•Stable & Reliable Power Supply

•Designed for High-End Car Programming

•9-Step Smart Charging

•Adjustable Voltage and Current

V4500 Plus

•Powerful 4500A Peak Current

•Energize 12V Vehicles with Up to 16L Engines

•Act as A Battery Tester

•PD100W Fast Charging

Welcome to the latest issue of the magazine and to your personal copy of the Show Guide for The Aftermarket Event — taking place at Farnborough International on October 2-3.

If you have already got your ticket for this dynamic event, dedicated to the UK’s garage trade, just flip the magazine over to see our special Show Guide, starting at the back, to get the inside track on all that awaits you.

Farnborough has long been the nation’s go-to destination for pioneers of the present and the future and our Show Guide, with a special cover supported by another innovator — Delphi and its DS Hub — will guide you through the two-day showcase of technology, skills, and the latest information and data powering all aspects of the aftermarket that will be on display.

If you have not yet registered for your FREE ticket to attend, a quick browse through the Show Guide should convince you to come and take part!

Meanwhile, our regular pages are

Editor

John Shepherd

john@aftermarket.co.uk

+44 (0) 1732 370 345

Head of Sales

Angela Lyus

angela@aftermarket.co.uk

+44 (0) 7823 736 629

Managing Director

Ryan Fuller ryan.fuller@dfamedia.co.uk

Operations Manager

Emma Godden-Wood emma.godden-wood@dfamedia.co.uk

packed as usual with all the latest news and features to keep you better informed about our industry.

Plus, find out who is in the running to take home this year’s Top Garage and Top Technician trophies as we head to the finals of the competitions.

And don’t miss our round-up of Automechanika Frankfurt, including the inside story on the 100-plus auto firms from the UK that took part.

After visiting the Frankfurt expo myself and seeing all the paraphernalia of AI systems and array of electronic devices on display, I came away thinking how much of the latest tech would be wasted on my aging motor.

However, even technology can be a fair-weather friend, as I discovered on the way home from the show, when I became caught up in the German government’s ‘warning day’.

This was a test run of emergency alert systems via mobile phones and devices similar to one organised by the UK not too long ago.

I’m told a ‘pre-warning’ was sent out, but I didn’t get the memo. The first I heard of it was when my mobile

Marketing Manager

Hope Jepson

hope.jepson@dfamedia.co.uk

Production Design

Anthony Wi en

Finance Department

accounts@dfamedia.co.uk

+44 (0) 1732 370 340

Chief Executive

Ian Atkinson ian.atkinson@dfamedia.co.uk

Contributors

David Banks | Martin Pinnell-Brown

Nick Crossley | Bill Fennel Abhishek Tanwar

started blaring away at the very second I clicked ‘pay’ while trying to order a co ee and a snack via an electronic screen at a burger restaurant in the airport.

As the sirens blared, the restaurant’s device briefly tried to charge me for several family-size bundles of fries, burgers and lakes of soft drinks.

It quickly became clear that I could not now use my card there or at any of the eateries because systems had crashed as the alert went out and cash was now king.

In common with most around me, I did not have enough currency of any denomination to even buy a drink to steady my nerves as the wailing warning tones faded.

In my younger, cub scout years, the motto was ‘be prepared’. Must keep that in mind for future. Meanwhile, readers, be prepared for a fantastic Aftermarket Event and enjoy the issue.

John Shepherd Editor

Published by DFA

192 High Street Tonbridge Kent TN9 1BE +44 (0)1732 370340 ISSN 2516-9149

Aftermarket

The government should consider offering financial and other incentives to UK garages that hire and train young people for careers in the auto sector, the Independent Garage Association has said.

The IGA’s call came after it congratulated the more than million students who received their GCSE and vocational qualification results during the summer.

An IGA spokesperson told Aftermarket it was discussing detailed proposals for a range of potential initiatives for “targeted support” with its members, and details will be disclosed when finalised.

However, the association said to tackle the skills gap in the auto sector, government support should not only focus on training young people but also on assisting independent garages that are eager to hire and train new technicians.

‘Subsidies’

“Small and medium-sized garages often face financial and logistical

barriers when it comes to recruiting and training apprentices,” the IGA said.

“By providing incentives, grants, or subsidies to these businesses, the government can ensure that more young people have access to quality training environments and real-world experience.”

IGA chief executive officer Stuart James said: “The independent garage sector is at the forefront of automotive innovation, and with the right backing, we can provide the next generation with the skills and experience they need to thrive.

“By supporting garages in their efforts to recruit and train young technicians, we can ensure that our

industry continues to flourish and that young people have access to rewarding careers.”

‘Pivotal’

On the announcement of academic results, the IGA said it marked a pivotal moment in students’ educational journeys, “opening doors to a variety of pathways, including A-levels, apprenticeships, vocational-technical qualifications and the expanding T-levels”.

Separately, the CEO of Easy2Recruit, which helps garages hire overseas talent, said the independent garage sector should work within schools to encourage more young people to choose to join the automotive sector.

Ambi Singh said: “Many of those getting their exam results will already have chosen a career and, sadly for us as an industry, not enough will be looking towards the garage sector.

“If we want young people to join our industry, we need to go into schools; we need to be the ambassadors talking to them when they are forming their career aspirations.”

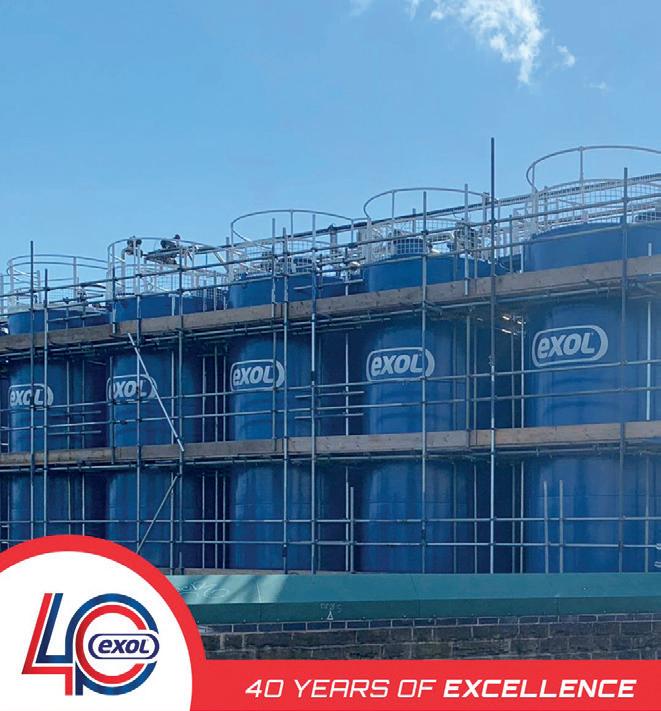

Exol Lubricants has made an undisclosed “significant investment” in its Rotherham blending plant, as part of the firm’s multimillion-pound plans to improve facilities and operations.

Exol said on August 14 that the five-week project included a comprehensive refurbishment of the plant’s infrastructure, aimed at boosting efficiency and ensuring the highest standards of safety and quality.

The work included a high-pressure jet wash of the tanks, followed by a makeover involving repainting of tanks and other parts of the plant.

Exol said the project enhanced the look of the facility and contributed to

greater efficiency and safety of daily operations.

Simon Matthews, product development manager at Exol Lubricants, said: “By investing in our

facilities, such as the Rotherham blending plant makeover, we are not only enhancing our operational capabilities but also reinforcing our brand’s commitment to quality, safety and continued improvements.”

In 2022, Exol installed solar panels its head office in Wednesbury to reduce its carbon footprint and save energy.

The firm has also increased its use of canals, using its Exol Pride barge to transport products in a more environmentally-friendly manner via inland waterways.

Last year, a new automated liquid transfer system, called a pigging line, was installed at Rotherham to reduce waste product lost during the blending process.

Steer Automotive has acquired accident repair business

Rye Street Group for an undisclosed sum.

Steer said on September 2 said the move would extend its reach into Hertfordshire and Essex and strengthen its capabilities in parts procurement and estimation.

Rye Street, operating since 1990, manages a network of seven repair centres and holds 23 manufacturer approvals and 24 insurer approvals.

Steer said the “strategic geographical acquisition” underscored the group’s commitment to expanding service capabilities and enhancing customer experience.

Rye Street MDs Bill Du y and Lee McNaughton will be leaving the business as part of the transition while Nick Ferris and the senior management

Automotive industry charity Ben has unveiled new details about its two biggest events of the year in a bid to raise a total of £150,000 to help fund its life-saving support for those struggling or in crisis.

Ben’s Big Breakfast aims to serve up food for thought and encourage everyone to dish up practical support by organising a breakfast gettogether during the week of World Mental Health Day, which will be marked on October 10.

According to the charity’s recent research, one in four automotive people are struggling with their

mental health and 29% are experiencing loneliness, so breakfast can be an ideal opportunity for colleagues to catch up with a co ee or bond over a bacon butty, Ben said.

Automotive companies or groups are invited to host a breakfast event during the week of October 7-13 and encourage colleagues, customers, friends and family to bring, bake or make a spread and then sell their goodies to raise money.

Meanwhile, the charity has revealed this year’s Ben Ball will be a ‘Great Gatsby’-themed event with all the glitz and glamour of the 1920s.

Entertainment at the ball will be from the Electro Swing Project. As featured on London’s West End, the awe-inspiring show will be by the same performers who captivated the Ben Ball 2020 audience with their ‘Greatest Showman’ performance.

team will remain to ensure continuity and stability, Steer said.

“This will allow the team to continue delivering the high standards of service that Rye Street is known for, while benefiting from the additional resources and expertise that the group brings.”

Steer CEO Richard Steer said: “This acquisition is a strategic step towards our vision of providing unmatched automotive repair services across the UK.

“We are particularly excited to welcome our new colleagues, whose expertise and dedication have laid a strong foundation that we are eager to build upon.”

Technical support provider for electric and hybrid vehicles, HEVRA, has launched its ‘rEVive’ supercar support programme.

The move is in response to growing demand for specialised technical assistance with exclusive vehicles.

HEVRA technical director Peter Melville said even the most exclusive models on the road can now receive the care they deserve. Support can be provided remotely or in person or a combination of both, HEVRA said. The service is available in mainland England and Wales, but could be expanded depending on demand.

Details of rEVive are on the company’s website.

The automotive sector relies heavily on all kinds of compressed air equipment to enable repairs, services and refurbishments.

From tyre fitting and inflation to paint application, cutting, grinding and polishing, there are multiple tasks that involve compressor-driven tools being carried out every minute of every day.

Thanks to the compact SEP60 condensate cleaner, SEPURA™ is now able to offer compliance and peace of mind to many of the thousands of garages and service centres across the UK.

compressed air condensate filters. What’s more, only genuine SEPURA products contain Bowman’s unique, patented SILEXA™ filtration media.

Managing Director Richard Potts believes that all of the automotive sector should invest in compressed air filtration equipment as part of its wider commitment to ensuring a greener future.

Having proven itself in a diverse range of industries, the SEP60 can ensure workshops meet current environmental requirements for oil/ water discharge. They are quick to fit, easy to dispose of and can be wall or cabinet-mounted to optimise space. Plus, a service life of around 4,000 operating hours* makes SEPURA a

See-through SEP 60 with outlet. SEP60 units contain Bowman Stor’s unique SILEXA™ filtration media

highly cost-effective solution.

SEPURA Garage-Workshop Ad 185x126L.qxp 01/08/2024 14:07 Page 1

This vital workshop product has been developed by UK-based Bowman Stor — the company behind the groundbreaking SEPURA range of

Richard said: “Helping industry comply with environmental targets has always been at the core of our operation and we are always striving to evolve our products and find better, more efficient commercial solutions. The SEP60 really is a must-have for every professional garage or auto centre.”

To place an order or for further information on SEPURA’s unique range of filtration products.

contact: Multi Factor Europe Ltd online: sales@mfeuk.co.uk / sepuratechnologies.com or call us —01978 855995.

Recent UK figures showing a surge in the use of cars for daily domestic travel presents significant business opportunities for garages, the Independent Garage Association has said.

Department of Transport data comparing current transport usage to pre-pandemic levels revealed a significant trend, according to the IGA.

Car usage has not only returned to but has surpassed pre-pandemic levels, while methods of public transport including buses, National Rail, and the London Tube network, continue to fall behind.

According to the DoT’s figures updated on August 14, motor traffic in Great Britain in that month reached 103% of its pre-Covid-19 levels, indicating a strong and sustained reliance on private vehicles.

In contrast, public transport usage remained below pre-pandemic levels, with buses outside London at 70%, National Rail at 88%, and the London Tube at 75% of 2019 usage levels.

IGA chief executive Stuart James said the data highlighted a critical shift in how the public is choosing to travel

post-pandemic.

“The sustained increase in car usage presents a significant opportunity for the independent garage sector. As more people rely on their personal vehicles, the demand for maintenance, repairs, and overall vehicle care will continue to grow.

“Independent garages are uniquely positioned to meet this demand, providing essential services that ensure vehicle longevity and safety.”

As the public continues to favour private vehicle usage over public transport, independent garages can expect to see a steady or even increased volume of customers requiring a wide range of services, from routine check-ups and diagnostics to

more complex repairs, he said.

The IGA also cited data released last year by the European Automobile Manufacturers’ Association (ACEA) in its ‘Vehicles In Use’ report. According to the ACEA, the average car in the UK is now 10 years old.

This average age will likely increase in the coming years due to a notable decline in new car sales. ACEA’s findings showed that 21.5 million of the 36.7 million cars registered in the UK are less than 10 years old.

Key advice from the IGA for garages includes:

l Prepare for a sustained increase in service demand;

l Focus on vehicle longevity — as car owners rely more heavily on their vehicles, there will be a heightened focus on maintaining performance and extending their lifespan;

l Shifting service areas — as the data also suggests that as public transport usage remains lower, there may be a shift in service demand from urban centres to suburban and rural areas, where car dependency is higher. Garages in these regions could see increased business as a result.

Unipart is strengthening its presence in the UK manufacturing sector with the acquisition of lightweight components producer Formaplex Technologies.

Formaplex, established two decades ago as a specialist tooling partner in the F1 automotive sector, is a key UK supplier of polymer and composite solutions and one of the few premium polymer injection moulding specialists in the UK supply chain.

Unipart did not disclose terms of the deal, but confirmed on August 6 it was integrating Formaplex operations into the group following the acquisition. Formaplex has been rebranded as

Polymer and Composite Solutions.

Darren Leigh, Unipart CEO, said: “Growing our manufacturing capabilities through this acquisition expands our offering and aligns perfectly with Unipart’s growth strategy to offer our existing and new customers a breadth of supply chain solutions and performance improvement technologies.

“I am excited about the potential this acquisition unlocks for innovation and growth, enabling us to expand our portfolio and strengthen our position in the UK manufacturing sector.”

Unipart Manufacturing Group MD

Burke said the acquisition will further support supply chains involved in delivering powertrain products used for internal combustion engines and electrification, as well as enhancing Unipart’s products for uses in other sectors such as construction and rail.

Ministers are being urged to use the upcoming autumn budget to chart a new course for car dealerships and boost the wider garage sector.

The National Franchised Dealers Association (NFDA) said on September 11 it was recommending three key areas for action by the new government, including boosting the automotive sector by driving vehicle electrification, creating a more equitable business rates framework and developing a clearer plan for future road taxation policy.

NFDA chief executive Sue Robinson said the budget, scheduled for October 30, would be the first under a Labour government since 2010, presenting a crucial opportunity for the new administration to define and articulate its vision for the future of the sector.

Robinson said: “NFDA continues to oppose increases in fuel duty rates, which will only impose higher costs for British motorists at a time of relative global instability, adding to the burden of rising insurance premiums — a concern also addressed in the submission.”

She said the budget would be a chance for the chancellor, Rachel Reeves (pictured), to demonstrate the government’s support for the sector.

“The right policies can ensure the industry prospers in the coming years during the transition to electric. Dealerships have already made significant investments in this shift.

“As we near the end of the year, a key focus will be the ZEV mandate, particularly as the EV market share remains below the 22% target set for this year,” Robinson said.

“By restimulating the private EV

The owner of an award-winning garage in Derbyshire has shared what lies behind its success — and how the power of being online has helped it get to where it is today.

Julian Hazeldine said when he took over Stoney Cross Garage he knew that being online was key to making it work.

In fact, his belief in the power of the internet to get the business going was so strong, he paid for the website with his own money until the garage could afford to take over the monthly subscription cost.

It’s a strategy that paid off. Stoney Cross is the current holder of the Servicesure Autocentre of the Year award and its five ramps are constantly booked up three weeks in advance.

Hazeldine said: “The impact the website has had on the business is massive. When I took over the garage it was only small. Most of the customers were friends of the previous owners so

it was like starting from scratch.

“Even all those years ago, I knew a website was key to not just establishing the garage, but to its continual growth and ongoing success.

“Servicesure recommended Garage Services Online (GSO) and we’ve never looked back. They are outstanding, both in terms of customer service and being specialists in independent garage websites. We rank at the top

market through price incentives, establishing a more equitable business rates framework, developing a clearer plan for future road taxation policy and improving the UK motorist experience, the government can support the industry in achieving its far-reaching objectives.

“NFDA urges the chancellor to drive investment in the economy and address the needs of the automotive retail sector as a priority.”

of a Google search for most of our services.”

Hazeldine said repeat customers make up around 60% of the business and the website consistently generates the other 40%.

“We get up to 20 online enquiries every week via the website. People also say they call us after reading our Google reviews and being directed to a very professional website. It’s easy to navigate and just sells the garage services for us. Customers love it.”

Jim Lang, MD at GSO, said: “When I took the initial call from Julian years ago, Stoney Cross was a very different garage to the one it is today.

“It’s been wonderful to watch the business evolve, and the website has grown with it. It’s an online mirror of the professional, award-winning garage on the ground. And that’s the secret behind a seamless experience for the customer.”

Mastering the essentials of fair, swift and e ective dispute resolution

Disputes in relation to a service and repair make up the largest volume of case submissions by motorists to The Motor Ombudsman on an annual basis after used cars.

Given that a vehicle is usually a substantial investment and a critical part of daily life for many consumers, time o the road in a workshop can lead to significant inconvenience and stress.

The added expense of repairs, whether it is routine or ad hoc maintenance, can equally compound the issues at hand, potentially leading to heightened emotions and dissatisfaction.

As a result, strained interactions may follow as a customer expresses their frustration towards the garage — which may ultimately have done all they can to assist them.

Therefore, to help defuse a ‘chilly reception’ from a consumer, a business can take the following five key steps:

Use clear and proactive communication

As well as having a clear and well laid out complaints resolution process

Even the smallest of gestures from a business can make a big di erence

that both a business and consumer can follow should a dispute arise, transparent and open dialogue is also key to directly addressing the concerns of customers, and to getting to the root cause of the issues raised.

Understanding the key drivers of dissatisfaction can then help garages to implement e ective and viable solutions that best respond to customer needs.

An apology can go a long way… If it is found that the standard of work or service provided to a customer has fallen beyond expectations, it is important to o er, without delay, a personalised apology that directly addresses the course of events and what has happened. A resolution does not have to be monetary or physical. A simple and sincere acknowledgment of the customer’s concerns, and a listening ear, may be su cient to restore trust.

O er an incentive to return

Even the smallest of gestures from a business can make a big di erence. A token of goodwill, such as a discount or a voucher for a future visit, can help preserve the relationship and encourage future loyalty at minimal cost.

These actions not only show that the customer is valued, but also reinforce a business’s commitment to complete satisfaction.

Signpost in the event of stalemate

If deadlock is reached, despite the best e orts of a garage to conclude the complaint, it is best practice and the law for a garage to signpost a customer to a certified alternative

Bill Fennell, chief ombudsman and MD at The Motor Ombudsman, looks at what garages can do to help rebuild relationships if they have been given the cold shoulder by a customer

dispute resolution (ADR) provider, such as The Motor Ombudsman.

This is a far less confrontational and costly route to resolution than going to court and helps to safeguard a viable long-term relationship with a customer. It is also free of charge for consumers to engage in such a service, from beginning to end.

up for feedback

Regardless of whether a resolution is achieved, it is always valuable for a business to follow up with a customer and seek feedback on the level of service provided.

This demonstrates a garage’s commitment to long-term customer satisfaction and making procedural changes to continually improve the way they do things.

Visit www.TheMotorOmbudsman. org/join for more information about accreditation to The Motor Ombudsman’s Service and Repair Code.

Nick Crossley, industry director, auto, at Teads UK, on the power of brand storytelling in the premium market and the challenges that the sector is facing when it comes to brand loyalty

Using the findings of Teads’ recent ‘Shifting Gears: New Dynamics of Auto buying Study’, Crossley has looked into the channels and touchpoints that drive car purchasing decisions. He says the key to engaging current customers is by captivating them at the most impactful moments — ensuring brand messaging is not just seen but remembered.

As the automotive world rapidly evolves, traditional brand loyalty is fading. With electric vehicles levelling the playing field, premium features like performance and innovation are now widely accessible. This shift makes brand positioning more critical than ever.

To stand out and avoid over-focusing on lower-funnel activities, premium auto brands must craft compelling narratives and unique selling propositions (USPs) that resonate with both existing and potential customers.

Recent Teads research shows 79% of UK auto buyers are open to switching brands, highlighting the need for strong customer loyalty strategies, especially in the premium segment, as despite the current economic climate, 1 in 5 buyers

plans to upgrade to a larger or more premium vehicle.

Customer engagement should span the entire journey from research to purchase. Understanding the latest research and purchase behaviours from consumers across the digital ecosystem is becoming increasingly important — as 43% of consumers that Teads surveyed now feel that online resources play a more important role compared to previous purchases.

For example, negotiation and purchase, once strictly in-person activities, are now being embraced as part of the online experience.

of opportunity. This window is of the upmost importance when it comes to brand loyalty.

Here’s how premium automotive brands can strengthen retention at each stage of the vehicle purchase journey:

Be hyper focused on a clear brand narrative and highlight USPs — all elements need to emotionally resonate and be accessible across digital platforms. If your brand doesn’t resonate or spark desire, then often it won’t even be considered in the research phase.

79% of UK auto buyers open to switching brands, highlighting need for strong customer loyalty strategies

The Teads ‘Shifting Gears’ global study highlighted that today’s purchase cycle is accelerated, with nearly half of all car buyers dedicating only two weeks or less to researching di erent brands and models.

This learning underscores the need for automakers and retailers to adopt a consistent and proactive engagement strategy to capture consumer attention within a shrinking window

Despite all the technological gains in recent years, reliability, safety and fuel e ciency were listed as the most important factors for consumers when choosing a new vehicle. Highlighting the need for brands to appeal to both the heart and the head throughout the process.

The transition from the digital brand experience to the physical should be seamless and done without delay.

If your brand doesn’t resonate or spark desire, then often it won’t even be considered in the research phase

Personalise communications to reinforce the brand’s narrative, using digital tools to tailor information to consumer interests and ensure previous customer preferences and behaviours are reflected.

Over 50% of consumers in the UK have just two brands under consideration by the time they arrange a test drive. It is therefore crucial that retailers o er high quality or unique experiences to underscore the brand and product positioning and stand out from the competition

Use interactive tools to personalise the vehicle and integrate storytelling that highlights brand attributes.

Provide transparent, flexible solutions that position the brand as customercentric.

Maintain exclusivity through personalised product specification, quotes and o ers that reinforce loyalty.

Deliver a seamless, premium buying experience complemented by postpurchase perks like personalised follow-ups and exclusive brand events. Customers are not just purchasing a product; they’re investing in a lifestyle and in some cases a community.

The rise of EVs has made di erentiation both challenging and crucial. Brands like Land Rover demonstrate the e ectiveness of strong narratives and a robust digital presence.

However, premium auto brands should not only focus on lower-funnel tactics but also invest in brand building to create a consistent, compelling experience that resonates at every stage of the purchase journey. This approach will help retain loyalty and attract new buyers in an increasingly competitive market.

With over 20 years of experience in the automotive industry, Nick Crossley has had a career in sales, marketing, and media for both volume and luxury brands. Throughout his career, he has worked at global and regional market level, leveraging his industry knowledge to drive growth and innovation.

Nick’s expertise spans various facets of the automotive sector, including strategic planning, brand management, market analysis, customer relationship management, and media strategy. He has been responsible for launching and promoting numerous high-profile models for renowned brands such as Peugeot and McLaren, ensuring their competitive positioning in the marketplace.

He has a proven track record of delivering results across the automotive customer journey, and is a champion for marketing innovation and responsible advertising.

How new investment and the development of AI is helping PartsForMachines — an online aftermarket site serving the construction, agriculture and industrial sectors — expand its business beyond the UK

Partsformachines.com has secured next-stage funding that paves the way for expanding in its launch market, in the UK, and pushing into wider European markets.

The online aftermarket platform, which services agriculture, construction and general industry, has shown consistent growth since its launch in 2021. Two recent major developments include the expansion of the business into Ireland and the launch of sister business — MachineRefurb.com — a consolidated sales platform for manufacturer-refurbished equipment.

PartsForMachines is the brainchild of Abhishek Tanwar, who co-founded the company and is now MD. He said the platform has shown consistent growth since launch and is now set for major expansion thanks to the latest tranche of undisclosed funding.

“Our new funding allows us to take advantage of the opportunities afforded to us by emerging AI technology, as well as broadening our marketing reach and expanding our team to fill the roles necessary to encompass further growth.”

As a trailblazer, in terms of aftersales platforms for the industries it serves, PartsForMachines has been quick to realise the potential that AI has to offer. The sales philosophy is based on four pillars: easy to find; easy to buy; great service and hassle-free returns.

Tanwar said the platform boasts a “near perfect” TrustPilot rating, which endorses the company’s commitment to ensuring an excellent customer experience. AI will help speed up the overall buying process and support future purchasing patterns and requirements.

The supplier partner programme is also increasing, attracting leading brands onto the site.

“Bringing in major industry names was by no means easy in the beginning, Tanwar said.

“We are very grateful to those who made the initial leap of faith and joined us. Other brands soon came to realise that we were offering a new route to market, and over the last few years, both the number of brands and the quantity of parts that each supplier partner brings to the platform has increased exponentially.”

Tanwar said the platform is now approaching the 50 brand mark, with hundreds of thousands of parts listed.

MachineRefurb.com, which offers customers factory-refurbished

machinery, tools and workshop items, came about following conversations with manufacturers who were seeking a bespoke platform for such goods.

“It has the additional benefit of us helping increase sustainability by effectively being part of a recycling process, while at the same time offering customers the opportunity to buy high quality kit and machinery they might otherwise not be able to afford,” Tanwar said.

Looking to the future, following the Ireland launch, Tanwar said more sites will be launched in the not-to-distant future serving others countries in their respective languages.

“We are constantly looking to the future. Though we are making real, consistent progress in terms of sales growth, we have several areas of the business that need further resource to deliver our planned expansion, both in the UK and in overseas markets.”

Visit www.partsformachines.com to find out more.

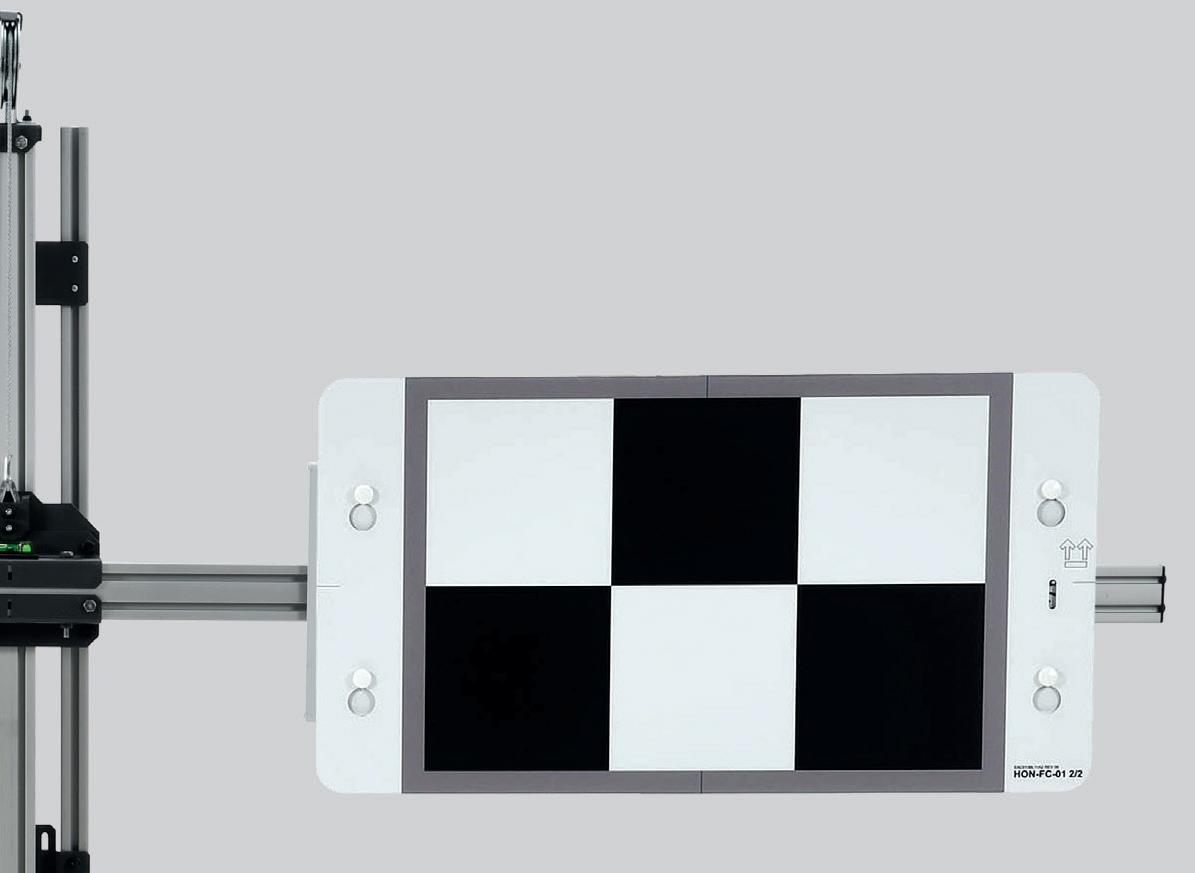

Accurate, Portable, Guided Calibration

The THINKCAR ADAS (Advanced Driving Assistance System) calibration unit is a portable device developed

instrumentation to assist in centering and positioning for high accuracy THINKCAR ADAS integrates with ACC, LDW, AVM, RCW, BSD system calibration functions.

Easy Installation Universal calibration components, different tools can be freely assembled to calibrate different car models.

High Accuracy

The calibration data reaches millimeter-level, for high accuracy

Guided Function Guided calibration for simple operation

Wide Coverage

Mercedes-Benz, BMW, Volkswagen, Audi, Land Rover, Jaguar, Porsche, Volvo, Fiat, Opel, SEAT, Skoda, Renault, Citroen, Peugeot, Alfa Romeo, SMART, MINI, GM, Buick, Cadillac, Chevrolet, Ford, Lincoln, Chrysler, Dodge, Jeep, Toyota, Lexus,

Mitsubishi, Suzuki, Subaru and other models

Full System Support Lane Departure Warning (LDW), Adaptive Cruise Control (ACC), 360 Panoramic Monitoring (AVM), Rear Collision Warning (RCW), Blind Spot Monitoring (BSD) and more

Repairify Innovations director Martin Pinnell-Brown looks at trends looming in the new year we should be aware of

Most cars that have come o a manufacturer’s production line in the last couple of years have some form of ADAS technology as standard. But as we know with this type of technology, it will continue to evolve. Here are some trends to be aware of as we head into 2025

As ADAS systems continue to evolve we will see an increase in the processing of real-time data that is provided by the systems on the vehicle.

Having the ability to do this with the help of AI will have two distinct benefits. The first is improved decision making and the second, and probably most important, is enhancing sensors on the vehicle so they are not only better at recognising objects but can also map an environment that can be shared with other vehicles, so they are aware of it even if they have not been near it.

There are various sensors on cars that range from LIDAR to sensors for adaptive cruise control.

Currently, these each perform their own role, and don’t ‘talk’ to each other. However, sensor fusion delivers improved communication between the sensors in the vehicle enabling them to work together to predict issues ahead of time and provide the driver with the

necessary warnings and information.

The amount of data generated by ADAS systems in vehicles is considerable. In 2025, we will be seeing the data that is collated used to map roads and signs, as well as highlight issues or obstacles so that cars are aware of them and the internal systems can be proactive.

In addition, the data will be used by manufacturers to help the sensors and cameras perform at an optimal level in all conditions.

Connected cars provide the user with features such as up-to-the-minute tra c information and connectivity with smartphones. In 2025, more vehicleto-vehicle communication will arise as cars are now using 5G and WIFI to

In 2025, we will be seeing data collated used to map roads, signs and to highlight issues or obstacles

transmit data to other connected vehicles, which will become an asset because the data that is shared will help alleviate congestion and reduce the risk of accidents.

The result will be safer roads for drivers, passengers and other road users.

Overall, it is important to be aware of ADAS trends because they are constantly evolving, so technicians have the necessary knowledge and skills to understand them and perform related work.

In addition, they will enable businesses to have a greater understanding of how the industry is changing to be able to respond to its demands.

Following the Top Tech semi-final competition in September, judges have now chosen the five contenders who go through to the final later this month. Aftermarket editor John Shepherd looked on as all semi-finalists were put through their paces…

The state-of-the-art Delphi Training Centre in Warwickshire hosted the semi-finals of Top Technician last month as contenders were put through their paces.

All 10 semi-finalists had to successfully conduct five 20-minute fault-finding tasks on live vehicles and be scored accordingly.

The highest scoring five (listed in the panel) now go through to the finals of the competition at our awards evening on Saturday, October 26, at the Double Tree by Hilton in Coventry.

My DFA Media Group colleagues

John Fountain

Andrew Ruellan

David Weston

Gordon Wright

Emma Godden-Wood, operations manager, and Hope Jepson, marketing manager, joined me at Delphi for the event — and they were key to supporting

our venue hosts, judges and contestants with the smooth running of the event.

But of course, a special mention and all credit for the judges. They guided the contestants through the arduous day of testing on September 7 with the utmost skill and professionalism.

And in the ‘big reveal’ at the end of the tasks, each of the judges outlined what the contestants should have picked up in a friendly and collegiate manner.

What the contestants said… John Hall said he was unsuccessful in reaching the semi-finals of Top Technician last year and was happy to

get through this time. He praised the competition for contributing to his career and knowledge development.

Bryan Swales said the competition proved “you can also always learn something”.

First-time competition entrant Gordon Wright said: “I wanted to be challenged and the contest really does that.”

David Weston, who has now made it through to the semi-finals on four occasions, said: “I am surprised every time in terms of the challenges I’m presented with, and I love that.”

Gary Birse, a former competition finalist and a runner-up in last year’s competition, praised the style and content of the contest, as did John Shuttleworth, who made it through to the Top Technician semi-finals for the first time.

John Fountain, who first entered the competition in 2017, said he was delighted to be in the semi-finals, adding: “There is always something to learn.”

James McCallum, speaking ahead of undergoing his tasks, said he was pleased to have made it into the semifinals for the first time and was looking forward to the tasks.

Andrew Ruellan, who has made it through to the semi-finals previously,

said he was delighted to be back facing a fresh challenge from the judges. Everyone taking part sent their best wishes to Adam Cannell, who had secured a place in the semi-final but could not take part on the day because he was unwell.

Luke Garratt, UK & Nordics technical services manager for Delphi said: “For Delphi, sponsoring and hosting Aftermarket Top Technician and Top Garage is about much more than just putting our name to an event for publicity and exposure.

“We want to actively engage with technicians, continually showing that we support their ongoing skills development and dedication to the industry.

“By providing the perfect environment for the competition to take place and our technical resource to assist with the technical faults and judging process, we look to become a part of the technicians through process.”

Garratt said Delphi is a proud supporter of Top Technician and Top Garage because of the competitions’ high standard and the “fiercely competitive yet supportive nature of the event”.

The competitions not only highlight the exception skills of technicians but also promote an environment

of continuous improvement and professional growth, Garratt said.

“We firmly believe in recognising and enhancing the expertise and dedication that drives our industry forward.”

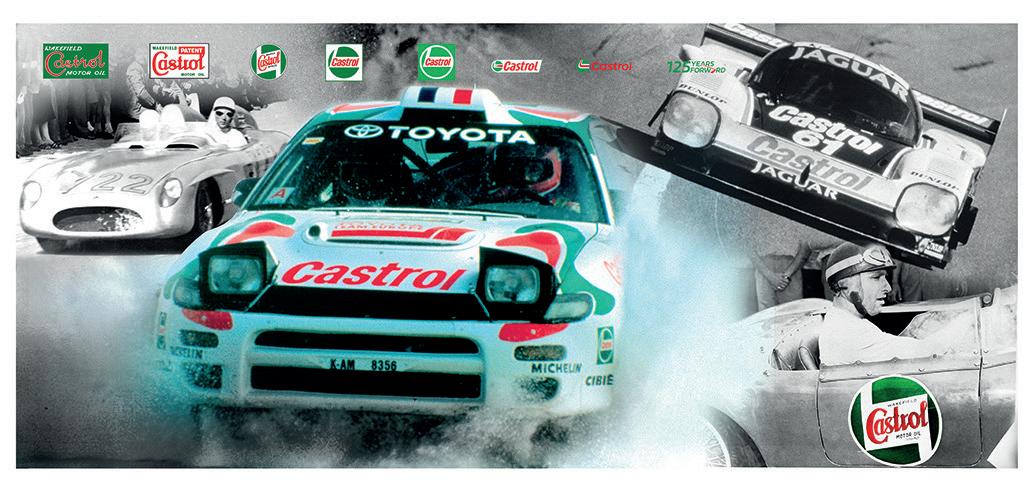

Marc Perkins, automotive sales director UK & Ireland for lubricants at bp/Castrol said: “Top Technician and Top Garage highlight and reward the best in the industry, and Castrol & The Race Group are delighted to join in the celebration as Full Event Partner for both competitions this year.

“The focus on technical excellence, business development and networking with like-minded industry experts

line up with the values we encourage through our Castrol-branded programmes.

“We wish all those taking part ‘good luck’ and we’re looking forward to sharing their successes on October 26!”

We are proud to announce an exciting new development for 2025, when we will also be looking for the UK’s Top Apprentice, as part of our established

Top Technician competition.

The formal launch announcement of Top Apprentice will be made at The Aftermarket Event on October 2-3 at Farnborough International — see our Show Guide on the flip side of this issue of the magazine.

Top Apprentice will be open to

all apprentices nationwide who are currently in level 2 or level 3 study, from all colleges and training centres.

The competition will o cially open in early December but for now, all interested can register their interest online: https://bit.ly/4fJVMb2

Aftermarket magazine is delighted to announce the finalists of the Ben Workplace Health & Wellbeing category in this year’s Top Garage competition.

The category’s award winner will be announced on Saturday, October 26, at the Double Tree by Hilton in Coventry.

The finalists are:

Alga Garage

Automax Group

Boyds Motor Engineers

D & D Autos (Ashford) Ltd

Fife Autotech

Lawson Autotech

Maitland Motors

Repayr My Car

Shaikly Motor Company

The Mini Repair Shop

Final held at Delphi Academy, Warwick

Book your table now:

DENSO Aftermarket Europe explains how innovative technical support can help professionals install products crucial to safety and performance efficiently and effectively

DENSO Aftermarket Europe is dedicated to providing high quality automotive parts and solutions to the aftermarket and with a strong commitment to innovation, reliability, and customer satisfaction, it helps to ensure that the vehicles continue to operate at optimum performance

The same quality-led ethos drives the company’s support for the independent service and repair sector by offering access to these OE products, across seven product categories with 33 product types, covering more than 7,500 part numbers and catering for millions of applications — as well as the technical support to ensure that professionals can install them efficiently and effectively.

DENSO wiper blades are the choice of many vehicle manufacturers and are fitted as OE on a host of high-end vehicles.

As a crucial component of a car’s safety system, our car wiper blades are meticulously manufactured and tested to ensure they meet precise standards of fit and performance.

The aftermarket range combines intelligent design, top quality materials and accurate manufacture to ensure they wipe better and last longer, and consists of four product types: flat,

conventional, hybrid and rear blades.

Although wiper blades are one of the most important safety features fitted to vehicles, drivers rarely give them a second thought, despite the fact that efficient windscreen wiping and visibility are vital all year round.

Therefore, it’s important for wiper blades to be replaced as soon as their performance begins to drop, but notwithstanding, at least once a year.

In addition to making it straightforward to identify and select the correct replacement, DENSO has now gone several steps further.

As well as providing written instructions with supporting diagrams on its product packaging, DENSO has produced a series of videos that clearly demonstrate the fitting process, to make their replacement a quick and easy job.

Reflecting the range of wipers the company offers, DENSO has produced a specific video for its three primary designs — standard, flat and hybrid — that not only provides motorists with the widest choice of options in terms of their blade preference, but also ensures that whatever style they choose, they can be fitted correctly.

After identifying the wiper blade to wiper arm fixing system, the videos explain where the wiper arms need to be

positioned to enable the safe removal of the existing blade.

They also provide a really useful tip, often overlooked during the replacement process, which is to thoroughly clean the windscreen before the old blades are removed and new ones fitted, in order to prevent scratches and ensure the proper seating of the new blades.

Key to correct replacement is understanding how the existing blades are attached, which is the next step in the video and without this visual explanation, is often difficult to imagine. Another valuable tip included at this stage is to check the condition of the arm where the blade attaches, as corrosion here could present a safety issue and would require advice from a professional technician.

Finally, the new blade fitting process is shown, including the all-important locking position, and once completed, a final system check is carried out, by activating the windscreen washer function, which will confirm that the blades have been replaced successfully.

These new videos are available alongside a wide variety of useful wiper blade advice and information on the DENSO Aftermarket website.

https://www.denso-am.eu/ products/wiper-blades

Ivor Searle, the UK’s leading remanufacturer of automotive products, offers a fast turnaround offvehicle diesel particulate filter (DPF) cleaning service for cars and vans.

Alongside free collection and delivery, the professional DPF cleaning service includes a detailed inspection report, plus a 12-month no quibble

unlimited mileage warranty.

Utilising state-of-the-art flash cleaning technology, Ivor Searle DPF cleaning provides as-new levels of cleanliness by removing all soot deposits, including PM10 particles, cerium oxide deposits and oil residues, from the DPF.

Unlike chemical-based cleaning processes, which

only remove soot, flash cleaning eliminates both soot and ash deposits.

This returns a DPF back to OE levels of performance at a much lower cost than purchasing a new OEM unit or risking fitment problems that may occur with a generic replacement.

To find out more about Ivor Searle’s fast turnaround off-

vehicle DPF cleaning service call the Ivor Searle sales team on 01353 720531 or visit our website.

UK LED lighting designer and manufacturer for commercial vehicles, Labcraft, has presented its latest Banksman lighting systems alongside a new range of compatible harness kits, designed to save time and money during installation.

Labcraft’s range, unveiled at the IAA Transportation show in Hanover last month, features four models – BM2, BM3, BM4 and BM6. The products deliver additional bright light around the vehicle, helping drivers to manoeuvre more easily and with confidence, in open and confined spaces.

With over 30,000 installations, ranging from large fleets to single vehicles, operators who have fitted the regulation

23-compliant lamp are reporting that safer manoeuvring has resulted in significant reduction in costs associated with accident damage and vehicle downtime, Labcraft said.

To make Banksman even easier to fit for vehicle manufacturers, operators, and workshops, Labcraft is introducing a range of preassembled electrical harness kits, to reduce installation time and ensure long-term reliability for all vehicles — from rigids and urban vehicles to trailers up to 13.6m.

Visitors to Labcraft’s stand also saw a selection of high intensity low voltage LED lighting solutions, and could even build their own using the new Labcraft Product Configurator.

OE manufacturer and lighting specialist OSRAM is pushing ahead on sustainable packaging and has now begun to replace packaging for its entire retrofit bulb portfolio in the automotive lighting sector with ecofriendly alternatives.

The company’s goal is to have carbon neutrality of its own operations by 2030 and it is applying the strategy principle ‘avoid, reduce, compensate’ to its reduction path.

OSRAM is already contributing to a significant reduction in its ecological footprint through continual technological product development. The latest examples are the extremely

durable ULTRA LIFE halogen bulbs with longer lifetime and the development of on-road and off-road retrofit LED bulbs, which require 60% less energy than conventional halogen bulbs and have a longer service life.

The company is now taking the next important step towards even greater sustainability by changing to 100% plastic-free and fully recyclable packaging made from recycled materials for all its automotive bulbs.

The new packs are as durable and robust as their predecessors. Products in the box are no longer visible, but they are depicted full size on the packaging to be easily identifiable.

Since Bosch ESI[tronic] Evolution diagnostic software went live in January, many workshops have been enjoying the fresh look and enhanced experience provided by the convenient new Start Screen user interface, including direct links to comprehensive service and maintenance information.

What’s more, ESI[tronic] Evolution now o ers access to an abundance of additional information. Enhanced content includes the OE documents for Audi, VW, Fiat vehicles, BMW, Mini and Rolls-Royce.

As the Evolution continues, Bosch has now introduced another feature of ESI[tronic] Evolution that simplifies

vehicle identification for UK registered vehicles.

Previously, this software allowed identification through manual selection criteria, vehicle identification number (VIN) reading, or RB Key. However, with the 2024/3 update, vehicle identification can now also be carried out via the number plate, making it even easier for IAM workshops to handle UK vehicles.

While the new update o ers the convenience of licence plate identification, the software still supports identification through all the other options available in the vehicle selection screen, including free text, VIN identification and manual selection.

https://aftermarketonline.net/the-journey-so-far-of esitronic-evolution/

Castrol has launched two new high-performance fully synthetic fluids designed for EVs that feature transmissions with wet e-motors.

Castrol ON EV Transmission Fluid W2 and W5 are demonstrated in bespoke testing and development to go further, charge faster and last longer. The low-viscosity formulations of W2 and W5 have been specifically developed to deliver low electrical conductivity and enhanced system protection, helping the e-motor run at cooler temperatures and at optimal e ciency.

Both products have been designed and extensively tested to handle the high torque outputs that EV motors can generate even from low speeds.

Delphi is encouraging garage owners and technicians to take advantage of its evergrowing online library of ‘how-to’ videos, to help tackle the increasingly complex and diverse range of workshop jobs.

The PHINIA brand said each video is part of Delphi’s ongoing Masters of Motion programme. They cover key concepts with expert tips and step-by-step guidance.

Luke Garratt, UK & Nordics technical services manager at Delphi, said: “These videos are created by technicians, for technicians.”

Some of the latest videos include ‘How to adapt a lowpressure EGR valve’, which walks technicians through the correct procedure from checking for fault codes in the exhaust gas recirculation valve to a final road test. Another, ‘How to perform real-time data recording’.

https://www.delphiautoparts.com/en-gb/mom

Thinkcar UK is bringing a range of task-specific tools to the market to help technicians looking for innovative solutions to diagnose faults on ageing yet complex modern vehicles.

The announcement comes as data from sector analysts GiPA indicate one of the fastest growing car parc

segments is vehicles aged 10 years and above.

Among tools unveiled include the Thinkcar ES401 Steering Endoscope.

Alex Gillbanks, MD of Impact Diagnostics, the specialist supplier behind Thinkcar UK, said the tool is designed to support techs performing inspections in tight spaces.

First Line has added a further 35 new parts to its product portfolio, including 11 drive shafts, nine new steering and suspension components, seven friction parts, four filters, and two cables and cooling solutions.

In the steering and suspension category, the First Line brand has added stand-out references such as part number FCA8023, a left and right suspension arm for Volvo XC40.

In the drive shaft portfolio, the Borg & Beck brand enhances its lineup with several new parts including

BDS1615, a drive shaft compatible with the Citroën Dispatch III and Spacetourer, Peugeot Expert and Traveller, Toyota Proace, and Vauxhall Vivaro.

Latest friction parts include part number BBD5562, a brake disc designed for the Fiat 500L and Tipo Estate.

A key addition to cables is part number BKG1370, a gear cable compatible with the Toyota Auris and Avensis.

For cooling, First Line has introduced part number FTK558, a thermostat kit compatible with a wide range of vehicles including the Audi A1, A3, and A4.

Hella Gutmann has announced the launch of its mega macs PC second edition (SE) giving technicians the very latest diagnostic capabilities –including support for cybersecure vehicles and those using diagnostics over internet protocol or CAN FD protocol.

The mega macs PC SE covers more than 40 manufacturers and over 48,000 vehicle models. Workshops simply plug the vehicle communication interface into the OBD port for wireless communication

www.firstlineltd.com www.hella.com

with the vehicle using any Windows tablet, laptop, or PC.

Julian Goulding, head of sales at Hella Gutmann, said: “From vehicle servicing to ADAS calibration, mega macs PC SE is incredibly versatile. We offer the tool with a Windows tablet but technicians can also use their own tablet or PC.”

For vehicles protected by a cyber security gateway, mega macs PC SE simplifies the diagnostic process by allowing workshops to bypass the hassle of individual manufacturer registrations.

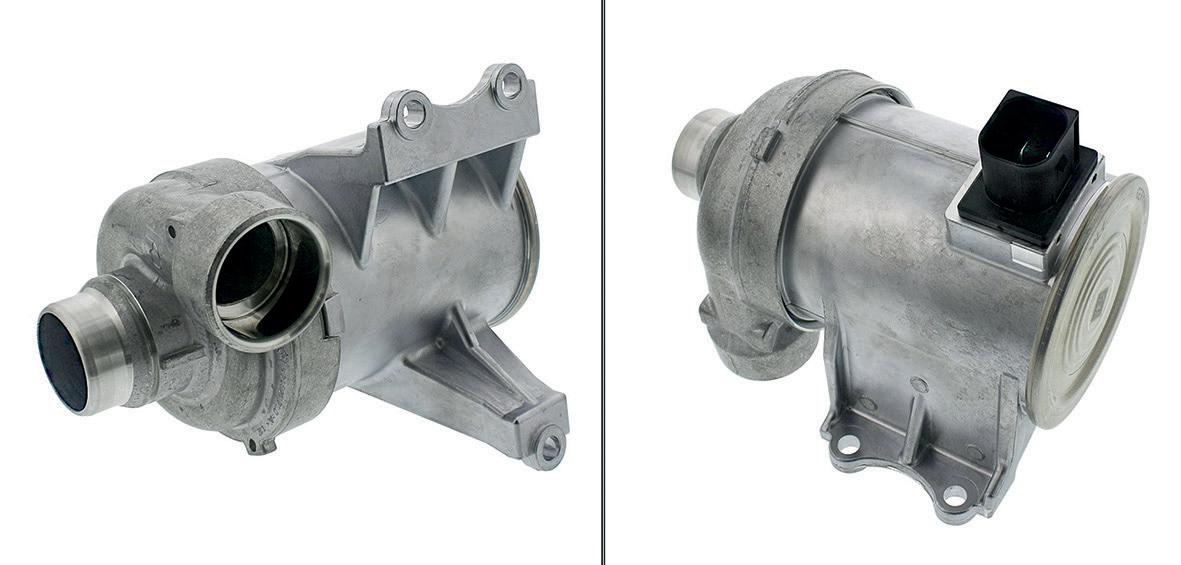

Schaeffler’s range of INAbranded electric auxiliary water pumps now includes a new reference for the Volvo XC60, the most popular model currently offered by the brand, along with several other models. The range meets OEM standards and offers wide coverage of the European vehicle parc. The launch earlier this year included an initial batch of 11 parts, with more set to be released soon

as the portfolio continues to evolve.

Electric water pump 538 1018 10 covers Volvo vehicles

equipped with the B4204 engine, including various iterations of the S60, S90, V40, V60, V70, V90, XC40,

XC70 and XC90. The most popular vehicle covered is the Volvo XC60 Hybrid AWD, in production since 2018.

Maik Evers, head of product management powertrain systems at Schaeffler Automotive Aftermarket, said the new pump is notable for its precise controllability. “As it is powered by the vehicle’s electrical system, not the belt drive, the delivery rate is continuously regulated.

EASY TOUSE, EZ ADAS APP

KNOW WHICH TARGETS YOU NEED. SEARCH BY MAKE, MODEL AND YEAR - STEP BY STEP INSTRUCTIONS AND TUTORIALS

CALIBRATIONS OPTIONAL

LET US TAKE THE STRESS AND HASSLE AWAY

SPEAK TO YOUR SNAP-ON® FRANCHISEE OR TECHNICAL REPRESENTATIVE FOR A

Castrol’s all-new Magnatec formulation deploys ‘intelligent molecules’ to boost protection and performance for range of Ford engines

Castrol has launched a new formulation of its car engine lubricant, Magnatec, to meet the specific needs of some of Ford’s most popular petrol engines.

Castrol Magnatec 0W-20 E is compatible with Ford’s 1.0L EcoBoost, 1.5L EcoBoost I3, and 2.5L DuratecHybrid powerplants, which can be found in models such as the Fiesta, Focus and Kuga1.

Castrol’s latest Magnatec lubricant is compatible with Ford’s new WSSM2C954-A1 petrol engine specification and is also backwards-compatible to applications that require SAE 5W-20 viscosity oils that meet Ford’s WSSM2C948-B specification.

When engines aren’t running, oil can drain away to leave critical parts exposed, with 75% of wear typically taking place during the warm-up phase, whereas Castrol Magnatec’s intelligent molecules do not.

Instead, they cling to critical engine parts to make them more resistant to wear. It provides continuous levels of protection in high and low temperatures and when faced with different driving conditions and styles.

The new product also provides additional performance benefits,

including improved fuel economy, protection against timing chain wear, and defence against low-speed preignition.

Over the past year, Castrol and Ford have continued to galvanise their longstanding relationship, which originally began in 1914, by extending their European cooperation agreement until December 2027.

As part of its 125th anniversary celebrations, Castrol has launched ‘First Car Love Stories’, a new campaign that encourages workshop customers to share their motoring stories for a chance to win £10,000. The promotion aims to capture car drivers’ emotive stories about their very first car — while boosting sales and driving brand awareness.

Car enthusiasts who do not yet own a car may also participate by submitting a

brief description of their first dream car and explaining their choice.

The partnership ensures that Castrol will remain the recommended lubricant supplier across Ford’s European dealer network, while the two companies will also continue the co-development of advanced fluids for new powertrains that deliver optimal performance and reliability.

In addition, Castrol works closely with the Ford M-Sport WRC team to continually test its engine oils in the toughest of conditions. Away from top tier motorsport, Castrol provides Ford with first fill lubricants and co-branded products made exclusively for Ford’s official aftersales network.

Marisa Sobrino, brand and product specialist at Castrol Europe, said: “Our long association with Ford is further strengthened with the launch of Castrol Magnatec 0W-20 E. Workshops will be able to call upon a product that can service many of Ford’s most popular vehicles, while drivers can benefit from a product that exceeds the requirements set by Ford.”

Castrol Magnatec 0W-20 E is available to workshops, retailers and distributors in 1L, 5L, 60L and drum formats.

Visit https://bit.ly/3z8ub2A to find out more.

Castrol-branded workshops will be provided with a campaign toolkit that includes promotional assets to show their customers how to enter.

The workshops can also enter their own competition, with the best story winning a one-of-a-kind Snap-on masters series roll cabinet, valued at around £11,000.

Visit https://bit.ly/4dTkd4h for competition details.

Did you know that myComma rewards your workshop for using Comma?

Plus it equips your team with essential tools and training to keep your garages running smoothly. A win, win that’s...

up Free access to training Nice and easy sign-up Rewards for every litre Free MOT data tool

How one UK lubricants company intends to stay ahead of the game amid advances in the sector

Morris Lubricants has announced a £3 million investment at its Shrewsbury production plant.

The company said on August 22 that the move makes it even more equipped to meet the demands of a rapidly changing lubricants industry.

The days of having one oil fits all engine types and small selection product lines are long gone, Morris said.

After years of planning, designing, and scheduling the build, phase one of the new production facility has been completed, tested and is now fully operational. This new facility sees it optimised for the sustainable manufacture of sophisticated small-batch formulations.

The design and development of the new facility is in response to customer requirements and with a backdrop of optimising the manufacture of sophisticated small-batch product formulations in a more sustainable way.

Morris said it believes it now has one of the most technologically advanced and flexible oil blending capabilities in Europe.

As well as the increased efficiency, reduced energy use and optimised workflows, one of the major benefits of the new facility is the increased flexibility. Smaller volumes of high-quality products can be manufactured to the specifications expected by customers, demanded by the OEMs and stipulated by

industry regulations.

Morris executive chairman Andrew Goddard said:

“Moving with the times is something we’ve done for over 150 years and this project has enabled us to ensure we are at the very leading edge of technological advancements so that we can continue to provide the quality and service our customers have a right to expect from us.”

and analysis has resulted in higher levels of productivity by significantly reducing transfer times of raw material, packaging and finished product, as well as reducing the amount of wasteful double handling.

This investment builds upon the existing sustainable solutions which includes onsite solar power generated electricity, ultrasonic product

With a focus on efficiency and flexibility, as well as the mitigation of carbon emissions and the reduction of waste within operations, improvements to the production plant have included the installation of a new tank farm comprising 30 stainless steel storage vessels, the relocation and reconfiguration of production lines, and the integration of a state-of-the art, fully automated control and recovery system.

As well as the capital investment in new pieces of manufacturing equipment, investigation of the workflows on the factory floor took place over two years to establish the most efficient ways of working. This investment in equipment, monitoring

blending capabilities, the removal of unnecessary dye in in some products, the use of recyclable packaging and the introduction of recycled plastic bottles.

To ensure the purity and quality of each product batch, at various stages of its manufacture, tests are performed and checked in the onsite Morris Lubricants’ quality control laboratory. Around 5,000 tests are performed monthly.

To prevent crosscontamination when moving oils and lubricants between different areas of the plant, for example, strict procedures have always been in place.

The improved and expanded infrastructure of stainless steel pipework — which features product

specific pigged routes — combined with the advancements that have been made in regulating the different aspects of its operation through computerisation and automation, such as cleaning and waste recovery, further minimise the risk.

Part of the masterplan is to facilitate the repeat manufacture of the more bespoke formulations that industry regulations stipulate and OEMs require. This ability to maintain the flow of production means Morris can manufacture multiple grades simultaneously.

A small-batch production run of 2,000 litres, which can be filled in less than 40 minutes, can be processed at the same time as a batch comprising 100,000 litres. Morris believes the fragmentation of the oil and lubricant market will continue as emission legislations tighten. The introduction of alternative fuel types such as hydrogen, e-fuels and synthetics, will also pose new challenges for the industry and formulation for oils, greases and other lubricants must meet these everchanging requirements.

Goddard said: “As technology and customer needs change, our service and product offering will change. We plan on being here for the long term, so investing in the future has always been a priority. Whatever the future brings Morris Lubricants will be well placed to supply whatever is needed.”

Battery manufacturer Clarios is investing around €200 million (nearly £170m) in its European plants to continuously expand its production capacities for advanced adsorbent glass mat (AGM) vehicle batteries starting in 2022.

As of 2026, around 50% more units will be produced each year. In Europe, the Middle East and Africa (EMEA), Clarios operates 13 production sites including two recycling centres.

The investments announced on August 8 are part of Clarios’ strategy to invest globally in projects specifically focused on AGM production in the short-term, which allows Clarios in EMEA and its aftermarket brand VARTA Automotive to strengthen their leading position in this region by being able to deliver to customers even faster.

The expansion creates around 150 jobs in modern plants in Germany, Spain, the Czech Republic and France.

The automotive industry is changing fundamentally, driven by the trends of electrification, digitalisation and circularity, said Clarios. As platforms become increasingly complex and power-hungry, the need to develop advanced low-voltage systems capable of providing the energy needed for performance and safety, becomes even more crucial.

The battery giant expects global demand for advanced low-voltage

systems will grow by 7% annually up to 2030.

AGM batteries from Clarios are essential for sustainable mobility. They ensure optimum performance in EVs and provide constant power for crucial safety and comfort functions in both EVs and modern commercial vehicles. In vehicles with a combustion engine, they enable fuel-saving functions such as start-stop technology.

In Europe, Clarios is the undisputed market leader with its advanced battery solutions, which include VARTA Automotive. In seven out of 10 new vehicles with start-stop technology, it is Clarios’ AGMs that start the engine reliably.

Furthermore, the xEV batteries for EVs, which were launched by VARTA Automotive last year, already account for 90% of electrified vehicles on European roads and are suitable for future models.

Investments allow Clarios and its VARTA aftermarket brand to strengthen their leading position and serve customers faster

The largest expansion of AGM capacity will be at the Hanover plant in Germany, which is also home to the European headquarters of Clarios. The company will use most of the investment to finance new assets and is also optimising processes and shifting the entire site, including case production, to advanced battery technologies.

To create the necessary space, a significant part of the production of conventional batteries and the advanced EFB batteries for OE manufacturers has been relocated from Hanover to the Czech Republic. Additionally, plastic housing for AGM batteries and small parts such as plugs and handles will also be increasingly produced in the Czech Republic.

The annual capacity there has increased significantly, which is based on an investment volume of several millions. Since the start of AGM production in 2002, more than 80 million batteries have been supplied from Zwickau.

The recycling operation in Krautscheid, Germany, supports the AGM expansion with increased recycling of lead alloys for the grids used in AGM batteries. Krautscheid complements the capacity expansion in the production network for central Europe, which secures the supply to vehicle manufacturers in the region and in the aftermarket.

An additional production cluster is located on the Iberian Peninsula. In the future, conventional and EFB batteries for OE manufacturers, which were previously manufactured in Hanover, will be produced at the Spanish sites in Burgos and in the battery case plant in Ibi. Equipment is being moved from Hanover and a further investment of millions will be made at the two Spanish sites.

In addition, the plant in Guardamar, Spain, will also manufacture 50% more PowerFrame grids for EFB batteries and be equipped with an additional production line to do so, Clarios said. AGM is a further development of the lead acid battery. The electrolyte is bound within a glass fibre mat. This prevents electrolyte stratification, the main cause of faults in lead starter batteries; this significantly increases service life. An additional benefit of AGM technology is the very high charging capacity.

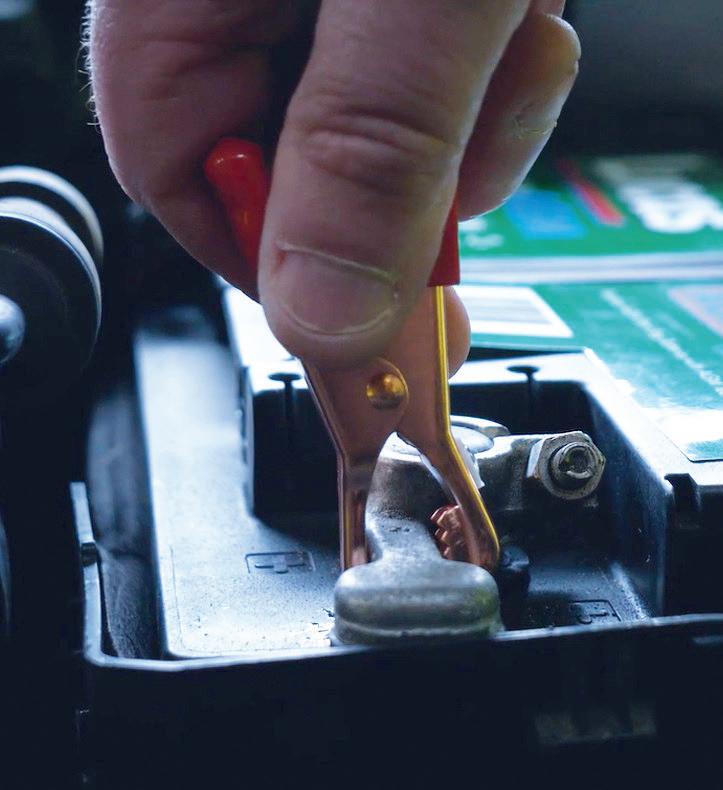

Ecobat urges workshops to check out clues for underlying issues when it comes to dealing with battery problems

Although diagnosis of this kind is a necessary part of the job for many repairs, battery related analysis is still often overlooked and a faulty or discharged battery simply swapped, without any thought as to why it might have failed.

While replacement might fix the immediate problem, failure to understand why it failed may mean that simply replacing the battery merely provides a temporary fix, after which, the fault will return.

Irrespective of the powertrain, a 12V battery is almost always at the heart of a vehicle’s electrical system, powering many of its related functions. But in common with every other component, it has a natural service life, after which its performance will deteriorate and eventually fail.

Ecobat Battery, the UK’s largest battery distributor, is encouraging technicians to be inquisitive and ask themselves why the battery is discharged, for example, and follow a step-by-step guide to make sure that battery replacement is a first-time fix, not an ongoing saga.

As it is likely that the vehicle will be brought in by the customer, start by asking how regularly it is driven, typically for how long and what type of journeys does it generally take. This will reveal whether the battery should be getting a decent amount of charge on a regular basis, or if it is usually using more power starting the engine, than it gets back from the alternator.

Assuming the initial problem is reported as a ‘flat battery’, instead of just checking the voltage, which is likely to be around 12V (the rate that constitutes a fully discharged battery), the battery should be charged and its state of health (SoH) tested to find out

whether it can still hold a charge. If it can, it is a good indication that there is another underlying issue that is causing the battery to discharge, rather than it just reaching the end of its life.

Another consideration is the battery’s age. Under normal circumstances, even a reasonable quality battery should last two or three years.

If the SoH is okay, then begin with the obvious things. Check the condition of the cables and terminal clamps, how secure they are and if there is any corrosion that could be impeding charging.

If everything there is in order, then it could be a problem with the alternator, which should be tested to assess whether it is operating to the vehicle manufacturer’s (VMs) specifications.

Parasitic drains are a persistent problem, so look for any aftermarket additions, such as alarm systems or daytime running lights that might not have been installed correctly — or for simple issues like the light in the boot, glove box or under the bonnet staying on.

In more modern vehicles, updates to apps can be the cause of considerable electrical demand. Combined with a

vehicle that has been used infrequently or only for multiple short journeys, this could bring the battery’s state of charge to a potentially problematic low level.

If none of these potential issues can be identified as the cause of the battery problem and its SoH is found to be low, then replacement is unavoidable, but even in this instance questions should be asked and procedures followed.

First, make sure the replacement matches the VMs specification for the make and model by using a resource, such as Ecobat’s battery finder.

The only normal exceptions to this rule are if the vehicle covers an unusually low annual mileage, or is fitted with additional, non-original electrical equipment, both of which could mean it requires a higher capacity battery. In these instances, consulting with a battery expert is crucial.

Second, after the correct battery has been identified, even if the workshop already offers its customers a ‘good, better, best’ option, it is always wise to encourage them to opt for the best quality replacement.

Third, make sure the replacement battery is fully charged before its installation.

Finally, ensure the battery is securely mounted in its tray, with the appropriate clamps to hold it in its correct position. Problems here could indicate the battery is not of the correct size or specification, which emphasises the need for the first step to be adhered to. In addition, to prevent any possible electrical short circuit, attach the positive cable to the terminal first, then the negative cable — and reverse the procedure when disconnecting the battery.

https://www.ecobatbattery.com/ applications/cars-vans/

TPS has supercharged its battery o er to customers with almost 100 products now available as part of its largest ever range.

As a result of its partnership with the tier 1 supplier GS Yuasa, TPS can now o er through its Quantum range 98 battery types, including the lead acid, EFB, AGM and auxiliary options, plus some leisure batteries too.

The range has also been updated to include a number of Asian market types to meet the demand for some popular applications such as the Toyota Prius.

The auxiliary options systems are available for conventional ICE vehicles, EVs and hybrids. In newer hybrids and EVs, auxiliary batteries support a range of features such as backup power in the event of a primary battery failure, voltage bu ering during an ignition cycle (hybrids) and other critical low voltage applications.

GS Yuasa’s extensive range of HJ auxiliary batteries provide enhanced cycling capability for ultimate reliability and increased performance to power a vehicle’s on-board electrics and computer management system.

Adam Hockley, TPS parts product manager, said: “Working closely with our partner GS Yuasa gives us access to their full range of product including many OEM products manufactured by GS Yuasa for several global manufacturers.

“With such a comprehensive range of products comes the reassurance for customers that whatever the requirements of their vehicle, TPS will have a battery option for them.”

A good example of GS Yuasa’s innovative approach is its lithium ion batteries, representing the latest advancement in technology, o ering high energy density, extended lifespan and lightweight construction. They are

used extensively as starter batteries for modern ICE vehicles and to power the drivetrain on EVs and hybrids, due to their lightweight design and high-power output.

Batteries provide reliability, long life, superior performance and come with a one year-warranty. They also come equipped with specially developed internal components designed to combat the causes of battery failure.

The partnership between TPS and GS Yuasa further benefits customers by generating regular discounts and o ers — such as up to 15% o Yuasa batteries until September 30.

https://tps.trade/promotions

In recent years additives have really earned their place in the workshop. Especially when it comes to DPF cleaning. But for some time-served techs these additives are still off limits.

Independent testing of the key ingredients has revealed that some DPF cleaning fluids have zero active ingredients despite the labels promising miraculous cleans.

Others including DPF regeneration additives have such a high iron content that they risk irreparable thermal damage to the DPF from overuse. Does this mean the workshop technician must now add ‘forensic chemist’ to their list of responsibilities?

Mike Schlup from Kalimex, the UK distributor of the JLM Lubricants’ range of ‘liquid tools’, wants to establish the key points of difference between a JLM product and the others.

“Our unrelenting focus is on laying bare the active ingredients in every JLM

product to show beyond doubt they really do live up to their claims.

“In recent years, with motorists feeling the pinch at the pumps and at home, we’ve seen a real surge in workshop demand for the JLM Diesel DPF Cleaning Toolkit and the DPF Cleaning Fluid and Flush pack. For a time-pressed workshop, even the most badly blocked DPF can be cleaned on the vehicle.”

Schlup said when it comes to cleaning a DPF that’s not reached the badly blocked stage, the technician needs a product that does not use iron as the catalyst.

“In an ideal world the DPF would enter a regeneration

cleaning phase where the temperature in the filter is artificially elevated to burn off the particles to reduce soot load.

“For this to happen, the vehicle must be driven for a minimum distance at high revs on the motorway. But the regeneration cycle must complete.”