SF Marina is a world-renowned expert on developing new or existing premium marinas. We provide state-of-the-art floating breakwaters and concrete pontoons to anyone anywhere who plans on building a marina with superyacht berths. And who wants it to still be there after the storm.

www.marinaindustry.net

Number

As reported on page 25 of this issue, Metstrade, the world’s leading trade show for marine leisure equipment, systems and materials, recorded its highest-ever attendance of leading marine professionals from across the globe. Visitor data and excellent feedback from exhibitors confirmed the expanded audience was accurately targeted, reinforcing the trade show’s long-standing status as the must-attend global hub at which to network, research and do business in the marine leisure sector.

and make the industry better for everybody by collaborating, communicating and committing to work together.”

PUBLISHER

Paul Barrett

Hartswood Media

8 Lindsey Close, Brentwood, Essex CM14 4PN, United Kingdom

Tel: 44 (0)1277 211691 paulbarrett@hartswoodmedia.com

EDITOR AND ADVERTISEMENT SALES

David Young

Young Editorial Services

Tel: +44 (0)1737 551687 youngeditorial1@btinternet.com

PRODUCTION

Anthony Wiffen

Tel: +44 (0)1460 261011

Mob: 07851 612799 anton_print_1@mac.com

PRINTING

Brown Knight and Truscott

Tunbridge Wells, Kent, TN2 3BW, United Kingdom

Tel: +44 (0)1892 511678

ISSN 2517-7478

©2024 Hartswood Media

This long-standing event is run in association with the International Council of Marine Industry Associations (ICOMIA), which represents trade organisations from all key markets around the world. The organisation’s CEO, Joe Lynch, commented: “The Metstrade team is to be congratulated for bringing in more customers on each day of the show. That’s a phenomenal effort.

“Attending Metstrade is inspiring, productive and educational. You see great examples of innovations in the world of technology, safety, electronics, electrics and the many other facets of our industry that are improving the customer experience. I was particularly inspired this year by the show content that was focused on connecting with new audiences – something that is so important to the marine leisure sector.

“It is also motivating when you see the industry gather in one place. There are different challenges wherever we work in the world. Metstrade provides the opportunity to unite

2025 Guide to Suppliers features a number of our regular advertisers, as well as profiles of other market leaders in the marina industry, including; Dura Composites; Inland and Coastal Marina Systems; Lee Sanitation; Marina Projects, Marine Travelift; Pacsoft Marina Management Solutions; RMCS Marina & Holiday Park Solutions; Roodberg/Frisian Industries; SF Marina; Walcon Marine; and Water Witch

Speaking at the close of this year’s show, the exhibition’s Director, Niels Klarenbeek, stated: “The excellent results of this year’s show provide a confident foundation on which to base ambitious plans for 2025. I’m pleased to announce that Metstrade will expand into hall 8, which will add around 10,000 square metres of space. This will enable us to eliminate the current waiting list for The Superyacht Pavilion, provide options for exhibitors seeking more stand space and open a circular route around halls to improve the visitor experience. There are further exciting initiatives in the pipeline that we will unveil in coming months.

“Given the significant enhancements made to Metstrade in recent editions we are introducing an up-to-date brand image to reflect where we are today. Metstrade has evolved from a trade show into a global platform driving the leisure marine industry forward. Our rebrand will reflect this growth and our commitment to fostering innovation, collaboration and long-term success across the marine leisure industry. Our new slogan, ‘Propelling Growth Harbouring Innovation’, summarises exactly what Metstrade is all about.”

The next event in the series takes place at the RAI Convention Centre from 18-20 November during Amsterdam’s 750th anniversary celebrations – it promises to be some party!

David Young

Front cover: A significant investment of £13.6 million to improve infrastructure and sustainability in the ongoing 2024/25 season has been announced by MDL Marinas, reaffirming the company’s commitment to enhancing facilities and services for its berth-holders, tenants and visitors (see page 4).

As demand for secure, convenient and costeffective boat storage rises, MDL Marinas continues to lead the way with its state-of-the-art dry stack facilities. Designed for RIBs and motorboats up to 13 metres, MDL offers boat-owners full protection and peace of mind during the

colder months.

With recent shifts in the local boating market, MDL’s dry stack facilities has seen increased interest from boaters looking for secure and well-managed storage solutions. With expanded capacity and a range of premium benefits, MDL has solidified its position as a reliable choice for boaters seeking high-quality storage

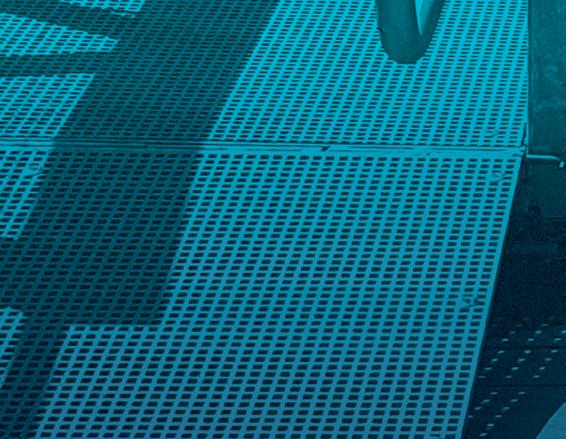

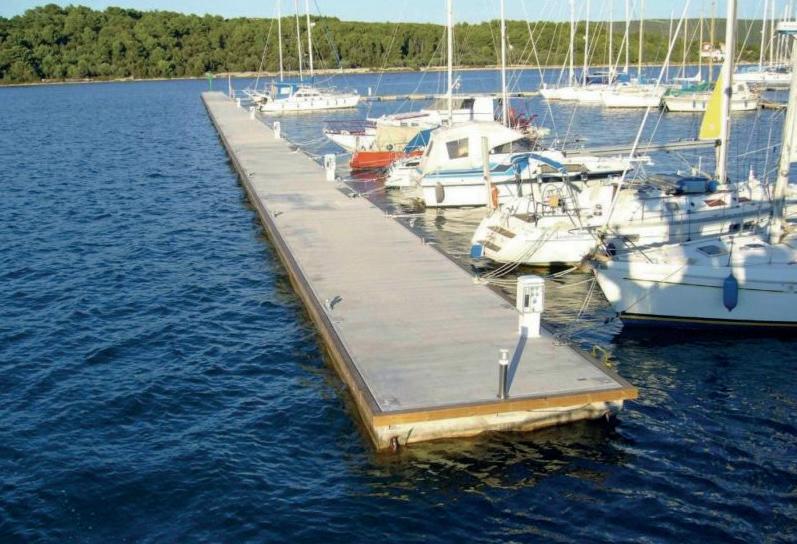

Palm Beach, Florida, is known for its balance of small-town charm and over-the-top luxury. Because the area is such a draw to superyacht-owners and captains, Safe Harbor Rybovich – Berth One has added 119 metres of state-of-the-art floating concrete berths from Swedish company SF Marina.

Vance Marine Construction installed the six SF Marina Type 2060 floating concrete pontoons needed for the project. Virtually unsinkable, they have a low centre of gravity and enormous mass that ensures exceptional stability in all weather conditions.

The L-shaped dock at Safe Harbor Rybovich – Berth One is comprised of a 43 metre section perpendicular to

shore and a 76 metre section facing South towards the Port of Palm Beach. A generous 6 metres in width, the docks have a 0.9 metre freeboard with a double row of 10 x 15 cm timber rub rails to accommodate a wide range of vessel sizes.

Vance also drove 12 new 76 cm steel piles in an offset pattern that allows small vehicles to service superyachts on either side of the dock. The piles ride within SF Marina’s innovative guides that feature safety covers and cushion block technology for silent movement during the 0.9 metre tide. Integrated utility ducts in the pontoons are supplied for future installation of electricity, water, fuel and pump-out facilities.

and service.

A recent survey revealed MDL’s dry stack occupancy rates outperform industry averages. It has achieved steady growth in occupancy, reflecting its ongoing investment in first-class facilities and exceptional customer service, with Sparkes Marina’s expanded services helping to cater to the growing demand along the South

Coast of England.

Beyond the core benefits of dry stack storage – such as easy access, enhanced peace of mind, reduced maintenance costs and unlimited launching on demand seven days a week – MDL Marinas enhances the boating experience with its exclusive Otium Rewards program. Dry stack customers earn loyalty points redeemable across MDL’s extensive range of services.

“With four dry stack facilities along the South Coast, we’ve become the first choice for boat owners,” said Tim Mayer, Sales and Marketing Director at MDL Marinas. “Our facilities deliver not just secure storage, but a premium experience that makes boating easy and enjoyable. The growth we’ve experienced reflects our unwavering commitment to exceeding customer expectations and staying ahead in a competitive market.”

During its 20th Anniversary celebrations, Fambridge Yacht Haven achieved a significant milestone in its sustainability programme, successfully diverting 66,505 kg of waste from landfill in 2024 through its partnership with Green Recycling. This initiative reflects the marina’s commitment in 2022 that no waste generated on-site would be sent to landfill as part of a wider project to reduce its impact on the environment.

The 2024 results demonstrate the success of this approach: 77% of waste collected was recycled; 23% of waste was converted into energy; and 0% of waste was sent to landfill.

Fambridge Yacht Haven provides Green Recycling skips at its River Crouch marina to support berth and mooring-holders in managing their waste responsibly. These skips accommodate a wide range of materials, including food, paper, cardboard, glass, metal, wood and plastics.

The ‘zero waste to landfill’ pledge forms part of Fambridge Yacht Haven’s broader environmental efforts, which have become a significant part of the marina’s appeal in recent years. In 2023,, the marina became the first destination on the East Coast to install two environmental wash centres, designed to capture and filter runoff from boat cleaning to prevent pollutants such as oil and paint fragments from entering the river. Furthermore, this process reduces water usage, by cleaning and recycling water used during boat cleaning processes.

Earlier in 2024, the marina invested heavily in solar energy by installing a thermal water heating system on their washroom facilities to provide hot water for taps and showers, reducing the reliance of traditional boiler and immersion heaters. By adopting sustainable practices, Fambridge Yacht Haven continues to protect its marina environment and safeguard it for future generations.

MDL Marinas, one of Europe’s leading marina operators, has announced a significant investment of £13.6 million in the ongoing 2024/25 season, reaffirming the company’s commitment to enhancing facilities and services for its berth-holders, tenants and visitors.

The investment has been strategically directed towards a wide range of projects focused on improving infrastructure, sustainability and overall customer experience.

Key areas of expenditure include: Over £249,000 invested in upgrading showers and toilet facilities; £962,000 allocated to maintaining navigable waters; £466,000 directed towards modernising lifting, storage and utility systems; £7.5 million spent on significant improvements to roads, buildings and critical marina facilities, with major projects at Ocean Village and Northney Marina, and expansion at Shamrock Quay; £2.7 million dedicated to ensuring the safety and stability of vital marina infrastructure; £588,000 channelled into projects such as photovoltaic (solar) installations to reduce the marinas’ carbon footprint; and £395,000 used to improve connectivity and operational efficiency.

“We are deeply committed to

investing in our marinas to create exceptional environments for our customers and to future-proof our operations,” confirmed Tim Mayer, Sales and Marketing Director at MDL Marinas.

“By focusing on innovative, sustainable and customer-centric investments, we aim to enhance the marina experience for everyone who visits and makes MDL Marinas their home. The £40 million planned investment over the next five years underscores our long-term vision to be at the forefront of the marina industry.”

With an additional £4.1 million set to be invested by the end of March, 2025, MDL Marinas is committed to maintaining its leading position through continuous improvement. The £40 million investment plan over the next five years aims to further drive innovation, enhance service delivery and reinforce the marinas’ infrastructure well into the future.

“By prioritising sustainability and operational excellence, we’re not only improving our marinas’ functionality and appearance, but also preserving the natural beauty of our waterfront environments,” added Mayer. “Our goal is to deliver a world-class marina experience while safeguarding the ecological health of our waterside locations.”

PT Marina Development Indonesia (MDI) and Pelindo have announced the ground-breaking for Indonesia’s first full-service marina to international standards. This milestone project represents a significant leap forward in the country’s maritime tourism and infrastructure.

The new marina will be able to accommodate 180 on-water berths, including more than 50 for superyachts up to 90 metres in length. It will have a modern yacht service area equipped with a mobile hoist capable of handling up to 200 tons and a high-quality fuel station. Strategically located in the Bali Maritime Tourism Hub (BMTH) in Benoa, just 15 minutes from the airport, it is set to become the region’s premier yachting hub, serving both international and domestic sailors.

MDI is developing the marina in collaboration with globallyrenowned and locally-recognised companies, including SF Marina, the Swedish producer of floating breakwaters and concrete pontoons. With over a century of experience and acclaimed projects like Marina Port Vell in Barcelona and Pier 66 in Fort Lauderdale, the marina in Benoa will be constructed to the same exceptional standards, with pontoons produced locally by SF Marina Indonesia.

Plus Marine from Italy will install

state-of-the-art electricity and water pedestals with SmartCloud remote metering. Renowned for its work at marinas such as Port Hercule in Monaco and Porto Montenegro, its product portfolio ensures precise control, efficient charging and exceptional service for yacht-owners through expertly designed and managed systems.

Complementing these stateof-the-art utilities and design is a suite of luxury services provided by Discover Luxury Indonesia, offering seamless bespoke on and off-boat experiences, and comprehensive logistical support for owners and their crews.

The marina’s design and facilities will adhere to the highest international standards, focusing on sustainability and environmental preservation. Yacht-owners and visitors can look forward to an array of premium amenities, including a prestigious yacht club, luxury dining and hospitality options, entertainment and commercial areas with extensive retail outlets.

Most notably, the new marina in Benoa intends to become a key initiative in stimulating local economies by creating employment opportunities, promoting tourism and cultivating a lively yachting community. With construction already begun, the new marina is scheduled to welcome yachts to the first dock in the second half of 2025.

At a ceremony held at the Southampton International Boat Show (SIBS), Walcon Marine and British Marine signed a contract for Walcon to continue to deliver the marina for the annual show for the next 15 years. It is believed to be among the largest recurring temporary marinas in the world.

“We are delighted that British Marine has shown their confidence in our ability to deliver their marinas well into the future,” said James Walters, Managing Director of Walcon Marine. “We built our first

marina for what has become one of Europe’s largest on-the-water boat shows in 1972. Since then, it has grown and evolved into what it is today, a facility hosting 350 power and sailing boats of all types and sizes.”

After the signing ceremony, Lesley Robinson, CEO of British Marine, declared: “Walcon are great supporters of the boat show and have been for a long time. Their dedication and expertise helps us create one of the most impressive temporary marinas in the world. It’s not just a functional space, it’s a true

centrepiece of the show, offering an unmatched experience on the water and setting SIBS apart as a mustvisit event for boating enthusiasts”, The building and breaking down of the marina is a major logistical feat. Each year, work begins early in the Spring, as the fabrication of the pontoons gets underway, with finalisation of the layout following sometime later. The next phase is the installation of around 50 piles using Walcon’s piling rig, after which there is process of installing almost 10,000 square metres of pontoons, all of which are brought in by sea on Walcon’s barges. Last of all, just a week or two before the show opens

and with the boats already coming in, the three bridges that link the marina to the shore are installed.

“It is a major planning and logistical challenge,” added James Walters, “but the experience that we have accumulated over the years serves us well. Since we installed our first SIBS marina back in 1972, they have experienced all sorts of weather, including some serious storms and the waves that go with them, but they have come through thanks to our heavy duty, wave attenuating pontoons that form the outer perimeter and which also host the largest yachts, tall ships and other vessels”.

After exceptional service pumping black water and waste water from boats for over 23 years, the old pump at Hobbs Boatyard at Henley on the River Thames finally required replacing.

The original unit was installed back in 2001 by sewage and waste water specialist LeeSan, so Hobbs naturally contacted them to discuss an upgraded replacement.

LeeSan is now owned by the Pump Technology Ltd Group, but interestingly, Chris Coburn, the founder of LeeSan (now retired) still lives locally and, because of his friendship with the management at Hobbs, offered them his own pump to use as an interim measure while the new

unit was built and installed.

The team at LeeSan pulled out all the stops and within seven days of the old pump needing to be replaced, had designed, built, delivered and installed a new peristaltic LS30T pump and a dedicated operation panel fitted with its own RCD safety cut-out for overload protection. The pump is also ‘timer controlled’ to protect it from running dry and to avoid accidental misuse.

Karl Sutcliffe, Technical Director at LeeSan, commented: “This was a convenient one for us as Henley is on our doorstep. We surveyed the site and recommended a new, more powerful, quieter and technically-advanced pump. This

is about a tenth of the size of the old unit and means that the boatyard team have now also gained valuable storage space in the pump house”.

Peter Herbert, Director, Hobbs of Henley, responded: “LeeSan came to the rescue of Hobbs of Henley when our pump-out machine broke down during a busy period earlier this Summer. We desperately needed to pump out our fleet of Passenger Boat tanks. We contacted LeeSan and they said they could supply and fit a new system for us within the next few days.

“They did a great job and the pump out system was up and running in two days.”

Huelva’s first urban marina has become TransEurope Marinas’ latest member in Spain. Marina del Odiel is a well-appointed facility located within the Marismas del Odiel Nature Reserve, a large expanse of semi-tidal marshland, hosting a rich fauna and flora biodiversity. Declared a UNESCO Biosphere Reserve in 1983, the park is a fantastic site for bird-watching.

The recently opened 400-berth marina sits on Huelva’s Eastern river bank, the site from which Christopher Columbus set out on his famous voyage to the Americas and the city is rich with cultural history dating from the Phoenicians, Romans and the Al-Andalus caliphate.

Managing Director Manuel Jiménez Marquéz recently

Walcon Marine Australia has renewed its licence agreement with Walcon Marine (UK), marking over 20 years of collaboration between the two companies. The agreement was signed by Leo Wu, Managing Director of Walcon Marine Australia, and James Walters, Managing Director of Walcon Marine Ltd, during a ceremony at METSTRADE in Amsterdam on 21 November.

This renewed partnership enables Walcon Marine Australia to continue offering world-class marina solutions, leveraging the UK team’s engineering expertise and innovative product designs. It also paves the way for further growth in Australia and the Asia-Pacific region, ensuring clients access to cuttingedge marina and pontoon technology.

The collaboration underscores both companies’ dedication to delivering excellence in the marina industry and Walcon Marine Australia expressed gratitude to Walcon Marine (UK) for its ongoing support and looked forward to setting new benchmarks in marina infrastructure.

announced his plans and objectives, which is for the marina to become a cornerstone of Huelva’s economic and social development. Its strategic location on the Odiel River, coupled with modern facilities and a commitment to sustainability, holds great potential for attracting both domestic and international visitors.

By prioritising eco-friendly practices, including waste management, renewable energy and ecosystem conservation, the marina aims to create a model of balanced coastal development. This approach will not only minimise environmental impact, but also attract investment, generate jobs and foster collaboration with local industries such as fishing and tourism.

D-Marin’s three Turkish marinas have been honoured with five prestigious awards at the Abu Dhabi Maritime Awards, which recognise excellence in marinas across the Middle East and Turkey. The operator received the top three awards in the ‘Outstanding Marina’ category. Turgutreis secured the gold award for the second consecutive year, while D-Marin Göcek received silver and D-Marin Didim earned the bronze award.

The ‘Outstanding Marina’ award recognises exceptional performance and continuous improvement through new ideas and technology to enhance operations and customer experience. The judges particularly praised D-Marin for its ability to deliver outstanding customer interactions, understand customer needs and foster loyalty through feedback. They also commended D-Marin for its exemplary health and safety practices alongside its effective staff development initiatives.

In addition, D-Marin Göcek won gold in the ‘Customer Experience’ category, while D-Marin Didim secured gold for ‘Sustainability’, in recognition of its strong environmental efforts and state-of-the-art facilities.

A UK-based yacht maintenance company, PSA Prime Marine, has announced the global expansion of its PrimePlus service.

This luxury offering will debut internationally in Antigua’s Falmouth Harbour where it has been selected to provide a comprehensive bi-annual maintenance bespoke package for an Arcona 385 yacht, ensuring its readiness for the regional hurricane season and prepared for the subsequent upcoming sailing season.

A two-person team will spend ten days delivering meticulous cleaning, polishing, winch servicing, engine maintenance, rig inspections and sail checks. This five-figure project underscores PSA Prime Marine’s commitment to excellence, ensuring yachts remain in peak condition year-round.

Fuel dock safety ● Marina visit to Cyprus

Deadline: Friday, 7th February

www.marinaindustry.net

Volume 12, Number 58 December 2024

Contact information

Paul Barrett

Hartswood Media 8 Lindsey Close, Brentwood, Essex CM14 4PN, United Kingdom

Tel: 44 (0)7778 357722 paulbarrett@hartswoodmedia.com

EDITOR AND ADVERTISEMENT SALES

David Young

Young Editorial Services

Tel: +44 (0)1737 551687 youngeditorial1@btinternet.com

PRODUCTION

Anthony Wiffen

Tel: +44 (0)1460 261011 Mob: 07851 612799 anton_print_1@mac.com

PRINTING

Brown Knight and Truscott Tunbridge Wells, Kent, TN2 3BW, United Kingdom

Tel: +44 (0)1892 511678

ISSN 2517-7478

©2024 Hartswood Media

This Guide features a number of our advertisers and includes a more comprehensive directory of suppliers on pages 18-19, together with their websites. These are listed under sections relevant to

operators seeking to improve their marinas and introduce or enhance the services they offer to berthholders, visiting yachts and the general public of the area in which they are located.

The Guide is designed as a pullout section, occupying the centre 12 pages of the issue, so that readers can remove these pages and retain them as a reference throughout the year.

Aleading supplier of GRP products for the marina industry, Dura Composites, has introduced a new 30 mm Mini Mesh product to its d2 GRP grating range, which will be available to purchase in early 2024.

Produced in popular and efficient panel sizes of 3007x1027 and 4027x1267 mm, the 30 mm Mini Mesh range comes in Green, Grey, Dark Grey and Sand to suit a wide range of environments. As with the entire Mini Mesh range, the 13 mm open hole size meets requirements of the European Ball Fall tests and it still maintains a 900 mm span on 1.5Kn point load at L/100.

The d2 Dura Grating is a patented GRP grating series designed, developed and available exclusively from Dura Composites and is known for its safer, stronger, faster

This Irish manufacturer has gained a deserved reputation for designing, building, installing and maintaining water access solutions. From marina pontoons to concrete breakwaters, ICMS systems are designed to enable boats of all shapes and sizes to moor safely and securely. The company drives constant improvement in its products, people and processes through ISO9001 certification

The company’s standard leisure pontoon system is manufactured from galvanised steel with polystyrene flotation blocks encased in a skin of reinforced glassfibre. This provides an extremely robust structure, which offers strength and stability even in the most onerous of conditions.

Pontoon decking options available include glassfibre reinforced concrete panels, timber, timber composite or glassfibre reinforced plastic mesh and the pontoons can be protected with hardwood, softwood, plastic or

and proven attributes. The marketleading design has advanced antislip properties and is anti-corrosive,

making it ideally suited to the harsh conditions of marinas, harbours, piers and promenades. State-

of-the-art composition ensures maximum safety tested to over one million footfalls.

As well as its small hole size, safety features and excellent strength-to-weight ratio, d2 30 mm Mini Mesh uses 17.33% less embodied carbon than the 30 mm grating available elsewhere in the industry, making it a sustainable choice.

The d2 GRP Mini Mesh range was previously available in sizes of 23, 35, 45 and 55 mm. A 30 mm Mini Mesh product was available as part of the previous grating range several years ago, but has now been design-engineered for maximum performance and efficiency as part of the exclusive d2 product range.

Dura Composites Ltd info@duracomposites.com www.duracomposites.com

rubber fenders.

Heavy duty pontoons are designed to accommodate the berthing of larger vessels such as superyachts

in marinas and ports. When using a double fender, freeboard heights from 500 mm to 1200 mm can be accommodated.

Since 1991, Lee Sanitation (LeeSan) has specialised in the design, installation and maintenance of sewage pump-out stations at both coastal and inland locations. During this time, it has acquired vast experience in supplying quayside pump-out systems for any size of marina and harbour, including workboat landing stages.

Now a member of the Pump Technology Group, LeeSan is capable of specifying, supplying and supporting clients with all manner of sanitation equipment, including toilets, tanks, pipework, water and waste pumps, valves and all ancillary equipment for any type of leisure craft or workboat and if advice is needed, support and help is readily available on the telephone from skilled staff at the company’s office in Warwickshire, which is close to major transport

links in the English Midlands. LeeSan stocks an extensive range of products at its 6,500 sq ft warehouse and can provide spare parts for most marine toilets and pumps – new models as well as

those dating back many years. Its ‘One stop pump shop’ includes manufacturers such as Whale, Jabsco, Raritan, Rheinstrom, Blakes, Microphor, Sanimarin, Dometic/Sealand, Rule, Lowara,

Tru-design, Gobius, LeeStrom, Grundfos, DAB, Mono and many more.

Lee Sanitation Ltd sales@leesan.com www.leesan.com

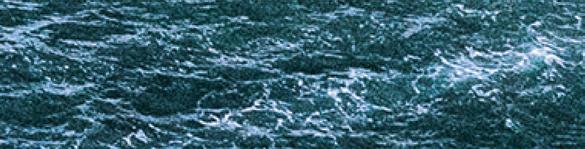

Founded in 2002, Marina Projects is now one of the world’s leading marina consultancies, with the skills and expertise to make a unique and highly valuable contribution to marina and waterfront projects anywhere in the world. It has offices in the UK, Hong Kong and Cyprus from where it has provided expertise for the development of 400 projects in 41 countries across five continents.

It works with a wide range of clients, including government bodies, commercial organisations, private developers and investment groups, and collaborates with world-renowned architects, engineers and other professionals to deliver a client’s vision for any marina or integrated waterfront project.

Marina Projects is certified to the ISO 9001-2015 standard. By maintaining a robust and effective Quality Management System, it is

able to demonstrate its constantly improving processes and procedures to ensure any marina project meets its ultimate goals.

During 2024, Marina Projects completed an innovative design of new superyacht berths at Ocean Village and Marina Bay in Gibraltar. The redevelopment of the marina, which consists of 144 waterfront rental apartments, is built over water on mini-piles, with access provided via a landscaped pier. The

development features an awardwinning Marina Club, over 10,000 square metres of residential space and is designed to accommodate superyachts up to 80 metres. The berths were strategically arranged around the perimeter of the development, showcasing a modern design and high-quality berthing systems to attract some of the world’s most prestigious vessels. The scope of services undertaken by Marina Projects included a

comprehensive design study that identified the preferred berthing arrangements taken forward to construction. As part of the study process, several critical design interfaces were resolved that included the co-ordination of detailed mooring analysis and interactions with quayside infrastructure.

Marina Projects Ltd enquiries@marinaprojects.com www.marinaprojects.com

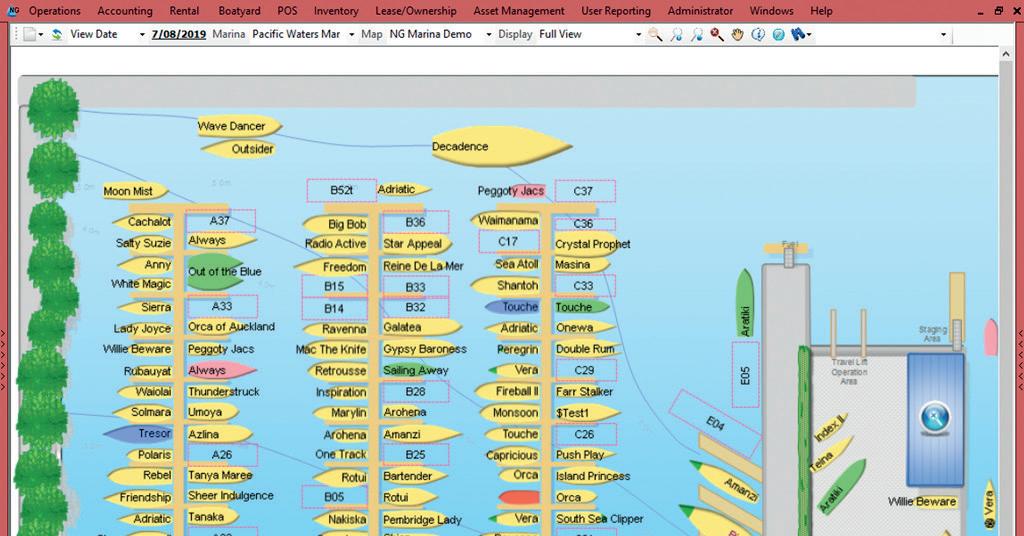

Supporting all the needs of a marine business to maximise growth, PacsoftNG Cloud marina management software is a one-stop marine management software solution catering for marinas, harbours and yacht clubs, providing small and large operations with a comprehensive set of rich features to run all aspects of the business.

This software allows both time and money to be saved through automating and integrating daily tasks, serving customers more effectively while maintaining tight control over business processes and performance.

The system provides enhanced management insight and control as its ‘Visual Marina’ provides a simple and easy audit for management to ensure the invoicing system is up-to-date

and accurate. Staff can make fast, informed decisions based on accurate, current and future data, with information at the user’s fingertips. Integrated accounts receivable allows

quick and efficient resolution of customer queries online, visibility of outstanding balances and easy overdue debt chasing.

It also has the ability to interface with ‘Utility Metering Systems’

and can turn meter on, allocate to a boat, record meter readings, take final reading and turn meter off. Pacsoft MMS sales@pacsoft.com www.pacsoft.com

CONCEPT DESIGN & MARINA MASTER PLANNING

FEASIBILITY STUDIES & MARKET RESEARCH

BUSINESS PLANNING

MARINA & WATERFRONT DESIGN

TENDER AND PROJECT MANAGEMENT

MARINA OPERATIONS MANAGEMENT

ENVIRONMENTAL & LEGISLATIVE ADVICE

PROPERTY CONSULTANCY SERVICES

GLOBAL WATERFRONT & MARINA DEVELOPMENT

CONSULTANCY AT ITS BEST

Now in its 70th year of innovation in mobile boat hoists from 25-1500 tons, with an established reputation for manufacturing world-class boat handling equipment, the team at Marine Travelift – aided by its global network of dealers – understands that it takes hard work to achieve satisfied customers. From In-house engineers to its knowledgeable Customer Care team, the company works with marina-owners and boatyard operators to build the machines that keep them in motion for years to come. However, support doesn’t end when a hoist is delivered. Marine Travelift provides operation and service training in the field before the equipment begins service and, once in use, highly-trained technicians are ready for immediate attendance. If a repair becomes necessary, only genuine Marine Travelift replacement parts are supplied to match the original specifications of specific machines. An extensive in-house inventory of parts reduces

lead times, with global shipping and online parts for same-day order processing. It also operates a quality system, certified by QAS according to Standard ISO 9001-2015, which allows it to offer customers a higher level of consistency with its products and services.

In 2023, Marine Travelift introduced a variable width option for its line-up of mobile boat hoists. This revolutionary customisation option is available on both the BFMII and C-Series machines and allows marinas and shipyards around the globe to safely and efficiently optimise space for service and storage.

The first Marine Travelift model with the variable width option was a 75BFMII (75 metric ton lifting capacity) and was delivered to The Marine Group Boat Works’ San Jose del Cabo location. This model offered 9 ft of width variability and can seamlessly expand and retract under full load in 60 seconds.

The most important benefit this option offered is the opportunity

to block vessels closer together in order to maximise space previously unavailable because of overall width dimensions on a standard fixed width boat hoist. This means marinas and service yards can maximise valuable service and storage space to serve more customers within their existing footprint.

The variable width option can also provide the ability to move vessels through a doorway that was previously not an option, with the width of a standard machine sized to fit piers. This would eliminate the need to double handle vessels when moving them in and out of the building. The design allows for handling a wider range of vessels,

providing marinas and yards more flexibility to grow into different markets.

Whether an operator is storing boats indoors for the Winter or wanting more space for hurricane storage, the width variation gives them the ability to fit more vessels in the same footprint without the use of yard trailers. This allows the yard to reduce equipment and also makes the operation more efficient when time is short.

Another development that year was a new model of marina forklift specifically engineered for the growing centre console market.

The M4200H (42,000 lb capacity) centre cab Hydro M_Drive forklift was delivered to Viking Yachts in Riviera Beach, Florida, for use in hauling boats. While designing the M4200H, Marine Travelift put extra emphasis on serviceability, cycle speeds and turning radius. All of the improvements made on this high capacity forklift were also applied to the M3600H (36,000 lb capacity) and M5200H (52,000 lbs capacity) models. Shorter wheelbase, combined with a tighter turn radius, allows marinas to

upgrade without needing to make major infrastructure changes. The M4200H marina forklift comes in either a 140 in or 129 in wheelbase and as Marine Travelift makes its own steering axles, it provides an unrivalled turning radius.

The standard centre cab configuration on these high capacity lifts also moves the operator as far forward as possible, achieved by setting the steering column forward of the front guard rails. The forward position and standard rear back-up camera displayed on a 10 in colour screen, gives the operator maximum visibility of his surroundings. These features, combined with the Moment Indicator System, which provides a green/yellow/ red scale to indicate the limits of the machine, allow the operator to safely and efficiently move a variety of craft.

Marine Travelift continues to innovate and the latest development is the introduction of the Electric Series mobile boat hoists. After over two years of design, manufacturing and indepth factory testing, the Electric

Series performance is everything you would expect from a machine produced by the company, without the emissions of a diesel engine.

The Marine Travelift engineering team spent countless hours designing and perfecting the 700 V battery-powered system for its 50BFMII boat hoist, which provides 50 metric ton lift capacity. Power consumption was optimised to ensure the Electric Series met or exceeded the performance of the standard engine machine.

Every feature and option available on the diesel-powered boat hoists is also available on the Electric Series. The first E-Series machine was equipped with options such as electronic all-wheel steering, 5 ft top beam extension, work/drive lights and two-speed hoists to ensure the correct power requirement was chosen to accommodate all option configurations. Extensive performance testing was done over an 18-month period in various weather conditions, load configurations and travel distances to ensure optimal performance of the system in all working scenarios.

The hydraulic functions of the boat hoist are powered by a reputable world leader in electric powered components and the batteries are manufactured in the United States. The system utilises scalable DC fast-charging interfaces from on-road electric vehicles to safely charge the batteries and a full charge can be accomplished in an eight-hour period with the recommended 30 kW high speed smart charger.

The E-Series machines utilise multiple layers of safety features from the moment the machine is keyed to the ‘on’ position. High voltage junction boxes, isolation monitor, fuses and grounding straps are just a few of the safety features that ensure the operator and batteries are kept safe during every phase of operation. Both the batteries and electric motor are temperature-regulated with a glycol cooling system to maintain a safe operating temperature, regardless of the ambient temperature.

Marine Travelift Inc sales@marinetravelift.com www.marinetravelift.com

Marina and Holiday Park Solutions Ltd (t/a RMCS) are one of the UK’s premier suppliers, manufacturers and designers of services associated with busy marinas, harbours and ports.

All products are British-made, with the emphasis on quality and reliability. The last 12 months have seen the portfolio of products increase, with a new range of metering solutions for every budget, from simple read-only solutions to app-based systems. Unlike many providers, all RMCS products are supplied without contracts or other ongoing costs.

Marina and Holiday Park Solutions offers electrical designs, water systems, pumpout facilities, lighting and security systems. Introduced for the first time this year to counter soaring energy costs are photo-voltaic (solar) systems.

Martin Georgeson, a well-known name in the industry with 30 years’

Sexperience, joined the company in October to strengthen the team and has been welcomed aboard.

ince it was established in 1936, Roodberg (a trade name of Frisian Industries BV) has developed, produced and supplied top-of-theline boat hoists and trailers for use on slipways and to transport craft for yacht builders, boatyards and marinas. The company employs innovative technologies based on over 70 years’ of experience in designing and building both hydraulic and electric hoisting and transportation systems. Roodberg has concentrated its development, engineering, production, assembly and service operations under one roof, which makes it possible to reduce the time taken to manufacture and deliver orders to a minimum. This makes the production lines and delivery times short and allows the company to respond quickly as new developments and technologies emerge. It also enables customised equipment to be built for customers

without delay. Its wide range of hoisting and moving systems are developed and

Gothenburg-based SF Marina, with its main production facility located at Walllhamn on the West Coast of Sweden, celebrated its centenary last year. The company’s heritage began with the construction of Brandholmens shipyard in 1918 to specialise in concrete structures for use on water and it was not long before floating concrete pontoons became the main product

manufactured by the enterprise.

A continuous programme of development and innovation honed though experience shaped by installations in Sweden, where harsh Winter conditions are a good test of marina infrastructure, enabled the company to design pontoons and breakwaters that provided the strength and durability to perform well under a wide range of difficult conditions from Tropical heat to Arctic ice,

as well as challenges presented by storms, tides and constant exposure to salt water and ultraviolet light.

In 1972, SF Marina was chosen as a supplier to the Summer Olympics and delivered pontoons used by six sailing classes at the event. This was followed by another ‘first’ in 1983, when it installed its first marina in the USA

Two years later, the company moved to its new factory in Wallhamn from where pontoons weighing up to 250 tons can be loaded directly on to ships moored at a deep-water quay for delivery anywhere in the world.

SF Marina info@sfmarina.com www.sfmarina.com

Founded in 1963, Walcon Marine is a market leader in the design, construction and installation of marinas, yacht harbours and berthing facilities around the world. As probably the longest-established and most experienced company in its field, Walcon Marine is a global organisation with manufacturing facilities in the UK and Australia. Its range of walkway and finger pontoons caters for every need, from low freeboard versions for dinghies and paddleboards to its tubular steel Docking Solutions pontoons for workboats, fishing boats and superyachts, as well as other specialist units for exposed locations.

Today, its pontoons and associated infrastructure can be found in over 30 different countries on five continents. Notable projects in 2021 have included the complete removal and replacement of the Noss on Dart Marina in the UK’s West Country, resulting in a brandnew, 232-berth facility.

A full list of recent projects and services can be viewed on the company’s website.

This family-owned business aims to provide cost-effective, efficient solutions to help clean up the marine environment and is estimated to have cleared more than two million tonnes of plastic trash from the ocean.

Over 200 of the company’s

debris collection and trash retrieval workboats operate around the world, including Hong Kong, New York, Cape Town, Kuwait and

London. Its range of workboats has been developed to offer users a versatile, multi-purpose craft or pontoon boat that can perform a wide variety of duties in addition to efficient aquatic trash and debris removal.

The Versi-Cat workboat is extremely adaptable for applications such as providing a fast-response to marine pollution, supplying a mobile pump-out service, lifting moorings (with removable lifting frame), diving and maintenance support.

The design incorporates various ‘pods’ that sit between the twin hulls, enabling many tasks to be undertaken. The pod system allows heavy items to be loaded directly on to the quayside and lifted aboard the vessel via a crane with no need to manhandle the equipment to the water.

Water Witch Workboats info@waterwitch.com www.waterwitch.com

Water Witch provide Marinas, Harbour Authorities, Waterway management and waterfront resort operations with cost-effective, efficient solutions for the management and cleanup of the marine environment by employing the firm’s tried and tested range of customisable craft.

The multi-purpose range of workboats and trash-skimmers can perform many functions, including debris collection, aquatic weed harvesting, trash removal, mobile pump-out, oil spill response and marina maintenance roles.

These craft are supported by a worldwide network of experienced distributors and technical representatives.

Alto Service Italia Srl www.altoservice.it

Ascom SpA

www.ascom-italy.it

Boat Lift Srl www.boatlift.it

Cimolai Technology SpA www.cimolaitechnology.com

FGM. Tecnology Srl www.fgmtecnology.com

GH Cranes & Components www.ghcranes.com

Golden Manufacturing Inc www.goldenboatlifts.com

Hostar Marine Transport Systems Inc www.hostarmarine.com

Kropf Industrial Inc www.kropfindustrial.com

Marine Travelift Inc www.marinetravelift.com

Roodberg/Frisian Industries BV www.roodberg.com

Wiggins Lift Co Inc www.wigginslift.com

Wise Handling Ltd www.wiseboathoists.co.uk

Absolute Magnitude www.absolute-magnitude.com

Accon Marine www.acconmarine.com

Bosch www.bosch-professional.com

Brownell Boat Stands www.boatstands.com

Falch GmbH www.falch.com

Gisatex GmbH & Co KG www.gisatex.de

Hammelmann GmbH www.hammelmann.de

Heskins Ltd www.heskins.com

International NDT Ltd www.int-ndt.com

International Yacht Paint www.international-yachtpaint.com

Larius Srl www.larius.com

Nautipark www.nautipark.com

Naval Tecno Sud Boat Stand Srl www.navaltecnosud.it

Nitty-Gritty Srl www.nitty-gritty.it

Sailing Technologies www.sailingtechnologies.com

Rasor Elettromeccanica Srl www.rasor-cutters.com

Sea-Fire Europe Ltd www.sea-fire.co.uk

Seajet www.seajetpaint.com

Smart Antifouling www.smart-antifouling.com

Solbian Energie Alternative Srl www.solbian.eu

Arrol Consultancy www.arrol.com

Camper & Nicholsons Marinas Ltd www.cnmarinas.com

Daniel S. Natchez and Associates Inc www.dsnainc.com

International Waterfront Consultants www.iwclic.com

Marina Management Services Inc www.marinamanagement.com

Marina Projects Ltd www.marinaprojects.com

Marina Solutions International www.marinasolutionsintl.com

MDL Marina Consultancy www.mdlconsultancy.com

Salt Technologies www.lindley.pt

Captrad Composites www.captrad.com

DeckSafe Solutions Ltd www.decksafe.co.uk

Dura Composites Ltd www.duracomposites.com

Pro Composites www.procomposites.co.uk

ThruFlow Inc www.thruflow.comTitanDeck Voyager Industries www.titandeck.net

Aister www.aister.com

Astel Marine www.astel-marine.com

Atlantic Aluminium & Marine Products www.atlanticaluminiummarine.com

Goodocks Marine (Hong Kong) Co Ltd www.goodocks.com

Ibericamar SL www.ibericamar.es

Naval Tecno Sud Boat Stand Srl www.navaltecnosud.it

Port-Safety www.port-safety.com

Potona Marine Co Ltd www.potona.com

Reid Lifting Ltd www.reidlifting.com

Sidermarine Sl www.sidermarine.com

SMBL GmbH www.smbl.eu

Xunzel www.xumzel.com

Capria SA www.domingocapria.com

Drystack Australia Pty Ltd www.drystackaustralia.com.au

Nautipark www.nautipark.com

Wickens Engineering Ltd www.wickens.co.uk

Dan-Fender www.danfender.com

Den Hartog Industries Inc www.denhartogindustries.com

E.V.A. Bumper di S. I. Lazzari SAS www.evabumper.com

Ibericamar SL www.ibericamar.es

Inmare Srl www.inmare.net

Polytec Thelen GmbH www.polytec-industrial.com

Portmere Rubber Ltd www.portmererubber.co.uk

SeaEQ GmbH www.seaeq.com

Walcon Marine Ltd www.walconmarine.com

Harbour Assist www.harbourassist.com

Havenstar www.havenstar.com

Marina Master www.marina-master.com

Marinacloud www.marinacloud.net

Nauticspot www.nauticspot.fr

PacsoftMMS www.pacsoftmms.com

Deckfab Marine

www.deckfabmarine.com

Eurodesign www.eurodesign.se

Italvipla Srl www.italvipla.com

CBG Composites GmbH www.cbg-composites.de

Airfloat Ltd www.airfloatmps.com

Balex Marina Ltd www.balexmarine.com

Buldock Ltd www.buldock.com

Candock Inc www.candock.com

Jetfloat www.jetfloat.com

Magic-Float www.magicfloat.ru

Marine IP Ltd www.versadock.com

Marine Floor Europe SAS www.marinefloor.fr

Otto SAS www.gmiotto.it

PMS Dockmarine www.pmsdockmarine.com

TAFF Modular Floating System www.taf-f.com

Aqua superPower www.aqua-superpower.com

Depagne www.depagne.fr

Eaton Marina Power & Lighting www.marinapower.com

Gigieffe Srl www.gigieffe.com

Hubbell Marine www.hubbell-marine.com

Jo Bird www.jobird.co.uk

KEHA3 www.keha3.ee

Maricer www.maricer.com

Marina & Holiday Park Solutions Ltd www.rmcs.co.uk

Microcustom International Ltd

www.microcustom.co.uk

M-Tech Marine Technologies www.m-tech.com.au

New VMR Srl

www.vmrsrl.com

Plus Marine Srl www.plusmarine.com

Rolec Services Ltd

www.rolecserv.com

Ruban Bleu www.rubanbleu.com

Seijsener Marina Services www.seijsener.com

Sureline Electrical Modules Ltd www.sureline-em.co.uk

DualDocker GmbH www.dualdocker.com

Hazelett Marine www.hazelettmarine.com

Marine Structures www.marinestructures.com.au

Profextru Products BV www.profextru.com

Seaflex www.seaflex.net

Shoreline Plastics www.shorelineplastics.com

GPA Seabots www.gpaseabots.com

IADYS www.iadys.com

Wave International www.waveinternational.co.uk

Aister www.aister.com

AquaBanas www.aquabanas.com

ATIC

www.atic.fr

Bellingham Marine Industries www.bellingham-marine.com

Bluet Oy Ltd www.bluet.fi

Bluewater Marine & Dock Specialities Inc www.bluewaterdocks.com

Clement Germany GmbH www.clement-germany.de

Dock Marine Systems www.dockmarinesystems.com

Gael Force www.gaelforcemarinas.com

Ingemar Srl www.ingemar.it

Inland and Coastal Marina Systems Ltd www.inlandandcoastal.com

Marina Dock Systems www.marinadocksystems.com.au

Marina Pods www.marinapods.com

Marinetek Finland Oy www.marinetek.fi

Martini Alfredo SpA www.martinialfredo.it

Metalu Marinas www.metalu.com

Poralu Marine www.poralu.com

Potona Marine Co Ltd www.potona.com

Ronautica Marinas www.ronauticamarinas.com

SF Marina www.sfmarina.com

Solent Marine Ltd www.solentmarina.com

System Group Marine Division www.systemgroupmarine.com

Walcon Marine Ltd www.walconmarine.com

Yacht Port Marinas SL www.ypmarinas.com

Edson International www.edsonpumps.com

Keco Pump & Equipment www.pumpahead.com

Lee Sanitation Ltd www.leesan.com

Sanitrade Srl www.sanitrade.it

Almarin SL www.almarin.es

Pharos Marine Automatic Power Ltd www.automaticpower.com

EcoTank www.ecotank-worldwide.com

Efinor Sea Cleaner www.seacleaner.efinor.com

Water Witch Workboats www.waterwitch.com

YACHT TRANSPORT

DYT Yacht Transport www.yacht-transport.com

Peters & May Ltd www.petersandmay.com

Sevenstar Yacht Transport BV www.sevenstar-yacht-transport.com

By Dan Natchez, CMP*

We here at our office were recently thinking about those times when a marina finds itself in a battle, particularly one with a regulatory agency, an unhappy neighbour, a citizens’ group or some similar adversary and the marina’s team is gathered in a real or virtual room to work out strategies and options for getting through the fight. It’s a room no one really wants to be in, but it’s worth thinking about before you find yourself in the thick of it, including who you would have or need to have in there with you. We have great deal of respect for regulatory agencies, who have a job to do, as well as neighbours resistant to change or prefer ‘Not In My Back Yard’ and organisations that seek to promote improvements. Honest people can have honest disagreements. More often than not, talking things through early in

the process and understanding the various perspectives can lead to very desirable, cost-effective and timely determinations.

However, for better (at times) or worse (often), we live in an increasingly litigious society, regardless of whether there is merit or not. Adding to the complexity are the regulatory world’s hurdles becoming more and more difficult to overcome, and the approval process becoming so densely bureaucratic that it is increasingly easy for an adversary to challenge even issued approvals.

We happen to know of a perfect case in point where an agency made a mistake in the process of issuing an approval and someone from the public subsequently challenged the decision. It involved a relatively small family-owned marina that had done

everything the agency had requested, received their approval and went ahead and built their expansion. The approval was then challenged by a distant neighbor, who had a longstanding history of launching legal attacks against the marina, hoping to make it go away. The marina initially turned to a family lawyer (quite common is such instances), who entered the case on behalf of the marina. Unfortunately, the family lawyer did not have the necessary expertise for this type of situation and the marina had assumed that the state agency could make the case in defending their issuance of the approval. When it came to trial, the agency did not rise to the occasion, the family lawyer, while earnest, was a bit out of his element and the court’s decision went against the state, which then invalidated the marina’s approval. This was definitely a worst nightmare type of scenario

and the result was that the marina had to start the approval process again from scratch, this time making sure that both they and the agency dotted every ‘i’ and crossed every ‘t’. This time, the marina also set up a more robust war room, bringing in a knowledgeable marina consultant and, in turn, a legal team with the right experience.

Hindsight is always 20-20, or at least a lot closer to it, but one of the morals of this story is to do all you can to make sure all is correctly undertaken in the application process, even if the agency needs to be led. While it takes time and likely costs money upfront, it can save a great deal of problems and much greater expense later on.

Doing your homework

Of course, no one wants to get to the point where a ‘war room’ is needed, particularly a fully

lawyered-up one and there are ways to help you not get there, beginning with always doing your homework. There really are no shortcuts to homework, starting at the beginning to truly understand the site advantages, as well as challenges, and how what you have or want to do complies with or deviates from the programmatic

perspectives of the agencies, both promulgated and the unpromulgated ‘causes du jour’ (the desires of a particular agency or individual with a desire that is beyond a promulgated regulation).

Other items typically include undertaking meaningful and thorough hydrographic and upland hydrographic surveys of both the project and abutting properties, looking at the various state and federal mappings for not only regulatory lines, but also designations for endangered species, water fowl migration areas, sensitive habitats, subaquatic vegetation, mapped and/or perceived navigational lanes and view lines from all angles.

Understanding the past history of the site and surrounding areas, the community and other development plans and programs for the area, and talking with the neighbours, as well as local environmental, conservation and civic groups are especially important.

There is often hesitation in talking with the neighbours and others for fear of tipping them off, creating a problem and/or activating a concern, but in the overwhelming majority of times, these discussions can help pave the way for the project and avoid costly delays and other problems. People in general, including you the reader, react to how they are treated – when one finds out about an issue or a project without having

been consulted, that can often be a major error. The project will become public and the neighbours, as well as ‘involved’ citizen groups, will typically be formally notified. Preempting the notification with personal contact and discussion, including a review of your concept site plans, can go a long way to defining, identifying and potentially defusing various potential hurdles and issues. More often than not, the identified concerns can be dealt with through relatively minor project modifications, which will also be easier to make before you go too far down a different path. In addition, even if there are issues or concerns that can’t be accommodated, whether irrational or not, knowing what they are and who the protagonists may be is always helpful. The sooner you know how big a war room you might need the better!

Knowing the issues will also be helpful in preparing them for presentation and discussions with all of the agencies, including a review of the concerns. These should include those raised by others along with the alternatives that were considered and determined not to be viable, as well as providing the information needed for supporting favourable determinations for the project. Similarly, once the homework is done, the initial project concepts may need to be refined to either meet the identified regulatory

parameters or to have significant justification for the deviation from the programmatic desires, as well as all of the mitigating factors for the project area, including for the environment. Our advice is to address upfront the deviations from the programmatic approaches, as well as the unresolved concerns by others, including why they are being proposed and what the justifications and benefits are. This helps put the potential issues into perspective as creating a more desirable mind set.

What we have found is that working with the agencies at the very early concept stages goes a long way to achieving the approvals on a desired project or very close thereto. However, there are times that some individual(s) in some agencies can be a bit more cantankerous and difficult to work with. At that point, some agencies may take the position that they never make a mistake and dig their heels in. Although, even in those circumstances, there may be ways to work through the process with a meaningful result and avoid the war room.

In one instance, a regulatory agency made a site visit for a project that included rehabilitating a damaged yet still functional seawall that had professionally prepared survey plans showing that the Mean High Tide line was

significantly below the top of the seawall and the wall itself had water stains clearly showing the high tide being well below the top. The plans were stamped by a licensed surveyor and engineer. Yet the agency sent a letter stating that the seawall was no longer functional and that there was significant daily tidal inundation of the upland well beyond the seawall.

Master Planning - In-Water and Upland Integration

Comprehensive Marina and Marina Resort Design

Proficient Project Management

Functional Marine Services and Launching Facilities

International in Scope

Site Evaluation and Economic Analysis

Cost Effective Solutions

Three Decades of Experience

It turns out the agency had made their site inspection just days after a substantial (though not much publicised) episodic storm, with considerable flooding of the entire coastal area, including the site, sending flotsam and jetsam well into the upland. The agency focused on the remnants of the flooding rather than the actual facts, elevations and drawings. Instead of just admitting a rush to judgement, they insisted on the site being resurveyed and on the applicant providing additional justification for being able to repair the seawall. Not until they came back to the site with the updated plans and an agreement to meet there did they finally agree that the plans were correct, the seawall was functional and the tide did not flood the upland on a daily basis!

In another instance, a marina wanted to put a fuel station/ marina office/store building on a floating dock. One regulatory agency said that the fuel station/ office was a structure in a FEMA zone and you cannot put a structure in the FEMA zone because it floods. The reviewer did not understand that the dock will rise and fall with the water, and will therefore always be above the water and was thus permissible under FEMA, so long as you had an adequate anchoring system (note that this was not in a ‘floodway’ or other high velocity flood zone).

Of course, there may be times when an agency simply will not agree. If the project makes sense and has major givebacks and justifications, and an agency is going to deny the project as presented, there usually is an appeal process of going to a hearing. In one such case, we were working with a marina that wanted to expand. Despite all of the documentation that was presented,

the reviewer basically came down with two choices: change, including substantially reducing, the project; or go to hearing. Due to all of the homework that had been undertaken and the major justifications of the project refuting the reviewer’s perspective, the marina elected to go to hearing. The hearing was scheduled for two days. We presented the project for about 45 minutes, documenting every step of the way, including what the agency’s objections were and what were the mitigation factors and givebacks, with everything being documented with clear and clean exhibits. These included highlighting the significant mitigation approaches and the fact that the alternatives to the project, including reducing its scope, would eliminate the major environmental benefits. The agency then presented their objections for about 30 minutes. The hearing lasted another hour, with the rest of the hearing being members of the public, who came speaking in favour of the project. They were the same people that we talked with early on in the concept phase. At the end of the hearing, the officer rendered a favourable opinion on the project and directed the agency to issue the permit. So, whenever you find yourself approaching a project, whether for a new marina, an expansion, reconfiguration or even substantial repairs these days, it just makes sense to approach it as if there will be some opposition. Doing one’s homework and using experienced professionals to help guide one through the process are meaningful suggestions and while it is not desirable to go to war, the old adage, ‘Forewarned is forearmed’ comes to mind, as does the wellknown Scout motto, ‘Be Prepared’!

*Dan Natchez, CMP, is President of Daniel S. Natchez and Associates Inc, an international environmental waterfront design consulting company specialising in the design of marinas and marina resorts throughout the world.He can be contacted on Tel: +1 914 698 5678, by WhatsApp at +1 914 381 1234,by E-mail: dan.n@dsnainc.com or on his Website: www.dsnainc.com

15-17 October 2025

Position

MDL Marinas has announced the expansion of the 2025 South Coast & Green Tech Boat Show, which takes place at its iconic Ocean Village Marina in Southampton from 9-11 May. The show will feature an extended waterside area opposite the popular Banana Wharf restaurant, providing the perfect backdrop for a larger and more diverse fleet of boats. With more space than ever before, the 2025 show is set to be the largest and most impressive yet.

Taking place slightly later in the season to capture the warmer weather, the show will once again play host to a vast array of on-

water and shoreside exhibitors, showcasing a line-up of motor boats, sailing yachts, RIBs and the latest in cutting-edge electric and

The 36th edition of the world’s leading trade show for leisure marine equipment, systems and materials recorded its highest-ever attendance of leading marine professionals from across the globe. METSTRADE 2024 hosted close to 1,600 exhibitors, across 12 halls at RAI Amsterdam, The Netherlands, in November.

The show received 31,824 visits from 19,779 attendees spanning 134 nationalities. The overall increase in attendance was up 10% and 6%, respectively, when compared to 2023, the previous historic high-water mark.

Attendance records were surpassed on each of the three days for this strictly trade-only show.

METSTRADE registration@rai.nl www.metstrade.com

Daniel S. Natchez and Associates Inc 22 www.dsnainc.com

ICOMIA World Marinas Conference 23 www.icomia.org

Inland and Coastal Marina Systems Ltd 9 www.inlandandcoastal.com

LeeSan 7 www.leesan.com

Marina & Holiday Park Solutions Ltd 3 www.rmcs.co.uk

Marina Projects Ltd 11 www.marinaprojects.com

sustainable marine technologies. MDL Marinas t.mayer@mdlmarinas.co.uk www.mdlboatshow.co.uk

The UK Harbour Masters Association (UKHMA) will return to Seawork on 11 June for the 2025 event. Building on the success of this year’s programme, which saw the UKHMA host its Annual General Meeting on-site at Mayflower Park for the first time, the Association is set to continue its long-standing support of Seawork. The UKHMA, a professional body representing harbour masters, port marine operations officers and related organisations, has been a key partner of Seawork since the exhibition’s inception 25 years ago. Mercator Media corporate@mercatormedia.com www.mercator media.com

www.seawork.com

Marina

www.sfmarina.com

Walcon Marine Ltd

www.walconmarine.com Water Witch

www.waterwitch.com

Diary of events

Please check websites for up-to-date information before booking hotels or confirming travel plans.

Boot Düsseldorf Düsseldorf, Germany 18-26 January, 2025 www.boot.de

Miami International Boat Show Miami, Florida, USA 18-26 February, 2025 www.miamiboatshow.com

Korea International Boat Show Ara Marina, Gimpo, South Korea 28 February-2 March, 2025 www.kibs.com

Auckland Boat Show

Auckland, New Zealand 6-9 March, 2025 www.auckland-boatshow.com

China (Shanghai)

International Boat Show

Shanghai, China 30 March-2 April, 2025 www.boatshowchina.com

Palma International Boat Show

Palma de Mallorca, Spain 30 April-3 May, 2025 www.palmainternationalboatshow. com

Sanctuary Cove International Boat Show

Queensland, Australia 22-25 May, 2025 www.sanctuarycoveboatshow.com.au

Seawork

Southampton, England 10-12 June, 2025 www.seawork.com

Sydney International Boat Show

Darling Harbour, Australia 30 July-2 August, 2025 www.sydneyboatshow.com.au

Southampton International Boat Show

Southampton, England 19-28 September, 2025 www.southamptonboatshow.com

ICOMIA World Marinas Conference

Venice, Italy 15-17 October, 2025 www.worldmarinas conferencevenice.com