Whether you work in board and paper, tissue, pulp or energy industry, Valmet’s comprehensive service offering helps to lower your environmental footprint significantly – at the same time improving your operational results. The key is a close collaboration and the right combination of services for every stage of the lifecycle. As most of the environmental impact comes from the operational phase, by working consistently in close cooperation with your team, we can offer many concrete solutions.

From energy, water and raw material savings to circularity and lower emissions, together we’ll keep the process reliable, optimized and sustainable to the fullest extent – benefiting both your business and the environment.

Are you ready to succeed with us? Explore how on www.valmet.com/waytoserve

Welcome to the first issue of 2024, which also marks our 60th anniversary. Since this pioneering title was launched in January, 2011, the landscape has changed dramatically in terms of the integration of multi-discipline green energy technologies to the supply of renewable energy.

This has moved forward in leaps and bounds, and the early reliance on single source renewables has seen integration of many forms of energy supply being adopted. The mix of renewables can now offer long-term energy security, with a mix of forest-based bioenergy, solar, hydro, thermal and hydrogen energy, not to mention nuclear power.

Sustainable energy has been catapulted to the forefront of most governments given the increase in global warming data released over the past 12 months and while some countries still rely on coal as a primary source of energy production, pressure continues on them to abandon this highly polluting form of energy production.

Moving forwards to the next issue, we will be looking at waste to energy production and the latest solar power developments plus our annual review of biomass shipping, handling and logistics. Any news or contributions for the issue should be with us no later than 10 May.

Vince Maynard,

Volume 12, Number 60 – Spring 2024

PUBLISHER & EDITORIAL DIRECTOR

Vince Maynard

KVJ Enterprises, Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

E: pulppaperlogistics@virginmedia.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

E: youngeditorial1@btinternet.com

ISSN 2045-8514

©2023

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

E: anton_print_1@mac.com

PRINTING

KNOCK OUT PRINT

+44 (0) 1892 823540

Unit 2 The Coppice, Petteridge Lane, Matfield, Kent TN12 7LP info@knockoutprint.co.uk www.knockoutprint.co.uk

Heitkamp Industrial Solutions GmbH has been awarded the contract as main contractor of Asiyan Enerji, a company of the Rönesans Group, for the installation of wind turbines in three Turkish provinces. Heitkamp will be responsible for the technical and commercial management of these projects as EPC contractor. The turbines will be equipped with Nordex Group technology and are a further important step towards achieving Turkey’s renewable energy and sustainability targets.

“Our focus is on high-quality project management in the industrial construction sector, enabling environmentally-friendly and economically-viable construction projects. At a time when resource scarcity and dependence on critical raw materials are becoming increasingly problematic, we are determined to break new ground, forging alliances with other players in the industry,” said Christopher Hambleton, CEO of Heitkamp Industrial Solutions.

Heitkamp is a key component in the Rönesans Group’s impressive portfolio. Rönesans Enerji’s partnership with the Nordex Group in three pioneering wind turbine projects underlines the Group’s commitment to energy transition.

In the Sivas region, the Group will install seven turbines for the 49 MW ‘R3-Sivas 1-2 RES’ wind farm, while eight turbines have been ordered

for the 56 MW ‘R3-Çorum 1 RES’ project in Çorum. The largest of the three orders involves the delivery of 12 turbines with a total output of 84 MW for the ‘R3-Malatya 1 RES’ wind farm in the province of Malatya in Eastern Anatolia. With a total installed capacity of 189 megawatts in the three Turkish provinces, these projects will cover the electricity consumption of around 380,000 households. In addition, around 370,000 tons of CO2 emissions will be avoided each year. This is a concrete example of the transformative impact achieved by the co-operation between Heitkamp, Rönesans Enerji and Nordex in Turkey.

Dr Erman Ilıcak, President of Rönesans Holding, and İpek Ilıcak

Kayaalp, CEO of Rönesans Holding, recently announced Rönesans’ ambitious targets: to reach net zero emissions by 2040, with an interim target of reducing emissions by 55% by 2030.

Emre Hatem, Vice-Chairman of the Board of Directors of Rönesans Enerji, emphasised the importance of this partnership: “Rönesans Enerji already has a total installed capacity of 166 megawatts through its hydropower projects. We are proud to join forces with Nordex to expand our investments in renewable energy in Turkey and strengthen our commitment to the country’s net-zero targets. In close co-operation with the renowned wind turbine manufacturer Nordex

and our German subsidiary Heitkamp Industrial Solutions, we are confident that we can contribute significantly to the reduction of CO2 emissions in Turkey. With these three new projects with Nordex, our total installed capacity will grow to 355 megawatts. Our goal is to build a 100% renewable energy portfolio and become one of the top three green energy companies in Turkey”.

The N163/6.X turbines used, mounted on 113 metre high steel towers with a rotor diameter of 163 metres, are the most powerful turbines currently available in Turkey. They are expected to go into operation at the end of 2024.

More information:

www.heitkamp-solutions.com

Scottish clean energy developer

Intelligent Land Investments (ILI) Group has announced the successful sale of their 50 MW Battery Storage project to EDP Renewables (EDPR), a global leader in the renewable energy sector.

The Balnacraig project, located near Alness in the Highlands, will contribute approximately 50 MW of capacity to the region’s power grid and hold enough energy to power every home in the Highlands for two hours. This asset will also play an

important role in grid management, offering flexibility and supporting the country’s renewable energy strategy. Construction is set to begin in a few months’ time, with the aim of starting operation at the beginning of 2025.

This significant transaction brings the total to 900 MW of energy storage projects that ILI Group has progressed to the development stage. The company has an ’overall portfolio of 4.7 GW of energy storage projects across Scotland, including 2.5 GW of Pumped Storage Hydro and 2.5 GW of

Battery Storage.

With over 15 GW of wind and solar energy assets developed globally, EDPR brings substantial large-scale project expertise. The company is investing in optimising resources and improving energy efficiency by developing energy storage projects in the UK, one of its key European markets. Early this year, EDPR acquired its first Battery Energy Storage System in Kent, England. EDPR’s experience spans Europe, North and South America, and Asia-

Pacific markets.

In its updated Business Plan for 2023-2026, EDPR aims to achieve a storage capacity of over 500 MW, with co-located assets and standalone assets such as this project. Besides the projects in the UK, which amount to 100 MW, EDPR also has nearly 200 MW of contracted storage capacity in North America and over 4 MW under construction in the AsiaPacific region.

More information:

www.edpr.com

The power and district heating supply at the Reuter West cogeneration plant in Berlin is to be converted from coal to climateneutral energy sources. In order to achieve this goal, Vattenfall Wärme Berlin AG (VWB) has commissioned Kraftanlagen Energies & Services GmbH with Lot 2 of the construction of a new combined heat and power (CHP) plant. Depending on the demand for electricity and heat, the new plant – consisting of a steam turbine

plant and a large heat pump – will be able to flexibly supply the West of Berlin with around 30 MW of electricity or more than 180 MW of heat.

Kraftanlagen was awarded the contract for the basic engineering in July of last year. The company has now also been awarded the overall contract for Lot 2 for the supply of the higher-level plant technology, including the process engineering, as well as the electrical and I&C integration of all plant components. The scope of supply

also includes a heat pump, which will use the waste heat from the mechanical cooling circuit to feed up to an additional 2 MW of thermal power into Berlin’s district heating network.

The new CHP plant, which is scheduled for completion at the end of 2026, will enable Vattenfall to utilise existing energy sources intelligently. For example, the steam turbine will be operated with steam generated by the incineration of unavoidable waste in the existing waste-to-energy

plant of Berliner Stadtreinigung (BSR). The large heat pump system with an average thermal output of 75 MW will utilise the residual heat of the clear water from the nearby Berliner Wasserbetriebe sewage treatment plant as a heat source and raise it to a higher temperature level. Both technologies will thus make an important contribution towards a climate-neutral energy supply for Berlin.

More information:

www.kraftanlagan.com

On 19 February, Kimberly-Clark (K-C), one of the world’s leading manufacturers of personal care and hygiene products, and integrated energy solutions company, Energy Partners (EP), signed a long-term Power Purchase

Agreement (PPA) to install one of the largest rooftop solar photovoltaic (PV) systems in Cape Town, South Africa.

According to the terms of the agreement, EP will install a 2.2 MW rooftop system at K-C’s

manufacturing site in the Epping industrial area of the city.

Once the project is completed, the rooftop system at K-C’s facility will allow an annual energy production of 3,478 MWh per year, which

will save over 3,130 tonnes of CO2 emissions each year, equivalent to powering 1,030 median residential homes in the country every year

More information:

www.energypartners.co.za

On 13 February, The longest established solar company in Europe, AES Solar announced that its founder, George Goudsmit (82), was stepping down as Managing Director. Management of the business, which is based in Moray, Scotland, will be taken over by the existing senior leadership team as part of a management buy-out, which secures the company’s long-term future.

Commercial Director Jamie Di Sotto and the other members involved in the buy-out are Technical Director Campbell MacLennan and Finance Director Lynn Davidson. Despite being in his 80s, George Goudsmit has no intention of retiring and will use his extra time to explore new technologies and trends on behalf of AES Solar.

Mr Goudsmit took on AES Solar when he moved to Scotland from London in 1989. At that time, it was a

small heating company, which had a sideline in solar panel manufacture.

George focused on the solar side of

Global renewable energy company Low Carbon has announced that it has successfully connected 42 MW of new solar capacity to the grid in the UK and The Netherlands. The three solar farms are the latest projects to reach this key milestone as the company scales up to create 20 GW of new renewable energy capacity by 2030.

Low Carbon’s St Clere’s Solar Farm in Essex will produce 23 MW of clean energy and is their second UK project to be energised following the Fox Covert Solar Farm in Buckinghamshire announced in October, 2023.

The two Dutch projects located in the province of Utrecht at Wijkerbroek East and Wijkerbroek West are the latest installment of more than 120 MW of Dutch solar that is expected to come

online early this year. The projects have a capacity of 10 MW and 9 MW, respectively, and have been developed by LC Energy, Low Carbon’s joint venture with engineering firm Qing and one of the leading renewables developers in The Netherlands.

Roy Bedlow, Founder and Chief Executive of Low Carbon, stated: “We are delighted to connect more new renewable capacity to the grid as we make progress on our journey towards building a global independent power producer. The latest milestone for these projects reinforces our strong track record of delivering renewable energy infrastructure on time and on budget as we maximise our efforts to tackle climate change”.

More information:

www.lowcarbon.com

the business, becoming the only UK manufacturer of solar thermal panels and expanding into a range of solar

technology. From a modest turnover of £30,000, the business now has a turnover of £10 million, with significant growth occurring over the last three years.

In 2021, Mr Goudsmit was awarded a Lifetime Achievement Award at the Solar and Storage Awards. As well as noting his infectious enthusiasm and advocacy on behalf of the industry, he was recognised for personally convincing the late Queen Elizabeth II to install solar energy at Balmoral. The company won the royal client by providing Scottish-made products along with an installation that was sympathetic to the historic importance of the Royal Estate. The following year, AES Solar was awarded The Queen’s Award for Enterprise in recognition of its work in sustainable development.

More information: www.aessolar.co.uk

New statistics released on 26 January by the Scottish Government reveal that renewable energy technologies generated the equivalent of 113% of Scotland’s overall electricity consumption in 2022 – the highest recorded figures to date and a 26% increase year-on-year.

Responding, Claire Mack, Chief Executive of Scottish Renewables, said: “These record-breaking figures are a major milestone on Scotland’s journey to netzero, clearly demonstrating the enormous potential of our world-class renewable energy resources.

“We know that increasing clean energy generation leads to significant benefits for our economy with Scotland’s renewable energy industry and supply chain already supporting

more than 42,000 jobs and an economic output of over £10.1 billion.

“However, with electricity demand set to rise significantly in the years ahead, we must continue to swiftly deploy renewable energy projects at scale. Not only will this provide clean, cheap energy for Scotland’s homes and businesses, but also support our wider heat and transport decarbonisation ambitions.

“Maximising capacity in Contracts for Difference Allocation Round 6 this year will be vital to that effort, alongside enabling the critical infrastructure and investment needed to deliver a truly home-grown clean energy system.”

More information:

www.scottishrenewables.com

Agreen hydrogen production plant and refuelling station is to be constructed by Exolum in the Tees Valley as part of the Tees Valley Hydrogen Vehicle Ecosystem project. The project, which has been awarded £7 million of grant support from the Department for Transport in partnership with Innovate UK under the Tees Valley Hydrogen Transport Hub Competition, is expected to be fully operational in 2025.

The planned project will feature the construction of a water electrolyser and a hydrogen refuelling station at Exolum’s

Riverside terminal in Stockton-onTees, near to Middlesbrough town centre and at the intersection of the strategic A19 and A66 roads. The electrolyser will produce green hydrogen using renewable electricity and will supply both the refuelling station, with a capacity of 1.5 tonnes per day, and other customers in the region using a ‘hub and spoke’ delivery model.

The project also includes UK fuel cell electric vehicle manufacturer Electra Commercial Vehicles and German manufacturer Quantron AG, in partnership with Novuna Vehicle Solutions, who together will deploy

at least 20 fuel cell electric trucks, ranging from 4.2 to 27 tonnes. These manufacturers will receive a total of £5 million under the same funding competition. The vehicles will be used by some of the region’s largest vehicle operators, who will replace existing diesel vehicles, thereby reducing local air pollution and carbon emissions.

Data monitoring and performance evaluation of the hydrogen trucks will be carried out by Teesside University’s School of Engineering Computing and Digital Technologies and Net Zero Industry Innovation Centre, which has extensive

experience in the field of hydrogen fuel cells, to inform further development of the hydrogen transport sector.

The Tees Valley Hydrogen Vehicle Ecosystem is a vital first step towards the development of a nationwide network of hydrogen refuelling stations, serving as a model for other regions to deploy similar hydrogen mobility ecosystems. This project will help accelerate the UK’s transition to zero-emission fuel cell vehicles and reduce carbon emissions in line with its ambition to achieve net zero.

More information:

www.exolum.com

In close co-operation with project developer Vast, which specialises in concentrated solar thermal power (CSP) energy systems, Hamburgbased Mabanaft intends to build a solar methanol plant in Port Augusta, South Australia, with a capacity of approximately 7,500 tonnes per year and a 10 MW electrolyser. The planned demonstration plant could be operational at the beginning of 2027 to provide customers with green methanol based on renewable energy. In future, after evaluation of effectiveness, other project sites in or near Europe could be added.

In Germany, the project is granted public funding of approximately 12.4 million Euros from Projektträger Jülich, which is a partner to the public sector in science, business and politics. The Australian government, through the Australian Renewable Energy Agency, has pledged to support the project equivalent to approximately 11.9 million Euros after it was selected as part of

the German-Australian Hydrogen Innovation and Technology Incubator (known as HyGATE).

The HyGATE initiative intends to establish a German-Australian supply chain for green hydrogen and to strengthen co-operation between the two countries in the field of hydrogen technologies. For Germany, the initiative also has the potential to contribute to the National Hydrogen

Strategy: importing sustainable energy sources and exporting climate protection technologies ‘Made in Germany’.

For Mabanaft, the planned demonstration plant can provide increased expertise for the possible construction of similar plants on a commercial scale worldwide. The aim is to supply existing and future customers with green methanol

and enable them to fulfil their commitment to decarbonisation. “With access to green methanol, our range of sustainable energy solutions for our customers would continue to grow,” said Philipp Kroepels, Director of New Energy at Mabanaft. He continued, “The funding agreement makes a crucial recognition and validation of our decarbonisation efforts and can be a strong contribution to strengthening Germany’s leading role in the global energy transition”.

Craig Wood, CEO of Vast, added: “This is a significant milestone for Vast and for green fuel production globally. Solar Methanol has the potential to make a huge difference to the transport sector as it urgently looks at ways to decarbonise its fuels. The funding is a testament to Vast’s technology, as well as our partners within the Solar Methanol Consortium”.

More information:

www.mabanaft.com

Orkney Island Council’s Development and Infrastructure Committee has given its backing to the West of Orkney Windfarm’s offshore plans.

Orkney Islands Council is a statutory consultee for Section 36 consent and marine licence applications for the proposed multi-billion pound offshore windfarm, located 30 km West of the Orkney Mainland and 25 km North of the Sutherland coast.

The council’s committee met in the first week of February to consider the windfarm

developer’s offshore plans, which were outlined in a comprehensive offshore consent application submitted to Scottish Ministers in October, and gave the proposal their support.

The offshore plans contain detailed information on how the windfarm will be constructed, including the proposed location of turbines and cable routes.

They also include a comprehensive suite of environmental assessments based on survey data collected over two and a half years.

The final decision on the offshore consent will be

Jack Farnham.made by Scottish Ministers following recommendations by the Marine Directorate Licensing Operations Team and taking into account comments made by statutory consultees, including Orkney Islands Council.

The project will have up to 125 turbines on fixed foundations, an expected capacity of around two gigawatts and aims to deliver power in 2029. It is being developed by a joint venture comprising Corio Generation, TotalEnergies and the Renewable Infrastructure Development Group.

Commenting on the Council’s backing, West of Orkney Windfarm Development Manager Jack Farnham said: “We welcome this positive support from Orkney Islands Council. We have been working closely with the community and businesses in Orkney for a number of years to ensure our ambitious project will bring positive, long-term benefits to Orkney, Caithness and Sutherland, and we are extremely

grateful to the officials and elected representatives of the council for their endorsement of our detailed plans.

“The Scottish Government has a stated ambition to deploy 8-11 GW of offshore wind in Scottish waters by 2030. As the first ScotWind project to enter the planning process, securing timely offshore consent from the Scottish Government and onshore planning permission from The Highland Council will be critical if Scotland is to meet this target, which will unlock significant inward investment and with it economic and social benefits to the Far North.”

The West of Orkney Windfarm has engaged in a £105 million investment initiative during the development phase of the project to develop the supply chain that is planned to be enhanced to £140 million by match funding from third parties.

More information:

www.westoforkney.com

Several challenges arise in recovery boiler performance optimisation – the overall target is to increase availability, optimise chemical recovery efficiency and improve emission control. At the same time, operational safety cannot be compromised.

If the recovery boiler is not in operation, the entire production at a mill stops. To maximise availability, the mill should aim for the longest possible time between cleaning shut-downs and eliminate

completely unplanned outages.

Jarmo Mansikkasalo, Senior Manager, Recovery Boiler Solutions at Valmet, explained: “The reduction rate – the chemical recovery efficiency – has a major influence on a mill’s

overall effectiveness and operating costs. The recovery boiler is also a source of potential safety hazards. Carry-over promotes superheater tube corrosion and increases fouling in the superheater area. This can lead to tube leaks – in the worst case, an explosion can occur and in many countries, emission limits are getting stricter, especially for NOx gases.

“On the other hand, there are limited ways to measure boiler operation. For example, some aspects can be evaluated by measuring the reduction rate and the green liquor’s Total Titratable Alkali (TTA), but now, with Valmet Recovery Boiler Combustion Diagnostics, we can get information about boiler operation that is

unavailable with normal measuring methods,” Mansikkasalo said.

The Valmet Recovery Boiler Combustion Diagnostics application utilises Computational Fluid Dynamics (CFD) to simulate and visualise the state of the combustion inside the furnace. The application calculates

a variety of process parameters, which are impossible to measure in practice, using them to provide very valuable information about how the combustion process is actually happening. This information enables operators to make decisions about how to improve the current situation and optimise performance, availability and emissions.

“The application allows mill operators to trigger a physics-based simulation of the current boiler operation or to simulate how the boiler was behaving at a specific point in the actual control history. This enables the customer to investigate, understand and iron out the potential root causes of process anomalies and assess how the combustion process can be fine-tuned in the future.

For example, the diagnostics tool visualises process parameters such as temperature fields, flow patterns and black liquor droplet trajectories showing droplet hits on furnace walls or how droplets escape the furnace, resulting in carry-over. All these parameters are very difficult to measure with other methods,” Mansikkasalo explained.

The Recovery Boiler Combustion Diagnostics application has been

used to simulate pulp mill recovery boiler performance since 2021, and it has proven beneficial for finding the right solutions for recovery boiler performance optimisation.

A key area for optimisation is the availability of a recovery boiler and the application’s CFD modeling capabilities make it possible to find the optimal operation mode to minimise carry-over. In turn, this

minimises superheater fouling and improves the availability and safety of operations.

Finding the optimal combustion air split and black liquor firing temperature balance for a high reduction rate is also a common challenge in many recovery boilers. To achieve the optimal droplet size and air distribution, the application provides key information about issues like temperature and oxygen profiles close to the char bed and how black liquor droplets end up on the char bed.

When the combustion process is optimised, the recovery boiler operates with minimal carbon monoxide (CO)

emissions. This enables the boiler to operate with a lower oxygen content, which also means NOx emissions can be reduced.

Although each recovery boiler has slightly different demands, with Valmet Recovery Boiler Combustion Diagnostics operators can now optimise their recovery boiler performance and achieve the most competitive boiler operation. More information: www.valmet.com

*Marketing and External Communications,Pulp & Energy, Valmet.

As part of its CircleToZero initiative to reduce emissions and waste at pulp mills, ANDRITZ never stops innovating to obtain maximum results. One of the latest developments for pulp mills has resulted in a new recovery boiler concept with low emissions while maintaining high energy efficiency at the same time.

The recovery boiler has come a long way since it was first invented in the early 1930s. At the time, it was a revolution and is now often described as the “beating heart of a pulp mill”, as it performs its duty of recovering the inorganic chemicals, burning organic chemicals so they are not discharged from the mill as pollutants and recovering heat in the form of steam to generate power.

Over the years, that first revolutionary recovery boiler design has developed and evolved into a showcase of sustainability for all pulp mills around the world.

Hamilton Brandao, Technology Director, Recovery Boilers, ANDRITZ, stated: “The recovery boiler design and function has come a very long way since its invention back in the 1930s. Safety, mechanical design, process performance, operational

controls and environmental emissions make the modern recovery boiler unrecognisable when compared to the first ones.

“Over the past two decades, in particular, recovery boiler capacity has increased steadily, while thermal performance improvement has enabled customers to not only be self-sufficient in power generation, but also create a valuable new revenue stream by selling surplus green energy to national grids.”

The modern recovery boiler may be a showcase of sustainability, but there are still some areas that need working on, in particular, NOx emissions. These are becoming strictly monitored as they impact the environment in the long-term and most countries have their own rules

on allowed emissions. One example is China, which has recently seen a rapid tightening of NOx emission

regulations in high density urban areas. It is expected that Europe will follow suit in regards to NOx

emissions, leading to similar limits.

“In general, environmental emissions from the recovery boiler have decreased substantially over the last decades, for instance CO2, particulates and low sulphur emissions,” continued Brandao, “but this trend is not applicable to NOx, which still requires new technologies to enable a further decrease in its emissions”.

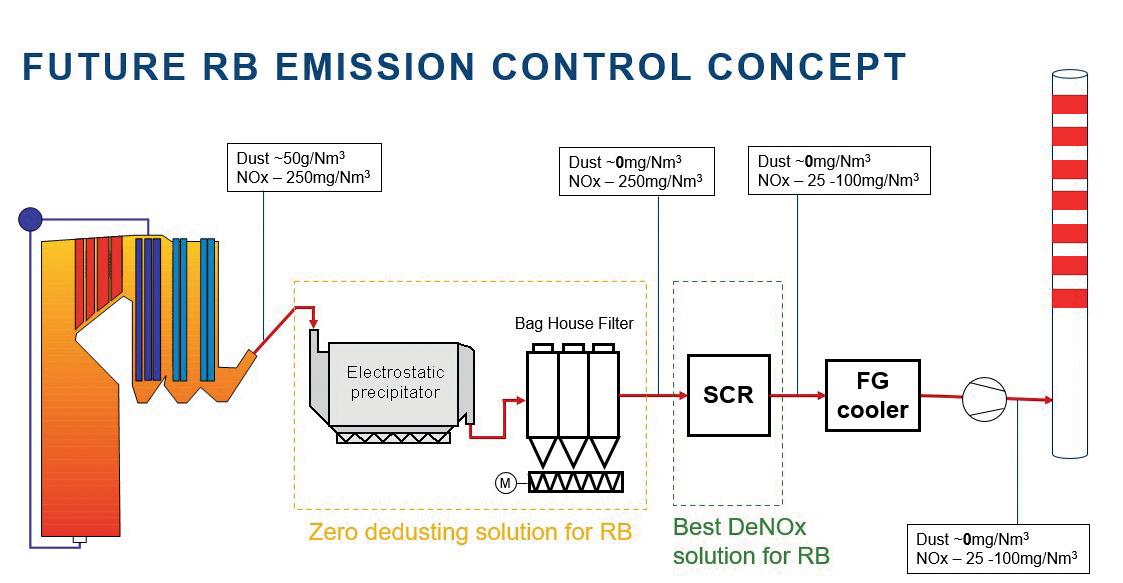

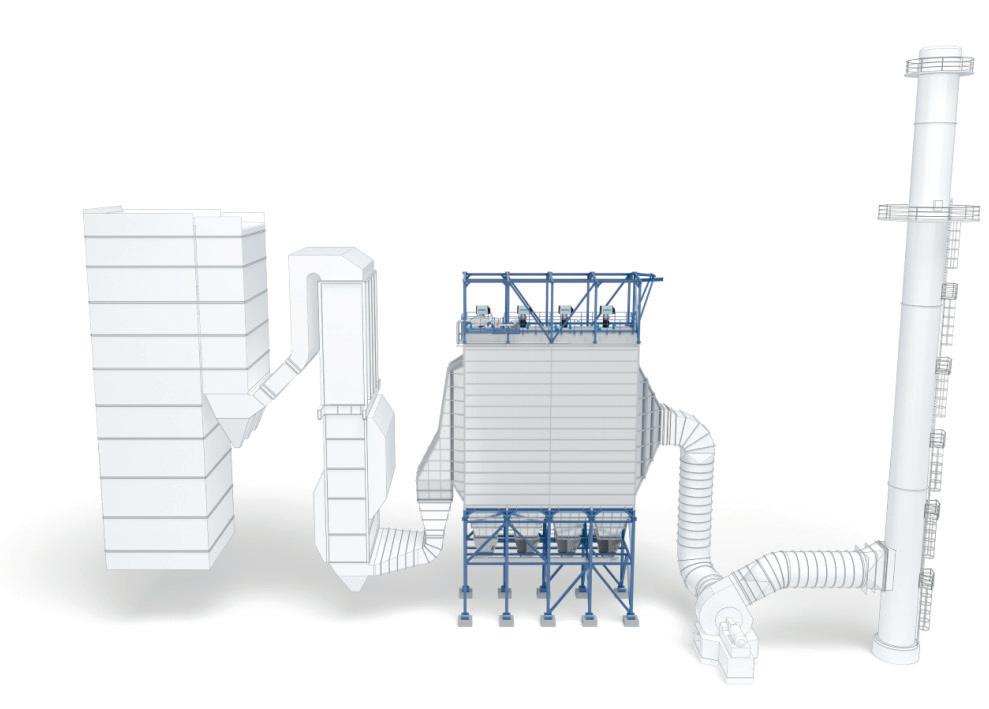

The challenge of NOx emissions from the recovery boiler is an area that ANDRITZ has been working on over the last two years and has successfully come up with a solution. Naveen Chenna, Director of Research and Innovation at ANDRITZ, reported: “More than 70% of the NOx coming from a pulp mill emits from the recovery boiler. This means if a pulp mill produces 1.5 kg of NOx per tonne of pulp, about 1.2 kg is coming from the recovery boiler.

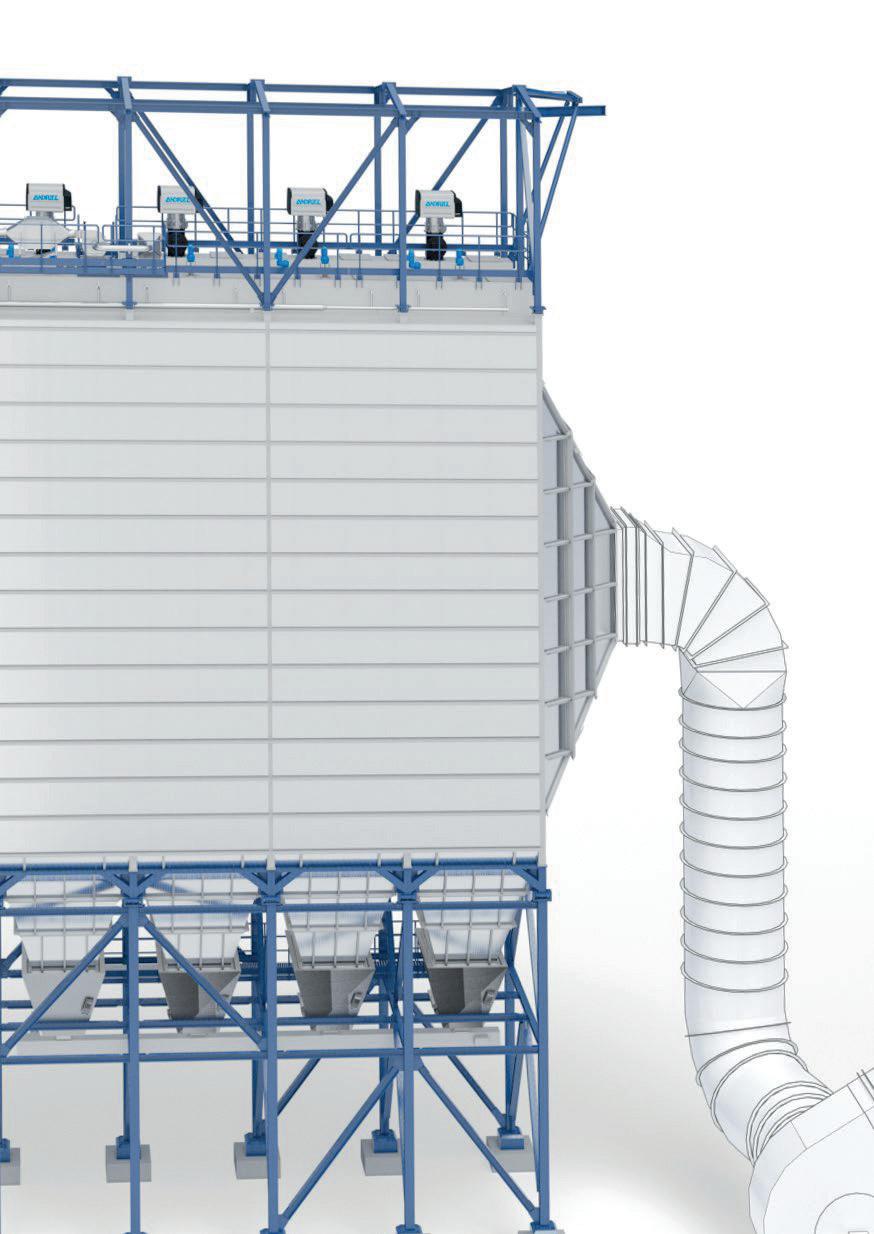

“For the last two years, we have built and operated a demo plant containing various solutions at pulp mills in Finland along with earlier studies in Sweden. After testing different technologies including electrostatic precipitators (ESP), fabric filters (FF) and catalysts, we have devised proven ways to reduce NOx emissions from the recovery boiler by as much as 95%.”

The dramatic reduction of NOx emissions is made possible by secondary methods that ANDRITZ experts have configured by using an FF for recovery boiler dust after the ESP and selective catalytic reduction (SCR). The FF ensures low dust emission and safe operation of the SCR. There are no other references of this configuration in the pulp

After testing different technologies, we have now devised proven ways to reduce NOx emissions from the recovery boiler by as much as 95%

Manager ESP and FF, ANDRITZ, explained, “The reduction or elimination of NOx is made possible by secondary methods that can be designed to reach 95% efficiency of reduction. Particulate reduction can be achieved down to 5-10 mg/Nm3 with conventional ESP technology. Typical levels today range from 10 mg/Nm3 in China all the way up to 70 mg/Nm3 in Brazil.

industry worldwide, with the demo plant tests showing normal collection and release of the dust on the fabric surface.

Kasper Skriver, Global Product

“By applying the fabric filter technology, we will enable continuous particulate emissions less than 5 mg/Nm3, which is what we consider close to zero.” The technology for NOx reduction and elimination, the Lo-NOx recovery boiler concept, is now available for ANDRITZ customers worldwide and can be part of a greenfield mill project or retrofitted to existing mill operations.

More information: www.andritz.com

First Minister Humza Yousaf, MSP, opened the Scottish Renewables’ Offshore Wind Conference at the Scottish Event Campus in Glasgow on 24 January, which was attended by over 1,100 delegates. In his ministerial address, the First Minister spoke of the Scottish Government’s commitment to being a partner with the offshore wind industry to “unleash its potential for every single person living in this country”. He also announced that a select group of three initial projects have been invited to move to stage two of the Strategic Investment Model – a collaborative framework with industry, which fosters joint investment into offshore wind, supply chain and infrastructure – in a significant milestone for Scotland’s offshore wind programme.

Scottish Renewables’ Offshore Wind Conference, headline sponsored by SSE Renewables, was the industry’s most hotlyanticipated event, setting the agenda for 2024. With a worldleading pipeline, the conference kickstarted a critical year of action to address the big challenges affecting the deployment of offshore wind and the success of Scotland’s supply chain companies.

From thought leadership to practical supply chain advice, the conference brought together industry experts, developers, suppliers and stakeholders to review the state of Scotland’s offshore wind ambitions.

Speaking at the conference, the First Minister said: “The offshore wind industry brings substantial benefits to people living in Scotland and requires the government as a

partner. It also promises to create thousands of high-quality, green jobs for new entrants and experienced individuals choosing to transfer their skills.

“There are moments when certain industries can stand confident that when they look ahead, they will see a future in which they play a pivotal role in securing the wealth and wellbeing of a nation – Scotland’s offshore wind industry is at that moment.

“Together, we can create the right conditions to attract investment, build the supply chain, recruit and deliver the infrastructure needed to ensure that these projects will thrive.”

Claire Mack, Chief Executive of Scottish Renewables, stated: “Scottish Renewables’ Offshore Wind Conference 2024 is a world-

class, must-attend event for anyone keen to play a role in the deployment of offshore wind. It’s exciting to see such a diverse set of voices coming together to look at the scale, pace and change needed to deliver the supply chain and offshore wind required to achieve net-zero. It is also an opportunity to highlight Scotland as a globally-competitive destination to invest in a sector, which is delivering benefits across the country.

“It is clear that 2024 is going to be another critical year for the collaboration and innovation, which is driving Scotland to the forefront of the global clean energy race and I would therefore like to thank the First Minister for his continued support of our industry.”

More information: www.scottishrenewables.com

European Pellet Conference 2023: As a CO2-neutral fuel, sustainable bioenergy has a key role to play in decarbonising and securing our energy supply. Over 400 experts discussed this and more in Wels, Austria. ″It was wonderful to see conference participation back up at pre-corona levels″ , reports Conference Director Christiane Egger.

In 2023, the European Pellet Conference focussed on the importance of pellets in responding to the energy crisis and highlighted latest trends in markets, policies, technologies and innovations.

The strategy session presented the policy and market context for the clean energy transition and provided input on how to deal with the current challenges. In the panel discussion ″ The future of wood pellets″, leading biomass experts shared their insights on how to separate facts from fiction on topics such as forestry, air quality and sustainability.

The event showcased cutting-edge developments and R&D results in the pellet and bioenergy sectors, and start-ups presented their innovations for the pellet market. Also, international experts offered updates and outlooks on pellet markets around the world.

The European Pellet Conference offers a comprehensive package, including the Young Biomass Researchers Conference, a poster presentation, valuable networking opportunities and a major tradeshow on energy efficiency with a strong focus on pellet-related exhibitors (the ″Energiesparmesse″ ).

The event is part of the World Sustainable Energy Days (WSED), an international conference on the energy transition and global climate neutrality with over 650 experts from more than 60 countries each year. The WSED is organised by the OÖ Energiesparverband, the energy agency of the Region of Upper Austria.

The next edition of the event will be held on 6 - 7 March 2024 in Wels/Austria

The deadline for the Call for Papers & Speakers (also for the Young Biomass Researchers Conference) is 10 October 2023. For more information: www.wsed.at

www.pellets23.eu

The pulp and paper industries play a key role in the transition and transformation towards a fossil-fuel free circular bioeconomy. By developing circular operations to eliminate unused side streams, and creating new value-added bio-based products, it can be the global leader in zero emissions and zero waste industrial processes.

CircleToZero brings together the continuous development and improvement of existing ANDRITZ technology solutions to achieve this leadership position with clear environmental and financial benefits.

Our shared journey towards zero emissions and zero waste has already started.