Review & PIM Renewable Energy

The pulp and paper industries play a key role in the transition and transformation towards a fossil-fuel free circular bioeconomy. By developing circular operations to eliminate unused side streams, and creating new value-added bio-based products, it can be the global leader in zero emissions and zero waste industrial processes.

CircleToZero brings together the continuous development and improvement of existing ANDRITZ technology solutions to achieve this leadership position with clear environmental and financial benefits.

Our shared journey towards zero emissions and zero waste has already started.

Having now completed this year’s re-registration process, welcome to the Autumn issue of Forest Bioenergy Review and PIM Renewable Energy. We have to thank all our readers who took the time to confirm their continued wish to receive the magazine.

We also have to welcome our newly-registered readers, who have joined us in the past 12 months, and look forward to continue providing the news and articles for which we have become respected. In the Winter issue, we will also be able to update you on the schedule of topics selected for inclusion next year and the specific areas that we have been asked to cover.

As many will have seen in the news recently, energy and the need to reduce reliance on fossil fuels was emphasised by the UK’s £500 million support for Tata Steel’s Port Talbot steelworks in South Wales to assist in converting the traditional, coal-fired blast furnaces to electric arc versions estimated to have a cost of £1.25 billion, but at what cost to jobs?

In a further announcement, the UK Government stated that they would push back the deadlines for selling new petrol and diesel cars, as well as phasing out gas boilers. Some will see this as a major U-turn while others will see the logic when many are facing a severe reduction in their standard of living. Another factor is that there is simply not yet the infrastructure in place for a major shift to electric vehicles.

In the Winter issue, we will be looking at solar power developments, gasification technology and geothermal power production. Contributions for the issue should be with us no later than 13 November and sent to pulppaperlogistics@virginmedia.com

Vince Maynard, Publisher

Vince Maynard, Publisher

Volume 11, Number 58 – Autumn 2023

PUBLISHER & EDITORIAL DIRECTOR

Vince Maynard

KVJ Enterprises, Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724

Mobile: +44 (0) 7747 002286

E: pulppaperlogistics@virginmedia.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687

Mobile: +44 (0) 7785 796826

E: youngeditorial1@btinternet.com

ISSN 2045-8514

REGIONAL REPRESENTATIVE

Einar Johansson

Mobile: +44 (0) 7747 002286

E: pulppaperlogistics@virginmedia.com

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011

Mobile: +44 (0) 7851 612799

E: anton_print_1@mac.com

PRINTING

Brown Knight and Truscott

Tunbridge Wells, Kent, TN2 3BW, UK

Tel: +44 (0)1892 511678

Technology leader ABB has secured its ninth contract with TOYO Engineering Corporation in Japan to supply its distributed control system (DCS), ABB Ability™ Symphony Plus, to the Wakayama Gobo Biomass Power Plant, around 120 km South of Osaka.

When operational in 20251 the 50 MW biomass power plant, which will use wood pellets and agricultural by-products as a feedstock, will be capable of supplying enough power for up to 110,000 Japanese households a year. The plant is being developed in partnership by Enewill (formerly JAG Energy), Osaka Gas and SMFL MIRAI Partners, who have employed engineering, procurement and construction (EPC) contractor TOYO to design and build the facility.

ABB’s DCS solution will deliver complete visibility of operations, enabling operators to make informed decisions in real time to help optimise production, improve processes and drive efficiencies. ABB will also deploy its Adaptive Execution™ project management methodology which utilises digitalisation to speed up delivery schedules and achieve faster

site start-up.

The new order, booked in January this year, follows ongoing collaboration between ABB and TOYO, with the company integrating its automation solutions at eight other biomass facilities being constructed across Japan.

With domestic supply of energy increasing over 4% year-on-year, Japan, previously seen as a carbon intensive country2, is investing in ways to match growth in demand with reducing its reliance on fossil

fuels. In 2022, its renewable energy output increased by 11.7%, driven primarily by solar power and biomass generation3.

“In its sixth Basic Energy Plan4, Japan’s Ministry of Economy, Trade and Industry announced a target of 8 GW for installed biomass capacity in the country by 2030, which would cover 5% of its projected power demand,” said Brandon Spencer, President of ABB Energy Industries. “The nine projects that we are involved in will deliver a

collective generation capacity of 500 MW, achieving over 6% of the government’s target and providing energy to power more than one million households.”

Japan is currently the world’s fifth largest biomass market5 and is expected to grow by 5.4% a year until 2025 and 3.7% a year through the following decade6. ABB is an established leader in the power generation market in Japan, with expertise when delivering process control systems. This, coupled with new initiatives that have been proven on other TOYO projects, made ABB the partner of choice.

More information:

www.abb.com

1. https://www.osakagas. co.jp/en/whatsnew/__icsFiles/ afieldfile/2022/05/19/220420.pdf

2. Japan 2021 – Analysis - IEA

3. FY2021 Energy Supply and Demand Report (Revised Report) (meti.go.jp) 4. 6th_outline.pdf (meti.go.jp)

5. Japan: biomass energy market size 2035 | Statista

6. Biomass in Japan: the case for small local plants | S-GE

Leading sugar producer Hungrana has recently invested in a tailormade biomass boiler to support its operations. This investment is part of Hungrana’s ongoing commitment to sustainability and re-ducing its environmental impact while increasing its production capacities.

ANDRITZ TEP d.o.o, a provider of complete power plant solutions and one of the leading Euro-pean boiler manufacturers, was chosen for the design, production, delivery, associated civil works and erection of the boiler and all related equipment.

Hungrana already operates several boilers using different biomass fuels. The new wood chips boil-er from ANDRITZ will further increase

Hungrana’s steam production capacity from renewable resources. Operating at 12 bar(g) and 220°C, it will add 32 tons of steam per hour. Thus, Hungrana is positioning itself as a leader in the industry, providing customers with high-quality products while reducing its usage of gas.

“We are excited about this investment and the positive impact it will have on our business and the environment,” said Zoltán Reng, CEO of Hungrana. “We are committed to sustainable practices and reducing our carbon footprint, and the biomass boiler is a significant step in that direction.”

More information: www.andritz.com

Ukraine’s largest private energy company, DTEK, has announced that it plans to trans-form its war-shattered electricity network in areas surrounding Kyiv by building a smart grid capable of withstanding military assault and able to accelerate Ukraine’s energy tran-sition.

The Kyiv regional power grid, which excludes the capital itself, was extensively damaged in Spring, 2022, as the invading forces advanced towards Kyiv, and again after October, 2022, when Ukraine’s civilian energy infrastructure was deliberately targeted. Moscow’s attacks are now sub-ject to separate investigations from the International Criminal Court and United Nations over pos-sible war crimes and crimes against humanity.

After Ukrainian forces liberated areas near the capital in the first months of the war, DTEK crews from around Ukraine immediately moved in to reconnect homes and businesses. Although they restored power in just 45 days, the network remains in need

of extensive repairs and major upgrades to raise it to modern European standards.

DTEK Grids, the company’s grid operating business, is, therefore, seeking EUR2.4 billion of funding in a ten-year-project to transform the region’s power infrastructure. The plans, which need to be approved by Ukraine’s Ministry of Energy, envisage building a smart grid with 20,000 km of new overhead and underground cables, 250 substations, 6,000 transformers and nearly a million

smart meters. Key advantages include:

l A resilient smart grid infrastructure that will continue to operate even when individual segments are damaged or destroyed.

l Increased usage of power produced from renewable sources.

l Digital Twin technology allowing engineers to model how the upgraded network will function.

l A flexible system enabling consumers to become contributors through ‘home-grown’ energy from

A new report from Bloomberg Intelligence (BI) has found that global wind installations could jump to about 110 gigawatts this year versus a lull of 87 GW in 2022 and that a doubledigit growth pace could be sustained in 2024-26. Nearly half of this year’s capacity additions are likely to be in China, according to BI’s Global Wind Energy Midyear Outlook, with the country’s largest turbine manufacturer, Goldwind, set to boost top-line growth 16%, based on consensus. Growth expectations are more tepid for European manufacturers Vestas, Siemens Energy and Nordex, yet BI sees potential upside to analysts’ 2024-26 numbers.

Rob Barnett, BI Senior Clean Energy Analyst, said: “Global wind additions could rebound to about 110 gigawatts in 2023 after dipping to 86 GW last year and we believe there’s scope for

that figure to soar to nearly 150-190 GW by 2027, propelled by the Inflation Reduction Act, REPowerEU and other favourable policies. Such a scenario would likely drive a significant surge in Vestas, Nordex and peers’ orders”.

According to BI, European windturbine makers’ consensus sales growth is in the doldrums compared with the International Energy Agency’s net-zero outlook, though BI sees the potential for much faster advancement. The top lines of Vestas, Siemens Energy’s renewable-energy unit and Nordex could increase by an average of about 10% a year in 2023-26. These companies expanded revenue at a compound annual rate of around 16% in 2015-21 and BI believes similar gains can be achieved in 202530, assuming net-zero goals boost demand.

Global wind installations expanded

at a compound annual rate of about 15% in 2005-21, and though that pace may stall in 2021-23 amid supplychain and permitting bottlenecks, BI believes that favourable economics and policy support could buoy 202425 growth. The IEA’s accelerated scenario calls for annual installations to climb to about 190 gigawatts by 2027.

Turbine manufacturer Vestas’ sales expanded at a compound annual rate of more than 15% in 2018-21 and though guidance calls for deliveries to fall in 2023 amid persistent supplychain bottlenecks, revenue could still climb thanks to higher turbine prices. Deliveries may also return to growth in 2024 on a solid order book. Consensus calls for the top line at the median company in BI’s peer group to increase by 7% in 2023, compared with a 7% decline in 2022.

household solar panels or even by de-charging car batteries.

DTEK Grids is planning to test the new grid concept in a three-year pilot phase across Irpin-BuchaBorodyanka, an area 15 miles from the capital that suffered now-infamous attacks after the full-scale invasion in February, 2022. The company is seeking to attract initial funding of EUR145 million for the pilot.

Announcing the plans at the Ukraine Recovery Conference in London, CEO Maxim Timchenko said: “DTEK does not seek to only rebuild what was destroyed, but to build a new power sector for Ukraine that is cleaner, innovative and more resilient. This investment will give the Kyiv region a world-class Smart Grid infrastructure that enables Ukraine’s energy transition: integrating re-newable generation and preparing Ukraine to become a major clean energy hub for the European Union”. More information: www.dtek.com

Most segments in the wind-supply chain, including turbine production, could benefit from passing elevated costs on to consumers. In BI’s view, equipment manufacturers and project developers (excluding turbine OEMs) may report sales gains of about 10% in 2023. That figure is likely to rise in line with strong, policy-driven demand.

Rob Barnett, BI Senior Clean Energy Analyst, added: “Profit margins at Vestas, Nordex and peers could improve this year on sustained easing of steel costs, which have fallen more than 50% since running up to a peak in 2022. Though European steel prices are about 40% above their pre-pandemic level, they’ve declined significantly since Russia invaded Ukraine, which is likely to set the stage for a profit recovery at Europe’s main turbine manufacturers Vestas and Nordex. Rival Siemens Energy has been hamstrung by operational issues and warranty provisions, but lower steel prices could also help to lift margin once those issues are resolved”.

More information:

www.bloomberg.com

Agroup of bioenergy experts has welcomed the government’s new UK Biomass Strategy, but says urgent action is now vital to shape its ambitions into deliverable policies.

Researchers at the Supergen Bioenergy Hub – led by Aston University – worked closely with government departments to provide scientific evidence to inform the strategy, which outlines the role biomass will play in supporting the UK’s transition to net zero and how this will be achieved.

Professor Patricia Thornley, who leads the Hub, said: “This is a comprehensive and considered biomass strategy that, rightly, places sustainability at the heart of UK bioenergy development. The challenge is now to produce actions that can deliver the sustainable system of biomass required to achieve net zero”.

Sustainability is a major theme within the new strategy. It includes a review of how existing sustainability policies could be improved, as well as a commitment to developing a crosssectoral sustainability framework (subject to consultation) to ensure sustainability across the many different applications of biomass. This

follows previous work led by Dr Mirjam Rӧder, Systems Topic Group Lead in the Supergen Bioenergy Hub, calling for harmonised sustainability standards across different biomass applications, which is referenced in the strategy.

Dr Rӧder added, “We need rigorous approaches to sustainability governance that go beyond emissions. Considering wider environmental, social and economic trade-offs is essential for true sustainability and building trust in bioenergy projects”.

The strategy considers the amount of biomass resource that might be available to the UK in the future, highlighting the importance of both imported and domesticallyproduced biomass resources. Professor Thornley commented: “It is important that the strategy recognises the potential of imported as well as indigenous biomass in achieving global greenhouse gas reductions. Sustainable systems should grow, convert and use biomass in the locations where they can deliver most impact, ensuring we take account of all supply chain emissions. We shouldn’t shy away from imports where the source is sustainable and the overall system makes environmental, economic and social

sense”.

The strategy also considers how biomass should be prioritised across a variety of applications to best support the transition to net zero. Biomass applications ranging from transport fuels and hydrogen to domestic and industrial heating are recognised as important, but in the medium to long-term the focus is on integration of bioenergy with carbon capture and storage (BECCS).

This is an emerging technology where the CO2 that may be released during the production and use of electricity, fuels or products derived from biomass is captured and stored, potentially resulting in negative emissions.

Professor Thornley agreed, “The priority use framework outlined in the Biomass Strategy makes eminent sense. The UK (and the global energy system) needs carbon dioxide removals to deliver net zero. BECCS has an absolutely key role to play, as reflected in the strategy. Again, while this is encouraging to see, we must not underestimate the challenges of moving towards such a radically different system at scale”.

Dr Joanna Sparks, Biomass Policy Fellow at the Supergen Bioenergy Hub,

Antti Koulumies, MSc (Eng), has been appointed Senior VicePresident, Timber and Forest. Koulumies will take the leadership of UPM Forest and continue to lead UPM Timber. The current leader of UPM Forest, Sauli Brander, BSc (Eng), eMBA, has been appointed Vice-President, UPM Global Forest Affairs. He will focus on global forest advocacy, as well as global forestry themes, such as climatepositive forestry and biodiversity. Both appointments took effect on 1 September. Koulumies and Brander will continue to report to Bernd Eikens, Executive Vice-

President, UPM Fibres, and they will also continue as members of UPM Fibres business area management team.

“The Finnish wood market is in a new situation. UPM Forest and UPM Timber form a system that enables competitive wood sourcing

who engaged closely with government departments as they developed the strategy, added: “Relying on future BECCS deployment alone to counterbalance the current excess of greenhouse gas emissions would not enable the full potential and benefits of BECCS. It should be deployed alongside measures to transition away from the use of fossil fuels, not instead of them”.

Dr Sparks led an extensive policy engagement and knowledge transfer process to ensure that those developing the strategy had full access to the breadth and depth of UK scientific and engineering academic expertise, ensuring a robust, independent scientific base.

Professor Thornley believes continued engagement between policymakers, academics and the wider sector is vital in achieving the next steps in the delivery of the government’s strategy. She stated, “The key to successful longterm results is a close partnership between academia, industry and policy stakeholders, so that we can anticipate problems and plan the pathways to success”.

More information: www.supergen-bioenergy.net

for our mills. Through this leadership rotation, we aim to further intensify collaboration between UPM Timber and UPM Forest and support further development of our Finnish operations. At the same time, global forest affairs are increasingly important for UPM as 60% of the company’s pulp capacity is now in Uruguay and wood sourcing outside Finland is increasing. Thus, we have a growing need for expertise related to the latest regulation and science in sustainable forestry,” explained Bernd Eikens.

More information: www.upm.com

Wave energy pioneers Mocean Energy have secured over £3 million EU funding to develop and deploy a 250 kW wave machine in Orkney. The large-scale wave energy device – named Blue Horizon 250 – will be manufactured in Scotland and will be deployed in a grid-connected berth at the European Marine Energy Centre (EMEC) in Orkney as early as 2025.

It’s hoped the project could then pave the way to a small wave farm delivering 1-2 MW of low carbon electricity by 2030.

The Edinburgh firm has been awarded £3.2 million in Phase 3 of EuropeWave, a pre-commercial procurement programme, funded through the EU and managed in collaboration with Wave Energy Scotland, the Basque Energy Agency and Ocean Energy Europe.

Mocean Energy is one of three wave companies to have been awarded funds in Phase 3, each of which has successfully passed through competitive stage gates in Phases 1 and 2 of the programme.

The other successful companies are IDOM Consulting and CETO Wave Energy Ireland, who will install their devices at the Biscay Marine Energy Platform (BiMEP) in Northern Spain.

“This is a major milestone for

Mocean Energy,” states company co-founder and Managing Director Cameron McNatt. “We have already demonstrated our technology successfully at small scale and this programme will allow us to build a significantly larger machine based on our proven hinged raft design, and incorporate our novel direct drive generator.

“We are already working with a range of supply chain partners

across Scotland and the UK who bring tremendous experience and professionalism to the wave energy sector, and I am confident we have the right suppliers on board to bring this ambitious project to fruition.

“Innovation funding is crucial for early-stage technologies and I am grateful to EuropeWave for this support which will help leverage the additional private investment this project will require.

A global leader in advanced pump solutions and water technologies, Grundfos has announced a new ambitious partnership with renowned German renewable energy company ABO Wind. This strategically important partnership means 80% of Grundfos’ European energy consumption will be sourced from renewable energy. It also allows Grundfos to reach its 2030 targets of reducing Scope 1 and 2 greenhouse gas (GHG) emissions by 50% in 2025. With the new partnership, Grundfos will receive clean, green

energy from a wind farm, currently being built in the municipality of Haapajärvi, Finland. The wind farm, consisting of 14 Vestas turbines, will be fully commissioned by the end of 2023. With significant manufacturing presence in Europe, Grundfos has committed itself to buying energy sourced from the wind farm for the next ten years.

The agreement links to Grundfos’ overall emission reduction strategy. Last year, the company became the first in the water solutions sector to receive full validation of its 2050 net-

zero targets from the Science-Based Targets initiative (SBTi). which also validated the company’s near-term targets of halving its Scope 1 and 2 GHG-emissions by 2030.

Karolin Pampel, Head of Department Project Finance & Sales Finland of ABO Wind, said: “It’s very encouraging when businesses, who are leaders in their industry, are determined to take the lead in the green transition and invest heavily in renewable energy solutions. We look forward to helping Grundfos lead the way towards a future powered by

“Looking further ahead, our goal is to deliver a small array in UK waters this decade and I am confident that with appropriate innovation funding in place we can realise our ambition to build commercial wave energy arrays and generate home-grown green energy from our seas, both in the UK and around the world,” he concluded.

More information: www.mocean.energy

clean, green energy”.

Mikael Geday, Executive VicePresident & Chief Financial Officer of Grundfos, commented: “We took bold steps forward in our sustainability ambitions in setting net-zero and 2030 science-based targets. Our science-based targets highlight our leadership in taking climate action across our footprint. We now take our sustainability journey to the next level by reaching our 2030 targets five years ahead of time. The partnership with ABO Wind will significantly reduce our carbon footprint and is a statement of our intent and a signal we have a clear roadmap to deliver on our promises”.

More information: www.grundfos.com

reach emission targets

The construction of the first solar parks from its portfolio of around 1.1 gigawatts has been started by SECURSUN. In total, more than 50 utility solar PV parks will be completed between the end of 2023 and 2026. All plants will be planned and constructed by the Berlin-based project developer securenergy solutions and SUNOTEC, Europe’s market leader in the construction of solar parks. The two companies each have a half share in the joint venture SECURSUN.

Construction of at least seven solar parks from the SECURSUN portfolio will begin this year. Amongst the first are the PV plants in Utzedel (near Demmin) and Brusow (near Kröpelin) both in Mecklenburg-Western Pomerania. Ground-breaking of the site in Dallgow-Döberitz in Branden-burg (outside Berlin) will follow soon.

The average project size in the over 1.1 gigawatt large pipeline will be around 20 MW peak (MWp). Individual

solar parks with up to 150 MWp are also planned. The PV plant in Frankenförde near Luckenwalde, about an hour’s drive South-East of Berlin, for example, will have a ca-pacity of about 42 MWp. Construction is scheduled to start at the end of the year.

“Since the launch of our joint venture last November, less than

a year has passed. The fact that the planning went so quickly was only made possible by the close co-operation between securenergy solutions and SUNOTEC. Now work has started at several locations at the same time,” said Hol-ger Stabernack, CEO of securenergy solutions AG. “The first SECURSUN projects prove how

quickly things can be implemented when the right partners come together,” agreed Bernhard Suchland, CEO of the general contractor SUNOTEC. “We are proud that we can deliver everything from a single source.”

More information: www.secursun.com

Norwich-based PSH Environmental Ltd has unveiled a pioneering new project to transform waste into a renewable energy source using only solar power.

The announcement comes following a significant re-investment into a new 12,000 sq ft building, 40% extension to the yard, new wash plant, solar system and an UNTHA XR3000C mobil-e shredder, which lies at the heart of the facility.

Capable of processing a range of difficult waste materials for alternative fuels, the electric-driven XR3000C runs entirely from solar energy generated on-site by PSH Environmental.

A 90 mm screen processes grade C wood down to a homogenous biomass product for a local en-ergy plant, while a 130 mm screen can be interchanged in as little as 15 minutes to enable PSH En-vironmental to reduce the density of other skip, bulky and C&I wastes for Refuse Derived Fuel. The flexible shredder can also

handle other bespoke products –even those notoriously considered economically unshreddable or too difficult to handle.

The plant is now capable of throughputs of 40 tonnes of material per hour, which equates to 80,000 tonnes per annum.

Commenting on the project, PSH Environmental’s Director, Daniel Parker, said: “There will al-ways be

waste and it’s up to us to process it in the most efficient and sustainable way. That is what we are aiming to achieve here at PSH Environmental. Running a 38 tonne shredder entirely off so-lar power may seem far-fetched, but we’ve proven it’s possible”.

Talks with UNTHA began at a shredding showcase in Lancashire, back in 2021. “We’ve been col-

laborating with UNTHA UK for almost two years on this project – once you see the machine in action, you know exactly why you need it,” continued Daniel.

“From experience, once you press the start button on a shredder, they’re on a route to self-destruct. I mean look at what you’re trying to tackle with them, but with the UNTHA XR3000C, you can see it is built to last. This is high quality engineering at its finest and the level of craft that has gone into manufacturing such a robust and refined machine is outstanding.”

Daniel concluded: “We are PSH Environmental and we take our name seriously. We can’t simply talk about caring for the environment; we have to make sure we do. The waste industry is constant-ly evolving and you cannot stand still. Hopefully this project shows just how progressive waste processing can be”.

More information: www.parkersskips.com

On 26 September, it was announced that Sappi Europe’s Kirkniemi Mill in Lohja, Finland, had successfully made the switch from using fossil fuels to renewable energy to fuel production of the Galerie paper range. A EUR16.5 million investment in state-of-the-art facilities and machinery for the reception, storage and handling of biofuels is the latest in a series of efforts by Sappi in meeting its Science-Based Targets Initiative (SBTi) approved emissions reduction goal across all its regions.

The official inauguration of the new facilities for reception, storage and handling of biofuels on 30 August 30, was attended by Kai Mykkänen, the Finnish Minister for Climate and the Environment, who spoke about

how the multiple environmental investments by Sappi at Kirkniemi fit with Finland’s ambitious goals for carbon neutrality and leadership in the

Following the award of multiple contracts in Europe and the Far East, ACE Winches continues its strategy to further expand its global renewables expertise. The projects, with a combined seven-figure value, advance the Aberdeenshire-based company’s drive to increase its market share in the renewables sector, an area identified as a key part to its continued international growth.

ACE has been awarded a contract to provide equipment and personnel to support the delivery of a 300 MW offshore wind farm in Taiwan, which is expected to be installed over several campaigns during the next few years. The company is also supporting the development of an additional offshore wind farm in Taiwan, which will be completed in 2025.

The Taiwanese renewable energy market is accelerating rapidly as the country seeks to improve energy selfsufficiency. Taiwan aims to produce at least 60% of its total energy from renewable sources, including boosting its wind power capacity to 40 gigawatts by 2050.

Chief Commercial Officer of ACE,

Gary Wilson, said: “The latest contract win in Taiwan is a testament to the quality of work we are delivering in the renewables space. Enhancing our offering in this important sector is one of several growth markets the company is engaged in.

“The recent contract awards in both Europe and the Far East demonstrate our capabilities in delivering highquality work in a fast-growing sector and it is something we will continue to grow. We have further invested in our global rental fleet over the last two years and these latest contract awards are in line with our twin objectives of diversification and geographic expansion to position the business to serve a Net Carbon Future.”

More information:

www.ace-winches.com

new energy sector.

Biomass residues such as bark, sawdust and wood chips, largely locally-sourced, now fuel the Kirkniemi

Mill Galerie paper operations, setting the stage for a 90% reduction in direct fossil greenhouse gas emissions. This upgrade now works alongside the multi-fuel boiler built in 2015, enabling the mill to reduce output of nearly 230,000 tons of carbon dioxide annually.

It also means that Kirkniemi Mill is now able to slash the carbon footprint of the Galerie paper range by 40%. All this comes as part of a long-standing sustainability focus at Kirkniemi that has, in recent years, brought continuous improvements in environmental performance across areas, including freshwater usage, emissions to watercourses and energy efficiency.

More information: www.sappi.com

Germany’s Deutsche Bahn is expanding its use of renewable diesel significantly this year by purchasing around 13,300 tons (17 million litres) of renewable diesel produced by Neste. Switching from fossil diesel to Neste MY Renewable Diesel™ will enable Deutsche Bahn to reduce greenhouse gas emissions from the operation of their diesel-powered locomotives and railcars by up to 90%. In total, the purchased amount will save Deutsche Bahn around 46,000 tons of greenhouse gas emissions (CO2e) compared to the use of fossil diesel.

Deutsche Bahn has already approved HVO-type 100% renewable diesel for use in around 1,000 of its vehicles and its subsidiary, DB Cargo AG, in its entire fleet of 800 vehicles. Neste MY Renewable Diesel is a drop-in fuel, suitable for use in diesel-powered vehicles without any modifications to their engines.

“We are happy that Deutsche Bahn chose Neste MY Renewable Diesel as a solution on their journey of becoming climate neutral. Companies can reduce their climate emissions in an instant by just switching to Neste MY Renewable Diesel,” said Peter Zonneveld, Vice-President, Europe and APAC from the Renewable Road Transportation business unit at Neste.

“With our renewables production capacity increasing to 5.5 million tons by the end of 2023 and further to 6.8 million tons by the end of 2026, we are well-equipped to help our customers around the world to make the switch to more sustainable solutions,” he added. Neste MY Renewable Diesel is produced 100% from renewable raw materials such as used cooking oil.

More information: www.neste.com

An existing third-party automation system will be replaced with a Valmet DNA Automation System at Oy Alholmens Kraft AB’s power plant unit AK1 in Pietarsaari, Finland. Valmet’s delivery scope will cover a Valmet DNA Automation System, including system hardware and software, as well as installation and commissioning. It will be handed over to the customer in November, 2023.

“Our other power plant unit, AK2, which is one of the world’s largest biomass-fired combined heat and power (CHP) plants, has been run reliably with the Valmet DNA since its start-up in 2001. Now we want to have the same system for our AK1 unit too. After the retrofit, we will have only one automation system throughout the entire plant,” explained Johannes Östman, Automation Engineer, Oy Alholmens Kraft AB.

system makes support and future updates easier for the customer. Valmet has extensive experience and know-how in replacing other suppliers’ automation systems,” said Tom Bäckman, Sales Manager, Automation Systems business line, Valmet.

Close co-operation between Alholmens Kraft and Valmet goes back for decades. One of the latest projects includes a Valmet DNA turbine automation retrofit on AK2 in 2022.

More information:

Technology group Wärtsilä has signed a repeat order with EDF Renewables UK to deliver a gridscale energy storage system (ESS) in Bramford, UK. The 57 MW/114 MWh project will support the transition to a decarbonised electricity system and help achieve the UK’s net zero goals. The order was booked in Q1 2023 and is expected to be delivered in Q1 2024.

This is Wärtsilä’s sixth project with EDF Renewables UK and Ireland, and builds on the strong, longterm partnership between the two companies. Wärtsilä’s energy storage portfolio in the UK now exceeds 1 GWh.

The new storage facility will be connected to the transmission network, enabling the integration of renewable energy into the grid. The facility will strengthen the resilience of the electricity system and automatically charge and discharge to balance supply and demand in this Suffolk village.

The Bramford project will also be capable of supporting any future developments in electric vehicle (EV) charging and the electrification of public transport.

More information: www.wartsila.com

The art of paper-making has been practiced in Greiz for more than 400 years and the paper factory in the German town has been part of the Koehler Group for over 25 years. The site, renowned for its innovation, produces novel and sustainable products of the highest standard. For example, Koehler Paper produces silphie fibrebased paper and cardboard grades in collaboration with OutNature.

As an energy-intensive company, Koehler Group has set itself the goal of producing more renewable energy within its own plants than is required for its paper production by 2030. To safeguard jobs at the Greiz site, there is a specific need to set aside space for systems for generating renewable energy.

In 2021, the Koehler Group announced that it was converting its power plant at the Koehler Paper site in Greiz from pulverised lignite to fine wood fraction fuel. Switching from lignite to fine wood fraction will enable savings of more than 24,000 metric tons of carbon emissions per year at the site.

Koehler is investing around EUR7.6 million in the conversion, which is part of the sustainable strategy being implemented at the site. This will bring Koehler even closer to its objective of company-wide decarbonisation. The plan is to reduce scope 1 direct greenhouse gas emissions by 80% by 2030 in comparison to the levels from the base year 2003.

The Koehler Paper site in Greiz is a pioneer in this area and has already made a start towards this with its pilot system. In addition, there are also concrete plans for converting the existing black coal-fired power plant at the Oberkirch site to biomass by 2024, with the project to cost Koehler over EUR70 million.

The conversion of the power plant is the first step toward increasing sustainability at the Greiz site. Koehler

plans to continue investment at the plant in the future and thereby make a contribution toward sustainable development in Thuringia.

Kai Furler, CEO of the Koehler Group, emphasised: “By converting our

power plant in Greiz to biomass, we have clearly demonstrated that we have long-term plans for our location in Thuringia. Now, we need support from politicians to continue pushing ahead with our sustainable approach”.

He continued, “In order for us to keep the Koehler Promise 2030, we also need more facilities for generating sustainable energy at the company’s site. We need designated areas for turbines and photovoltaic parks to generate energy for our production facility”.

Climate strategy praised Politicians are enthusiastic about Koehler’s sustainable company policy and climate strategy.

On his last visit to the Koehler Paper plant in Greiz during the fall of 2021, Thuringian Premier Bodo Ramelow stated: “We need companies like Koehler that are committed and courageous. I’m pleased that Koehler has helped to boost Thuringia’s status as a sustainable business location”. More information

www.koehler.com

A pioneering BFB concept for 100% agrofuel and catalytic pyrolysis are examples of how Valmet is driving energy technology development forward. Key to these and other developments are the company’s continuous innovation work and unique pre-industrial scale test facility for energy technologies.

The target of converting renewable resources into sustainable results keeps people at Valmet innovating. One of the facilities where this innovation takes place is Valmet’s Energy R&D Centre in Tampere, Finland. Since 1990, this

has carried out more than 11,000 hours of pilot operations. It offers complete fluidised bed combustion and pyrolysis pilots on a megawatt scale for customer pilot trials, including comprehensive analysis services and access to Valmet’s network of deeply knowledgeable

and experienced experts. In addition to serving customers from around the world, the facility plays a key role in Valmet’s own R&D work.

“This unique pre-industrial scale test facility has enabled us to develop our fluidised bed combustion and

pyrolysis technologies. In combustion, fuel trends over the decades have changed from fossil fuels to more sustainable, but at the same time more challenging biomasses and waste fractions. The driving force for development of pyrolysis technology has been to maximise the value

of resources,” points out Katriina Jalkanen, R&D Project Manager.

One of Valmet’s long-term development projects is the Valmet BFB Boiler for agrofuels. This can run on high-alkaline fuels like wheat straw, sunflower husks, empty fruit bunches and rice straw – fuels that typically are agro-residues and previously were unsuitable for BFB combustion. The concept has been piloted on 30 kW and 2 MW scales at Valmet’s Energy R&D Centre.

“The main issue in fluidised bed technology that uses high-alkaline fuels is bed agglomeration. This can

now be prevented with Valmet’s advanced combustion principles,” says Jukka Leppälä, Project Manager.

“Another risk for bed sintering with agrofuels is heavy furnace fouling. We have a patented solution for a furnace arrangement using two-zone combustion to keep the bed fluid without disruption.”

Compared to grate combustion, BFB combustion is significantly more efficient and features better emission control.

“After years of development work, the concept is now ready and we’re looking for a customer to build a 30–80 MW demo plant. This could be a new BFB boiler or a boiler rebuild. The latter option is possible,

as we can use a lot of an existing plant’s technology and just change the furnace structure,” Leppälä confirmed.

In accordance with its vision, Valmet is looking for ways to maximise the value of resources. For example, good-quality biomass should be used to produce more valuable products than heat and electricity, such as chemicals or transportation fuels.

Pyrolysis is the thermal decomposition of feedstock without air. In an ongoing R&D project, Valmet is further developing its fast

pyrolysis technology with catalytic treatment. With catalytic pyrolysis, the target is to produce renewable feedstock – biocrude – for refineries and the petrochemical industry for the production of transportation fuel from sustainable biomass sources.

“Right now, we use wood biomass and forest residues as fuels, and later, we’ll also use agrofuels,” said Joakim Autio, Solution Development Manager. “In the Spring of 2023, our project entered the test phase in a 400 kg/h pilot plant at Valmet’s Energy R&D Centre. We’ll follow successful piloting with demo-scale development.”

More information:

www.valmet.com

Biomass gasification for lime kilns – going fossil fuel-free is an urgent sustainability topic that has become even more critical due to the current global energy crisis. It is clear we must reduce our dependence on fossil fuel.

“Pulp mills are in an ideal situation to introduce gasification due to their ability to source woody biomass efficiently.”

The largest heat demand in a kraft pulp mill comes from the lime kiln and gasification is a prime solution to reduce the usage of fossil fuels.

Jean Taillon, Director, Business Development of Gasification at ANDRITZ, stated “With the high price of oil and natural gas, as well as carbon pricing and low biomass costs, there is a real push for the replacement of fossil fuel used in lime kilns.

“Pulp mills are in an ideal situation to introduce gasification due to their ability to source woody biomass efficiently.”

The biomass Taillon refers to is mostly a low-cost biomass side stream from the woodyard at a pulp mill, for example, bark and chip screening rejects of various species that are ideal for the gasification process.

A typical gasification plant package supplied by ANDRITZ is mainly composed of a belt dryer, biomass handling equipment, gasification plant with some auxiliary systems and lime kiln burner (for existing lime kilns).

“This is really a benefit that all of these areas are in-house technologies at ANDRITZ and that the gasification, lime kiln and causticising processes are supplied by the white liquor plant product group with common technology and project execution resources,” said Taillon.

Typically, wet biomass is fed to the dryer. The initial moisture may be as high as 60%-w and dried to as low as 5%-w. The dried biomass is then conveyed through a flight chain conveyor to minimise the distance between the dryer and the gasification plant.

The gasifier itself is an air-blown, circulating, fluidised bed (CFB) gasifier operating at atmospheric pressure. “The purpose of gasification is to convert the carbon from the biomass into a combustible gas, called product gas,” explained Taillon. “In simple terms, to do this, a small quantity of air is used, just enough air to create some heat, but not enough to fully oxidise the carbon so as to be able to deliver a combustible gas composed mainly of H2, CO and CH4.”

A gasification plant is equipped with various subsystems, such as a heat supply to dry the wet biomass, biomass handling to feed the material, bed material feeding to help the fluidisation of the biomass inside the reactor, start-up burner – also an in-house technology – to warm up the reactor when cold and gasification air to provide the necessary air to favour the

thermo-chemical gasification reactions. Hot air from the lime kiln sector cooler can be used.

Plant safety also plays an important role in the design of the overall plant to fulfill EU Machine Directives and various HAZOP reviews.

ANDRITZ’s references currently in operation are at Metsä Fibre, Joutseno (48 MW) in Finland, Chenming Group Zhanjiang (65 MW) and Meilun (80 MW) mills in China, and Klabin and Ortigueira (51 MW) in Brazil. Deliveries under project execution are Suzano Cerrado (2 x 67 MW) in Brazil and Liansheng (115 MW, largest CFB capacity in the world) in China.

“Biomass gasification for lime kilns was used in the 80’s and 90’s followed by a long pause in the market,” said Taillon. “However, as the usage of fossil fuels came under the spotlight, we have seen renewed interest for lime kiln biomass gasification. This message can be heard from many other actors and consultants to pulp mills’ owners. So we believe this technology will be used more and more in kraft pulp mills around the world,” he concluded.

Gasification is the combination of various thermo-chemical reactions of biomass with air under sub-stoichiometric conditions. The energy in the product gas is approximately 5-7 MJ/Nm3 where approximately 80% comes from the chemical content of the product gas in the form of H2, CO and CH4. The rest of the energy comes from the high temperature of the product gas and the unburnt carbon contained in the product gas. Finally, the product gas is fed and burned in the multi-fuel lime kiln burner. More information: www.andritz.com

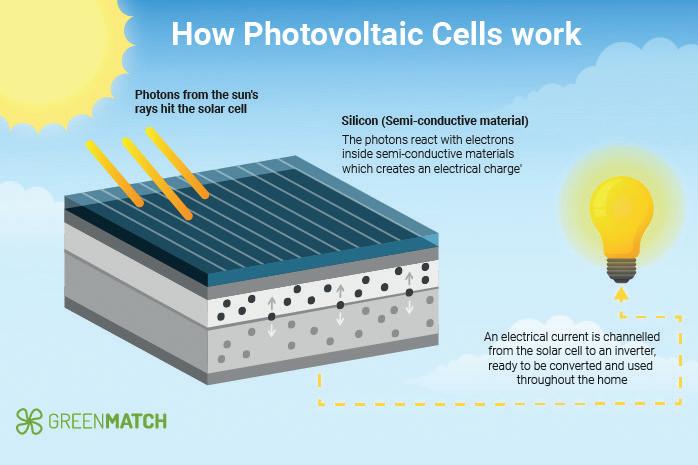

On 30 August, GreenMatch UK, a leading sustainable energy solutions provider, shared insights into the science behind solar panel energy conversion to electricity. Understanding the technology behind solar panels is essential as the world moves towards renewable energy sources.

Solar panels, also known as photovoltaic (PV) panels, harness sunlight and convert it into electrical energy. The efficiency of solar panels has improved dramatically in recent years, with average conversion rates now ranging from 15% to 22%. This increased efficiency has made solar energy more accessible and costeffective for various applications.

Understanding the underlying mechanisms at play is crucial for optimising the efficiency and performance of solar panels. GreenMatch’s research findings contribute significantly to this knowledge base, paving the way for advancements in solar technology.

The study explored the role of photovoltaic cells, the heart of solar panels, in converting sunlight to electricity. By analysing the behaviour of different materials

used in solar cells, such as silicon and thin-film semiconductors, the researchers gained valuable insights into the various factors influencing energy conversion efficiency.

Furthermore, the study examined the effect of temperature on solar panel performance. This highlights the importance of proper

cooling mechanisms in solar panel systems to maintain optimal performance and maximise energy output. Beyond that point, it reveals significant implications for optimising solar panel installations in regions with varying sunlight intensities.

“The science of solar panel energy

conversion is a symphony of physics, engineering and innovation,” said Dr Joshua Pearce, Solar PV expert at GreenMatch UK. “Every advance in materials, design and manufacturing techniques brings us closer to a future where solar energy is not just a viable alternative, but a dominant force.”

The widespread adoption of solar panel technology has fuelled the transition to cleaner energy and generated jobs and economic growth. Solar farms and residential installations dot the landscape, representing a collaborative effort to combat climate change and secure a sustainable future for future generations.

GreenMatch UK is committed to promoting the adoption of solar energy and educating the public about the science behind solar panel energy conversion. By understanding the technology and its benefits, home-owners and businesses can make informed decisions about adopting solar energy solutions.

More information: www.greenmatch.com

10–11 April 2024 | Messukeskus

Helsinki Expo and Convention Centre

Pulp & Beyond is the leading forum bringing together the latest forest-based bioeconomy innovations, products, services and technologies as well as key people throughout the ecosystem.

Pulp & Beyond offers new encounters, inspiration, networking and business possibilities for marketing global and sustainable solutions, products and services within the forest-based bioeconomy. The event provides the widest available showcase on the latest trends and innovative new products within the forest-based bioeconomy, supporting learning, employer branding and competence development.

Whether you work in board and paper, tissue, pulp or energy industry, Valmet’s comprehensive service offering helps to lower your environmental footprint significantly – at the same time improving your operational results. The key is a close collaboration and the right combination of services for every stage of the lifecycle. As most of the environmental impact comes from the operational phase, by working consistently in close cooperation with your team, we can offer many concrete solutions.

From energy, water and raw material savings to circularity and lower emissions, together we’ll keep the process reliable, optimized and sustainable to the fullest extent – benefiting both your business and the environment.

Are you ready to succeed with us? Explore how on www.valmet.com/waytoserve