible while providing the necessary protection and performance.

• How do you envision the future of façade design, considering the evolving technologies and materials in the field?

With conventional architecture where the structure, fenestrations, and finishes were indistinguishable and designed as a larger system forming the external building wall, façade design as a specialized discipline barely existed. Façade meant the 'exterior road facing side of a building'.

With evolving building technology, the advent of new materials, and the growing general scale and pace of construction, façade design has found a new meaning. Today, façade systems serve as the primary and many times the only barrier between the inside and outside, hence making it necessary for them to be robust from structural, environmental as well as safety perspectives. Façades need to perform all the functions of a conventional external wall, along with imparting a unique and contemporary appearance to the structure.