Targeting emissions zero

WE ENABLE OUR CUSTOMERS TO REDUCE CO 2 EMISSIONS

Targeting emissions zero

WE ENABLE OUR CUSTOMERS TO REDUCE CO 2 EMISSIONS

Renewable energy can be readily identified, but getting permission to build can be very drawn out and expensive. Here in the United Kingdom, current planning laws mean proposals can take years to progress to a decision. Self-sufficiency in terms of energy supply is a key target for many countries around the world, but at what cost?

There are, however, some notable examples where car park roofs have been successfully covered in solar panels and fields designated for sheep have been used for a solar farm that also supports grazing.

A very recent example of wind power generation can be seen with power being generated from the Shetland Isles to mainland Britain for the first time and hailed as the UK’s most productive onshore wind farm as it comes on stream. SSE says its 103-turbine project, known as Viking, can generate 443 megawatts (MW) of electricity, enough to power nearly 500,000 homes.

Shetland is the windiest part of the UK, which means it will be rare for the blades, which reach a massive 155m at their tip, not to be spinning.

Looking forwards, our next issue this Winter, we will be taking a gander at battery storage solutions. Other topics will include biomass as part of a green energy strategy, wave and hydro power production plus green hydrogen.

Submissions for this issue should be with us no later than 12 November and sent to Vince Maynard via e-mail: pulppaperlogistics@ virginmedia.com

Vince Maynard, Publisher

PUBLISHER & EDITORIAL DIRECTOR

Vince Maynard

KVJ Enterprises, Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

E: pulppaperlogistics@virginmedia.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

E: youngeditorial1@btinternet.com

ISSN 2045-8514

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

E: anton_print_1@mac.com

PRINTING

KNOCK OUT PRINT

+44 (0) 1892 823540

Unit 2 The Coppice, Petteridge Lane, Matfield, Kent TN12 7LP info@knockoutprint.co.uk www.knockoutprint.co.uk

Electrifying

The second phase of investment in UPM Energy’s innovative ultracapacitor project, which will further strengthen the ability of hydropower to balance the grid has now been made. The new installation will be located next to the Kuusankoski hydropower plant and is expected to be operational by Summer, next year. The system was successfully piloted at the Katerma hydropower site in 2022 and the concept is now being replicated at Kuusankoski. The

Kuusankoski ultracapacitor system will enable UPM Energy to provide faster reserves through short-term energy storage, responding to grid balancing needs in mere milliseconds. This responsiveness is crucial as the transmission grid operators are trying to cope with increased volatility in the electricity supply. This has been brought about by the rapid growth of weather-dependent renewable energy sources, such as wind and solar power.

UPM Energy is the second largest

NextEnergy Capital (NEC), a specialist in the solar+ infrastructure sector, has announced that all four of its Contact for Difference (CfD) auction bids across both its UK Private Fund, ‘NextPower UK ESG’, and in-house development company, ‘Starlight’, were successful in the sixth allocation round (AR6) auction announced by The Department for Energy Security and Net Zero on the 3 September. The winning CfD bids by NEC cover the full generating capacity of 165.8 MW across four solar assets with solar prices successfully secured at a fixed price of £50.07, representing a £3-4 increase on the same 2012 pricing

terms when compared to last year’s fourth and fifth allocation rounds (AR4 & and AR5). Approximately 3.3 GW of solar capacity was successful in AR6, which makes it the most successful auction to date and another important step forward for the UK’s Net Zero transition plans.

The CfD mechanism was introduced by the UK Government in 2014 to support low-carbon electricity generation by reducing financial risks faced by developers of renewable assets and providing 100% secure, inflation-linked regular income to drive further investment into cheap renewable energy in the UK.

electricity producer in Finland and 99% of its portfolio is CO2free. The Kuusankoski project will utilise modern digital systems and automation processes to optimise the performance of the energy system and provide more balancing power to the grid.

“The ultracapacitor concept has proven its capability at Katerma and it will be an essential part of the hydropower generation,” said Antti Raukola, Project Manager at UPM Energy. “This technology is

not just about innovation, but also about preparing for the future of grid balancing.”

Ultracapacitors are known for their ability to discharge at high power and react in milliseconds without losing capacity. They are maintenance-free and have a significantly longer lifetime than batteries, making them an ideal choice for sustainable energy solutions.

More information: www.upmenergy.com

Michael Bonte-Friedheim, CEO and Founding Partner of NextEnergy Group, said: “Our success in the government’s latest CfD auction further cements NextEnergy Capital as one of the world’s largest specialist solar+ investment managers, with four projects with a generating capacity of c.166 MW securing successful bids. The CfD mechanism continues to provide stability to investors in new solar projects in the UK by providing long-term contracted revenues, which match the contracted revenue strategies of all NEC funds. The success of the whole AR6 auction should provide further comfort to

all investors in the UK renewable infrastructure space”.

Paul Barwell, Head of Energy Sales at NextEnergy Capital, commented: “The fixed price of £50.07 represents roughly £69.50 in terms of 2024 pricing terms and further demonstrates strong government support towards developers of renewable assets whilst providing a further boost of confidence in the UK renewable energy landscape. This pricing cements new-build solar infrastructure as the cheapest source of decarbonised new-build power generation in the UK”. More information: www.nextenergycapital.com

On 24 july, it was announced that International technology group ANDRITZ had been selected to perform the front-end engineering design (FEED) for a large-scale carbon capture unit for Westenergy’s waste-to-energy plant in Mustasaari, Finland. This project will make a significant contribution to decarbonisation and the circular economy.

The order was received from ECCU Ltd, a joint venture of

Westenergy Ltd, CPC Finland Oy and funds managed by Prime Capital AG. The aim is to capture all the carbon dioxide from the flue gases of the Mustasaari waste-to-energy plant, which produces district heating and electricity from sorted, non-recyclable municipal waste. The captured carbon dioxide will be liquefied and a large portion will be made available to produce carbonneutral synthetic e-fuels.

As the FEED contractor, ANDRITZ will refine the carbon capture plant

concept and prepare the design documentation as a basis for the joint venture’s final investment decision. The concept will place a focus on the optimal integration of the carbon capture process into the waste-to-energy plant to maximise the utilisation of available heat and the reuse of residues in a closed loop.

The joint venture plans to decide on the implementation of the project in early 2025.

The carbon captured at

Low Carbon has announced its plans to grow its presence in Germany, with an initial solar pipeline of more than 400 MW and the potential to develop a significant portfolio of renewable assets. The first project, Weißholz (Whitewood) solar farm, located in the state of

Brandenburg in Wusterhausen, is expected to enter construction in 2025 and will have a peak capacity of 63 MW, with an expected production of 69 GWh. Once operational, it will avoid more than 35,000 tonnes of CO2 emissions per annum and could power the

equivalent of approximately 40,000 homes.

The project recently received municipality approval, marking a key milestone in its development, and now awaits the completion of environmental mapping and zoning changes.

Westenergy’s plant would be supplied to a power-to-x plant planned to be built in Kristinestad, Finland, to produce synthetic e-fuel from green hydrogen and carbon dioxide. ANDRITZ also provided the FEED for the green hydrogen plant for the Kristinestad project. More information: www.andritz.com

In addition to the initial development pipeline of solar capacity, Low Carbon is actively exploring opportunities in wind and storage projects as it aims to expand its renewables portfolio in Germany. More information: www.lowcarbon.com

ANGI Energy Systems, a Vontier (NYSE: VNT) business and leading provider of sustainable biogas and biomethane compression and decompression solutions has announced its expansion into Europe. This expansion leverages ANGI’s extensive North American experience to bring its industryleading technology to a new market and builds upon its already wellestablished reputation for expertise in the field of compressed natural gas (CNG) compression in Europe.

Over the last 40 years, ANGI has become North America’s leading supplier of complete systems for CNG, biomethane and, most recently, hydrogen. Its dedicated biomethane business offers a wide range of highly engineered solutions to support diverse use cases, with compression solutions tailored to biomethane anaerobic digestion capacities of between 37 kW and 300 kW, and experience extending to projects as large as 746 kW. The resulting clean, pipeline-quality biomethane

can be used to serve a wide range of applications, from home energy to commercial transportation. “The European biomethane market is on an exciting growth trajectory as the region wakes up to what is a sustainable

and low carbon fuel with a massively diverse range of applications,” said Peter Crowe, European Sales Manager for ANGI.

The company’s European biomethane business will leverage

On 6 August, the European Investment Bank (EIB) and Matrix Renewables have signed a €50 million green loan to support the design, construction and operation of five solar photovoltaic plants with an installed capacity of 240 MW located in the regions of Castilla y Leon and Extremadura in Spain. Matrix Renewables is a global renewable energy platform backed by TPG Rise. The financing operation contributes to consolidate the EIB’s position as the EU climate bank aiming to meet the objective of supporting €1 trillion in green investment in the critical decade to 2030 and committing at least half

of its annual financing to climate action and sustainability.

“With this operation, the EIB continues to accelerate the energy transition in Spain by increasing renewable energy generation capacity,” said Alessandro Izzo, EIB Director of Equity, Growth Capital and Project Finance. “The project is also part of the EIB contribution to a more sustainable and independent energy model for Europe.”

The new photovoltaic plants are in cohesion regions, where per capita income is lower than EU average, underlining the EIB’s commitment to economic growth and convergence among regions. It is expected

that the new plants will be fully operational by the end of 2025.

The project supports the decarbonisation objectives of the European Green Deal and is also part of the EIB’s action plan to support REPowerEU, the EU plan designed to end dependence on fossil fuel imports by increasing energy efficiency and ramping up production from renewables.

Nicolás Navas, Matrix Renewables CFO, confirmed: “We are thrilled to partner with the EIB in this significant project that not only advances our mission of sustainable energy development, but also contributes to Spain’s and Europe’s

sister company Gilbarco Veeder-Root’s Salzkotten, Germany, and Basildon, United Kingdom, regional facilities to serve the EU and UK markets. More information: www.angienergy.com

broader energy transition goals. This project highlights Matrix’s commitment to innovation and sustainability. The development of these new solar plants will provide clean energy to thousands of homes and businesses, reinforcing our dedication to creating a greener future”.

The project is supported by InvestEU, the EU flagship programme to mobilise more than €372 billion of additional investment from public and private sector funds to support EU policy goals in the period 2021-27.

More information: www.eib.org

On 20 June, Sunmaxx PVT, a leading developer and manufacturer of photovoltaic-thermal solar modules, and Oxford PV, a producer of high-efficiency tandem solar cells, announced the launch of ‘Solar Hammer’, the most innovative solar PVT module to date. This partnership marks the first use of perovskiteon-silicon tandem solar cells in a photovoltaic thermal module, enabling a very high conversion efficiency. Both the cells and the modules are produced in Germany. Sunmaxx’s PVT modules combine proven thermal management technology from the automotive industry with photovoltaics, leading to a total conversion efficiency of 80%, certified by Fraunhofer ISE.

Oxford PV’s perovskite-on-silicon tandem solar cells have broken multiple records for conversion efficiency at the cell level and were

recently used to create the world’s most efficient full-size tandem module so far, with 25% efficiency also certified by Fraunhofer ISE. In combination, these technologies enable more usable electricity and heat to be generated from the sun’s energy, meaning the ‘Solar Hammer’

modules will be well-suited for complete decarbonisation. The new module comes at a record efficiency of 26.6% electrical and 53.4% thermal efficiency, totalling 80% overall efficiency on aperture area level of 1.63 sq m. The electrical power of the module with 6x10 M6

cells is 433 W, surpassing the previous record of Fraunhofer ISE.

With all major components produced in Germany, the ‘Solar Hammer’ represents a step forward to increasing European competitiveness in solar PV technologies. PVT and especially perovskite-onsilicon cells are undergoing rapid technological development worldwide due to their potential for efficiency breakthroughs. The use of both technologies in a single module marks an important benchmark toward their broader deployment. The technology will be commercialised in the next 12 to 18 months. Oxford PV will supply the cells from their manufacturing line in Brandenburg an der Havel, while Sunmaxx will produce the “Solar Hammer” modules at their 50MW factory in Ottendorf-Okrilla. More information: www.sunmaxxsolar.com

Koehler Paper and Badische Stahlwerke (BSW), a steel producer, have teamed up with the Rhine port of Kehl to study the feasibility of harvesting wind energy at the port facilities. They hope to find out if building wind turbines is a feasible solution to supplying their own energy at the companies’ sites in Kehl.

Energy costs in Germany have risen drastically in the last two years – a huge challenge for energy-intensive companies such as Koehler Paper and Badische Stahlwerke, especially given the intense international competition faced by both companies. At the same time, both companies need to source a significant quantity of electricity from renewables to meet the climate goals of the German national government and the government of the state of Baden-Württemberg, as well as the self-imposed climate goals of the companies themselves. To meet these challenges head on, the two companies have launched a joint feasibility study for wind energy in

co-operation with the Port of Kehl Administration. The objective of the study is to find out whether a wind power plant can be constructed at the facilities of the Rhine port of Kehl to supply the operational energy required by the two companies.

Koehler Renewable Energy and Ökostromgruppe Freiburg, a green-

energy company, will provide support for the project. A species protection assessment and an environmental impact study have already been commissioned. The feasibility study also includes an analysis of noise emissions and economic viability. It is scheduled to last through the Summer of 2025 and should indicate

whether the site is suitable for wind turbines. If the results are positive, Ökostromgruppe Freiburg and Koehler Renewable Energy expect to submit an application for the construction of a wind power plant by the end of that year.

More information: www.koehlerpaper.com

The output of the plant, which has two 530 kW CHP units, covers the energy requirements of the biogas plant and is able to power both the facility itself and the sewage treatment plant. Excess energy is exported to the electricity grid.

The plant has a processing capacity of 33,000 tons of organic waste from food processors and restaurants to generate around 7,500,000 kW hours

of energy per year. Accepted waste includes fats, oils, brewery and dairy residues, fruit and vegetables, which are fed into stainless steel containers. The plant has already won prestigious awards for its technology: These include the Premier‘s Sustainability Award for leading innovation and practice in Victoria and the Banksia Award for Leading in the Circular Economy.

At the start of modernisation, the tanks will be completely emptied. In

addition, the roofs of the two 3,573 cubic metre stainless steel fermenters and internal plant components such as the agitator technology will be replaced. The plant will then be commissioned and operational management will be secured. The digester contents will be temporarily stored in the storage tank and material can be filled back into the tanks after the refurbishment so the plant can be up and running quickly. This saves

A leading green tech company that converts municipal solid waste (MSW) to fuel, WastAway, has launched a bold, modern new logo that positions the company for future growth in the waste-to-fuel revolution.

The logo, featuring three chasing arrows, is a powerful representation of recycling. Each arrow twists and turns, evoking the continuous pursuit of recycling, grinding, shredding and separating in its unique way. They signify crucial steps in the recycling process, forming a closed loop. This

loop is the DNA of WastAway’s commitment to sustainability, green technology, clean fuel and environmental responsibility. A vibrant gray-to-green palette accentuates the recycling story by highlighting the transformational

change of converting waste to clean, renewable energy, which is the company’s vision. The WastAway website has also been updated with this new logo design.

The company is poised for explosive growth in the coming years. Two major plants that turn MSW into fuel are set for construction this year. One in Murfreesboro is based in an industrial area of the city’s South Side and diverts 85% of the city’s trash from the Middle Point Landfill. The second is in Kern County,

resources and costs. In addition, it is easier to restart the biological process when the fermented material is immediately available.

Last but not least, the processes also comply with occupational safety requirements, which are a high priority in Australia – especially when emptying and filling the tanks. Weltec will also provide on-site staff training.

More information: www.weltec-biopower.com

California, near Bakersfield. It too will divert 85% of the waste, processing it into renewable fuel and other useful products. The two plants will cost an estimated $150 million to build and will process 400 tons of MSW a day each.

That’s the carbon equivalent of removing 96,000 cars from the highway, eliminating 866 billion pounds of carbon from the air and adding 517,000 acres of forest land producing clean oxygen each year.

More information: www.wastaway.com

Honeywell and the DTEK Group, Ukraine’s largest private energy company, have announced a new strategic agreement. The companies will work together to advance Ukraine’s energy independence, automation and transition to renewable energy sources. The agreement, which deepens a longstanding collaboration between the companies, underscores a shared commitment to building energy infrastructure advancement and resilience in response to the war in Ukraine.

The memorandum for strategic collaboration provides a framework to enable the companies to help strengthen Ukraine’s energy generation, expand DTEK’s battery storage capabilities and implement advanced modular refining and gas processing solutions. The memorandum also addresses Ukraine’s long-term energy transition, focusing on optimising production and decarbonisation.

Honeywell and DTEK’s collaboration in Ukraine goes back to May, 2021, when the

companies launched Ukraine’s first energy storage system in Energodar. The announcement underscores both companies’ commitment to extending the resilience of Ukraine’s energy sector, during the ongoing conflict and for the long-term.

The agreement was signed by Maxim Timchenko, DTEK CEO and Przemek Szuder, President Central and Eastern Europe, Honeywell, in the presence of Geoffrey Pyatt, Assistant Secretary of State for Energy Resources at the US

Department of State.

Under the terms of the memorandum, DTEK and Honeywell agreed to explore opportunities for:

The fast-track restoration and maximisation of DTEK’s energy generation capabilities that have been damaged in Russian attacks on Ukraine’s energy infrastructure; deployment of Honeywell’s battery energy storage systems; and deployment of Honeywell’s advanced modular refining and modular gas processing solutions.

The companies will also work

together on supporting DTEK’s overall long-term energy transition strategy by offering solutions to optimise and decarbonise energy production.

Honeywell will support DTEK in assessing Ukraine’s critical energy requirements and provide recommendations to fast-track the maximisation of the country’s infrastructure, including opportunities to deploy its Battery Energy Storage System (BESS) technology alongside DTEK’s existing battery storage assets. More information: www.honeywell.com

Goldbeck Solar has been contracted to build the Kabeljauwbeek ground-mounted solar plant in the municipality of Woensdrecht, The Netherlands. With around 88,000 solar modules, the solar park will be embedded in a wind farm and generate around 44,500 MWh of green electricity per year.

The construction of the solar park with an output of 51 MWp began in March and is scheduled for completion by the end of 2024. The plant will be located in Nieuwe Dijk, Ossendrecht, directly on the border between The Netherlands and Belgium, which once again underlines the international nature of renewable energies. With an

expected annual energy yield of 44,500 MWh, the solar park will supply the equivalent of the power use of around 15,000 households and thus make a significant

contribution to sustainable energy generation in the region. Due to the proximity to the wind farm, existing grid connections can be used and grid overloads avoided.

However, existing supply lines within the construction site posed a challenge when planning the solar park. A detailed 3D visualisation of the entire construction site was therefore carried out. For example, some areas will be able to be dismantled in order to be prepared for possible assembly work on the windmills. With the help of precise 3D planning, it was possible to ensure that all factors were taken into account, so that construction could proceed smoothly. Native foliage will also be planted on the North and West sides of the park to attract insects and thus benefit birds and small mammals.

More information: www.goldbecksolar.com

The PowerCell Group has received an Approval in Principle (AiP) from Den Norske Veritas (DNV) for a new Methanol-to-Power solution. This solution has a fully-integrated methanol reformer from RIX Industries combined with the newly launched PowerCell Marine System 225. The complete product solution can offer a significant step in the maritime industry’s transition to cleaner energy.

Methanol is emerging as one additional fuel to hydrogen to support maritime decarbonisation and electrification since it is already available in most of the world’s large harbours. The use of methanol

can increase the availability of hydrogen for marine electrification. Therefore, PowerCell and RIX Industries have developed an integrated power system solution that reforms methanol into hydrogen used in a fuel cell, offering a clean, efficient energy source. This joint system simplifies integration, enhances safety and meets the marine industry’s needs.

“The Methanol-to-Power solution follows our ‘Industrialised Innovation’ strategy,” said Richard Berkling, CEO of PowerCell Group. “The strategy integrates our industrialised fuel cell components to generate higher value for our customers by minimising time-to-

market, technical risk and technical investment for customers that are pioneering marine electrification and decarbonisation. We continue to drive value-creation for marine customers beyond having the best marine fuel cells. PowerCell works with industry leaders towards the maritime industry’s transition, with technology that simplifies bunkering, integration and commissioning.”

Dr Andreas Bodén, SVP & CTO of PowerCell Group, added: “Our collaboration with RIX Industries has optimised our technologies for greater efficiency and safety. This AiP from DNV confirms that we are on the right path”.

NextEnergy Capital (NEC), a leading global renewables manager focussed on the solar+ infrastructure sector, has announced that its latest international OECD Fund, NextPower V ESG (NPV ESG), has entered into a binding agreement to acquire a 248 MW portfolio of 12 solar PV projects in North-Eastern Spain. This portfolio marks the fourth investment that the Fund has made. The announcement came just after the recent closing of a long-term debt financing for an operational portfolio managed by NPV ESG’s predecessor Fund NextPower III ESG in the same region. This transaction for NPV ESG follows the recent acquisitions of a 100 MW solar project in the USA, as well as two operational CfD portfolios of 50 MW and 66 MW in Europe.

NPV ESG’s portfolio has been significantly built out during the last six months, with 348MW in construction, 116 MW in operations and over 500 MW in exclusivity or advanced negotiation. Since

Bryan Reid, CSO of RIX Industries, stated: “RIX is proud to partner with PowerCell in bringing this new and novel technology to market, empowering early adopters to lead the charge in decarbonising the marine industry. These power systems directly address our customers’ needs for increased energy density and simplified integration, enabling the immediate deployment of Net Zero solutions”.

This approval underscores the system’s design is in line with safety standards, paving the way for sustainable maritime operations. More information: www.powercellgroup.com

the launch of NPV ESG, NEC has evaluated over 88 GW of pipeline with 18 GW of highquality, attractive investment opportunities identified for more detailed evaluation.

To date, NPV ESG has secured $745 million (including $150 million for co-investments) in total commitments with investors ranging from a UK LGPS investment pool and a Dutch pension fund, alongside re-ups from existing NextPower III ESG investors, including KLP, a German occupational pension fund, and a large Nordic pension fund. NextEnergy Capital continues to build on its positive fundraising momentum with a number of investors around the globe currently in due diligence and the team continues to work towards NPV ESG’s target of $1.5 billion.

More information from: www.nextenergycapital.com

The electrification of businesses is a pivotal step towards achieving net-zero carbon emissions. As the demand for new and upgraded grid connections surges, along with the integration of renewable energy sources like solar photovoltaics (PV), onshore wind and battery energy storage systems (BESS), the need for an efficient, reliable and client-centric grid connection service has never been more critical.

Independent Distribution Network Operator (IDNO) Vattenfall, a key player in the UK’s energy landscape, is dedicated to electrifying businesses and facilitating the transition to a low-carbon economy. Through its Grid Connections Consultancy, Vattenfall IDNO offers a comprehensive suite of grid connection services tailored to meet the diverse needs of businesses seeking new, or larger, grid connections for their operations. Whether it’s navigating complex regulatory frameworks or optimising the design of a grid connection, these

approach is its emphasis on value engineering. By leveraging more than a century of grid infrastructure and management expertise, and cutting-edge R&D, the company works with its clients to deliver innovative solutions that maximise efficiency and minimise costs. This commitment to value engineering not only accelerates the grid connection process, but also enables businesses to unlock significant savings, making the transition to renewable energy more economically viable.

responsiveness, ensuring that clients’ needs are met every step of the way. For example, this is a quote from an Ideal Customer Profile client:

“When choosing to select an IDNO partner there are intangible factors to consider other than simply the AAV on offer. I really appreciate that I’m able to pick up the phone to you, get clear answers to e-mails and your general ‘can-do’ attitude. It’s a real pleasure to work with you!”

are vital for the transition to net zero. This collaborative approach is essential for accelerating the development of the UK grid, which needs significant development. UK electricity consumption is predicted to triple from roughly 300 TWh today to around 900 TWh by 2050, so it is essential that IDNOs are able to support the DNOs as much as possible.

By taking responsibility for electrical grid infrastructure and connections, and developing, owning and managing primary substations, switchgear and other essential electrical assets, Vattenfall IDNO allows Distribution Network Operators (DNOs) to focus on essential grid upgrades that

By providing businesses and renewable energy projects with the support, resources and expertise they need to integrate into the electrical grid, Vattenfall IDNO is accelerating the transition to net zero in the UK, one connection at a time.

More information: www.vattenfall.com

consultancy services streamline the connection process, ensuring swift and hassle-free integration into the electrical grid. One of the key features of

Vattenfall IDNO’s competitive Asset Adoption Value payments provide businesses with a compelling commercial incentive to partner with it, thus reducing overall project costs. By offering attractive financial incentives for adopting and maintaining assets, it ensures that businesses are rewarded for their contributions to the development of the UK grid. This collaborative approach not only benefits individual businesses and project developers, but also strengthens the overall stability of the energy network, paving the way for a more sustainable future.

Central to Vattenfall IDNO’s mission is its unwavering commitment to client-focused collaboration. From initial consultation

and energisation, it prioritises open communication, transparency

IDNO’s mission is its to project implementation and energisation, communication, transparency and

Vattenfall.

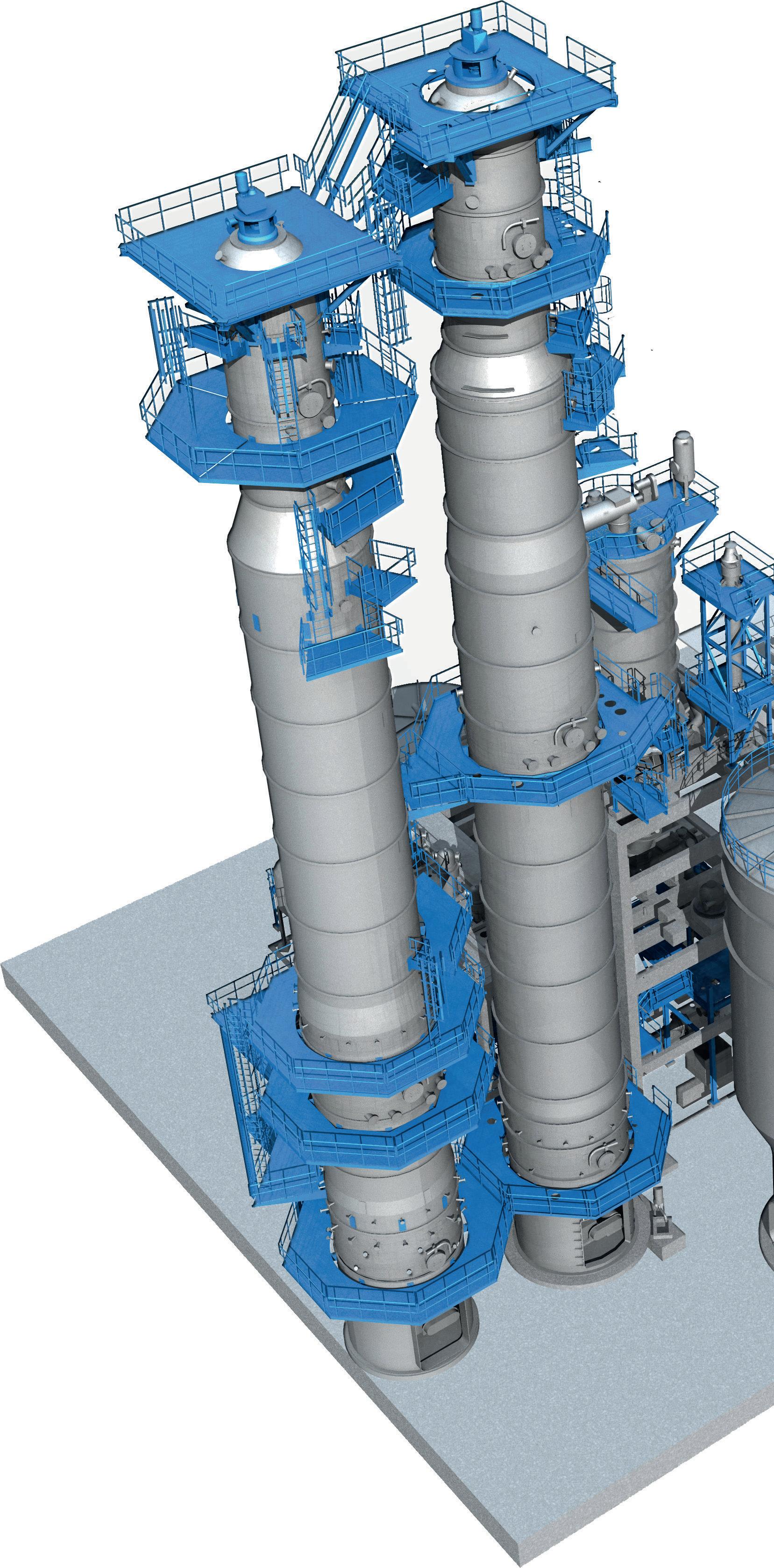

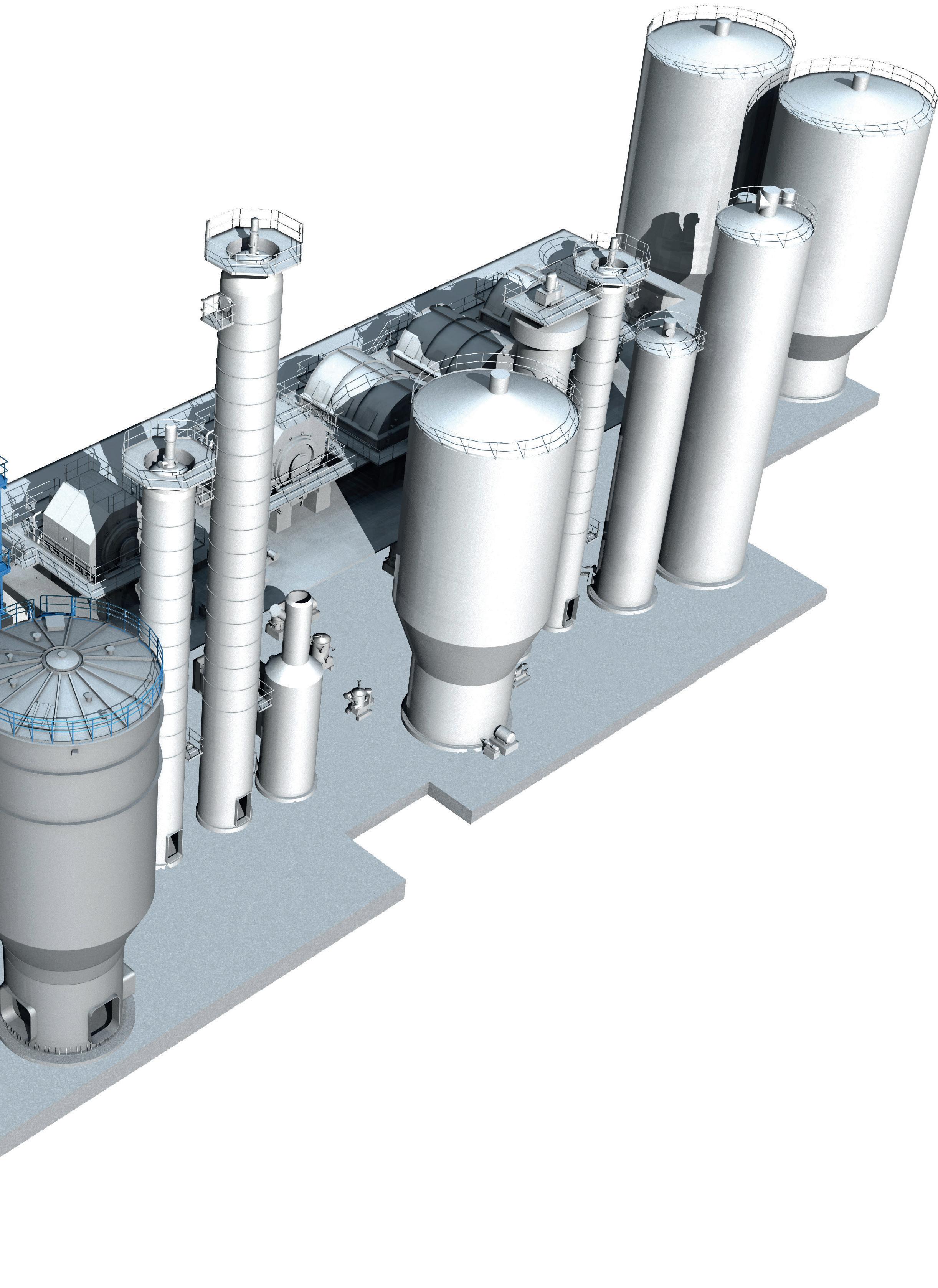

Textiles made from cellulose fibres are becoming more and more important as the world rapidly moves away from fossil fuel-derived products and seeks more environmentally-friendly raw materials. ANDRITZ has developed the A-ConFlex™ continuous cooking method for bleached dissolving pulp production to make it easy for pulp producers to switch between dissolving pulp and kraft pulp according to market demand.

ANDRITZ has made it easy for pulp producers to switch between producing kraft and dissolving pulp, but it is by no means a simple process. There are major differences between the two pulps when it comes to qualities and production processes. However, with the A-ConFlex concept, ANDRITZ has taken a complex challenge and transformed it into a user-friendly and reliable solution.

The A-ConFlex is the only potential system available on the market for continuous dissolving pulp production and is already a proven technology with ten systems delivered to ANDRITZ customers around the world.

Key changes to a kraft mill fibreline

There are a number of differences in the production of kraft pulp and dissolving pulp. Viscosity is the main difference as it needs to be much lower in dissolving pulp than in kraft pulp. Another difference is that the pulp needs to be much cleaner. All hemicellulose has to be removed along with all traces of metals and impurities such as sand. The third main difference is that the liquid supply needs to be changed to purified water to ensure purity of the final pulp.

“Basically the quality of the dissolving pulp needs to be at a much higher quality level, when compared to kraft pulp,” said Michael Bloder, Head of Product and Technology Management, Wet End, ANDRITZ.

To address these differences, a number of adaptations need to be made on a kraft pulp fibreline to enable the production of dissolving pulp. Sampsa Laakso, Technology Manager, Fibreline Cooking, explained, “The most important change to the fibreline is

the installation of a pre-hydrolysis vessel before the digester; this is for the removal of hemicellulose. This is carried out by adding steam and heat to the chips with the reaction then hydrolysing the hemicellulose”.

When it comes to lowering the viscosity, the process has been adapted to reduce the level by up to half at the oxygen delignification stage. Taneli Alajoutsijärvi, Technology Specialist, Fibreline Washing and Bleaching, ANDRITZ, said, “In dissolving pulp we want to have a low viscosity, around 400500 ml/g, whereas in kraft pulp we want as high viscosity as possible, around 800-850 ml/g. So, we have to significantly reduce the viscosity levels. This we do in various ways on the fibreline, including the possibility of introducing an ozone stage, which gives more flexibility to the control of viscosity.

“The viscosity issue is very important, as if it is too high, the dissolvability of the pulp is reduced.”

ANDRITZ DD-Washers in the fibreline are also put to good use in the production of dissolving pulp; Alajoutsijärvi added, “Production rates are higher for kraft pulp and lower when it comes to producing dissolving pulp, so we use DDWashers more efficiently by adding more washing stages for dissolving pulp production. For example, there can be two washing stages per DD-Washer for kraft and three for dissolving pulp due to the lower production level. These changes can be flexible according to quality parameters and are carried out by the operators on the run”.

Adaptions to the drying line When it comes to pulp drying, the majority of the drying machine remains unchanged, with just some minor adaptions. The main difference is that the drainability is far higher as the dissolving pulp is

cooked longer and does not hold as much water as in the kraft process. Also, adaptations can be made to ensure that the pulp is as clean as

possible with minimised traces of metals or foreign particles such as sand.

“The biggest change we need to

make in the drying area is to replace the post screening installed for the kraft process, with a pure cleaner plant to ensure that silicates and any other heavy impurities are removed,” said Bloder. “The cleaner plant removes heavy particles such as sand and silicates in a very efficient way.”

Cleanliness of the pulp before drying is further ensured by adding a hot shower in the forming section, as well as a final berol surfactant spray. Bloder explained, “In kraft pulp

production, we usually add steam to the pulp to heat it up in the forming section. However, when switching to dissolving pulp, we usually add a hot water shower instead, again to make sure that remaining metals such as magnesium and calcium can be removed properly.”

Just before the sheet enters the dryer, a berol spray is added that produces a chemical reaction with the fibre itself. This is important when it comes to the production process of

dissolving pulp end-user products. Due to the changes in properties and conditions when operating with dissolving pulp, the risk of creating dust increases. The dryer is designed for minimal dust creation, including, for example, the blow boxes, which are from the beginning designed and manufactured for optimal performance and runability for different types of fibres. When it comes to the bale finishing, the duo wrapper is usually

replaced or bypassed and a so-called ‘paper wrapper’ is installed.

Making the switch without stopping the line

Once the pre-hydrolysis vessel is heated, and chip feeding and transfer lines are in dissolving mode, the switch from producing kraft pulp to producing top quality dissolving pulp takes place. The time taken during this part of the process is dependent on the grade of dissolving pulp required. “First, we fill up the pre-hydrolysis vessel with chips while making room in the digester,” said Laakso. “Pre-hydrolysis chip filling is the only time when the digester blowline is closed. After the prehydrolysis vessel is full of chips, we then start transferring the chips to the digester. At the same time the digester blowline is opened again. It depends on the digester size, but normally it takes a couple of hours before dissolving pulp comes out of the digester.”

Alajoutsijärvi continued, “Transition from the cooking plant drying machine takes about 24 hours. It takes some time to fine-tune the process to meet the prime quality properties of the dissolving pulp. However, with the A-ConFlex concept, you can continuously control the reaction degree of the hemicellulose hydrolysis, adjust the viscosity of the pulp and ensure cleanliness of the pulp to meet the highest criteria of dissolving pulp, such as Lyocell grade, which can be produced with the ANDRITZ concept”.

When it comes to drying, there are only minor adjustments to be carried out. Bloder confirmed, “In the pulp drying area, there are only small adjustments, such as adapting the production and basis weight, to be made, which are usually done within the few hours before the dissolving pulp arrives in the pulp drying area.

“This is not a totally easy process, but with the A-ConFlex technology we have developed a solution that works really well,” concluded Alajoutsijärvi. “Most importantly, we can continuously make a change from kraft to dissolving pulp and back, without stopping the process.”

More information: www.andritz.com

By Peter Cura

The green transition creates sustainability challenges for the fibre-related industry. How can we use coinnovation to tackle these challenges?

Pulp, paper and board companies, and other fibre-based businesses, are under increasing pressure to improve the sustainability of their operations and products, both from their customers and regulators. To meet these demands, companies need to invest in new, more efficient and lower carbon solutions. The markets, which are changing ever faster, provide favourable conditions for the emergence of new and disruptive technologies. At Valmet Customer Days 2023, Sampo Immonen, Director, Line R&D, Board and Paper Mills, Valmet, explained how disruptive co-innovation can help

create solutions that support the green transition.

innovation?

A disruptive development is a big jump in technology that changes the way we do things. It’s not an iterative development, it’s something completely new. “There’s a quote from the business professor, Oren Harari, which illustrates the idea very well,” said Immonen. “The electric light did not come from the continuous improvement of candles. While continuous improvement is always important, a disruptive development is needed every now and then to take humankind forward.”

Co-innovation is a method of co-operating with partners, such as research institutes, companies and experts in a network, to create and develop new ideas, processes, services and products together. When you put disruptive development and co-innovation together, you get disruptive co-innovation, which is a co-operative way of seeking out and developing innovations that have the potential to transform an industry.

Simple ideas and the ripple effect

“Many times, big innovations are rather simple in the end, you just have to make them happen,” said Immonen. “One example of this is

Valmet’s newly developed Sleeve roll technology. Basically, it’s a prepressing technology that presses the water out in the forming section, instead of using vacuum for the dewatering. In the end, it’s a really simple idea. Originally, we were aiming to improve energy efficiency, but we noticed a kind of ripple effect. A ripple effect is when other things happen due to the innovation that you didn’t expect in the beginning and it’s often associated with disruptive development.

“For example, we noticed that the new Sleeve roll technology didn’t only increase the energy efficiency of the process, but it also improved the machine capacity,” Immonen added.

“Traditionally, in the forming section, the faster you run, the relatively harder it is to dewater. With our Sleeve roll this old truth about dewatering is ready to retire. The faster you run, the more water you remove, giving us flexibility on the capacity side. We also found that it improved the strength properties in the board and, at the other end of the machine, it has resulted in higher winder capacity. Again, things we weren’t expecting.

It has also turned out that the technology is very flexible and during different pilot trials, we have noticed that the technology fits with pretty much any concept we have.”

When there’s uncertainty and change in a market, it creates more need and opportunity for innovations.

“Before about 2010, the market was calm – sure, there were faster, wider machines, but the basic products and principles stayed pretty much the same,” stated Immonen. “Since then, there have been big changes led by the market, by the decline in the paper business and by the shifted dynamics in the industry. Now customers are more sustainability-oriented, and legislation and all the mega trends are pushing towards change. This means that more money is being invested and more technological innovation is happening.”

The changes in the market will also impact market entry barriers.

“Our industry – at least part of the industry – is clearly moving to a market state where both the market and the technology are leading change. This is creating new blue oceans for the industry and traditional entry barriers are disappearing,” Immonen continued.

“I asked the audience at the Valmet Customer Days how they thought the market entry barriers for emerging new technologies in the fibre-based industry will change in the future. Over half of the respondents thought that the barrier will lower in the future.”

“Time is a very important topic when we talk about disruptive development and fast market change,” Immonen explained. “Typically, if you move fast, it means you take a bigger risk at the beginning and invest more money in R&D. However, the benefit is that if you hit your target, you have the possibility to grow much faster than either medium risk or safe investments. If you’re first, it can determine your market position after the early phases of R&D and technical development.

“On the other hand, being first is not an easy choice to make – you

don’t always win,” he added. “When you are first, you are more likely to also make the inevitable mistakes and these always cost money. Copycats will learn from your mistakes and try to get around your patents and ideas. In the end, the big question is whether you came up with the right solution or not. You cannot know at the start and someone might come up with a better solution. However, it is good to remember that the majority of the world’s largest companies have reached their status by excelling in embracing the disruptive elements of innovation and pushing the boundaries forward. Being first is not easy, but it undoubtedly holds potential for great value.”

The benefits of co-innovation “We have a disruptive co-innovation project together with Metsä Spring and an extensive co-operation network of partners. In this project, we are creating the next leap forward in the area of molded fire technology,” Immonen said. “Why did we decide to tackle this beast with the method of co-innovation? Typically, in our industry a big development project from cradle to industrial scale takes from ten to 17 years. That’s much too slow in a fast-moving market like molded fiber. When we looked at the market and business potential for our solution – Valmet 3D Fibre – we knew we had to hit a full development time of five to six years. That’s a challenging time frame. With co-innovation, we have an R&D partner network that gives us access to the best and most capable minds, we get capabilities that we don’t have to develop from scratch, and because everyone already knows what they’re doing in their own field, progress is much faster and we can mitigate risks and get through the required development steps faster.

“With this approach, we’ve been able to shorten the timeframe for development to one third of what it normally would have been and with this we’re enabling the disruptive innovation to happen and letting the ripple effect come to be – hopefully revealing benefits we didn’t even expect in the beginning,” Immonen concluded.

More information: www.valmet.com

The appointment of Tom Sater as the RO Group’s new Head of Energy was recently announced. In his new role, Tom will be based at the company’s Potters Bar office and will work across the Group’s extensive land and property portfolio, as climate change challenges business operations and how we consume resources, but also offers significant opportunities.

Tom brings a wealth of experience to the RO Group, having previously served as a Commercial Manager at Clean Energy Capital in London, where he led and supported on numerous contract negotiations for solar PV developments, individually ranging from £10-£50 million in potential lifetime revenues.

He also led on hydrogen development projects for the deployment of private wire solar PV and supported development of commercial methodologies. This experience will allow Tom to build on the RO’s history in large scale groundmounted solar developments.

While at Clean Energy Capital, Tom led and evaluated land acquisitions for 500+ acres of solar PV development. He is also adept at

financial evaluation of commercial and data models, including cash flows and generation profiles.

Tom graduated with a distinction from the University of Exeter with an MSc in Renewable Energy Engineering. He previously worked in the insurance industry and founded an online retail platform for desktop 3D printers.

Edward Rowlandson, Group Managing Director, commented: “In 2022, we established RO Energy as a nascent generation business, with a 5MW solar development on our 140 acre farm on the Western edge of Milton Keynes. Building on the success of the project, further sites are being considered as we aim to build a portfolio of generating assets. Tom is the perfect candidate to lead those efforts.

“Since his graduation, Tom has made significant achievements in the fields of clean energy specifically, and engineering more generally. He has not only built up deep experience in solar PV developments, but has a wide understanding of the UK’s commercial property ecosystem; experience that also dovetails with our organisation’s activities at large.”

More information: www.rogroup.co.uk

European Pellet Conference 2024: As a CO2-neutral fuel, sustainable bioenergy is a key component in the energy transition. Over 400 experts discussed this and more on 6 March 2024 in Wels/Austria at the meeting place for the global pellet community.

The last few years have been challenging for the pellets industry: the sustainability discussions at European level and in some Member States, market fluctuations and supply chain issues were some of the topics.

The European Pellet Conference 2024 showed how we can increase the acceptance of pellets as an important element in the clean energy transition and the positive contribution of pellets to the circular economy. It highlighted latest trends in markets, policies, technologies and innovations, helping the participants stay on top of developments in the pellet and bioenergy world. Cuttingedge developments and R&D results in the pellet and bioenergy sectors were showcased. Also, international experts offered updates and outlooks on pellet markets around the globe.

The European Pellet Conference offers a compact and comprehensive package including the Young Biomass Researchers Conference, a poster presentation, valuable networking opportunities and a major tradeshow on energy efficiency with a strong focus on pellet-related exhibitors (the "Energiesparmesse").

The event is part of the World Sustainable Energy Days (WSED) – an international conference on the energy transition and global climate neutrality with over 650 experts from more than 60 countries each year. The WSED is organised by the OÖ Energiesparverband, the energy agency of the Region of Upper Austria.

The next edition of the event will be held on 5 March 2025 in Wels/Austria. The deadline for the Call for Papers & Speakers (also for the Young Biomass Researchers Conference) is 10 October 2024. For more information: www.wsed.at